LG MFL65003102 Installation Manual

INSTALLATION MANUAL

AIR CONDITIONER

• Please read this installation manual completely before installing the product.

• Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

• Please retain this installation manual for future reference after reading

it thoroughly.

P/NO : MFL65003102

www.lg.com

TYPE: Vertical Air Handling Unit

ENGLISH FRANÇAIS ESPAÑOL

2 Vertical Air Handling Unit

Installation Manual 3

ENGLISH

Vertical Air Handling Unit Installation Manual

TABLE OF CONTENTS

❏ Four type "A" screws

❏ Pipes: Gas side

Liquid side (Refer to

Product Data)

❏ Insulation materials

❏ Additional drain pipe

❏ Level gauge

❏ Screw driver

❏ Electric drill

❏ Hole core drill

❏ Hexagonal wrench

❏ Gas-leak detector

❏ Vacuum pump

❏ Gauge manifold

❏ Owner's manual

❏ Thermometer

❏ Electric Heater installation

manual

Features ......................................4

Accessories ..............................4

Duct Connection Dimensions ..5

Safety Precautions....................6

Installation ..................................8

Selection of the best location ...8

Upflow Installation ....................9

Duct work................................10

Horizontal-left Installation .......11

Connecting Pipes to the Indoor

Unit ..........................................12

Preparation of Piping..............12

Insulation.................................15

Condensate Drain ..................16

Wiring Connection..................18

Installation of Wired Remote

Controller ................................20

Name and function of wired

remote controller(Accessory).22

Name and function of wireless

remote controller(Accessory).23

Electric Heater ........................24

Dip Switch Setting of Indoor unit

PCB.........................................25

Group Control Setting ............26

How to Set E.S.P? ...................30

Product Data ............................32

External Static Pressure & Air

Flow.........................................32

Minimum airflow by heater

capacity...................................33

Electric Heater Static pressure

drop factors.............................33

Air Filter (Field supply) Static

pressure drop factors .............34

Installation Requirements

Required Parts Required Tools

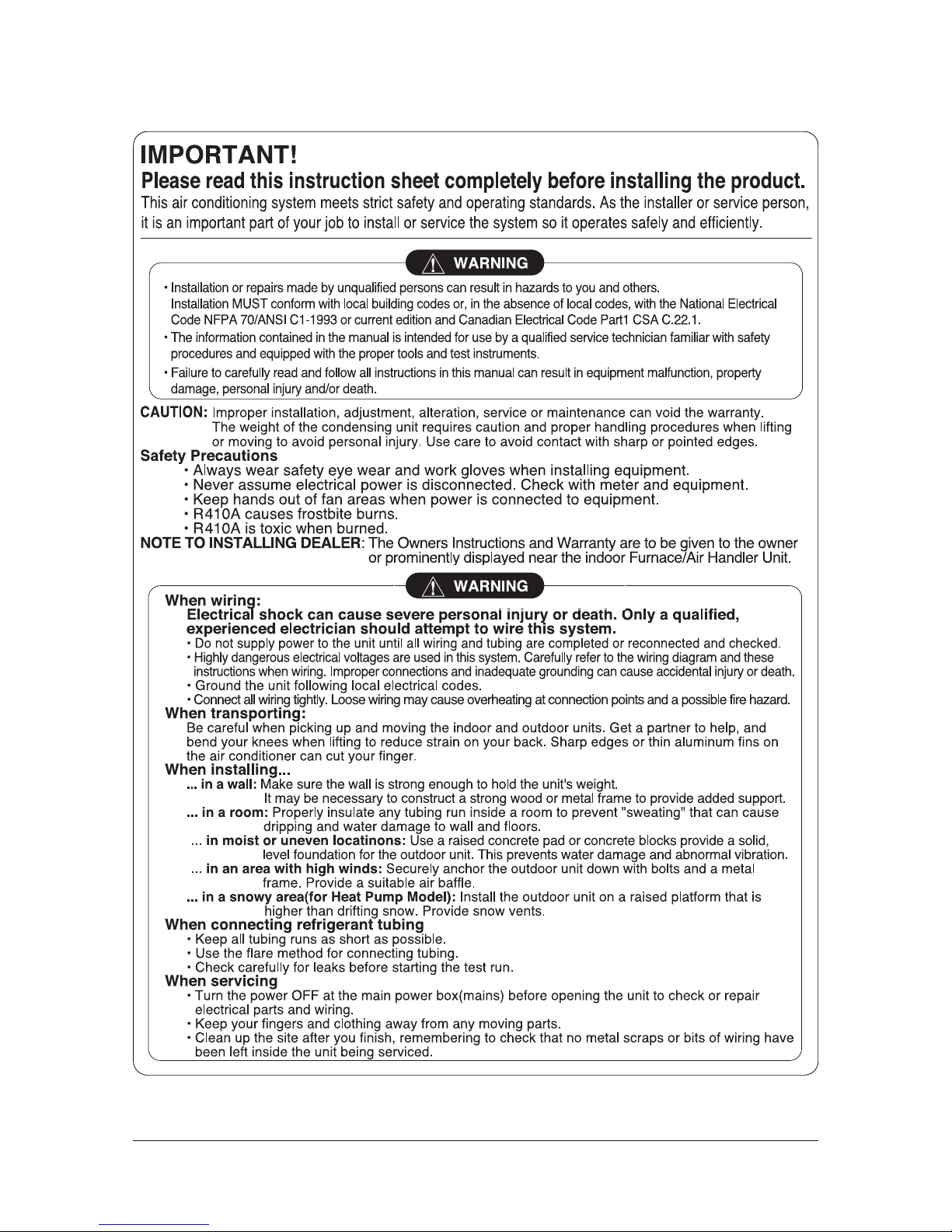

Wiring knockouts

for conduit

Wiring knockouts

for conduit

Refrigerant

connections

Drain connections

for horizontal

application

Filter access

Drain connections for

upflow application

Feature

Accessories

Accessory Model Name

Wired remote controller

PQRCVSL0 (Black Color)

PQRCVSL0QW (White Color)

Wireless remote controller

PQWRCDF0 (Heat pump)

PQWRHDF0 (Cooling only)

Electric heater

ANEH053B1

ANEH103B2

ANEH153B2

ANEH203B2

4 Vertical Air Handling Unit

Features

ENGLISH

Feature

Installation Manual 5

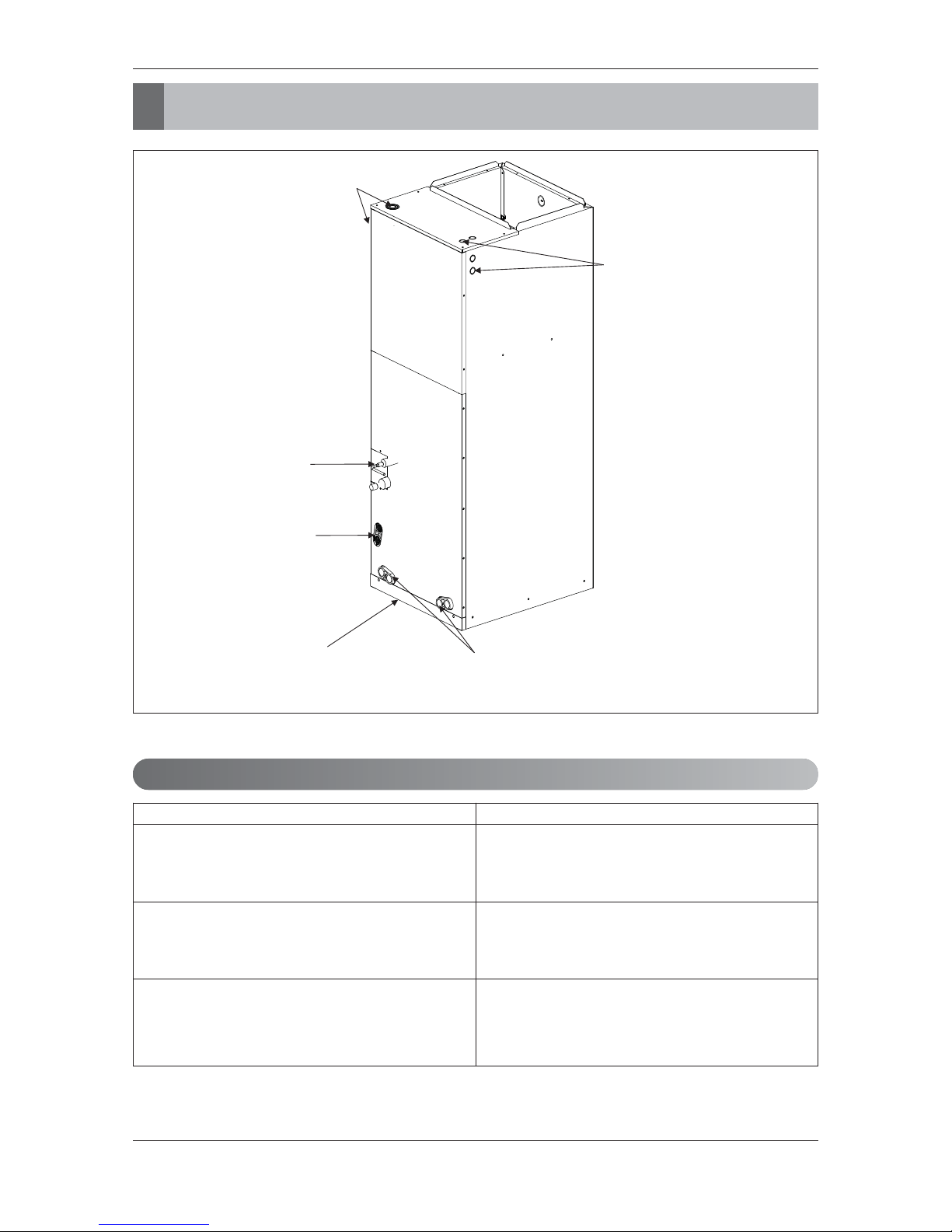

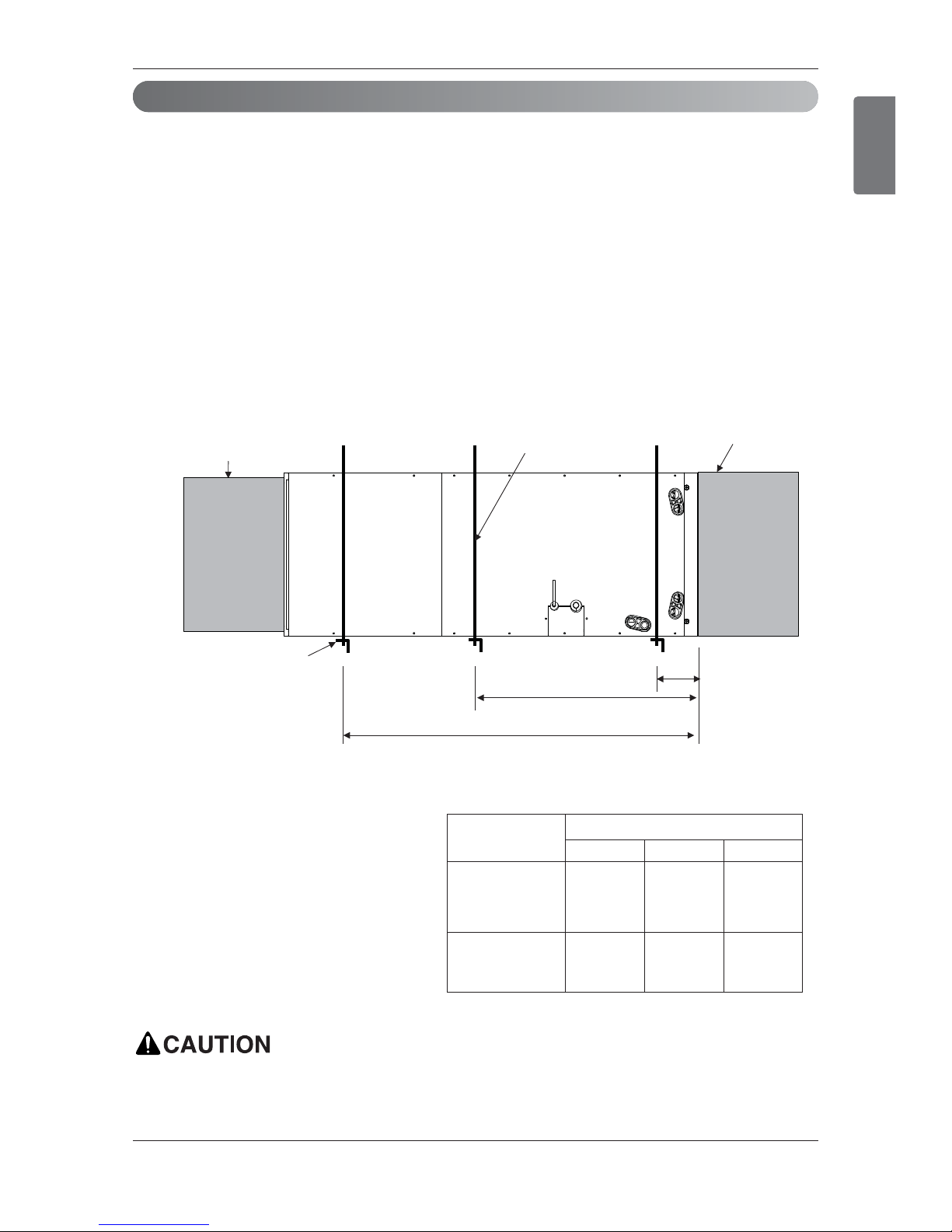

Duct Connection Dimensions

<Top>

<Front>

<Bottom>

<Side-right>

Refrigerant

connections

Drain connections

for horizontal

application

Drain

connections

for upflow

application

Air filter cover

(Unit: inch(mm))

Capacity

(kBtu/h (RT))

Dimensions

Wiring

Knock out

Refrigerant

Connections

Pipe size

A B C

D E F G H

I J

Height Width Depth Power

Commu

nication

Liquid Gas

18(1.5)

48-5/8

(1236)18(457)

21-3/8

(540)

1-9/16

(40)

17-1/2

(445)20(530)17(432)

12-1/8

(308)

1-11/16

(43)

7/8

(22)

1/4

(6.35)

1/2

(12.7)

24(2.0)

30(2.5)

36(3.0)

48-5/8

(1236)18(457)

21-3/8

(540)

1-9/16

(40)

17-1/2

(445)20(530)17(432)

12-1/8

(308)

1-11/16

(43)

7/8

(22)

3/8

(9.52)

5/8

(15.88)

42(3.5)

48(4.0)

54(4.5)

55-1/8

(1401)25(635)

21-3/8

(540)

1-9/16

(40)

24-1/2

(623)20(530)24(610)

12-1/8

(308)

1-11/16

(43)

7/8

(22)

3/8

(9.52)

5/8

(15.88)

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

■ Be sure to read before installing the air conditioner.

■ Be sure to observe the cautions specified here as they include important items related to safety.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the

following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

Do not use a defective or

underrated circuit breaker.

Use this appliance on a dedicated circuit.

• There is risk of fire or electric

shock.

For electrical work, contact

the dealer, seller, a qualified

electrician, or an Authorized

Service Center.

• Do not disassemble or repair

the product. There is risk of

fire or electric shock.

Always ground the product.

• There is risk of fire or electric

shock.

Install the panel and the

cover of control box securely.

• There is risk of fire or electric

shock.

Always install a dedicated

circuit and breaker.

• Improper wiring or installation

may cause fire or electric

shock.

Use the correctly rated breaker or fuse.

• There is risk of fire or electric

shock.

Do not modify or extend the

power cable.

• There is risk of fire or electric

shock.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and

wet or damage furniture.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause

injury. Be especially careful of

the case edges and the fins

on the condenser and evaporator.

6 Vertical Air Handling Unit

■ Installation

Always check for gas (refrigerant) leakage after installation or repair of product.

• Low refrigerant levels may

cause failure of product.

Install the drain hose to

ensure that water is drained

away properly.

• A bad connection may cause

water leakage.

Keep level even when

installing the product.

• To avoid vibration or water

leakage.

Do not install the product

where the noise or hot air from

the outdoor unit could damage the neighborhoods.

• It may cause a problem for your

neighbors.

Use two or more people to lift

and transport the product.

• Avoid personal injury.

Do not install the product

where it will be exposed to

sea wind (salt spray) directly.

• It may cause corrosion on the

product. Corrosion, particularly on

the condenser and evaporator

fins, could cause product malfunction or inefficient operation.

If you eat the liquid from the

batteries, brush your teeth and see doctor. Do

not use the remote if the batteries have leaked.

• The chemicals in batteries could cause burns or

other health hazards.

Safely dispose of the packing materials.

• Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.

• Tear apart and throw away plastic packaging bags

so that children may not play with them. If children

play with a plastic bag which was not torn apart,

they face the risk of suffocation.

Safety Precautions

■ Operation

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric

shock, explosion, or injury.

Do not install the product on

a defective installation stand.

• It may cause injury, accident,

or damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air

conditioner could fall with it,

causing property damage,

product failure, and personal

injury.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

ENGLISH

Installation Manual 7

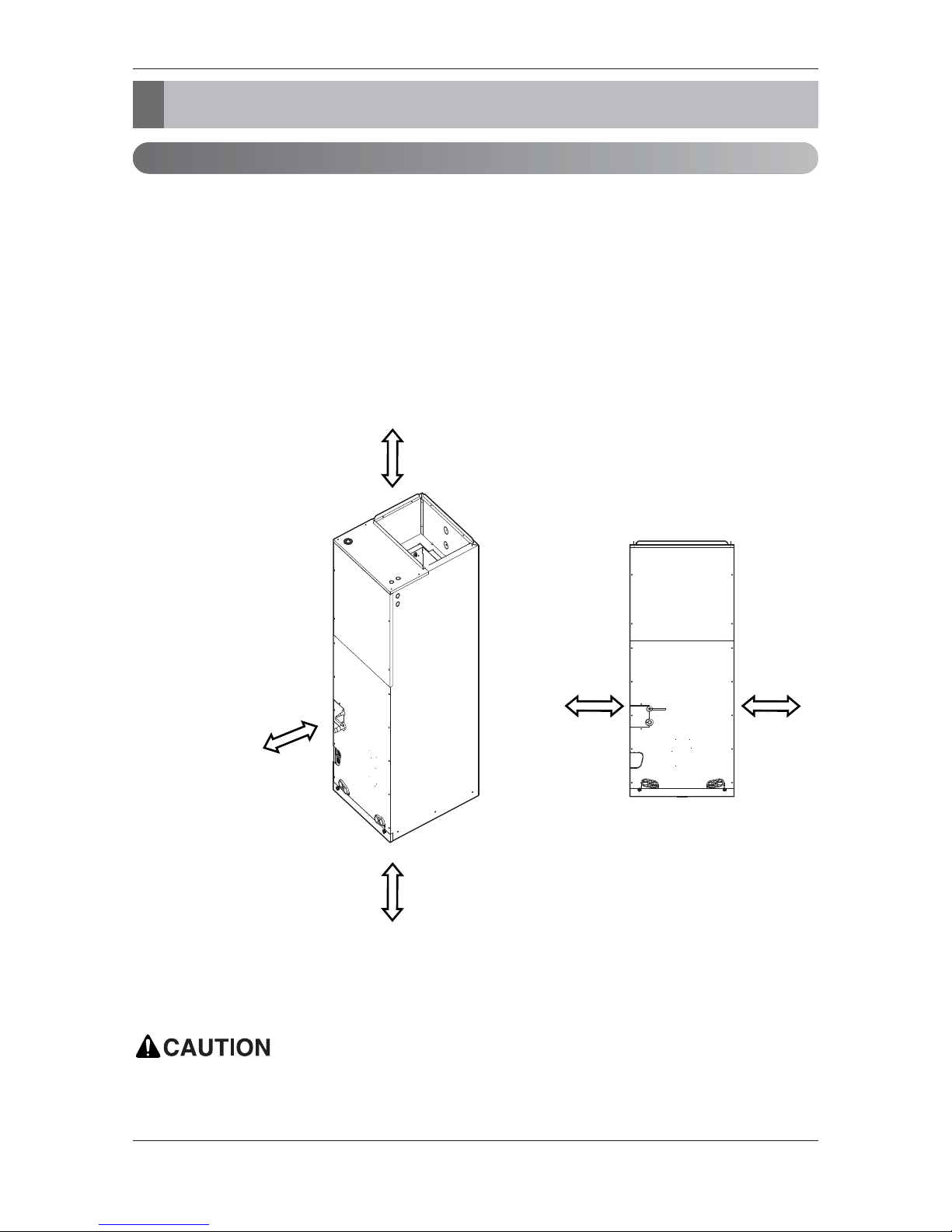

Installation

• Where optimum air distribution can be ensured.

• Where nothing blocks air passage and install the duct work.

• Where condensate can be properly drained.

• Where the ceiling is strong enough to bear the indoor unit weight.

• Where the false ceiling is not noticeably on an incline.

• Where sufficient clearance for maintenance and service can be ensured.

• Where piping between indoor and outdoor units is possible within the allowable limit. Refer to the

installation manual for the outdoor unit.

• Vertical Air Handling Unit can be installed for upflow and horizontal-left positions.

NOTE : The primary and secondary drain line must be trapped to allow proper drainage of condensate

water, If the secondary drain line is not used, it must be capped.

Selection of the best location

More than 23-5/8 inch

(600 mm)

clearance from

access panels

for Service

More than

10 inch

(250mm)

More than

10 inch

(250mm)

More than 14 inch

(350 mm)

More than 14 inch

(350 mm)

In the case of sea coast installation, salt residue may cause corrosion of cabinet and component

parts. Please take appropriate anti-corrosion measures.

8 Vertical Air Handling Unit

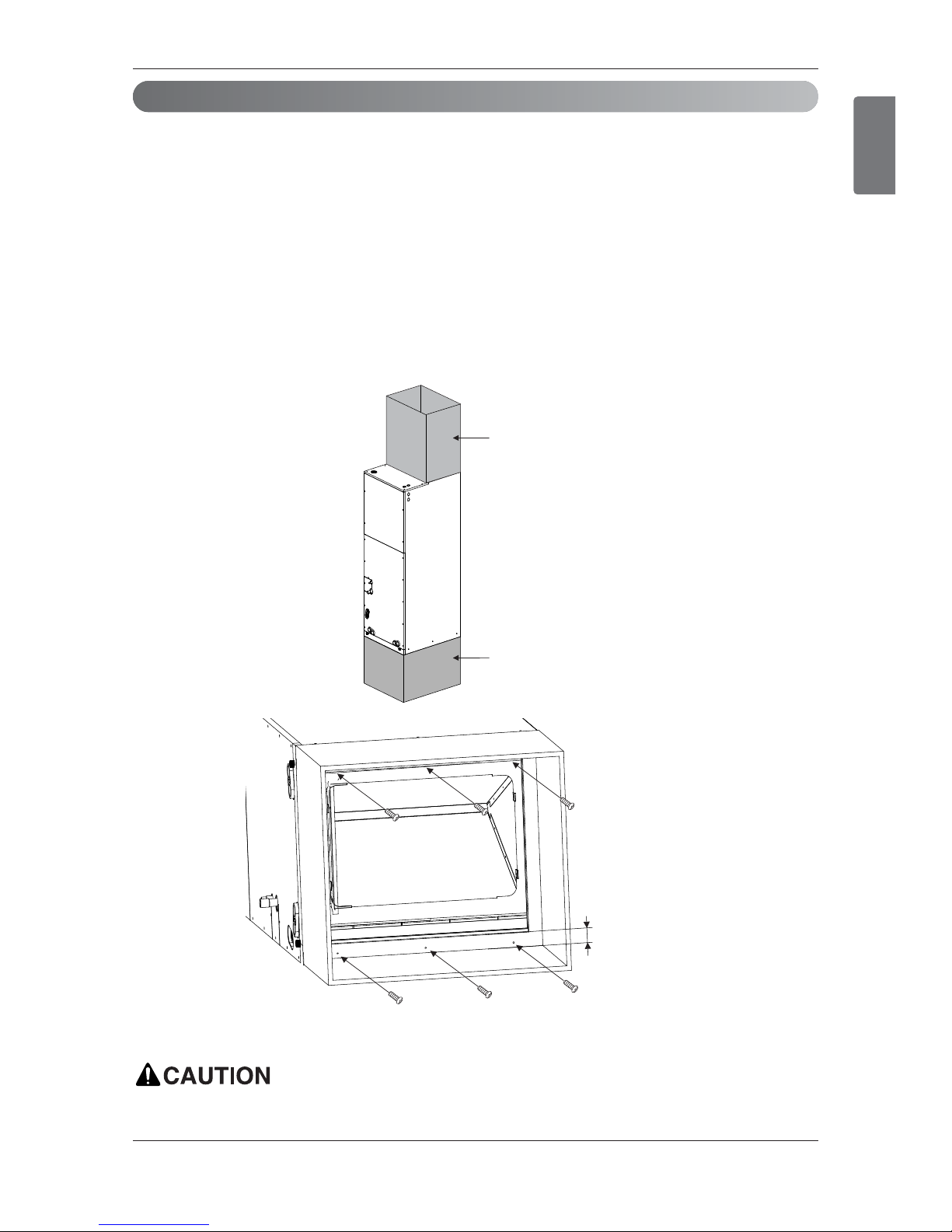

Installation

• Position unit for plenum installation.

• The plenum should be secured in order to support the installation of adapter callers accommodate the

installation of any duct work.

• Seal all duct work according to local codes to prevent air leakage. Ensure that filter access is unobstructed.

• The air handler support platform should be sturdy enough to support the cabinet plus any accessory

components including filter box.

• The minimum height clearance is 14inches(350mm) to maintain proper air flow.

• Vibration isolators (purchased locally) must be placed between the unit and the pedestal.

• An illustration showing an example of where a vibration isolator should be added would clarify what

the installing contractor should do to properly position the isolator.

More than 6 screws (M4*25L)

Field

Supplied Return

Plenum

More than

1inch (25mm)

Field Supplied

Supply Duct

Installation

Upflow Installation

Do not connect the screws on Front and Rear side, it may cause the filter can not be mounted.

ENGLISH

Installation Manual 9

10 Vertical Air Handling Unit

Installation

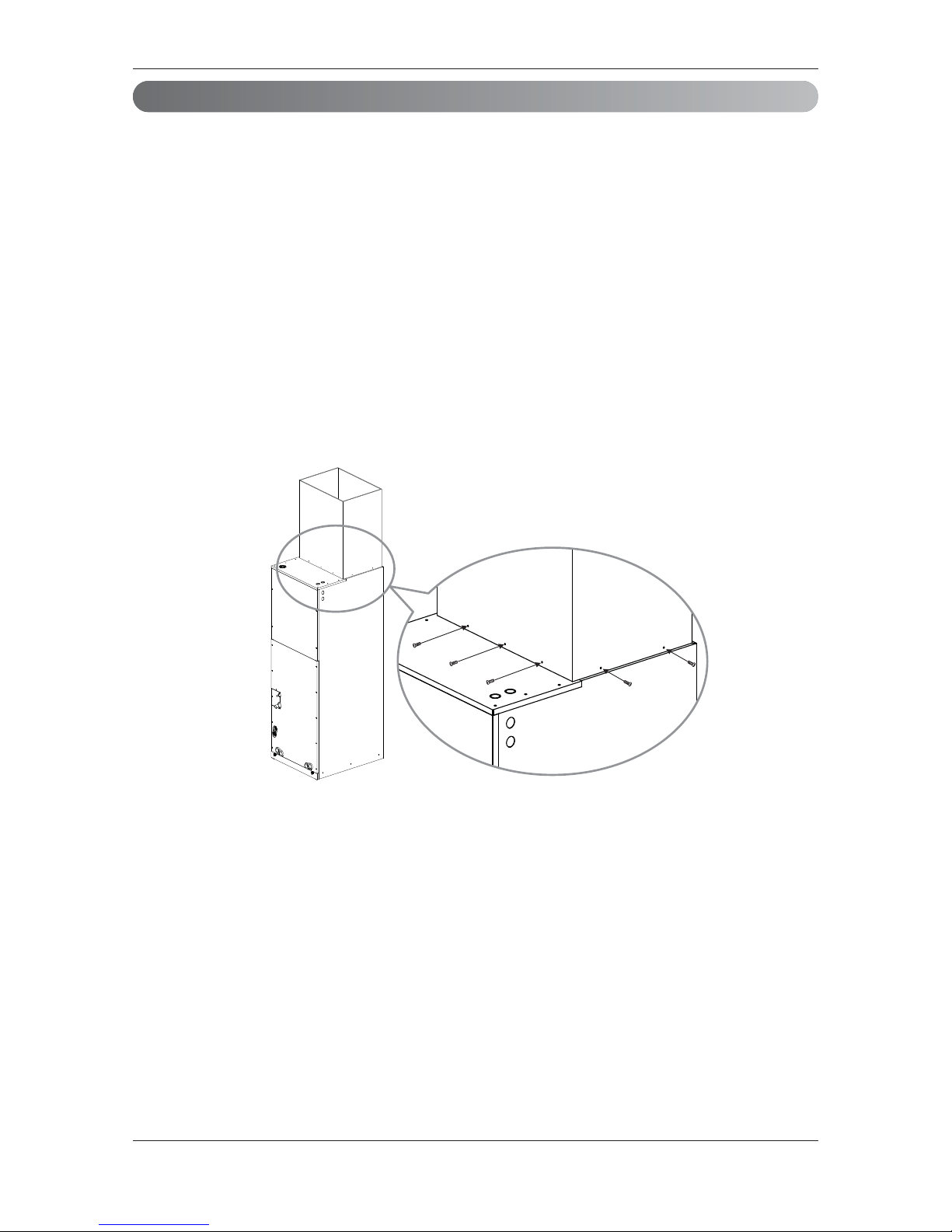

Duct work

• Over 10 screws should be used for joining supply duct with the unit.

• To prevent vibration transmission, exploit flexible connectors between duct and the unit. It is mandatory that the flexible connector between unit and duct at discharge connection should be made off heat

resistive material when electric heater is installed.

• Duct work must be insulated and covered with vapor barrier when routed through unconditioned

space.

• Internal acoustical insulation lining may necessary for the metal duct system if it do not have 90°

elbow and 10ft. of main duct to first branch takeoff.

• It is advised that a fibrous duct work could be used as a substitute if built and installed in accordance

with the most recent edition of SMACNA construction standard on fibrous glass ducts.

• Collectively fibrous duct work and acoustical lining shall obey National Fire Protection Association

standards 90A or B as tested by UL standard 181 for class 1 air ducts.

• Seal around the delivery duct subsequent to when the duct is secured so that to facilitate prevention

of air leakage.

More than 10 screws

(M4*25L)

Installation Manual 11

ENGLISH

• It is particular that the units should not be installed in such a manner that the access panels facing up

or down

• It should be confirmed that the installation is in accordance with all relevant building codes that may

necessitate installation of external condensate pan.

-Set up a support for unit by locating it in or above external condensate pan.

• Angle steel support brackets with threaded rods which supporting the units from the underside should

be used as shown in the figure below if the units are suspended.

• If not suspended then also it should be supported as same as mentioned above and also carefully

isolated to avoid sound transmission. The size of the support should comparatively bigger than the

unit and the unit must be place at centre of the support.

• Locally available vibration isolators must be placed between the unit and the support.

• The same installation method of up flow type has to be used in the case of Return Plenum and supply duct.

Installation

Horizontal-left Installation

To ensure proper drainage for horizontal installations, unit must be installed so it is within 1/8” level of

the length and width of unit.

B

A

C

More than 1-1/2

inch(38 mm) X 1-1/2

inch(38 mm) angle

Recommended

length more than 26

inch(660 mm) with

2 inch(50 mm)

clearance on both

sides of unit

More than 3/8 inch

(9.5mm) threaded rod

Field Supplied

Supply Duct

Field Supplied

Return Plenum

Suspension support locations

Caapcity

(kBtu(RT))

Dimension

ABC

18(1.5)

24(2.0)

30(2.5)

36(3.0)

4(100) 23(580)

41-1/2

(1050)

42(3.5)

48(4.0)

54(4.5)

4(100) 29(730) 48(1220)

(Unit : inch(mm))

Loading...

Loading...