LG RU-44SZ63D Service Manual

DLP PROJECTION TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MB-042H

MODEL : RU-44SZ63D

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//lgservice.com/techsup.html

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

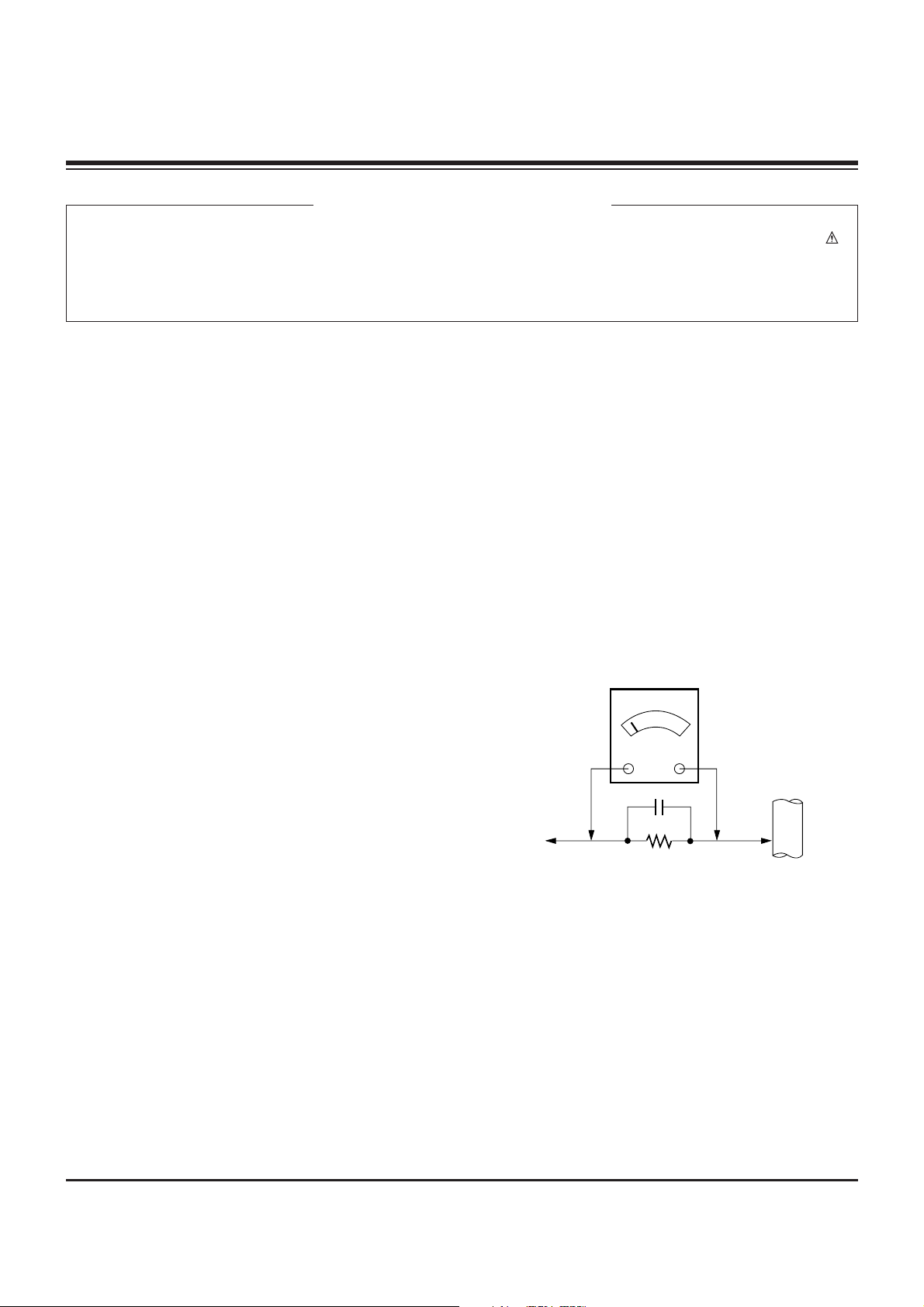

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

- 3 -

SPECIFICATIONS.................................................................4

DESCRIPTION OF CONTROLS...........................................5

ADJUSTMENT INSTRUCTION...........................................12

PRINTED CIRCUIT BOARDS.............................................19

BLOCK DIAGRAM...............................................................29

EXPLODED VIEW...............................................................36

EXPLODED VIEW PARTS LIST.........................................37

REPLACEMENT PARTS LIST............................................38

SCHEMATIC DIAGRAM..........................................................

TABLE OF CONTENTS

- 4 -

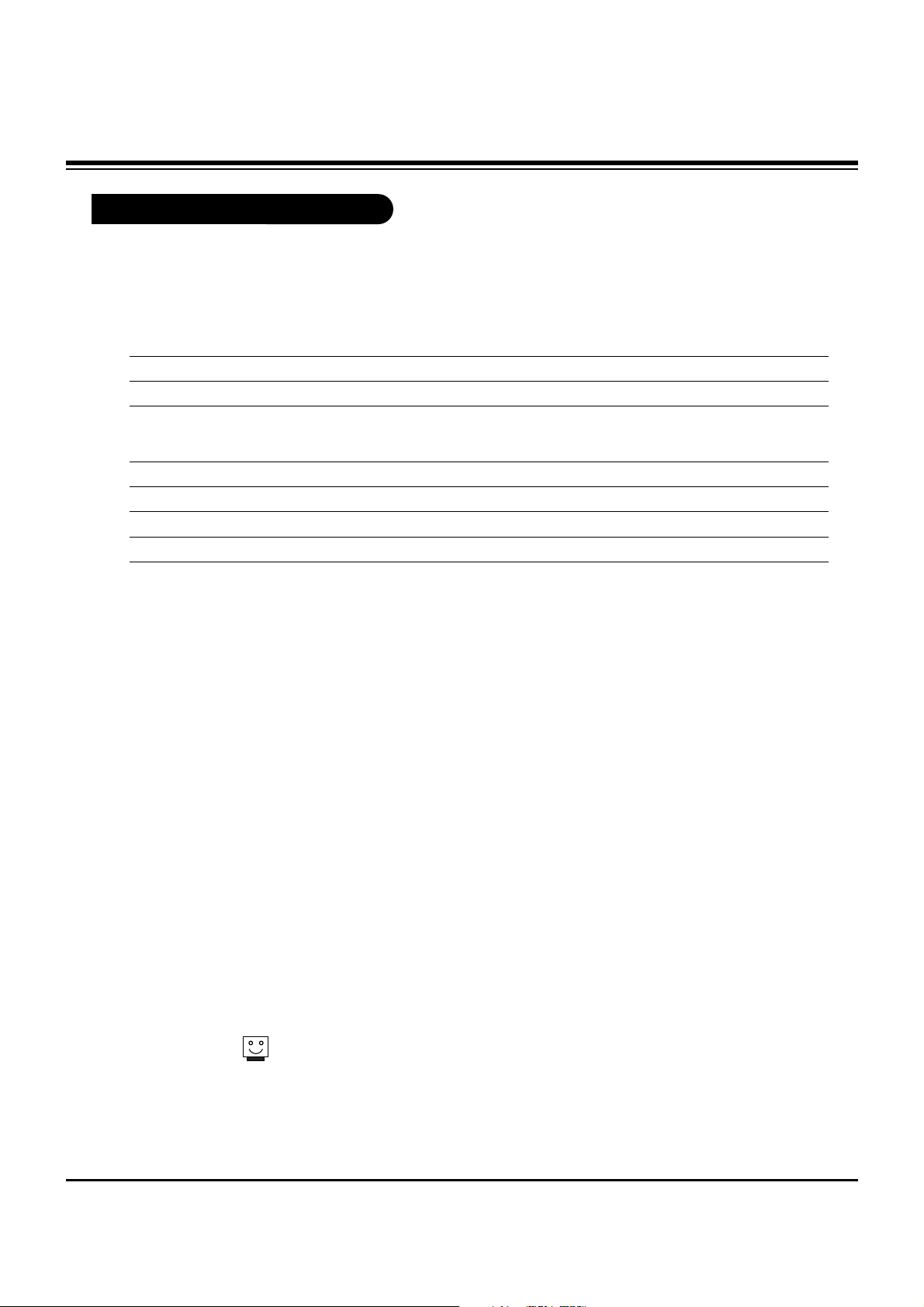

Product Specifications

Models

RU-44SZ63D Horizontal Size (Inches) 41.7

Height (Inches) 30.1

Depth (Inches) 14.2

Weight (lbs.) 65

Power Requirement AC 120V, 60Hz

Television System American TV Standard, NTSC, ATSC with STB

Television Channels VHF: 2 - 13

UHF: 14 - 69

CATV: 1 - 125

Power Consumption (W) 240W

Antenna 75 ohm External Terminal for VHF/UHF

Audio Output (W) 12W x 2

Supplied Accessories Remote Control, 2 size AAbatteries, 2 filters.

External Input/Output Ports A/V input (3 set)

A/V output (1 set)

S-Video input (2)

Component input (2 set)

RGB input (1)

DVI input (1)

RGB/DVI audio input (1 set)

Variable audio output (1 set)

Audio center mode input (1)

Calibration port (1)

Design and specifications are subject to change without prior notice.

SPECIFICATIONS

- 5 -

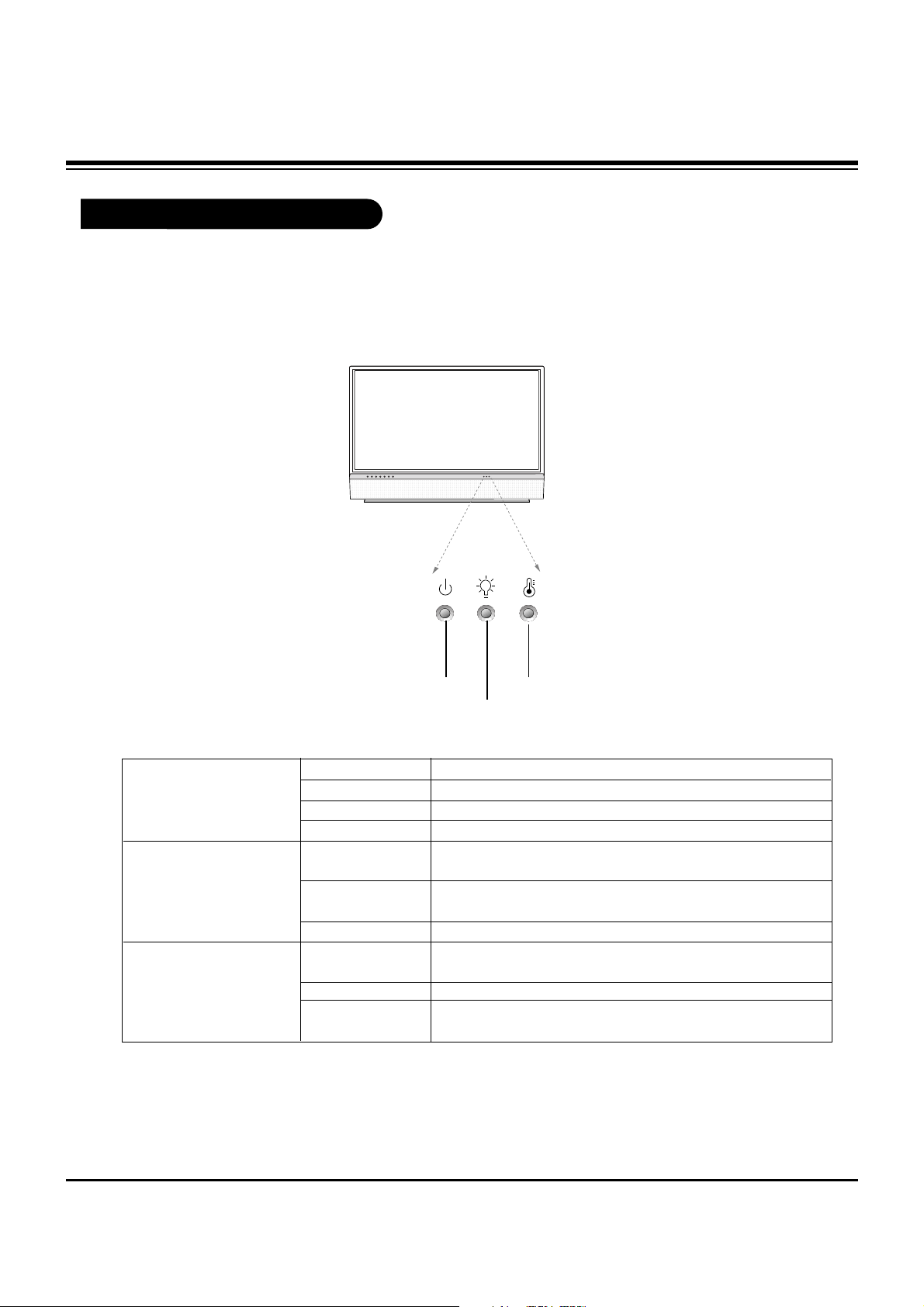

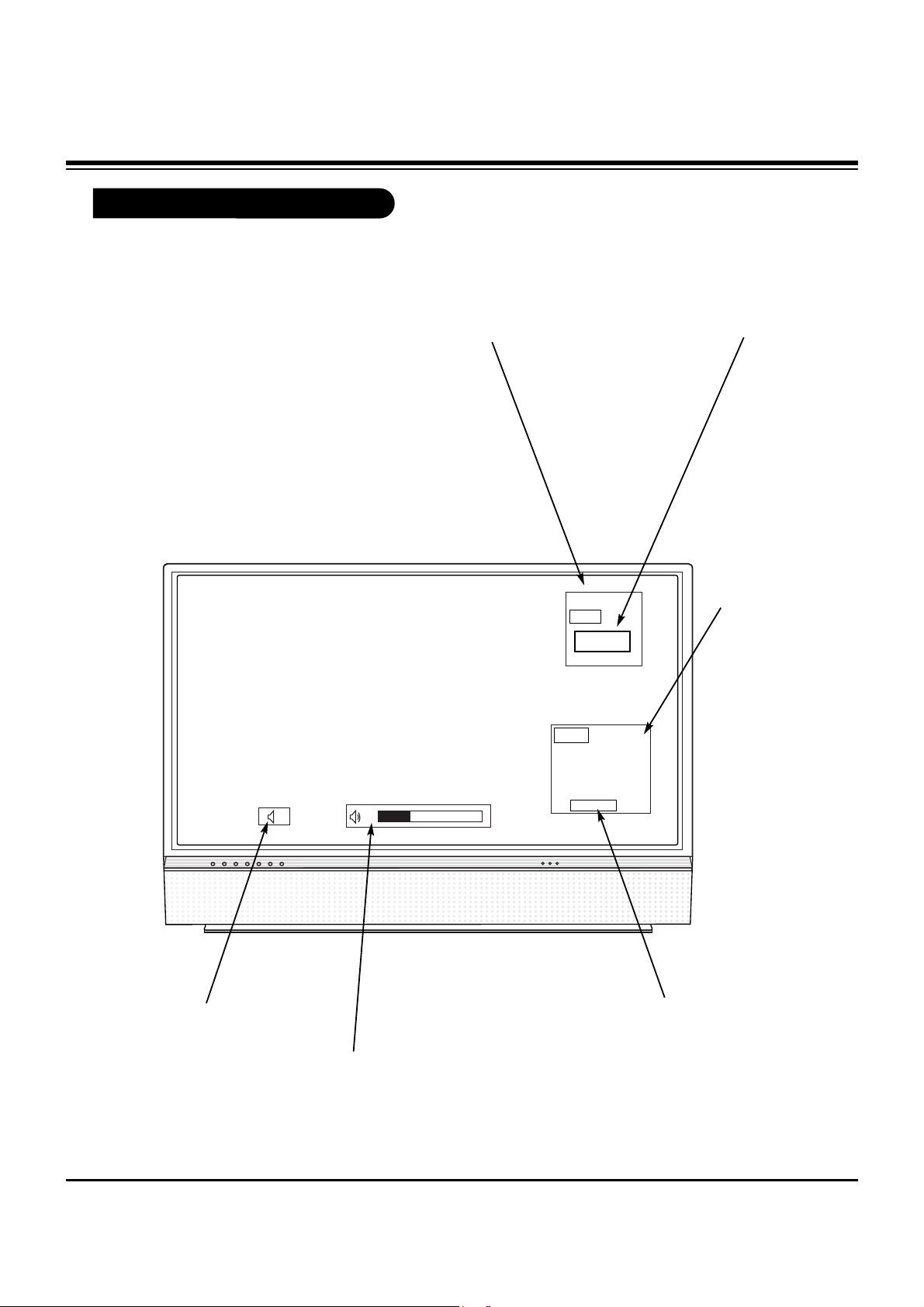

Function Status Indicators

Lamp indicator, operation indicator, and temperature indicator located below the front panel

controls, reveal the operating status of the DLP projection TV.

Operation Indicator

Lamp Indicator

Temperature Indicator

Off Power cord is not connected.

Red Power Cord is connected, TV is in standby mode.

Green TV turns on.

Orange (flashing) Preparing operation in standby mode.

Orange Projection lamp is reaching the end of its life and needs to

be replaced with a new lamp. Contact your service center.

Red (flashing) There is a problem with the lamp or around it. Contact an

authorized service center.

Green (flashing) The lamp cover is not closed.

Orange The projection TV is overheating. Check the blocked vents of

the projection TV and the accumulated dust in the dust filter.

Red The projection TV shut down due to overheating.

Red (flashing) The projection TV shut down, check the cooling fan. Contact

your service center.

Operation Indicator

Lamp Indicator

Temperature Indicator

DESCRIPTION OF CONTROLS

- 6 -

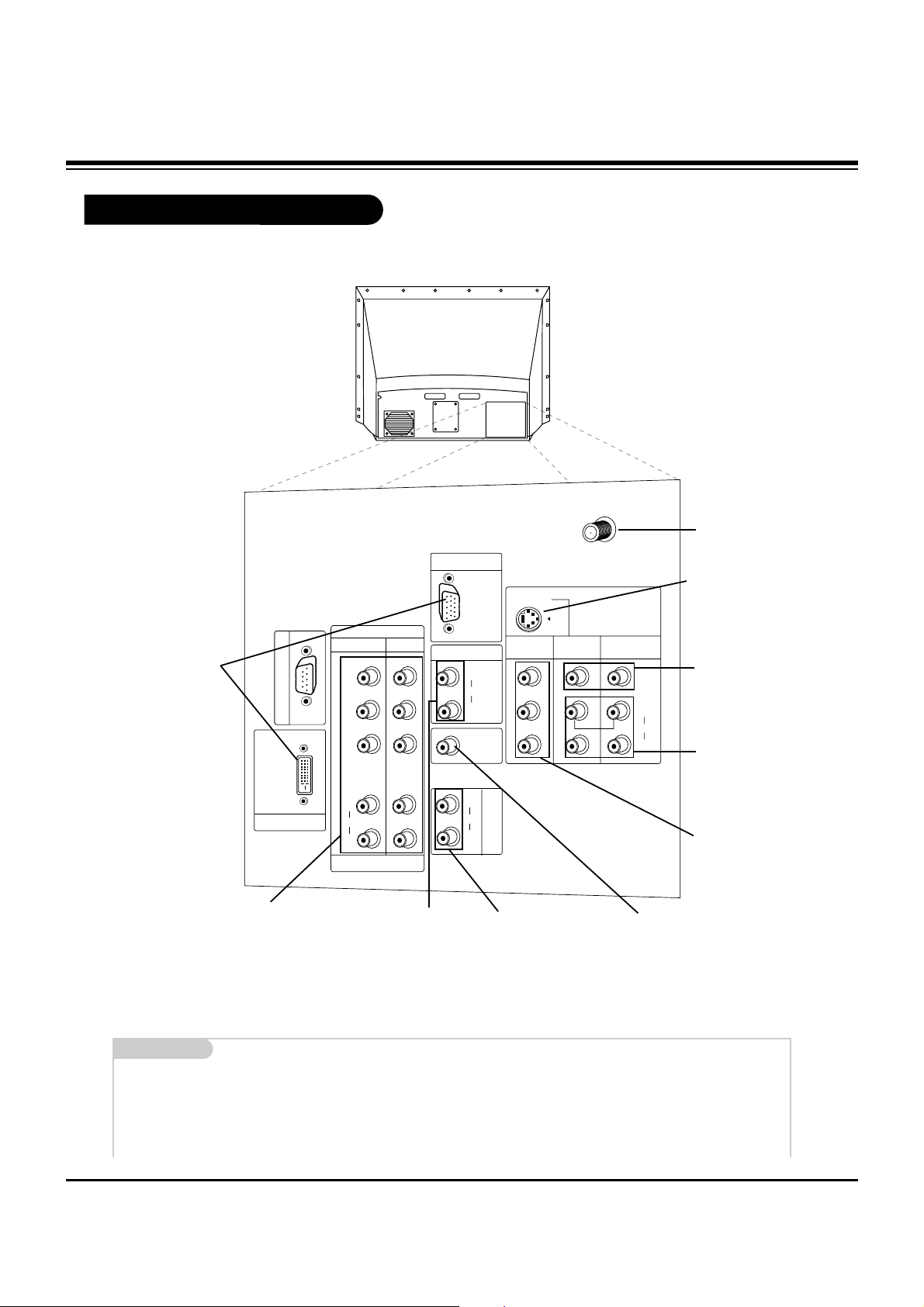

Rear Connections Panel

Mini glossary

JACK A connection on the back of a TV, VCR, or any other A/V device. This includes the RF jack and the Audio/Video jacks that are

color-coded.

SIGNAL Picture and sound traveling through cable, or over the air, to your television screen.

C

A

L

I

B

R

A

T

I

O

N

PC/DTV

(XGA

/480p

/720p

/1080i)

AUDIO

CENTER

MODE IN

P

R

DVI INPUT

DTV/DVD INPUT

COMPONENT

INPUT2 INPUT1

PB

Y

PC/DTV

(XGA

/480p

/720p

/1080i)

RGB INPUT

RGB/DVI INPUT

(R)

(L)

AUDIO

(R)

(L)

AUDIO

(R)

(L)

AUDIO

V

A

R

I

A

B

L

E

A

U

D

I

O

O

U

T

MONITOR

OUT

VIDEO

INPUT 2

VIDEO

INPUT 1

S-VIDEO

(R)

(L)

AUDIO

VIDEO

MONO

+75 Ω

ANT IN

S-VIDEO In

A connection available with

some high-end equipment

that provides even better picture quality for Video 2.

Variable Audio Out

Used to connect either

an external amplifier, or

add a sub-woofer to your

surround sound system.

RF Connector: Antenna

Used to connect analog

cable or antenna signals

to the television, either

directly or through your

cable box.

Video 1 or 2

Connects the video signals from various types

of equipment.

Y, Pb, Pr

DVD Component Video and HD Component

Video

Some top-of-the-line DVD players use what is

called “component video,” for extremely accurate picture reproduction. Refer to your DVD

manual for further information.

Connecting cables and external equipment to your TV.

Monitor Out

Connects to a second TV

or Monitor.

Left/Right Audio

Used for stereo sound

from various types of

equipment.

PC and HD-STB Input

Used to connect from a

PC source or HD-STB

Satellite system.

PC and HD-STB Audio

Input

Used for audio connec-

tions from a PC source or

HD-STB Satellite system.

Audio Center Mode In

Connect to external Dolby

Digital Center “preamp output.”

DESCRIPTION OF CONTROLS

- 7 -

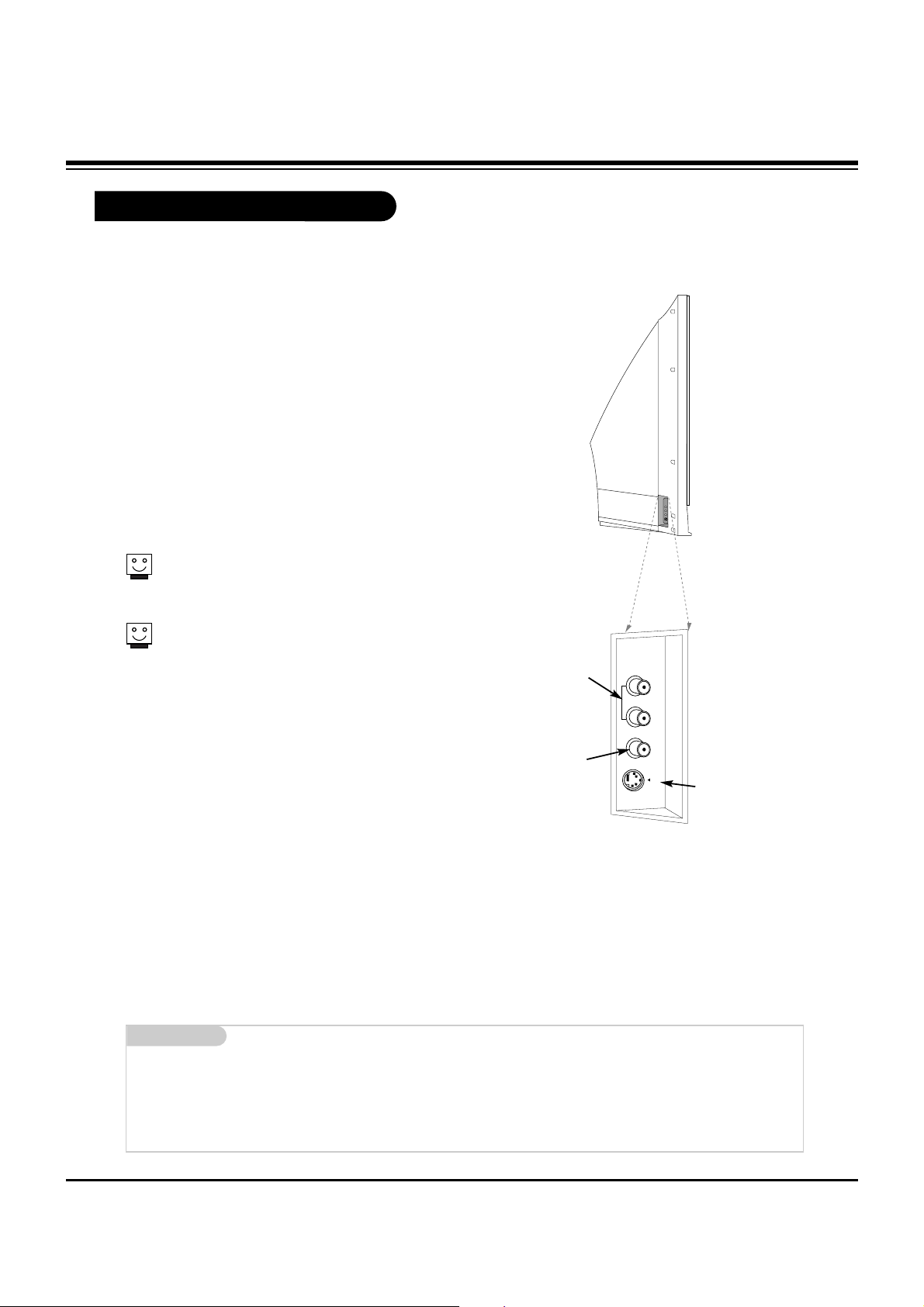

Front Connection Panel

There are four jacks on the left side on your projection TV

that make connecting Audio/Video devices like video games

and camcorders very simple.

The jacks are like those found on the back jack connection

panel. This means that most equipment that connects to

those types of jacks on the rear jackpack, may be connected to the front connection panel.

To use the front jacks as the signal source, select them

using Main Input menu as described on page 25. They will

be named “Front Video” in the Main Input menu.

If you input both Front Video and

S-Video, only the S-Video will

work.

If you’re connecting a video game

device, make sure to change the

picture settings with the EZ

Picture option in the Video menu.

Mini glossary

A/V CABLES Audio/Video cables. Three cable connector—Right audio (red), Left audio (white), and Video (yellow). A/V cables are used

for stereo playback of videocassettes and for higher quality picture and sound from other A/V devices.

A/V DEVICE Any device that produces video or sound (VCR, DVD, cable box, or television).

Front A/V Panel

S-VIDEO

VIDEO

FRONT A/V

AUDIO

(R)

(L)/

MONO

Left/Right Audio

Used for stereo

sound from various

types of equipment.

Video

Connects the video

signals from any

piece of equipment.

S-Video

A connection available on

some very high-end equipment that provides better

picture quality than video

input.

DESCRIPTION OF CONTROLS

- 8 -

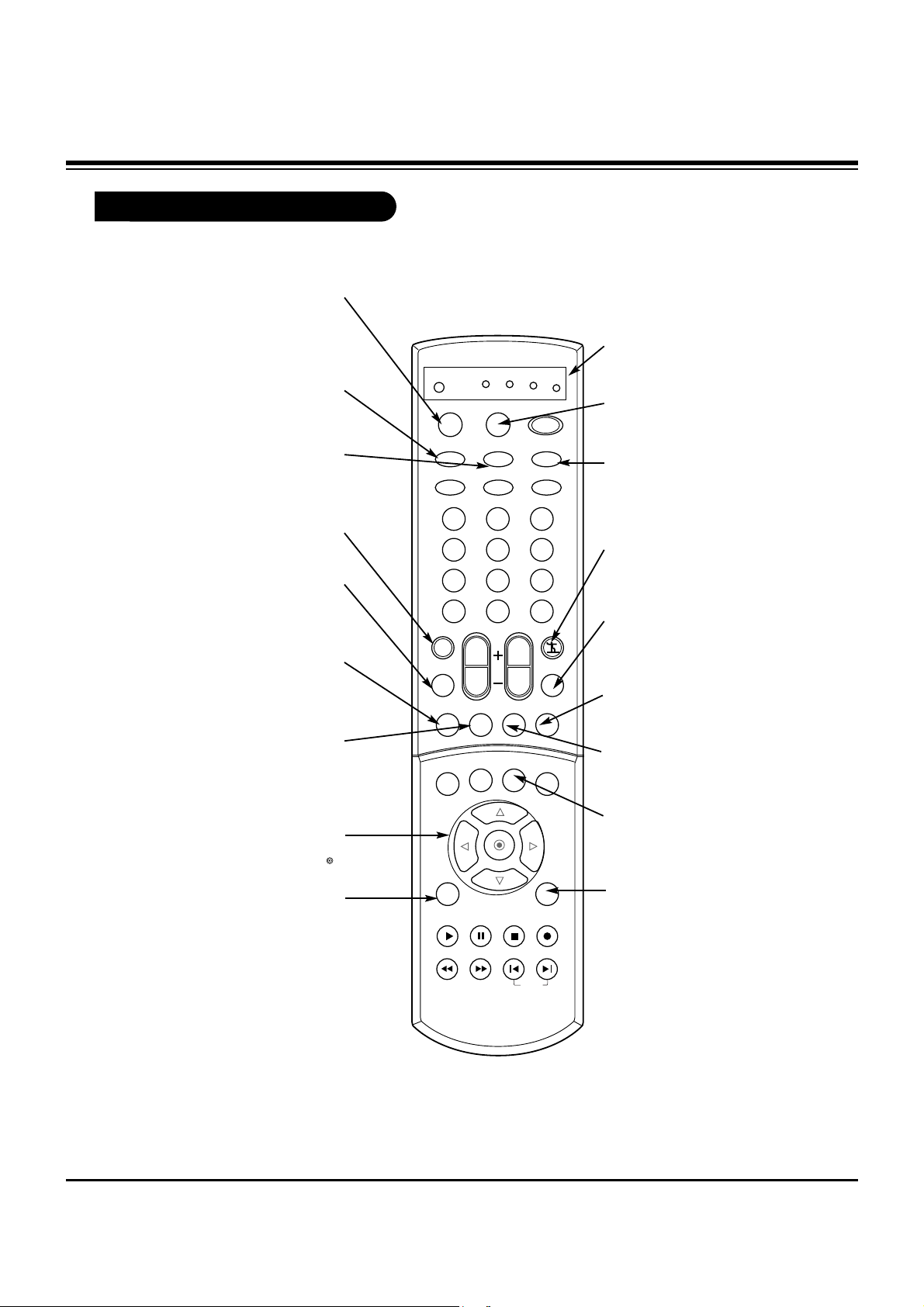

Remote Control Functions in TV Mode

1 2 3

4 5 6

7 8 9

0

TV

MODE

LIGHT

POWER

TV/VIDEO

DVI

RGB

VCR

CABLE

DVD

SAT

MUTE

SWAPPIPCH- PIPCH+

PIP

RATIO

RECORD

STOP

PAUSE

REW

PLAY

FF

MENU EXIT

CC FREEZE

PIP INPUT

VOL

CH

SURF

SAP

VIDEO

COMP2COMP1

FRONT

SKIP

ENTER

FLASHBK

SURF

Scrolls the Surf channel list.

MENU

Brings up the main

menu to the screen.

EXIT

Clears all on-screen displays and returns to TV

viewing from any menu.

FREEZE

Captures and freezes the currentlyviewed main picture.

VIDEO

Adjusts the factory preset picture according to the room.

PIPCH+

Changes to next higher PIP

channel.

SWAP

Switches the picture from

PIP, POP, or twin picture to

the main screen.

MUTE

Switches the sound on or off

THUMBSTICK

Allows you to navigate the on-screen

menus and to adjust the system set-

tings and preferences, by moving to

an option with

F G

and selecting the

highlighted option with .

TV/VIDEO

Selects: Analog, Video1,

Video2, Front video,

Component1-2, RGB, and DVI

input sources.

MODE

Selects the remote operating

mode: TV, VCR, Cable, DVD

and Satellite. Select other oper-

ating modes, for the remote to

control external devices.

FRONT

Selects the front video signal if

a device, such as a camcorder

or game player, is connected

to the front video input jack.

DVI

Selects: DVI-DTV and DVIPC input sources.

SAP

Selects: Mono, Stereo, and

SAP.

PIPCH-

Changes to next

lower PIP channel

PIP

Toggles between PIP, POP

(Picture-outside-Picture)

and Twin picture mode.

LIGHT

Illuminates the remote control keys.

INDICATOR LIGHTS

Show active remote mode

every time any button is

pressed.

D

E

DESCRIPTION OF CONTROLS

- 9 -

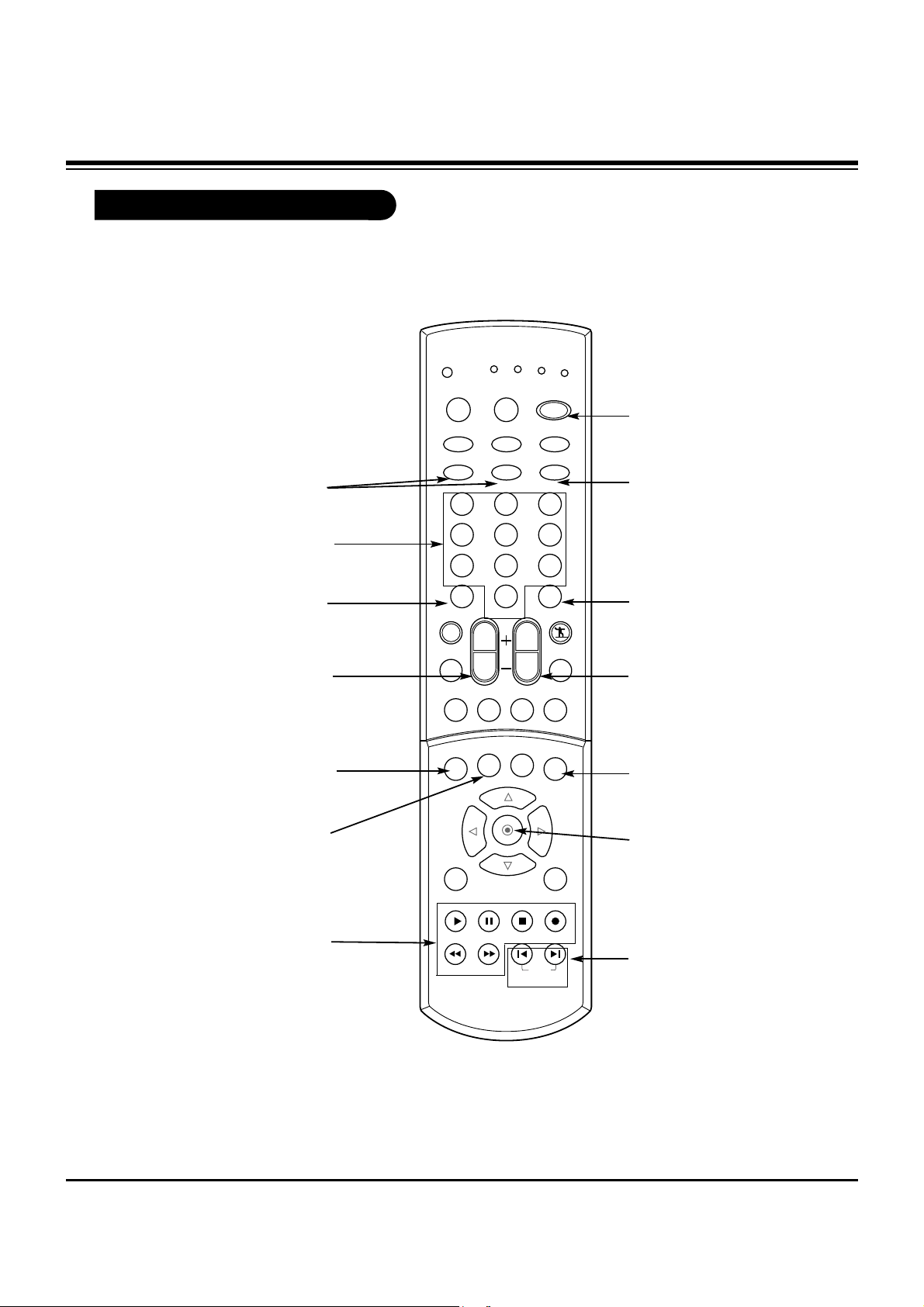

Remote Control Functions in TV Mode

1 2 3

4 5 6

7 8 9

0

TV

MODE

LIGHT

POWER

TV/VIDEO

DVI

RGB

VCR

CABLE

DVD

SAT

MUTE

SWAPPIPCH- PIPCH+

PIP

RATIO

RECORD

STOP

PAUSE

REW

PLAY

FF

MENU EXIT

CC FREEZE

PIP INPUT

VOL

CH

SURF

SAP

VIDEO

COMP2COMP1

FRONT

SKIP

ENTER

FLASHBK

POWER

Turns your TV or any other

programmed equipment on

or off, depending on mode.

CHANNEL UP/DOWN

Scrolls through available

channels in EZ Scan memory.

NUMBER KEYPAD

For direct channel selection and

programming functions.

ENTER

When in the menu system

and other on-screen displays, selects highlighted

options.

RECORD, PAUSE, REW,

FFWD, PLAY, STOP

Control the functions on your VCR.

VOLUME UP/DOWN

Increases/decreases the sound

level.

RATIO

Changes the screen format or

aspect ratio.

SKIP

Playing CDs: Selects

songs.

Playing DVDs: Selects

movie chapters.

COMPONENT 1, 2

Selects component signal sources,

such as DVD or HD receiver.

ENTER

When in the menu system and

other on-screen displays,

selects highlighted options.

FLASHBK

Tunes to the last channel

viewed.

CC

Selects a closed caption mode

for displaying captioning infor-

mation if available on program.

PIP INPUT

Selects the input source for the

sub picture.

RGB

Selects: RGB-DTV and

RGB-PC input sources.

DESCRIPTION OF CONTROLS

- 10 -

On-Screen Displays

This page describes your on-screen display and information banner options.

10

AM 3:00

TV 13

MONO

TV 6

Main Channel Display

Displays current channel number.

Channel Label

If a channel label has been

set, then it will appear here.

PIP Display

This display

appears when

PIP is active.

Volume

Volume level is displayed while

adjusting the sound.

Mute

Appears

when sound

is muted.

Time

Appears when

pressing the

enter button.

ABC

DESCRIPTION OF CONTROLS

- 11 -

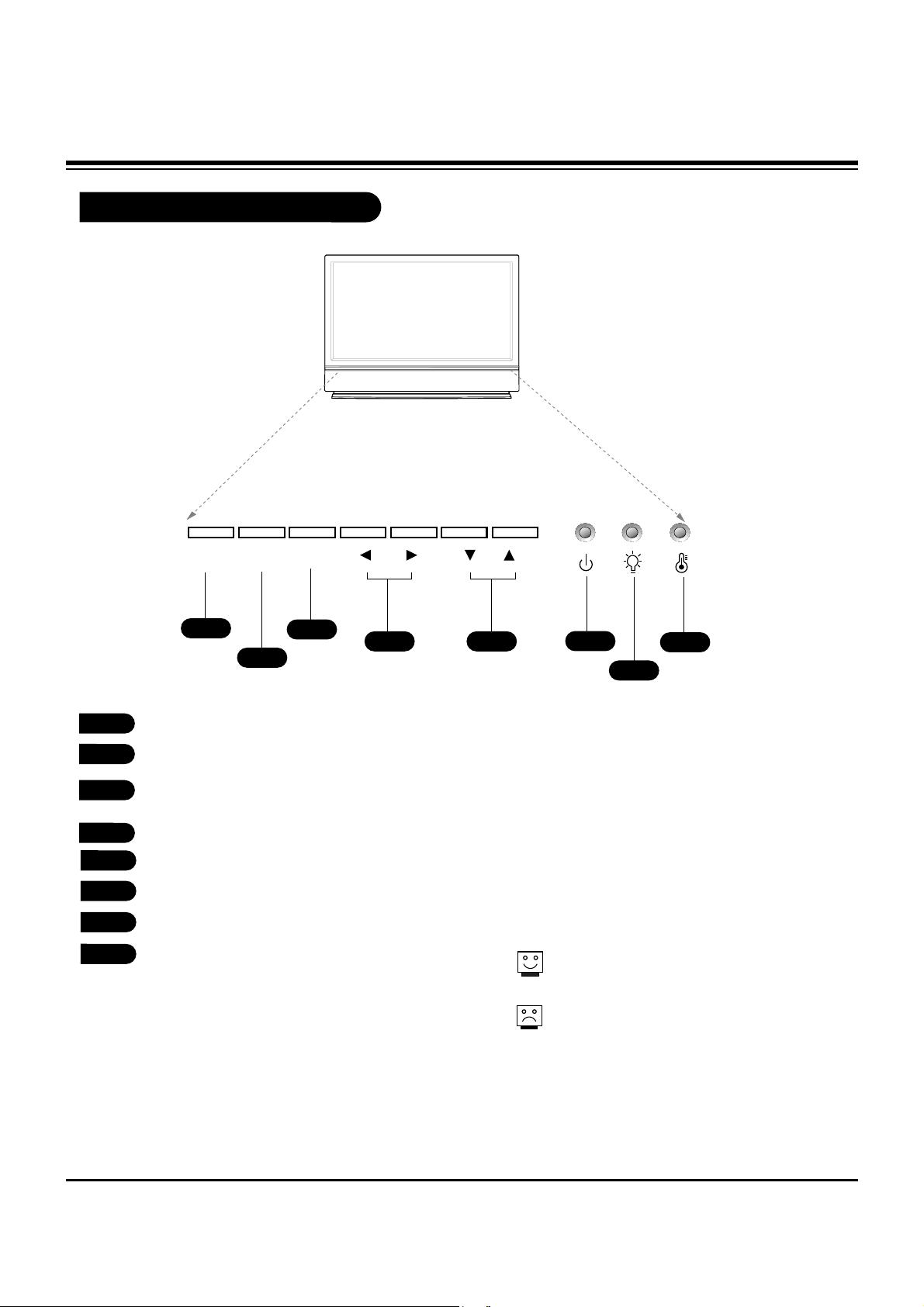

Front Panel Controls

POWER

MENU ENTER VOL CH

1

2

4

3

6

7

8

5

POWER

MENU

ENTER (Same as ENTER button on your

remote control)

VOLUME UP / DOWN

CHANNEL UP / DOWN

Operation indicator.

Lamp indicator.

Temperature indicator.

1

2

3

4

5

6

7

8

The POWER, CHANNEL, TV/VIDEO, and VOLUME

buttons work just as they do on your remote control.

If TV is moved from cold to normal room temperature, humidity may form inside TV, wait 3

hours for TV to adjust to room temperature

before turning it on.

DESCRIPTION OF CONTROLS

- 12 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions apply to the DLP Projection(Chassis:

MB-042H).

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of an insolation

transformer will help protect test equipment.

(2) The adjustments must be performed in the correct

sequence.

(3) The adjustments must be performed in the condition of

25±5°C of temperature and 65±10% of relative humidity if

there is no other specific designation.

(4) The input voltage of the receiver must keep AC 120V,

60Hz in adjusting.

(5) Unless stated otherwise, the set must be operated for at

least 5 minutes prior to adjustments.

The heat-run should be performed with a 100% white

pattern, but reception of a moving picture may also be

possible in unavoidable cases.

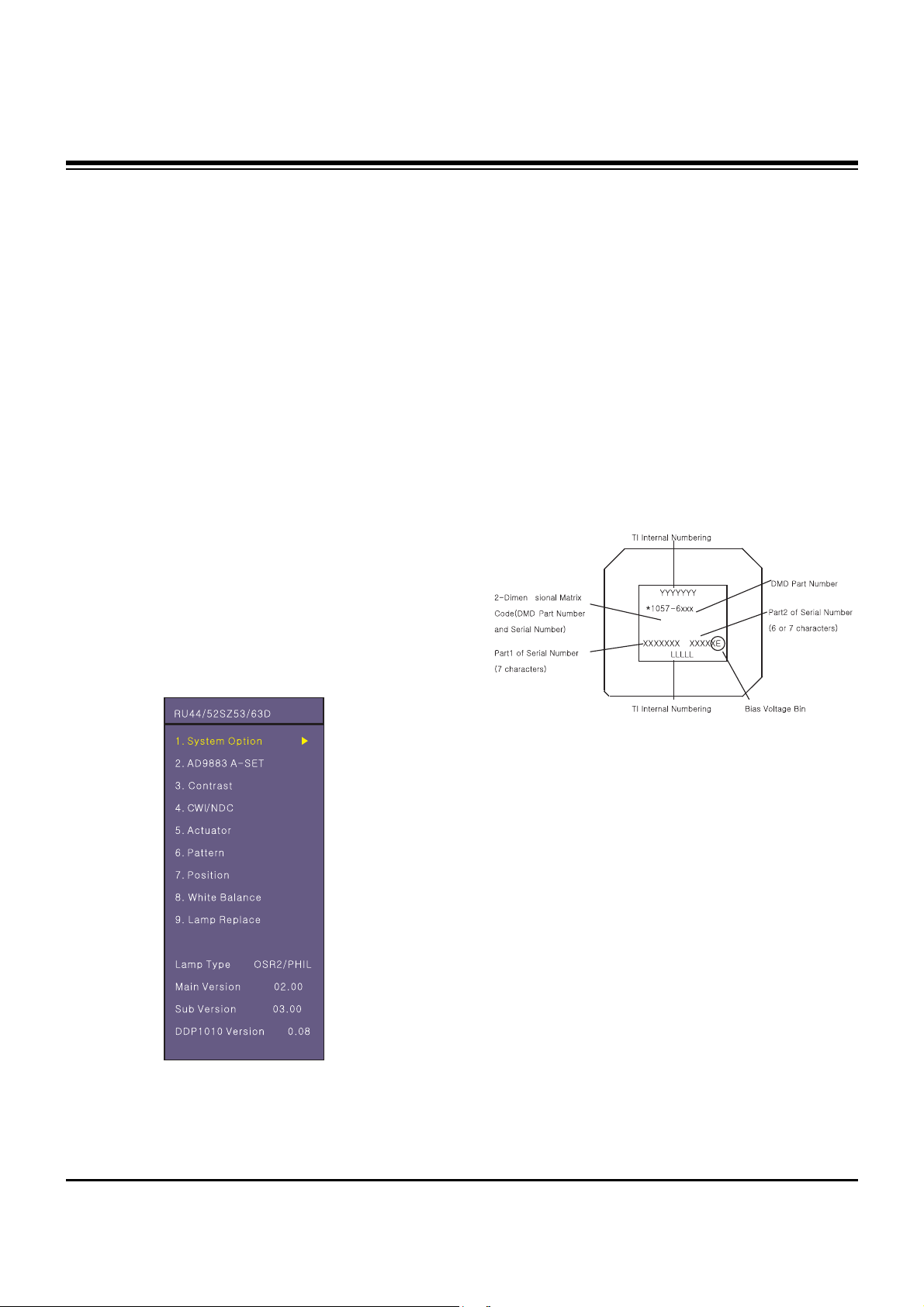

3. Composition of Adjustment Mode

(1) Adjustment modes are entered by pressing the ADJ key

on the Service Remore Control, after adjustments press

the ADJ key to exit.

(2) Initial Adjustment mode menu is shown below. <Fig. 1>

(3) As shown <Fig. 1>, using the CH+ (

D), CH- (E) keys, to

select an item, press the ENTER or VOLUME+ (

G) keys to

enter the appropriate item and begin the adjustment.

(4) Change the value of adjustment by using the volume +(

G ),

volume -(

F) keys. To change adjustment item, use the

CH+ (

D), CH- (E) keys in ADJ Mode.

(5) Press the ADJ key to exit after adjustments.

(6) Preparation for Adjustment

1) Connect the power to TV Set and set “Power on”.

2) Allow set to Heat-Run for at least 5 minitues before

adjusting.

4. Driver Board Bin Setting

HD3 DMD sets Bias Voltage Bin setting with S/W.

Only, is not the E Type and case of the different DMD sets a

Bin setting value at adjustment mode. (DDP1010 adjustment

item on subordinate position existence)

<Fig. 2> DMD Marking Locations

<Fig. 1> Adjustment Mode OSD

- 13 -

ADJUSTMENT INSTRUCTIONS

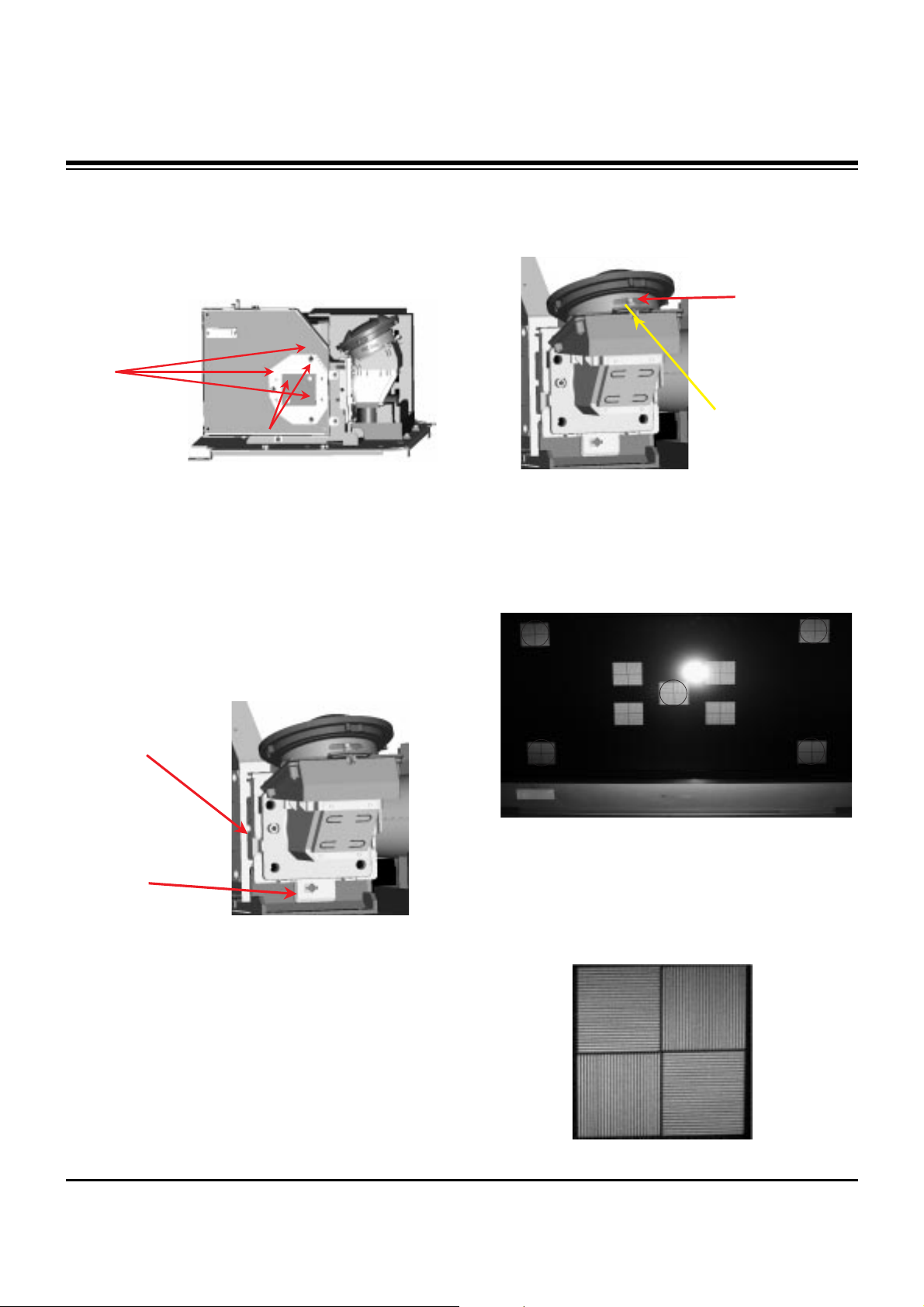

5. Adjusting the Optical Engine

(1) After placing the optical engine on the JIG, adjust

illuminator by adjuting with automatic adjustment the B as

shown <Fig. 3>.

1) When adjust illuminator, search the scope does not fall

in illuminator and Tilt adjustment complete with

automation equipment in that scope.

2) After adjusting, A fix with Screw using automation

equipment.

(2) In order to move Optical system the Tilt is adjusted to

center of the screen, image with top/bottom direction adjust

using B as shown <Fig. 4>.

1) Turn B CW to move the image up, CCW to move the

image down.

2) Turn A CC to move the image right, CCW to move the

image left

(3) After adjusting the illuminator, adjust the focus by using

the focus adjustment screw of projection lens. After

adjusting, fasten the screw tighty and secure with sealer.

[ Note: The focus check point is not the screen center but the

upper/lower screen.

1) <Fig. 6> shows the pattern for Focus adjustment

2) Adjust the 4 green ellipse so that all are in equal focus.

3) If you can’t check the DMD cell bourder at red center

position after adjustment, regard as NG.

4) <Fig. 7> shows the magnified pattern for checking the

focus adjustment

<Fig. 6>

<Fig. 7>

A

B

<Fig. 3>

A

B

<Fig. 4>

Inject the resilock

Screw Fix.

<Fig. 5>

- 14 -

ADJUSTMENT INSTRUCTIONS

6. Adjusting the Actuator

(Initial Data: ACT Phase=220, ACT Gain=60)

6-1. Required Test Equipment

Service Remote Control

6-2. Preparation for Adjustment

(1) Connect a power source with TV Set and turn TV set on.

(2) Using the Service Remote Control, enter from ADJ to

Actuator.

(3) ACT Gain and Phase is variable and the Tartan plaid of R,

G, B, W Horizontal Line adjust not distinguished not to be.

1) The Phase variable adjust Mutation point of Actuator.

2) The Gain adjust mutation quantity of Actuator.

* The Tartan plaid of R, G, and B adjust not visible not to be.

But, when the R, G and B will not agree, adjust with point R

and G agree.

7. Caution for DMD

(Digital Micro-mirror Device)

7-1. Caution for DMD ESD

(1) Use a grounding strap to prevent ESD (Electrostatic

Dischage) damage when handing the DMD.

(2) Connect the grounding strap to a ground point on the

workbench.

(3) Keep the DMD in an ESD Safe container when not being

used or in transit.

(4) Wearing gloves will help prevent ESD damage and help

preserve the physical condition of the DMD.

(5) All work should be performed in a static free environment.

(6) Use caution and remove any dust particles on the DMD

front glass or back pins/pads.

7-2. Caution for DMD Cleaning

(1) Use caution to prevent scratches to the DMD glass.

(2) When DMD glass stains with dust, polish the front and

back DMD glass with soft cloth. Then, rotate the DMD 180

degrees and polish again.

(3) Do not use pressure when cleaning the DMD. The static

electricity and pollution can damage the DMD.

8. EDID Data Input

8-1. Required Test Equipment

(1) A Jig for adjusting PC, DDC (PC serial to D-sub

connection device)

(2) S/W for writing DDC(EDID data write & read)

(3) D-sub terminal

8-2. Adjustment Preparation and Setting of

Device

(1) Setup as in <Fig. 9> and turn on the PC & JIG.

(2) Operate the S/W for writing DDC(EDID data write & read)

8-3. Sequence of Adjustment

(1) Put the SET(or Digital Board) on the table and turn the

power on.

(2) Input the product code, production week / year, serial

number (if it is not input, write “01”) to the S/W for writing

DDC.

(3) Operate EDID Write command by pressing Function Key

F8.

(4) When “OK” letter appear, completed the Write.

<Fig. 8> Test Pattern

Before Actuator Adjustment After Actuator Adjustment

<Fig. 9> Device Setting Diagram of Input EDID Data

- 15 -

ADJUSTMENT INSTRUCTIONS

9. CPLD Download Work

9-1. Required Test Equipments &

Preparation for Adjustment

(1) Connect the PC and memory JIG as shown in <Fig. 10>.

(2) Turn on JIG MAIN POWER SW.

(3) After turning on the PC and moniter, operate the device

programming software.

9-2. Adjustment Sequence

(1) Once the program is running, [OPTION MODE

SELECTION] is displayed in the window.

Check the “Load configuration File(.cdf, .pdr)” in this window

and click the finish button

(2) When the screen displays the open window, select the

suitable file(*.cdf) according to model.

(3) IC figure is change to green by clicking it.

(Refer to <Fig. 11>)

(4) Select program options.

(5) Check the [Erase before programming] and [Verify] menu

as shown <Fig. 12> and press the OK button.

(6) At this time, the download starts. The download will finish

in about 10 seconds.

10. Tilt & Keystone Adjustment

(Apply the HD3(DLP) Engine)

10-1. It followed in Screen Condition,

Projector Lens Direction

(1) When the upper portion of the screen is larger than the

bottom: Adjust Projection lens upward.

(2) When the upper portion of the screen is smaller than the

bottom: Adjust Projection lens downward.

3.3V

<Fig. 10 > How to connect the MEMORY JIG and PC>

<Fig. 11>

<Fig . 12>

- 16 -

ADJUSTMENT INSTRUCTIONS

10-2. It followed in Screen Form,

Adjustment Method

(1) When the screen is rotated: Rotate the Engine to adjust

1) Badness Type: Tilt Badness

2) Adjustment Method:

Engine Base rotate with the left/right and fix the

horizontality horizontal line of Cross Pattern

(2) In case of the upper screen size is large bottom screen

size than: upward projector

1) Badness Type: Keystone Badness

2) Adjustment Method:

The Engine Base front part raises at upper direction and

projection lens to be downward projector.

Bottom screen size a lot, fix the top/bottom screen size to

be same as.

(2) In case of

the upper screen size is

smaller

bottom screen

size than:

downward projector

1) Badness Type: Keystone Badness

2) Adjustment Method:

The Engine Base front part down at bottom direction

and projection lens to be upward projector.

Top screen size a lot, fix the top/bottom screen size to

be same as.

11. Screen Position Adjustment

(Base value --> H: 384, V: 168)

11-1. Required Test Equipment

Service Remote Control

11-2. Horizontal Position Adjustment

(1) Press ADJ key on the remote control to enter the

adjustment mode.

(2) Select POSITION in the adjustment menu.

(3) AThe adjustment pattern below appears.

(4) Select H_position with CHANNEL key.

(5) Change data with using the VOLUME keys on the remote

control in order adjust left/right screen semmetry

(6) If symptom is out of adjustable range: N.G.

11-3. Vertical Position Adjustment

(1) Select V_position with CHANNEL key.

(2) Change data with using the VOLUME key on the remote

control in order to adjust up/downscreen semmetry

(3) If symptom is out of adjustable range: N.G.

Loading...

Loading...