Page 1

STEREO CAR CD

RECEIVER

SERVICE MANUAL

MODEL : TCH-500

MODEL : TCH-500SERVICE MANUAL

P/NO : 3828REF007F

FEBRUARY, 2001

Printed in Korea

Page 2

-2-

CONTENTS

SECTION 1 SUMMARY

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ESD PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LOCATION OF CUSTOMER CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 2 ELECTRICAL

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. TEST & ADJUSTMENT POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2. FM ADJUSTMENT POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. AM(MW) ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4. LW ADJUSTMENT(OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ERROR INDICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ELECTRICAL TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION OF IC’s . . . . . . . . . . . . . . . . . 18

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1. MAIN CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2. AM(MW)/TUNER/FRONT CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PRINTED CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1. MAIN P.C.BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2. TUNER P.C.BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3. FRONT P.C.BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SECTION 3 CABINET MAIN CHASSIS & MACHANISM

• EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SECTION 4 REPLACEMENT PART LIST

CABINET MAIN CHASSIS & MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Page 3

-3-

SECTION 1 SUMMARY

SERVICING PRECAUTIONS

(1) Always disconnect the power source before:

1) Removing or reinstalling any component, circuit board, module or any other instrument assembly.

2) Disconnecting or reconnecting any instrument electrical plug or other electrical connection.

3) Connecting a test substitute in parallel with an electrolytic capacitor in the instrument.

CAUTION : Awrong part substitution or incorrect polarity installation of electrolytic capacitors may result

in an explosion hazard.

(2) Do not defeat any plug/socket B+ voltage interlocks with which instruments covered by this service manual

might be equipped.

(3) Do not apply power to this instrument and or any of its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

(4) Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the test

instrument positive lead. Always remove the test instrument ground lead last.

1) The service precautions are indicated or printed on the cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions and service materials.

2) The Components used in the unit have a specified conflammability and dielectric strength. When replacing any components, use components which have the same ratings. Components marked in the circuit diagram are important for safely or the characteristics of the unit. Always replace with the exact components.

3) An insulation tube or tape is sometimes used and some components are raised above the printed writing

board for safely. The internal wiring is sometimes clamped prevent contact with heating components.

Install them as they were.

4) After servicing always check that the removed screws, components and wiring have been installed correctly

and that the portion around the service part has not been damaged. Further check the insulation

between the blades of attachment plug and accessible conductive parts.

Page 4

-4-

ESD PRECAUTIONS

Some semiconductor(solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD devices are integrated circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

(1) Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a know earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons prior to applying power to the unit under test.

(2) After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive sur-

face such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or unsolder ESD device.

(4) Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

(6) Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it.(Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

(7) Immediately before removing the protective material from the leads of a replacement ESD device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handing unpackaged replacement ESD device. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ESD device).

Page 5

-5-

SPECIFICATIONS

1.RADIO SECTION

1) FM

• Frequency range ......................................................................................................87.5 ~108.0 MHz

65.0~74.0 MHz(Optional)

• Intermediate frequency.............................................................................................10.7 MHz

• Usable sensitivity ......................................................................................................10 dBµV

• Signal to noise ratio..................................................................................................60 dB

2) AM(MW)

• Frequency range ......................................................................................................522 ~ 1620 kHz or

520~1,620kHz /

530 ~ 1710 kHz(optional)

• Intermediate frequency.............................................................................................450 kHz

• Usable sensitivity ......................................................................................................28 dBµV

• Signal to noise ratio..................................................................................................50 dB

3) LW (OPTIONAL)

• Frequency range ......................................................................................................144 ~ 281 kHz

• Intermediate frequency.............................................................................................450 kHz

• Usable sensitivity ......................................................................................................35 dBµV

• Signal to noise ratio..................................................................................................50 dB

2. COMPACT DISC SECTION

• Frequency response.................................................................................................40 Hz ~ 20 kHz

• Channel separation ..................................................................................................50 dB(1 kHz)

• Signal to noise ratio..................................................................................................60 dB

3. AUDIO SECTION

• Maximum output power(per channel).......................................................................45 Watt x 4 ch

• Frequency response.................................................................................................40 Hz ~ 20 kHz

• Speaker impedance..................................................................................................4~8 Ω x 4

• Signal to noise ratio..................................................................................................60 dB

4. GENERAL

• Power requirements .................................................................................................12 ~ 15 V DC

• Ground system.........................................................................................................Negative

NOTE: Specifications are subject to change without notice in the course of product improvement.

Page 6

-6-

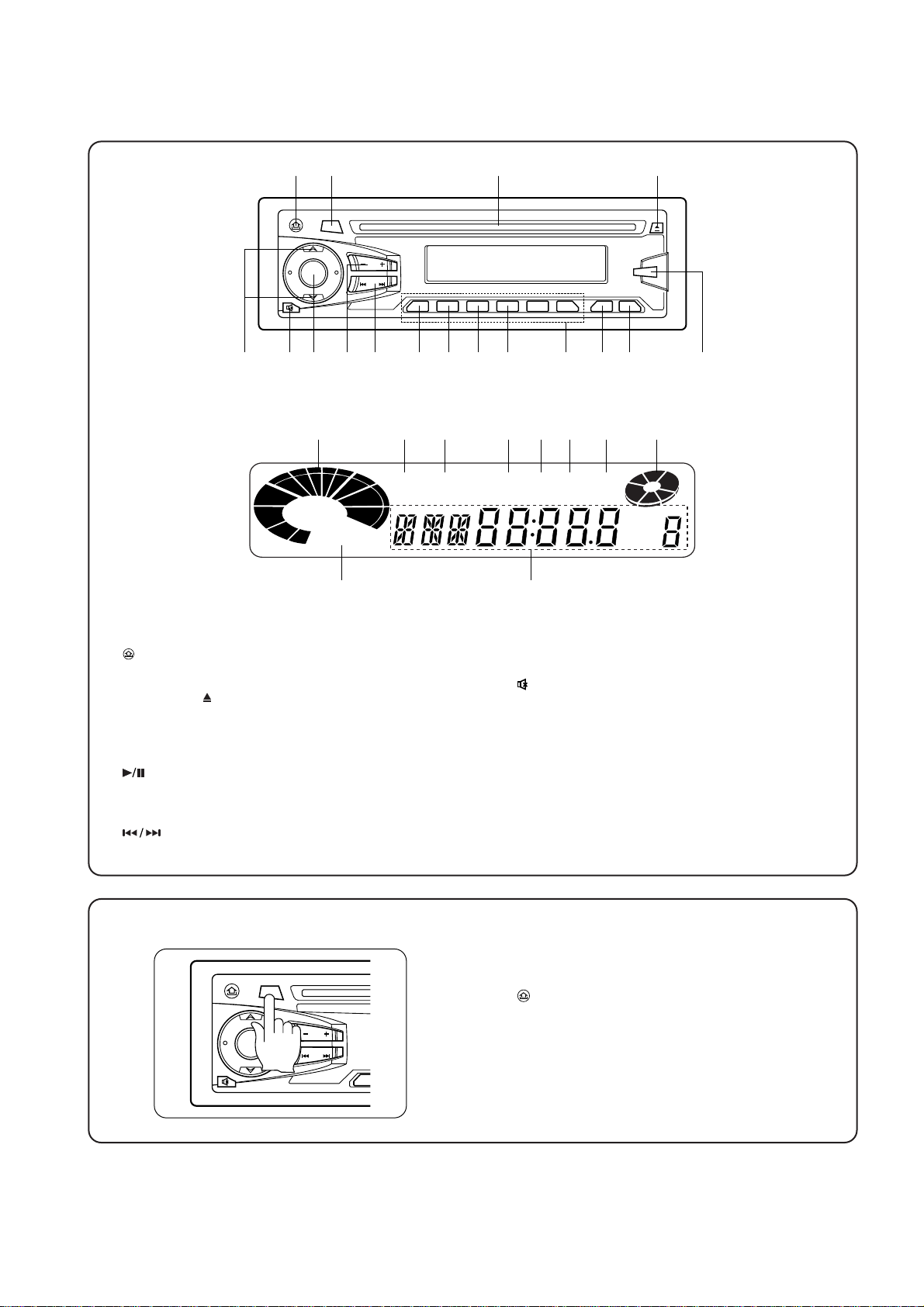

LOCATION OF CUSTOMER CONTROLS

FRONT

Display window

TURNING ON/OFF THE UNIT

CHLOUD

MUTE RDMINTRPTDISCST

1 2 3 4

6

5789101112131516

27 18 19 20 21 22 23 24

26 25

17 14

11. (DETACH) BUTTON

12. PWR(POWER) BUTTON

13. DISC SLOT

14. LOAD EJECT BUTTON

15. FUNC(FUNCTION) BUTTON

16. AS/PS(AUTO STORE/PRESET SCAN) BUTTON

17. BAND BUTTON

18. PRESET STATION BUTTONS 1~6

19. (PLAY/PAUSE) BUTTON

10. RDM(RANDOM) BUTTON

11. RPT(REPEAT) BUTTON

12. INT(INTRO) BUTTON

13. (SKIP/SEEK) BUTTON

14. -/+ (SEARCH/TUNE) BUTTON

15. MD/LD (MODE/LOUDNESS) BUTTON

16. (MUTE) BUTTON

17. VOLUME(UP/DOWN) BUTTON

18. MUTE INDICATOR

19. ST(STEREO) INDICATOR

20. DISK INDICATOR(CDC OPTION)

21. INT(INTRO) INDICATOR

22. RPT(REPEAT) INDICATOR

23. RDM(RANDOM) INDICATOR

24. CD OPERATING INDICATOR

25. MAIN DISPLAYSECTION

26. LOUD INDICATOR

27. LEVEL INDICATOR

To turn on the unit

Press PWR or any other button

(except ).

To turn off the unit

Press PWR.

That document from http://cxema.ru

Page 7

-7-

SECTION 2 ELECTRICAL

ADJUSTMENTS

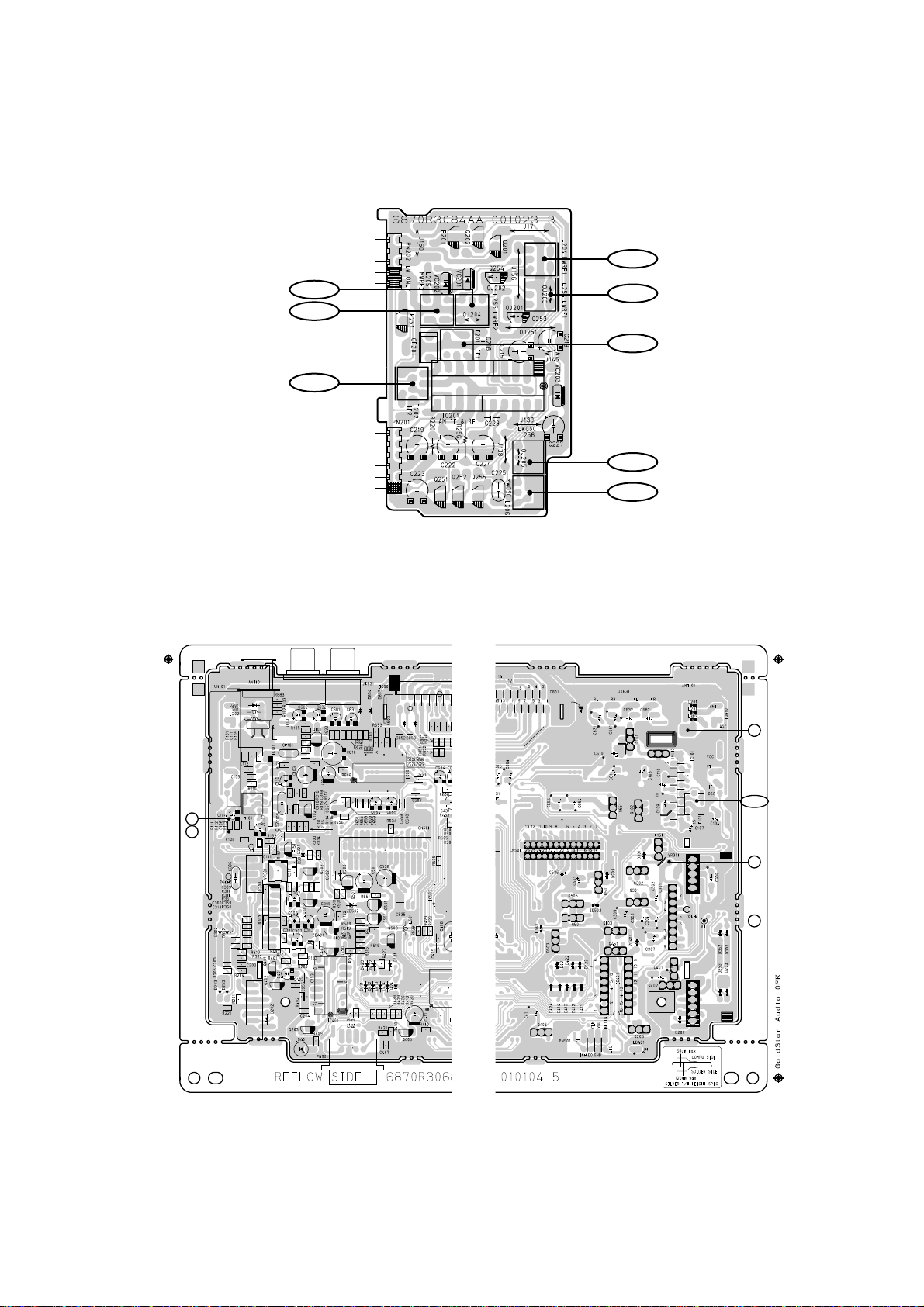

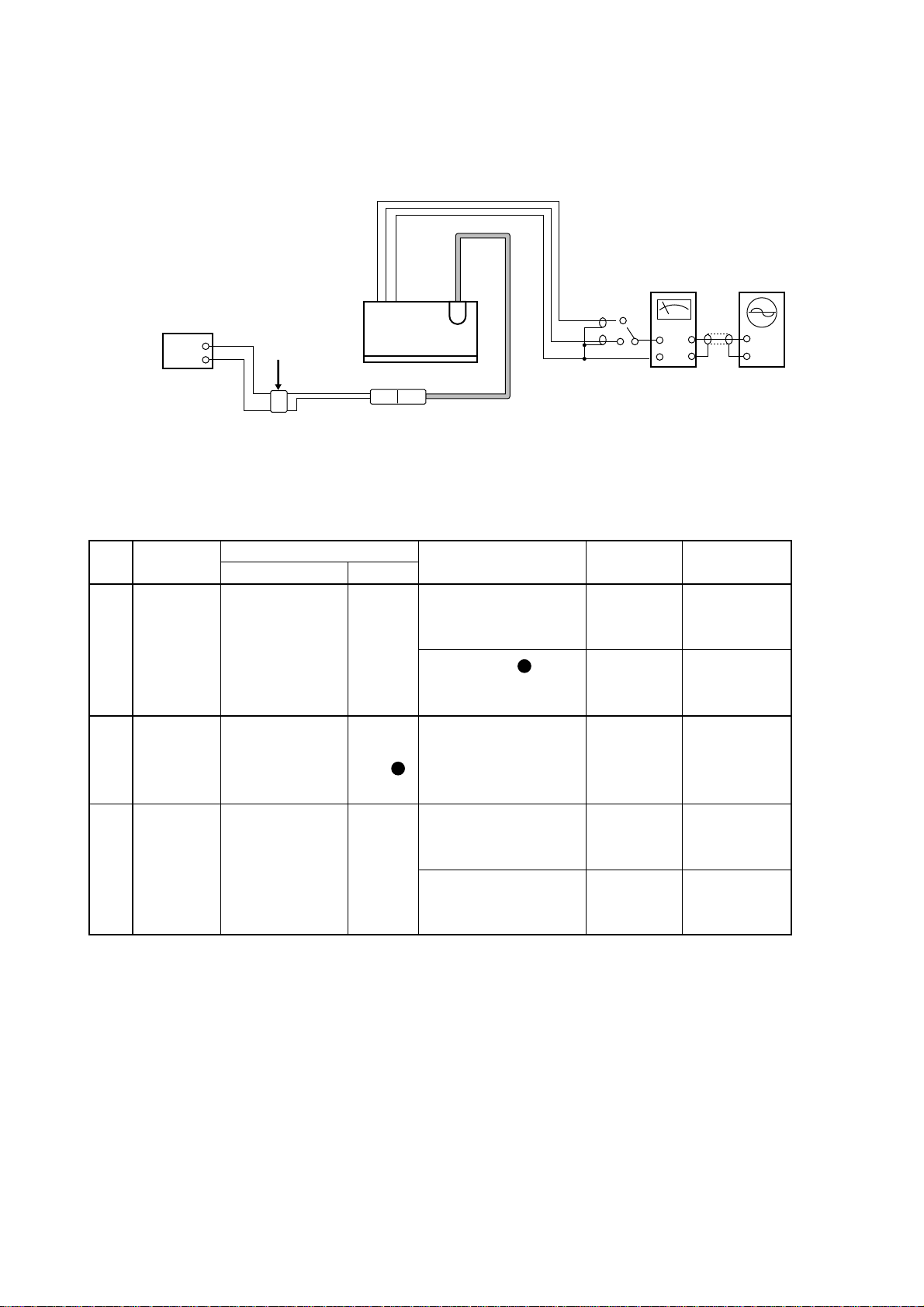

1. Test & Adjustment point

<TOP VIEW>

<TOP VIEW> <BOTTOM VIEW>

L204

L254

T201

L256

T202

L205

L255

L206

C

D

A

T101

B

E VR301

Figure 1. Tuner PCB Board

Figure 2. MAIN PCB Board

Page 8

-8-

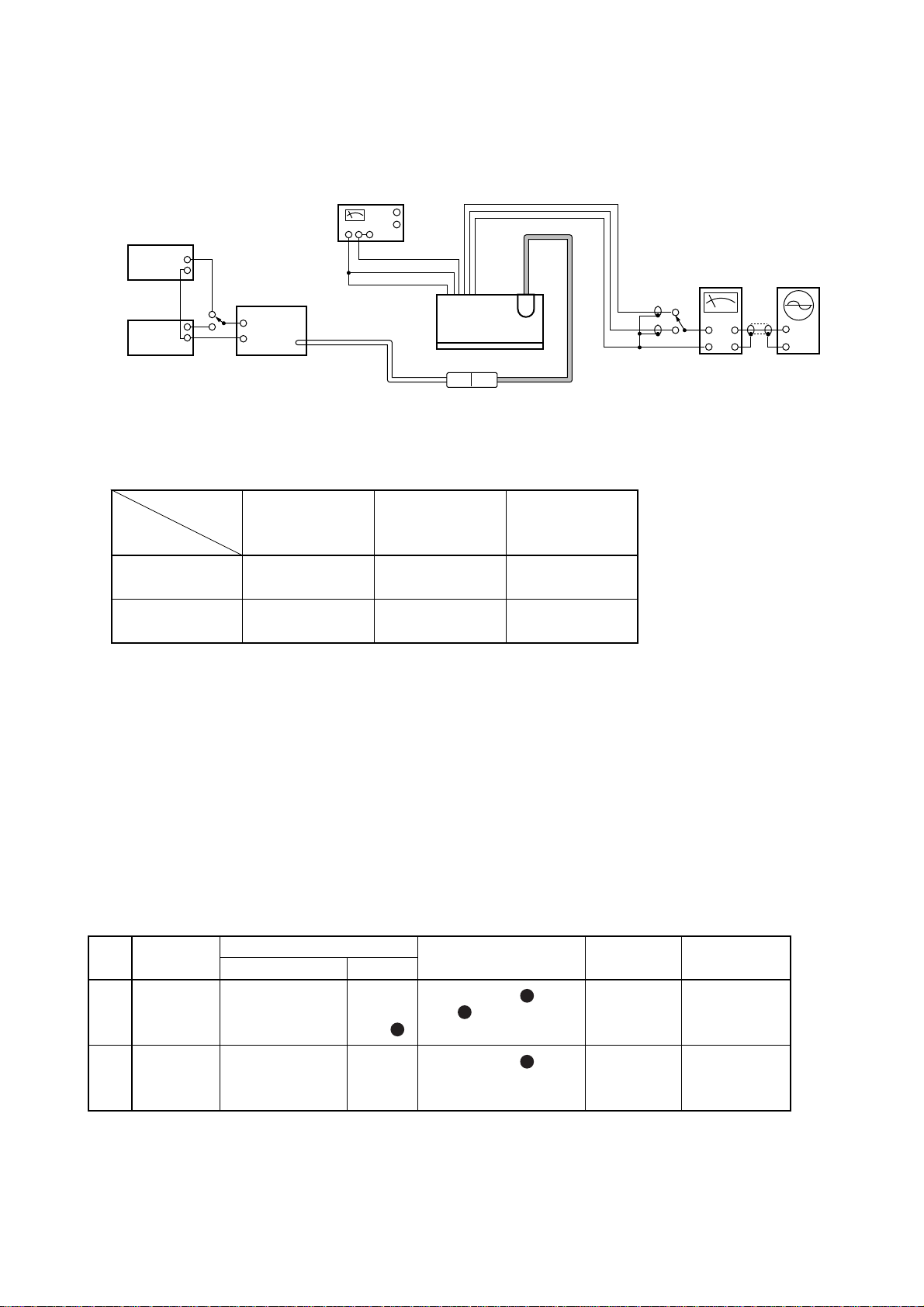

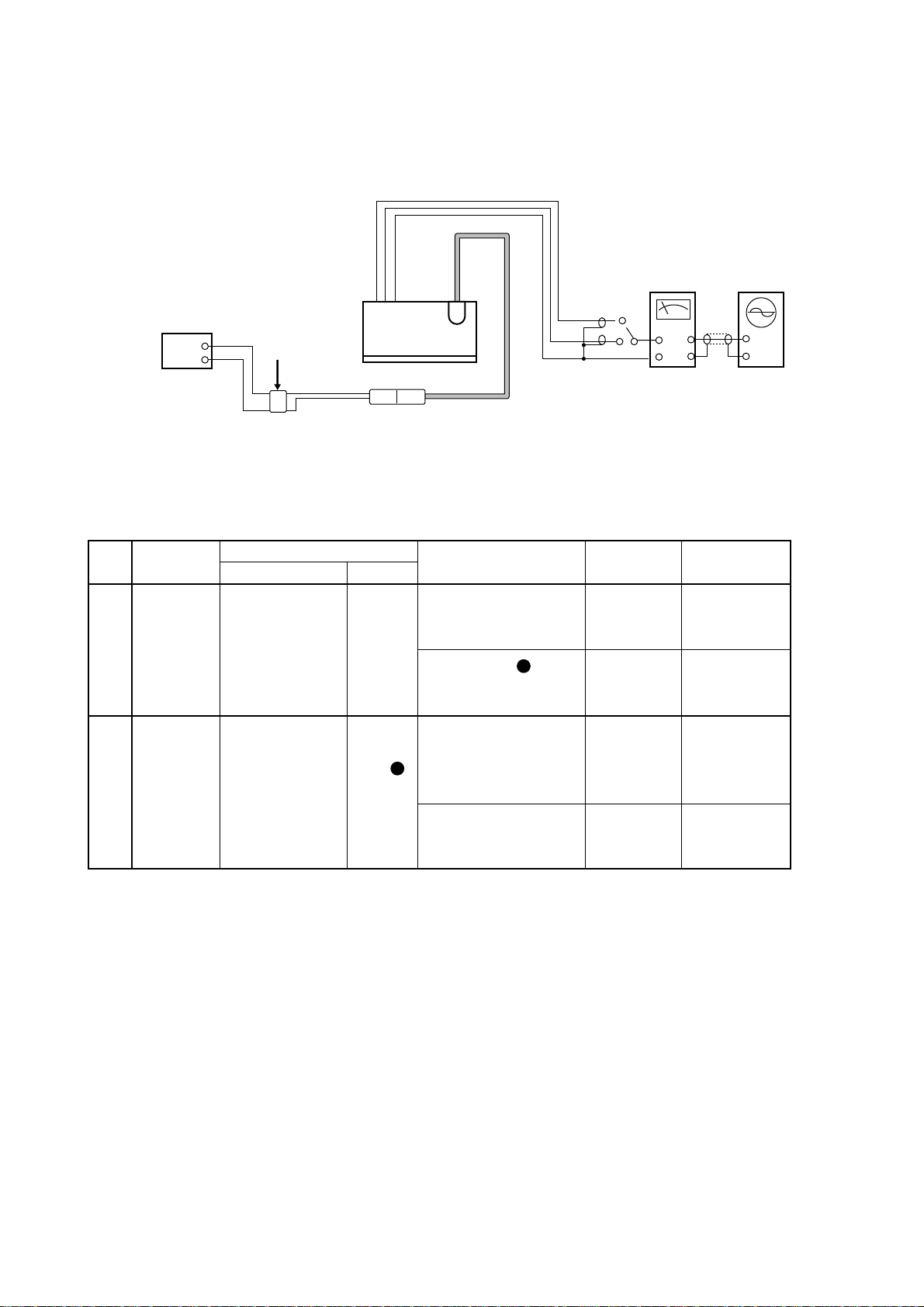

2. FM Adjustment point

Stereo modulator

SSG

Power Supply

PRE OUT

VTVM

IN OUT

SCOPE

+

GND

(Black Lead)

(Red Lead)

(Yellow Lead)

-

EXT

MODE

OUT

AUDIO OSC

Unit

ANT

Jack.

Figure 3.

(1) The impedance of FM antenna terminal is 75Ω.

Therefore, connect coaxial cable (3C-2V etc.) between FM SG and antenna terminal when wiring.

(2) There are two kind in indication of FM SG output attenuator.

1) Attenuator with marking of 75Ω open...open indication type.

2) Attenuator with marking of 75Ω load or close...load or close indication type.

(3) FM SG output level in this FM adjustment are described as open indication type. The left table shows rela-

tion among FM SG attenuator indication (dB), available power ratio (dBf) and antenna terminal voltage

(dB/µV) in each indication type.

Note :

1. BAND Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FM

2. BALANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Center

3. TREBLE/BASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Center

4. Connect as shown in figure 3.

5. Refer to figure 1~2 for Adjustment Points.

Item

Type

Open indication

type

0dB

60dB

0dB

54dB

5.2dBf

65.2dBf

11.2dBf

65.2dBf

6dB/µV

66dB/µV

12dB/µV

66dB/µV

Load or close

indication type

FM SSG

Attenuator

Indication

STEP SUBJECT

FEED SIGNAL

MEASURE OUTPUT

ADJUST-

MENT

ADJUST FOR

TOFROM

Available

Power

Ratio

Antenna

Terminal

Voltage

1

Discriminator

MPX

Adjustment

68MHz 60dB

22.5kHz Dev.

FM SSG

98MHz 60dB

75kHz Dev.

FM SSG

ANT Jack

or

Point A

Same as

above

Between Point C &

Point D , DC Volt Meter.

Between Point E ,

Frequency Counter

T101

VR301

DC 0V ± 10mV

76kHz ± 50Hz

2

Page 9

-9-

3. AM(MW) Adjustment

SSG

AM Dummy ANT

PRE OUT

VTVM

IN

OUT

SCOPE

OUT

Unit

ANT

Jack.

Figure 4.

Note :

1. BAND Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AM(MW)

2. Connect as shown in figure 4.

3. Refer to figure 1~2 for Adjustment Points.

STEP SUBJECT

FEED SIGNAL

MEASURE OUTPUT

ADJUST-

MENT

ADJUST FOR

TOFROM

1

2

3

520 or

522kHz

Tuning

Voltage

Adjustment

IF Coil

Adjustment

600kHz

or 603kHz

RF

Adjustment

No Input

600kHz or 603kHz

ANT input, 30dB,

400Hz (30%MOD)

SSG

600kHz or 603kHz

ANT input, 30dB,

400Hz (30%MOD)

SG.

ANT Jack

or

Point A

Same as

above

LCD Display

(Reception Frequency)

Output L or R ch,

VTVM & Oscilloscope

LCD Display

(Reception Frequency)

Output L or R ch,

VTVM & Oscilloscope

Between Point B and

GND, DC Volt Meter

TUNE +/Button

T201 & T202

TUNE +/Button

L204 & L205

L206

520 or 552kHz

Max.Output

600 or 603kHz

Max.Output

DC 1.2V ± 0.05V

Page 10

-10-

4. LW Adjustment(Optional)

SSG

AM Dummy ANT

PRE OUT

VTVM

IN

OUT

SCOPE

OUT

Unit

ANT

Jack.

Figure 5.

Note :

1. BAND Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LW

2. Connect as shown in figure 5.

3. Refer to figure 1~2 for Adjustment Points.

STEP SUBJECT

FEED SIGNAL

MEASURE OUTPUT

ADJUST-

MENT

ADJUST FOR

TOFROM

1

2

144kHz

Tuning

Voltage

Adjustment

150kHz

RF

Adjustment

No Input

150kHz

ANT input, 30dB,

400Hz (30%MOD)

SSG.

ANT Jack

or

Point A

LCD Display

(Reception Frequency)

LCD Display

(Reception Frequency)

Output L or R ch,

VTVM & Oscilloscope

Between Point B and

GND, DC Volt Meter

TUNE +/Button

TUNE +/Button

L254 & L255

L256

144kHz

150kHz

Max.Output

DC 1.2V ± 0.05V

Page 11

-11-

ERROR INDICATION

INDICATION CAUSE SOLUTION(Check Point)

• Mechanism.

• Mechanism connector CN501.

• TR Q502, ZD501

• IC503 Pin 9.14.15.16.20

• IC402 Pin 46.49.50.53.54

• Mechanism.

• Mechanism connector CN501.

• TR Q502, ZD501

• IC503 Pin 7.9.14.15.16.20

• IC402 Pin 46.49.50.53.54

• Mechanism connector CN501.

• TR Q502, ZD501

• IC503 Pin 7.17.18.19.

• IC501 Pin 43

• IC402 Pin 3

• Mechanism connector CN501.

• TR Q502, Q504.Q505

• IC503 Pin 1.2.4.7.10.11.12.24.26.27

• IC501 Pin 40.48.50

• IC402 Pin 2.13.

• TR Q501

• Mechanism pick-up laser diode.

• Will disappear when the temperature return to operation

range.

• TH401

• IC402 Pin 32.

E-01

E-02

E-03

E-04

E-09

LOADING malfunction

EJECT malfunction

SLID malfunction

SERVO malfunction

HIGH Temperature

Page 12

-12-

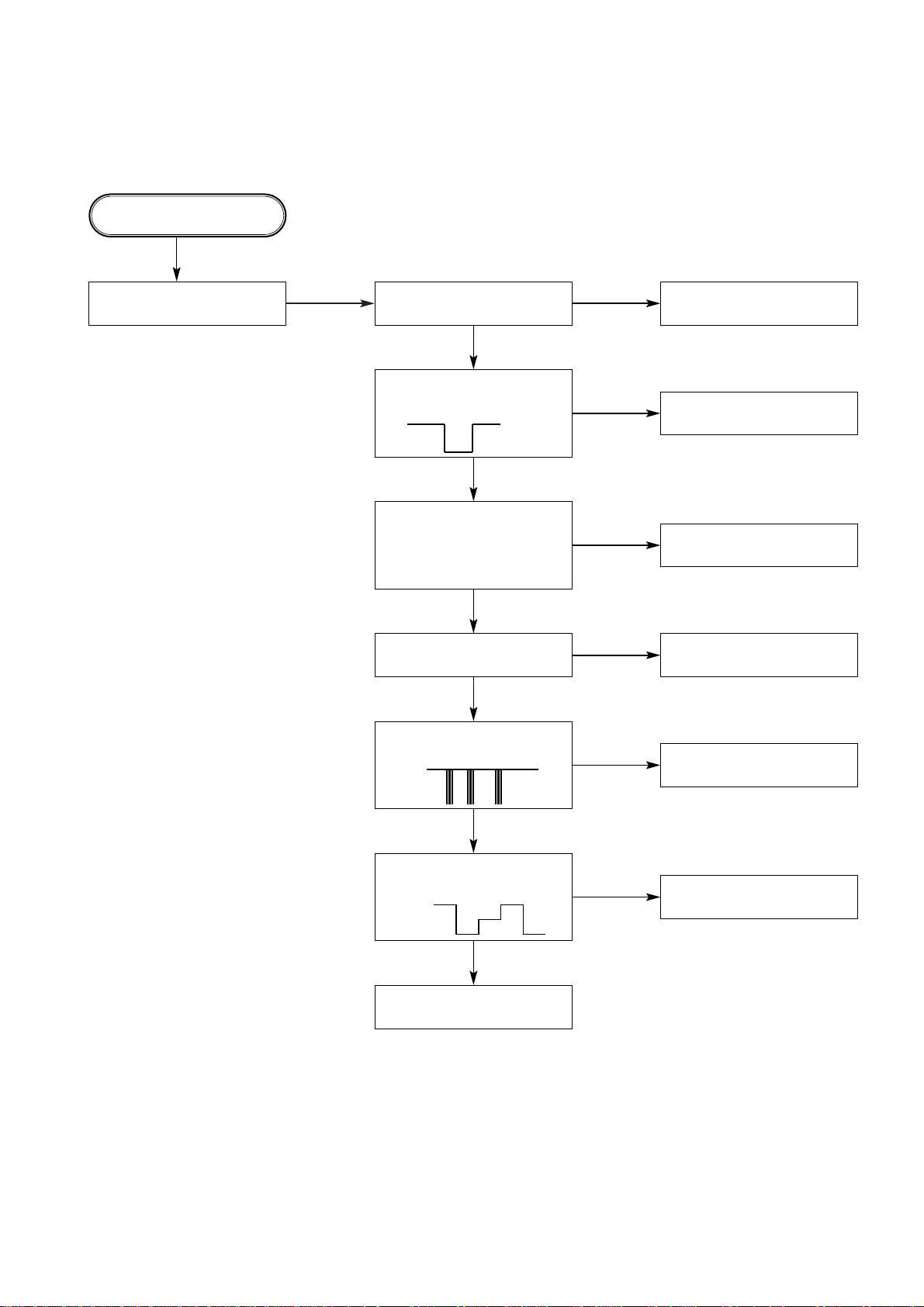

ELECTRICAL TROUBLESHOOTING GUIDE

1. No Power

ANY KEY POWER ON

YES

YES

YES

YES

YES

YES

NO

Check power supply circuitry.

Q805, Q806, Q802, IC402 Pin 33.

NO

Check Loading supply circuitry.

Q502, Q504, IC402, IC503.

NO

Check laser circuitry.

Q501, Q504, Q505, IC501, IC503

Check focusing circuitry.

IC501, IC502, IC503

Check DISC.

NO

Check tracking servo circuitry.

IC501, IC502, IC503

NO

Check audio circuitry.

IC501, IC502, IC402, IC601, IC801

Is power turned on?

DISC loading?

Does initial reading occur?

Can disc be played?

Is audio output supplied?

OK

Page 13

-13-

(2) LCD light abnornal

ANY KEY POWER ON

(without DISC)

YES

NO

Check voltage in the power

supply circuitry.

YES

Is u-com IC402 reset circuit

normal? Pin36

4.8V

0V

NO

Power supply circuitry defective.

Q407, Q802, Q805, Q806

NO

Reset circuit defective.

Q403, Q404 Surrounding circuit

defective.

YES

Is u-com IC402 X1,X2 terminal

Pin 40.41 input?

OSC : 4.5MHz

NO

X401,C408,C409 defective.

YES

Is u-com IC402 keyin Pin28

5volt input?

NO

Q407,PN901,front PCB pattern

defective.

YES

Is u-com IC402 Pin61,pin62

output waveform normal?

5V

NO

IC402 pin61~64,front PCB

pattern defective.

Is IC901 com1,com2,com3

output waveform normal?

Display LCD connector defective.

5V

NO

IC901 Surrounding circuit PCB

pattern defective.

Do display LCD then light?

Page 14

-14-

(3) Initial reading is not carried out(with disc)

DISC loading?

YES

NO

NO

NO

NO

NO

NO

NO

NO

Is IC402 pin54 input waveform

normal?

IC401

pin54

open close

YES

Does laser light?

CN501 pin14

YES

YES

YES YES

Is signal output at tracking

output IC501 Pin 53?

Does IC502 Pin25(LKFS) GFS

as figure?

Disc initial reading damaged or

defective.

Disc defective.

Is rotation normal?

Is there any irregularity in

frequency?

YES

Is RF signal normal without

dropout?

NO

Check voltage in the power

supply circuitry.

Q502, Q504, Q505, IC503

NO

Leaf SW contact defective.

Connector defective.

Pattern short.

NO

(A)

(B)

Does disc motor rotate?

Is RF wave output?

RF

Is tracking servo operating?

Is the lower envelope of RF

waveform flat?

Is signal output at TEO?

Is signal output at IC501

Pin50?

IC501 defective.

Pattern defective.

Connector defective.

Pick-up defective.

IC502 defective.

NO

IC502 defective.

Page 15

-15-

(A) when laser does not light.

Is below signal “L” at IC501

Pin 70?

NO

NO

NO

NO NO

NO

NO

NO

YES

Slide motor defective.

Connector defective.

YES

IC503 defective.

IC501defective.

IC501 defective.

Surrounding circuitry defective

Q501 defective.

Connector defective.

Laser defective

Connector defective.

Laser defective

IC501,502 defective.

NO

NO

Reset SW defective

Connector defective.

NO

IC401 defective.

Has Pick-up returned to the

innermost position?

Does pick-up stop after having

moved to the innermost position?

IC402 Pin 3

Has laser power source returned

to the Q501?

(Q501 collector voltage about

2.2V)

Flow laser current?

Both voltage of Q501 is about

1.0V?

NO

YES

R501, 511 % 1.0V

R501, 511 & 1.0V

Are data transferred from

IC402 Pin 6, 7, 8?

Is below signal output at IC502

Pin 26,27?

Are detect output input at IC501

Pin38?

Page 16

-16-

(B) when laser light.

Do lenses move up and down?

Insert disc and

in the case of

check of initial

leading.

Is RF(HF) signal waveform

output?

NO

NO

Is signal output at focus search

terminal? IC501 Pin48

NO

IC501 defective.

Is signal output at IC503 Pin1, 2?

NO

IC503 defective.

YES

YES

YES

Actuator short.

Connector short.

IC501 defective.

Connector short.

The waveform of RF(HF) is

below figure?

Amplitude

0.5~1.0v

NO

YES

IC501 defective.

Q501 IC501 surrounding circuitry

defective.

Is FOK signal output? RF(HF)

0.4V over OK.

FOK

NO

YES

IC501 defective.

Is FOK signal to IC402 Pin2?

(C)

FOK

NO

YES

Pattern defective.

YES

Page 17

-17-

(C)

YES

NO

IC501 defective.

Pick-up defective.

Connector defective.

Is FE1 signal output ?

IC501 Pin59

YES

NO

IC501 defective.

Is FE1 signal output at IC601

Pin31(ISTAT) ?

ISTAT

FE1

YES

NO

Pattern defective between IC502

Pin 72, 73, 75, 76 and IC401.

Is SMON signal output by IC602

Pin73?

Is SMPO signal output by IC602

Pin75?

YES

NO

IC501,503 defective .

Surrounding circuitry defective.

Has voltage at disc motor?

0v

YES

Disc motor defective .

CN501 connector defective.

Page 18

-18-

INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION OF IC’s

12

Vcc

VOLTAGE

REGULATOR

1IF Input

7 AFC

8

AF

Output

5

Mute

Attenuation

Adjust

2

3

Bias

4GND

16

AGC

15

Signal

Meter

Output

14

Mute

Drive

10

GND

6

Mute

Input

9

IF

Out

11

Quad

In

13

V

ref

1st

Amp

2nd

Amp

3rd

Amp

4th

Amp

5th

Amp

6th

Amp

OUAD

LIMITER

OUADRATURE

DETECTOR

AFC

CLAMF

AF

MUTE

Amp

LEVEL

DETECTOR

LEVEL

DETECTOR

LEVEL

DETECTOR

INVERTER

HOLE

DETECTOR

DC LEVER

DETECTOR

MUTE

DRIVER

SIGNAL

METER

DRVE

AGC

DRVE

• DBL 1018 (LA 1140) (IC101 : FM IF)

ALC

RF DETECTOR

19

Local

OSC2

18

Local

OSC1

17

IF

AGC

16

Signal

Meter Out

15

Signal

Meter In14Vcc

13

Detector

Out12GND

11

Detector

In

20

Local OSC

Butter Out

2 3 4 5 6 7 8 9 101

RFAmp2InRF

AGC

ANT

Damping

Driver

GND MIX in &

RF AMP1 In

MIX

Out

Vcc IF AmpInIF Amp

Out

RFAGC

Out

LOCAL

OSC

BUFFER

IF

AGC

LOCAL

OSC

SIGNAL

METER

IF

DETECTOR

RF

AGC

ATTENUATOR

DRIVER

RF

AMP1

RF

AMP2

MIX

IF

AMP

• DBL 1019 (LA1135) (IC201 : MW RF&IF)

Page 19

-19-

1

INPUT

3.5V

2 4

356

FC

798

AF

6.6V

L.P.F-1

7.1V

9019kHZ

019kHZ

38kHZ

Vco ADJUSTMENT

PHASE

DETECTOR

DC

VCO 76kHz 1/2 1/2

1/2

STEREO

SWITCH

STABILZED

POWER SUPPLY

PILOT

DETECTOR

STEREO

DECODER

4V 4V 7.4V

RIGHT L.P.F-2

SW2

COUNTER

38kHz CHECK

Vcc

OUTPUT

SW1

SW1 VCO STOP SWITCH

SW2 38kHz MONITOR SWITCH

LED

GND

0V

8VLEFT

TRIGGER

• KIA6043S (IC301 : FM MPX)

FM

FM MODE LF

RESET

1mS

OSC

HF

PSC

V

DD

GND

FM

IN

FM

L

S

AM

AMP

XT

XT

DATA

CLOCK

PERIOD

OT-1 OT-3

OT-2 OT-4

TEST

8

4

24

4

OT-4

XT

OT4

1mS

GATE

AMP

AMP

1/0-9 IF

1/0-6

1/0-5/CLK

DO2

(DO2/OT-4)

DO1

IN2

(1/0-6 IF )

IN2

1/0-8 IF

IN1

1/0-7 SC

IN

(1/0-5 IF )

IN1

5

5

4

4

15

12

22

10

IN

11

10

2

1

5

4

6 7 8

9 12

15

16

13

14

3

REFERENCE COUNTER MAX

UNLOCK

TRI-STATE

BUFFER

TRI-STATE

BUFFER

2 MODULUS

PRESCALER

4 bit SWALLOW

COUNTER

12 bit PROGRAMMABLE COUNTER

OSC

CIRCUIT

POWER ON

RESET

1/2

ADDRESS

DECODER

1/0-PORT

PHASE

COMPARATOR

OUTPUT PORT

24bit REGISTER

20bit BINARY COUNTER

UNIVERSAL COUNTER CONTROL

24bit SHIFT REGISTER

24bit REGISTER

• KIC9256P (IC401 : PLL)

Page 20

-20-

LIN1

Input

Voume &

Loudness

Voume

&

Loudness

Supply

Bass

Bass

Treble

Treble

RB

Speaker

ATT

Mute

Mute

Mute

Mute

Speaker

ATT

Speaker

ATT

Speaker

ATT

RB

Selector

Serial Bus Decoder & Latches

& Gain

control

LIN2

LIN3

RIN3

RIN2

RIN1

2 3 1 7 6 8 21 20 5

VDD AGND REF ROUT RIN LOUD BOUT_R BIN_R TREB_R

22

24

26

27

28

23

25

RROUT

RFOUT

DGND

DATA

CLK

LROUT

LFOUT

4

TREB_L

10

BIN_L

19

BOUT_L

12

LOUD_L

10

LIN

17

LOUT

15

14

13

9

10

11

LIN1

LIN2

LIN3

RIN3

RIN2

RIN1

• PT2313L (IC601 : ELECTRONIC VOLUME)

+

30 kΩ

30 kΩ

TDA8571J

IN1

IN2

SGND

DIAGNOSTIC

V

ref

MODE

V

P1

15 1

10

11

12

8 16 23

2

4

7

5

9

V

P2

V

P3

V

OUT1+

OUT1–

OUT2+

OUT3+

OUT3–

OUT4+

OUT4–

OUT2–

P4

V

DIAG

+

+

+

+

30 kΩ

30 kΩ

IN3

IN4

V

ref

13

14

17

19

22

20

3

PGND1

+

+

+

6

PGND2

18

PGND3

21

PGND4

• TDA8571J (IC801 : POWER AMP.)

Page 21

-21-

COMMON

DRIVER

LATCH & DRIVER

SHIFT REGISTER

ADDRESS

DETECTOR

CLOCK

GENERATOR

VCL1

VCL2

INH

VDD

VSS

OSC

SI

SCK

COM1

COM2

COM3

SEG52

SEG51

...........

SEG1

CE

SEG49

SEG50

SEG51

SEG52

COM1

COM2

COM3

VDD

INH

VCL1

VCL2

VSS

OSC

CE

SCK

SI

SEG32

SEG31

SEG30

SEG29

SEG28

SEG27

SEG26

SEG25

SEG24

SEG23

SEG22

SEG21

SEG20

SEG19

SEG18

SEG17

48 33

49

64

1

32

17

16

SEG48

SEG47

SEG46

SEG45

SEG44

SEG43

SEG42

SEG41

SEG40

SEG39

SEG38

SEG37

SEG36

SEG35

SEG34

SEG33

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

HL15203

• HL15203 (IC901 : LCD DRIVER)

Page 22

-22-

■

KB9223 (IC501 : SSP)

OVERVIEW

The KB9223 is a 1-chip BICMOS integrated circuit to perform the function of RF AMP and Servo signal processor for compact disc player

application. It consist of blocks for RF signal processing, focus, tracking,

sled and spindle servo. Also this IC has adjustment free function and

embedded opamp for audio post filter.

FEATURES

• RF amplifier & RF equalizer

• Focus error amplifier & servo control

• Tracking error amplifier & Servo control

• Mirror & Defect detector circuit

• Focus OK detractor circuit

• APC(Auto Laser Power Control) circuit for constant laser power

• FE bias & focus servo offset adjustment free

• EF balance & tracking error gain adjustment free

• Embedded audio post filter

• The circuit for Interruption countermeasure

• Double speed play available

• Operating voltage range 5V

PIN CONFIGURATION

ORDERING INFORMATION

APPLICATIONS

• CD PLAYER

• Video-CD

RELATED PRODUCT

• KS9286 Data Processor

• KS9284 Data Processor

• KS9258D/KA9259D Motor Driver

Device Package Temp. Range

KB9223 80-QFP-1420C -20~+70ºC

#1

80-QFP-1420C

64

DVEE

63

FEBIAS

62

TG2

61

TGU

60

FDFCT

59

FE158FE2

57

TDFCT

56

DVDD

55

LPFT

54

TE153TE2

52

TZC

51

ATSC

50

TEO

49

TE-

48

FEO

47

FE-

46

SPDLD

45

SPDL-

44

SL-

43

SLO

42

SL+

41

SSTOP

40FOK

39MIRROR

38RESET

37MLT

36MDATA

35MCK

34VSSA

33EFM

32ASY

31ISTAT

30TRCNT

29LOCK

28FGD

27FS3

26FLB

25SMEF

65 PD1

66 PD2

67 F

68 E

69 PD

70 LD

71 VR

72 VCC

73 RF74 RFO

75 IRF

76 EQO

77 RF1

78 EQC

79 EI

80 GND

1

MCP2DCB3FRSH4DCC25DCC16FSET7VDDA8VCCP9GC2110GC2011CH2I12CH2O13CH1O14CH1I15CH1O16CH1I17RRC18VSSP19MUTEI20ISET21VREG22WDCK23SMDP24SMON

KB9223

Page 23

-23-

PIN DESCRIPTION

1 MCP Capacitor connection pin for mirror hold

2 DCB Capacitor connection pin for defect Bottom hold.

3 FRSH Capacitor connection pin for time constant to generate focus search waveform

4 DCC2 The input pin through capacitor of defect bottom hold output

5 DCC1 The output pin of defect bottom hold

6 FSET

The peak frequency setting pin for focus, tracking servo and cut off frequency CLV LPF

7 VDDA Analog ACC for servo part

8 VCCP VCC for post filter

9 GC2I Amplifier negative input pin for gain and low pass filtering of DAC output CH2

10 GC2O Amplifier output pin for gain and low pass filtering of DAC output CH2

11 CH2I The input pin for post filter channel2

12 CH2O The output pin for post filter channel2

13 CH1O The output pin for post filter channel1

14 CH1I The input pin for post filter channel1

15 GC1O Amplifier output pin for gain and low pass filtering of DAC output CH1

16 GC1I Amplifier negative input pin for gain and low pass filtering of DAC output CH1

17 RRC The pin for noise reduction of post filter bias

18 VSSP VSS for post filter

19 MUTEI The input pin for post filter muting control

20 ISET The input pin for current setting of focus search, track jump and sled kick voltage

21 VREG The output pin of regulator

22 WDCK The clock input pin for auto sequence

23 SMDP The input pin of CLV control output pin SMDP of DSP

24 SMON The input pin for spindle servo ON through SMON of DSP

25 SMEF The input pin of provide for an external LPF time constant

26 FLB Capacitor connection pin to perform rising low bandwidth of focus loop

27 FS3 The pin for high frequency gain change of focus loop with internal FS3 switch

28 FGD Reducing high frequency gain with capacitor between FS3 pin

29 LOCK Sled runaway prevention pin

30 TRCNT Track count output pin

31 ISTAT Internal status output pin

32 ASY The input pin for asymmetry control

33 EFM EFM comparator output pin

34 VSSA Analog VSS for servo part

35 MCK Micom clock input pin

PIN DESCRIPTION

Pin No. Symbol Description

Page 24

-24-

PIN DESCRIPTION

Pin No.

36 MDATA Micom data input pin

37 MLT Micom data latch input pin

38 RESET Reset input pin

39 MIRROR The mirror output for test

40 FOK The output pin of focus OK comparator

41 SSTOP The pin for detection whether pick_up position is innermost or ton

42 SL+ The noninverting input pin of sled servo amplifier

43 SLO The output pin of sled servo amplifier

44 SL- The inverting input pin of sled servo amplifier

45 SPDL- The noninverting input pin of spindle servo amplifier

46 SPDLO The output pin of spindle servo amplifier

47 FE- The inverting input pin of focus servo amplifier

48 FEO The output pin of focus servo amplifier

49 TE- The inverting input pin of tracking servo amplifier

50 TEO The output pin of tracking servo amplifier

51 ATSC The input pin for Anti-shook detection

52 TZC The comparator input pin for tracking zero crossing detection

53 TE2 Tracking servo input pin

54 TE1 Tracking error amplifier output pin

55 LPFT The input pin of tracking error low pass filtering signal

56 DVDD The power supply pin for logic circuit

57 TDFCT The capacitor connection pin for tracking defect compensation

58 FE2 Focus servo input in

59 FE1 Focus error amplifier output pin

60 FDFCT The capacitor connection pin for focus defect compensation

61 TGU The capacitor connection pin for high frequency tracking gain switch

62 TG2

The pin for high frequency gain change of tracking servo loop with internal TG2 switch

63 FEBIAS Focus error bias voltage control pin

64 DVEE The DVEE pin for logic circuit

65 PD1 The negative input pin of RF I/V amplifier1(A+C signal)

66 PD2 The negative input pin of RF I/V amplifier2(B+D signal)

67 F The negative input pin of F I/V amplifier(F signal)

68 E The negative input pin of E I/V amplifier(E signal)

69 PD The input pin for APC

70 LD The output pin for APC

Symbol Description

Page 25

-25-

PIN DESCRIPTION

BLOCK DIAGRAM

73RF-

74RFO

65PD1

66

63

PD2

67F

FEBIAS

68

79

E

EI

69

70

71

PD

LD

VR

78

76

75

ARF

EQC

IRF

32

33

77

2

ASY

EFM

RFI

DCB

DCC2

4

40

1

39

6

25

24

23

45

46

42

44

43

61

62

55

53

50

49

57

48

47

60

FOK

MCP

MIRROR

FSET

SMEF

SMON

SMDP

SPDL-

SPDLO

SL+

SL-

SLO

TGU

TG2

LPFT

TE2

TEO

TE-

TDFCT

FEO

FE-

FDFCT

5

DCC1

15

FS1 ~

FS4

TM1 ~

TM6

BAL1 ~

BAL5

PS1 ~

PS4

GA1 ~

GA4

16 13 14 19 17 12 11 9 10

GC10

GC1I

CH10

CH1I

MUTEI

RRC

CH20

CH2I

GC2I

GC2O

RF AMP

FOCUS ERROR

AMP FE-BIAS

Adjustment

Tracking Error Amp

E/F Balance & Gain

Control

APC Amp

LDON

Center Voltage Amp.

RF Level AGC

&

Equalizer

EFM

Comparator

Defect Detection

Circuit

59 54 22 30 29 31 38 37 36 35 51 52

FE1

TE1

WDCH

TRCNT

LOCK

ISTAT

RESET

MLT

MDDATA

MCK

ATSC

TZC

58 26 28 27

FE2

FLB

FGD

FS3

FRSH

3

Built-in Post Filter Amp(L&R)

Micom Data

Interface Logic

Focus Phase

Compensation &

Offset cancel circuit

MICOM TO SERVO CONTROL

AUTO SEQUENCER

ADJUSTMENT-FREE CONTROL

Tracking Phase

Compensation

Block &

Jump Pulse GEN.

Sled Servo

Amplifier

& Sled Kick GEN

Spindle Servo LPF

(Double Speed)

MIRROR

DETECTION CIRCUIT

FOK DETECTION

CIRCUIT

Pin No.

71 VR The output pin of(AVEE+AVCC)/2 voltage

72 VCC VCC for RF part

73 RF- RF summing amplifier inverting input pin

74 RFO RF summing amplifier output pin

75 IRF The input pin for AGC

76 EQO The output pin for AGC

77 RFI The input pin for EFM comparison

78 EQC The capacitor connection pin for AGC

79 EI Feedback input pin of E I/V amplifier EF Balance control

80 GND GND for RF part

Symbol Description

Page 26

-26-

■

KB9286 (IC502 : DSP)

DIGITAL SIGNAL PROCESSOR

The KS9286 is a CMOS integrated circuit designed for the Digital Audio

Signal Processor for Compact Disc Player. It is a monolithic IC that

builts-in 16 bit Digital Analog Convertor, ESP interface and Digital Deemphasis additional conventional DSP function.

FEATURES

• EFM data demodulation

• Frame sync detection/protection/insertion

• Powerful error correction (C1: 2error, C2 : 4erasure)

• Interpolation

• 8fs digital filter(51th+13th+9th)

• Subcode data serial output

• CLV servo controller

• Micom interface

• Digital audio output

• Digital de-emphasis

• ESP interface

• Built-in 16K SRAM

• Built-in Digital PLL

• Double speed play available

• Built-in 16 bit D/A converter

• VDD = 3.4~5.5V

ORDERING INFORMATION

Device Package Temp. Range

KB9286 80-QFP-1420C +20 ~ +75ºC

#1

80-QFP-1420C

64

SRAM63CDROM62TEST061XTALSEL60/CS59/WE58C16M57C4M56/JIT55ULKFS54FSDW53DVSS252/PBCK51C2FL50C2F249C2F148C1F247C1F146DB145DB244DB343DB442DB541DB6

40 DB7

39 DB8

38 MCK

37 MDAT

36 MLT

35 MUTE

34 DVDD1

33 SDAT

32 SBCK

31 SQOK

30 SQDT

29 SQCK

28 /ESP

27 RESET

26 S0S1

25 LKFS

65TEST1

66EFMI

67ADATAI

68/ISTAT

69TRCNT

70LOCK

71PBFR

72SMEF

73SMON

74DVDD2

75SMDP

76SMSD

77BCKI

78TESTV

79DSPEED

80LRCHI

1

AVDD1

2

DPDO

3

DPFIN

4

DPFOUT

5

CNTVOL

6

AVSS1

7

DATX

8

XIN

9

XOUT

10

WDCHO

11

LRCHO

12

ADATAO

13

DVSS1

14

BCKO

15

C2PO

16

VREFL217VREFL1

18

AVDD2

19

RCHOUT

20

LCHOUT

21

AVSS2

22

VREFH123VREFH2

24

EMPH

KS9286

Page 27

-27-

PIN DESCRIPTION

Pin No. Symbol I/O Description

1 AVDD1 - Analog VCC1

2 DPDO O Charge pump output for Digital PLL

3 DPFIN I Filter input for Digital PLL

4 DPFOUT O Filter output for Digital PLL

5 CNTUOL I VCO control voltage for Digtial PLL

6 AVSS1 - Analog Ground1

7 DATX O Digital Audio output data

8 XIN I X’tal oscillator input

9 XOUT O X’tal oscillator output

10 WDCHO O Word clock output of 48 bit/Slot(88.2KHz)

11 LRCHO O Channel clock output of 48 bit/Slot (44.1KHz), 88.2KHz when ESP ON

12 ADATAO O

Serial audio data output of 48 bit/Slot(MSB first), double speed output when ESP ON

13 DVSS1 - Digital Ground1

14 BCKO O Audio data bit clock output of 48 bit/Slot (2.1168MHz), 4.2336MHz when ESP ON

15 C2PO O C2 Pointer for output audio data

16 VREFL2 I Input terminal2 of reference voltage “L” (Floating)

17 VREFL1 I Input terminal1 of reference voltage “L” (GND connection)

18 AVDD2 - Analog VCC2

19 RCHOUT O Right-Channel audio output through D/A converter

20 LCHOUT O Left-Channel audio output through D/A converter

21 AVSS2 - Analog ground2

22 VREFH1 I Input terminal1 of reference voltage “H” (VDD connection)

23 VREFH2 I Input terminal2 of reference voltage “H” (Floating)

24 EMPH O Emphasis/Non-Emphasis output, H:Emphasis ON, L:Emphasis OFF

25 LKFS I The Lock status output of frame sync.

26 S0S1 O Output of subcode sync signal(S0+S1)

27 RESET I System reset at “L”

28 ESP I ESP function ON/OFF control (“L”:ESP function ON, “H”:ESP function OFF)

29 SQCK I Clock for output Subcode-Q data

30 SQDT O Serial output Subcode-Q data

31 SQOT O The CRC (Cycle Redundancy Check) check result signal output of Subcode-Q

32 SBCK I Clock for output subcode data

33 SDAT O Subcode serial data output

34 DVDD1 - Digital VDD1

35 MUTE I Mute control input(“H”:Mute ON)

Page 28

-28-

PIN DESCRIPTION (continued)

Pin No. Symbol I/O Description

36 MLT I Latch Signal input from Micom(Schmit Trigger)

37 MDAT I Serial data input from Micom(Schmit Trigger)

38 MCK I Serial clock input from Micom(Schmit Trigger)

39 DB8 I/O SRAM data I/O port8(MSB)

40 DB7 I/O SRAM data I/O port7

41 DB6 I/O SRAM data I/O port6

42 DB5 I/O SRAM data I/O port5

43 DB4 I/O SRAM data I/O port4

44 DB3 I/O SRAM data I/O port3

45 DB2 I/O SRAM data I/O port2

46 DB1 I/O SRAM data I/O port1(LSB)

47 C1F1 I/O Monitoring output for C1 error correction(RA1)

48 C1F2 I/O Monitoring output for C1 error correction(RA2)

49 C2F1 I/O Monitoring output for C2 error correction(RA3)

50 C2F2 I/O Monitoring output for C2 error correction(RA4)

51 C2FL I/O

C2 decoder flag(RA5, “H”:When the processing C2 code is impossible correction status)

52 /PBCK I/O Output of VCO/2 (4.3218MHz) (RA6)

53 DVSS2 I/O Digital ground 2

54 FSDW I/O Window or unprotected frame sync(RA7)

55 ULKFS I/O Frame sync protection state(RA8)

56 /JIT I/O Display of either RAM overflow or underflow for ± 4 frame jitter margin(RA9)

57 C4M I/O Only monitoring signal(4.2336MHz) (RA10)

58 C16M I/O 16.9344MHz signal output (RA11)

59 /WE I/O Terminal for test

60 /CS I/O Terminal for test

61 XTALSEL I Mode Selection 1(H:33.8688MHz, L:16.9344MHz)

62 TEST0 I TEST input terminal(GND connection)

63 CDROM I Mode Selection2 (H:CDROM, L:CDP)

64 SRAM I TEST input terminal(GND connection)

65 TEST1 I TEST input terminal(GND connection)

66 EFMI I EFM signal input

67 ADATAI I Serial audio data input of 48 bit/Slot(MSB first)

68 /ISTAT O The internal status output

69 TRCNT I Tracking counter input signal

Page 29

-29-

PIN DESCRIPTION

Pin No. Symbol I/O Description

70 LOCK O Output signal of LKFS condition sampled PBFR/16(if LKFS is “H”, LOCK is “H”, if

LKFS is sampled “L” at least 8 times by PBFR/16, LOCK is “L”)

71 PBFR O Write frame clock(Lock:7.35KHz)

72 SMEF O LPF time constant control of the spindle servo error signal

73 SMON O ON/OFF control signal for spindle servo

74 DVDD2 - Digital VDD2

75 SMDP O Spindle Motor drive(Rough control in the SPEED mode, Phase control in the

PHASE mode)

76 SMSD O Spindle Motor drive(Velocity control in the PHASE mode)

77 BCKI I Audio data bit clock input of 48 bit/Slot(2.1168MHz)

78 TESTV I TEST input terminal (GND connection)

79 DSPEED I TEST input terminal(VDD connection)

80 LRCHI I Channel clock input of 48 bit/Slot(44.1KHz)

BLOCK DIAGRAM

66

5

3

4

2

72

73

75

76

70

9

8

37

38

36

69

68

EFMI

CNTVOL

DPFIN

DPFOUT

DPDO

SMEF

SMON

SMDP

SMSD

LOCK

XOUT

XIN

MDAT

MCK

MLT

TRCNT

/ISTAT

17

24

60

67

77

14

12

11

30

33

32

26

SDAT

SBCK

S0S1

29

22

VREFL1

EMPH

LRCHI

ADATA1

BCKI

BCKO

ADATAO

LRCHO

SQDT

SQCK

VREFH1

616263

65

7

19

20

XTALSEL

TEST0

CDROM

TEST1

DATX

RCHOUT

LCHOUT

EFM

PHASE

DETECTOR

DIGITAL

PLL

DIGITAL

CLV

SERVO

CPU

INTERFACE

MODE

SELECTOR

DIGITAL

OUTPUT

TRACK

COUNTER

X-TAL

TIMING

GENERATOR

FRAME SYNC

DETECTOR

PROTECTOR

INSERTOR

SUBCODE

SYNC

DETECTOR

23BIT

SHIFT

REGISTER

SUBCODE

OUTPUT

SUBCODE-Q

REGISTER

EFM

DEMODULATOR

ADDRESS

GENERATOR

16K

SRAM

ECC

INTERPOLATOR

DIGITAL

FILTER

& DE-EMPH

D/A

CONVERTER

8BIT DATA BUS

Page 30

-30-

■

U-COM uPD780022A

PIN DESCRIPTION

48 P71/TI01

47 P70/TI00/TO0

46 P03/INTP3/ADTRG

45 P02/INTP2

44 P01/INTP1

43 P00/INTP0

42 Vss1

41 X1

40 X2

39 IC

38 XT1

37 XT2

36 RESET

35 AV

DD

34 AVREF

33 P10/ANI0

1P50/A8

2P51/A9

3P52/A10

4P53/A11

5P54/A12

6P55/A13

7P56/A14

8P57/A15

9V

SS0

10V

DD0

11P30

12P31

13P32

14P33

15P34/SO31

16P35/SO31

49

P72/TI50/TO50

50

P73/TI51/TO51

51

P74/PCL

52

P75/BUZ

53

P64/RD

54

P65/WR

55

P66/WAIT

56

P67/ASTB

57

P40/AD0

58

P41/AD1

59

P41/AD2

60

P43/AD3

61

P44/AD4

62

P45/AD5

63

P46/AD6

64

P47/AD7

32

P11/ANI1

31

P12/ANI2

30

P13/ANI3

29

P14/ANI4

28

P15/ANI5

27

P16/ANI6

26

P17/ANI7

25

AV

SS

24

V

DD1

23

P25/ASCK0

22

P24/TxD0

21

P23/RxD0

20

P22/SCK30

19

P21/SO30

18

P20/SI30

17

P36/SCK31

PIN DESCRIPTION

1 P50/A8 LED O L Used as blinking LED On duty = 10%

2 P51/A9 FOK I H I FOCUS OK STATUS DETECTOR

3 P52/A10 LIMITSW I L I SLID LIMIT S/WINPUT

4 P53/A11 TRCNT I TRACKING COUNTER INPUT

5 P54/A12 SENS I H I DSP/SSP STATUS DETECTOR

6 P55/A13 ZCLK O L DSP/SSP SIREAL DATAOUTPUT CLOCK

7 P56/A14 ZDATA O H L DSP/SSP SIREAL DATAOUTPUT

8 P57/A15 ZXLT O H L DSP/SSP SIREAL DATALATCH PORT

9 VSSO

10 VDDO

Symbol NAME I/O ACTIVE STAHDBY PIN DESCRIPTION

PIN

NO

Page 31

-31-

U-COM uPD780022A pin description

11 P30 MUTE O L L AUDIO MUTE CONTROL

12 P31 XRST O H L DSP/SSP RESET PORT

13 P32 GFS I L I GFS SIGNAL INPUT PORTL:GFS ERROR

14 P33 CDCO O H L CD CHANGER CONTROL DATA OUTPUT

15 P34/S131 SUBQ I H I SUBCODE-Q DATA INPUT PORT

16 P35/S031 EMPH O H L EMPHASIS OUTPUT

17 P36/SCK31 SQCH O L I SUBCODE-Q DATA CALL CLOCK OUTPUT

18 P20/SI30 POWER O H L ACC POWER CONTROL OUTPUT

19 P21/SO30 PLLDATA I/O L PLL IC SIREAL DATA OUTPUT

20 P22/SCK30 PLLCLK O L PLL IC SIREAL CLOCK OUTPUT

21 P23/RxD0 EVDATA O L E/VOLUME IC SIREAL DATAOUTPUT

22 P24/TxD0 EVCLK O L E/VOLUME IC SIREAL CLOCK OUTPUT

23

P25/ASCK0

PLLPERI O PLL IC PERIODE communication port

24 VDD1

25 AVSS GND

26 P17/AN17 STIN I L FM Stereo detect input Active=Low

27 P16/AN16 SDIN I Tuner SEEK stop detector input

-Seek Stop threshold voltage:

AM:1.2V FM:1.5V

28 P15/AN15 KEYIN I AD KEY-IN input

Used for also front panel detecting

29 P14/AN14 NC

30 P13/AN13 LEVELBAR I VOLUME LEVEL INDICATE INPUT (R ONLY)

31 P12/AN12 NC

32 P11/AN11 TEMP I H I CD OPERATING TEMPERATURE DETECTOR

33 P10/AN10 TEST I 8VOLT MAIN POWER MONITORING PORT

34 Avref A/D CONVERTOR REFERENCE VOLTAGE

35 AVDD

36 RESET I L I MICOM RESET PORT

37 XT2

38 XT1

39 IC GND

40 X2 MAIN SYSTEM CLOCK

41 X1 MAIN SYSTEM CLOCK

42 VSS1 I GND

Symbol NAME I/O ACTIVE STAHDBY PIN DESCRIPTION

PIN

NO

Page 32

-32-

U-COM uPD780022A pin description (continued)

43 P00/INTP0 ACCIN I L I ACC DETECT INPUTACTIVE = LOW

44 P01/INTP1 SCOR I I SCOR SIGNAL INPUT PORT

45 P02/INTP2 CDCI I L I CD CHANGER DATA INPUT

46 P03/INP3 MDSW1 I H I CD DISC DETECT S/W1 INPUT

47 P70/TI00 CDON O H L When CDE mode this port is high output

(future function)

48 P71/TI01 AMUTE O H Used as Power IC mute. Active=Low

49 P72/TI50 MDLO+ O H I LOADING MOTOR (LOADING)

50 P73/TI51 MDLO- O H I LOADING MOTOR (EJECT)

51 P74/PCL CDPOWER O H L CD POWER CONTROL OUTPUT PORT

52 P75/BUZ PBEEP O

53 P64/RD MDSW2 I H I CD DISC DETECT S/W2 INPUT

54 P65/WR MDSW3 I H I CD DISC DETECT S/W3 INPUT

55 P66/WAIT AREAO2 O I Diode matrix DATA OUTPUT2 line

56 P67/ASTB AREAO1 O I Diode matrix DATA OUTPUT1 line

57 P40/AD0 AREAI4 I I Diode matrix DATA INPUT4 line

58 P41/AD1 AREAI3 I I Diode matrix DATA INPUT3 line

59 P42/AD2 AREAI2 I I Diode matrix DATA INPUT2 line

60 P43/AD3 AREAI1 I H I Diode matrix DATA INPUT1 line

61 P44/AD4 LCDDATA O FRONT LCD DIRIVE IC DATA OUTPUT

62 P42/AD5 LCDCLK O FRONT LCD DIRIVE IC CLOCK OUTPUT

63 P46/AD6 LCDCE O FRONT LCD DIRIVE IC CE OUTPUT

64 P47/AD7 LCDINH O FRONT LCD DIRIVE IC INH OUTPUT

Symbol NAME I/O ACTIVE STAHDBY PIN DESCRIPTION

PIN

NO

Page 33

-33-

■

KA9259BD (IC503 : DRIVER)

5-CH MOTOR DRIVER

The KA9259BD is a monolithic integrated circuit, and suitable for 5-ch

motor driver which drives focus actuator, sled motor, spindle motor and

loading motor of CD system.

FEATURES

• 1 phase, full-wave, linear DC motor driver

• Built-inTSD (Thermal shutdown) circuit

• Built-in 5V regulator (With an external PNP TR)

• Built-in mute circuit

• Built-in loading motor speed control circuit

• Wide operating supply voltage range : 6V~13.2V

ORDERING INFORMATION

Device Package Temp. Range

KA9259D 28-SSOPH-375 -25 ºC ~ +75ºC

28-SSOPH-375

2228 27

Level

shift

Level

shift

Level

shift

Level

shift

COMP

TSD

Level

shift

FIN

(GND)

FIN

(GND)

10k

10k

10k

10k

10k 10k

10k

10k

10k

10k

2.5V

50k

50k

Mute

Regulator

GND3

DO4.2

DO4.1

DI4.2

DI4.1

VREF

LD CTL

DI3

DO3.2

DO3.1

DO5.2

DO5.1

V

DO1.1

DO1.2

DI1.1

DI1.2

REB

REO

MUTE

GND1

DI5.1

DI2

DO2.1

DO2.2

GND2

DI5.2

CC2

V

CC1

26 25 24 23 1521 20 19 18 17 16

71 2 3 4 5 6 148 9 10 11 12 13

–

–

–

–

+

+

–

–

–

+

+

+

+

+

–– ++

–+

–

+

–

+

Page 34

-34-

BLOCK DIAGRAM

Page 35

-35-

IC801

TDA8571J

CIRCUIT DIAGRAMS

1. MAIN CIRCUIT DIAGRAM

Page 36

-36-

2. AM(MW)/TUNER/FRONT CIRCUIT DIAGRAM

Page 37

C

D

-37-

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD

(TOP VIEW)

Page 38

-38-

1. MAIN P.C.BOARD

(BOTTOM VIEW)

Page 39

-39-

2. TUNER P.C.BOARD 3. FRONT P.C.BOARD

LOCATION GUIDE

(TOP VIEW) (TOP VIEW) (BOTTOM VIEW)

(BOTTOM VIEW)

Page 40

-40-

SECTION 3. CABINET MAIN CHASSIS & MACHANISM

• EXPLODED VIEWS

A40

A41

A42

450

450

281

443

A44

A45

260

441

445

OPTION

446

441

320

287

443

330

444

285

444

A00

286

443

442

288

A46

A

5

4

3

2

1

B C D

E F G H

*CD MECHANISM(A00) P/N:4404R-C001A

(SVC Supply unit : Assembly only!)

Page 41

MEMO MEMO

Page 42

-41-

SECTION 4. REPLACEMENT PARTS LIST

. CANINET MAIN CHASSIS & MACHANISM

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

ASSEMBLY SECTION

A00 4404R-C001A MECHANISM TN-CCD1001Z-151J TANASHIN CAR

A40 6762RF0009A DETACHABLE UNIT ASSY FRONT ASSY(TCH-500)

A41 3111R-0150A CASE ASSY FRONT PANEL(TCH-500)

A42 6871RF3069A PWB(PCB) ASSY,FRONT(AUDIO) TCH-500 UKL01 FRONT

A44 3721R-Z009A PANEL ASSY TRIM BASE ASSY(TCH-500)

A45 6871RT3084A PWB(PCB) ASSY,TUNER/IF CAR MW TUNER NEW ASSY

A46 6871RM3068A PWB(PCB) ASSY,MAIN(AUDIO) TCH-500 UKL01 MAIN

PARTS SECTION

260 3140R-0020A CHASSIS MAIN(TCH-500)

281 3110R-0219A CASE TRIM PLATE(TCH-500)

285 4810R-0088A BRACKET DECK B(TCH-500)

286 4810R-0087A BRACKET DECK A(TCH-500)

287 3110S-P026A CASE DIN SLEEVE (TCC-670/570/680 AL

288 3110S-P035A CASE TERMINAL TCC-5610

320 4921RFD001A HEAT SINK ASSY AL DC 178*50*15

330 3550R-0321A COVER TOP(TCH-500)

SCREW

441 353-022B SCREW TAPTITE 2.6X6 FZMY BIND

442 353-022C SCREW TAPTITE 2.6X4 FZMY PAN

443 353-025AAAA SCREW TAPTITE 3X6 FBK

444 353-051B SCREW SPECIAL

446 1MRC0303018 ROUND HEAD MACHINE SCREW D 3.0 L 14 MSWR3/FZY

450 353-028B SCREW TAPTITE 2X8 FZMY

OWNERS MANUAL

801 3828RCF004A MANUAL,OWNERS TCH-500 ENG/RUSSIAN LG

Page 43

-42-

. ELECTRICAL

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION

SOCKET

ANT101 6620S-G001A SOCKET (CIRC) 6620S-G001A DAIHEE FM

COILS

L201 0LA0221K019 INDUCTOR AXIAL LEAD 2.2M K 2.3X3.4 L5 TP(52M/M)

L202 0LA0221K019 INDUCTOR AXIAL LEAD 2.2M K 2.3X3.4 L5 TP(52M/M)

L204 631N709B COIL ANTENNA 631N709B KWANGSUNG RF BULK MWR

L205 631N709C COIL ANTENNA 631N709C KWANGSUNG RF BULK MWR

L206 634N047W COIL OSCILLATOR MW OSC (=037W) KSC

L501 0LA0332K019 INDUCTOR AXIAL LEAD 33M K 2.3X3.4 L5 TP(52M/M)

L502 0LA0102K019 INDUCTOR AXIAL LEAD 10M K 2.3X3.4 L5 TP(52M/M)

T101 647N021L DISCRIMINATOR COIL DISC (=011L) KSC

T201 644N049V TRANS KS950509-04 KWANGSUNG IFT BULK

T202 644N049U TRANS 644N049U KWANGSUNG IFT BULK MW

LCD

LCD901 6304R-T002A LCD(LIQUID CRYSTAL DISPLAY),TN IS09054E RCL TCH-500

FILTER

CF101 616-010J FILTER(CIRC),CERAMIC SFE10.7MJA10-A MURATA 10700000

CF201 616-028B FILTER(CIRC),CERAMIC AHCFM2-A450AL TOKO-KOREA 450KH

FET

F151 667T009A FET KTK161-Y TAPE MINI KEC

F201 D67T101B 667T101B FET

IC

IC101 0IDW101800A IC,DAEWOO DBL1018 FM IF D/W

IC201 0IDW101900A IC,DAEWOO DBL1019 AM RF/IF D/W

IC301 0IKE604300A IC,KEC KIA6043S (KIA7343AP) KEC

IC401 0IKE925600A IC,KEC KIC9256P 16P DIP BK FM/AM PLL

IC402 0IMCRNE001A IC,MICRO CONTROLLER UPD780022AGC-557-AB8 NEC 64 QF

IC501 0ISS922300A IC,SAMSUNG ELECTRONICS KB9223 80P QFP BK CD ASP

IC502 0ISS928600B IC,SAMSUNG ELECTRONICS KS9286B 80P QFP BK DSP FOR CD

IC503 0IFA925900A IC,FAIRCHILD KA9259C 28P SOP ST 5CH MOTOR D

IC601 0IPY231300B IC,PTC PT2313 28P SOP TP DIGITAL CNTR

IC801 0IPH857100A IC,PHILIPS TDA8571J SOT411-1 BK 40W BTL P

IC901 0IHY152030A IC,HYUNDAI HL15203 64P QFP BK LCD DRIVER

LED

LD901 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD902 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD903 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD904 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD905 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD906 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD907 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD908 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD909 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD910 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD911 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD912 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD913 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD914 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD915 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD916 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD917 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LD918 0DL310009DA LED SML-310PT TP ROHM GREEN 4

LAMP

PL901 6912R-BC01C LAMP D3.05+L18 5.0V/115MA GREEN

PL902 6912R-BC01C LAMP D3.05+L18 5.0V/115MA GREEN

PL903 6912R-BC01B LAMP D3.05+L18 5.0V/115MA BLUE

Page 44

-43-

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION

DIODE

D201 0DD133009AB DIODE,SWITCHING 12

D202 0DD133009AB DIODE,SWITCHING 12

D203 0DD133009AB DIODE,SWITCHING 12

D253 0DD133009AB DIODE,SWITCHING 12

D301 0DD133009AB DIODE,SWITCHING 12

D302 0DD133009AB DIODE,SWITCHING 12

D352 0DD133009AB DIODE,SWITCHING 12

D401 0DD133009AB DIODE,SWITCHING 12

D402 0DD133009AB DIODE,SWITCHING 12

D411 0DD133009AB DIODE,SWITCHING 12

D422 0DD133009AB DIODE,SWITCHING 12

D501 0DD133009AB DIODE,SWITCHING 12

D502 0DD133009AB DIODE,SWITCHING 12

D801 0DD540200CA DIODE 1N5402 BK LITEON DO-201AD 3W 1

D802 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D803 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D804 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D805 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D852 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D853 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D854 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

D855 0DR160408AA DIODE,RECTIFIER RB160L-40 PMDS R/TP ROHM-KOREA

VC201 0DD321000AB DIODE,VARICAP SVC321SP-A BK SONY NON 459.1PF

VC202 0DD321000AB DIODE,VARICAP SVC321SP-A BK SONY NON 459.1PF

VC203 0DD321000AB DIODE,VARICAP SVC321SP-A BK SONY NON 459.1PF

SWITCH

SW901 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW902 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW903 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW904 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW905 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW906 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW907 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW908 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW909 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW910 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW911 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW912 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW913 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW914 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW915 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW916 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW917 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW918 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

SW919 6600S-TV02A SWITCH,TACT SKQN J-ALPS NON 12V 0.5A VERTI

THERMISTOR

TH401 6322R-0003A THERMISTOR,NTC NTH5G20P40B333K07TE MURATA +/-

TUNER

TUN101 6700S-F008A TUNER KST-F102VD-1 KWANGSUNG FM CAR

TRANSISTOR

Q101 0TR319209AA TRANSISTOR KTC3192-O(KTC380TM) TP KEC TO9

Q102 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q103 0TR105009AD TRANSISTOR KRA 105M KEC

Q201 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q202 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q203 0TR105009AD TRANSISTOR KRA 105M KEC

Q301 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Page 45

-44-

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION

Q302 0TR126709AB TRANSISTOR KTA1267-O MINI TP KEC

Q401 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q402 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q403 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q404 0TR126709AB TRANSISTOR KTA1267-O MINI TP KEC

Q406 0TR126709AB TRANSISTOR KTA1267-O MINI TP KEC

Q407 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q451 0TR105009AD TRANSISTOR KRA 105M KEC

Q501 0TR126609AA TRANSISTOR KTA1266-TP-Y (KTA1015) KEC

Q502 0TR320509AB TRANSISTOR KTC3205-TP-Y (KTC2236A)KEC

Q503 0TR103009AE TRANSISTOR KRC103M-TP (KRC1203) KEC

Q504 0TR127309AA TRANSISTOR KTA1273-TP-Y (KTA966A)KEC

Q505 0TR320200AB TRANSISTOR KTC3202-Y, KEC

Q601 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q651 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q801 0TR319909AA TRANSISTOR KTC3199-GR (2SC3199) TP KEC TO

Q802 0TR202601AA TRANSISTOR KTC2026 ST KEC TO220I =D2058

Q803 0TR127109AA TRANSISTOR KTA1271-TP-Y (KTA950)KEC

Q804 0TR103009AE TRANSISTOR KRC103M-TP (KRC1203) KEC

Q805 0TR127309AA TRANSISTOR KTA1273-TP-Y (KTA966A)KEC

Q806 0TR103009AE TRANSISTOR KRC103M-TP (KRC1203) KEC

VARIABLE RESISTOR

VR301 0RV1472D230 RESISTOR,DRAWING 4.7K OHM 6 ST L3P5 -

X-TAL

X401 617T601D CRYSTAL 4.5000000MHZ HC-18U

X501 616-020X RESONATOR CSA16.93MX040 MURATA 16930000H

ZENER DIODE

ZD401 0DZ475209AB DIODE,ZENER UZ-4.7BSB 52MM TP PYUNG CHANG

ZD402 0DZ565209AA DIODE,ZENER UZ-5.6BSB 52MM TP PYUNG CHANG

ZD501 0DZPC00069A DIODE,ZENERS UZ-7.5BSC 52MM PYUNG CHANG TP

ZD502 0DZ565209AA DIODE,ZENER UZ-5.6BSB 52MM TP PYUNG CHANG

ZD801 0DZ915209AA DIODE,ZENER UZ-9.1BSC 52MM TP PYUNG CHANG

CAPACITOR

C101 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C102 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C103 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C104 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C105 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C106 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C107 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C108 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C109 0CQ2231N409 CAPACITOR,POLYESTER(MYLAR) 0.022U 100V J POLY TP

C110 0CE4753F619 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SRE,SE 16V 20% FL TP 2.5

C111 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C112 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C151 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C152 0CH4150K416 CAPA,CHIP CERAMIC M/L T.C F/S 15P 50V J COG 2.0X1.2 R/TP

C153 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C201 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C202 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C203 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C204 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C212 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C213 0CE2266F618 CAPACITOR,ELECTROLYTIC 22M SMS 16V M FM5 TP(5)

C214 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C215 0CE1056K618 CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

C216 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C217 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

Page 46

-45-

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION

C218 0CN2230H949 CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

C219 0CE1076D618 CAPACITOR,ELECTROLYTIC 100M SMS 10V M FM5 TP(5)

C220 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C221 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C222 0CE4756K618 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SMS,SG 50V 20% FL TP 5

C223 0CE2256K618 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SMS,SG 50V 20% FL TP 5

C224 0CE4756K618 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SMS,SG 50V 20% FL TP 5

C225 0CQ4711N449 CAPACITOR,POLYESTER(MYLAR) 470PF 100V J PP TP

C226 0CH4120K416 CHIP CAPA CERAMIC M/L T.C F/S 12P 50V NPO 2.0X1.25 R/TP

C227 0CE4756K618 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SMS,SG 50V 20% FL TP 5

C228 0CN2230H949 CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

C230 0CH4050K116 CAPA,CHIP CERAMIC M/L T.C F/S 5PF 50V D NP0 2012 R/TP

C255 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C301 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C302 0CE4753F619 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SRE,SE 16V 20% FL TP 2.5

C303 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C304 0CE3353K619 CAPACITOR,FIXED ELECTROLYTIC 3.3UF SRE,SE 50V 20% FL TP 2.5

C305 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C306 0CQ1021R449 CAPACITOR POLYESTER(MYLAR) 1000P 250V J PYLN TP

C307 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C308 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C309 0CH1153K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.0150UF 50V K X7R(X) 2012 R/T

C310 0CH1682K566 CAPA,CHIP CERAMIC M/L H.D F/S 6800PF 50V K X7R(X) 2012 R/TP

C311 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C312 0CH4221K416 CAPA,CHIP CERAMIC M/L T.C F/S 220P 50V J 2.0X1.25 R/TP

C359 0CH1153K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.0150UF 50V K X7R(X) 2012 R/T

C360 0CH1682K566 CAPA,CHIP CERAMIC M/L H.D F/S 6800PF 50V K X7R(X) 2012 R/TP

C401 0CE2253K619 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SRE,SE 50V 20% FL TP 2.5

C402 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C403 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C404 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C405 0CE3363F619 CAPACITOR,FIXED ELECTROLYTIC 33UF SRE,SE 16V 20% FL TP 2.5

C408 0CH4560K416 CHIP CAPA CERAMIC M/L T.C F/S 56P 50V J NPO 2.0X1.25 R/TP

C409 0CH4560K416 CHIP CAPA CERAMIC M/L T.C F/S 56P 50V J NPO 2.0X1.25 R/TP

C410 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C411 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C412 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C413 0CH4470K416 CAPA,CHIP CERAMIC M/L T.C F/S 47P 50V J NP0 2.0X1.25 R/TP

C414 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C415 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C417 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C431 0CE3363D619 CAPACITOR,ELECTROLYTIC 33M SRE 10V M FL TP2.5

C432 0CH1473K946 CHIP CAPA CERAMIC M/L H.D F/S 0.047UF 50V Z Y5V(F) 2012 R/TP

C501 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C502 0CH1102K566 CAPACITOR,CHIP[CERAMIC M/L HD 1000PF 50V K X7R(X) 2012 R/TP

C504 0CH4050K116 CAPA,CHIP CERAMIC M/L T.C F/S 5PF 50V D NP0 2012 R/TP

C505 0CH4020K016 CAPACITOR,FIXED CERAMIC(High d 2PF 50V O.25 pF NP0 2012 R/TP

C506 0CH1472K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.0047UF 50V 10% X7R(X) 2012 R

C507 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C508 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C509 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C510 0CH1152K566 CAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 2012 R/T

C511 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C512 0CE4753F619 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SRE,SE 16V 20% FL TP 2.5

C513 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C514 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C515 0CH1333K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.0330UF 50V K X7R(X) 2012 R/T

C516 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C517 0CE4753F619 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SRE,SE 16V 20% FL TP 2.5

C520 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

Page 47

-46-

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION

C521 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C522 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C523 0CH4561K416 CAPA,CHIP CERAMIC M/L T.C F/S 560PF 50V J NP0 2012 R/TP

C524 0CH1333K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.0330UF 50V K X7R(X) 2012 R/T

C525 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C526 0CH1473K946 CHIP CAPA CERAMIC M/L H.D F/S 0.047UF 50V Z Y5V(F) 2012 R/TP

C527 0CH1152K566 CAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 2012 R/T

C528 0CH1222K566 CAPACITOR,FIXED CERAMIC(Temp.c 2200PF 50V 10% X7R(X) 2012 R/T

C529 0CE1044K629 CAPACITOR,FIXED ELECTROLYTIC 0.1UF SRA,SS 50V 20% FM2.5 TP

C530 0CH1472K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.0047UF 50V 10% X7R(X) 2012 R

C531 0CH4101K416 CAPA,CHIP CERAMIC M/L T.C F/S 100P 50V J NP0 2.0*1.25 R/TP

C532 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C533 0CH1683K516 CAPACITOR,FIXED CERAMIC(Temp.c 0.068UF 50V 10% B(5YP) 2012 R/

C534 0CE1063F619 CAPACITOR,FIXED ELECTROLYTIC 10UF SRE,SE 16V 20% FL TP 2.5

C535 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C536 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C537 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C538 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C539 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C541 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C542 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C543 0CH1333K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.0330UF 50V K X7R(X) 2012 R/T

C544 0CE4743K619 CAPACITOR,ELECTROLYTIC 0.47UF SRE 50V M FL TP2.5

C545 0CE4743K619 CAPACITOR,ELECTROLYTIC 0.47UF SRE 50V M FL TP2.5

C546 0CH1103K566 CAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 2012 R/T

C548 0CH1473K946 CHIP CAPA CERAMIC M/L H.D F/S 0.047UF 50V Z Y5V(F) 2012 R/TP

C550 0CH1152K566 CAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 2012 R/T

C551 0CH4330K416 CAPA,CHIP CERAMIC M/L T.C F/S 33P 50V J C 2.0X1.2 R/TP

C552 0CH4330K416 CAPA,CHIP CERAMIC M/L T.C F/S 33P 50V J C 2.0X1.2 R/TP

C553 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C554 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C556 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C557 0CH1223K566 CAPACITOR,CHIP[CERAMIC M/L HD 0.022UF 50V K X7R(X) 2012 R/TP

C558 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C559 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C580 0CE4753F619 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SRE,SE 16V 20% FL TP 2.5

C581 0CH4121K416 CHIP CAPA CERAMIC M/L T.C F/S 120P 50V J NP0 2.0X1.2 R/TP

C582 0CH1152K566 CAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 2012 R/T

C583 0CH4331K416 CAPACITOR,CHIP[CERAMIC M/L TC 330P 50V J NP0 2.0X1.2 R/TP

C584 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C589 0CH1102K566 CAPACITOR,CHIP[CERAMIC M/L HD 1000PF 50V K X7R(X) 2012 R/TP

C590 0CE4753F619 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SRE,SE 16V 20% FL TP 2.5

C591 0CH4121K416 CHIP CAPA CERAMIC M/L T.C F/S 120P 50V J NP0 2.0X1.2 R/TP

C592 0CH1152K566 CAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 2012 R/T

C593 0CH4331K416 CAPACITOR,CHIP[CERAMIC M/L TC 330P 50V J NP0 2.0X1.2 R/TP

C594 0CE1053K619 CAPACITOR,ELECTROLYTIC 1.0M SRE 50V M FL TP(2.5)

C598 0CE1073D619 CAPACITOR,AL.ELECTROLYTIC 100M SRE 10V M FL TP2.5

C601 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C602 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C603 0CH1102K566 CAPACITOR,CHIP[CERAMIC M/L HD 1000PF 50V K X7R(X) 2012 R/TP

C604 0CE2253K619 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SRE,SE 50V 20% FL TP 2.5

C605 0CE2253K619 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SRE,SE 50V 20% FL TP 2.5

C607 0CH1224H946 CAPACITOR,FIXED CERAMIC(Temp.c 0.22UF 25V 80%,-20% Y5V(F) 201

C608 0CH1224H946 CAPACITOR,FIXED CERAMIC(Temp.c 0.22UF 25V 80%,-20% Y5V(F) 201

C609 0CH1272K566 CAPACITOR,FIXED CERAMIC(Temp.c 2700PF 50V 10% X7R(X) 2012 R/T

C610 0CE477CF638 CAPACITOR,AL.ELECTROLYTIC 470UF SHL TYPE 16V M FM5 TP 5

C611 0CE3363D619 CAPACITOR,ELECTROLYTIC 33M SRE 10V M FL TP2.5

C651 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C652 0CH1104K946 CAPA,CHIP CERAMIC M/L H.D F/S 0.1UF 50V Z Y5V(F) 2012 R/TP

C653 0CH1102K566 CAPACITOR,CHIP[CERAMIC M/L HD 1000PF 50V K X7R(X) 2012 R/TP

Page 48

-47-

S AL LOCA. NO. PART NO. DESCRIPTION SPECIFICATION

C654 0CE2253K619 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SRE,SE 50V 20% FL TP 2.5

C655 0CE2253K619 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SRE,SE 50V 20% FL TP 2.5

C657 0CH1224H946 CAPACITOR,FIXED CERAMIC(Temp.c 0.22UF 25V 80%,-20% Y5V(F) 201

C658 0CH1224H946 CAPACITOR,FIXED CERAMIC(Temp.c 0.22UF 25V 80%,-20% Y5V(F) 201

C659 0CH1272K566 CAPACITOR,FIXED CERAMIC(Temp.c 2700PF 50V 10% X7R(X) 2012 R/T

C801 0CH1105F946 CAPACITOR,CHIP[CERAMIC M/L HD 1UF 16V Z Y5V(F) 2012 R/TP

C802 0CH1105F946 CAPACITOR,CHIP[CERAMIC M/L HD 1UF 16V Z Y5V(F) 2012 R/TP

C804 0CE2263F619 CAPACITOR,ELECTROLYTIC 22M SRE 16V M FL TP2.5