Page 1

MINI HOME THEATER SYSTEM

SERVICE MANUAL

MODELS: MBD-K62Q, MBS-K62V

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

MODELS: MBD-K62Q, MBS-K62V

SERVICE MANUAL

P/NO : AFN33894946 MAY, 2007

http://biz.lgservice.com

Page 2

CONTENTS

SECTION 1

SUMMARY

SERVICING PRECAUTIONS ......................................1-2

• NOTES REGARDING HANDLING OF THE PICK-UP

•

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

ESD PRECAUTIONS ...................................................1-4

SPECIFICATIONS ........................................................1-5

SECTION 2

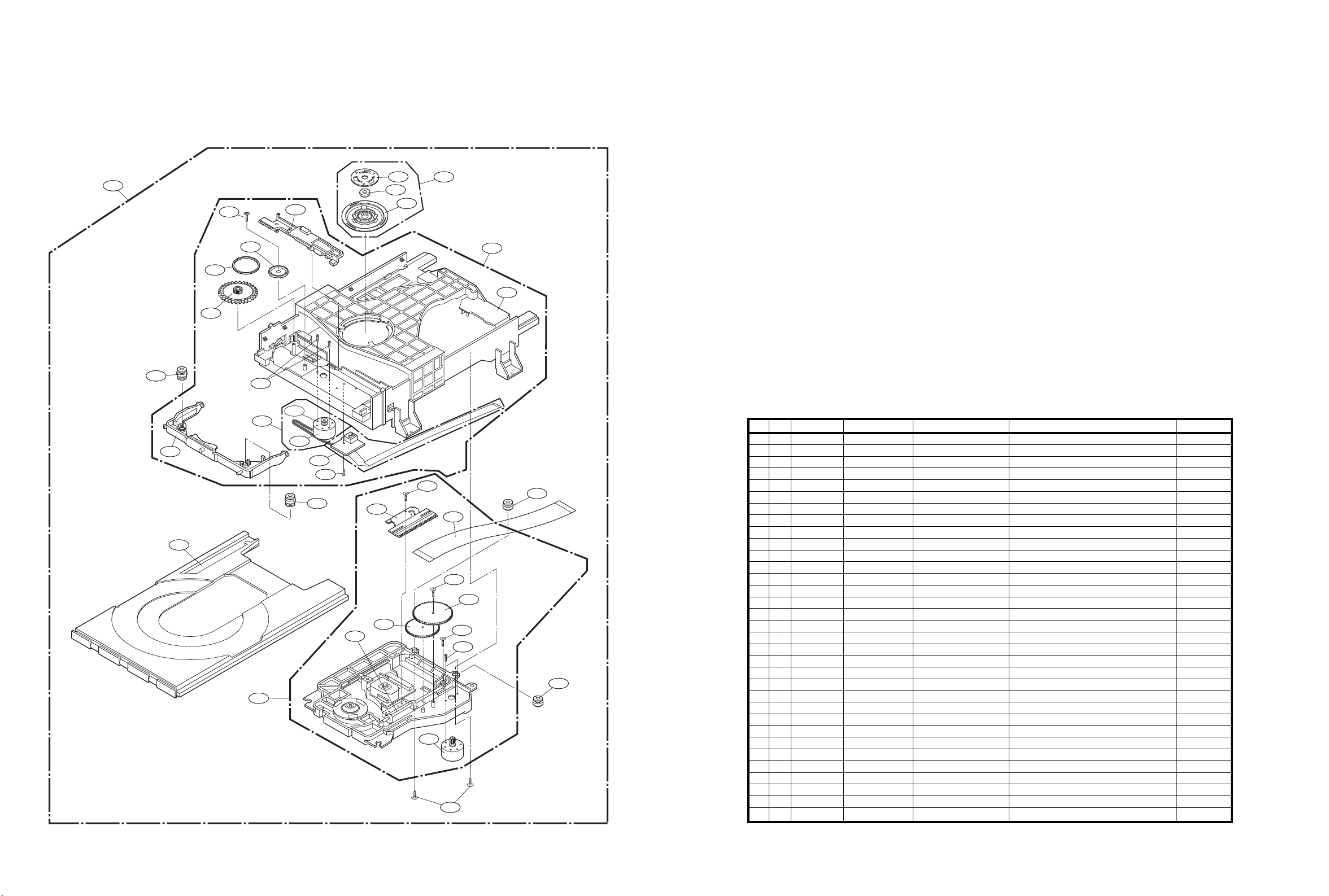

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION..............2-1

2. DECK MECHANISM SECTION (DP-10A).............2-3

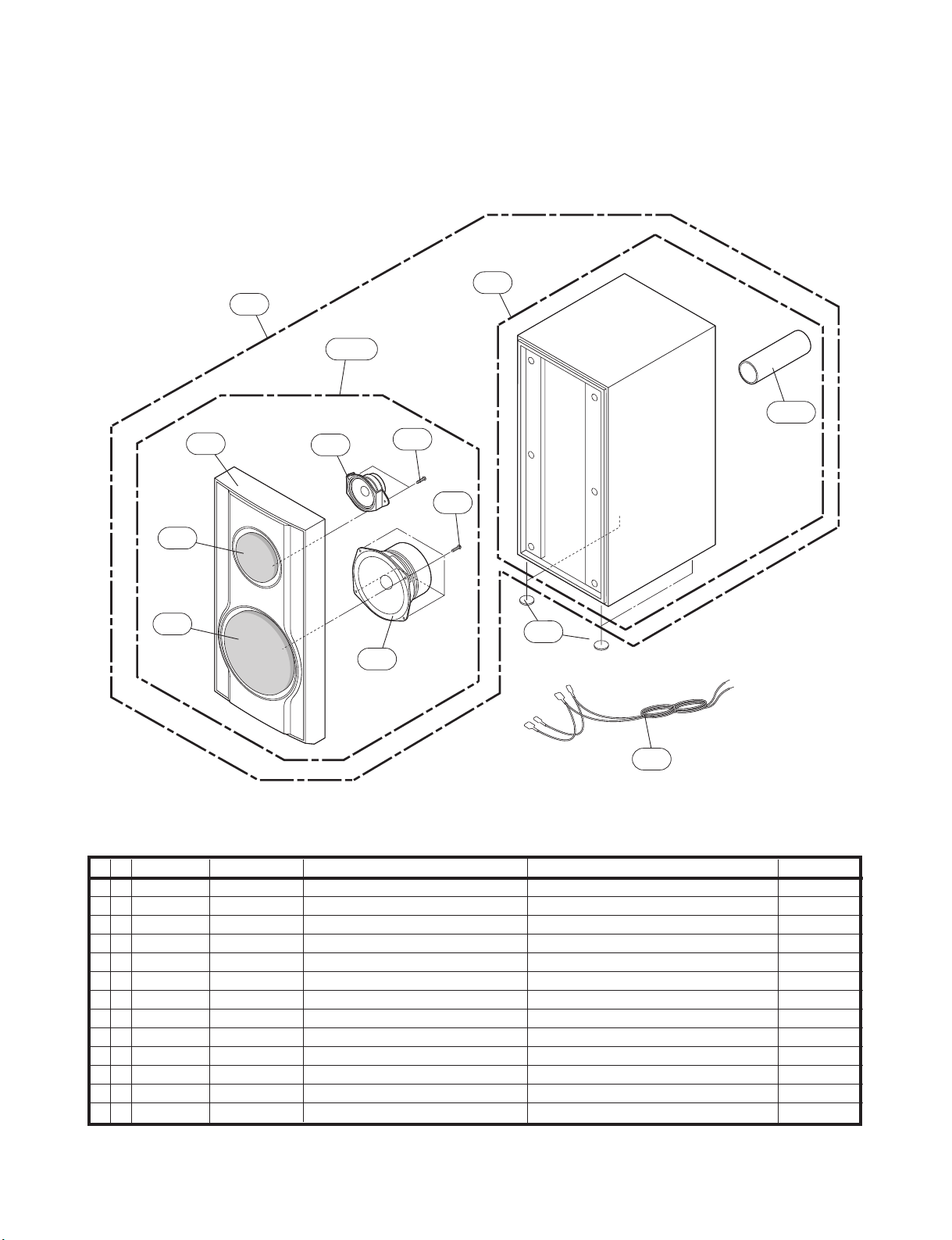

3. SPEAKER SECTION (MBS-K62V) ........................2-5

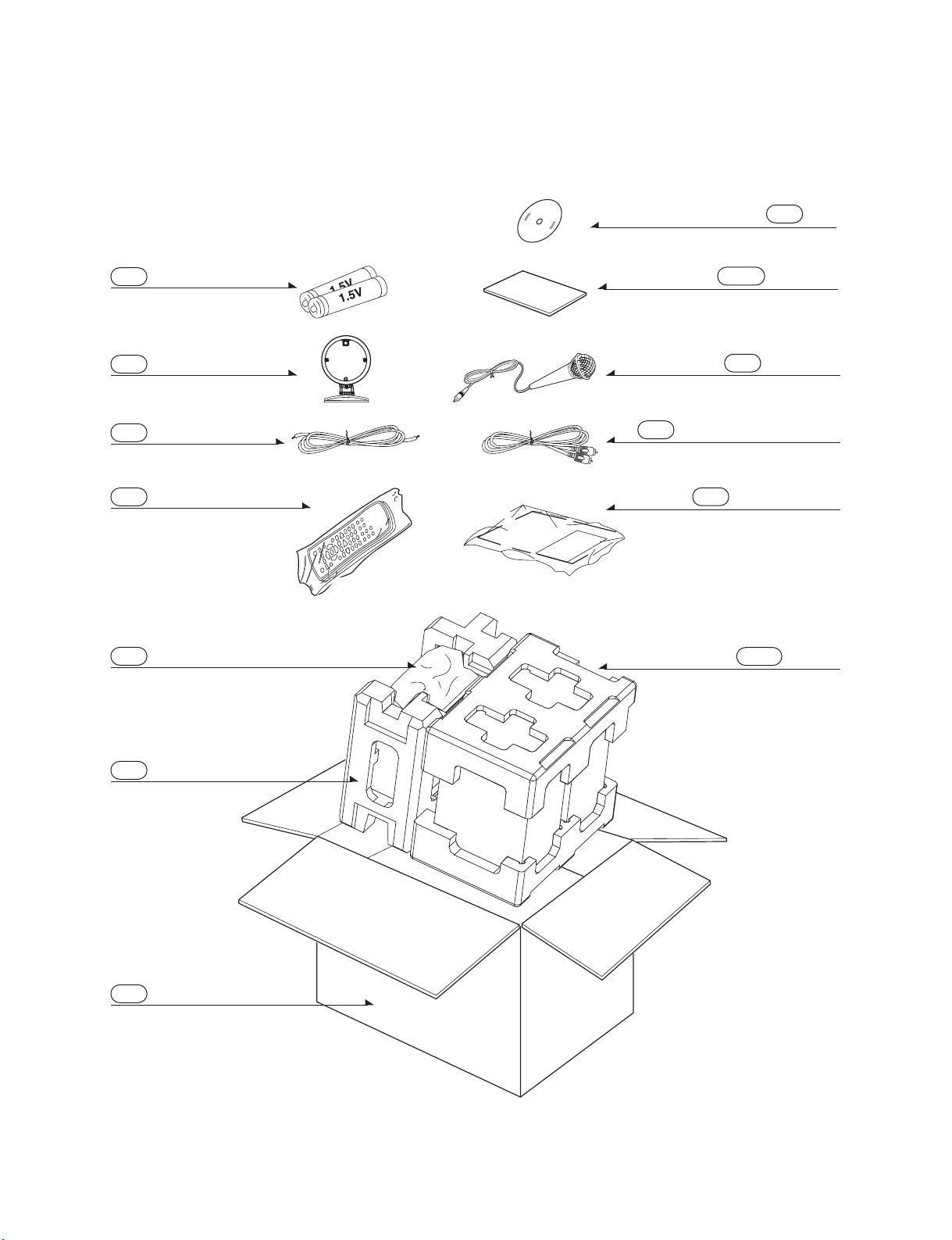

4. PACKING ACCESSORY SECTION .......................2-6

SECTION 3

ELECTRICAL

ELECTRICAL TROUBLESHOOTING

GUIDE OF AUDIO PART.............................................3-1

1. MICOM PART CHECK I ....................................3-1

2. MICOM PART CHECK II ...................................3-2

3. IC103 KS4CD21CS CHECK.............................3-3

4. FLD DISPLAY CHECK ......................................3-4

5. PWM MODULATION PART ..............................3-5

6. POWER AMP PART CHECK............................3-6

7. PORTABLE FUNCTION ....................................3-7

8. TV-AUDIO FUNCTION ......................................3-8

9. TUNER FUNCTION CHECK ............................3-9

10. SMPS POWER TROUBLESHOOTING.........3-10

11. BLUETOOH PART (OPTIONAL PART)..........3-13

12. IPOD PART (OPTIONAL PART) .....................3-14

ELECTRICAL TROUBLESHOOTING

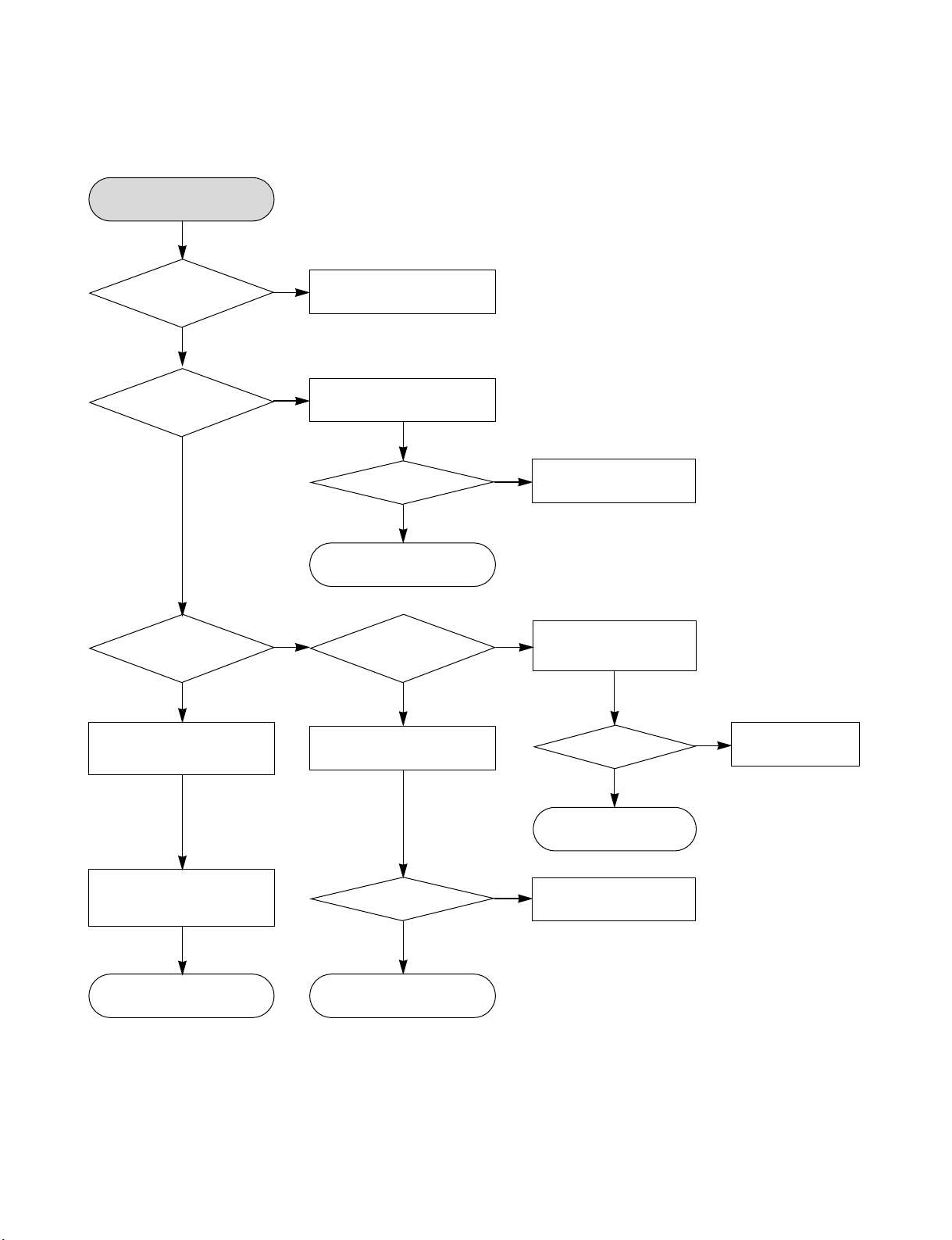

GUIDE OF DVD PART...............................................3-15

1. POWER CHECK GUIDE.................................3-15

2. TEST & DEBUG FLOW...................................3-16

3. USB PART ........................................................3-21

WAVEFORMS.............................................................3-22

1. WHEN POWER ON, RESET & DATA

ETC WAVEFORM ............................................3-22

2. OPEN / CLOSE WAVEFORM AT

POWER ON......................................................3-23

3. STARTING ACTION WAVEFORM

IN MD DEVICE ................................................3-23

4. FOCUS WAVEFORM ......................................3-24

5. AT POWER ON, SPINDLE SIGNAL AT

MD DECK .........................................................3-25

6. AT FIRST ACTION, FOCUS

SIGNAL A, B, C, D............................................3-25

7. TRACKING SIGNAL ........................................3-26

8. RF WAVEFORM ..............................................3-26

9. DISK TYPE JUGEMENT WAVEFORM..........3-27

INTERNAL BLOCK DIAGRAM OF ICs...................3-28

1. AK5358..............................................................3-28

2. EM639165 ........................................................3-30

3. ES29LV160E ....................................................3-32

4. HT1000 .............................................................3-34

5. IP9009...............................................................3-37

6. KS24L161 .........................................................3-38

7. MC4580 ............................................................3-39

8. PS9829B...........................................................3-40

9. PT6324..............................................................3-41

10. STR-A6252 .......................................................3-44

11. µPD78F0546R (R)............................................3-45

WIRING DIAGRAM ....................................................3-49

BLOCK DIAGRAMS ..................................................3-51

1. SMPS BLOCK DIAGRAM...............................3-51

2. MAIN & FRONT BLOCK DIAGRAM ..............3-53

SCHEMATIC DIAGRAMS .........................................3-55

1. SMPS SCHEMATIC DIAGRAM......................3-55

2. MAIN, INTERFACE & PWM

SCHEMATIC DIAGRAM..................................3-57

3. MPEG SCHEMATIC DIAGRAM .....................3-59

4. SERVO SCHEMATIC DIAGRAM ...................3-61

5. INTERFACE SCHEMATIC DIAGRAM ...........3-63

6. FRONT SCHEMATIC DIAGRAM ..................3-65

7. FRONT MIC SCHEMATIC DIAGRAM ...........3-67

8.

IPOD-1 SCHEMATIC DIAGRAM (OPTION)

9.

IPOD-2 SCHEMATIC DIAGRAM (OPTION)

2 CHANNEL AMP SCHEMATIC DIAGRAM

10.

11. BLUTHOOTH MODULE

SCHEMATIC DIAGRAM (OPTION) ................3-75

CIRCUIT VOLTAGE CHART.....................................3-77

PRINTED CIRCUIT BOARD DIAGRAMS ...............3-79

1. MAIN P.C.BOARD............................................3-79

2. FRONT P.C.BOARD ........................................3-83

3. SMPS P.C.BOARD ..........................................3-85

4. MIC JACK P.C.BOARD ...................................3-87

5. IPOD P.C.BOARD (OPTION)..........................3-87

.....3-69

.....3-71

......3-73

SECTION 4

REPLACEMENT PARTS LIST

........4-1

1-1

Page 3

SECTION 1 SUMMARY

SERVICING PRECAUTIONS

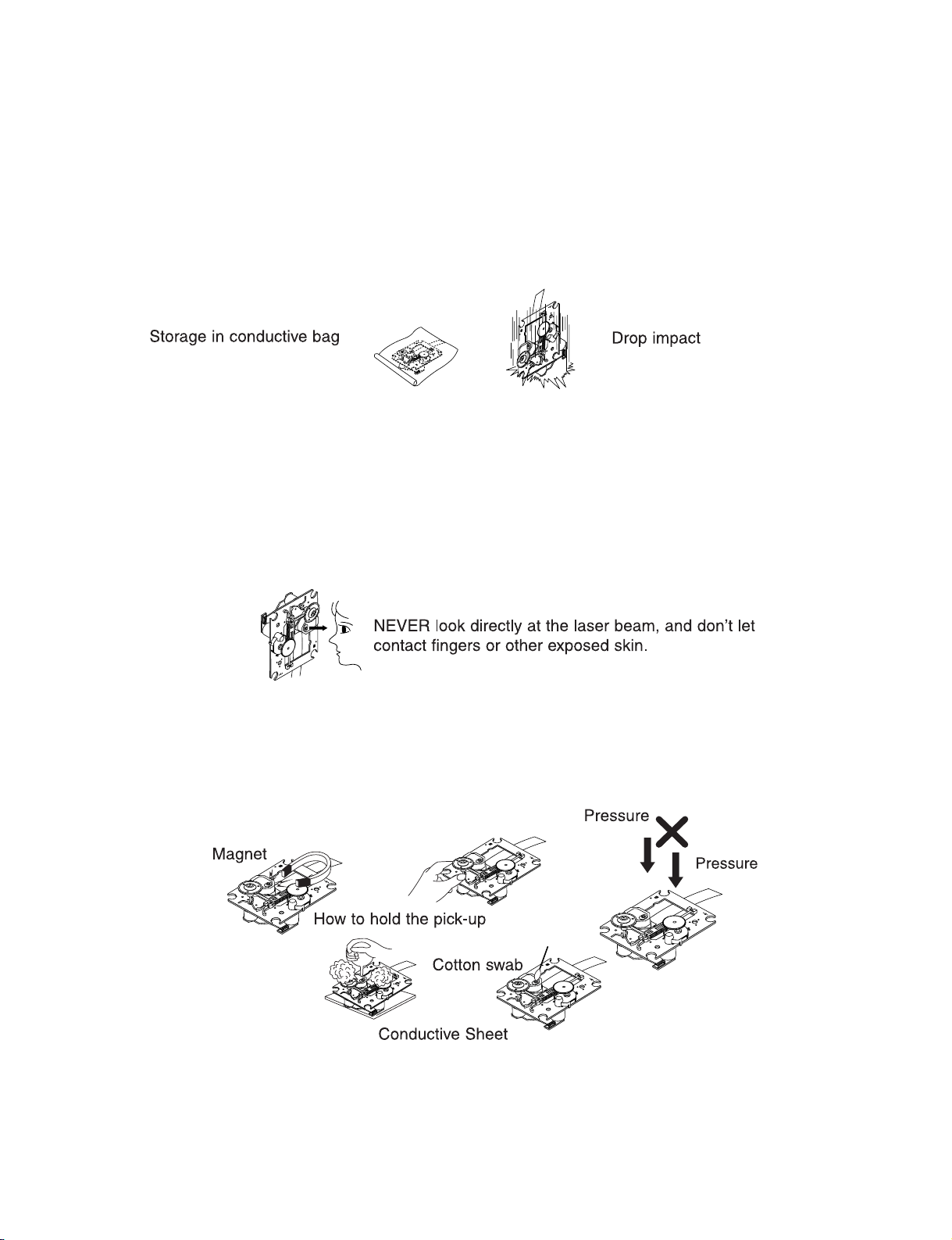

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton

swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do not

use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of this

alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

1-2

Page 4

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

1-3

Page 5

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called electrostatically sensitive devices (ESD). Examples of typical ESD devices are

integrated circuits and some field-effect transistors and semiconductor chip components. The following

techniques should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a know earth ground. Alternatively, obtain and

wear a commercially available discharging wrist strap device, which should be removed for potential

shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static"

can generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together

by conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch

the protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor

can generate static electricity sufficient to damage an ESD device).

[CAUTION. GRAPHIC SYMBOLS]

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL. WITHIN AN EQUILATERAL

TRIANGLE, IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE

OF UNINSULATED "DANGEROUS VOLTAGE" THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENED TO

ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION IN SERVICE LITERATURE.

1-4

Page 6

SPECIFICATIONS

• GENERAL

Power supply Refer to the back panel of the unit.

Power consumption Refer to the back panel of the unit.

Net Weight 3.00kg

External dimensions (WxHxD) 300 x 130 x 243mm

• CD/DVD

Laser Semiconductor laser, wavelength 650nm

Signal system PAL 625/50, NTSC 525/60

Frequency response (audio) 40Hz to 20kHz

Signal-to-noise ratio (audio) More than 75dB (1kHz, NOP -3dB, 20kHz LPF/A-Filter)

Dynamic range (audio) More than 75dB

Harmonic distortion (audio) 0.5 % (1kHz, at 1W position) (20kHz LPF)

• VIDEO

Video output 1.0V (p-p), 75Ω, negative sync./ RCA jack x 1/ SCART (TO TV)

COMPONENT VIDEO OUT (Y) 1.0V (p-p), 75ohms, negative sync, RCA jack x 1

(Pb)/(Pr) 0.7V (p-p), 75ohms, RCA jack x 1

• TUNER

FM Tuning Range 87.5 ~ 108.0MHz or 65 ~ 74MHz, 87.5 ~ 108.0MHz

Intermediate Frequency 10.7MHz

Signal to Noise Ratio 60/55dB

Frequency Response 50 ~ 10000Hz

AM Tuning Range 522 ~ 1620kHz or 520 ~ 1720kHz

Intermediate Frequency 450kHz

Signal to Noise Ratio 30dB

Frequency Response 80 ~ 1800Hz

• AMPLIFIER

Output Power 30W + 30W

T.H.D 0.5%

Frequency Response 40 ~ 20000Hz

Signal-to-noise ratio 75dB

• SPEAKERS

Speaker Name MBS-K62V

Type Bass Reflex 2 Way 2 Speaker

Impedance 4Ω

Frequency Response 60 ~ 20000Hz

Sound Pressure Level 82dB/W (1m)

Rated Input Power 30W

Max. Input Power 60W

Net Dimensions (WxHxD) 160 X 308 X 204mm

Net Weight (1EA) 2.5kg

Designs and specifications are subject to change without notice.

1-5

Page 7

MEMO

1-6

Page 8

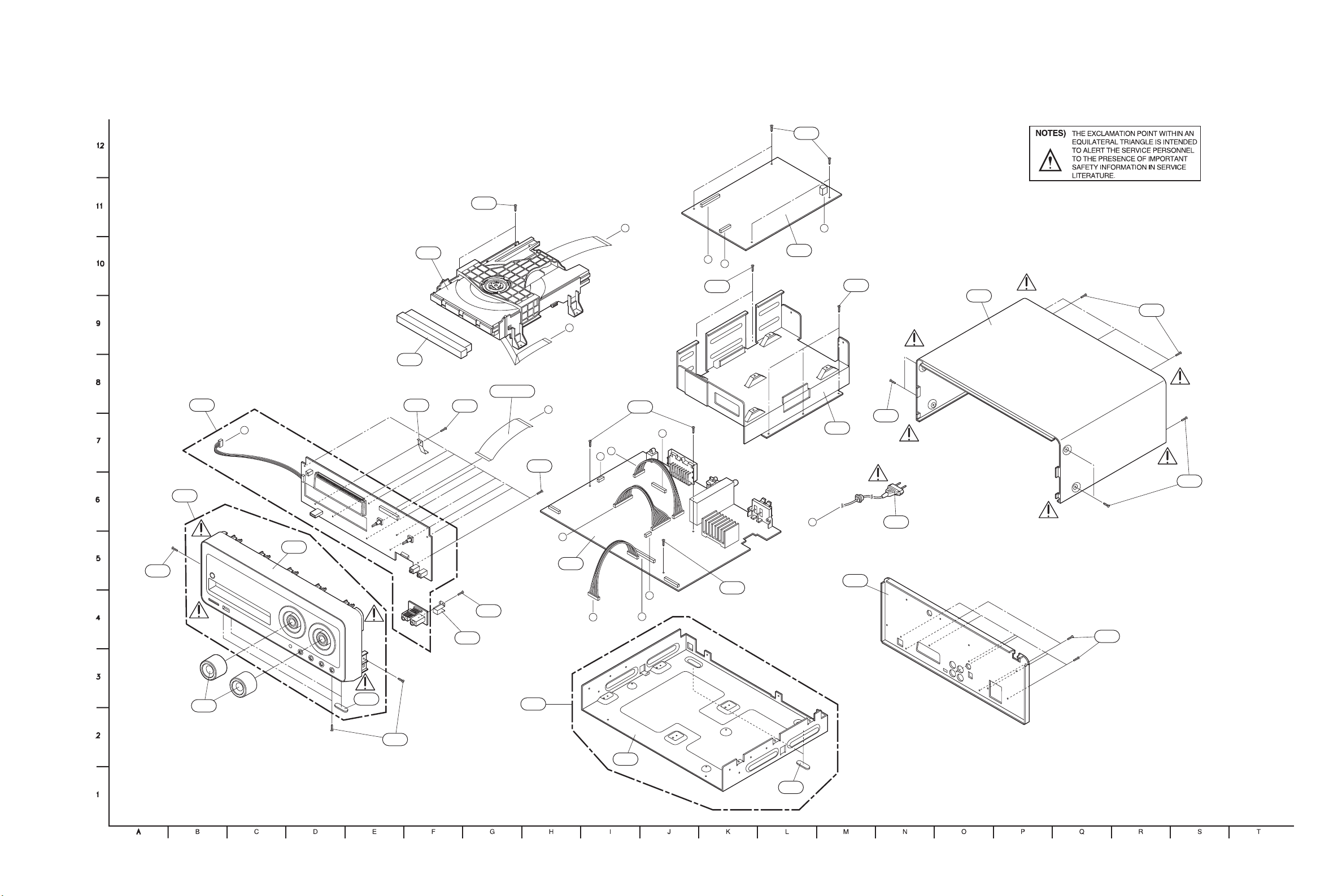

SECTION 2 EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

463

461

463

A43

A50

A26

A

C

D

461

E

A47

463

250

463

B

257

CABLE3

277

G

463

F

G

461

A

H

275

463

463

463

E

C

300

256

A46

276

463

B

D

F

461

258

259

463

272

463

A44

273

274

2-1 2-2

Page 9

2. DECK MECHANISM SECTION (DP-10A)

A26

012

019

026

013

017

439

014

435

015

A03

018

015B

015A

016

012

440

036

030

025

001

002

003

432

021

A01

430

010

439

431

435

024

A02

020

012A

012A

NSP : Non SVC Parts

SALLOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

A26 6721RJD100T Deck Assembly,DVD HOME THEATER DP-10A (HZ) NSP

A01 4861R-0016B Clamp Assembly DVD DISC DP7 - SH Clamp Assemb

A02 3041R-T010B Base Assembly DP-10A LOADING

A03 3041R-T011C Base Assembly SLED DP-10A (HZ)

001 3300R-0547A Plate PRESS SUS301 0.3 CDM-300 PRESS NSP

002 5016H-1016B Magnet CLAMP(LDM-R608,10*5,1*1.5T) NSP

003 4860R-0021A Clamp MOLD POM UPPER DP7 NSP

010 6850R-JW14B Cable,FFC 1.0 x 23 x 140 x B(0.035 x 0.6

012 5040R-0083A Damper PRINTING DVD DP-6, DP-8 FRONT

012A 5040R-0110A Damper PRINTING DVD REAR DP8 RIGHT 20

013 4400R-0006B Belt MOLD RUBBER DECK/MECHA DP2-5,

014 4470R-0154A Gear COMPLEX DVD DECK/MECHA DP8 PUL

015 4681R-A015A Motor,Unclassified DECK/MECHA LOADING DP-9 SH

015A 4680R-E008A Motor,DC RF-300EA-1D390(80MM) 2V 90MA 2 NSP

015A EAU36590901 Motor,DC FC08I20TLG-1 2V 100MA 0A 1.37K ALTERNATE

015B 4560R-0008A Pulley MOLD POM MOTOR

016 6871R-9297A PCB Assembly DP-10T LOADING/FEEDING

017 4470R-0176A Gear MOLD POM DVD DP-9 LOADING MO

018 4974R-0067A Guide MOLD POM DVD DP-9C UP/DOWN MOL

019 3210R-M008A Frame MOLD ABS DP-9C UP/DOWN MOLD

020 MAM32408101 Base MOLD ABS XR-401 MAIN MOLD DP-1

021 4681R-B009C Motor,Unclassified DECK/MECHA DP-10 FEEDING

024 4470R-0179A Gear MOLD POM DVD DP-9 PINION MOL

025 4470R-0178A Gear MOLD POM DVD DP-9 MIDDLE MOLD

026 3390R-0032A Tray MOLD ABS DVD DP-9MC DISK MOLD

030 4470R-0180A Gear MOLD POM DVD DP-9 RACK MOLD

036 4370R-0136A Shaft CUTTING STS 301 DVD PU, DR-02

430 1SZZR-0064B Screw,Customized - + 1.7MM 7MM SWRCH FZB SIN J

431 1SZZR-0062A Screw,Customized - + 1.7MM 4.5MM SWRCH NI PLT

432 1SZZR-0072A Screw,Customized - + 1.7MM 4.5MM SWRCH FZY SIN

435 1SZZR-0011A Screw,Customized MACHINE

439 1SZZR-0075A Screw,Customized - + 1.7MM 10MM SWRCH FZW SIN

440 1SZZH-1007B Screw,Customized + D2.0 6MM SWRCH16A/ZNBK 4MM 1

2-3 2-4

Page 10

3. SPEAKER SECTION (MBS-K62V)

A70

A70A

757

757A

750

753

755

756

751

752

758

754

759

NSP : Non SVC Parts

SALLOCA. NO. LG PART NO. DESCRIPTION SPECIFICATION REMARKS

A70 EAB38086501 Speaker Assembly MBS62V 049-01368-07 SAMMI MBS6

A70A AGL33753501 Panel Assembly,Front SPK MBS62V BK 1coated spray NSP

750 MGC37897301 Panel,Front MOLD ABS SPK MBS102 MOLD BK GL NSP

751 MDX37897601 Grille PRESS EGI 0.4 MBS102 PRESS T/W NSP

752 MDX37897501 Grille PRESS EGI 0.6 MBS102 PRESS W/F NSP

753 EAB38121201 Speaker,Tweeter CTR-50B30L-1 FERRITE 30W 4OHM NSP

754 EAB38120701 Speaker,Woofer MCW-125B30L FERRITE 30W 4OHM 8 NSP

755 353M025F Screw,Customized - - 3MM 8MM - FZY SIN JIN BOL NSP

756 353M050M Screw,Customized - + 3.5MM 10MM MSWR FZY SIN J NSP

757 ACQ33753301 Cover Assembly SPK MBS62V CABINET ASSY, PB9T, NSP

757A 5208RM0056D Duct CUTTING PAPER SPK MBS102 OTHER NSP

758 3610RM0005A Foot CUTTING EVA HOME EVA EVA PHI 2 NSP

759 EBR36664806 PCB Assembly,Sub SAMMI MBS62 MBS62 NETWORK ASSY NSP

2-5

Page 11

4. PACKING ACCESSORY SECTION

832

Disc

Battery

808

Antenna Loop

824

825

Antenna

900

Remote control

Bag804

827

Plug Ass'y, 1Way(BLACK)

811

Instruction Ass'y

801

803A

Song Book801S

Microphone

Packing

803

Packing

Box802

2-6

Page 12

SECTION 3 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

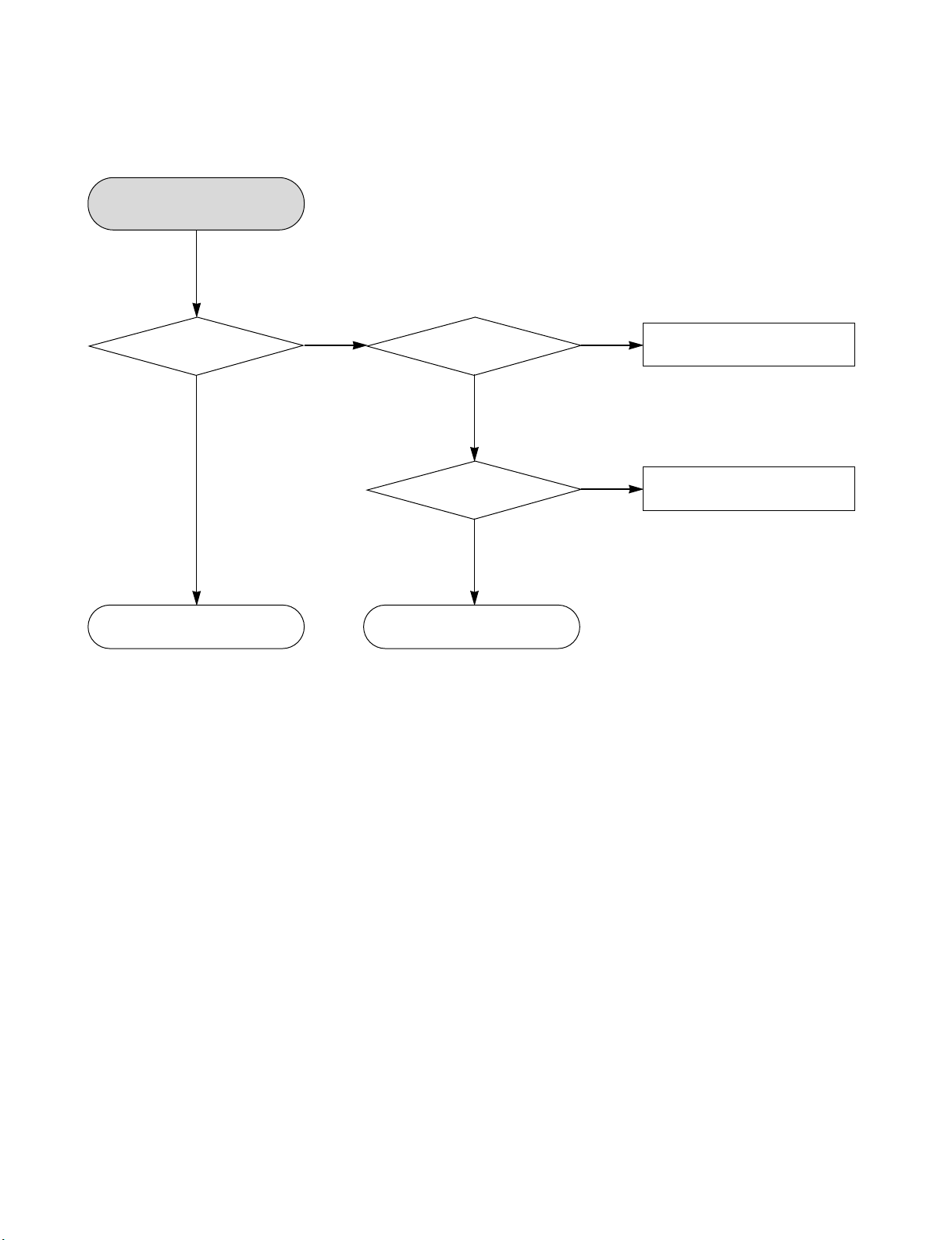

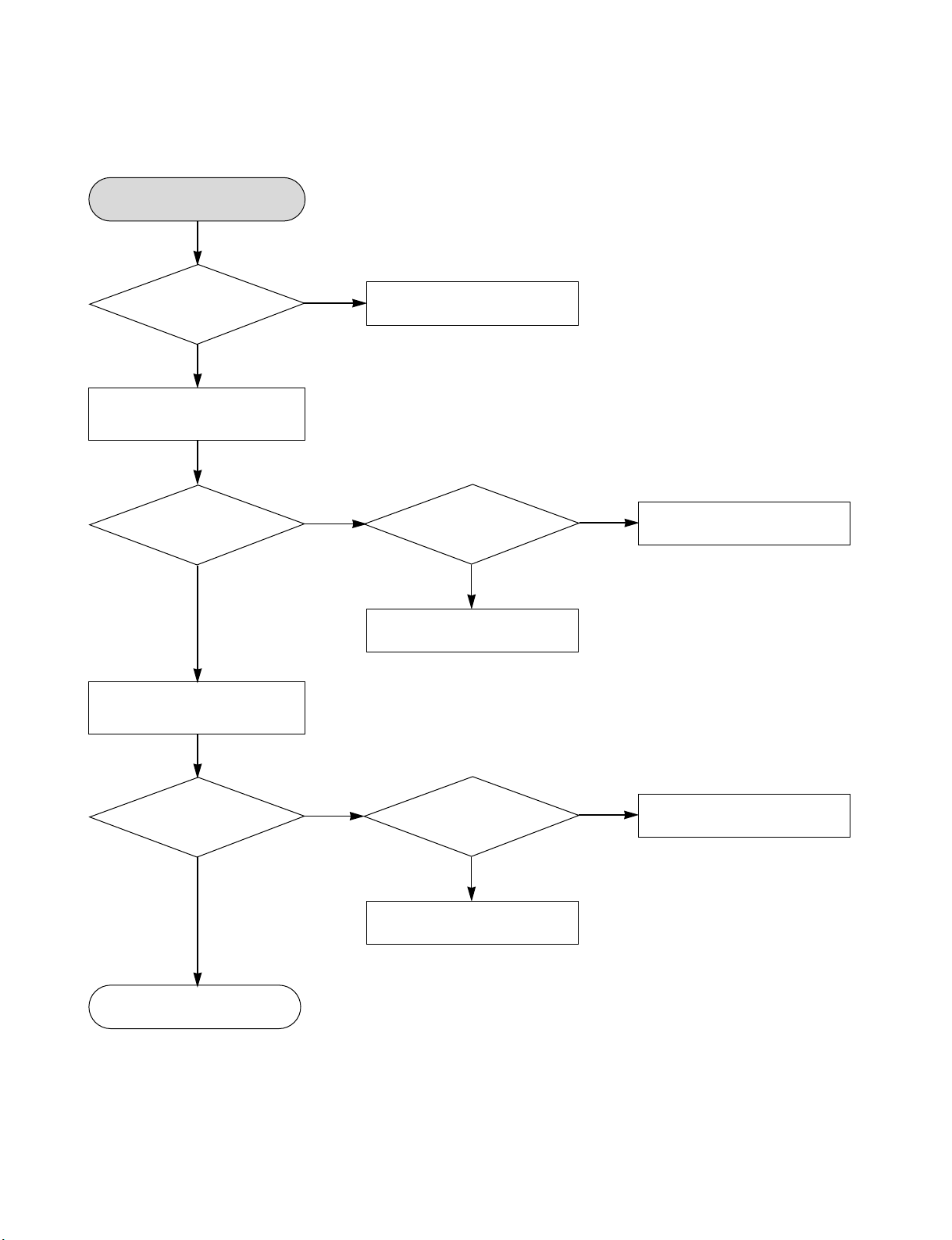

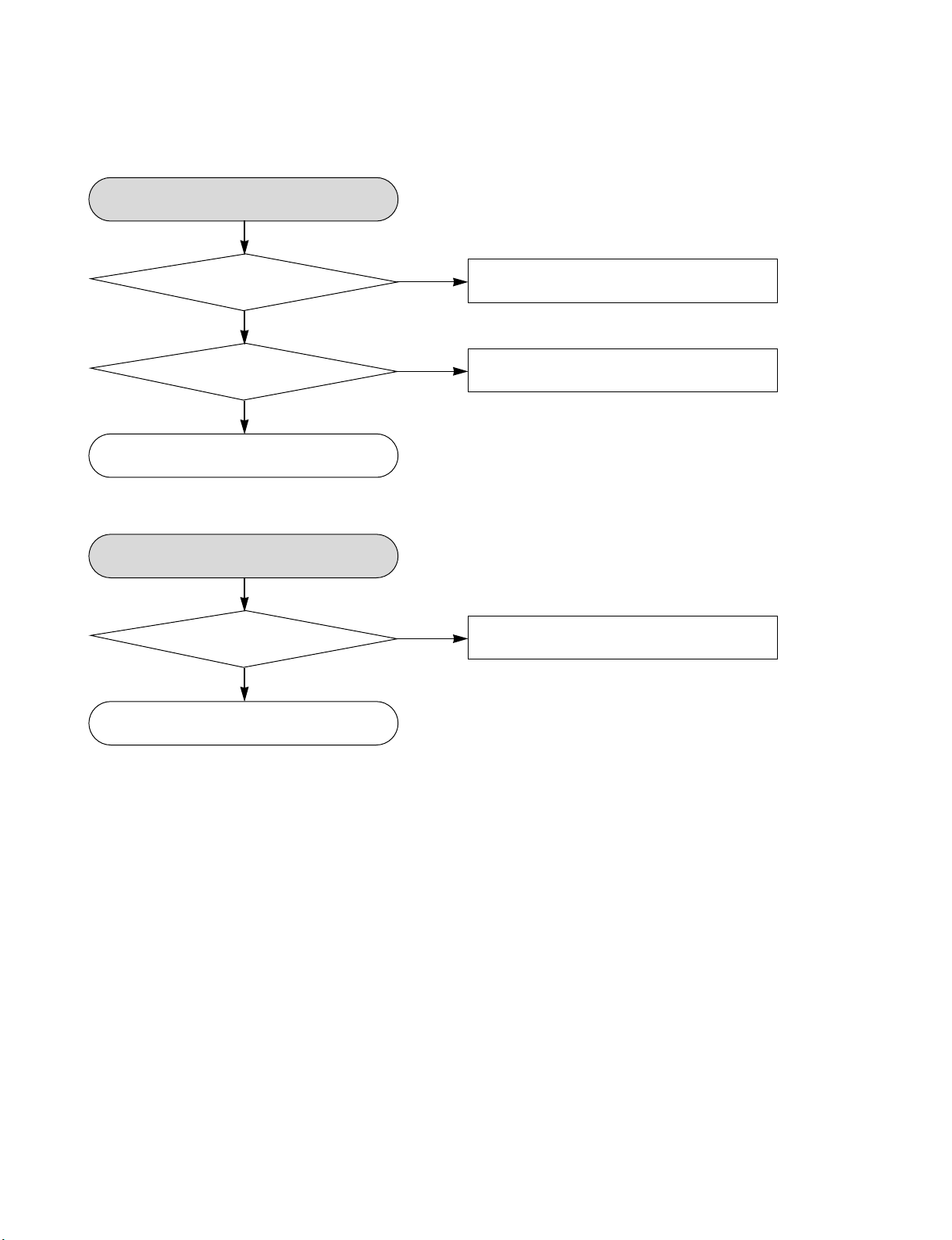

1. MICOM PART CHECK I

MICOM part check I

YES

Check P7904

6PIN P-SENS

YES

Check

power of both

terminals of IC101

KIA7042

YES

Check IC100 78KO/KF2

1PIN power

YES

OK OK

NO

NO

Refer to SMPS

Troubleshooting

Check

if IC101 KIA7042

input is over 5V.

YES

Check if output voltage

of IC101 KIA7042 is 4.3V

YES

NO

Check

the related part of

IC101 KIA7042

YES

NO

Replace the

related parts

3-1

Page 13

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

2. MICOM PART CHECK II

MICOM part check II

YES

Check P7904

5PIN 5.6V

YES

Check power of

both terminals of D101

1SR35

YES

Check

Q101 EMITTER 5V

and COLLECTOR

5V

YES

Check IC103 8PIN IC100

19, 20, 59PIN 5V

NO

NO

NO NO

Refer to SMPS

Troubleshooting

Check D101 1SR35

output is working on 5V

YES

Check the

related part

YES

OK

Check Q102

BASE PIN 0.6V

HIGH

YES

Check Q102 COLLECTOR

NO

Replace the

related parts

Check output power

of IC101 KIA7042 is

over 4.3V.

YES

Check the

related part.

NO

Replace the

related parts

YES

Check the working condition

X101: 32.768kHz

X100: 9.8304MHz

YES

OK

YES

Check the

related part.

YES

OK

3-2

NO

YES

OK

Replace the

related parts

Page 14

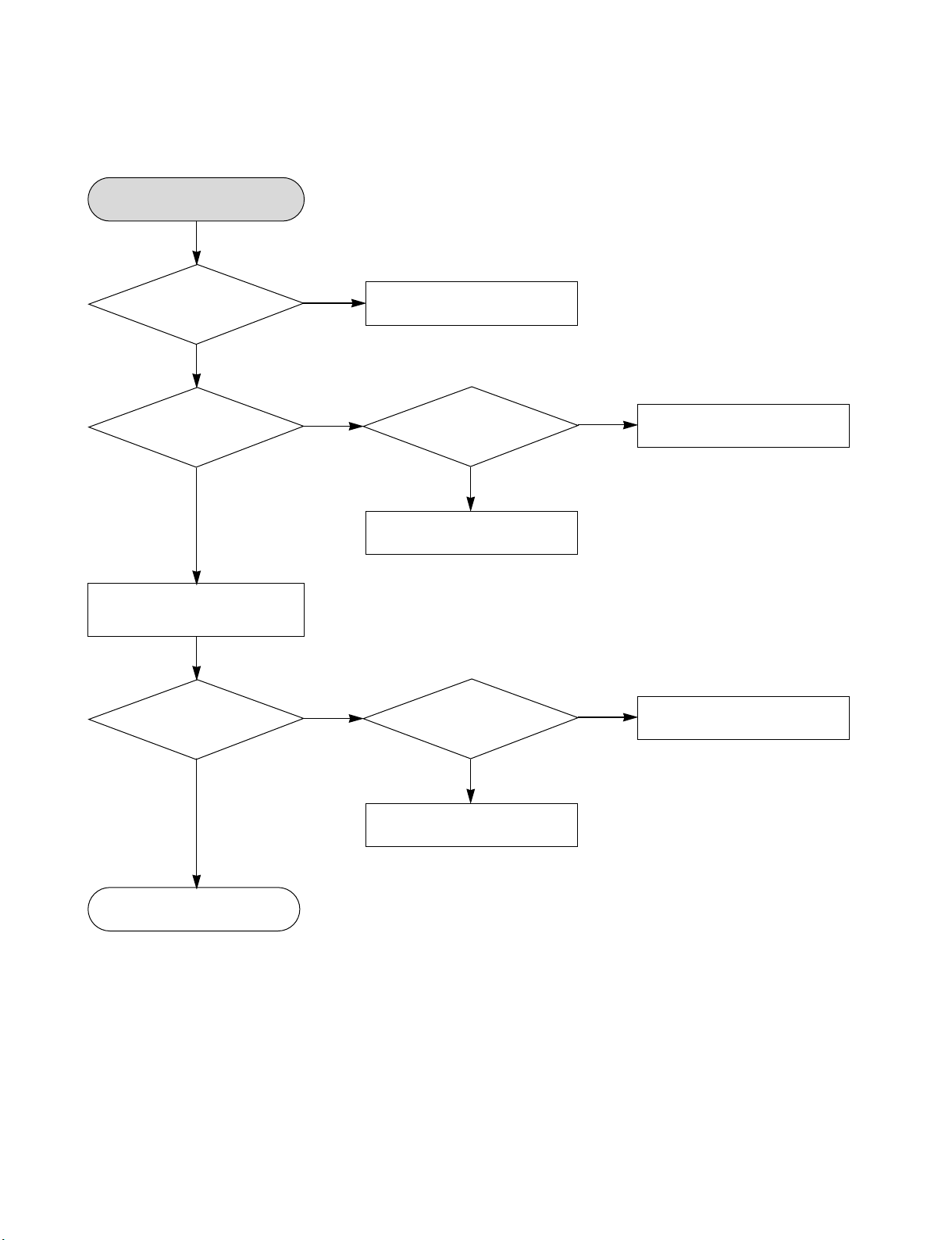

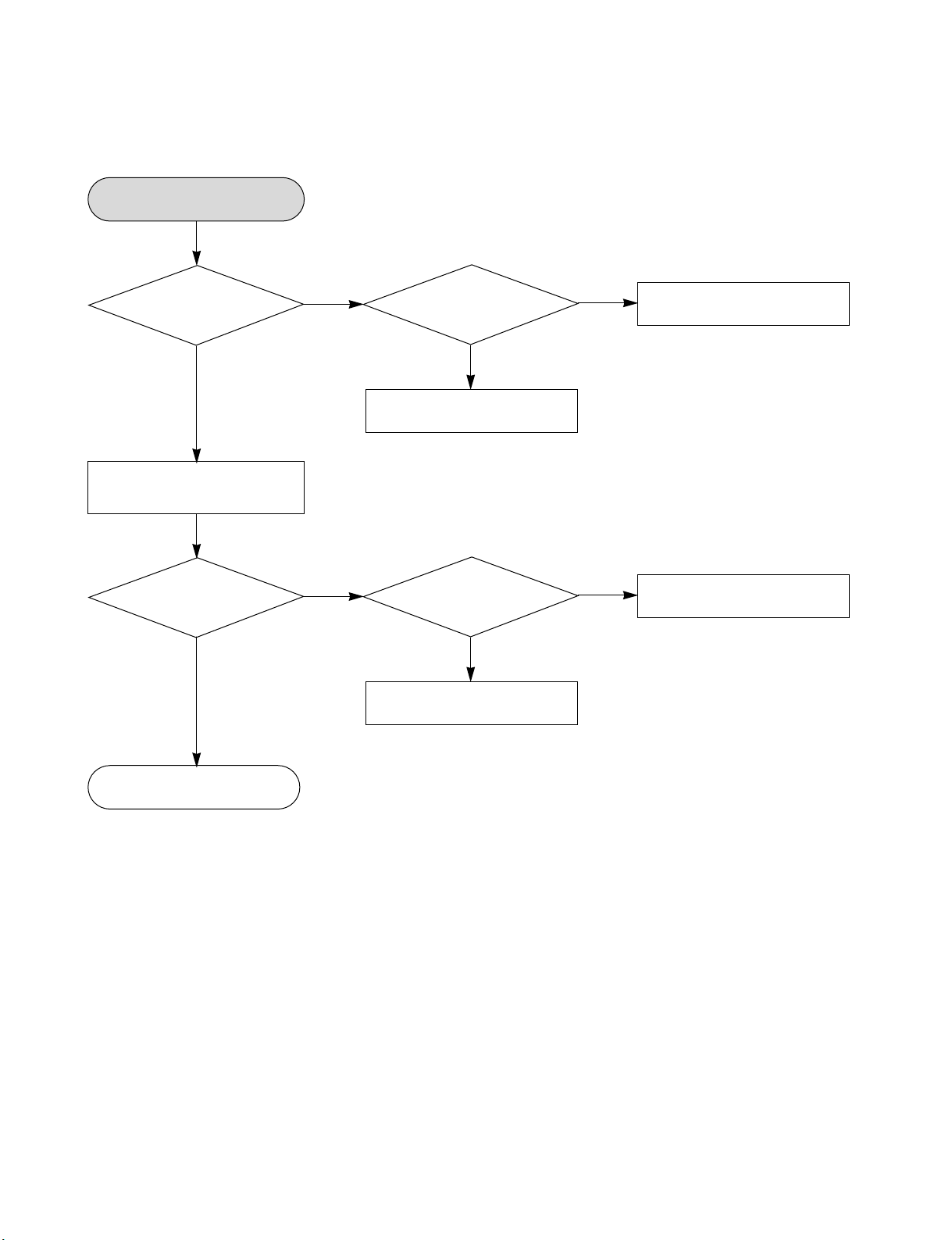

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

3. IC103 KS4CD21CS CHECK

Check IC100 78KOKF2

22, 24PIN

YES

22 PIN DATA

24 PIN CLK

YES

OK

Check MICOM

power 5V

YES

Check the

related part

YES

OK

NONO

NO

Refer to MICOM

Troubleshooting

Replace the related parts

3-3

Page 15

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

4. FLD DISPLAY CHECK

FLD display check

YES

Check P7904

1,2,3 power.

YES

F1+,F2- both

terminals: over 3.7V

Check power VKK: over -28V.

YES

Check

P7302 connection

condition and power F1+,

F2- both terminals: over 3.7V

Check power VKK: over

-28V Check 24

PIN:5.6V

YES

Check IC301

PT6324 power

50PIN VKK: -28V

9.51PIN +5V

NO

NO

NO

Refer to SMPS

Troubleshooting

Check P7302 assembly

YES

Check power

of each PIN

YES

OK

When 5V fails, check

D301SR35 input and

output power

YES

NO

Replace the related part

YES

Check IC100

--> IC301 DATA

communication

PIN PIN

75PIN-->3PIN STB

76PIN-->2PIN DO

78PIN-->1PIN

CLK

YES

YES

NO

Check the

related part

YES

OK

IC100

75PIN - > STB

78PIN - > 1PIN CLK

Check Data output.

YES

76PIN--> DO

--> DATA input

YES

Check the

related part

YES

OKOK

3-4

NO

NO

Replace the related part

Replace the related partFLD light on?

Page 16

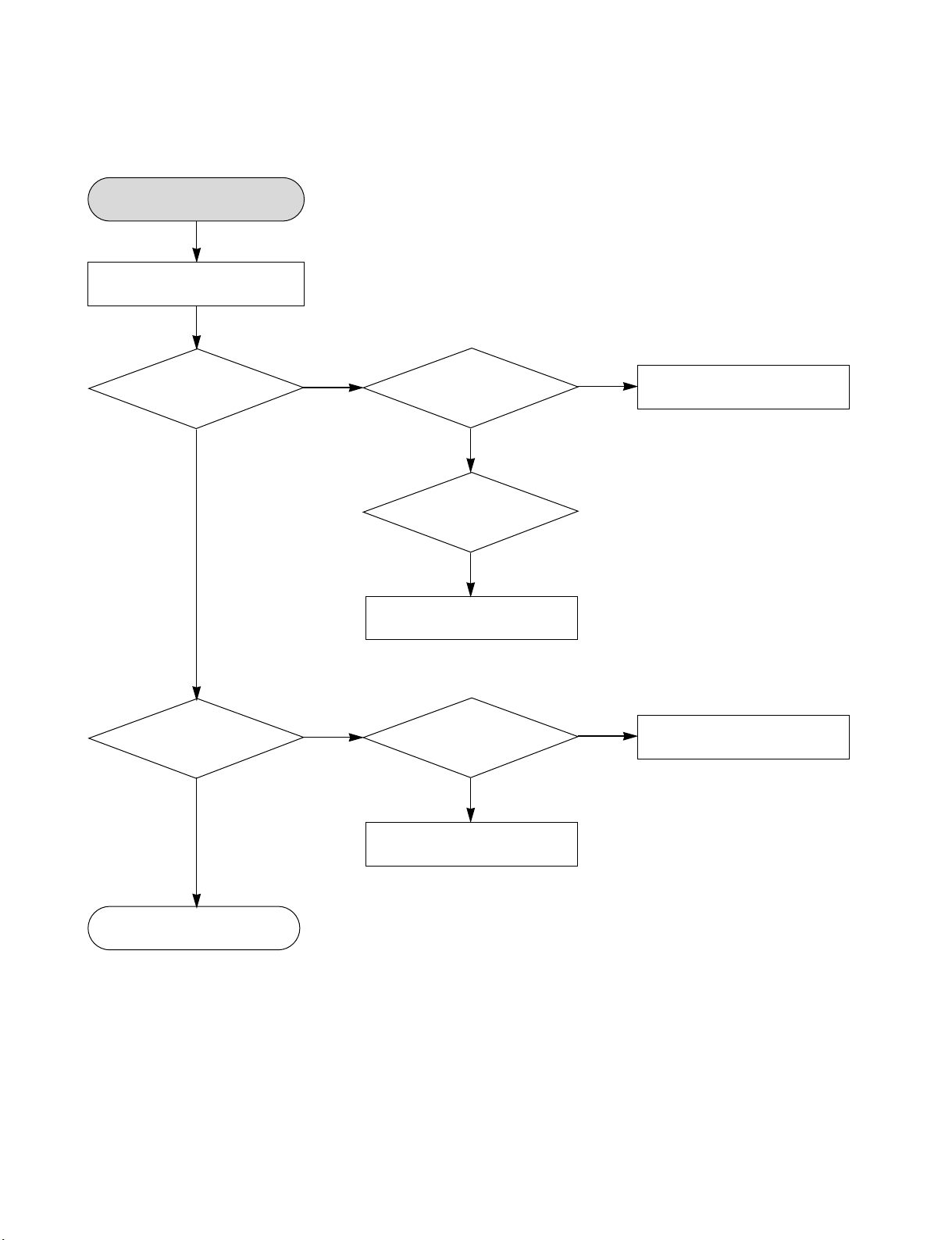

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

5. PWM MODULATION PART

PWM modulation part

YES

Check P7905

9PIN 3.3V

YES

Check IC604 PS9829 VDD PIN

power (3,10,22,29,39,47,56,65,

72,87,94) Check X601 2PIN 3.3V

YES

Check if

X601 12.288MHz is

working.

YES

Check IC604

PS9829 86PIN

CLK input

YES

Check

output of IC100

78KOKF2

21-->PWM_CLK

22-->PWM_DATA

43-->PWM_REST

NO

NO

NO

NO

Refer to SMPS

Troubleshooting

Check the

related part of X601

YES

OK

Check R668(470Ω)

output

YES

OK

Check

resistance

output of LINE DATA:

R623 CLK: R624

RST: R619

NO

NO

NO

Replace the related part

Replace the related part

Replace the related part

YES

Check

IC604

PS9829 DATA input

78 PIN-->DATA

79 PIN-->CLK

96 PIN-->REST

YES

Check PWM

MODULATOR

output FL:75(+)74(-)

FR:71(+)70(-)

YES

NO

NO

YES

OK

Check

DVD ASS`Y PS9829

communication condition

(DVD INTERFACE)

YES

Check IC604

PS9829 DATA input

YES

OK

Check IC604 PS9829 part.OK

3-5

NO

NO

Refer to DVD

Troubleshooting

Check resistance

output of each LINE

Page 17

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

6. POWER AMP PART CHECK

Power AMP part check

YES

P7905 3PIN +

13, 14, 15PIN 21.5V

YES

Check input power IC700

34, 29, 26, 21PIN.

YES

Check input power of IC700,

1, 36, 17, 18, 19PIN +12V

YES

Check PWM MODULATOR

input 4, 6, 14, 16PIN

YES

Check POWER IC 700 34,

29, 27, 20PIN output.

NO

NO

Refer to SMPS

Troubleshooting

Check resistance power

IC700: R702, 701, 726, 727, 724

YES

Check output LINE COIL

YES

OK

NO

Replace the related parts

3-6

Page 18

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

7. PORTABLE FUNCTION

Portable function

YES

Check if JK305 contacts with

YES

Check IC200

(BU4052) 4, 11PIN input

waveform.

YES

Check IC200 (BU4052)

3, 13PIN output waveform.

YES

Check IC801

(MC4580) 2, 6PIN input

waveform.

YES

NO

NO

Check IC200

(BU4052) 16PIN V

8PIN VSS power.

Replace the related parts

Check IC801

(MC4580) 4PIN V

8PIN V

DD power.

Replace the related parts.OK

YES

YES

DD

SS,

,

NO

NO

Check u-COM (IC100)

3, 69PIN communication.

Refer to SMPS

Troubleshooting.

3-7

Page 19

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

8. TV-AUDIO FUNCTION

TV-Audio function

YES

Check Video out

YES

Check Audio in

YES

Check IC200

(BU4052) 5, 14PIN

input waveform

YES

Check IC200

(BU4052) 3, 13PIN

output waveform

NO

NO

Check SW4S1

Check IC200

(BU4052) 16PIN VDD

8PIN VSSpower

YES

Replace the related parts.

,

NO

Check u-COM

3, 6PIN communication

YES

Check IC801

(MC4580) 2, 6PIN

waveform

YES

OK

NO

Check IC801

(MC4580) 4PIN VSS,

8PIN VDD power

YES

Replace the related parts.

3-8

NO

Refer to SMPS

Troubleshooting.

Page 20

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

9. TUNER FUNCTION CHECK

TUNER function check

YES

TUNER module (TUN800)

Check

is working.

YES

Check IC200

(BU4052) 1, 12PIN input

waveform.

YES

Check IC200 (BU4052)

3, 13PIN output waveform.

YES

Check IC801

(MC4580) 2, 6PIN input

waveform.

NO

NO

NO

Check TUNER MODUEL

power (Check 2PIN 9V)

Check IC200

(BU4052) 16PIN VDD,

8PIN VSS power

YES

Replace the related parts

Check IC801

(MC4580) 4PIN VSS,

8PIN VDD power

NO

NO

Check u-COM (IC100)

3, 69PIN communication.

Refer to SMPS

Troubleshooting.

OK

YES

YES

Replace the related parts.

3-9

Page 21

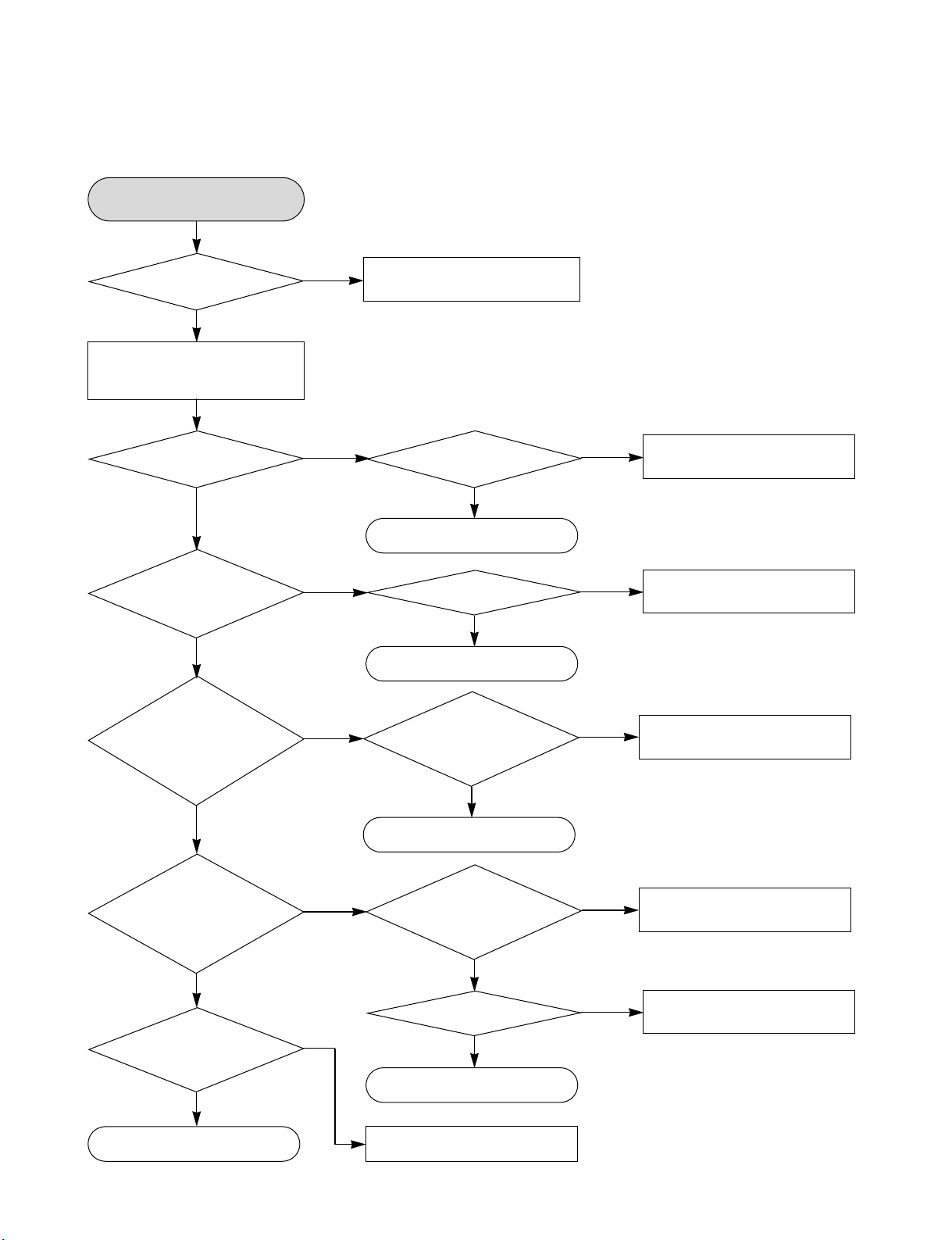

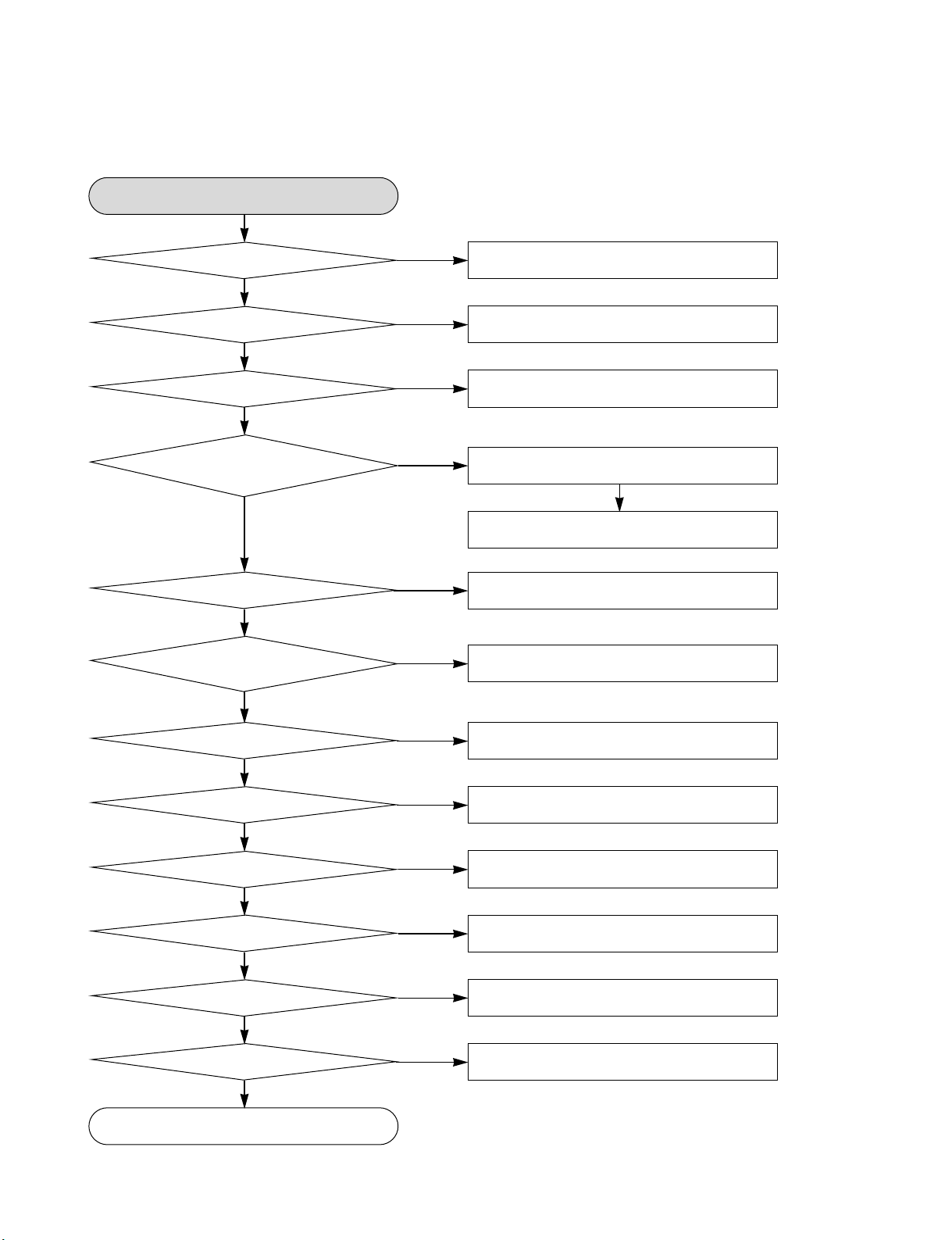

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

10. SMPS POWER TROUBLESHOOTING

No. 5.6VA

YES

Is the F101 Normal?

YES

Is the BD101Normal?

YES

Is the TH101 Normal?

YES

NO

NO

NO

Replace the F101 (Use the same Fuse)

Replace the BD101

Replace the R101

Is Vcc (9V ~ 18V)

supplied to IC101

2PIN?

YES

IS the D959 normal?

YES

Is there about 2.5V

at the IC103 1PIN?

YES

Is the IC102 normal?

YES

Is the D947 Normal?

YES

Is the D949 Normal? Replace the D949

YES

Is the D940 Normal?

NO

NO

NO

NO

NO

NO

NO

Is the D102 normal?

NO

Check or Replace the D102

Replace the D959

Replace the IC103

Replace the IC102

Replace the D947

Replace the D940

YES

Is the D943 Normal?

YES

Is the D941 Normal?

YES

Power Line of Main PCB is short

NO

NO

Replace the D943

Replace the D941

3-10

Page 22

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

No 5.0V

YES

Is the Vcc(5.6V)

supplied to IC957

1PIN?

YES

Is the IC957 4PIN “H”?

YES

Check or Replace the IC957

No 3.3V

YES

Is the Vcc(4.2V)

supplied to IC955

1PIN?

YES

Is the IC955 4PIN “H”?

NO

NO

NO

NO

Check or Replace the D959

Check the CD CTL “H”

signal from µ-com

Check or Replace the D943

Check the P CTL “H”

signal from µ-com

YES

Check or Replace the IC955

No 12V

YES

Is the Vcc(13.5V)

supplied to IC947

1PIN?

YES

Is the IC947 4PIN “H”?

YES

Check or Replace the IC947

NO

NO

Check or Replace the D940

Check the P CTL “H”

signal from µ-com

3-11

Page 23

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

No -12V

YES

Is the voltage of

C932 -13V

YES

Is the IC155 2PIN

12V?

YES

Check or Replace the Q942

No VF+

YES

Is the ZD950

Normal?

YES

Replace the R993 or Q950, Q943

NO

NO

NO

Check or Replace the D970

Check the PWR CTL

“H” signal from µ-com

Replace the ZD950

3-12

Page 24

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

11. BLUETOOH PART (OPTIONAL PART)

Check bluetooth module

YES

Check IC200

(BU4052) 2, 15PIN input

waveform.

YES

Check IC200 (BU4052)

3, 13PIN output waveform.

YES

Check IC801

(MC4580) 2, 6PIN input

waveform.

YES

NO

NO

Check IC200

(BU4052) 16PIN V

8PIN VSS

Replace the related parts

Check IC801

(MC4580) 4PIN V

8PIN V

DD power

Replace the related parts.

power

YES

YES

DD

SS,

,

NO

NO

Check u-COM (IC100)

3, 69PIN communication.

Refer to SMPS

Troubleshooting.

OK

3-13

Page 25

ELECTRICAL TROUBLESHOOTING GUIDE OF AUDIO PART

12. IPOD PART (OPTIONAL PART)

Turn on IPOD

YES

Loading

YES

OSD IPOD

YES

Check IC200

(BU4052) 2, 15PIN input

waveform.

NO

NO

NO

Check the P5801 13PIN, 30PIN

YES

Check the P5801

13PIN and 30PIN line

YES

OK

Check the P5801

18PIN, 19PIN

YES

Check the P5801

18PIN and 19PIN line

YES

OK

Check IC200

(BU4052) 16PIN V

8PIN VSS power

DD,

NO

Check u-COM (IC100)

3PIN, 6PIN communication.

YES

Check IC200 (BU4052)

3, 13PIN output waveform.

YES

Check IC801

(MC4580) 2, 6PIN input

waveform.

YES

OK

NO

YES

Replace the related parts

Check IC801

(MC4580) 4PIN VSS,

8PIN V

DD power

YES

Replace the related parts.

3-14

NO

Refer to SMPS

Troubleshooting.

Page 26

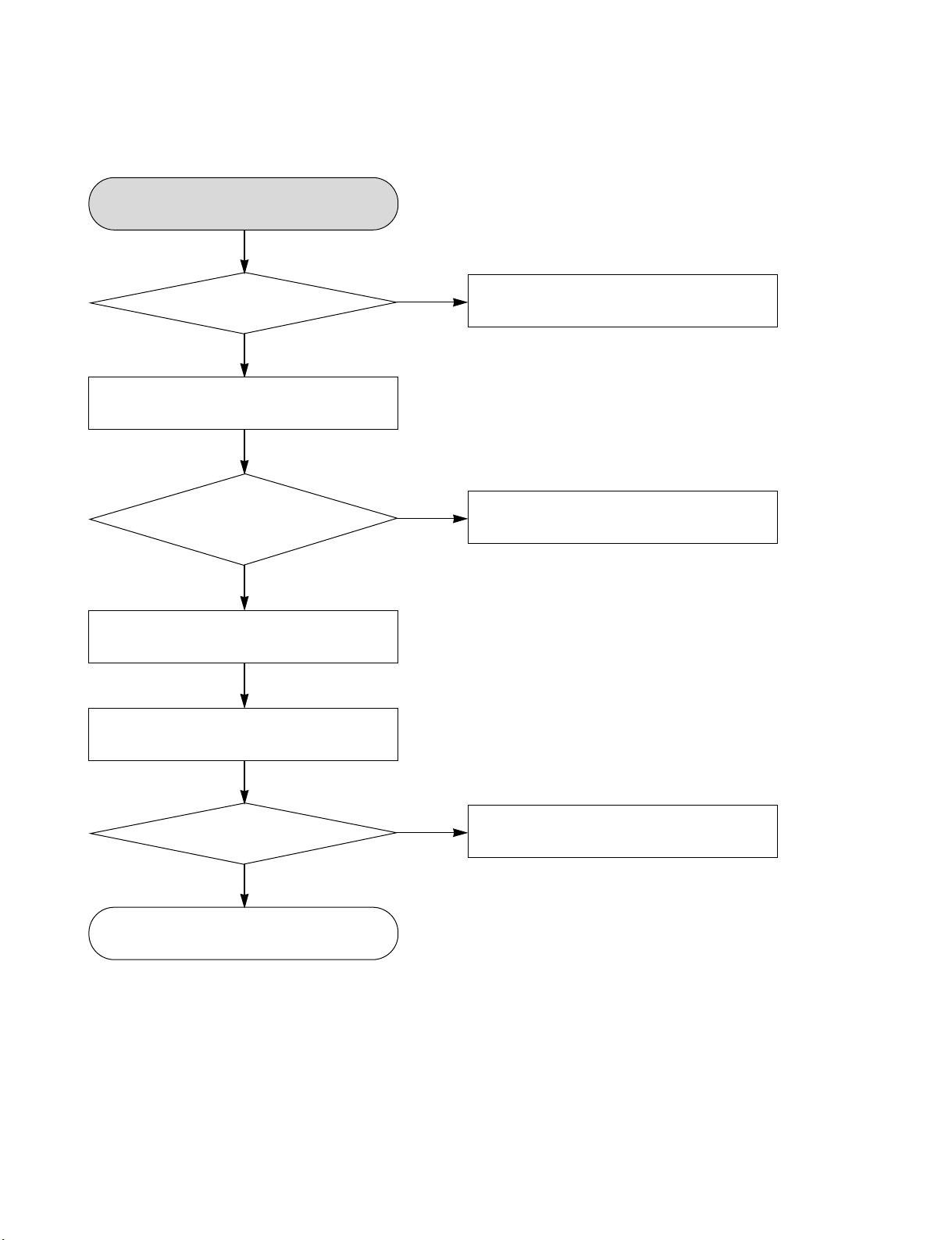

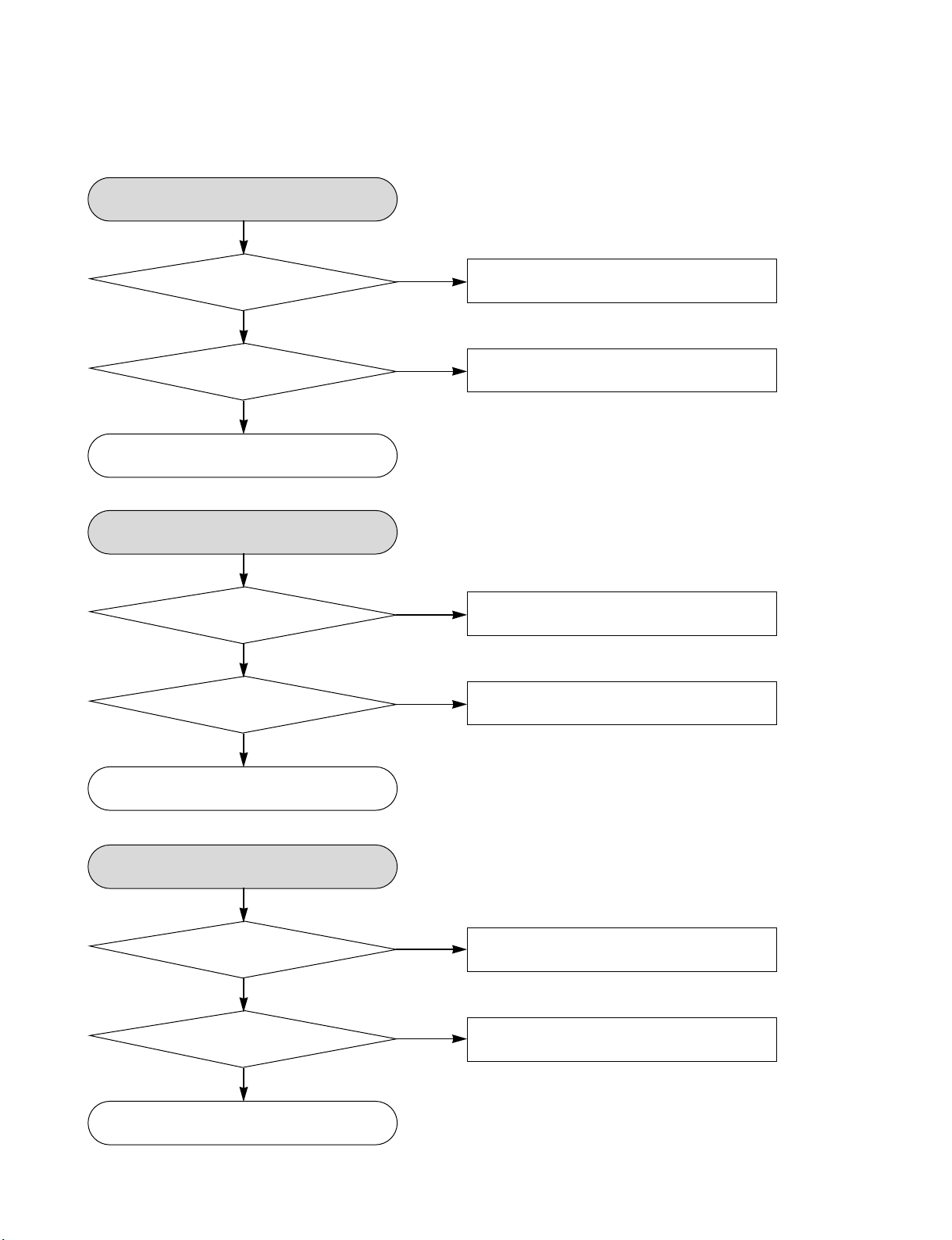

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

1. POWER CHECK GUIDE

Power ON

YES

Select the DVD Mode

YES

Does DVD

appear at FLD?

YES

Does No DISC or

Time are appeared at

FLD?

NO

NO

Does it

appear DVD ERROR

at FLD?

YES

Check

Connector

(P400, P401).

YES

Reconnect it.

Check the

voltage of each pin on

P7905 (3, 5, 7, 9,

10PIN)

YES

NO

NO

Check an Audio

(DVD INTERFACE)

Refer to SMPS

Troubleshooting.

OK

YES

Check DVD MD Module.

3-15

Page 27

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

2. TEST & DEBUG FLOW

Power ON

Show LOGO?

YES

Does

tray move

inside when it is at

closed position?

NO NO

connection to TV set.

NO NO

Flash

memory operates

properly?

YES

SDRAM works

properly?

YES

ES8380

VIDEO outputs

properly?

YES

Check AV cable

OPEN / CLOSE

signals on

P401 are OK?

NO

NO

Check connection lines

between FLASH & ES8380 or

the FLASH access time whether

is suitable or not.

Check connection lines

between SDRAM (IC502) &

ES8380 or the SDRAM is

damaged.

Check the related

circuit of ES8380 (IC501)

PIN133, 134,137, 138, 139, 140

Check the MD mecha

A

YES

YES

OPEN / CLOSE

signals on IC401 are

OK?

YES

Load+&load

signals on P401

are OK?

YES

Check the cable

connection between DVD

PCB and MD (MECHA)

3-16

NO

NO

Check the output signal

of ES8380 to IC401 for

control OPEN / CLOSE

Check the tray control

I/O PIN on IC401.

Page 28

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

A

Does

the SLED

move to inner side

when it is at outer

position?

NO

Moter driver

DRV_MUTE

PIN is high?

YES

NO

Check the MD

YES

Do not put in disc

and tray close.

YES

Optical

Lens is moving

for searching

Focus?

YES

NO

SLED

signal is OK?

YES

Check the cable

connection with MECHA.

Proper

focus outputs to

motor driver?

YES

Proper

F+ & F- outputs?

NO

NO

NO

Check the related

circuit of SLED and

motor driver IC (IC401)

Check focus connection on

ES8380 and motor

driver IC.

Check the motor

driver (IC401).

YES

Check cable connection

B

with pick-up head.

3-17

Page 29

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

B

Laser

turns on when

reading disc?

YES

Put disc in tray. Laser off

YES

Does SPINDLE

rotate?

NO

Check cable connection

NO

NO

DVDLD

or CDLD output

properly?

Collector

voltage of power

transistor is OK?

(Q405, Q406)

YES

between P400 and

pick-up head.

Proper

SPINDLE signal

on ES8380.

YES

NO

NO

NO

Check the laser power circuit

between ES8380 and power

transistor. (Q405, Q406)

Check the related circuit of

laser power transistor.

Check the SPINDLE related

circuit on ES8380

YES

SPIN+ &

YES

C

SPIN- output

properly?

YES

Check the cable

connection between

P400 and MD

NO

Check the SPINDLE control

of motor driver.

3-18

Page 30

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

C

Focus on OK?

YES

Track on OK?

YES

NO

NO

Proper

signal on A, B, C, D

from MD?

YES

Proper

FOO signal on

IC401?

YES

Check cable connection

between P400 and MD.

Proper

TRO signal on

IC401?

YES

T+ & T- output

properly?

NO

NO

NO

NO

Check the connections between

P400 and pick-up head.

Check the related circuit of

ES8380 focus signal.

Check the related circuit

between IC401 and ES8380

Check the tracking control

on motor driver (IC401).

Disc play?

YES

D

NO

YES

Check cable connection

on pick-up head.

Check RF signal

waveform.

3-19

Page 31

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

D

All

outputs are OK

during playing

DISK?

YES

TEST END

NO

NO

Audio

signal data on

DVD INTERFACE

is OK?

YES

Check the MAIN PCB

Picture

signal data on

ES8380 is OK?

NO

NO

Check the connections between

ES8380 and DVD INTERFACE.

For example composite video,

check the video mute TR

(Q411), output of video buffer

IC (IC407) and ES8380

video signal data

3-20

Page 32

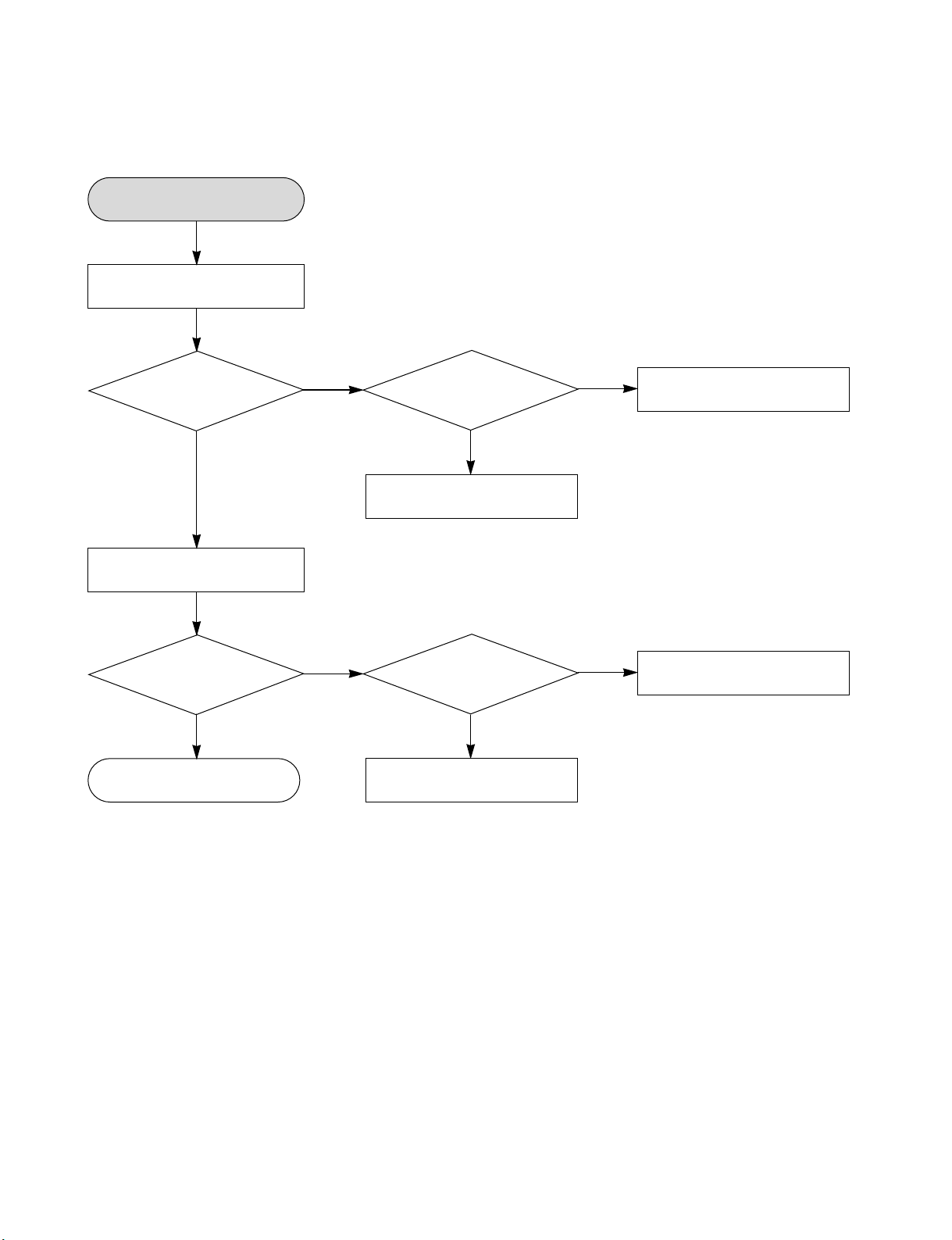

ELECTRICAL TROUBLESHOOTING GUIDE OF DVD PART

3. USB PART

TURN ON USB

“Checking” or

“USB” display check

YES

Reading OK check

YES

NO

NO

Check the POWER supply circuit.

(Check P7905)

YES

Check the HRST# signal

YES

Check the USB PART and

DVD PART line.

Check the USB JACK POWER supply.

(Check P5301)

YES

Check the USB DATA LINE. (P5301)

YES

Check the IC501 (ES8380).

Check DATA LINE

PIN 97 (USB-No), 98 (USB-Po)

OK

3-21

Page 33

WAVEFORMS

1. WHEN POWER ON, RESET & DATA ETC WAVEFORM

1. RESET(DVD)

2. RX

3. TX

4. LCS3# (FLASH)

Playing at USB function

1. HRST#

2. 5V

3. D-

4. D+

3-22

Page 34

2. OPEN / CLOSE WAVEFORM AT POWER ON

1.Limit SW

2.OPEN

3.CLOSE

3. STARTING ACTION WAVEFORM IN MD DEVICE

1.SLO

(from MPEG)

2.SLED-

3.SLED+

(At Power on )

3-23

Page 35

4. FOCUS WAVEFORM

1.FDO

2.F+

3.F-

(INSERT CD )

(INSERT DVD )

1.FDO

2.F+

3.F-

3-24

Page 36

5. AT POWER ON, SPINDLE SIGNAL AT MD DECK

1. Spind

2. Spin+

3. Spin-

6. AT FIRST ACTION, FOCUS SIGNAL A, B, C, D

1. A

2. B

3. C

4. D

3-25

Page 37

7. TRACKING SIGNAL

1. Tro

2. Tr-

3. Tr+

8. RF WAVEFORM

3-26

Page 38

9. DISK TYPE JUGEMENT WAVEFORM

(DVD)

1. F+

2. FDO

3. SVRRF

(CD)

3-27

Page 39

INTERNAL BLOCK DIAGRAM OF ICs

1. AK5358

1-1. PIN CONFIGURATION

AINR

AINL

CKS1

VCOM

AGND

VA

VD

DGND

1-2. BLOCK DIAGRAM

VA AGND VD DGND MCLK

1

2

3

4

Top View

5

6

7

8

16

15

14

13

12

11

10

9

CKS0

CKS2

DIF

PDN

SCLK

MCLK

LRCK

SDTO

AINL

AINR

VCOM

Modulator

Modulator

Volt ag e Reference

Decimation

Filter

Decimation

Filter

3-28

Clock Divider

Serial I/O

Interface

DIFPDNCKS0CKS1CKS2

LRCK

SCLK

SDTO

Page 40

1-3. PIN DESCRIPTION

NO PIN NAME I/O SYMBOL

1 AINR I Rch Analog Input Pin

2 AINL I Lch Analog Input Pin

3 CKS1 I Mode Select 1 Pin

4 VCOM O Common Voltage Output Pin, VA/2

Bias voltage of ADC input.

5 AGND - Analog Ground Pin

6 VA - Analog Power Supply Pin, 4.5 ~ 5.5V

7 VD - Digital Power Supply Pin, 2.7 ~ 3.6V

8 DGND - Digital Ground Pin

9 SDTO O Audio Serial Data Output Pin

“L” Output at Power-down mode.

10 LRCK I/O Output Channel Clock Pin

“L” Output in Master Mode at Power-down mode.

11 MCLK I Master Clock Input Pin

12 SCLK I/O Audio Serial Data Clock Pin

“L” Output in Master Mode at Power-down mode.

13 PDN I Power Down Mode & Reset Pin

“H”: Power up, “L”: Power down & Reset

The AK5358 must be reset once upon power-up.

14 DIF I Audio Interface Format Pin

“H”: 24bit I2S Compatible, “L”: 24bit MSB justified

15 CKS2 I Mode Select 2 Pin

16 CKS0 I Mode Select 0 Pin

3-29

Page 41

2. EM639165

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

VDD

DQML

/WE

/CA S

/RA S

/CS

BA0

BA1

A10(AP)

A0

A1

A2

A3

VDD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

VSS

DQ15

V SSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

V SSQ

DQ10

DQ9

VDDQ

DQ8

VSS

NC

DQMU

CLK

CK E

NC

A11

A9

A8

A7

A6

A5

A4

VSS

2-1. PIN CONFIGURATION

3-30

Page 42

Buffer

DQ0

|

DQ15

Column Decoder

De

co

der

2 MX16

CELL ARRAY

(BANK #A)

Column Decoder

De

co

der

2 MX16

CELL ARRAY

(BANK #C)

Column Decoder

De

co

der

2 MX16

CELL ARRAY

(BANK #D)

Column Decoder

De

co

der

2 MX16

CELL ARRAY

(BANK #B)

CONTROL

SIGNAL

GENERATOR

MODE

REGISTER

CLOCL

BUFFER

COMMAND

DECODER

CLOCK

CKE

CS#

RAS#

CAS#

WE#

UDQM

LDQM

COLUMN

COUNTER

ADDRESS

BUFFER

A0

A11

BA0

BA1

~

REFRESH

COUNTER

CLOCK

BUFFER

2-2. BLOCK DIAGRAM

3-31

Page 43

3. ES29LV160E

Command

Registe

r

Analog Bias

Generato

r

Address Latch

BYTE#

CE#

OE#

A<0:19>

RESET#

Vcc

Vss

Chip Enable

Output Enable

Logi

c

Vcc Dete

ctor

Timer/

Counter

Y-Decode

r

X-Deco

der

Y-Decode

r

Ce

ll Array

Data Latch/

Sense Amp

s

Input/Output

Buff

ers

Sector Switches

DQ0-DQ15(A-1

)

RY/BY

#

Write

State

Machin

e

WE

#

3-1. PIN CONFIGURATION

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

3-2. BLOCK DIAGRAM

48-Pin Standard TSOP

ES29LV160

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

Vss

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

Vcc

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

Vss

CE#

A0

3-32

Page 44

3-3. PIN DESCRIPTION

Pin Description

A0-A19 20 Addresses

DQ0-DQ14 15 Data Inputs/Outputs

DQ15/A-1

DQ15 (Data Input/Output, Word Mode)

A-1 (LSB Address Input, Byte Mode)

CE# Chip Enable

OE# Output Enable

WE# Write Enable

RESET# Hardware Reset Pin, Active Low

BYTE# Selects 8-bit or 16-bit mode

RY/BY# Ready/Busy Output (N/A SO 044)

Vcc

3.0 volt-only single power supply

(see Product Selector Guide for speed options and voltage supply tolerances)

Vss Device Ground

NC Pin Not

Connected Internally

3-33

Page 45

4. HT1000

4-1. PIN CONFIGURATION

DKD PACKAGE

(T

OP VIEW)

GVDD_B

OTW

SD

PWM_A

RESET_AB

PWM_B

OC_ADJ

GND

AGND

VREG

M3

M2

M1

PWM_C

RESET_CD

PWM_D

VDD

GVDD_C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

GVDD_A

BST_A

PVDD_A

OUT_A

GND_A

GND_B

OUT_B

PVDD_B

BST_B

BST_C

PVDD_C

OUT_C

GND_C

GND_D

OUT_D

PVDD_D

BST_D

GVDD_D

3-34

Page 46

4-2. SYSTEM BLOCK DIAGRAM

OTW

System

Microcontroller

AS5508

T

VALID

SD

RESET_AB

RESET_CD

SD

OTW

BST_A

BST_B

Bootstrap

Capacitors

Left-

Channel

Output

Right-

Channel

Output

System

Power

Supply

35 V

Hardwire

Mode

Control

PVDD

PWM_A

PWM_B

PWM_C

PWM_D

M1

M2

M3

Input

H-Bridge 1

Input

H-Bridge 2

PVDD_A, B, C, D

GND_A, B, C, D

4

44

PVDD

Power

Supply

Decoupling

2-Channel

H-Bridge

BTL Mode

GVDD_A, B, C, D

VDD

GND

GVDD

VDD

VREG

Power Supply

Decoupling

Output

H-Bridge 1

Output

H-Bridge 2

VREG

AGND

OC_ADJ

Hardwire

OC Limit

OUT_A

OUT_B

OUT_C

OUT_D

BST_C

BST_D

2nd-Order L-C

Output Filter

for Each

Half-Bridge

2nd-Order L-C

Output Filter

for Each

Half-Bridge

Bootstrap

Capacitors

VA C

GND

12 V

GND

GVDD (12 V)/VDD (12 V)

3-35

Page 47

4-3. FUNCTIONAL BLOCK DIAGRAM

OTW

Internal Pullup

Resistors to VREG

SD

M1

M2

M3

RESET_AB

RESET_CD

PWM_D OUT_D

PWM_C OUT_C

PWM_B OUT_B

PWM_A OUT_A

PWM

Rcv.

PWM

Rcv.

PWM

Rcv.

PWM

Rcv

Protection

and

I/O Logic

Ctrl.

Ctrl.

Ctrl.

.

Ctrl.

iming

T

Timi ng

Timi ng

Timi ng

Under-

voltage

Protection

Power

On

Reset

Temp.

Sense

Overload

Protection

Gate

Drive

Gate

Drive

Gate

Drive

Gate

Drive

VDD

4

VREG VREG

AGND

GND

Isense

OC_ADJ

GVDD_D

BST_D

PVDD_D

BTL/PBTL Configuration

Pulldown

Resistor

GND_D

GVDD_C

BST_C

PVDD_C

BTL/PBTL Configuration

Pulldown Resistor

GND_C

GVDD_B

BST_B

PVDD_B

BTL/PBTL Configuration

Pulldown Resistor

GND_B

GVDD_A

BST_A

PVDD_A

BTL/PBTL Configuration

Pulldown Resistor

GND_A

3-36

Page 48

5. IP9009

28 27 26 25 24 23 22 21 20 19 18 17 16 15

1234567 891011 12 13 14

BIAS REBadj REOadj Reset Vdet IN4 IN3 PGND MUTE PVCC2 GND VO4- VO4+ VO3- VO3+

FWD REV CTL PS IN1 IN2 SVCC PGND PVCC1 VOL- VOL+ VO2- VO2+ VO1- VO1+

I P 9 0 0 9

28 27 26 25 24 23 22 21 20 19 18 17 16 15

BIAS REBadj REOadj Reset Vdet IN4 IN3 PGND MUTE PVCC2 GND VO4- VO4+ VO3- VO3+

123456

7

891011 12 13 14

FWD REV CTL PS IN1 IN2

SVCC

PGND PVCC1 VOL- VOL+ VO2 - VO2 + VO1- VO1+

Reset

MUTE

TSD

LEVEL SHIFT

-+

LEVEL SHIFT

-+

LEVEL SHIFT

-+

LEVEL SHIFT

-+

LEVEL SHIFT

-+

P/S

MSC

SWITCH

D

DD D DDD

DDD

45K45K

45K45K

10K 10K

10K 10K

5-1. PIN CONFIGURATION

5-2. BLOCK DIAGRAM

5-3. PIN DESCRIPTION

No SYMBOL I/O SYMBOL

1 FWD I Loading motor forward input

2 REV I Loading motor reverse input

3 CTL I Loading motor speed control

4 PS I Power save

5 IN1 I CH1 input

6 IN2 I CH2 input

7 SVCC - Signal power supply

8 PVCC1 - Power supply 1

9 VOL- O Loading driver output(-)

10 VOL+ O Loading driver output(+)

11 VO2- O CH2 driver output(-)

12 VO2+ O CH2 driver output(+)

13 VO1- O CH1 driver output(-)

14 VO1+ O CH1 driver output(+)

3-37

No SYMBOL I/O SYMBOL

15 VO4+ O CH4 driver output(+)

16 VO4- O CH4 driver output(-)

17 VO3+ O CH3 driver output(+)

18 VO3- O CH3 driver output(-)

19 GND - Ground

20 PVCC2 - Power supply 2

21 MUTE I Mute

22 IN3 I CH3 input

23 IN4 I CH4 input

24 Vdet I Reset controller input

25 Reset O Reset controller output

26 REOadj O Adjustable regulator feedback

27 REBadj O Adjustable regulator control

28 BIAS I Bias

Page 49

6. KS24L161

Vcc

A0WPA1

SCLA2SDA

Vss

KS24L161

SDA

Start/Stop

Logic

Control Logic

HV Generation

Timing Control

Word Address

Pointer

Row

Decoder

EEPROM

Celt Array

2,048 x 8 Bits

Column Decoder

Data Register

D

OUT

and ACK

Slave Address

Comparator

WP

SCL

6-1. PIN CONFIGURATION

6-2. BLOCK DIAGRAM

6-3. PIN DESCRIPTION

Name Type Description Circuit Number

A0, A1,A3 - No internal connection -

VSS - Ground pin. -

Bi-directional data pin forthe I

SDA I/O open-drain output. An external pull-up resistor must be connected to V

for this pull-up resistor are 4.7KΩ(100kHz) and 1KΩ(400kHz).

2

C-bus serial data interface. Schmitt tigger input and

DD. Typical values 3

SCL Input Schmitt tigger input pin for serial clock input. 2

WP Input function is disabled to protect previously written data in the entire memory; if you tie it 1

to VSS, the write function is enabled.

V

CC - Single power supply. -

3-38

Input pin for hardware write protection control. If you tie this pin to V

CC, the write

Page 50

7. MC4580

7-1. PIN CONFIGURATION

7-2. TEST CIRCUIT

7-3. ABSOLUTE MAXIMUM RATINGS (TA=25°C)

3-39

Page 51

8. PS9829B

IO_VDD

PLL_DVDD

IO_VSS

IO_VSS

PLL_AVDD

IO_VSS

PLL_AVSS

PLL_DVSS

MLRCK

MBCK

MSDIN0

MIC_LRCK

MIC_BCK

MIC_MCLK

PWM_HP_R_P

IO_VSS

PWM2_P

PWM2_M

PWM3_P

PWM3_M

PWM4_P

IO_VDD

PWM4_M

SPI/I2C

/CS/I2C_AD2

SI/I2C_AD0

SO/SDA

SCK/SCL

/RESET

SCAN_ENA

CLK_IN

DVSS

IO_VSS

IO_VSS

IO_VSS

DVDD

DVSS

IO_VDD

IO_VSS

MSDIN1

MSDIN2

SLRCK

SBCK

DVSS

PWM5_P

PWM5_M

DVDD

TEST_MODE3

DVSS

IO_VSS

PWM6_P

PWM6_M

IO_VSS

IO_VSS

PWM1_P

PWM1_M

OVERLOAD

IO_VSS

IO_VSS

SSDIN1

EXT_MUTE

DVDD

IO_VDD

DVDD

SSDIN0

MSDIN3

SSDIN2

SSDIN3

IO_VSS

IO_VDD

MIC_SDIN

PWM_SWL_P

PWM_SWL_M

PWM_HP_L_P

PWM_HP_L_M

PWM_HP_R_M

IO_VSS

PWM7_P

PWM7_M

PWM8_P

PWM8_M

EPD_ENA

TEST_MODE2

TEST_MODE1

IO_VSS

DMIX_LRCK

DMIX_BCK

DMIX_SDOUT

DMIX_MC

L

K

9

8

9

9

1

0

0

9

6

9

7

9

3

9

4

9

5

9

1

9

2

8

5

8

6

8

7

8

8

8

9

9

0

8

3

8

4

8

1

8

2

71

72

73

74

75

61

62

63

64

65

66

67

68

69

70

53

54

55

56

57

58

59

51

52

60

46

47

48

49

50

9101112131415

16

1234567

8

30

31

32

33

34

35

36

37

26

27

28

29

7

6

7

7

7

8

7

9

8

0

171819

20

38

39

40

41

42

43

44

45

2122232425

IO_VDD

IO_VSS

IO_VDD

DVDD

DVSS

IO_VDD

IO_VDD

IO_VDD

DVSS

DVDD

IO_VDD

PULSUS

PS9829B

PLL

PWM

M

odulator

Internal Controls

MLRCK

MBCK

MSDIN[0:3]

CLK_IN

SCK/SCL

SO/SDA

SI/I2C_AD0

/CS/I2C_

AD2

PWM2_P/M

PWM3_P/M

PWM4_P/M

PWM5_P/M

PWM6_

P/M

/RESET

OVERLOAD

EXT_MUTE

PWM1_P/M

PWM8_P/M

Internal Clock

SPI/I2C

PWM7_P/M

SLRCK

SBCK

SSDIN[0:3]

PWM_HP_R_P/M

PWM_HP_L_P/M

EPD_ENA

PWM_SW

L_P/M

MIC_LRCK

MIC_BCK

MIC_SDIN

MIC_

MCLK

DMIX_MCLK

OLRCK

OBCK

DMIX_

SDOUT

PLL_DVDD

PLL_DVSS

PLL_AVDD

PLL_AVSS

DVDD

DVSS

IO_VDD

IO

_VSS

Power Supply

Reset & Power

Down

Internal Reset

Serial Audio

Output

interfa

ce

Automatic

Gain

Lim

iter

Main

Volume

Trim

Volume

Bass

Manager

4 Band

EQ

Down

Mi

xer

Mi

xer

Mic.

Input

Process

or

Input

Mapper

Sample

Rate

Converter

Input

&

Output

MUX

Host

Interface

(I

2

C, SPI)

Serial

Audio

Output

interfa

ce

Output Mapper

POP

NR

8-1. PIN CONFIGURATION

8-2. BLOCK DIAGRAM

3-40

Page 52

9. PT6324

9-1. PIN CONFIGURATION

GND

VDD

VEE

GR16

GR15

GR13

GR12

GR11

GR10

GR9

GR8

GR14

GR7

CLK

DIN

STB

DOUT

K1

K2

OSC

GND

VDD

SG1/KS1

SG2/KS2

SG 3KS3

SG4/KS4

52 50 49 48

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

47

PT6324

18 19 20

17

46 45

21 22

44

43

23

42 41

25 2615

24

4051

39

38

37

36

35

34

33

32

31

30

29

28

27

GR6

GR5

GR4

GR3

GR2

GR1

SG24

SG23

SG22

SG21

SG20

SG19

SG18

SG17

SG6/KS6

SG5/KS5

SG7/KS7

SG8/KS8

SG9/KS9

SG11/KS11

SG10/KS10

SG12/KS12

SG13/KS13

SG14/KS14

SG16/KS16

SG15/KS15

3-41

Page 53

9-2. BLOCK DIAGRAM

DIN

DOUT

CLK

ST

OSC

Control

Serial

Data

Interface

B

Display Memory

ming Generator

Ti

Key Matrix Memory

Segment Driver

SG1/KS1

SG2/KS2

SG3/KS3

SG4/KS4

SG5/KS5

SG6/KS6

SG7/KS7

SG8/KS8

SG9/KS9

SG10/KS10

SG11/KS11

SG12/KS12

SG13/KS13

SG14/KS14

SG15/KS15

SG16/KS16

SG17

SG18

SG19

SG20

SG21

SG22

SG23

SG24

K1 K2

mming Circuit

Di

3-42

VDD GND VEE

Grid

Drive

GR1

GR2

GR3

GR4

GR5

GR6

GR7

GR8

r

GR9

GR10

GR11

GR12

GR13

GR14

GR15

GR16

Page 54

9-3. PIN DESCRIPTION

Pin Name I/O Description Pin No.

CLK

Clock input pin

This pin reads serial data at the rising edge and outputs data at

the falling edge.

1

DIN

Data input pin

When this pin acts as input pin, serial data is inputted at the

rising edge of the shift clock (starting from the lower bit)

2

STB

Serial interface strobe pin

The data input after the STB has fallen is processed as a

command. When this in is ìHIGHî, CLK is ignored.

3

DOUT

Data output pin (N-channel, Open-drain)

When this pin acts as output pin, serial data is outputted at the

falling edge of the shift clock (starting from the lower bit)

4

K1 to K2

I

I

I

I

O

Key data input pins

The data inputted to these pins is latched at the end of the

display cycle.

5, 6

OSC

Oscillator input pin

A resistor is connected to this pin to determine the oscillation

frequency.

7

GND - Ground pin

8, 52

VDD -

-

Logic power supply 9, 51

SG1/KS1 to

SG16/KS16

O

High-voltage segment output pins

Also acts as the key source

10 to 25

SG17 to SG24 O High-voltage segment output pins

26 to 33

GR1 to GR16 O High-voltage grid output pins 34 to 49

VEE Pull-down level

50

3-43

Page 55

10. STR-A6252

10-1. BLOCK DIAGRAM

5

VCC

32V

TSD

OVP

+

-

140℃ typ

10µs

Delay

7.2V

D

8

1.2mA

Bias

UVLO

+

-

14.3V/10V

R

+

Q

S

Internal

(7, 8Pin)

GND

3

PWM OSC

46~54kHz

Noize

Reducer

FB/OCP

R

Q

S

PWM

Latch

+

-

BURST

+

0.52V

0.75V

3R

R

CV/CC

Control

Q

Start

11

µA

4.5V/3.6V

R

S

Soft

Q

tFMx128

R

S

+

-

Timer

Blanking

(350ns)

22

µA

Drive

7.1V

310

µA

Over Load

protection

Frequency

Modulation

10V

-

1

4

2

S/OCP

FB/CC

/OLP

FM/SS

18

µA

+

8.6V

10-2. PIN FUNCTION

Terminal No. SYMBOL Description Functions

1 Source/O.C.P Source/O.C.P terminal MOSFET Source/Over current protect

2 FM/SS FM terminal Capacitor connection terminal for frequency jitter and soft start

3 GND Ground terminal Ground

Input of constant voltage signal /

4 FB/CC/OLP FB/CC/OLP terminal constant current operation control signal /

over load protection signal

5 Vcc Power supply terminal Input of power supply for control circuit

7

8

D Drain terminal MOSFET drain / Input of Startup current

3-44

Page 56

11. µPD78F0546R (R)

11-1. PIN CONFIGURATION (TOP VIEW)

P140/PCL/INTP6

P141/BUZ/BUSY0/INTP7

P142/SCKA0

P143/SIA0

P144/SOA0

P145/STB0

P00/T1000

80 79 78 77 76 75 74 7372 71 7069 6867 66 65 64 6362 61

1P120/INTP0/EXLVI

2P47

3P46

4P45

5P44

6P43

7P42

8P41

9P40

10RESET

11P124/XT2/EXCLKS

12P123/XT1

13FLMD0

14P122/X2/EXCLK

15P121/X1

16REGC

17VSS

18EVSS

19VDD

20EVDD

21 22 23 24 25 26 27 2829 30 3132 3334 35 36 37 3839 40

P01/T1010/TO00

P02/SO11

P03/SI11

P04/SCK11

P130

ANI0/P20

ANI1/P21

ANI2/P22

ANI3/P23

ANI4/P24

ANI5/P25

ANI6/P26

ANI7/P27

AVSS60

AVREF59

P5758

P5657

P5556

P5455

P10/SCK10/TxD054

P11/SI10/RxD053

P12/SO1052

P13/TxD651

P14/RxD650

P15/TOH049

P16/TOH1/INTP548

P17/TI50/TO5047

P30/INTP146

P5345

P5244

P5143

P5042

P31/INTP241

P60/SCL0

P61/SDA0

P62/EXSCL0

P63

P64

P65

P66

P33/TI51/INTP4

P67

3-45

P77/KR7

P76/KR6

P75/KR5

P74/KR4

P73/KR3

P72/KR2

P71/KR1

P70/KR0

P06/TI011/TO01

P05/TI001/SSI11

P32/INTP3

Page 57

11-2. BLOCK DIAGRAM

TO00/TI010/P01

TI000/P00

RxD6/P14 (LINSEL)

TO01/TI011/P06

TI001/P05

TOH0/P15

TOH1/P16

TI50/TO50/P17

TI51/TO51/P33

RxD0/P11

TxD0/P10

RxD6/P14

TxD6/P13

SI10/P11

SO10/P12

SCK10/P10

SI11/P03

SO11/P02

SCK11/P04

SCK11/P05

SIA0/P143

SOA0/P144

SCKA0/P142

STB0/P145

BUSY0/P141

EXSCL0/P62

SDA0/P61

SCL0/P60

ANI0/P20 to

ANI7/P27

AV

REF

AV

INTP0/P120

INTP1/P30 to

INTP4/P33

INTP5/P16

INTP6/P140,

INTP7/P141

SS

RxD6/P14 (LINSEL)

16-bit timer/

event counter 00

16-bit timer/

event counter 01

Internal low-speed

8-bit timer

event counter 50

8-bit timer

event counter 51

Serial

interface UART0

Serial

interface UART6

Serial

interface CSI10

Serial

interface CSI11

Serial

interface CSIA0

Serial

interface IIC0

8

4

2

8-bit timer H0

8-bit timer H1

oscillator

Watchdog timer

Watch timer

LINSEL

A/D converter

Interrupt

control

78K/0

CPU

core

BANK

Internal

high-speed

RAM

1 KB

VDD,

EVDD

VSS,

EVSS

Flash

memory

96 KB

Internal

expansion

RAM

4 KB

FLMD0

Port 0 P00 to P06

Port 1 P10 to P17

Port 2 P20 to P27

Port 3 P30 to P33

Port 4 P40 to P47

Port 5 P50 to P57

Port 6 P60 to P67

Port 7 P70 to P77

Port 12 P120 to P124

Port 13

Port 14 P140 to P145

Buzzer output

Clock output

control

Power on clear/

low voltage

indicator

Key return

Reset control

Multiplier &

divider

System

control

Internal high-speed

oscillator

Volt age

regulator

7

8

7

4

8

8

8

8

5

P130

6

BUZ/P141

PCL/P140

POC/LVI

control

KR0/P70 to

8

KR7/P77

RESET

XT1/P121

X2/EXCLK/P122

XT1/P123

XT2/EXCLKS/P124

REGC

EXLVI/P120

3-46

Page 58

11-3. PIN FUNCTION

Function Name I/O Function After Reset Altemate Function

P00

P01

P02

P03

P04

P05

P06

P10

P11

P12

P13

P14

P15

P16

P17

P20 to P27 ANI0 to ANI17

I/O Port 0. Input port

7-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified by

a software setting.

I/O Port 1. Input port

8-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified by

a software setting.

I/O Port 2. Analog input

8-bit I/O port.

Input/output can be specified in 1-bit units.

TI000

TI010/TO00

SO11

SI11

SCK11

TI001/SSI11

TI011/TO01

SCK10/TxD0

SI10/RxD0

SO10

TxD6

RxD6

TOH0

TOH1/INTP5

TI50/TO50

P30

P31

P32

P33

P40 to P47 -

P50 to P57 -

P60

P61

P62

P63 to P67

I/O Port 3. Input port

4-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified by

a software setting.

I/O Port 4. Input port

8-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified by

a software setting.

I/O Port 5. Input port

8-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified by

a software setting.

I/O Port 6. Input port

8-bit I/O port.

Output of P60 to P63 is N-ch open-drain output(6V tolerance).

Input/output can be specified in 1-bit units.

Only for P64 to P67, use of an on-chip pull-up resistor

can be specified by a software setting.

INTP1

INTP2

INTP3

TI51/TO51/INTP4

SCL0

SDA0

EXSCL0

-

3-47

Page 59

Function Name I/O Function After Reset Altemate Function

P70 to P77

P120

P121

P122

P123

P124

P130 -

P140

P141

P142

P143

P144

P145

I/O Port 7. Input port

8-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified by

a software setting.

I/O Port 12. Input port

5-bit I/O port.

Input/output can be specified in 1-bit units.

Only for P120, use of an on-chip pull-up resistor can

be specified by a software setting.

Output Port 13. Output port

1-bit output-only port

I/O Port 14. Input port

6-bit I/O port.

Input/output can be specified in 1-bit units.

Use of an on-chip pull-up resistor can be specified

by a software setting.

KR0 to KR7

INTP0/EXLVI

X1

X2/EXCLK

XT1

XT2/EXCLKS

PCL/INTP6

BUZ/BUSY0/INTP7

SCKA0

SIA0

SOA0

STB0

3-48

Page 60

WIRING DIAGRAM

3-49 3-50

Page 61

AC

NPU

ZN

R &

FI

LTER

MAI

&

PW

M I

FL1-FL2

(4.

V)

-12V

12V

(78R12

5V(P-SENS)S)

6VA

(KIA278R

05

CN2

CN1

FEED

ACK

AM

) 3

.5V

5V (278R35

-31.

5V(VK

RECTIFIER

SMOOTHING

CIRCUIT

BLOCK DIAGRAMS

1. SMPS BLOCK DIAGRAM

AM

P (+(+) 3

1.5V

RECTIFIER

SMOOTHING

CIRCUIT

ZN

R &

FI

LTER

MAI

N&

PW

M I

C

T

R

A

N

S

3.3.5V (278R35

12V

5V(P-SEN

5.5.6VA

)

(78R12

(KIA278R

-12V

)

05

CN1

)

AC

INPU

T

3-51 3-52

-31.

FL1-FL2

FEED

5V(VK

(4.

BACK

K)

CN2

5V)

Page 62

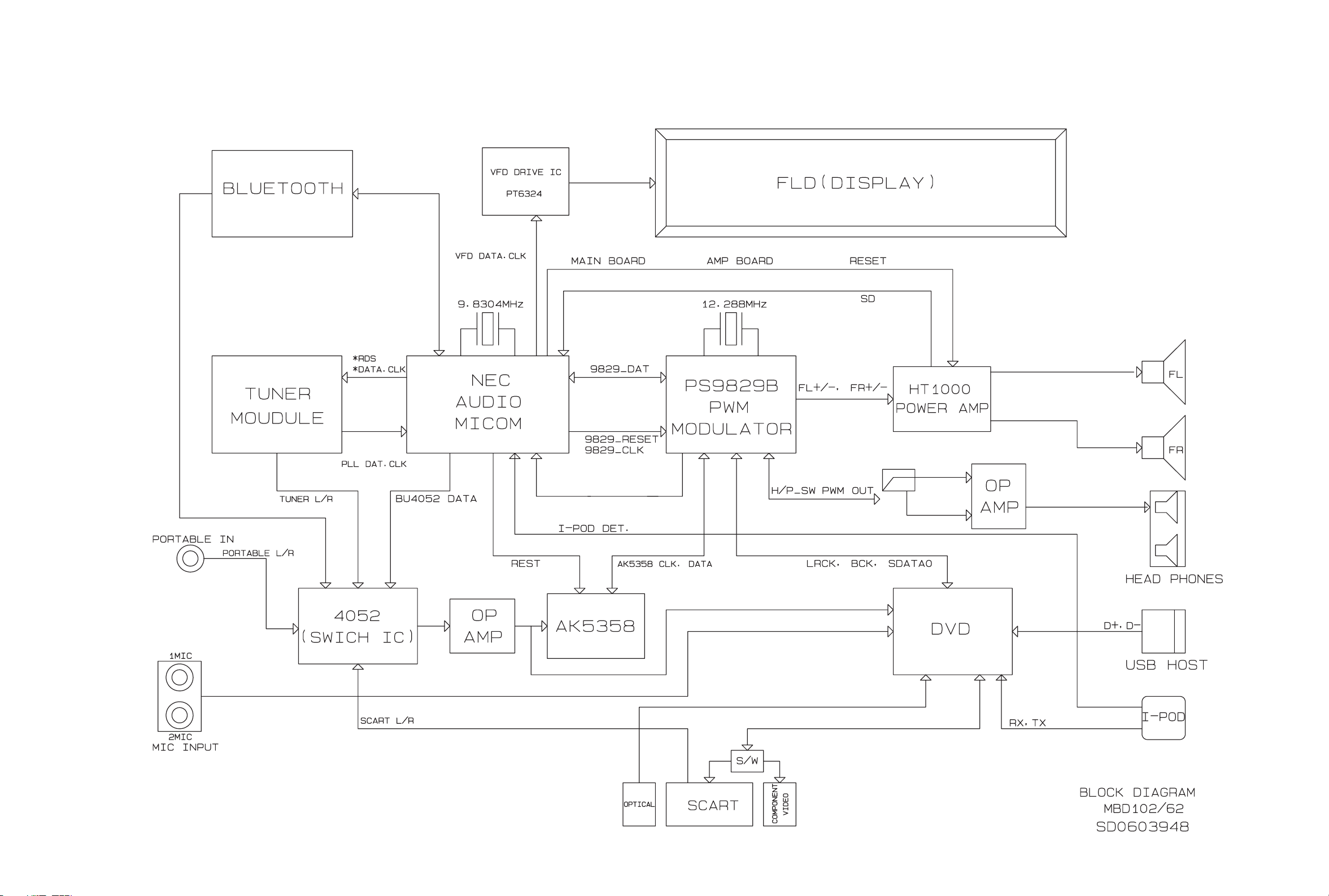

2. MAIN & FRONT BLOCK DIAGRAM

3-53 3-54

Page 63

SCHEMATIC DIAGRAMS

1. SMPS SCHEMATIC DIAGRAM

IMPORTANT SAFETY NOTE :

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN

BE MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES

IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT.

SPECIAL COMPONENTS ARE SHADED ON THE

SCHEMATIC FOR EASY IDENTIFICATION. THIS

CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER

FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTILTHE NEW SERVICE

LITERATURE IS PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

3-55 3-56

Page 64

2. MAIN, INTERFACE & PWM SCHEMATIC DIAGRAM

3-57 3-58

Page 65

3. MPEG SCHEMATIC DIAGRAM

3-59 3-60

Page 66

4. SERVO SCHEMATIC DIAGRAM

3-61 3-62

Page 67

5. INTERFACE SCHEMATIC DIAGRAM

3-63 3-64

Page 68

6. FRONT SCHEMATIC DIAGRAM

3-65 3-66

Page 69

7. FRONT MIC SCHEMATIC DIAGRAM

3-67 3-68

Page 70

8. IPOD-1 SCHEMATIC DIAGRAM (OPTION)

3-69 3-70

Page 71

9. IPOD-2 SCHEMATIC DIAGRAM (OPTION)

3-71 3-72

Page 72

10. 2 CHANNEL AMP SCHEMATIC DIAGRAM

3-73 3-74

Page 73

11. BLUTHOOTH MODULE SCHEMATIC DIAGRAM (OPTION)

3-75 3-76

Page 74

• CIRCUIT VOLTAGE CHART

MEMO

PIN No. Voltage

IC100

19PIN 4.87V

20PIN 4.87V

59PIN 4.87V

IC103

8PIN 4.87V

IC301

9PIN 4.8V

51PIN 4.8V

IC302

6PIN 10.8V

IC401

7PIN 5V

8PIN 5V

20PIN 5V

IC409

6PIN 5V

7PIN 3.3V

IC501

1PIN 3.29V

10PIN 3.29V

17PIN 1.47V

24PIN 3.29V

36PIN 3.29V

46PIN 3.29V

53PIN 3.29V

59PIN 3.29V

66PIN 1.47V

73PIN 3.29V

80PIN 1.47V

90PIN 3.29V

97PIN 3.2V

104PIN 3.2V

111PIN 3.2V

120PIN 3.29V

127PIN 1.47V

130PIN 3.29V

177PIN 3.29V

179PIN 1.47V

196PIN 1.47V

180PIN 3.29V

188PIN 3.29V

IC502

37PIN 3.3V

IC503

1PIN 3.25V

3PIN 3.25V

9PIN 3.25V

PIN No. Voltage

14PIN 3.25V

27PIN 3.25V

43PIN 3.25V

49PIN 3.25V

IC504

8PIN 3.3V

IC506

20PIN 4.94V

IC507

32PIN 4.94V

IC511

8PIN 5V

14PIN -12V

IC604

3PIN 1.92V

4PIN 3.43V

6PIN 1.9V

10PIN 3.43V

13PIN 1.9V

22PIN 3.43V

29PIN 3.43V

34PIN 1.9V

39PIN 3.43V

42PIN 1.9V

47PIN 3.43V

56PIN 3.43V

65PIN 3.44V

66PIN 1.9V

72PIN 3.44V

80PIN 1.9V

87PIN 3.4V

91PIN 1.9V

94PIN 3.4V

IC605

8PIN 3.4V

IC700

17PIN 11.8V

21PIN 29V

26PIN 29V

29PIN 29V

34PIN 29V

IC801

8PIN 11.6V

IC802

8PIN 4.99V

RM301

3PIN 4.6V

3-77 3-78

Page 75

PRINTED CIRCUIT BOARD DIAGRAMS

1. MAIN P.C.BOARD

(TOP VIEW)

3-79 3-80

Page 76

MAIN P.C.BOARD

(BOTTOM VIEW)

3-81 3-82

Page 77

2. FRONT P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3-83 3-84

Page 78

3. SMPS P.C.BOARD

3-85 3-86

Page 79

4. MIC JACK P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

MEMO

5. IPOD P.C.BOARD (OPTION)

(TOP VIEW) (BOTTOM VIEW)

3-87 3-88

Loading...

Loading...