LG MICRO Hi-Fi SYSTEM, RBD154, RBS154V Service Manual

MODEL: RBD154 (RBS154V)

SERVICE MANUAL

P/NO : AFN72956676 APRIL, 2009

MODEL: RBD154 (RBS154V)

Website http://biz.lgservice.com

Internal Use Only

MICRO Hi-Fi SYSTEM

SERVICE MANUAL

1-1

[CONTENTS]

❍ SECTION 1. GENERAL

• SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

• ESD PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

• SERVICE INFORMATION FOR EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

•

PROGRAM DOWNLOAD GUIDE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

• SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

❍ SECTION 2. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

• DECK MECHANISM EXPLODED VIEW (DP-12AV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

• SPEAKER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

• PACKING ACCESSORY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

❍ SECTION 3. ELECTRICAL PART

• TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

• DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING . . . . . . . . . . . . . . . 3-17

• WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

• BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

• CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

• CIRCUIT VOLTAGE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

• PRINTED CIRCUIT DIARGAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

❍ SECTION 4. MECHANISM (DP-12AV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

❍ SECTION 5. REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1-2

SERVICING PRECAUTIONS

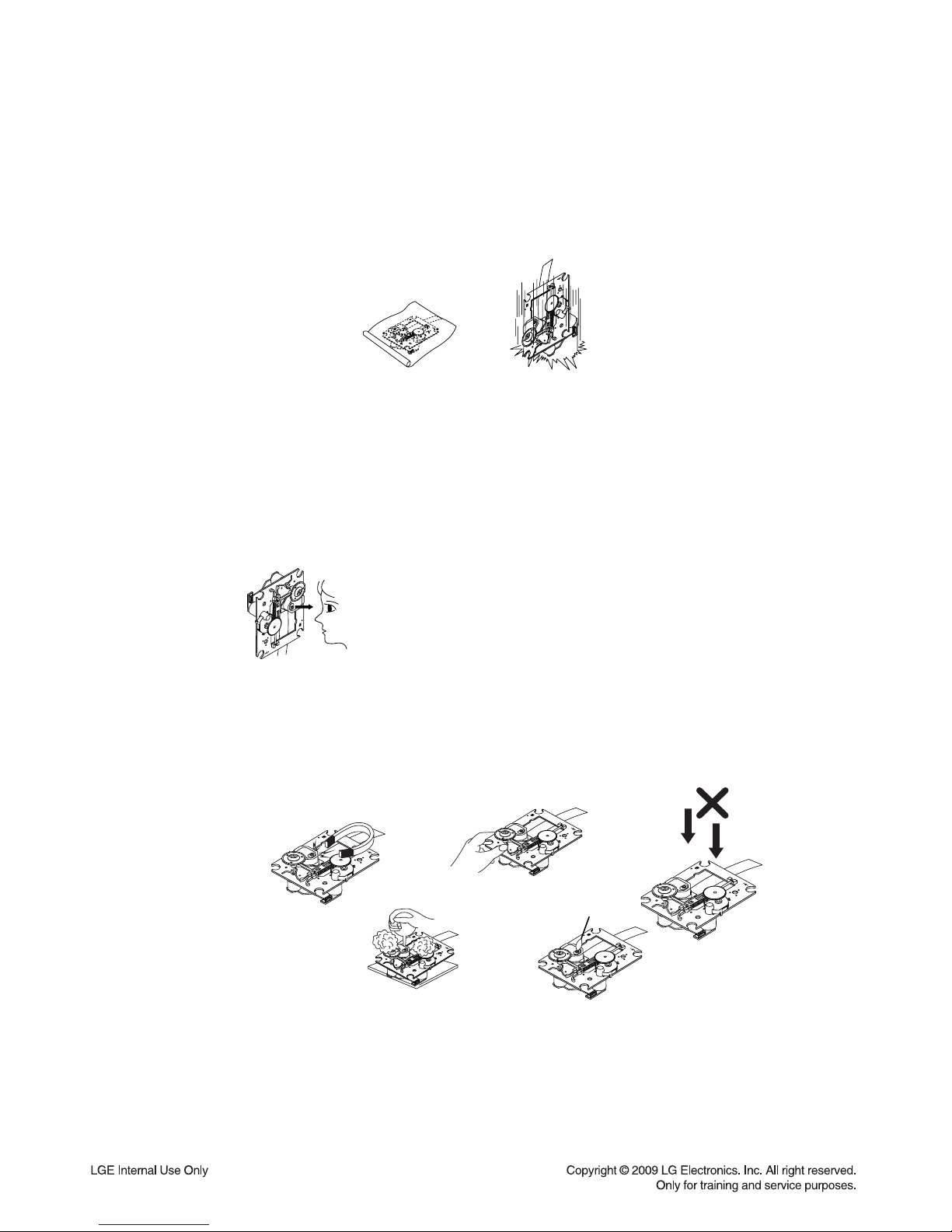

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort lens.

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

Magnet

How to hold the pick-up

Conductive Sheet

Cotton swab

Pressure

Pressure

SECTION 1. GENERAL

1-3

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

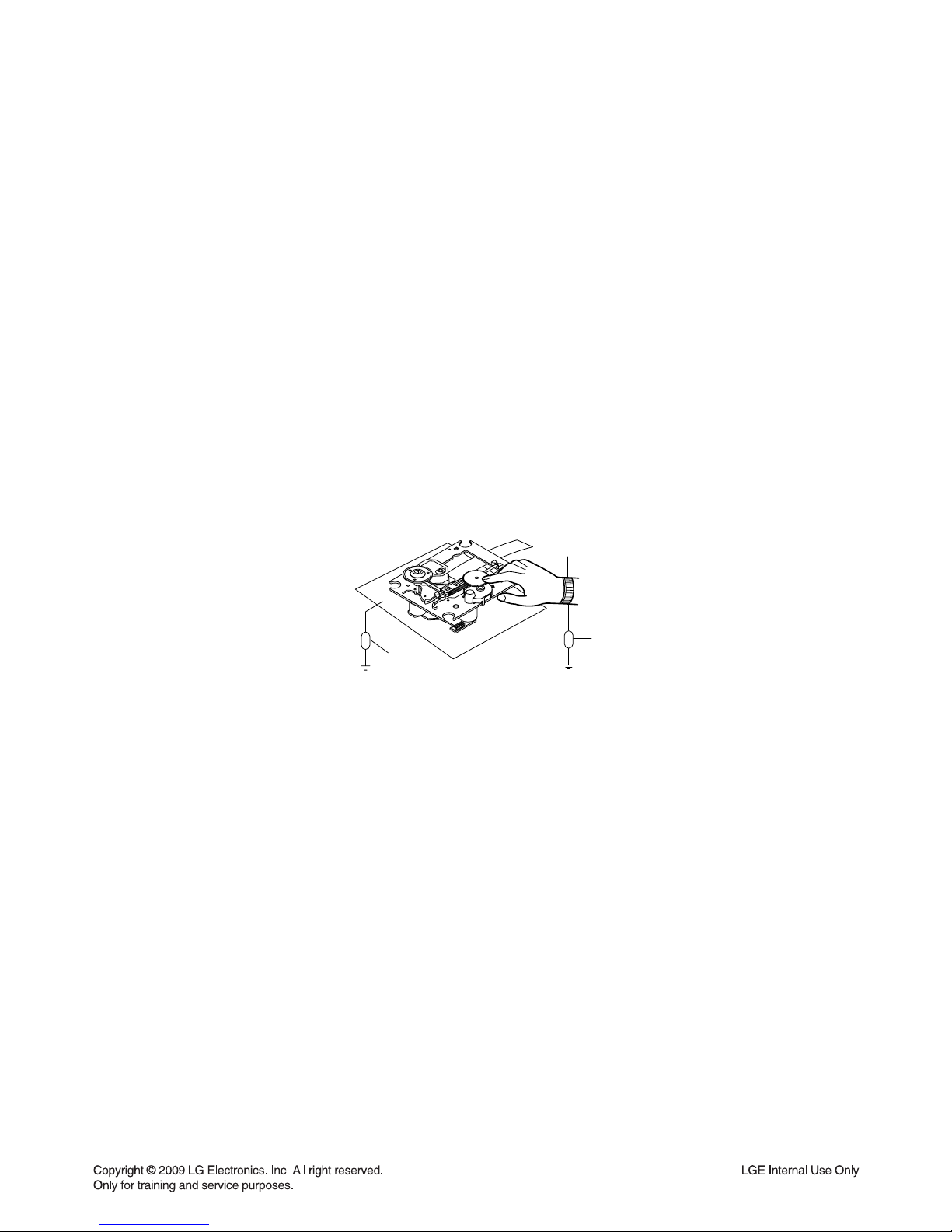

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M Ω)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Resistor

(1 M Ω

Conductive

Sheet

Resistor

(1 M Ω)

Armband

1-4

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4 . Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static"

can generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

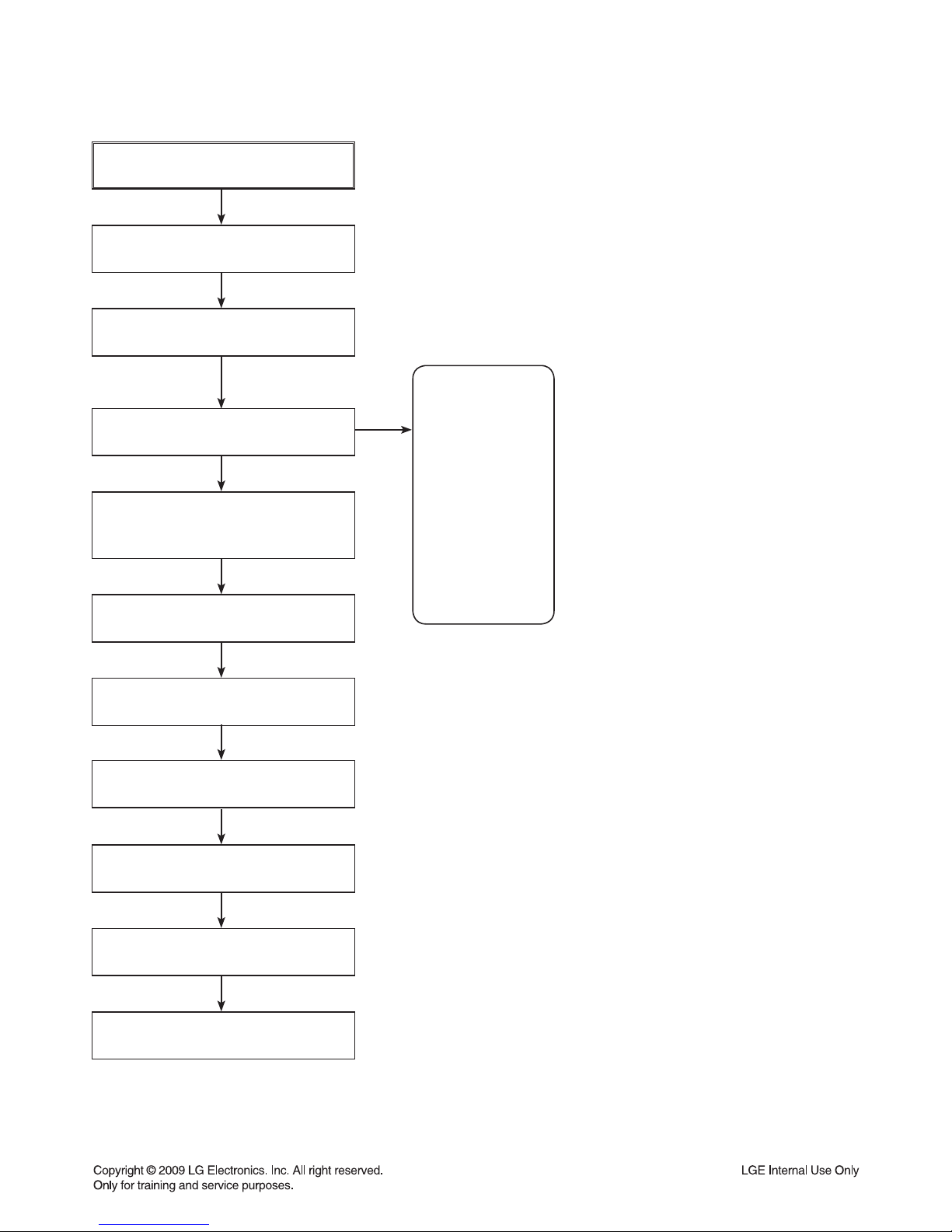

SERVICE INFORMATION FOR EEPROM

POWER ON

FLD no disc status

Remote control

“pause →1→4→7→2”

FLD ‘OP-0….

Move to appropriate position

and make changes

with Rmc ‘cursor,number’ key.

Press Enter key

FLD ‘write ok’

Remote control ‘Pause’

FLD ‘E2P CLR’

(Set “stop” + Rmc “0”)

Completed

NAME

OPT 0

OPT 1

OPT 2

OPT 3

OPT 4

OPT 5

OPT 6

OPT 7

OPT 8

OPT 9

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

HEX

F9

00

B4

DD

00

11

A0

00

30

00

Factory Reset

Rmc “1→3→9→7→1→3→9→ enter”

1-6

PROGRAM DOWNLOAD GUIDE

1. AUDIO PROGRAM

Download program file name must be RBD154.HEX

→ If security program (Water Wall) is activated on your PC, you must save the file to the usb storage

device and disable the security software, then download the file to your set.

Caution: When downloading the file, you should neither unplug the usb device, change to the other

function, nor power off the device. Usb device must be unplugged when the downloading

process is completed.

ON VFD DISPLAY SCREEN

NO USB

↓← Insert usb device at usb function

READ

↓

FIRMWARE

↓

WRITE 00 .. 100

↓

UPDATED

↓

POWER OFF AUTOMATICALLY

← When completed, remove usb device.

1-7

2. DVD PROGRAM

Download program file name must be HB001_DATE_00.BIN

→ If security program (Water Wall) is activated on your PC, you must save the file to the usb storage

device and disable the security software, then download the file to your set.

Caution: When downloading the file, you should neither unplug the usb device, change to the other

function, nor power off the device. Usb device must be unplugged when the downloading

process is completed.

ON VFD DISPLAY SCREEN

NO USB

↓← Insert usb device at usb function

READ

↓

FIRMWARE

↓

FINISH

↓

UPDATED

↓

POWER OFF AUTOMATICALLY

← When completed, remove usb device.

1-8

SPECIFICATIONS

GENERAL

Power supply Refer to main label.

Power consumption Refer to main label.

Net Weight 3.8 kg

External dimensions (W x H x D) 202 x 307 x 262 mm

Operating conditions Temperature 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

Laser Semiconductor laser, wavelength 650 nm

Tuner FM

FM Tuning Range 87.5 ~ 108.0 MHz or 87.50 ~ 108.0 MHz

FM Intermediate Frequency 128 kHz

AM Tuning Range (optional) 522 ~ 1,620 kHz or 520 ~ 1,710 kHz or 520 ~ 1,710 kHz

AM Intermediate Frequency 45 kHz

AMPLIFIER

Output Power 80 W + 80 W

T.H.D 0.5 %

SPEAKERS (RBS154V)

Type 2 Way 2 Speaker

Impedance 4 Ω

Rated Input Power 50 W

Max. Input Power 100 W

Net Dimensions (W x H x D) 165 x 316 x 198 mm

Net Weight 2.8 kg

Designs and specifications are subject to change without notice.

I

F

D

I

C

E

G

H

G

L

465

251

264

451

276

263

465

265

300

273

A44

257

463

465

463

C

256

465

A45

K

K

M

N

261

258

259

A41

M

N

KARAOKE

USB

SCART

H

480

MIC

465

CABLE4

252

253

254

465

255

465

250

A42

A43

CABLE3

463

B

F

E

D

463

266

277

MAIN

B

CABLE2

CABLE1

SMPS

A47

465

465

465

274

262

465

A46

OPTIONAL PART

SECTION 2. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION (RBD154)

2-1 2-2

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

A42 ASSY INCLUDES TOUCH PCB

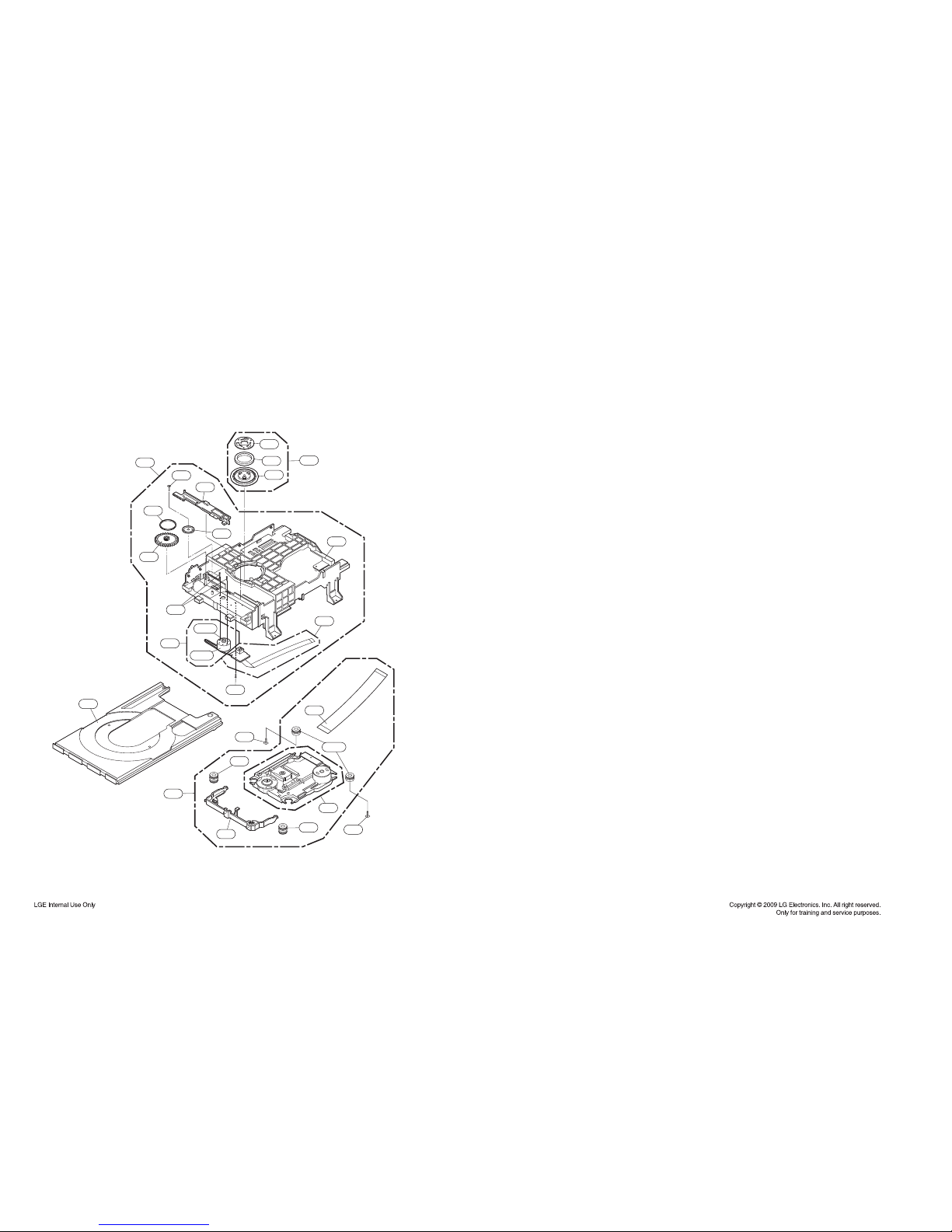

2-3 2-4

• DECK MECHANISM EXPLODED VIEW (DP-12AV)

012

010

012

037

012A

019

442

442

A02

A01

A03

001

002

003

439

018

013

017

014

020

016

440

015

015B

015A

435

026

2-5

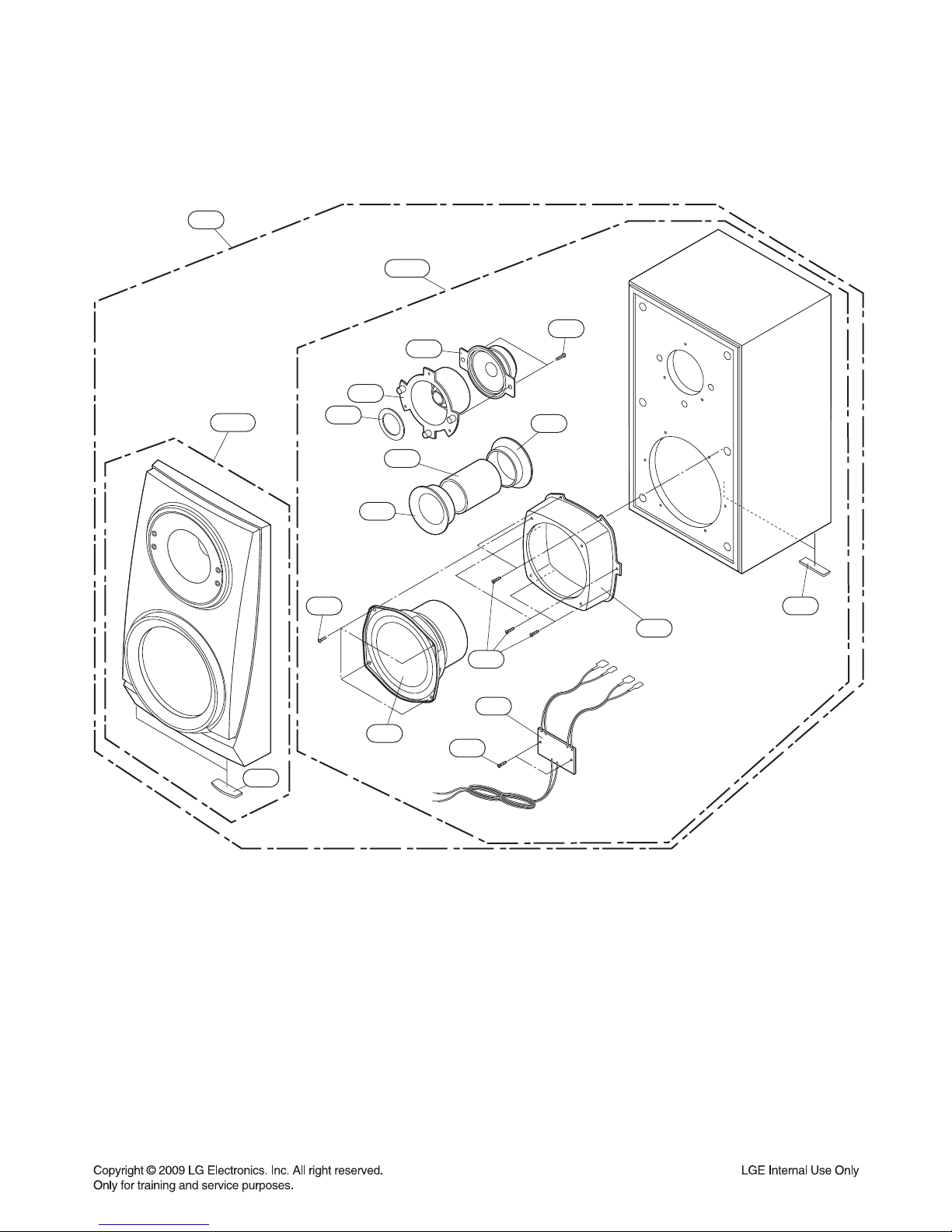

655

655

651

652

653

654

A61B

656

657

654

654

658

659

662

661

A61A

660

A60

• SPEAKER SECTION

1. FRONT/REAR SPEAKER (RBS154V)

2-6

• PACKING ACCESSORY SECTION

825 FM Wire Antenna

900 Remote Control

808 Battery

801 Instruction Ass'y

803 Packing

802 Box

804 Bag

811 Plug Ass'y, 1Way

827 Micro Phone

832 Disc

3-1

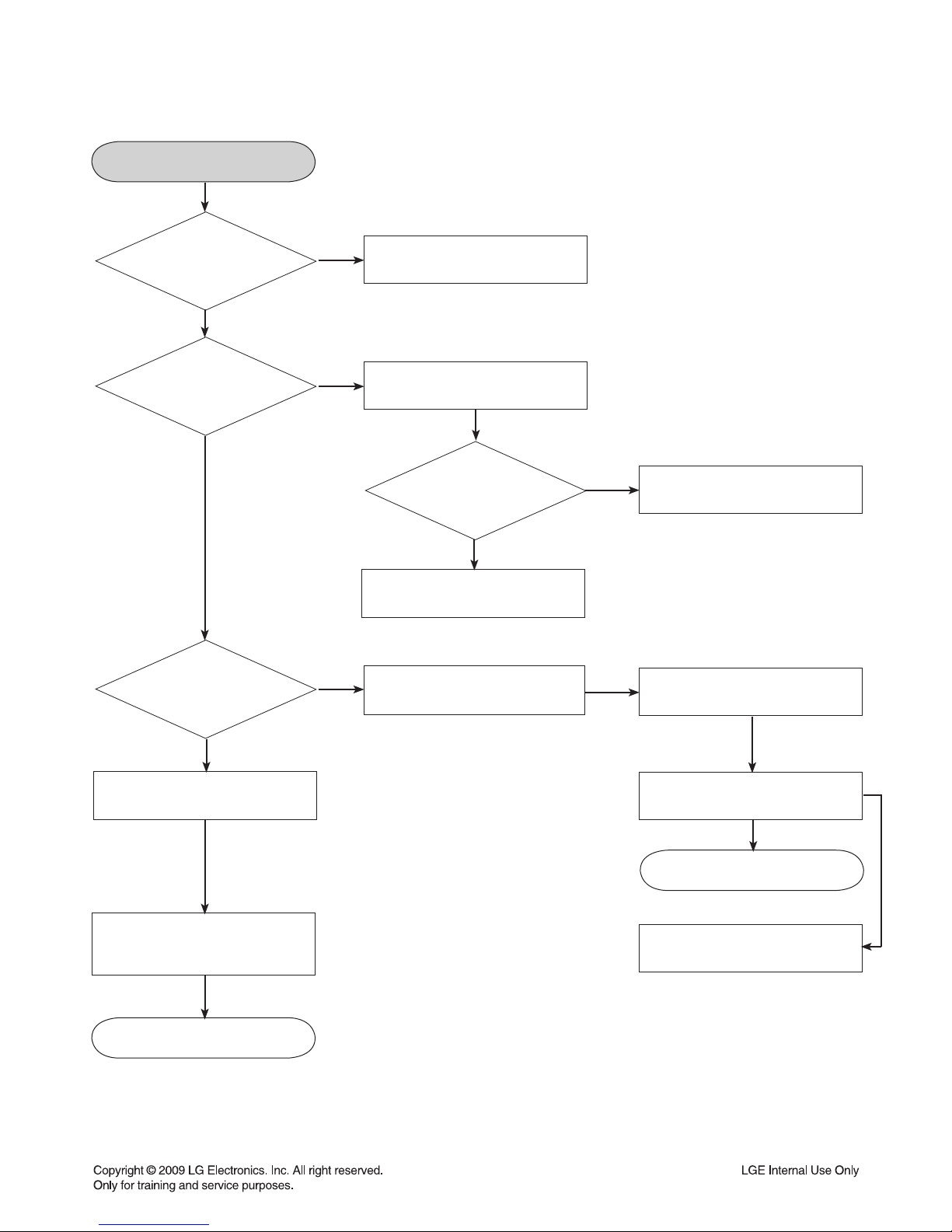

1. POWER (SMPS)

NO

Replace the fuse

YES

Check the fuse

F901

NO

Check BD901, LF901, 902

NO

Check short of P9702 line

Check short of P9701, P9702 line

NO

Check short of P9701 line

NO

Replace IC901, 902

YES

Check

the DC V of C905

if DC V is over

400V

NO

YES

Check the

DC V of C909,C903,C921

If DC V is in 14~19V

and it is steady

Check IC901, 902

YES

YES

Check the

DC V of C981,C945.

If DC V is 6.1V

YES

Check the

DC V of C950,C951

If DC V is in

26V

YES

OK

POWER (SMPS)

SECTION 3. ELECTRICAL PART

AUDIO ELECTRICAL TROUBLESHOOTIHG GUIDE

3-2

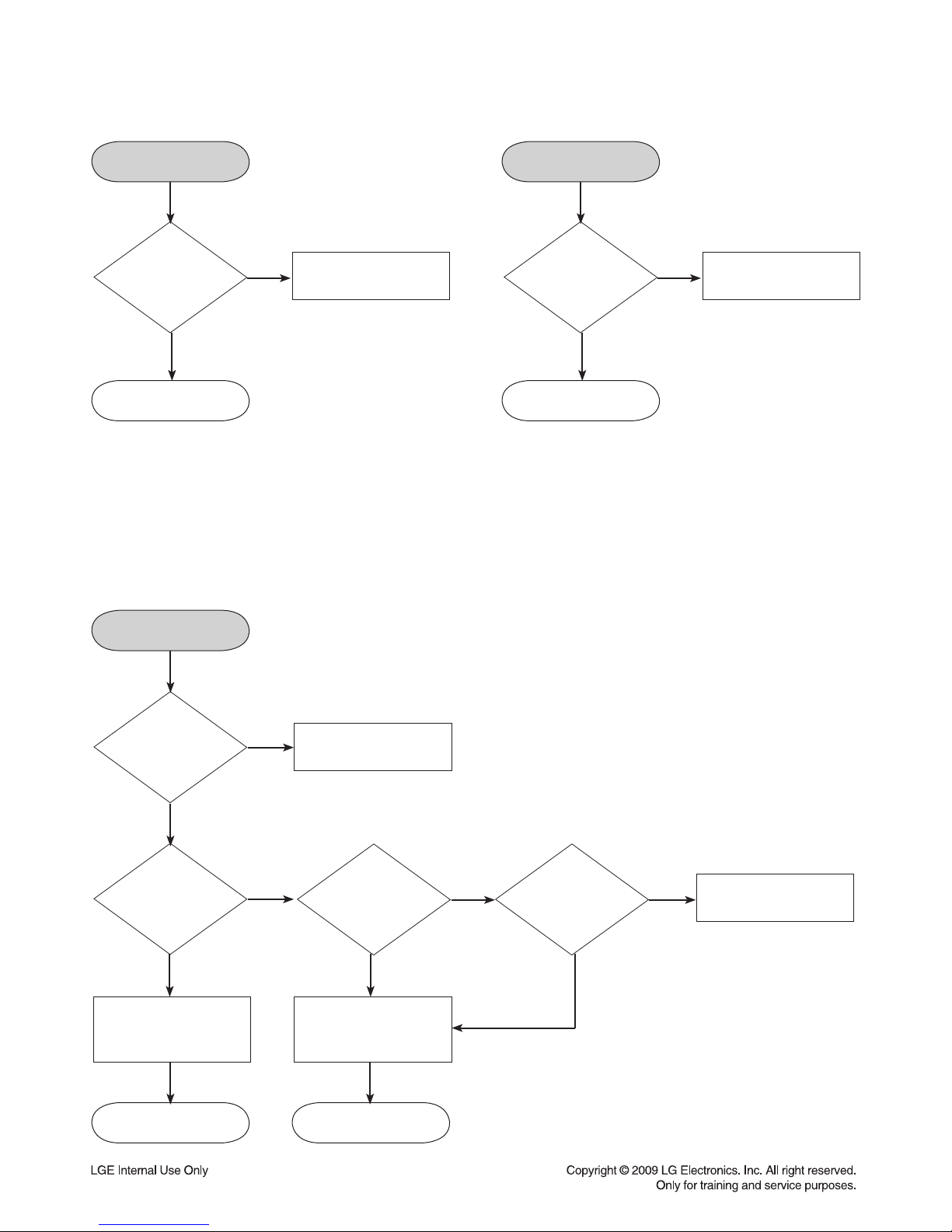

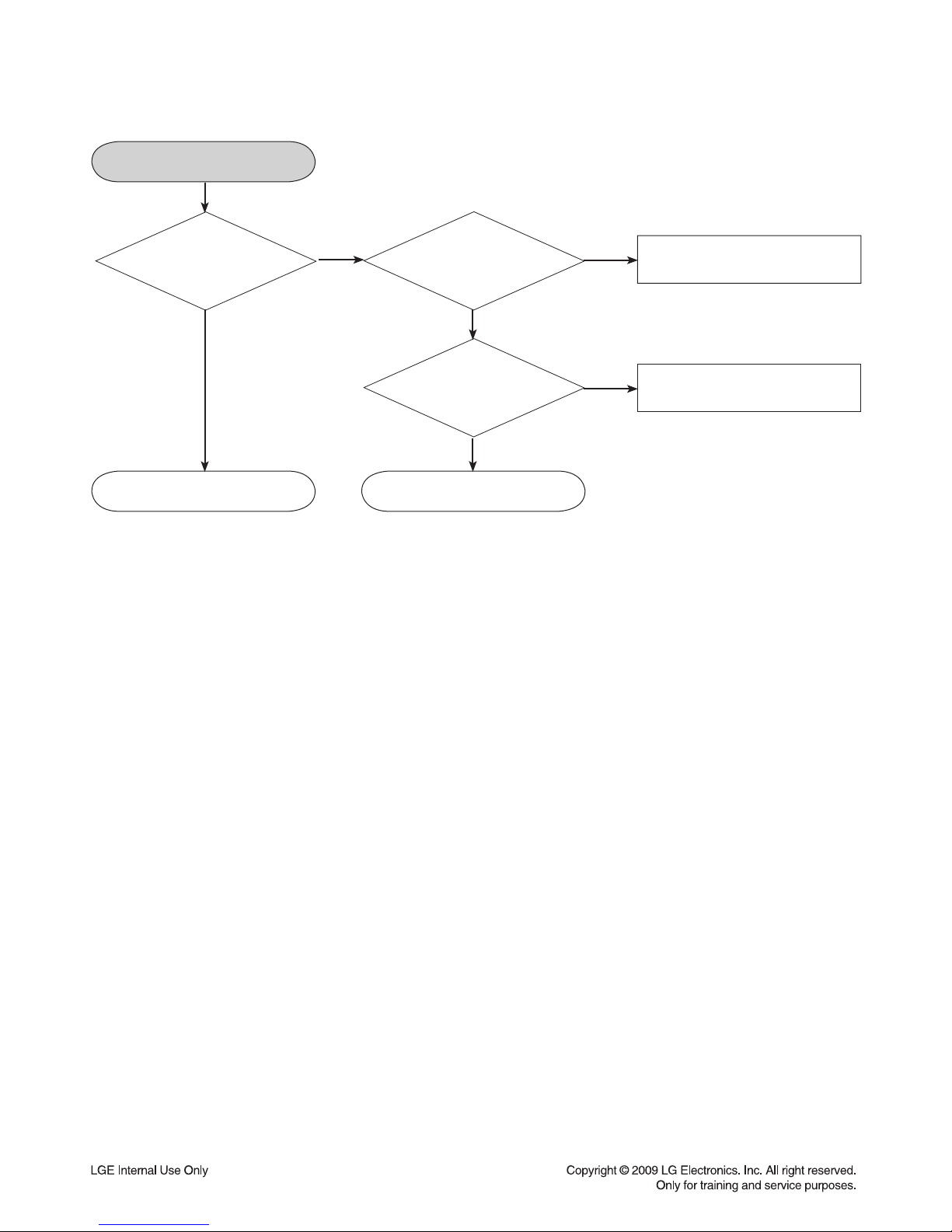

2. P-SEN 3. VKK PART CHECK

Check power circuit

troubleshooting

NO

YES

P-SENS

Check

the pin6 of P9702

if DC V is over

5.6V

YES

OK

Check power circuit

troubleshooting.

NO

YES

VKK CHECK

Check

the pin3 of P9702

if DC V is over

32V ±1

YES

OK

4. MICOM PART CHECK I

OK OK

NO

Replace the

related parts

NO

Check if output voltage

of IC101 KIA7042 is

4.3V

YES

YES

YES YES

YES YES

Check IC100

LC87F5NC8A 4pin

power

YES

Refer to SMPS

troubleshooting

MICOM PART

CHECK I

NO

Check

P7904 6pin

P-SENS

NO

Check

power of both

terminals of IC101

KIA7042

Check if

IC101 KIA7042

input is over 5V

Check the

related part of IC101

KIA7042

3-3

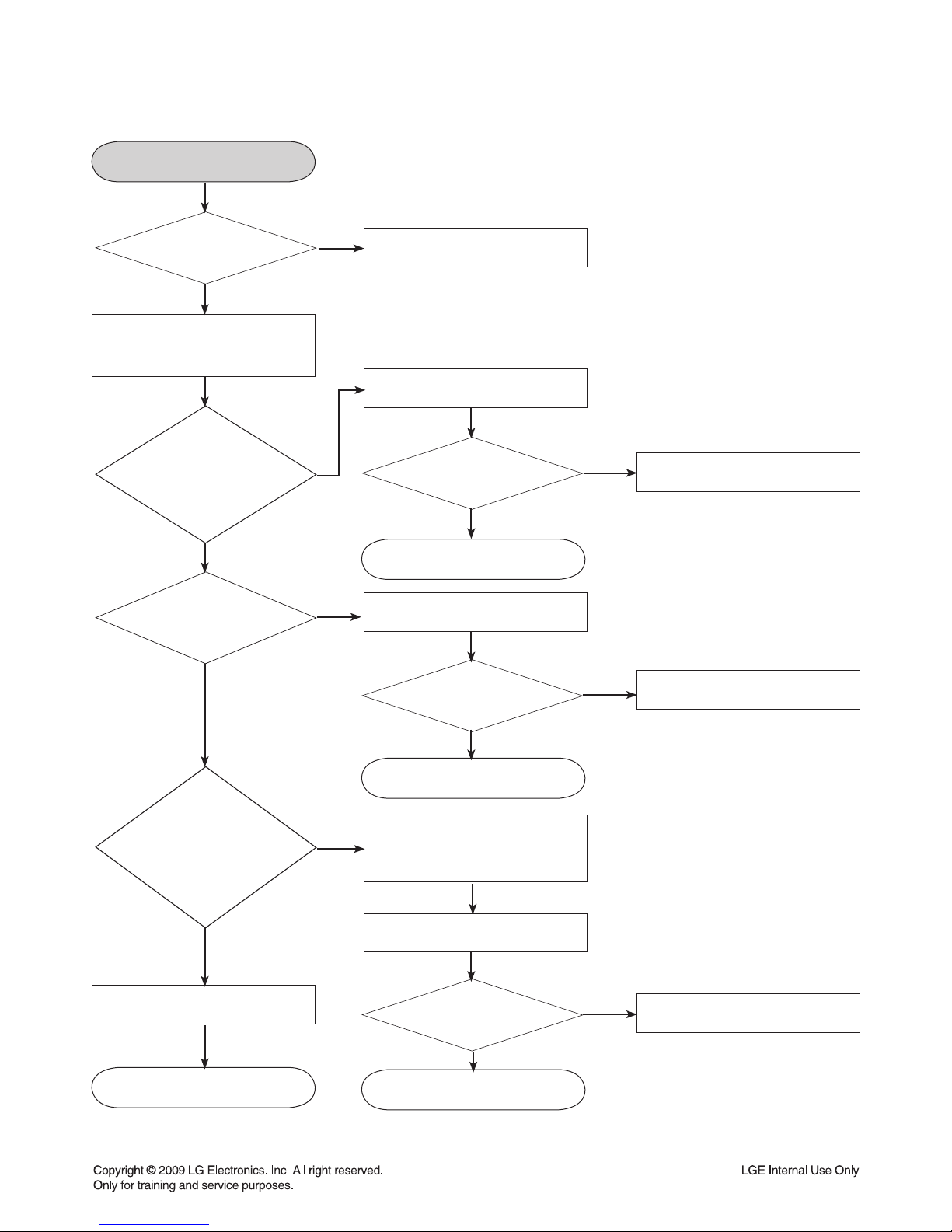

5. MICOM PART CHECK II

YES

NO

Refer to SMPS

troubleshooting

Check D101 RS1G

output is working on 5V

YES

Check IC100

14, 55, 89pin 5V

YES

YES

OK

YES

Check the related part

Replace the related parts

YES

Check the working condition

X101:32.768kHz

X100:9.8304MHz

Check P7904 5pin 5.6V

YES

NO

Check power

of both terminals of D101

RS1G

YES

NO

Check IC102

KIA7027 3pin 4V

Check the related part

MICOM PART CHECK II

NO

NO

Replace the related parts

Check IC102 1pin high

NO

Check output power of IC101

KIA7042 is over 4.3V

YES

OK

YES

OK

3-4

6. IC103 S-24CS16A01 PART CHECK

YES

YES

YES

YES

93pin DATA 94pin CLK

Check the related part

NO

Check MICOM power 5V

CHECK IC100 LC87F5NC8A

93, 94 PIN

NO

Replace the related parts

NO

Refer to micom

troubleshooting

OK OK

3-5

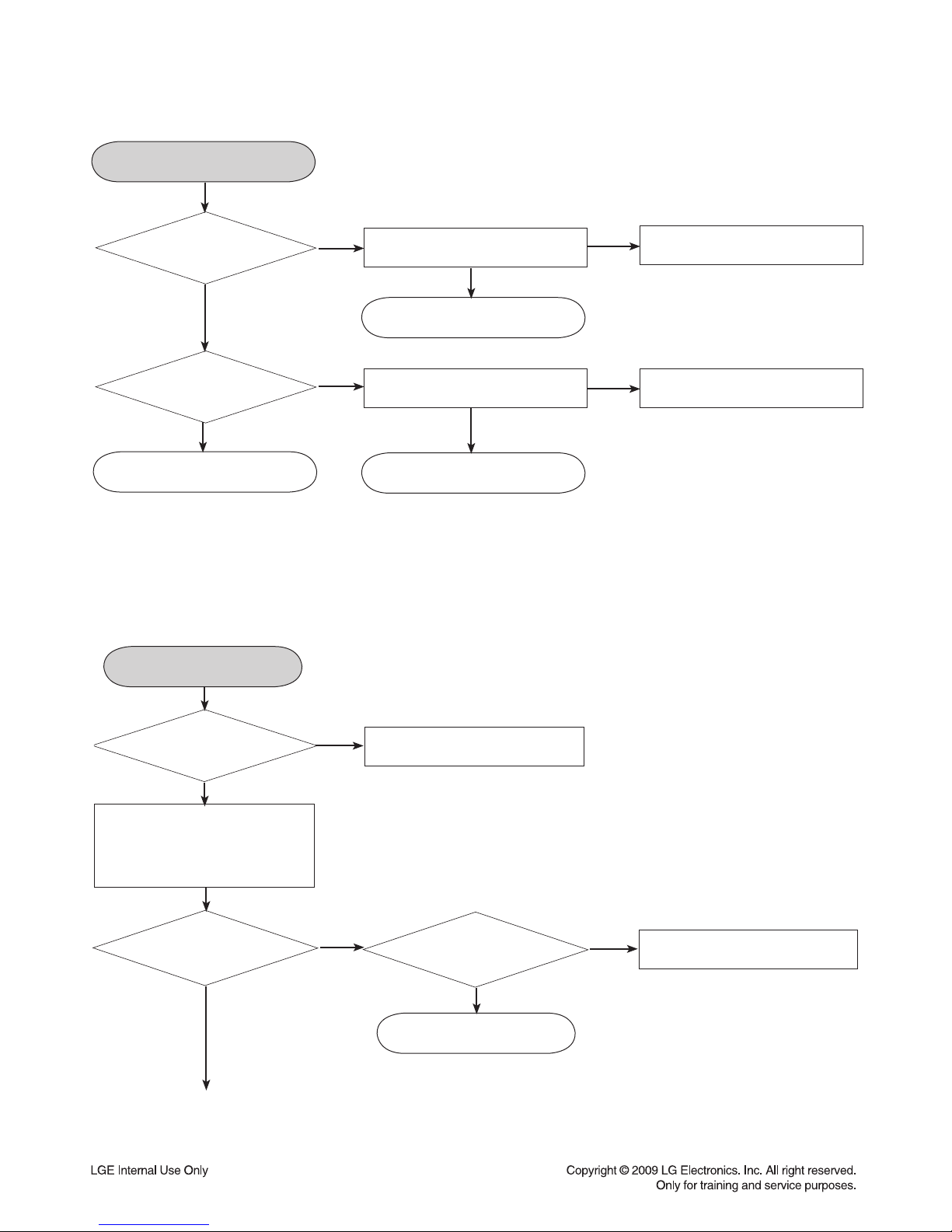

7. FLD DISPLAY PART CHECK

YES

YES

YES

YES

NO

Refer to SMPS

troubleshooting

F1+,F2-both terminals:over 4.4V

Check power VKK:over -32V

YES

FLT light on?

Check

P7904 1,2,3 power

YES

Check

P7904 connection

condition and power F1+,F2-

both terminals:over 4.4V

check power VKK:over 32V

check 5

pin

:5.6V

YES

Check

IC301 PT6302

power 48pin VKK:-32V

57pin +5V

IC100

check→IC301

data communication

pin pin

26pin→55pin DO

28pin→54pin CLK

27pin→53pin STB

5pin→52pin RST

OK

OK

NO

Replace the related part

Check P7904 assembly

YES

YES

Check

power of each pin

OK

NO

NO

NO

NO

Replace the related part

IC100 27pin→STB

28pin→CLK

check data output

Check 26 PIN→DO→DATA input

YES

YES

Check the related part

NO

Replace the related part

When 5V fails,check D303 SR35

input and output power

YES

YES

Check the related part

OK

YES

FLD DISPLAY CHECK

3-6

8. TOUCH-PAD PART CHECK

NO

NO

YES

YES

PN352 1pin 5V

NO

Replace the related part

NO

Refer to SMPS

troubleshooting

Check resistance output of

line CLK:R128 DATA:R126

IC305

28pin check 5V

Check

IC305 13pin, 11pin,

IC100 96pin:CLK,

95pin:DATA

TOUCH-PAD CHECK

YES

OK

YES

OK

YES

OK

9. PWM MODULATION PART CHECK

Check

P7905 9,10pin 3.3V

PWM MODULATION

PART CHECK

Refer to SMPS

troubleshooting

NO

Check if X701

12.288MHz is working

YES

YES

YES

YES

Check IC604 PS9831 VDD

pin power (4,10,22,29,39,47,

56,65,72,87,94) check X601

2pin 3.3V

Replace the related part

NO

YES

Check the

related part of

X701

OK

NO

Loading...

Loading...