LG RU-60PZ61 Service Manual

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : RF-043A

MODEL : RU-60PZ61

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//lgservice.com/techsup.html

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

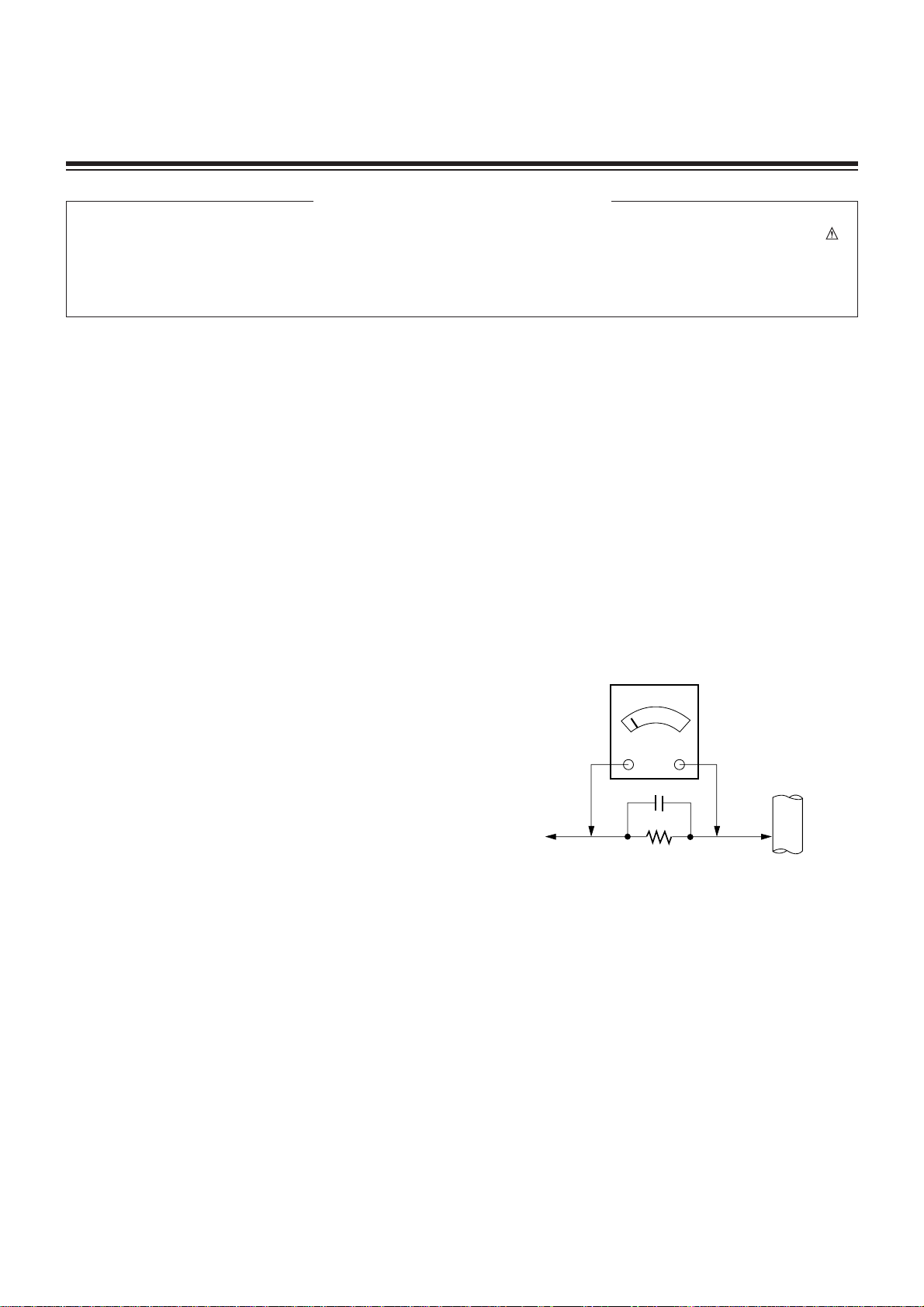

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

- 3 -

DESCRIPTION OF CONTROLS...........................................4

SPECIFICATIONS.................................................................7

ADJUSTMENT INSTRUCTIONS ..........................................8

TROUBLE SHOOTING GUIDE...........................................12

PRINTED CIRCUIT BOARD ...............................................24

BLOCK DIAGRAM...............................................................29

EXPLODED VIEW...............................................................32

EXPLODED VIEW PARTS LIST.........................................33

REPLACEMENT PARTS LIST............................................34

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARD ...................................................

TABLE OF CONTENTS

- 4 -

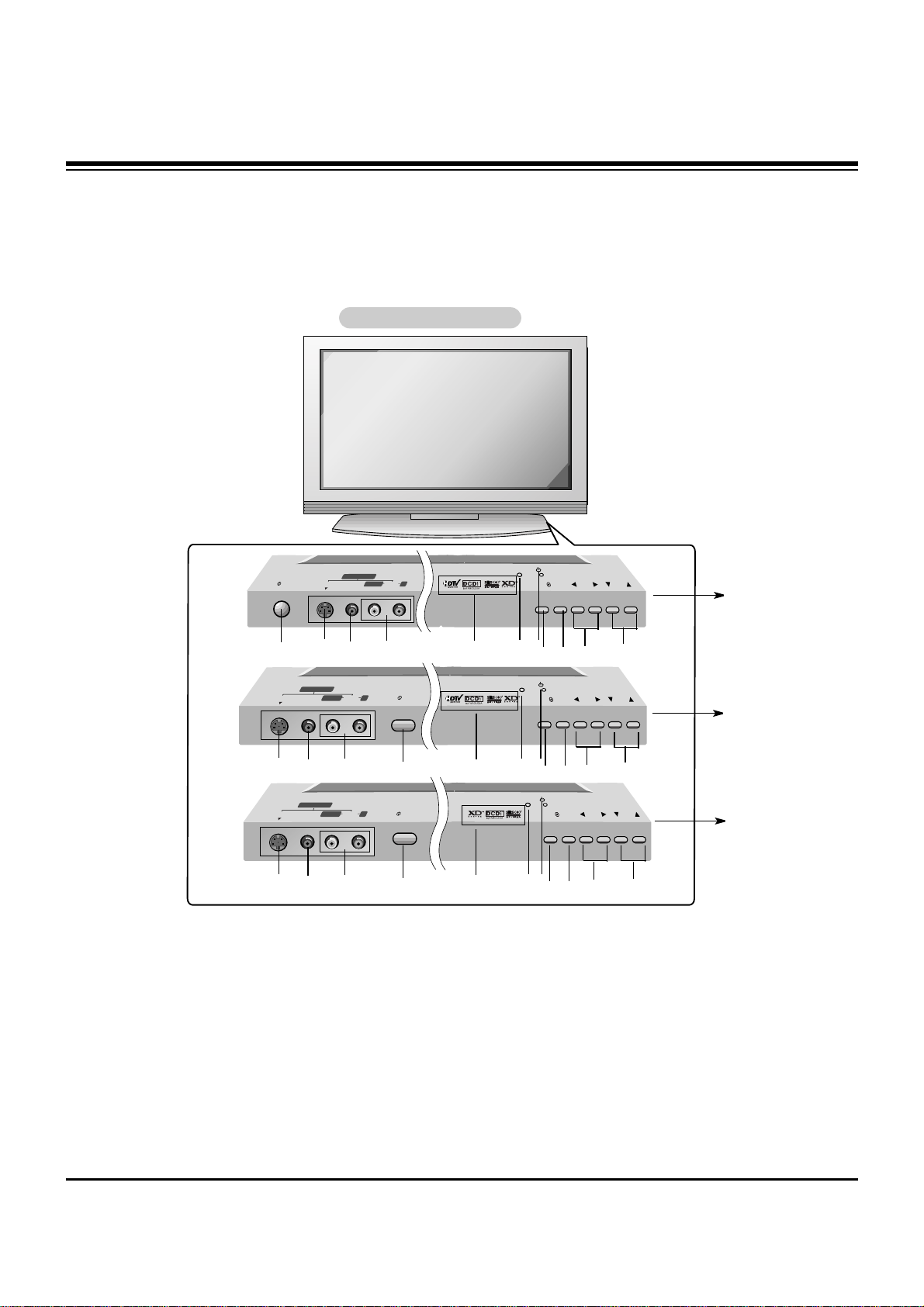

S-VIDEO VIDEO AUDIO

L/MONO R

TV/VIDEO

MENU

VOL

CH

ON/OFF

FRONT A/V INPUT

R

TruSurround XTruSurround XT

ON/OFFS-VIDEO VIDEO AUDIO

L/MONO R

ON/OFFS-VIDEO VIDEO AUDIO

L/MONO R

FRONT A/V INPUT

FRONT A/V INPUT

TV/VIDEO

MENU

VOL

CH

R

TruSurround XTruSurround XT

TV/VIDEO

MENU

VOL

CH

R

TruSurround XTruSurround XT

Controls

Controls

- This is a simplified representation of front panel.

Here shown may be somewhat different from your TV.

Front Panel Controls

Front Panel Controls

1. ON/OFF Button

2. S-VIDEO Input

A connection available to provide better picture quality than

the video input.

3.

VIDEO Input

Connects the video signal from a video device.

4. AUDIO Input

Use to connect to hear stereo sound from an external device.

5. INDEX

Switches LED Display on or off.

6. Remote Control Sensor

7. Power Standby Indicator

Illuminates red in standby mode, Illuminates green when the

TV is turned on.

8. TV/VIDEO or ENTER Button

9. MENU Button

10. VOLUME (FF,GG) Buttons

11. CHANNEL (EE, DD) Buttons

5

1

2

3

4

6

8

9

10 11

7

5

1

2

3

4

6

8

9

10 11

7

5

1

2

3

4

6

8

9

10

11

7

RU-50PZ61

RU-60PZ61

RU-42PZ61

RU-42PZ71

DESCRIPTION OF CONTROLS

- 5 -

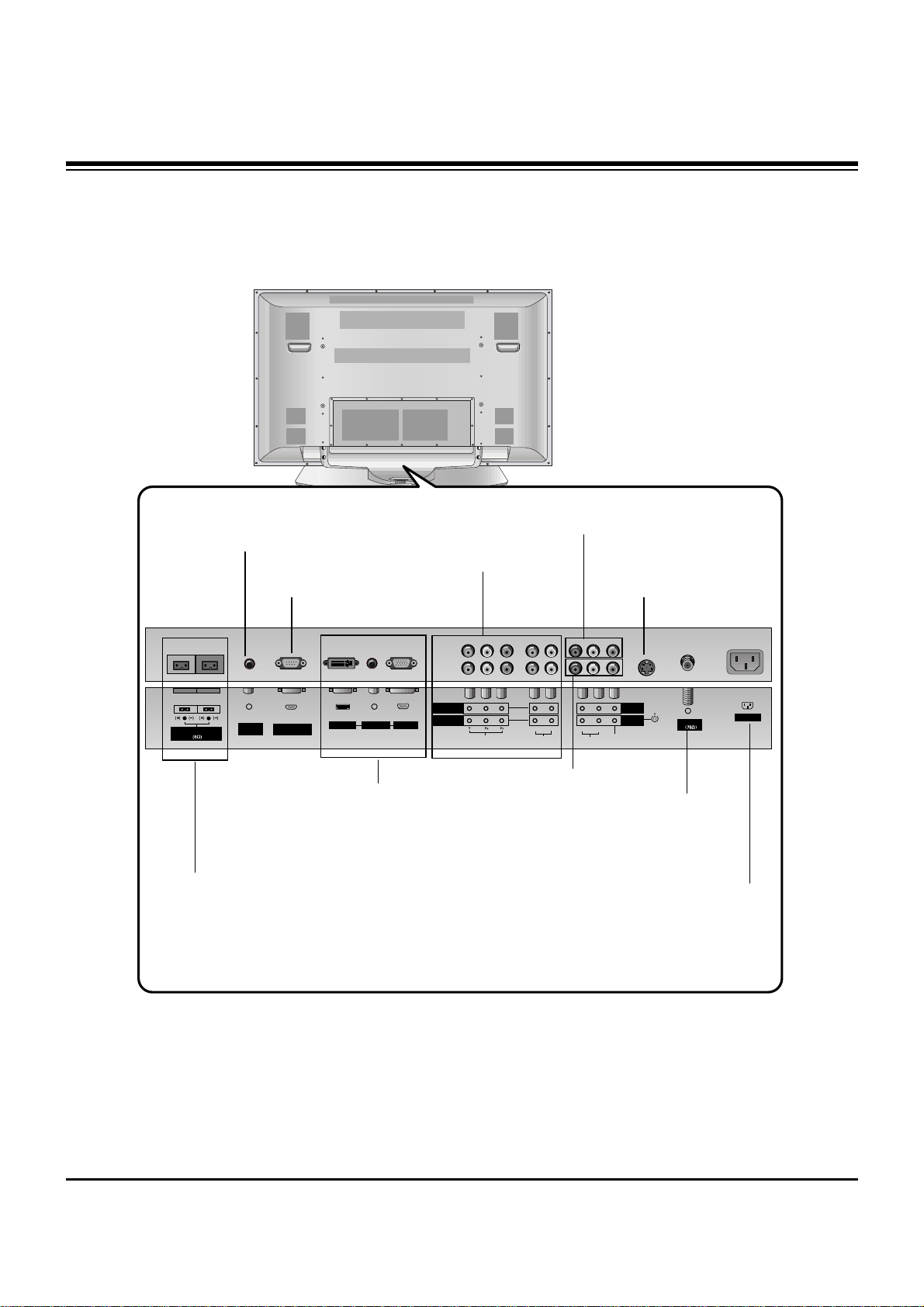

Connection Options

Connection Options

RGB INPUT

Antenna

AUDIO INPUT

DVI INPUT

REMOTE

CONTROL

AC INPUT

R

EXTERNAL SPEAKER

R

L

RS-232C INPUT

(CONTROL/SERVICE)

S-VIDEO

AUDIOVIDEO

COMPONENT

INPUT 2

COMPONENT

INPUT 1

MONITOR

OUTPUT

A/V

INPUT 1

(R) (L)

AUDIO

VIDEO

(L/MONO)

(R)

DVI Input/Audio Input/ RGB

Input

Connect the monitor output con-

nector from a PC to the appropri-

ate input port.

Remote Control Port

Connect your wired

remote control here.

External Speaker (8 ohm Output)

Connect to optional external speaker(s).

* For further information, refer to ‘Speaker & Speaker

Stand’ manual.

RS-232C INPUT

(CONTROL/SERVICE) PORT

Connect to the RS232C port on a PC.

DVD/DTV Input (Component 1-2)

Connect a component video/audio

device to these jacks.

Audio/Video Input 1

Connect audio/video

output from an external

device to these jacks.

Monitor Output

Connect a second TV or

Monitor.

S-Video Input

Connect S-Video out from an SVIDEO device to the S-VIDEO

input.

Antenna Input

Connect cable or antenna

signals to the TV, either

directly or through your

cable box.

Power Cord Socket

This TV operates on AC power. The voltage

is indicated on the Specifications page.

Never attempt to operate the TV on DC

power.

DESCRIPTION OF CONTROLS

- 6 -

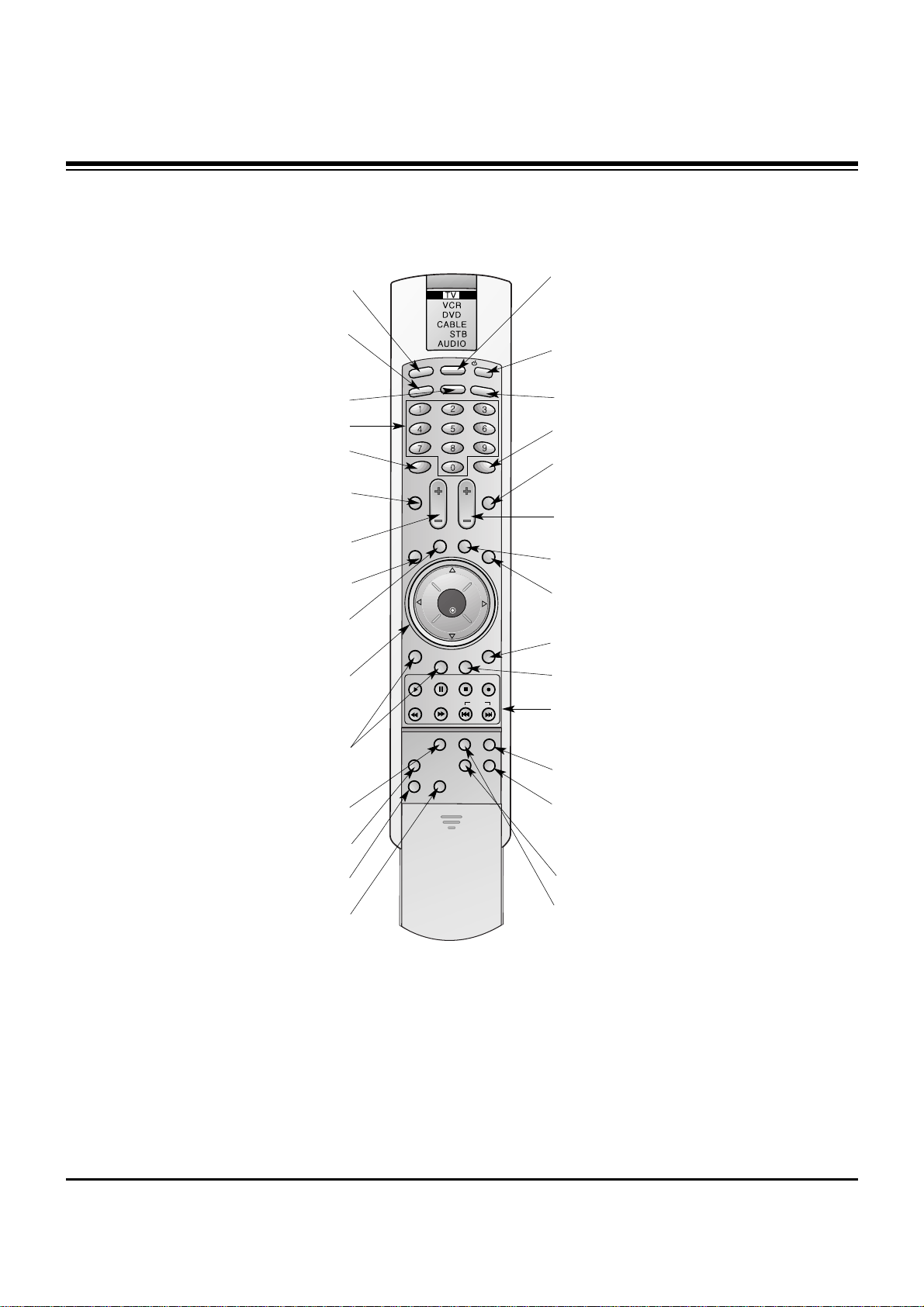

- When using the remote control, aim it at the remote control sensor on the TV.

TV/VIDEO

MULTIMEDIA

MODE

ARC

APC

VOL CH

MENU

PIP/DW

CAPTION

EXIT

PIP CH-

PIP CH+ SWAP

PIP INPUT

PLAY PAUSE STOP RECORD

WIN.SIZE

WIN.POSITION

SLEEP

A.PROG

ENTER

MTS

MEMORY/ERASE

SPLIT ZOOM

REW FF SKIP

REVIEW

LIGHT

POWER

FCR

MUTE

DASP

HD

TV/VIDEO

Selects: TV, Video1-2, Component 1-2,

RGB, and DVI input sources.

MULTIMEDIA

Selects: Component 1-2, RGB, and

DVI input sources.

ARC

Changes the aspect ratio.

NUMBER buttons

FCR

Use to scroll the Surf channel list.

APC

Adjusts the factory preset picture according

to the room.

VCR/DVD BUTTONS

Control some video cassette recorders or

DVD player ("RECORD" button is not available for DVD player).

CAPTION

Selects CAPTION mode.

MODE

Selects the remote operating mode: TV,

VCR, DVD, CABLE, HDSTB or AUDIO.

Select other operating modes, for the

remote to operate external devices.

POWER

Turns your TV or any other programmed

equipment on or off, depending on mode.

MUTE

Switches the sound on or off.

DASP

Selects the sound appropriate for the program's character.

EXIT

Clears all on-screen displays and returns

to TV viewing from any menu.

REVIEW

Tunes to the last channel viewed.

THUMBSTICK (Up/Down/Left/Right/ENTER)

Allows you to navigate the on-screen

menus and adjust the system settings to

your preference.

CHANNEL UP/DOWN

Selects available channels found

with Auto program.

PIP INPUT

Selects the input source for the sub picture.

SWAP

Exchanges the sub/main images.

VOLUME UP/DOWN

Increases/decreases the sound level.

PIP/DW

Switches between PIP, and

Double Window modes.

PIPCH-/PIPCH+

Changes to next lower/higher PIP channel.

MENU

Brings up the main menu to the screen.

MTS

Selects the MTS sound: Mono, Stereo, or

SAP.

WIN.POSITION

Moves the sub picture.

SLEEP

Sets the sleep timer.

MEMORY/ERASE

Memorizes or erases selected channel.

A.PROG (AUTO PROGRAM)

Searches for available channels.

SPLIT ZOOM

Enlarges the picture.

Remote Control Key Functions

Remote Control Key Functions

WIN. SIZE

Adjusts the sub picture size.

LIGHT

Illuminates the remote control buttons.

DESCRIPTION OF CONTROLS

- 7 -

• The specifications shown above may be changed without notice for quality improvement.

MODEL

RU-50PZ61

57.7 / 1465

33.3 /845.6

13.2 / 335

117.5 / 53.3

1366 x 768 (Dot)

AC100-240V, 60Hz

NTSC

VHF 2 ~ 13, UHF 14 ~ 69, CATV 1 ~ 125

75 Ω

16,770,000 (256 steps of each R, G and B)

32 ~ 104°F (0 ~ 40°C)

Less than 80%

6561 feet (2000m)

Width (inches / mm)

Height (inches / mm)

Depth (inches / mm)

Weight (pounds / kg)

Resolution

Power requirement

Television System

Program Coverage

External Antenna Impedance

Color

Operating Temperature Range

Operating Humidity Range

Maximum Elevation

49.6 / 1260

28.5 / 724.8

11.3 / 287

96.7 / 43.84

RU-60PZ61

56.5 / 1436

36 / 913.2

3.9 / 98.6

172.3 / 78.15

1366 x 768 (Dot)

1024 x 768 (Dot) 852 x 480 (Dot)

RU-42PZ61

RU-42PZ71

MODEL

RU-50PZ61

4.7 / 120

30.7 / 779.4

3.9 / 98.2

5.7 / 2.57

Width (inches / mm)

Height (inches / mm)

Depth (inches / mm)

Weight (pounds / kg)

4.3 / 110

26.4 / 669.3

Speaker

Speaker

RU-42PZ61 RU-42PZ71

3.7/95

4.5 / 2.03

3.6/90.5

49.6 / 1260

28.6 / 726.2

11.3 / 287

96.7 / 43.84

SPECIFICATIONS

- 8 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions apply to the RF-043A Chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100~220V,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

O After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display 100% full WHITE

PATTERN.

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

Caution) If you turn on a still screen more than 20 minutes

(Especially digital pattern, cross hatch pattern), an

afterimage may be occur in the black level part of the

screen.

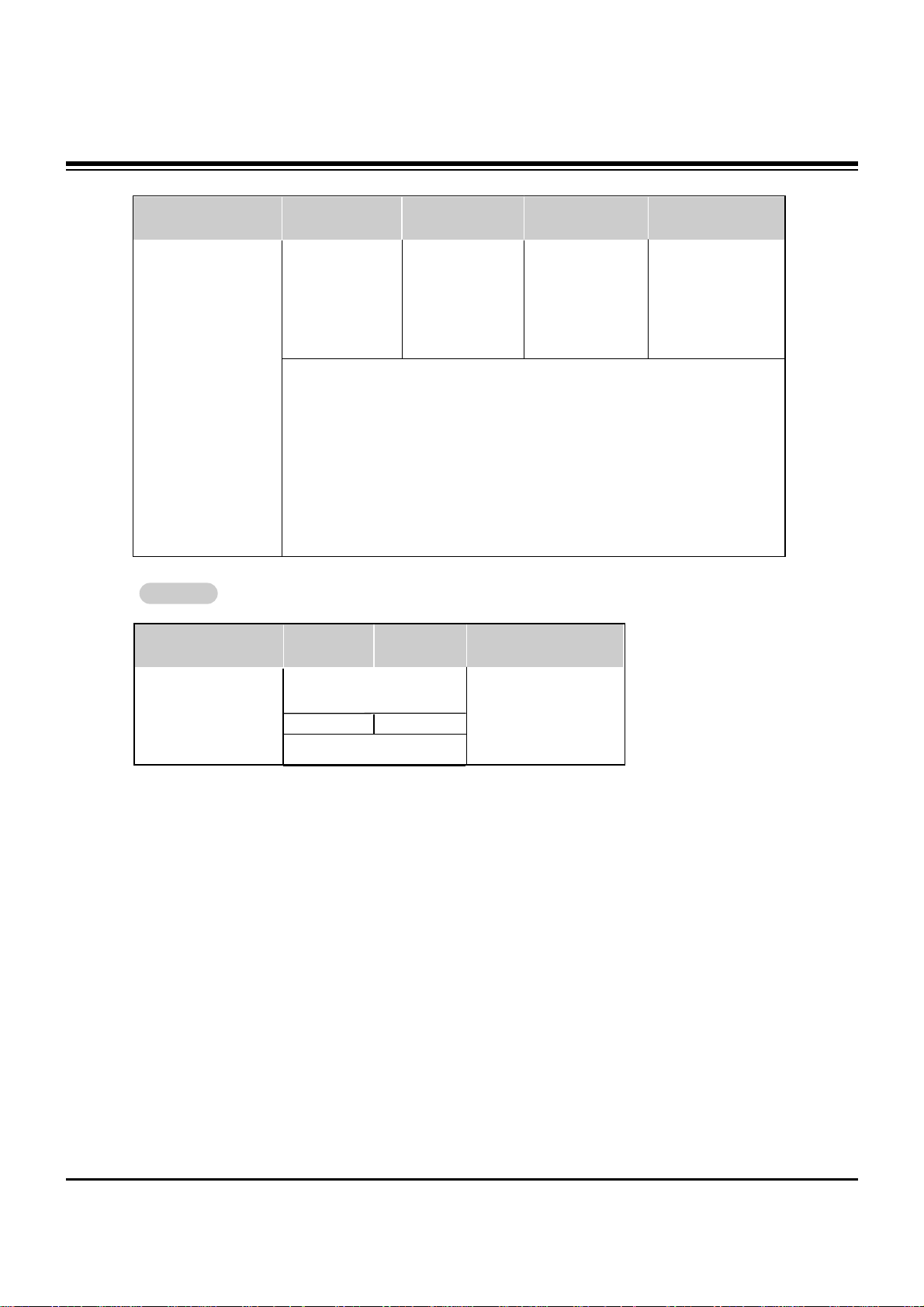

3. Channel memory

3-1. Setting up the LGIDS

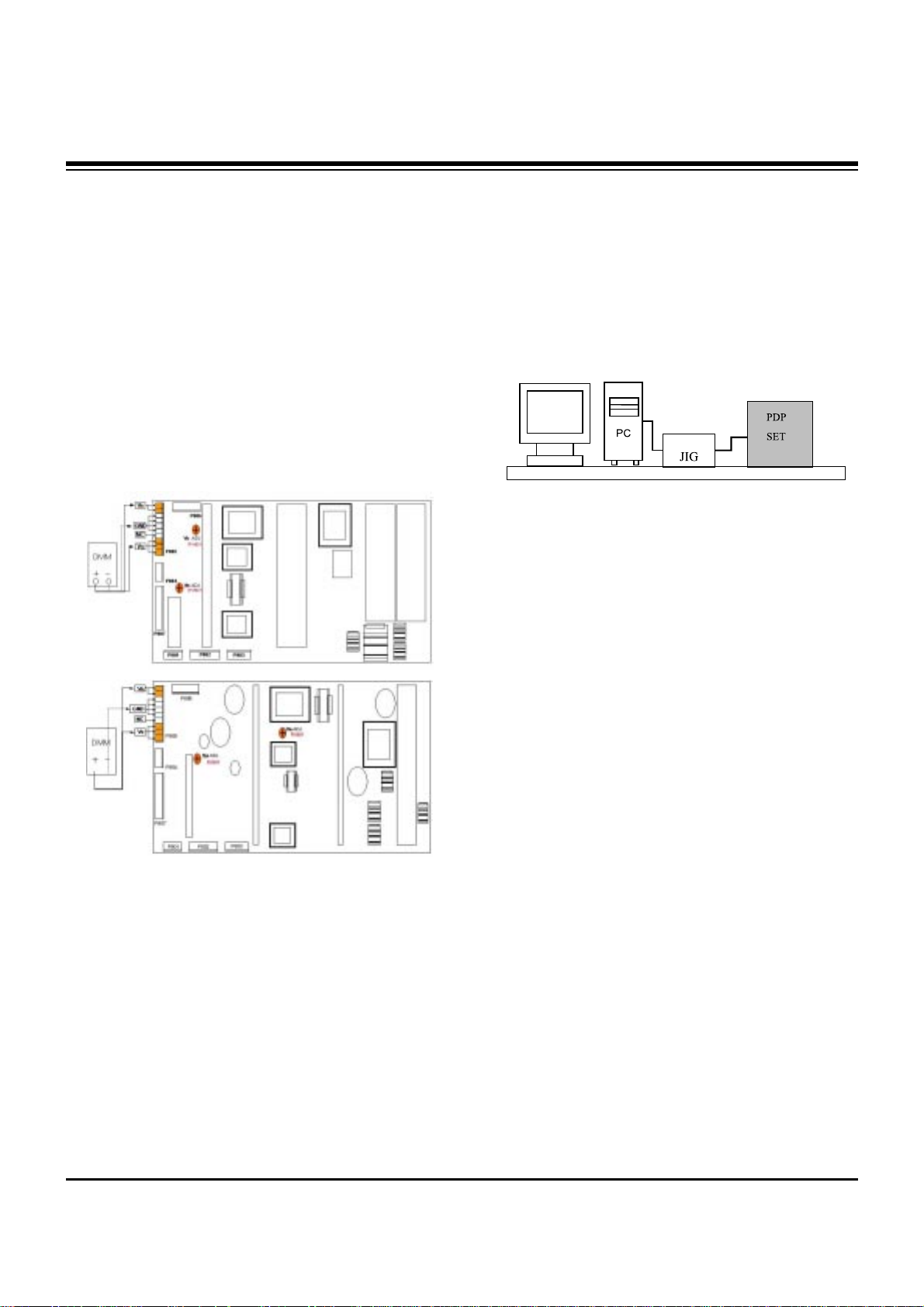

(1) Install the LGIDS. (idsinst.exe)

After installation has completed, check if the file shown in

(Fig. 1) has been created.

(2) Right click on 'LGIDS' and select ‘Create Shortcut’

Then move the shortcut icon onto the desktop.

(3) Double-click on the ‘LGIDS’ icon on the desktop to

execute the program.

3-2. Channel memory Method

(1) Check if ‘Malibu’ has been selected on ‘Model’.

(2) Check if ‘Connection’ under ‘Communication’ is ‘OK’.

(3) If it is ‘NG’ , look on ‘PORT’(COM1,2,3...) and make sure

that it’s on the right port.

(4) After connecting RS-232C cable, turn on the power.

If it the communication has been done correctly, ‘READY’

is displayed at the lower right corner of the window shown

as (Fig. 2).

[ When the TV SET is not assembled completely and only

the PCB is supplied by Stand-by 5V, download at the

Stand-by state (LED is Red).

(5) Select proper CH_memory file(*.nvm) for each model at

[NVRAM Download]

$ [Write Batch]

Next, select proper binary file(*.bin) including the CH

information for each model at [NVRAM File].

(6) Click the [Download] button.

It means the completion of the CH memory download if all

items show ‘OK’ and Status is changed by ‘PASS’ at the

lower right corner of the window.

(7) If you want to check whether the CH information is

memorized correctly or not, click the [Verify] button.

And then compare NVRAM File(*.bin) with the CH

information downloaded.

(Fig. 1)

(Fig. 2)

- 9 -

ADJUSTMENT INSTRUCTIONS

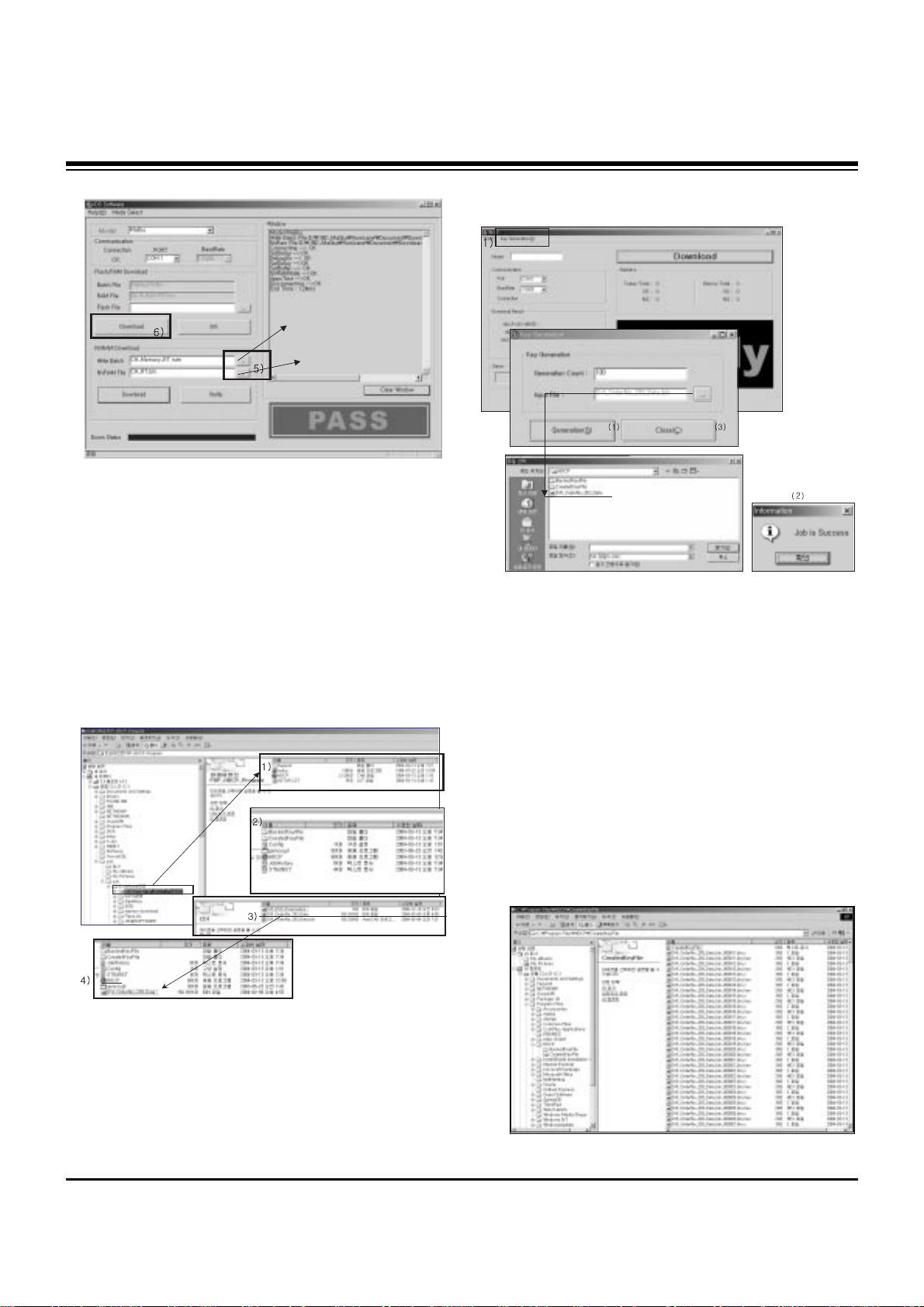

4. HDCP Download

4-1. LGIDS Setting Method

(1) Click on ‘setup’ to install in your directory.

(2) After installation has completed, check if the file shown on

(Fig. 4) has been created.

(3) Copy the KEY from source CD into the HDCP directory

which was installed just now.

(DVI_orderNo_2003_data)

(4) After running HDCP(application program) which is inside

the HDCP directory, setup the Communication.

Port : COM1(modification possible)

BaudRate : 115200

4-2. KEY Generation

(1) Click on ‘Key Generation (G)’.

(2) Input the number of the key in Generation count.

ex) If 100 Keys are required, then just register 100 and

next time it will automatically get 101.

(3) Input file : When installing the program for the first time,

you must find the original KEY that you copied and open it.

It is crucial that you copy the original KEY into this

directory.

When you use Generation, the information is recorded in

Config.ini.

(4) Click on ‘Generation’ ———————————————(1)

If it is done correctly, you will see “Job is Success.”——(2)

Click on ‘close’——————————————————(3)

(5) Check the Generation Data(Confirmation it’s possible

within HDCP\CreatedKeyFile)

(Fig. 3)

(Fig. 5)

(Fig. 6)

(Fig. 4)

- 10 -

(6) It is possible to check how many Generations are created

at this point.

(Fig. 7) shows that you have created 130 Generations and

you will start from 131 next time.

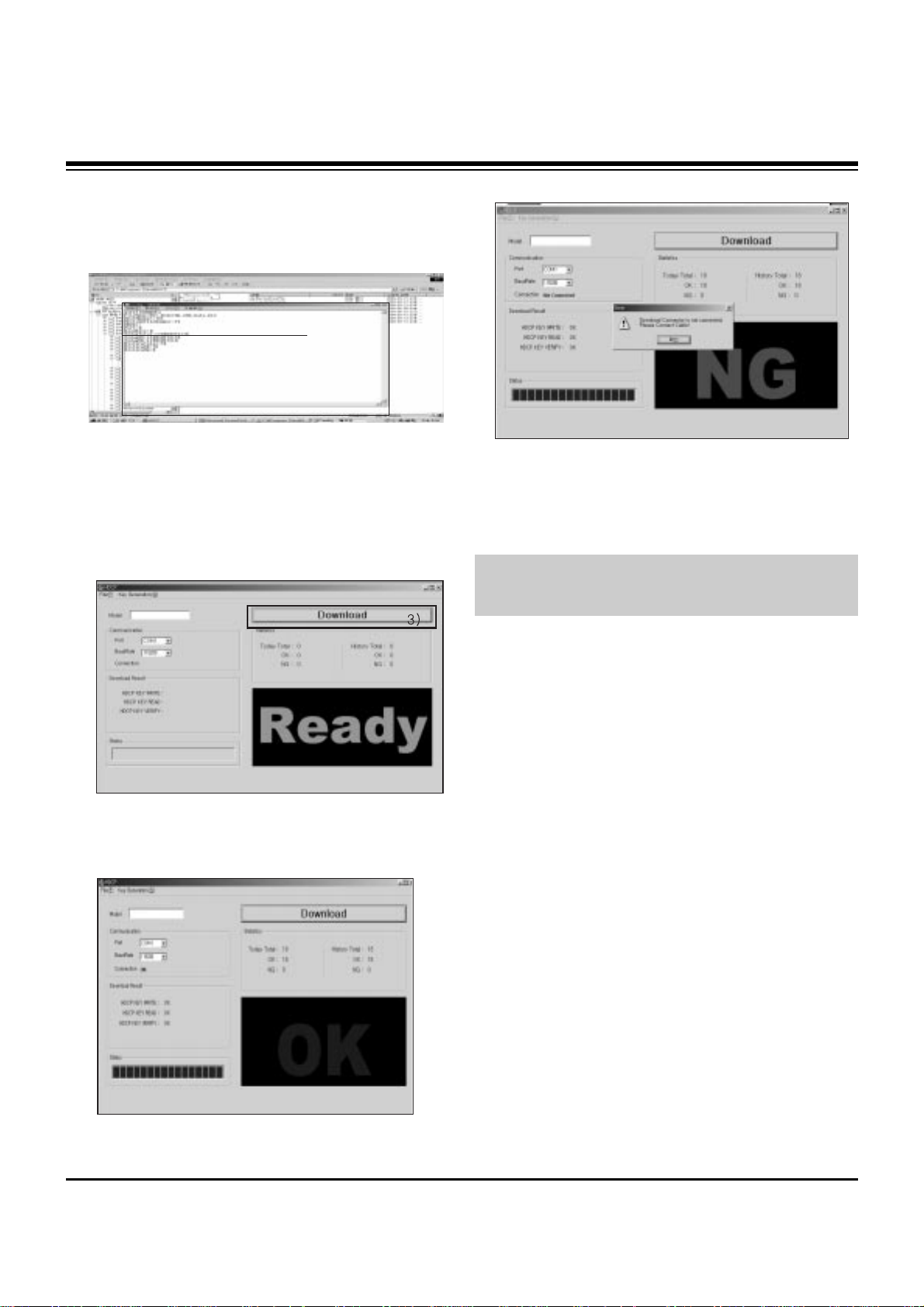

4-3. HDCP Download Method

(1) Input power of Stand-By 5V.

(Download must be executed only when it is on Stand-by)

(2) The RS-232C(9PIN) must be connected to the COM1 on

the PC.

(3) If all the preparation is completed, click on ‘Download’.

(4) If abnormal state (Fig. 10) display then (3) execute.

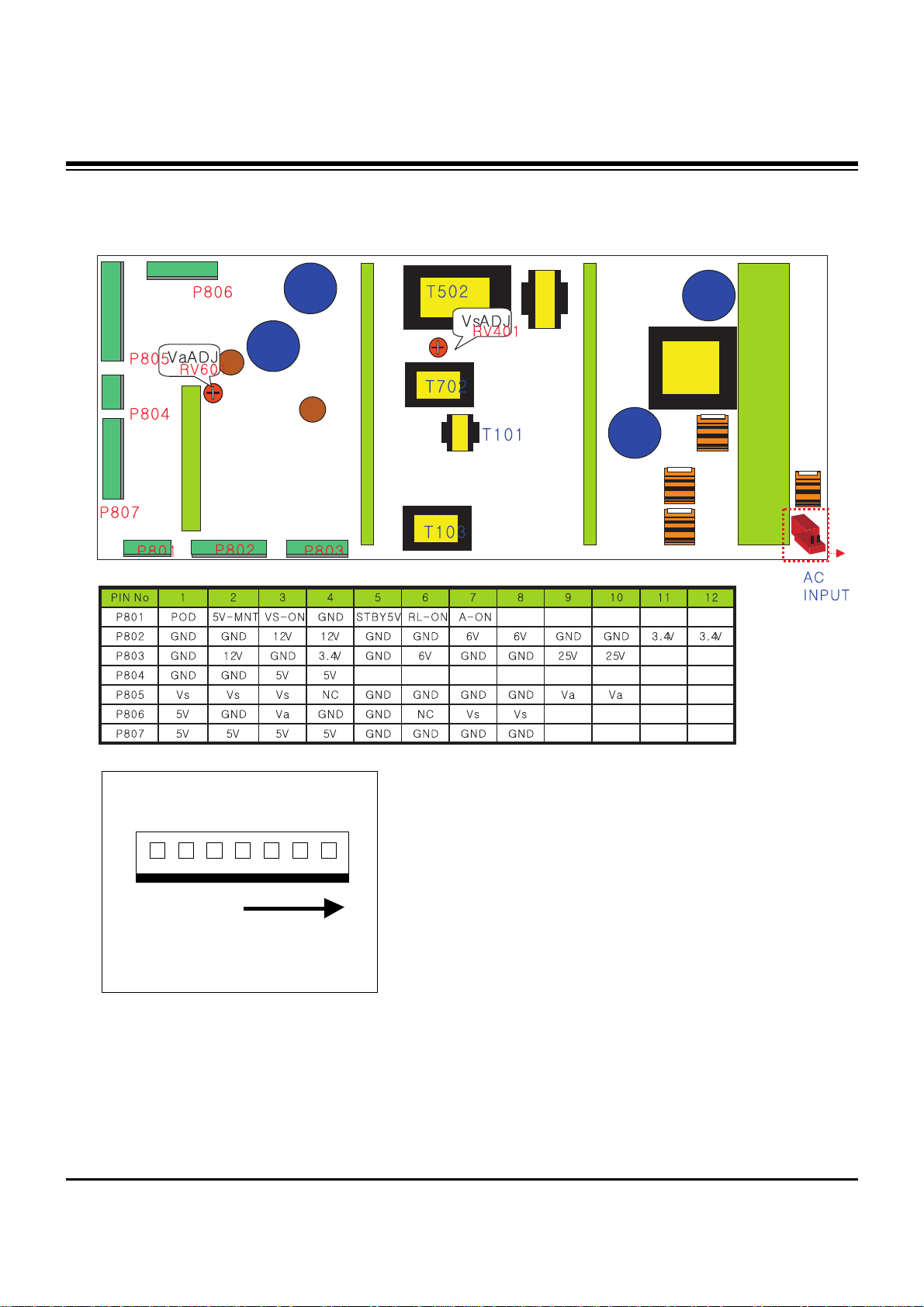

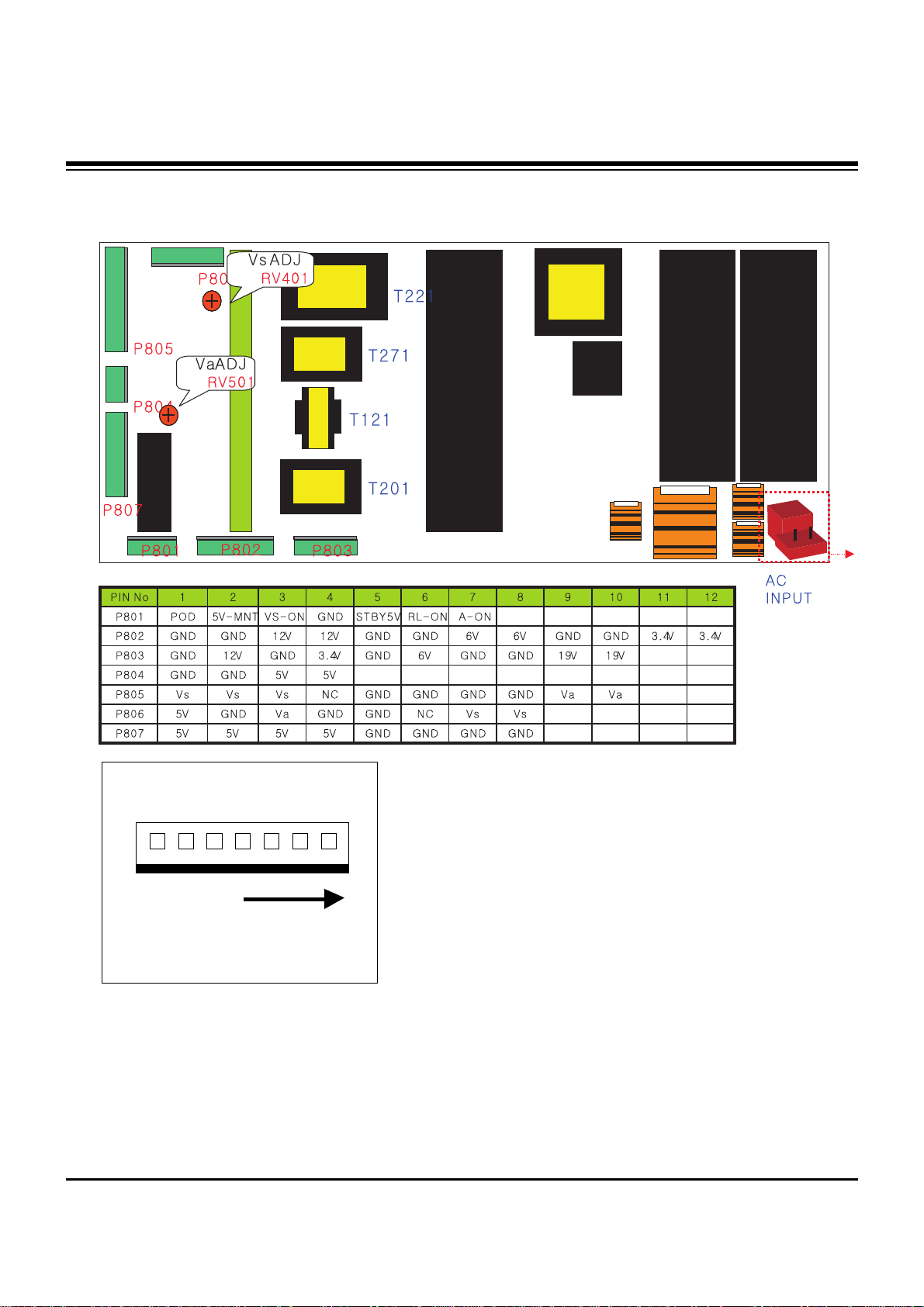

5. POWER PCB Assy Voltage

Adjustments

(Va, Vs Voltage Adjustments)

5-1. Test Equipment :D.M.M. 1EA

5-2. Connection Diagram for Measuring

Refer to (Fig 11).

5-3. Adjustment Method for

P/No. 3501V00180A B/D

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) Turn RV501, to adjust the Va voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

2) Turn RV401, to adjust the Vs voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

ADJUSTMENT INSTRUCTIONS

(Fig. 7)

(Fig. 8)

(Fig. 9) Normal State

(Fig. 10) Abnormal State

Each PCB assembly must be checked by Check JIG Set

before assembly. (Take special note of the Power PCB, which

can easily damage the PDP module)

- 11 -

ADJUSTMENT INSTRUCTIONS

5-4. Adjustment Method for

P/No. 3501V00182A B/D

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) Turn RV601, to adjust the Va voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

2) Turn RV401, to adjust the Vs voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

6. DDC Data Input

6-1. Required Test Equipment

(1) A jig for adjusting PC, DDC (PC serial to D-sub

Connection equipment)

(2) S/W for writing DDC (EDID Data Write & Read)

(3) D-sub 15P Cable, D-Sub to DVI Connector (Connect to

DVI Jack)

6-2. Setting of Device

6-3. Preparation for Adjustment

(1) Set devices as above and turn the PC and jig on.

(2) Put S/W for writing DDC (EDID data Write & Read) into

operation. (operated in DOS mode.)

6-4. Sequence of Adjustment

(1) DDC Data Input for Analog-RGB

1) Put the set on the table and turn the power on.

2) Connect PC Serial to D-sub 15P Cable of jig for DDC

adjustment to RGB terminal (D-Sub 15Pin).

3) Operate S/W for DDC record and select DDC data for

Analog RGB in Model Menu.

4) Operate EDID Write command.

5) Operate EDID Read command and check whether

Check Sum is 53.

6) If Check Sum is not 53, repeat 3) ~ 4).

7) If Check Sum is 53, DDC data for Analog-RGB input is

completed.

(2) DDC Data input for Digital-RGB(DVI)

1) Connect PC Serial to DVI Cable of jig for DDC

adjustment to DVI terminal (DVI Jack).

2) Operate S/W for DDC record and select DDC data for

digital RGB in model menu.

3) Operate EDID Write command.

4) Operate EDID Read command and check whether

Check sum is D2(1page), BF(2page).

5) If Check sum is not D2(1page), BF(2page), repeat 3) ~

4).

6) If Check sum is D2(1page), BF(2page), DDC data for

Analog-RGB input is completed.

< 3501V00180A >

< 3501V00182A >

(Fig. 11) Connection Diagram of Power Adjustment for

Measuring

- 12 -

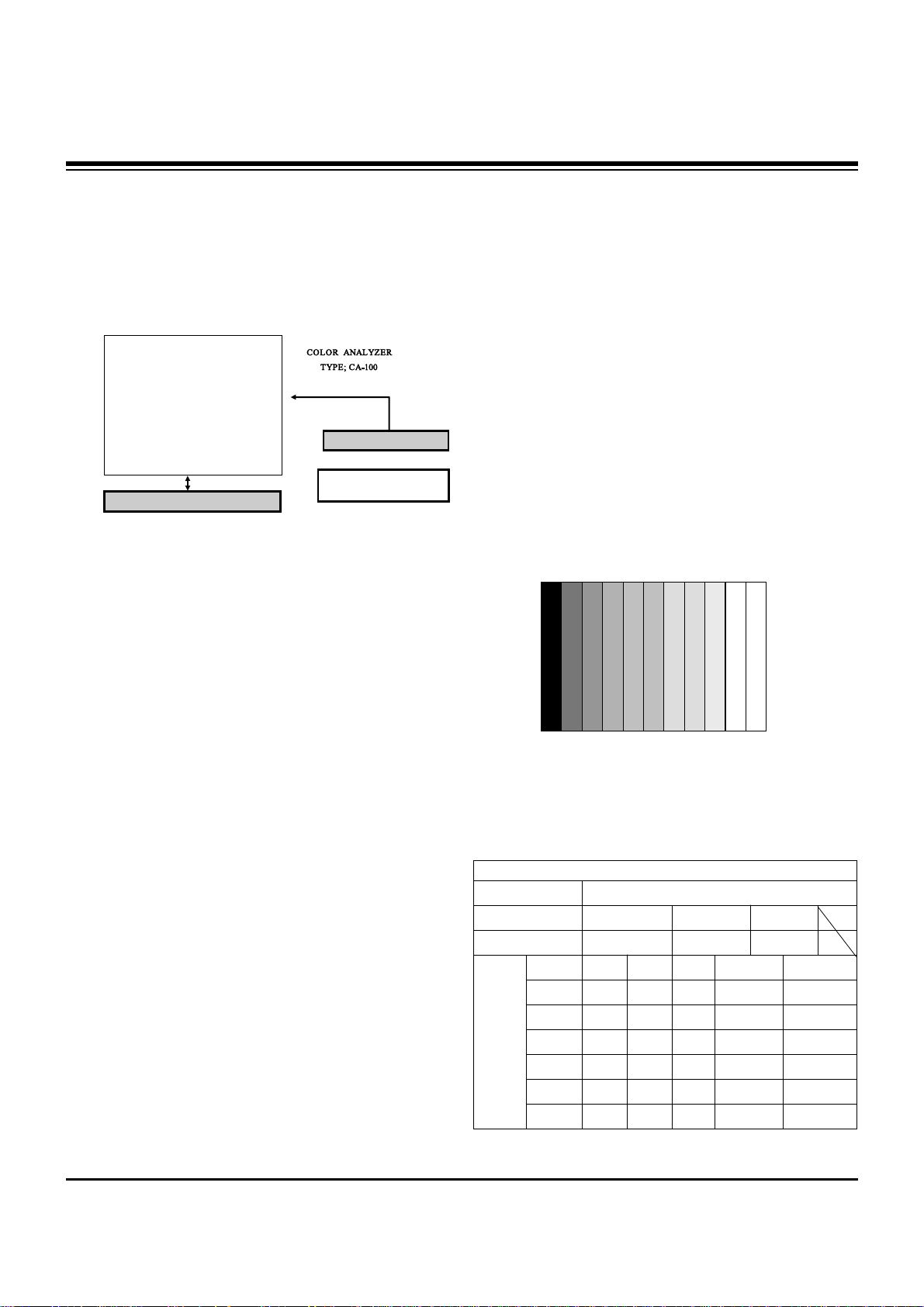

7. Adjustment of White Balance

7-1. Required Equipment

Color Analyzer (CA-100 or similar product)

7-2. Connection Diagram of Equipment for

Measuring

7-3. Adjustment of White Balance

O Operate the Zero-calibration of the CA-100, then stick

sensor to PDP module surface when you adjust.

O For manual adjustment, it is also possible by the following

sequence.

(1) Select white pattern of heat-run mode by pressing power

key on the Service Remote Control (S R/C) then allow to

heat run at least 15 minutes.

(2) Supply Gray Pattern (216 Level Full Size Pattern: Signal

level=0.59V±0.03V) signal to VIDEO input. (AV2 Input

60Hz) (Refer to Fig. 12)

(3) Press the FRONT-AV KEY on R/C for converting input

mode.

(4) To adjust, stick sensor to 216 Gray Level Pattern, press

ADJ key twice(White Balance) on S R/C and

D, E on S

R/C to select Red Gain and Green Gain.

Press VOL +, - keys to adjust until color coordination

matches below.

[ 216 Gray level=Signal level 0.59V±0.03V

X; 0.283±0.003, Y; 0.297±0.003

Color Temperature; 9,300°K±500°K

(5) Exit adjustment mode using

A Key.

8. Auto Component Color Balance

8-1. Required Test Equipment

Pattern Equipment: MSP3240A or similar product

(16 Gray Scale Pattern output(Component output Level:

0.7Vp-p)

8-2. Method of Auto RGB Color Balance

(1) Input RGB Source : Component 480p/576p 16 Gray Scale

Pattern

At this time, only connect the Y signal, not Pb and Pr.

(2) Press ADJ KEY on the S R/C.

(3) Press Vol. + KEY and operate To set.

(4) Auto-RGB OK means completed adjustment.

9. Auto RGB Color Balance

9-1. Required Test Equipment

Pattern Equipment: PC Pattern Generator (VG828, VG854,

801GF, MSP3240A)

(16 Gray Scale Pattern output(RGB output Level: 0.7Vp-p)

9-2. Method of Auto RGB Color Balance

(1) Input RGB Source : 16 Gray Scale Pattern output (RGB

output Level : 0.7Vp-p)

(2) Press ADJ KEY on the S R/C.

(3) Press Vol. + KEY and operate To SET.

(4) Auto-RGB OK means completed adjustment.

10. Auto Adjustment Map(RS-232C)

Window

MSPG-2100 or

MSTG-5200

AV Signal Input

Full Size Pattern

216 Gray Level

RS-232C Serial Communication

60Hz

(Fig. 12) White Balance Adjustment

(Fig. 13) Auto RGB/ Component Color Balance Test Pattern

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

j a

j b

j c

j d

j e

j f

Stop bit

1

Parity

NONE

RF-043A

Protocol

Setting

Data Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

RS232

ADJUSTMENT INSTRUCTIONS

- 13 -

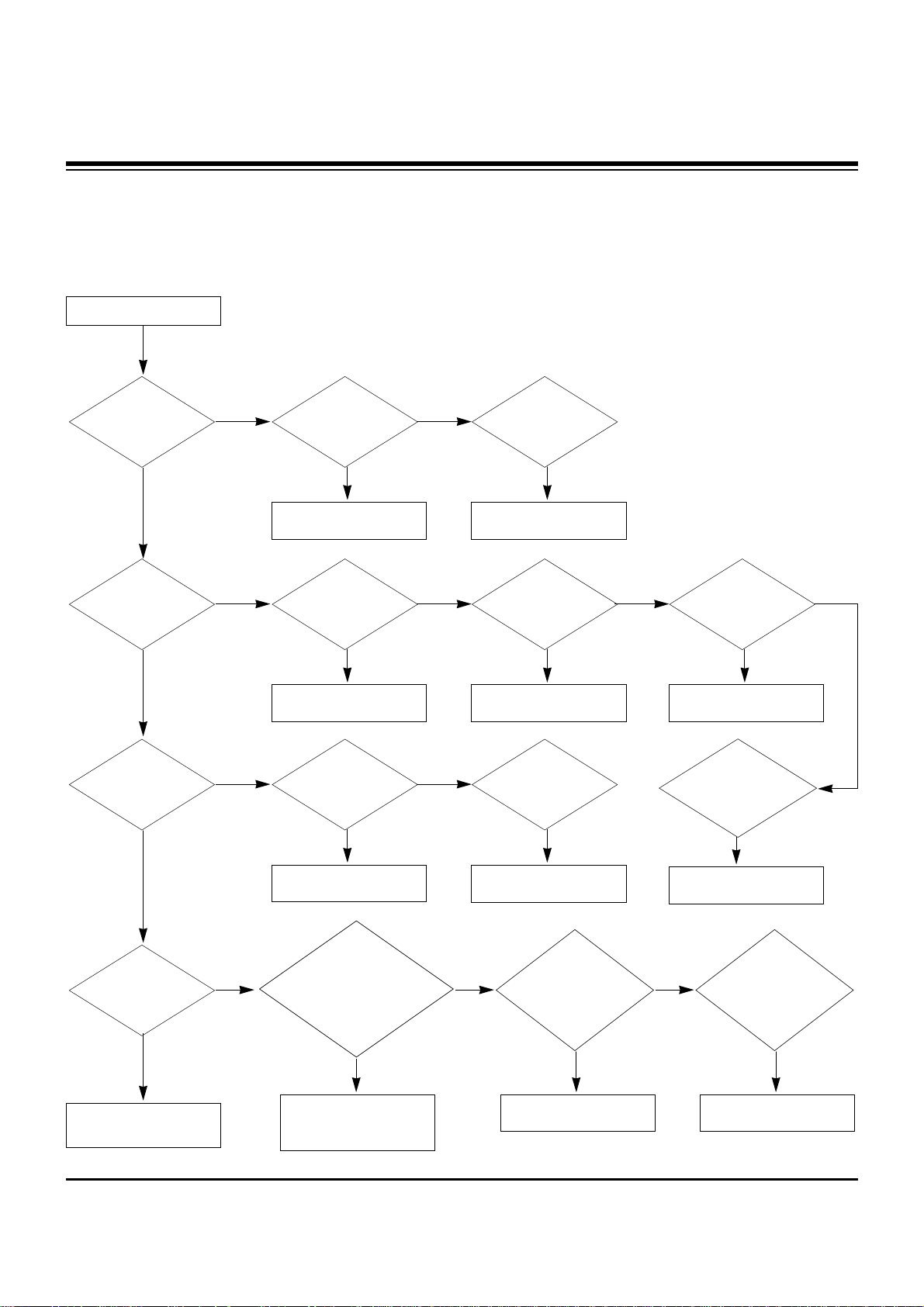

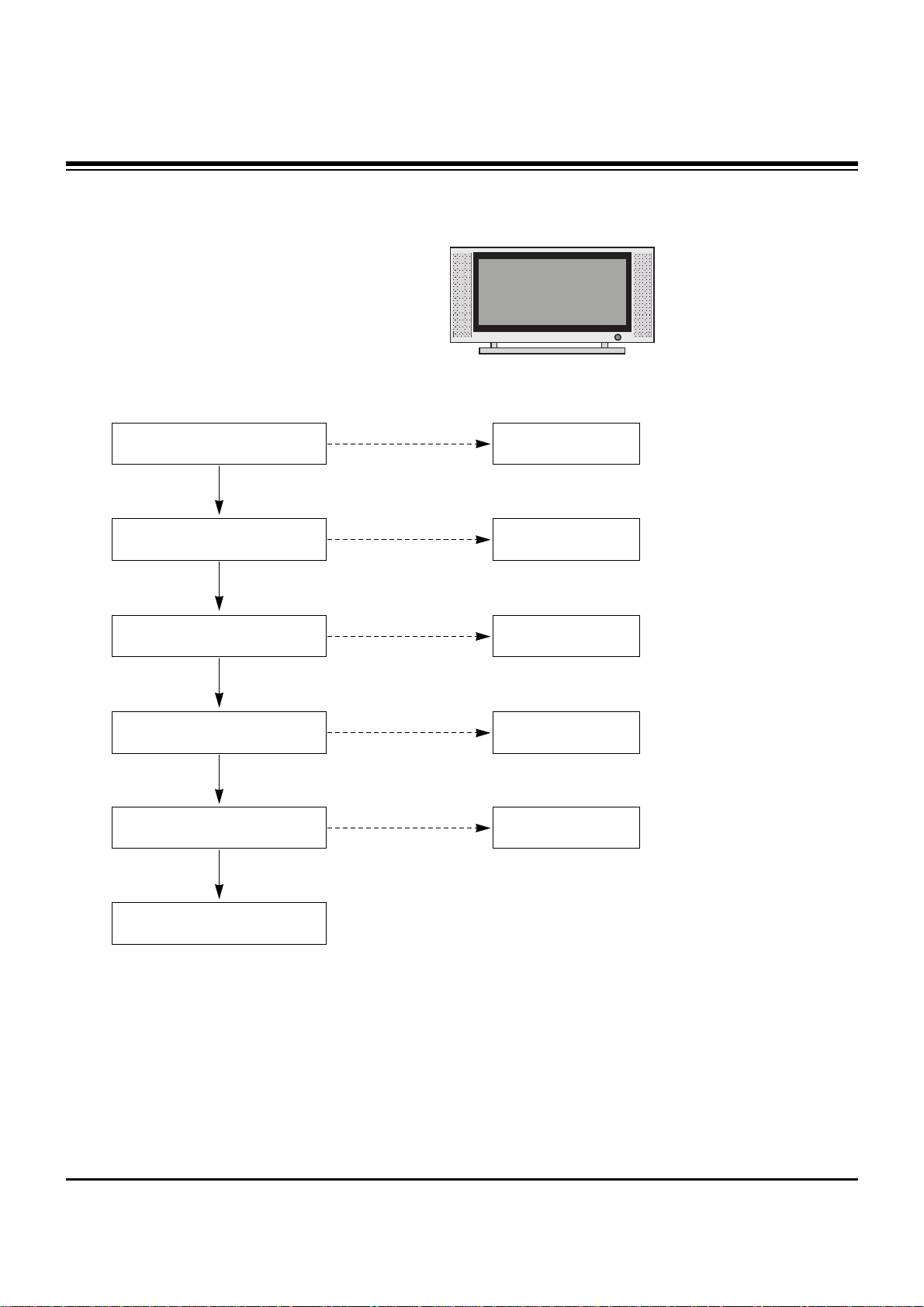

TROUBLE SHOOTING GUIDE

1. Power Board

1-1. General Power Flow

Start check

Manufacture enterprise

meaning of a passage

1. Check the Power Off

condition.

Doesn't the

screen whole come

out?

It is identical

with Power Off

condition?

Yes

Yes

No

No

No

No

No

2. Check the Interface

signal condition.

Is the Interface

signal operated?

Yes

3. Check the St-by 5V

signal circuit.

Doesn't the

low pressure output

come out?

Doesn't the

St-by 5V signal

come out?

Yes

Yes

No

4. Check the 5V Monitor

signal circuit.

Doesn't the

5V Monitor signal

come out?

Yes

7. Check the VSC Vs-ON

signal

Doesn't the

high tension output

come out?

Doesn't the

VSC signal Vs-ON

come out?

Yes

Yes

High tension

output voltage Drop

it occurs?

When

remove the

Y B/D Module

Input Connector, output

voltage Drop

it occurs?

When remove

the Y, Z B/D Module

Input Connector, Power

Board high tension output

voltage Drop

it occurs?

Yes No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module Coutput circuit

Yes

When

remove the

Z B/D Module

Input Connector, output

voltage Drop

it occurs?

11. Check the Y B/D

Module Coutput circuit

Yes

No

8. Check the Vs, Va

voltage output circuit.

Doesn't the

Vs, Va voltage output

come out?

Yes

No

No

5. Check the VSC RL-ON

signal.

Doesn't the

VSC signal RL-ON

come out?

Yes

6. Check the VSC low

pressure output

Doesn't the

VSC low pressure

output come out?

Yes

- 14 -

TROUBLE SHOOTING GUIDE

1-2. 3510V00182A Power Board Structure

T502: Vs Trans

T702: Va Trans

T101: St-by Trans

T103: Low Voltage Trans

1 2 3

- 15 -

TROUBLE SHOOTING GUIDE

1-3. 3501V00180A Power Board Structure

T221: Vs Trans

T271: Va Trans

T121: St-by Trans

T201: Low Voltage Trans

1 2 3

- 16 -

TROUBLE SHOOTING GUIDE

2. No Power

(1) Symptom

¯ Does’t minute discharge at module.

¯ No front LED.

(2) Check follow

Power cord connected? Plug in power cord.

Yes

No

Cable connecting the Line Filter

and Power Switch connected?

Connect Cable.

Yes

No

Is the Power Switch connected to

Power Board?

Connect Cable.

Yes

No

Is Fuse(F101) on Power Board

good?

Replace Fuse.

Yes

No

Is the Power Board connected to

7P of VSC Board?

Connect Cable.

Yes

No

When ST-BY 5V does not operate,

replace Power Board.

Loading...

Loading...