Page 1

LCD MONITOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MF-02HA

MODEL : MW-30LZ10

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Aug., 2002

Printed in KoreaP/NO : 3828VD0120B

Page 2

- 2 -

CONTENTS

Contents .................................................................................................. 2

Safety Precautions ..................................................................................3

Adjustment Instruction ............................................................................4

Troubleshooting .......................................................................................6

Printed Circuit Board ...............................................................................7

Block Diagram.........................................................................................11

Exploded View ...................................................................................... 16

Exploded View Parts List.......................................................................17

Replacement Parts List ........................................................................ 18

SVC. Sheet .................................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

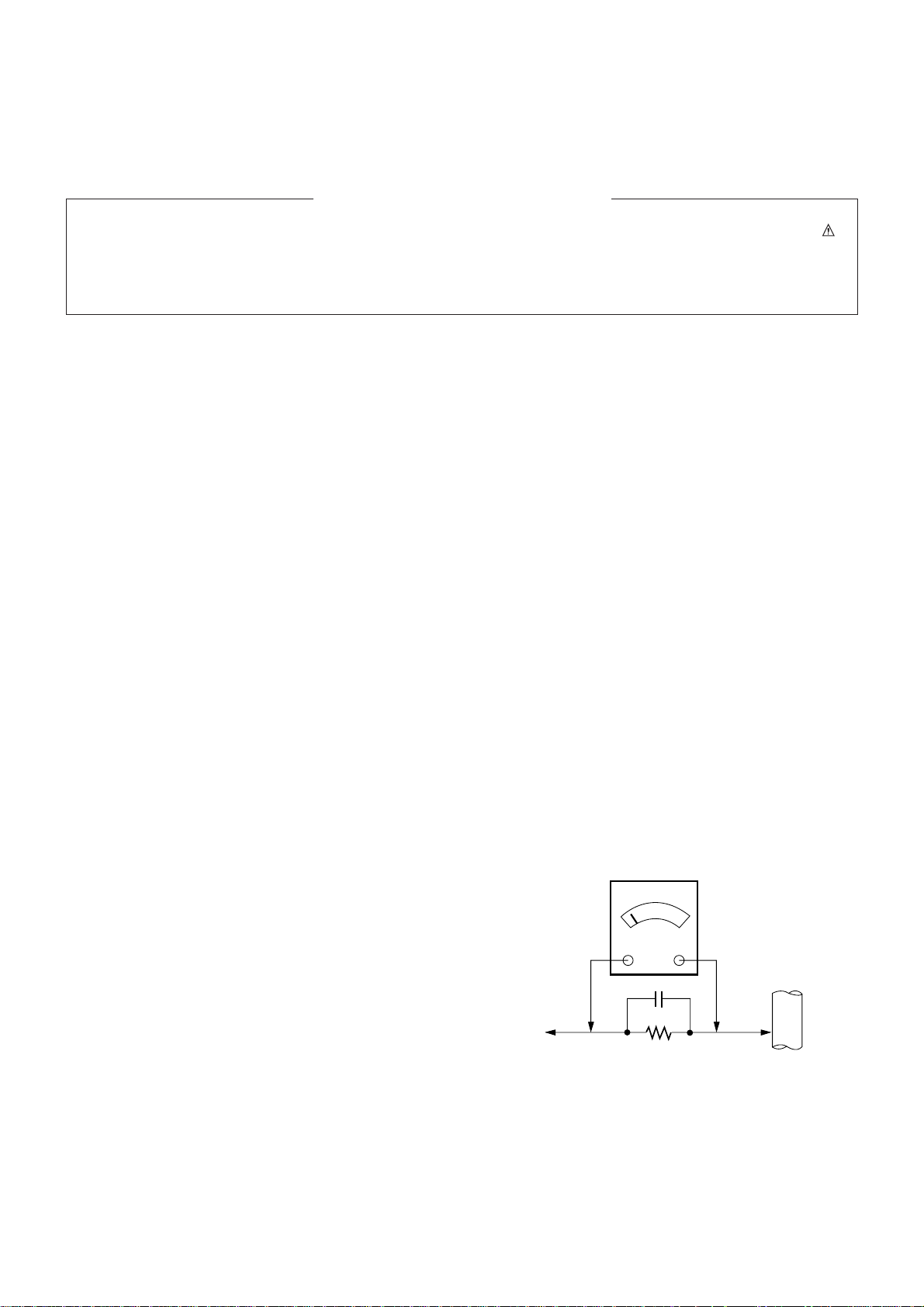

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

1. Application Object

These instructions are applied to all of the MODELS of LCD

MONITOR, MF-02HA.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order. But, it can

be changed in consideration of mass production.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220V, 60Hz in

adjusting.

[ Input voltage is possible from 85V to 260V because the

power voltage applied to this chassis is Wide-Range. But,

adjustment should be operated in 220V/60Hz if there is no

specific designation.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

¤ After receiving 100% white pattern(06CH), the receiver

must be operate prior to adjustment.(Or white condition

in HEAT-RUN mode)

¤ŁEnter into HEAT-RUN mode

- Select HEAT RUN OFF by pressing ADJ button on

Remote Control for adjustment.

- Press the VOL + button in HEAT-RUN OFF.

(OSD displays HEAT-RUN WHITE and screen

displays 100% full WHITE PATTERN)

[ Set is activated HEAT-RUN without signal generator

in this mode.

[ Single color pattern of HEAT-RUN mode can be used

to check PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes

(especially, Digital pattern[13 CH], Cross Hatch

Pattern[09CH]), a afterinage may be occur in the black

level part of the screen.

3. Adjustment Items

3-1. Whole Assembly Adjustment

(1) White Balance Adjustment

(2) SUB-BRIGHT Adjustment : Sub-Bright adjustment in LCD

panel is not necessary. Do not adjust sub-bright if there is

no specific designation.

(3) RGB CUT-OFF Adjustment : Under examination about

auto adjustment which correspond to the new Rembrandt1A.

3-2. EDID (The Extended Display

Identification Data) Adjustment

(1) This is the function that is made for the realization of “Plug

and Play” which makes possible to use the user

environment right after reorganization by communicating

with monitor automatically.

(2) EDID DATA for DVI of MF-02HA

EDID table =

00 01 02 03 04 05 06 07 08 09

_________________________________

000 | 00 FF FF FF FF FF FF 00 1E 6D

010 | D7 3A 01 01 01 01 33 0B 01 01

020 | 81 40 26 96 08 B7 FB A1 56 48

030 | 98 24 13 48 4B AF EF 00 81 00

040 | 31 59 45 59 61 59 81 80 71 4F

050 | 01 01 01 01 BC 34 00 98 51 00

060 | 2A 40 10 90 13 00 40 26 00 00

070 | 00 1E 00 00 00 FC 00 4D 57 20

080 | 33 30 4C 5A 31 30 0A 20 20 20

090 | 00 00 00 FD 00 3C 78 1F 5B 10

100 | 00 0A 20 20 20 20 20 20 D5 09

110 | 80 A0 20 E0 2D 10 10 60 A2 00

120 | EE F0 75 00 00 18 00 BD

(3) EDID DATA for RGB of MF-02HA

EDID table =

00 01 02 03 04 05 06 07 08 09

__________________________________

000 | 00 FF FF FF FF FF FF 00 1E 6D

010 | D7 3A 01 01 01 01 33 0B 01 01

020 | 1E 40 26 96 08 B7 FB A1 56 48

030 | 98 24 13 48 4B AF EF 00 81 00

040 | 31 59 45 59 61 59 81 80 71 4F

050 | 01 01 01 01 BC 34 00 98 51 00

060 | 2A 40 10 90 13 00 40 26 00 00

070 | 00 1E 00 00 00 FC 00 4D 57 20

080 | 33 30 4C 5A 31 30 0A 20 20 20

090 | 00 00 00 FD 00 3C 78 1F 5B 10

100 | 00 0A 20 20 20 20 20 20 D5 09

110 | 80 A0 20 E0 2D 10 10 60 A2 00

120 | EE F0 75 00 00 18 00 BD

(4) Refer to Service Manual related to EDID communication.

4. Whole Assembly Adjustment

<Caution> Each PCB Assy must be checked by Check JIG Set

before assemling.(Be careful about power PCB ASSY

which can give a fatal damage to the LCD Module)

4-1. White Balance Adjustment

(1) Required Equipment

Color analyzer(CA-100 or same production)

ADJUSTMENT INSTRUCTION

Page 5

- 5 -

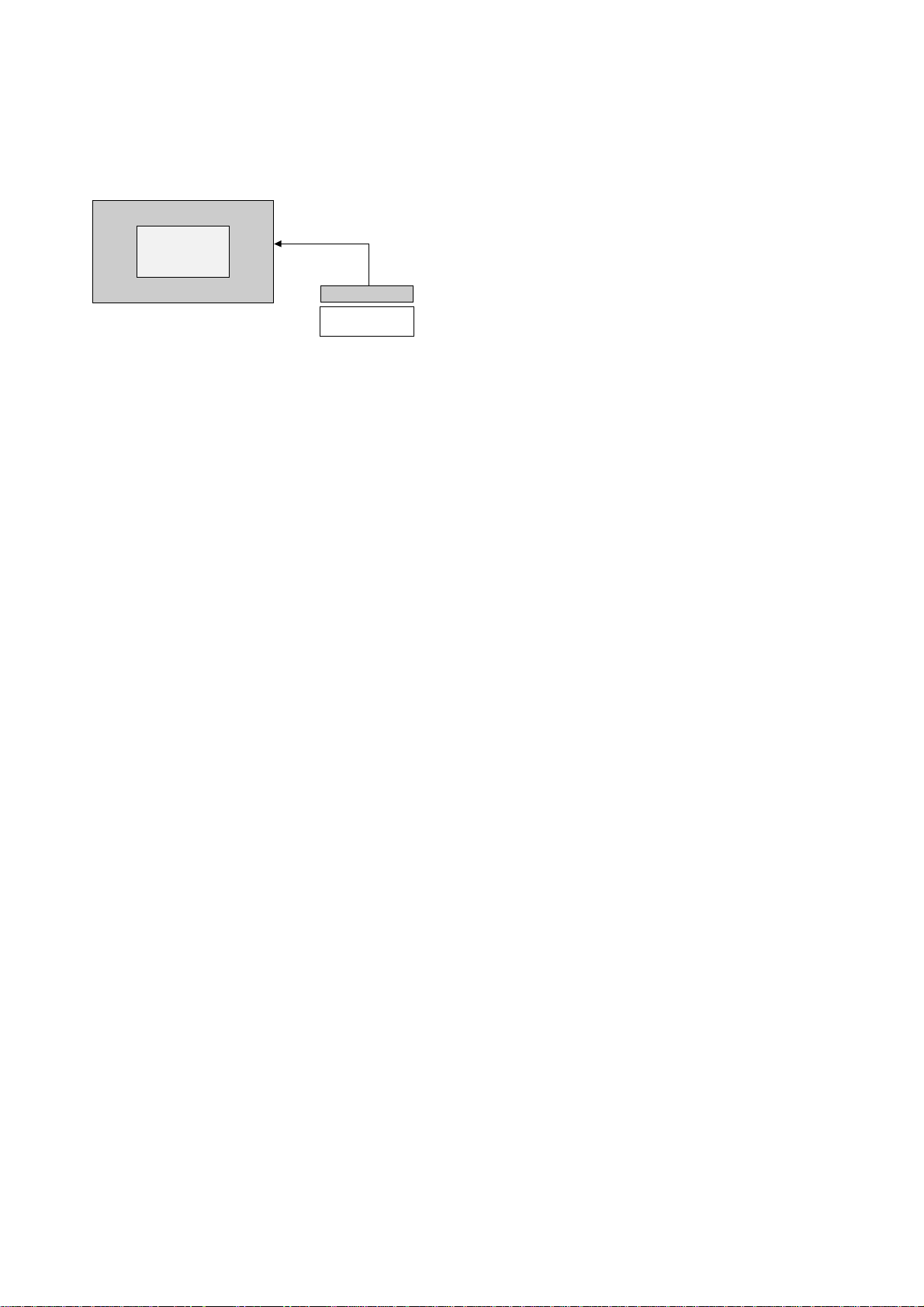

(2) Connection Diagram of Equipment for

Measuring (Automatic Adjustment)

Connect RS-232C to Adjustment Equipment and SET.

Automatization operating room has in charge of managing and

repairing about adjusting equipment.

Only adjust HIGH LIGHT and RGB input adjusts R-GAIN/GGAIN/B-GAIN automatically.

Automatic adjustment equipment decides the values of RGAIN/G-GAIN/B-GAIN by correcting color coordinates/white

balance and transmits them into SET and finally the SET

saves data values.

(3) White Balance Adjustment(Manual Adjustment)

¯ Operate Zero Calibration of CA-100 and Sensor must be

stick completely to the surface of LCD module

¯ Devide Manual adjustment into AV/PC and operate

adjustment by the following sequence.

¯ Manual adjustment is a temporary method when automatic

adjustment is not correspondent.

1. AV W/B adjustment

1) Select WHITE PATTERN of HEAT RUN mode by

pressing ADJ button on Remote Control for adjustment

then operate HEAT RUN more than 15 minute

2) Supply pattern signal for WB adjustment in pattern

generator. (AV INPUT)

3) Low Light has no special adjustment.

4) To adjust High Light, stick sensor to 2th pattern(White),

select and adjust the AV GAIN by pressing INSTSRT

button on Remote Control for adjustment.

After select the R GAIN and G GAIN, enter Adjustment

Mode by pressing ENTER button and press the VOL +/Key and adjust it until color coordination becomes (B

GAIN is fixed)

color coordination : X=0.283±0.003, Y=0.296±0.003

color temperature : 9,350°K ± 500°K

5) Exit adjustment mode using Enter button.

2. PC W/B Adjustment

1) Select WHITE PATTERN of HEAT RUN mode by

pressing ADJ button on Remote Control for adjustment

then operate HEAT RUN more than 15 minute.

2) Supply pattern signal for WB adjustment in pattern

generator.(RGB1 INPUT)

3) Low Light has no special adjustment.

4) To adjust High Light, stick sensor to 2th pattern(White),

select and adjust the PC GAIN by pressing INSTSRT

button on Remote Control for adjustment.

After select the R GAIN and G GAIN, enter Adjustment

Mode by pressing ENTER button and press the VOL +/-

Key and adjust it until color coordination becomes (B

GAIN is fixed)

color coordination : X=0.283±0.003, Y=0.296±0.003

color temperature : 9,350°K ± 500°K

(R Gain is used to adjust X-coordinates while adjusting

and X-coordinates could be shortened when R Gain is

increased.

G Gain is used to adjust Y-coordinates while adjusting

andY-coordinates could be shortened when G Gain is

increased.)

5) Exit adjustment mode using Enter button.

3. Component (480p~1080i) Offset Adjustment

¯ Use this adjustment when the Grayscale out of Ch13.

Pattern has red or blue while producing set.

¯ This adjustment is used to remove the declination of

YPbPr Offset in AD9888.

1) Operate the adjustment after PC/AV White Balance

adjustment progress.

2) Select Ch.14 after connect DTV STB to Component

(480p~1080i) terminal and AV terminal.

3) When you press ADJ button twice on the R/C for

adjustment, the SET goes to DWI condition and Main

Window(right side)/Sub Window(left side) are set to AV

mode.

4) In this condition, adjust R with ‘DTV R OFFSET’ and B

with ‘DTV B OFFSET’ based on ‘foundation color(Gray)’

of Ch.14.

5) Exit adjustment mode using Enter button.

Window

MASTER or

QUANTUM DATA

COLOR

ANALYZER

TYPE;CA-100

RGB Signal Input

LCD MONITOR

High Light

450±70cd/m

2

(Fig. 1) Connection Diagram of Automatic Adjustment

Page 6

- 6 -

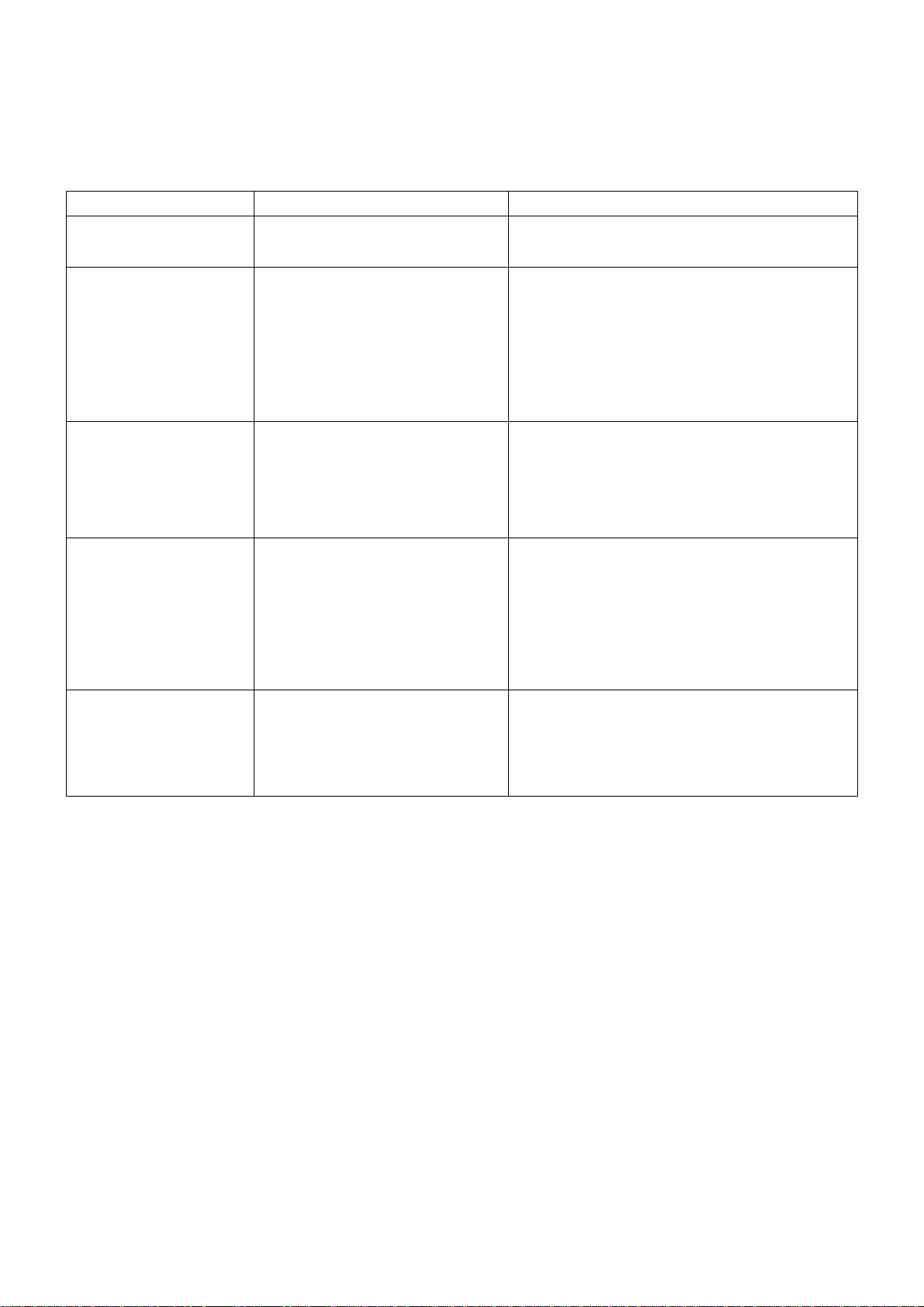

Symptom Cause Check Point

1) Check BD801, Q801, Q802, Q804

2) Check BD801, L801, L802, TH800, TH801

1) Check the second side parts and Pattern short

2) Check reverse input of PH801, D916, CR802

3) Check R941~R944 when the Pin Bias power no7. of

U902 is abnormal. (normal: 15V~25V)

- Replace U902(FAN7554) parts

- Check the error of Q804

4) Replace T803

1) Check the peripheral parts of 18V and Pattern short.

2) Check reverse input of D916(SB560)

3) No Input of L812 when both terminal voltage of C830

are low. (normal voltage: +24V)

- Replace U802(PQ1CG203) parts when there is no

error.

1) Check the peripheral parts of 5VS and Pattern short.

2) Check reverse input of D802, CR801

3) Check R937~R939 when the Pin Bias power no7. of

U903 is abnormal. (normal: 15V~25V)

- Replace U903(FAN7554) parts

- Check the error of Q802

4) Replace T802

1) Replace U901(MC33368D) when there is no error in

the peripheral parts.

- Check the error of Q801

2) Replace T801

1) Fuse open

2) Error of rectying circuit/EMI Filter

1) Short of output terminal

2) Input error of parts

3) Error of U902 and peripheral circuits.

4) Error of T803

1) Short of output terminal

2) Input error of parts

3) Error of U802 and peripheral circuits.

1) Short of output terminal

2) Input error of parts

3) Error of U903 and peripheral circuits.

4) Error of T802

1) Drop of output power due to the error

of PFC circuit.

2) Error of T801

1. No power from all outputs

2. No power from +24V/+12V

/+18V

3. No power from +18V

4. No power from +5VS

5. No power from +24V/+12V

/+18V in 110VAC Input

TROUBLESHOOTING

Page 7

- 7 -

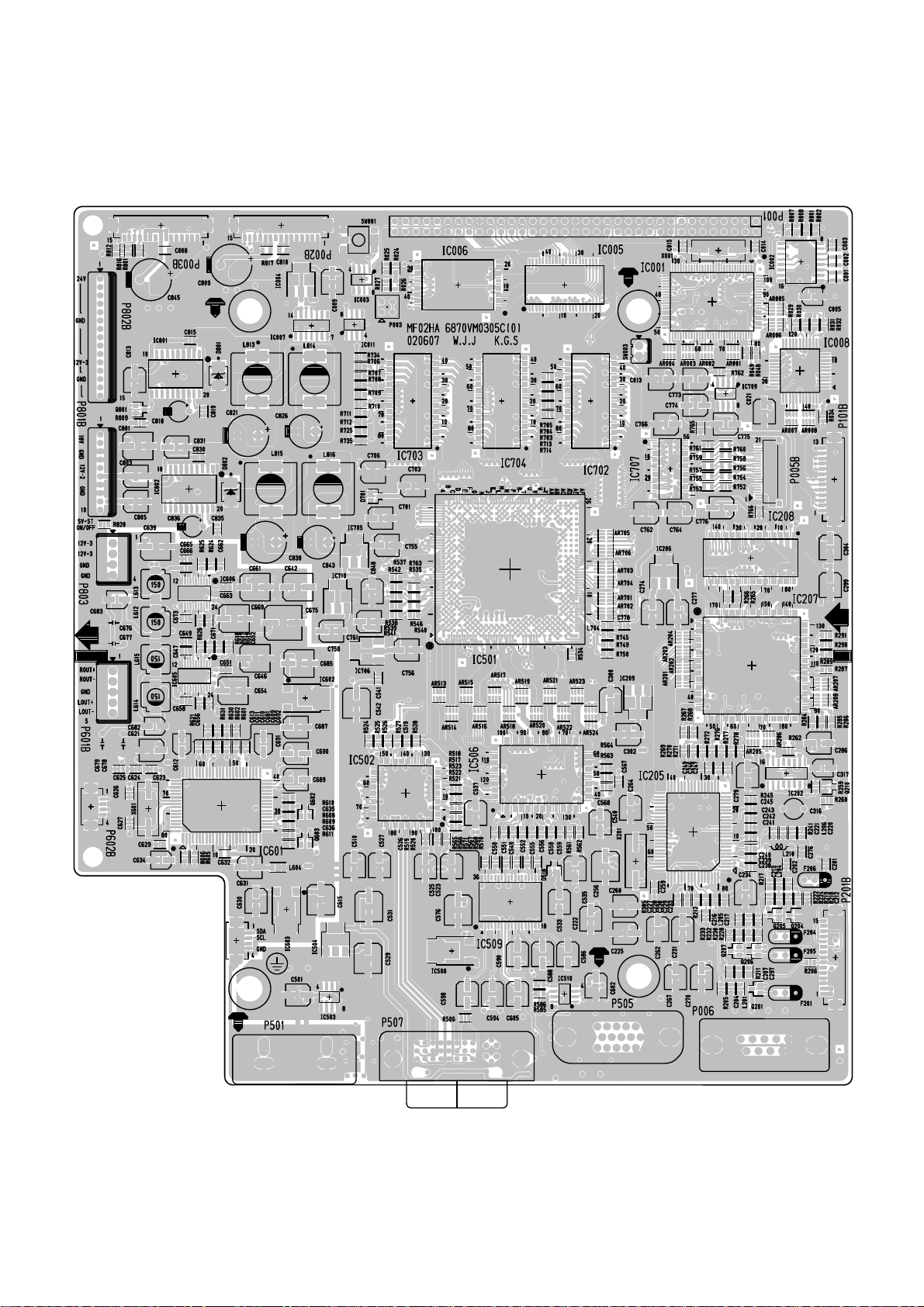

PRINTED CIRCUIT BOARD

MAIN(TOP)

Page 8

- 8 -

MAIN(BOTTOM)

Page 9

- 9 -

SIDE A/V(TOP)

SIDE A/V(BOTTOM)

Page 10

- 10 -

CONTROL(TOP)

POWER(TOP) POWER(BOTTOM)

CONTROL(BOTTOM)

Page 11

- 11 -

BLOCK DIAGRAM

1. VSC Board

Page 12

- 12 -

2. System Block Diagram & Function

2-1. Input Source Ranges

(1) Input Paths

: CVBS, S-Video, Component (480i, 480p, 720p, 1080i), RGB 1, RGB 2, RS-232C

(2) Video System Recognition (Multi-system ; Refer to Product Specification)

: NTSC M, NTSC 4.43, PAL, PAL M, PAL N, PAL 4.43, SECAM

(3) RGB 1 Mode Compatibility

: Up to SXGA 75Hz (See Compatibility Table in Product Specification in detail.)

(4) RGB 2 Mode Compatibility

: Up to SXGA 60Hz (See Compatibility Table in Product Specification in detail.)

2-2. Video Controls

(1) RGB Video Controls

: Contrast, Brightness, Color Red, Color Green, Color Blue, User Setting Reset

: Clock, Phase, Auto Tracking (Automatic Clock & Phase Optimization)

(2) AV Video Controls (AV1, AV2, S-Video, Component 1, Component 2)

: Contrast, Brightness, Color Level(Saturation), Tint(Hue), Sharpness, User Setting Reset

¡ See the OSD Spec. for more detail information of video controls.

2-3. Audio Controls

(1) Volume, Treble, Bass, Balance Control

(2) Sound Mute

Page 13

- 13 -

3. Power

Page 14

- 14 -

3-1. Explanation of Circuit Movement

If the AC Input voltage(1) is confirmed to power device, this Input voltage is adjusted as DC wave form through EMI

FILTER(2) and the first adjusting part(3). This adjusted wave form is input to PFC(4, Power Factor Correction) and makes

the PFC circuit works and the output voltage(+390Vdc) by PFC circuit becomes a Main Input voltage of MAIN(5),

STANBY(10) Switching part.

Input voltage is input to Switching part(5, 10) and make this High voltage DC voltage(390Vdc) to be a High Voltage

spherical wave with high frequency through the Switching by the elements such as FET, PWM IC.

To keep the secondary adjusted voltage to be regular and safe in changing Input voltage and Output load, the output voltage

is watched and feedback to switching part(5, 10) through the control circuit(9).

BLOCK 2 works as Forward converter method by receiving Input of BLOCK 1 and supplies MAIN DC(+24V, +12V) voltage

and the Step Down circuit(8) supplies +18V.

Also, BLOCK 3 works as Flyback converter method by receiving Input of BLOCK 1 and supplies +5V for Stanby.

Protection circuit is built in switching part(5, 10) to protect over electric-current, short, over voltage of the secondary output.

This circuit protects the output and stick the Terminal Switch(15) to radiator while PFC and protect a fire or other accident by

turning the AC voltage off while overheating.

To minimize power consumption, if the OFF signal is transmitted to PFC part(4), Main part(5) through the control circuit

connected from Main board to Power board, only the +5V circuit for Standby works and others are OFF.

Page 15

MEMO

- 15 -

Page 16

- 16 -

EXPLODED VIEW

112

300

400

520

501

530

580

531

420

410

550

551

540

570

943

Page 17

- 17 -

EXPLODED VIEW PARTS LIST

112 6305V00001A LCD ASSEMBLY,30” LCD PANEL LC30W01-A3 AND I

300 3091V00A73E CABINET ASSEMBLY

400 3809V00A33B BACK COVER ASSEMBLY

3809V00A33D BACK COVER ASSEMBLY

410 3501V00083A BOARD ASSEMBLY,BASE MW-30LZ10

420 3508V00306A DECO,REAR COVER

501 4980V00505B SUPPORTER ASSY,MODULE

520 6871VMN648A PCB ASSEMBLY,MAIN MF-02HA MW-30LZ10 MAIN BO

6871VMN637A PCB ASSEMBLY,MAIN MF-02HA MW-30LZ10 MAIN BO

530 6871VSN182B PCB ASSEMBLY,SUB A/V MF-02HA MW-30LZ10 AV BOARD

531 4930V00226E HOLDER,AV

540 3141VPN048A CHASSIS ASSEMBLY,SMPS MF-02HA LCD30 SWITCH

550 6871VSN181A PCB ASSEMBLY,SUB SPK MF-02HA MW-30LZ10 SPK BOAR

551 4930V00224C HOLDER,SPK JACK

560 6633VA0004A INVERTER ASSEMBLY,24VOLT 1100VOLT K.S. KLS300W1

570 6871VSN180A PCB ASSEMBLY,SUB CONT MF-02HA MW-30LZ10 CONTROL

580 3501V00091A BOARD ASSEMBLY,SMPS PFC MW-30LZ10 MF-02HA LCD

943 1FBF0403122 SCREW,D4.0 L16.0

No.

PART NO.

DESCRIPTION

Page 18

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC802

IC709

Q01

Q02

Q201

Q203

Q204

Q205

Q206

Q207

Q208

Q209

Q210

Q211

Q212

Q213

Q214

Q301

Q302

Q303

Q304

Q602

Q603

Q604

Q606

Q701

Q801

D001

D003

D004

D005

D006

D201

D202

D203

D204

D205

D501

D502

D503

D504

D505

D506

D507

D508

0IMCRSG003A

0TF492509AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR102009AG

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR102009AG

0TR102009AG

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DD226239AA

0DD226239AA

L4973D5.1 SGS-THOMSON 20P SOP

FET,SI4925DY TP TEMIC 30V 6.1A SO

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC102S SOT-23 TP KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

LOCA. NO PART NO DESCRIPTION

IC001

IC002

IC003

IC004

IC005

IC006

IC007

IC008

IC009

IC011

IC201

IC202

IC203

IC204

IC205

IC206

IC207

IC208

IC209

IC501

IC502

IC503

IC504

IC505

IC506

IC508

IC509

IC510

IC511

IC601

IC602

IC603

IC604

IC605

IC606

IC701

IC702

IC703

IC704

IC705

IC706

IC707

IC708

IC710

IC801

0IMCRRS001A

0IDS232000A

0IDS170800A

0ISJ111733A

0IMMRSS064A

0IMMRMR006A

0IPH748600D

0IOK825522A

0IKE704200J

0IAL241610A

0IMCRFA008A

0IFA741230A

0IMCRFA008A

0ISJ111733A

0IIT323000E

0IPRPML001A

0IMCRG2001A

0ISS464323A

0ISJ111733A

0IMCROT001A

0IMCRS5002A

0IAL242110A

0ISJ111733A

0ISJ111733A

0IMCRAD003A

0IMCRFA008A

0IMCRMI006A

0IAL242110A

0IMCRTI001A

0IMCRMN011D

0IMCRFA009A

0IMCRFA008A

0IKE704200J

0IMCRTI015A

0IMCRTI015A

0ISJ111733A

0ISS464323A

0ISS464323A

0ISS464323A

0IMCRSJ001A

0ISJ111733A

0IMCRTH001A

0ISJ111733A

0ISJ111733A

0IMCRSG003A

R8820LV RDC SEMICONDUCTOR LTD

DS232AS 16P,SOP TP RS-232 DRIV

DS1708S 8P SOIC ST MICROMONITO

EZ1117CST-3.3 3P,SOT-223 TP 3.

K6R4016V1C-TC10 SAMSUNG ELECTR

MX29LV160TTC-70 MACRONIX 48P T

74HC86 SOIC-14 TP QUAD 2-INPUT

MSM82C55A-2GS-2K 44P QFP ST CM

KIA7042AF SOT-89 TP 4.2V VOLTA

AT24C16N-10SI 8P SOIC ST EEPRO

KA78M05RTM, FAIRCHILD 2P D-PAK

DM74LS123MX 16SOP TP DUAL RETR

KA78M05RTM, FAIRCHILD 2P D-PAK

EZ1117CST-3.3 3P,SOT-223 TP 3.

VPC3230D C5 80P QFP

MIC39100 MICREL 3P SOT223 R/TP

FLI2200 SAGE 176P,QFP TRAY VID

K4S643232E(C)-TC/L60(70) (KM43

EZ1117CST-3.3 3P,SOT-223 TP 3.

REMBRANT-1A OPLUS TECHNOLOGIES

SIL161BCT RX SILICON IMAGE 100

AT24C21-10SI-2.5 8P,SOP TP 1K

EZ1117CST-3.3 3P,SOT-223 TP 3.

EZ1117CST-3.3 3P,SOT-223 TP 3.

AD9888KS-140 ANALOG DEVICE 128

KA78M05RTM, FAIRCHILD 2P D-PAK

M52758FP MITSUBISHI 36PIN, R/T

AT24C21-10SI-2.5 8P,SOP TP 1K

SN74HCT157D TEXAS INSTRUMENT 1

MSP3410G QA B8 V3 MICRONAS 80P

KA78M08RTM, FAIRCHILD 2P D-PAK

KA78M05RTM, FAIRCHILD 2P D-PAK

KIA7042AF SOT-89 TP 4.2V VOLTA

TPA3000D1 TEXAS INSTRUMENT 24P

TPA3000D1 TEXAS INSTRUMENT 24P

EZ1117CST-3.3 3P,SOT-223 TP 3.

K4S643232E(C)-TC/L60(70) (KM43

K4S643232E(C)-TC/L60(70) (KM43

K4S643232E(C)-TC/L60(70) (KM43

SC1565IST-1.8 SEMTECH 3P SOT22

EZ1117CST-3.3 3P,SOT-223 TP 3.

THC63LVDM83R THINE ELECTRONICS

EZ1117CST-3.3 3P,SOT-223 TP 3.

EZ1117CST-3.3 3P,SOT-223 TP 3.

L4973D5.1 SGS-THOMSON 20P SOP

IC

- 18 -

TRANSISTOR

DIODE

Page 19

- 19 -

LOCA. NO PART NO DESCRIPTION

D509

D510

D511

D512

D513

D514

D515

D516

D517

D518

D519

D520

D521

D522

D523

D524

D525

D526

D601

D602

D603

D604

D701

D702

D801

D802

LD01

ZD501

C005

C009

C013

C016

C021

C222

C225

C231

C234

C238

C239

C240

C241

C256

C260

C262

C264

C267

C270

C274

C277

C279

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD181009AB

0DD181009AB

0DD226239AA

0DD226239AA

0DR190309AA

0DR190309AA

0DL200000CA

0DZRM00178A

0CE106SF6DC

0CE476SF6DC

0CE476SF6DC

0CK224DF56A

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CK224DF56A

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

KDS181 TP KEC - 85V - - - 300M

KDS181 TP KEC - 85V - - - 300M

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

MBRS190T3 TP MOTOROLA - 90V 1A

MBRS190T3 TP MOTOROLA - 90V 1A

LED,SAM5670(DL-2LRG) BK Y-GREEN -

ZENERS,UDZS TE-17 5.1B

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

220000PF 2012 16V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

LOCA. NO PART NO DESCRIPTION

C286

C299

C300

C302

C304

C311

C312

C313

C314

C315

C316

C317

C323

C325

C501

C510

C523

C525

C527

C529

C531

C533

C535

C537

C540

C542

C576

C586

C588

C590

C594

C598

C602

C605

C612

C615

C621

C630

C631

C634

C639

C642

C646

C654

C661

C669

C676

C677

C678

C679

C682

C683

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

181-064P

0CE106SF6DC

0CE107VF6DC

0CE107VF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE106SF6DC

0CE476VH6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE106SF6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

0CE476VH6DC

181-007F

181-007F

181-007F

181-007F

0CE105SK6DC

0CE105SK6DC

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

10UF 0 16V K CA TP 5

10UF MVG 16V 20% R/TP(SMD) SMD

100UF MV 16V 20% R/TP(SMD) SMD

100UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

47UF MV 25V 20% R/TP(SMD) SMD

MPE ECQ-V1H224JL3(TR), 50V 0.2

MPE ECQ-V1H224JL3(TR), 50V 0.2

MPE ECQ-V1H224JL3(TR), 50V 0.2

MPE ECQ-V1H224JL3(TR), 50V 0.2

1UF MVG 50V M SMD R/TP

1UF MVG 50V M SMD R/TP

CAPACITOR

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 20

- 20 -

LOCA. NO PART NO DESCRIPTION

C685

C687

C689

C690

C691

C701

C703

C706

C755

C756

C758

C761

C762

C764

C766

C773

C774

C775

C776

C801

C803

C805

C809

C813

C815

C818

C821

C826

C830

C831

C836

C838

C843

C845

C848

L210

L302

L303

L304

L612

L613

L614

L615

L813

L814

L815

L816

P101

0CE476VH6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE335SK6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476VH6DC

0CE476SF6DC

0CE476SF6DC

0CE477BJ618

0CE476SF6DC

0CK224DF56A

0CE106BF618

0CE108DD618

0CE477DD618

0CK224DF56A

0CE476SF6DC

0CE106BF618

0CE108DD618

0CE477DD618

0CE477BJ618

0CE476SF6DC

0LA0101K119

0LA0472K119

0LA0101K119

0LA0102K119

6140VR0005A

6140VR0005A

6140VR0005A

6140VR0005A

6140VR0001C

6140VR0001C

6140VR0001C

6140VR0001C

6612J00010A

47UF MV 25V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

3.3UF MVG 50V 20% SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MV 25V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

470UF KME TYPE 35V 20% FL TP 5

47UF MVG 16V M SMD R/TP

220000PF 2012 16V 10% R/TP X7R

10UF KME 16V M FL TP5

1000UF STD 10V M FL TP5

470UF STD 10V M FL TP5

220000PF 2012 16V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

10UF KME 16V M FL TP5

1000UF STD 10V M FL TP5

470UF STD 10V M FL TP5

470UF KME TYPE 35V 20% FL TP 5

47UF MVG 16V M SMD R/TP

INDUCTOR,1.0UH K

INDUCTOR,47UH K

INDUCTOR,1.0UH K

INDUCTOR,10UH K

COIL,SLF7045T-150M1R1 TDK 15UF

COIL,SLF7045T-150M1R1 TDK 15UF

COIL,SLF7045T-150M1R1 TDK 15UF

COIL,SLF7045T-150M1R1 TDK 15UF

COIL,SB1260-470 GET 47UH

COIL,SB1260-470 GET 47UH

COIL,SB1260-470 GET 47UH

COIL,SB1260-470 GET 47UH

JACK,RCA PPJ128A-1 A/V 2P MONO

LOCA. NO PART NO DESCRIPTION

P102

P103

P104

P501

P502

P507

AR001

AR002

AR003

AR004

AR005

AR006

AR007

AR008

AR201

AR202

AR203

AR204

AR205

AR206

AR207

AR208

AR513

AR514

AR515

AR516

AR517

AR518

AR519

AR520

AR521

AR522

AR523

AR524

AR701

AR702

AR703

AR704

AR705

AR706

R501

R502

R503

R504

SW01

SW001

SW02

SW03

380-363K

6612J00010B

6612TAH002A

6612VJH018A

6612JH003EA

6612BBBHN6A

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RRZVTA001D

0RF0111K607

0RF0111K607

0RF0111K607

0RF0111K607

140-315A

6600VR1004A

140-315A

140-315A

JACK,DIN PJ6046G H=8.0 W/O S/W

JACK,RCA PPJ128A-2 A/V 3P WITH

JACK,PHONE DC-001 UNITOP DC-001

JACK,RCA PJ6058C-A A/V 2P MON

JACK,RCA UST-AG-013 UGCOM 2P SPK TERMIN

JACK,DIN 440062-1 AMP DVI INTERACED

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

22 OHM 1 / 16 W 1608 5%

1.1 OHM 2 W 5.00%

1.1 OHM 2 W 5.00%

1.1 OHM 2 W 5.00%

1.1 OHM 2 W 5.00%

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHMPW 5P CHIP TACT NON

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

JACK

COIL & TRANSFORMER

RESISTOR

SWITCH

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 21

- 21 -

LOCA. NO PART NO DESCRIPTION

SW04

SW05

SW06

SW07

F201

F204

F205

F206

L206

L207

L208

L209

L212

L231

L503

L504

L505

L506

L507

L511

L601

L603

L604

L605

L609

L611

L701

L703

L704

L705

L804

L805

L806

L810

L811

L812

X001

X201

X601

P02

P006

P106

P505

A1

A2

A3

140-315A

140-315A

140-315A

140-315A

166-F01D

166-F01D

166-F01D

166-F01D

6210TCE001G

6210TCT002B

6210TCT002B

6210TCT002B

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210VC0005A

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001A

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6212AB2015C

6202VDT002E

6202VDT002H

6726VH0001A

6630VGA004B

366-922C

6630VGA001C

3828VA0338D

6710V00092E

6410VWH005B

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

SWITCH,TACT SKHV17910B NON 12V

FILTER,EMC DSN6NC51H271Q93A

FILTER,EMC DSN6NC51H271Q93A

FILTER,EMC DSN6NC51H271Q93A

FILTER,EMC DSN6NC51H271Q93A

FILTER,EMC HH-1M3216-501

FILTER,EMC ACB2012M-300-T

FILTER,EMC ACB2012M-300-T

FILTER,EMC ACB2012M-300-T

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC BK2125 HS 750

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HB-1S2012-080JT

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

FILTER,EMC HH-1M3216-501

RESONATOR,CRYSTAL HC-49/SM4H 25MHZ +/- 50

RESONATOR,CRYSTAL SX-1SMD 20250000H

RESONATOR,CRYSTAL SX-1 18.432MHZ

REMOTE CONTROLLER RECEIVER,38KHZ

CONNECTOR,D-SUB 9P 2.77MM FOR

CONNECTOR,2.5MM 4P

CONNECTOR,D-SUB 15PIN 2.29MM

MANUAL,OWNERS MF02HA MW-30LZ10 LG

REMOTE CONTROLLER,MF-02HA W/O TXT

POWER CORD,SA16A+V1625 VOLEX

LOCA. NO PART NO DESCRIPTION

A3

A4

A5

A6

A7

6410VBH003A

174-208D

6850V00001A

6851V00001F

6866VA9001A

POWER CORD,MP5004 VOLEX

CORD,A/V(3P,3.0M)

CABLE,FLAT 1566075-1 DVI A/D TO A/D 2000M

CABLE ASSEMBLY,3M RCA-PLUG(2P) TO STEREO 118

CONNECTOR,2990-9C,AT,L1830,COOL GRAY 3C

FILTER & CRYSTAL

ACCESSORIES

MISCELLANEOUS

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 22

Page 23

Loading...

Loading...