Page 1

1-1

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS ............. 1-2

SERVICING PRECAUTIONS .................................................................................................. 1-3

THE STEPS FOR CHANGE THE OPTION CODE ........................................................... 1-4

UP-DATING PROGRAM ........................................................................................................... 1-5

SPECIFICATIONS ...................................................................................................................... 1-7

Page 2

1-2

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from PHILIPS Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard. These components are indicated by the letter “x” included in their component designators and are required to maintain safe performance. No deviations

are allowed without prior approval by PHILIPS Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes

into the set is not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized modifications will not only void the warranty, but may lead to property damage or

user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to

alert the service personnel to important safety information in the

service literature.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the service personnel to the presence of

noninsulated “dangerous voltage” that may be of sufficient magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral triangle is intended to convey to the service personnel the

following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items trans-ported to and

from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields,

strain reliefs, power supply cords, and other hardware have been reinstalled

per the original design. Be sure that the safety purpose of the polarized line

plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a high current device or a resistor rated

at 1 watt or more. Lead tension around protruding metal surfaces must be

avoided.

6. After reassembly of the set, always perform an AC leakage test on all

exposed metallic parts of the cabinet (the channel selector knobs, antenna

terminals, handle and screws) to be sure that set is safe to operate without

danger of electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS TEST. Use an AC voltmeter having 5000 ohms per

volt or more sensitivity in the following manner: Connect a 1500 ohm, 10

watt resistor, paralleled by a .15 mfd 150V AC type capacitor between a

known good earth ground water pipe, conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC voltage across the combination of

1500 ohm resistor and .15 mfd capacitor. Reverse the AC plug by using a

non-polarized adaptor and repeat AC voltage measurements for each

exposed metallic part. Voltage measured must not exceed 0.75 volts RMS.

This corresponds to 0.5 milliamp AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting

shelf space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where

dew is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must

follow the factory-approved mounting instructions. A product mounted to a

shelf or platform must retain its original feet (or the equivalent thickness in

spacers) to provide adequate air flow across the bottom. Bolts or screws

used for fasteners must not touch any parts or wiring. Perform leakage tests

on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous consequences to home and family.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. Voltmeter

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.15uF

1500 OHM

10 WATT

Place this probe

on each exposed

metal part.

Page 3

1-3

SERVICING PRECAUTIONS

CAUTION: Before servicing the VCR + DVD RECODER covered by this service data and its supplements and addends,

read and follow the

SAFETY PRECAUTIONS. NOTE: if

unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the VCR + DVD RECODER AC power cord

from the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this VCR + DVD

RECODER or any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this VCR + DVD RECODER

and / or any of its electrical assemblies unless all solidstate device heat sinks are correctly installed.

6. Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate an electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil,or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 4

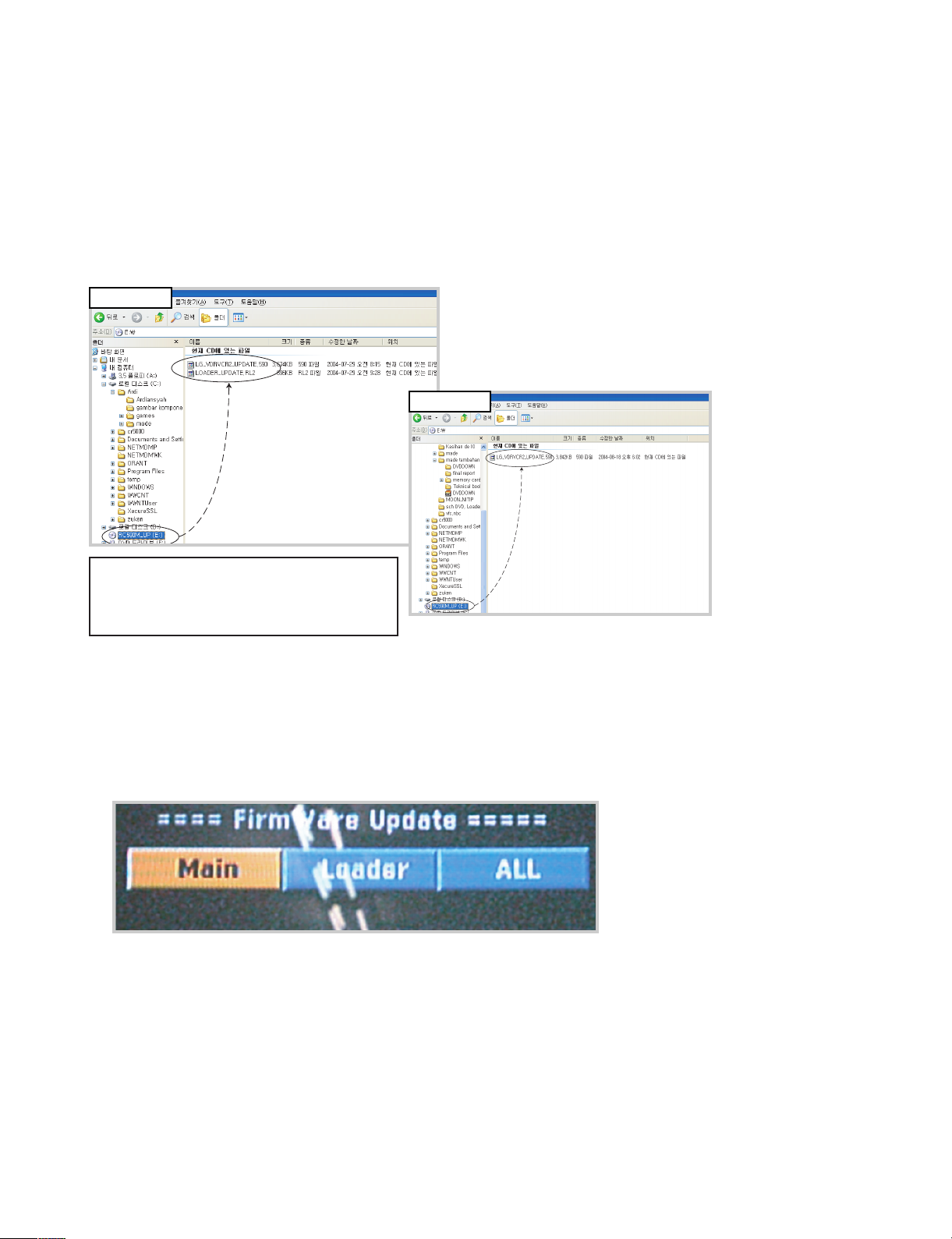

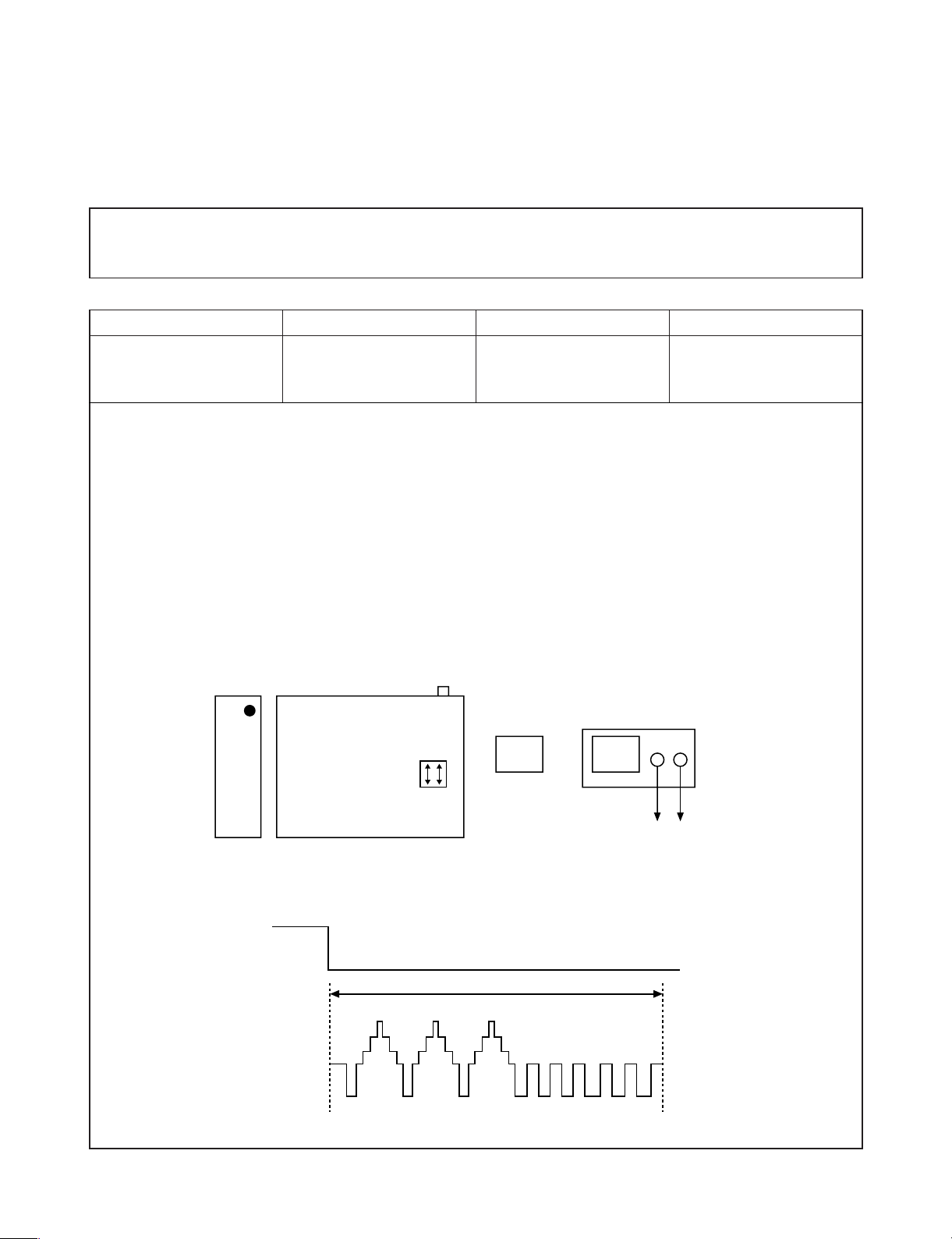

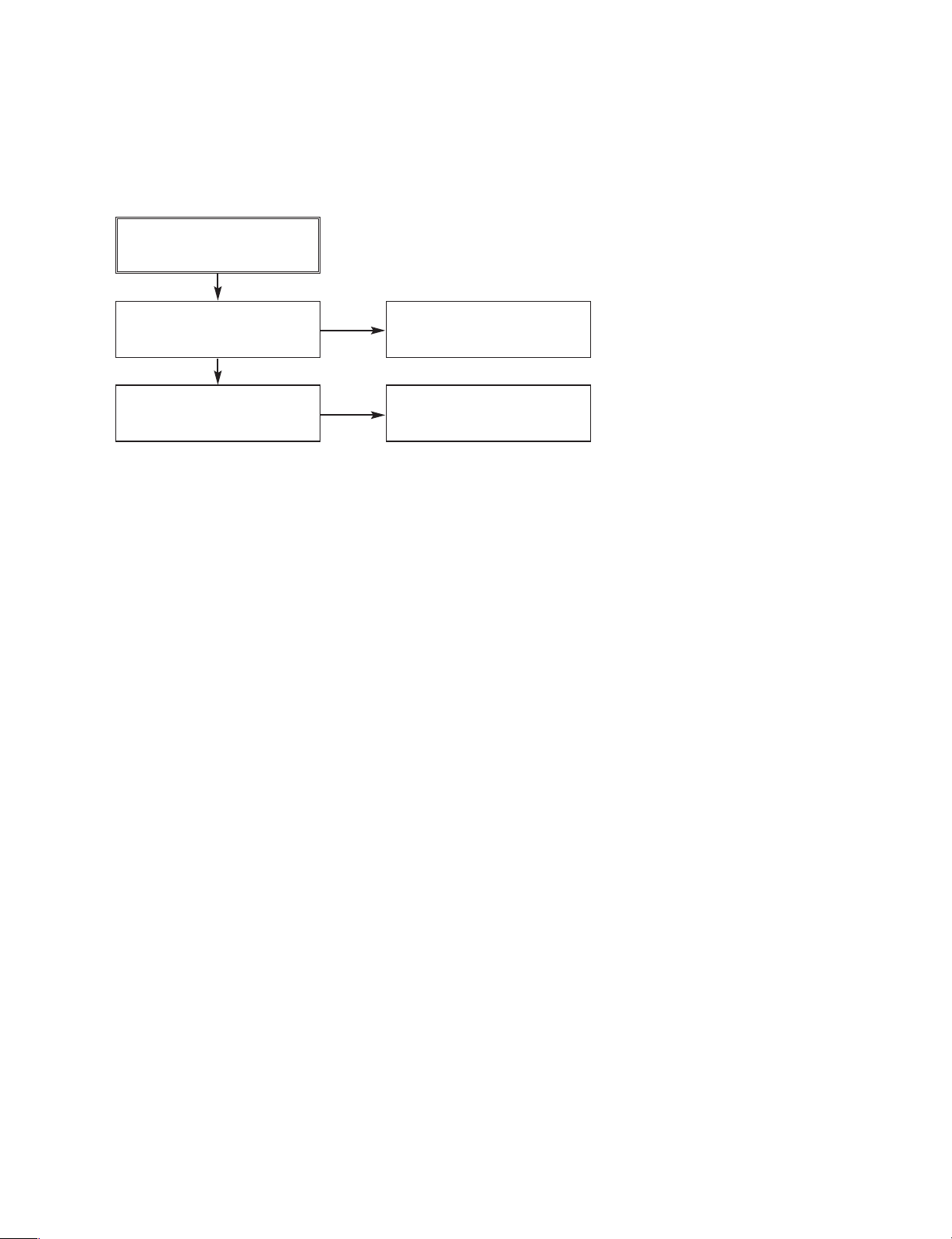

BURNING DISC

• For up-dating the DVD program using the disc, it must burning the disc which include the DVD software.

• For recorder combi set which using the disc downloader program are DVD Program and Loader Program.

• In 2nd generation for recorder combi can download the DVD program and Loader program one by one, or all

together.

• If you format like number 1 you’ll see capture like (figure 1)

• And you have three choice:

1. Main. It’s mean if you chose this it’ll up-dating only DVD prgram.

2. Loader.It’s mean if you chose this it’ll up-dating only Loader program.

3. ALL. It’s mean if you chose this it’ll up-dating DVD and Loader program.

• If you format like number 2 you’ll not see capture like figure 1 that give you choices, you have no choice only

update DVD program

1-5

UP-DATING PROGRAM

* There is two way to format disc DVD Program

1. DVD and LOADER program format in one

disc

2. Only DVD program format in one disc

(Figure 1)

Number 1

Number 2

Page 5

1-6

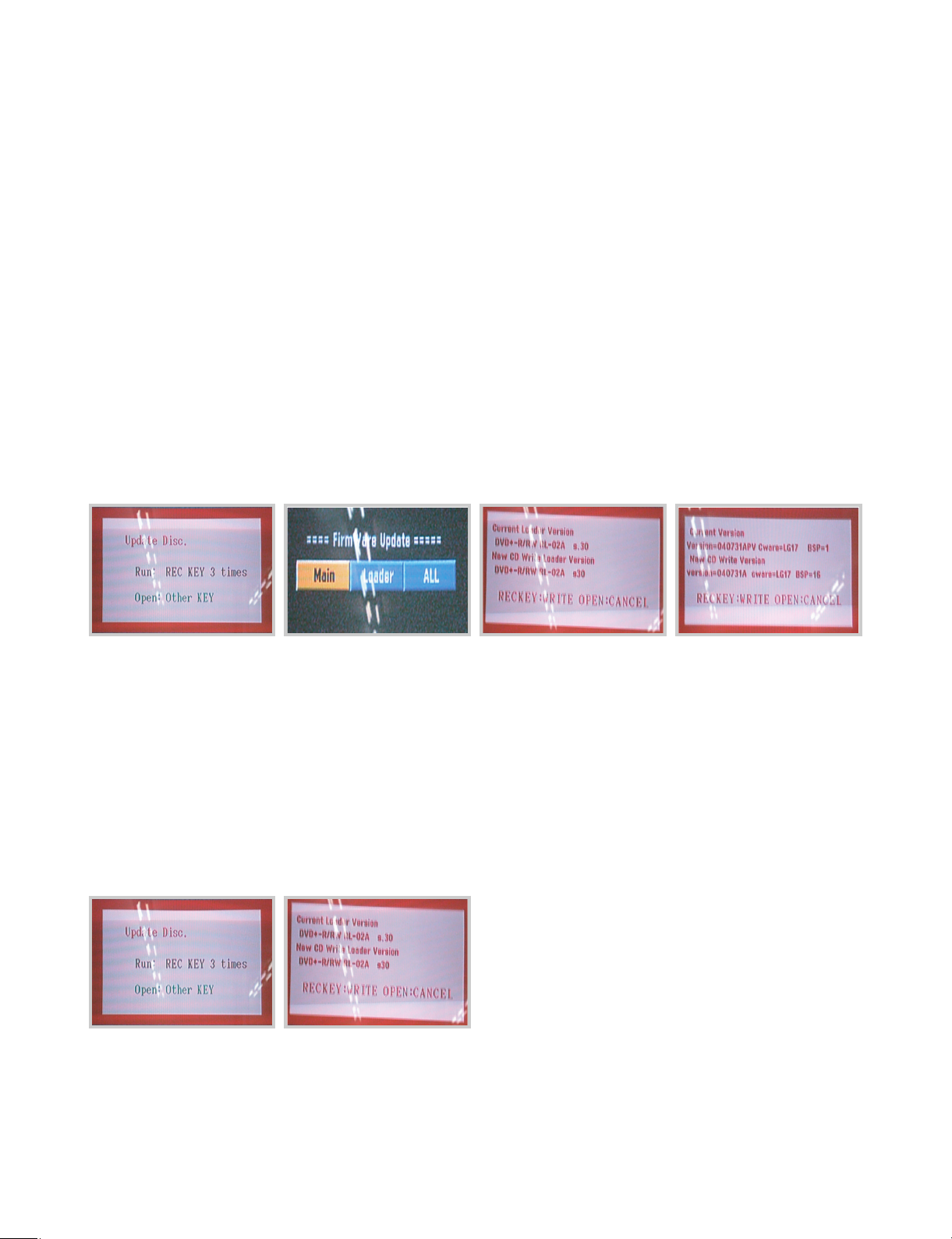

DVD UPGRADE INSTRUCTION

FORMAT NO 1

1. Press POWER KEY to turn on.

2. After booting, insert the upgrade disc, and you will see massage like [FIGURE 1]

3. Press “REC” key (front or remote) 3 times and you will see as [FIGURE 2] with remote Chose one of them

then Press enter

4. For update both of them [MAIN & LOADER] we chose “ALL” and first you will see [FIGURE 3] DVD update

→ Check the “Current Version” and “ New CD Write Version” and press “REC” key.

5. The DVD update will be on progress.And when finish update MAIN Version it’s automatically continue to

Update Loader Version and You will see [FIGURE 4]

→ Check the “Current Version” and “New CD Write Version “ and Press “REC” key once more

6. The LOADER update will be on progress. And tray will open.

7. Remove the disc and wait until finish

8. The tray will be close and open automatically after completing “UNDER UPDATE” 100%

9. Turn off the unit

10. Turn on again the unit is operation with new software

FORMAT NO 2

1. Press POWER KEY to turn on.

2. After booting, insert the upgrade disc, and you will see massage like [FIGURE 1]

3. Press “REC” key (front or remote) 3 times

4. The DVD update will be on progress.

→ Check the “Current Version” and “New CD Write Version “ and Press “REC” key once more

5. The tray will be open automatically after completing “UNDER UPDATE” 100%

6. Remove the disc andTurn off the unit

7. Turn on again the unit is operation with new software

[FIGURE 1] [FIGURE 2] [FIGURE 3] [FIGURE 4]

[FIGURE 1] [FIGURE 2]

Page 6

1-7

SPECIFICATIONS

General

Power requirements AC 200-240V, 50 Hz

Power consumption 35W

Dimensions (approx.) 430 X 78.5 X 354 mm (w x h x d)

Mass (approx.) 5.7 kg

Operating temperature 5°C to 35°C

Operating humidity 5 % to 90 %

Television system PAL B/G, PAL I/I, SECAM D/K colour system

Recording format PAL

SYSREM

Laser Semiconductor laser, wavelength 650 nm

Video head system Double azimuth 4 heads, helical scanning

Signal system PAL

Recording

Recording format DVD VideoRecording, DVD-VIDEO

Recordable discs DVD-ReWritable, DVD-Recordable, DVD+ReWritable, DVD+Recordable

DVD+Recordable (Double Layer)

Recordable time DVD (4.7GB) : Approx. 1 hour (XP mode), 2 hours (SP mode),

4 hours (LP mode), 6 hours (EP mode)

DVD+R DL (8.5GB) : Approx. 1 hour 50 minutes (XP mode), 3 hours

40 minutes (SP mode), 7 hours 10 minutes (LP mode),

11 hours (EP mode)

Video recording format

Sampling frequency 27MHz

Compression format MPEG 2

Audio recording format

Sampling frequency 48kHz

Compression format Dolby Digital

Playback

Frequency response DVD (PCM 48 kHz): 8 Hz to 22 kHz, CD: 8 Hz to 20 kHz

DVD (PCM 96 kHz): 8 Hz to 44 kHz

Signal-to-noise ratio More than 100 dB (AUDIO OUT connector)

Harmonic distortion Less than 0.008% (AUDIO OUT connector)

Dynamic range More than 95 dB (AUDIO OUT connector)

Inputs

AERIAL IN Aerial input, 75 ohms

VIDEO IN 1.0 Vp-p 75 ohms, sync negative, RCA jack x 1 / SCART x 2

AUDIO IN 0 dBm more than 47 kohms, RCA jack (L, R) x 1 / SCART x 2

DV IN 4 pin (i.LINK/IEEE 1394 standard)

S-VIDEO IN (Y) 1.0 V (p-p), 75 Ω, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 Ω

Outputs

VIDEO OUT 1.0 Vp-p 75 ohms, sync negative, SCART x 2

S-VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 Ω

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync, RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack x 2

Audio output (digital audio) 0.5 V (p-p), 75 Ω, RCA jack x 1

Audio output (optical audio) 3 V (p-p), 75 Ω, Optical connector x 1

Audio output (analog audio) 2.0 Vrms (1 KHz, 0 dB), 600 Ω, RCA jack (L, R) x 1 / SCART

• Design and specifications are subject to change without notice.

• Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby

Laboratories.

• DTS and DTS Digital Out are registered trademarks of Digital Theater Systems, Inc.

Page 7

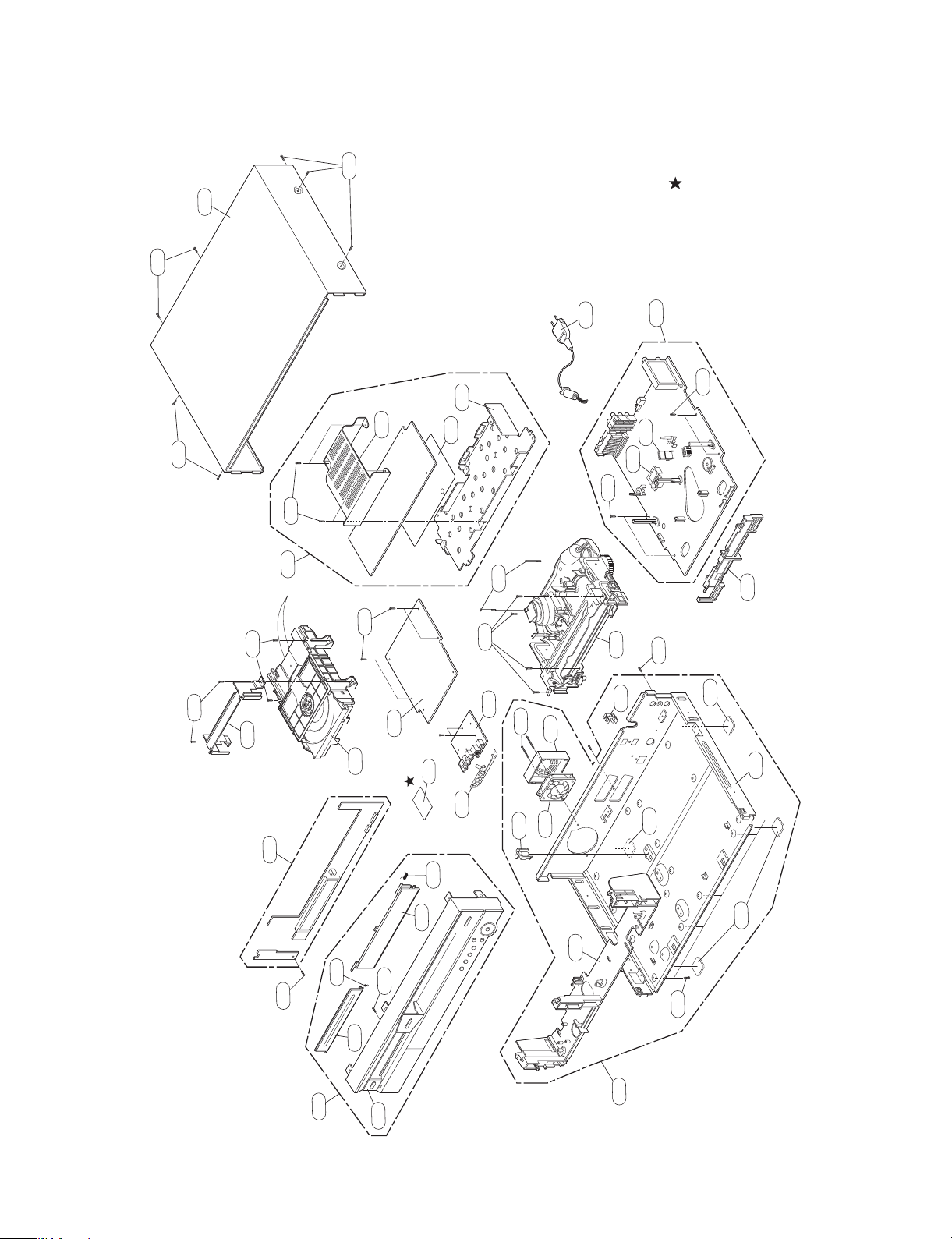

2-1

SECTION 2

EXPLODED VIEWS

CONTENTS

EXPLODED VIEWS .....................................................................................................................2-2

1. Cabinet and Main Frame Section ...........................................................................................2-2

2. Deck Mechanism Section (RL-05) ..........................................................................................2-3

3. Packing Accessory Section ....................................................................................................2-4

Page 8

2-2

EXPLODED VIEWS

1. Cabinet and Main Frame Section

463

463

250

469

A47

463

255

256

257

470

300

OPTIONAL PART

A46

469

321

323

469

276

457

278

457

A50

457

286

A60

285

469

469

A52

283

A54

284

274

457

A48

468

266

264

263

260

A00

265

465

261

320

261

261

452

A43

A44

280

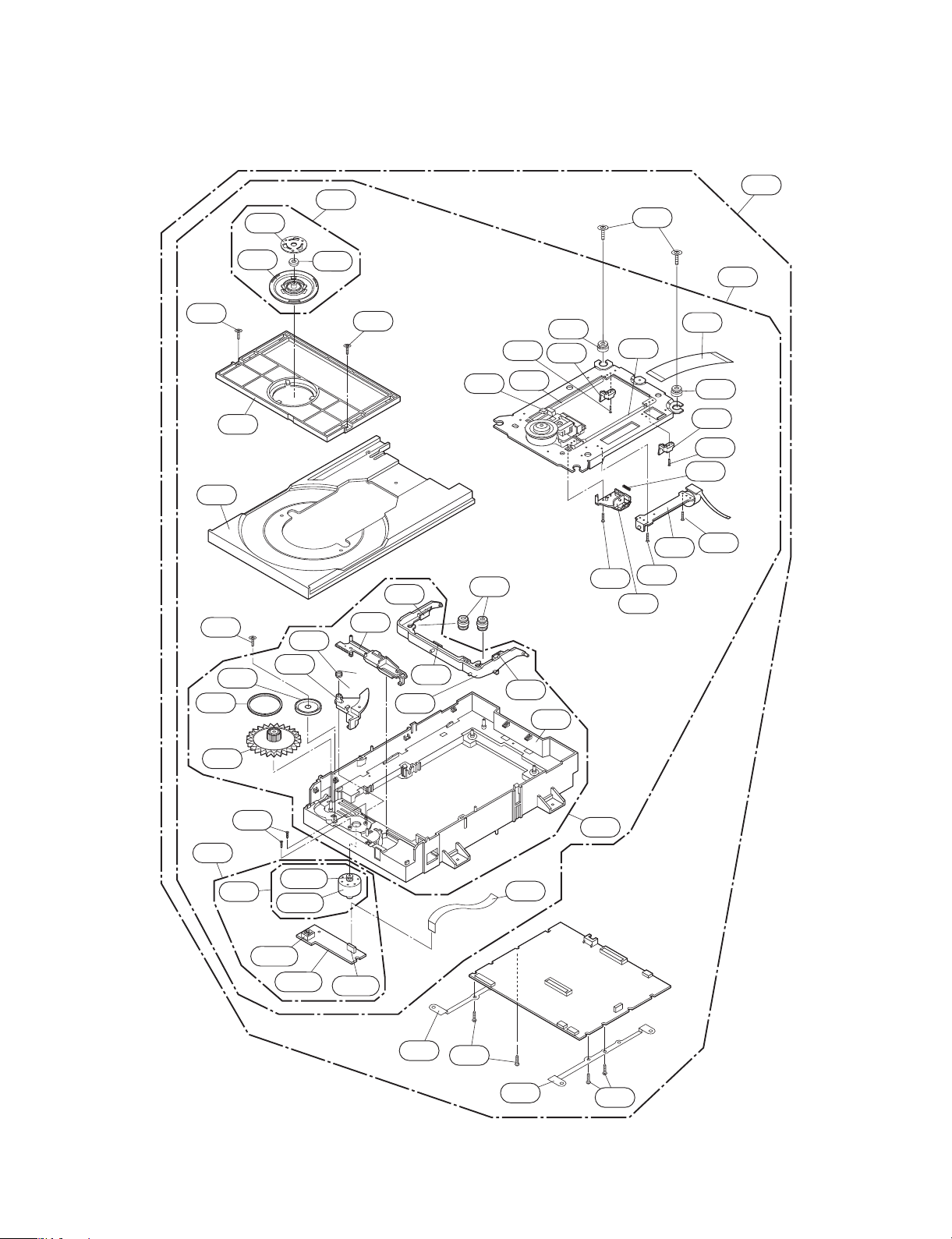

Page 9

2-3

2. Deck Mechanism Section (RL-05)

1434

1026

1435

1015

1005

1016

1001

1003

1013

1014

A001

1002

1

434

1012

1019

1011

1009

1038

1024

1432

1029

1019

1025

1027

1020

1433

1437

1029

1432

1033

1021

A60

A000

1030

1025

1027

1432

1032

1432

1017

A004

1436

1018

1018A

1018B

1018C

1018E

1018D

1042

1434

1006

1041

A002

1434

Page 10

2-4

3. Packing Accessory Section

810

808

BATTERY

900

REMOCON

826

FILTER

803

P

ACKING

CABLE ASS'Y

RF

OPTIONAL PARTS

806

CABLE(COAXIAL)

811

PLUG ASS'Y 1WAY

812

PLUG ASS'Y 2WAY

821

SCART CABLE

INSTRUCTION ASSEMBLY

801

803

804

ACKING

P

BAG

802

BOX CARTO

N

Page 11

3-1

SECTION 3

ELECTRICAL

CONTENTS

OVERALL WIRING DIAGRAM..............................3-2

VCR PART

ELECTRICAL ADJUSTMENT

PROCEDURES

............................................................3-3

VCR ELECTRICAL TROUBLESHOOTING

GUIDE

.............................................................................3-4

1. POWER(SMPS) CIRCUIT .......................................3-4

2. SYSTEM/KEY CIRCUIT ..........................................3-7

3. SERVO CIRCUIT.....................................................3-8

4. Y/C CIRCUIT..........................................................3-11

5. HI-FI CIRCUIT .......................................................3-15

6. TUNER/IF CIRCUIT...............................................3-18

BLOCK DIAGRAMS................................................3-20

1. POWER(SMPS) BLOCK DIAGRAM......................3-20

2. TUNER/MTZ BLOCK DIAGRAM ...........................3-22

3. VPS BLOCK DIAGRAM ........................................3-23

4. Y/C BLOCK DIAGRAM ..........................................3-24

5. HI-FI BLOCK DIAGRAM........................................3-26

6. SYSTEM BLOCK DIAGRAM.................................3-28

7. SCART & SWICH BLOCK DIAGRAM ...................3-30

CIRCUIT DIAGRAMS..............................................3-32

1. POWER(SMPS) CIRCUIT DIAGRAM ...................3-32

2. TU/IF CIRCUIT DIAGRAM ....................................3-34

3. A/V CIRCUIT DIAGRAM........................................3-36

4. HI-FI CIRCUIT DIAGRAM .....................................3-38

5. SYSTEM CIRCUIT DIAGRAM...............................3-40

6. SCART(JACK) CIRCUIT DIAGRAM

(SCART MODEL ONLY).........................................3-42

7. TIMER CIRCUIT DIAGRAM( 2 TOOL ).................3-44

8. TIMER CIRCUIT DIAGRAM( 3 TOOL, 8 TOOL ) ..3-46

9. TIMER CIRCUIT DIAGRAM( 4 TOOL ).................3-48

10. TIMER CIRCUIT DIAGRAM( 6 TOOL )...............3-50

11. TIMER CIRCUIT DIAGRAM( 7 TOOL ) ...............5-52

• WAVEFORMS .........................................................3-54

• CIRCUIT VOLTAGE CHART ...................................3-56

PRINTED CIRCUIT DIAGRAMS .........................3-60

1. VCR P.C.BOARD(TOP VIEW)...............................3-60

2. VCR P.C.BOARD(BOTTOM VIEW).......................3-62

3. SMPS P.C.BOARD ................................................3-64

4. JACK P.C.BOARD .................................................3-66

5. KEY P.C.BOARD ...................................................3-68

6. TIMER P.C.BOARD ...............................................3-68

VDR PART

VDR ELECTRICAL TROUBLESHOOTING

GUIDE

...........................................................................3-70

1. POWER(SMPS) CIRCUIT .....................................3-70

2. NO COMPONENT VIDEO SIGNAL WHEN

PLAYING DISC......................................................3-72

3. NO COMPOSITE / S-VIDEO SIGNAL WHEN

PLAYING DISC......................................................3-73

4. NO TV, EXTERNAL INPUT VIDEO SIGNAL.........3-74

5. WHEN PLAYING DISC, NO AUDIO OUTPUT ......3-75

6. NO TUNER AUDIO OUTPUT ................................3-75

7. NO OPTICAL / DIGITAL OUTPUT ........................3-75

8. NO EXTERNAL INPUT 1, 2 AUDIO ......................3-76

9. NO EXTERNAL INPUT 3 AUDIO ..........................3-76

BLOCK DIAGRAMS................................................3-77

1. VDR SET TOTAL BLOCK DIAGRAM....................3-77

2. VDR MAIN H/ W BLOCK DIAGRAM .....................3-78

3. POWER BLOCK DIAGRAM ..................................3-79

4. AUDIO IN/ OUT BLOCK DIAGRAM ......................3-80

5. CPU & CONTROL REGISTER

BLOCK DIAGRAM.................................................3-81

6. VIDEO IN/ OUT BLOCK DIAGRAM ......................3-82

7. DV 1394 IN/OUT BLOCK DIAGRAM ....................3-83

8. MEMORY CARD IN/ OUT BLOCK DIAGRAM ......3-84

CIRCUIT DIAGRAMS..............................................3-85

1. BGA 308P CIRCUIT DIAGRAM.............................3-85

2. DDR & B TO B CONNECTOR

CIRCUIT DIAGRAM ..............................................3-87

3. POWER, FLASH, CONNECTOR CIRCUIT

DIAGRAM ..............................................................3-89

4. RST, CONTROL/STATUS_REG., ATAPI,

HOST_CPLD, LATCH CIRCUIT DIAGRAM ..........3-91

5. VIDEO_IN, VIDEO_OUT CIRCUIT DIAGRAM......3-93

6. DV1394, HDMI CIRCUIT DIAGRAM .....................3-95

7. AUDIO IN/OUT CIRCUIT DIAGRAM .....................3-97

• WAVEFORMS .........................................................3-99

• CIRCUIT VOLTAGE CHART .................................3-101

PRINTED CIRCUIT DIAGRAMS .......................3-103

1. VDR P.C.BOARD(TOP VIEW).............................3-103

2. VDR P.C.BOARD(BOTTOM VIEW) .....................3-115

Page 12

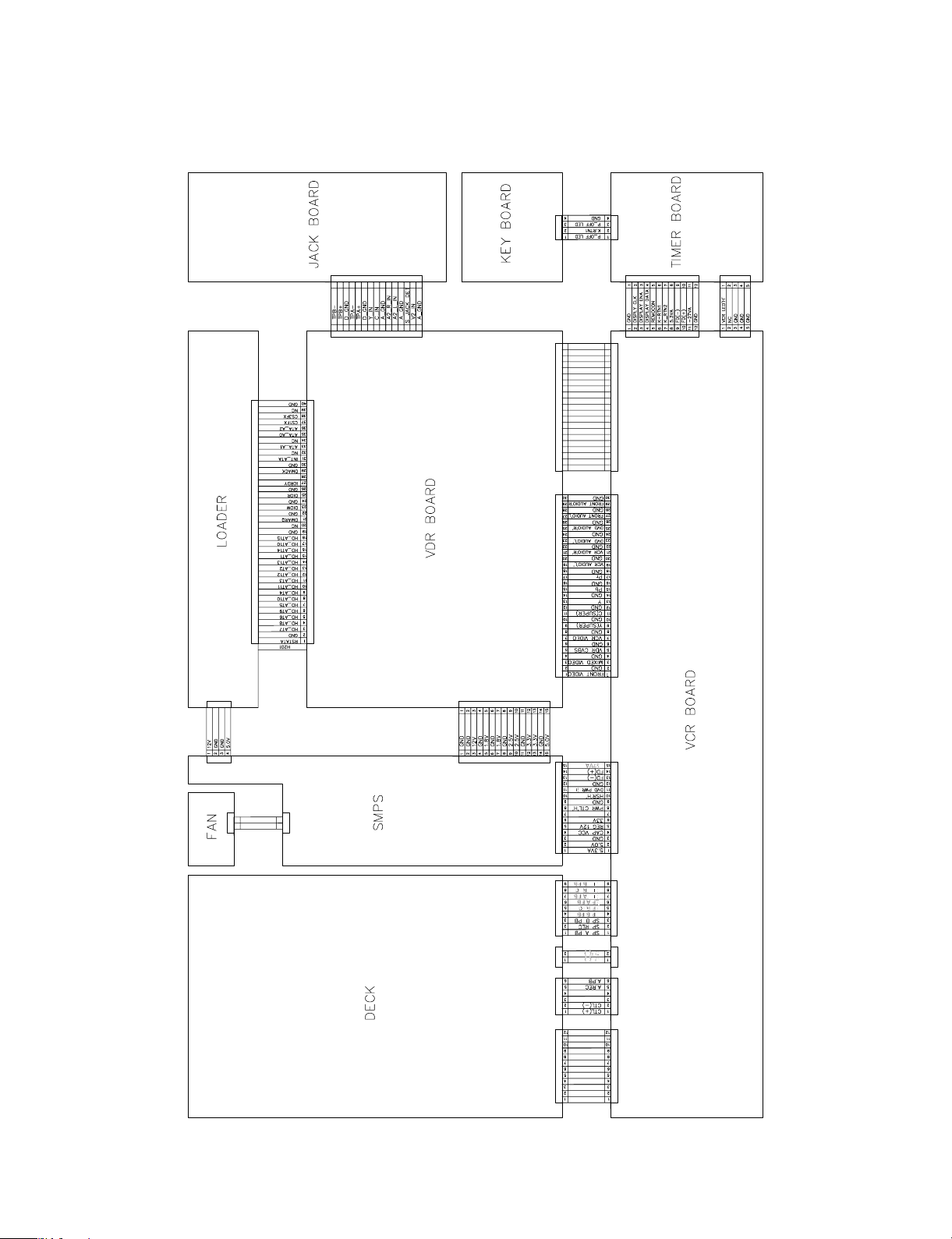

3-2

OVERALL WIRING DIAGRAMS

1514131211

10

987654321

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

SPD.F

GND

INTR/PROG

NC

GND

RADIO'H'

AMP ON

VDR REDET

NC

NC

NC

VDR CLK

DATA(VCR-VDR)

DATA(VDR-VCR)

VDR ENA

AMP CLK

AMP RX

AMP TX

AMP READY

AMP MUTE

NC

1514131211

10

987654321

P6603

P6602

PM601PN302

PN302

PN301

PN301

PMD01PMD02

PN304

CON401

CON401

PPM01

P101

P3D01P3D03

P104

P103

P103

P104

P3D02

P3D02

PMC01

PMC01

P3D03

P3D01

PN303

PM602

PM603 P6M01

13.5VA(DRUM)

A/E(-)

A/E(+)

CFG

CAP.VCC

SERVO VCC

CAP.REV'H'

I-LIMIT

MOTOR GND

S.GND

DRUM VCC(13.5VA)

CAP.CTL

L/M CTL

DPG/DFG

DRUM CTL

8.7V

GND12

1

2

R493

Page 13

3-3

ELECTRICAL ADJUSTMENT PROCEDURES

1. Servo Adjustment

1) PG Adjustment

• Adjustment And Specification

• Test Equipment

a) OSCILLOSCOPE : PAL SP TEST TAPE

MODE

PLAY

• Adjustment Procedure

a) Insert the SP Test Tape and play.

b) Connect the CH1 of the oscilloscope to the H/SW and CH2 to the “VCR VIDEO” TP for the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW, and then check the distance (time dif-

ference), which is from the selected A(B) Head point of the H/SW signal to the starting point of the vertical synchronized signal, to 6.5H ± 0.5H (416µs, 1H=64µs).

• PG Adjustment Method

a-1) Playback the SP standard tape

b-2) Wait for 3seconds with F/P “REC” key and “PLAY” key presseed at the same time. < Digitron[ - - ] >

c-3) Repeat the above step(No.b-2), then it finishes the PG adjusting automatically. < Digitron[ PG ] >

d-4) Stop the playback, then it goes out of PG adjusting mode after mony the PG data.

• CONNECTION

• WAVEFORM

V.Out

H/SW(TP)

R/C TRK JIG KEY 6.5 ± 0.5H

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

H/SW

(TP)

TP

(VCR

VIDEO)

(CH2)

(CH1)

OSCILLOSCOPE

CH1 CH2

R/C KEY

H/SW

(TP)

VCR BOARDVDR BOARD

"VCR VIDEO" TP

VCR PART

H/SW

Composite

VIDEO

6.5H(416µs)

Page 14

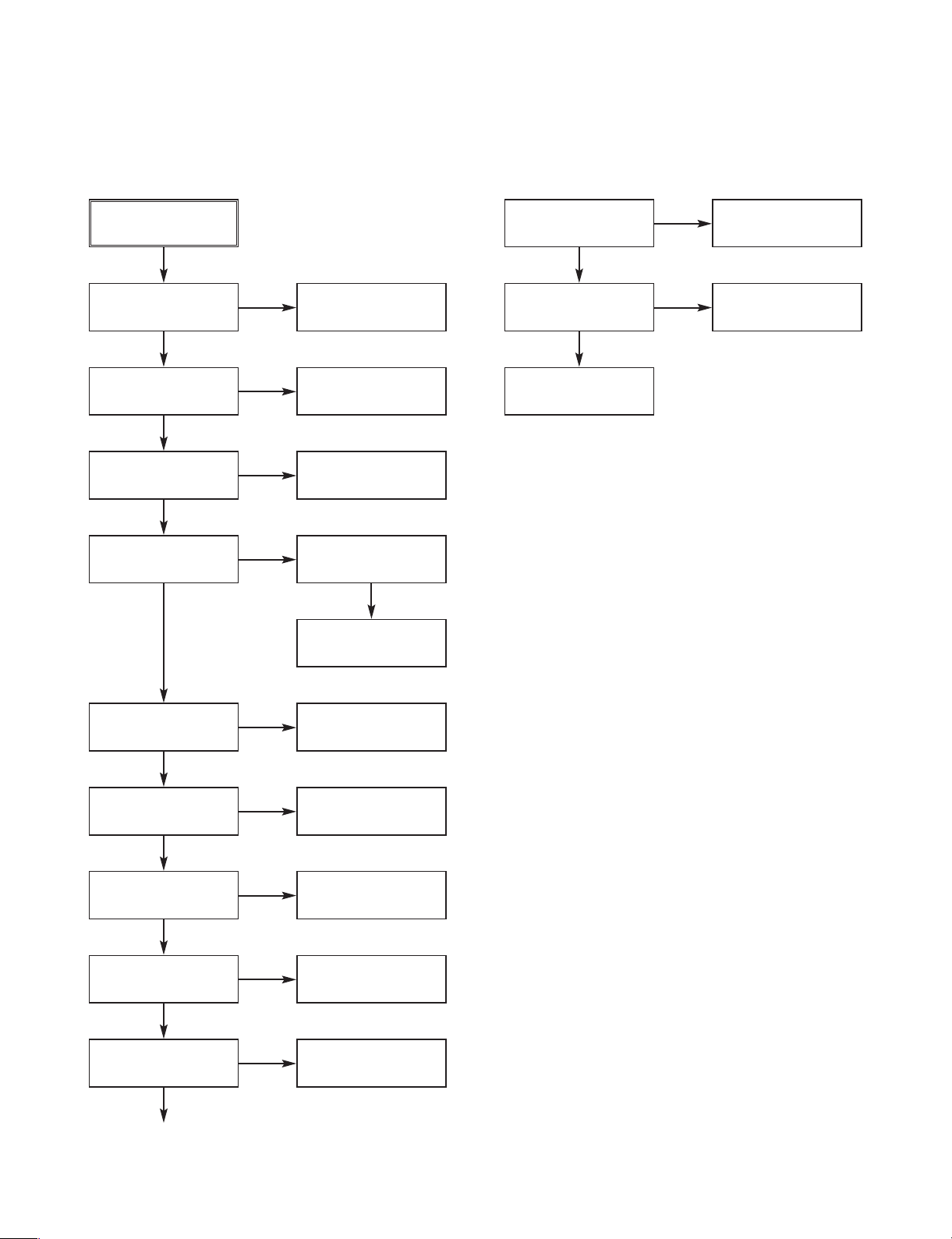

3-4

VCR ELECTRICAL TROUBLESHOOTING GUIDE

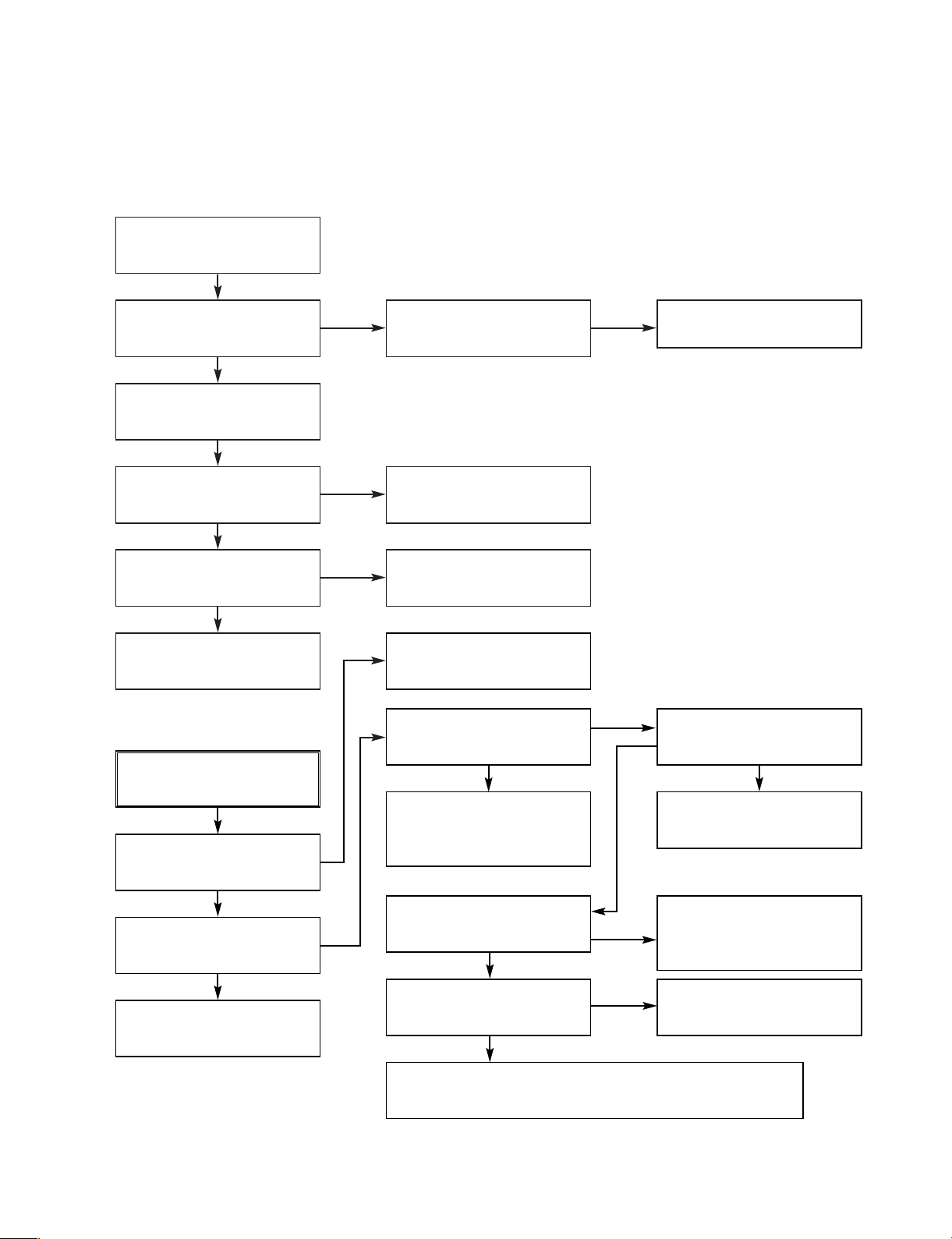

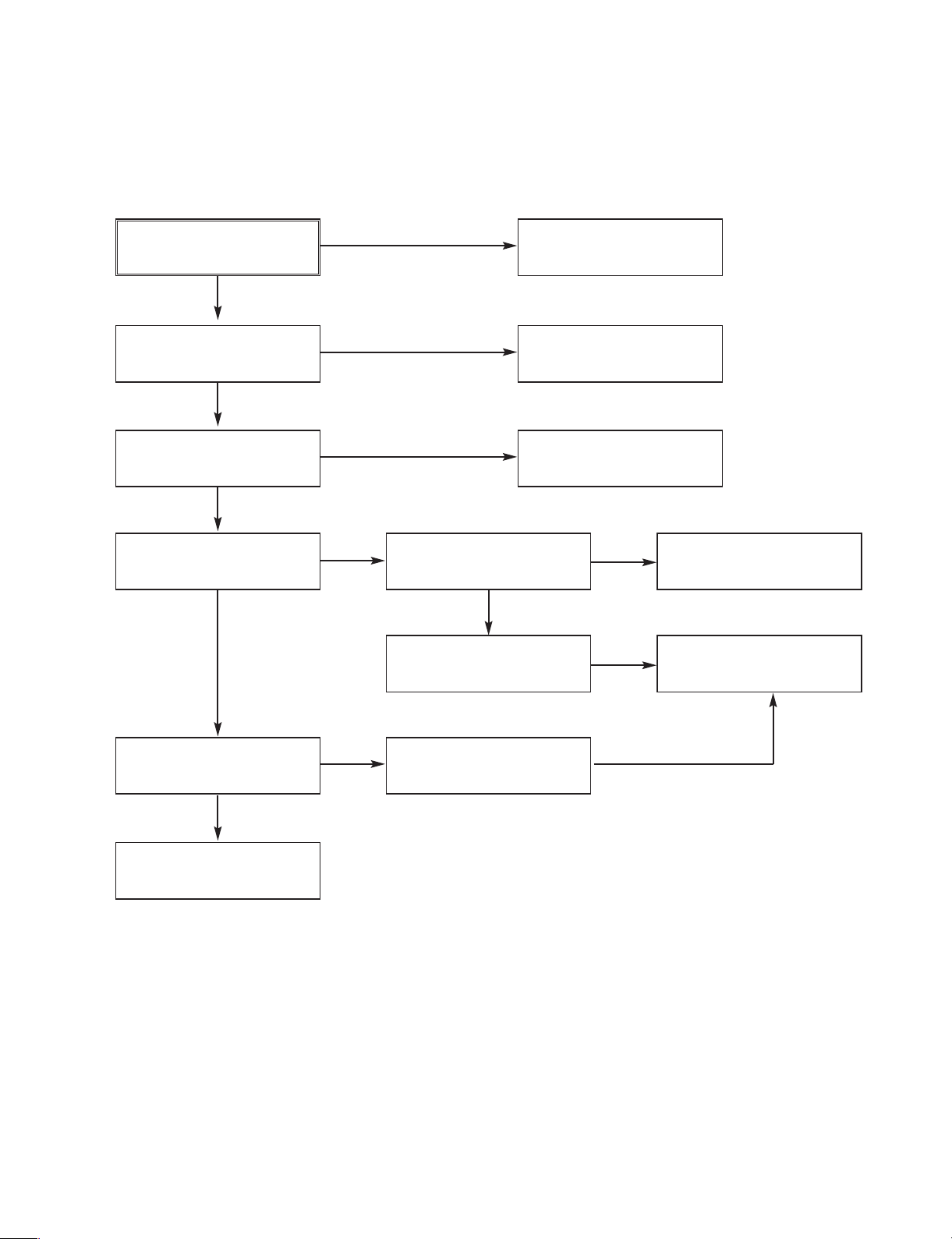

1. Power(SMPS) CIRCUIT

NO 5.3VA.

Replace the F101

(Use the same Fuse)

Is the F101 normal?

Is the TH01

Normal?

Is the BD101

Normal?

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

Replace the BD101

Replace the TH01

Is the D102

normal?

Check or Replace

the D102

Replace the D121

Replace the IC103

Replace the D126

Replace the D129

Replace the D130

Replace the D127

Replace the D128

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Is the Vcc (11V - 18V)

supplied to IC101 Pin2?

NO

Is the D121

normal?

Is there about 2.5V

at the IC103 Pin1?

Is the D126

normal?

Is the D129

normal?

Is the D130

normal?

Is the D127

normal?

Is the D128

normal?

YES

Power Line of Main

PCB(VCR) is short

Page 15

3-5

VCR ELECTRICAL TROUBLESHOOTING GUIDE

No 12VA

Check or Replace

the D126

Is the Vcc(13V)

supplied to C130?

Check or Replace

the Cap / Drum

Is the D132

Normal?

NO

NO

Replace the D132

YES

YES

(To Cap, Drum Motor )

No REG 12V

Check or Replace

the D126

Check the ‘PWR CTL

“H”’signal from µ-com

Check the 33V Line

Replace the Q126

Is the Vcc(13V) supplied to Q126Collector?

Is the Vcc(33V) supplied to Q126 Base?

Is the Q126 Nomal?

Check or Replace

the D126

NO

NO

NO

YES

YES

YES

NO VFD

Check or Replace

the R107

Is the R107

Normal?

Is the D128

Normal?

NO

Check or Replace

the D128

Check or Replace

the ZD151

NO

NO

YES

Is the ZD151

Normal?

Check or Replace

the D127

YES

YES

No 33V

Check or Replace

the D130

Is the Vcc(33V) supplied to Q123 Emittor?

Is the Q123 Base

‘H’?

NO

Check the ‘PWR CTL

“H”’signal from µ-com

NO

YES

Check or Replace

the Q123

YES

Page 16

3-6

VCR ELECTRICAL TROUBLESHOOTING GUIDE

No 28V (HSR)

Check or Replace

the D129

Is the Vcc(30V) supplied

to Q120 Collector?

Is the Vcc(33V) supplied

to Q121 Collector?

Is the Vcc(30V) supplied to Q120 Base?

NO

NO

Check or Replace

the ZD153

NO

Check the ‘HSR “H”

signal from µ-com

Check or Replace the

Q121/Q122 & 33V line

YES

YES

Check or Replace

the Q120

YES

Page 17

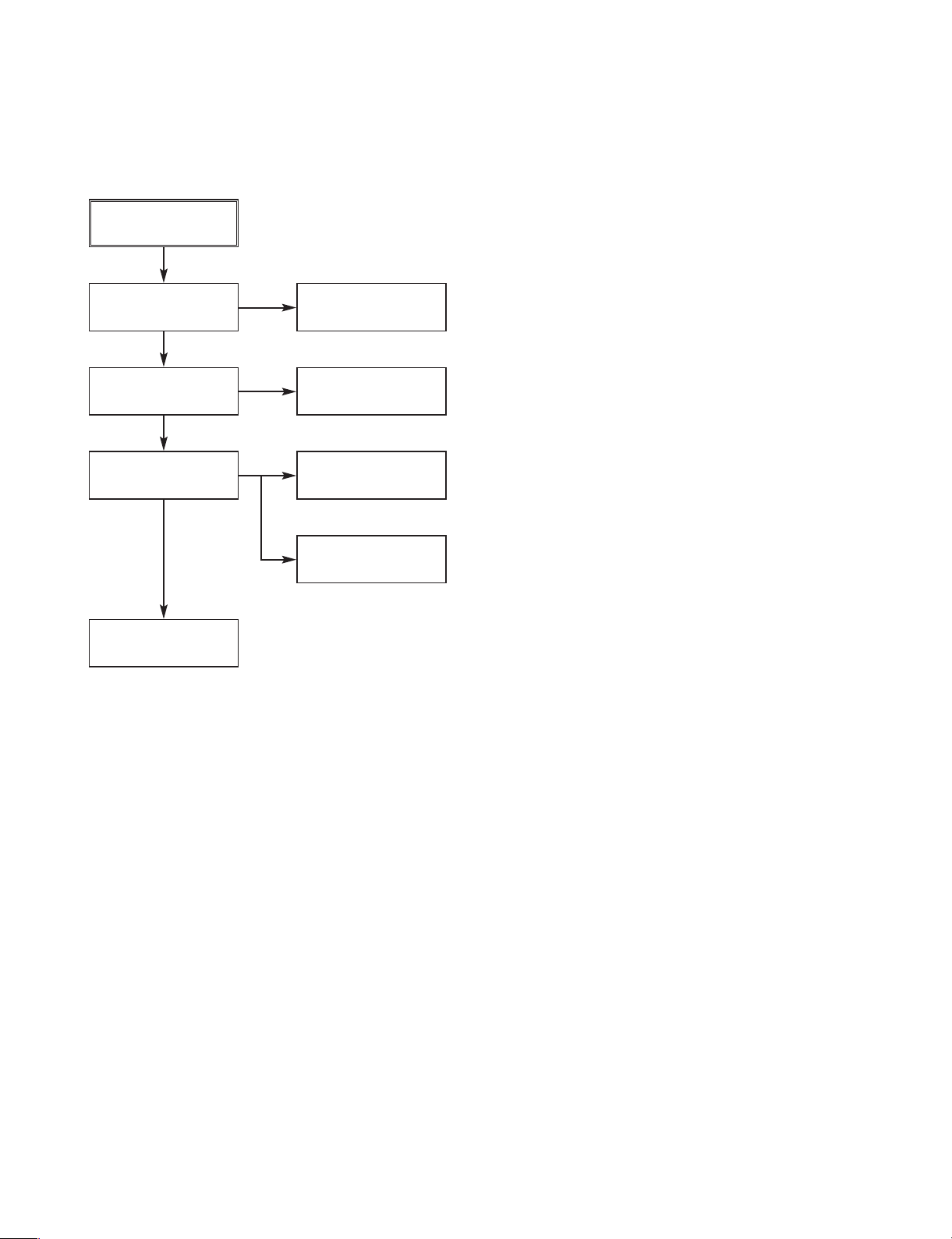

3-7

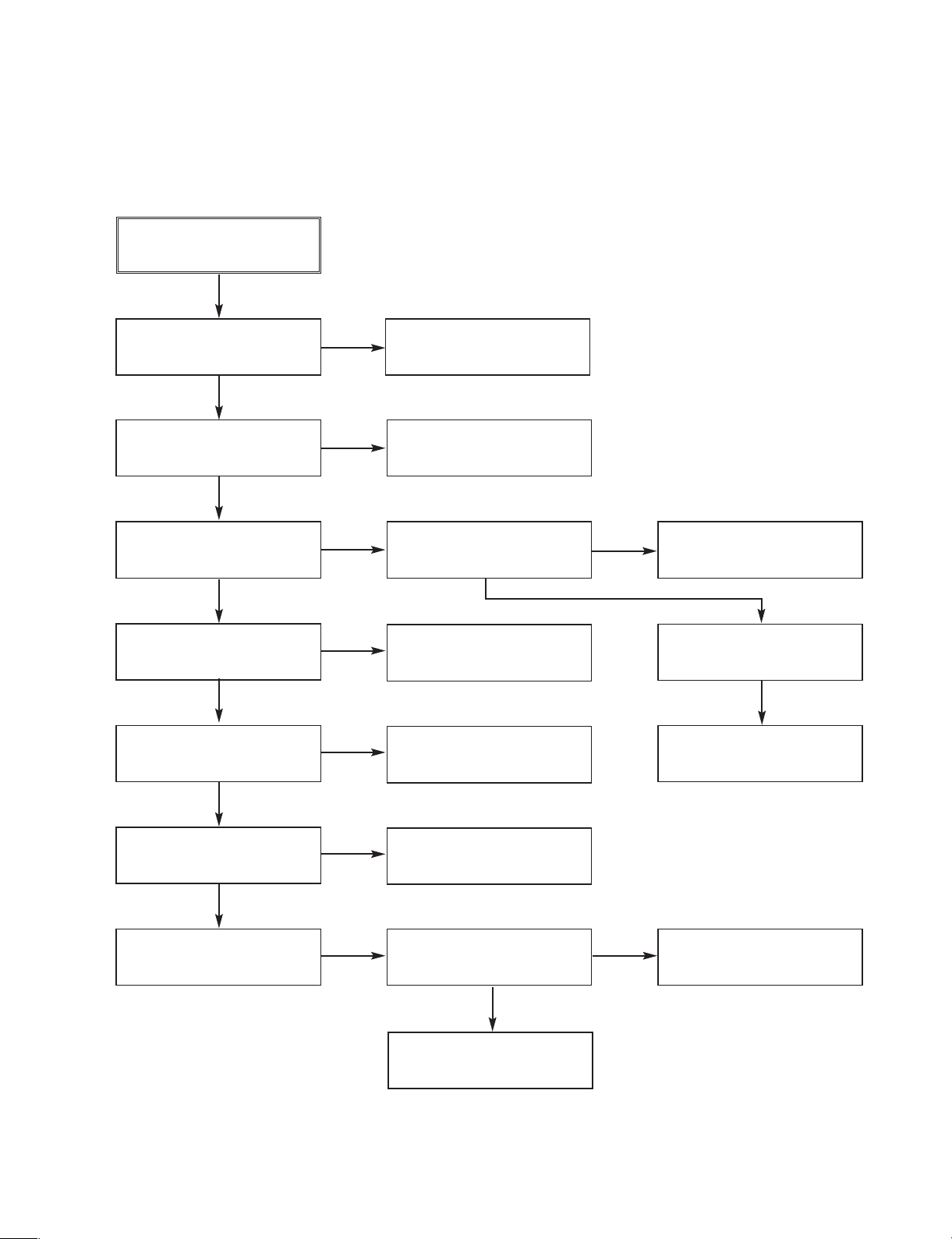

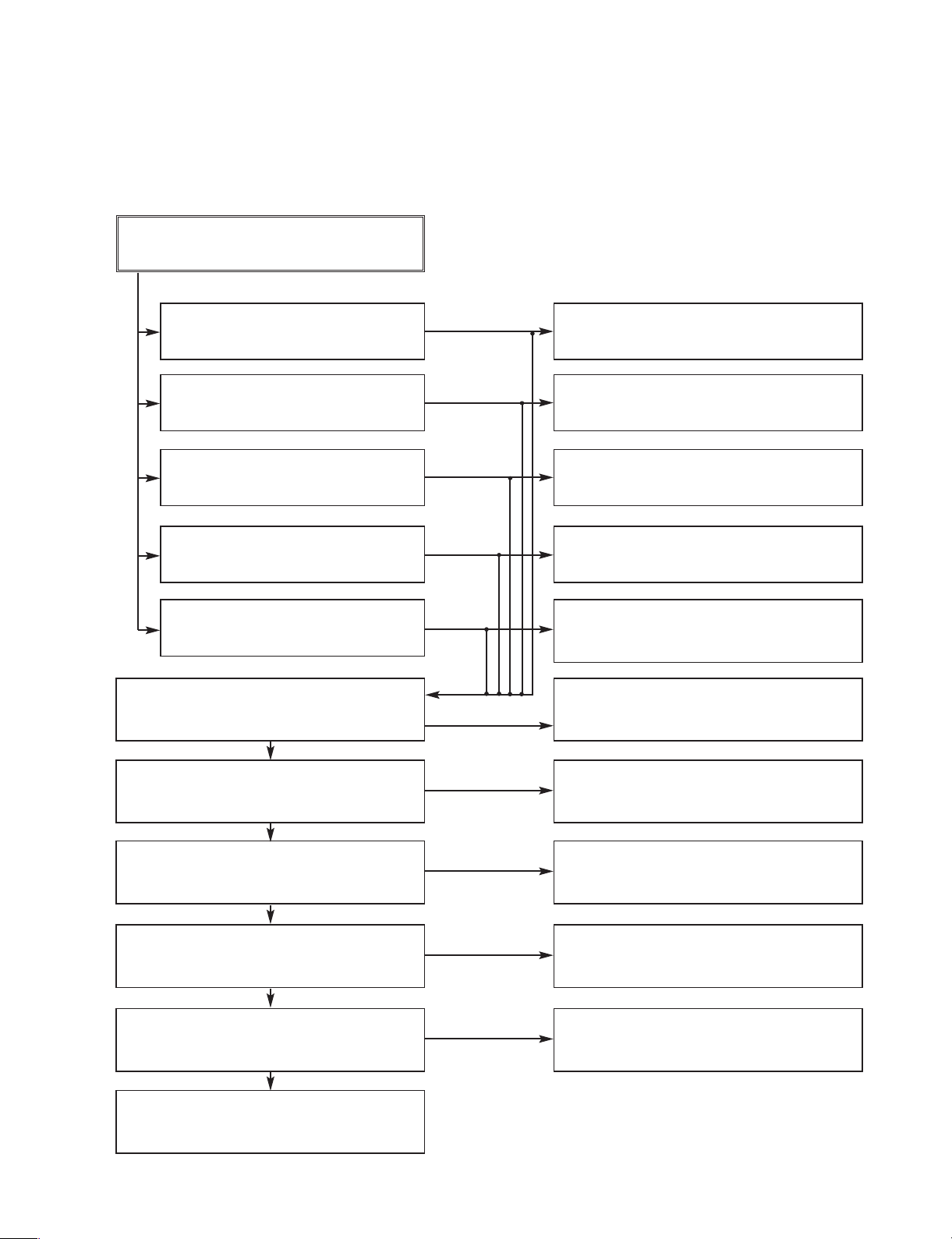

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

(2) The unstable loading of a Cassette tape

Auto Stop

Does the H/SW waveform

appear at IC501 Pin23?

Do the T-UP Reel Pulses

appear at IC501 Pin3?

Is 12V applied to PMC01

Pin8?

Check the Drum Motor

signal.

Does 5.0V appear at the

RS501?

Check the Power Circuit.

Check the power.

Is 5.0V applied to the

R544 ?

Refer to SMPS 5.3VA

troubleshooting.

Check IC501

Pins86, 87, 88, 89.

Do T/UP Reel Pulses

appear at the Q514 Base

terminal?

Replace the T/UP Reel

Sensor (RS501).

Check the CST SW and

the peripheral circuitry.

Replace the IC501.

The unstable loading of a

Cassette tape

Does the “H” signal appear

at IC501 Pin32 during

inserting the CST ?

Does the “L” signal appear

at IC501 Pin19 while

inserting the CST?

Check the Deck

Mechanism.

Note :

Auto stop can occur because Grease or Oil has dried up

YES

YES

NO

YES

YES

YES

NO

NO

NO

NO

NO

NO NO

YES

YES YES

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 18

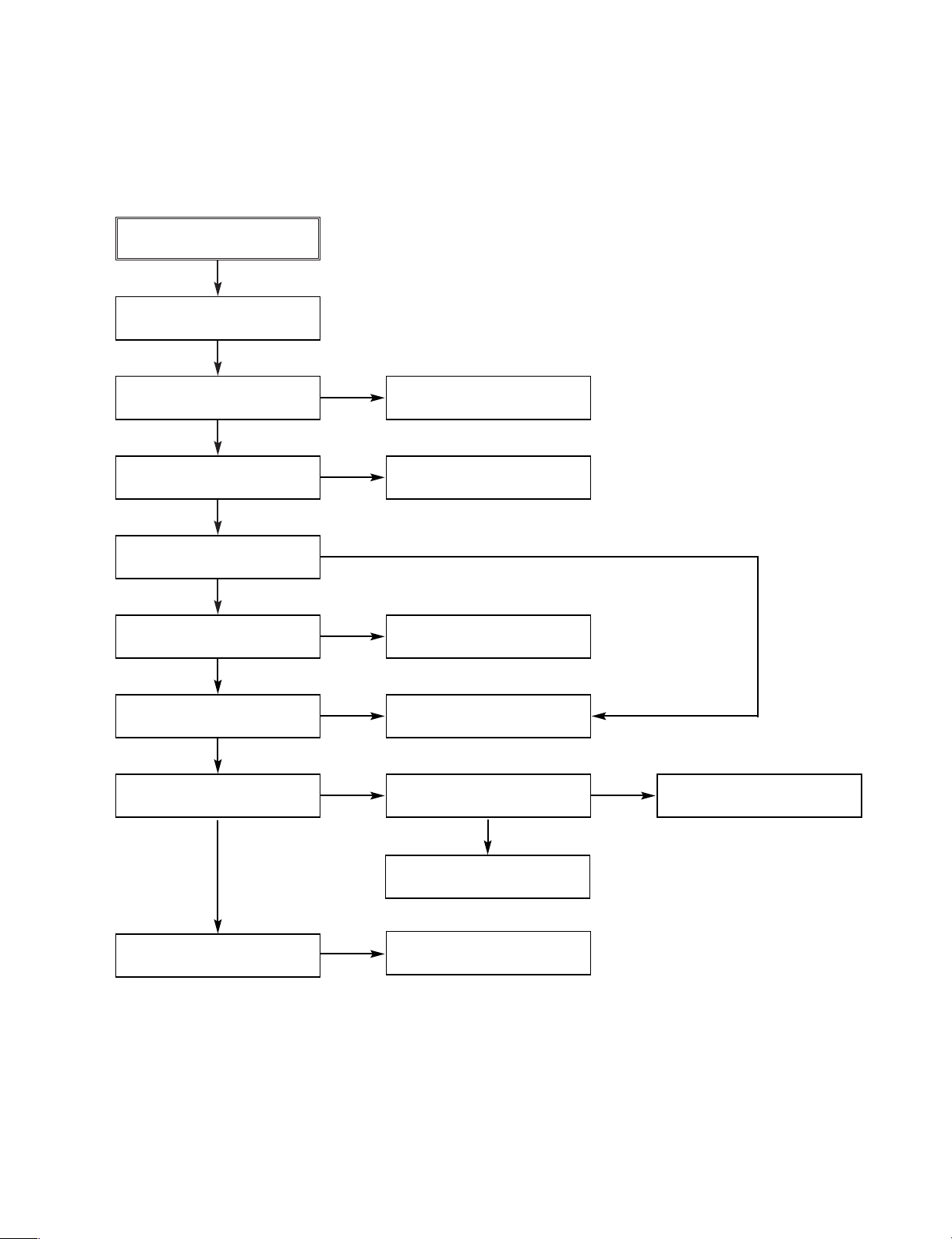

3-8

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Does the Noise level of the

screen change

periodically?

Do the CTL pulses appear

at IC501 Pin8?

Is adjusting the height of

the CTL Head accurate?

Readjust the height of the

CTL Head.

Replace the IC501.

Refer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Does the CFG waveform

appear at the IC501 pin9?

On tracking, do the CTL

pulses move?

Does the Video Envelope

waveform appear at IC501

Pin24?

Replace IC501.

YES

YES

YES

NO NO

NO

NO

(2) When the Drum Motor

(2) doesn’t run.

Do the DFG Pulses appear

at PMC01 Pin11?

Replace the Cap M.

Aren’t the foil patterns and

the Components between

IC501 Pin 104 and PMC01

Pin11 shorted?

Replace the IC501.

Refer to “(2)

No 12VA of Power section”

Do the Drum PWM Pulses

appear at IC501 Pin107?

Aren’t the foil patterns and

the Components between

IC501 Pin107 and PMC01

Pin12 shorted?

Do the DFG Pulses appear

at IC501 Pin104?

Do the Drum PWM Pulses

appear at IC501 Pin107?

Are the connecting patterns and the Components

between IC501 Pin107 and PMC01 Pin12 shorted?

When the Drum Motor

doesn’t run,

Does 12V appear at

PMC01 Pin8?

Does 2.8V appear at

PMC01 Pin12?

Check the connector

(PMC01) and the Drum

Motor Ass’y.

NO

YES

YES

YES

NO

NO

NO

NO

NO

YES

YES

YES

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 19

3-9

Does the CFG signal appear at

PMC01 Pin1?

Does the PWM signal appear at IC501

Pin108?

Does 2.8V appear at PMC01?

Check the PMC01 and the Capstan

Motor Ass’y.

Does the Capstan PWM signal appear at

IC501 Pin108?

Aren’t the foil patterns and Components

between IC501 Pin108 and PMC01

Pin9 short?

Does the CFG signal come into IC501

Pin9?

Aren’t the foil patterns and Components

between IC501 Pin108 and PMC01

Pin9 short?

2. SERVO CIRCUIT

(3) When the Capstan Motor doesn’t run,

NO

NO

NO

YES

YES

YES

When the Capstan Motor doesn’t run,

Does 12VA appear at PMC01?

YES

Replace the IC501.

YES

NO

NO

YES

Refer to “SMPS(CAPSTAN/12Volt)

Trouble Shooting”.

Aren’t the foil patterns and component

between IC501 Pin87 and PMC01

Pin1 shorted?

Check the Capstan Motor Ass’y.

NO

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 20

3-10

Keys do not work

Is 5V applied to IC501

Pin36?

Does FLD change when

a function button is

pressed?

Refer to “SMPS 5.3VA

Trouble Shooting”.

Replace the defective

switches.

YES

NO

NO

2. SERVO CIRCUIT

(4) Keys do not work

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 21

3-11

4. Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Does the Video signal

appear at IC301 Pin15?

Check the IC802 Pin28

Is REG 5.0V applied to

IC301Pins4, 22, 41, 47, 50,

52, 60, 84, 92?

Does the Video signal

appear at IC301 Pin29?

Does the Video signal

appear at the PMD02

Pin7?

Does the Video signal

appear at the PMD02

Pin5?

Check the 5.0V, 5.3VA

Line. (Power Circuit)

Is I2C BUS signal applied to

the IC301 Pins73, 74?

Check C327. (AGC)

Replace IC301.

Check the Video Buffer

Q905.

Check the DVD Board

Video path.

Check the System Circuit.

(Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’)

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

Does the Video signal

appear at the IC802

Pin29?

IC802 Pins2, 4(Vcc),

Pins32, 33(I

2

C BUS)

YES

NO

NO

Does the Video signal

appear at the IC901

Pin23?

Does the 12VT, 5.3VA

appear at the IC901 Pin3, 4.

Check the 12V, 5.4VA

Line. (Power Circuit)

Replace IC901.

YES

NO

NO

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 22

3-12

3. Y/C CIRCUIT

(2) When the Y(Luminance) signal doesn’t appear on the screen in PB Mode,

Is 5.0V 5.3VA applied to IC301

Pins22, 41, 47, 50, 52, 60, 84?

Is I2C BUS signal applied to

the IC301 Pins73, 74?

Does the normal RF signal

appear at IC301 Pin76?

Check the line of the 5.0V

5.3V Line. (Power Circuit)

Check the System Circuit.

(IC501 Pin23)

Check the V.H.S/W level.

(Check R303, R304)

Refer to ‘SYSTEM I2C

BUS CHECK Trouble

Shooting’.

Is the V.H.S/W signal

applied to IC301 Pin80?

Is the V.H.S/W “H” about

3.4V at the IC301 Pin80?

Clean the Drum.

Check the path of the

Y(Luminace) RF signal.

(Check the C327)

Check the path of the

Y(Luminace) RF signal.

(Check the C312)

Does the Y(Luminance)

RF signal appear at

IC301 Pin79?

Is the Y(Luminance) Video

waveform showed up at

IC301 Pin43?

Replace IC301.

NO

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Replace the IC301.

NO

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 23

3-13

3. Y/C CIRCUIT

(3) When the C(Color) signal doesn’t appear on the screen in PB Mode,

Is 5.0V 5.3VA applied to the

IC301 Pins24, 42, 55, 72, 81.

Does the Color signal

appear at IC301

Pin25?

Check the line of the 5.0V

5.3VA Line. (Power Circuit)

Replace the X301.

Check the Color Pass.

Does the X301

(4.43MHz) osxillate?

Replace the IC301.

Does the Color signal

appear at IC301 Pin48?

Replace the IC301.

NO

YES

Is the Color Rotary signal

applied to the IC301 Pin70?

Check the Color Rotary

Circuit. (IC501 Pin98)

NO

YES

Is Color Rotary “H” about

3.4V?

NO

Check the Color Rotary

level. (Check the R303)

YES

YES

YES

NO

NO

NO

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 24

3-14

3. Y/C CIRCUIT

(4) When the Video signal doesn’t appear on the screen in REC Mode,

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Is the EE signal normal?

Does the RF signal

appear at the IC301

Pin76?

Check EE Mode.

Check the System of REC

‘H’.(the IC501 Pin27 / the

D301)

Replace the IC301.

Is the REC ‘H’ signal

(about 4V) applied to the

IC301 Pin80?

Check the circuit of the

IC301 Pin85, 86.

Check REC Luminace pass

& Color pass.

Does the REC RF signal

appear at the IC301

Pins88, 89, 94, 95?

NO

YES

Is 5.0V 5.3VA applied to the

IC301 Pins22, 41, 47, 50,

52, 60, 84?

Check the line of the 5.0V

5.3VA line. (Power Circuit)

NO

YES

Does PB Mode operate

nomally?

NO

Check PB Mode.

YES

Check the Drum & Drum

Connector

YES

YES

YES

NO

NO

NO

NO

Page 25

3-15

VCR ELECTRICAL TROUBLESHOOTING GUIDE

5. Hi-Fi CIRCUIT

(1) No Sound(EE Mode)

YES

No Sound.

Check the AV1 Audio of IC801

Pins6, 7.

Check the AV2 Audio of IC801

Pins8, 9.

Check the AV3 Audio of IC801

Pins10, 11.

Check the Vcc of IC801 Pins34, 40,

IC802 Pins2, 4.

YES

Check the IIC Clock and DATA at

IC801 Pins42, 43.

YES

YES

Check the Audio of IC801 Pins16, 17.

Check the SC901, JK901.

Check the Scart1 Jack.

(SC901 Scart1 Audio in Pin2, 6).

NO

NO

Check the Scart2 Jack.

(SC901 Scart2 Audio in Pin2, 6).

NO

Check the front Jack.

Check the Power 5.0V, 12V.

YES

NO

Check the IC501 Pins59, 60.

NO

Replace IC801.

NO

Check the Audio of PMD02 Pin19, 21.

Check the Pcb Pattern between IC801

Pin16, 17 with PMD02 Pin19, 21.

NO

YES

YES

Check the Audio of PMD02 Pin23, 25. Check the DVD Board Audio path.

NO

Check the TU Audio of IC801

Pins2, 3.

Check the IC751 Pin30, 31.

NO

Check the DVD Audio of IC801

Pins4, 5.

Check the DVD Audio OUT.

(JK902 DVD_A_L_L/R).

NO

Page 26

3-16

VCR ELECTRICAL TROUBLESHOOTING GUIDE

3. Y/C CIRCUIT

(2) Hi-Fi Playback

YES

YES

YES

YES

PB mode

No Sound.

Check the Vcc of IC801

(Pins34, 40)

Check the Hi-Fi Selection switch.

(IC801 Pin41) and the Tape quality.

Is the RF Envelope at

IC801 Pin44 over 2Vp-p?

YES

Check IC801 Pin42(Data),

Pin43(Clock)

YES

Do Audio Signals appear at

IC801 Pin16(L-CH), 17(R-CH)?

YES

Do Audio Signals appear at

IC802 Pin25(L-CH), 21(R-CH)?

YES

Do Audio Signals appear at

JK901, SC901?

YES

Check the IC802 Pins6, 12

Check Power 5.0V, 12V.

NO

Check IC501 Pin26

(A.H/SW)

NO

NO

Check the parts of µ-COM

(IC501 Pins17, 18)

NO

Check the Connection at

P3D01 Pins7, 9.

NO

Check the Audio PMD02

Pin23, 25.

NO

Check the Jack(JK901,

SC901)

NO

Check the DVD Board

Audio Path

NO

Page 27

3-17

(3)

Hi-Fi REC.

It can’t be recorded Hi-Fi Audio

signal.

Check Vcc of IC801. (Pins34. 40)

YES

YES

Check IC801 Pin42(Data), Pin43(CLOCK).

YES

Do Audio signals appear at IC801

Pins16, 17?

YES

Do FM Audio signals appear at IC801

Pin36?

YES

Check the Contact Point of Drum

Connector if good then Replace the Drum.

YES

Check Power 5V, 12V.

NO

Check ports of µ-COM.

(IC501 pins 17, 18)

Check Audio input signal of IC801

Pins2, 3(TU.A.), 4, 5(DVD.A.), 6,

7(AV2.A.), 10, 11(AV3.A).

NO

Replace IC801.

NO

NO

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 28

3-18

6. Tuner/IF CIRCUIT

(1) No Picture on the TV screen

No picture on the TV

screen

Does the Video signal

appear at TU701 Pin19.

YES

Is 33V applied to TU701

Pin17?

Is +5V applied to TU701

Pin4?

NO

Does the video signal at

the PMD02 Pin5?

NO

NO

NO

Does the Video signal at

the IC802 Pin 29.

Does the Video signal at

the IC901 Pin 23.

Check 33V line.

NO

NO

NO

Check 5V line.

Does the Clock signal

appear at TU701 Pin12?

Check the llC Clock Signal

of µ-COM Pin18.

Does the data signal

appear at TU701 Pin13?

Replace Tuner.

Check the DVD Board

Video Path.

Replace the IC802.

Replace the IC901.

Does the video signal

appear at IC802 Pin28.

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

Check the Pattern between IC901

Pin23 with SC901 Pin19

Does the Video signal at

the IC802 Pin31.

Check the Pattern between

TU701 Pin19 and IC802 Pin28.

Replace the IC802.

NO

YES

Does the Video signal at

the IC301 Pin15.

Check the Pattern between

IC802 Pin31 and IC301 Pin15.

NO

YES

Does the Video signal at

the IC301 Pin29.

Replace the IC301.

Check the llC Data Signal

of µ-COM Pin17.

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Page 29

3-19

VCR ELECTRICAL TROUBLESHOOTING GUIDE

(B) No Sound

No Sound.

Check the Vcc of IC751 Pins1, 11, 19,

22, 33.

YES

Check 5.2V Line.

NO

Check the Tuner SiF signal at IC751

Pin2.

YES

Check the oscillator of IC751 Pins5, 6.

YES

Check the Audio of IC751 Pins30, 31.

YES

Check the Audio of IC801 Pins2, 3.

YES

Check the Audio of IC801 Pins16, 17.

YES

YES

Check the Tuner SIF of TU701 Pin16.

NO

Replace X751

NO

Check the IIC Clock and Data at IC751

Pins12, 13.

NO

Check the signal flow from IC751

Pins30, 31 to IC801 Pins2, 3.

NO

Check the IIC Clock and Data at IC801

Pins42, 43.

NO

Check the Audio of IC802 Pins21, 25.

Check the Signal flow from IC802

pins21, 25 SC901 Pins1, 3.

YES

Check the DVD Board Audio Path.

NO

Page 30

3-20 3-21

BLOCK DIAGRAMS

1. POWER(SMPS) BLOCK DIAGRAM

BD

101

!

NOISE FILTER

BLOCK

(C101,L102,

L101, C102)

!

FUSE

(F101)

BR BL

(BK)(WH)

!

Y-CAP

C110

TH01

C103

!

+

Y-CAP

111

C

SNUBBER

BLOCK

(D101,C105

C106,R103)

5 6 7 8

DRIVE & S/W BLOCK

(IC101, D102, R105,

C108,C1

SNUBBER

BLOCK

(D103,C115,C116

,R112,R115)

6 7 8

DRIVE & S/W BLOCK

5

(IC104, D104, R113,

C117,C114)

1

!

T101

12)

3

3

2

!

PHOTO COUPLER

C102)

(I

102

T

!

2

!

PHOTO COUPLER

(IC105)

RECTIFIER &

SMOOTING BLOCK

(D128,C133,R130)

RECTIFIER &

SMOOTING BLOCK

(D126,C136,L122,C1

RECTIFIER &

SMOOTING BLOCK

(D129,C128,R147)

RECTIFIER &

SMOOTING BLOCK

(D130,C137,R146)

RECTIFIER &

SMOOTING BLOCK

(D121,C122,L121,C124)

ERROR AMP

(IC103)

RECTIFIER &

SMOOTING BLOCK

(D125,C139,L127,C140)

RECTIFIER &

SMOOTING BLOCK

(D124,C129)

RECTIFIER &

SMOOTING BLOCK

(D123,C126,L124,C127)

RECTIFIER &

SMOOTING BLOCK

(D122,C123,L123,C1

ERROR AMP

(IC106)

30)

FEED-BACK

BLOCK

R121,R122,

C121,R123.

R124.R125

R126)

FEED-BACK

BLOCK

R131,R132,

C141,R133.

R161.R162

R163)

RECTIFIER &

SMOOTING BLOCK

(D127,C131,L125,C132)

HSR S/W B l ock

(Q120,ZD153,C135,

R144,R145,D155,C157)

12V REG & S/W Block

(Q126,R150,ZD152,

C156,C153)

33V S/W B l oc k

(Q123,R143,R13

(Q124,R140,R135,R136

(Q121,Q122,R141)

(Q125,R137,R13

12V REG & S/W Block

(IC157,R156,C155)

5.0V REG & S/W Block

(IC151,R151,C151)

1.8V REG & S/W Block

(IC160,R159,C152)

25)

3.3V REG & S/W Block

(IC154,R154,C154)

4)

5.0V S/W B l ock

D134,C134

HSR CTL Block

PWR CTL Block

)

8)

TO VCR

(P101)

5.3VA

5.0V

Cap Vc

c

REG 12V

33V

12VA( DRUM)

PWR C TL 'H'

HSR 'H'

DVD PWR CTL

FD(-)

FD(+)

-28VA

TO FAN

(P103)

8.7V

TO VDR

(P102)

-12V

12V

1.8V

2.5V

3.3V

5.0V

TO LOADER

(P103)

12V

5.0V

VCR+DVD REC SCART+RCA

Page 31

3-22 3-23

2. TU/IF, NICAM & A2 BLOCK DIAGRAM 3. VPS BLOCK DIAGRAM

SW1

SW2

151 5.4VA

871

159

872

S.V.W

(From Power)

94

93

59

60

AS

158

A.OUT

AFT

SIF

MSP3417

MSP3407

27

159

731

VCR+DVD REC SCART+RCA

Page 32

3-24 3-25

4. Y/C BLOCK DIAGRAM

IIC DATA

IIC CLK

IC501

NJM2274

SUPER 'C'

SUPER 'Y'

S/W

VIDEO

AV3

VIDEO

DVD

CVBS

MIXED

Y/C

15PIN

17PIN

19PIN

21PIN

IC301

AVCP

29PIN

82PIN

77PIN

2V

BUFFER

2V

MICOM

VIDEO

SEC/MES DET ëHí

SEC.REC.COLOR

IIC CLK

IC802

MM1443

CANAL

1V

AVCP

VIDEO

IC501

MICOM

DVD

VIDEO

SYSTEM

IC302

LA70100

SECAM

IIC DATA

TU

AV1

AV2

DVD CVBS

FRONT

I/O

JACK

IC901

MM1623

6dB AMP

JC901

SACRT

JACK

V.OUT

Page 33

3-26 3-27

5. Hi-Fi BLOCK DIAGRAM

CANNAL IC

AV1 out

AV

DVD AUDIO

ADC

MPEG

DAC

VCR Audio

VCR

Hi-Fi

AV1 IN

TUNER AUDIO

AV3 IN

AV2 in/out

SCART1

Tuner

Front

Jack

SCART2

RF

TV

RCA

DECODER

BOX

Page 34

3-28 3-29

6. SYSTEM BLOCK DIAGRAM

TO/FROM AVCP

TO/FROM DECK

TO/FROM AUDIO(Hi-Fi)

TO/ FROM TU/IF

FROM TO SCART/SWITCH

COM

5V

TO/FROM DECK

MODE S/W

T-UP END

ES501

LD501

DECK IR LED

RS501

T-UP REEL

SUP REEL

MS501

To/FROM DVD

SUP END

RS502

5.3VA

GND

MODE S1

MODE S2

MODE S3

MODE S4

ES502

R564

X502

32.768KHz

X501

14MHz

OSC

OSC

34

74

CTL +

CAP. PWM

DRUM PWM

75

33

20

I-Limit

89

MODE S1

88

MODE S2

87

MODE S3

86

MODE S4

10

VDR ENA

12

VDR DATA

13

VCR DATA

11

VDR CLK

38

X in

37

X out

Xc in

40

Xc out

41

6

T-UP Sensor

85

SUP Sensor

C535

3

T-UP Reel

2

Sup Reel

21 19

67

65

CFG

CTL -

DPFG

IC501

MN01D10X

LD CTL

CAP. REV 'H'

82

23

24

V. ENV

D.V.Sync

V.H.SW30

SECAM DET 'H'

TU. SECAM VL 'H'

99

H.A.SW

REC 'H'

C.ROT

FLD DATA

FLD ENA

FLD CLK

V. MUTE 'L'

RGB OUT 'H'

RGB SW 'H'

AV3 'H'

Super Det 'H'

Others 'L'

Ct Det 'H'

SCART 'H'

16:9 'H'

VCR 'H'

A. ENV

A. H.SW

A. MUTE 'H'

REC 'H'

IIC CLK

IIC DATA

AFT

IIC CLK

IIC DATA

DAV 'L'

Tu. SECAM 'H'

POWER FAIL

49

100

27

98

84

16

28

14

62

59

94

60

61

7

57

96

97

8

83

26

58

27

18

17

81

18

17

93

63

64

4

CV IN

COMP IN

TO/FROM AVCP

DIG601

DISPLAY

IC601

FROM TO SCART/SWITCH

µ – COM

TO/FROM AUDIO(Hi-Fi)

TO/ FROM TU/IF

5.3VA

CST.SW/REC TAP

CS501

CST IN S/W

32

14

R/C

RC601

Vcc (OSD)

A. Vcc (servo, A/D)

51

73

25

Vcc

(SYSCON)

RESET

36

+ +

C500 C501

IC504

3

Q503

Q501

+

+

L504

5.3VA

IC505

3

5V

Vcc

Vcc

GND

2

1

GND

2

1

VCR+DVD REC SCART+RCA

Page 35

3-30 3-31

7. SCART & SWICH BLOCK DIAGRAM

AVCP

Mixed

Y/C

DVD

(CVBS)

Dvd_CVBS

Tuner

AV1

super

S/W video

CANAL

TU

AV1

AV1

AV2

CVBS

VPS

REC/PB

BLOCK

AV2

JACK

DECODER

RGBYC

6dB

Amp

&

75

Drive

DECODER

BOX

ADC

R

G

B

MPEG

RG B

Y

C

CVBS

Slide Switch

RGB_S/W'H'

C+DET'H'

MODULATOR

AV1

JACK

RCA

SCART

RCA

SCART

RCA

SCART

Scart

'H'

VCR

MICOM

RGB_OUT'H'

CPLD

S/W

BLOCK

DAC

ENCODER

TV

SET

Scart

8Pin

16:9 'H'

S/W

BLOCK

CVBS

Y

C

Scart

16Pin

Page 36

3-32 3-33

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

NOTE) Warning

NOTE) Parts that are shaded are critical

NOTE) With respect to risk of fire or

NOTE) electricial shock.

A B C D E F G H I J K L M N O P Q R ST

CIRCUIT DIAGRAMS

1. POWER(SMPS) CIRCUIT DIAGRAM

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG ELECTRONICS CORPORATION. ALL

COMPONENTS SHOULD BE REPLACED ONLY WITH

TYPES IDENTICAL TO THOSE IN THE ORIGINAL CIR-

CUIT. SPECIAL COMPONENTS ARE SHADED ON THE

SCHEMATIC FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTIL THE NEW SERVICE

LITERATURE IS PRINTED.

NOTE :

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

S/W Error

IC101,IC104 is Defective

Switching Error

IC105, IC106 are Defective

3. 3V No Power

D122 is Defective

28V No Power

D129 is Defective

12V No Power

D126 is Defective

5. 3VA No Power

D121 is Defective

No Power

D102 is Defective

No Power

F101 is Defective

12V No Power

IC157 is Defective

5V No Power

IC151 is Defective

1.8V No Power

IC160 is Defective

3.3V No Power

IC154 is Defective

Switching Error

IC105,IC106 are Defective

30VA No Power

D130 is Defective

No Power

BD101, TH01 is Defective

-29VA No Power

D127 is Defective

28V No Power

Q120 or ZD153 are Defective

12V No Power

Q125 or ZD152 are Defective

2. 5V No Power

IC152 is Defective

12V No Power

D125 is Defective

No Power

D104 is Defective

5V No Power

D124 is Defective

1.8V No Power

D123 is Defective

No Digitron Displayed

D128,R107,ZD151 are Defective

Page 37

3-34 3-35

A B C D E F G H I J K L M N O P Q R ST

2. TUNER CIRCUIT DIAGRAM

Page 38

3-36 3-37

A B C D E F G H I J K L M N O P Q R ST

3. A/V CIRCUIT DIAGRAM

Page 39

3-38 3-39

A B C D E F G H I J K L M N O P Q R ST

4. Hi-Fi CIRCUIT DIAGRAM

Page 40

3-40 3-41

WAVEFORM

1

2

7

4

3

6

5

A B C D E F G H I J K L M N O P Q R ST

5. SYSTEM CIRCUIT DIAGRAM

Page 41

3-42 3-43

A B C D E F G H I J K L M N O P Q R ST

6. SCART CIRCUIT DIAGRAM (SCART MODEL ONLY)

Page 42

3-44 3-45

A B C D E F G H I J K L M N O P Q R ST

7. TIMER CIRCUIT DIAGRAM( 2 TOOL )

Page 43

3-46 3-47

8. TIMER CIRCUIT DIAGRAM( 3 TOOL, 8 TOOL )

A B C D E F G H I J K L M N O P Q R ST

Page 44

3-48 3-49

9. TIMER CIRCUIT DIAGRAM( 4 TOOL )

A B C D E F G H I J K L M N O P Q R ST

Page 45

3-50 3-51

10. TIMER CIRCUIT DIAGRAM( 6 TOOL )

A B C D E F G H I J K L M N O P Q RST

Page 46

3-52 3-53

11. TIMER CIRCUIT DIAGRAM( 7 TOOL )

A B C D E F G H I J K L M N O P Q RST

Page 47

3-54 3-55

WAVEFORMS

IC301 Pins 8, 9

PB mode

500mvp-p

IC301 Pins 15, 17,

19, 21

Video in 1Vp-p

IC301 Pin 31

PB/REC mode

4.0Vp-p

IC301 Pin 98

REC mode

1.1Vp-p

IC301 Pin 94

REC mode

2.0Vp-p

IC301 Pin 29

PB mode

2.02Vp-p

IC301 Pin 57

PB mode

400mVp-p

IC301 Pin 63

PB mode

400mVp-p

IC301 Pin 73

PB/REC mode

5Vp-p

IC301 Pin 74

PB/REC mode

5Vp-p

IC301 Pin 77

REC mode

340mVp-p

IC301 Pin 42

PB mode

300mVp-p

IC301 Pin 53

PB mode

400mVp-p

IC301 Pin 80

PB mode

3.6Vp-p

✦ IC301 Oscilloscope Waveform

✦ IC501 Waveform Photographs

V.HSW

(IC501 Pin 23)

1V/10mS

REC/PB MODE

DV.SYNC

(IC501 PIN 24)

1V/100uS

QUE/REV MODE

CTL(+)

(IC501 Pin 74)

1V/10mS

CTL(-)

(IC501 Pin 75)

1V/10mS

DFG/DFG

(IC501 PIN 65)

1V/10mS

REC/PB MODE

CFG

(IC501 Pin 67)

1V/10mS

V.IN

(IC501 Pin 49)

500mV/20uS

Page 48

3-56 3-57

1 20m 100m

2 20m 100m

3 20m 100m

4 1.95V 4.88V

5 1.94V 1.88V

6 2.64 3.12V

7 2.8V 2.74

8 2.5V 1.7V

9 2.04 1.3

10 1.80V 1.88

11 2.0V 1.8

12 1.6V 0.72

13 0V 0

14 1.26V 1.3

15 3.40V 3.36

16 0 4.78

17 2.38V 2.32

18 1.88V 2.84

19 3.02V 2.94

20 0 0

21 2.38V 2.34V

22 4.88V 4.82

23 2.64V 2.24

24 0 0

25 2.08V 2.14

26 3.08V 2.66V

27 0 0

28 150mV 140m

29 3.88V 3.18V

30 2.08V 2.74V

31 4.74V 4.72m

32 2.08V 2.12V

33 2.42V 2.26

34 1.58 1.54V

35 3.30V 3.36

36 2.50V 2.32

37 3.10V 3.18

38 2.60V 2.28

39 1.40V 1.42V

40 2.30V 2.16V

41 1.08V 1.58V

42 1.82V 1.84V

43 2.04V 2.28V

44 0 0

45 2.88V 3.04V

46 2 2.98

47 4.82 4.78

48 120mV 2.40

49 3.48 1.94V

50 4.78 4.74

51 2.08V 1.98

52 4.8V 4.70

53 2.60V 2.8

54 0 0

EE PLAY

MODE

PIN NO.

IC301

55 1.3 1.48

56 0 0

57 2.08V 2.18

58 1.78V 2.14

59 4.6V 4.62

60 4.62V 4.62

61 3.82V 0

62 2.2V 2.08V

63 2.32V 2.32

64 1.62V 1.64

65 1.62 2.28

66 2.30V 1.68

67 0 0

68 1.12V 1.14

69 2.3V 2.38V

70 0.82 0.82V

71 2.2V 2.18V

72 100m 2.42

73 4.96V 4.98

74 4.96V 4.98

75 2.56V 2.54

76 2.34V 2.18

77 2.68V 2.64

78 0 4.72

79 0V 0

80 2.16 2.68

81 4.06V 20M

82 0V 0

83 120M 2.72

84 2.76V 4.74

85 2.114 2.42

86 2.04V 2.08V

87 2.04 2.08V

88 0V 0

89 2.14 2.08V

90 2.14 2.08

91 2.14V 2.08

92 4.88V 4.89

93 300MV 260M

94 2.48V 2.40V

95 2.48V 1.86

96 2.06V 1.86

97 0 0

98 2.30V 2.46V

99 0V 20M

100 2.48 2.42V

10 0

2 4.52 4.82

3 4.84 4.84v

4 4.64 4.58v

5 4.56 4.56v

6 80m 60m

70 0

8 4.98 4.98

EE PLAY

MODE

PIN NO.

• CIRCUIT VOLTAGE CHART

9 4.98 5.30

10 4.8 4.80v

11 4.82 4.82

12 4.72v 4.82

13 4.92 4.92

14 5.02 5.02

15 0 0

16 4.98v 4.98

17 5.04 5.04

18 4.98v 9.98

19 2.46v 2.46

20 3.36V 3.36

21 0 0

22 0 0

23 4.96v 4.96v

24 120mv 140m

25 4.94 4.94

26 4.92v 4.92v

27 20m 20mv

28 5.02 5.02v

29 4.98v 4.98

30 4.84v 4.84

31 5.00v 5.00v

32 0 0

33 4.98 4.94

34 0 5.00v

35 5.02 100m

36 3.16 3.12v

37 5.7v Da/Clk(5.5)

38 0 5.7v

39 520m 0

40 4.84 520m

41 4.83 Da/Clk(5.62)

42 4.86v 4.86v

43 0 0

44 5.02 5.0v

45 0 0

46 3.94 3.94v

47 2.88 2.88v

48 0 0

49 0.98 2.94

50 1.84 1.94v

51 0.98 4.78

52 3.28 3.28v

53 2.38 2.38v

54 2.52 2.54v

55 1.88 1.88

56 0 0

57 0 0

58 120m 120m

59 4.92v 4.92v

60 4.92v 4.92v

61 0 0

62 4.82 4.82v

63 3.98 3.98v

EE PLAY

MODE

PIN NO.

64 0 0

65 2.36 2.36v

66 0 0

67 4.68 9.68v

68 0 0

69 2.48 2.48v

70 2.48 2.48

71 0 0

72 2.48 4.98

73 4.92 4.92v

74 0 0

75 2.52 2.42

76 2.42 2.48

77 80m 80m

78 0 0

79 4.02v 4.96v

80 4.96v 4.96

81 2.8 280m

82 1v 2.62v

83 120m 3.24v

84 0 1.96

85 0 0

86 4.98 4.9v

87 4.98 4.98

88 5.0v 5.0v

89 0 0

90 4.88 4.88v

91 0 0

92 0 0

93 5.04v 5.04v

94 4.88 0

95 4.98 4.98

96 0 0

97 0 0

98 4.98 4.98

99 20m 4.98v

100 0 0

1 4.88 4.88v

2 1.46 1.48

3 1.38 1.38

40 0

5 2.26v 2.24

6 2.38 0

70 0

80 0

90 0

10 0 0

11 0 5.0v

12 5.0v 5.0

13 5.0v 0

14 0 0

15 0 0

16 0 0

17 0 0

EE PLAY

MODE

PIN NO.

IC751

IC501

18 0 0

19 4.88 4.88

20 0 0

21 0 0

22 0 0

23 0 0

24 0 0

25 0 0

26 0 0

27 0 0

28 0 0

29 0 0

30 2.96v 3.98

31 2.96 3.98

32 0 0

33 4.88v 4.88

34 3.64v 3.58v

35 0 0

36 2.62v 2.58

37 0 0

38 0 0

39 0 0

40 2.54v 2.54

41 2.54 2.56

42 2.48 2.48

43 2.3v 2.34

44 0 0

10 0

20 0

3 0 142M

4 DA/CL(5.34) DA/CL(5.34)

5 DA/CL(5.34) DA/CL(5.34)

60 0

7 DA/CL(5.34) DA/CL(5.34)

80 0

9 DA/CL(5.34) DA/CL(5.34)

10 DA/CL(5.34) DA/CL(5.34)

11 0 41M

12 DA/CL(2.82) DA/CL(2.82)

13 0 0

14 DA/CL(2.82) DA/CL(62M)

15 2.89 1.41

16 1.53 950M

17 DA/CL(1.14) DA/CL(810M)

18 0 0

19 5.26 5.24

20 5.26 5.24

1 3.28 3.24

2 3.28v 3.28

3 3.32 3.26

4 3.28 3.92

5 3.28 3.92

6 3.28 3.26

EE PLAY

MODE

PIN NO.

IC7V1

IC801

7 3.28v 3.74

8 3.28 3.24

9 3.28v 3.24

10 3.28 3.24

11 3.28v 3.26

12 0 0

13 3.78 4.52

14 0 0

15 0 640m

16 5.82 6.64

17 5.28v 6.68

18 0 620m

19 6.28 6.66

20 6.28 6.72

21 4.46v 4.42

22 3.28 4.02

23 3.62 3.68

24 3.74 4.12

25 3.74 3.76

26 0.1 640m

27 0 0

28 3.7v 3.68

29 3.66 3.64

30 0.7 680m

31 3.72 3.72v

32 3.74v 4.08

33 3.62 3.68

34 13.4v 13.32

35 580m 520m

36 0 520m

37 580m 520m

38 0 0

39 0 20m

40 4.7 4.76

41 0v 1.68

42 5.0v 5.04m

43 50.v 4.96

44 20m 3.38

1 4.76 4.68

2 2.02v 2.24

3 4.88 4.88

4 1.64 1.78

5 4.72 4.78

6 1.88 1.88

70 0

8 2.26 2.18

90 0

10 1.64v 1.72

11 0 0

12 1.92v 2.08

13 4.86 4.82

14 1.92v 2.08

15 0 2.31

16 2.26v 2.64

EE PLAY

MODE

PIN NO.

IC901

17 0 0

18 2.28 2.74

19 0 0

20 2.56v 2.58

21 2.64v 2.68

22 0 0

23 2.56v 2.92

24 0 0

25 0 0

26 2.52v 2.98

27 20m 0

28 4.72 4.68

1 2.51 2.51

2 2.39 2.39

3 3.54 3.53

4 2.57 2.56

5 1.52 1.34

6 0.43 3.68

7 1.3m 0

8 1.2m 0

9 3.04 3.03

10 2.52 2.52

11 2 2.05

12 3.22 1.97

13 3.99 3.99

14 2.5 2.495

15 3.11 1.93

16 3.2 3.18

17 27.4m 4.11

18 112.1m 3.35

19 2.27 2.26

20 1.99 2.12

21 2.31 2.37

22 0.78 0.81

23 5.02 5.01

24 5.02 5

25 2.44 2.27

26 2.44 2.26

27 2.82 2.85

28 181.5m 187.4m

29 371.6m 212.2m

30 2.08 2.08

1 3 2.99

2 36.3m 38.1m

3 3.04 3.04

4 6.4m 39.1m

5 3.04 3.04

6 5.02 5.03

7 2.24 2.23

80 0

1 6.71 6.66

2 5.05 5.05

EE PLAY

MODE

PIN NO.

IC901

IC302

IC804

3 6.02 5.96

40 0

5 6 5.96

6 5.99 5.94

7 22.3m 21.3m

8 6.68 6.65

9 6.7 6.67

10 1.1m 0

11 6.71 6.68

12 5.04 5.05

13 12.03 11.99

14 6.7 6.7

15 0 0

16 6.73 6.69

1 1.3 1.3

2 4.9 4.9

3 1.66 1.56

40 0

50 0

6 4.9 4.9

7 1.7 1.6

80 0

1 1.37 1.37

25 5

3 2.18 2.17

40 0

50 0

6 5.21 5.21

7 2 2.17

80 0

EE PLAY

MODE

PIN NO.

IC902

IC903

Page 49

3-58 3-59

Q501 0 0 740M

Q503 5.19 5.19 4.57

Q504 Y/C_VIDEO 0 Y/C_VIDEO

Q505 Y/C_VIDEO 0 Y/C_VIDEO

Q506 0 2Fsc 2Fsc

Q514 0 0 4.87

Q515 0 0 4.87

Q301 0 5.04 0

Q302 5.04 0 5.04

Q303 0 0 0

Q304 0 0 0

Q306 4.93 4.81 4.79

Q308 Y/C_VIDEO 0 Y/C_VIDEO

Q311 5.04 5.04 0

Q7S1 0 1.47 0

Q7S2 0 0 5.13

Q901 5.1 0 4.5

Q902 0 0 0

Q903 0 0 0

Q904 0 4.5 0

Q905 2.69 0 2

Q906 1.7 0 1.7

Q907 11.9 11.8 0

Q908 0 0 5

Q909 0 7.4 0

Q910 4.6 5 5.1

EC B

E-MODE

NO.

C203 3.55 0 3.51 0

C204 3.34 0 3.59 0

C207 3.12 0 1.93 0

C210 2.26 0 2.94 0

C213 3.29 0 2.77 0

C215 4.97 0 4.89 0

C301 5.01 0 0 0

C302 5.03 0 4.24 0

C304 4.99 0 4.85 0

C307 2.29 4.87 2.27 0

C311 5.11 5 190M 0

C314 2.35 0 2.31 0

C315 2.92 2.79 2.83 2.31

C316 1.48 0 1.57 0

C318 4.1 0 2.85 0

C320 2.39 0 2.2 0

C322 4.13 0 4.09 0

C323 2.35 0 2.31 0

C324 2.42 0 0 0

C325 2.95 0 3.13 0

C327 2.61 2.46 3.18(Y/C) 3.18(Y/C)

C331 17.5M 0 0 0

C333 4.94 0 4.88 0

C336 5.04 0 5.01 0

C337 3.36 0 2.53 0

C339 3.38 0 2.62 0

C346 5 0 4.91 0

C347 2.16 0 2.14 0

C348 1.62 0 1.5 0

C349 5.02 0 4.92 0

C353 2.31 0 2.25 0

C356 1.97 0 2.07 0

C357 2.17 0 2.02 0

C359 264M 0 130M 0

C362 5.2 0 5.19 0

C391 2.99 2.7 3.02 780M

C392 3.03 2.75 3.07 2.75

C393 3.03 2.76 3.12 0

C501 5.2 0 5.19 0

C502 5.19 0 5.19 0

C504 2.36 2.06 2.3 2

C505 5.22 0 5.19 0

C507 4.95 0 4.95 0

C511 2.41 1.32 2.41 1.3

C522 2.61 0 2.64 0

C523 2.61 2.61 2.64 0

C524 2.61 0 2.64 0

C526 16.74 0 13.6 0

C534 4.24 0 62M 0

C546 14.73 0 14.2 0

C7S1 4.9 4.17 4.85 4.09

C7S2 4.9 0 4.85 0

C7V1 5.22 0.91 5.28 0

C7V3 2.86 1.47 2.16 950M

C710 32.61 0 32.4 0

EE PLAY

+–+–

SECTION

NO.

C718 5.05 0 4.96 0

C719 5.04 0 4.96 0

C724 2.39 164M 2.31 0

EE PLAY

+–+–

SECTION

NO.

Page 50

3-60 3-61

LOCATION GUIDE

PRINTED CIRCUIT DIAGRAMS

1. VCR P.C.BOARD(TOP VIEW)

Page 51

2. VCR P.C.BOARD(BOTTOM VIEW)

3-62 3-63

LOCATION GUIDE

Page 52

3-64 3-65

3. SMPS P.C.BOARD

LOCATION GUIDE

Page 53

3-66 3-67

4. JACK P.C.BOARD

( 2 TOOL, 3 TOOL )

LOCATION GUIDE

( 4 TOOL, 8 TOOL )

LOCATION GUIDE

( 6 TOOL )

LOCATION GUIDE

Page 54

3-68 3-69

5. KEY P.C.BOARD 6. Timer P.C.BOARD

( 2 TOOL ) ( 2 TOOL )

( 3 TOOL ) ( 3 TOOL )

( 4 TOOL ) ( 4 TOOL )

( 6 TOOL ) ( 6 TOOL )

( 8 TOOL ) ( 8 TOOL )

Page 55

Page 56

3-70

VDR ELECTRICAL TROUBLESHOOTING GUIDE

1. Power(SMPS) CIRCUIT

No 3.8VA

Replace the F101

(Use the same Fuse)

Is the F101

Normal?

Is the TH01

Normal?

Is the BD101

Normal?

NO

NO

NO

NO

NO

NO

NO

NO

NO

Replace the BD101

Replace the TH01

Is the D104

normal?

Check or Replace

the D104

Replace the D122

Replace the IC106

Replace the D123

Replace the D124

Replace the D125

YES

YES

YES

YES

YES

YES

YES

YES

YES

Is Vcc (11V - 18V)

supplied to IC101 Pin3?

NO

Are the D122

normal?

Is there about 2.5V

at the IC106 Pin1?

Is the D123

normal?

Is the D124

Normal?

Is the D125

Normal?

Power Line of Main

PCB(VDR) is short

VDR PART

No 3.3V

Check or Replace

the D122

Is there about 3.8V

at the IC154 pin1?

Check the IC154 and

Replace

Is there about 3.3V~ 5V

at the IC154 pin4?

NO

NO

Check the ‘DVD PWR CTL

“H”’ signal from µ-com

YES

YES

Page 57

3-71

VDR ELECTRICAL TROUBLESHOOTING GUIDE

No 2.5V

Check or Replace

the D122

Check the ‘DVD PWR CTL

“H”’ signal from µ-com

Is there about 3.8V

at the IC152 pin1?

Is there about 3.3V~

5V at the IC152 pin4?

Check the IC152

and Replace

NO

NO

YES

YES

No 5.0V

Check or Replace

the D124

Is there about 5.5V

at the IC151 pin1?

Is there about 3.3V~ 5V

at the IC151 pin4?

NO

Check the ‘DVD PWR CTL

“H”’ signal from µ-com

NO

YES

Check the IC151

and Replace

YES

No 1.8V

Check or Replace

the D123

Is there about 2.3V

at the IC160 pin1?

Is there about 3.3V ~

5V at the IC60 pin4?

NO

Check the ‘DVD PWR CTL

“H”’ signal from µ-com

NO

Check or Replace

the R167,R168

NO

YES

Are the R167,R168

normal?

YES

Check the IC160

and Replace

YES

Check or Replace

the D124

NO

YES

No 12V

Check or Replace the

D125

Is there about 13.5V

at the IC157 pin1?

Check the IC157 and

Replace

Is there about 3.3V~

5V at the IC157 pin2?

NO

NO

Check the ‘DVD PWR CTL

“H”’ signal from µ-com

YES

YES

Page 58

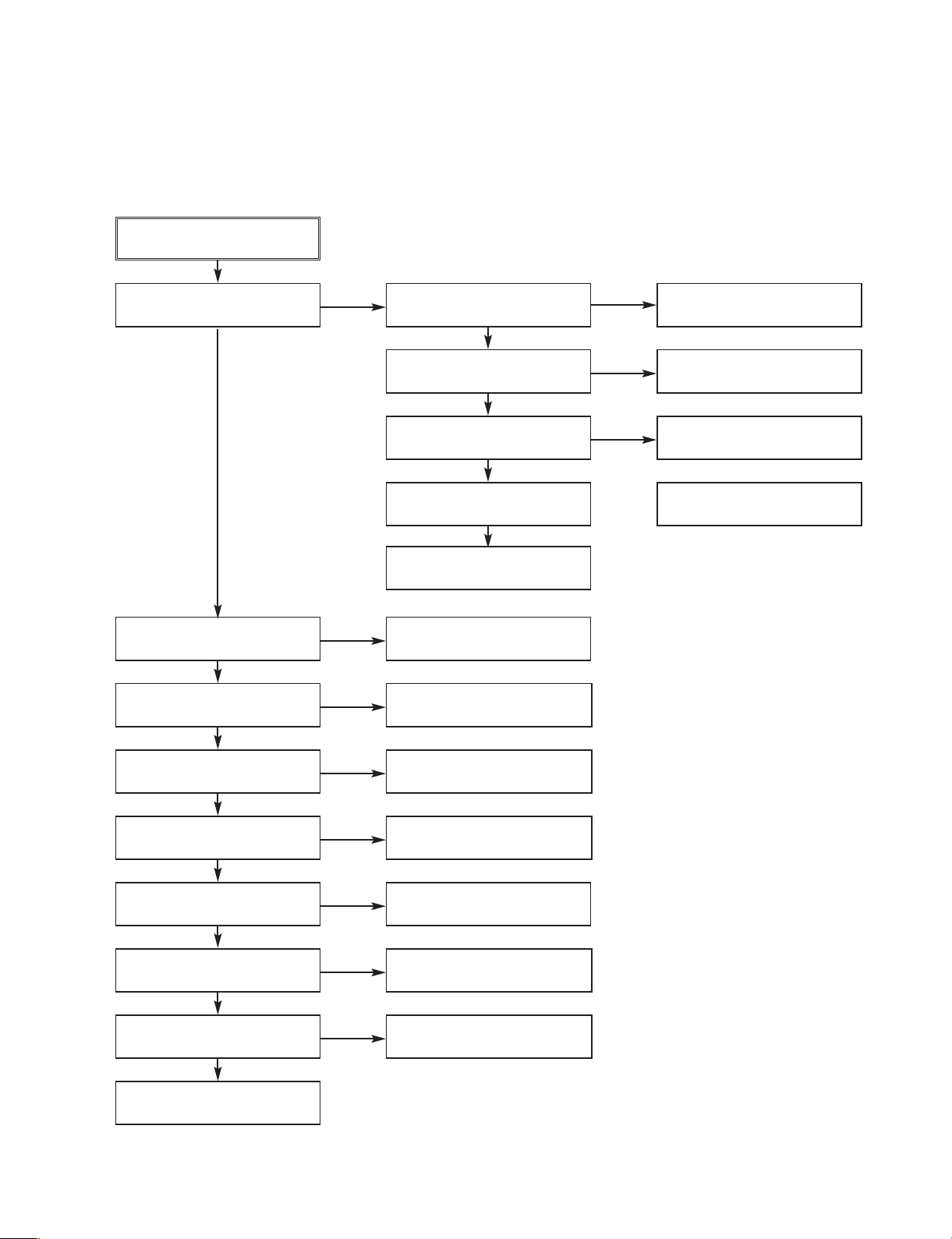

3-72

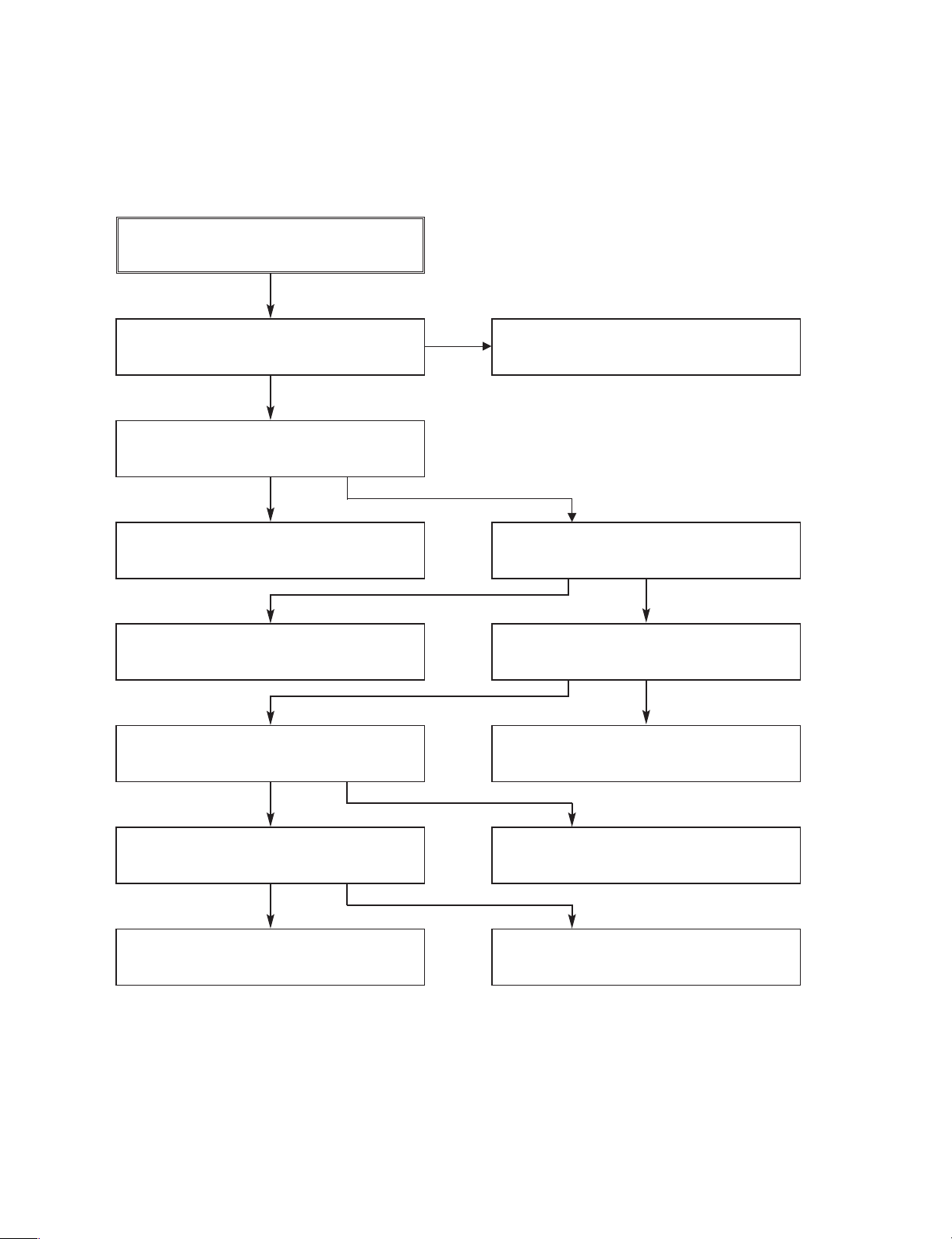

2. No Component video signal when playing DISC

Component : No Y Signal Component : No Pb Signal Component : No Pr Signal

R905, C923 R904, C922 R903, C921

IC601 – 12

Check input

IC601 – 14

Check input

C907 C908

IC601 – 10

Check input

C906

FL505, FL506, FL507

Check Signal in DVD

Board

Check CLK X101

Check IC101 Power and

Other Circuits

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO NO

NO NO

NO

VDR ELECTRICAL TROUBLESHOOTING GUIDE

Page 59

3-73

VDR ELECTRICAL TROUBLESHOOTING GUIDE

3-73

3. No COMPOSITE / S-VIDEO signal when playing DISC

COMPOSIT : No Signal S-VIDEO : No Y Signal S-VIDEO : No C Signal

R911, C927 R902, C920 R901, C919

IC601 – 6

Check input

IC601 – 2

Check input

C904 C902

R4103, R4107

Check Signal

IC601 – 4

Check input

C903

IC5101-40 : HIGH

/RST_VENC

R154, R155

Signal and 3.3V level

IC5101 41,42

Check I2C Clk, Data

Check R5101 CLOCK

R5124~R5131

Check VO_D0 ~VO_D15

Check IC101 power

And Other circuits

IC5101 9~16 Check

MP7~MP0 signal

YES

YES

YES

YES

YES

YES

YES YES

YES

YES

YES

YES

YES

YES

YES

YES

NO NO

NO NO

NO

NO

NO

NO

Page 60

3-74

VDR ELECTRICAL TROUBLESHOOTING GUIDE

4. No TV, External Input video signal

No : TV signal AV3No : AV1 signal No : AV2 signal

No : S-JACK

signal

TU701 1-19

Check signal

And circuit

IC802 - 1 IC802 - 3

IC501 – 1, 3, 8

check in the

DVD Board

Replace X501 XTAL

IC301 – 21

check

IC802 - 28

IC802 – 31

Check output

IC301 - 15

IC301 – 29 check

Q310 collector

Signal, power 12 V

C909, Q905

Check circuit

FL501

Check signal

YESYES YESYES

YES

YES YES

YES YES

YES

YES

YES

YES

YES

YES

YES

YES

IC502-34 : HIGH

/RST_VDEC

R4103, R4106

signal

YES

NO

when reset IC502

– 28, 29 Check I

2

C

Clk, Data

Check R533,

R526 Signal and

3.3V level

YES

NO

check IC502 - 40

(VI_CLK)

Check X501 clock

oscillated

YES

NO NO

<When playing DISC, no COMPONENT,

COMPOSIT/S-VIDEO signal> Check

IC502 -> IC101

Check VI_D0~VO_D9

signal

Check IC502

power and other

circuits

YES

NO

NO

IC301 - 17

NO NO

Page 61

3-75

VDR ELECTRICAL TROUBLESHOOTING GUIDE

Check VCR PART

PN303-1 signal

normal

Check FFC Cable

Signal flow

NO

YES

Audio output even

When playing DISC

PN304-19~22 Check

audio signals

NO

Check FFC Cable

and VCR part

NO

Check FFC Cable

and VCR part

Check IC801 power

and other circuits

NO

Check AV_RST1 and

power, other circuits

NO

YES

IC803 – 1, 7 Check

audio signals

YES

IC802-9 Check

High?

YES

Check IC802 power

And Other circuits

YES

NO

YES

5. When playing DISC, no audio output

6. No TUNER audio output

7. No OPTICAL / DIGITAL output

IC802 – 15, 18

Check audio signals

Check IC802 power

and other circuits

NO

Check AV_RST1 and

power, other circuits

NO

IC802-10 Check

High?

YES

Check IC802 power

And Other circuits

YES

Page 62

3-76

VDR ELECTRICAL TROUBLESHOOTING GUIDE

3-76

<when playing DISC,

no audio output> check

Check FFC Cable

and VCR part

Audio output even

When playing DISC

PN304-19~22 Check

audio signals

IC802 – 15, 18

Check audio signals

NO

NO

Check IC802 power

and other circuits

NO

Check AV_RST1 and

power, other circuits

NO

YES

YES

IC802-10 Check

High?

YES

Check IC802 power

And Other circuits

YES

<when playing DISC,

no audio output> check

Check Audio Cable

Audio output even

When playing DISC

PN5401 – 4~6 Check

audio signals

PN304-27~30 :

Check audio signals

NO

NO

Check PN302-5,6

and Front Jack Cable

NO

Check FFC Cable

and VCR part

NO

Check IC804 power

and other circuits

NO

YES

YES

PN304-19~22

Check audio signals

YES

IC804 – 10, 12

Check audio signals

YES

Check /RST-Audio and

power, other circuits

IC804-9 Check

High?

Check IC804 power

And Other circuits

NO

YESYES

YES

IC802 – 15, 18

Check audio signals

Check IC802 power

and other circuits

NO

Check AV_RST1 and

power, other circuits

NO

YES

IC802-10 Check

High?

YES

Check IC802 power

And Other circuits

YES

Check IC804 power

and other circuits

NO

IC804 – 10, 12

Check audio signals

YES

Check /RST-Audio and

power, other circuits

IC804-9 Check

High?

Check IC804 power

And Other circuits

NO

YESYES

YES

8. No External Input 1, 2 audio 9. No External Input 3 audio

Page 63

BLOCK DIAGRAMS

1. VDR SET TOTAL BLOCK DIAGRAM

3-77

REAR JACK

AV1_IN

3

AV1

S_Jack

Y/C

2

A_R/L

2

Stereo

V_cvbs

CVBS

YPbPr

VCR_A_R/L

YPbPr

Coaxial

3

VCR BOARD

COAXIAL

OPTICAL

Optical

D2

D_out

TU_AV_out

6

2

TUNER

2

TU_AV_in

D_control

R_Pr_OUT

G_Y_OUT

C_OUT

Y_OUT

CVBS_OUT