Page 1

TD-V10247G

TD-V14247E

TD-V14247G

Thank you for buying an LG Dryer.

Please read your manual carefully, as it provides instructions

on safe Installation, use and maintenance.

Record the model and serial numbers,

and retain the manual for future reference.

P/No.: 3828EL3004P

Page 2

PRODUCT FEATURES

OUTSTANDING PERFORMANCE

1

Not to mention unmatched big capacity, you can benefit from good

time efficiency, quiet operation and energy saving system.

ARTISTIC DESIGN

2

Modern front panel look and big crystal-clear glass door make your house look stylish.

DIGITAL FABRIC CARE

3

Multi-level temperature control heater takes a better care on your valued clothes.

EASY OF USE

4

A whole selection of user-friendly functions always make you comfortable with dryer operation.

What are Sensor Dry and Time Dry?

Your dryer provides sensor drying and time drying programs.

Sensor Dry

The dryer senses the dampness of the laundry and automatically determines the heat level and operation time. You might

see a sudden increase or decrease in operation time if the sensor determines more or less drying is required. This is not a

malfunction.

Time Dry

Use TIME DRY to select heat level and drying time manually. This can be used if clothes are not as dry as you like them

at the end of the cycle. Use TIME DRY for heavy and bulky items and thick work.

TABLE OF CONTENTS

PART 1. SPECIFICATIONS ................................................................................................................................................................................................................ 3

PART 2. IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS .............................................................................................................................................. 4

PART 3. INITIAL STEPS FOR INSTALLING YOUR DRYER ........................................................................................................................................................... 11

PART 4. ACCESSORIES INSTALLATION ....................................................................................................................................................................................... 16

PART 5. ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS ............................................................................................................................................. 18

PART 6. ELECTRICAL REQUIREMENTS FOR GAS DRYERS........................................................................................................................................................ 22

PART 7. GAS REQUIREMENTS AND INSTRUCTIONS ................................................................................................................................................................... 23

PART 8. EXHAUST REQUIREMENTS AND MAINTENANCE .......................................................................................................................................................... 24

PART 9. OPERATING YOUR DRYER ............................................................................................................................................................................................... 26

PART 10. TROUBLESHOOTING GUIDE........................................................................................................................................................................................... 32

22

Page 3

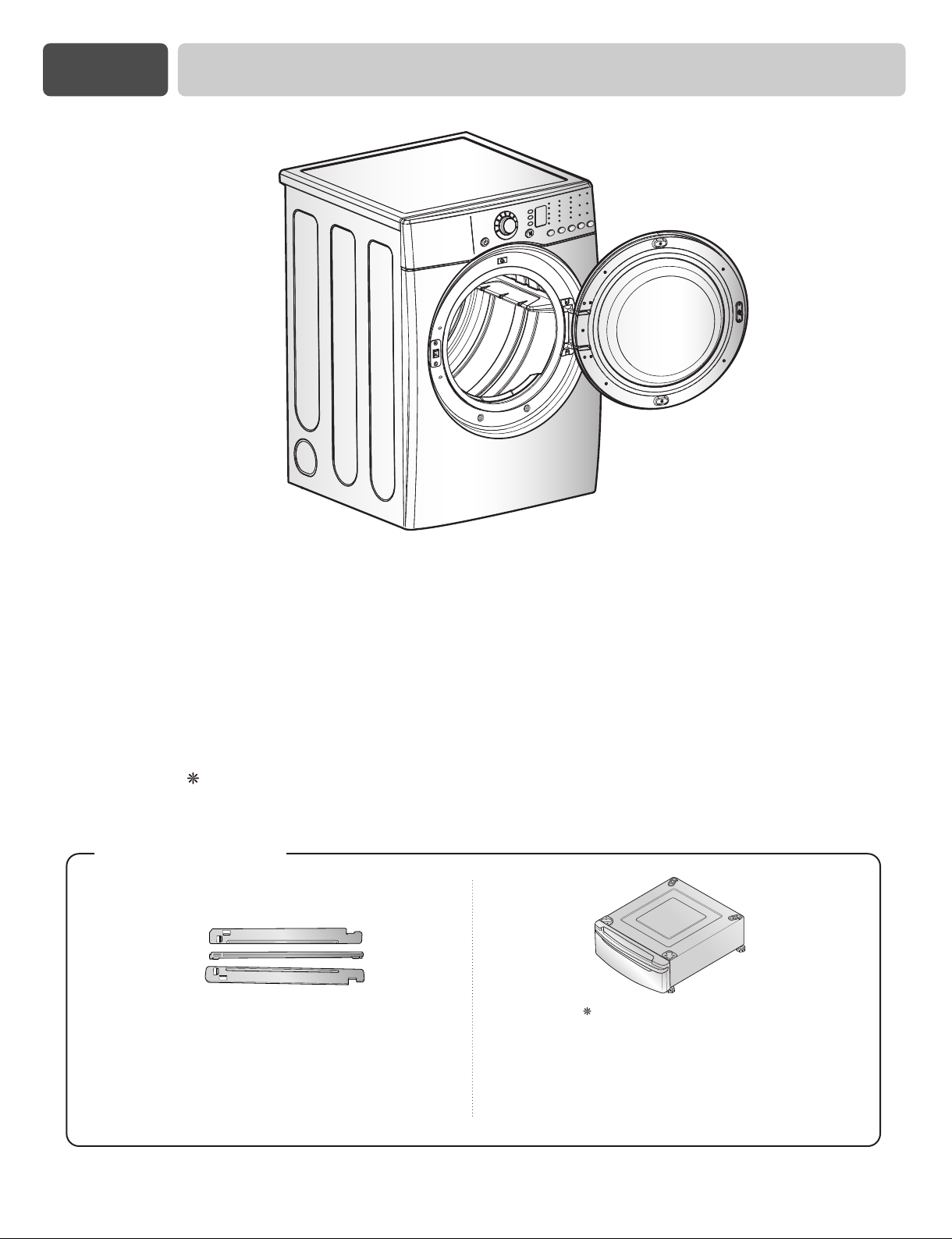

Part 1 SPECIFICATIONS

■ Type : Electric and Gas Dryer

■ Rating : Please refer to the rating label regarding detailed information.

■ Size : 686 x 761 x 983(mm)

■ Capacity : Please refer to the rating label regarding detailed information.

■ Weight : 57.2 kg

Specifications are subject to change by manufacturer.

■ ACCESSORIES

Design of pedestals is subject to

change without manafaturers notice.

Stacking Kit

Purchased Separately

See page 16 for instructions. See page 17 for instructions.

Purchased Separately

Pedestal

3

Page 4

Part 2

IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

SEEKING WARRANTY SERVICE

The warranty for your dryer is located at the end of this manual. Warranty Service is

available by contacting your nearest LG Service Center. If this product is installed and

operated according to the instructions in this manual, LG will repair or replace any parts

defective in material or workmanship throughout the warranty period, beginning with the

date of purchase.

WARNING!

For your safety, the recommendations in this manual must be followed. To reduce the risk

of fire or explosion, electric shock or to prevent property damage, personal injury, or death

when using your appliance follow basic precautions.

Warranty Restriction: If the dryer is subjected to other than single family use, all warranty

coverage is effective for only 90 days.

You will need the complete model and serial number when requesting warranty service. proof of

purchase date is required.

Use the space below to record the model number and serial number of your new LG dryer.

Model Number.

Serial Number.

Date of Purchase

❈ Staple your receipt here for convenience when contacting service.

4

Page 5

Part 2 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING

For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, personal injury, or loss of life.

Your Safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or WARNING.

These words mean:

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how the reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

You can be killed or seriously injured if you don’t Immediately follow instructions.

You can be killed or seriously injured if you don’t follow instructions.

BASIC SAFETY PRECAUTIONS

WARNING

To reduce the risk of fire, electric shock or injury to persons when using your

appliance, follow basic precautions, including the following :

• Read all instructions before using the dryer.

• Before use, the dryer must be properly installed

as described in this manual.

• Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a load to catch fire.

Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable

or explosive substances as they give off vapors

that could ignite or explode.

• Do not reach into the dryer if the drum is moving.

• Do not repair or replace any part of the dryer or

attempt any servicing unless specifically

recommended in this Use and Care Guide or in

published user-repair instructions that you

understand and have the skills to carry out.

• Do not tamper with controls.

• Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

• Do not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children.

• Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

• Do not use heat to dry articles containing foam

rubber or similarly textured rubber-like materials.

• Keep area around the exhaust opening and

adjacent surrounding areas free from the

accumulation of lint, dust, and dirt.

• The interior of the dryer and exhaust vent should

be cleaned periodically by qualified service

personnel.

• Do not install or store the dryer where it will be

exposed to the weather.

• Do not reach into the dryer while parts are

moving.

• Always check the inside of the dryer for foreign objects

• Clean lint screen before or after each load.

SAVE THESE INSTRUCTIONS

5

Page 6

Part 2 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING

• Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this appliance or any other appliance.

For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion, electric shock, or to prevent property damage, personal injury, or loss

of life.

BASIC SAFETY PRECAUTIONS

WARNING

GROUNDING INSTRUCTIONS

This appliance must be grounded.

In the event of malfunction or breakdown,

grounding will reduce the risk of electric shock

by providing a path of least resistance for

electric current. This appliance must be

equipped with a cord having an equipmentgrounding conductor and a grounding plug.

The plug must be plugged into an appropriate

outlet that is properly installed and grounded

in accordance with all local codes and

ordinances.

To reduce the risk of fire, electric shock or injury to persons when using your

appliance, follow basic precautions, including the following :

• Installation and service must be performed

by a qualified installer, service agency, or

the gas supplier.

WARNING -

equipment- rounding conductor can result in a

risk of electric shock. Check with a qualified

electrician or service person if you are in doubt

as to whether the appliance is properly

grounded.

Do not modify the plug provided with the

appliance.

If it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This appliance must be connected to a

grounded metal, permanent wiring system or an

equipment-grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

appliance.

Improper connection of the

6

Page 7

Part 2 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING

For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion, electric shock, or to prevent property damage, personal injury, or loss

of life.

WHAT TO DO IF YOU SMELL GAS

WARNING

1. Do not try to light a match or cigarette, or

turn on any gas or electrical appliance.

2. Do not touch any electrical switches.

Do not use any phone in your building.

3. Clear the room, building, or area of all

occupants.

To reduce the risk of fire, electric shock, or injury to persons when using the

appliance, follow basic precautions, including the following:

4. Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

phone. Follow the gas supplier’s

instructions carefully.

5. If you cannot reach your gas supplier, call

the fire department.

7

Page 8

Part 2 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING

For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion, electric shock, or to prevent property damage, personal injury, or loss

of life.

SAFETY INSTRUCTION FOR INSTALLATION

WARNING

• Properly ground dryer to conform with

all governing codes and ordinances.

Follow details in the installation

instructions.

Electrical shock can result if the dryer is not

properly grounded.

• Before use, the dryer must be properly

installed as described in this manual.

Electrical shock can result if the dryer is not

properly grounded.

• Install and store the dryer where it will

not be exposed to temperatures below

freezing or exposed to the weather.

All repairs and servicing must be performed

by an authorized servicer unless specifically

recommended in this Owner's Guide.

Use only authorized factory parts.

Failure to follow this warning can cause

serious injury,fire, electrical shock or death.

To reduce the risk of fire, electric shock, or injury to persons when using the

appliance, follow basic precautions, including the following:

• Connect to a properly rated, protected,

and sized power circuit to avoid

electrical overload.

Improper power circuit can melt, creating

electrical shock and/or fire hazard.

• Remove all packing items and dispose

of all shipping materials properly.

Failure to do so can result in death,

explosion, fire or burns.

• Place dryer at least 18 in. above the floor

for a garage installation.

Failure to do so can result in death,

explosion, fire or burns.

• Do not install the washer in humid

spaces to reduce the risk of electric

shock.

Failure to follow this warning can cause

serious injury,fire, electrical shock or death.

8

Page 9

Part 2 IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING

For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion, electric shock, or to prevent property damage, personal injury, or loss

of life.

SAFETY INSTRUCTION FOR INSTALLATION (cont.)

Exhaust/Ducting:

• Gas dryers MUST be exhausted to the

outside.

Failure to follow these instructions can result

in fire or death.

• The dryer exhaust system must be

exhausted to the outside of the dwelling.

The dryer is not exhausted outdoors, some

fine lint and large amounts of moisture will

be expelled into the laundry area. An

accumulation of lint in any area of the home

can create a health and fire hazard.

• Use only rigid metal or flexible metal 4in.

Diameter ductwork inside the dryer

cabinet or for exhausting to the outside.

• Ductwork is not provided with the dryer,

and you should obtain the necessary

ductwork locally. The end cap should

have hinged dampers to prevent back

draft when the dryer is not in use.

Failure to follow these instructions can result

in fire or death.

• The exhaust duct must be 4 in. (10 cm)

in diameter with no obstructions. The

exhaust duct should be kept as short as

possible. Make sure to clean any old

ducts before installing your new dryer.

Failure to follow these instructions can result

in fire or death.

Use of plastic or other combustible ductwork

can cause a fire. Punctured ductwork can

cause a fire if it collapses or becomes

otherwise restricted in use or during

installation.

•Rigid or semi rigid metal ducting is

recommended for use between the dryer

and the wall. In special installations when

it is impossible to make a connection

with the above recommendations, a ULlisted flexible metal transition duct may

be used between the dryer and wall

connection only. The use of this ducting

will affect drying time.

Failure to follow these instructions can result

in fire or death.

• DO NOT use sheet metal screws or other

fasteners which extend into the duct that

could catch lint and reduce the efficiency

of the exhaust system. Secure all joints

with duct tape. ¶U For complete details,

follow the Installation Instructions.

Failure to follow these instructions can result

in fire or death.

9

Page 10

Part 2

IMPORTANT WARRANTY AND SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING

For your safety, the information in this manual must be followed to minimize the risk of

fire or explosion, electric shock, or to prevent property damage, personal injury, or loss

of life.

SAFETY INSTRUCTION FOR CONNECTING ELECTRICITY

WARNING

• Do not, under any circumstances, cut or

remove the ground prong from the power

cord.

To prevent personal injury or damage to the

dryer, the electrical power cord must be

plugged into a properly grounded

• For personal safety, this dryer must be

properly grounded.

Failure to do so can result in electrical shock

or injury

• Refer to the installation instructions in

this manual for specific electrical

requirements for your model.

Failure to follow these instructions can

create electrical shock and/or a fire hazard.

• This dryer must be plugged into a

properly grounded outlet.

Electrical shock can result if the dryer is not

properly grounded.

• Have the wall outlet and circuit checked

by a qualified electrician to make sure

the outlet is properly grounded.

This will prevent shock hazard and assure

stability during operating.

To reduce the risk of fire, electric shock or injury to persons when using the appliance,

follow basic precautions, including the following :

• The dryer should always be plugged into

its own individual electrical outlet which

has a voltage rating that matches the

rating plate.

This provides the best performance and also

prevents overloading house wiring circuits

which could cause a fire hazard from

overheated wires.

• Never unplug your dryer by pulling on

the power cord. Always grip plug firmly

and pull straight out from the outlet.

The power cord can be cut by any

movement of the core, resulting in electrical

shock.

• Repair or replace immediately all power

cords that have become frayed or

otherwise damaged. Do not use a cord

that shows cracks or abrasion damage

along its length or at either end.

These power cord can melt, creating

electrical shock and/or fire hazard.

• When installing or moving the dryer, be

careful not to pinch, crush, or damage

the power cord.

This will prevent injury and damage to the

dryer from fire and electrical shock.

10

Page 11

Part 3 INITIAL STEPS FOR INSTALLING YOUR DRYER

The following instructions will help guide you through the initial steps of setting up your dryer for use.

Please note that every section of this manual provides important information regarding the preparation and

use of your dryer, and it is important that you review this entire manual before proceeding with any

installation or use. More detailed instructions concerning electrical connections, gas connections, and

exhaust requirements are provided in other parts of this manual.

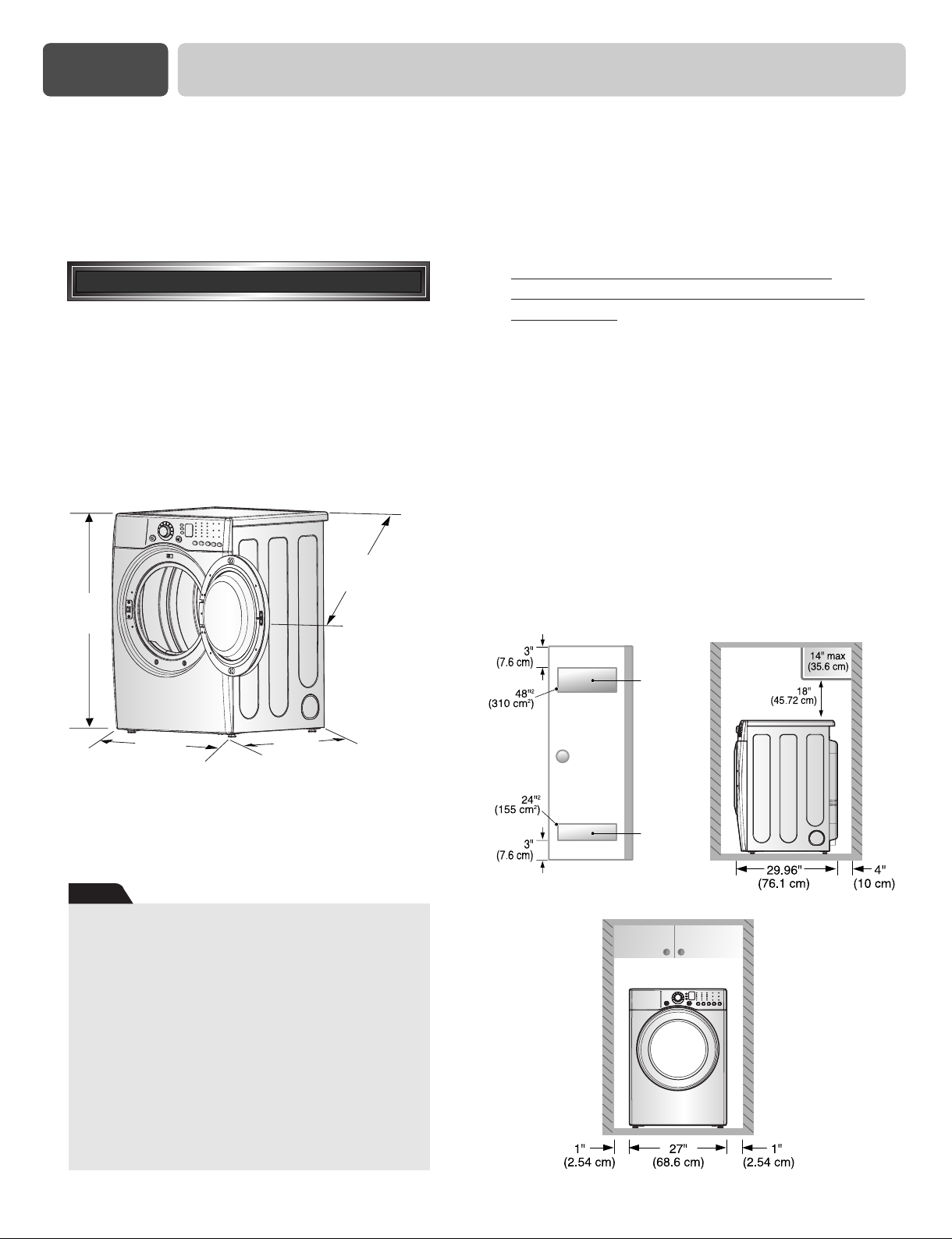

STEP 1 Positioning the Dryer.

Choose a location with a solid floor for your dryer.

Place the dryer at least eighteen inches above the

floor for a garage installation. After placing the

dryer in the desired location, please make sure that

it has the required clearances shown below. If you

are installing your dryer in a manufactured or

mobile home, please refer to STEP 9 for additional

instructions.

49.8”

(126.4 cm)

38.7”

(98.3 cm)

Certain minimum clearances are required

above, behind, and to the sides of the unit, as

shown below. Those required minimum clearances

are set forth in the picture below. Please keep the

following instructions in mind when installing in a

closet or recessed area:

• Consider allowing additional clearance for

installation and servicing.

• Wall, door and floor molding may necessitate

additional clearances.

• An additional inch of clearance is recommended to

minimize noise transfer.

• Consider space needed for companion appliances.

• For closet installations, the picture below shows the

minimum required ventilation openings for the door.

A louvered door with comparable ventilation openings

is also acceptable.

ventilation

hole

27”

(68.6 cm)

29.96”

(76.1 cm)

* Most installations require a minimum 51/2 inches.

(14 cm) clearance behind the dryer for the exhaust

vent with elbow.

Note

Leveling legs should be secured.

All four legs are stably placed on a solid and

even floor.

If dryer is not level, laundry may not tumble

properly and sensor will not detect accurate

humidity information.

When leveling, please be cautious not to injure

your fingers and toes.

If you install the dryer on the optional pedstal,

it is nessary to level with the pedestal leveling

legs.

ventilation

hole

Closet-side ViewCloset Door

Closet-front View

11

Page 12

Part 3 INITIAL STEPS FOR INSTALLING YOUR DRYER

Once in position, adjust the leveling legs of the dryer

until it is level from left to right and front to back.

The leveling legs must remain firmly on the floor

and the dryer should not rock. The maximum slope

of the dryer from left to right or front to back should

not exceed 2.5 cm (1 inch). If the dryer is not level,

and if the slope exceeds 2.5 cm (1 inch), a load may

not tumble properly and internal sensors may

malfunction. Note: Other sections of this manual

also provide important information concerning the

placement of and clearances for your dryer. Please

review this entire manual before proceeding with any

installation.

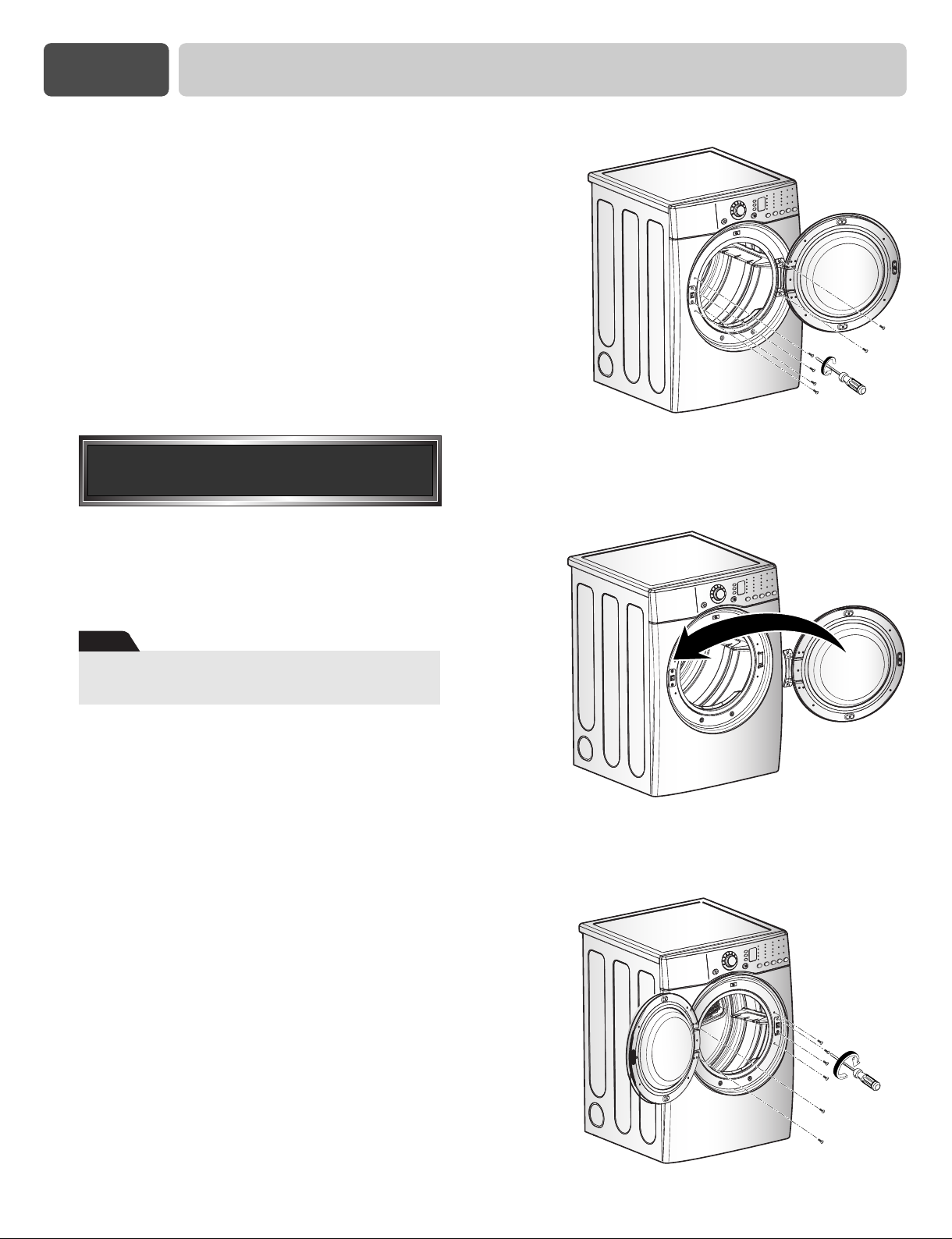

STEP 2:

STEP 2 Procedure for

Reversing the Door

1

The door on your dryer can be installed to open

either to the left or the right. Follow these

instructions to reverse the direction in which your

door opens:

Note

Door and latch should be aligned at the center

when closed.

2

3

12

Page 13

Part 3 INITIAL STEPS FOR INSTALLING YOUR DRYER

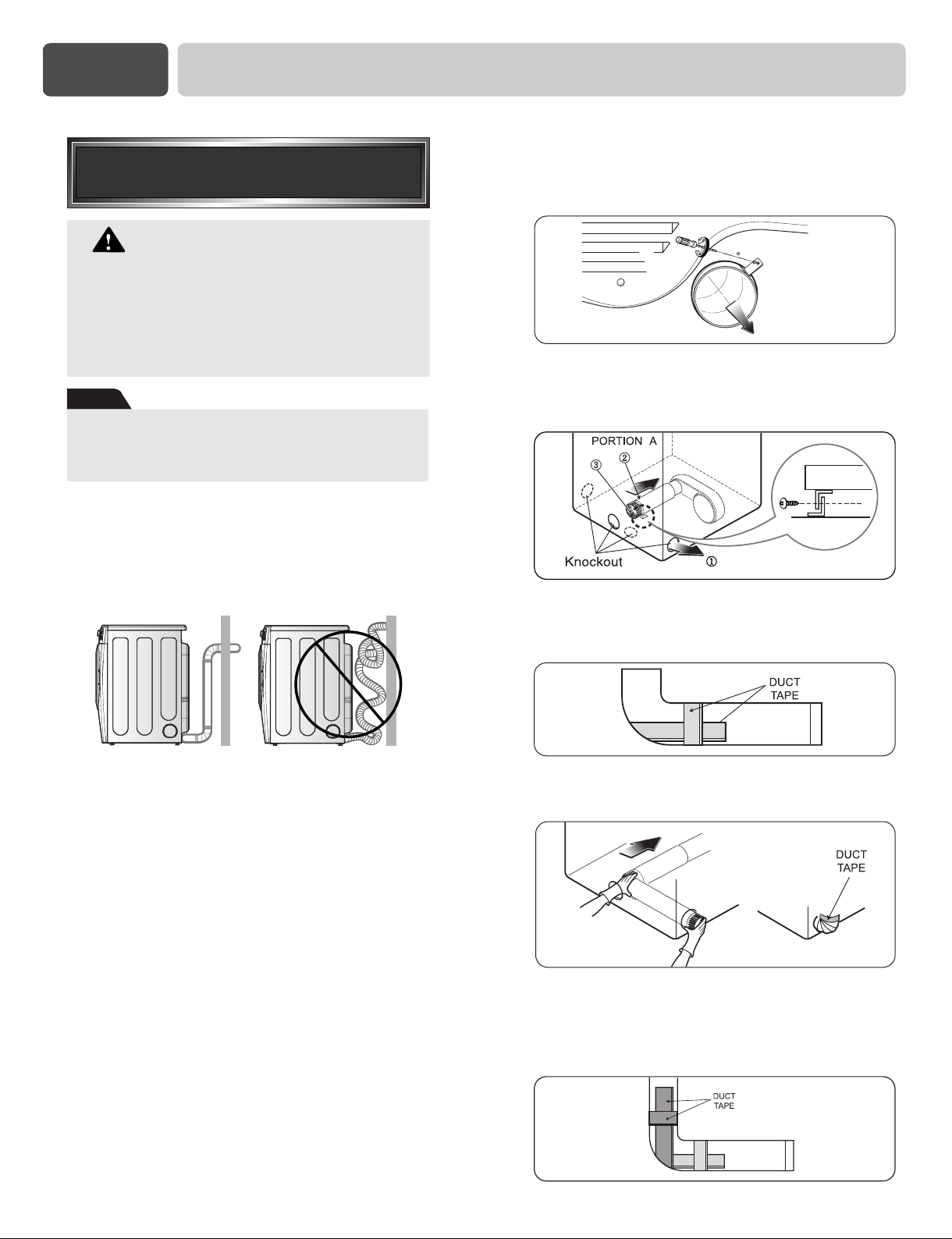

■ ALTERNATE EXHAUST DIRECTIONS

STEP 3 Connecting the Exhaust

and Venting System.

WARNING!

• Use a heavy metal vent.

• Do not use plastic or thin foil duct.

• Clean old ducts before installing this dryer.

• Failure to follow these instructions can

result in death or fire.

Note

The exhaust must be vented to the outside.

Improper taping and incorrect installation will

cause dryer malfunction.

In addition to the following warnings, please refer

to manual section on Exhaust Requirements and

Maintenance. Warning: The dryer must be vented

to the outdoors. Please follow the instructions (and

all others in this manual) very carefully. Failure to

follow these instructions can result in death or fire.

1.

Remove screw and exhaust duct.

(Use exhaust kit part #3911EZ9131X.)

2-1.

Detach and remove the knockout that

matches the desired venting direction

(Right side not available on Gas Dryers)

2-2.

Connect a short piece of duct to the

blower housing and attach the duct to

the base.

• Do not use plastic or thin foil duct.

• Rigid or semi-rigid metal ducting is recommended

for use as transition ducting between the dryer and

and the wall. In special installations when it is

impossible to make a connection with the above

recommendations, then a UL-listed flexible metal

transition duct may be used between the dryer and

wall connection only. The use of this ducting will

affect dry time.

• Position the dryer such that the exhaust duct run is

as short as possible.

• Clean old ducts before installing this dryer

• The male end of each section of exhaust duct must

point away from the dryer.

• Use as few elbow joints as possible.

• Use duct tape on all duct joints.

• Insulate ductwork that runs through unheated

areas in order to reduce condensation and lint

build-up on pipe walls.

• PLEASE BE AWARE THAT FAILURE TO

EXHAUST THE DRYER CORRECTLY WILL

VOID THE DRYER’S WARRANTY.

3-1.

Insert the male end of a 4" elbow into the

female end of a short duct. Tape the joint.

3-2.

Insert this assembly elbow first through the

hole in the dryer and push the female end

of the elbow onto the male end of the

blower output shaft. Tape the joint.

13

Page 14

Part 3 INITIAL STEPS FOR INSTALLING YOUR DRYER

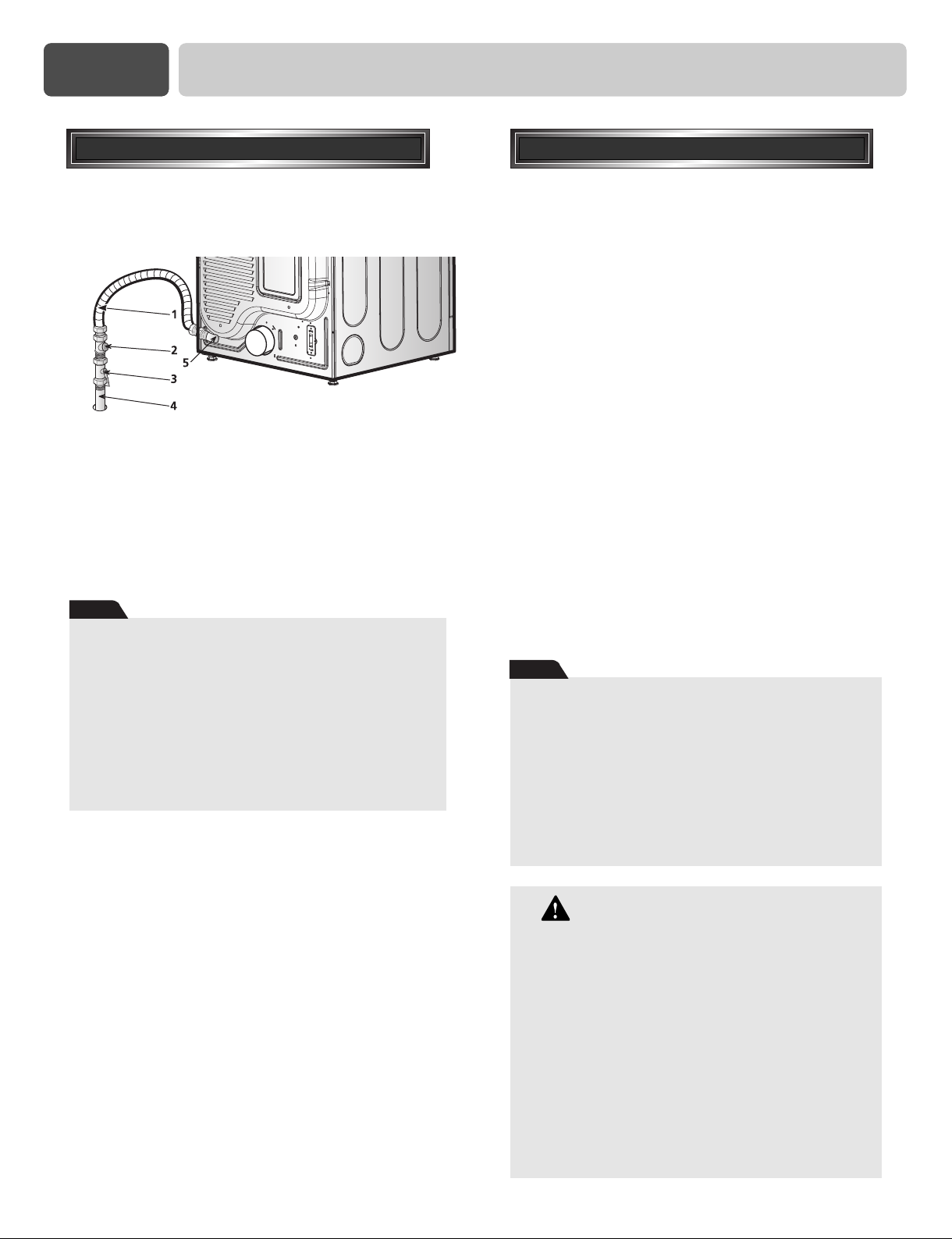

STEP 4

Connection of Gas Supply

(Gas dryer only). In addition to the following,

please refer to manual section on Gas Requirements

and Instructions.

1. New stainless steel flexible connector. Use this type of

connector only if allowed by local codes. Use Design AGA

Certified Connector.

2. 1/8" NPT Pipe Plug (for checking inlet gas pressure)

3. Equipment Shut-Off Valve

Installed within 6’ (1.8 m) of dryer.

4. Iron Pipe. Shorter than 20’ (6.1 m)

Use 3/8" pipe.

Longer than 20’ (6.1 m) - Use 1/2" pipe.

5. 3/8" N.P.T. Gas Connection.

Note

Make sure the burner orifice is proper for the type of

gas you have.

For instance, using LPG with LNG orifice will result

in death, fire or explosion. Or using LNG with LPG

nozzle will not allow the burner to ignite.

If needed, orifice conversion should be done by a

qualified service technician and mark or put the

label of the current type of orifice on the dryer.

If changing the orifice, also adjust the gas valve.

1. Confirm that the type of gas available in your laundry

room is appropriate for the dryer. The dryer is prepared

for Natural Gas with a 3/8" NPT gas connection.

2. Remove the shipping cap from the gas connection at the

back of the dryer. Make sure that you don’t damage the

threads of the gas connection pipe when you remove the

shipping cap.

3. Connect the dryer to your laundry room’s gas supply

using a new flexible stainless steel connector (as noted

below, use a new stainless steel flexible connector if

allowed by your local codes).

4. Securely tighten all connections between the dryer and

your laundry room’s gas supply. Turn on your laundry

room’s gas supply and check all pipe connections (both

internal and external) for gas leaks with a non-corrosive

leak detection fluid. Refer to Part 7 (page 20)

5. For LP (Liquefied Petroleum) gas connection, refer to

this manual’s section entitled Gas Requirements and

Instructions.

14

STEP 5

Following are several warnings and instructions

concerning making the electrical connection for electric

dryers. More detailed information concerning the

electrical connection is provided in the manual section

entitled Electrical Requirements for Electric Dryer.

It is important that you thoroughly review that section

and the remainder of this manual, before taking any

steps to install or use this dryer.

1. Use only a new UL listed No. 10 (copper wire only)

three conductor power supply cord kit rated 240

Volts (minimum) 30 Amperes and labeled as suitable

for use in a clothes dryer.

2. A four-wire cord is required for manufactured

(mobile) home installations and where local codes do

not allow grounding of this appliance through

neutral.

Electrical Plug Connections

3. Electrical Plug Connections.

4. For additional instruction on connecting the dryer to

an electrical power source, please refer to this

manual’s section on Electrical Requirements and

Electric Dryer.

Note

Burner input requirements

If your house is located at the elevations up to

10,000 feet.

Adjusting burner input setting is not needed at this

elevation because AGA certifies this dryer will not have

any problem with the BTU rating at this altitude.

If your house is above 10,000 feet, you are required to

adjust a four percent (4%) reduction of the burner BTU

rating indicated on the model/serial rating plate.

WARNING!

• Use a new UL listed 30 amp power supply cord.

• Use a UL approved strain relief.

• Disconnect power before making electrical

connections.

• Connect neutral wire (white or center wire) to

center terminal.

• Ground wire (green or bare wire) must be

connected to green ground connector.

• Securely tighten all electrical connections

• See installation instructions for complete

instructions.

Failure to do so can result in fire or electrical

•

shock.

Page 15

Part 3 INITIAL STEPS FOR INSTALLING YOUR DRYER

STEP 6

Prior to the first use of this appliance, use allpurpose cleaning products or a solution of detergent

and water, with damp cloth to remove from the

inside of the dryer drum/drying compartment any

dust or dirt that may have accumulated inside the

dryer. Plug-in your dryer after reviewing the

following parts on your dryer’s Electrical

Requirements.

STEP 7

Preparation of the Dryer.

Confirming Heat Source

Operation.

Confirming Heat Source in Gas Dryers

Close the door to the dryer drum/drying

compartment and, after completing all steps in this

manual for proper installation of this dryer, start the

dryer on a heat setting. After the dryer starts, the

igniter will glow red and the main burner will

ignite.

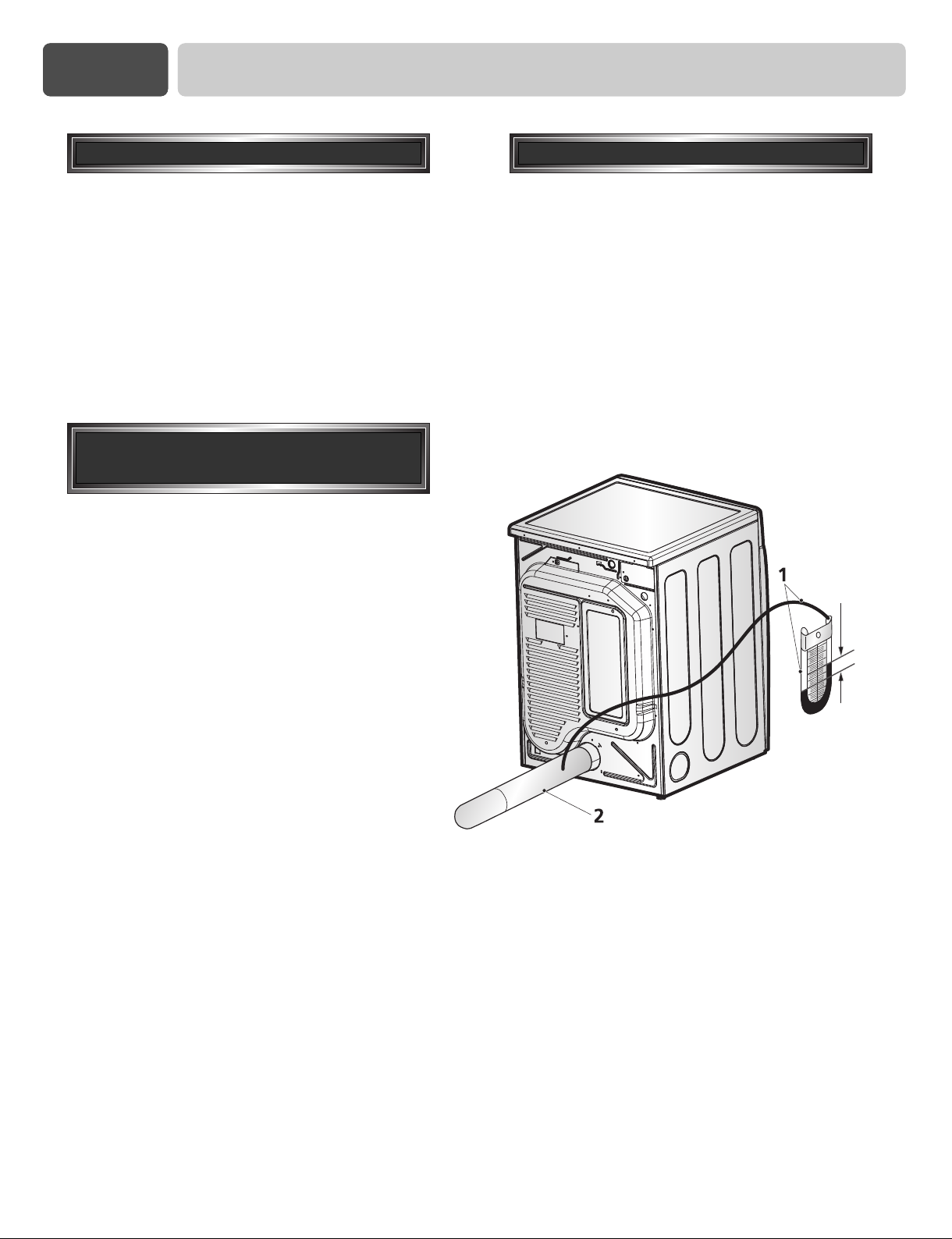

STEP 8

Effective dryer operation requires appropriate dryer

airflow. The adequacy of the airflow can be

measured by evaluating the static pressure.

Static pressure in the exhaust duct can be measured

with a manometer, placed on the exhaust duct

approximately 2 ft. (60.9 cm) from the dryer.

Static pressure in the exhaust duct should not

exceed 5/8 inches (1.5 cm). The dryer should be

checked while the dryer is running with no load.

Dryer Airflow.

Measuring Static pressure

Manometer

Warning: If all air is not purged from the gas line,

the gas igniter may go off before the gas and the

main burner have ignited. If this happens, the

igniter will re-attempt gas ignition after

approximately two minutes.

Confirming Heat Source in Electric Dryers

Close the door to the dryer drum/drying

compartment and, after completing all steps in this

manual for proper installation of this dryer, start the

dryer on a heat setting. The exhaust air or the

exhaust pipe should be warm after the dryer has

been operating for three minutes.

Exhaust Duct

MAXIMUM STATIC

PRESSURE IN

WATER COLUMN

5/8 inches (1.5 cm)

15

Page 16

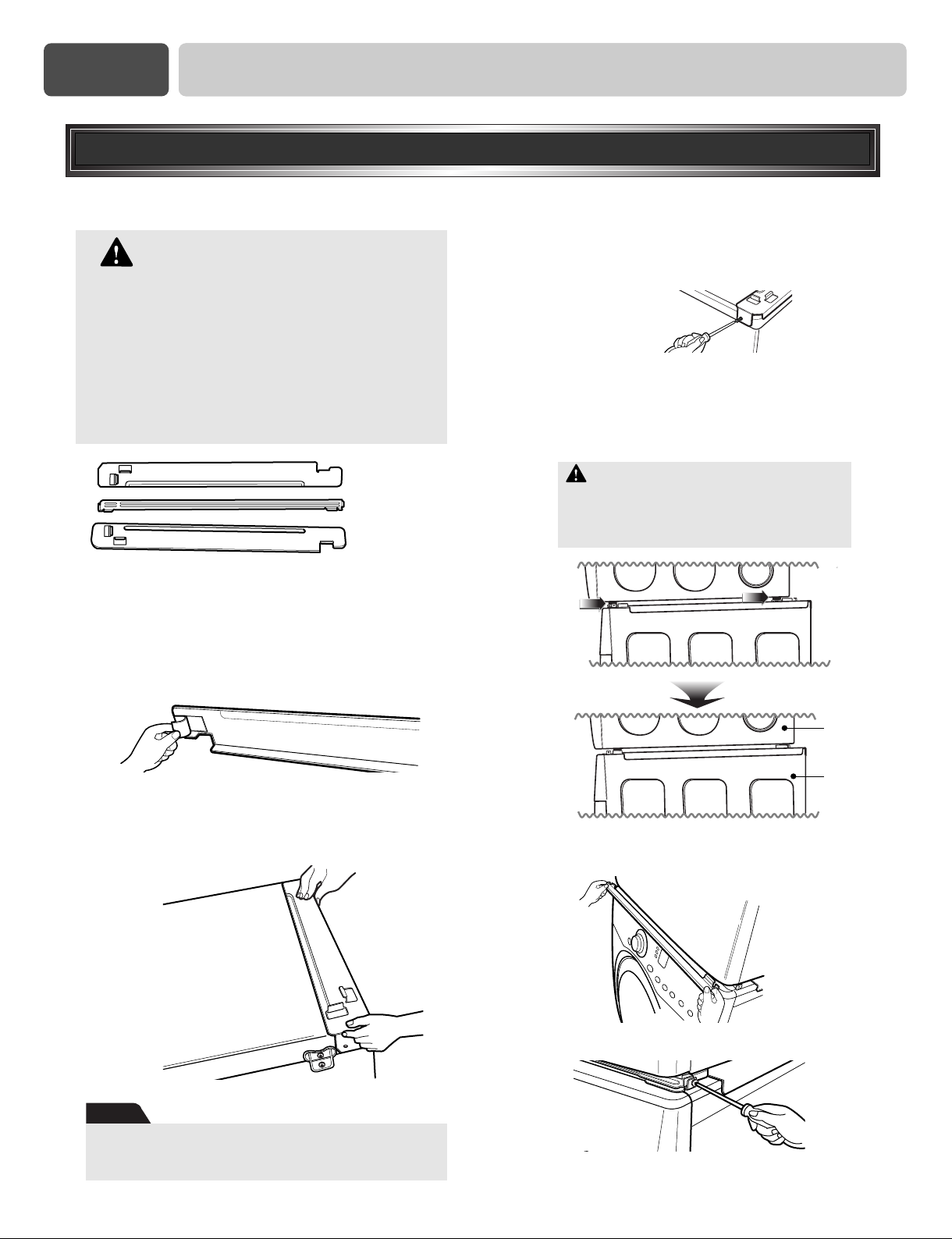

Part 4 ACCESSORIES INSTALLATION

Stacking Kit Installation Instructions

To ensure safe and secure installation, please

observe the instructions below.

WARNING!

• The weight of the dryer and the height of

installation makes the stacking procedure

too risky for one person. This procedure

should be performed by 2 or more

experienced service personnel.

• Incorrect installation can cause serious

accidents.

Stacking kit

4

5

Secure stacking kit side bracket to the

washer with a screw on the back of bracket.

Repeat Steps 2, 3, 4 for the other side.

Place the dryer on top of the washer by fitting

legs as shown in the picture. Avoid finger

injuries - be careful not to pinch fingers

between the washer and dryer. Slide dryer

slowly backwards to the stopper of kit.

WARNING!

• Do not stack a washer on the top of the dryer.

• Incorrect installation can cause serious

accidents.

1

2

3

Place washer firmly on a stable, even and

solid floor.

Peel protective paper off the tape from the

stacking kit side bracket.

Fit the stacking kit side bracket firmly to the

side of top plate by attaching the doublesided tape to top plate as picture shows.

6

7

Dryer

Washer

Insert the front rail. Push the front rail back

to the stoppers of side stacking kit.

Attach both sides of the front kit with screws.

Note

Clean the surface before attaching the brackets

and double-sided tape.

16

• Do not use stacking kit with a gas dryer in potentially

unstable conditions like a mobile home.

Page 17

Part 4 ACCESSORIES INSTALLATION

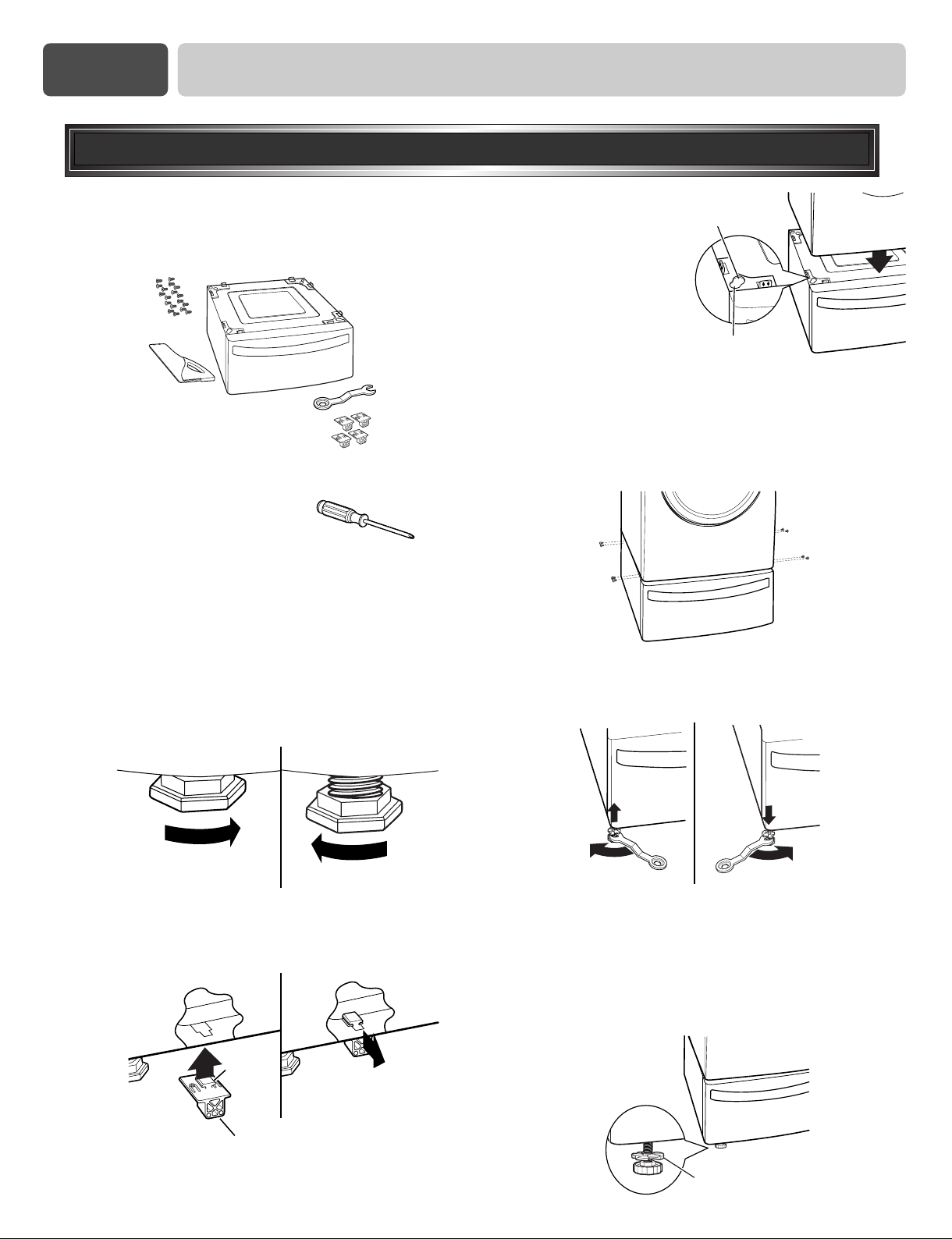

Pedestal Installation Instructions

The pedestal accessory includes:

Drawer divider (1)

•

Screws (18) †

•

† Dryer installation only uses 8 screws

†† For dryer only

Tools Needed for Installation:

Phillips-head screwdriver

•

Wrench (supplied)

•

To ensure safe and secure installation, please

thoroughly follow the instructions below.

To set the dryer to the same height as the

washer, fully retract the leveling feet of the

1

dryer by turning them counterclockwise, then

turn them clockwise 1-1/2 turns.

NOTE: The appliance and pedestal assembly

must be placed on a solid, sturdy, level floor

for proper operation.

Wrench (1)

•

Retainers (4) ††

•

3

4

5

Place the dryer on the

pedestal. Make sure

the front and back

feet are in the correct

positions. The dryer

feet will fit into the

innermost positions as

shown.

Make sure the screws on the pedestal align with

the holes in the retainers, then install 4 screws at

each corner to securely attach the appliance to the

pedestal.

NOTE: If the screws are not installed properly, noise

and vibration may result.

Move the appliance to the desired location.

Loosen the locknuts on all 4 leveling feet of the

pedestal until you can turn them with the wrench.

Turn clockwise to raise or counterclockwise to lower

until the pedestal is level and all 4 feet are solidly

against the floor.

For dryer

For washer/combo

2

Retract fully

Insert the T-clip of the 4 retainers into the dryer

base as shown. Press up on the back of the

clip and pull outward to lock into place.

T-clip

Retainer

Then loosen

1-1/2 turns

6

Raise

Securely tighten all locknuts by hand.

NOTE: Noise and vibration may result if locknuts are not

tightened.

Be sure to connect the appliances to all water, power,

or gas lines and draining or venting connections before

operation.

If there is excessive vibration during the first operation

after installation, slightly adjust the leveling feet.

Locknut

Lower

17

Page 18

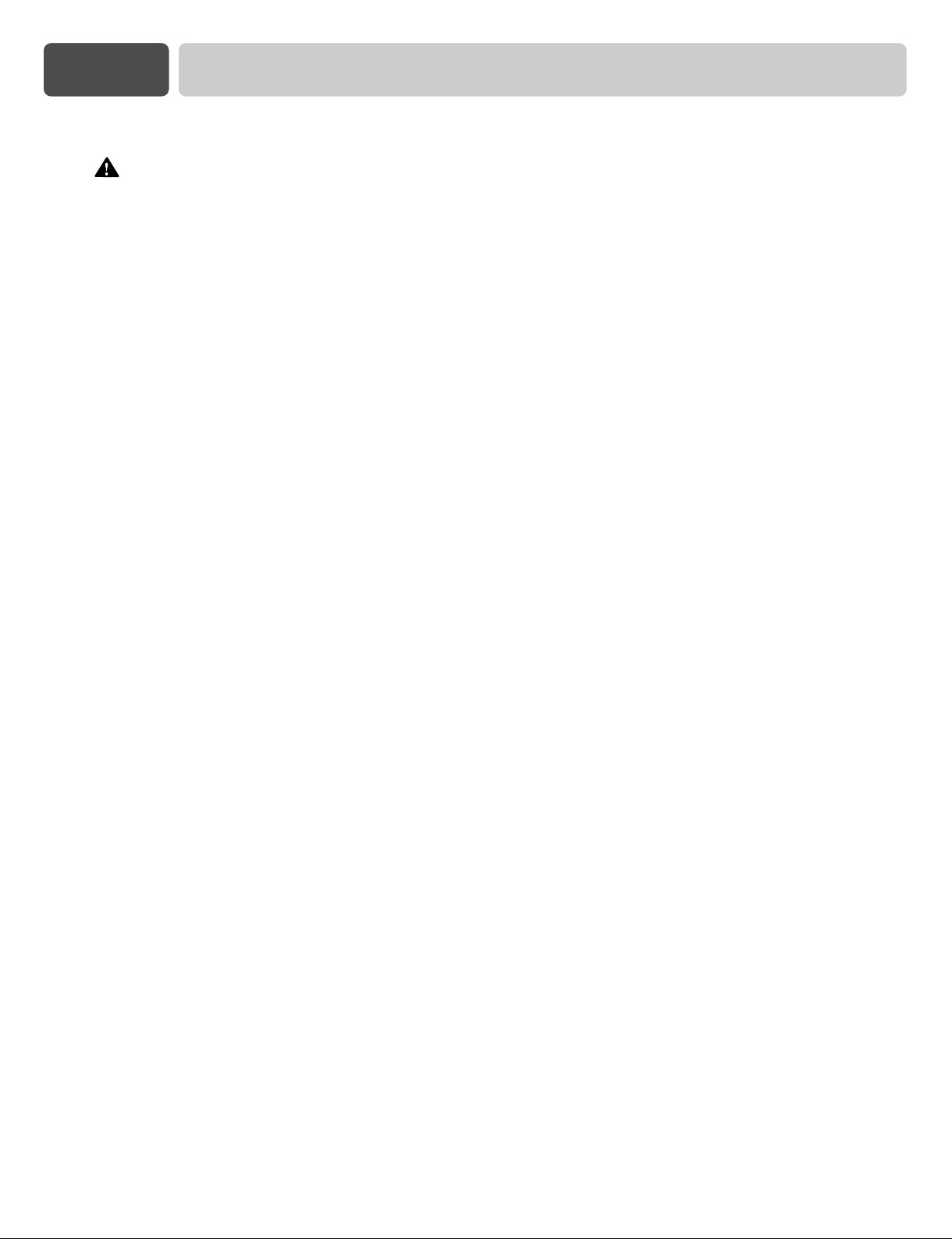

Part 5 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

The following are additional instructions regarding electrical connections and requirements for electric dryers.

Warning: The wiring and grounding must conform to the latest edition of the National Electrical Code,

ANSI/NFPA 70 and all applicable local regulations. Please contact a qualified electrician to check your home’s

wiring and fuses to ensure that your home has adequate electrical power to operate the dryer. Failure to do so can

result in fire or electrical shock.

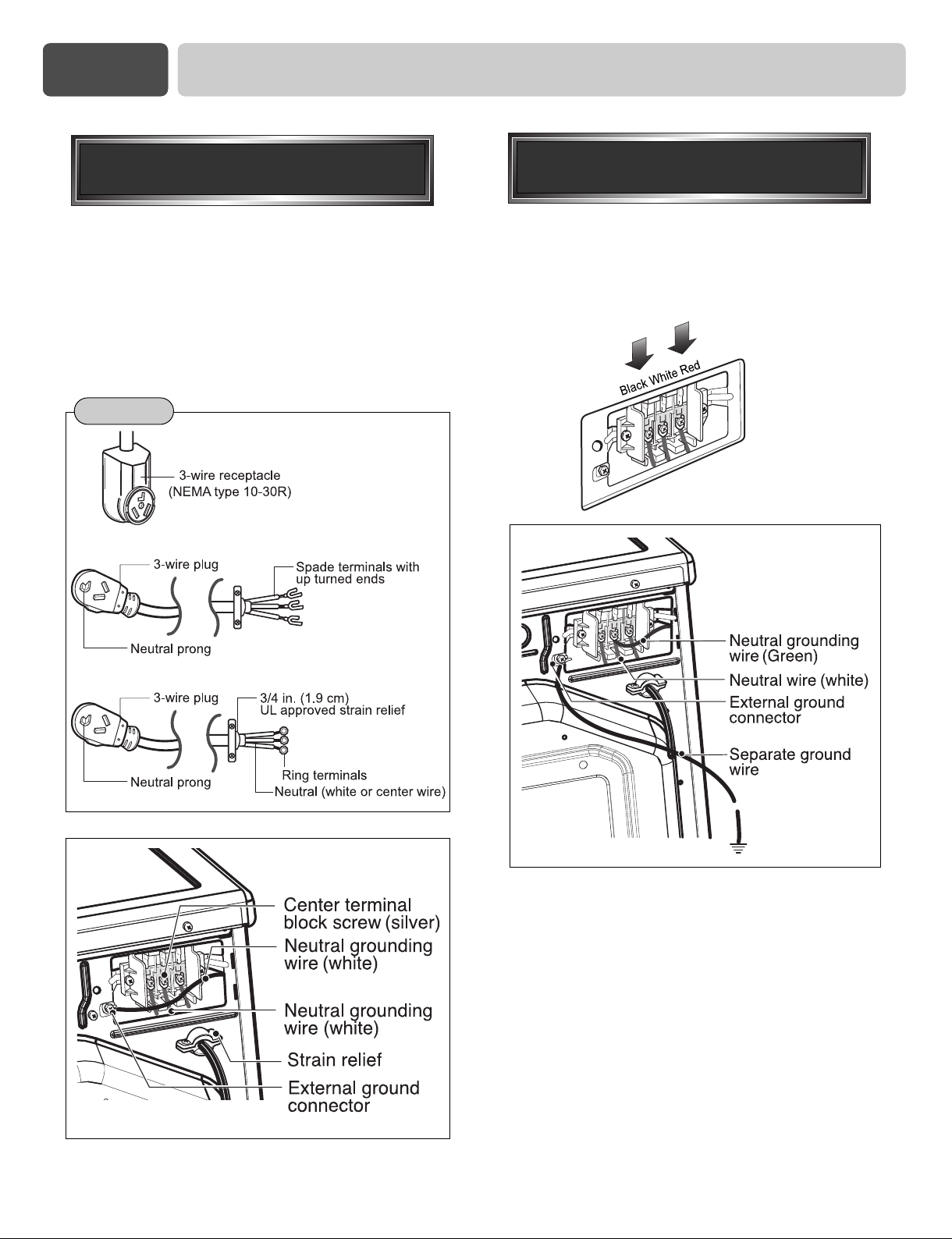

120V/ 240V, 60 Hertz, 3-Wire Installation

Instructions for Grounding of your Electric

Dryer:

a) This dryer must be connected to a grounded

metal, permanent wiring system or an

equipment-grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

dryer.

b) The dryer has its own terminal block that must

be connected to a separate 60 Hertz single

phase AC circuit, fused at 30 Amperes (the

circuit must be fused on both sides of the line).

ELECTRICAL SERVICE FOR THE DRYER

SHOULD BE OF MAXIMUM RATE

VOLTAGE LISTED ON THE NAMEPLATE.

DO NOT CONNECT DRYER TO 110, 115,

OR 120 VOLT CIRCUIT.

c) If branch circuit to dryer is fifteen feet (4.50 m)

or less in length, use U.L. (Underwriters

Laboratories) listed No. 10 A.W.G. wire (copper

wire only), or as required by local codes. If over

fifteen feet (4.50 m), use U.L. (Underwriters

Laboratories) listed No. 8 A.W.G. wire (copper

wire only), or as required by local codes. Allow

sufficient slack in wiring so dryer can be moved

from its normal location when necessary.

d) The power cord (pigtail) connection between

wall receptacle and dryer terminal block IS NOT

supplied with dryer. Type of pigtail and gauge of

wire must conform to local codes and with

instructions mentioned on the following pages.

e) The method of wiring the dryer is optional and

subject to local code requirements. Refer to

examples on next page.

f) You must select the method by which to wire

your dryer according to local code and ordinance

requirements. Sample methods are included in

the following pages.

18

Page 19

Part 5 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

Review the following options to determine the appropriate electrical connection

for your home:

4-wire receptacle

(NEMA type14-30R)

Use the instructions in this section if your home has

a 4-wire receptacle (NEMA type 14-30R) and you

will be using a UL listed, 120/240 volt minimum,

30 amp, dryer power supply cord.

3-wire receptacle

(NEMA type10-30R)

Use the instructions in this section if your home has

a 3-wire receptacle (NEMA type 10-30R) and you

will be using a UL listed, 120/240 volt minimum,

30 amp, dryer power supply cord.

4-wire direct

If this type is available at your home. you will be

connecting to a fused disconnect or circuit breaker

box.

4-wire connection : Direct wire

Warning : Grounding through the neutral conductor is

prohibited for (1) new branch-circuit installations, (2)

mobile homes, (3) recreational vehicles, and (4) areas

where local codes prohibit grounding through the

neutral conductor. Failure to do so can result in fire or

electrical shock.

Prepare minimum 5 ft (1.52 m) of length in order for

dryer to be replaced.

First, peel 5 inches (12.7 cm) of covering material from

end. Strip 5 inches of ground wire insulation. After

cutting 1

insulation back 1 inch (2.5 cm). Make ends of 3 wires a

hook shape.

Then, put the hooked shape end of the wire under the

screw of the terminal block (hooked end facing to the

right) and pinch the hook together and screw tightly.

1

/2 inch (3.8 cm) from 3 other wires peel

3-wire direct

If this type is available at your home. you will be

connecting to a fused disconnect or circuit breaker

box.

Note

• Connect the power supply wire to the terminal

block. Colored wire should be connected to

same color screw. Wire color indicated on

manual is connected to the same color screw in

block. Otherwise,a short or excessive current

flow may result.

1. Connect neutral wire (white) of power cord to center

terminal block screw.

2. Connect red and black wires to the left and right

terminal block screws.

3. Connect ground wire (green) of power cord to external

ground screw and move neutral ground wire of

appliance and connect it to center screw.

4. Make sure that the strain relief screw is tightened.

Be sure that all terminal block nuts are on tight and

power cord is in right position.

19

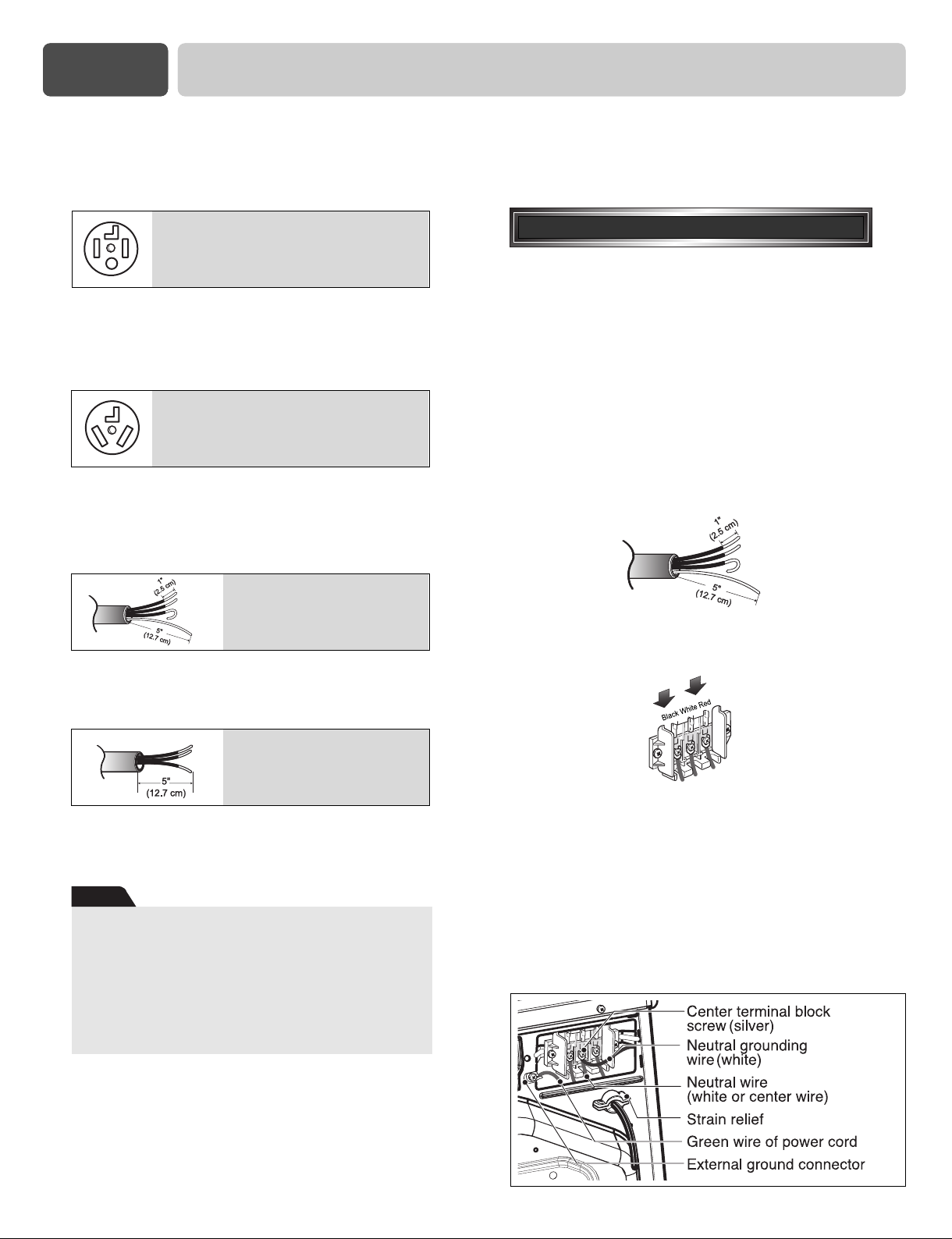

Page 20

Part 5 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

3-wire connection : Direct wire

Warning :

is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4)

areas where local codes prohibit grounding through the

neutral conductor. Failure to do so can result in fire or

electrical shock.

Prepare minimum 5 ft (1.52 m) of length in order

for dryer to be replaced.

First, strip 3

end and strip 1 inch of insulation from each

conductor.

Then, put the hooked shape end of the wire under

the screw of the terminal block (hooked end facing

rightward) and pinch the hook together and tighten

the screw securely.

Grounding through the neutral conductor

1

/2

inches (8.9 cm) of outer sheath from

Option 1: 4-wire connection with

a power supply cord.

• lf your local codes or ordinances do not allow the

use of a 3-wire connection, or you are installing

your dryer in a mobile home, you must use a

4-wire connection.

1. Connect neutral wire (white) of power cord to

center terminal block screw.

2. Connect red and black wires to the left and right

terminal block screws.

3. Make sure that the strain relief screw is tightened.

Be sure that all terminal block nuts are on tight

and power cord is in right position.

20

1. Connect neutral wire (white) of power cord to

center terminal block screw.

2. Connect red and black wires to the left and right

terminal block screws.

3. Connect ground wire (green) of power cord to

external ground screw and move neutral ground

wire of appliance and connect it to center screw.

4. Make sure that the strain relief screw is tightened.

Be sure that all terminal block nuts are on tight

and power cord is in right position.

Page 21

Part 5 ELECTRICAL REQUIREMENTS FOR ELECTRIC DRYERS

Option 2: 3-Wire connection with

a power supply cord.

lf your local codes or ordinances permit the

connection of a frame-grounding conductor to the

neutral wire, use these instructions. If your local

codes or ordinances do not allow the connection of

a frame-grounding conductor to the neutral wire,

use the instructions under Section 1: Optional 3wire connection.

Section 1

Option 3: Optional 3-wire

connection.

• If your local codes or ordinances do not allow the

connection of a frame-grounding conductor to the

neutral wire, use the instructions under this

section.

1. Connect neutral wire (white) of power cord to

center terminal block screw.

2. Connect ground wire of appliance and neutral

wire of power cord to center terminal block

screw.

3. Connect red and black wires to the left and right

terminal block screws.

4. Make sure the strain relief screw is tightened.

Be sure that all terminal block nuts are on tight

and power cord is in right position.

5. Connect a independent ground wire from external

ground connector to proper ground.

21

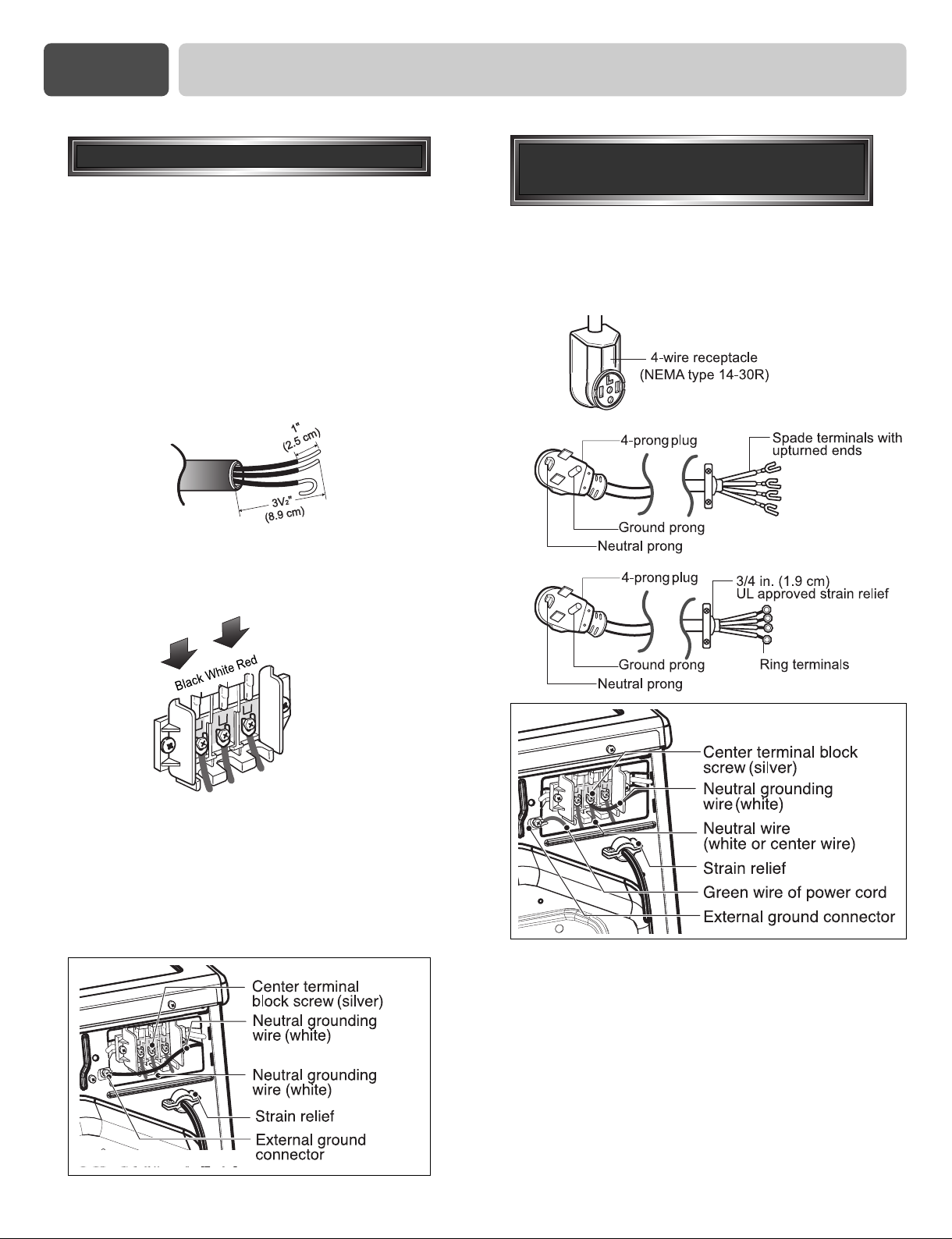

Page 22

Part 6 ELECTRICAL REQUIREMENTS FOR GAS DRYERS

120 Volt, 60 Hertz, with 3-Prong Grounding Plug

Following are additional instructions regarding electrical connections and requirements for gas dryers.

Warning: The wiring and grounding must conform to the latest edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1, and all applicable local regulations. Please contact a

qualified electrician to check your hom’s wiring and fuses to ensure that your home has adequate electrical power

to operate the dryer. Failure to do so can result in fire or electrical shock.

Electrical Requirements for Your Dryer:

a) Please note that the wiring diagram is provided

inside the dryer control hood. Label all wires

prior to disconnection when servicing the dryer,

because wiring errors can cause serious injury to

you and your dryer.

b) Your dryer is designed to be used on a separate

branch, polarized, three-wire, effectively

grounded, 120 Volt, 60 Hertz, AC (alternating

current) circuit protected by a 15 Ampere fuse,

equivalent fuse or circuit breaker.

c) Use separately fused circuits for washers and

dryers, and DO NOT operate a washer and a

dryer on the same circuit.

WARNING!

• Do not overload the circuit by operating

other appliances on the same circuit when

this appliance is operating, by using an

extension cord to connect the dryer to the

power source, or by using any adapter to

allow additional cords to connect to the

same outlet.

• Failure to do so can result in fire or

electrical shock.

WARNING!

• DO NOT modify the plug provided with

the dryer. If it does not fit the outlet in your

laundry room, a proper outlet will need to

be installed in your laundry room by a

qualified service person or company.

• Failure to do so can result in fire or

electrical shock.

STANDARD 120 VOLT, 60 HERTZ, 3-WIRE

EFFECTIVELY GROUNDED CIRCUIT

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

a) The dryer has a three-prong plug to help guard

against shock. The plug should be plugged

directed into a properly grounded three-prong

receptacle that is rated 120 Volts AC (alternating

current) 15 Amps. This plug, in order to be

properly and fully effective, must be plugged into

a properly installed outlet that is grounded in

accordance with all local codes and ordinances.

b) The dryer must be grounded in order to reduce

the risk of electric shock, including a

malfunction or breakdown.

c) If your laundry room does not meet the

specifications required by this manual, or if you

are uncertain whether or not your laundry room

meets these specifications, please have a

qualified service person or company.

Review your laundry room’s electrical supply for

any problems.

22

Page 23

Part 7 GAS REQUIREMENTS AND INSTRUCTIONS

Following are important instructions and information concerning the requirements for the gas supply and service for

gas dryers. Warning: The gas supply and service for a gas dryer must comply with all local codes and

ordinances. In the absence of any local codes or ordinances in your area, the gas supply and service for your gas

dryer must comply with the latest edition of the National Fuel Gas Code, ANSI Z223.1/NFPA 54. Failure to do so can

result in death, explosion, or fire.

1. Gas supply requirements: Liquefied Petroleum

(L.P.) Gas (2,500 Btu/ft3 (93.1 MJ/m3)) service

must be provided at 10 + 1.5 in. water column

pressure.

2. Do not attempt to connect the dryer to Liquified

Petroleum (LP Gas) Gas service without a

qualified professional.

3. Isolate the dryer from the gas supply piping

system by closing its individual manual shut-off

valve during any pressure testing of the gas

supply system at test pressure equal to or less

than 2/1 psi (3.45 kPa).

4. Supply Line Requirements. Your laundry room

must have a rigid gas supply line to your dryer.

In the United States, an individual manual shutoff

valve MUST be installed within at least 6 feet

(1.8 m) of the dryer, in accordance with the

National Fuel Gas Code ANSI Z223.1. A 1/8 in.

N.P.T. pipe plug must be installed as shown.

5. If using a rigid pipe, the rigid pipe should be 1/2

inch IPS. If acceptable under local codes and

ordinances and when acceptable to your gas

supplier, 3/8 inch approved tubing may be used

where lengths are less than 20 feet (6.1 m).

Larger tubing should be used for lengths in

excess of 20 feet (6.1 m). It is also important that

you use pipe joint compound that is insoluble in

LP gas.

WARNING!

• DO NOT attempt any disassembly of the

dryer. Any disassembly requires the

attention and tools of an authorized and

qualified service person or company.

6. To reduce the danger of gas leaks, explosion, and

fire, please follow and observe the following

instructions and WARNINGS.

• Connect the dryer to the type of gas shown on the

nameplate.

• Use new flexible stainless steel connectors.

• Use Teflon tape and pipe joint compound

insoluble in LP gas on all pipe threads.

• Purge gas supply of air and sediment before

connecting the gas supply to the dryer in order to

prevent gas valve contamination. Before

tightening connection between gas supply and

dryer, purge remaining air until odor of gas is

identified.

• DO NOT use an open flame to inspect for gas

leaks; instead use a non-corrosive leak detection

fluid.

WARNING!

• Use a new AGA or CSA approved gas

supply line.

• Install a shut-off valve.

• Securely tighten all gas connections.

• If connected to LP, have a qualified person

make sure gas pressure does not exceed

13 in. water column.

• Examples of a qualified person include

licensed heating personnel, authorized gas

company personnel, and authorized service

personnel.

• Failure to do so can result in death,

explosion, or fire.

• Failure to do so can result in death,

explosion, or fire.

23

Page 24

Part 8 EXHAUST REQUIREMENTS AND MAINTENANCE

Following are important instructions and information concerning the exhaust requirements for your dryer.

Warning: DO NOT exhaust dryer air into an enclosed and unventilated area, such as an attic, wall, ceiling,

crawl space, chimney, gas vent, or concealed space of a building. To reduce the risk of fire, DO NOT exhaust the

dryer with plastic or thin foil Ducting. Failure to do so can result in death, explosion, or fire.

Weather Hood

Type

Recommended

4”

(10.2 cm)

(10.2 cm)

Use Only for Short Run

Installations

4”

Number of 90°

Elbows

0

1

2

3

4

0

1

2

3

Maximum length of 4”

(10.2 cm) diameter rigid

metal duct

65 feet (19.8 m)

55 feet (16.8 m)

47 feet (14.3 m)

36 feet (11.0 m)

28 feet (8.5 m)

55 feet (16.8 m)

47 feet (14.3 m)

41 feet (12.5 m)

30 feet (9.1 m)

Maximum length of 4”

(10.2 cm) diameter

flexible metal duct

45 feet (13.7 m)

35 feet (10.7 m)

30 feet (9.1 m)

25 feet (7.6 m)

20 feet (6.1 m)

35 feet (10.7 m)

27 feet (8.2 m)

21 feet (6.4 m)

17 feet (5.2 m)

4

2-1/2”

(6.35 cm)

NOTE : Deduct 6 feet (1.8 m) for each additional elbow.

It is not recommended to use more than 4 90° elbows.

Exhaust Requirements and Instructions:

1. Venting materials are not provided with the dryer

and you should obtain the necessary venting

materials locally. For example, the outer end of

exhaust pipe must have a weather hood with hinged

dampers to prevent back-draft when the dryer is not

in use.

2. The exhaust duct must be four inches (10.2 cm) in

diameter with no obstructions. The exhaust duct

should be kept as short as possible. Make sure to

clean any old ducts before installing your new dryer.

22 feet (6.7 m)

15 feet (4.5m)

3. Rigid or semi-rigid metal ducting is recommended

for use as transition ducting between the dryer and

and the wall. In special installations when it is

impossible to make a connection with the above

recommendations, then a UL-listed flexible metal

transition duct may be used between the dryer and

wall connection only. The use of this ducting will

affect dry time.

4. DO NOT use sheet metal screws on exhaust pipe

joints or other fastening means which extend into

the duct that could catch lint and reduce the

efficiency of the exhaust system. Secure all joints

with duct tape.

5. To maximize operating results, please observe the

duct length limitations noted in the chart above.

24

Page 25

Part 8 EXHAUST REQUIREMENTS AND MAINTENANCE

Exhaust and Dryer Maintenance

WARNING!

• Disconnect the dryer’s electric power

prior to any cleaning or maintenance.

• Failure to do so can result in fire or

electrical shock.

1. After one year of use, the interior and complete

exhaust system of the dryer should be examined

and cleaned if necessary.

2. Before one year of use, when drying performance has become

unsatisfactory, please examine and clean the exhaust duct for

better drying performance.

3. Check the weather hoods frequently to ensure

the dampers are moving freely, that the dampers

are not pushed in and that nothing has been set

against the dampers.

4. A qualified service person or company should be

used to perform this maintenance.

5. A Flexible Metal Vent Kit, available at extra cost,

can be used to exhaust the dryer when it is placed

in hard to reach places. This Kit comes in two

pieces, one of which is attached to the dryer and

the other is attached to the wall exhaust outlet.

Following attachment of the two separate pieces

to the dryer and the wall, the dryer may be

returned to its final position, after which the two

pieces themselves can be connected.

7. Ordinarily, the dryer drum will need no care.

Wipe the exterior of the dryer as required, and

always wipe the exterior of the dryer in the event

any detergent, bleach, or other washing products

is spilled on the dryer.

8. Clean the control panel with a damp cloth as

necessary. Warning: spray pre-wash products

may damage the finish of the control panel.

9. Please clean the lint filter either before drying

each load or after drying each load.

10. Always make sure the lint filter is clean before

starting a new load, because a clogged lint filter

may increase drying times.

11. Annually remove the lint filter and attach it to

the vacuum duct. See item #2 above.

12. Please note that the wiring diagram is provided

inside the dryer control hood. Label all wires

prior to disconnection when servicing the dryer,

because wiring errors can cause serious injury

to you and your dryer.

Cleaning the Lint Screen

1. Clean the lint filter either before drying each load

or after drying each load. Always make sure the

lint filter is clean before starting a new load,

because a clogged lint filter may increase drying

times.

2. To clean, pull the lint screen straight up and roll

any lint off the screen with your fingers.

Do not rinse or wash screen to remove lint. Push

the lint screen firmly back into place.

3. Always ensure the lint screen is firmly secured

before running the dryer. Running the dryer with

a loose lint screen may cause overheating and

damage to the dryer and articles being dried.

4. Some articles of clothing may shed more lint than

others (towels for example), causing the lint

screen to fill rapidly. Remove lint from the lint

screen before and after drying these articles, such

as new towels.

5. In the event lint falls off of the lint screen and

into the dryer during removal, inspect the exhaust

hood and remove any lint.

6. Laundry detergent and fabric softener residue can

build up on the lint screen, causing longer drying

times. The screen is likely blocked if lint falls off

the screen. In order to prevent this type of build

up, and help ensure proper operation of your

dryer, clean the lint screen with a nylon brush

every six months or, if necessary, more

frequently. The lint filter can also be washed as

follows:

a) After rolling the lint off of the screen with your

fingers, wet both sides of the screen with hot or

warm water.

b) Wet a nylon brush with hot water and liquid

detergent and scrub the lint screen with the brush

to remove the buildup of detergent and fabric

softener.

c) After the residue has been removed, rinse screen

with hot water.

d) After drying the lint screen with a clean towel,

firmly replace the lint screen in your dryer.

25

Page 26

Part 9 OPERATING YOUR DRYER

Following are instructions for starting and using your new dryer. Please refer to specific sections of this manual for

more detailed information. Important Warning: To reduce the risk of fire, electric shock, or injury to person, read

this entire manual, including the IMPORTANT SAFETY INSTRUCTIONS, before operating this dryer.

WARNING!

Fire Hazard

• No washer can completely remove oil.

• Do not dry anything that has ever had any

type of oil on it (including cooking oils).

• Items containing foam, rubber, or plastic

must be air dried.

• Failure to follow these instructions can result

in death or fire.

11

Power Button

• Use this button for power on or off.

26

WARNING!

Explosion Hazard

• Keep flammable materials and vapors,

such as gasoline, away from dryer.

• Do not dry anything that has ever had

anything flammable on it (even after

washing).

• Failure to follow these instructions can

result in death, explosion, or fire.

Page 27

Part 9 OPERATING YOUR DRYER

22

22

Cycle Selection

Cycle Selection

• Turn the knob to select the desired cycle based on

laundry types and conditions.

1. Sensor Dry Cycles

Sensor Dry Cycles allow you to match the cycle to

the load you are drying. Each cycle dries certain

fabrics at the recommended temperature. A sensor

detects the moisture in the load and automatically

adjusts the drying time for optimal drying

Cotton/T

Use for drying denims, towels, heavy cottons.

Nor

Use for drying sturdy fabrics such as work casual

clothes.

Per

Use for permanent press and synthetic items.

Delicates

Use for drying synthetic fabrics, washable knit

fabrics and no-iron finishes.

mal

m. Pr

owels

ess

2. Manual Dry Cycles

Use Manual Cycles to select a specific amount of

drying time and a drying temperature. When a

Manual Cycle is selected, the ESTIMATED TIME

REMAINING display shows the actual time

remaining in your cycle. You can change the actual

time in the cycle by pressing MORE TIME or LESS

TIME.

Speed Dr

Use for small loads or loads that need a short drying

time.

eshen Up

Fr

Use this cycle to remove wrinkles from items, such

as clothes packed in a suitcase or items wrinkled

from being left in the dryer too long.

Air Dr

Use the Air Dry Modifier for items that require

drying without heat such as rubber, plastic and heatsensitive fabrics.

y

y

Sensor Dry Preset Cycle Settings

Sensor Dry

Cycles Load Type

COTTON/TOWELS

Towel, denim pants

NORMAL

Work clothes, corduroys

PERM. PRESS

Synthetics , permanent

press

DELICATES

Lingerie, sheets, blouses

Temp.

Medium

High

Medium

Low 36

Low

Time*

(Minutes)

55

41

32

Manual Preset Cycle Settings

Manual Dry

Cycles Load Type

SPEED DRY

SMALL LOADS

FRESHEN UP

Remove Wrinkles

AIR DRY

Temp.

High

Medium

High

Air Dry

Default Time*

(Minutes)

25

20

30

27

Page 28

Part 9 OPERATING YOUR DRYER

33

Custom Program

Set up your favorite

combination of settings and

save them here for one-touch

recall.

1. Select a cycle.

2. Change DRY LEVEL and TEMP. CONTROL.

3. Select OPTIONS you want.

4. Press and hold the CUSTOM PROGRAM.

To recall your stored CUSTOM PROGRAM

Press CUSTOM PROGRAM button, then press

START/PAUSE.

44

Time Change Button

• Press MORE TIME or LESS

TIME until the desired drying

time is set.

55

LED Display

1. CHECK FILTER REMINDER

The display will show CHECK FILTER when the

dryer is turned on as a reminder to check the filter.

It turns off when the START/PAUSE button is pressed.

WARNING!

• For better drying performance and safety, clean

lint filter every single use.

• Failure to follow these instructions can result in

death or fire.

2. Estimated Time Remaining

Note

Time change button is available only with Manual

Dry, Time Dry and Rack Dry programs.

The display shows the estimated time remaining.

In addition to this, if the dryer has some problem, it

displays error messages.

3. CYCLE COMPLETION INDICATOR

Shows how much of the current drying cycle has been

completed.

4. STATUS/CYCLE DISPLAY

This portion of the display shows the selected cycle,

operating status, and special messages. If a cycle has

special instructions, they will also be displayed in this

area.

28

Page 29

Part 9 OPERATING YOUR DRYER

66

Option Buttons

1. Child Lock

Child Lock can be used to prevent

your children from changing options

on control panel while the dryer is

running.

When Child Lock is enabled, all the

buttons will be locked and

Child Lock glows.

To enable Child Lock, Press and hold OPTION for

3 seconds, A single beep tone is heard and Child

Lock is displayed on the status window.

To disable Child Lock, press and hold OPTION for

3 seconds again.

77

Beeper

The BEEPER controls the

volume of the beep that is made

when you press any of the

buttons on the control panel.

Press BEEPER to adjust the

sound level or turn off the

signal.

88

Time Dry

Use Time Dry Option to change

Drying Time on your own.

You can select the desired

operation time manually by

pressing Time Dry button

between 20 to 60 minutes.

2. Wrinkle Care

This option helps to prevent wrinkles

in your laundry.

When you select the wrinkle free

option, the dryer will periodically

tumble for up to three hours after the

cycle has completed.

You can use this option in case you

can not remove laundry immediately

after drying is done.

3. Damp Dry Beep

When you select the damp dry beep option, a beep will

alert you when your load is approximately 80% dry.

This notice will allow you to remove lightweight items

that are dry or other items that you may wish to iron.

99

Temp. Control

Use Temp. Control Option to

select temperatures for the Manual

Cycles. Press TEMP. CONTROL

until the desired temperature

setting glows. Temperature

modifiers cannot be used with the

Sensor Dry Cycles.

29

Page 30

Part 9 OPERATING YOUR DRYER

When Using Air Dry

This chart shows examples of items that can be

dried using AIR DRY.

Type of Load Default Time*

(Minutes)

Foam rubber-pillows,

padded bras, stuffed toys

Plastic shower curtains,

tablecloths

Rubber-backed rugs

Olefin, polypropylene,

shear nylon

Reset cycle to complete drying, if needed.

• Check to see that coverings are securely stitched.

• Shake and fluff pillows by hand periodically

during the cycle.

• Dry item completely. Foam rubber pillows are

slow to dry.

NOTE: Air Dry is not available with Sensor Dry

Cycles.

1100

Dry Level

20 - 30

20 - 30

40 - 50

10 - 20

❁ Starting your dryer

1. Befor

• Clean lint screen before or after each cycle.

• Place laundry into dryer and shut door. See Loading.

• Turn the knob to select the drying cycle you want.

The preset setting for Sensor Dry Cycles or Manual

Cycles will glow. The estimated or actual cycle time (in

minutes) will show in the display.

Following are sample loads for Super Capacity

Dryers:

Heavy Work Clothes

4 jeans

4 workpants

4 work shirts

Cotton/Towels

10 bath towels

10 hand towels

Mixed Load

3 sheets (1 king, 2 twin)

4 pillowcases

3 shirts

3 blouses

e use

2 sweatpants

2 sweatshirts

14 wash cloths

9 T-shirts

9 shorts

10 handkerchiefs

• Use these buttons to set dry level

• First, select sensor dry cycle.

• Select dry level to adjust how

much you want to dry the load.

As the cycle runs, the control

senses the dryness of the load

and adjusts the time

automatically based on the

selected dryness level.

Note

DRY LEVEL selections can only be made while

using Sensor Dry Cycles. Selecting

MORE Dry or LESS Dry automatically adjusts the

needed time which is already sensed.

1111

Start / Pause Button

• Use this button for start or pause.

2. Loading

• Determine load size by the amount of space the load

requires rather than the weight of the load.

• Avoid overloading the dryer.

Following these instructions can help reduce your utility

bill, prolong the life of your clothes, and decrease the

likelihood of uneven drying and wrinkle.

3. To use a sensor dry cycle

• Select DRY LEVEL to adjust how dry you want

the load. As the cycle runs, the control senses the

dryness of the load and adjusts the time

automatically for the selected dryness level.

• Select the desired options.

• Press START/PAUSE

Note

DRY LEVEL selections can only be made while

using Sensor Dry Cycles. Selecting MORE Dry or

LESS Dry automatically adjusts the sensed time

needed.

30

Page 31

Part 9 OPERATING YOUR DRYER

4. To use a manual dry cycle

• Select a Manual Dry Cycle.

• Press MORE TIME or LESS TIME until the

desired drying time is displayed. Tap MORE TIME

or LESS TIME and the time will change by 1

minute interval.

Note

The MORE TIME or LESS TIME feature can be used

with Manual Dry and Time Dry.

• Press TEMP. CONTROL until the desired

temperature indicator glows.

• (OPTIONAL STEP) If desired, select OPTIONS.

For more details, see Options.

• Press START/PAUSE. Be sure the door is closed.

• If you do not press START/PAUSE within 10

minutes of selecting the cycle, the dryer

automatically shuts off.

• If you wish to end your drying cycle after pressing

START/PAUSE, press START/PAUSE again.

To stop your dryer at any time

Press START/PAUSE or open the door.

5. Pausing or r

• To pause the dryer at any time:

Open the door or press START/PAUSE.

• To restart the dryer

Close the door. Press START/PAUSE.

Note

Drying will continue from where the cycle

was interrupted if you close the door and press

START within 10 minutes. If the cycle is

interrupted for more than 10 minutes, the dryer

will shut off. Select new cycle settings before

restarting the dryer.

estarting

Maintenance

Clean lint filter

Clean the lint filter after each use and check it

before use. Not cleaning or emptying the filter

will increase drying time and energy

consumption, therefore dryer life expectancy

could be shortened after all.

■ Clean the door and its opening

1. Wipe out the door

opening. Otherwise,

build-ups of dirty and

foreign objects will

damage sealing of

door.

2. Clean the transparent

glass door to keep

inside view clear

through the glass.

1.Open the door

and pull the filter

straight up.

2.Clean the filter using one of the following methods.

1

Run the fingers

across the filter.

2

Vacuum the lint filter.

3

Wash the lint screen

in warm, soapy

water.

Dry thoroughly and

replace.

31

Page 32

Part 10 TROUBLESHOOTING GUIDE

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

1. Problem: My Dryer Won’t Start

Question What to Do

• Is the dryer plugged in?

• Is the fuse blown, or is the circuit

breaker tripped?

Confirm that the dryer’s plug is securely and completely pushed into the laundry

room’s power outlet.

Check your home’s or laundry room’s fuse box/circuit breaker box and replace the

fuse or reset the circuit breaker. (IMPORTANT: electric dryers generally use two

fuses or breakers.)

2. Problem: My Dryer Doesn’t Heat

Question What to Do

• Is the fuse blown, or is the circuit

breaker tripped?

• Is the gas supply or service

blocked or off?

If the fuse is blown or the circuit breaker tripped, the dryer might tumble but not

heat. Check your home’s or laundry room’s fuse box/circuit breaker box and replace

the fuse or reset the circuit breaker. (IMPORTANT: electric dryers generally use

two fuses or breakers.)

Confirm that the house gas shutoff and the dryer gas shutoff are both fully open.

3. Problem: There Are Greasy Spots On My Clothes.

Question What to Do

• Did you follow the instructions on

your fabric softener product?

• Are you drying clean and dirty

clothes together?

• Were your clothes entirely clean?

Confirm and follow the instructions provided with your fabric softener product.

Make sure to use your dryer to dry only clean items, because dirty items can soil

clean clothes placed in the same load or later placed in the dryer drum.

Stains on dried clothes are actually stains that weren’t cleansed during the washing

process. Please review and confirm that you are following your washing

instructions and that the clothes are being completely cleaned.

4. Problem: My Dryer Displayed An Error Code.

Question

It is displayed when thermistor is open. In this case, thermistor should be replaced

tE1

tE2

32

and call a service center.

It is displayed when thermistor is shorted. In this case, thermistor should be

replaced by a service center.

What to Do

Page 33

Part 10 TROUBLESHOOTING GUIDE

5. Problem: There Is Lint On My Clothes

Question What to Do

• Is your lint filter full?

• Did you properly sort your load of

laundry?

• Do your clothes have excess static

electricity?

• Did you overload your dryer?

• Did you place any paper, tissue, or

other similar material in the load?

Please refer to the manual section on cleaning the lint filter, and please confirm that the

lint filter is clean. It is important that the lint filter is clean before each new load of

laundry.

In order to reduce the amount of lint in a load of laundry, sort lint producers (like a

fuzzy white cotton towel) separately from clothes that might catch lint (such as a pair

of black linen pants).

See comments below under. There Is Static In My Clothes After Drying.

Divide your larger load into smaller loads.

Sometimes a person might forget to take a piece of paper or a tissue out of a pocket,

and this paper, tissue, or similar material can cause excess lint in a load of laundry.

Confirm that the pockets of pants, shirts, and other articles of clothing are empty

before washing and drying.

6. Problem: There Is Static In My Clothes After Drying

Question What to Do

• Did you use fabric softener?

• Did you over dry the load of

laundry?

• Are you drying synthetic, permanent

press and blends?

Try using a fabric softener to reduce static electricity.

Over-drying a load of laundry can cause a build up of static electricity.

Try using a fabric softener or adjust your settings and use a shorter drying time.

These materials can cause static to build up in a load of dried clothes.

Try using a fabric softener.

7. Problem: The Drying Time Is Not Consistent

Question

• Are you using consistent heat

settings and consistent load sizes?

The drying time for a load will vary depending on the heat setting, the type of heat

used (electric, natural or LP gas), the size of the load, the type of fabrics, the wetness

of the clothes and the condition of the exhaust ducts and lint filer.

What to Do

8. Problem: Water Is Found Around The Cabinet Cover When Opening The Door.

Question What to Do

• Is water found around cabinet cover

when opening the door?

It is not out of order because this is condensed moisture by drying.

33

Page 34

Part 10 TROUBLESHOOTING GUIDE

9. Problem: It Takes Too Long For My Clothes To Dry

Question What to Do

• Did you properly sort your loads of

laundry?

• Are you drying large loads of heavy

fabrics?

• Are the dryer controls properly set?

• Is the lint filter clean before each

new load of laundry?

• Are the exhaust ducts clear and

properly configured?

• Is the fuse blown, or is the circuit

breaker tripped?

• Did you overload your dryer?

• Did you under load your dryer?

Separate heavy weight items from light weight items when creating loads.

Heavy fabrics take longer to dry because they tend to retain more moisture. To help

reduce and maintain more consistent drying times for large and heavy fabrics,

separate these items into smaller loads of a consistent size.

Use the appropriate control settings for the type of load you are drying.

Please confirm that the lint filter is clean prior to each new load of laundry.

Confirm through review of the appropriate sections of this manual that the exhaust

venting ductwork is properly configured. Confirm that the venting is free of

obstructions. Confirm that the outside wall dampers are moving freely, that the

dampers are not pushed in, and that nothing has been set against the dampers.

Check your home’s or laundry room’s fuse box/circuit breaker box and replace the

fuse or reset the circuit breaker. (IMPORTANT: electric dryers generally use two

fuses or breakers.)

Divide your larger load into a number of smaller loads.

If you are only drying a handful of items, add a few extra pieces to help ensure

proper tumbling action.

10. Problem: My Clothes Are Wrinkled

Question What to Do

• Are you over drying your laundry?

• Are you removing your laundry

from the dryer soon after the

drying cycle is complete?

Over drying a load of laundry can lead to wrinkled clothes. Try a shorter drying

time, and remove items while they still retain a slight amount of moisture.

Remove your laundry from the dryer after the drying cycle ends and either hang or

fold the items.

11. Problem: My clothes are shrinking

Question What to Do

• Are you following the care

instructions for your garment?

To avoid shrinkage, please carefully follow the care and use instructions for your

garment, because some fabrics will naturally shrink when washed. Other fabrics

can be washed but will shrink when dried in a dryer.

12. Problem: RLM (Remote Laundry Monitor)

Question What to Do

• RLM problem

34

See the Owner’s Manual of RLM & PLC modem.

Page 35

TD-V10247G

TD-V14247E

TD-V14247G

Gracias por comprar una Secadora LG. Por favor lea su