Page 1

TV/AV MENU OK VOL PR

DOLBYDOLBY

VIRVIRTUALTUAL

¢

LCD Projection TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MB-03CA

MODEL : RT-48SZ40RB

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

CONTENTS ..................................................................................................................... 2

SAFETY PRECAUTIONS ................................................................................................3

SERVICING PRECAUTIONS .......................................................................................... 4

CONTROL DESCRIPTIONS ............................................................................................6

SPECIFICATIONS ..........................................................................................................10

ADJUSTMENT INSTRUCTIONS....................................................................................14

BLOCK DIAGRAM..........................................................................................................19

PRINTED CIRCIUT BOARD...........................................................................................23

EXPLODED VIEW ......................................................................................................... 34

EXPLODED VIEW PARTS LIST.....................................................................................35

REPLACEMENT PARTS LIST .......................................................................................36

SVC. SHEET ......................................................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS

on page 3 of this publication.

NOTE:

If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug

or other electrical connection.

c.

Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first connecting

one end of an insulated clip lead to the degaussing or kine

aquadag grounding system shield at the point where the

picture tube socket ground lead is connected, and then (b)

touch the other end of the insulated clip lead to the picture

tube anode button, using an insulating handle to avoid

personal contact with high voltage.

4. Do not spray chemicals on or near this receiver or any of its

assemblies.

5. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator; 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%-99%

strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication

of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which receivers covered by this service manual might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test receiver

positive lead.

Always remove the test receiver ground lead last.

9.

Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to

any heatsink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called

Electrostatically Sensitive (ES) Devices.

Examples of

typical ES devices are integrated circuits and some fieldeffect

transistors and semicounductor "chip" components. The

following techniques should be used to help reduce the

incidence of component damage caused by static by static

electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed to prevent potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as "anti-static" can

generate electrical charges sufficent to demage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a repalcement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the ieads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

CAUTION:Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such

as the bruching together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintan tip

temperature within the range or 500

¡£F to 600¡£F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thorohly clean the surfaces to be soldered. Use a mall

wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500¡£F to 600¡£F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuiboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500¡£F to 600¡£F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

SERVICING PRECAUTIONS

Page 5

- 5 -

c. Qulckly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it

there only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess

or splashed solder with a small wire-bristle brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following

technique should be used to remove and replace the IC. When

working with boards using the familiar round hole, use the

standard technique as outlined in parapraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit boare.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the "U" with long nose pliers to insure metal to metal

contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicula y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them

and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board

to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board.

The following guidelines and procedures should be followed

whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely

necessary).

2. carefully scratch away the solder resist and acrylic coating

(if used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped end

of the good copper pattern. Solder the overlapped area and

clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involoves the installation of a jumper wire on the component

side of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of

the nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so

the it does not touch components or sharp edges.

Page 6

- 6 -

CONTROL DESCRIPTIONS

123

456

789

0

DVD

STB

AUDIO

MODE

POWER

MUTE

TV/AV

MULTIMEDIA

ARC

PSM

+

-

+

-

SSM

EXIT

MENU

PIP PR-

LIST

I/II

PIP INPUT

PIP PR+

PLAY

PAUSE

STOP

RECORD

REW

FF

SKIP

SWAP

OK

PIP/DW TEXT

CABLE

VCR

POSITION

SIZE

STILL

MODE

M

TV

SLEEP

Q.VIEW

VOL

PR

INDEX

TIME

?

REVEAL

MIX

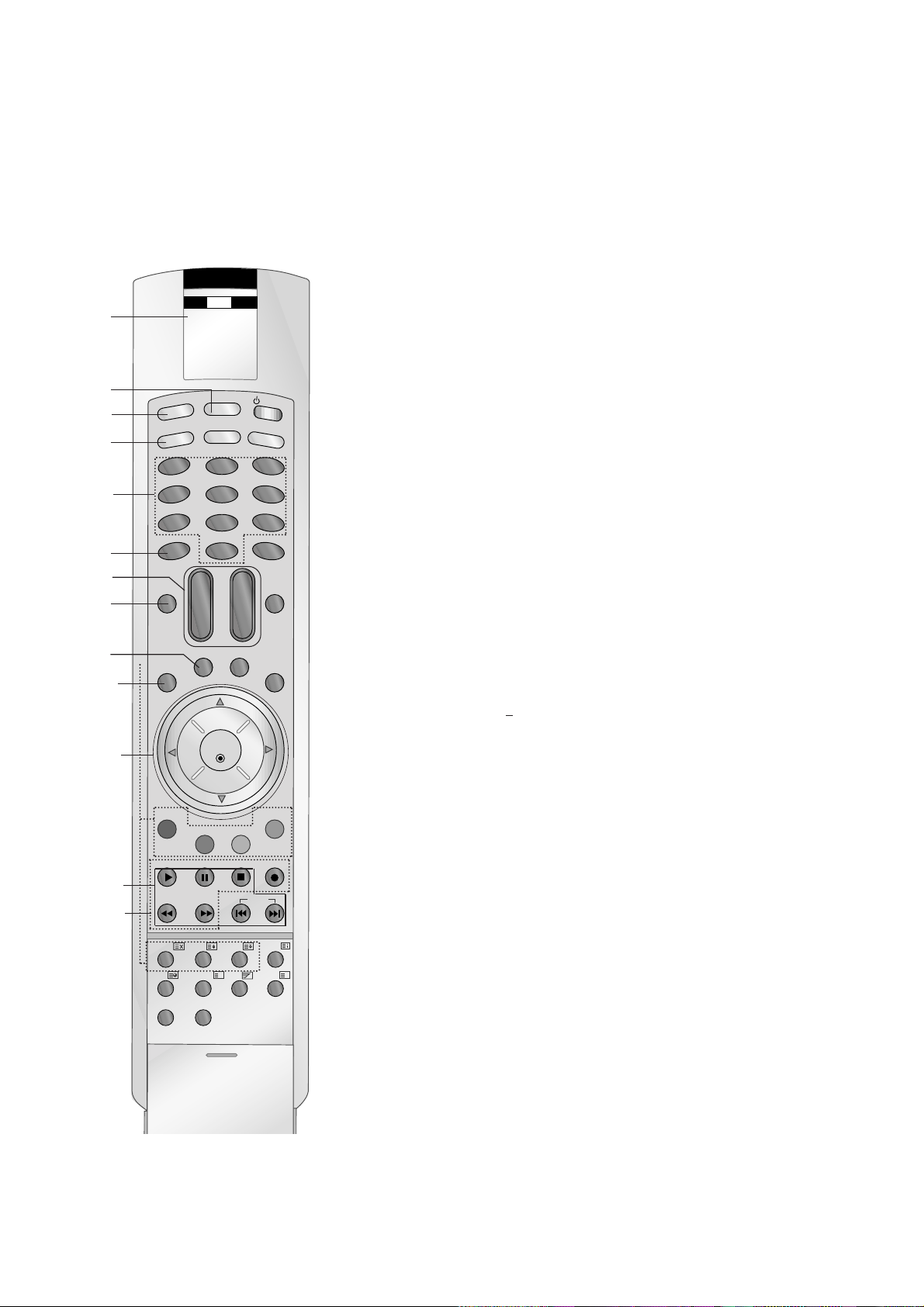

All the functions can be controlled with the remote control handset.

Some functions can also be adjusted with the buttons on the front

panel of the set.

Remote control handset

Before you use the remote control handset, please install the batteries. See the next page.

1.

Displays the selected device

2. MODE

selects a LG TV, VCR or DVD function.

3. TV/AV

selects the remote operating mode.

switches the set on from standby.

4. MULTIMEDIA

selects

Component 1/2 or RGB-DTV, RGB-PC modes.

5. NUMBER BUTTONS

switches the set on from standby or directly select a number.

6. SLEEP

sets the sleep timer.

7. VOL +

/

- (Volume Up/Down)

Increases/decreases sound level.

PR +/ - (Programme Up/Down)

selects a programme.

8.

PSM (Picture Status Memory)

recalls your preferred picture setting.

9. PIP BUTTONS (option)

PIP/DW

switches the sub picture on or off.

selects PIP, POP or DW modes.

PIP PR +/-

selects a programme for the sub picture.

SWAP

alternates between main and sub picture.

PIP INPUT

selects the input mode for the sub picture.

SIZE

adjusts the sub picture size.

STILL

freezes motion of the sub picture.

POSITION

relocates the sub picture in clockwise direction.

10. MENU

selects a menu.

11.

OK

accepts your selection or displays the current mode.

D / E

or

F / G

Adjusts menu settings.

Selects menu item.

12. DVD BUTTONS

control a LG DVD player.

13. VCR BUTTONS

control a LG video cassette recorder.

1

3

2

5

8

6

10

9

7

13

12

11

4

Page 7

- 7 -

1 2 3

4 5 6

7 8 9

0

DVD

STB

AUDIO

MODE

POWER

MUTE

TV/AV

MULTIMEDIA

ARC

PSM

+

-

+

-

SSM

EXIT

MENU

PIP PR-

LIST

I/II

PIP INPUT

PIP PR+

PLAY

PAUSE

STOP

RECORD

REW

FF

SKIP

SWAP

OK

PIP/DW TEXT

CABLE

VCR

POSITION

SIZE

STILL

MODE

M

TV

SLEEP

Q.VIEW

VOL

PR

INDEX

TIME

?

REVEAL

MIX

14. POWER

switches the set on from standby or off to standby.

15. MUTE

switches the sound on or off.

16. ARC (Aspect Ratio Control)

changes the picture format.

17.

Q.VIEW

returns to the previously viewed programme.

18. SSM (Sound Status Memory)

recalls your preferred sound setting.

19. TELETEXT BUTTONS (option)

These buttons are used for teletext.

For further details, see the ‘Teletext’ section.

20. EXIT

Clears all on-screen displays and returns to TV viewing from any

menu.

21. I/II

selects the language during dual language broadcast.

selects the sound output (option).

22. LIST

displays the programme table.

Note : In teletext mode, the PIP PR +/-, SWAP and PIP INPUT buttons are used for teletext function.

14

15

16

17

18

20

19

21

22

Page 8

- 8 -

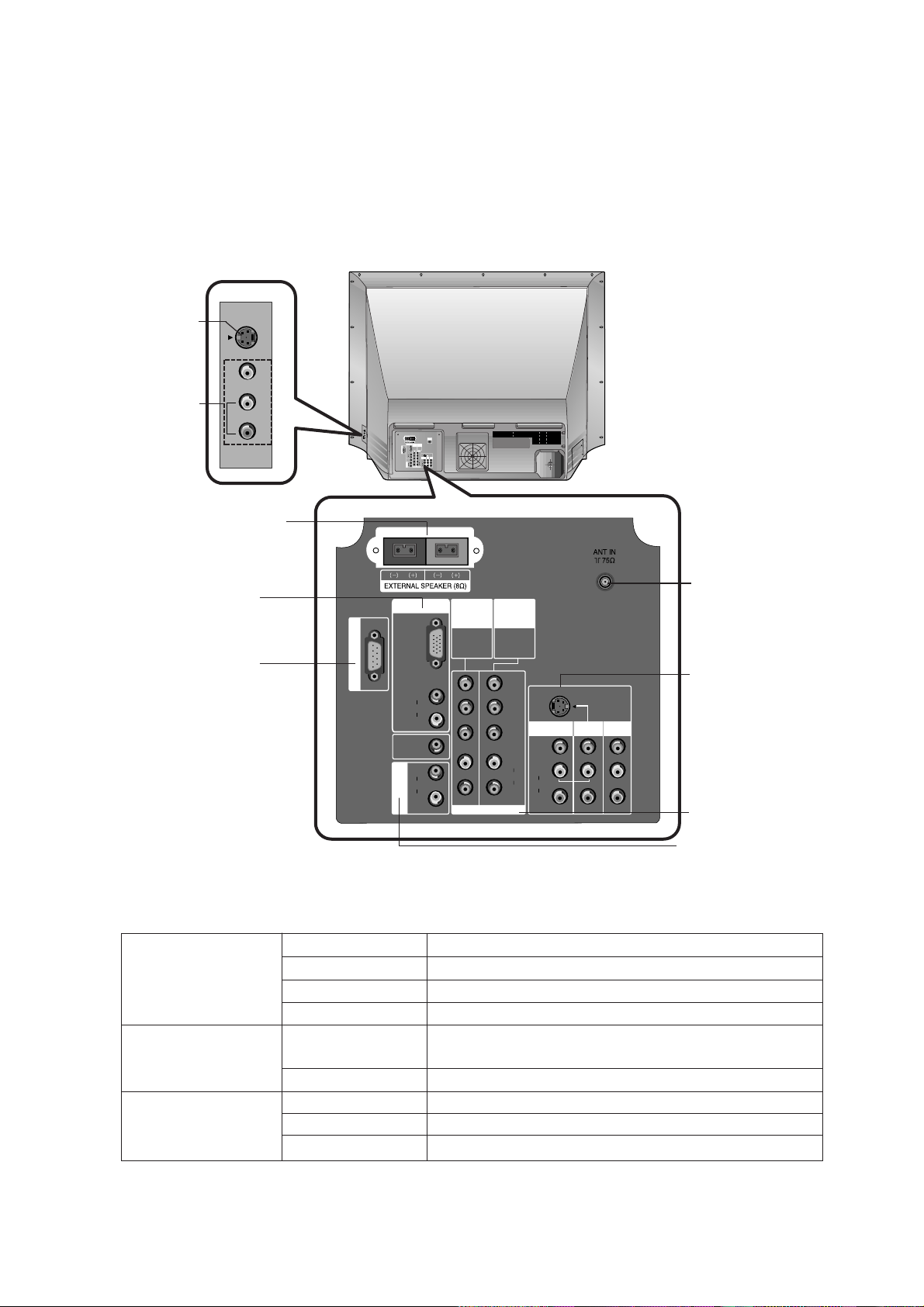

1. MAIN POWER (ON/OFF)

switches the set on or off.

2. LED (Light Emitting Diode) DISPLAY

3. OPERATION INDICATOR (Refer to p.7)

4. LAMP INDICATOR (Refer to p.7)

5. TEMPERATURE INDICATOR (Refer to p.7)

6. TV/AV

selects the remote operating mode.

switches the set on from standby.

7. MENU

selects a menu.

8. OK

accepts your selection or displays the current

mode.

9.

FF/GG

(Volume Down/Up)

adjusts the volume.

adjusts menu settings.

10.

DD/EE

(Programme Up/Down)

selects a programme or a menu item.

switches the set on from standby.

11. REMOTE CONTROL SENSOR

Note : There might be a faint white trace on the

center of the screen according to the position.

This is normal and is a characteristic of the

screen.

Front panel

TV/AV MENU OK VOL PR

TV/AV MENU OK VOL PR

DOLBYDOLBY

VIRVIRTUALTUAL

¢

DOLBYDOLBY

VIRVIRTUALTUAL

¢

1

2 3 4 5 6 7 8 9 10 11

Lamp indicator, operation indicator, and temperature indicator, located below the front panel controls reveal the operating status of the LCD projection TV.

Page 9

- 9 -

AV 3

S-VIDEO

VIDEO

SIDE A/V

(L)/

(R)

MONOAUDIO

INPUT

ANT IN

75‰

L

L

ANT IN

75‰

R L

L

L

P

O

R

T

U

P

G

R

A

D

E

P

R

P

B

Y

DTV/DVD INPUT

RGB

(XGA/

576p/

480p/

720p/

1080i)

(L)

AUDIO

(R)

V

A

U

D

I

O

O

U

T

A

A

B

L

E

R

I

(L)

AUDIO

(R)

MONO

A/V 1

INPUT

A/V 2

INPUT

MONITOR

OUT

(L)

AUDIO

(R)

(L)

AUDIO

(R)

AUDIO

CENTER

MODE IN

PC/DTV INPUT

COMPONENT

INPUT 1

576i/480i

576p/480p

720p/

1080i

576i/480i

576p/480p

720p/

1080i

COMPONENT

INPUT 2

S-VIDEO

R L

P

O

R

T

U

P

G

R

A

D

E

P

R

P

B

Y

DTV/DVD INPUT

RGB

(XGA/

576p/

480p/

720p/

1080i)

(L)

AUDIO

(R)

V

A

U

D

I

O

O

U

T

A

A

B

L

E

R

I

(L)

AUDIO

(R)

MONO

A/V 1

INPUT

A/V 2

INPUT

MONITOR

OUT

(L)

AUDIO

(R)

(L)

AUDIO

(R)

AUDIO

CENTER

MODE IN

PC/DTV INPUT

COMPONENT

INPUT 1

576i/480i

576p/480p

720p/

1080i

576i/480i

576p/480p

720p/

1080i

COMPONENT

INPUT 2

S-VIDEO

AV 3

S-VIDEO

VIDEO

SIDE A/V

(L)/

(R)

MONOAUDIO

INPUT

Rear panel

AERIAL SOCKET

UPGRADE PORT

This port is used to

upgrade the software

version and debug

without changing the

hardware.

Be careful not to use

this port. Just contact

your dealer or service

centre.

DTV/DVD INPUT

SOCKETS

RGB INPUT

SOCKETS

S-VIDEO

INPUT

SOCKET

AV3 INPUT

SOCKET

VARIABLE AUDIO

OUT SOCKETS

EXTERNAL SPEAKER

OUTPUT (8 ohm)

Connect to optional

external speaker(s).

Off Power cord is not connected.

Red Power Cord is connected, unit is on standby.

Green On

Orange (flashing) Preparing operation in standby.

Orange Projection lamp is reaching the end of its life and

needs to be replaced with a new lamp.

Green (flashing) The lamp cover is not closed.

Orange The set is overheating.

Red The set has shut down due to overheating.

Red (flashing) The set has shut down, check the cooling fan.

Operation Indicator

Lamp Indicator

Temperature Indicator

•Status Indicators

AV1/2 / MONITOR

OUT(AUDIO/VIDE

O), S-VIDEO

INPUT SOCKETS

Page 10

- 10 -

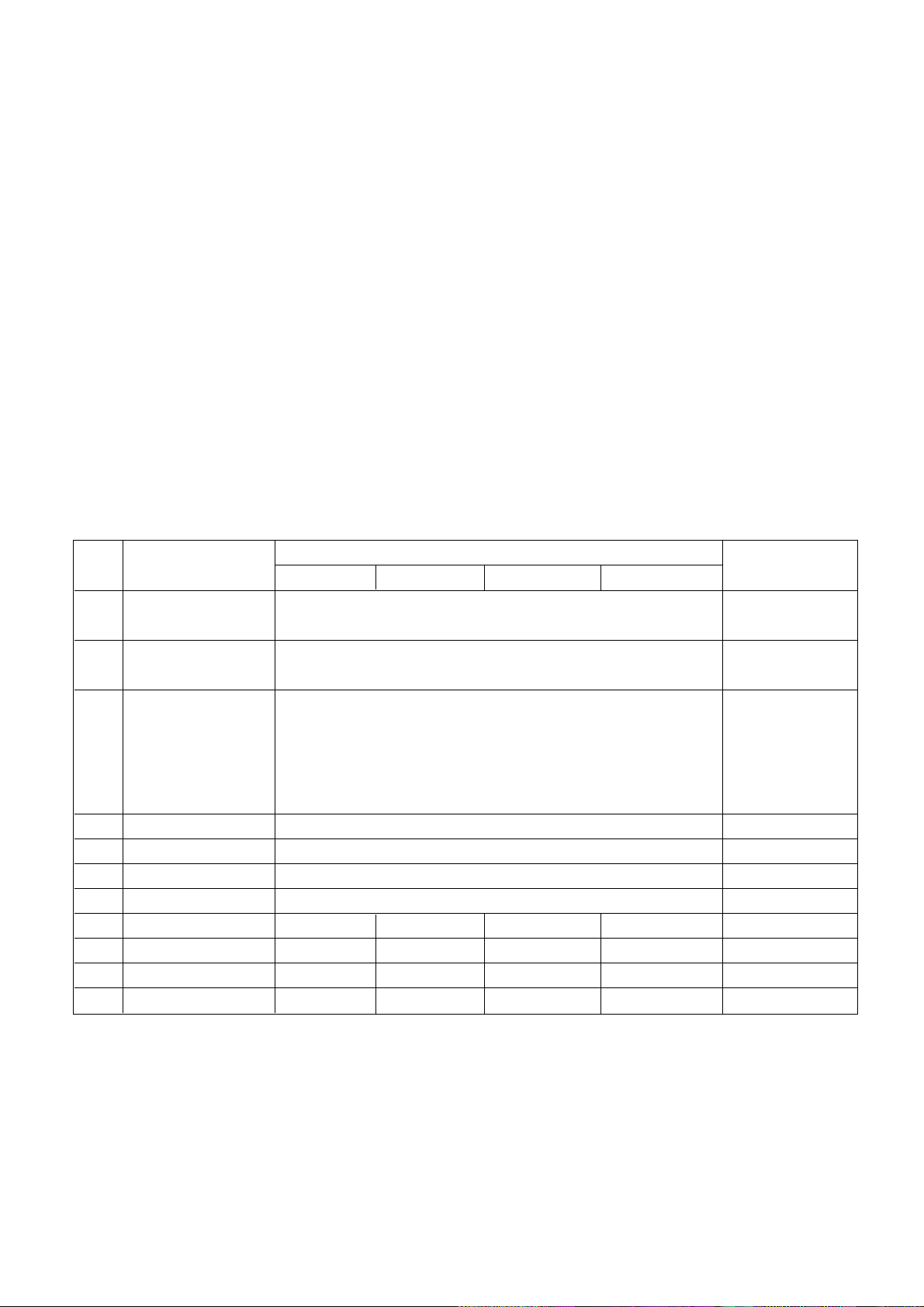

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Scope

This specification can be applied to the LCD Projection(RT-48SZ40RB)

V Test and Inspection Method

1) performance:Follow the Standard of LG TV test

2) Standards of Etc requirement

Safety: Follow the standard of CB

EMC : Follow the standard of CE

V Test Condition

1) Temperature :25¡ 5°C

2) Relative Humidity:65¡ 10%

3) PowerVoltage:Standard input voltage(AC 230V¡ 10%, 50Hz)

But Standard input voltage mark value is marked by model.

4) Use the parts only designated in B.O.M.,PARTS SPEC.,or drawings.

5) Follow each drawing or spec for spec and performance of parts,based upon P/N of B.O.M

6) Warm up TV set for more than 30min. before the measurement.

Specification

PAL – B/G, D/K, I, M, N

SECAM B/G, D/K, L/L’

PAL/SECAM

NTSC 3.58/ 4.43

VHF : E2 ~ E12

UHF : E212 ~ E69

CATV : S1~ S20

HYPER : S21 ~ S41

L/L’ VHF : B,C,D (Option)

AC 230V, 50HHz

EU

48 inch

16:9 (wide)

0

-20

V General Specification

1

2

3

4

5

6

7

8

9

10

11

except PAL-M/N

Video input applicable

system

AV receiving system

Available Channel

Input Voltage

Market

Screen size

Aspect ratio

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

Min

Typ Max Unit

No

Item Remark

deg

%

deg

%

40

85

60

85

Page 11

- 11 -

V Feature and Function

LG Code

1 Separate

1 L/R

2 Y, P

B

, P

R

2 L/R

Bottom : Full Scart (AV1) 1

Half Scart 9AV2/S-video2)

4 Half Scart(AV3)

Top : S-Video (AV4)

A/V Input (AV4)

1 1Rear

1 1Rear

1

Left/Right

Power, Menu, ok, Volume (F, G), Channel (D, E)

Dynamic/ Standard/ Mild/ Game/ User

Contrast/ Brightness/ Colour/ Sharpness/ Tint

PC : 16:9/ 4:3/ User

CVBS : 4:3/ 16:9/ Zoom/ Auto/ 14:9

Dolby Virtual/ Flat/ Music/ Movie/ Speech

A2 : B/ G, D/ K, NICAM : B/ G, D/ K, I, L/ L’

O

O

Top/ Flop

Sleep Timer/ Auto Sleep

EU 17 Nation

Off/ Dark/ Normal/ Bright

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

D-Sub 15 Pin

Scart1 Out

Scart2 Out

External out

Item

Specification

Remark

REMOCON

RGB Input

RGB Audio (L, R) Input

Component Audio (R, L) Input

Component Input

AV Input

TV out

Monitor out

Serial Port

Speak Out

Local key

Picture, EZ Video mode

Picture, User Control

Display mode

Sound, EZ Sound mode

Sound Stereo/ Dual

PIP/ POP Mode

SSC (Split Screen) Mode

Teletext

Timer

OSD Language

Index

At Room Temperature

At -10

°C

1

2

3

4

5

6

7

8

Power ON/OFF operation

Staring Voltage (AC INPUT)

Staring Voltage (AC INPUT)

DC Voltage, Ballast

DC Voltage, Audio AMP

DC Voltage, 3.3V, stand-by

DC Voltage, Analog 3.3V

DC Voltage, Analog 2.5V

10000

-20

-15

360

28

3.15

3.15

2.438

380

32

3.3

3.3

2.5

400

36

3.45

3.45

2.600

times

%

%

V

V

V

V

V

No Item

Specification

Min Typ Max Unit

Remark

V Power

Min

Typ Max Unit

Page 12

- 12 -

9

10

11

12

13

14

15

DC Voltage, Digital, 5V

DC Voltage, Turning voltage

DC Voltage, LCD Driver, 5V

DC Voltage, LCD Driver, 17.5V

DC Voltage 3.3, SUB MICOM

DC Voltage 2.5V, SUB MICOM

DC Voltage, FAN

4.875

29

4.5

17

3.15

2.438

11.5

5

31

5.0

17.5

3.3

2.5

12

5.125

33

5.5

18

3.45

2.600

12.5

V

V

V

V

V

V

V

No Item

Specification

Min Typ Max Unit

Remark

75 ohm

(480I/P, 576I, 720P, 1080I)

75 ohm

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Video Input Level

Video Input Frequency Response

Video output S/N

S-Video Input Level (Y)

S-Video Input Level (C-Burst)

Component Video Input Level

(Y, C

B

/ PB, CR/ PR)

R/G/B Video Input Level

Audio Input S/N

Audio Input Distortion

Audio Input Dynamic Range

Audio Input Level

Audio Input Frequencyl Response

0.85

3

40

0.85

0.256

0.6

0.6

40

2

0.47

0.05

a1

1

0.286

0.7

0.7

0.63

1.15

1.15

0.316

0.8

0.8

2

0.79

10

Vpp

MHz

dB

Vpp

Vpp

Vpp

Vpp

dB

%

V

Vrms

kHz

No Item

Specification

Min Typ Max Unit

Remark

V External Interface

SDTV, DVD 480I

SDTV, DVD 480I

EDTV 480P

SDTV, DVD 576I

EDRV 576P

HDTV 720P (60Hz)

HDTV 720P (50Hz)

HDTV 1080I (60Hz)

HDTV 1080I (50Hz)

1.

2.

3.

4.

5.

6.

7.

8.

9.

640x480

640x480

704x480

720x576

720x576

1280x720

1280x720

1920x1080

1920x1080

15.75

15.73

31.47

15.625

31.250

45.00

37.50

33.75

28.125

60

59.94

59.94

50

50

60.00

50

60.00

50

No

V Component Video Input (Y, P

B

, PR)

Proposed

Specification

Resolution H-freq(kHz) V-freq(Hz) Pixel clock

Page 13

Volume Curve

Text Top

I_II SVC

Lamp_Type

C_Mute

system

Text Language

- 13 -

0 : Standard

1 : Non-Standard (Southeast Asia,Central America)

0 : Support FLOP

1 : Support All (FLOP + TOP)

0 : Do not save DUAL When converting Channel

1 : Save DUAL when Converting Channel

0 : OSRAM

1 : PHILIPS

0 : Not Ready to Over-Modulation in DK Mono

1 : Ready to Over-Modulation in DK Mono

BG/i/DK/LL’

0 : west EU

1 : East EU 1

2 : East EU 2

3 : Turkey EU

4 : Cyrillic 1

5 : Cyrillic 2

6 : Cyrillic 3

7 : Turk GRE 1

8 : Turk GRE 2

9 : Turk GRE 3

10 : Arab FRA

11 : Arab ENG

12 : Arab HEB 1

13 : Arab HEB 2

14 : FARS ENG

15 : FARS FRA

16 : FARS All

1.

2.

3.

4.

5.

6.

7.

0

1

0

1

0

2

0

No Item

Specification

Min Typ Max Unit

Remark

V Option

Page 14

- 14 -

1. Application Object

This instruction is for the application to the LCD Projection

2. Notes

(1) The power source insulation of this LCD Projection is not

charging type and you may not use the transformer for

insulation. But you’d better adjust the set after operating it

with insulation transformer between power supply cable

and input part of the set for protecting the adjusting

equipments.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25+/-5°C of temperature and 65

¡ 10% of relative humidity

if there is no specific designation.

(4) The input voltage of the receiver must keep 230V, 50Hz in

adjusting.

(5) The set must be operated for 5 minutes preliminarily

before adjustment if there is no specific designation.

The preliminary operation must be performed after

receiving 100% white pattern,but reception of the moving

picture may also be possible in unavoidable case.

3. Composition of Adjustment Mode

(1) All adjustment mode are entered by pressing the ADJ key

on the remote control,after adjustment press the ADJ key

to come out.

(2) Below picture is screen composition when press the first

ADJ key.

(3) Select menu to adjust with using (CH+(

D),CH-(E)) key

above screen and press Volume+(

G)key to adjust on the

wanting menu.

(4) Adjust the value of adjustment with using the volume

+(

F),volume -(G) key.

(5) Press the ADJ key to come out after adjustment.

(6) ex.) Composition of each adjustment mode.

1). RGB Alignment:This is the sub adjustment item by

selected Adjust key.

2)

F, G (Vol +/ -): This is the key to change the data.

3)

D, E (CH +/ -):This is the key to change the sub menu.

4. LCD adjustment

4-1. NRS adjustment

[When the LCD panel load data on regular pixel using high

speed charge/ discharge with sample & holder, the drain width

of TFT gradually decreases and the non-resistance increases,

and comes out regular noise on screen (shows vertical line by

12 pixel]

(1) Required Test Equipments

1) PC Pattern generator; 16 Gray Pattern

2) Fixation stand

3) Remote control for adjustment

4) Circuit thing Jig for adjustment (Except Driver Board Assy)

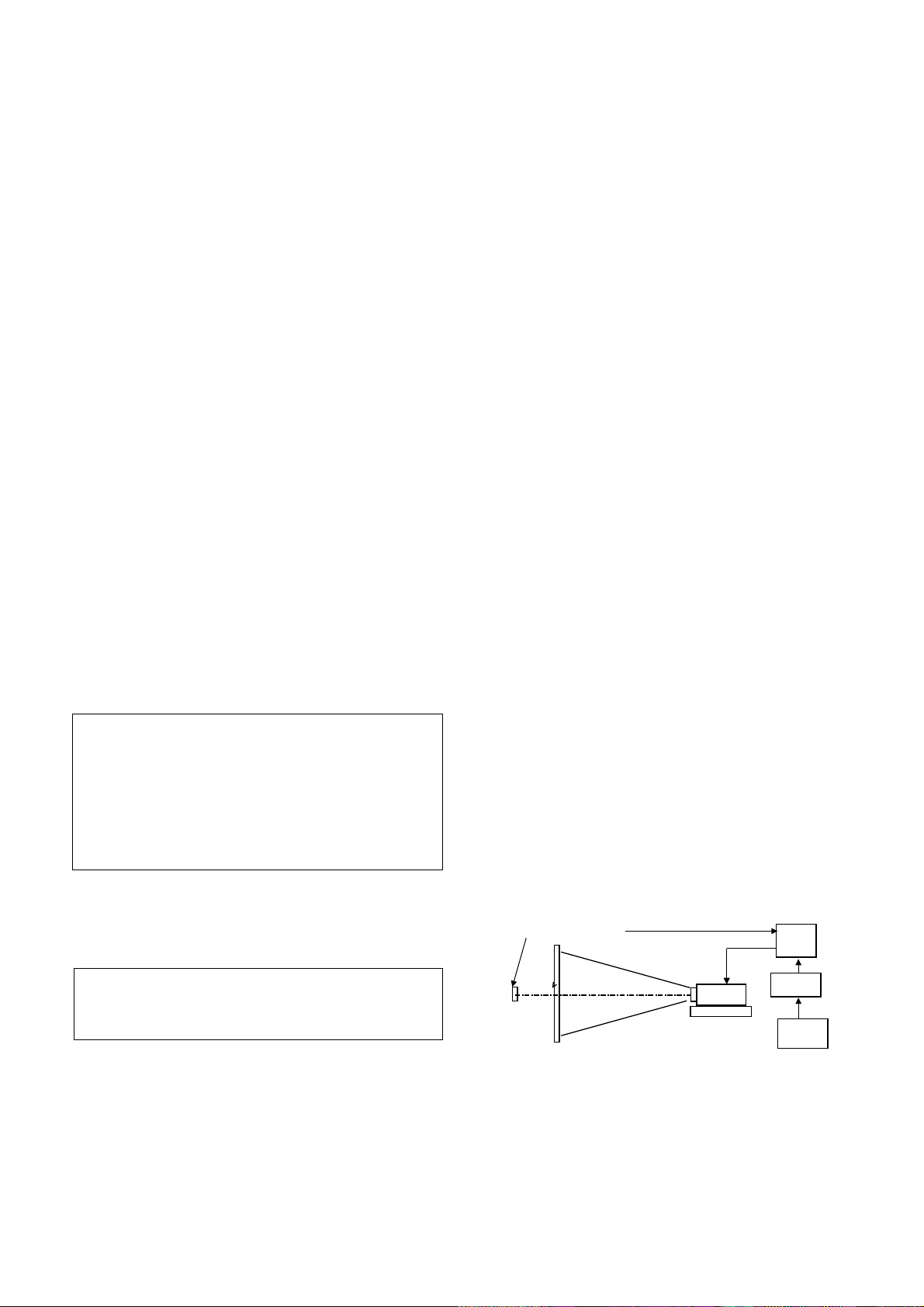

(2) Equipment composition : Refer to <Fig 2>

(3) Preparation for Adjustment

1) Connect PC PATTERN GENERATOR to JIG SET as

shown <Fig 2>.(Except drive part of a circuit block)

2) Select 16 Gray pattern of PC PATTERN GENERATOR

(4) Adjustment Sequence

1) Turn on power supply in the JIG for adjustment.

2) Press the INPUT key to select RGB_PC mode.

3) Press the ADJ key on remote control for adjustment to

enter the adjustment mode.

4) Select the ‘62352’ and press the

G key. Then select 6.

RNRSH, 9.GNRSH, 11.BNRSH of ADJUST MODE to

adjust.

5) Let’s decrease vertical line Noise by using Volume button.

(Input a R, G, B input signal, then adjust it individually)

6) When finishing the adjustment, get out of adjustment mode

by pressing Adjust key.

4-2. VCOM ADJUSTMENT

(1) Required Test Equipments

1) PC PATTERN GENERATOR ; Pattern Generator which

can generator each R, G, B signal and can observe the

FLICKER best (ex : me Character Pattern)

2) <Fig.2> Equipment composition

3) Remote control

4) Circuit thing Jig for Adjustment (Except Driver Board Assy

of adjustment model)

(2) Equipment Composition

(3)Preparation for Adjustment

1) Connect the PC PATTERN GENERATOR, circuit for

adjustment and adjustment JIG as shown <Fig 2>.

2) Adjust output pattern of PC PATTERN GENERATOR to

possible display and then turn on the power.

ADJUSTMENT INSTRUCTIONS

RT52SZ30RB [V*.*]

RGB Alignment

62352

Uniformity Adj

Gamma Adjust

AD9883 Adjust

Sub Micom Ver. **

Main Micom Ver. **

<The first screen of adjustment mode>

RGB Alignment

9.DXOUTB

D

10.H_positon F 0 G

E

<Fig 1.Adjustment of circuit>

Optical measuring equipment

Screen

Adjustment Jig

Optical box

Set stand

Circuit for

Adjustment

PC Pattern

Generator

PC

Page 15

(4) Adjustment Sequence

1) Turn on the adjustment Jig

2) Select RGB_PC by pressing input Select Key on Remote

control.

3) Enter to adjustment mode by pressing Adjust key on

Remote control.

4) Select the ‘62352’, then ready to adjust 4. RVCOM, 7.

GVCOM, 10.BVCOM

5) Let’s decrease flicker by using Volume key

(Input a R, G, B input signal, then adjust it individually)

6) When finishing the adjustment, get out of adjustment mode

by pressing Adjust key.

5. CPLD Download Work

(1) Required Test Equipments & Preparation for Adjustment

1) Connect the PC and memory JIG as shown <fig3>.

2) Turn on JIG MAIN POWER SW.

3) After turn on the PC and monitor, operate the device

programming.

(2) Adjustment Sequence

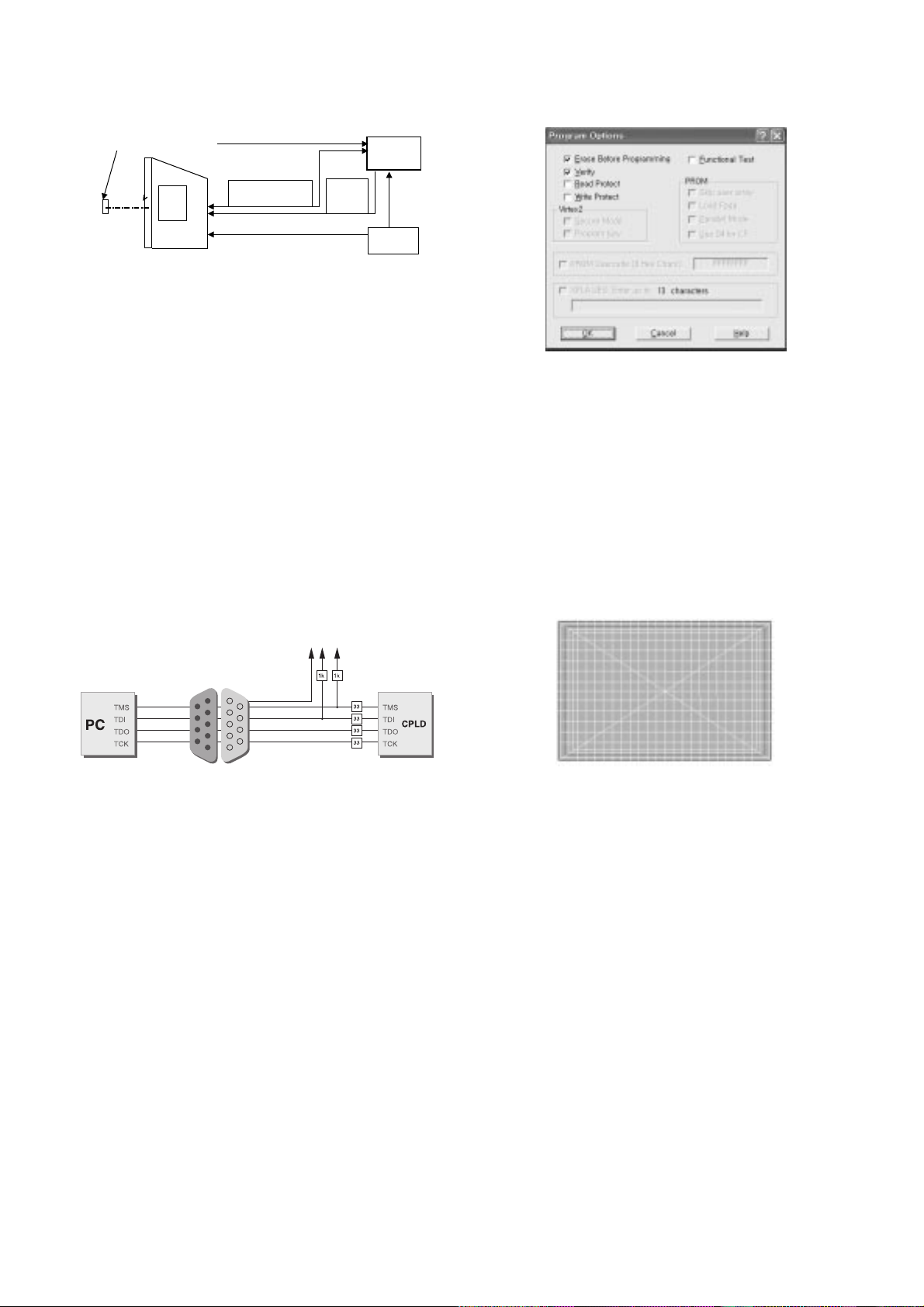

1) After program running, displayed [OPTION MODE

SELECTION] window.

Check the “Load configuration File(.cdf, .pdr)” in this

window and click the finish button

2) When the screen displays the open window, select the

suitable file(*.cdf) according to model.

3) IC figure is change to green by clicking it.

4) Select the program of operations.

5) Check the [Erase before programming] and [Verify] menu

as shown <Fig4> and press the OK button.

f) At this time, the download starts. The download finished

after 10 seconds.

6. H/V Position Adjustment

(1) Required Test Equipments

A remote control of adjustment

(2) Preparation for Adjustment

1) Turn TVset on and press EYE key on the remote control.

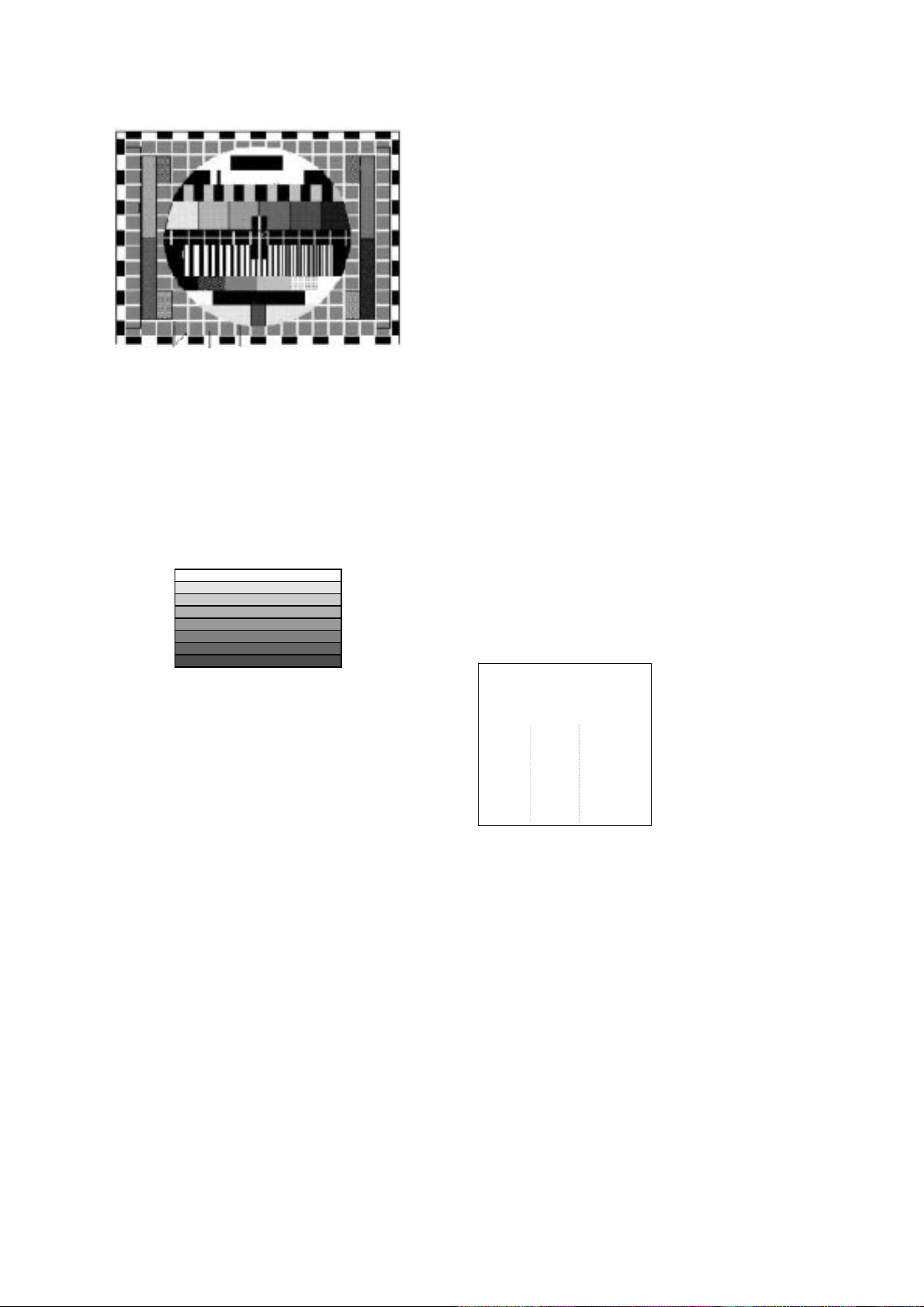

2) 11th screen - Select the pattern that has 11th white small

square/ diagonal, and the red big square.

(3)Adjustment Sequence

Adjust data with using the up/down/left/right key on the

remote control

7. Screen position adjustment

(1) Required Test Equipments

A remote control of adjustment

(2) Preparation for Adjustment

1) Connect the power source with TV Set and turn TVset on

2) Do Heat Run for 5 minutes and over before adjustment.

(3) Horizontal Position Adjustment

1) Press ADJ key on the remote control to enter the

adjustment mode

2) Select the RGB Alignment of the adjustment menu.

3) Select H-position with

G key.

4) Adjust data with using the left/right key on the remote

control in order to be left/right symmetry screen.

(4). Vertical Position Adjustment

1) Select V-position with channel key.

2) Change the data to symmetrized upper and down of screen

(refer to Fig6) and then press the Volume key on Remote

control to get out of adjustment mode.

- 15 -

Optical measuring equipment

TV

Set

Connector for

Adjustment

RS-232C

Cable

PC

PC Pattern

Generator

Adjustment

Jig

<Fig 2.TV set status Adjustment>

<Fig 3.How to connect the MEMORY JIG and PC>

<Fig 6. Eye Pattern-Tilt/ keystone & H.V Position adjustment>

<Fig 4. Program Options>

Page 16

8. Component Offset Adjustment

(1) Required Test Equipments :

A remote control for adjustment, 801GF

(2) Preparation for Adjustment

1) Connect a power source with TV Set and turn TV set on.

2) Do Heat-Run for 5 minutes and over before adjustment.

3) Receive the Component 1 or 2.

4) Receive the 720P/60Hz, HozTVBar Pattern of 801GF

(3) Offset Adjustment

1) Press Adjust key on the remote control to enter the

adjustment mode after more than 10 seconds of receiving

the signals.

2) Press “4.AD9883 Adjust” to adjust.

3) When the OSD of “AD9883 Adjust End” appeared and

disappears,The adjustment is completed

(4) Component & RGB Mode White Balance passivity

adjustment

1) After inputting the 16 Gray pattern (RGB or Component),

check the White Balance status of Low Level (2-6 Gray

Level).

2) After Pressing the IN-START key of remote control, select

the AD9883 and press the

G key. - Red Offset, Blue Offset

is able to adjust.

3) After selecting the adjustment mode with the channel key,

adjust Red Offset, Blue Offset value with the volume key to

adjust passively white Balance in Low Level.

adjustment limit : Red Offset - +/-2 step

Blue Offset - +/-4step

9. White Balance & Gamma Adjustment

(1) Required Test Equipments

1) CA100 : 1EA

-> Measure colour of projecting screen center

[CA-110(name of model) is possible to measure White

Balance and Gamma - leave it 20Cm from screen center

Follow a measurement machine manual to set CA-100and

CA-110 measurement machine.]

2) pattern Generator : 1EA -> 16 step Gray Pattern, 64 step

Gray Pattern

3) SET Fixation Stand : 1EA

4) Remote control : 1EA

5) Circuit thing Jig for adjustment (Except Drive Board Assy of

adjustment model)

--- Programmed Digital Board so that the VDP Test Pattern

can output white signal by 1 level from 0 to 255 level.

(2) Equipment composition : Follow <Fig 2>

Adjust at same condition of equipment composition diagram.

(3) Preparation for Adjustment

Compose the equipment follow Fig.2 and place the set on the

fixation stand.

1) Select the VDP Test Pattern signal to R1, G1, B1.

2) Press the Adjust key to select 62352 and then select

RVREF, GVREF, BVREF in adjust mode

3) Adjust the luminance of CA100 to be below 0.75Cd by

volume key.(Range : 196~ 202)

4) Exit adjustment mode by pressing Adjust key.

5) Press the IN-START key on the remote control and select

the 7050 RGB Set of adjustment mode and then press the

G key.

6) Check the data value of R contrast, Gconrast, B contrast is

515, Otherwise set the data 515 by using volume key.

(4) Adjustment Sequence

1) Output 255,255,255 signal of VDP TEST PATTERN, then

display maximum WHITE PATTERN on screen.

2) Gamma Adjust Mode is display as below when select

Gamma adjust by pressing ADJ key on remote control.

*First column : R adjustment data

display

*Second column : G adjustment

data display

*Third column : B adjustment data

display

3) Change the 16 Step RGB data to select white balance

x:283, y:297(D9300K).[48inch - X:269, Y:294;11000K]

4) Measure the luminance with changed data.

5) Set the every Gamma data of 16 step to 2.2 on the basis of

measured luminance data in 3)clause. (Max luminance

*(n1/16)**2.2)

--- Max luminance : measured luminance data n1 : every

step unit when separating signal level to 16 step

6) Output the 240, 240, 240 (15th data in max white output

signal level) in the VDP Test Pattern, change the 15th

RGB data value to come out white valance x=283,

y=297(D9300K) and measured step luminance in 5)clause.

7) Output the 224, 224, 224 (14th data in max white output

signal level) in the VDP Test Pattern, change the 14th

RGB data value to come out white valance x=283, y=297

and measured step luminance in 5)clause.

8) As shown above, output the VDP Test Pattern signal

(208/192/176/160/144/128/112/96/80/64/48/32/16) and

change the RGB data value of each step to come out white

balance x=283, y=294 and measured luminance in

3)clause.

- 16 -

[EU 05 CH]

<Fig 7. 720P HozTVBar Pattern>

Gamma Adjust

R:1 G:2 B:3

80 100 100

234 216 216

453 411 387

--------------------------

-------------------------724 690 780

Page 17

- 17 -

10. White Uniformity Adjustment

(1) Required Test Equipments

1) Uniformity measuring equipment : Equipment which can

measure chromaticity in the whole screen

2) Set stand : 1EA

3) Remote controller for adjustment : 1EA

4) Circuit thing Jig for Adjustment (Except Driver Board Assy

of adjustment model)

--- Programmed Digital Board so that the VDP Test Pattern

can output white signal by 1level form 0 to 255 level.

(2) Equipment composition

Compose the equipment as Fig.2

(3) Preparation for Adjustment

1) Composite the equipment as shown Fig.2, and place the

set on fixation stand.

2) After inputting company channel 13, adjust colour uniformity

like Horizontal/ Vertical position adjustment of input signal

part adjustment by using remote control for adjustment.

3) After pressing IN_START key on remote control for

adjustment, select the adjustment mode 7050 Uniformity.

<Resister Explanation about uniformity adjustment>

1. RamCtrl : s/w saving uniformity write order (Do not adjust)

2. CSHP : Horizontal start point designation --- adjustable

3. CSVP : Vertical start point designation --- adjustable

4. CEHP : Horizontal END point designation --- adjustable

5. CEVP : Vertical END point 6.designation --- adjustable

6. Mode : uniformity mode select --- adjustable if need

*** 0 : 221point & 3level ---- default value

*** 1 : 221point & 4level

*** 2 : 825point & 3level

*** 3 : 825point & 4level

7. KHH : Upper 2byte of horizontal line correction coefficient -Change according to CSHP, CEHP value.

8. KHL : Upper 2byte of vertical line correction coefficient -Change according to CSHP, CEHP value.

** How to calculate KHH, KHL value

LCD panel size = 1280 x 720

Correction Point = 221 point

--> 17 horizontal points x 13 vertical points

(16 horizontal segments x 12 vertical points)

O H Coefficient(KHH, KHL)

--> Calculation method (CEHP-CSHP=1280, Horizontal

segment value =16)

9. KVH : Upper 2byte of vertical line correction coefficient

-- Change according to CSVP, CEVP value.

10. KVL : Upper 2byte of vertical line correction coefficient

-- Change according to CSVP, CEVP value.

O V Coefficient(KVH, KVL)

Calculation method (CEVP-CSVP=720, Vertical segment

value =12)

11. RL1H : Upper 9bit of MID2 brightness correction

coefficient in R MIN.

--- Change according to RMIN and RMID2 value.

12. RL1L : Lower 9bit of MID2 brightness correction coefficient

in R MIN.

--- Change according to RMIN and RMID2 value.

13. RL2H : Upper 9bit of MID1 brightness correction

coefficient in R MID2.

--- Change according to RMID2 and RMID1 value.

14. RL2L : Lower 9bit of MID1 brightness correction coefficient

in R MID2.

--- Change according to RMID2 and RMID1 value.

15. RL3H : Upper 9bit of MAX brightness correction coefficient

in R MID1.

--- Change according to RMID1 and RMAX value.

(use it while adjusting 4 coefficient)

16. RL3L : Lower 9bit of MAX brightness correction coefficient

in R MID1.

--- Change according to RMID1 and RMAX value.

(use it while adjusting 4 coefficient)

<L Coefficient Calculation Method>

Using 3coefficient Level

Assume that the value of R/G/B MIN, MID2,MID1 is 192, 448,

704.

R/G/B MIN = 192

R/G/B MID2 = 448

R/G/B MID1 = 704

O L Coefficient(RL1H~BL3L)

- Calculation method (L1)

- calculate L2, L3 same with L1

17. GL1H : Upper 9bit of MID2 brightness correction coefficient

in G MIN.

--- Change according to GMIN and GMID2 value.

18. GL1L : Lower 9bit of MID2 brightness correction coefficient

in G MIN.

--- Change according to GMIN and GMID2 value.

19. GL2H : Upper 9bit of MID1 brightness correction coefficient

in G MID2.

--- Change according to GMID2 and GMID1 value.

20. GL2L : Lower 9bit of MID1 brightness correction coefficient

in G MID2.

--- Change according to GMID2 and GMID1 value.

21. GL3H : Upper 9bit of MAX brightness correction coefficient

in G MID1.

--- Change according to GMID1 and GMAX value.

(use it while adjusting 4 coefficient)

22. GL3L : Lower 9bit of MAX brightness correction coefficient

H coefficient = 1/(number of pixel intervals between setting in the horizontal

direction)

Hcoeff = 1/((1280/16)-1) = 0.012658227

hex (0.012658227 x 2

16

) = 0 x 033D, Hcoeff (hex) = 0 x 033D + 1 = 0 x 33E

V coefficient = 1/(number of pixel intervals between setting in the vertical

direction)

Vcoeff = 1/((720/12)-1) = 0.016949152

hex (0.016949152 x 2

16

) = 0 x 0456, Vcoeff (hex) = 0 x 0456 + 1 = 0 x 0457

L2 coefficient =1/(brightness level(MID1) - brightness level(MID2)

L3 coefficient = 1/(brightness level(MAX) - brightness level(MID1)

: case of 4 brightness Level

L1 coefficient = 1/(brightness level(MID2) - brightness level(MIN))

L1 coeff = 1/(448 - 192) = 1 / 256 =0.00390625

L1 coeff(hex) =hex(0.00393625 x 2

18

) =0 x 0400

-> L1H(high 9bit) = b’000000010 L1L(low 9bit) = b’000000000

Page 18

in G MID1.

--- Change according to GMID1 and GMAX value.

(use it while adjusting 4 coefficient)

23. BL1H : Upper 9bit of MID2 brightness correction coefficient

in B MIN.

--- Change according to BMIN and BMID2 value.

24. BL1L : Lower 9bit of MID2 brightness correction coefficient

in B MIN.

--- Change according to BMIN and BMID2 value.

25. BL2H : Upper 9bit of MID1 brightness correction coefficient

in B MID2.

--- Change according to BMID2 and BMID1 value.

26. BL2L : Lower 9bit of MID1 brightness correction coefficient

in B MID2.

--- Change according to BMID2 and BMID1 value.

27. BL3H : Upper 9bit of MAX brightness correction coefficient

in B MID1.

--- Change according to BMID1 and BMAX value.

(use it while adjusting 4 coefficient)

28. BL3L : Lower 9bit of MAX brightness correction coefficient

in B MID1.

--- Change according to BMID1 and BMAX value.

(use it while adjusting 4 coefficient)

29. RLMIN : Setting up the MINIUM Level of R --- Set under

200

30. RLMID2 : Setting up the MIDDLE 2nd Level of R ---Middle

level when 3coefficient

31. RLMID1 : Setting up the MIDDLE 1st Level of R --- Max

level when 3coefficient

32. RLMAX : Setting up the MAX Level of R

33. GLMIN : Setting up the MINIUM Level of G --- Set under

200

34. GLMID2 : Setting up the MIDDLE 2nd Level of G ---Middle

level when 3coefficient

35. GLMID1 : Setting up the MIDDLE 1st Level of G --- Max

level when 3coefficient

36. GLMAX : Setting up the MAX Level of G

37. BLMIN : Setting up the MINIUM Level of B --- Set under

200

38. BLMID2 : Setting up the MIDDLE 2nd Level of B --- Middle

level when 3coefficient

39. BLMID1 : Setting up the MIDDLE 1st Level of B --- Max

level when 3coefficient

40. BLMAX : Setting up the MAX Level of B

41. HVSCAN : Setting up the scan direction while adjusting

unifomity - Do not adjust

42. Test Mode : uniformity adjustment test - Do not adjust

(4) Adjustment Sequence

1) Adjust the screen coordinates as shown below.

2) Output the VDP TEST PATTERN signal correspond to the

Max value.

Read the white coordinates and communicate 3 line with

ET7050 IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color

uniformity of max point.

At this time, make sure that deviation is +5~-5% and

standard is color coordinate of center.

3) Output the VDP TEST PATTERN signal correspond to the

MID value.

Read the white coordinates and communicate 3 line with

ET7050 IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color

uniformity of mid point.

At this time, make sure that deviation is +5~-5% and

standard is color coordinate of center.

4) Output the VDP TEST PATTERN signal correspond to the

MIN value.

Read the white coordinate and communicate with ET7050

IC through measurement equipment of optics.

Adjust screen coordinates data to adjust the color

uniformity of miner point.

At this time, make sure that deviation is +5~-5% and

standard is color coordinate of center.

5) White the miner, middle, maximum data for each point to

confront to each MICOM address.

11.Brightness Adjustment of Main/Sub

screen

Operate this adjustment when the brightness of Main/Sub

screen is different.

(1) Receive RF 06Ch. to Main/Sub screen in twin picture.

(2) Let the screen clearly.

(3) Check the “US06CH” with naked eyes in 06Ch. pattern

and if there is difference, adjust like this.

- The field and the letters are distinguished.

(4) Adjusting Main screen

1) Press the “IN Start” key on R/C for adjustment to select

VPC3230_Main.

2) Adjust to Luma Contrast of adjustment item with

Channel key. (initial value 32)

(5) Adjusting Sub screen

1) Press the “IN Start” key on R/C for adjustment to select

VPC3230_Sub.

2) Adjust to Lima Contrast of adjustment item with +/- key.

(initial value 32)

12. Lamp Replace

Use it when the Lamp time is ‘0’.

At the same time press the ‘OK’ key and ‘Mute’ key during 5

seconds.

Displaying the OSD as <Fig.8> , press the Volume +(

G)

Displaying the OSD as <Fig.9>, press the ‘OK’ key to reset

the lamp use time.

Press the IN-START key on R/C for adjustment to select

Lamp replace and adjust with volume key.

- 18 -

0 1 2 3 ............xx..........15 16

1

.

yy

.

11

12

<Screen division diagram for uniformity adjustment>

<Fig9. Reset Confirm>

<Fig8. Lamp Use Time Reset Menu>

Page 19

- 19 -

RGB_PC

RGB_DTV

COMP1

COMP2

R/G/B

TV_S(V)

AV1(V)

AV2(V,Y,C)

MNT_OUT(V)

VPC3230_S

(IC102)

CXA2151

YCbCr(HD)

M_V,Y,C

S_V/Y,C

SDA5550

VPC3230_M

(IC104)

TXT_R,G,B

TXT_Y,Cb,Cr

ReaeyII

D_Y,Cb,Cr

D_Y,Cb,Cr

CH_A

CH-B

DTV_HS/VS

LPF_CTL2

* H : 30MHz, L: 6MHz

AV3(V,Y,C))

Tuner(Main)

Tuner(Sub)

CXA2119

TXT_FB

SC-R,G,B

SC-R,G,B

Component Board

Tuner/AV

Digital Board

Main Board

CX2069

Switching

LPF

AD9883A

(ADC)

16

3

3

3

3

5

1. Video Input Path

BLOCK DIAGRAM

Page 20

- 20 -

ADC9883

VPC3230_S

(IC102)

CXA2151

SDA5550

VPC3230_M

(IC104)

ReaeyII

CH_A

CH-B

RGB_HS/VS(DTV)

Component Board

Tuner/AV

Digital Board

Main Board

74HC4053

CTL-A

RGB_HS/VS(PC)

Comp/RGB-DTV

HS/VS

S-V

Comp_Y

XC95144XL

(CPLD)

AV-HS

S-V/Y

TXT-HS/VS

HS/VS_VDP_S

M-V

M-Y

HS/VS_VDP_M

HS/VS_ADC

FID_VDP_S

FID_VDP_M

* H:Comp/RGB-DTV

L: RGB-PC

74VHC123

AV-VS

V_sync

R,C LPF

2. Syns I/O Path

Page 21

- 21 -

2003.04.30

CXA2069

Tuner(M)

Tuner & AV

MAIN

MSP3411G LA4282

SIF

L/R1

L/R3

L/R2

L/R-TV

L/R-COM2

L/R-COM1

L/R-PC

Main -L/R

L/R-out

Main-R/Lout

L/R-Var

Component

CTR(Center)-IN

KA4558D

Audio Mute

3. Audio Input Path

Page 22

- 22 -

SDA5550

M360V3

M37272

L/S

IIC0-3.3

IIC0-5

IIC1-5

IIC2-5

24LC256

IIC0-3.3

THC63D164

LGDT1502

VPC3230(S)

VPC3230(M)

AD9883A

IIC2-5

IIC2-5

IIC3-3.3

IIC1-3.3

Tuner(main)

Tuner(sub)

MSP3411G

CXA2069

CXA2151

IIC0-5

IIC0-5

L3E07050

ATC24C256

M62352

SCLK

SDATA

ATC24C16

IIC0 : General Control

(Signal & Control)

IIC1 : Communication

BtwnV3 and SDA550

IIC2 :Communication

Btwn V3 and M37272

IIC3 : Key Board & LED

Control

IICX: Driver Control &

Driving Bias Generator

& Line for adjustment

( SCLK/SDATA)

PURPOSE OF IIC

M62320 M62320

L/S

IIC3-3.3

IIC3-5

IIC3-5

Voltage Level

In IICn-M,

2.5 ; 2.5V 5; 5V

3.3 ; 3.3V

What is M

L/S

IIC1-5IIC1-3.3

Tuner & AV

COM/PC

Main

Digital Driver

Key & IR

4. Control Signal Connection Diagram- IIC

Page 23

- 23 -

PRINTED CIRCUIT BOARD

MAIN (TOP)

Page 24

- 24 -

MAIN (BOTTOM)

Page 25

- 25 -

DIGITAL(TOP)

DIGITAL(BOTTOM)

Page 26

- 26 -

COMPONENT(TOP)

COMPONENT(BOTTOM))

Page 27

- 27 -

TUNER

Page 28

- 28 -

TUNER(BOTTOM)

Page 29

- 29 -

SMPS AC INPUT

Page 30

- 30 -

DRIVER(TOP) CONTROL(TOP)

Page 31

- 31 -

DRIVER(BOTTOM) CONTROL(BOTTOM)

Page 32

- 32 -

SIDE A/V

BALLAST

SPEAKER

PRE-AMP

POWER S/W

CASE S/W

Page 33

- 33 -

MEMO

Page 34

- 34 -

EXPLODED VIEW

430

400

410

401

300

610

330

304

590

174

630

306

305

301

302

520

550

501

530

540

600

201

200

202

211

213

214

560

219

640

217

570

212

216

218

620

600

403

580

402

420

210

220

215

503

650

660

Page 35

- 35 -

EXPLODED VIEW PARTS LIST

174 6410VUH004A POWER CORD, UL/CSA3000MM 3P HUG BLACK VOLEX CSA 3000MM HUG BLACK 500MH 7A

201 4810V00710A BRACKET, NON RN-48SZ40 NON NON LAMP

202 4980V00620A SUPPORTER, NON AL LAMP COVER RN-48SZ40H

210 3680V00067A LENS, RICOH OPTICAL ENGINE RN-48SZ40 .

211 5900V11001D FAN,DC, B1232S12B2-LG DONGYANG 120*120*30 12V 950+-10 RPM 8-14V 300MM

212 5900V09005A FAN,DC G9225S12B2-RG DONGYANG 92*92*25 12V/140MA 1650+-10 RPM 8-14V 600MM

213 4810V00717A BRACKET, SUPPORTER RN-48SZ40 NB03JA ABS, AF-303S FAN

214 3550V00281A COVER, NON RN-48SZ40 ABS, AF-303S INLET FAN

215 4850V00012M CUSHION, FILTER 109*109*2 POLYURETHAN RN-48SZ40

216 6913V00002B BALLAST, EUC-100L/100V PHILIPS RN48SZ40H FOR LAMP CABLE 280MM

217 4810V00718B BRACKET, NON RN-48SZ40H NB03JA PP LAMP HOUSE

218 4980V00671A SUPPORTER, SMPS SECC RN-48SZ40 SMPS CHASSIS

219 3210V00166A FRAME, HIPS 40AF RN-48SZ40 MAIN CHASSIS

220 4810V00714A BRACKET, DUCT RN-48SZ40 NB03JA ABS, AF-303S COMBO GUIDE

300 3091V00475A CABINET ASSEMBLY, RN-48SZ40 STEREO NB03JA MIDDLE

301 3211V00107B FRAME ASSEMBLY, ASSY RZ-48SZ40RB TOTAL

302 3508V00399D DECORATION, FRONT ACRYL MIRROR HALF RT-48SZ40RB

304 3351V00006A SCREEN ASSEMBLY, TOPPAN NON RN-48SZ40H 1094*617*3.15 GAIN 4.7

305 3790V00702B FILTER(MECH), RZ-48SZ40RB LG LOGO

306 3720V00237C PANEL, ASSY RZ-48SZ40RB VFD 16ML09HA1 MD PJT

310 5020V00751A BUTTON, CONTROL RN-48SZ40 ABS, HF-380 7KEY .

330 5020V00655A BUTTON, POWER RN-52SZ10H ABS 1 KEY SET

400 3809V00324E BACK COVER ASSEMBLY, RZ-48SZ40RB NON UPPER

402 3550V00278C COVER, LAMP RZ-48SZ40RB ABS, AF-303S SIDE

403 3110V00257A CASE, NON RN48SZ40H PC-ABS LAMP DUCT

410 3809V00325F BACK COVER ASSEMBLY, RT-48SZ40RB NON LOWER

420 3550V00277A COVER, MIDDLE RN-48SZ40 ABS, AF-303S DUST

430 5018V00054A MIRROR, LCD SSC(SAMSUNG CORNING) NON LCD48 MIRROR ..

501 3210V00165B FRAME, ABS, AF-303S RN-48SZ40H MAIN CHASSIS

503 4810V00713H BRACKET, REAR AV RT-48SZ40/41RB MB03CA ABS, AF-303S FOR AUSTRALIA

520 6871VMMS11A PWB(PCB) ASSEMBLY,MAIN MB-03CA RT-48SZ40RB AUS MAIN BOTTOM M/I

530 6871VSMX90E PWB(PCB) ASSEMBLY,SUB DIGITAL MB03CA RT-48SZ40RB AUS DIGITAL M/I

540 6871VSMX91C PWB(PCB) ASSEMBLY,SUB MB03CA RT-48SZ40RB AUS COMP M/I

550 6871VSMX92D PWB(PCB) ASSEMBLY,SUB TUNER MB03CA RT-48SZ40RB AUS TUNER M/I

560 6871VPMA38E PWB(PCB) ASSEMBLY,POWER SMPS MB-03CA RT-48SZ40RB AUS ACINPUT M/I

570 6871VSMX89A PWB(PCB) ASSEMBLY,SUB MB03CA RZ-48SZ40RB DRIVER MAIN ASSY

580 6871VSME03C PWB(PCB) ASSEMBLY,SUB S/W MB03CA RZ-48SZ40RB CASE S/W

590 6871VSME01A PWB(PCB) ASSEMBLY,SUB NB03JA CONTROL RN-48SZ40H

600 6871VSNA02B PWB(PCB) ASSEMBLY,SUB MB03CA RT-48SZ40RB AUS SIDE-AV M/I

610 6912V00006B LAMP,HIGH PRESSURE MECURY UHP100W 1.3 PHILIPS 100V 1A RN48SZ40H CABLE 160MM,130MM

610 6871VSN222B PWB(PCB) ASSEMBLY,SUB PSW MB03CA RZ-48SZ40RB POWER S/W

620 6871VSME02C PWB(PCB) ASSEMBLY,SUB INTER MB03CA RZ-48SZ40RB BALLAST INT

630 6871VSN221C PWB(PCB) ASSEMBLY,SUB P/AMP MB03CA RZ-48SZ40RB PRE-AMP

640 6871VPMA36G PWB(PCB) ASSEMBLY,POWER SMPS MB-03CA RT-48SZ40RB AUS SMPS M/I

660 6871VSNA01A PWB(PCB) ASSEMBLY,SUB SPK MB03CA SUB PCB ASSY

No.

Part No.

Description

Page 36

- 36 -

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC401

IC401

IC402

IC403

IC403

IC404

IC404

IC405

IC406

IC407

IC407

IC408

IC409

IC410

IC411

IC412

IC413

IC414

IC415

IC4558

IC5

IC601

IC602

IC603

IC801B

IC802B

IC811

IC820

IC831

IC832

IC841

IC845

IC851

Q111

Q112

IC202

IC203

Q01

Q02

Q03

Q04

Q05

Q06

Q10

Q101

Q102

Q102

Q103

Q103

Q106

Q106

0ICTMMI038B

0ISH052100C

0IFA752700A

0IMCRSG010A

0IMCRKE006B

0IMCRTI019A

0ISH052100C

0IMP242560A

0IKE780500Q

0IPRPFA007A

0IPH741400E

0IMCRKE008A

0IMCRFA015A

0ISH052100C

0IKE780800J

0IKE780900M

0IKE780900M

0ISH302122A

0ITK118100B

0ISS455880A

0IMX811000A

0IMCRMN001C

0IFA753307A

0ISS455880A

0ISH817300B

0ISH817300B

0IMCRON002A

0ISK666813A

0ISK615311B

0ISH817300B

0ISH817300B

0ISS781200H

0IMO257633A

0IFA270000A

0IFA270000A

0TR830009BA

0TR830009BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

COPY M306V3FGFP MITSUBISHI 100P QFP

PQ05RD21 4SIP ST REGULATOR KA75270Z 3 TP RE-SET IC MC-007

ST3232CDR SGS-THOMSON SOP16

KIA278R33PI KEC TO-220IS 4P

TFP410 TEXAS INSTRUMENT 64P TQFP

PQ05RD21 4SIP ST REGULATOR

24LC256-I/SM 8P,SOP TP

KIA7805API 3P TO-220 ST

RC1117S25T FAIRCHILD SOT-223

74HC14D 14SOP TP

KIA78D33F KEC 3P DPAK

KA7805R FAIRCHILD 2P D-PAK

PQ05RD21 4SIP ST REGULATOR

KIA7808API 3 ST REGULATOR .

KIA7809API TO220 ST 3P 9V

KIA7809API TO220 ST 3P 9V

PQ30RV21 TO-220

TK11840L 8P SOT23L

KA4558D 8SOP OP AMP

MAX811REUT-T 128QFP

MSP3411G QA B8 V3 MICRONAS 80P QFP

KA75330ZTA(KA7533ZTA) 3P,TO-92 TP

KA4558D 8SOP OP AMP

PC817XF3 4D PHOTO COUPLER

PC817XF3 4D PHOTO COUPLER

MC33262P ON SEMI 8P DIP ST

STR-F6668B(LF1352) 5PIN

STR-G6153T(LF1101) 5PIN

PC817XF3 4D PHOTO COUPLER

PC817XF3 4D PHOTO COUPLER

KA78R12 4P,TO-220F

LM2576TV-3.3 5PIN ST

2N7000TA TO-92, 3P TP

2N7000TA TO-92, 3P TP

BSS83 TP PHILIPS NON N-CHANNEL S/W TR

BSS83 TP PHILIPS NON N-CHANNEL S/W TR

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

LOCA. NO PART NO DESCRIPTION

IC01

IC02

IC1

IC101

IC102

IC103

IC104

IC105

IC1101

IC1102

IC1103

IC1104

IC1105

IC1106

IC1107

IC120

IC1200

IC1200

IC1202

IC1202

IC1203

IC1300

IC1301

IC1302

IC1303

IC1304

IC1305

IC1400

IC1401

IC1402

IC1403

IC1404

IC1405

IC1500

IC1501

IC1502

IC1503

IC1504

IC1505

IC1601

IC1602

IC1603

IC208

IC301

IC302

IC303

IC304

IC305

IC306

IC320

IC4

0IMI623200B

0IMI623200B

0ISM555000A

0IMCRAD002A

0IIT323000E

0IMCRXL003A

0IIT323000E

0IFA741230A

0IMI623520B

0IAL242561B

0IPRPTI001A

0IKE704200J

0IPRPFA006A

0IPRPFA006A

0IPRPSH001A

0ISJ111733A

0IMCRSO008A

0IPRPFA007A

0IMCRSB010A

0IMO744053B

0IPRPFA006A

0IMO324000C

0IMCRET001A

0IMCRSB009A

0IMCRSB009A

0IMCRSB008A

0IPRPFA006A

0IMO324000C

0IMCRET001A

0IMCRSB009A

0IMCRSB009A

0IMCRSB008A

0IPRPFA006A

0IMO324000C

0IMCRET001A

0IMCRSB009A

0IMCRSB009A

0IMCRSB008A

0IPRPFA006A

0ISA428200A

0IKE780500Q

0ISA722200A

0ISO206900A

0ICTMLG003C

0ITI740000Q

0ITI740000Q

0IMMRHY033A

0IMMRHY033A

0IIC271600A

0IPH741400E

0IMCRAL006A

M62320FP,I/O EXPANDER 16P SOP TP

M62320FP,I/O EXPANDER 16P SOP TP I/O

SDA5550 MQFP100 BK MICOM TXT MC006A

AD9883AKST-110 ANALOG DEVICE 80P TQFP

VPC3230D C5 80P QFP

XC95144XL-10TQ100C 3.3V XILINX TQFP 100P

VPC3230D C5 80P QFP

DM74LS123MX 16SOP TP

M62352GP 20P SSOP TP 8BITS 12CH D/A

AT24C256W-10SI-2.7V 8P

TFP401PZP TEXAS INSTRUMENT 100,TQFP

KIA7042AF SOT-89 TP

RC1117S33T FAIRCHILD SOT-223

RC1117S33T FAIRCHILD SOT-223

PQ20WZ1U SHARP 5P SC63

EZ1117CST-3.3 3P,SOT-223

CXA2151Q SONY 48P QFP

RC1117S25T FAIRCHILD SOT-223

L3E07050K0A SEIKO EPSON 176QFP

MC74HC4053DW 16SOP 3*2CH.MUX

RC1117S33T FAIRCHILD SOT-223

LM324D SO-14 TP OP AMP

EL2244CS-T13 ELANTEC 8P SO

L3E06070D0A SEIKO EPSON 48QFP

L3E06070D0A SEIKO EPSON 48QFP

L3E01031F0A SEIKO EPSON 48QFP

RC1117S33T FAIRCHILD SOT-223

LM324D SO-14 TP OP AMP

EL2244CS-T13 ELANTEC 8P SO

L3E06070D0A SEIKO EPSON 48QFP

L3E06070D0A SEIKO EPSON 48QFP

L3E01031F0A SEIKO EPSON 48QFP

RC1117S33T FAIRCHILD SOT-223

LM324D SO-14 TP OP AMP

EL2244CS-T13 ELANTEC 8P SO

L3E06070D0A SEIKO EPSON 48QFP

L3E06070D0A SEIKO EPSON 48QFP

L3E01031F0A SEIKO EPSON 48QFP

RC1117S33T FAIRCHILD SOT-223

LA4282 12S 2CHX10W AUDIO AMP

KIA7805API 3P TO-220 ST

LA7222 (1280 AUDIO)

CXA2069Q QFP64 BK I2C BUS AV S/W

LGDT1502M LG IC 304P QFP

SN74LVC00AD 14SOP

SN74LVC00AD 14SOP

HY57V643220C(L)T-6 HYNIX 86P TSOP

HY57V643220C(L)T-6 HYNIX 86P TSOP

MK2716STR 8P,SOP TP

74HC14D 14SOP TP

AT24C16AN-10SI-2.7 ATMEL 8P SOIC

IC

TRANSISTOR

Page 37

- 37 -

LOCA. NO PART NO DESCRIPTION

Q107

Q108

Q108

Q109

Q110

Q110

Q111

Q112

Q113

Q113

Q114

Q114

Q115

Q115

Q116

Q116

Q1200

Q1201

Q1202

Q1203

Q1204

Q1205

Q1206

Q1207

Q1208

Q1209

Q1210

Q1211

Q1212

Q1213

Q1214

Q1215

Q1216

Q1217

Q1218

Q1219

Q1221

Q1222

Q1223

Q1230

Q1232

Q1235

Q1236

Q1237

Q1601

Q2

Q201

Q202

Q203

Q204

Q205

Q206

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR830009BA

0TR387500AA

0TR830009BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR102009AG

0TR127009AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR102009AG

0TR127009AA

0TR387500AA

0TR387500AA

0TR102009AG

0TR150400BA

0TR150400BA

0TR102009AG

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

BSS83 TP PHILIPS NON N-CHANNEL S/W TR

CHIP 2SC3875S(ALY) KEC

BSS83 TP PHILIPS NON N-CHANNEL S/W TR

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP KRC102S KEC TP SOT-23 NA NA

KTA1270-Y(KTA562TM) KEC TP TO92 50V 100MA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP KRC102S KEC TP SOT-23 NA NA

KTA1270-Y(KTA562TM) KEC TP TO92 50V 100MA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC102S KEC TP SOT-23 NA NA

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP KRC102S KEC TP SOT-23 NA NA

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

LOCA. NO PART NO DESCRIPTION

Q207

Q208

Q209

Q210

Q213

Q3

Q301

Q302

Q304

Q400

Q501

Q510

Q511

Q601

Q602

Q810

Q841

Q842

Q851

D01

D02

D03

D1

D100

D1001

D101

D102

D1200

D1202

D1602

D1603

D1605

D2

D200

D201

D3

D300

D4

D400

D400

D401

D402

D402

D403

D403

D404

D404

D404

D405

D405

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TRKE80038A

0TR102009AG

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TF283700AA

0TR945009AA

0TR322709AA

0TR945009AA

0DL200000CA

0DL200000CA

0DL200000CA

0DD184009AA

0DD184009AA

0DD226239AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD181009AB

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD226239AA

0DL112100AA

0DD184009AA

0DD184009AA

0DD226239AA

0DD226239AA

0DR050008AA

0DD414809ED

0DR050008AA

0DD414809ED

0DR050008AA

0DD184009AA

0DD414809ED

0DR050008AA

0DD226239AA

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

KTC3552T-RTK KEC R/TP SOT-23F 50V 3A

CHIP KRC102S KEC TP SOT-23 NA NA

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SA1504S(ASY) KEC

2SK2837 BK TOSHIBA 500V 20A TO3P

KSC945C-Y SAMSUNG TP TO92 50V 150MA

KTC3227-Y,TP(KTC1627A),KEC

KSC945C-Y SAMSUNG TP TO92 50V 150MA

LED,SAM5670(DL-2LRG) BK Y-GREEN LED,SAM5670(DL-2LRG) BK Y-GREEN LED,SAM5670(DL-2LRG) BK Y-GREEN KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS181 TP KEC - 85V - 300MA

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

LED,SR3411(DL-11S2RN1) BK RED

KDS184S CHIP 85V 300MA KEC TP

KDS184S CHIP 85V 300MA KEC TP

CHIP KDS226 SOT-23

CHIP KDS226 SOT-23

SD05.TC R/TP SEMTECH SOD323 5V 5A 15A

1N4148 TP GRANDE

SD05.TC R/TP SEMTECH SOD323 5V 5A 15A

1N4148 TP GRANDE

SD05.TC R/TP SEMTECH SOD323 5V 5A 15A

KDS184S CHIP 85V 300MA KEC TP

1N4148 TP GRANDE

SD05.TC R/TP SEMTECH SOD323 5V 5A 15A

CHIP KDS226 SOT-23

DIODE

Page 38

- 38 -

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

LOCA. NO PART NO DESCRIPTION

D406

D406

D410

D411

D431

D432

D433

D434

D435

D437

D5

D6

D601

D602

D7

D8

D801

D810

D820

D821

D822

D832

D833

D834

D841

D845

D851

D852

D871

D881

Q810

ZD01

ZD02

ZD03

ZD1

ZD10

ZD2

ZD3

ZD4

ZD5

ZD6

ZD841

ZD851

ZD9

C01