LG RP 21FD10 Diagram

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : SC-023A

MODEL : RP-21FD10 RN-21FD10T

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

- 2 -

CONTENTS

SAFETY PRECAUTIONS ...........................................................................................................................................................................3

ADJUSTMENT INSTRUCTIONS ................................................................................................................................................................4

EXPLODED VIEW.......................................................................................................................................................................................8

EXPLODED VIEW PARTS LIST .................................................................................................................................................................9

REPLACEMENT PARTS LIST..................................................................................................................................................................10

SCHEMATIC DIAGRAM ...............................................................................................................................................................................

COMPONENT LOCATION GUIDE .........................................................................................................................Back of Circuit Diagram

PRINTED CIRCUIT BOARD....................................................................................................................................Back of Circuit Diagram

BLOCK DIAGRAM...................................................................................................................................................Back of Circuit Diagram

SPECIFICATIONS

POWER INPUT ....................................................................................................................................................... AC100-240V~50/60Hz

POWER CONSUMPTION ....................................................................................................................................................................95W

ANTENNA INPUT IMPEDANCE .....................................................................................................................VHF/UHF 75 ohm Balanced

CHANNEL RANGE

VHF .................................................................................................................................................................................................. 2-13

UHF ................................................................................................................................................................................................. 14-69

CATV(125) .................................................................................................................................................................01, 02

¡›13, 14¡›125

INTERMEDIATE FREQUENCIES

Picture I-F carrier frequency........................................................................................................................................................45.75MHz

Sound I-F carrier frequency ......................................................................................................................................................41.25 MHz

Color Sub-carrier frequency ..................................................................................................................................................... 42.17 MHz

Center frequency ............................................................................................................................................................................44 MHz

CHASSIS CONSTRUCTION ..................................................................................................................................... IC-Solid state chassis

PICTURE TUBE ..................................................................................................................................................... Type No. A51QDJ279X

SOUND OUTPUT ........................................................................................................................................................................... 3W+3W

CABINET ........................................................................................................................................................................................... Plastic

ABBREVIATIONS: Used in this book

ADJ ...............................................................Adjustment or Adjust

AFC .................................................Automatic Frequency Control

AGC.......................................................... Automatic Gain Control

AMP .................................................................................Amplifier

CRT .................................................................Cathode Ray Tube

DEF ............................................................................... Deflection

DET.................................................................................. Detector

FBT............................................................... Flyback Transformer

H.V............................................................................ High Voltage

OSC................................................................................ Oscillator

SEP................................................................................ Separator

SYNC................................................................... Synchronization

S.I.F.............................................. Sound Intermediate Frequency

V.I.F ...............................................Video Intermediate Frequency

H ....................................................................................Horizontal

V ........................................................................................Vertical

IC ......................................................................Intergrated Circuit

OSD .................................................................On-Screen Display

SAP ......................................................... Second Audio Program

BPF .....................................................................Band Pass Filter

ST ...................................................................................... Stereo

LPF .......................................................................Low Pass Filter

DP .................................................................... Differential Phase

DG .....................................................................Differential Group

PLL ................................................................ Phase Locked Loop

APC ......................................................Automatic Picture Control

BM ....................................................................................B+ Main

BT .................................................................................B+ Tuning

- 3 -

SAFETY PRECAUTIONS

1. Before returning an instrument to the customer, always make a safety

check of the entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are defective and/or have

been defeated during servicing. (1) Protective shields are provided on

this chassis to protect both the technician and the customer. Correctly

replace all missing protective shields, including any removed for

servicing convenience. (2) When reinstalling the chassis and/or other

assemblies in the cabinet, be sure to put back in place all protective

devices, including, but not limited to, nonmetallic control knobs,

insulating fishpapers, adjustment and compartment covers/shields, and

isolation resistor/capacitor networks.

Do not operate this instrument

or permit it to be operated without all protective devices correctly

installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or

child might be able to insert their fingers and contact a hazardous

voltage. Such openings include, but are not limited to, (1) spacing

between the picture tube and the cabinet back, (2) excessively wide

cabinet ventilation slots, and (3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check-With the instrument AC plug removed from any

AC source, connect an electrical jumper across the two AC plug prongs.

Place the instrument AC switch in the on position. Connect one lead of

an ohmmeter to the AC plug prongs tied together and touch the other

ohmmeter lead in turn to each tuner antenna input exposed terminal

screw and, if applicable, to the coaxial connector. If the measured

resistance is less than 1.0 megohm or greater than 5.2 megohm, an

abnormality exists that must be corrected before the instrument is

returned to the customer. Repeat this test with the instrument AC

switch in the off position.

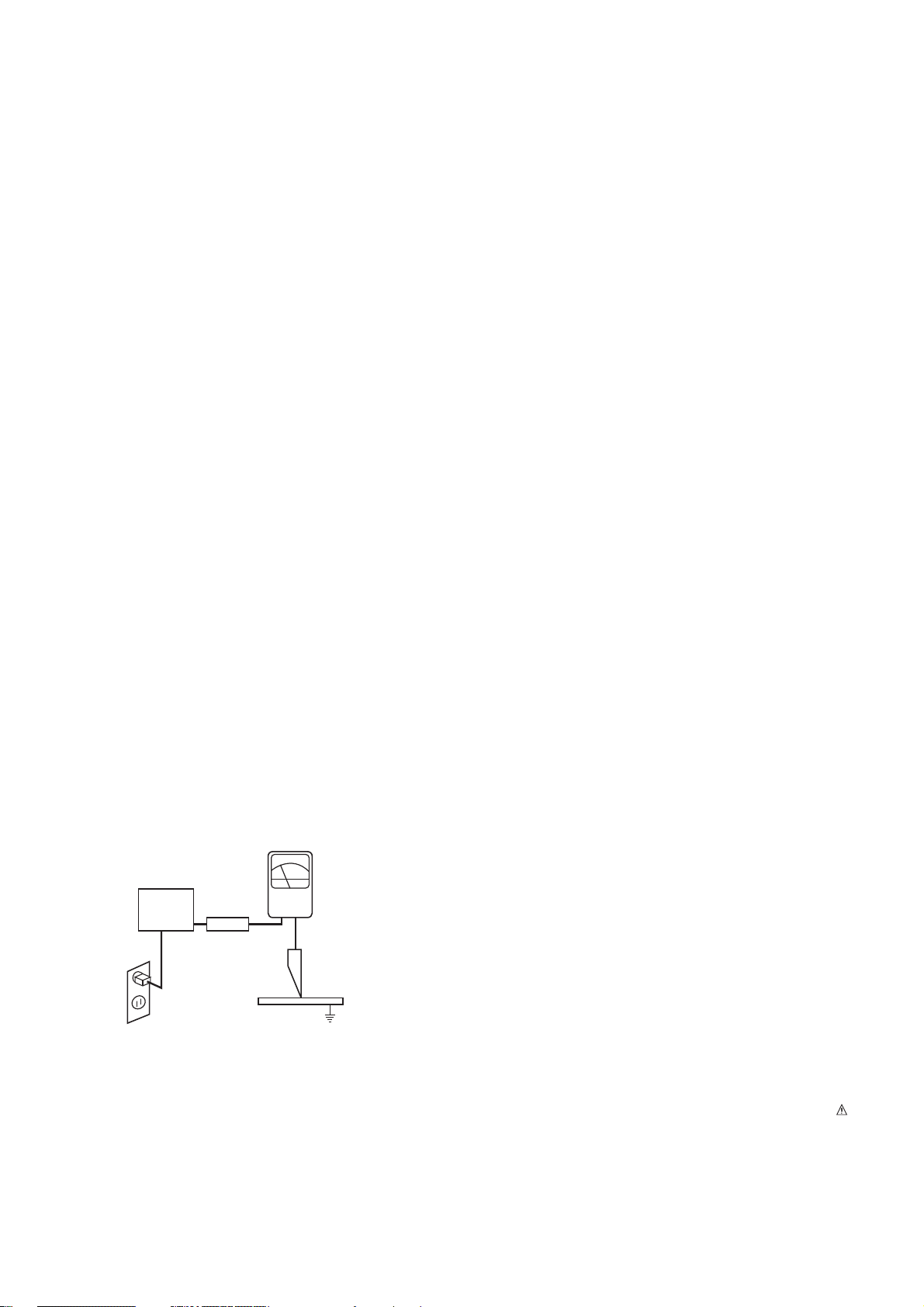

d. Leakage Current Hot Check-With the instrument completely

reassembled, plug the AC line cord directly into a 120 V AC outlet.

(Do not use an isolation transformer during this test.) Use a leakage

current tester or a metering system that complies with American

National Standards Institute (ANSI)

C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL) 1410, (50.7). With the

instrument AC switch first in the on position and then in the off position,

measure from a known earth ground (metal waterpipe, conduit, etc.) to

all exposed metal parts of the instrument (antennas, handle bracket,

metal cabinet, screwheads, metallic overlays, control shafts, etc.),

especially any exposed metal parts that offer an electrical return path to

the chassis. Any current measured must not exceed 0.5 milliamp.

Reverse the instrument power cord plug in the outlet and repeat the

test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER.

e. X-Radiation and High Voltage Limits-Because the picture tube is the

primary potential source of X-radiation in solid-state TV receivers, it is

specially constructed to prohibit X-radiation emissions. For continued Xradiation protection, the replacement picture tube must be the same

type as the original. Also, because the picture tube shields and mounting

hardware perform an X-radiation protection function, they must be

correctly in place.

High voltage must be measured each time servicing is done that

involves B+, horizontal deflection, or high voltage. Correct operation of

the X-radiation protection circuits also must be reconfirmed each time

they are serviced. (X-radiation protection circuits also may be called

"horizontal disable" or "hold-down.") Read and apply the high voltage

limits and, if the chassis is so equipped, the X-radiation protection circuit

specifications given on instrument labels and in the Product Safety & Xradia

tion Warning note on the service data chassis schematic.

High voltage is maintained within specified limits by close-tolerance

safety-related components/adjustments in the high-voltage circuit.

If high voltage exceeds specified limits, check each component

specified on the chassis schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside

the receiver cabinet, on the receiver chassis, or on the picture tube.

3. Design Alteration Warning- Do not alter or add to the mechanical or

electrical design of this TV receiver. Design alterations and additions,

including, but not limited to, circuit modifications and the addition of

items such as auxiliary audio and/or video output connections, might

alter the safety characteristics of this receiver and create a hazard to

the user. Any design alterations or additions will void the manufacturer's

warranty and will make you, the servicer responsible for personal injury

or property damage resulting therefrom.

4. Picture Tube Implosion Protection Warning-The picture tube in this

receiver employs integral implosion protection. For continued implosion

protection, replace the picture tube only with one of the same type and

number. Do not remove, install, or otherwise handle the picture tube in

any manner without first putting on shatterproof goggles equipped with

side shields. People not so equipped must be kept safely away while

picture tubes are handled. Keep the picture tube away from your body.

Do not handle the picture tube by its neck. Some "in-line" picture tubes

are equipped with a permanently attached deflection yoke; because of

potential hazard, do not try to remove such "permanently attached"

yokes from the picture tube.

5. Hot Chassis Warning-a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC power cord and may be

safely serviced without an isolation transformer only if the AC power

plug is inserted so that the chassis is connected to the ground side of

the AC power source. To confirm that the AC power plug is inserted

correctly, with an AC voltmeter measure between the chassis and a

known earth ground. If a voltage reading in excess of 1.0 V is obtained,

remove and reinsert the AC power plug in the opposite polarity and

again measure the voltage potential between the chassis and a known

earth ground. b. Some TV receiver chassis normally have 85 V AC (RMS)

between chassis and earth ground regardless of the AC plug polarity.

These chassis can be safely serviced only with an isolation transformer

inserted in the power line between the receiver and the AC power

source, for both personnel and test equipment protection. c. Some TV

receiver chassis have a secondary ground system in addition to the main

chassis ground. This secondary ground system is isolated from the AC

power line. The two ground systems are electrically separated by

insulating material that must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead

dress in the following areas: a. near sharp edges, b. near thermally hot

parts- be sure that leads and components do not touch, c. the AC

supply, d. high voltage, and e.antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring. Do not change spacing

between components, and between components and the printed circuit

board. Check the AC power cord for damage.

7. Components, parts, and/or wiring that appear to have overheated or are

otherwise damaged should be replaced with components, parts, or

wiring that meet original specifications. Additionally, determine the

cause of overheating and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

8. PRODUCT SAFETY NOTICE

Some electrical and mechanical parts have special safety related

characteristics which are often not evident from visual inspection, nor can

the protection they give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts that have

special safety characteristics are identified by shading, by a ¡ ,or by

on schematics and parts lists. Use of a substitute replacement that does

not have the same safety characteristics as the recommended

replacement parts might create shock, fire, and/or other hazards. Product

safety is under review continuously and new instructions are issued

whenever appropriate.

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

LEAKAGE

CURRENT

TESTER

(READING SHOULD

NOT BE ABOVE

0.5mA)

+ -

AC Leakage Test

1. Application Object

These instructions are applied to SC-023A chassis.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep

(100~240V)±10%, 50/60Hz in adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment. But adjusting on the board can be done

in jig state right away.

(6) Signal : The standard color signal is approved in

65±1dBµV.

The standard color signal means digital pattern signal.

(7) If not specified, APC ON is CLEAR.

3. AGC Voltage Adjustment

3.1 Preliminary steps

(1) Input 65dB(±1dB) digital pattern signal into 75Ω antenna

terminal.

(2) Connect digital multimeter to the C102 left terminal(with

Hole/J5) marking with AGC Check.

3.2 Adjustment

(1) Select the SUB 0(RF AGC) mode with a INSTART Key.

(2) Adjust the adjustment data with VOL +, - key until the

digital multimeter voltage show 2.2±0.05V.

(3) CAUTION : Since the signal strength can be easily

changed by the condition of signal cable, you need to

check the signal strength frequently in order to prevent

misadjustment.

4. Screen Voltage Adjustment

4.1 Preliminary steps

(1) Input digital pattern signal into 75Ω terminal.

(2) Set Picture condition to “CLEAR”.

CLEAR CONTRAST : 100

BRIGHTNESS : 50

COLOR : 50

SHARPNESS : 50

TINT : 0

4.2 Adjustment

(1) Press “ADJ” or “SVC” button on the remote control to make

one horizontal line.

(2) Turn the Screen volume not to see one horizontal line and

turn oppositely until it starts to display.

5. Purity and Convergence Adjustment

5.1 Purity Adjustment

(1) Preliminary steps

1. Receive Red Raster Pattern.

2. Degauss CPT and Cabinet with degaussing coil.

(2) Horizontal Line Adjustment

1. Pre-adjust Static Convergence(STC) with 4-pole & 6pole magnet.

2. Check if the beam lands at mask hole by setting two 2Pole magnets in opposite direction repectively.

3. If not, adjust 2-Pole magnet so the beam as to land at

mask hole accurately.

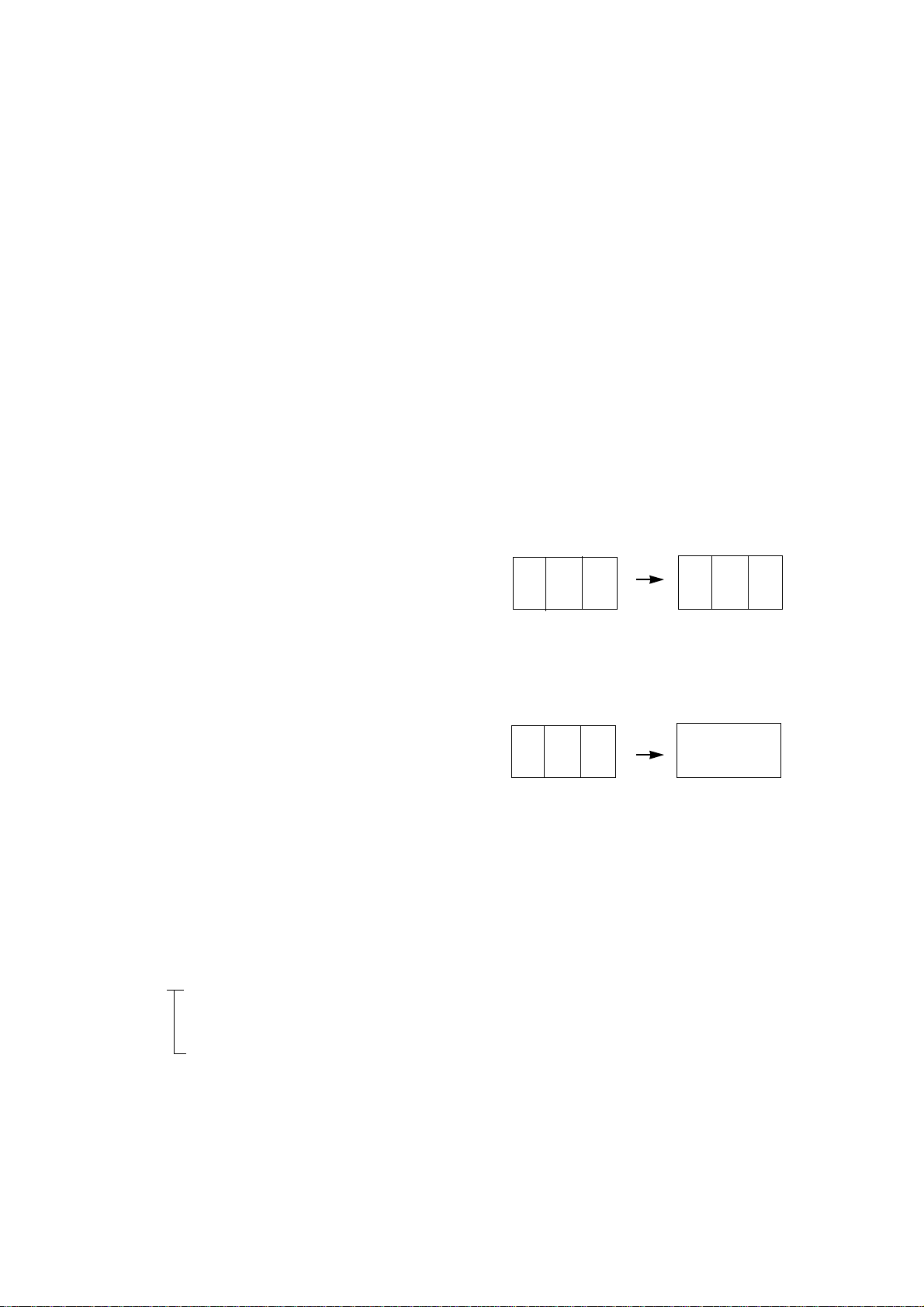

(3) Purity Adjustment

1. Adhere DY closely to CPT.

2. Receive Red Pattern and adjust the 2-Pole magnet so

Red Color Bar as to locate center and make the portion

of Green color and Blue color same. <Fig. 1>

(Be careful of HALO if two 2-Pole magnet are open over

30 degree)

3. Make the full screen Red by pulling DY back slowly.

<Fig. 2>

(When adhering DY, use the electric driver of which

turning force is lower than 10Kg/Cm.)

5.2 Convergence Adjustment

(1) Test equipment

1. Degaussing Coil

2. Convergence fixing jig

(2) Preliminary steps

1. Heat run over 30 minutes before adjustment.

2. Degauss CPT and Cabinet with degaussing coil.

3. Rececive Cross Hatch Pattern.

4. Adjust Contrast and Brightness for easy observation.

(3) Static Convergence (STC) Adjustment

1. Receive Crosshatch Pattern.

2. Adjust Focus with focus volume.

3. Open two 4-Pole magnets until vertical Red and Blue

lines are unified.

4. Rotate the 4-Pole magnets keeping the angle between

two 4-Pole magnets until horizontal Red and Blue lines

are unified.

5. Open two 6-Pole magnets until vertical Red and Green

lines are unified.

- 4 -

ADJUSTMENT INSTRUCTION

G R BG R B

RG R B

<Fig. 1>

<Fig. 2>

6. Rotate the 6-Pole magnets keeping the angle between

two 6-Pole magnets until horizontal Red and Blue lines

are unified.

(4) Dynamic Convergence (DYC) Adjustment

1. Vertical Line Adjustment : Adjust by moving DY right and

left.

2. Horizontal Line Adjustment : Adjust by moving DY up

and down.

6. White Balance Adjustment

6.1 Test Equipment

(1) Automatic White Balance meter(Can generate Low/High

light pattern)

(2) White Balance meter(CRT color Analyzer, CA-100)

(3) SVC Remote control for adjustment

6.2 Preliminary steps

Do screen adjustment first.

6.3 Adjustment

(1) White Balance should be adjusted with the SVC remote

control.

(2) Enter into adjustment mode by “INSTART” button.

(3) Adjust the item with CH

D,E.

(4) Adjust the data with VOL F, G.

(5) Adjustment Procedure

1. Adjust “CONTRAST” and “BRIGHT” so the bright level to

be 35Ft_L.

2. Select G-DRIVE(SUB 7) and adjust Y coordinate in High

Light and select B-DRIVE(SUB 8) and adjust X

coordinate so the color coordinates in High light as to

be the values in Table below.

3. Adjust “CONTRAST” and “BRIGHT” so the bright level to

be 4.5Ft_L.

4. Select G-CUT(SUB 5) and adjust Y coordinate in Low

Light and select B-CUT(SUB 6) and adjust X coordinate

so the color coordinates in Low light as to be the values

in Table below.

5. Repeat 1 ~ 4 until the color coordinates in High and

Low color satisfies the Table.

6. Check the adjusted color coordinates with the white

balance meter.

7. Focus Voltage Adjustment

Adjust after operating the receiver enough.

7.1 Preliminary steps

(1) Receive Digital Pattern.

(2) Set Picture condition to “CLEAR”.

7.2 Adjustment

Adjust center focus with upper Focus volume and adjust

corner focus with lower Focus volume.

Repeatedly adjust focus until getting proper focus.

8. Sub-Brightness Adjustment

Do white balance adjustment first.

8.1 Preliminary steps

(1) Receive Mono Scope.

(2) Set Picture condition to “CLEAR”.

8.2 Adjustment

(1) Select “SUB BRI” mode pressing “ADJ” button on the SVC

Remote control.

(2) Adjust until number “2” almost disappears on Gray Scale

of Mono Scope signal by VOL F, G key.

Adjust 21” FLAT Model until number “3” almost disappears.

9. Sub-Tint Adjustment

This adjustment must be done when the TINT is on.

(1) Receive SMPTE.

(2) Select the TINT adjustment mode(Sub-Tint) with the ADJ

key(or SVC key).

(3) Adjust the up and down cyan color same with VOL F, G

key.

- 5 -

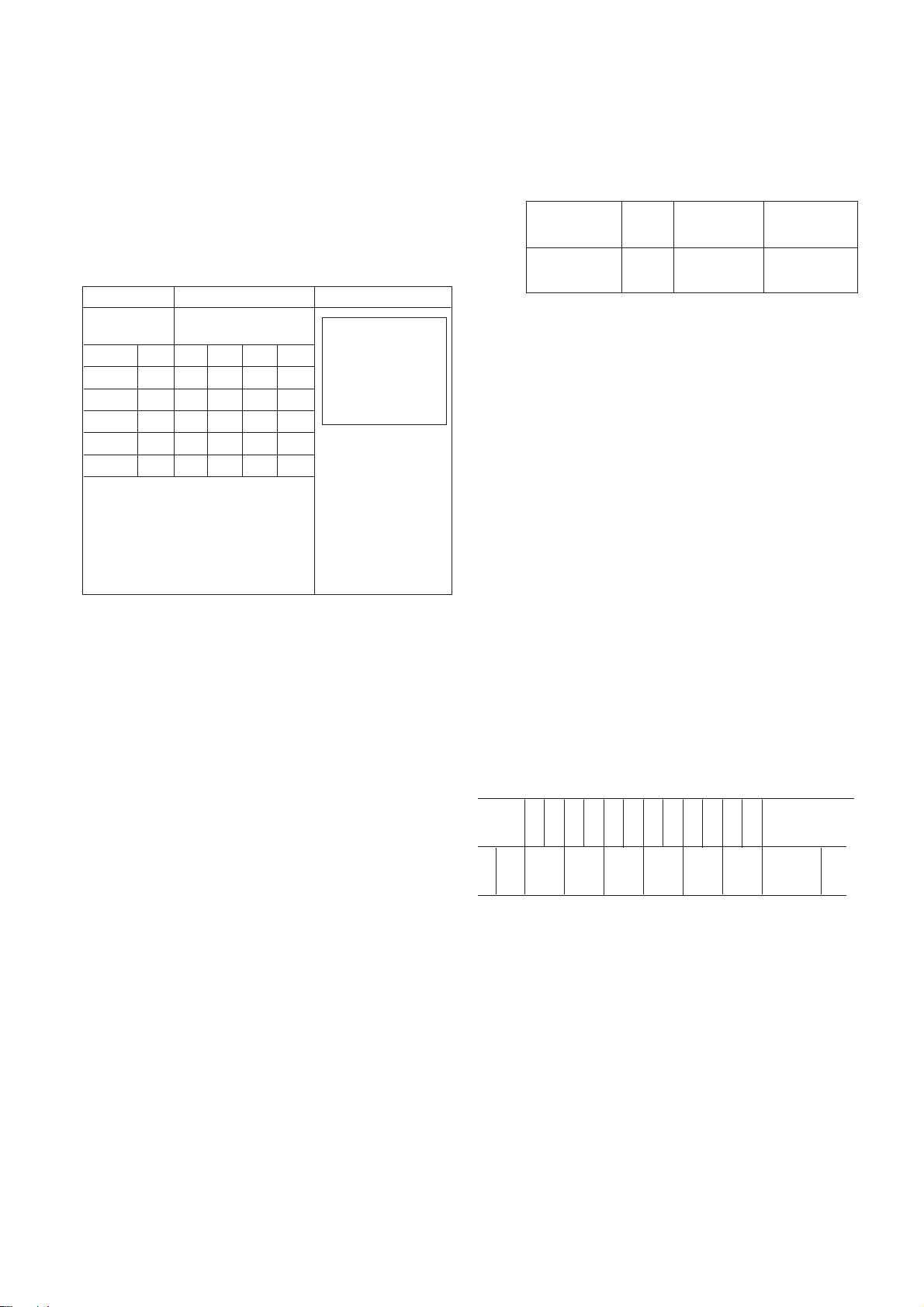

Location

C

L,R,X,Y

A,B,D,E

3,6,9,12

2,4,8,10

Convergence

Colors : R/B, R/G, B/G <Unit : mm>

* Each indicator stands

for the 30ø circle.

O

Adjust after warming

the Braun tube up for

15 minutes.

O

Adjustment position is

the center of the circle

above.

O

The specification of

horizontal and vertical

direction is equal

10 12 2

A X B

9 L C R 3

D Y E

8 6 4

ConditionSpecificationContent

Colors

Colors

Colors

Colors

Colors

14”

-

0.8

0.8

1.0

1.4

15”

-

0.8

0.8

1.0

1.4

20”

-

0.8

0.8

1.0

1.4

21”

-

0.8

0.8

1.0

1.4

Color

temperature

13,000¡ 800

MPCD

¡ 10

X Coordinate

0.266¡ 0.008

Y Coordinate

0.282¡ 0.008

0 1 2 3 4 5 6 7 8 9

MONO SCOPE

F GRAY SCALE

F COLOR BAR

10. Deflection Data Adjustment

10.1 Preliminary Steps

(1) Set the Deflection data with the SVC Remote control.

(2) Enter into Deflection adjustment mode by “INSTART”

button.

(3) Use “CHD”, “CHE” button for changing adjustment item

(4) Use “VOLF, VOLG” button for Data change.

10.2 Adjustment

(1) Horizontal Position Adjsutment

Select SUB 1(H POSIT) and adjust until left and right

screen are symmetrically equal.

(2) Vertical Position Adjustment

Select SUB 2(V-POS) and adjust until the mechanical

center point and the center of screen unite.

(3) Vertical Size Adjustment

Select SUB 3(V SIZ) and adjust until the smaller inscribed

circle of Digital Pattern coincides with the outer frame of

screen as figure below.

- 6 -

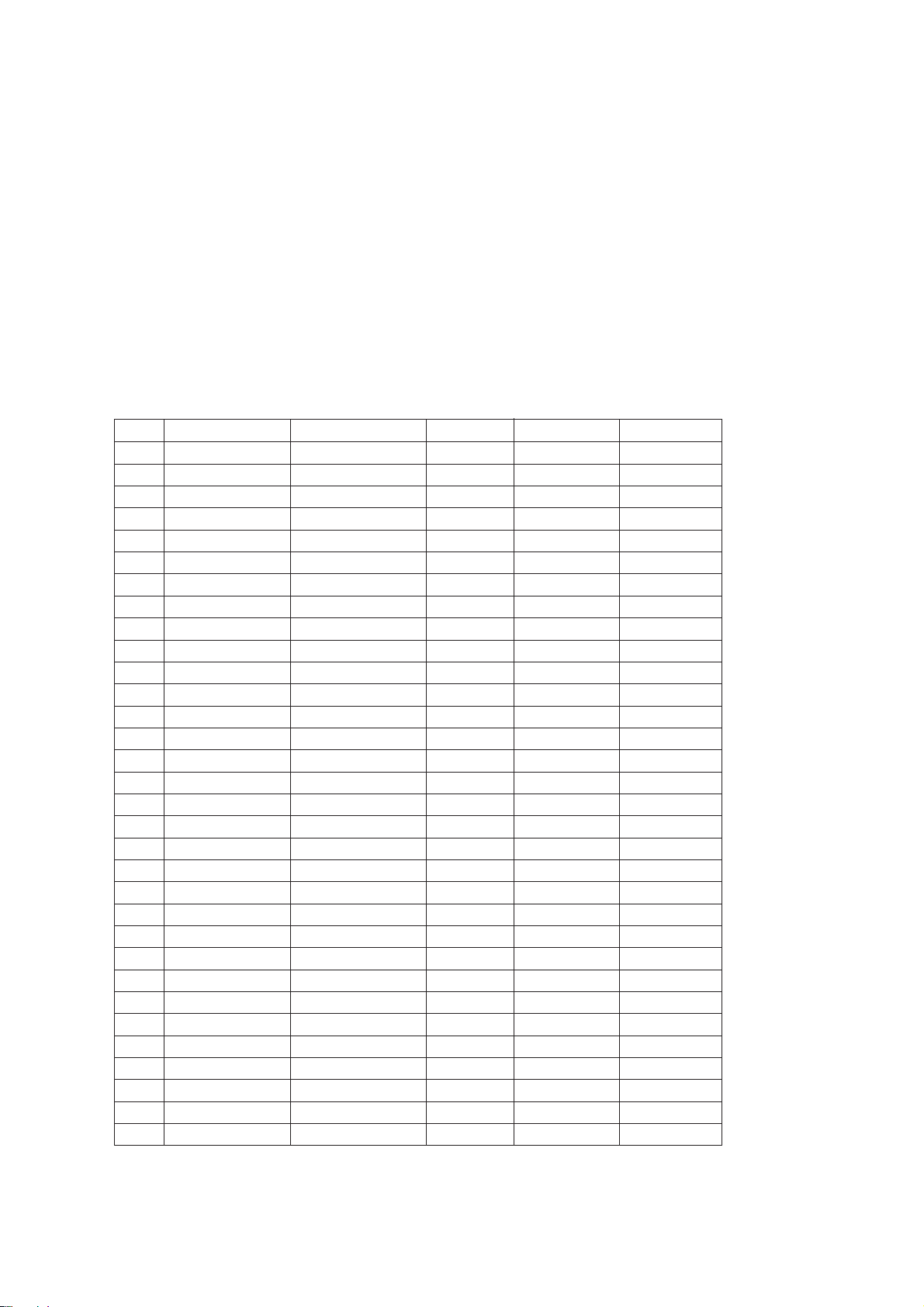

11. IIC BUS Adjustment Data Table

11.1 21

¡¡––

FLAT Model

* Adjustment is necessary from SUB 0 to SUB 8 and the OSD is Blue.

* Adjustment is unnecessary from SUB 9 to SUB 30 and the OSD is Red.

Menu

S - 0

S - 1

S - 2

S - 3

S - 4

S - 5

S - 6

S - 7

S - 8

S - 9

S - 10

S - 11

S - 12

S - 13

S - 14

S - 15

S - 16

S - 17

S - 18

S - 19

S - 20

S - 21

S - 22

S - 23

S - 24

S - 25

S - 26

S - 27

S - 28

S - 29

S - 30

S - 31

Adjustment

AGC Voltage Adj.

Horizontal Postilion

Vertical Position

Vertical SIZE

R CUT OFF

G CUT OFF

B CUT OFF

Inside TEST Pattern

Range

0 ~ 63

0 ~ 31

0 ~ 7

0 ~ 63

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 127

0 ~ 127

0 ~ 63

0 ~ 15

0 ~ 15

0 ~ 3

0 ~ 3

0 ~ 1

0 ~ 1

0 ~ 3

0 ~ 7

0 ~ 1

0 ~ 1

0 ~ 1

0 ~ 3

0 ~ 3

0 ~ 7

0 ~ 3

0 ~ 1

0 ~ 1

0 ~ 1

0 ~ 1

0 ~ 1

0 ~ 70

OSD

RF AGC

H POSIT

V-POS

V SIZE

R-CUT

G-CUT

B-CUT

G-DRIVE

B-DRIVE

V CENTE

V LINEA

V S COR

AFC GAI

ABL GAI

YPL

C-GAMMA

N MATRI

A-SHARP

RGBMUTE

AU GAIN

MIX GAI

Y-GAMMA

BLK STR

Y DL

ABL POI

BPT-TOF

V AGC

V R BIA

SYN SEP

OVER MOD

OSD POSITION

Initial setting

50

13

3

53

128

128

128

64

64

36

9

7

0

3

1

1

1

3

0

0

0

3

3

1

0

1

0

1

0

0

17

Remark

Necessary

Necessary

Necessary

Necessary

Necessary

Necessary

Necessary

Necessary

Necessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Unnecessary

Loading...

Loading...