LG MU-42PZ41 Service Manual

1. Application Object

These instructions are applied to all of the PDP monitor, RF02RA.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 110~240V,

50/60Hz in adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

¤ After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEATRUN mode)

¤ŁEnter into HEAT-RUN mode

- Select the HEAT-RUN OFF by pressing ADJ Key on

Remote Control for adjustment.

- Press the VOL + Key in HEAT-RUN OFF.

(OSD display HEAT-RUN WHITE and screen display

100% FULL WHITE PATTERN)

[ Set is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes, a

afterimage may be occur in the black level part of the

screen.

Each PCB Assy must be checked by the Check JIG Set before

whole assembly. (Be careful the POWER PCB Assy not to

damage to PDP Module)

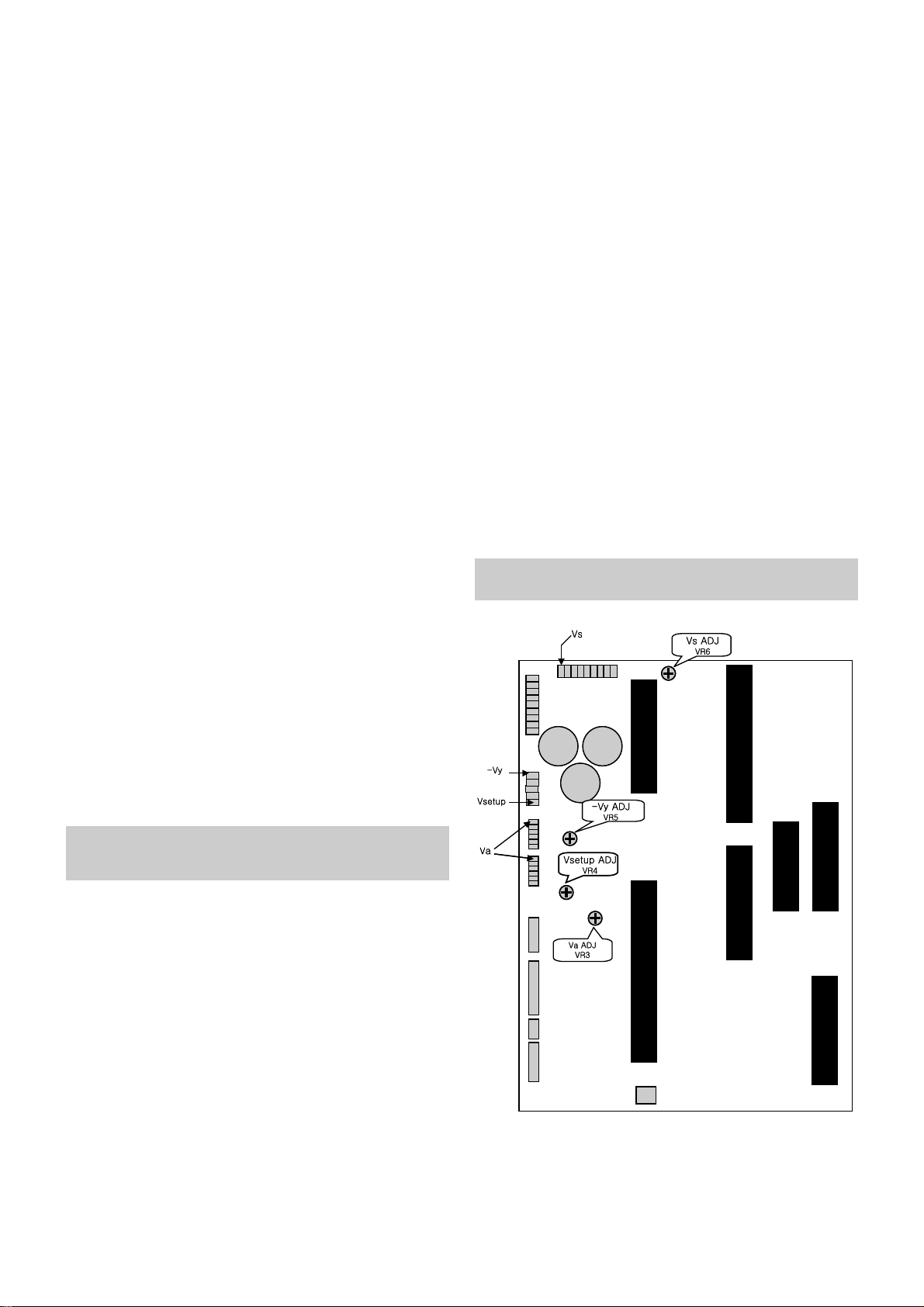

3. POWER PCB Assy Voltage Adjustment

(Va, Vs, -Vy, Vsetup Voltage Adjustment)

3-1. Test Equipment

D.M.M 1EA

3-2. Connection Diagram for Measuring

Refer to Fig 1.

3-3. Adjustment Method(POWERWELL)

(1) Va Adjusment

¤ Connect pin 1 of CN205 to (+) jack of D.M.M.

¤ŁAfter turning the VR3(Va ADJ), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel right/top.(Deviation : ±0.5V)

(2) Vs Adjustment

¤ Connect pin 1 of CN207 to (+) jack of D.M.M.

¤ŁAfter turning the VR6(Vs ADJ), voltage of D.M.M adjust

as same as Vs voltage which indicated on label of panel

right/top.(Deviation : ±0.5V)

(3) -Vy Adjustment

¤ Connect pin 1 of CN208 to (+) jack of D.M.M.

¤ŁAfter turning the VR5(-Vy ADJ), voltage of D.M.M adjust

as same as -Vy voltage which indicated on label of

panel right/top.(Deviation : ±0.5V)

(4) Vsetup Adjustment

¤ Connect pin 5 of CN208 to (+) jack of D.M.M.

¤ŁAfter turning the VR4(Vsetup ADJ), voltage of D.M.M

adjust as same as Vsetup voltage which indicated on

label of panel right/top.(Deviation : ±0.5V)

[ Refer to Typical Voltage

1. Va : 35 ~ 45V

2. Vs : 170 ~ 185V

3. -Vy : -60 ~ -90V

4. Vsetup : 210 ~ 240V

[ Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

- 6 -

ADJUSTMENT INSTRUCTIONS

<Fig 1> Connection Diagram of POWERWEL Power Adj. for

Measuring

- 7 -

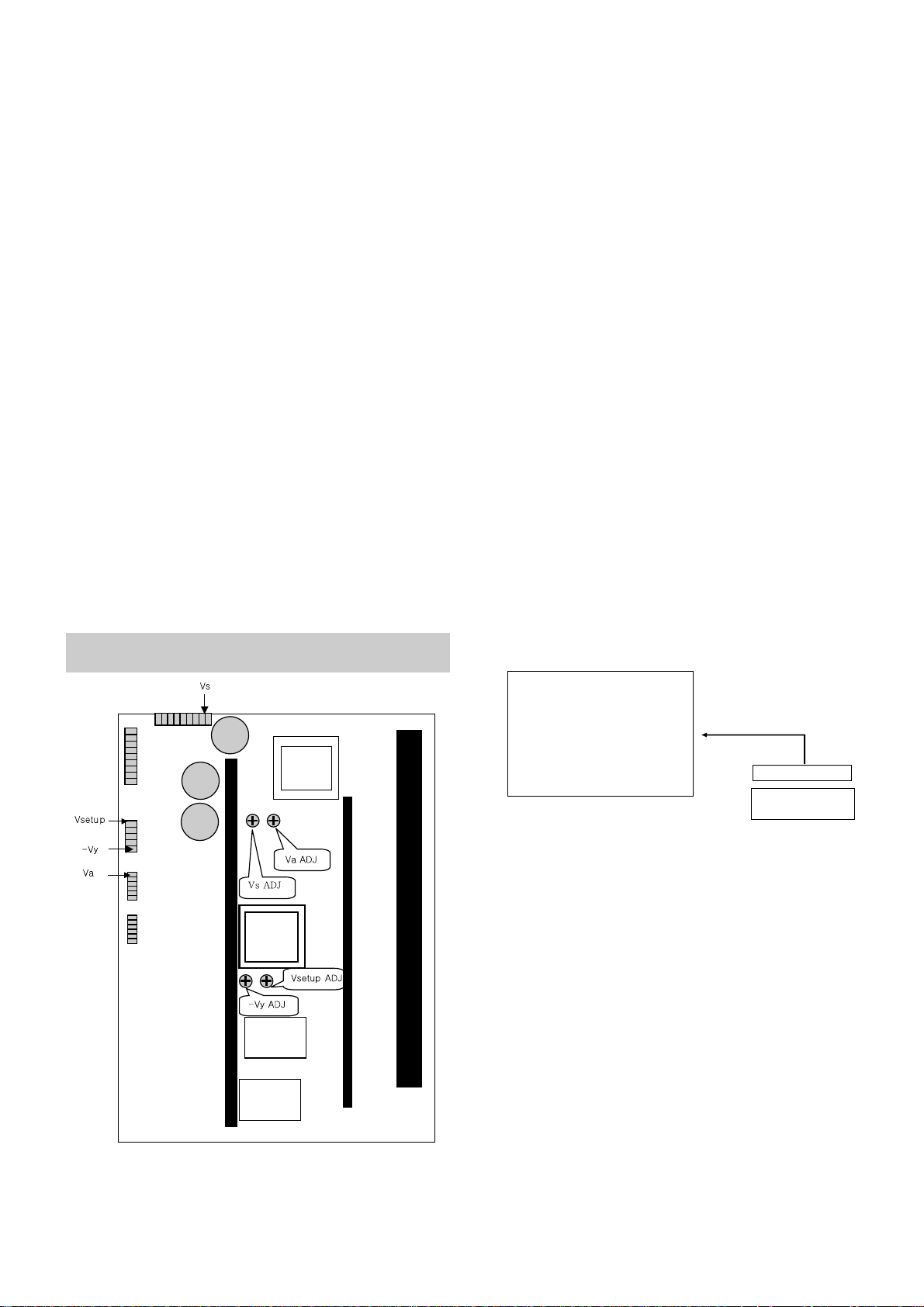

3-4. Adjustment Method(SONY)

(1) Va Adjusment

¤ Connect pin 1 of CN209 to (+) jack of D.M.M.

¤ŁAfter turning the VR402(Va ADJ), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel right/top.(Deviation : ±0.5V)

(2) Vs Adjustment

¤ Connect pin 8 of CN207 to (+) jack of D.M.M.

¤ŁAfter turning the VR401(Vs ADJ), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/top.(Deviation : ±0.5V)

(3) -Vy Adjustment

¤ Connect pin 5 of CN208 to (+) jack of D.M.M.

¤ŁAfter turning the VR403(-Vy ADJ), voltage of D.M.M

adjust as same as -Vy voltage which indicated on label

of panel right/top.(Deviation : ±0.5V)

(4) Vsetup Adjustment

¤ Connect pin 1 of CN208 to (+) jack of D.M.M.

¤ŁAfter turning the VR404(Vsetup ADJ), voltage of D.M.M

adjust as same as Vsetup voltage which indicated on

label of panel right/top.(Deviation : ±0.5V)

[ Refer to Typical Voltage

1. Va : 30 ~ 50V

2. Vs : 170 ~ 185V

3. -Vy : -60 ~ -90V

4. Vsetup : 210 ~ 240V

[ Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

4. Adjustment of AUTO RGB

4-1. Outline

AUTO RGB adjustment is the function to set the optimum

black-level and Gain automatically in Analog --> Digital

converter and to correct RGB deviation.

4-2. Required Equipment

PC Pattern Generator

(It can be possible to output 16Gray Scale Pattern and RGB

output level is corrected to 0.7±0.1Vp-p)

4-3. Adjustment Method

(1) It can be possible to RGB input 16Gray Scale Pattern

signal of PC Mode and select RGB.

(2) Press the ADJ Key on R/C to enter adjustment mode and

select 2.W/B and then press the VOL + Key.

(3) Turn the HEATRUN OFF and select AUTO RGB and then

press the VOL + Key.

5. Adjustment of White Balance

5-1. Required Equipment

(1) Color analyzer(CA-100 or same production)

(2) Auto Regulator(Required while auto adjustment, and

possible to communicate with RS-232C)

(3) AV Pattern Generator

5-2. Connection Diagram of Equipment for

Measuring

[ After stop the Micom by pressing IN-START Key on Remote

Control, insert the P1002 with automatic adjustment of

connector.

After remove connector, move the Micom by pressing ENTER

Key.

<Fig 1> Connection Diagram of SONY Power Adj. for

Measuring

COLOR

ANALYZER

TYPE; CA-100

CVBS Signal Input

PDP MONITOR

85IRE Full White

85IRE

Full White

MSPG-2100 or

MSTG-5200

<Fig 2> Connection Diagram of Automatic Adjustment

- 8 -

5-3. Adjustment of White Balance

• Operate the Zero-calibration of the CA—100, then stick

sensor to PDP module surface when you adjust.

• For manual adjustment, it is also possible by the following

sequence.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

ADJ button on Remote Control for adjustment then operate

HEAT RUN more than 15 minute.

(2) Supply Full White signal(signal output level : 85IRE) in AV

Pattern Generator.

(3) Select image regulation status to ‘Clear Image’.

(4) Stick sensor to the center of screen and press the ADJ Key

on R/C to select W/B and then press the VOL + Key to

enter the adjustment mode.

After selecting R ADJ and B ADJ, press the VOL +/- Key

and adjust it until color coordination becomes(B GAIN

fixation)

color coordination : X=0.280±0.003, Y=0.290±0.003

color temperature : 10,000

cK ± 500cK

(5) Exit adjustment mode using Enter button.

- 9 -

BLOCK DIAGRAM

- 10 -

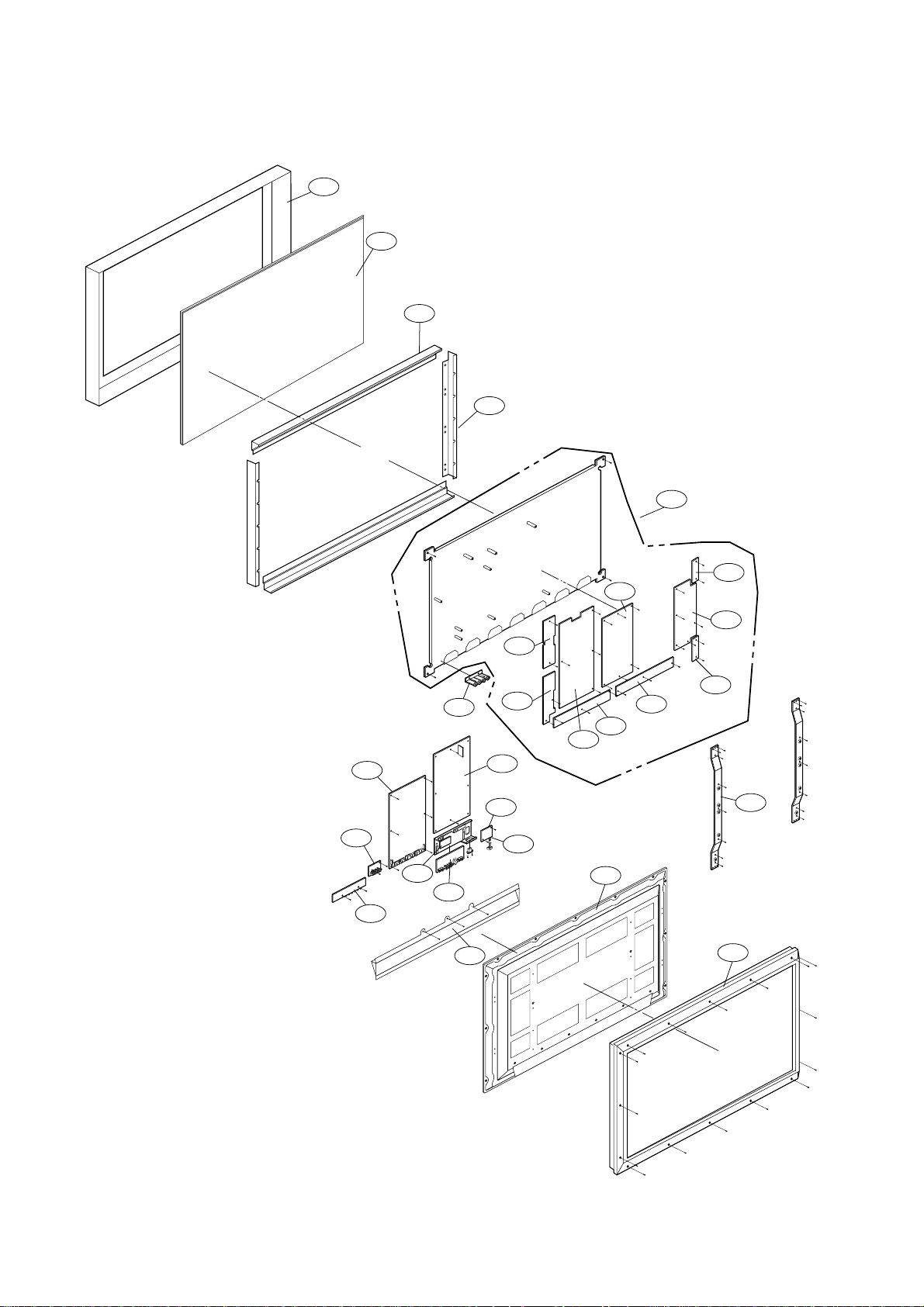

EXPLODED VIEW

200

203

201

202

205

204

207

208

209

206

540

401

550

310

551

520

560

570

400

410

530

580

210

301

302

300

305

- 11 -

EXPLODED VIEW PARTS LIST

200 6348Q-E034A PDP,42 16:9 LOW VOTAGE DRIVING, FOR INTERCOMPANY DOMESTIC

201 6871QTH025A PCB ASSEMBLY,ZCNT ASSY HAND INSERT 42SD4 ZCNT TOP

202 6871QZH023A PCB ASSEMBLY,ZSUS ASSY HAND INSERT 42SD4

203 6871QTH026A PCB ASSEMBLY,ZCNT ASSY HAND INSERT 42SD4 ZCNT(BTM)

204 6871QRH021A PCB ASSEMBLY,XRRT ASSY HAND INSERT 42SD4

205 6871QLH021A PCB ASSEMBLY,XRLT ASSY HAND INSERT 42SD4

206 6871QYH022A PCB ASSEMBLY,YSUS ASSY HAND INSERT 42SD4

207 6871QDH061A PCB ASSEMBLY,YDRV ASSY HAND INSERT 42SD4 YDRV BTM

208 6871QDH060A PCB ASSEMBLY,YDRV ASSY HAND INSERT 42SD4 YDRV TOP

209 6871QCH024A PCB ASSEMBLY,CTRL ASSY HAND INSERT 42SD4 CTRL B/D (4011/4021)

210 4980V00460A SUPPORTER,VERTICAL MN-42PZ40

300 3091V00B01H CABINET ASSEMBLY,MU-42PZ41B NON - BLACK

3091V00B01C CABINET ASSEMBLY,MU-42PZ41

301 4980V00457A SUPPORTER,FILTER NON MN-42PZ40

302 4980V00458A SUPPORTER,FILTER NON MN-42PZ40

305 3790V00281D WINDOW,1142G02D MN42PZ10 ETCHING MESH NBK

310 5020V00667B BUTTON,CONTROL MU-42PZ41B ABS, AF-303 6KEY BLACK COLOR

5020V00667A BUTTON,CONTROL MU-42PZ40

400 3809V00A47D BACK COVER ASSEMBLY,MU-42PZ41V NON PIVOT INNER

3809V00A47C BACK COVER ASSEMBLY,MU-42PZ40

401 3301V00010C PLATE ASSEMBLY,A/V 3300V00205A MU/MP-42PZ41

410 3809V00A58C BACK COVER ASSEMBLY,MU-42PZ41B NON BLACK SPRAY

3809V00A58A BACK COVER ASSEMBLY,MU-42PZ40

520 6871VMMD05A PCB ASSEMBLY,MAIN RF-02RA PIVOT MU-42PZ41V

6871VMMC14A PCB ASSEMBLY,MAIN RF-02RA MU-42PZ40

530 6871VSMD84A PCB ASSEMBLY,SUB A/V RF02RA SAGE2

540 6871VSMD92A PCB ASSEMBLY,SUB CONT RF02RA MU-42PZ41

550 6871VSMD94A PCB ASSEMBLY,SUB PSW RF02RA MU-42PZ41

551 5020V00666B BUTTON,POWER MU-42PZ41B ABS, AF-303 1KEY BLACK COLOR

5020V00666A BUTTON,POWER MU-42PZ40

560 6871VSMD93A PCB ASSEMBLY,SUB SPK RF02RA MU-42PZ41

570 3501V00115A BOARD ASSEMBLY,POWER BOARD SONY 40/42 PDP ONE BOARD

3501V00116A BOARD ASSEMBLY,POWER BOARD SONY 40/42 PDP ONE BOARD

580 6871VSMD85A PCB ASSEMBLY,SUB INTER RF02RA SAGE2 FIX BD

No.

Part No.

Description

Loading...

Loading...