Page 1

DETACHABLE FRONT

PANEL CAR RECEIVER

SERVICE MANUAL

MODEL: TCC-6210

P/N: 3828REF007M OCTOBER, 2002

SERVICE MANUAL MODEL: TCC-6210/6220/6230

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Page 2

- 1-1 -

CONTENTS

SECTION 1. SUMMARY

• SERVICING PRECAUTIONS

.....................................................................................................................

1-2

• ESD PRECAUTIONS

..................................................................................................................................

1-3

• SPECIFICATIONS

......................................................................................................................................

1-4

SECTION 2. ELECTRICAL

• ADJUSTMENTS

..........................................................................................................................................

2-1

• INTERNAL BLOCK DIAGRAM of ICS

........................................................................................................

2-6

• BLOCK DIAGRAM

....................................................................................................................................

2-11

• WIRING DIAGRAM(Deck Mechanism)

.....................................................................................................

2-12

• SCHEMATIC DIAGRAM (TCC-6210)

........................................................................................................

2-13

• PCB LAYOUT

............................................................................................................................................

2-15

• MAIN P.C. BOARD(SOLDER SIDE)

.......................................................................................................

2-15

• MAIN P.C. BOARD(COMPONENT SIDE)

...............................................................................................

2-17

• FPONT P.C. BOARD

...............................................................................................................................

2-19

• RF P.C. BOARD

.....................................................................................................................................

2-19

SECTION 3. CABINET MAIN CHASSIS & MECHANSIM

• EXPLODED VIEW & PART LIST

..................................................................................................................

3-1

SECTION 4. REPLACEMENT PARTS LIST

...........................................................................................

4-1

Page 3

- 1-2 -

1. Always disconnect the power source before:

1) Removing or reinstalling any component, circuit board, module or any other instrument assembly.

2) Disconnecting or reconnecting any instrument electrical plug or other electrical connection.

3) Connecting a test substitute in parallel with an electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic capacitors may result in

an explosion hazard.

2. Do not defeat any plug/socket B+ voltage interlocks with which instruments covered by this service

manual might be equipped.

3. Do not apply power to this instrument and or any of its electrical assemblies unless all solid-state

device heat sinks are correctly installed.

4. Always connect a test instrument’s ground lead to the instrument chassis ground before connecting

the test instrument positive lead. Always remove the test instrument ground lead last.

1) The service precautions are indicated or printed on the cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions and service materials.

2) The Components used in the unit have a specified conflammability and dielectric strength. When

replacing any components, use components which have the same ratings. Components marked in

the circuit diagram are important for safety or for the characteristics of the unit. Always replace with the

exact components.

3) An insulation tube or tape is sometimes used and some components are raised above the printed writing

board for safety. The internal wiring is sometimes clamped to prevent contact with heating components.

Install them as they were.

4) After servicing always check that the removed screws, components and wiring have been installed

correctly and that the portion around the service part has not been damaged. Further check the insulation

between the blades of attachment plug and accessible conductive parts.

SECTION 1. SUMMARY

SERVICING PRECAUTIONS

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL

TRIANGLE, IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE

OF UNINSULATED “DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE

TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT

THE SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION

IN SERVICE LITERATURE.

Page 4

- 1-3 -

ESD PRECAUTIONS

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such omponents

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are

integrated circuits and some field-effect transistors and semiconductor chip components. The following

techniques should be used to help reduce the incidence of component damage caused by static electricity.

1) Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and

wear a commercially available discharging wrist strap device, which should be removed for potential

shock reasons prior to applying power to the unit under test.

2) After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3) Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4) Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage ESD devices.

5) Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6) Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together

by conductive foam, aluminum foil or comparable conductive material).

7) Immediately before removing the protective material from the leads of a replacement ESD device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8) Minimize bodily motions when handling unpackaged replacement ESD devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor

can generate static electricity sufficient to damage an ESD device).

Page 5

- 1-4 -

1. GENERAL

Power requirements

.....................................................................................................................

DC12V~15V

Ground system

...................................................................................................................................

Negative

Dimensions(W x H x D)

......................................................................................................

188 x 58 x 166mm

Weight

..............................................................................................................................................

Net: 1.3kg

2. RADIO SECTION

FM AM(MW) LW(Optional)

Frequency range

.................................

65.0~74.0MHz(Optional), 522~1,620kHz 144~281kHz

87.5~108MHz (Optional:530~1,710kHz/

520~1,620kHz)

Intermediate frequency

.......................

10.7MHz 450kHz 450kHz

Usable sensitivity

................................

10dBµV 28dBµV 35dBµV

Signal to noise ratio

............................

60dB 50dB 50dB

3. TAPE SECTION

Tape type

.................................................................................................................

2 track 2 channel system

Tape speed

....................................................................................................................................

4.75cm/sec

Wow and flutter

..........................................................................................................................

0.2%(WRMS)

Signal to noise ratio

.................................................................................................................................

50dB

4. AUDIO SECTION

Maximum output power

.......................................................................................................................

45W x 4

Frequency response

............................................................................................................

40Hz to 14,000Hz

Speaker impedance

...............................................................................................................

4Ω x 4 or 8Ω x 4

Signal to noise ratio

.................................................................................................................................

60dB

NOTE: The design and specifications are subject to change without notice in the sourse of product

improvement.

SPECIFICATIONS

Page 6

- 2-1 -

SECTION 2. ELECTRICAL

ADJUSTMENTS

Figure 1. MAIN PCB Board

<BOTTOM VIEW> <TOP VIEW>

1. Test & Adjustment point

A

B

C

D

E

T101

VR301

Figure 2. RF PCB Board

Page 7

- 2-2 -

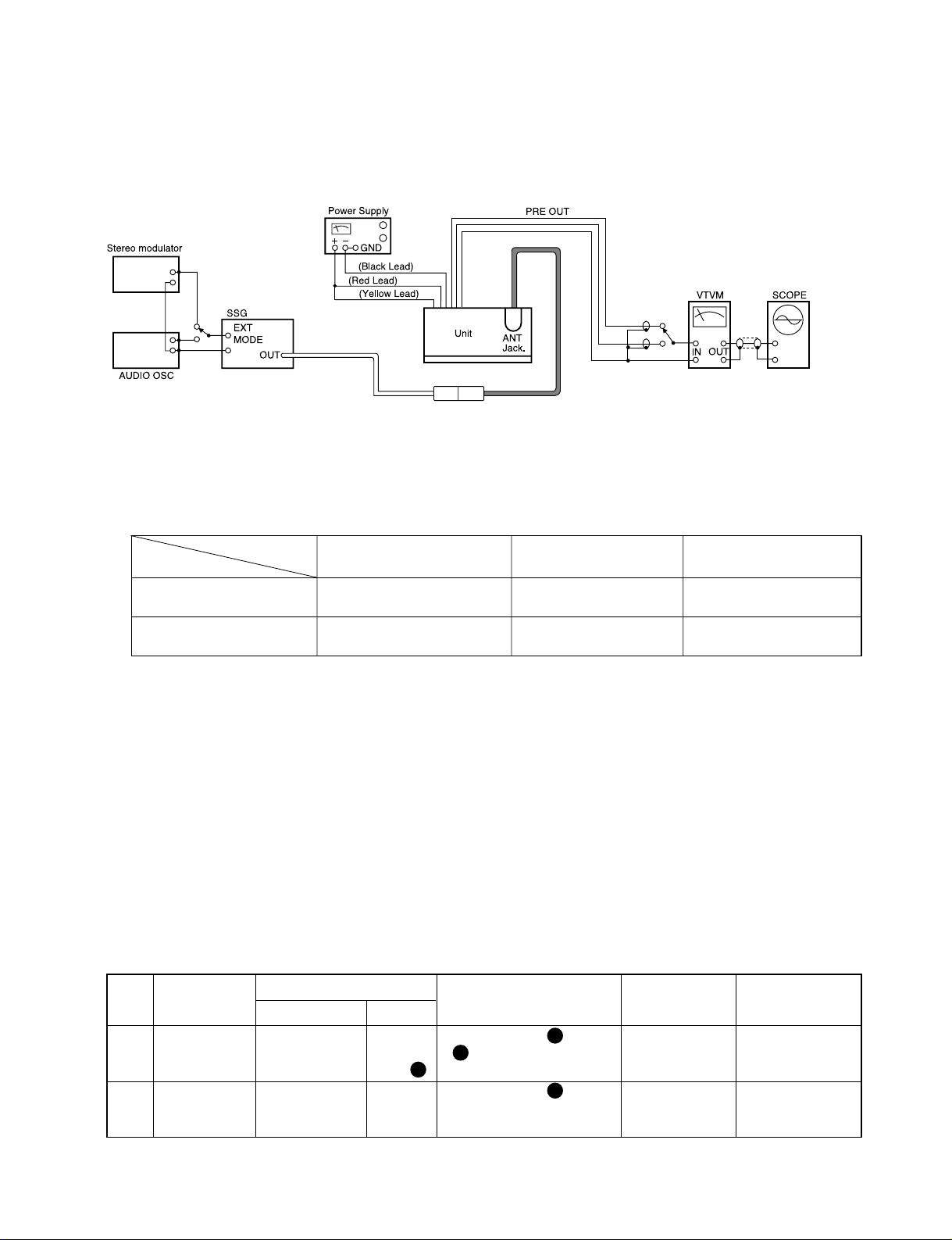

2. FM Adjustment

Figure 3.

(1) The impedance of FM antenna terminal is 75Ω

Therefore, connect coaxial cable (3C-2V etc.) between FM SG and antenna terminal when wiring.

(2) There are two kind in indication of FM SG output attenuator.

1) Attenuator with Marking of 75Ω open...open indication type.

2) Attenuator with marking of 75Ω load or close...load or close indication type.

(3) FM SG output level in this FM adjustment are described as open indication type. The left table shows

relations among FM SG attenuator indication(dB), available power ratio(dBf) and antenna terminal

voltage(dB/µV) in each indication type.

Notes:

1. BAND Switch

........................................................................................................................................

FM

2. BALANCE

.......................................................................................................................................

Center

3. TREBLE/BASS

................................................................................................................................

Center

4. Connect as shown in figure 3.

5. Refer to figure 1~2 for Adjustment Points.

Item FM SSG Attenuator Available Antenna

Type Indication Power Ratio Terminal Voltage

Open indication type

0dB 5.2dBf 6dB/µV

60dB 65.2dBf 66dB/µV

Load or close 0dB 11.2dBf 12dB/µV

indication type 54dB 65.2dBf 66dB/µV

FEED SIGNAL

STEP SUBJECT

FROM TO

MEASURE OUTPUT ADJUSTMENT ADJUST FOR

1 Discriminator 98MHz 60dB ANT Jack Between Point XX & Point T101 DC 0V±10mV

22.5kHz Dev. or XX, DC Volt Meter.

1kHz FM SSG Point XX

2 MPX 98MHz 60dB Same as Between Point XX & GND, VR301 76kHz±50Hz

Adjustment

75kHz Dev.1kHz

above

Frequency Counter

FM SSG

A

C

D

E

Page 8

- 2-3 -

3. AM(MW) Adjustment

Notes:

1. BAND Switch

...................................................................................................................................

AM(MW)

2. Connect as shown in figure 4.

3. Refer to figure 1~2 for Adjustment Points.

Figure 4.

FEED SIGNAL

STEP SUBJECT

FROM TO

MEASURE OUTPUT ADJUSTMENT ADJUST FOR

1 520 or 522kHz No Input LCD Display TUNE +/- Button 520 or 522kHz

(Reception Frequency)

Tuning Voltage Between Point XX and GND, L206 DC 1.2V ± 0.05V

Adjustment DC Volt Meter

2 IF Coil 600kHz or ANT Jack Output L or R ch, T201 & T202 Max. Output

Adjustment 603kHz ANT or PointXX VTVM & Oscilloscope

input, 30dB,

400Hz (30%

MOD) SSG.

3 600kHz or 600kHz or Same as LCD Display TUNE +/- Button 600 or 603kHz

603kHz 603kHz ANT above (Reception Frequency)

RF Adjustment input, 30dB,

400Hz (30%

Output L or R ch, L204 & L205 Max. Output

MOD) SG.

VTVM & Oscilloscope

A

B

Page 9

- 2-4 -

4. LW Adjustment(Optional)

Notes:

1. BAND Switch

...........................................................................................................................................

LW

2. Connect as shown in figure 5.

3. Refer to figure 1~2 for Adjustment Points.

Figure 5.

FEED SIGNAL

STEP SUBJECT

FROM TO

MEASURE OUTPUT ADJUSTMENT ADJUST FOR

1 144kHz No Input LCD Display TUNE +/- Button 144kHz

(Reception Frequency)

Tuning Voltage Between Point XX and GND, L256 DC 1.2V ± 0.05V

Adjustment DC Volt Meter

2 150kHz 150kHz ANT Jack LCD Display TUNE +/- Button 150kHz

RF Adjustment ANT input, or PointXX (Reception Frequency)

30dB, 400Hz

(30% MOD)

Output L or R ch, L254 & L255 Max. Output

SSG.

VTVM & Oscilloscope

A

B

Page 10

- 2-5 -

5. Cassette Deck Adjustment

(1) Before this adjustment, clean PLAYBACK head surface.

(2) For this adjustment, use test tape MTT-114.

(3) VOLUME

......................................

Center

(4) BALANCE

....................................

Center

(5) TREBLE/BASS

............................

Center

(6) Connect as shown in figure 6.

Figure 6.

Figure 7.

SUBJECT MEASURE OUTPUT SETTING ADJUSTMENT ADJUST FOR REMARKS

P.B Head L-CH, R-CH, VTVM and Playback(FWD & Adjust the azimuth Max. Output After this

Adjustment Scope See figure 6. REV) the TEST adjusting screw both channels adjustment, lock

TAPE MTT-114 (in figure 7). on FWD and the screw with

REV PLAY paint.

Forward Head Azimuth

Adjustment Screw

Head

Screw Driver

Reverse Head Azimuth

Adjustment Screw

Page 11

- 2-6 -

INTERNAL BLOCK DIAGRAM of Ics

■ IC101 DBL 1018(LA 1 140)

■ IC201 DBL 1019 (LA1 135)

Page 12

- 2-7 -

■ IC301 KIA6043S

NOTE: Mark terminals are not existence in KIC9256P, KIC9256F

Terminal name of KIC9256P, KIC9256F is shown in parentheses.

Others are common terminals.

■ IC401 KIC9256P

Page 13

- 2-8 -

■ IC402 μμPD789104GS-204

PIN Port P-NAME I/O Act DESCRIPTION When not used REMARK

1 P23 FRTCLK O FRONT IC CLOCK Data OUTPUT

I DIODE MATRIX as DIO IN2 line

2 P24 ACC IN I ACC DETECT INPUT ACTIVE = LOW

3 P25 CDC DI I L CD CHANGER DATA INPUT

4 Avdd A/D Reference Voltage (5V)

5 P60 KEYIN I AD KEY - IN input.

Used for also front panel detecting.

Less than 0.17V : regarded as the panel opened.

Refer to application circuit.

6 P61 DIR I H/L TAPE DIRECTION INPUT (H = FORWARD)

7 P62 SD Tuner SEEK stop detector input

- Seek Stop threshold voltage :

AM : 1.2V, FM : 1.5V

8 P63 STIN I L FM Stereo detect input Active = Low

9 AVSS GROUND

10 NC NO CONNECTION

11 P50 CDCO O CDC Data Output : Should be connected to CDCI

12 P51 PEVDATA O E VR Communication DATA OUT

13 P52 MUTE/LED O Used as Power IC mute. Active = Low

Used as blinking LED. On duty = 10%

14 P53 TPMUTE I L TAPE MUTE INPUT (LOW = MUTE)

15 P00 FRTDO/ O FRONT IC DATA Out communication port

DIO IN0 I Diode matrix IN0 input

16 P01 CDON O H When CDC mode this port is high output

(future function)

17 P02 POWER O H When system is on, this port is used as power out

port

18 P03 TAPE IN I H For tape mode, Active high voltage should be applied.

L = RADIO mode.

19 RESET RESET INPUT

20 IC Connect to GROUND

21 NC NO CONNECTION

22 X2 X-tal

23 X1 X-tal

24 Vss System ground

25 Vdd System Power Supply (5V)

26 P10 FINH O L Front IC INH port.

27 P11 PERI/ O PLL IC PERIODE communication port

DIO OUT2 O Diode matrix DIO OUT 2 line

28 P20 PEVCLK O PLL IC and E. VOL IC CLOCK communication port

DIO OUT0 O Diode matrix DIO OUT 0 line

29 P21 PDATA O PLL IC DATA communication port

DIO OUT1 O Diode matrix DIO OUT 1 line

30 P22 FRTCE O FRONT IC CE communication port

DIO IN1 I Diode matrix DIO IN 1 line

Page 14

- 2-9 -

■ IC501 LA3160

■ IC601 PT2313L

Page 15

- 2-10 -

■ IC801 TDA8571J

■ IC901 LC75833E

Page 16

- 2-11 -

BLOCK DIAGRAM

NOTE: Block diagram for this model are subject to change for improvement without prior notice.

Page 17

- 2-12 -

WIRING DIAGRAM(Deck Mechanism)

CN502

ICC • 100H

CN501

IEE • 100H

BANDING

OWR1305R091

OWR1306R091

LEAF SW

HEAD SW PWG

BANDING

BH BL

RDWHBK

RO

MOTOR

DECK P/N : 6730R-K001A

RO

BK

HOLDER P/N : 324-973B

WH

Page 18

2-13 2-14

SCHEMATIC DIAGRAM (TCC-6210)

R

L

NOTE: 1. Resistance values are indicated in ohms unless otherwise specified (K=1,000, M=1,000,000).

2. Capacitance values are shown in microfarads unless otherwise (P=MICRO-MICRO FARADS).

3. Schematic diagram for this model are subject to change for improvement without prior notice.

Page 19

2-16 2-15

PCB LAYOUT

• MAIN P.C. BOARD(SOLDER SIDE)

Page 20

2-17 2-18

• MAIN P.C. BOARD(COMPONENT SIDE)

Page 21

2-20 2-19

• FRONT P.C. BOARD MODEL: TCC-6210

NEW RF P.C. BOARD

(TOP VIEW)

(BOTTOM VIEW)

Page 22

3-1 3-2

SECTION 3. CABINET MAIN CHASSIS & MECHANISM

EXPLODED VIEW & PART LIST

• Main Section

302

A42

A43

271

273

276

275

A47

280

274

272

276

455

455

455

330

260

320

A55

457

OPTION(353-025F)

301

456

A00

A46

281

288

456

DECK MECHANISM(A00)

SVC Supply unit: Assembly only!

CAUTION

Exposed blade will cause

severe injury

NOTE) Refer to “SECTION 4 REPLACEMENT

PARTS LIST” in order to look for the

part number of each part.

Loading...

Loading...