Page 1

LCD PROJECTION TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : NB-03JA

MODEL : RU-52SZ30 RU-60SZ30

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SERVICING PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ELECTROSTATICALLY SENSITIVE (ES) DEVICES . . . . . . . . . . . . . . . . . . . . . . . . 4

DESCRIPTION OF CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ADJUSTMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

REPLACING THE LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

BLOCK DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

EXPLODED VIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24, 26

EXPLODED VIEW PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25,27

REPLACEMENT PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- 2 -

Page 3

- 3 -

SAFETY PRECAUTIONS

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

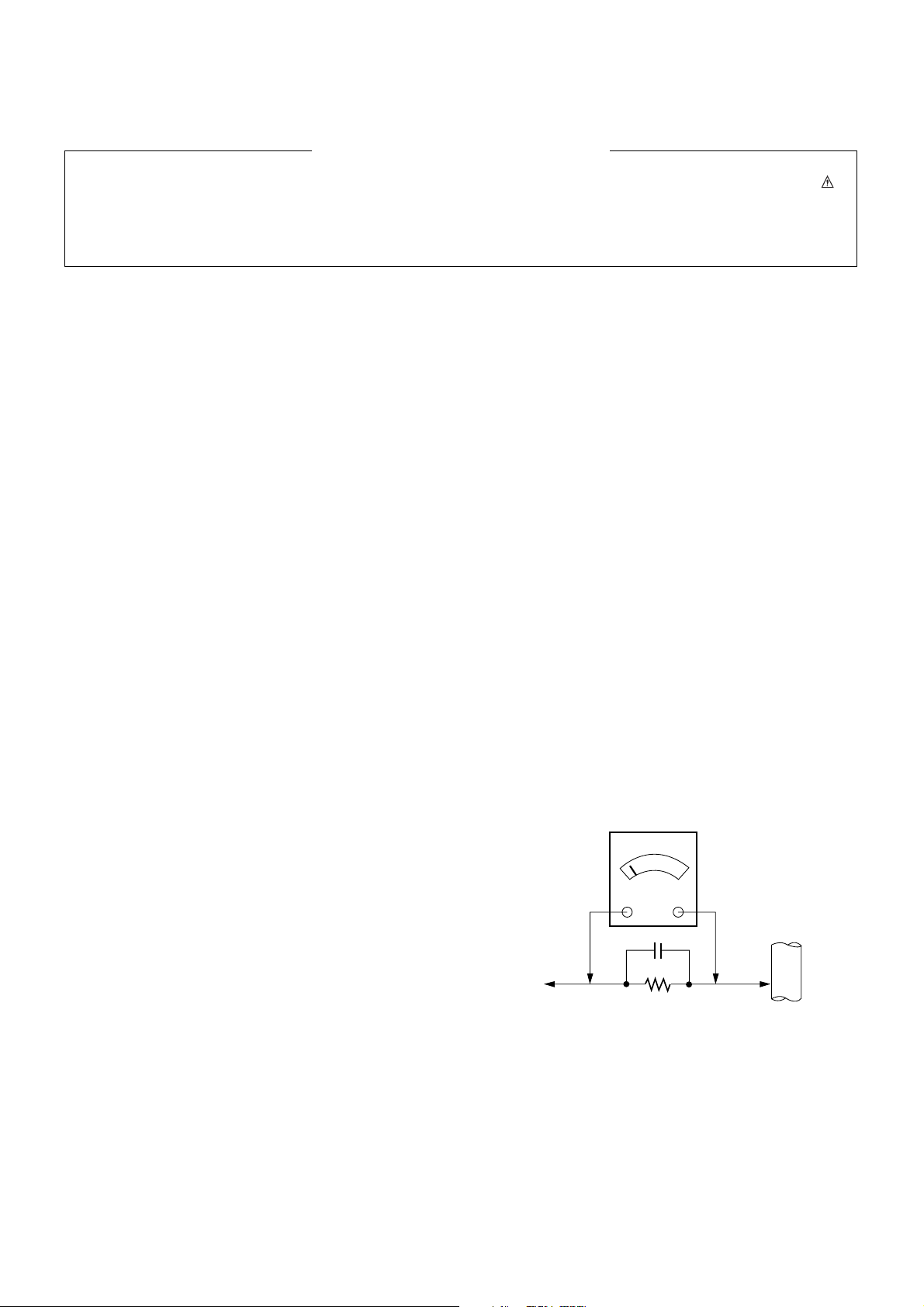

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

0.15uF

Page 4

SERVICING PRECAUTIONS

- 4 -

CAUTION: Before servicing instruments covered by this service manual and

its supplements, read and follow the SAFETY PRECAUTIONS section of this

manual. Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1. a. Always unplug the instrument AC power cord from the AC power source

before: (1) removing or reinstalling any component, circuit board, module,

or any other instrument assembly. (2) disconnecting or reconnecting any

instrument electrical plug or other electrical connections. (3) connecting a

test substitute in parallel with an electrolytic capacitor in the instrument.

Caution: A wrong part substitution or incorrect polar-ity installation of

electrolytic capacitors may result in an explosion hazard.

b. Do not defeat any plug/socket B+ voltage interlocks with which instru-

ments covered by this service manual might be equipped.

c. Do not apply AC power to this instrument and/or any of its electrical

assemblies unless all solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead to the instrument chassis

ground before connecting the test instrument positive lead.

Always remove the test instrument ground lead last.

Note: Refer to the Safety Precautions section of this manual.

2. The service precautions are indicated or printed on the cabinet, chassis, or

components. When servicing, follow the printed or indicated service precautions and service materials.

3. The components used in the unit have a specified flame resistance and

dielectric strength. When replacing any components, use components

which have the same ratings. Components identified by shading, by

*

, or

by in the circuit diagram are important for safety or for the characteristics

of the unit. Always replace with the exact replacement components.

4. An insulation tube or tape is sometimes used and some components are

raised above the printed wiring board for safety. The internal wiring is sometimes clamped to prevent contact with heating components. Install them as

they were.

5. After servicing, always check that the removed screws, components, and

wiring have been installed correctly and that the portion around the service

part have not been damaged. Further, check the insulation between the

blades of the attachment plug and accessible conductive parts.

INSULATION CHECKING PROCEDURE

Disconnect the attachment plug from the AC outlet and turn the power on.

Connect the insulation resistance meter (500 V) to the blades of the attachment plug. The insulation resistance between each blade of the attachment

plug and accessible conductive parts (Note 1) should be more than 1 Mohm.

Note: Accessible conductive parts include metal panels, input terminals, earphone jacks, etc.

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any electrostatic charge on the body by touching a known earth ground.

Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install

t.(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil, or

comparable conductive material.)

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to the chassis or circuit assembly into which the device will

be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replace

ment ES devices. (Otherwise, seemingly harmless motion,

such as the brushing together of your clothing or the lifting of

your foot from a carpeted floor, can generate static electricity

sufficient to damage an ES device.)

Page 5

- 5 -

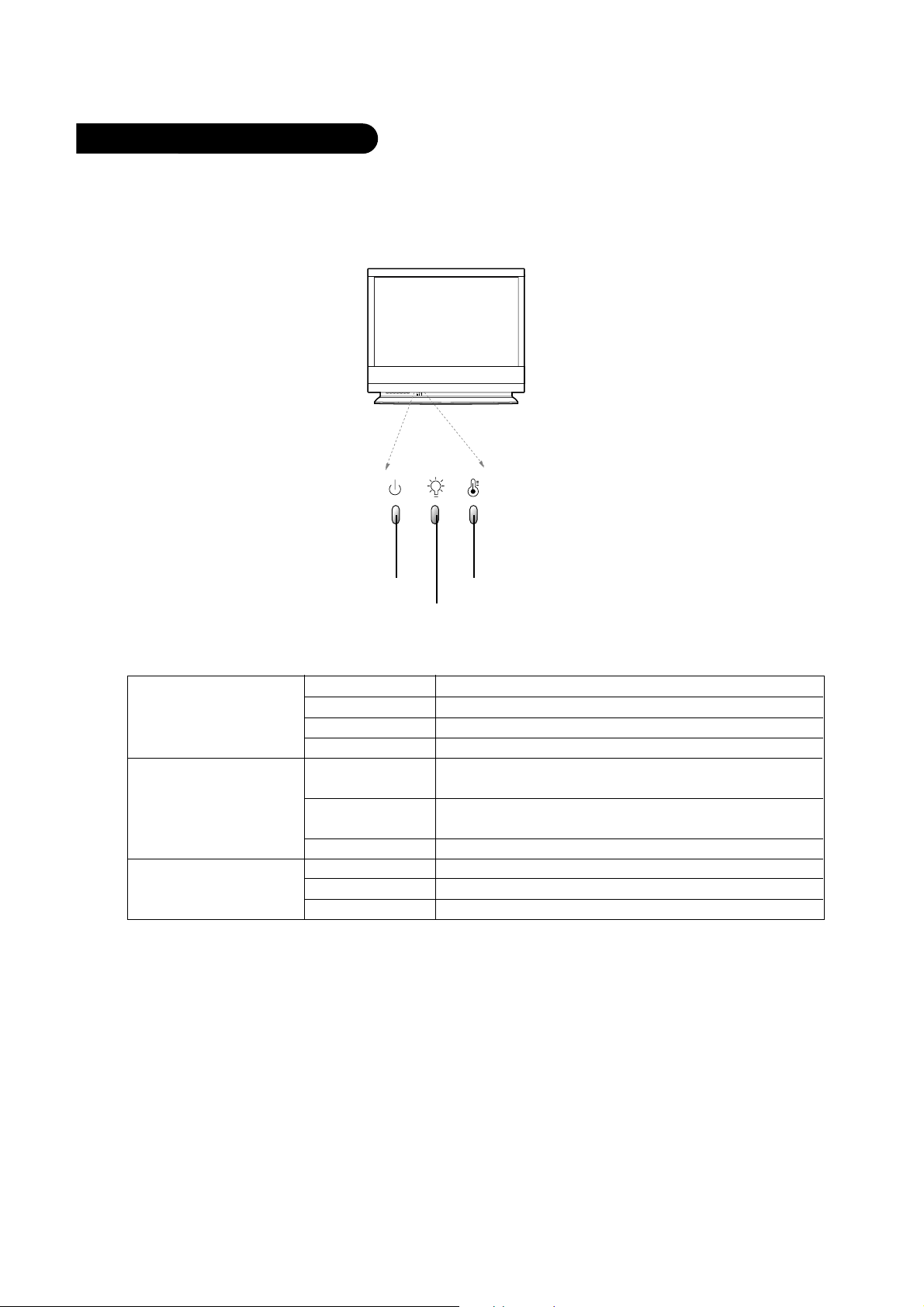

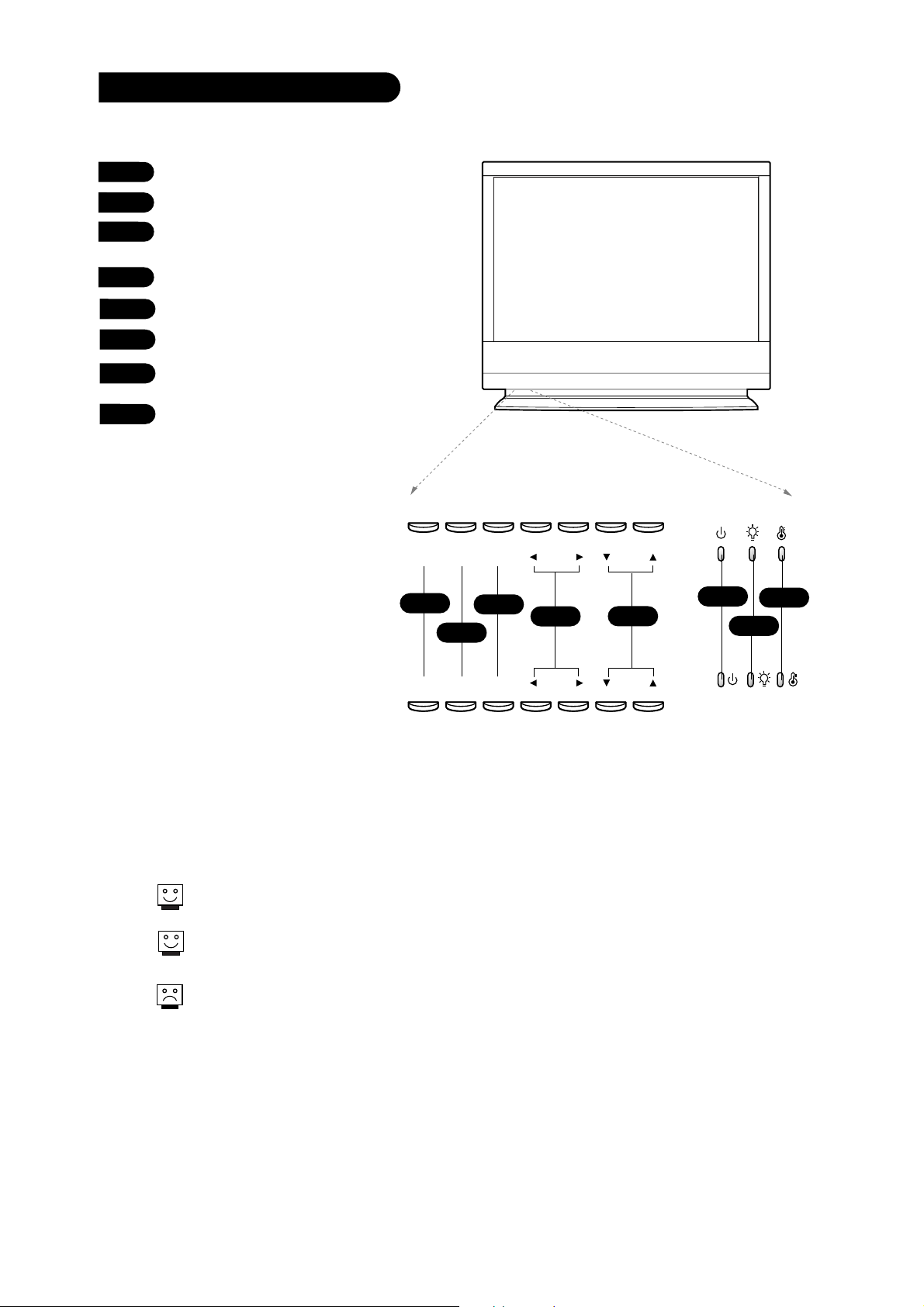

DESCRIPTION OF CONTROLS

Function Status Indicators

Lamp indicator, operation indicator, and temperature indicator located below the front panel

controls, reveal the operating status of the LCD projection TV.

Operation Indicator

Lamp Indicator

Temperature Indicator

Operation Indicator

Lamp Indicator

Temperature Indicator

Off Power cord is not connected.

Red Power Cord is connected, TV is in standby mode.

Green On

Orange (flashing) Preparing operation in standby mode.

Orange Projection lamp is reaching the end of its life and needs to

be replaced with a new lamp.

Red (flashing) There is a problem with the lamp or around it. Contact an

authorized service center.

Green (flashing) The lamp cover is not closed.

Orange The projection TV is overheating.

Red The projection TV shut down due to overheating.

Red (flashing) The projection TV shut down, check the cooling fan.

Page 6

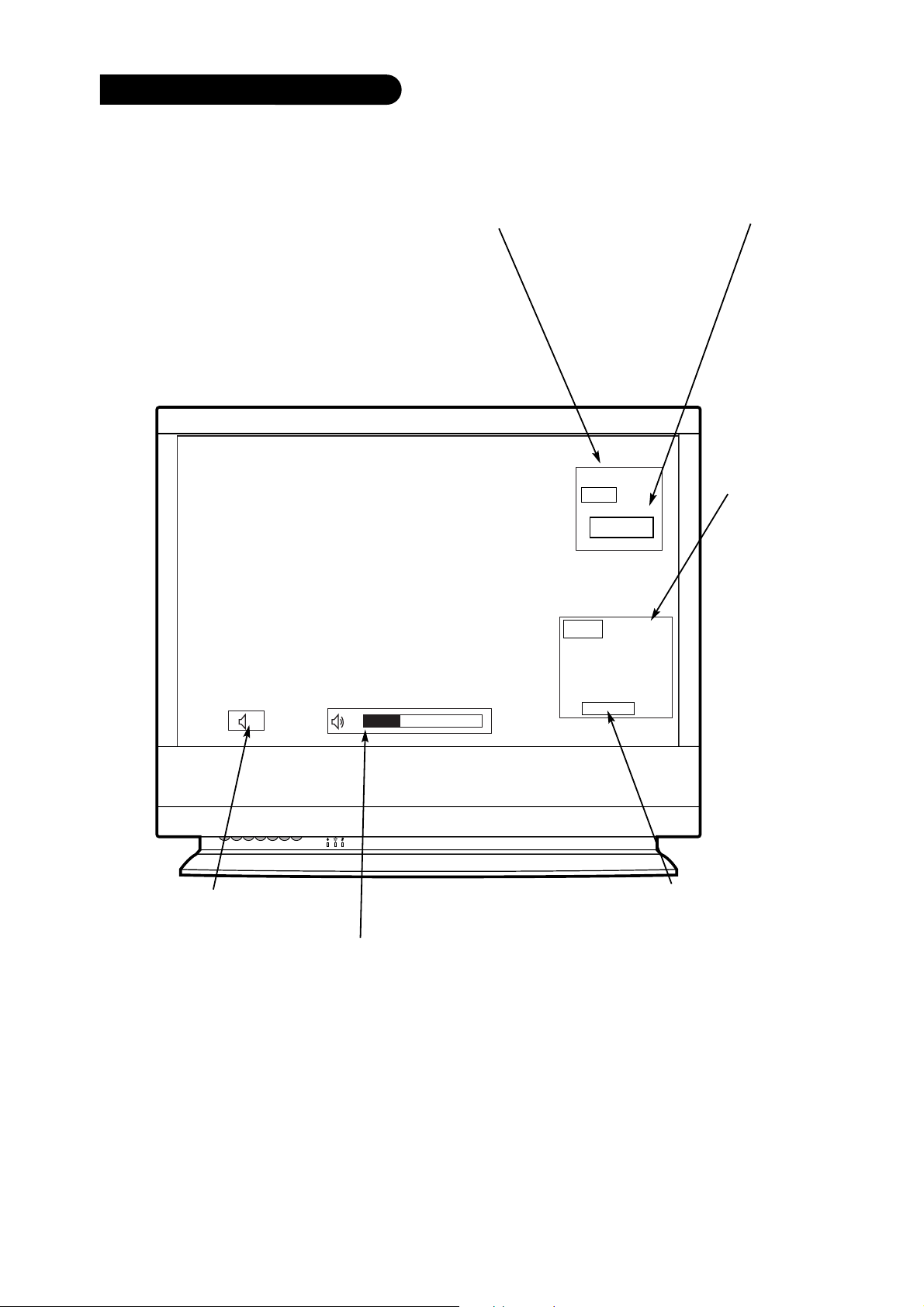

- 6 -

On-Screen Displays

10

AM 03:00

TV 13

MONO

TV 6

This page describes your on-screen display and information banner options.

Main Channel Display

Displays current channel number.

Channel Label

If a channel label has been

set, then it will appear here.

PIP Display

This display

appears when

ABC

PIP is active.

Mute

Appears

when sound

is muted.

Volume

Volume level is displayed while

adjusting the sound.

Time

Appears when

pressing the

enter button on

remote control.

Page 7

- 7 -

Front Panel Controls

power menu enter vol ch

power menu enter vol ch

1

2

3

4

5

6

7

8

Power On / Off

Menu

Enter (Same as ENTER button on

your remote control)

VOLUME UP / DOWN

CHANNEL UP / DOWN

Operation indicator.

Lamp indicator.

Temperature indicator.

RU-52SZ30

1

3

4

5

6

2

8

7

See menu pages for instructions on using the

on-screen menus.

The POWER, CHANNEL and VOLUME buttons

work just as they do on your remote control.

Don’t turn TV on after placing TV from low temperature to normal temperature. It may cause humidity of

inside TV. Try it again after about 3 hours.

RU-60SZ30

Page 8

- 8 -

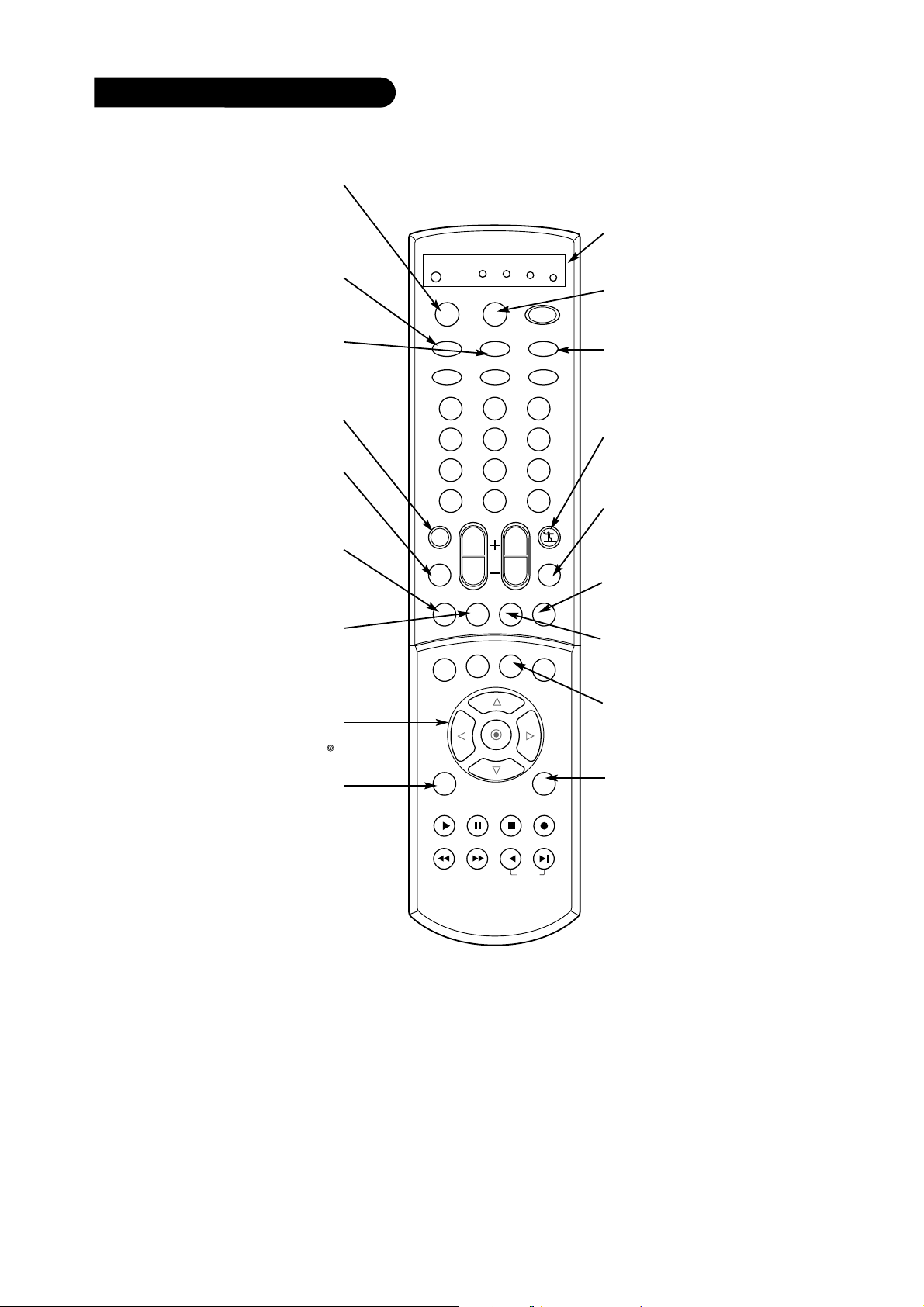

Remote Control Functions in TV Mode

1 2 3

4 5 6

7 8 9

0

tv

mode

light

power

tv/video

dvi

rgb

vcr

cable

dvd

sat

mute

swappipch- pipch+

pip

ratio

recordstop

pause

rew

play

ff

menu exit

cc freeze

pip input

vol

ch

surf

sap

video

comp2comp1

front

skip

enter flashbk

Allows you to navigate the on-screen

menus and to adjust the system set-

tings and preferences, by moving to

an option with

Selects the remote operating

mode: TV, VCR, Cable, DVD

and Satellite. Select other oper-

ating modes, for the remote to

control external devices.

TV/VIDEO

MODE

Selects: Analog, Video1,

Component1-2, RGB, and DVI

Video2, Front video,

input sources.

FRONT

Selects the front video signal if

a device, such as a camcorder

or game player, is connected

to the front video input jack.

MUTE

Switches the sound on or off

SAP

Selects: Mono, Stereo, and

SAP.

PIP

Toggles between PIP, POP

(Picture-out-of-Picture) and

Twin picture mode.

PIPCH-

Changes to next

lower PIP channel

THUMBSTICK

D

F G

and selecting the

E

highlighted option with .

INDICATOR LIGHTS

Show active remote mode

every time any button is

pressed.

LIGHT

Illuminates the remote control keys.

DVI

Selects: DVI-DTV and DVIPC input sources.

SURF

Scrolls the Surf channel list.

VIDEO

Adjusts the factory preset picture according to the room.

SWAP

Swap the signal from your

PIP, POP, twin picture

mode to the main screen.

PIPCH+

Changes to next higher PIP

channel.

FREEZE

Captures and freezes the currentlyviewed sub picture in PIP mode.

Brings up the main

menu to the screen.

MENU

EXIT

Clears all on-screen displays and returns to TV

viewing from any menu.

Page 9

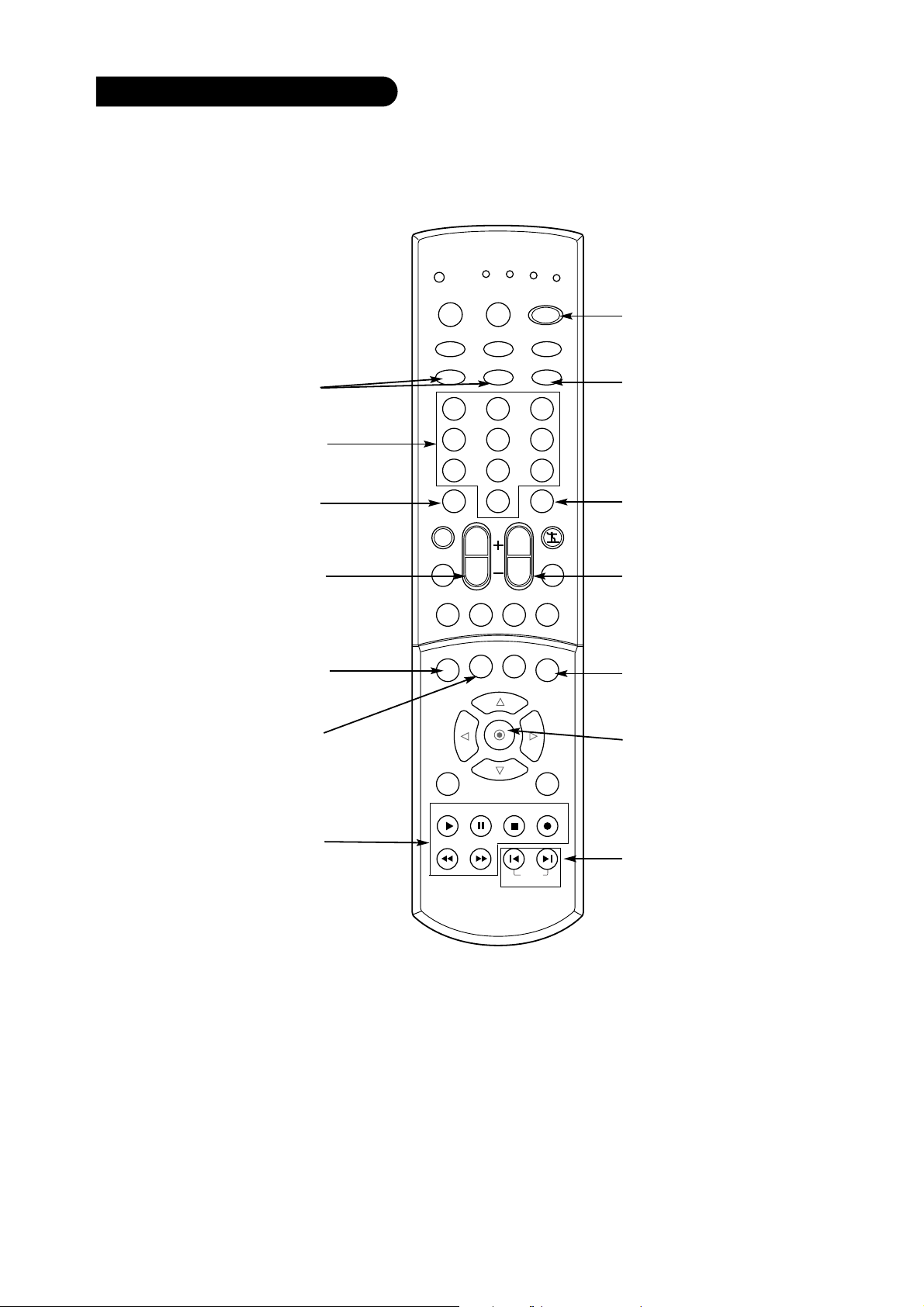

- 9 -

Remote Control Functions in TV Mode

1 2 3

4 5 6

7 8 9

0

tv

mode

light

power

tv/video

dvi

rgb

vcr

cable

dvd

sat

mute

swappipch- pipch+

pip

ratio

recordstop

pause

rew

play

ff

menu exit

cc freeze

pip input

vol

ch

surf

sap

video

comp2comp1

front

skip

enter flashbk

POWER

Turns your TV or any other

programmed equipment on

or off, depending on mode.

Selects component signal sources,

such as DVD or HD receiver.

NUMBER KEYPAD

COMPONENT 1, 2

For direct channel selection and

programming functions.

When in the menu system and

other on-screen displays,

selects highlighted options.

VOLUME UP/DOWN

Increases/decreases the sound

Changes the screen format or

Lets you select a closed caption

mode for displaying captioning

information when provided.

RECORD, PAUSE, REW,

Control the functions on your VCR.

FFWD, PLAY, STOP

ENTER

level.

RATIO

aspect ratio.

CC

RGB

Selects: RGB-DTV and

RGB-PC input sources.

FLASHBK

Tunes to the last channel

viewed.

CHANNEL UP/DOWN

Scrolls through available channels in EZ Scan memory.

PIP INPUT

Selects the input source for the

sub picture.

ENTER

When in the menu system

and other on-screen displays, selects highlighted

options.

SKIP

Playing CDs: Selects

songs.

Playing DVDs: Selects

movie chapters.

Page 10

- 10 -

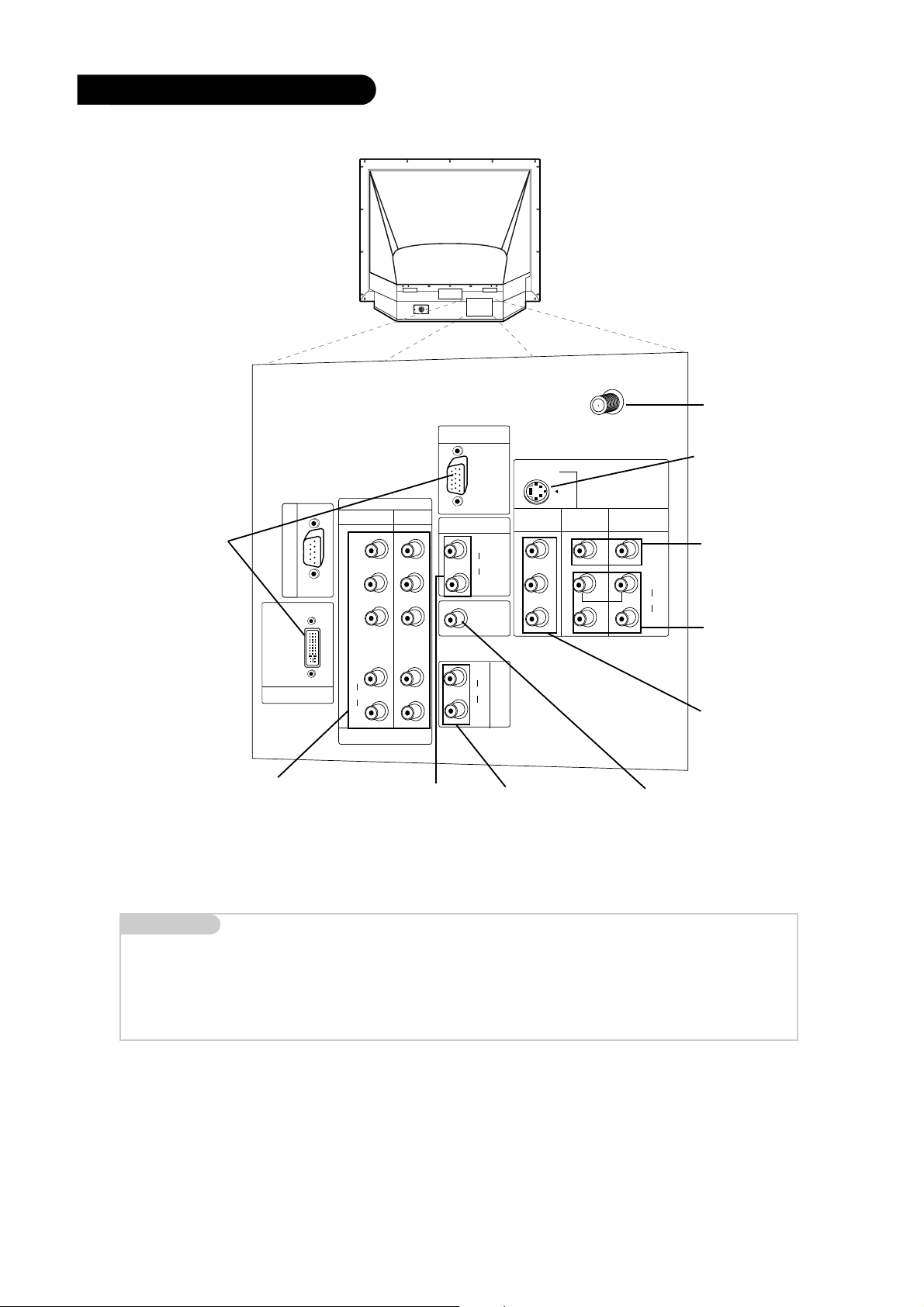

Rear Connections Panel

C

A

L

I

B

R

A

T

I

O

N

PC/DTV

(XGA

/480p

/720p

/1080i)

AUDIO

CENTER

MODE IN

P

R

DVI INPUT

DTV/DVD INPUT

COMPONENT

INPUT2 INPUT1

PB

Y

PC/DTV

(XGA

/480p

/720p

/1080i)

RGB INPUT

RGB/DVI INPUT

(R)

(L)

AUDIO

(R)

(L)

AUDIO

(R)

(L)

AUDIO

V

A

R

I

A

B

L

E

A

U

D

I

O

O

U

T

MONITOR

OUT

VIDEO

INPUT 2

VIDEO

INPUT 1

S-VIDEO

(R)

(L)

AUDIO

VIDEO

MONO

+75 Ω

ANT IN

Connecting cables to your TV.

PC and HD-STB Input

Used to connect from a

PC source or HD-STB

Satellite system.

RF Connector: Antenna

Used to connect analog

cable or antenna signals

to the television, either

directly or through your

cable box.

S-VIDEO In

A connection available with

some high-end equipment

that provides even better

picture quality for Video 2.

Video 1 or 2

Connects the video signals from various types

of equipment.

Left/Right Audio

Used for stereo sound

from various types of

equipment.

Monitor Out

Connects to a second TV

or Monitor.

DVD Component Video and HD Component

Y, Pb, Pr

Video

Some top-of-the-line DVD players use what

is called “component video,” for extremely

accurate picture reproduction. Refer to your

PC and HD-STB Audio

Input

Used for audio connec-

tions from a PC source or

HD-STB Satellite system.

Variable Audio Out

Used to connect either

an external amplifier, or

add a sub-woofer to your

surround sound system.

Audio Center Mode IN

Connect to external Dolby

Digital Center “preamp output.”

DVD manual for further information.

Mini glossary

JACK A connection on the back of a TV, VCR, or any other A/V device. This includes the RF jack and the Audio/Video jacks that are

color-coded.

SIGNAL Picture and sound traveling through cable, or over the air, to your television screen.

Page 11

- 11 -

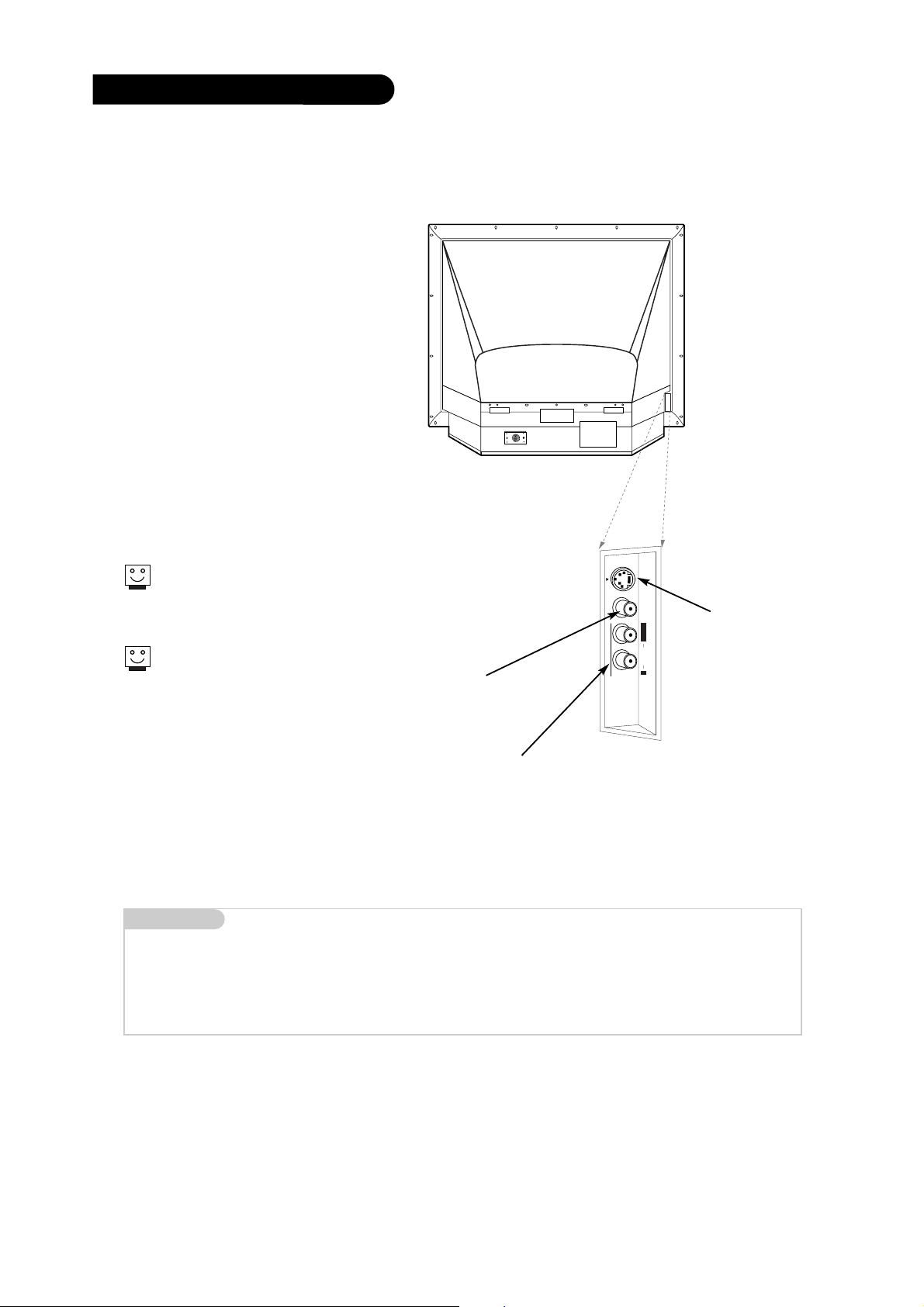

Front Connection Panel

Front A/V Panel

S-VIDEO

VIDEO

FRONT A/V

AUDIO

L/MONOR

There are four jacks on the left front

side behind the screen on your projection TV that make connecting

Audio/Video devices like video games

and camcorders very simple.

The jacks are like those found on the

back jack connection panel. This means

that most equipment that connects to

those types of jacks on the rear jackpack, may be connected to the front

connection panel.

To use the front jacks as the signal

source, select them using Main Source

menu as described on page 22. They

will be named “Front Video” in the Main

Source menu.

When you select Front Video or

Front S-Video, the Front audio

inputs are automatically selected as well.

If you’re connecting a video

game device, make sure to

change the

picture settings with the EZ

Video option in the Video menu.

Video

Connects the video

signals from any

piece of equipment.

Left/Right Audio

Used for stereo

sound from various

types of equipment.

S-Video

A connection available on some very

high-end equipment

that provides better

picture quality than

video input.

Mini glossary

A/V CABLES Audio/Video cables. Three cable connector—Right audio (red), Left audio (white), and Video (yellow). A/V cables are used

A/V DEVICE Any device that produces video or sound (VCR, DVD, cable box, or television).

for stereo playback of videocassettes and for higher quality picture and sound from other A/V devices.

Page 12

- 12 -

SPECIFICATION

Product Specifications

Models

RU-52SZ30 Horizontal Size (inches) 50.4

RU-60SZ30 Horizontal Size (inches) 56.7

Power requirement 120V, 60Hz

Television system American TV Standard, NTSC, ATSC with STB

Television Channel VHF: 2 - 13

Power consumption (W) 250W

Antenna 75 ohm external terminal for VHF/UHF

Audio Output (W) 10W x 2

Supplied accessories Remote control, batteries 2 size AA(Alkaline battery)

Screen Aspect Ratio 16 x 9

LCD Panel Size 0.87 inch (RU-52SZ30), 1.21 inch (RU-60SZ30)

External input ports Video input (3 set)

Height (inches) 38.8

Thickness (inches) 15.3

Weight (lbs) 119

Height (inches) 42.7

Thickness (inches) 19.4

Weight (lbs) 141

UHF: 14 - 69

CATV: 1 - 125

Video output (1 set)

S-Video input (2)

Component input (2 set)

RGB input (1)

DVI input (1)

RGB/DVI audio input (1 set)

Variable audio output (1 set)

Audio center mode input (1)

Calibration port (1)

Design and specifications are subject to change without prior notice.

Page 13

1. Application Object

This instruction is for the application to the LCD projection TV.

2. Notes

(1) The power source insulation of this LCD Projection TV is

not charging type and you may not use the transformer for

insulation. But you better adjust the set after operating it

with insulation transformer between power supply cable and

input part of the set for protecting the adjusting equipment.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25!5°C of temperature and 65!10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 120V, 60Hz in

adjusting.

(5) The set must be operated for 15 minuets preliminarily

before adjustment if there is no specific designation.

The preliminary operation must be performed after receiving 100% white pattern, but reception of the moving picture may also be possible in unavoidable case.

3. Compomation of Adjustment Mode

(1) All adjustment mode are entered by pressing the IN-

START key on the remote control, after adjustment press

the IN-START key to come out.

(2) Compomation of adjustment mode: The first screen com-

position of pressing IN-START key.

(fig. 1) The first screen of adjustment mode

(3) Select menu to adjust(turn to yellow) with using (CH+(D),

CH-(E)) key above screen and press the enter key to

adjust on the wanting menu.

(4) After being inputed for SUB menu, select the SUB menu

with using (CH+(D),CH-(E)) key and adjust the value of

adjustment with using the volume +(F),volume - (G) key.

(5) Press the IN-START key to come out after adjustment,

when (fig.1) is appeared, press again to come out the final

adjustment mode.

(6) SUB menu composition of each adjustment mode

1) Adjust Mode : Sub adjustment menu selected by INSTART key.

RGB alignment is selected in this case.

2) Step123 : Step selection when changing data.

ex) Step123:1 --> Change one by one when changing

data with Volume key

Step123:10 --> Change ten by ten when changing data

with Volume key

You can select 1 by press number key ‘1’, 10 by press

‘12’, 100 by press ‘123’. And you can change data by

1, 10, 100.

3) 10. H_position 315/315/315 : Actual adjusting menu.

4) Micom : V0.50 : Main Micom Version display of Digital

board.

5) SubMicom : V01.31 : Micom Version display of Tuner

board.

6) LCDMicom : V01.31 : Micom Version display of Drive

board.

7) Lamp : 16 : Lamp time display.

4. LCD Adjustment

4-1. NRS Adjustment

[ When the LCD pannel load data on regular pixel using high

speed charge/discharge with sample & holder, the drain

width of TFT gradually decreases and the non-resistance

increases, and comes out regular noise on screen(shows

vertical line by 12 pixel)

This NRS signal is enforced charge/discharge signal so

that the ON/OFF time of TFT mode quickly before starting

active video signal, H/L level adjustment is possible to

each R, G, B.

(1) Required Test Equipments

1) PC Pattern Generator : 16 Step Gray Pattern

2) Fixation Stand

3) Remote Control for Adjustment

4) Circuit thing Jig for Adjustment(Except Driver Board Assy)

(2) Equipment Composition : Follow Fig. 2

(3) Preparation for Adjustment

1) Connect PC Pattern Generator with adjustment Jig like

Fig. 2. (Except Drive part of a circuit block)

2) Select a PC Pattern Generator, 16 Gray.

(4) Adjustment Sequence

1) Turn on a adjustment Jig.

2) Select a RGB_PC by pressing Input Select button on

Remote Control.

3) Enter to adjustment mode by pressing IN-START button on

Remote Control.

EZ ADJUST V*.**

1. VPX3226 Main

2. VPX3226 Sub

3. RGB Alignment

4. 62352

5. Gamma Adjust

6. Uniformity Adj

7. AD9883 Adjust

8. MPX Level Adjust

9. SD-RAM CLK

10. Lamp Replace

Adjust Mode : RGB Alignment Step 123:1

Micom:V0.50 SubMicom:V01.31 LCDMicom:V01.31 Lamp:16

- 13 -

ADJUSTMENT INSTRUCTIONS

10. H_Position 315/315/315

Page 14

4) Select 4. 62352, then ready to adjust 6. RNRSH, 9.

GNRSH and 11. BNRSH.

5) Let’s decrease vertical line Noise by using Volume button.

(Input a R, G, B input signal, then adjust it individually)

6) When finishing the adjustment, get out of adjustment mode

by pressing IN-START button.

4-2. VCOM Adjustment

(1) Required Test Equipments

1) PC PATTERN GENERATOR : Pattern Generator which

can generate each R,G,B signal and can observe the

FLICKER best(ex: me Character Pattern).

2) (Fig. 2) Equipment compositon

3) Remote Control

4) Circuit thing Jig for Adjustment(Except Driver Board Assy

of adjustment model)

(2) Equipment Composition

(3) Preparation for Adjustment

1) Connect the PC Pattern Generator with circuit thing for

adjustment(circuit block except driver part) and adjustment

Jig. shown upper Fig. 2.

2) Set the PC Pattern generator with displayable

format(DTV720p, SVGA 60Hz, XGA 60Hz) and turn on it.

(4) Adjustment Sequence

1) Turn on the adjustment Jig.

2) Select a RGB_PC by pressing Input Select Key on

Remote Control.

3) Enter to adjustment mode by pressing IN-START button on

Remote Control.

4) Select 4. 62352, then ready to adjust 4. 62352 RVCOM, 7.

62352 GVCOM and 10. 62352 BVCOM.

5) Let’s decrease flicker by using Volume button.

(Input a R, G, B input signal, then adjust it individually)

6) When finishing the adjustment, get out of adjustment mode

by pressing IN-START button on Remote Control.

5. Assembling Adjustment

5-1. Screen Tilt & Keystone Adjustment

(1) Required Test Equipments

1) Six angles wrench and spanner for knob adjustment or fixation

2) XGA output PC

3) Remote Control

(2) Preparation for Adjustment

1) Do not assemble the front pannel equipment so that you

can adjust the adjustment knob(Fig. 3).

2) Turn the TV ON and select input mode to RGB_PC.

3) Connect XGA output terminal to PC input of TV.

4) Select window screen.

(3) Adjustment Sequence

1) Stick the Engine(Fig. 3) to the knob poll for adjustment and

check the key stone & tilt watching TV screen.

2) Rotate left/right adjustment knob below and adjust engine

angle.

3) Adjustment adjustment knob of both sides so that the tilt

and keystone are to be under the spec. (The gap between

max and min : under 4mm)

4) After adjusting like 3), fix the engine with screw for fixation

(2EA. adjustment knob and engine fixing screw)

5-2. Screen Position Adjustment

(1) Required Test Equipment

A remote control for adjustment

(2) Preparation for Adjustment

1) Connect a power source with TV Set and turn TV Set on.

2) Do heat run for 15 min and over before adjustment.

3) Receive the main/sub signal of company through 13CH by

split screen.

(3) Horizontal Position Adjustment

1) Press In-START key on the remote control to enter the

adjustment mode.

2) Select 3. RGB Alignment.

- 14 -

(Fig. 2-1) Using Adjustment of Circuit thing for Adjustment

(Fig. 2-2) TV Set status Adjustment

Adjustment Connecctor

Adj.

Jig

Equipment to measure

Optics

(Fig. 3)

Equipment to measure

Optics

SCREEN

Adjustment Jig

SET

Stand

Circuit thing

for Adjustment

PC Pattern

Generator

PC

Page 15

3) Select 10. H_position with channel key in adjust mode.

4) Adjust data with using the left/right key on the remote control in order to be left/right semmetry screen. (Three blocks

of the most outer block must be located the most outer

block.)

(4) Adjustment for Vertical Position

1) Select 16. V_position with channel key in adjust mode.

2) Change the data to symmetrized upper and down of

screen(refer to Fig. 4) and then press the IN-START button on Remote Control to get out of adjustment mode.

5-3. Component2 Offset Adjustment

(1) Required Test Equipment

A remote control for adjustment, 801GF

(2) Preparation for Adjustment

1) Connect a power source with TV Set and turn TV Set on.

2) Do heat run for 15 min and over before adjustment.

3) Receive the Component2.

4) Receive the 720P and HozTVBar Pattern of 801GF.

(3) Offset Adjustment

1) Press IN-START key on the Remote Control to enter the

adjustment mode after more than 10 seconds of receiving

the signals.

2) Press 7. AD9883 adjust to adjust .

3) When the AD9883 Gain Adjust is appeared after AD9883

Offset Adjust, the adjustment is completed.

5-4. Adjustment of White Balance and Gamma

(1) Required Test Equipments

1) Illuminometer (name of model : CA-100) 1EA —>

Measure color of projecting screen center

[ CA-110(name of model) is possible to measure White

Balance and Gamma —- leave it 20Cm from screen

center

Follow a measurement machine manual to set CA-100

and CA-110 measurement machine.

2) Pattern Generator 1EA —> 16 step Gray Pattern, 64 step

Gray Pattern

3) Set Fixation Stand 1EA

4) Remote Control 1EA

5) Circuit thing Jig for adjustment(Except Drive Board Assy of

adjustment model)

--- Programmed Digital Board so that the VDP Test Pattern

can output white signal by 1 level form 0 to 255 level.

(2) A equipment composition

Adjust at the same condition of equipment composition diagram.

(3) Preparation for Adjustment

Compose the equipment follow Fig. 2 and place the set on

the fixation stand.

1) Select the VDP Test Pattern signal to R1, G1, B1.

2) Press the IN-START key to select 4. 62352 and then select

5. RVREF, 8. GVREF, 12. BVREF in adjust mode.

3) Adjust the luminance of CA100 below 0.75Cd. (The adjustment range is 196~202)

4) Exit adjustment mode by pressing IN-START button on

Remote Control.

5) Press the IN-START key on R/C and select 3. 7050 RGB

Set.

6) Check the data 1. RContrast, 8. GContrast, 15. BContrast

is 515. Otherwise set the data 515 by using volume button.

(4) Adjustment Sequence

1) Output the 255,255,255 signal of VDP Test Pattern, then

display the maximum white pattern on screen.

2) Gamma Adjust Mode is display as below when select 5.

Gamma adjust by selecting IN-START key on R/C.

3) Change the 16 Step RGB Data to select white balance

x=283, y=297(D9300K).

4) Measure the luminace with changed data.

5) Set the every Gamma data of 16 step to 2.2 on the basis

of measured luminance data in 3).

(Max luminance *(n1/16)**2.2) — Max luminance : measured luminance data n1 = every step unit when separating signal level to 16 step)

6) Output the 240, 240, 240(15th data in max white output

signal level) in the VDP Test Pattern, change the 15th

RGB Data value to come out white balance x=283,

y=297(D9300K) and measured step luminance in 5).

7) Output the 224, 224, 224(14th data in max white output

signal level) in the VDP Test Pattern, change the 14th

RGB Data value to come out white balance x=283,

y=297(D9300K) and measured step luminance in 5).

- 15 -

(Fig. 4) Adjustment for Horizontal/Vertical Position on Screen

HozTVBar Pattern

* 1st Column : 16 Step Level

* 2nd Column : R Adjustment

Data

* 3rd Column : G Adjustment

Data

* 4th Column : B Adjustment

Data

US13CH

Gamma Adjust Mode

100

100

80

1

234

2

453

3

724

16

RGB 456 Step123

216

411

740

216

387

780

Page 16

8) As shown above, output the VDP Test Pattern signal(208/192/176/160/144/128/112/96/80/64/48/32/16) and

change the RGB Data value of each step to come out

white balance x=283, y=297(D9300K) and measured

lumincance in 3).

(5) Gamma adjustment manually

This is adjustment(after finish the 3-4) to check whether

Gamma/White Balance adjustment are well adjusted and

make correction manually.

1) Prepare the PC Pattern Generator which is possible to output R/G/B of 16 step and 64 step Gray Pattern.

2) Equipment composition : Follow Fig. 2.

3) Turn on the Jig for adjustment.

4) Select the RGB_PC by pressing the input select button on

Remote Control.

5) Output the 16 Gray Pattern in PC Pattern Generator.

Check it with the naked eye whether Screen Gamma and

W/B is right about each Gray.

If it’s not, press the IN-START button on Remote Control

and then adjust the level data of each step manually in

sub menu of 5. Gamma adjust.

6) Output the 64 Gray Pattern in PC Pattern Generator.

Check it with the naked eye whether Screen Gamma and

W/B is right about each Gray or whether there is Gamma

noise.

If there’s any problem, adjust in 5).

7) After finishing adjustment, exit adjustment mode by using

IN-START button on Remote Control.

5-5. White Uniformity Adjustment

(1) Required Test Equipments

1) Uniformity measurement equipment : Equipment which can

measure chromaticity in the whole screen

2) Set Stand 1EA

3) Remote Control for Adjustment

4) Circuit thing Jig for Adjustment(Except Driver Board Assy

of adjustment model)

--- Programmed Digital Board so that the VDP Test Pattern

can output white signal by 1 level form 0 to 255 level.

(2) A equipment composition

Compose the equipment follow Fig. 2 and place the set on

the fixation stand.

(3) Preparation for Adjustment

1) Composite the equipment as shown Fig 2, and place the

set on fixation stand.

2) After inputting company channel 13, adjust color uniformity

like Horizontal/Vertical position adjustment of input signal

part adjustment by using Remote Control for adjustment.

3) After pressing IN-START key on Remote Control for adjustment, select the adjustment mode 6. Uniformity adj.

Refer to register value and correct register value if need.

<Resister Explanation about uniformity adjustment>

1. RamCtrl : s/w saving uniformity write order(Do not adjust)

2. CSHP : Horizontal start point designation ---adjustable

3. CSVP : Vertical start point designation ---adjustable

4. CEHP : Horizontal END point designation ---adjustable

5. CEVP : Vertical END point designation ---adjustable

6. Mode : uniformity mode select --- adjustable if need

*** 0 : 221point & 3level ---- defalut value

*** 1 : 221point & 4level

*** 2 : 825point & 3level

*** 3 : 825point & 4level

7. KHH : Upper 2byte of horizontal line correction coefficient -

- Change according to CSHP, CEHP value.

8. KHL : Upper 2byte of vertical line correction coefficient -Change according to CSHP, CEHP value.

** How to calculate KHH, KHL value

LCD panel size = 1280 x 720

Correction Point = 221 point

--> 17 horizontal points x 13 vertical points

(16 horizontal segments x 12 vertical poins)

O H Coefficient(KHH, KHL)

--> Calculation method (CEHP-CSHP=1280, Horizontal

segment value =16)

9. KVH : Upper 2byte of vertical line correction coefficient -Change according to CSVP, CEVP value.

10. KVL : Upper 2byte of vertical line correction coefficient -Change according to CSVP, CEVP value.

O V Coefficient(KVH, KVL)

--> Calculation method (CEVP-CSVP=720, Vertical seg-

ment value =12)

11. RL1H : Upper 9bit of MID2 brightness correction coefficient in R MIN.

--- Change according to RMIN and RMID2 value.

12. RL1L : Lower 9bit of MID2 brightness correction coefficient in R MIN.

--- Change according to RMIN and RMID2 value.

13. RL2H : Upper 9bit of MID1 brightness correction coefficient in R MID2.

--- Change according to RMID2 and RMID1 value.

14. RL2L : Lower 9bit of MID1 brightness correction coefficient in R MID2.

--- Change according to RMID2 and RMID1 value.

15. RL3H : Upper 9bit of MAX brightness correction coefficient in R MID1.

--- Change according to RMID1 and RMAX value.

(use it while adjusting 4 coefficient)

16. RL3L : Lower 9bit of MAX brightness correction coefficient in R MID1.

--- Change according to RMID1 and RMAX value.

(use it while adjusting 4 coefficient)

- 16 -

H coefficient = 1/(number of pixel intervals between setting in the horizontal

direction)

Hcoeff = 1/((1280/16)-1) = 0.012658227

hex(0.012658227 x 2

16

) = 0 x 033D, Hcoeff(hex) = 0 x 033D + 1 = 0 X 33E

V coefficient = 1/(number of pixel intervals between setting in the horizontal

direction)

Vcoeff = 1/((720/12)-1) = 0.016949152

hex(0.016949152 x 2

16

) = 0 x 0456, Vcoeff(hex) = 0 x 0456 + 1 = 0 X 0457

Page 17

<L Coefficient Calculation Method>

Using 3coefficient Level

Assume that the value of R/G/B MIN, MID2,MID1 is 192, 448,

704.

R/G/B MIN = 192

R/G/B MID2 = 448

R/G/B MID1 = 704

O L Coefficient(RL1H~BL3L)

--> Calculation method (L1)

- calcuate L2, L3 same with L1

17. GL1H : Upper 9bit of MID2 brightness correction coeffi-

cient in G MIN.

--- Change according to GMIN and GMID2 value.

18. GL1L : Lower 9bit of MID2 brightness correction coeffi-

cient in G MIN.

--- Change according to GMIN and GMID2 value.

19. GL2H : Upper 9bit of MID1 brightness correction coeffi-

cient in G MID2.

--- Change according to GMID2 and GMID1 value.

20. GL2L : Lower 9bit of MID1 brightness correction coeffi-

cient in G MID2.

--- Change according to GMID2 and GMID1 value.

21. GL3H : Upper 9bit of MAX brightness correction coeffi-

cient in G MID1.

--- Change according to GMID1 and GMAX value.

(use it while adjusting 4 coefficient)

22. GL3L : Lower 9bit of MAX brightness correction coefficient in G MID1.

--- Change according to GMID1 and GMAX value.

(use it while adjusting 4 coefficient)

23. BL1H : Upper 9bit of MID2 brightness correction coefficient in B MIN.

--- Change according to BMIN and BMID2 value.

24. BL1L : Lower 9bit of MID2 brightness correction coefficient in B MIN.

--- Change according to BMIN and BMID2 value.

25. BL2H : Upper 9bit of MID1 brightness correction coefficient in B MID2.

--- Change according to BMID2 and BMID1 value.

26. BL2L : Lower 9bit of MID1 brightness correction coefficient in B MID2.

--- Change according to BMID2 and BMID1 value.

27. BL3H : Upper 9bit of MAX brightness correction coefficient in B MID1.

--- Change according to BMID1 and BMAX value.

(use it while adjusting 4 coefficient)

28. BL3L : Lower 9bit of MAX brightness correction coefficient

in B MID1.

--- Change according to BMID1 and BMAX value.

(use it while adjusting 4 coefficient)

29. RLMIN : Setting up the MINIUM Level of R --- Set under

200

30. RLMID2 : Setting up the MIDDLE 2nd Level of R --Middle level when 3coefficient

31. RLMID1 : Setting up the MIDDLE 1st Level of R --- Max

level when 3coefficient

32. RLMAX : Setting up the MAX Level of R

33. GLMIN : Setting up the MINIUM Level of G --- Set under

200

34. GLMID2 : Setting up the MIDDLE 2nd Level of G --Middle level when 3coefficient

35. GLMID1 : Setting up the MIDDLE 1st Level of G --- Max

level when 3coefficient

36. GLMAX : Setting up the MAX Level of G

37. BLMIN : Setting up the MINIUM Level of B --- Set under

200

38. BLMID2 : Setting up the MIDDLE 2nd Level of B --Middle level when 3coefficient

39. BLMID1 : Setting up the MIDDLE 1st Level of B --- Max

level when 3coefficient

40. BLMAX : Setting up the MAX Level of B

41. HVSCAN : Setting up the scan direction while adjusting

unifomity - Do not adjust

42. TestMode : uniformity adjustment test - Do not adjust

(4) Adjustment Sequence

1) Adjust the screen coordinates as shown below.

2) Output the VDP TEST PATTERN signal correspond to the

Max value.

Read the white coordinates and communicate 3 line with

ET7050 IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color uniformity of max point.

At this time, make sure that deviation is +5~-5% and standard is color coordinate of center.

3) Output the VDP TEST PATTERN signal correspond to the

MID value.

Read the white coordinates and communicate 3 line with

ET7050 IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color uniformity of mid point.

At this time, make sure that deviation is +5~-5% and standard is color coordinate of center.

4) Output the VDP TEST PATTERN signal correspond to the

MIN value.

Read the white coordinate and communicate with ET7050

IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color uniformity of miner point.

- 17 -

L1 coefficient = 1 / (brightness level(MID2) - brightness level(MIN)

L1coeff = 1 / (448-192) = 1 / 256 = 0.00390625

L1coeff(hex) = hex(0.00390625 x 2

18

) = 0 x 0400

--> L1H(high 9bit) = b’000000010 L1L(low 9bit) = b’000000000

L2 coefficient = 1 / (brightness level(MID1) - brightness level(MID2)

L3 coefficient = 1 / (brightness level(MAX) - brightness level(MID1)

: case of 4 Brightness Level

0 1 2 3 ............xx..........15 16

1

.

yy

.

11

12

(Fig. 5) Screen divisio diagram for uniformity adjustment

Page 18

At this time, make sure that deviation is +5~-5% and standard is color coordinate of center.

5) White the miner, middle, maximum data for each point to

confront to each MICOM address.

5-6. Brightness Adjusment of Main/Sub screen

Operate this adjustment when the brightness of Main/Sub

screen is different.

(1) Receive RF 06Ch. to Main/Sub screen in twin picture.

(2) Let the screen clearly.

(3) Check the “US06CH” with naked eyes in 06Ch. pattern

and if there is difference, adjust like this.

- The field and the letters are distinguished.

(4) Adjusting Main screen

1) Press the “IN Start” key on R/C for adjustment to select

1. VPX3226 main.

2) Adjust to 16. Contrast of adjustment item with +/- key.

(initial value 32)

(5) Adjusting Sub screen

1) Press the “IN Start” key on R/C for adjustment to select

2. VPX3226 sub.

2) Adjust to 16. Contrast of adjustment item with +/- key.

(initial value 32)

* Ask for repairs when the data value is changed over !3.

5-7. Lamp Replace

Use it when the Lamp time is ‘0’.

Press the IN-START key on R/C for adjustment to select

Lamp replace and adjust with volume key.

- 18 -

Page 19

* Connect your dealer or LG service center for replacing of new lamp.

You must replace the lamp when:

Ø The projector image get darker or start to be deteriorated.

Ø The lamp indicator is red(red, flashing alternately).

Ø The massage “LAMP REPLACE“ appears on the screen when turning the projec-

tor lamp on.

* Replace the lamp as below sequence

1. Turn off the projector and unplug the power cable.

(Cool the lamp for more than 1 hour.)

2. Remove the four retaing screws on the lamp cover with a screwdriver of “+“ type

and then lift off the lamp cover.

3. After lifting the lamp cover off, remove the two retaing screw on lamp case with

screwdriver of “-“ type. (refer to fig.2)

4. Lift up the fixed wire handle of the lamp. (refer to fig.3)

5. Pull out the handle slowly and remove the lamp case.

6. Insert the new lamp gently into the correct position. Make sure it is inserted correctly.

7. Tighten the screw you removed in step 3.

8. Replace the lamp cover and tighten the cover screws.(Make sure the almp cover

is securely fastend. If lamp cover is open, the lamp indicator flashes green and

the projector is not turn on.)

* Resetting the lamp time

After pressing the “?“ key on the remote control in Stand-By mode, press the “9876“

and press the “OK“ button.

And then three LED in the front is stop after flashing for a moment.

* Lamp Life Time Confirmation

1. Method1 : Enter ADJ mode with using the remote control. You can be confirmed

because “ Lamp Life Time XX hr“ is appeared.

2. Method2 : With using the remote control offerd to consumer if you press the

menu button continuously, OSD menus will disappear then press the “9876“ and

press the “OK“ button to enter ADJ mode you can see “Lamp Life Time XX hr“

- 19 -

REPLACING THE LAMP

< Fig. 1>

< Fig. 2>

< Fig. 3>

Page 20

Block Diagram

- 20 -

Page 21

- 21 -

Page 22

- 22 -

Page 23

- 23 -

Page 24

EXPLODED VIEW(RU-52SZ30)

- 24 -

430

690

410

420

120

121

300

310

640

650

630

303

307

304

302

305

301

306

123

308

620

670

621

610

611

600

612

124

125

520

550

560

503

502

530

122

174

540

501

680

570

580

401

660

Page 25

- 25 -

EXPLODED VIEW PARTS LIST

120 120-D38E SPEAKER,MID-RANGE LG FOSTER 8 OHM 15/25W 87DB 12

121 6400VG0001B SPEAKER,TWEETER NO FOSTER 8 OHM 20W/30W XX D77

122 3110V00123A CASE,SPEAKER BOX LEFT

123 3550V00159A COVER,SPEAKER BOX LEFT

124 3110V00124A CASE,SPEAKER BOX RIGHT

125 3550V00160A COVER,SPEAKER BOX RIGHT

174 174-225Y POWER CORD ASSEMBLY,6410VUH004A ASSY UL/CSA 3000MM

300 3091V00B46D CABINET ASSEMBLY,RU-52SZ30 NON NB03JA

301 4980V00591A SUPPORTER,SCREEN SBHG ,BOTTOM

302 4980V00592B SUPPORTER,SCREEN SECC RN-52SZ30H

303 3211V00080A FRAME ASSEMBLY,FRONT RN-52SZ10H 3210V00104

304 3211V00081K FRAME ASSEMBLY,FRAME RU-52SZ30 BASE

305 3350V00019B SCREEN,TOPPAN NON RN-52SZ30H 1178*670 SAME 19A PITCH

306 4811V00035B BRACKET ASSEMBLY,SPEAKER RU-52SZ30 NB03JA .

307 4980V00439B SUPPORTER,FRAME ET CENTER FIX RN-52SZ10H

308 3550V00225A COVER,LENS PC+ABS RN-52SZ10H .

310 5020V00654C BUTTON,CONTROL RN-52SZ30H ABS, HF-380 7KEY BUTTON

401 3550V00232B COVER,LAMP RN-52SZ30H PC-ABS .

410 3809V00A39F BACK COVER ASSEMBLY,RU-52SZ30 NON UPPER

420 3809V00A41E BACK COVER ASSEMBLY,RU-52SZ30 NON LOWER

430 5018V00025B MIRROR ASSY,NONE NONE NONE RN-52SZ10H

501 3210V00127A FRAME,RN-52SZ10H CHASSIS DIGITAL

502 3210V00073B FRAME,RU-60SZ10 CHASSIS(SMPS) AB-00EA

503 4811V00021G BRACKET ASSEMBLY,REAR AV RU-52SZ30 NB03JA BRACKET ASSY

520 6871VMMQ05A PCB ASSEMBLY,MAIN PCB ASSEMBLY,MAIN RU-52SZ30 MAIN NB03JA

530 6871VPMA07E PCB ASSEMBLY,POWER SMPS NB03JA RU-52/60SZ30

540 6871VSMV97A PCB ASSEMBLY,SUB TUNER NB03JA RU-52SZ30

550 6871VSMV99A PCB ASSEMBLY,SUB DIGITAL NB03JA RU-52SZ30

560 6871VSMV98A PCB ASSEMBLY,SUB NB03JA RU-52SZ30 COMP

570 6871VPM994H PCB ASSEMBLY,POWER SMPS NB03JA RU-52/60SZ30

580 6871VSMB13F PCB ASSEMBLY,SUB INTER MB03CA BALLAST

600 3141VSNA61D CHASSIS ASSEMBLY,SUB NB03JA BRACK OPTICAL RU-52SZ30

610 3110V00140B CASE ASSY,LAMP RU-60SZ10 PPS+GF40 .

611 6912V00006A LAMP,HIGH PRESSURE MECURY UHP100W 1.3 PHILIPS 100V 1A

612 4930V00230B HOLDER,DUCT BACK FAN PC+ABS RU-52SZ10

620 5900V09002C FAN,DC G9225L12B2-FL DONGYANG 92MM 12V140MA

621 3300V00179C PLATE,DUCT FAN SPCC . RU-60SZ10

622 5900V11001C FAN,DC B1232S12B2 DONGYANG 110MM 12V130MA

630 6871VSN156D PCB ASSEMBLY,MAIN SUB NB03JA PRE-AMP RU-52SZ30

640 6871VSMD03E PCB ASSEMBLY,SUB CONT NB03JA RN-52SZ30H

650 6871VSN194A PCB ASSEMBLY,SUB INTER NB02QA 52 LCD PJTV

660 6871VSN187C PCB ASSEMBLY,SUB LED NB03JA RN-52SZ30H

670 6871VSMU16B PCB ASSEMBLY,SUB NB02QA DRIVER RU-52SZ30

680 6913V00002A BALLAST,EUC-100L/100V PHILIPS FOR LAMP(UHP100W)

690 6871VSN155B PCB ASSEMBLY,SUB NB-02QA SIDE A/V

No. Part No.

Description

Page 26

- 26 -

EXPLODED VIEW(RU-60SZ30)

430

690

410

420

120

121

300

310

640

650

630

303

307

304

302

305

301

306

123

308

620

670

621

610

611

600

612

124

125

520

550

560

503

502

530

122

174

540

501

680

570

580

401

660

Page 27

- 27 -

EXPLODED VIEW PARTS LIST

120 120-D38E SPEAKER,MID-RANGE LG FOSTER 8 OHM 15/25W 87DB 12

121 6400VG0001B SPEAKER,TWEETER NO FOSTER 8 OHM 20W/30W XX D77

122 3110V00123A CASE,SPEAKER BOX LEFT

123 3550V00159A COVER,SPEAKER BOX LEFT

124 3110V00124A CASE,SPEAKER BOX RIGHT

125 3550V00160A COVER,SPEAKER BOX RIGHT

174 174-225Y POWER CORD ASSEMBLY,6410VUH004A ASSY UL/CSA 3000MM

300 3091V00468D CABINET ASSEMBLY,RU-60SZ30 NON NB03JA ,LG

301 4980V00764A SUPPORTER,NON SECC ,TOP FOR SCREEN(4.1T)

302 4980V00765A SUPPORTER,SCREEN SECC ,SIDE FOR SCREEN(4.1T)

303 3211V00047B FRAME ASSEMBLY,FRONT RU-60SZ10 3210V00074B

304 3211V00048J FRAME ASSEMBLY,FRONT LOWER ,RN-60SZ30H

305 3350V00015B SCREEN,TOPPAN NON RN-60SZ30H 1358*776 HARD COATING 2H

306 4811V00032C BRACKET ASSEMBLY,SPEAKER RU-60SZ30 NB03JA ,LG BRAND

307 4980V00359B SUPPORTER,BASE CENTER ET-C(3T) RN-60SZ10H

308 3550V00155B COVER,LENS RN-60SZ10H

310 5020V00654C BUTTON,CONTROL RN-52SZ30H ABS, HF-380 7KEY BUTTON

401 3550V00188C COVER ASSY,RN-60SZ30H PC-ABS ,7227V000056

410 3809V00246H BACK COVER ASSEMBLY,RU-60SZ30 NON ,LG

420 3809V00247E BACK COVER ASSEMBLY,WLP-60M10DW NON .

430 5018V00025C MIRROR ASSY,NONE NONE NONE RT-60SZ10

501 3210V00127A FRAME,RN-52SZ10H CHASSIS DIGITAL . .

502 3210V00073B FRAME,RU-60SZ10 CHASSIS(SMPS) AB-00EA .

503 4811V00034B BRACKET ASSEMBLY,REAR AV RU-60SZ30 NB03JA .

520 6871VMMQ05B PCB ASSEMBLY,MAIN PCB ASSEMBLY,MAIN RU-60SZ30 MAIN NB03JA

530 6871VPMA07E PCB ASSEMBLY,POWER SMPS NB03JA RU-52/60SZ30

540 6871VSMV97B PCB ASSEMBLY,SUB TUNER NB03JA RU-60SZ30

550 6871VSMV99B PCB ASSEMBLY,SUB DIGITAL NB03JA RU-60SZ30

560 6871VSMV98A PCB ASSEMBLY,SUB NB03JA RU-52SZ30 COMP

570 6871VPM994H PCB ASSEMBLY,POWER SMPS NB03JA RU-52/60SZ30

580 6871VSMB13F PCB ASSEMBLY,SUB INTER MB03CA BALLAST

600 3141VSN180F CHASSIS ASSEMBLY,SUB NB03JA BRACK OPTIC RU-60SZ30

610 3110V00140B CASE ASSY,LAMP RU-60SZ10 PPS+GF40

611 6912V00006A LAMP,HIGH PRESSURE MECURY UHP100W 1.3 PHILIPS 100V 1A

612 3110V00205A CASE ASSY,HEAT FLOW RU-60SZ10 . .

620 5900V09002C FAN,DC G9225L12B2-FL DONGYANG 92MM 12V140MA

621 3300V00179C PLATE,DUCT FAN SPCC . RU-60SZ10

622 5900V11001C FAN,DC B1232S12B2 DONGYANG 110MM 12V130MA

630 6871VSN156C PCB ASSEMBLY,SUB NB-02QA PRE-AMP MD 60

640 6871VSMD03D PCB ASSEMBLY,SUB CONT NB03JA RN-60SZ30H

650 6871VSN194A PCB ASSEMBLY,SUB INTER NB02QA 52 LCD PJTV

660 6871VSN187C PCB ASSEMBLY,SUB LED NB03JA RN-52SZ30H

670 6871VSMU16C PCB ASSEMBLY,SUB NB02QA DRIVER RU60SZ30

680 6913V00002A BALLAST,EUC-100L/100V PHILIPS FOR LAMP(UHP100W)

690 6871VSN155B PCB ASSEMBLY,SUB NB-02QA SIDE A/V

No. Part No.

Description

Page 28

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC303

IC304

IC305

IC4

IC400

IC401

IC404

IC405

IC406

IC407

IC407

IC409

IC409

IC410

IC411

IC413

IC5

IC500

IC501

IC503

IC600

IC601

IC601

IC601

IC602

IC603

IC800

IC801B

IC802

IC802B

IC804

IC806

IC807

IC808

IC811

IC820

IC831

IC832

IC841

IC845

T200

Q01

Q02

Q03

Q04

Q05

Q06

0ITI740000Q

0IMMRHY033A

0IMMRHY033A

0IMCRAL006A

0ICTMMI038B

0IMCRTI019A

0ISH052100C

0ISH302122A

0ISH302122A

0ISH302122A

0ISJ156612A

0IKE780500P

0IKE781200P

0ISH052100C

0IKE780800J

0IKE780900M

0IFA754207A

0ILNRMN005A

0ILNRMN005A

0IMCRET002B

0IMCRXL003A

0IFA741230A

0IMCRNS006A

0IMCRMN014A

0IFA754207A

0ISS455880A

0IPH741400E

0ISH817300B

0IKE702700D

0ISH817300B

0ITI740000Q

0IIC271600A

0IMCRSG010A

0IMP242560A

0IMCRON002A

0IMCRSK002A

0ISK615311B

0ISH817300B

0ISH817300B

0ISS781200H

0IZZVF0022B

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

SN74LVC00AD 14SOP R/TP LOGIC DTV

HY57V643220C(L)T6 86P TSOP TRAY 64M

HY57V643220C(L)T6 86P TSOP TRAY 64M

AT24C16AN10SI2.7 8P SOIC R/TP EEPROM

COPY M306V3FGFP 100P

TFP410 64P TRANSMITTER PANEL

PQ05RD21 4SIP ST REGULATOR

PQ30RV21 TO220

PQ30RV21 TO220

PQ30RV21 TO220

SC15661T2.5TR 3P TO2203L R/TP POWER

KIA78L05BP(AT) 3P 5V,150MA

KIA7812API TO220 ST 3P 12V

PQ05RD21 4SIP ST REGULATOR

KIA7808API 3 ST REGULATOR .

KIA7809API TO220 ST 3P 9V

KA75420ZTA 3P,TO92 TP 4.2V

VPX3226E 44 QFP TRAY VIDEO

VPX3226E 44 QFP TRAY VIDEO

EL2250CS ELANTEC 8P R/TP OP AMP

XC95144XL10TQ100C 3.3V 100P

DM74LS123MX 16SOP

LM4765T 15P TO220 ST AUDIO POWER

MSP3440G QA B8 V3 80 QFP TRAY SOUND

KA75420ZTA 3P,TO92 TP 4.2V

KA4558D 8SOP OP AMP

74HC14D 14SOP TP SHITTER TRIGGER

PC817XF3 4D PHOTO COUPLER

KIA7027AF 3, SOT89 TP RESET IC 2.7V

PC817XF3 4D PHOTO COUPLER

SN74LVC00AD 14SOP R/TP LOGIC DTV

MK2716STR 8P,SOP TP HDTV CLOCK

ST3232CDR SOP16 R/TP RS232

24LC256I/SM 8P,SOP TP 256K

MC33262P 8P DIP ST POWER

STRF6467 5P T0220(LB) ST SWITCHING

STRG6153T(LF1101) 5PIN BK STR

PC817XF3 4D PHOTO COUPLER

PC817XF3 4D PHOTO COUPLER

KA78R12 4P,TO220F BK LOW DROP 12V

AMF730F6M00X2(AF9397) 15P

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

LOCA. NO PART NO DESCRIPTION

IC01

IC02

IC1

IC100

IC1001

IC1002

IC1004

IC101

IC101

IC102

IC1100

“(52”)

IC1101

IC1102

IC1103

IC1104

IC1105

IC1106

IC1107

IC1200

IC1200

IC1202

IC1202

IC1203

IC1300

IC1301

IC1302

IC1303

IC1304

IC1305

IC1400

IC1401

IC1402

IC1403

IC1404

IC1405

IC1500

IC1501

IC1502

IC1503

IC1504

IC1505

IC1602

IC2

IC200

IC208

IC301

0IMI623200B

0IMI623200B

0IZZVC0051G

0IMCRS5003A

0IPRPFA006A

0IPRPFA007A

0IMMRNE002A

0IPH827150A

0ITK118100B

0IMMRAL014B

0IZZVA0072H

0IZZVA0072G

0IMI623520B

0IAL242561B

0IPRPTI001A

0IKE704200J

0IPRPFA006A

0IPRPFA006A

0IPRPML001B

0IMCRSO008A

0IPRPML001A

0IMO744053B

0IMCRSB010A

0IPRPFA006A

0IMO324000C

0IMCRET001A

0IMCRSB009A

0IMCRSB009A

0IMCRSB008A

0IPRPFA006A

0IMO324000C

0IMCRET001A

0IMCRSB009A

0IMCRSB009A

0IMCRSB008A

0IPRPFA006A

0IMO324000C

0IMCRET001A

0IMCRSB009A

0IMCRSB009A

0IMCRSB008A

0IPRPFA006A

0ISH052100C

0IFA754207A

0IMCRAD002A

0ISO206900A

0ICTMLG003C

M62320FP 16P SOP TP I/O EXPANDER

M62320FP 16P SOP TP I/O EXPANDER

M37272E8A(OTP) DIP 42P BK MICOM

SIL169 CL100 100P LQFP TRAY TMDS

RC1117S33T SOT223 R/TP 3.3VOLT

RC1117S25T SOT223 R/TP 2.5VOLT

UPD64083GF3BA 100 QFP ST 3D YC

P82B715T 8SOP R/TP IIC EXTENDER

TK11840L 8P SOT23L R/TP DCDC

AT24C02N10SI2.7 8P SOIC R/TP 2K

M37272E8A(OTP) DIP 42P DIP DRIVER

M37272E8A(OTP) DIP 42P DIP DRIVER

M62352GP 20P SSOP TP 8BITS 12CH

AT24C256W10SI2.7V 8P

TFP401PZP 100,TQFP R/TP DIGITAL

KIA7042AF SOT89 TP 4.2V

RC1117S33T SOT223 R/TP 3.3VOLT

RC1117S33T SOT223 R/TP 3.3VOLT

MIC29152 5P TO263 R/TP REGULATOR

CXA2151Q 48P QFP TRAY 60LCD

MIC39100 3P SOT223 R/TP LDO TYPE 2.5V

MC74HC4053DW 16SOP 3*2CH.MUX

L3E07050K0A 176QFP TRAY DRIVER IC

RC1117S33T SOT223 R/TP 3.3VOLT

LM324D SO14 TP OP AMP

EL2244CS 8P SO R/TP VIDEO AMPLIFIER

L3E06070D0A 48QFP TRAY DRIVER IC

L3E06070D0A 48QFP TRAY DRIVER IC

L3E01031F0A 48QFP TRAY DRIVE IC

RC1117S33T SOT223 R/TP 3.3VOLT

LM324D SO14 TP OP AMP

EL2244CS 8P SO R/TP VIDEO

L3E06070D0A 48QFP TRAY DRIVER IC

L3E06070D0A 48QFP TRAY DRIVER IC

L3E01031F0A 48QFP TRAY DRIVE IC

RC1117S33T SOT223 R/TP 3.3VOLT

LM324D SO14 TP OP AMP

EL2244CS 8P SO R/TP VIDEO

L3E06070D0A 48QFP TRAY DRIVER IC

L3E06070D0A 48QFP TRAY DRIVER IC

L3E01031F0A 48QFP TRAY DRIVE IC

RC1117S33T SOT223 R/TP 3.3VOLT

PQ05RD21 4SIP ST REGULATOR

KA75420ZTA 3P,TO92 TP 4.2V RESET IC

AD9883A 80P TQFP R/TP DIGITAL

CXA2069Q QFP64 BK I2C BUS AV S/W

LGDT1502M 304P

IC

- 28 -

RUN DATE : 2003.7.4

TRANSISTOR

Page 29

- 29 -

LOCA. NO PART NO DESCRIPTION

Q1

Q100

Q1001

Q1002

Q1003

Q1004

Q1005

Q1006

Q1007

Q1008

Q1009

Q101

Q1010

Q1011

Q1012

Q1013

Q1014

Q1015

Q1016

Q1017

Q102

Q103

Q107

Q109

Q1200

Q1201

Q1202

Q1203

Q1204

Q1205

Q1206

Q1207

Q1208

Q1209

Q1210

Q1213

Q1214

Q1215

Q1216

Q1217

Q1218

Q1219

Q2

Q201

Q202

Q203

Q204

Q205

Q206

Q207

Q208

Q209

0TR387500AA

0TR830009BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR830009BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TRKE80038A

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR102009AG

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

CHIP 2SC3875S(ALY) KEC

BSS83

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

KTC3552TRTK SOT23F 50V 3A

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP KRC102S

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

LOCA. NO PART NO DESCRIPTION

Q210

Q211

Q500

Q501

Q502

Q504

Q601

Q601

Q602

Q602

Q603

Q605

Q605

Q810

Q841

Q842

Q851

D01

D02

D03

D1

D100

D101

D2

D3

D300

D404

D430

D431

D432

D433

D435

D436

D437

D438

D439

D5

D601

D603

D605

D606

D607

D801

D801

D802

D803

D804

D805

D806

D810

0TR387500AA

0TR387500AA

0TR150400BA

0TR830009BA

0TR830009BA

0TR102009AG

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR322709AA

0TR387500AA

0TR150400BA

0TF283700AA

0TR945009AA

0TR322709AA

0TR945009AA

0DL200000CA

0DL200000CA

0DL200000CA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD226239AA

0DL233309AC

0DD184009AA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DS113379BA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DR050008AA

0DD606000AA

0DR050008AA

0DR050008AA

0DR050008AA

0DRSE00038A

0DRSE00038A

0DD100009AM

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

BSS83

BSS83

CHIP KRC102S

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

KTC3227Y,TP(KTC1627A),KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

2SK2837 500V 20A TO3P

KSC945CY TO92 50V 150MA

KTC3227Y,TP(KTC1627A),KEC

KSC945CY TO92 50V 150MA

LED,SAM5670(DL2LRG) BK YGREEN

LED,SAM5670(DL2LRG) BK YGREEN

LED,SAM5670(DL2LRG) BK YGREEN

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT23

LED,SAM2333

KDS184S CHIP 85V 300MA KEC TP

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

1SS133 T72 DO34 90V

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

SD05.TC SOD323 5V 5A 15A

RBV606 600V 6A 150A NA 10UA

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SDC15 SOT23 12.8V 10A .A .SEC 100NA

SDC15 SOT23 12.8V 10A .A .SEC 100NA

EU1ZV(1) TP SANKEN

DIODE

Page 30

- 30 -

LOCA. NO PART NO DESCRIPTION

D820

D821

D822

D832

D833

D834

D841

D845

D881

D881

Q810

ZD01

ZD1

ZD1

ZD10

ZD11

ZD12

ZD2

ZD2

ZD201

ZD202

ZD203

ZD204

ZD3

ZD3

ZD4

ZD5

ZD6

ZD601

ZD602

ZD8

ZD841

ZD851

ZD9

C01

C07

C1

C100

C101

C1011

C1013

C1019

C1020

C1023

C103

C1035

C1036

C1039

C1042

C1049

0DD100009AM

0DD100009AM

0DD100009AM

0DR010009AA

0DD100009AM

0DD260000BB

0DD100009AP

0DD414809ED

0DD120000BB

0DD420000BB

0DR260001AA

0DR050008AA

0DR050008AA

0DZ620009BB

0DZ620009BB

0DR050008AA

0DR050008AA

0DR050008AA

0DZ620009BB

0DZ560009CF

0DZ560009CF

0DZ560009CF

0DZ560009CF

0DR050008AA

0DZ620009BB

0DZ620009BB

0DZ620009BB

0DZ620009BB

0DZ560009CF

0DZ560009CF

0DR050008AA

0DZ620009BB

0DZ620009BB

0DZ620009BB

0CE226VF6DC

0CE476VF6DC

0CE476DF618

0CE226SF6DC

0CE106VF6DC

0CE476VF6DC

0CE476VF6DC

0CE105VK6DC

0CE476VF6DC

0CE476VF6DC

0CE475VK6DC

0CE106VF6DC

0CE106VF6DC

0CE476VF6DC

0CE106VF6DC

0CE106VF6DC

EU1ZV(1) TP SANKEN

EU1ZV(1) TP SANKEN

EU1ZV(1) TP SANKEN

EG01C 1000V 0.5A 10A 100NSEC 50UA

EU1ZV(1) TP SANKEN

BRIDGE D2SBA60(STK) SHINDENKEN

EG1ZV(1) TP SANKEN TP SANKEN

1N4148 TP GRANDE

FMLG12S

D4L20U SHINDENGEN

FMG26S TO220 600V 6A 50A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

ZENERS,MTZJ6.2B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

SD05.TC SOD323 5V 5A 15A

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ5.6B

ZENERS,MTZJ5.6B

SD05.TC SOD323 5V 5A 15A

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

ZENERS,MTZJ6.2B

22UF MV 16V 20%

47UF MV 16V 20%

47UF STD 16V M

22UF MVG 16V M

10UF MV 16V 20%

47UF MV 16V 20%

47UF MV 16V 20%

1UF MV 50V 20%

47UF MV 16V 20%

47UF MV 16V 20%

4.7UF MV 50V 20%

10UF MV 16V 20%

10UF MV 16V 20%

47UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

LOCA. NO PART NO DESCRIPTION

C105

C1055

C106

C1060

C108

C11

C110

C1100

C1101

C1102

C1103

C1104

C1105

C1106

C1107

C1108

C111

C1110

C1111

C1112

C1114

C1116

C1118

C112

C112

C1122

C1125

C1133

C1134

C1138

C1139

C1143

C117

C1200

C1201

C1202

C1202

C1204

C1205

C1206

C1207

C1208

C1209

C1216

C1217

C1218

C1226

C1234

C1237

C124

C1250

C1251

0CE476VF6DC

0CE106VF6DC

0CE476VK6DC

0CE476SF6DC

0CE106VF6DC

0CE226VF6DC

0CE476VK6DC

0CK103CK56A

0CE476VH6DC

0CK103CK56A

0CK103CK56A

0CE105VK6DC

0CC180CKH1A

0CC180CKH1A

0CK103CK56A

0CE476VH6DC

0CE476VF6DC

0CE476VH6DC

0CK103CK56A

0CE476VH6DC

0CE107VH6DC

0CE107SF6DC

0CE107SF6DC

0CE106SF6DC

0CE475VK6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CQ2231N509

0CE476VH6DC

0CE106VF6DC

0CE106VF6DC

0CE107SF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE106VF6DC

0CE476VH6DC

0CE476VF6DC

0CE105VK6DC

0CQ2231N509

0CE105VK6DC

0CE105VK6DC

47UF MV 16V 20%

10UF MV 16V 20%

47UF MV 50V 20%

47UF MVG 16V M

10UF MV 16V 20%

22UF MV 16V 20%

47UF MV 50V 20%

0.01UF 1608 50V 10%

47UF MV 25V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

1UF MV 50V 20%

18PF 1608 50V 2%

18PF 1608 50V 2%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 16V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

47UF MV 25V 20%

100UF MV 25V 20%

100UF MVG 16V M

100UF MVG 16V M

10UF MVG 16V 20%

4.7UF MV 50V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

0.022U 100V K

47UF MV 25V 20%

10UF MV 16V 20%

10UF MV 16V 20%

100UF MVG 16V M

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

10UF MV 16V 20%

47UF MV 25V 20%

47UF MV 16V 20%

1UF MV 50V 20%

0.022U 100V K

1UF MV 50V 20%

1UF MV 50V 20%

CAPACITOR

Page 31

- 31 -

LOCA. NO PART NO DESCRIPTION

C126

C128

C129

C1301

C1305

C1308

C1309

C131

C1310

C1311

C1313

C1319

C1320

C1321

C1322

C1324

C1325

C133

C1330

C1335

C1336

C1340

C1341

C140

C140

C1401

C1405

C1408

C1409

C1410

C1411

C1413

C1419

C1420

C1421

C1422

C1424

C1425

C1429

C1435

C1436

C144

C1441

C146

C149

C15

C1501

C1505

C1508

C1509

C1510

C1511

0CE226SF6DC

0CE476VK6DC

0CE226SF6DC

0CE476VH6DC

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CE476VK6DC

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CK103CK56A

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CK103CK56A

0CE476VH6DC

0CE226SF6DC

0CE475VK6DC

0CE476VH6DC

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CK103CK56A

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE226SF6DC

0CE476VH6DC

0CE106SF6DC

0CE106SF6DC

0CE105VK6DC

0CE476VH6DC

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CK103CK56A

0CK103CK56A

22UF MVG 16V M

47UF MV 50V 20%

22UF MVG 16V M

47UF MV 25V 20%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 50V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

47UF MV 25V 20%

22UF MVG 16V M

4.7UF MV 50V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

22UF MVG 16V M

47UF MV 25V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

1UF MV 50V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

LOCA. NO PART NO DESCRIPTION

C1513

C1519

C152

C1520

C1521

C1522

C1524

C1525

C1529

C1535

C1536

C1541

C16

C1620

C1621

C2

C20

C200

C202

C204

C205

C205

C206

C209

C212

C216

C218

C222

C223

C227

C228

C231

C245

C246

C247

C247

C248

C250

C252

C260

C261

C262

C29

C3

C31

C312

C314

C406

C406

C407

C408

C409

0CK103CK56A

0CE476VH6DC

0CE106SF6DC

0CE476VH6DC

0CK103CK56A

0CK103CK56A

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VF6DC

0CE107VF6DC

0CE107VF6DC

0CN1030F679

0CE105VK6DC

0CE226SF6DC

0CE106SF6DC

0CE105VK6DC

0CE106SF6DC

0CE105VK6DC

0CE106SF6DC

0CE105VK6DC

0CE105VK6DC

0CE105VK6DC

0CE105VK6DC

0CE105VK6DC

0CE105VK6DC

0CE226VF6DC

0CK823DK56A

0CE107SF6DC

0CE106SF6DC

0CE226SF6DC

0CE106SF6DC

0CE227VF6DC

0CE226SF6DC

0CE106SF6DC

0CE226SF6DC

0CE475VK6DC

0CE475VK6DC

0CE227VF6DC

0CE105VK6DC

0CE476VF6DC

0CE226VF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE227VF6DC

0CE107VH6DC

0CE107SF6DC

0CE107SF6DC

0.01UF 1608 50V 10%

47UF MV 25V 20%

10UF MVG 16V 20%

47UF MV 25V 20%

0.01UF 1608 50V 10%

0.01UF 1608 50V 10%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%

47UF MV 25V 20%