Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : RF-03OB

MODEL : RT-50PZ60/70

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

SAFETY PRECAUTIONS ...................................................................................3

DESCRIPTION OF CONTROLS ........................................................................ 4

SPECIFICATIONS .............................................................................................. 8

ADJUSTMENT INSTRUCTIONS ........................................................................9

PRINTED CIRCUIT BOARD ..............................................................................12

BLOCK DIAGRAM.............................................................................................18

EXPLODED VIEW..............................................................................................20

EXPLODED VIEW PARTS LIST........................................................................21

REPLACEMENT PARTS LIST...........................................................................22

SCHEMATIC DIAGRAM ........................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on position, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

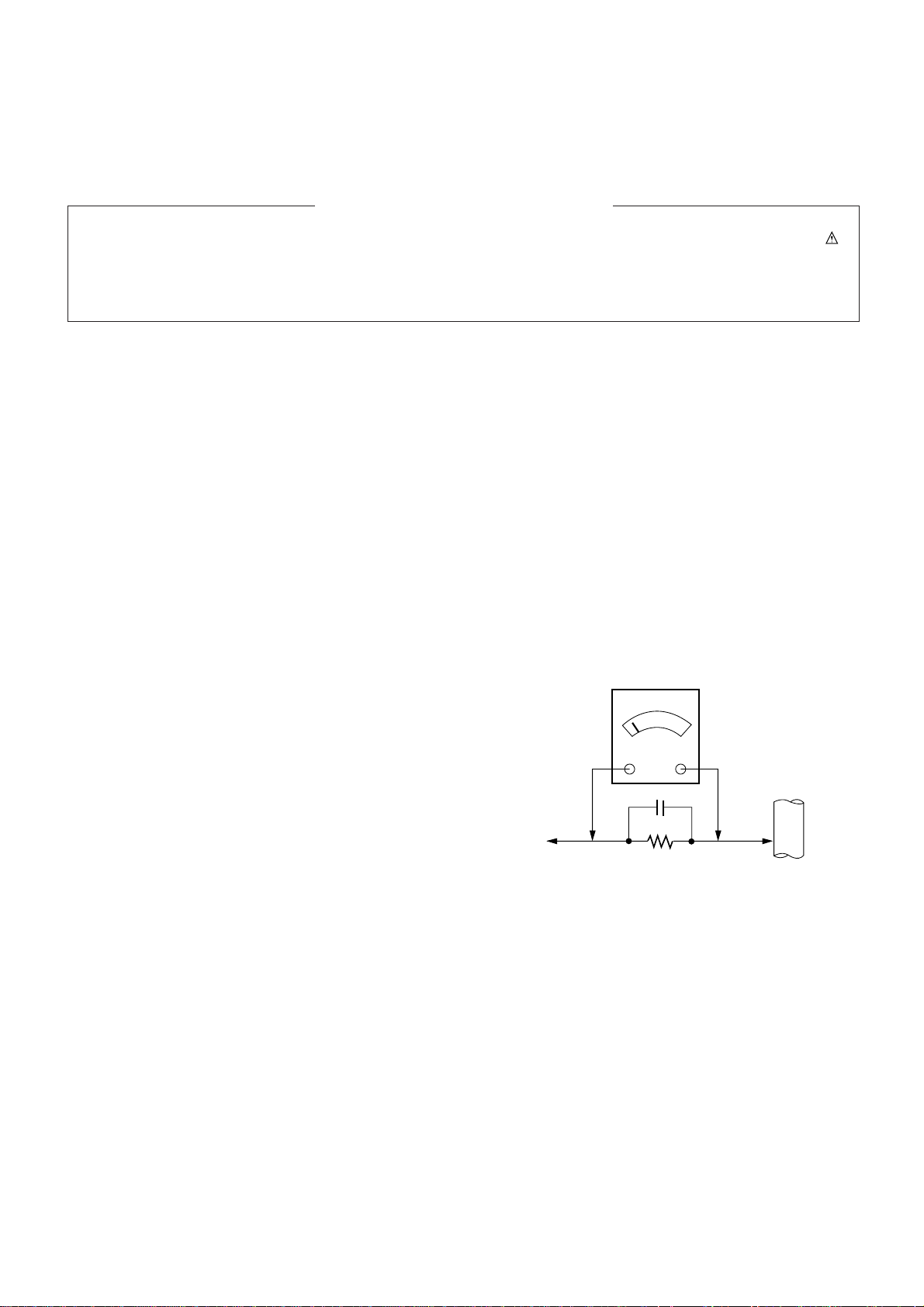

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

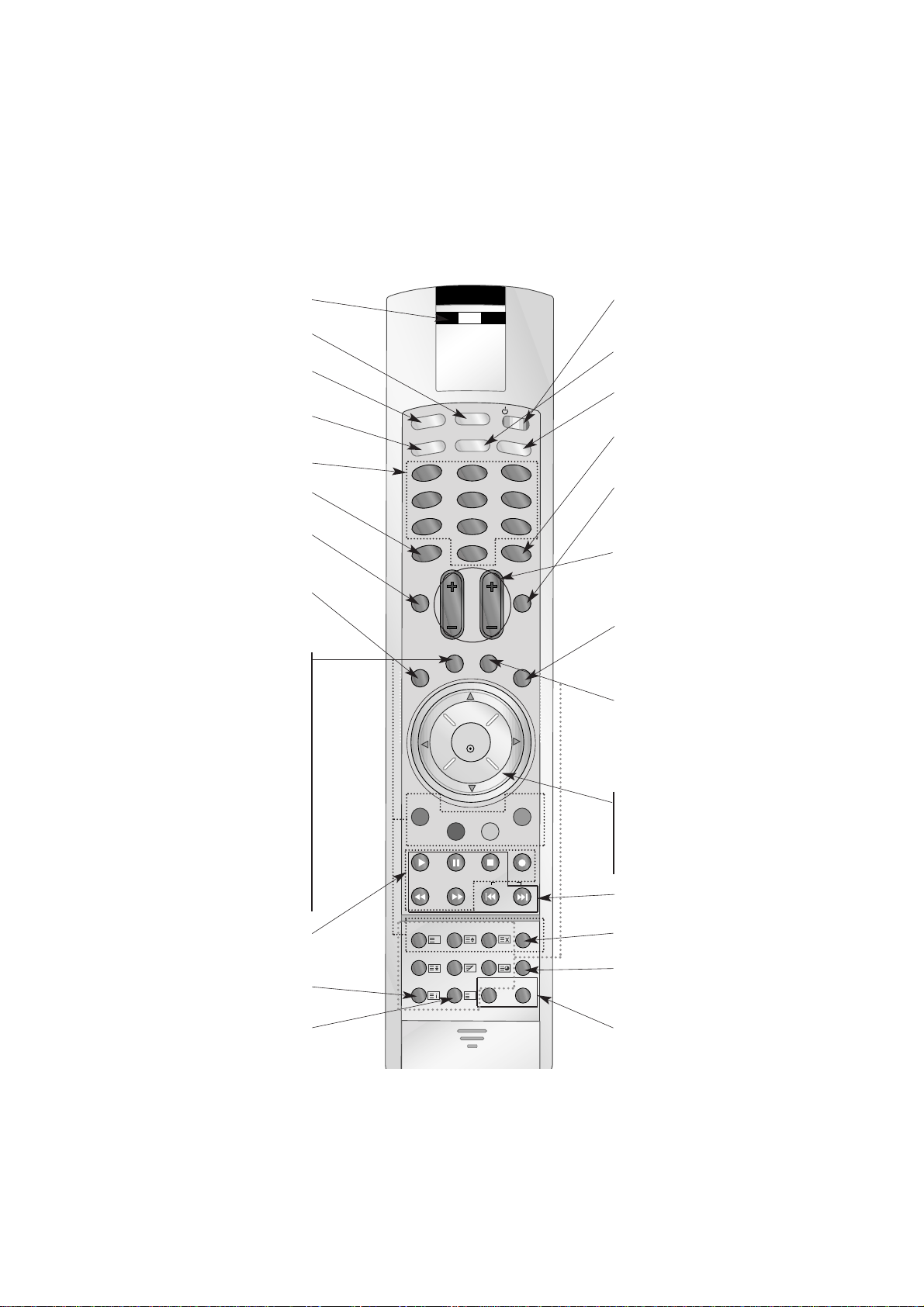

DESCRIPTION OF CONTROLS

123

456

789

0

DVD

STB

AUDIO

MODE

POWER

MUTE

TV/AV

MULTIMEDIA

ARC

SSM

Q.VIEW

PSM

FAVOURITE

MENU

PIP PR-

PIP ARC

LIST

PLAY

REW FF SKIP

PAUSE STOP

RECORD

ZOOM- ZOOM+

SPLIT ZOOM

SLEEP

I/II

WIN.SIZE

WIN.POSITION

PIP INPUT

PIP PR+ SWAP

OK

PIP/DW TEXT

EXIT

PR

VOL

CABLE

VCR

?

M

TV

Displays the selected device.

TV/AV

Selects the TV, AV, Component, RGB

or DVI modes.

MODE

Selects another device.

NUMBER buttons

PIP/DW

Switches the sub picture on or off.

Selects PIP or DW modes.

PIP PR + /-

Selects a program for the sub picture.

SWAP

Alternates between main and sub pic-

ture.

PIP INPUT

Selects the input mode for the sub pic-

ture.

WIN.SIZE

Adjusts the sub picture size.

WIN.POSITION

Moves the sub picture to

DD/ EE

or FF/

GG

direction.

PIP ARC

Changes the picture format for the

sub picture.

OK

accepts your selection or displays the

current mode.

DD/ EE

or FF/

GG

Adjusts menu settings.

Selects menu item.

POWER

switches the set on from standby or

off to standby.

ARC

Changes the picture format.

MUTE

Switches the sound on or off.

Q.VIEW

Returns to the previously viewed

programme.

SSM

To select the sound appropriate to

your viewing programme character.

VOL +/- (Volume Up/Down)

Increases/decreases sound level.

PR +/- (Programme Up/Down)

selects a programme.

EXIT

Clears all on-screen displays and

returns to TV viewing from any

menu.

DVD BUTTONS

Controls a LG DVD player.

SLEEP

Sets the sleep timer.

I/II

Selects the language during dual language broadcast.

Selects the sound output.

ZOOM+ / ZOOM-

Enlarges or reduces the main picture

size.

TEXT

These buttons are used for teletext.

For further details, see the ‘Teletext’

section.

Note : In teletext mode, the PIP PR

+/-, SWAP and PIP INPUT buttons are

used for teletext function.

MULTIMEDIA

Selects the Component, RGB or DVI

modes.

FAVOURITE

selects a favorite programme.

PSM

Adjusts the factory preset picture

according to the room.

MENU

Displays on screen menus one by one.

Exits the current menu.

Memorizes menu changes.

VCR BUTTONS

Controls a LG video cassette

recorder.

LIST

Displays the program table.

SPLIT ZOOM

Enlarge the screen with regular

ration.

Page 5

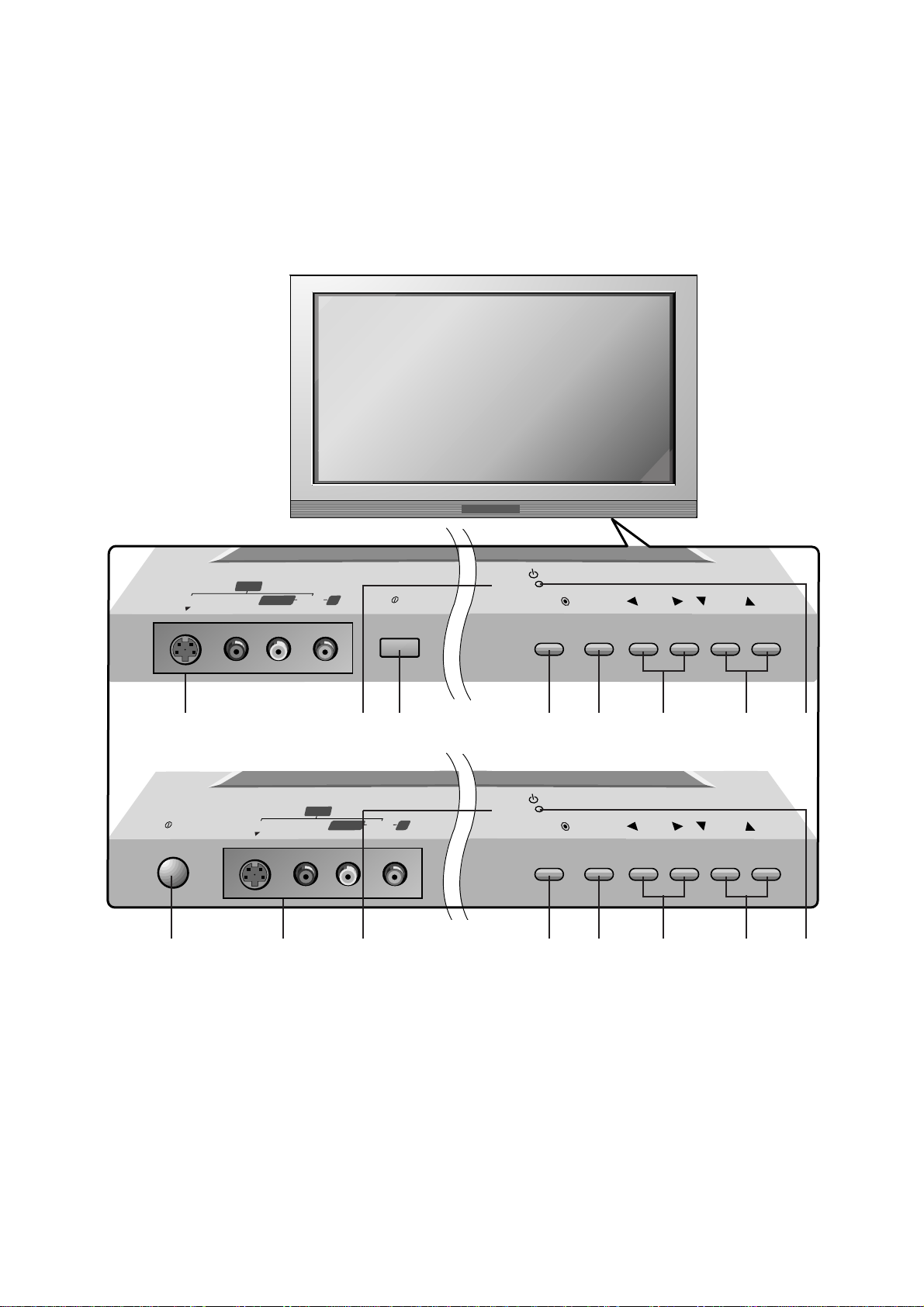

- 5 -

1.

AUDIO/VIDEO IN SOCKETS

S-VIDEO/AUDIO IN SOCKETS

2.

Remote Control Sensor

3. Main Power Button

4. TV/AV Button

Selects the TV, AV, Component, RGB or DVI modes.If OSD is

displayed, selects menu item.

5. MENU Button

6.

FF/ GG

(Volume Up/Down) Buttons

7.DD/EE(Programme Up/Down) Buttons

8. Power Standby Indicator

Illuminates red in standby mode, Illuminates green when the

set is turned on

<Front Panel Controls>

ON/OFFS-VIDEO VIDEO AUDIO

L/MONO

AV4

R

TV/AV

MENU

VOL

PR

S-VIDEO VIDEO AUDIO

L/MONO

AV4

R

TV/AV

MENU

VOL

PR

ON/OFF

- Shown is a simplified representation of the set.

- Here shown may be somewhat different from your set.

1 2 3 4

or

5 6 7 8

1 23 4 5 6 7 8

Page 6

- 6 -

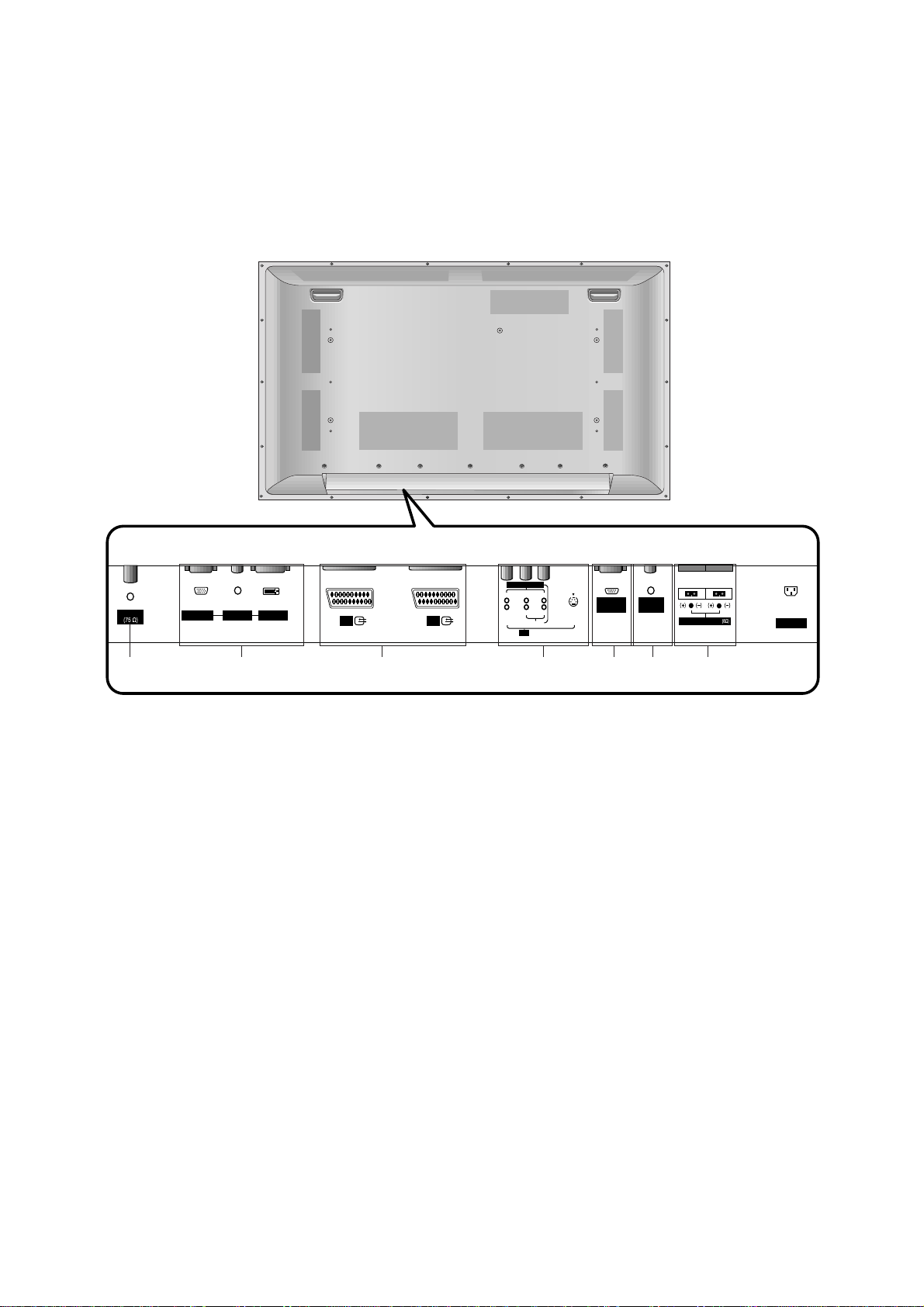

Location and Function of Controls

Location and Function of Controls

<Back Panel>

Antenna

RGB INPUT DVI INPUT

AV1

AUDIO INPUT

AV2

COMPONENT

AV3

Y P

B

L

(MONO)

AUDIO S-VIDEOVIDEO

R

P

R

RS-232C INPUT

EXTERNAL SPEAKER

R L

CONTROL

REMOTE

(CONTROL/SERVICE)

AC INPUT

1. ANTENNA INPUT

2. RGB INPUT / AUDIO INPUT / DVI INPUT

Connect the monitor output socket of the PERSONAL COMPUTER to this socket.

3. EURO SCART SOCKET

Connect the euro scart socket of the VCR to these sockets.

4. COMPONENT INPUT

AUDIO/VIDEO IN SOCKETS (AV3)

Connect the audio/video out sockets of external equipment to

these sockets.

S-VIDEO/AUDIO IN SOCKETS

Connect the S-VIDEO out socket of an VCR to the S-VIDEO

socket.

Connect the audio out sockets of the VCR to the audio sockets as in AV3.

5. RS-232C INPUT(CONTROL/SERVICE) PORT

Connect to the RS-232C port on a PC.

6. CONTROL LOCK / REMOTE CONTROL

7. EXTERNAL SPEAKER OUTPUT (8 ohms)

Connect to optional external speaker(s).

* For further information, refer to ‘Speaker & Speaker Stand’

manual.

1 2 3 4 5 6 7

Page 7

- 7 -

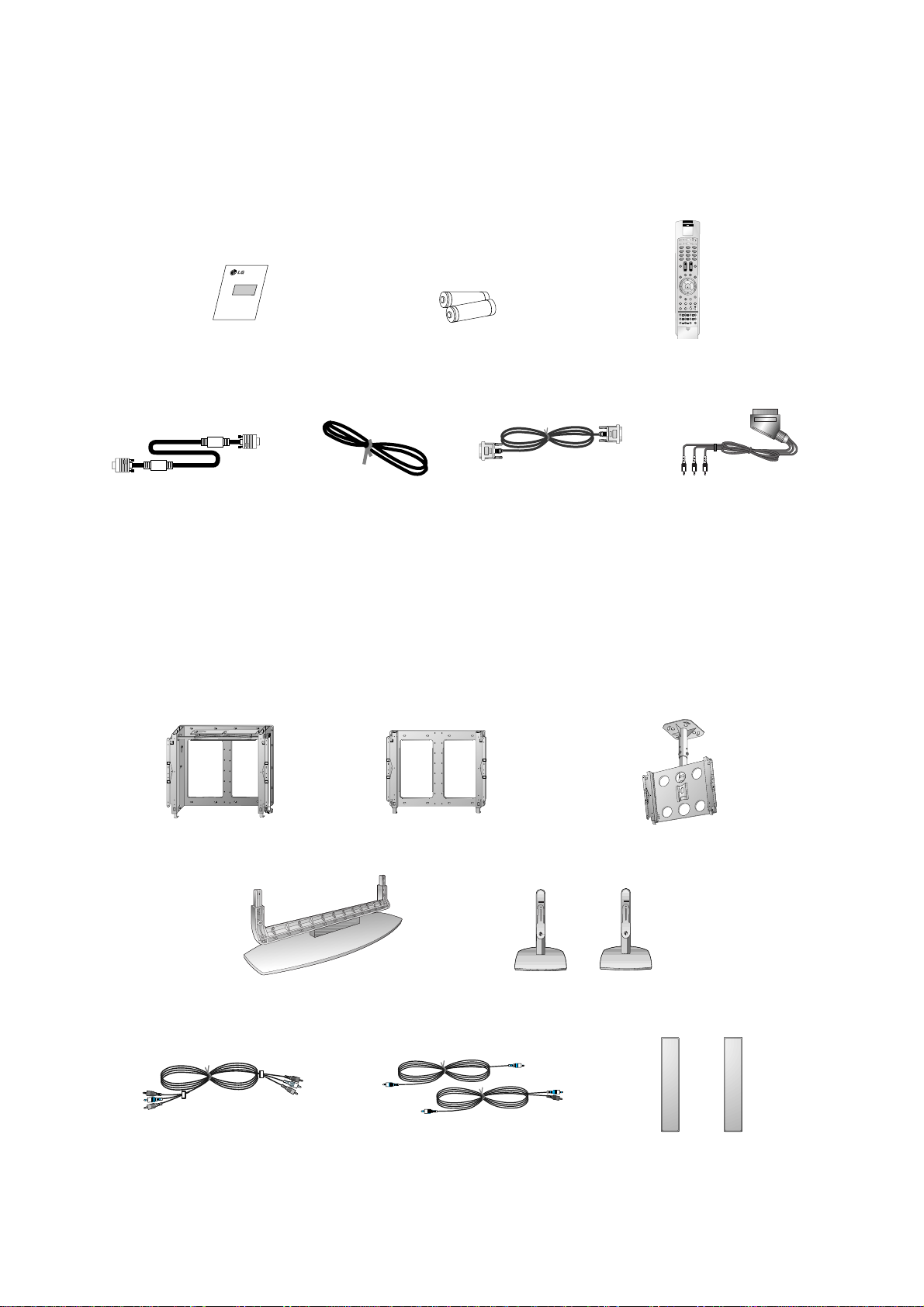

D-sub 15 pin cable

AS mark

LG TV

Owner’s Manual

1.5V

1.5V

Alkaline batteries

Power Cord

1 2 3

4 5 6

7 8 9

0

DVD

STB

AUDIO

MODE

POWER

MUTE

TV/AV

MULTIMEDIA

ARC

SSM

Q.VIEW

PSM

FAVOURITE

MENU

PIP PR-

PIP ARC

LIST

PLAY

REW FF SKIP

PAUSE STOP

RECORD

ZOOM- ZOOM+

SPLIT ZOOM

SLEEP

I/II

WIN.SIZE

WIN.POSITION

PIP INPUT

PIP PR+ SWAP

OK

PIP/DW TEXT

EXIT

PR

VOL

CABLE

VCR

?

M

TV

Remote Control handset

DVI-D Cable

Accessories

- Optional extras can be changed or modified for quality improvement without any notification new optional extras can be

added.

- Contract your dealer for buying these items.

Optional Extras

Phone scart cable (Optional)

Tilt wall mounting bracket

Video cables Audio cables

Desktop stand

Wall mounting bracket Ceiling mounting bracket

Speakers

Desktop Speaker stand

Page 8

- 8 -

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Scope

This specification can be applied to all model of 50”PDP TV related to RF-03OB Chassis.

V Test Condition

1) Temperature : 25±5°C (77±9°F)

2) Relative Humidity: 65±10%

3) Power Voltage:Standard Input Voltage

(AC 110V-240V~, 50/60Hz)

But Standard input voltage mark value is marked by model.

4) Follow each drawing or spec for spec and performance of parts,based upon P/N of RPL

5)

Warm up set for more than 20min before the

measurement.

V Test and Inspection Method

1) Performance : Follow the Standard of LG TV test

2) Extra standards

Safety: Follow the standard of CE, IEC

EMC : Follow the standard of CE, IEC

Remark

Safety : IEC60065, IEC60095

EMI : EN55013

EMS : EN55020

Safety : IEC60065, IEC60095

EMI : EN55013

Model Name

RZ-42PZ70

RT-42PZ70

Market

EU

N-EU

Chassis

RF-03OA

Model Name

RZ-50PZ60/70

RT-50PZ60/70

Market Place

EU

N-EU

Brand

LG

LG

Page 9

1. Application Object

These instructions are applied to all of the PDP monitor/

Tuner , RF-03OB chassis.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220V, 60Hz in

adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

¤ After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEATRUN mode)

¤ŁEnter into HEAT-RUN mode

- Select the HEAT-RUN OFF by pressing ADJ Key on

Remote Control for adjustment.

- Press the VOL + Key in HEAT-RUN OFF.

(OSD display HEAT-RUN WHITE and screen display

100% FULL WHITE PATTERN)

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

If you turn on a still screen more than 20 minutes, a

afterimage may be occur in the black level part of the

screen.

3. Board Adjustment Method

<Channel memory>

(1) Input the power to VSC board.

(2) Connect the PC for channel memory work to VSC board

whit RS-232C.

(3) Execute the program for channel memory that fit each

BOM

- Method to execute program for channel memory

¤ Click the “CHANNEL(RF03OA_B).EXE” to execution.

¤ŁSelect the setting PORT of PC in”SELECT PORT” and

then click the “SELECT PORT”.

¤ØClick the “DOWN LOAD TO E2PROM”

¤ŒClick the “OPEN“ in FILE NAME

¤ºClick a suitable data on BOM.

¤ºClick the “ENTER”

¤ Show the channel memory.

¤ When the channel memory is finished, divide the RS-

232C CABLE in VSC BOARD.

¤ In case VSC BOARD of same BOM, connect the RS-

232C CABLE and then repeat ¤º~¤ by same method.

4. RGB Auto Cut-Off & MIN Bia

Adjustment

(1) Input Full White (255 Gray) signal which generated from

Pattern Generator into RGB1 Input part.

(2) Press POWER ON KEY on R/C for adjustment and select

AUTO-CUT(Cut-off Auto Adjustment)

(3) Press Vol. + key and operate TO SET

(4) Screen adjustment starts with Full Black screen.

Original Full White screen will be presented about 3-5

seconds later. And if there is a mark of OK OSD, then the

Auto Cut-off and Min-Bias adjustment will be completed.

(5) Pass to the next MAX Bias Adjustment after Adjustment.

O You can check whether circuit adjustment is operated well or

not, as below.

(1) Display RGB to the Main picture, AV to the Sub picture in

the TWIN PICTURE.

(2) To check the MIN-Bias, input Full Black (0 gray) signal into

AV and RGB input part at the same time in the Pattern

Generator.

(3) To check the MAX-Bias, input Full White (255 gray) signal

into AV and RGB input part at the same time in the Pattern

Generator.

(4) Compare Black Level with White Level by eyes. And if

there is no Level difference, the adjustment is completed

well.

O Data value, which adjusted in the board, is valid until the VSC

Board is disuse and must be protected. For the protection of

data, Micom does not permit any more adjustment after

completion.

O In case of re-adjustment, operate First Value Setting.

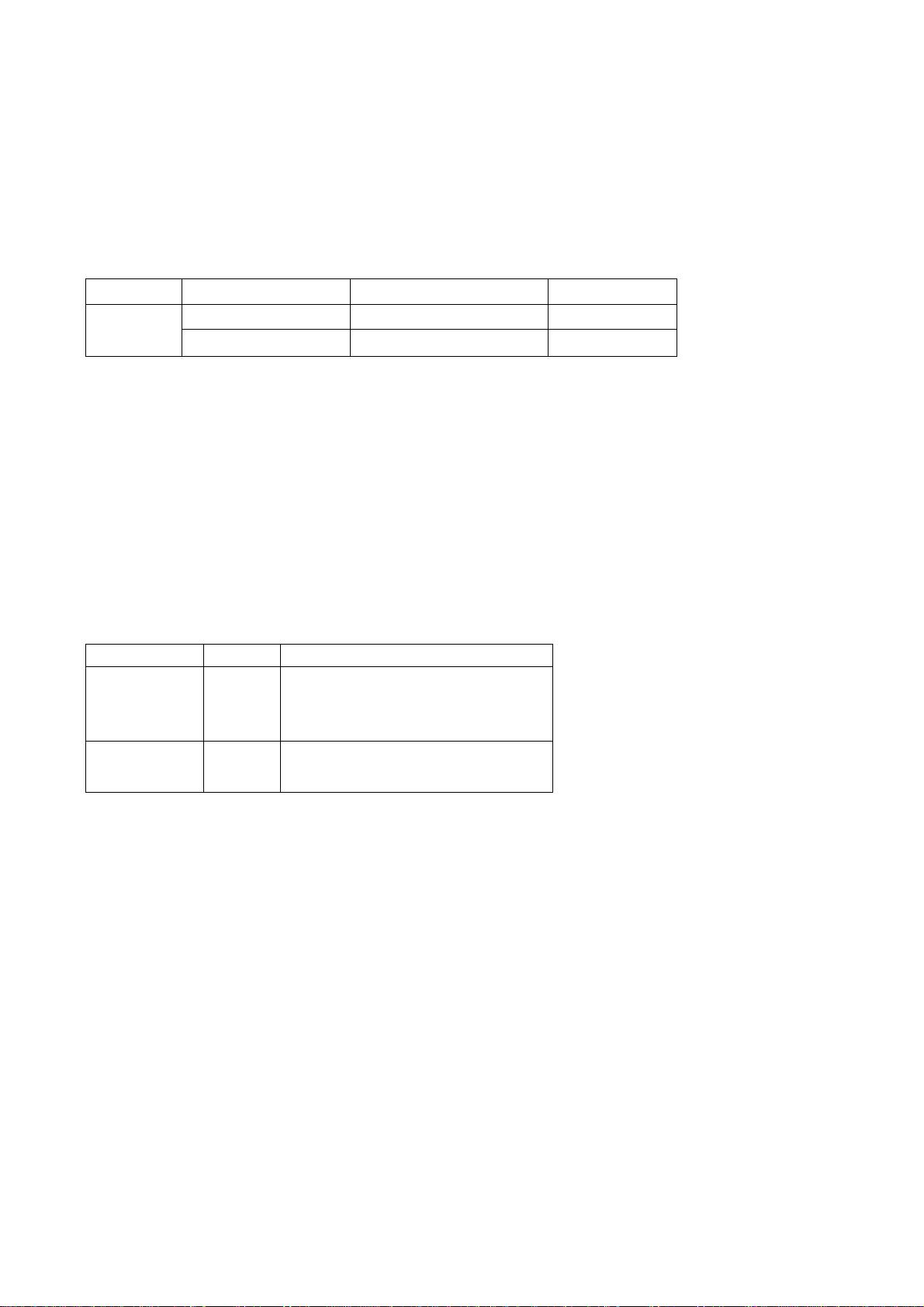

5. POWER PCB Assy Voltage

Adjustment (Va, Vs, Voltage Adjustment)

5-1. Test Equipment

: D.M.M 1EA

5-2. Connection Diagram for Measuring

: refer to<fig 1>

5-3. Adjustment Method

(1) Va Adjustment

¤ After receiving 100% white pattern, HEAT RUN.

¤Ł Connect + terminal of D.M.M to Va pin of P805 and

connect – terminal to GND pin of P805.

¤Ø After turning the VR351, voltage of D.M.M adjustment

as same as Va voltage which on label of panel

Right/Top. (Deviation : ±0.5V)

- 9 -

ADJUSTMENT INSTRUCTIONS

Each PCB Assy must be checked by the Check JIG Set before

whole assembly. (Be careful the POWER PCB Assy not to

damage to PDP Module)

Page 10

(2) Vs Adjustment

¤ Connect + terminal of D.M.M to Vs pin of P805 and

connect – terminal to GND pin of P805.

¤Ł After turning the VR551, voltage of D.M.M adjustment

as same as Vs voltage which on label of panel

Right/Top. (Deviation : ±0.5V)

(3) 5.2V Adjustment

¤ Connect + terminal of D.M.M to 5V pin of P804 and

connect – terminal to GND pin of P804.

¤Ł Turning VR251, adjust the volt value to 5.2v value.

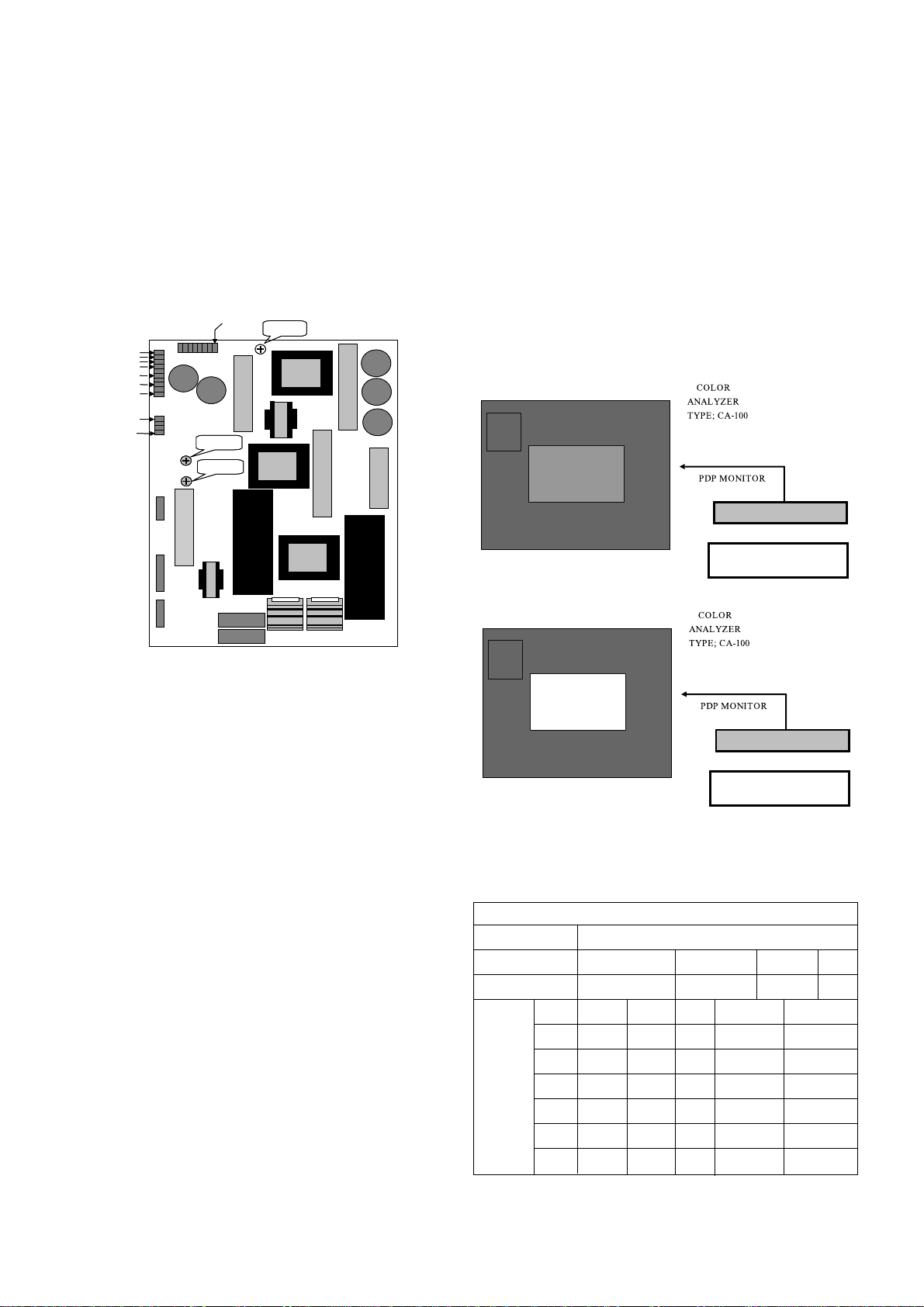

6. Adjustment of White Balance

6-1. Required Equipment

Color analyzer (CA-100 or same product)

6-2. Connection Diagram of Equipment for

Measuring (Manual Adjustment)

: refer to <fig 2>,<fig 3>

6-3. Adjustment of White Balance

O Operate the Zero-calibration of the CA-100, then stick

sensor to PDP module surface when you adjust.

O For manual adjustment, it is also possible by the following

sequence.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

POWER ON KEY on remote control for adjustment then

operate HEAT RUN more than 15 minute.

(2) Supply 70Gray, 216Gray Level, 100% size length and

breadth signal to AV input. (Refer to <fig 2>,<fig 3>)

RZ-50PZ60/70 : AV3, RT-50PZ60/70 : AV1

(3) White balance is adjusted from Low Light to High Light,

And pushing the V key, save the adjustment value.

(4) LOW Light, stick sensor to 70Gray Pattern and then press

ADJ Key on R/C for adjustment and press

D, E on R/C in

adjustment mode to select R-L or G-L, press VOL +, - Key

and adjust it until color coordination becomes as below.

[RZ-50PZ60/70, RT-50PZ60/70]

X: 0.285±0.003, Y: 0.285±0.003

Color temperature: 9,700°K±500°K

(5) High Light, stick sensor to 216Gray Pattern and then press

ADJ Key on R/C for adjustment and press

D, E on R/C in

adjustment mode to select R-H or G-H, press VOL +, - Key

and adjust it until color coordination becomes as below.

[RZ-42PZ70, RT-42PZ70]

X: 0.285±0.003, Y: 0.285±0.003

Color temperature: 9,700°K±500°K

(6) Exit adjustment mode using V Key.

7.

Map for Auto adjustment (RS-232C)

- 10 -

Va ADJ

VR351

Vs ADJ

VR551

CN 804

P805

P804

P803

P802

P801

VS

Va

Va

GND

GND

VS

VS

5V

GND

Va ADJ

VR251

<Fig 1> Connection Diagram for Measuring of Power Adjustment

Typ

Baud Rate

1150200

Index

R-L

G-L

R-H

G-H

Data bit

8

Cmd1 Cmd2

j j

j k

j a

j b

Stop bit1Parity

NONE

RF-03OB_PDP50

Protocol

Setting

Data Min Value

54(36)

54(36)

180(B4)

170(A4)

Max Value

90(5A)

85(FA)

254(FE)

250(FA)

RS232

R-L 70 R-L 70

G-L 70 G-L 70

R-M 128 R-M 128

G-M 128 G-M 128

R-H 216 R-H 216

G-H 216 G-H 216

Window

MSPG-2100 or

MSTG-5200

RGB Signal Input

High Light adjustment

70 Gray Level

<Fig 2> Low Light(Connection Diagram of Manual Adjustment)

R-L 70 R-L 70

G-L 70 G-L 70

R-M 128 R-M 128

G-M 128 G-M 128

R-H 216 R-H 216

G-H 216 G-H 216

Window

MSPG-2100 or

MSTG-5200

RGB Signal Input

High Light adjustment

216 Gray Level

<Fig 3> High Light (Connection Diagram of Manual Adjustment)

Page 11

- 11 -

8. Adjustment of Component Off-Set

8-1. Required Test Equipment

: HD-STB(SK-010T) or same product

8-2. Manual Adjustment of Component Off-

Set

(1) Input Video signal and Component 720P,1080i signal of

HD-STB.

(2) Press ADJ key of R/C twice for entering twin picture mode.

(3) Adjust the same color senses between main and sub,

using Volume +; -key of R/C in R, G, B Off-Set menu.

9. DDC Data input

9-1. Required Test Equipment

(1) A jig for adjusting PC, DDC. (PC serial to D-sub

Connection equipment)

(2) S/W for writing DDC(EDID data write & read)

(3) D-Sub 15P cable, D-Sub to DVI Connector (Connect to

DVI Jack)

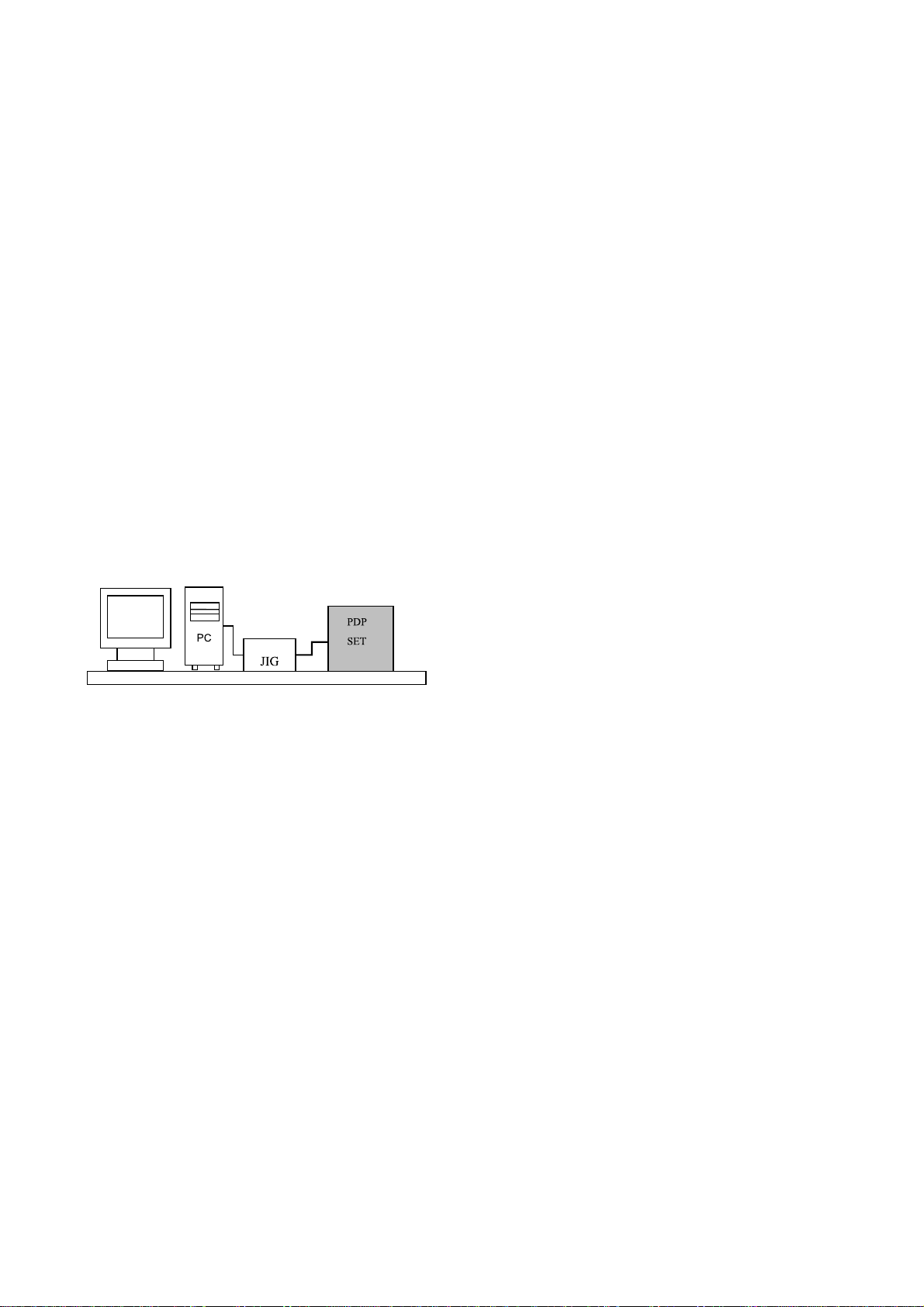

9-2. Setting of Device

9-3. Preparation for Adjustment

(1) Set devices as above and turn the PC, jig on.

(2) Put S/W for writing DDC (EDID data write & read) into

operation. (operated in DOS mode.)

9-4. Sequence of Adjustment

(1) DDC Data Input for Analog-RGB

¤ Put the set on the table and turn the power on.

¤ŁConnect PC Serial to D-sub 15P Cable of JIG for DDC

Adjustment to RGB terminal (D-Sub 15Pin).

¤Ø Operate S/W for DDC record and select DDC Data for

Analog RGB in Model Menu.

¤Œ Operate EDID Write command.

¤º Operate EDID Read command and check whether

Check Sum is OK.

¤ If Check Sum is NG, repeat ¤Ø~ ¤Œ.

¤ If Check Sum is OK, DDC Data for Analog-RGB input is

completed.

(2) DDC Data input for Digital-RGB

¤ Connect PC Serial to DVI Cable of JIG for DDC

Adjustment to RGB2 terminal (DVI Jack).

¤Ł Operate S/W for DDC record and select DDC Data for

Digital RGB in Model Menu.

¤ØOperate EDID Write command.

¤Œ Operate EDID Read command and check whether

Check Sum is OK.

¤ºIf Check Sum is NG, repeat ¤Ø~ ¤Œ.

¤ If Check Sum is OK, DDC Data for Digital-RGB input is

completed.

* If you change the Booster 0 to 1 in a fringe area, a

user ca set to Booster “On”.

Page 12

- 12 -

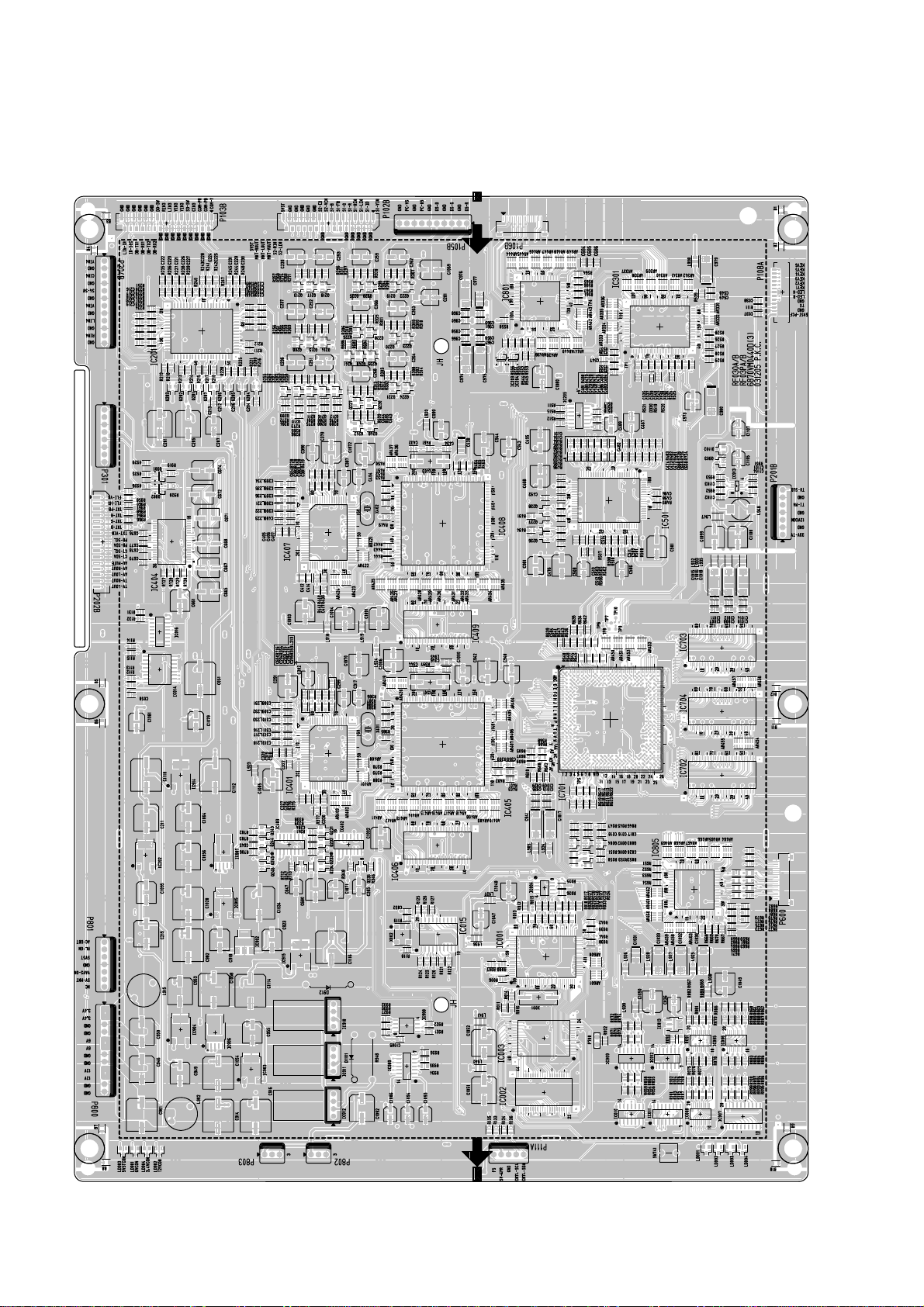

MAIN (TOP)

PRINTED CIRCUIT BOARD

Page 13

- 13 -

MAIN (BOTTOM)

Page 14

- 14 -

REAR AV (TOP) REAR AV (BOTTOM) FRONT AV (TOP)

FRONT AV (BOTTOM)

POWER SWITCH

Page 15

- 15 -

PREAMP (BOTTOM)

PREAMP (TOP)

SPEAKER (TOP)

SPEAKER (BOTTOM)

Page 16

- 16 -

TUNER (TOP)

Page 17

- 17 -

TUNER (BOTTOM)

Page 18

- 18 -

BLOCK DIAGRAM

cable

Page 19

MEMO

- 19 -

Page 20

- 20 -

EXPLODED VIEW

301

303

302

300

305

400

203

200

213

202

210

208

209

207

206

211

580

304

581

410

430

101

440

420

570

540

550

551

552

401

530

531

590

532

520

524

560

523

525

522

102

103

Page 21

- 21 -

EXPLODED VIEW PARTS LIST

101 5900V12001A FAN,DC G1225S12B2 DONGYANG 12X12X25 12V130MA 1500 168GM MOTOR L=260

102 4980V01017A SUPPORTER,FAN EGI RIGHT PDP DN-50PY10

103 4980V01018A SUPPORTER,FAN EGI LEFT PDP DN-50PY10

200 6348Q-C033S PDP,50 16:9 1365*768 PDP50X20330.AKLGG

201 6871QRH035B PWB(PCB) ASSEMBLY,DISPLAY XRRT ASSY HAND INSERT 50X2 BARE PCB

202 6871QPH008A PWB(PCB) ASSEMBLY,DISPLAY DCDC ASSY HAND INSERT KK MODEL

203 6871QZH031A PWB(PCB) ASSEMBLY,DISPLAY ZSUS ASSY HAND INSERT 50KK 2LAYER

205 6871QLH032B PWB(PCB) ASSEMBLY,DISPLAY XRLT ASSY HAND INSERT 50X2 BARE PCB 352.5 X 280

206 6871QXH021B PWB(PCB) ASSEMBLY,DISPLAY XRCB ASSY HAND INSERT 50X2 BARE PCB

207 6871QLH033B PWB(PCB) ASSEMBLY,DISPLAY XRLB ASSY HAND INSERT 50X2 BARE PCB 352.5 X 280

208 6871QDH049A PWB(PCB) ASSEMBLY,DISPLAY YDRV ASSY HAND INSERT 50WXDP2 4L(BTM)

209 6871QYH028A PWB(PCB) ASSEMBLY,DISPLAY YSUS ASSY HAND INSERT 50KK 4LAYER

210 6871QDH048A PWB(PCB) ASSEMBLY,DISPLAY YDRV ASSY HAND INSERT 50WXDP2 4L(TOP)

211 6871QRH036B PWB(PCB) ASSEMBLY,DISPLAY XRRB ASSY HAND INSERT 50X2 BARE PCB

212 6871QXH020B PWB(PCB) ASSEMBLY,DISPLAY XRCT ASSY HAND INSERT 50X2 BARE PCB

213 6871QCH028C PWB(PCB) ASSEMBLY,DISPLAY CTRL ASSY HAND INSERT 50X2 TMDS FOR 4022H

300 3091V00B68D CABINET ASSEMBLY,RT-50PZ60 NON RF03OB NON

3091V00B69E CABINET ASSEMBLY,RT-50PZ70 NON RF03OB NON

301 4980V00634A SUPPORTER,FILTER AL DN-50PZ60 TOP

302 4980V00636A SUPPORTER,FILTER AL DN-50PZ60

4980V00636B SUPPORTER,FILTER AL DN-50PZ70

303 4980V00637A SUPPORTER,FILTER AL DN-50PZ60 SIDE

304 4980V00374A SUPPORTER,MODULE EGI CENTER,MN-50PZ40

305 3790V00683C FILTER(MECH), - MN-50PZ41 1150G03EK NBK 50 MESH SINGLE GLASS FILTER

400 3809V00B03A BACK COVER ASSEMBLY,DN-50PZ60 NON NON

401 3301V00014E PLATE ASSEMBLY, AV 3300V00244 RP-50PZ60 C/SKD

410 4980V00790A SUPPORTER,MODULE AL DIE-CASTING DN-50PZ60 SUPP_MODULE ASSY

420 4980V00790B SUPPORTER,MODULE AL DIE-CASTING DN-50PZ60 SUPP.MODULE ASSY(R)

430 4980V00791C SUPPORTER,FAN EGI PRESS

440 4980V00792C SUPPORTER,FAN EGI PRESS

520 6871VMMS50A PWB(PCB) ASSEMBLY,MAIN RF-03OB 50KK ANALOG BUILT IN VSC B/D

6871VMMS49A PWB(PCB) ASSEMBLY,MAIN RF-03OB RT 50KK ANALOG BUILT IN VSC B/D

522 4814V00424A SHIELD,RZ-42PZ70 RF03OA ET ANALOG 2 TUNER TOP

523 4980V00641A SUPPORTER,NON SECC VSC_BOTTOM

524 4980V00642D SUPPORTER,VSC AL .

525 4814V00425A SHIELD,RZ-42PZ70 RF03OA ET ANALOG 2 TUNER BOTTOM

530 6871VSMF08A PWB(PCB) ASSEMBLY,SUB PSW AF03BA BUILT IN PDP

531 5020V00457A BUTTON, KEY BUTTON POWER FD-36X3

532 4810V00737A BRACKET,AV DN-50PZ60 AB00EA ABS, AF-303S PDP

540 6871VSMY20A PWB(PCB) ASSEMBLY,SUB A/V RF03OA RT-42PZ70 KK ANALOG 2TUNER B-IN

550 6871VSMX09A PWB(PCB) ASSEMBLY,SUB SPK RF03OB PDP 50 KK ANALOG BUILT IN SPEAKER B/D

551 4980V00647A SUPPORTER,NON AL DN-50PZ60 REAR A/V

552 4980V00962B SUPPORTER,NON SECC(EGI) RZ-50PZ70

560 6871VSMY70A PWB(PCB) ASSEMBLY,SUB,TUNER RF03OA RT SDA6001 42 50 PDP

570 6871VSMX31A PWB(PCB) ASSEMBLY,SUB,CONT RF03OB 50 KK ANALOG BUILT IN RZ-50PZ60/70

580 3501V00084D BOARD ASSEMBLY,POWER MN50PZ10 RF03GB SRX-75 SONY 50KK

581 3720V00237B PANEL,ASSY RZ-50PZ60 VFD 16ML07HA1 SDI VFD

590 6871VSMX08A PWB(PCB) ASSEMBLY,SUB A/V RF03FB 50 KK ANALOG BUILT IN FRONT B/D

No.

Description

Part No.

Page 22

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC704

IC801

IC805

IC902

IC903

IC904

IC905

IC906

IC907

IC908

IC909

IC910

IC911

IC912

IC913

IC914

IC915

IC203

IC204

Q001

Q001

Q001

Q002

Q002

Q002

Q003

Q003

Q004

Q004

Q005

Q006

Q101

Q102

Q103

Q104

Q105

Q106

Q107

Q108

Q109

Q110

Q201

Q202

Q203

Q204

Q205

Q206

Q207

Q208

Q209

Q210

0IMMRHY033A

0IPRPTI001A

0IS5160000A

0IMCRSJ001A

0IMCRFA010A

0IMCRRH001A

0IMCRRH001A

0IMCRSH001A

0IMCRSH001A

0IDS162100B

0IMCRPH015A

0IMCRKE007A

0ISS278120A

0IMCRKE007A

0ITK118100B

0IMCRRH001A

0IMCRRH001A

0TR830009BA

0TR830009BA

0TR387500AA

0TR387500AA

0TR830009BA

0TR387500AA

0TR387500AA

0TR830009BA

0TR387500AA

0TR830009BA

0TR387500AA

0TR830009BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

HY57V643220C(L)T-6 HYNIX 86P TSOP

TFP401PZP 100,TQFP

SIL160CT100 SILICON IMAGE 100 TQFP

SC1565IST-1.8 SEMTECH 3P SOT223

KA7809R, FAIRCHILD 2P D-PAK

BA033FP-E2 ROHM 3P-SOP,TO252-3

BA033FP-E2 ROHM 3P-SOP,TO252-3

PQ05DZ1U SHARP 5, SMD TYPE

PQ05DZ1U SHARP 5, SMD TYPE

DS1621V 8P SOIC ST THERMOSTAT

74LVC32AD PHILIPS 14P SOT108-1

KIA278R09PI KEC TO220IS,4P ST 2A

KA278R12 4P,TO-220F

KIA278R09PI KEC TO220IS,4P ST 2A

TK11840L 8P SOT23L

BA033FP-E2 ROHM 3P-SOP

BA033FP-E2 ROHM 3P-SOP

BSS83 TP PHILIPS

BSS83 TP PHILIPS

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83 TP PHILIPS

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83 TP PHILIPS

CHIP 2SC3875S(ALY) KEC

BSS83 TP PHILIPS

CHIP 2SC3875S(ALY) KEC

BSS83 TP PHILIPS

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

LOCA. NO PART NO DESCRIPTION

IC001

IC001

IC002

IC002

IC003

IC003

IC003

IC004

IC004

IC005

IC005

IC006

IC006

IC007

IC007

IC008

IC009

IC010

IC011

IC012

IC013

IC014

IC015

IC016

IC101

IC107

IC201

IC201

IC202

IC202

IC203

IC205

IC301

IC401

IC402

IC403

IC404

IC405

IC406

IC407

IC408

IC409

IC501

IC601

IC603

IC604

IC605

IC606

IC701

IC702

IC703

0IMCRMN023A

0IMCRRS001A

0IMMRHY001F

0IMMRSS064A

0IZZVA0087A

0IMMRSG028A

0IMMRMR006B

0IMCRAL006A

0IMMRAL025A

0IKE702700D

0IMCRFA013A

0ISJ111733A

0IMCRFA013A

0ISJ111725A

0ITI745740M

0IMCRPH017A

0IPH740800L

0IMCRPH015A

0IMCRPH016A

0IMCRPH014A

0IKE702700D

0IDS232000A

0IPH858400A

0IMCRTI001A

0IMI623200B

0ISA428200A

0ISO206900A

0IMCRTI003A

0IAL242110A

0IMCRFA010A

0IAL242110A

0IMCRTI003A

0IMCRAD003A

0IIT323000E

0IFA741230A

0IFA741230A

0IMCRMI006A

0IMCRGN001B

0IMMRHY033A

0IIT323000E

0IMCRGN002B

0IMMRHY033A

0ISO210100B

0IMCRMN004C

0IMCRFA009A

0IMCRFA015A

0IKE704200J

0IMCRSH001A

0IMCROT001B

0IMMRHY033A

0IMMRHY033A

SDA6001 QH B12 MICRONAS 128P

R8820LV RDC 100P PQFP

HY57V641620HGT-H HYNIX 54P

K6R4016V1D-TC10 44P

M37272E8A(OTP) DIP 42P ST

M27V160 STM 42P PDIP ST

MX29LV160ATTC-70 MACRONIX 48P

AT24C16AN-10SI-2.7 ATMEL 8P

AT24C32AN-10SI-2.7 ATMEL 8PIN

KIA7027AF 3, SOT-89 TP

74LCX244MTC FAIRCHILD 20P TSSOP

EZ1117CST-3.3 3P,SOT-223 TP 3.3V

74LCX244MTC FAIRCHILD 20P TSSOP

EZ1117ACST-2.5 3P SOT ST

SN74HC574NSR 14P,SOP

74LVC574APW PHILIPS 20P SOT360-1

74LVT08D 14SOP

74LVC32AD PHILIPS 14P SOT108-1

74LVC139D PHILIPS 16P SOT109-1

74LV132D PHILIPS 14P SOT108-1

KIA7027AF 3, SOT-89 TP

DS232AS 16P,SOP TP RS-232

PCF8584T 20P,SOP TP

SN74HCT157D TEXAS INSTRUMENT 16P

M62320FP,I/O EXPANDER 16P

LA4282 12S 2CHX10W

CXA2069Q QFP64 BK I2C

SN74HCT08D TEXAS INSTRUMENT 16P

AT24C21-10SI-2.5 8P,SOP TP 1K

KA7809R, FAIRCHILD 2P D-PAK

AT24C21-10SI-2.5 8P,SOP TP

SN74HCT08D TEXAS INSTRUMENT 16P

AD9888KS-140 ANALOG DEVICE 128P

VPC3230D C5 80P QFP

DM74LS123MX 16SOP TP

DM74LS123MX 16SOP TP

M52758FP MITSUBISHI 36PIN

FLI2310BC GENESIS 208P PQFP

HY57V643220C(L)T-6 HYNIX 86P TSOP

VPC3230D C5 80P QFP

FLI2300BC GENESIS 208P PQFP

HY57V643220C(L)T-6 HYNIX 86P TSOP

CXA2101AQ 80P,QFP BK

MSP3451G C12 MICRONAS 80P PQFP

KA78M08RTM, FAIRCHILD 2P D-PAK

KA7805R FAIRCHILD 2P D-PAK

KIA7042AF SOT-89 TP 4.2V

PQ05DZ1U SHARP 5, SMD TYPE

REMBRANT-102 352P PBGA

HY57V643220C(L)T-6 HYNIX 86P TSOP

HY57V643220C(L)T-6 HYNIX 86P TSOP

IC

TRANSISTOR

- 22 -

Page 23

- 23 -

LOCA. NO PART NO DESCRIPTION

Q211

Q212

Q213

Q214

Q215

Q216

Q217

Q218

Q219

Q220

Q221

Q222

Q223

Q224

Q225

Q226

Q227

Q228

Q229

Q230

Q231

Q232

Q233

Q234

Q235

Q236

Q237

Q238

Q239

Q240

Q241

Q242

Q243

Q244

Q245

Q246

Q247

Q248

Q249

Q601

Q602

Q603

Q604

Q605

Q606

Q901

Q902

Q903

D001

D002

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR388109AA

0TR388109AA

0TR388109AA

0TR388109AA

0TR388109AA

0TR388109AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR104009AF

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR104009AF

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR830009BA

0TR830009BA

0TRKE80038A

0DD226239AA

0DD226239AA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

KTC3881 CHIP KEC

KTC3881 CHIP KEC

KTC3881 CHIP KEC

KTC3881 CHIP KEC

KTC3881 CHIP KEC

KTC3881 CHIP KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC104S SOT-23 TP KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC104S SOT-23 TP KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

BSS83 TP PHILIPS

BSS83 TP PHILIPS

KTC3552T-RTK KEC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

LOCA. NO PART NO DESCRIPTION

D003

D004

D005

D006

D007

D008

D009

D010

D1101

D1102

D201

D207

D208

D209

D210

D211

D212

D213

D214

D215

D216

D217

D218

D219

D220

D221

D223

D225

D226

D227

D228

D229

D230

D601

D602

D603

D604

D904

D905

D906

D907

D908

D909

D910

D911

D912

LD001

LD001

LD002

LD003

LD004

LD901

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD100009AC

0DD184009AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD184009AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD110009DB

0DL200000CA

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

RU1V(1) TP SANKEN

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

RM11CV(1) TP SANKEN TP SANKEN

LED,SAM5670(DL-2LRG) BK Y-GREEN

LED,SAM2333 TP

LED,SAM2333 TP

LED,SAM2333 TP

LED,SAM2333 TP

LED,SAM2333 TP

DIODE

Page 24

- 24 -

LOCA. NO PART NO DESCRIPTION

LD902

LD903

LD904

ZD201

ZD202

ZD831

ZD832

ZD833

ZD834

C002

C004

C008

C009

C010

C011

C012

C020

C023

C026

C028

C030

C032

C034

C035

C036

C040

C044

C045

C046

C047

C051

C052

C1000

C1001

C1002

C1003

C1004

C1005

C1006

C101

C102

C1020

C103

C1034

C104

C104

C104

C104

C1047

C1048

0DL233309AC

0DL233309AC

0DL233309AC

0DZRM00178A

0DZRM00178A

0DR050008AA

0DR050008AA

0DR050008AA

0DR050008AA

0CE4763F618

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE105SK6DC

0CE106SF6DC

0CE476SF6DC

0CE106SF6DC

0CE105SK6DC

0CE106SF6DC

0CE107SF6DC

0CE107SF6DC

0CE106SF6DC

0CE106SF6DC

0CE477VF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE108DK61A

0CE108DK61A

0CE477WF6DC

181-120K

0CE477VF6DC

0CE476DF618

0CE474SK6DC

181-120K

0CE475SK6DC

0CE476SF6DC

0CE476SF6DC

LED,SAM2333 TP

LED,SAM2333 TP

LED,SAM2333 TP

UDZS TE-17 5.1B ROHM

UDZS TE-17 5.1B ROHM

SD05.TC R/TP SEMTECH

SD05.TC R/TP SEMTECH

SD05.TC R/TP SEMTECH

SD05.TC R/TP SEMTECH

47UF SRE 16V M FL TP5

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

1UF MVG 50V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

1UF MVG 50V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

470UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

1000UF STD 50V M FL TP7.5

1000UF STD 50V M FL TP7.5

470UF MVK 16V 20% SMD R/TP(SMD)

2200PF 4KV M E FMTW LEAD 4.5

470UF MV 16V 20% R/TP(SMD) SMD

47UF STD 16V M FL TP5

0.47UF MVG 50V M SMD R/TP

2200PF 4KV M E FMTW LEAD 4.5

4.7UF MVG 50V 20% SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

LOCA. NO PART NO DESCRIPTION

C1049

C105

C105

C1050

C1051

C1052

C1054

C1056

C1058

C106

C1064

C1069

C107

C107

C1070

C1071

C1072

C1079

C1080

C1081

C1086

C109

C1092

C1093

C1094

C1095

C1099

C110

C1100

C1105

C1107

C111

C1110

C1112

C1114

C1116

C113

C114

C116

C117

C118

C119

C119

C126

C129

C131

C134

C201

C205

C207

C211

C215

0CE107SF6DC

0CE476DF618

0CE108DK61A

0CE107SF6DC

0CE227VF6DC

0CE227VF6DC

0CE477WF6DC

0CE227WF6DC

0CE477WF6DC

0CE108DK61A

0CE227VF6DC

0CE107SF6DC

0CE106DK618

0CE477VF6DC

0CE107SF6DC

0CE476SF6DC

0CE107SF6DC

0CE476SF6DC

0CE107SF6DC

0CE476SF6DC

0CE106SF6DC

0CE227VF6DC

0CE227VF6DC

0CE105SK6DC

0CE105SK6DC

0CE107WF6DC

0CE107SF6DC

0CE477VF6DC

0CE107SF6DC

0CE475SK6DC

0CE475SK6DC

0CE477VF6DC

0CE477VF6DC

0CE477VF6DC

0CE477WF6DC

0CE477VF6DC

0CE227VF6DC

0CE477VF6DC

0CE475SK6DC

0CE477VF6DC

0CE106SF6DC

0CE474SK6DC

0CE475SK6DC

0CE477VF6DC

0CE477VF6DC

0CE107SF6DC

0CE475SK6DC

0CE227VF6DC

0CE227VF6DC

0CE476SF6DC

0CE227VF6DC

0CE227VF6DC

100UF MVG 16V M SMD R/TP

47UF STD 16V M FL TP5

1000UF STD 50V M FL TP7.5

100UF MVG 16V M SMD R/TP

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

470UF MVK 16V 20% SMD R/TP(SMD)

220UF MVK 16V 20% R/TP(SMD) SMD

470UF MVK 16V 20% SMD R/TP(SMD)

1000UF STD 50V M FL TP7.5

220UF MV 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

10UF STD 50V M FL TP5

470UF MV 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

1UF MVG 50V M SMD R/TP

1UF MVG 50V M SMD R/TP

100UF MVK 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

470UF MV 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

4.7UF MVG 50V 20% SMD R/TP

4.7UF MVG 50V 20% SMD R/TP

470UF MV 16V 20% R/TP(SMD) SMD

470UF MV 16V 20% R/TP(SMD) SMD

470UF MV 16V 20% R/TP(SMD) SMD

470UF MVK 16V 20% SMD R/TP(SMD)

470UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

470UF MV 16V 20% R/TP(SMD) SMD

4.7UF MVG 50V 20% SMD R/TP

470UF MV 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.47UF MVG 50V M SMD R/TP

4.7UF MVG 50V 20% SMD R/TP

470UF MV 16V 20% R/TP(SMD) SMD

470UF MV 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

4.7UF MVG 50V 20% SMD R/TP

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

CAPACITOR

Page 25

- 25 -

LOCA. NO PART NO DESCRIPTION

C231

C233

C236

C237

C239

C249

C250

C251

C251

C252

C253

C259

C262

C263

C264

C266

C268

C281

C284

C285

C291

C299

C300

C302

C307

C308

C309

C310

C311

C312

C313

C317

C320

C379

C387

C388

C390

C394

C395

C396

C397

C398

C399

C400

C404

C407

C467

C468

C476

C489

C495

C501

0CE476VF6DC

0CE476VF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE106VF6DC

0CE477VF6DC

0CE476SF6DC

0CE106VF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CN105EJ56A

0CE106SF6DC

0CE107SF6DC

0CE106SF6DC

0CK224DF56A

0CE106SF6DC

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CE106SF6DC

0CK224DF56A

0CE107SF6DC

0CE106SF6DC

0CK224DF56A

0CE106SF6DC

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CE106SF6DC

0CK224DF56A

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE105SK6DC

0CE107SF6DC

0CE107SF6DC

47UF MV 16V 20% R/TP(SMD) SMD

47UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

10UF MV 16V 20% R/TP(SMD) SMD

470UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

10UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

1.0UF 3216 35V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

220000PF 2012 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

220000PF 2012 16V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

220000PF 2012 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

220000PF 2012 16V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

1UF MVG 50V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

LOCA. NO PART NO DESCRIPTION

C506

C508

C601

C602

C604

C605

C606

C607

C608

C609

C610

C611

C612

C613

C614

C615

C617

C619

C621

C623

C632

C635

C636

C637

C638

C640

C645

C647

C653

C654

C655

C657

C658

C659

C660

C661

C661

C663

C665

C665

C667

C667

C668

C671

C672

C674

C680

C901

C908

C914

C916

C918

0CE106SF6DC

0CE106SF6DC

0CE227DK618

0CE227DK618

0CE107DH618

0CE106SF6DC

0CQ1521N509

0CE107DH618

0CQ1521N509

0CE106SF6DC

0CE107DH618

0CQ1041N509

0CE106SF6DC

0CE227VF6DC

0CQ1041N509

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CE335SK6DC

0CE106SF6DC

0CE107SF6DC

0CE106SF6DC

0CE106SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CN105EJ56A

0CE106SF6DC

0CE476SF6DC

0CE107SF6DC

0CE106SF6DC

0CE476SF6DC

0CE227DK618

0CE227DK618

0CE227DK618

0CE227DK618

0CE107SF6DC

0CE227VF6DC

0CE227VF6DC

0CE476XFKDC

0CE227VF6DC

0CE476XFKDC

0CE476XFKDC

0CE476XFKDC

0CE476XFKDC

0CE476XFKDC

0CE107SF6DC

0CE477VF6DC

0CN105EJ56A

0CE477WF6DC

0CE477VF6DC

0CE107WF6DC

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

220UF STD 50V M FL TP5

220UF STD 50V M FL TP5

100UF STD 25V M FL TP5

10UF MVG 16V 20% R/TP(SMD) SMD

0.0015UF D 100V 10% PE TP5

100UF STD 25V M FL TP5

0.0015UF D 100V 10% PE TP5

10UF MVG 16V 20% R/TP(SMD) SMD

100UF STD 25V M FL TP5

0.1UF D 100V 10% PE TP5

10UF MVG 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

0.1UF D 100V 10% PE TP5

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

3.3UF MVG 50V 20% SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

1.0UF 3216 35V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

220UF STD 50V M FL TP5

220UF STD 50V M FL TP5

220UF STD 50V M FL TP5

220UF STD 50V M FL TP5

100UF MVG 16V M SMD R/TP

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

47UF MVK-BP,CN 16V 20%,-20% SMD

220UF MV 16V 20% R/TP(SMD) SMD

47UF MVK-BP,CN 16V 20%,-20% SMD

47UF MVK-BP,CN 16V 20%,-20% SMD

47UF MVK-BP,CN 16V 20%,-20% SMD

47UF MVK-BP,CN 16V 20%,-20% SMD

47UF MVK-BP,CN 16V 20%,-20% SMD

100UF MVG 16V M SMD R/TP

470UF MV 16V 20% R/TP(SMD) SMD

1.0UF 3216 35V 10% R/TP X7R

470UF MVK 16V 20% SMD R/TP(SMD)

470UF MV 16V 20% R/TP(SMD) SMD

100UF MVK 16V 20% R/TP(SMD) SMD

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 26

- 26 -

LOCA. NO PART NO DESCRIPTION

C923

C940

C942

C943

C944

C946

C949

C950

C953

C955

C973

C981

C982

C999

AR001

AR002

AR330

AR332

AR333

AR334

AR335

AR336

AR337

AR338

AR339

AR340

AR341

AR342

AR400

AR401

AR402

AR403

AR404

AR405

AR406

AR407

AR408

AR409

AR410

AR411

AR412

AR413

AR414

AR415

AR416

AR417

AR418

AR421

AR422

AR423

0CE107WF6DC

0CE476SF6DC

0CE107SF6DC

0CE476SF6DC

0CE107SF6DC

0CE227VF6DC

0CE107WF6DC

0CE227VF6DC

0CE227WF6DC

0CE107WF6DC

0CE476SF6DC

0CE476SF6DC

0CE477WF6DC

0CE476SF6DC

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

100UF MVK 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

220UF MV 16V 20% R/TP(SMD) SMD

100UF MVK 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

220UF MVK 16V 20% R/TP(SMD) SMD

100UF MVK 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

470UF MVK 16V 20% SMD R/TP(SMD)

47UF MVG 16V M SMD R/TP

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

LOCA. NO PART NO DESCRIPTION

AR424

AR425

AR426

AR427

AR428

AR429

AR430

AR431

AR432

AR433

AR434

AR435

AR438

AR439

AR440

AR441

AR442

AR443

AR444

AR445

AR446

AR447

AR448

AR449

AR450

AR451

AR452

AR453

AR454

AR455

AR456

AR457

AR458

AR459

AR460

AR461

AR462

AR463

AR464

AR465

AR466

AR467

AR468

AR469

AR600

AR601

R105

R106

R601

R602

R610

R614

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001C

0RRZVTA001C

0RRZVTA001C

0RRZVTA001C

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RD4700H609

0RD4700H609

0RS2701K607

0RS2701K607

0RS0221H609

0RS0221H609

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

4.7K OHM 1 / 16 W 1608 5%

4.7K OHM 1 / 16 W 1608 5%

4.7K OHM 1 / 16 W 1608 5%

4.7K OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

470 OHM 1/2 W 5.00% TA52

470 OHM 1/2 W 5.00% TA52

2.7K OHM 2 W 5.00% TA62

2.7K OHM 2 W 5.00% TA62

2.2 OHM 1/2 W 5.00% TA52

2.2 OHM 1/2 W 5.00% TA52

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

RESISTOR

Page 27

- 27 -

LOCA. NO PART NO DESCRIPTION

R948

SW001

SW002

SW003

SW004

SW005

SW006

SW201

F101

F102

F103

L001

L002

L003

L004

L005

L006

L007

L008

L009

L010

L011

L012

L101

L102

L103

L103

L104

L104

L105

L106

L107

L108

L201

L202

L203

L204

L205

L206

L207

L208

L209

L210

L211

L212

L214

L215

L216

0RD0152H609

140-315A

140-315A

140-315A

140-315A

140-315A

140-315A

140-275A

6200VJS001A

6200VJS001B

6200VJS001B

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6210VC0006A

6210VC0006A

6200JB8010L

6210VC0006A

6200JB8010L

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

15 OHM 1/2 W 5.00% TA52

TACT SKHV17910B LG C&D NON 12V

TACT SKHV17910B LG C&D NON 12V

TACT SKHV17910B LG C&D NON 12V

TACT SKHV17910B LG C&D NON 12V

TACT SKHV17910B LG C&D NON 12V

TACT SKHV17910B LG C&D NON 12V

PUSH JDPB21SA EVLAND NON 30V 0.3A

ZJY51R5-4P TDK DIP DC 50VOLT 2A

ZJYS51R5-2PL(T) TDK R/TP 50VOLT 2A

ZJYS51R5-2PL(T) TDK R/TP 50VOLT 2A

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

MLB-201209-1000L-N2

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

MLB-201209-1000L-N2

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

LOCA. NO PART NO DESCRIPTION

L219

L220

L221

L224

L225

L226

L227

L228

L229

L229

L230

L230

L231

L232

L233

L234

L601

L602

L603

L606

L903

L904

L905

L906

L907

L908

L909

L910

L911

L912

L913

L914

L916

L917

L918

L919

L920

L921

L922

L923

L924

L925

L926

L927

L928

L929

L930

L931

L932

L933

L934

L935

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

BK2125 HS 750 2X1.25X0.85MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FILTER & CRYSTAL

SWITCH

Page 28

- 28 -

LOCA. NO PART NO DESCRIPTION

L936

L937

L938

L939

L940

L941

L942

L943

L944

L945

L947

R102

R103

R106

R107

R108

R110

R276

R277

R278

R279

R301

X001

X001

X401

X402

X403

X501

X601

JK103

JK105

JK107

JK109

JK112

JK113

JK201

JK202

JK203

A1

A2

A3

A3

A4

A5

A6

JK104

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6212AB2015C

6202VDT002K

6202VDB007B

6202VDB007B

6202VDT002J

6202VDT002J

156-A02M

6613V00004S

6612BBBHN6A

380-363G

380-068E

380-068E

6612JH003EB

6612VJH020B

6612VJH020C

6612VJH019B

3828VA0442A

6710V00116J

6410VBH003C

6410VSH001D

6410VCH001C

6850J00002A

6866VA9001B

6630VGA001C

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

FBMH3216 HM501NT 3.2X1.6X1.6MM R/TP

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

MLB-201209-1000L-N2

CRYSTAL,HC-49/SM4H BUBANG

CRYSTAL,SX-1 SUNNY

CRYSTAL,HC49U 20.250MHZ

CRYSTAL,HC49U 20.250MHZ 30PPM 13PF BK

CRYSTAL,SX-1 13.500000MHZ +/- 50 PPM

CRYSTAL,SX-1 13.500000MHZ +/- 50 PPM

CRYSTAL,HC49U 18.432MHZ 30PPM 10PF BK

PJ-6054R S-VHS+3P+GOLD

440062-1 AMP DVI INTERACED RIGHT ANGLE

6046B-01S H=8.0 WITH S/W,SHIELD

UEJ-CV-018 UGCOM D3.5 E/P

UEJ-CV-018 UGCOM D3.5 E/P

UST-AG-013 UGCOM

PPJ122B PARK ELEC. A/V 6P

PPJ122C A/V 6P(COMPONENT)

PPJ121B PARK ELEC. A/V 4P

MANUAL,OWNERS RF03OA 42PZ70 LG EN

REMOTE CONTROLLER,RF03OB

POWER CORD,MP5004(13A)+V1625

POWER CORD,M3203+V1625 SAA 2800MM

POWER CORD,V3203CA+V1625 CCEE 2800MM

CABLE,DVI-D TO DVI-D UL20276 3000MM

CONNECTOR,2990-9C UL 1161

CONNECTOR,68114-1521 15PIN 2.29MM

LOCA. NO PART NO DESCRIPTION

JK111

L604

L902

L915

PA001

TU101

TU102

X002

6630VGA004B

6140VB0004B

6140VB0004B

6140VB0004B

6726VH0001A

6700MF0001J

6700MF0001K

6204B47985D

CONNECTOR,69107-0921 9P 2.77MM

COIL,26UH 1UEWPHY 22.5TURN YL-9N 0.4

COIL,26UH 1UEWPHY 22.5TURN YL-9N 0.4

COIL,26UH 1UEWPHY 22.5TURN YL-9N 0.4

REMOTE CONTROLLER RECEIVER,TSOP1238RF1

TUNER,TAUH-Z340D LG INOTEK MULTI

TUNER,TAFH-Z341P LG INOTEK MULTI

OSCILLATOR,SCO-103 12MHZ +/-100PPM

JACK

ACCESSORIES

MISCELLANEOUS

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Jan., 2004

Printed in KoreaP/NO : 3828VD0164A

Loading...

Loading...