Page 1

ELECTRIC HEATERS

INSTALLATION INSTRUCTIONS

Models: LKAEH052, LKAEH102, LKAEH152,

LKAEH09B, LKAEH18B, LKAEH36B, LKAEH36BL

• Please read this instruction sheet completely before installing the product.

• Installation work must be performed in accordance with national wiring standards by authorized

personnel only.

P/No.: 3828A30038B

Page 2

2

Table 1 Accessory Heaters Electrical Data

Ton

3RT

4/5RT

6.25/7.5RT

8.5/10/12.5

RT

15/17.5RT

20/25RT

Heater

Model No.

LKAEH052

LKAEH102

LKAEH052

LKAEH102

LKAEH152

LKAEH09B

LKAEH18B

LKAEH09B

LKAEH18B

LKAEH18B

LKAEH36B

LKAEH36BL

Heater

KW Rating

3.6/5.0

7.2/10.0

3.6/5.0

7.2/10.0

14.4/15.0

7.8/9.0

15.6/18.0

7.8/9.0

15.6/18.0

15.6/18.0

31.2/36.0

31.2/36.0

Control

Stages

1

1

1

1

1

1

1

1

1

1

2

2

27.6/32.2

47.4/55

29.6/34.2

49.4/57.0

69.0/79.7

30.4/35.1

50.9/58.7

35.7/41.2

56.2/64.8

56.2/64.8

97.1/112.1

97.1/112.1

60/60

60/60

60/60

60/60

90/90

60/60

70/70

60/60

70/70

70/70

125/125

125/125

60/60

60/60

60/60

60/60

90/90

60/60

70/70

60/60

70/70

70/70

125/125

125/125

-

-

-

-

-

33.0/38.1

53.3/61.5

42.0/48.4

62.4/72.0

62.4/72.0

103.4/119.3

103.4/119.3

-

-

-

-

60/60

70/70

60/60

80/80

80/80

125/125

125/125

-

-

-

-

60/60

70/70

60/60

80/80

80/80

125/125

125/125

Heater

Rated Volts

208-240/60/1

208-240/60/1

208-240/60/1

208-240/60/1

208-240/60/1

208-240/60/3

208-240/60/3

208-240/60/3

208-240/60/3

208-240/60/3

208-240/60/3

208-240/60/3

Standard indoor fan motor

M.C.A M.C.AM.F.S M.F.SM.C.B M.C.B

Over size indoor motor

Note; Heater KW ratings are at 208/240V for 220V unit.

M.C.A; Minimum Circuit Ampere

M.F.S; Maximum Fuse Size

M.C.B; Maximum Circuit Breaker

* HACR type Circuit Breaker per NEC.

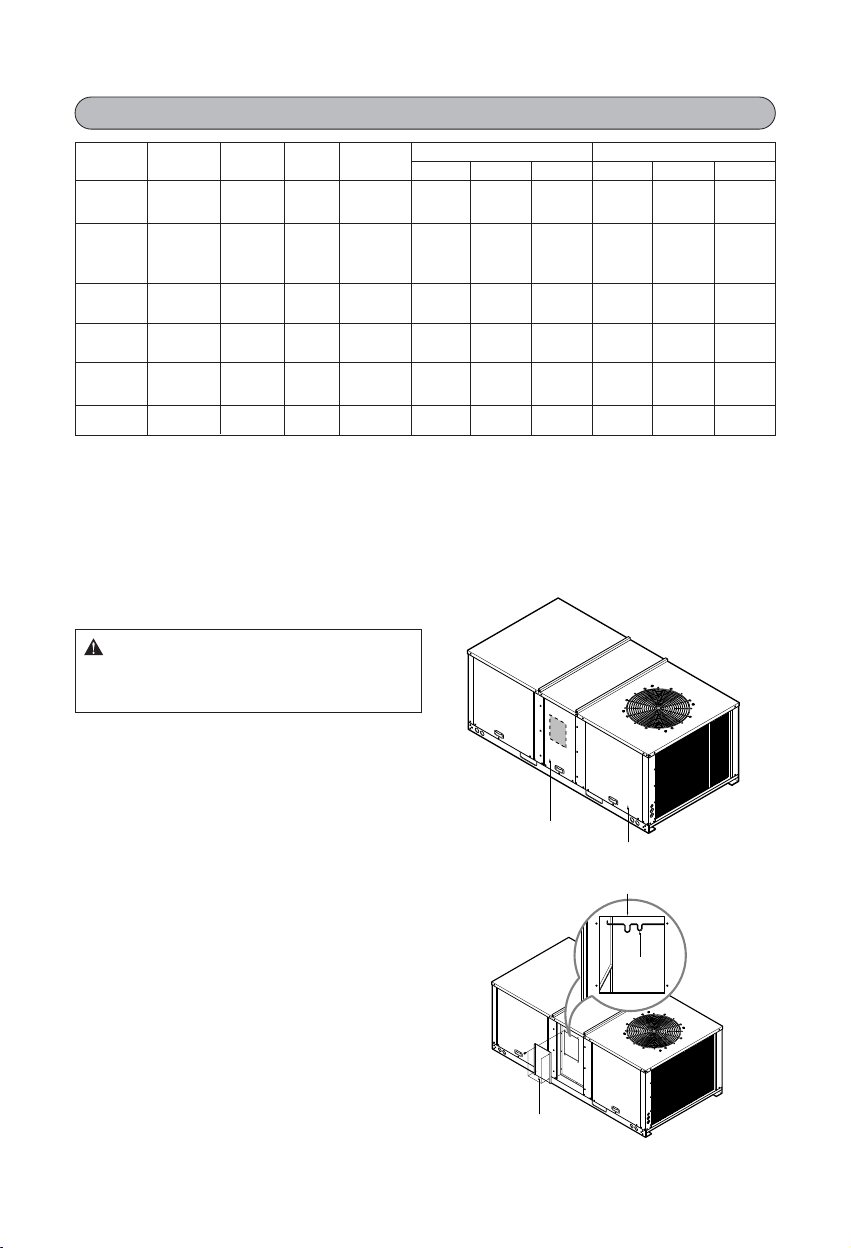

Installation

1. Loosen the screw that secures heater

compartment access panel. Lift up, pull

towards you and slide it down to remove.

2. Remove four(4) screws from block off panel

to expose heater cavity and heaterʼs back

support bracket. Save screws for installing

heater later.(See Figure 2.)

Heater Access Panel

Compressor Access Panel

Figure 1

Figure 2

: Open and lock unit disconnect

switch before installing this accessory to prevent

injury or death due to electrical shock or contact

with moving parts.

WARNING

Support

Bracket

Block off panel

Heater Cavity

Page 3

3

Heater and Control Box Assembly

3. Insert heater into the opening hole of heater

control box.

4. Align holes and secure screws to the control

box as shown in Figure 3.

Single Bank Heater Installation

-

LKAEH052, LKAEH102, LKAEH152,

LKAEH09B, LKAEH18B, LKAEH36BL

5. Place the heater control assembly in the

heater cavity.

6. Secure the heater control assembly of

heater cavity using four(4) screws. (See

Figure 4.)

Important: Make sure the heater arm slides

into heaterʼs back support bracket.

Two Bank Heaters Installation

-

LKAEH36B

7. For two heaters installation, align holes and

secure screws to the control box as shown

in Figure 3.

8. Secure the heater control assembly on

heater cavity using four(4) screws.(See

Figure 5)

Important: Make sure the heaterʼs arm slides

into heaterʼs back support bracket.

Heater Control Box

Heater

Figure 3

Figure 4

Figure 5

Page 4

9. Remove the nut, lock washer and flat

washer from heater terminal posts marked

L1, L2 and L3.

10. Connect wiring from control box panel to

the correct terminal post as shown on

heaterʼs wiring diagram.

Note: The correct sequence for replacing the

hardware on the heater terminal posts is: 1)

wire connector 2) flat washer 3) locking washer

4) nut. “DO NOT OVER TIGHTEN NUT ON

TERMINALS” use a nut driver only to tighten

connection.(See Figure 6.)

4

L3

L2

Figure 6

Control Wiring

11. Connect control wires(Brown) on terminal

block (and P.C.B) as shown on wiring

diagram attached on compressor access

panel.

Power Wiring

12. Then route wires down through the

opening in the top of control box. Connect

wires to high voltage terminal block. Refer

to wiring diagram supplied with heater.

13. Check to make certain the proper size

fuses are installed per the fuse table for

the exact heater being used.

14. Ground unit at the grounding lug

provided. Make sure all field wiring

complies with all applicable codes and

water tightness.(Figure 7)

15. Remove compressor panel, then remove

unitʼs control box cover. Connect high

voltage leads to bottom of compressor

contactor or terminal block.(See unitʼs

wiring diagram.) Replace control box

cover and access panel onto unit.

(Figure 7)

CAUTION: Use copper conductors only to

prevent equipment damage. Unit terminals

are not designed to accept any other wiring.

16. Replace control box cover using four(4)

screws.

17. Replace heater access panel.

CAUTION: Do not over tighten the nuts on the

heater terminals. if the nuts are over tightened

the ceramic insulators will break and heaters

must be replaced.

Maximum torque on nuts is 11 inch

pounds.

To Unit Control Box.

Ground

Power Supply

Terminal Block

Figure 7

Loading...

Loading...