Page 1

TV /

DIGITAL INDEX

CH:

LR

C

LS RS

CACATVTV

PROPRO LOGICLOGIC

MOVIE SPORMOVIE SPORTS MUSICTS MUSIC

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MP-015A

MODEL : PE/PL-43/48/53A82T

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Sep.,2001

Printed in KoreaP/NO : 3828VD0096A

Page 2

- 2 -

CONTENTS

Contents .......................................................................................................... 2

Safety Precautions ..........................................................................................3

Servicing Precautions .................................................................................... 4

Specifications ................................................................................................. 6

Control Descriptions ...................................................................................... 8

Adjustment......................................................................................................11

Troubleshooting.............................................................................................18

Block Diagram................................................................................................26

Printed Circuit Board.....................................................................................30

Wiring Diagram...............................................................................................42

Exploded View .................................................................................... 44,46,48

Exploded View Parts List.....................................................................45,47,49

Replacement Parts List ................................................................................ 50

SVC. Sheet .........................................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5

¡ 1.5KV: 14-19 inch, 26 ¡ 1.5KV: 19-21 inch,

29.0 ¡ 1.5KV: 25-29 inch, 30.0 ¡ 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

replacement tube must be the same type tube as specified in

the Replacement Parts List.

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS

on page 3 of this publication.

NOTE:

If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug

or other electrical connection.

c.

Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first connecting

one end of an insulated clip lead to the degaussing or kine

aquadag grounding system shield at the point where the

picture tube socket ground lead is connected, and then (b)

touch the other end of the insulated clip lead to the picture

tube anode button, using an insulating handle to avoid

personal contact with high voltage.

4. Do not spray chemicals on or near this receiver or any of its

assemblies.

5. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator; 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%-99%

strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication

of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which receivers covered by this service manual might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test receiver

positive lead.

Always remove the test receiver ground lead last.

9.

Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to

any heatsink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called

Electrostatically Sensitive (ES) Devices.

Examples of

typical ES devices are integrated circuits and some fieldeffect

transistors and semicounductor "chip" components. The

following techniques should be used to help reduce the

incidence of component damage caused by static by static

electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed to prevent potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as "anti-static" can

generate electrical charges sufficent to demage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a repalcement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the ieads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

CAUTION:Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such

as the bruching together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintan tip

temperature within the range or 500¡£F to 600¡£F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thorohly clean the surfaces to be soldered. Use a mall

wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500¡£F to 600¡£F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuiboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500¡£F to 600¡£F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

SERVICING PRECAUTIONS

Page 5

- 5 -

c. Qulckly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it

there only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess

or splashed solder with a small wire-bristle brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following

technique should be used to remove and replace the IC. When

working with boards using the familiar round hole, use the

standard technique as outlined in parapraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit boare.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the "U" with long nose pliers to insure metal to metal

contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicula y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them

and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board

to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board.

The following guidelines and procedures should be followed

whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely

necessary).

2. carefully scratch away the solder resist and acrylic coating

(if used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped end

of the good copper pattern. Solder the overlapped area and

clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involoves the installation of a jumper wire on the component

side of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of

the nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so

the it does not touch components or sharp edges.

Page 6

- 6 -

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement.

O Video input system:

Multi 26 System

(Refer to Table 1)

O Intermediate Frequency

Vision IF : 38.9MHz

Color IF : 34.47MHz *SECAM : 38.9-4.25MHz

35.32MHz(M) 38.9-4.40625MHz

Sound IF : 33.4MHz(B/G)

32.9MHz(I)

32.4MHz(D/K,K1)

34.4MHz(M)

O OSD (On Screen Display):

EZ Menu Method

O Antenna input impedance: VHF/UHF 75ohm, Unbalanced

O Voice coil impedance : 8 ohm

O External connections :

AV Input : V/L/R : 1 (Side)

V/L/R : 2 (Rear,PT-)

AV Output : V/L/R : 1 (Rear,PT-)

Component Input : Component 1 :480i/L/R

Component 2:480p/L/R

S-VIdeo Input : Y/C : 2 (Side 1,Rear 1)

Scart : Full Scart(With RGB Input) : 1

Half Scart : 1 (AV In/Out)

Half Scart : 1 (AV In/YC In)

O Power requirements :

110-240 Vac, 50/60HZ(PT-)

230 Vac, 50HZ(PE/PL-)

O Power consumption :

250 Wmax.

O Tuning system :

FVS 100 Program Memory(With Teletext Model)

FVS 200 Program Memory(W/O Teletext Model)

O Sound output :

R,L Out : 10 W+10W(48,53”),20W+20W(43”)

Center : 10W(Option)

SL/SR : 5W+5W (Option)

O Function :

Turbo Sound/Picture

PSM

SSM

Auto Sleep

CATV/Hyper band

Teletext (TOP/FLOF/LIST)-Option

Multi Window PIP

O Features

Picture quality improvement circuit

- YNR (Luminance Noise Reduction)

- Picture Outline Compensation

- Digital Comb Filter

- Color Transition Improvement

- Dynamic S-VM

- Black Stretcher

- Digital Eye

- Digital Convergence

- Digital 100Hz & Progressive

- Digital Index

- Dvd Input

Sound quality improvement circuit

- Pro Logic(48,53”)/ Virtual(43”)

- Equalizer

Video in/out

Audio in (2 way)

Audio out (2 way)

Specifications

1Vp-p¡ 3dB, 75ohm

0.63Vrms¡ 3dB, over 10Kohm

0.5Vrms¡ 3dB, below 1Kohm

(

O Tuning range

Band

VHF-Low

VHF-High

Hyper

UHF

S1'-S3', S1

S2-S10,

S11-S20

S21-S41

For TV

For CATV

B/G

Ch2-4

Ch5-12

D/K

Ch1-5

Ch6-12

I/I

Ch4-13

NTSC

Ch2-13

Ch21-69 Ch14-69

Page 7

- 7 -

Table 1 : Receiving System (26 System)

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Receiving System

PPAALL--BB

PPAALL--GG

PPAALL--II

PPAALL--DD

PPAALL--KK

SSEECCAAMM--BB

SSEECCAAMM--GG

SSEECCAAMM--DD

SSEECCAAMM--KK

SSEECCAAMM--KK11

NNTTSSCC--MM

NTSC 4.43/5.5MHZ

NTSC 4.43/6.0MHZ

NTSC 4.43/6.5MHZ

SECAM-I (6.0MHZ)

SECAM-L (Video In)

NTSC 3.58/4.5MHZ/50HZ

PAL 5.5MHZ/60HZ

PAL 6.0MHZ/60HZ

PAL 6.5MHZ/60HZ

SECAM 5.5MHZ/60HZ

SECAM 6.0MHZ/60HZ

SECAM 6.5MHZ/60HZ

NTSC 3.58/5.5MHZ

NTSC 3.58/6.0MHZ

NTSC 3.58/6.5MHZ

Receiving Channel

VVHHFF BBaanndd

PAL/SECAM-B

:: 22--1122

PAL/SECAM-D

:: 11--1122

SECAM-K1

:: 22--99

NTSC-M (US)

:: 22--1133

NTSC-M (JAPAN)

:: 11--1122

UUHHFF BBaanndd

PAL/SECAM-G

:: 2211--6699

PAL-I

:: 2211--6699

SECAM-K

:: 2211--6699

PAL-K

:: 1133--5566

NTSC-M (US)

:: 1144--7788

NTSC-M (JAPAN)

:: 1133--6622

Function

Reception of broadcast and playback for Video Tape Recorder

Play-back for special Video Tape

Recorder

Play-back for special Video

tape/Video disk player

Play-back for special Video Tape

Recorder

Page 8

- 8 -

CONTROLS DESCRIPTION

All the functions can be controlled with the remote control handset.

Some functions can also be adjusted with the buttons on the front

panel of the set.

Remote control handset

Before you use the remote control handset, please install the batteries. See the next page.

1. POWER

switches the set on from standby or off to standby.

2. SLEEP

sets the sleep timer.

3. STILL

freezes motion of the picture.

4. NUMBER BUTTONS

switches the set on from standby or directly select a number.

5. I/II

selects the language during dual language broadcast.

selects the sound output. (option)

6. TURBO SOUND BUTTON

selects Turbo sound.

TURBO PICTURE BUTTON

selects Turbo picture.

7. TELETEXT BUTTONS (option)

These buttons are used for teletext.

For further details, see the ‘Teletext’ section.

8. MENU

selects a menu.

9. MUTE

switches the sound on or off.

10.

DD / EE

(Programme Up/Down)

selects a programme or a menu item.

switches the set on from standby.

FF / GG (Volume Up/Down)

adjusts the volume.

adjusts menu settings.

OK

accepts your selection or displays the current mode.

12345

67890

POWER

PR

OK

VOL VOL

PR

MUTE

MENU

SOUND

PICTURE

PR -

PR +

SWAP

INPUT

PIPTEXTTV/AVI/II

SIZE P/STILL

REW

SCAN

PLAY

EYESTOP

FF

LIST

POSITION

TIME

REVEAL

?

MIX

SLEEP

M

STILL

TURBO

1

7

(With TELETEXT)

3

4

6

5

8

9

10

2

Page 9

- 9 -

1 2 3 4 5

6 7 8 9 0

POWER

PR

OK

VOL VOL

PR

MUTE

MENU

SOUND

PICTURE

PR -

PR +

SWAP

INPUT

PIPTEXTTV/AVI/II

SIZE P/STILL

REW

SCAN

PLAY

EYESTOP

FF

LIST

POSITION

TIME

REVEAL

?

MIX

SLEEP

M

STILL

TURBO

11. LIST

displays the programme table.

12. VCR BUTTONS

control a LG video cassette recorder.

13. EYE

switches the eye function on or off.

14. TV/AV

selects TV or AV mode.

clears the menu / text from the screen.

switches the set on from standby.

15. PIP BUTTONS

PIP

switches the sub picture on or off.

PR +/

-

selects a programme for the sub picture.

SWAP

alternates between main and sub picture.

INPUT

selects the input mode for the sub picture.

SIZE

adjusts the sub picture size.

STILL

freezes motion of the sub picture.

POSITION

relocates the sub picture in clockwise direction.

SCAN

switches on or off the programme scan mode through 12 sub

pictures.

16. SWAP

returns to the previously viewed programme.

Note : In teletext mode, the PR +/-, SWAP and INPUT buttons are

used for teletext function.

Internal generator charge

The remote control handset can be charged with the internal electric

generator. To charge the remote control handset do the followings;

1. In first use,

20 rotation of the handle in the arrow direction as picture below

-> waiting for one minute -> 20 rotation again -> waiting for one

minute again -> 20 rotation again -> beginning to use

2. In usual use

5 or 6 rotation -> resuming to use

Note : Do not rotate the handle too rapidly for the protection of the

remote control handset.

(Without TELETEXT)

11

12

13

14

15

16

Page 10

- 10 -

1. MAIN POWER (ON/OFF)

switches the set on or off.

2. FF / GG (Volume Up/Down)

adjusts the volume.

adjusts menu settings.

DD / EE

(Programme Up/Down)

selects a programme or a menu item.

switches the set on from standby.

3. POWER/STANDBY INDICATOR

illuminates brightly when the set is in standby

mode.

dims when the set is switched on.

4. DIGITAL INDEX

displays information which is input to the set

with three different brightness.

5. MENU

selects a menu.

6. OK

accepts your selection or displays the current

mode.

7. TV/AV

selects TV or AV mode.

clears the menu / text from the screen.

switches the set on from standby.

8. REMOTE CONTROL SENSOR

9. EYE (option)

adjusts picture according to the surrounding

conditions.

10. AUDIO/VIDEO IN SOCKETS (AV3)

Connect the audio/video out sockets of external equipment to these sockets.

S-VIDEO/AUDIO IN SOCKETS (S-AV)

Connect the video out socket of an S-VIDEO

VCR to the S-VIDEO socket.

Connect the audio out sockets of the SVIDEO VCR to the audio sockets as in AV3.

11. CENTRE SPEARKER (PT -48/53A82 series only)

LEFT/RIGHT LOUD-SPEARKERS

Only in PT-48/53A82 series model, the

left/right loud-speakers are detachable and

need to be connected to the SPEAKER OUT

sockets on the back panel of the set as indicated by red (+) and black (-) knobs.

Note : Before placing the speakers, screw the

speaker legs to the holes on them.

*

CASTERS (on the bottom)

turn and move the set easily.

Location and function of controls

S-VIDEO VIDEO

L/MONO RAUDIO

AV3

ON/OFF

PR

DIGITAL INDEX

MENU

OK

TV/AV

PR

VOL

VOL

L R

C

LS RS

CACATVTV

PROPRO LOGICLOGIC

MOVIE SPORMOVIE SPORTS MUSICTS MUSIC

Front panel

•

PT-48/53A82 series

(Side panel)

2

4

5

6

7

CACATVTV

MOVIE SPORMOVIE SPORTS MUSICTS MUSIC

ON/OFF

PR

DIGITAL INDEX

MENU

OK

TV/AV

PR

VOL

VOL

L R

C

LSRS

PROPRO LOGICLOGIC

8

9

10

11

1

3

PR

DIGITAL INDEX

MENU

OK

TV/AV

PR

VOL

VOL

ON/OFF

CACATVTV

MOVIE SPORMOVIE SPORTS MUSICTS MUSIC

L R

C

LSRS

PROPRO LOGICLOGIC

•

PT-43A82 series

8

9

11

Page 11

- 11 -

Caution :

1.Because this is not a hot chassis, it is not necessary to use an

isolation transformer.

However, the use of isolation transformer will help protect

test instrument.

2.Adjustment must be done in the correct order.

3.The receiver must be operated for about 60 minutes proir to

the adjustment.

Pre-heatrun must be operated receiving moving pictures or

100% white pattern.

O Raster Slant/Focus Adjustment

1. Preliminary steps

1) The lens focus and electrical focus must be provisional

alignment.

2) Tune the TV set to receive a EU 05 CH.

3)

Press the buttons of Remote Controller for adjustment (SVC$

$ 5$ OK$ ) to reset the convergence.

2. Adjustment

1) Set only green to be appeared on the screen.

2) Carefully rotate the DY of the green CRT so that the slant of

raster become the following figure.

3) Set two color (R or B and G) to be appeared on the screen.

4) Set the slant of Red or Blue correspond to the green.

Note)

O Beam Alignment Adjustment

1. Test Equipment

Signal Generator can produce DOT pattern

2. Preliminary steps

1) Heat run over 60 minutes.

2) Pre-adjust Raster slope,Raster position & Lens focus.

3) Check if the Magnet is located 45mm from the end of CRT.

4) Receive DOT pattern.

3. 2-Pole Magnet Adjustment

1) Make Green raster using lens cover.

2) Check the center position of DOT pattern on the center of

the screen after turning Green focus volume left.

3) Turning green focus volume right and adjust 2-Pole magnet

so the position to coincide that of item 2).

4) Ajust not to shift the screen by turning green focus volume

left & right.

5) If the screen shifts, readjust 2)~4).

6) Do the same method in Red and Blue. Here, be careful not

to be stained.

4. Beam Shape (4 & 6-Pole Magnet) Adjustment

1) Do after 2-Pole magnet adjustment.

2) Make Green raster using lens cover and turn the focus

volume right.

3) Make the dot in the center a perfect circle using 4 & 6-Pole

magnet.

4) Do the same method in Red & Blue.

5) Fasten the Magnet after adjustment.

6) Adjust focus accurately.

O Centering Magnet Adjustment

1. Preliminary steps

1) Tune the TV set to receive a EU 05 CH.

2)

Press the buttons of Remote Controller for adjustment (SVC$

$ 5¡ OK$ ) to reset the convergence.

2. Adjustment

1) LG Convergence assy

Make green raster using lens cover and coincide

horizontal/vertical center lines of pattern with those of

screen.

2) SGS-THOMSON Convergence assy

Adjust until the center of blue signal is shifted upto 30mm left

from that of green signal and center of red signal is shifted

upto 30mm right from that of green signal with turning the

centring magnet.

3) After adjusting, recover original convergence data.

ADJUSTMENT INSTRUCTIONS

L

L

Mechanical

center

1. Tighten the tightening iron after loose completely.

tighten iron which fixing DY when adjusting raster

slant and set position.

2. Never control to the tightening iron which fixed,

it's condition is not untied.

2 Pole Magnet

4 Pole Magnet

6 Pole Magnet

45mm

L ¡´ 2mm

MMM

MM

M

Page 12

- 12 -

O High Voltage Regulation Adjustment

1. Test Equipment

Digital Multi-Meter(DMM)

2. Preliminary steps

1) Switch picture mode to STANDARD in no signal input.

3. Adjustment

1) Connect “+” terminal(Red) of DMM to the Anode of D432

and “-” terminal(Black) to the Heat Sink of Q406.

2) Adjust VR401 so that the D432 terminal voltage is

21.3

!0.1V.

O CUT-OFF Adjustment

1) Press the “SVC” button and then press the “ ” button on

the remote controller for adjustment to display horizontal

line

.(Even though you enter into the SVC mode, the

horizontal line might not be seen according to the position

of Screen Volume.)

2) Adjust Screen Volume (R/G/B) in Focus Pack until

brightness of red/blue/green horizontal line is about not to

be seen.(At this moment, brightness of red, blue or green

horizontal line should be equal to one another.)

3) Exit the adjustment mode by pressing the “ ” button.

O Deflection Adjustment

1. Preliminary steps

1) Adjust differently based on input signal such as NTSC or

PAL.

2) NTSC adjustment should be done in STANDARD mode of

picture after receving 13CH signal,and PAL adjustment

should be done in STANDARD mode of picture after

receving EU05 CH.

3) Reset the data in convergence adjustment mode,quit the

mode.

Convergence Mode : SVC,

Data reset : 5 , OK

Adjustment mode out :

2. PAL Mode Deflection Adjustment

1) At SVC mode,press the YELLOW key get into the deflection

adjustment mode.

2) VS (Vertical Shift)

Adjust until geometric vertical certer line of the screen is

accord with the vertical center line of the screen JIG at EU

05 CH by pressing the VOLUME

F ,G button.

3) VA (Vertical Amplitude)

Adjust until fifth vertical line from upper and lower center of

the screen is accord with the edge of the frame.

4) HS (Horizontal Shift)

Adjust so that the horizontal center line of a digital circle pattern

is in accord with geometric horizontal center of the CPT.

5) EW (East-west Width)

Adjust until the outermost left and right vertical line of the

screen is accord with the edge of the frame.

6) EP (East-west Parabolar)

Adjust so that middle portion of the outermost left and right

vertical line looks like parallel with vertical lines of the CPT.

7) ET(East-west Trapezium)

Adjust to make the length of top horizontal line same with it

of the bottom horizontal line.

8) A-ANG(AFC Angle)

9) A-BOW(AFC BOW)

10) U-C(Upper Cotner Pincushion)

11) L-C(Lower Cotner Pincushion)

12) U-VL(Upper Vertical Linearity)

13) L-VL(Lower Vertical Linearity)

14) VL (Vertical Linearity)

Adjust so that the boundary line between upper and lower half is

in accord with geometric horizontal center of the CPT.

15) SC (Vertical “S” Correction)

Adjust so that all distance between each horizontal lines are

to be the same.

16) V-ASP(Vertical Aspect Ratio)

Adjust the vertical aspect ratio.

17) Store the adjusted data in EEPROM by pressing the “OK”

button before exiting adjustment mode.

18) Restore the convergence correction data by pressing the

“TV/AV” button before exiting adjustment mode

3. NTSC Mode Deflection Adjustment

1) Adjust vertical size (VA Adjustment) until fourth vertical bar

from upper and lower center screen is accord with the edge

of the frame.

2) Adjust horizontal size (EW Adjustment) until third bar to

indicate horizontal size of circle is accord with the edge of

the frame.

3) Do other adjustments the same as in PAL mode.

Fifth Vertical Line

Outmost Vertical Line

Fourth Vertical Line

Third Bar

MMMM

Page 13

O

Lens Focus & Electronic Focus Adjustment

1. Preliminary steps

1) Electronic focus,Raster slope & Raster position must be preadjusted.

2) Heat-run over 60 minutes.

3) Receive Crosshatch pattern.

4) Adjustment must be operated in a dark room(simple dark

room) and pay attention not to touch the lens during

adjustment.

5) Screen the optional two lens with a cover so that the single

color is appeared on the screen.

6) When turn the light the lens at front, chromatic aberration

which appeared in bright line of cross-Hatch signal changed

as below.

2. G-lens Adjustment

1) Turn the lens until the chromatic aberration changed Blue to

Red point.

2)

Viewing the all screen, in no case of the chromatic aberration

appeared slimly within 3.5 cross-Hatch of the picture center. At

this time, in case that the red chromatic aberration's bright line

isn't equal, adjust G-lens so that the red chromatic aberration is

appeared more than previous time.

3) Switching the signal to 13CH and operate adjustment

minutely.

4) Adjust G-focus control volume of focus pack so that the

external big circle's part appeared cleary.

5) Adjust accurately by repeat the upper control.

6) Especially, noting to the G-light because it influenced on

picture's function.

3. R-lens Adjustment

1) Turn the lens until the chromatic aberration changed orange

to scarlet.

2) Adjust the chromatic aberration so that it located center

correctly.

3) Switching the signal to 13CH and adjust it as same method

of G-lens.

4) Adjust as same method of G-lens with Red focus control

volume of focus pack.

4. B- lens Adjustment

1) Turn the lens until the chromatic aberration changed purple

to green which of 3.5 Cross-Hatch part from picture's center

toward left.

2) Adjust the chromatic aberration become center of purple and

green.

Note) After adjustment Red,Green & Blue lens, remove lens

cover and receive Cross-Hatch pattern and check the overall

focus. If need, repeat above.

O Convergence Adjustment

1. Preliminary steps

1) This adjustment should be performed after raster slant,

raster position, horizontal and vertical adjustment.

2) This adjustment should be performed after warming up 60

minutes.

3) Do it always with crosshatch pattern.

4) Adjust for both PAL and NTSC system.

5) Use the jig screen with the cross hatch pattern for each

mode.

2. Convergence Key

1) Convergence Mode : SVC,

2) Cursor shift :

F , G , D ,E

3) Cursor Movement/Adjustment Selection : OK

4) Cursor Color Selection : TV/AV

5) Adjustment mode out :

Note) When cursor flickers, its adjustment mode, and when

quiescent, its cursor movement mode.

O Mode Adjustment

1. Preliminary steps

Press the buttons SVC & of Remote Controller for

adjustment to get into the convergence adjustment mode.

2. Horizontal/Vertical phase Adjustment

1) Press the buttons 9 & 5 to get into the phase adjustment

mode.

2) Horizontal Phase Adjustment.

Press the volume

F /G button and move the convex part

to the middle of TV screen.

3) Vertical Phase Adjustment

Press the channel

D /E button and move the convex part

to the middle of TV screen.

4) Press the OK button to escape from the adjustment.

- 13 -

CHROMATIC

ABERRATION

CROSS HATCH

SIGNAL

Lens

Red

Green

Blue

Change of chromatic aberration

Orange ¤AScarlet

Blue ¤ARed

Purple ¤AGreen

MMM

Page 14

3. Pattern Position Adjustment

1) Change into pattern shift mode.

(Press numeric buttons “9” & “4”)

2) Make sure to overlap pattern and image.

(Use MUTEbutton)

3) Accord the center of image and pattern.

(Use

F , G , D ,E buttons)

4) Quit pattern shift mode. (Press “OK” button)

5) Save adjusted phase/pattern position adjustment

mode.(Press “9”, “2” & “OK” buttons)

4. Green Convergence Adjustment

1)

Show the OSD on screen by pressing 2 button,then change the

OSD to green(G) adjustment mode with pressing TV/AV button.

2) Close the cover of red CRT and blue CRT so that green

display on screen only.

3) Adjust to coincide green pattern with screen jig pattern.

(Use

F , G , D ,E buttons)

Move cursor and adjust convergence in same way with item 3).

Here, do it in the same order from center listed in figure.

5. Red Convergence adjustment

1)

Show the OSD on screen by pressing 2 button,then change the

OSD to red(R) adjustment mode with pressing TV/AV button.

2) If the need arises,close the cover of the blue lens.

3) Coincide the red screen with the green screen in same way

with that of green convergence adjustment.

6. Blue Convergence adjustment

1)

Show the OSD on screen by pressing 2 button,then change the

OSD to blue(B) adjustment mode with pressing TV/AV button.

2) Coincide the blue screen with the green screen in same way

with that of red convergence adjustment.

7. Adjusted Data saving

1) Save the data after adjustment.

(Press “9”, “1” & “OK” button)

2) Quit convergence adjustment mode. (“ ” button)

O White Balance Adjustment

1. Test Equipment

Brightness meter(CA110),Pattern Generator(Window Pattern)

2. Adjustment

1) This adjustment must be operated in a dark room or

equivalent.

2) Adjust after Cut-Off and Focus adjustment.

3) The brightness meter must be located in 20¡ 5cm distance

from the center of the screen.

4) Receive WINDOW signal.

5) Set BRIGHT to H/Light adjustment mode in 4) and enter

SVC mode by pressing the “SVC” button. Adjust RG (R

Gain) and BG (B Gain) until color coordinate becomes

X=0.280 and Y=0.300 (Deviation :

!0.01).

6) Set BRIGHT to L/Light adjustment mode and adjust CR (R

Cut Off) and CB (B Cut Off) until color coordinate becomes

X=0.282 and Y=0.286 (Deviation :

!0.01).

7) Repeat adjusting until the color coordinate of H/Light and

L/Light is satisfied.

8) Save the data after adjustment.

(Press “OK” button)

9) Quit adjustment mode. (“ TV/AV ” button)

O SUB-BRIGHT Adjustment

1) Tune the TV set to receive a EU 05 CH.

2) Enter

SVC mode by pressing the “SVC” button. Adjust SBRI data until 100% and 80% GRAY PATTERN is

classified.

(Use F , G , D ,E, ENTER buttons)

O DVCO Adjustment

1) Tune the TV set to receive a EU 05 CH.

2) Enter the adjustment mode by pressing SVC button of

Remote Controller for adjustment,then select DVCO menu.

Operate auto adjustment with VOL

G button.

If DVCO data is changed,auto adjustment has finished.

3) After finishing DVCO adjustment,save the data by pressing

OK button.

O PIP POSITION Adjustment

1) After receiving a PAL signal,show the multi-picture scan

screen on screen with pressing WD2 9/4PIP button.

2) Check the left,right blank on SCAN screen.(May be

20

±5mm)

3) If the left,right blank isn’t 20±5mm and symmetry,enter the

adjustment mode by pressing SVC button of

Remote

Controller for adjustment and select service adjustment

mode 5 by pressing YELLOW button.

4) Adjust M-HOR and M-VER to symmetry of left,right blank in

service adjustment mode 5.

5) When finishing adjustment,save the data by pressing OK

button.

- 14 -

8 6 5 4 5 6 8

7 5 3 2 3 5 7

6 4 2 1 2 4 6

7 5 3 2 3 5 7

8 6 5 4 5 6 8

100%,80% GRAY PATTERN

M

Left Blank

Right Blank

Page 15

O SVC Adjustment mode & Initial data

1. White Blalane adjustment data (IC:CXA2100)

2. Deflection adjustment data (IC:CXA2100)

3. Picture adjustment data (IC:CXA2100)

4. Sound adjustment data (IC:MSP3452)

5. Picture adjustment data (IC:SDA9410)

- 15 -

12

1F

19

0C

3F

19

1A

RD

GD

BD

RC

GC

BC

S-BRI

DVCO

Menu Description

Red Drive

Green Drive

Blue Drive

Red Cut-off

Green Cut-off

Blue Cut-off

Sub BRIGHT

Digital VCO

Range Default

10

13

2A

1E

20

6

11

11

D

7

6

7

7

3

1F

11

10

1A

1D

1E

6

11

11

C

5

6

7

7

3

1F

VS

VA

HS

EW

EP

ET

U-C

L-C

U-VL

L-VL

VL

A-ANG

A-BOW

SC

V-ASP

Menu Description

Vertical Shift

Vertical Amp

Horizontal Shift

East-West Width

East-West Parabola

East-West Trapezium

UP Corner Pincushion

LO Corner Pincushion

UP Vertical LIneality

LO Vertical LIneality

Vertical LIneality

AFC Angle

AFC Bow

Vertical S-Correction

Aspect ratio control

Range

Range

Range

Default

PAL NTSC

1

2

1

1

1

2

1

0

3

3

1

3

1

D-COL

COLAX

DCOL

LIMLE

CTILE

GAMMA

LTILE

BLKBO

ABLTH

ABLMO

VM-LE

PREOV

DPIC

Menu Description

Dynamic Color ON/OFF

Color matrix

Dynamic Color Temperate

RGB Amplitude Limiter Level

CTI Level

GAMMA correction

LTI Level

RGB Bottom LImiter Level

ABL threshold

ABL Mode

VM Level

Pre/Over-Shoot Control

Auto Pedestal level

Default

3

A

0

1

7

4

7

4

0

1

0

0

0

37

1B

A

C

DC-TR

LRGB2

DL-PA

SHPF0

CB-F1

CR-F1

CB-F2

CR-F2

VCOMP

EW-DC

AKBT2

HCOMP

VBLKW

LE-BL

RI-BL

S-CON

P-ABL

Menu Description

DC transmission control

RGB2 output level control

DElay Line switching

Sharpness f0

INput1 CB signal DC Offset

INput1 CR signal DC Offset

INput2 CB signal DC Offset

INput2 CR signal DC Offset

A-SAW output gain control

EW output DC level

AKB time shift

EW output DC control

VBLK width control

Left HBLK width control

Right HBLK width control

Sub contrast

PEAK ABL

Default

1B

73

18

50

50

24

FD

64

09

06

FM

NP

SP

S1 VOL

S2 VOL

MDB-ST

MDB-LIM

MDB-HMC

MDB-LP

MDB-HP

Menu Description

FM Prescaler

NICAM Prescaler

SCART Prescaler

SCART 1 Volume

SCART 2 Volume

MDB Effect Bass Strength

MDB Amplitude Limit

MDB Harmonic Content

MDB Low Pass

MDB High Pass

Range Default

13

0e

0a

00

00

Aa

13

3

A2

7

7

VDEM

NRY

NRC

NRKY

NRKC

ODELM

VDELS

FSEL

RF AGC

M-HOR

M-VER

Menu Description

Vsync input delay(main)

Temporal Noise Reduction of Y

Temporal Noise Reduction of C

Output Processing delay master

Vsync input delay(sub)

Filter Select

RF AGC Level

Horizontal PIP Position

Vertical PIP Position

Range Default

Page 16

6.

OPTION Data Adjustment

- 16 -

option3

Description

1: With Teletext

0: Without Teletext(CHINA)

1: RF 54% Modulation INput

0: RF 100% Modulation INput

1: China+AUST.Channel Table

0: Other countries Channel table

Range Default

TEXT

SCART

CH + AU

option1

option2

option3

Description

1: 200 Program(CHINA Only)

0: 100 Program

1: With TURBO Search

0: Without TURBO Search

1: Save Dual Sound Condition

0: Not Save Dual Sound

Condition

1: TOP + FLOF TEXT

0: FLOF TEXT

1: With Digital EYE

0: Without Digital EYE

1: With FM Stereo

0: Without FM Stereo

0 : BG/I/DK(PE-)

1 : BG/L(PL-)

2: BG/I/DK/M(PT-)

3 : RESERVED

1: Wih Channel Name Display

(All Countries except Austrailia)

0: Without Channel Name Display

(Austrailia)

1: Rushed Sound Curve

(Middle East ASIA,INDIA)

0: Standard Sound Curve

(Other countries)

1: With AV4 Input

0: Without AV4 Input

1: PE/PL Model

0: PT Model

1: With COMPONENT1 Input

0: Without COMPONENT1 Input

1: With COMPONENT2 Input

0: Without COMPONENT2 Input

1: With VGA Input

0: With VGA Input

1: With CENTER SPK

0: Without CENTER SPK

1: Digital Index button

0: SOUND MUTE button

1: RF Normal Sound Modulation(Others)

0:

High Deviation Modulation(CHINA)

1: With DOLBY Pro LOgic

0: Without DOLBY Pro LOgic

1: With DOLBY Virtual Surround

0: Without DOLBY Virtual Surroud

Range Default

200 PRO

TSEAR

I/II SV

TOP

EYE

A2 ST

SYS

ACMS

VOL

AV4

EU

DVD i

DVD p

VGA

C SPK

VFD

C MUTE

DOLBY

V-DOL

Page 17

- 17 -

State

LANG

T-LAN

Default

Language

0:E Only

1:EU 5EA

2:EU ETC

3:PARSI

4:ARAB DUAL

5:English+Hindi

6:English+I+M+V

7:English+THAI

8:English+China

0:West Europe

1:East Europe

2:Turkey

3:EAST EU2

4:Cyrillic 1

5:Cyrillic 2

6:Cyrillic 3

7:Turkey/Greek 1

8:Turkey/Greek 2

9:Turkey/Greek 3

10:Arab/France

11:Arab/English

12:Arab/Hebrew 1

13:Arab/Hebrew 2

14:Farsi/English

15:Farsi/France

16:Farsi all

Funciton

English

English/German/French/Italy/Spanish

Pol./Hungary/Czecho/Russia/Eng

English/Parsi

English/French/Arab+Urdu

English/Hindi

English/Indonesian/Malaysian/Vietnamese

English/Thai

English/China

English/French/Swedish/Czech/German/Spanish/Itallian

Polish/Fench/Swedish/Czech/German/Slovenian/Italian/Romanian

English/French/Swedish/Turkish/German/Spanish/Itallian

English/Hungarian/Serbian/Czech/German/Polish/Spanish/Itallian/

Romanian

option4

Page 18

- 18 -

Trouble Shooting

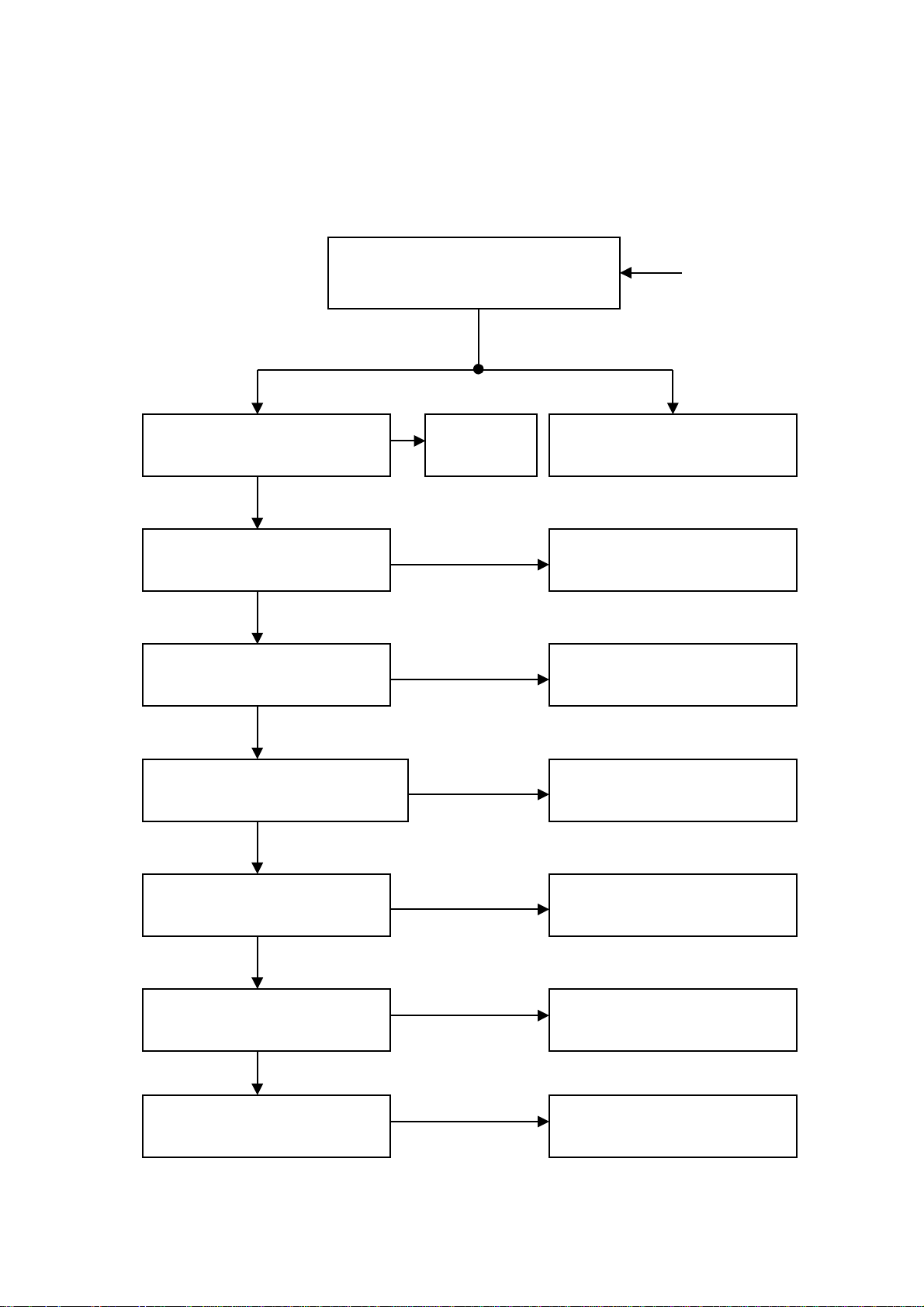

1. NO PICTURE ( SOUND OK )

Check MAIN1 Q101(E) Waveform.

CVBS Signal ?

(2Vpp)

Waveform of AV Board IC202 #63 ?

Check Tuner(TU101) VIDEO output

NO

Check around

IC202

Waveform of AV Board Q505(E) ?

Check around IC202

NO

Waveform of VIDEO Board

IC501 #72 ?

Check IC501

Waveform of VIDEO Board

IC501 #31~#50?

Check around IC501 #31~#50

Output circuit.

Waveform of VIDEO Board

IC706 #84,87,90 ?

Check around IC706

Waveform of VIDEO Board

IC702 #26,28,30 ?

Check around IC702

NO

NO

NO

NO

NOYES

YES

YES

YES

YES

YES

Waveform of

CPT SOKET CATHODE(RK/GK/BK) ?

YES

Check IC901 R.G.B

NO

Page 19

- 19 -

2. NO SOUND (PICTURE OK)

Waveform of AV Board IC205

#47,48,50,51,53,54,56,57

at each Mode ?

NO

Check arround

each Jack

Waveform of AV Board

IC205 #25,27,28 ?

YES

Waveform of

MAIN1 Q103

Q104 ( SIF ) ?

Check

TU101

Waveform of

AV Board IC205

#67 ?

Check

around

IC205

Check around IC205

Check around AV

Board Q215,216,217

Waveform of MAIN1

IC601?

Waveform of MAIN1

IC601 #7 #11 ?

Check around

IC601,602

YES

YES

YES

YES

NO

NO

<AV1,2,3,DVD(480i),DVD(480p) INPUT> < RF >

NO

NO

NO

Page 20

- 20 -

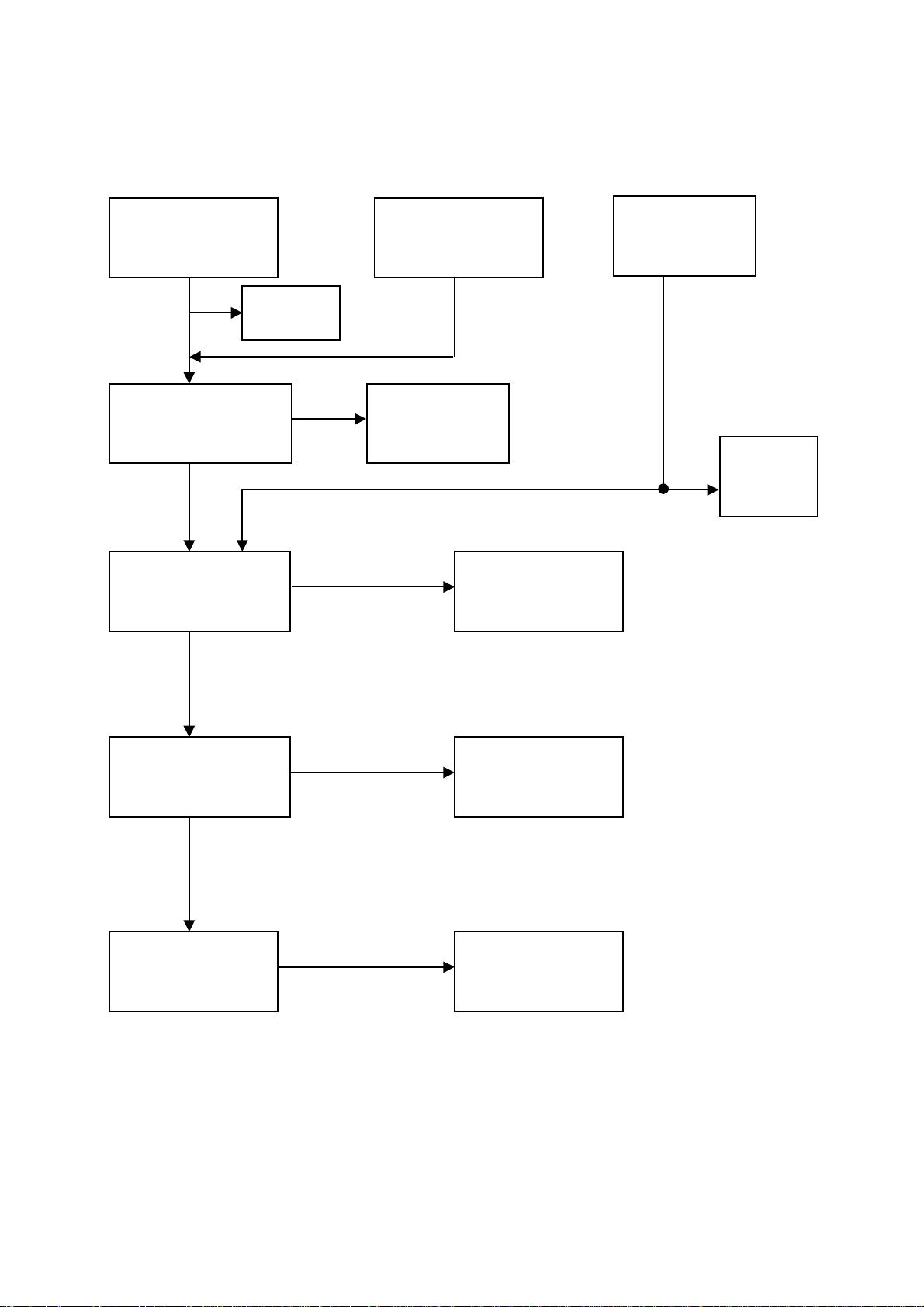

3. NO PIP

Waveform of AV Board

IC202 #8,15,22,35 ?

Waveform of Video Board

IC202 #44 ?

Waveform of Video Board

IC502 #72 ?

Waveform of Video Board

IC502 #31~#50 ?

(R,G,B, FB)

Waveform of Video

IC706 #51~#73 ?

( Y,U,V)

Check JA202

Waveform of PIP

Board IC502

#1,2,3,7,9 ?

Check

Scart Jack

JA204

Waveform of MAIN1

Q110(E) ?

Check Video Board

Q203,IC202

Check P212B

Check around IC502

Check PIP Board

IC706

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

<AV1,2,3> <RF> <SCART>

Page 21

- 21 -

4. NO Teletext (Picture OK)

Waveform of MAIN1

IC501 #4 ?

Micom Board Ic001 #21 ?

Check OPTION3 TEXT Code

(SVC MODE)

Check Micom IC001

#57~60

5. NO OSD (ON SCREEN DISPLAY)

Waveform of Micom Board IC001 #29,#30 ?

Horizontal, Vertical Fly Back Input

Waveform of Micom Board IC001 #57,58,59,

60 ?

Waveform of Video Board Ic702

#83,84,85,86 ? (R,G,B,FB)

Check DEF. Board.

Check Micom Board Q001,002

Check around IC001

Check around IC702

NO

YES

YES

NO

NO

NO

YES

YES

Page 22

- 22 -

6. NO POWER ON

Check input voltage of

IC001#6,8,22,40,56,73,75,92

Check SMPS Board

Check IC001 #52,53

(OSC)

Replace X001

YES

NO

NO

Check IC001 #11,12 (SCL,SDA)

NO

Replace Q003, Q004

Check IC001 #44 (ABN)

Check Abnormnal Circuit

Check IC001 #34 ( IR ),

#31~38 (Key In)

Check P004A connector

YES

YES

HIGH

LOW

NO

Page 23

- 23 -

7. NO VFD OPERATION (Option)

Check AV Board IC205 #5

Sound signal.

Check IC205sound output

Check IC205 #3 output Check around IC205

Check IC001 #45,46 Check Q008, 007

Check IC001 #47,48,49 Check Q011, Q012

YES

YES

YES

NO

NO

NO

NO

Page 24

- 24 -

Check +B voltage

115V or not

8.NO RASTER

Is the voltage

at Pin 76,69 of IC501 5V ?

Check 5V,9V,

12V lines

Check IIC bus lines

(SDA,SCL)

Does the square

waveform from Pin 17

of IC702 appear?

Is the waveform at

collector Q402 normal?

Is the waveform at

collector Q403 normal?

Check / Replace

T401

Check / Replace

Q403

Check / Replace

Q402,T401

Check / Replace

IC702

Check F801

Check the voltage

of C812(+)

Check the voltage

at pin 4 of IC801

Check/Replace IC887,IC871

Check the 2nd voltage are

short or not

Check / Replace

F801,D815

IC801

Check / Replace

D815

Check / Replace

D805,Q801

ZD801

OK 0V

Open

OK

0V

Lower than 6V

6~8V

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Page 25

- 25 -

9. INCORRECT CONVERGENCE

Does the static convergence

correct?

Check the input vlotage

at P201

Re-adjust static convergence

by remote controller

Check pulse pin125

of IC2051(4Mhz)

Check voltage on the

SMPS PCB

Check/Replace

IC2051

Check V,H at

Pin 2,4 of P404

Check / Replace

IC2002

Check H,V

on the DEF PCB

Are there pulse signal

at pin121 of IC2051

OK

Are there V,H pulse

at Pin 3,4 of P404

Check / Replace

Q2201

Check V,H signal

on the DEF PCB

Check /Replace

IC2051

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Not controlled

Controlled

Page 26

- 26 -

TUNER

(PIP)

TUNER

(MAIN)

SR

C

CRT G

CRT R

CRT B

TO DEF BOARD

IC202

VIDEO

S/W

(CXA2069)

IC205

SOUND CONTROL

(MSP3452)

AV3

(SIDE)

S-JACK (AV3)

(SIDE)

PC VGA IN

(SIDE)

IC001

MICOM

(SDA555)

IC206

BAND EQUAL.

(MSGEQ7)

IC602

TDA7265

IC601

TDA7265

R

IC801

VFD DRIVER

(UPD16311)

VFD801

HNR-09ML02

TDA6111

TDA6111

TDA6111

IC501

MAIN VIDEO

PROCESSOR

(VPC3230)

SIF

AV3-L-IN

CVBS(M)

CVBS(P)

V

Y,C

V/Y,C

V

V

VOUT3

Rout

Gout

Bout

IK

S,Cout

R,Lout

EEPROM

(24C16)

S_A/D,STRB,RST

G1~9

P1~16

Sout

Cout

R,Lout

EW,VD+,VD-

HD,SVM,DF

ABL, XRAY

DVD(480i)

(BACK)

DVD(480p)

(BACK)

SL

L

#67

YUV(M)

YIN1

YCbCr

R,G,B,FB

SCL1,SDA1

DATA

CLK

STRB

#33,34

IC502

PIP VIDEO

PROCESSOR

(VPC3230)

IC706

480i->100HZ

(SDA9410)

IC702

VCD

(CXA2100)

AV3-R-IN

AV4-L-IN

AV4-R-IN

480i-L-IN

480i-R-IN

480p-L-IN

480p-R-IN

SC3_R,L IN

SC4_R,L IN

(RF OUT)

SC1_OUT R,L

(MONITOR OUT)

SC2_OUT R,L

AV4/SAV4

(HALF)

V/Y,C

R,L_IN

AV2

(HALF)

AV1

(FULL)

SC1 R,L_OUT

SC2 R,L_OUT

V_IN

V_IN

R,L_IN

R,L_IN

SC2_R,L IN

SC1_R,L IN

MONITOR OUT

RF OUT

480p_Y

#41

#72,71

#72

YCbCr

R,G,B,FB

R,G,B,FB

SYNC

SEP.

480p_Y

480p_V

VGA_V

VGA_H

VGA_H

VGA_V

R,G,B

R,G,B

YPbPr

100Hz

YUV

VS_IN

Hout

HS_IN

YUV(P)

ROM

(M27V201)

SRAM

(1M BIT)

H_FBP

VPROT

IC004

IC003

480i_L,R

480p_L,R

YPbPr

YPbPr

OPTION

#8

#15

#44

PIP-V

#63

#60

#22

#24,26

#3,5

#49

Vout1

#53

V/Y,Cout1

#56,58

#4,5,6

#75

#1,2,3,79

#4,5,6

#1,2,3,79

#31-50

VGA_V

#17

Hout

#31-50

#31-47

#84,87,90

#4

#5

Vout

#60

#52,53,54

#56,57

,58

#39,40

,41

#59

#30

#28

#26

#25

#50,51

#47,48

#53,54

#36,37

#29,31

#27,28

#51-73

IC204 LA7222

IC203 LA7222

IC501

LA7016

SWITCH

V(P)

V(M)

CVBS

IC704

74LS157

V(M)

V(P)

OSD RGB

#33-36

BLOCK DIAGRAM(SIGNAL)

Page 27

- 27 -

BLOCK DIAGRAM(DEF)

VD +

VD-

H-DRIVE

TRANS

H-DY

FBT

T403

H-V

DET

H.V

BLOCK

DF

Q433

K2518

H-DRIVE

Q402

IRFIBC206

HV DRIVE

TRANS

T402

HV OUT

TR

Q416

2SD1887

H OUT

TR

Q403

2SC5446

DUMMY

FBT

T405

H.V

Stabilize

IC408,402

HVDRIVE

Q413

IRFIBC206

9V p-p

SAWTOOTH

Pulse Generator

FOCUS

PACK

H.V ADJUST

VR401

DF TRANS

T405

V-OUT

IC1401

LA7846

V-DY

DF TR

Q406

C4710

DF AMP

IC406

NJM4560

HD

V-DF

DYNAMIC

FOCUS

H-DF

H.V

FOCUS V

P411

PWM PULSE

B+

S/W

AMP

IC401

KIA4358

E/W

T401

Page 28

- 28 -

BLOCK DIAGRAM(SMPS-WIDE)

DC

RECTIFIER

POWER TR

IC801

STR-F6658B

POWER TR

IC802

STR83145

SMPS

TRANS

< SMPS >

AC INPUT

100~240V AC

POWER SW

T801

ERROR AMP

IC871

SE115

T405

DUMMY

FBT

T403

FBT

VERTICALICIC1401

LA7846

115V

30V

17V

-17V

IC410

7905

IC405

GL7824

H.V

BLOCK

40V

8V

12.4V

IC408

IC402

IC406

-22V

ST-8V

33V

26V

-26V

P805A

P810A

P811A

24V

200V

115V

8V

12V

-22V

ST-8V

45V

-26V

26V

5V

-5V

40V

P411A

P402A

P401

P404A

P405

< DEF >

<PIP>

<VM>

<CONVERGENCE>

<VFD>

<CPT>

<PRE AMP>

<EYE>

<MAIN>

<AV>

40V

45V

12V

8V

ST8V

5V

-20V

-26V

200V

12V

12V

8V

ST-

8V

8V

Page 29

- 29 -

BLOCK DIAGRAM(SMPS-NARROW)

DC

RECTIFIER

POWER TR

IC801

STR-F6658B

Current

Hamonics

SMPS

TRANS

< SMPS >

AC INPUT

230V AC

POWER SW

T801

ERROR AMP

IC871

SE115

T405

DUMMY

FBT

T403

FBT

VERTICALICIC1401

LA7846

115V

30V

17V

-17V

IC410

7905

IC405

GL7824

H.V

BLOCK

40V

8V

12.4V

IC408

IC402

IC406

-22V

ST-8V

33V

26V

-26V

P805A

P810A

P811A

24V

200V

115V

8V

12V

-22V

ST-8V

45V

-26V

26V

5V

-5V

40V

P411A

P402A

P401

P404A

P405

< DEF >

<PIP>

<VM>

<CONVERGENCE>

<VFD>

<CPT>

<PRE AMP>

<EYE>

<MAIN>

<AV>

40V

45V

12V

8V

ST8V

5V

-20V

-26V

200V

12V

12V

8V

ST-

8V

8V

Page 30

- 30 -

PRINTED CIRCUIT BOARD

SIGNAL

Page 31

COMPONENT LOCATION GUIDE(SIGNAL)

C001.......A5

C002.......B5

C003.......B5

C004 ......C5

C005 ......C5

C006.......B4

C007.......B4

C008.......A4

C009.......A2

C010.......B1

C011.......B1

C012.......A2

C013.......A1

C014.......A1

C015.......A1

C016.......A1

C017.......A1

C018 ......C3

C019.......B4

C020.......A4

C021.......A4

C022.......A3

C023.......A3

C024.......B3

C031 ......C5

C032 ......C5

C051.......B1

C101.......E5

C104.......E5

C105.......F5

C107......G5

C108......G5

C109.......E5

C110 ......D5

C111 ......D5

C112.......E5

C113.......E5

C115.......F5

C116.......F5

C118.......F5

C119.......F5

C121.......F5

C122.......F5

C123.......F5

C124......G5

C125......G5

C126......G5

C127.......F4

C130.......E4

C131.......E4

C132.......E4

C133.......E4

C134.......E4

C135.......E4

C136.......F4

C137.......E4

C138 ......D4

C139 ......D4

C140.......E4

C141.......E4

C144 ......D3

C145.......F4

C201.......F4

C202......G4

C203.......F3

C205......G4

C206......G2

C207......G2

C503 ......C2

C504 ......C2

C505.......E3

C506.......E3

C507.......E3

C508.......E3

C509.......E3

C510.......E3

C512.......E2

C513.......F3

C514.......F3

C515.......F3

C518.......F3

C519.......F3

C520.......F3

C521.......B1

C522.......B1

C523.......B1

C525 ......D3

C528 ......D2

C600 ......D2

C601.......F2

C602.......E2

C603.......E2

C604.......F1

C605......G1

C606 ......D2

C607.......E1

C608 ......D2

C609......G1

C610.......E2

C615.......E2

C616.......E2

C617 ......D2

C618.......F2

C619 ......D2

C620.......E2

C621......G2

C628.......F2

C629.......E2

C630......G2

C631.......F1

C632.......E2

C635......G1

C636.......F1

C637.......F2

C638 ......D2

C639 ......C1

C640 ......D2

C670.......E2

C671.......E2

D001.......B2

D002.......B2

D003 ......C4

D004 ......C4

D005 ......C4

D006 ......C4

D007 ......D4

D008 ......D4

D600.......F2

D601......G2

D602.......F2

D603 ......D2

D605 ......D2

D606.......E2

E005.......D1

E006.......D1

E007.......F1

E008.......F1

F001.......B5

F101.......F5

G001......D1

G002......D1

G003......D2

G004......D2

G005.......F2

G006.......F2

G007.......F1

G008.......F1

G009......G1

G010......G1

G011......C1

G012......C1

G013......D2

IC001......B5

IC002......A2

IC003......A3

IC004......B4

IC005......B2

IC006......A1

IC007 .....C5

IC101......F4

IC102 .....D3

IC201......F3

IC202.....G3

IC501......E3

IC502......B2

J2 ...........A2

J3 ...........A3

J4 ...........A3

J5 ...........A2

J6 ...........B2

J7 ...........B2

J8 ...........B2

J11 .........A4

J12 .........B4

J13 .........A2

J14 .........A1

J16 .........B1

J17 .........B4

J18 .........B4

J20 .........B4

J21.........C4

J22.........C4

J23.........C4

J24.........C3

J25 .........A2

J26.........C3

J28.........C5

J29.........C5

J30 .........B5

J31 .........B5

J32 .........B5

J33 .........B5

J34.........C4

J35.........C5

J36.........D3

J37 .........B5

J38 .........B2

J39.........C2

J40 .........B2

J41 .........B1

J42 .........B4

J43 .........B4

J44 .........B4

J45.........C4

J46.........C5

J47.........C5

J48.........C5

J49.........C4

J50.........C4

J52 .........B4

J53 .........B4

J54.........C5

J56.........D3

J59.........C3

J60.........D3

J61 .........B3

J62.........C3

J63.........C4

J64 .........B2

J65.........C3

J66 .........B2

J67.........D5

J68.........C5

J69 .........E4

J70.........C5

J71 .........B2

J72.........C3

J73.........C3

J74.........C3

J75.........C3

J76.........C3

J77.........D3

J78.........D4

J79.........C3

J80.........D4

J81.........C4

J82.........C4

J83.........C4

J84 .........B5

J85 .........E4

J87.........D2

J88.........D2

J89..........F2

J90.........C3

J91..........F3

J92.........D3

J93.........D3

J94 .........B5

J95 .........E3

J96.........D3

J97.........D4

J98 .........B3

J99 .........B3

J100 .......B4

J101.......D3

J102........F5

J103 .......B5

J104.......D4

J105 .......B3

J106.......C5

J107.......D4

J109.......D4

J110.......D4

J111.......G3

J112.......G3

J113.......G3

J114.......G2

J115.......G2

J118 .......E3

J119 .......E3

J120.......G4

J124 .......E2

J128........F3

J130.......G4

J131........F3

J133.......D1

J138.......G2

J139 .......E5

J141 .......E1

J142.......G4

J143.......D1

J144.......G3

J145 .......E1

J146........F4

J147.......G3

J148.......G4

J149........F2

J150.......G4

J151.......G3

J153 .......E4

J157.......G2

J160.......C3

J161........F1

J164.......G1

J165........F1

J167 .......A4

J168 .......E3

J169 .......E1

J170 .......E1

J171 .......E1

J172.......G2

J173.......C1

J174.......D1

J176.......G2

J177.......G2

J178 .......E3

J179 .......E2

J180 .......E2

J181 .......A5

J183.......D3

J184.......D2

J186........F2

J193 .......E2

J196.......D1

J200.......D5

J201 .......E5

J202........F4

J203........F4

J205 .......E3

J206........F5

J207.......D5

J208.......D5

J209 .......E5

J210........F5

J211........F5

J212........F5

J213........F5

J214.......G5

J215.......G5

J216.......G4

J217.......G4

J218.......G4

J219.......G4

J220.......G4

J221.......G4

J222.......G4

J223.......G4

J227.......G5

J228.......G5

J229.......G5

J501 .......B1

L001.......A4

L002.......A4

L003.......B3

L004.......D4

L102.......D5

L103.......D4

L104 .......F5

L105.......E4

L501.......B2

L502.......G4

L503.......D2

L504.......G4

L508 .......F3

L509 .......F3

L510 .......F3

L512.......G4

P602.......D2

P603 ......G1

P604.......F1

P002A ....B5

P003A ....A5

P004EP..B5

P005A ....B5

P006IP ...A5

P119A....G5

P201B....G4

P202B....G2

P211A.....F2

P212A ....E2

P213A....D2

P214A....C2

P401B ....A1

P402B ....B1

P403B....C1

P404B....C1

P405B....C1

Q001 ......A2

Q002 ......B2

Q003......C4

Q004......C4

Q005......C4

Q006......D3

Q007 ......B4

Q101 ......E5

Q102......D5

Q103 ......E5

Q104 ......E5

Q105 ......E5

Q106.......F5

Q107......G5

Q108......G5

Q109 ......E4

Q110......D4

Q502......D3

Q503 ......E3

Q600.......F2

Q601......D2

Q602......D2

Q603 ......E2

Q604 ......E2

R002.......A5

R003.......A5

R005.......B5

R007.......B5

R008.......B4

R009.......B4

R010.......A2

R011.......A2

R012.......A2

R013.......A2

R014.......B2

R015 ......C3

R016 ......D3

R017 ......C3

R018 ......C3

R019 ......C3

R020 ......C3

R021 ......C4

R023 ......D4

R024 ......C4

R025 ......C3

R026 ......D3

R027 ......C4

R028 ......C4

R029 ......D4

R030.......B4

R031.......B1

R032 ......D5

R033 ......D5

R034 ......D5

R035 ......D5

R036 ......D5

R037 ......D5

R038 ......D5

R039 ......D5

R040 ......D5

R041.......B4

R042 ......D5

R043 ......D3

R044 ......D3

R045 ......D3

R046 ......D3

R048 ......C5

R050 ......C5

R051.......B3

R052.......B4

R097.......A2

R101.......E5

R102.......E5

R103.......E5

R104 ......D5

R105 ......D5

R106 ......D5

R107 ......D5

R108......G5

R109......G5

R110......G5

R111......G5

R112......G5

R113......G5

R114.......F5

R116.......F5

R117.......F5

R118.......F5

R119.......F5

R120.......E5

R121.......E5

R122.......E5

R123.......E5

R124.......E5

R126.......E5

R127.......E5

R128.......E5

R129.......E5

R130 ......D4

R131 ......D4

R132.......E4

R133.......E4

R135......G5

R136.......E4

R137.......E4

R138 ......D4

R139.......E4

R140 ......D5

R141.......E5

R201......G2

R503 ......D4

R504 ......D4

R505 ......D3

R506.......E3

R507.......F3

R508.......E3

R509 ......D3

R510......G4

R511......G4

R512......G4

R516.......F3

R517.......F3

R518.......F3

R519 ......C1

R520 ......D4

R521.......F4

R600.......E2

R601.......E2

R602 ......D2

R603.......F2

R604 ......D2

R605.......E2

R606.......E2

R607.......F2

R608 ......D2

R609.......E2

R610.......E2

R611.......F2

R612......G1

R613.......F2

R614.......E1

R615.......E1

R616.......F1

R617.......E1

R618 ......D2

R619 ......D2

R620.......F1

R621 ......D2

R622.......F1

R623.......F2

R624 ......D2

R625 ......C1

R626.......E2

R636 ......D3

R638.......E2

R639.......E1

R641.......F1

R643.......F2

R650.......F2

R651.......E2

R652.......E2

R661 ......D2

R662.......F1

R663.......F1

R664......G1

R665 ......D2

R666.......E2

R667 ......D1

R668 ......D2

R669 ......D2

R670.......E2

R671 ......D2

TU01......G5

TU02.......F4

Z103.......E5

Z106.......G5

Z114.......E5

Z117.......F5

Z129.......E4

Z142.......D4

ZD004 ....A2

ZD101 ....E5

ZD102....D4

ZD501....C2

ZD601....D2

ZD602 ....E2

- 31 -

Page 32

- 32 -

MAIN2 (DEF)

Page 33

- 33 -

COMPONENT LOCATION GUIDE(DEF)

C301.......E2

C302.......E2

C303.......F2

C304.......E2

C305.......E1

C306.......E1

C307.......F2

C315 ......D2

C344 ......D1

C401.......A2

C402.......A2

C403 ......D3

C404 ......C1

C405.......E4

C406.......B2

C407.......A1

C408.......B2

C409.......B2

C410.......A3

C411.......A3

C412.......B3

C413......G2

C414......G1

C415 ......C2

C416.......E5

C417.......E3

C418.......F3

C419 ......D5

C421.......E5

C422 ......C4

C423.......F2

C424 ......D1

C425 ......D1

C426.......E2

C427.......E2

C428 ......D5

C429.......B3

C430 ......D3

C432......G2

C434 ......D2

C436.......B1

C437.......E2

C440.......B2

C441.......E4

C443.......F4

C444.......E4

C446 ......D2

C447.......E4

C448 ......D4

C449.......E4

C450.......E4

C451.......E5

C452.......E4

C454 ......D2

C457.......F3

C460.......E4

C461 ......C5

C462.......B3

C463 ......C5

C464 ......C5

C466 ......D3

C467 ......D3

C468.......A5

C469.......E3

C470 ......D4

C471 ......D3

C474.......B3

C475.......B2

C476.......A3

C478......G4

C479.......F5

C480.......F4

C481.......B3

C482.......B2

C483.......B3

C484.......B2

C485.......E3

C486.......F3

C487.......E3

C488.......B3

C490.......E3

C491.......E3

C492.......E4

D302.......E2

D401.......E4

D402.......F3

D403.......F4

D404.......F3

D405.......F3

D406.......E3

D408.......E5

D409.......E3

D410 ......D3

D414 ......C4

D415 ......C4

D416 ......C3

D417 ......C3