Page 1

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : ML-024F

MODEL : RZ-17LZ40

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

CONTENTS

Contents .................................................................................................. 2

Safety Precautions ..................................................................................3

Servicing Precautions ............................................................................ 4

Specifications ......................................................................................... 6

Description of Controls .......................................................................... 8

Adjustment Instruction ..........................................................................11

Block Diagram ........................................................................................17

Exploded View ...................................................................................... 18

Exploded View Parts List.......................................................................19

Replacement Parts List ........................................................................ 20

SVC. Sheet .................................................................................................

Page 3

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube. Do not

lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate high

impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5

1.5KV: 14-19 inch, 26 1.5KV: 19-21 inch,

29.0

1.5KV: 25-29 inch, 30.0 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service and

correction is required to prevent the possibility of premature

component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

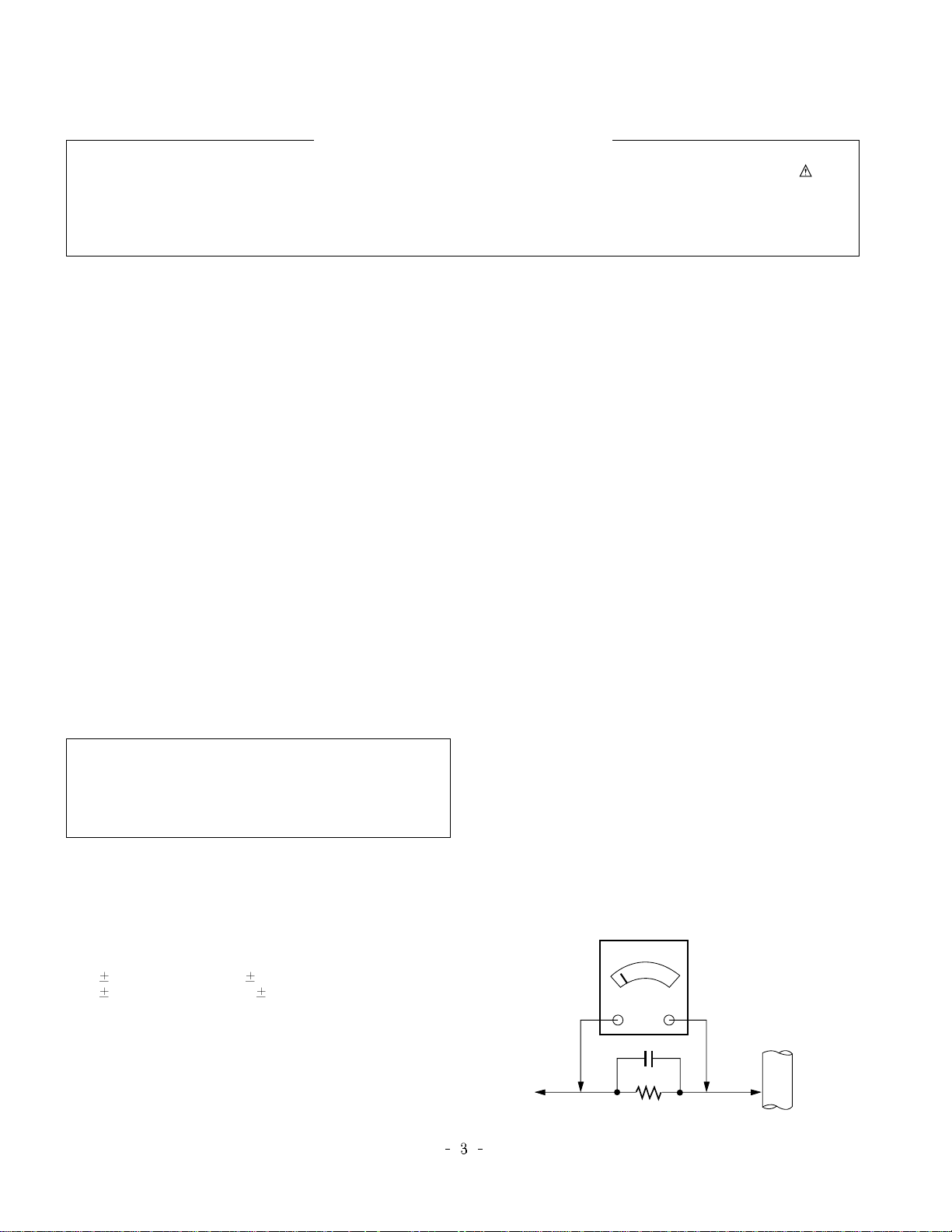

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the High

Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the replacement

tube must be the same type tube as specified in the

Replacement Parts List.

IMPORTANT SAFETY NOTICE

0.15uF

AC Volt-meter

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 4

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c.

Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first connecting

one end of an insulated clip lead to the degaussing or kine

aquadag grounding system shield at the point where the picture

tube socket ground lead is connected, and then (b) touch the

other end of the insulated clip lead to the picture tube anode

button, using an insulating handle to avoid personal contact with

high voltage.

4. Do not spray chemicals on or near this receiver or any of its

assemblies.

5. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

8. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION:Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500

F to 600 F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500

F to 600 F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500

F to 600 F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

SERVICING PRECAUTIONS

Page 5

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Page 6

1. Application range

This specification is applied to ML-024F chassis.

2. Requirement for Test

Testing for standard of each part must be followed in below

condition.

(1) Temperature: 25°C ± 5°C(But, CST must be tested 40°C ±

5°C)

(2) Humidity: 65% ± 10%

(3) Power: Standard input voltage (AC 100-220V, 50/60Hz)

(4) Measurement must be performed after heat-run more than

15min.

(5) Adjusting standard for this chassis is followed a special

standard.

(6) Use the parts only designated in B.O.M.,PARTS SPEC.,or

drawings.

(7) Follow each drawing or spec for spec and performance of

parts,based upon P/N of RPL

3. Test and Inspection method

(1) Capacity: Follow LG electronics TV Testing Standard.

(2) RCA JACK performance :Follow the standard of LG.

(3) Another Required Standard

Follow the standard of each nation.

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

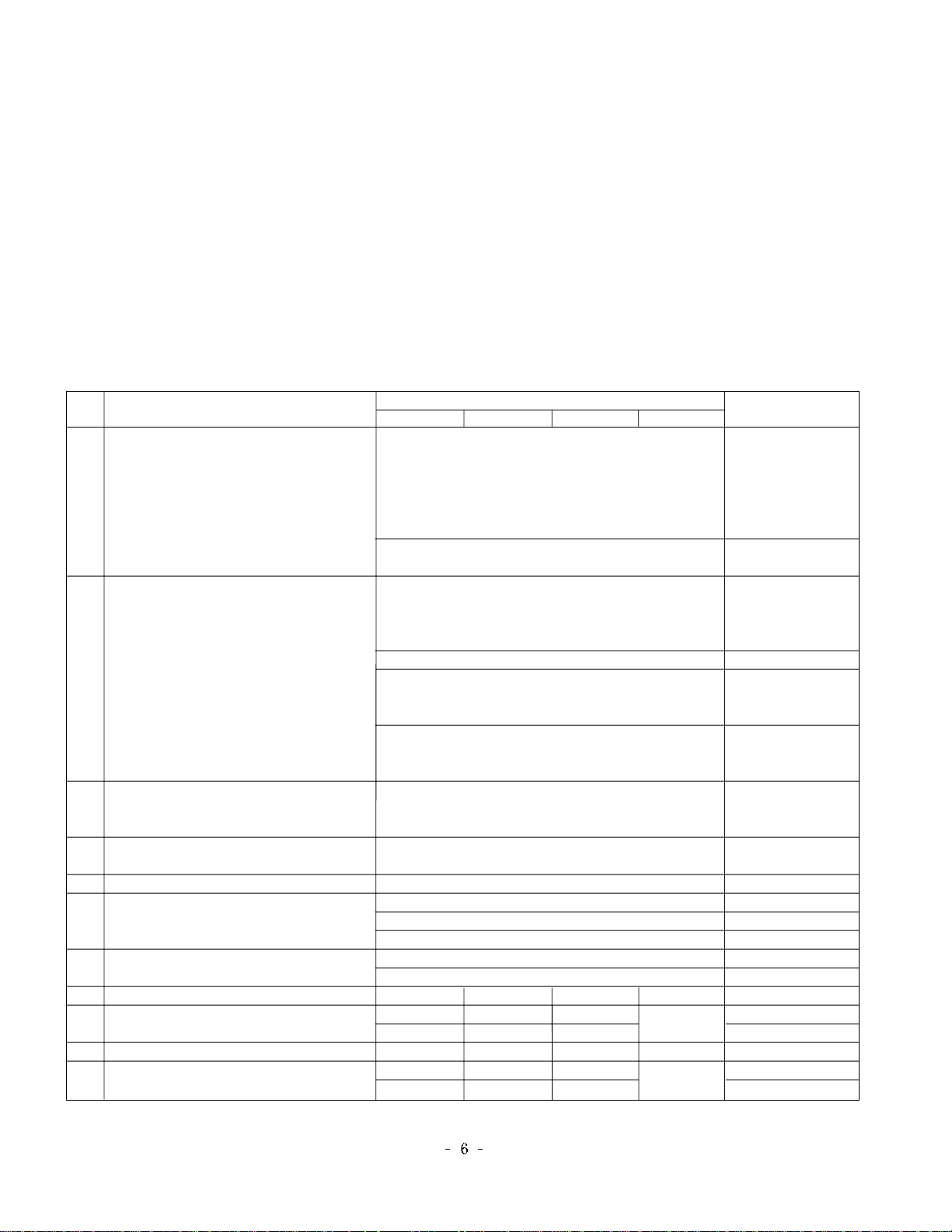

4.General Specification

1

2

3

4

5

6

7

8

9

10

11

Receivable broadcasting system

RF input channel

Input voltage

Tuning system

Market

Screen size

Aspect ratio

Operating temperature

Operating humidity

Storage temperature

Storage humidity

Specification

Min Typ Max Unit

1)PAL/SECAM-BG

2)PAL/SECAM-DK

3)PAL-I/I

4)SECAM-L/L’

5)NTSC -M

6)NTSC 4.43(AV)

7)PAL N/M

8)NTSC-M

VHF: E02 ~ E12

UHF : E21 ~ E69

CATV : S1 ~ S20

HYPER : S21 ~ S41

L/L’ : B,C,D

VHF : 2 ~13

UHF : 14 ~ 69

CATV : 1 ~ 125

VHF low : 1 ~M10

VHF high : 14 ~ 69

UHF : S23 ~ 62

110 - 220V ~± 10%, 50/60Hz

FVS 100 program

FS

World Wide

15.1” diagonal (384mm)

15” diagonal

17.1” diagonal

4:3

16:9

0 50 deg

10 90 %RH

20 85

-20 60 deg

10 90 %RH

585

Item

Remark

No.

EU/Non-EU

(PAL Market)

NTSC Market

PAL

FRANCE

NTSC

JAPAN

USA(120V/60Hz)

EU(230~240V/50Hz

JAPAN(100V/60Hz)

PAL, 200PR.(option)

NTSC

Initial : Zenith(RMS)

024A

024E

024F

024A/E

024F

024A/E/F

024A/F

024E

024A/E/F

024A/F

024E

Page 7

5. Feature and Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Teletext

REMOCON

RGB(VGA) input

Component input

PERI TV Connector

AV input

S-video input

RS232 Port

H/P output

PC sound Input

2 Carrier stereo

NICAM Stereo

2 Carrier Dual

NICAM Dual

Local Key

Main Power Key

DPM (Display power management)

AVL

On/Off Timer

APC

DASP

TOP,FLOF,LIST

NEC code

1 Rear

0 Y, P

B

, PR

1 Rear (Full Scart)

1 Rear

1 Rear

1 Rear

1 Rear

1

BG, DK

BG, I, LL’

BG, DK

BG, I, LL’

TV/video, menu, enter

Volume (

), Channel( )

O

O

O

O

O

O

Item

Specification

Min Typ Max Unit

Remark

No.

TOP(option)

D-Sub 15 pin

Option, Non-EU

Option, EU

Only for RMS

PAL : PSM

PAL : SSM

Page 8

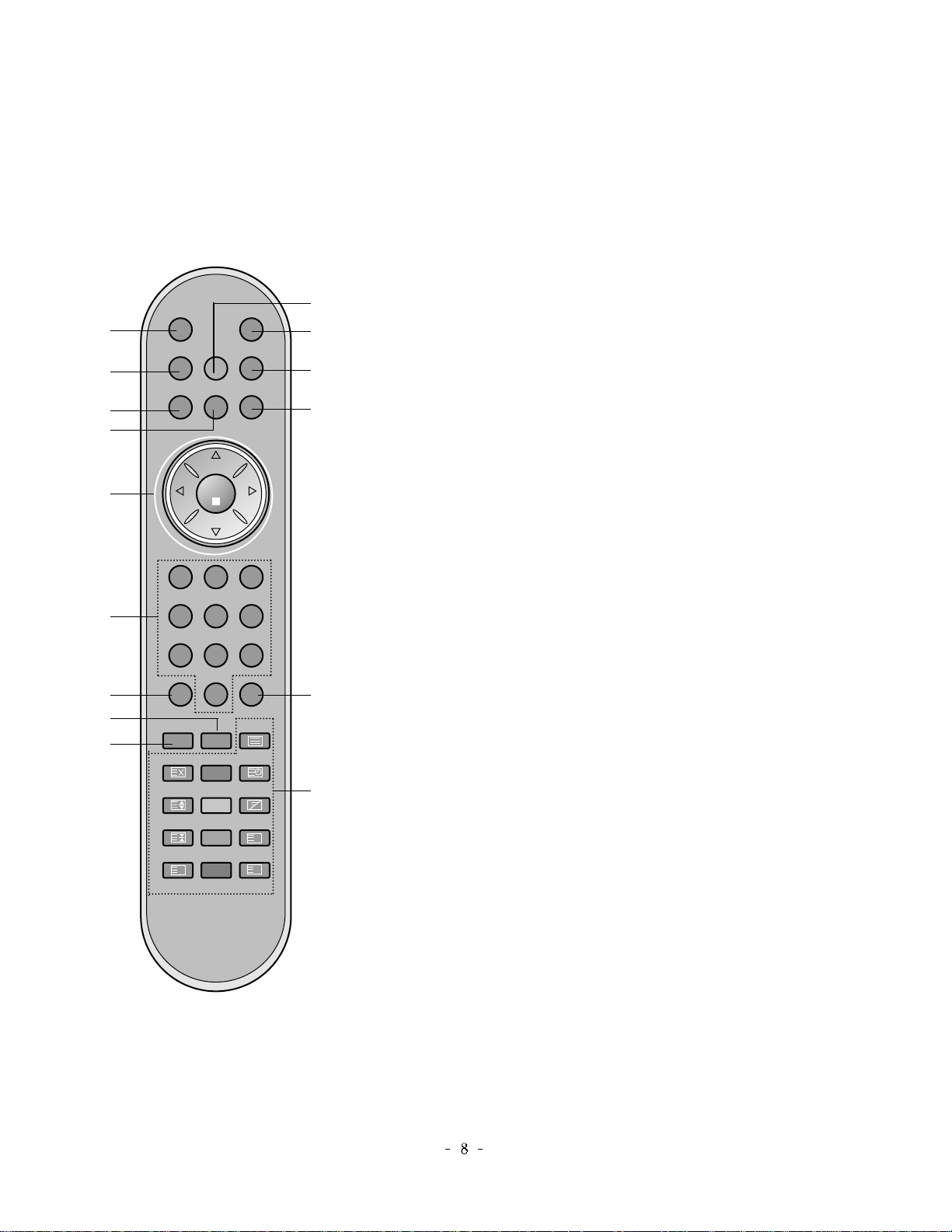

DESCRIPTION OF CONTROLS

POWERMUTE

TV/AV I/II

LIST

PR

PR

VOL

OK

123

456

789

SSM PSM

0

VOL

Q.VIEW MENU

SLEEP

ARC

TEXT

TIME

SIZE MIX

HOLD

REVEAL

INDEX MODE

?

i

M

UPDATE

TV/PC

All the functions can be controlled with the remote control handset.

Some functions can also be adjusted with the buttons on the side

panel of the set.

Only the remote control handset supplied will operate this set.

Remote control handset

Before you use the remote control handset, please install the batteries. See the next page.

10

1

2

3

4

5

6

7

8

9

11

1. MUTE

switches the sound on or off.

12

2. TV/AV

13

selects TV or AV mode.

clears the menu from the screen.

switches the set on from standby.

3. LIST

displays the programme table.

4. Q.VIEW

returns to the previously viewed programme.

selects a favourite programme.

5. DD / EE (Programme Up/Down)

selects a programme or a menu item.

switches the set on from standby.

FF / GG (Volume Up/Down)

adjusts the volume.

adjusts menu settings.

14

OK

accepts your selection or displays the current mode.

6. NUMBER BUTTONS

switches the set on from standby or directly select a number.

15

7. SSM (Sound Status Memory)

recalls your preferred sound setting.

8. ARC (option)

select your desired picture format.

9. SLEEP

sets the sleep timer.

Page 9

10. TV/PC

POWERMUTE

TV/AV I/II

LIST

PR

PR

VOL

OK

123

456

789

SSM PSM

0

VOL

Q.VIEW MENU

SLEEP TEXT

TIME

SIZE MIX

HOLD

REVEAL

INDEX MODE

?

i

M

UPDATE

TV/PC

selects TV or PC mode.

clears the menu from the screen.

switches the set on from standby.

11. POWER

switches the set on from standby or off to standby.

10

12. I/II

selects the language during dual language broadcast.

selects the sound output (option).

13. MENU

selects a menu.

14. PSM (Picture Status Memory)

recalls your preferred picture setting.

15. TELETEXT BUTTONS (option)

These buttons are used for teletext.

For further details, see the ‘Teletext’ section.

: No function

*

COLOURED BUTTONS : These buttons are used for teletext (only

TELETEXT models) or programme edit.

1

2

3

11

12

13

4

5

6

7

14

9

15

Page 10

RL

VIDEO

AV2

AUDIO

(MONO)

H/P

S-VIDEO

R

TV/AV/PC

MENUOKVOLPR

/I

ON/OFF

R

• RZ-17LZ40 series

ON/OFF TV/AV/PC MENU OK VOL PR

MONO DPM

STEREO

ST

DUAL

R

PR

VOL

MENU

OK

ON/OFF

TV

AV/PC

/ I

S-VIDEO VIDEO

AUDIO

R

AV3

L / MONO

MONO

TEREO

ST

DUAL

DPM

• RZ-15LA70 series

Top panel

2

1

3

4

65

7

8

9

10

Side panel

6

5

4

3

7

8

2

1

Back panel

• RZ-15LA66 series

9

10

1. ON/OFF

switches the set on from standby or off to

standby.

Note : Power line lives even when the power

is off.

2. TV/AV/PC

selects TV, AV or PC monitor mode.

clears the menu from the screen.

switches the set on from standby.

3. MENU

selects a menu.

4. OK

accepts your selection or displays the current

mode.

FF / GG (Volume Up/Down)

5.

adjusts the volume.

adjusts menu settings.

DD / EE (Programme Up/Down)

6.

selects a programme or a menu item.

switches the set on from standby.

7 8

7. POWER/STANDBY INDICATOR (rr)

illuminates red in standby mode.

illuminates green when the set is switched on.

8. REMOTE CONTROL SENSOR

(option)

illuminates brightly when the set is switched

on.

: POWER/STANDBY indicator

: MONO indicator

: STEREO indicator

: DUAL indicator

: DPM indicator

9. HEADPHONE SOCKET

Connect the headphone plug to this socket.

10. AUDIO/VIDEO IN SOCKETS (AV2)

Connect the audio/video out sockets of external equipment to these sockets.

S-VIDEO/AUDIO IN SOCKETS (SAV)

Connect the video out socket of an S-VIDEO

VCR to the S-VIDEO socket.

Connects the audio out sockets of the SVIDEO VCR to the audio sockets as in AV2.

6

5

4

3

2

1

Page 11

1. Application Object

This instruction is for the application to the LCD TV/Monitor,

ML-024F.

2. Notes

(1) This LCD TV has power within set. Connect the power

correctly, then start the adjustment.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100~220V,

50/60Hz in adjusting.

(5) The set must be operated for 15 minutes preliminary

before adjustment if there is no specific designation.

‘Heat Run’ must be performed with the full white signal or TV

noise signal in the internal part of the set.

The time for ‘Heat Run’ can be changed owing to production

plan.

Condition of Line Test : Standard color signal - 65±1dBuV

3. PC Mode Adjustment

3-1. Required Test Equipment

(1) Window Pattern which satisfied with VESA Spec. or

pattern which has White-Black signal simultaneously.

(2) Remote control for adjustment

3-2. Preparation for Adjustment

(1) Perform ‘Heat Run’ for more than 15 minutes in white

pattern.

(2) Connect the signal of pattern generator with LCD TV of PC

Input Jack.

(3) Confirm the XGA(1024x768) Window Pattern or

signal(White-Black) using the 801-GF/GD, VG819.

(4) Use the IN-START Key on R/C for adjustment to enter the

PC adjustment mode.

(5) Example of adjustment screen.

(6) Enter into the adjustment mode as <Fig. 1> and select the

cursor(red letters) to “RGBSE

” with the channel key on

R/C for adjustment.

(7) Press the Volume (

) key on R/C for adjustment.

(8) At this time the adjustment starts automatically changing

the number in order of RO --> GO --> BO --> RD --> GD -> BD.

In adjustment, the lastest line, “60 Swver:2.5” is change to

“adjust”. When adjustment is finished it’s return to “60

Swver:2.5”.

(9) Press the MENU or EXIT key to come out of the

adjustment mode.

4. COMPONENT Adjustment

(Only CMO MODULE)

4-1. Required Test Equipment

(1) Standard Color bar (75% Full Color bar) -> refer <fig.2>

(2) Remote control for adjustment

4-2. Preparation for Adjustment

(1) Operate Component Mode adjustment, after PC Mode

adjustment.

(2) Connect the signal of pattern generator with LCD TV of

Component Input Jack

(3) Confirm the Color bar (75% Full Color bar) signal using the

801-GF/GD, VG819.

(4) Use the IN-START Key on R/C for adjustment to enter the

Component adjustment mode.

(5) Example of adjustment screen.

(6) Enter into the adjustment mode as <Fig. 2> and select the

cursor(red letters) to “DTVADJT

” with the channel key

on R/C for adjustment.

(7) Press the Volume (

) key on R/C for adjustment.

(8) At this time the adjustment starts automatically changing

the color of Color bar.

Changing a color bar color, the adjustment srart. When

adustment is finished, the of previors adjustment and

changt the data’s cost.

(9) Press the ENTER key. and then press EXIT key to come

out of the adjustment mode.

ADJUSTMENT INSTRUCTION

<Fig. 1>

<Fig. 2>

Page 12

5. Option1 data(200PR~A2 ST:1bit,SYS:2bit)

OPTION

Data

200PR

TEXT

I/II

SAVE

TOP

A2

STER

SYS

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

SCART

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

OPTION

Data

200PR

TEXT

I/II

SAVE

TOP

A2

STER

SYS

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

SCART

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

Page 13

OPTION

Data

200PR

TEXT

I/II SV

TOP

A2 ST SYS

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

SCART

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

OPTION

Data

200PR

TEXT

I/II SV

TOP

A2 ST SYS

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

SCART

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

Page 14

OPTION

Data

200PR

TEXT

I/II SV

TOP

A2 ST SYS

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

SCART

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

OPTION

Data

200PR

TEXT

I/II SV

TOP

A2 ST SYS

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

01

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

SCART

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

Page 15

OPTION

Data

200PR

TEXT

I/II SV

TOP

A2 ST SYS

248

249

250

251

252

253

254

255

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

1

1

1

1

0

1

2

3

0

1

2

3

SCART

1

1

1

1

1

1

1

1

6. Option2 data(ACMS~BBACK:1bit,LANG:3bit)

Data

ACMS VOL BBACK

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

LANG

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Data

ACMS VOL BBACK

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

LANG

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Page 16

MONO CH+AUS

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

7. Option3 data(IIC AFT~CH+AU:1bit)

OPTION

Data

HiDEV

TSS

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

IIC T

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

Page 17

BLOCK DIAGRAM

Page 18

EXPLODED VIEW

401

521

400

522

523

524

350

330

340

360

370

380

500

311

112

120

541

310

550

560

300

120

Page 19

112 6306V17001B LCD(LIQUID CRYSTAL DISPLAY),LC171W03-A4K4 LG PHILPS TFT COLOR

120 6400GKTX01A SPEAKER,FULLRANGE F1527C-6428 K-TONE 8OHM 7/12W 83DB OTHERS 34.5X71

300 3091V00623B CABINET ASSEMBLY,RZ-17LZ40 MONO E_PHONE ML024F C/SKD

310 5020V00798D BUTTON,CONTROL RZ-17LZ40 ABS, HF-380 8KEY .

311 4810V00836B BRACKET,CONTROL KZ-17LZ21 ML027C ABS, HF-380 .

330 4950V00157F METAL,HINGE ASSY NON 15LA70

340 4810V00777D BRACKET,STAND RU-15LA61 ML012C HIPS 60HR FRONT

350 4810V00778D BRACKET,STAND RU-15LA61 ML012C HIPS 60HR REAR

360 4810V00949A BRACKET,STAND RZ-17LZ40 ML024F ABS, HF-380 .

370 4950V00203A METAL,BASE EGI 17LZ40

380 4950V00194A METAL,STAND SPCC(CR) SUPPORTER(LA70)

400 3809V00427B BACK COVER ASSEMBLY,RZ-17LZ40 1SCART 1PHONE C/SKD

3809V00427C BACK COVER ASSEMBLY,RZ-17LZ40 1SCART 1PHONE C/SKD 412-36D

401 3550V00335C COVER,REAR AV RU-17LZ22 ABS, HF-380 SKD

500 6871VMMR43A PWB(PCB) ASSEMBLY,MAIN ML-024F RZ-17LZ40(PCB ASSY MAIN)

521 4950V00168F METAL,SHIELD EGI 0.8T ML-024F C/SKD

522 4950V00198A METAL,NON NON SHIELD REAR AV

4950V00198C METAL,SHIELD ET.

523 4810V00932A BRACKET,REAR AV RZ-17LZ40 NON ABS, HF-380 .

524 4950V00167K METAL,FRAME EGI 1T ML-024F C/SKD

541 4810V00969A BRACKET,NON RZ-17LZ40 ML024F HIPS 60HR NO HOLE

550 6871VSMQ47A PWB(PCB) ASSEMBLY,SUB POWER ML024F RZ-17LZ40 (PWR ASSY)

560 6871VSMQ46B PWB(PCB) ASSEMBLY,SUB CONT ML024F RZ-17LZ40 CONTROL ASSY

EXPLODED VIEW PARTS LIST

No.

PART NO. DESCRIPTION

Page 20

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

Q403

Q404

Q405

Q406

Q407

Q501

Q502

Q510

Q551

Q602

Q603

Q701

Q706

Q801

Q802

D100

D1101

D1102

D1103

D1104

D1105

D1106

D701

D702

D704

D706

D707

D710

D711

LED1

ZD1101

ZD1102

ZD202

ZD203

ZD400

ZD701

ZD704

C10

C101

C1101

C1102

C1103

C1104

C1105

C1106

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR322709AA

0TR387500AA

0TR150400BA

0DD181009AB

0DD181009AB

0DD181009AB

0DD181009AB

0DD181009AB

0DD181009AB

0DD181009AB

0DRSA00150A

0DD100009AM

0DD100009AM

0DR060009AA

0DRSD00091A

0DR340009AA

0DR340009AA

0DL200000CA

0DZRM00178A

0DZRM00178A

0DZRM00178A

0DZRM00178A

0DZ330009BA

0DZ910009AJ

0DZ110009AD

0CE227DF618

0CE107BF618

0CC15003G06

0CC15003G06

0CC15003G06

0CC15003G06

0CC15003G06

0CC15003G06

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,KTC3227-Y,TP(KTC1627A),KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

DIODE,KDS181 TP KEC - 85V300MA

DIODE,KDS181 TP KEC - 85V300MA

DIODE,KDS181 TP KEC - 85V300MA

DIODE,KDS181 TP KEC - 85V300MA

DIODE,KDS181 TP KEC - 85V300MA

DIODE,KDS181 TP KEC - 85V300MA

DIODE,KDS181 TP KEC - 85V300MA

DIODE,RBV-406 BK USC 600V 4A 80VA .SEC 10MA

DIODE,EU1ZV(1) TP SANKEN

DIODE,EU1ZV(1) TP SANKEN

DIODE,TVR06J TP GULF DO41 600V 0.6A

DIODE,SF20JC10 ST FTO220(4115) 100V 20A 200A

DIODE,MBRS340 - 40V 3A 80A - 2MA

DIODE,MBRS340 TP FAIRCHILD - 40V 3A 80A - 2MA

LED,SAM5670(DL-2LRG) BK Y-GREEN DIODE,UDZS TE-17 5.1B ROHM

DIODE,UDZS TE-17 5.1B ROHM

DIODE,UDZS TE-17 5.1B ROHM

DIODE,UDZS TE-17 5.1B ROHM

DIODE,ZENER HZT33 TAPING

DIODE,MTZJ9.1B TP ROHM-K DO34 0.5W 9.1V 5UA

DIODE,MTZJ11B TP ROHM-K DO34 - 11V 5UA

220UF STD 16V M FL TP5

100UF KME 16V M FL TP5

15PF D 3KV 10%,-10% SL FMTW

15PF D 3KV 10%,-10% SL FMTW

15PF D 3KV 10%,-10% SL FMTW

15PF D 3KV 10%,-10% SL FMTW

15PF D 3KV 10%,-10% SL FMTW

15PF D 3KV 10%,-10% SL FMTW

LOCA. NO PART NO DESCRIPTION

IC1

IC100

IC101

IC102

IC1101

IC1106

IC1110

IC1111

IC1112

IC1116

IC1121

IC1122

IC351

IC352

IC500

IC501

IC502

IC601

IC603

IC604

IC650

IC701

IC702

IC801

PC1

Q101

Q102

IC1102

IC1103

IC1104

IC1105

IC1223

IC1224

IC2

Q1

Q100

Q1101

Q1101

Q1102

Q1103

Q1200

Q200

Q202

Q353

Q402

0IMCRTH001A

0ISM555000B

0IAL241610B

0IFA752700A

0IMCRO2001A

0IKE704200J

0IMCRRH005A

0IMCRRH005A

0IMCRRH005A

0IMCRKE010A

0IMCRMZ001A

0IMCRMZ001A

0IMCRFA010A

0ISO204000A

0IMCRFA016A

0IMCRTW001B

0ICTMMO005B

0IMCRMN011D

0IKE704200J

0IMCRFA009A

0IMCRTI022D

0IPMGSK012A

0IMCRFA007A

0IMCRAD002A

0ILI817000G

0IFA270000A

0IFA270000A

0TFFC80044A

0TFFC80044A

0TFFC80044A

0TFFC80044A

0TF492509AA

0TF492509AA

0TF492509AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

IC,HC63LVDM83R THINE 56P TSSOP

IC,SDA555XFL 52DIP ST FLASH MEMORY

IC,AT24C16A-10PI-2.7 8PIN DIP ST

IC,KA75270Z 3 TP RE-SET IC MC-007

IC,OZ960S O2MICRO 20P SSOP

IC,KIA7042AF SOT-89 TP 4.2V VOLTAGE

IC,UM6K1N ROHM 6P SOT363 R/TP 30V 0.1A

IC,UM6K1N ROHM 6P SOT363 R/TP 30V 0.1

IC,UM6K1N ROHM 6P SOT363 R/TP 30V 0.1A R

IC,KIA7812AF KEC 2P DPACK R/TP 12V

IC,MP1583DN POWER SYSTEM 8P TSOP

IC,MP1583DN POWER SYSTEM 8P TSOP

IC,KA7809R, FAIRCHILD 2P D-PAK

IC,CXA2040AQ 32P,QFP BK IIC BUS VIDEO S/W

IC,KA78RH33RTF FAIRCHILD 2P D-PAK

IC,LG8801-H TECHWELL 160P QPFD

IC,SC786110DW MOTOROLA SOIC 16P

IC,MSP3410G QA B8 V3 MICRONAS 80P QFP

IC,KIA7042AF SOT-89 TP 4.2V VOLTAGE

IC,KA78M08RTM, FAIRCHILD 2P D-PAK

IC,TPA3004D2 TEXAS INSTRUMENT 48P PQFP

IC,STR-W6853P SANKEN 6P T0-220 ST

IC,KA431Z FAIRCHILD 3DIP,TO-92 TP

IC,AD9883AKST-110 ANALOG DEVICE 80P TQFP

IC,LTV817M-VB 4P,DIP BK

IC,2N7000TA TO-92, 3P TP

IC,2N7000TA TO-92, 3P TPIFT 60V/0.2A

TR,FDS8958A FAIRCHILD R/TP SO-8 30V 7A

TR,FDS8958A FAIRCHILD R/TP SO-8 30V 7A

TR,FDS8958A FAIRCHILD R/TP SO-8 30V 7A

TR,FDS8958A FAIRCHILD R/TP SO-8 30V 7A

TR,SI4925DY TP TEMIC 30V 6.1A SO-8

TR,SI4925DY TP TEMIC 30V 6.1A SO-8

TR,SI4925DY TP TEMIC 30V 6.1A SO-8

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

IC

DIODE

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

TRANSISTOR

CAPACITOR

Page 21

LOCA. NO PART NO DESCRIPTION

C1107

C1127

C1128

C113

C1132

C1132

C1133

C1133

C1134

C1134

C1137

C1137

C1140

C1141

C1142

C1143

C1144

C1145

C1146

C1147

C1150

C1151

C1200

C1202

C1207

C1208

C1209

C1210

C1211

C1222

C1226

C1227

C1228

C1229

C1230

C1231

C1234

C1235

C13

C200

C201

C209

C211

C212

C215

C216

C219

C220

C225

C226

C289

C331

0CE4772J618

0CK105DF64A

0CK105DF64A

0CE107BF618

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK225DFK4A

0CK225DFK4A

0CK225DFK4A

0CK225DFK4A

0CK225DFK4A

0CK225DFK4A

0CK225DFK4A

0CK225DFK4A

0CE4772J618

0CE4772J618

0CE227DH618

0CN475FH67A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CN475FH67A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CK105DF64A

0CN475FH67A

0CK105DF64A

0CK105DF64A

0CE107DD618

0CE227DF618

0CK225DFK4A

0CK225DFK4A

0CE476DF618

0CE106DF618

0CE227DD618

0CE106DF618

0CE106DF618

0CE226DF618

0CE226DF618

0CK225DFK4A

0CK225DFK4A

0CE104DK618

0CE107DF618

470UF KMF 35V 20% TP 5 FL

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

100UF KME 16V M FL TP5

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

470UF KMF 35V 20% TP 5 FL

470UF KMF 35V 20% TP 5 FL

220UF STD 25V M FL TP5

4.7UF 3225 25V 20% R/TP X5R

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

4.7UF 3225 25V 20% R/TP X5R

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

4.7UF 3225 25V 20% R/TP X5R

1UF 2012 16V 20% R/TP F(Y5V)

1UF 2012 16V 20% R/TP F(Y5V)

100UF STD 10V M FL TP5

220UF STD 16V M FL TP5

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

47UF STD 16V M FL TP5

10UF STD 16V M FL TP5

220UF STD 10V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

22UF STD 16V M FL TP5

22UF STD 16V M FL TP5

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

2.2UF 2012 16V 20%,-20% F(Y5V) R/TP

0.1000UF STD 50V M FL TP5

100UF STD 16V M FL TP5

LOCA. NO PART NO DESCRIPTION

C351

C353

C354

C356

C357

C362

C364

C380

C381

C383

C403

C404

C408

C410

C412

C413

C499

C501

C523

C526

C541

C581

C613

C614

C616

C617

C617

C620

C621

C624

C625

C629

C633

C643

C700

C701

C703

C704

C706

C707

C708

C709

C710

C717

C718

C719

C725

C726

C727

C727

C728

C730

0CE227DF618

0CE475DK618

0CE476DF618

0CE106DF618

0CE106DF618

0CE107DF618

0CE336DF618

0CE105DK618

0CE106DF618

0CE106DF618

0CE476DH618

0CE108DD618

0CE106DK618

0CE227DF618

0CE105DK618

0CK224DF56A

0CE476DK618

0CE107DF618

0CE104DK618

0CE107DF618

0CE107DF618

0CE107DF618

0CE106DF618

0CE106DF618

0CE107DF618

0CE107BF618

0CE107BH618

0CE335DK618

0CE107BF618

0CK224DF56A

0CK224DF56A

0CE107DF618

0CE107DF618

0CE476BF618

181-091D

0CF474285B0

181-120P

181-120P

0CE226BK618

0CE1072V610

181-091D

181-120K

181-120K

181-091D

181-091D

0CE227BJ618

0CE4772J618

181-091N

0CE226BK618

0CE226BN618

0CE476BK618

0CE4772J618

220UF STD 16V M FL TP5

4.7UF STD 50V 20% FL TP 5

47UF STD 16V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

100UF STD 16V M FL TP5

33UF STD 16V M FL TP5

1UF STD 50V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

47UF STD 25V 20% FL TP 5

1000UF STD 10V M FL TP5

10UF STD 50V M FL TP5

220UF STD 16V M FL TP5

1UF STD 50V M FL TP5

220000PF 2012 16V 10% R/TP X7R

47UF STD 50V M FL TP5

100UF STD 16V M FL TP5

0.1000UF STD 50V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

10UF STD 16V M FL TP5

10UF STD 16V M FL TP5

100UF STD 16V M FL TP5

100UF KME 16V M FL TP5

100UF KME 25V M FL TP5

3.3UF STD 50V 20% FL TP 5

100UF KME 16V M FL TP5

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

100UF STD 16V M FL TP5

100UF STD 16V M FL TP5

47UF KME TYPE 16V 20% FL TP 5

DEHR33A102KN2A 1000PF 1KV 10%,-10%

0.47UF S 275V 10% PCX2 337 BULK

470 PF 4KV K JE R FL 10

470 PF 4KV K JE R FL 10

22UF KME 50V M FL TP5

100UF KMF 450V 20% FL BULK

DEHR33A102KN2A 1000PF 1KV 10%,-10%

2200PF 4KV M E FMTW LEAD 4.5

2200PF 4KV M E FMTW LEAD 4.5

DEHR33A102KN2A 1000PF 1KV 10%,-10%

DEHR33A102KN2A 1000PF 1KV 10%,-10%

220U KME 35V M FL TP5

470UF KMF 35V 20% TP 5 FL

SL 100PF 1KV 10%,-10% R/TP TP5

22UF KME 50V M FL TP5

22UF KME 100V M FL TP5

47UF KME 50V M FL TP5

470UF KMF 35V 20% TP 5 FL

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 22

LOCA. NO PART NO DESCRIPTION

C731

C733

C734

C743

C744

C745

C746

C747

C777

C810

C832

L1201

L1202

L1203

L1204

L401

L705

L706

T1101

T1102

T1103

T1104

T1105

T1106

T701

FR704

L502

L503

L504

L505

L506

L507

L518

L521

L522

L523

L524

L525

L526

R702

R703

R704

R705

R706

R711

R712

R714

R715

0CE227BJ618

181-120N

0CE4772J618

0CE477BD618

0CE227DK618

0CE477BD618

0CE477BD618

0CE477BD618

181-091D

0CK823DK56A

0CE107DF618

6140VR0005B

6140VR0005B

6140VR0005B

6140VR0005B

0LA0272K139

6140VR0008B

6140VR0008B

6170VH0002A

6170VH0002A

6170VH0002A

6170VH0002A

6170VH0002A

6170VH0002A

6170VMCA65A

0RP0020J809

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RKZVTA001C

0RKZVTA001K

0RS5602K619

0RS5602K619

0RS1203K607

0RS5602K619

0RS5602K619

0RS5602K619

180-A01E

220U KME 35V M FL TP5

1000PF 4KV M E FMTW LEAD4.5

470UF KMF 35V 20% TP 5 FL

470UF KME TYPE 10V 20% FL TP 5

220UF STD 50V M FL TP5

470UF KME TYPE 10V 20% FL TP 5

470UF KME TYPE 10V 20% FL TP 5

470UF KME TYPE 10V 20% FL TP 5

DEHR33A102KN2A 1000PF 1KV 10%,-10%

82000PF 2012 50V 10% R/TP X7R

100UF STD 16V M FL TP5

COIL,SLF7045T-330MR82 TDK 33UF SMD

COIL,SLF7045T-330MR82 TDK 34UF SMD

COIL,SLF7045T-330MR82 TDK 35UF SMD

COIL,SLF7045T-330MR82 TDK 36UF SMD

INDUCTOR,27UH K 4X10.5 TP

COIL,SLF12575T-150M3R2 15UH SMD

COIL,SLF12575T-150M3R2 15UH SMD

TRANSFORMER,UI-11.7 860000UH 1-CH 5W TRS1002A

TRANSFORMER,UI-11.7 860000UH 1-CH 5W TRS1002A

TRANSFORMER,UI-11.7 860000UH 1-CH 5W TRS1002A

TRANSFORMER,UI-11.7 860000UH 1-CH 5W TRS1002A

TRANSFORMER,UI-11.7 860000UH 1-CH 5W TRS1002A

TRANSFORMER,UI-11.7 860000UH 1-CH 5W TRS1002A

TRANSFORMER,EER3019 450UH RZ-15/20LA70

0.02 OHM 1 W 20% TA52

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

MNR-14-E0A-J-101 R OHM 100 OHM 5%

8.2M OHM 1/2 W 5% TA52 UL PILKOR

0.47M OHM 1/2 W 5% TA52 PILKOR

56K OHM 2 W 5.00% TR

56K OHM 2 W 5.00% TR

120K OHM 2 W 5.00% TA62

56K OHM 2 W 5.00% TR

56K OHM 2 W 5.00% TR

56K OHM 2 W 5.00% TR

2 W RW ROUND G 2W 0.33J TA31(63)

LOCA. NO PART NO DESCRIPTION

R727

R736

SW1101

SW1102

SW1103

SW1104

SW1105

SW1106

SW1107

SW1108

JA201

RJ201

SC204

L1

L101

L1101

L1101

L119

L1200

L1205

L1206

L200

L201

L202

L204

L205

L206

L207

L208

L209

L298

L299

L351

L400

L402

L501

L515

L516

L517

L581

L601

L602

L603

L701

L702

L703

0RD0472H609

0RD0472H609

140-313A

140-313A

140-313A

140-313A

140-313A

140-313A

140-313A

140-313A

6612VCH003B

6613V00008F

381-091B

6210TCE001G

6210TCE001G

6210TCE001A

6210TCE001G

6210TCE001A

6210TCE001G

6210TCE001G

6210TCE001G

6200JB8010L

6200JB8010L

6200JB8010L

6210TCE001A

6210TCE001A

6210TCE001G

6200JB8010L

6210TCE001A

6210TCE001A

6210TCE001A

6210TCE001A

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210VC0004A

6210TCE001G

6210TCE001A

6210TCE001G

6210TCE001G

6210TCE001G

125-022K

125-022K

6210TCE001G

47 OHM 1/2 W 5.00% TA52

47 OHM 1/2 W 5.00% TA52

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

SWITCH,TACT 2LEAD 100G(TA) NON 5V 0.001A

JACK,PEJ012C H=6.5 STEREO 1P W/O S/W WHITE

JACK,PMJ014F E/P(ST)+S-VHS+3P H6.5

JACK,S-091B UGCOM SCART 21 PIN W/O BOSS

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,MLB-201209-1000L-N2 R/TP 1000OHM 350MA

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,BK3216 4S600 3.2X1.6X0.8MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,FERRITE NON 62MM 1UH NY 3.5X6.0MM

FILTER,FERRITE NON 62MM 1UH NY 3.5X6.0MM

FILTER,HH-1M3216-501 CERATEC 3216MM

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

COIL & TRANSFORMER

RESISTOR

SWITCH

CRYSTAL & FILTER

JACK

Page 23

LOCA. NO PART NO DESCRIPTION

L704

L801

L802

L803

L99

LF701

R226

R228

R229

R230

R505

R710

Z100

Z500

Z600

A1

A1

A1

A1

A2

A3

A3

A3

A4

A5

F701

P701

P900

PA1101

TH701

TU401

VA701

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6200JB8012Q

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6210TCE001A

125-022K

156-A01L

156-A02X

156-A02M

3828VA0450B

3828VA0450D

3828VA0450F

3828VA0450K

6710V00126N

6410VBH005A

6410VEH008A

6410VEH008D

6851V00004D

6866VA9001A

131-098B

6620VZ0002A

6630G15E215

6726VV0006D

163-048D

6700PF0002A

164-003K

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,HH-1M3216-501 CERATEC 3216MM

FILTER,OR 14*7*7.5H SMC BK 6.0-11.0MH 0.55PHY

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,MLB-201209-1000L-N2 MAG LAYERS

FILTER,HB-1S2012-080JT CERATEC 2012MM

FILTER,FERRITE NON 62MM 1UH NY 3.5X6.0MM

CRYSTAL HC49U 6.000MHZ 30PPM 16PF