Page 1

PLASMA MONITOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : RF-043E

MODEL : MU-50PM10

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//lgservice.com/techsup.html

Page 2

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

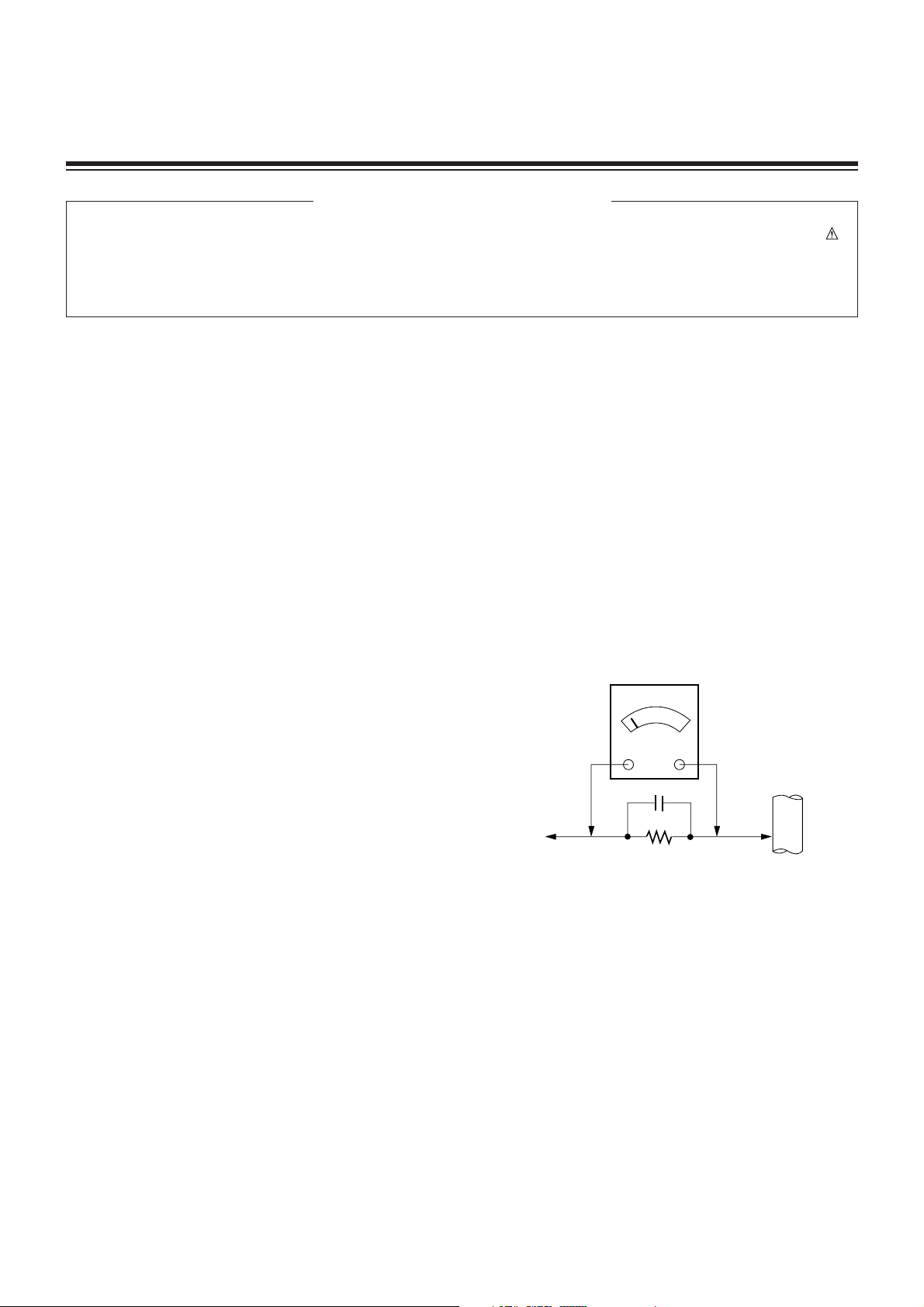

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

- 3 -

DESCRIPTION OF CONTROLS...........................................4

SPECIFICATIONS.................................................................7

ADJUSTMENT INSTRUCTIONS ..........................................8

TROUBLE SHOOTING GUIDE...........................................13

BLOCK DIAGRAM...............................................................24

EXPLODED VIEW...............................................................26

EXPLODED VIEW PARTS LIST.........................................27

REPLACEMENT PARTS LIST............................................28

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARD ...................................................

TABLE OF CONTENTS

Page 4

- 4 -

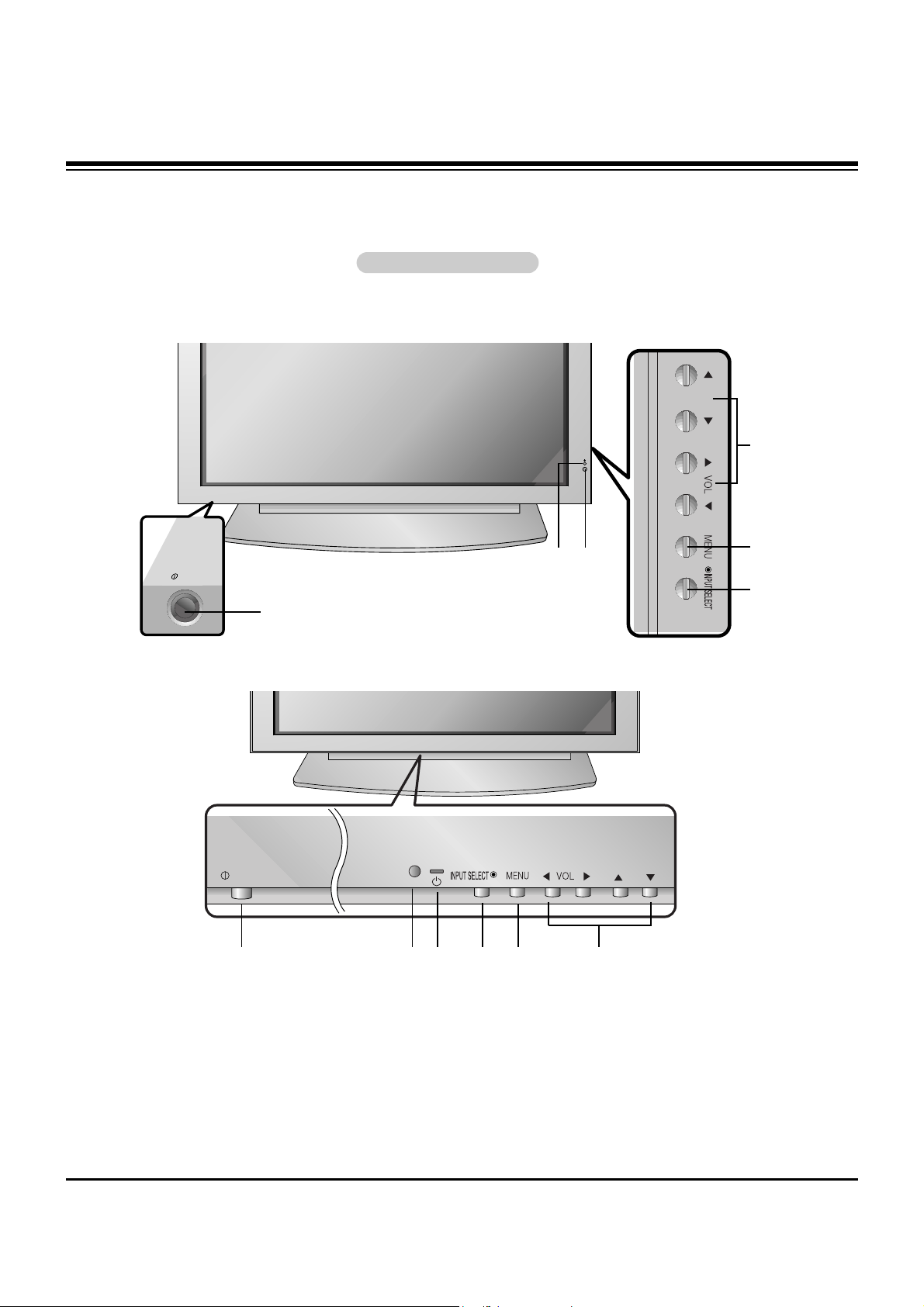

Controls

Controls

Front Panel Controls

Front Panel Controls

- This is a simplified representation of a typical front panel.

The Front Panel Controls shown here may be somewhat different from your monitor.

MU-42/50PM10/11 series

MU-42/50PM20 series

ON/OFF

ON/OFF

1

2

3 4 5 6

1

4

5

6

3

2

1. Main Power Button

2. Remote Control Sensor

3. Power Standby Indicator

Illuminates red in standby mode. Illuminates green when the

Monitor is turned on.

4. INPUT SELECT Button

5. MENU

Displays on screen menus one by one.

Exits the current menu.

Memorizes menu changes.

6.

DD/ EE

Selects a menu option.

FF/ GG

(Volume Up/Down)

Increases/decreases sound level.

Adjusts menu settings.

DESCRIPTION OF CONTROLS

Page 5

- 5 -

Connection Options

Connection Options

AC INPUT

AUDIO INPUT RGB OUTPUTRGB INPUTDVI INPUT

RS-232C INPUT

(CONTROL/SERVICE)

REMOTE

CONTROL

( )

( )

( )

( )

EXTERNAL SPEAKER

R

L

R

L

AUDIO INPUT

VIDEO INPUT

AUDIO INPUT

S-VIDEO

YPBP

R

(MONO)

COMPONENT INPUT

R

L

5

1. REMOTE CONTROL

Connect your wired remote control to the remote control

port on the Monitor.

2. RS-232C INPUT (CONTROL/SERVICE) PORT

Connect to the RS-232C port on a PC.

3. DVI (Digital Visual Interface) INPUT/

AUDIO INPUT/ RGB INPUT JACKS

Connect the monitor output connector from a PC to the

appropriate input port.

4. RGB OUTPUT PORT

You can watch the RGB signal on another monitor, connect

RGB OUTPUT to another monitor’s PC input port.

5. COMPONENT INPUT/AUDIO INPUT JACKS

Connect a component video/audio device to these jacks.

6. S-VIDEO INPUT SOCKETS

Connect S-Video out from an S-VIDEO device to the SVIDEO input.

NOTE: AUDIO INPUT of S-VIDEO is worked by L(mono).

7. VIDEO / AUDIO (L/MONO) INPUT SOCKETS

Connect audio/video output from an external device to

these jacks.

8. EXTERNAL SPEAKER (8 ohm output)

Connect to optional external speaker(s).

* For further information, refer to ‘Speaker & Speaker

Stand’ manual.

9. POWER CORD SOCKET

This Monitor operates on an AC power. The voltage is indicated on the Specifications page. Never attempt to operate

the Monitor on DC power.

Back Connection Panel

Back Connection Panel

1

3

4

2

8

6

9

7

- Connection panels shown may be somewhat different from your monitor.

DESCRIPTION OF CONTROLS

Page 6

- 6 -

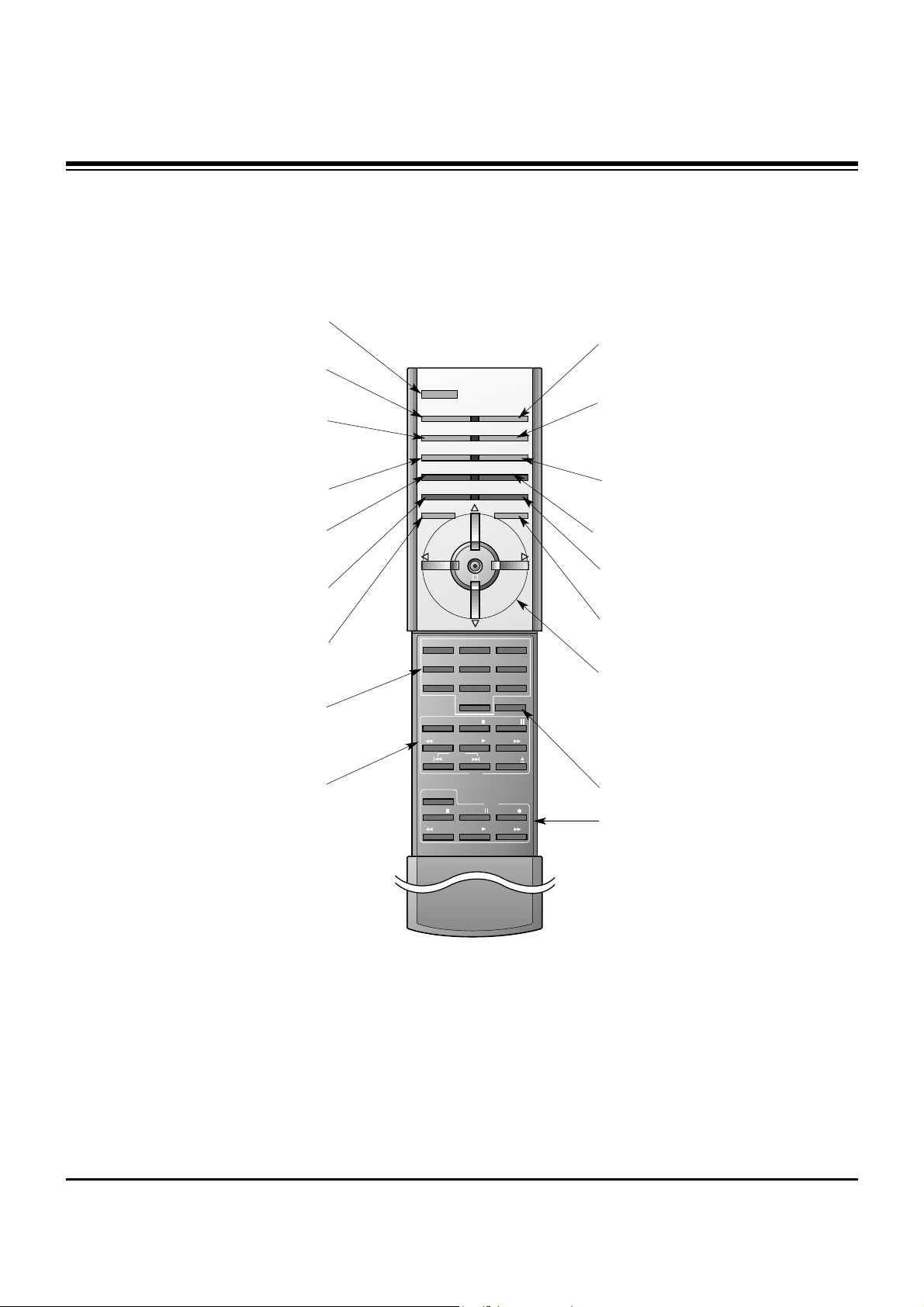

- When using the remote control, aim it at the remote control sensor on the monitor.

- Under certain conditions such as if the remote IR signal is interrupted, the remote control may not function. Press

the key again as necessary.

1 2 3

4 5 6

7 8

0

9

POWER

SLEEP INPUT SELECT

APC DASP

ARC SPLIT ZOOM

PIP/DW

WIN.POSITION

SWAP

MENU MUTE

OK

VOL

POWER

REW

STOP

PLAY FF

REC

PAUSE

W

WIN.P

VOL

SUB INPUT

STOP P/STILL

REW

PLAY FF

POWER

VCR

DVD

OPEN/CLOSE

WIN.SIZE

SKIP

POWER

Switches the Monitor between

ON and STANDBY.

SLEEP

Sets the Sleep Timer.

APC

Adjusts the factory preset picture

according to the room.

ARC

Changes the picture format.

PIP/DW

Switches the sub picture on or off.

SWAP

Exchanges main and sub picture

images.

MENU

Displays on screen menus one by one.

Exits the current menu.

NUMBER buttons

VCR BUTTONS

Control some video cassette

recorders.

OK

DD / EE

Selects menu option.

Memorizes menu changes.

FF / GG

(Volume button)

Increases/decreases sound level.

Adjusts menu settings.

INPUT SELECT

Selects source:

RGB, DVI, Component,

Video, or S-Video mode.

DASP

To select the sound appropriate to

your viewing program character:

Flat, Music, Movie, Sports, SRS TSXT or

Off.

SPLIT ZOOM

Enlarges the picture.

SUB INPUT

Selects the input source for the sub

picture.

MUTE

Switches the sound on or off.

WIN.POSITION

Moves the sub picture.

Remote Control Key Functions

Remote Control Key Functions

DVD buttons

Control some DVD cassette

recorders.

WIN.SIZE

Adjusts the sub picture size.

DESCRIPTION OF CONTROLS

Page 7

- 7 -

• The specifications shown above may be changed without notice for quality improvement.

MODELS

42 / 1066

25.8 / 656

3.8 / 97.5

64.6 / 29.3

1024 x 768 (Dot)

16,770,000 (256 steps of each R, G and B)

32 ~ 104°F (0 ~ 40°C)

Less than 80%

MU-50PM10/11/20

49.3 / 1253

29.3 / 745

3.9 / 99.5

84.7 / 38.4

1366 x 768 (Dot)

Width (inches / mm)

Height (inches / mm)

Depth (inches / mm)

Weight (pounds / kg)

Resolution

Power requirement

Color

Operating Temperature Range

Operating Humidity Range

852 x 480 (Dot)

MU-42PM11/20

MU-42PM12X

AC100-240V, 50/60Hz

AC100-240V, 60Hz

SPECIFICATIONS

Page 8

- 8 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions apply to the RF-043E Chassis.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be performed in the correct order.

(3) The adjustments must be performed in the circumstance

of 25±5°C of temperature and 65±10% of relative humidity

if there is no specific designation otherwise..

(4) The input voltage of the receiver must keep 100~220V,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to adjustments.

O The unit must be Heat Run with a RGB Full pattern, prior to

adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on Service R/C.

2) OSD display and screen display 100% full WHITE

PATTERN.

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode can be used to check PANEL.

Caution) If you turn on a still screen for more than 20 minutes

(Especially digital pattern, cross hatch pattern), an

afterimage may occur in the black level part of the

screen.

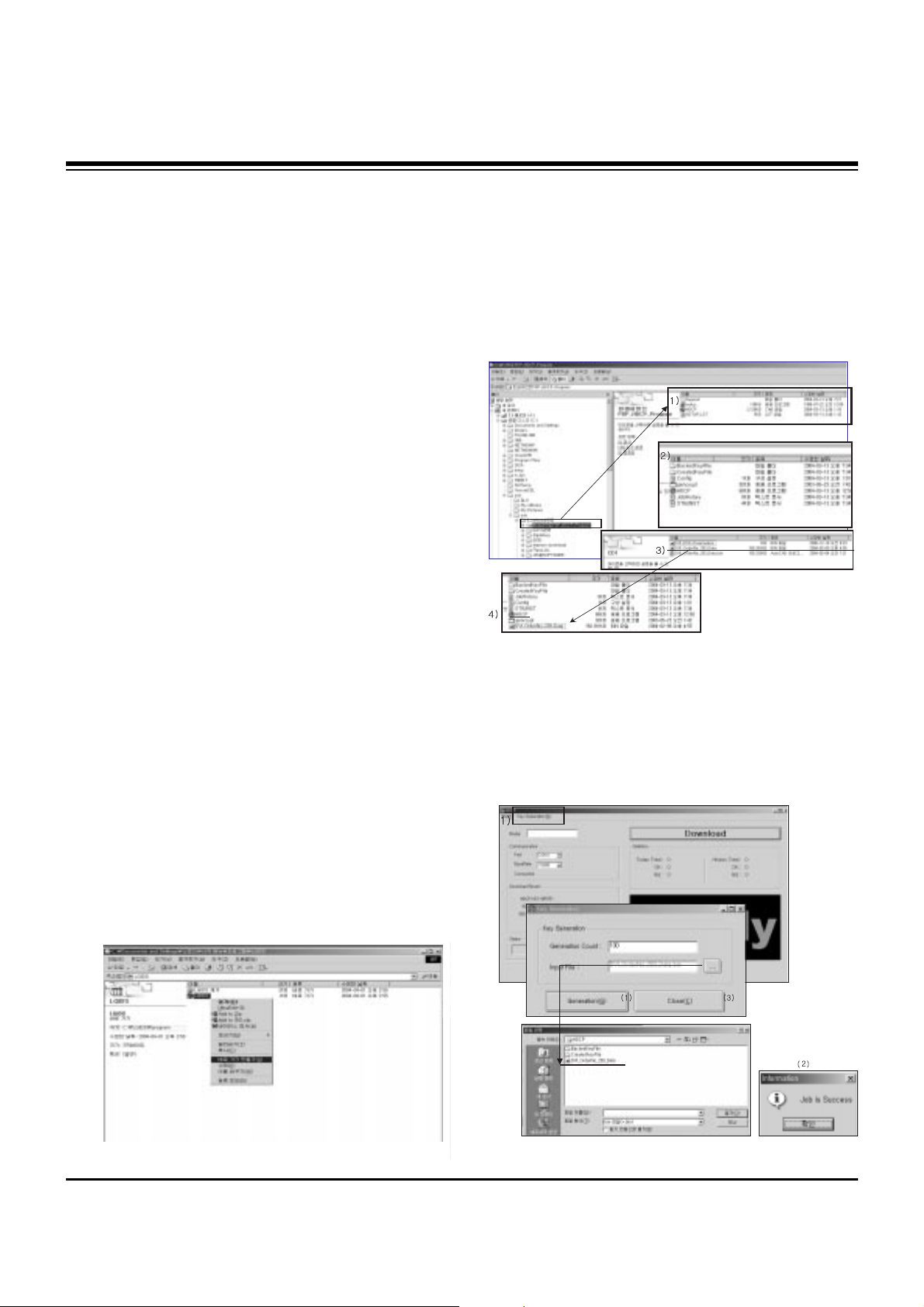

3. Setting Up the LGIDS

(1) Install the LGIDS. (idsinst.exe)

After installation has completed, check if the file shown in

(Fig. 1) has been created.

(2) Right click on 'LGIDS' and select ‘Create Shortcut’

Then move the shortcut icon onto the desktop.

(3) Double-click on the ‘LGIDS’ icon on the desktop to

execute the program.

4. HDCP Download

4-1. Setting Up the LGIDS

(1) Click on ‘setup’ to install in your directory.

(2) After installation has completed, check if the file shown on

(Fig. 2) has been created.

(3) Copy the KEY from source CD into the HDCP directory

which was installed just now.

(DVI_orderNo_2003_data)

(4) After running HDCP(application program) which is inside

the HDCP directory, setup the Communication.

Port : COM1(modification possible)

BaudRate : 115200

4-2. KEY Generation

(Fig. 1)

(Fig. 2)

(Fig. 3)

Page 9

- 9 -

ADJUSTMENT INSTRUCTIONS

(1) Click on ‘Key Generation (G)’.

(2) Input the number of the key in Generation count.

ex) If 100 Keys are required, then just register 100 and

next time it will automatically get 101.

(3) Input file : When installing the program for the first time,

you must find the original KEY that you copied and open it.

It is crucial that you copy the original KEY into this

directory.

When you use Generation, the information is recorded in

Config.ini.

(4) Click on ‘Generation’ ———————————————(1)

If it is done correctly, you will see “Job is Success.”——(2)

Click on ‘close’——————————————————(3)

(5) Check the Generation Data(Confirmation it’s possible

within HDCP\CreatedKeyFile)

(6) It is possible to check how many Generations are created

at this point.

(Fig. 5) shows that you have created 130 Generations and

you will start from 131 next time.

4-3. HDCP Download Method

(1) Input power of Stand-By 5V.

(Download must be executed only when it is on Stand-by)

(2) The RS-232C(9PIN) must be connected to the COM1 on

the PC.

(3) If all the preparation is completed, click on ‘Download’.

(4) If abnormal state (Fig. 8) display then (3) execute.

(Fig. 4)

(Fig. 5)

(Fig. 6)

(Fig. 8) Abnormal State

(Fig. 7) Normal State

Page 10

- 10 -

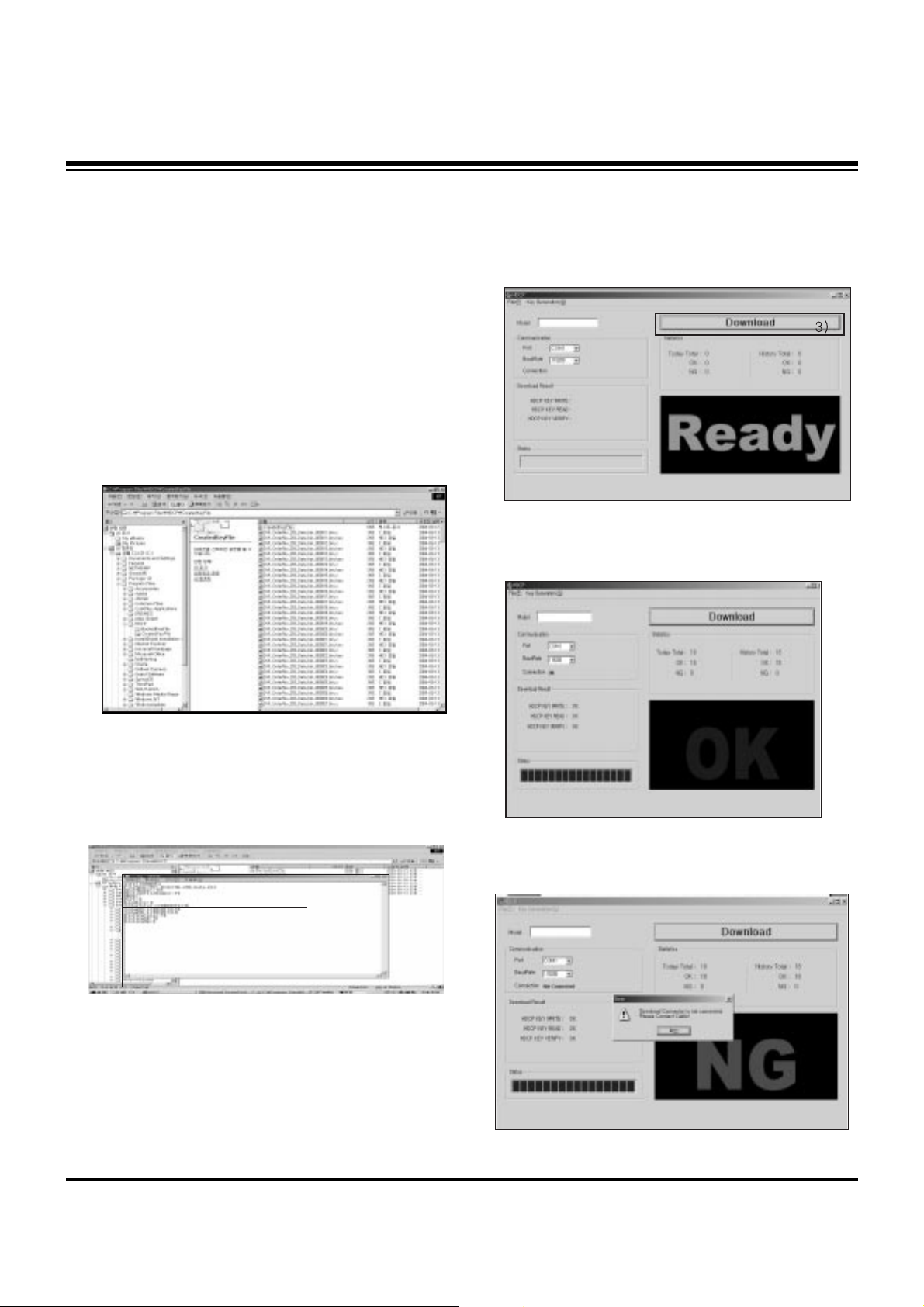

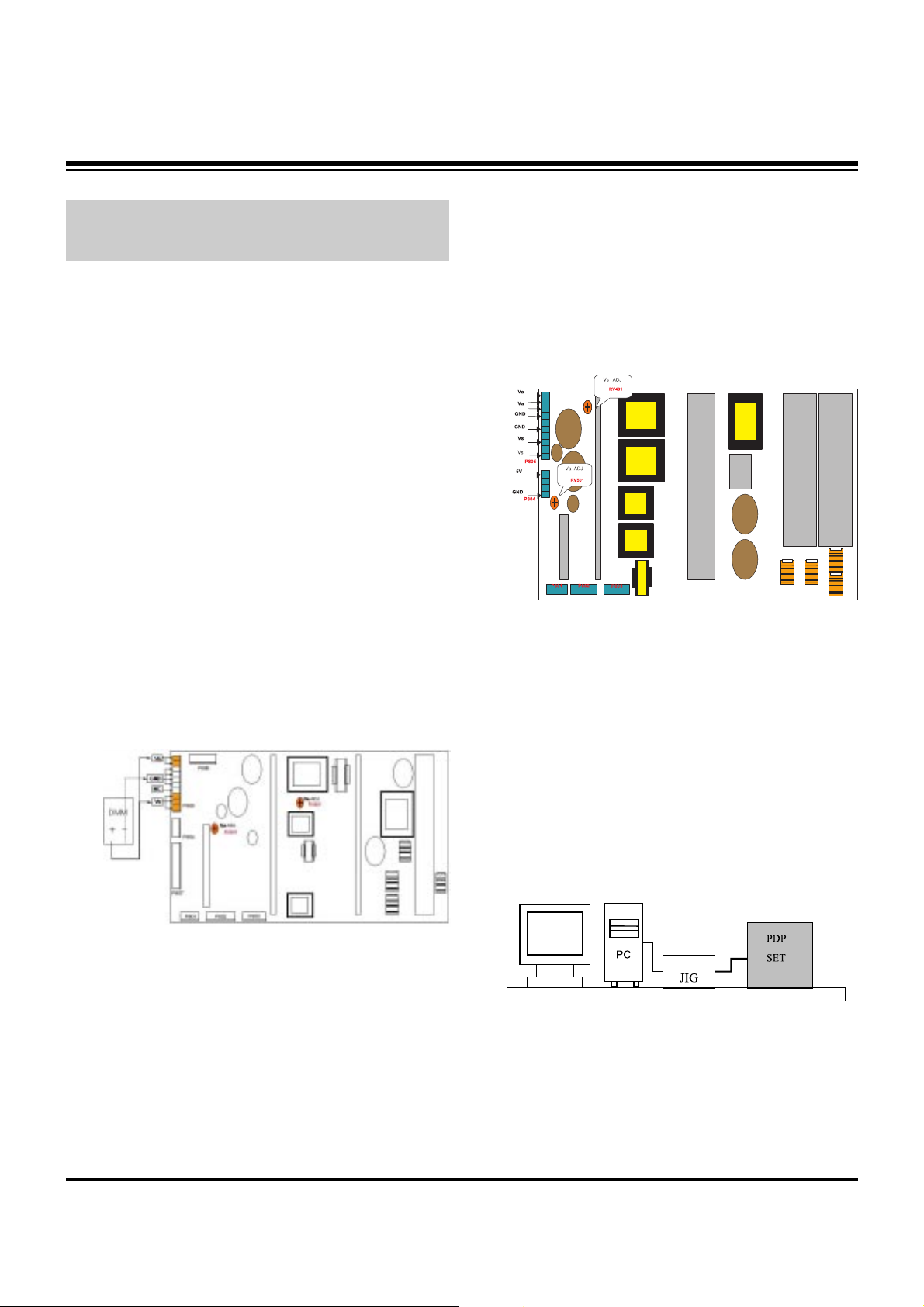

5. POWER PCB Assy Voltage

Adjustments

(Va, Vs Voltage Adjustments)

5-1. Test Equipment :D.M.M. 1EA

5-2. Connection Diagram for Measuring

Refer to (Fig 9).

5-3. Adjustment Method for

P/No. 3501V00182A/B B/D

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) Turn RV601, to adjust the Va voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

2) Turn RV401, to adjust the Vs voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

5-4. Adjustment Method for

P/No. 3501V00187A B/D

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P805, connect

- terminal to GND pin of P805.

3) Turn RV501, to adjust the Va voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805, connect

– terminal to GND pin of P805.

2) Turn RV401, to adjust the Vs voltage to match the value

marked on the label on the right/top of the panel.

(Deviation; ±0.5V)

6. DDC Data Input

6-1. Required Test Equipment

(1) A jig for adjusting PC, DDC (PC serial to D-sub

Connection equipment)

(2) S/W for writing DDC (EDID Data Write & Read)

(3) D-sub 15P Cable, D-Sub to DVI Connector (Connect to

DVI Jack)

6-2. Setting of Device

6-3. Preparation for Adjustment

(1) Set devices as above and turn the PC and jig on.

(2) Put S/W for writing DDC (EDID data Write & Read) into

operation. (operated in DOS mode.)

ADJUSTMENT INSTRUCTIONS

Each PCB assembly must be checked by Check JIG Set

before assembly. (Take special note of the Power PCB, which

can easily damage the PDP module)

(Fig. 9-1) Connection Diagram of Power Adjustment for

Measuring(3501V00182A/B)

(Fig. 9-2) Connection Diagram of Power Adjustment for

Measuring(3501V00187A)

(Fig. 10)

Page 11

- 11 -

ADJUSTMENT INSTRUCTIONS

6-4. Sequence of Adjustment

(1) DDC Data Input for Analog-RGB

1) Put the set on the table and turn the power on.

2) Connect PC Serial to D-sub 15P Cable of jig for DDC

adjustment to RGB terminal (D-Sub 15Pin).

3) Operate S/W for DDC record and select DDC data for

Analog RGB in Model Menu.

4) Operate EDID Write command.

5) Operate EDID Read command and check whether

Check Sum is as below.

MU-42PM11: CB

MU-42PM12X/MU-50PM10: DC

6) If Check Sum is not CB(or DC), repeat 3) ~ 4).

7) If Check Sum is CB(or DC), DDC data for Analog-RGB

input is completed.

(2) DDC Data input for Digital-RGB(DVI)

1) Connect PC Serial to DVI Cable of jig for DDC

adjustment to DVI terminal (DVI Jack).

2) Operate S/W for DDC record and select DDC data for

digital RGB in model menu.

3) Operate EDID Write command.

4) Operate EDID Read command and check whether

Check sum is as below.

MU-42PM11: 4A

MU-42PM12X/MU-50PM10: CD

5) If Check sum is not 4A(or CD), repeat 3) ~ 4).

6) If Check sum is 4A(or CD), DDC data for Analog-RGB

input is completed.

7. Adjustment of White Balance

7-1. Required Equipment

Color Analyzer (CA-100 or similar product)

7-2. Connection Diagram of Equipment for

Measuring

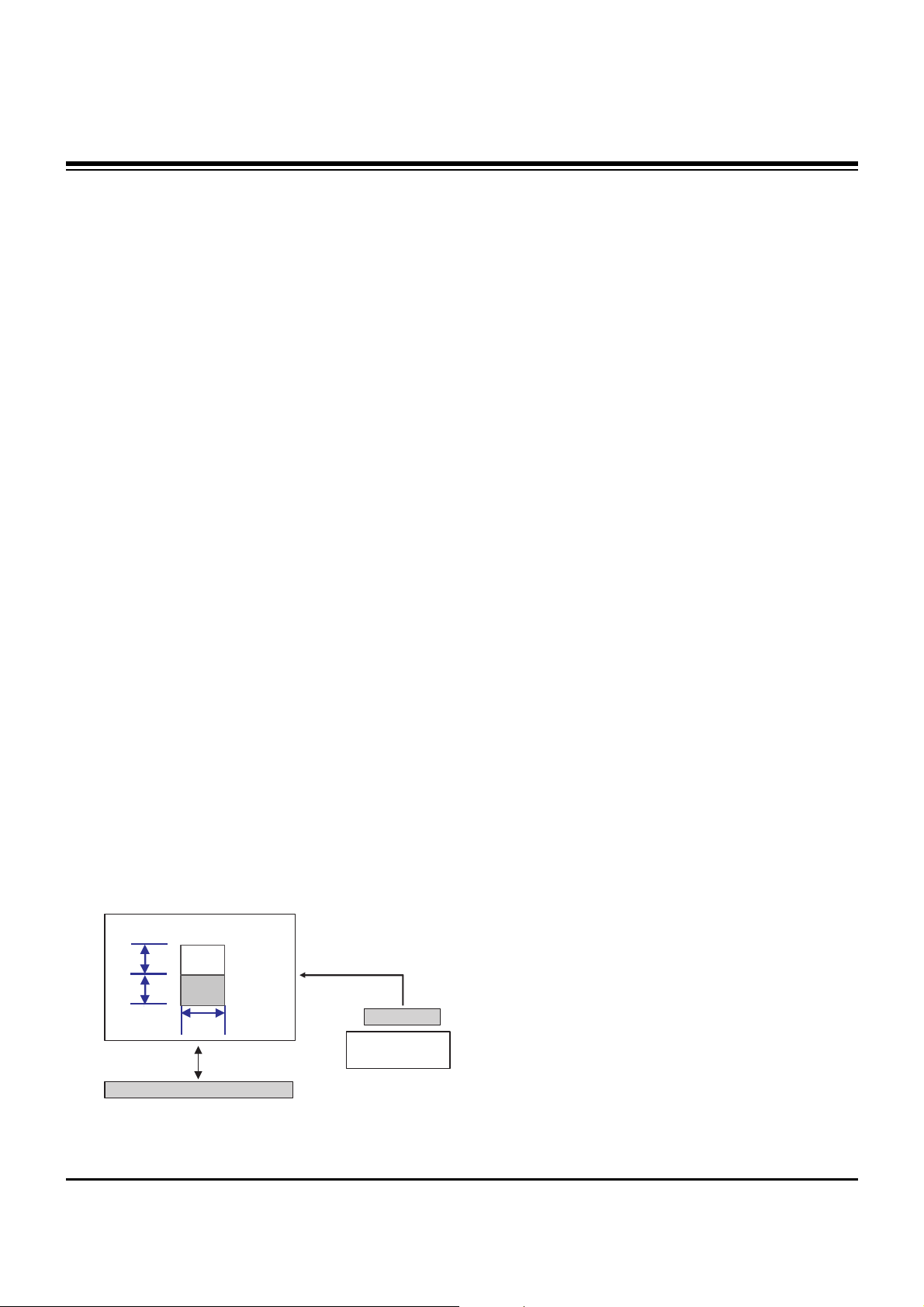

7-3. Adjustment of White Balance

O Operate the Zero-calibration of the CA-100, then stick

sensor to PDP module surface when you adjust.

O Manual adjustment is also possible by the following

sequence.

(1) Select white pattern of heat-run mode by pressing power

key on the Service Remote Control (S R/C) then allow to

heat run at least 15 minutes.

(2) Supply Window Pattern signal to DVI input using Pattern

Generator.

1) Input Signal: XGA 60Hz

2) Input the Window Pattern(Horizontal 25%, Vertical

50%(Top High 25% + Bottom Low 25%))

(Refer to Fig. 11)

(3) Press the FRONT-AV KEY on R/C for converting input DVI

mode.

(4) Press ADJ key twice on S R/C. (White Balance)

(5) High Adjustment

Stick sensor to center of 160 Gray Level(High Window

Pattern), select Red Gain and Green Gain using

D, E key

on S R/C.

Press VOL +, - keys to adjust until color coordination

matches below.

X; 0.285±0.003, Y; 0.285±0.003

(6) Low Adjustment

Stick sensor to center of 80 Gray Level(Low Window

Pattern), select Red Offset and Green Offset using

D, E

key on S R/C.

Press VOL +, - keys to adjust until color coordination

matches below.

X; 0.285±0.006, Y; 0.285±0.006

(7) Repeat above step (5) and (6) for the best condition of

High and Low.

(8) Exit adjustment mode using

A Key.

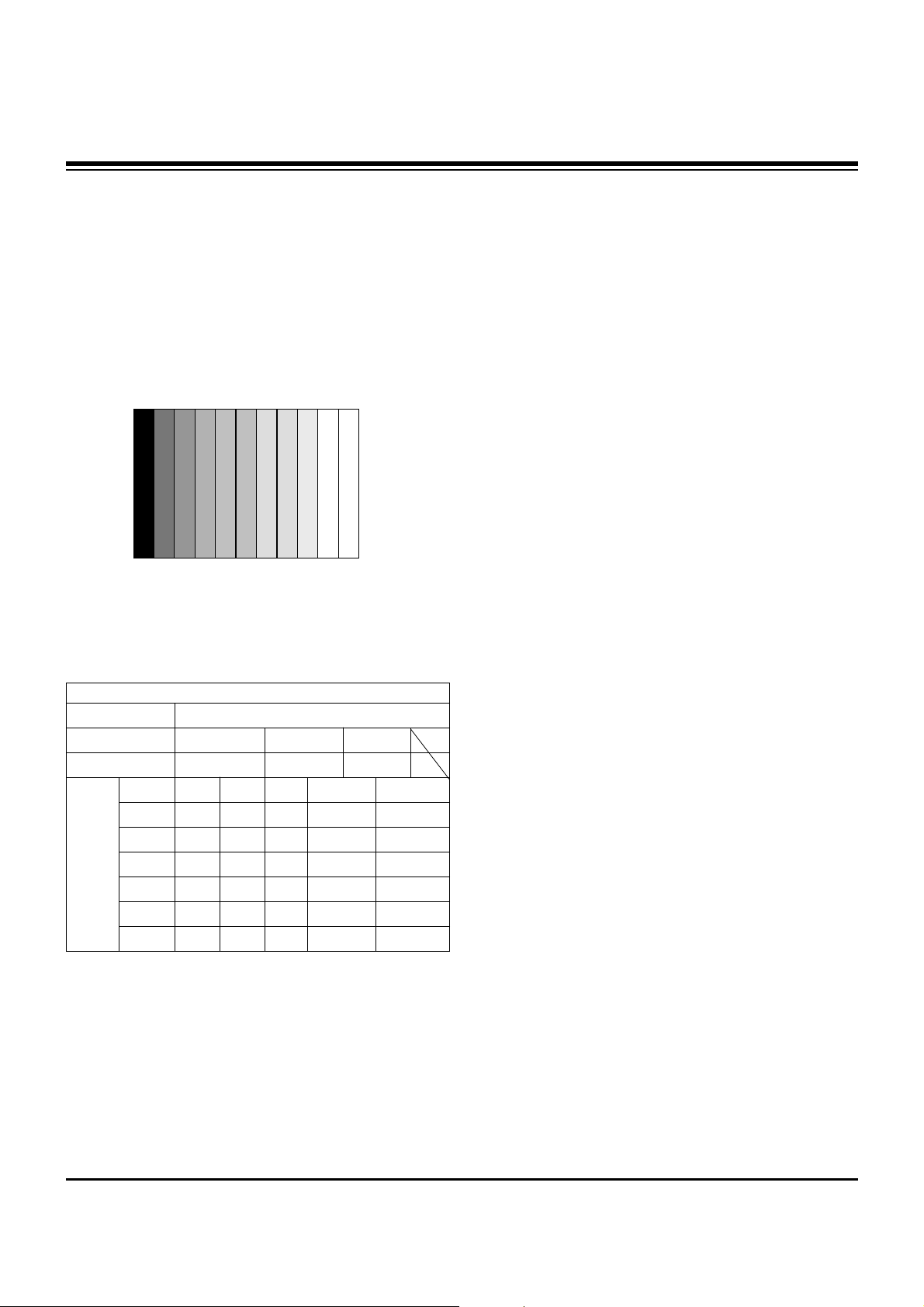

8. Auto Component Color Balance

8-1. Required Test Equipment

Pattern Equipment: MSP3240A or similar product

(16 Gray Scale Pattern output(Component output Level:

0.7Vp-p)

8-2. Method of Auto RGB Color Balance

(1) Input RGB Source : Component 720p 16 Gray Scale

Pattern

At this time, input the Y, Pb and Pr signal.

(2) Press ADJ KEY on the S R/C.

(3) Press Vol. + KEY and operate To set.

(4) Auto-RGB OK means completed adjustment.

1/4 H

1/4 H

1/4 W

High

160 gray

Low

80 gray

RS-232C Serial Communication

DVI Signal Input

XGA 60Hz Signal

COLOR ANALYZER

TYPE; CA-100

Window

MSPG-2100 or

MSTG-5200

(Fig. 11) White Balance Adjustment

Page 12

- 12 -

9. Auto RGB Color Balance

9-1. Required Test Equipment

Pattern Equipment: PC Pattern Generator (VG828, VG854,

801GF, MSP3240A)

(16 Gray Scale Pattern output(RGB output Level: 0.7Vp-p)

9-2. Method of Auto RGB Color Balance

(1) Input RGB Source : XGA 60HZ 16 Gray Scale Pattern

(2) Press ADJ KEY on the S R/C.

(3) Press Vol. + KEY and operate To SET.

(4) Auto-RGB OK means completed adjustment.

10. Auto Adjustment Map(RS-232C)

(Fig. 12) Auto RGB/ Component Color Balance Test Pattern

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

j a

j b

j c

j d

j e

j f

Stop bit

1

Parity

NONE

RF-043A

Protocol

Setting

Data Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

RS232

ADJUSTMENT INSTRUCTIONS

Page 13

- 13 -

TROUBLE SHOOTING GUIDE

1. Power Board

1-1. General Power Flow

Start check

Manufacture enterprise

meaning of a passage

1. Check the Power Off

condition.

Doesn't the

screen whole come

out?

It is identical

with Power Off

condition?

Yes

Yes

No

No

No

No

No

2. Check the Interface

signal condition.

Is the Interface

signal operated?

Yes

3. Check the St-by 5V

signal circuit.

Doesn't the

low pressure output

come out?

Doesn't the

St-by 5V signal

come out?

Yes

Yes

No

4. Check the 5V Monitor

signal circuit.

Doesn't the

5V Monitor signal

come out?

Yes

7. Check the VSC Vs-ON

signal

Doesn't the

high tension output

come out?

Doesn't the

VSC signal Vs-ON

come out?

Yes

Yes

High tension

output voltage Drop

it occurs?

When

remove the

Y B/D Module

Input Connector, output

voltage Drop

it occurs?

When remove

the Y, Z B/D Module

Input Connector, Power

Board high tension output

voltage Drop

it occurs?

Yes No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module Coutput circuit

Yes

When

remove the

Z B/D Module

Input Connector, output

voltage Drop

it occurs?

11. Check the Y B/D

Module Coutput circuit

Yes

No

8. Check the Vs, Va

voltage output circuit.

Doesn't the

Vs, Va voltage output

come out?

Yes

No

No

5. Check the VSC RL-ON

signal.

Doesn't the

VSC signal RL-ON

come out?

Yes

6. Check the VSC low

pressure output

Doesn't the

VSC low pressure

output come out?

Yes

Page 14

- 14 -

TROUBLE SHOOTING GUIDE

1-2. 3510V00182A Power Board Structure

T502: Vs Trans

T702: Va Trans

T101: St-by Trans

T103: Low Voltage Trans

1 2 3

Page 15

- 15 -

TROUBLE SHOOTING GUIDE

1-3. 3501V00180A Power Board Structure

T221: Vs Trans

T271: Va Trans

T121: St-by Trans

T201: Low Voltage Trans

1 2 3

Page 16

- 16 -

TROUBLE SHOOTING GUIDE

2. No Power

(1) Symptom

¯ No indication of Power.

¯ No front LED.

(2) Check follow

Power cord connected? Plug in power cord.

Yes

No

Cable connecting the Line Filter

and Power Switch connected?

Connect Cable.

Yes

No

Is the Power Switch connected to

Power Board?

Connect Cable.

Yes

No

Is Fuse(F101) on Power Board

good?

Replace Fuse.

Yes

No

Is the Power Board connected to

7P of VSC Board?

Connect Cable.

Yes

No

When ST-BY 5V does not operate,

replace Power Board.

Page 17

- 17 -

TROUBLE SHOOTING GUIDE

3. Protect Mode

(1) Symptom

¯ Will not fully turn on

¯ The Relay "clicks"

¯ Front LED changes from Green to Red

(2) Check follow

Is the Power Board

good?

Replace Power

Board.

Is output the normality Low/High

voltage except Stand-by 5V?

Yes

No

No

Are all connectors

connected?

Replace

connector.

Replace

Y-Board.

After connecting each connector well,

is operation good?

Yes

No

No

Is the Ctrl Board

good?

Replace

X-Board.

Is the output voltage good after

removing P1, 2, 101, 300, 701, 702

connector of Ctrl-B/D?

Yes

No

Yes

Is the Y-Board good?

Is the output voltage

good after removing

P5, P6 connector of

Y-B/D?

Check Fuse(F52) on Y-B/D?

(In case of open, replace fuse)

Yes

No

Yes Yes

Replace

Z-Board.

Is the Z-Board good?

Is the output voltage

good after removing

P1 connector of Z-

B/D?

Check Fuse(FS1, FS2) on Z-B/D?

(In case of open, replace fuse)

Yes

No

Yes

Is the X-Board good?

Is the output voltage good after

removing P1, 2, 3, 4, 6, 7 connector

of X-B/D?

If after removing P1, P2, P3, P4 the output

voltage is normal: Replace Right X-B/D.

If after removing P6, P7 the output voltage

is normal: Replace Left X-B/D.

Yes

No

Yes

Is the VSC Board

good?

Is the output voltage good after

removing P1000, P1200?

After crisis COF of each board, check the normality operates.

If in case normality operates, correspondence COF Fail is

replace the module.

If after removing P1000 the output is

normal: Replace Analog Board

If after removing P1200 the output is

normal: Replace Digital Board

Yes

No

Is normal the

COF of X, Y, Z?

No

Yes

Yes

Page 18

- 18 -

TROUBLE SHOOTING GUIDE

4. No Raster

(1) Symptom

¯ Powers on but, no output on display.

¯ Front LED is green but, no Raster.

(2) Check follow

Is the Power Board

good?

Replace Power

Board.

Is output the normality Low/High

voltage except Stand-by 5V?

Yes

No

No

Are all connectors

connected?

Replace

connector.

Replace

Y-Board.

After connecting each connector well,

is operation good?

Yes

No

No

Is the Ctrl Board

good?

Replace

X-Board.

Is the output voltage good after

removing P1, 2, 101, 300, 701, 702

connector of Ctrl-B/D?

Yes

No

Yes

Is the Y-Board good?

Is the output voltage

good after removing

P5, P6 connector of

Y-B/D?

Check Fuse(F52) on Y-B/D?

(In case of open, replace fuse)

Yes

No

Yes Yes

Replace

Z-Board.

Is the Z-Board good?

Is the output voltage

good after removing

P1 connector of Z-

B/D?

Check Fuse(FS1, FS2) on Z-B/D?

(In case of open, replace fuse)

Yes

No

Yes

Is the X-Board good?

Is the output voltage good after

removing P1, 2, 3, 4, 6, 7 connector

of X-B/D?

If after removing P1, P2, P3, P4 the output

voltage is normal: Replace Right X-B/D.

If after removing P6, P7 the output voltage

is normal: Replace Left X-B/D.

Yes

No

Yes

Is the VSC Board

good?

Is the output voltage good after

removing P1000, P1200?

After crisis COF of each board, check the normality operates.

If in case normality operates, correspondence COF Fail is

replace the module.

If after removing P1000 the output is

normal: Replace Analog Board

If after removing P1200 the output is

normal: Replace Digital Board

Yes

No

Is normal the

COF of X, Y, Z?

No

Yes

Yes

Page 19

- 19 -

TROUBLE SHOOTING GUIDE

5. Abnormal Display

5-1. No OSD

(1) Symptom

¯ LED is green

¯ No OnScreen Display

(2) Check follow

Check the LVDS

cable?

Is the VSC Digital

Board good?

Is the LVDS cable

connected well?

Reset cable.

Yes

No

No

Yes

Operates the Thine

IC(IC1100)?

Replace Thine

IC(IC1100).

No

Is the Ctrl Board

good?

Replace Ctrl B/D.

No

No

Check

IEP(IC500)?

Replace

IEP(IC500).

Yes

No

Check

Scaler(IC700)?

Replace

VSC Digital

B/D.

Replace

Scaler(IC700).

Yes Yes

No

Replace cable.

Yes

Page 20

- 20 -

TROUBLE SHOOTING GUIDE

5-2. In case of does’t display the screen into specific mode

(1) Symptom

¯ The screen does not become the display from specific input mode

(AV, Component, RGB, DVI).

(2) Check follow

¯ Check the all input mode should become normality display

.

¯ Check the Video(Main)/Data(Sub), Video(Main)/Video(Sub) should become

normality display from the PIP mode or DW mode. (Re-Check it Swap)

(3) Abnormal display in AV mode

Is IC400 (Switch)

CXA2069Q good?

Yes

Is the Video Decoder

VPC3230 good?

Is normal the Input voltage, IIC

Communication and HV sync?

No

Replace IC400

No

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Page 21

- 21 -

TROUBLE SHOOTING GUIDE

(4) Abnormal display in Component 480i mode

(5) Abnormal display in Component DTV mode(480p, 720p, 1080i)

Is the Video Decoder

VPC3230 good?

Yes

Is the DeInterlacer

S2300 good?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Yes

Is Scaler good?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Is normal the

74LS123?

Yes

Is IC401 (CXA2101)

good?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC401

No

Yes

Is normal the

M52758?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Yes

Is Scaler good?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Page 22

- 22 -

TROUBLE SHOOTING GUIDE

(6) Abnormal display in RGB DTV mode

(7) Abnormal display in RGB PC mode

(8) Abnormal display in DVI mode

Is normal the

CXA2101?

Yes

Is normal the

M52758?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Is normal the

M52758?

Yes

Is normal the Scaler?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Is normal the Scaler?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Yes

Is normal the Scaler?

Are the Input voltage, IIC

Comm. and HV sync good?

No

Replace IC

No

Page 23

- 23 -

TROUBLE SHOOTING GUIDE

6. No sound

(1) Symptom

¯ LED is green

¯ Screen display but no audio

(2) Check follow

Check Speaker

cable?

Is the SPK cable

connected well?

Reset cable.

No

No

Reset cable.

No

Replace IC800

No

Replace IC801

No

Replace SPK cable

Yes

Yes

Audio normal on

RGB/DVI?

Is the Flat cable

connected well?

No

No

IC800 good?

Yes

IC801 good?

Replace IC802

No

IC802 good?

Replace

VSC Analog B/D

Yes

Yes

Yes

Audio normal on

RF/AV/Component?

Page 24

- 24 -

BLOCK DIAGRAM

Page 25

- 25 -

NOTES

Page 26

- 26 -

EXPLODED VIEW

305

300

501

530

590

520

540

541

301

302

303

304

560

310

400

102

103

220

230

101

205

212

201

203

200

202

210

208

209

207

206

211

580

Page 27

- 27 -

EXPLODED VIEW PARTS LIST

101 5900V12003B FAN,DCD12025S SDS 120MM*120MM*25MM 12V/0.2A 1300 5V-13.2V RPM

102 4980V01018A SUPPORTER,FAN EGI LEFT PDP DN-50PY10

103 4980V01017A SUPPORTER,FAN EGI RIGHT PDP DN-50PY10

200 6348Q-C036H PDP,50 16:9 1365*768 PDP50X20562.AKLGG

201 6871QRH041C PCB ASSEMBLY,DISPLAY XRRT ASSY 50X2A COF RESISTOR

202 6871QCH045A PCB ASSEMBLY,DISPLAY CTRL ASSY 4023 50X2 FOR CI

203 6871QZH036B PCB ASSEMBLY,DISPLAY ZSUS ASSY 50X2A 4LAYER

205 6871QLH035C PCB ASSEMBLY,DISPLAY XRLT ASSY 50X2A COF RESISTOR

206 6871QXH025C PCB ASSEMBLY,DISPLAY XRCB ASSY 50X2A COF RESISTOR

207 6871QLH036C PCB ASSEMBLY,DISPLAY XRLB ASSY 50X2A COF RESISTOR

208 6871QDH081A PCB ASSEMBLY,DISPLAY YDRV ASSY 50X2A YDRV_BTM

209 6871QYH032B PCB ASSEMBLY,DISPLAY YSUS ASSY 50X2A YSUS 4LAYER

210 6871QDH080A PCB ASSEMBLY,DISPLAY YDRV ASSY 50X2A YDRV_TOP

211 6871QRH042C PCB ASSEMBLY,DISPLAY XRRB ASSY 50X2A COF RESISTOR

212 6871QXH024C PCB ASSEMBLY,DISPLAY XRCT ASSY 50X2A COF RESISTOR

220 4980V00C28A SUPPORTER,MODULE EGI ASSY R

230 4980V00C29A SUPPORTER,MODULE EGI ASSY L

300 3091V00724A CABINET ASSEMBLY,50PM10 NON RF04GA NON

301 4980V00C24A SUPPORTER,FILTER EGI TOP ASSY

302 4980V00C27A SUPPORTER,FILTER EGI SIDE L ASSY

303 4980V00C25A SUPPORTER,FILTER EGI BOT ASSY

304 4980V00C26A SUPPORTER,FILTER EGI SIDE R ASSY

305 5230V00017A FILTER(MECH),LGM50-01 MITSUI 50 CLASS B GLASS FILTER

310 5020V01004A BUTTON,CONTROL 50PM10 NON 6KEY NON

400 3809V00502B BACK COVER ASSEMBLY,MU-50PM10 .AALLKG NON WARNING LABEL

501 3301V00041B PLATE ASSEMBLY,3300V00425B AND 3300V00319D MU-50PM10_20

520 6871VMMU18C PCB ASSEMBLY,MAIN RF-043A MU-50PM10 MAIN DIGITAL B/D MANUAL

530 6871VSMACBC PCB ASSEMBLY,SUB A/V RF043E MU-50PM10 SUB ANALOG MANAUL

540 6871VSME92A PCB ASSEMBLY,SUB PSW RF043A MAILBU

541 5020V01005A BUTTON,POWER 50PM10 NON 6KEY NON

560 6871VSMG62A PCB ASSEMBLY,SUB CONT RF043E MU-42PM10 LOCAL KEY ASSY

580 3501V00187A BOARD ASSEMBLY,POWER RF043B 1H211W1 PDP 50 PSU H/C

590 3141VSNH95A CHASSIS ASSEMBLY,SUB RF043E MU-50PM10 AC IN LET

No.

Part No.

Description

Page 28

- 28 -

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC800

IC801

IC801

IC802

IC803

IC805

IC9000

Q001

Q002

Q100

Q101

Q102

Q103

Q1100

Q1101

Q1102

Q1103

Q1104

Q1105

Q1106

Q1107

Q1108

Q1109

Q1110

Q1111

Q1112

Q1113

Q1114

Q1115

Q1116

Q1117

Q1118

Q1119

Q1200

Q1201

Q1202

Q1501

Q1503

Q207

Q208

Q209

Q210

Q211

Q214

Q300

Q301

0IMCRMN027D

0IMMRMR023B

0IMCRNL001A

0IMCRTI028C

0IPRPJR017A

0IKE704200J

0IPRPBB005A

0TR387500AA

0TR387500AA

0TR830009BA

0TR830009BA

0TR830009BA

0TR830009BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR102009AG

0TR387500AA

0TR387500AA

0TR387500AA

0TR830009BA

0TR830009BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR104009AF

0TR387500AA

0TR387500AA

0TR387500AA

MSP4440K 80P MULTI SOUND

MX29LV800BTTC-70 48P

NSP-6241B 64P DIGITAL AUDIO

TAS5122DCAR 56P

NJU26901E2 JRC 8P

KIA7042AF SOT-89 TP 4.2V

OPA3692IDBQ 16PIN

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83

BSS83

BSS83

BSS83

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC102S SOT-23 NA NA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83

BSS83

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC104S SOT-23 TP KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

LOCA. NO PART NO DESCRIPTION

IC100

IC1000

IC1001

IC1002

IC101

IC102

IC103

IC104

IC1100

IC1100

IC1101

IC1200

IC1201

IC1202

IC1300

IC1301

IC1302

IC1303

IC1304

IC1305

IC1306

IC1307

IC200

IC201

IC202

IC203

IC400

IC401

IC403

IC500

IC5001

IC5003

IC5004

IC5004

IC5005

IC5006

IC5007

IC600

IC600

IC601

IC601

IC602

IC700

IC701

IC702

IC800

0IMMRAL014B

0IMCRFA010A

0IPRPML001A

0IMCRSH001A

0IMMRAL014B

0IMCRTI003A

0IMCRTI021A

0IMCRTI021A

0IMCRTH002A

0IMMRNE002A

0ISA715100D

0IMCRSJ001A

0IPRPML001A

0IMCRFA010A

0IMCRRH001A

0IMCRSH001A

0IMCRSH001A

0IMCRRH001A

0IMCRSJ001A

0IMCRRH001A

0IPRPML001A

0IMCRRH001A

0IFA742530B

0IMCRSG010A

0IMCRMI006A

0ISTLSG009A

0ISO206900A

0ISO210100B

0ISTLSG009A

0ICTMLG018A

0IKE780500Q

0ISH092100B

0ISH122100B

0ISH092100B

0IMI623200B

0IDS162100B

0ISH122100B

0IMCRGN002C

0IMCRMI006A

0IMMRHY025C

0IIT323000E

0ISA715100D

0IPRPGN012A

0IMMRAL025A

0IKE704200J

0IMMRHY020B

AT24C02N-10SI-2.7 8P

KA7809R 2P

MIC39100 3P SOT223

PQ05DZ1U 5

AT24C02N-10SI-2.7 8P

SN74HCT08D 16P

SN74LVTH541PWR 20P

SN74LVTH541PWR 20P

THC63LVD103 64P

UPD64083GF3BA 100

LA7151M 10SOP AUDIO SW

SC1565IST-1.8 3P SOT223

MIC39100 3P SOT223

KA7809R 2P

BA033FP-E2 3P-SOP,TO252-3

PQ05DZ1U SHARP 5

PQ05DZ1U SHARP 5

BA033FP-E2 3P-SOP,TO252-3

SC1565IST-1.8 3P SOT223

BA033FP-E2 3P-SOP,TO252-3

MIC39100 3P SOT223

BA033FP-E2 3P-SOP,TO252-3

74ACT253SC 16P

ST3232CDR SOP16 RS232

M52758FP 36PIN

M74HC123RM13TR 16P

CXA2069Q QFP64 I2C BUS AV S/W

CXA2101AQ 80P

M74HC123RM13TR 16P

LGDP4410 176P

KIA7805API 3P TO-220

PQ09RD21 4SIP

PQ12RD21 4SIP

PQ09RD21 4SIP

M62320FP 16P

DS1621V 8P

PQ12RD21 4SIP

FLI2300BD 208P DIGITAL VIDEO

M52758FP 36PIN

HY57V643220DT-6 86P

VPC3230D C5 80P VIDEO PROCESSOR

LA7151M 10SOP AUDIO SW

GM1501HBD 416P

AT24C32AN-10SI-2.7 8PIN

KIA7042AF SOT-89 TP 4.2V

HY5DU283222AQ-5 100P

IC

TRANSISTOR

RUN DATE : 2004.11.11

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 29

- 29 -

LOCA. NO PART NO DESCRIPTION

Q302

Q305

Q306

Q307

Q308

Q309

Q310

Q319

Q320

Q400

Q400

Q401

Q401

Q402

Q403

Q403

Q405

Q406

Q600

Q601

Q602

Q603

D100

D1000

D1002

D1003

D101

D102

D105

D106

D116

D117

D118

D119

D120

D1200

D1201

D1206

D121

D122

D123

D124

D125

D126

D127

D128

D129

D130

D1300

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD184009AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA

KDS184S CHIP 85V 300MA

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

LOCA. NO PART NO DESCRIPTION

D1301

D1302

D1303

D1304

D1305

D1306

D131

D1501

D1503

D400

D5001

LD001

LD1000

LD1001

LD1002

LD1003

LD1100

LD1203

LD1204

LD1206

LD1207

ZD100

ZD101

ZD102

ZD103

ZD104

ZD105

ZD400

ZD401

ZD800

C002

C1002

C1006

C1016

C1017

C1018

C1020

C1022

C1027

C1031

C1037

C1042

C1045

C1058

C1059

C1060

C1063

C1067

C1072

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD100009AM

0DL200000CA

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DL233309AC

0DR050008AA

0DR050008AA

0DR050008AA

0DR050008AA

0DR050008AA

0DR050008AA

0DR050008AA

0DR050008AA

0DZ820009AH

0CE476SF6DC

0CE227VF6DC

0CE477SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE477SF6DC

0CE107SF6DC

0CE477SF6DC

0CE477SF6DC

0CE477SF6DC

0CE107SF6DC

0CE107SF6DC

0CE477DJ618

0CE227VF6DC

0CE227VF6DC

0CE477DJ618

0CE107SF6DC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA

EU1ZV(1) TP SANKEN

LED,SAM5670(DL-2LRG)

LED,SAM2333

LED,SAM2333

LED,SAM2333

LED,SAM2333

LED,SAM2333

LED,SAM2333

LED,SAM2333

LED,SAM2333

LED,SAM2333

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

SD05.TC SOD323 5V 5A 15A

ZENERS,MTZJ8.2B

47UF MVG 16V M

220UF MV 16V 20%

470UF MVG 16V 20%

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

470UF MVG 16V 20%

100UF MVG 16V M

470UF MVG 16V 20%

470UF MVG 16V 20%

470UF MVG 16V 20%

100UF MVG 16V M

100UF MVG 16V M

470UF STD 35V 20%

220UF MV 16V 20%

220UF MV 16V 20%

470UF STD 35V 20%

100UF MVG 16V M

REPLACEMENT PARTS LIST

DIODE

CAPACITOR

Page 30

- 30 -

LOCA. NO PART NO DESCRIPTION

C1074

C1077

C1108

C1128

C1129

C1145

C1146

C1147

C1152

C1159

C1160

C120

C1202

C1205

C1206

C121

C1211

C1212

C1215

C1216

C1218

C1220

C1223

C1229

C1233

C1249

C1250

C1251

C1254

C1256

C1257

C1259

C1273

C1274

C1275

C1279

C1305

C1314

C1315

C1317

C1331

C1333

C1353

C1355

C1362

C1366

C1368

C1373

C1374

C1384

C1388

0CE107SF6DC

0CE107SF6DC

0CE106SF6DC

0CE106SF6DC

0CN105EJ56A

0CN105EJ56A

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE477SF6DC

0CE476SF6DC

0CE477SF6DC

0CE477SF6DC

0CE477SF6DC

0CE227VF6DC

0CE477SF6DC

0CE227VF6DC

0CE107SF6DC

0CE227VF6DC

0CE477SF6DC

0CE227VF6DC

0CE227VF6DC

0CE477SF6DC

0CE227VF6DC

0CE227VF6DC

0CE227VF6DC

0CE227VF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE477SF6DC

0CE477SF6DC

0CE477SF6DC

0CE477SF6DC

0CE107SF6DC

0CE227VF6DC

0CE227VF6DC

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

100UF MVG 16V M

100UF MVG 16V M

10UF MVG 16V 20%

10UF MVG 16V 20%

1.0UF 3216 35V 10%

1.0UF 3216 35V 10%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

100UF MVG 16V M

470UF MVG 16V 20%

47UF MVG 16V M

470UF MVG 16V 20%

470UF MVG 16V 20%

470UF MVG 16V 20%

220UF MV 16V 20%

470UF MVG 16V 20%

220UF MV 16V 20%

100UF MVG 16V M

220UF MV 16V 20%

470UF MVG 16V 20%

220UF MV 16V 20%

220UF MV 16V 20%

470UF MVG 16V 20%

220UF MV 16V 20%

220UF MV 16V 20%

220UF MV 16V 20%

220UF MV 16V 20%

47UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

47UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

470UF MVG 16V 20%

470UF MVG 16V 20%

470UF MVG 16V 20%

470UF MVG 16V 20%

100UF MVG 16V M

220UF MV 16V 20%

220UF MV 16V 20%

100UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

LOCA. NO PART NO DESCRIPTION

C1391

C1400

C1402

C1404

C1410

C1415

C1425

C222

C223

C224

C230

C251

C254

C258

C261

C263

C272

C274

C301

C303

C316

C317

C334

C335

C400

C401

C402

C404

C406

C410

C423

C429

C435

C440

C442

C5007

C5009

C5016

C5017

C5018

C5019

C5023

C5025

C601

C608

C611

C612

C614

C626

C627

C632

0CE477SF6DC

0CE476SF6DC

0CE476SF6DC

0CE477SF6DC

0CE477SF6DC

0CE477SF6DC

0CE107SF6DC

0CE476XFKDC

0CE476XFKDC

0CE476XFKDC

0CE107SF6DC

0CE106SF6DC

0CN105EJ56A

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE227VF6DC

0CE476SF6DC

0CE107SF6DC

0CE227VF6DC

0CE476SF6DC

0CE107SF6DC

0CE105SK6DC

0CE107SF6DC

0CE107SF6DC

0CE106SF6DC

0CE106SF6DC

0CE107SF6DC

0CE107SF6DC

0CE227VF6DC

0CE105CK636

0CE105CK636

0CE105CK636

0CE105CK636

0CE105CK636

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

470UF MVG 16V 20%

47UF MVG 16V M

47UF MVG 16V M

470UF MVG 16V 20%

470UF MVG 16V 20%

470UF MVG 16V 20%

100UF MVG 16V M

47UF MVK-BP,CN 16V 20%,-20%

47UF MVK-BP,CN 16V 20%,-20%

47UF MVK-BP,CN 16V 20%,-20%

100UF MVG 16V M

10UF MVG 16V 20%

1.0UF 3216 35V 10%

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

220UF MV 16V 20%

47UF MVG 16V M

100UF MVG 16V M

220UF MV 16V 20%

47UF MVG 16V M

100UF MVG 16V M

1UF MVG 50V M

100UF MVG 16V M

100UF MVG 16V M

10UF MVG 16V 20%

10UF MVG 16V 20%

100UF MVG 16V M

100UF MVG 16V M

220UF MV 16V 20%

1UF SHL,SD 50V M

1UF SHL,SD 50V M

1UF SHL,SD 50V M

1UF SHL,SD 50V M

1UF SHL,SD 50V M

100UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

47UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

REPLACEMENT PARTS LIST

Page 31

- 31 -

LOCA. NO PART NO DESCRIPTION

C634

C637

C651

C671

C672

C673

C674

C703

C720

C723

C737

C744

C752

C757

C762

C769

C777

C778

C785

C800

C801

C802

C803

C812

C822

C825

C827

C828

C829

C834

C837

C840

C841

C847

C851

C852

C862

C863

C872

C873

C874

C9001

C9002

C9004

C9006

C9007

C9008

C9009

C9010

C9013

C9014

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE226SF6DC

0CE335SK6DC

0CE226SF6DC

0CE226SF6DC

0CE476SF6DC

0CE226VF6DC

0CE226VF6DC

0CE107SF6DC

0CE335SK6DC

0CE107SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE107SF6DC

0CN105EJ56A

0CE108DH618

0CE108DH618

0CF4741L438

0CF4741L438

0CE335SK6DC

0CN105EJ56A

0CE108DH618

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

0CE477VF6DC

0CE107SF6DC

0CE477VF6DC

0CE477VF6DC

0CE107SF6DC

0CE107SF6DC

0CE107SF6DC

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

3.3UF MVG 50V 20%

22UF MVG 16V 20%

22UF MVG 16V 20%

47UF MVG 16V M

22UF MV 16V 20%

22UF MV 16V 20%

100UF MVG 16V M

3.3UF MVG 50V 20%

100UF MVG 16V M

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

10UF MVG 16V 20%

100UF MVG 16V M

1.0UF 3216 35V 10%

1000UF STD 25V M

1000UF STD 25V M

0.47UF D 63V 5%

0.47UF D 63V 5%

3.3UF MVG 50V 20%

1.0UF 3216 35V 10%

1000UF STD 25V M

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

470UF MV 16V 20%

100UF MVG 16V M

470UF MV 16V 20%

470UF MV 16V 20%

100UF MVG 16V M

100UF MVG 16V M

100UF MVG 16V M

LOCA. NO PART NO DESCRIPTION

JK200

JK201

JK202

JK203

P101

P102

P200

P201

SP1

L1004

L1005

L1006

L1007

L1200

L1203

L1209

L1213

L803

L804

L805

L806

AR500

AR501

AR502

AR503

AR504

AR505

AR513

AR600

AR600

AR601

AR601

AR602

AR602

AR603

AR603

AR604

AR605

AR606

AR607

AR608

AR609

AR610

AR611

AR612

6612JH003CA

6612J00010A

6612VJH019C

6612VMV002A

380-068E

6612BBBHN6A

380-363K

380-068E

6612VLH002A

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0024A

6140VB0024A

6140VB0024A

6140VB0024A

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

JACK,RCAPPJ137A

JACK,RCAPPJ128A-1 2P

JACK,RCAPPJ121-22 4P

JACK,DRAWING UCT-EX-020

JACK,PHONE UEJ-CV-018

JACK,DIN 440062-1

JACK,DIN PJ6046G

JACK,PHONE UEJ-CV-018

JACK,RCASP026B 4P

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE 26UH

COIL,CHOKE LPK-1322A 22UH +-10%

COIL,CHOKE LPK-1322A 22UH +-10%

COIL,CHOKE LPK-1322A 22UH +-10%

COIL,CHOKE LPK-1322A 22UH +-10%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

REPLACEMENT PARTS LIST

JACK

COIL

RESISTOR

Page 32

- 32 -

LOCA. NO PART NO DESCRIPTION

AR613

AR614

AR615

AR616

AR617

AR618

AR701

AR707

AR708

AR709

AR710

AR711

AR712

AR713

AR714

AR715

AR717

AR718

AR719

R5026

R801

R802

SW001

SW002

SW003

SW004

SW005

SW006

SW700

SW800

F801

F802

F802

F803

F803

L100

L1000

L1002

L1008

L1009

L101

L1010

L1011

L1013

L1014

L1015

L1016

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RD0222H609

0RKZVTA001L

0RKZVTA001L

140-313B

140-313B

140-313B

140-313B

140-313B

140-313B

140-313B

6600VM2006A

6200VJS001A

6200VJS001A

6200VJS001B

6200VJS001A

6200VJS001B

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1/2 W 5.00%

1.0M OHM 1/2 W 5%

1.0M OHM 1/2 W 5%

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,TACT 2LEAD 160G(TA)

SWITCH,PUSH SDDF3PATP011

FILTER,EMC ZJY51R5-4P

FILTER,EMC ZJY51R5-4P

FILTER,EMC ZJYS51R5-2PL(T)

FILTER,EMC ZJY51R5-4P

FILTER,EMC ZJYS51R5-2PL(T)

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

LOCA. NO PART NO DESCRIPTION

L1017

L1018

L1019

L102

L103

L105

L106

L107

L108

L1102

L1201

L1206

L1207

L1210

L1211

L1216

L1217

L1300

L1302

L1307

L1310

L1311

L1312

L1313

L1314

L1315

L1316

L1317

L1318

L1321

L1322

L1325

L1326

L1327

L1328

L1329

L1330

L1331

L1332

L1333

L1500

L200

L202

L203

L204

L205

L205

L206

L207

L208

L209

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6200JB8010L

6200JB8010L

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6200JB8013L

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0006A

6210VC0005A

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC 60 OHM TB201209U060

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC BK2125 HS 750

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC BK2125 HS 750

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC BK2125 HS 750

REPLACEMENT PARTS LIST

FILTER & CRYSTAL

SWITCH

Page 33

- 33 -

LOCA. NO PART NO DESCRIPTION

L210

L211

L212

L213

L214

L215

L215

L216

L216

L217

L301

L302

L303

L400

L400

L401

L401

L402

L403

L404

L405

L406

L408

L5001

L609

L610

L700

L800

L807

L808

L9000

LT1100

LT1101

LT1102

LT1103

X1100

X600

X600

X700

X800

F801

P100

P200

P300

PA001

A1

“

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6200JB8010L

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0005A

6210VC0005A

6210VC0005A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6210VC0006A

6200JB8010L

6200JB8010L

6210VC0005A

6200C000010

6200C000010

6200C000009

6200C000009

6212AB2015B

6202VDB007B

6202VDT002J

6202VDT002B

156-A02M

0FS1002B53K

6630VGA001C

6630VGA004B

6630VGA001C

4930V00413A

3828VA0520B

3828VA0520C

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC BK2125 HS 750

FILTER,EMC BK2125 HS 750

FILTER,EMC BK2125 HS 750

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC FBMH3216 HM501NT

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC MLB-201209-1000L-N2

FILTER,EMC BK2125 HS 750

FILTER,B.P. H354LAI-K5202

FILTER,B.P. H354LAI-K5202

FILTER,B.P. H354LAI-K5225

FILTER,B.P. H354LAI-K5225

RESONATOR,CRYSTAL HC-49/SM5H 20MHZ

RESONATOR,CRYSTAL HC49U 20.250MHZ

RESONATOR,CRYSTAL SX-1 13.500000MHZ

RESONATOR,CRYSTAL SX-1 SC14.3MHZ

RESONATOR,CRYSTAL HC49U 18.432MHZ

FUSE,SLOW BLOW 10000MA 250V

CONNECTOR,D-SUB 15PIN 2.29MM

CONNECTOR,D-SUB 9P 2.77MM

CONNECTOR,D-SUB 15PIN 2.29MM

HOLDER,PRE-AMP&LED XR-401

MANUAL,OWNERS

MANUAL,OWNERS *LGECI

LOCA. NO PART NO DESCRIPTION

A2

A3

A4

A5

6710V00136H

6410VUH005C

6612VMV002B

6850J00005A

REMOTE CONTROLLER

POWER CORD,BP-301 2800MM V1625

JACK,DRAWING UCT-EX-031

CABLE,DVI LVDS UL20276 AWG30 500MM

REPLACEMENT PARTS LIST

MISCELLANEOUS

ACCESSORIES

Page 34

Nov., 2004

Printed in KoreaP/NO : 3828VD0206A

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Electronics Alabama, Inc.

P.O.Box 240007, 201 James Record Road Bldg 3

Huntsville, AL 35824

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

MAIN(TOP)

TUNER(TOP)

TUNER(BOTTOM)

MAIN(BOTTOM) CONTROL(TOP)

CONTROL(BOTTOM)

POWER S/W(TOP) POWER S/W(BOTTOM)

Loading...

Loading...