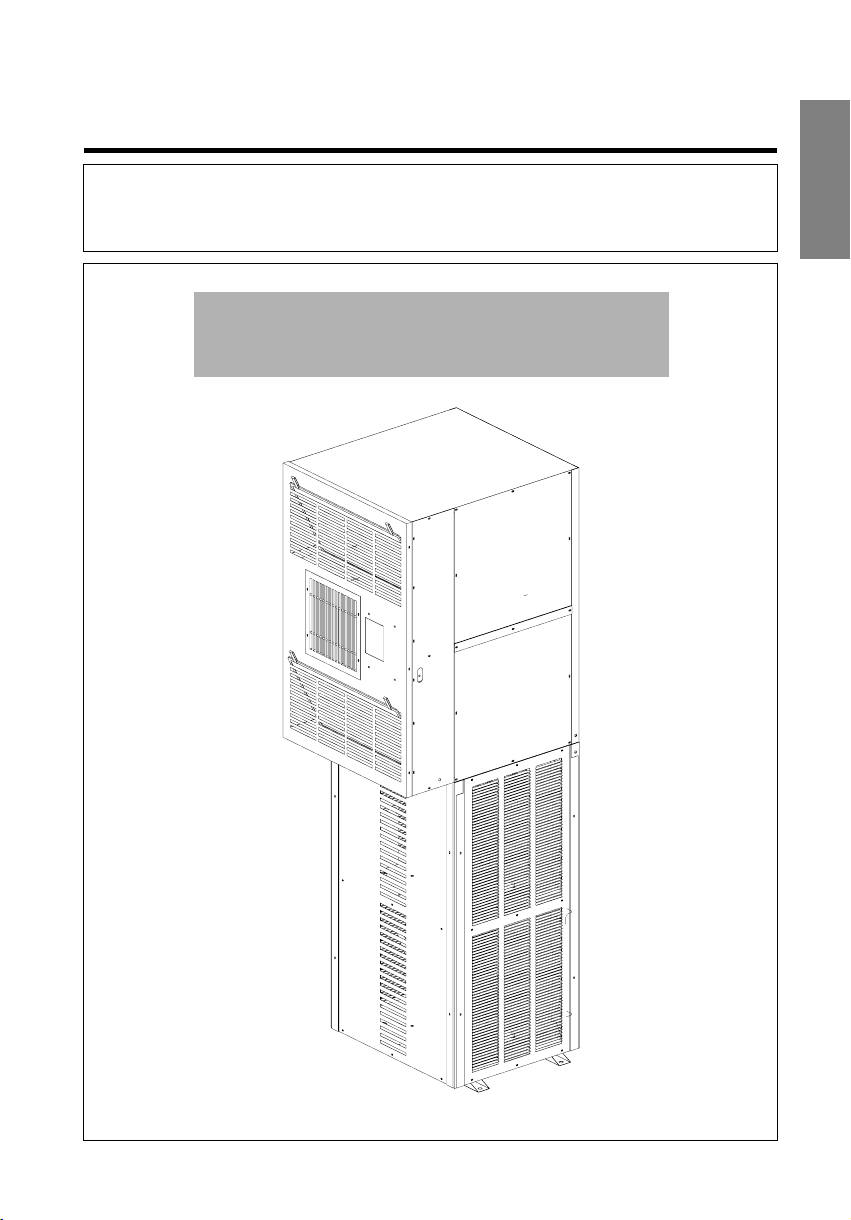

LG LXN0356QC Owner’s Manual

TELECOM AIR CONDITIONERS

INSTALLATION INSTRUCTIONS

l Please read this instruction sheet completely before installing the product.

l When the power cord is to be replaced, replacement work shall be performed by authorized

personnel only.

l Installation work must be performed in accordance with national wiring standards by authorized

personnel only.

3.0TR SINGLE PHASE: LX-0356QC

3.5TR SINGLE PHASE: LX-0456QC

ENGLISH

INDEX

ENGLISH

1.The following should be always observed for safety ...................

2. Product Specification ..........................................................................

2.1 Product Description .............................................................................

2.2 Inspection ............................................................................................

2.3 Technical specification .......................................................................

3. Installation Standard ..........................................................................

3.1 Pre-check ...........................................................................................

3.2 Levelling of Airconditioner ..................................................................

3.3 Shelter Cut - out sealing ......................................................................

3.4.Condensate Drain Pipe .......................................................................

3.5 Air purging of connecting pipes & Indoor unit ......................................

3.6 Filter Cleaning .....................................................................................

3.7 Installation Drawing - Cases 1& 2 ...............................................

3.8 Installation Drawing - Foundation ......................................................

4. Controller ............................................................................................

4.1 Display & Indicators ...........................................................................

4.2 Pre-Startup instructions ....................................................................

4.3 Operations ...................................................................................

4.4 LCD menu details ........................................................................

5.Trouble Shooting ...............................................................................

5.1 Symptoms & Problems .....................................................................

6.Electrical wiring diagram ..................................................................

6.1 Indoor wiring Diagram .......................................................................

6.2 Outdoor wiring Diagram ....................................................................

6.3 Controller Connection Diagram .........................................................

7.Exploded view .....................................................................................

7.1 indoor unit ..........................................................................................

7.2 Outdoor unit .......................................................................................

7.3 Part List ........................................................................................

4~5

11~14

18~19

20~27

33~34

6

6

6

7

8

8

9

9

9

10

10

15

16

16

17

28

28

29

29

29

30

31

31

32

3

1. The following should be always observed for safety

The supplied unit requires 3 phase supply to operate, so please make sure to have authorised

connection by the supply authority before connecting to the system.

Be sure to read "THE FOLLOWING SHOULD BE ALWAYS OBSERVED FOR SAFETY" before

installing the air conditioner.

Be sure to observe the cautions specified here as they include important items related to safety.

The indications and meanings are as follows.

WARNING

CAUTION

Could lead to death, serious injury, etc.

Could lead to serious injury in particular environments when operated incorrectly.

After reading this manual, be sure to keep it together with the owner's manual in an accessible place.

WARNING

Do not install it yourself (customer).

Incomplete installation could cause injury due to fire, electric shock,

the unit falling or a leakage of water Consult the dealer from whom

you purchased the unit or authorised installer.

Install the unit securely in a place which can bear the

weight of the unit.

When installed in a n insufficient strong place, the unit could f all

causing injured.

Use the specified wires to connect the indoor and the

outdoor units securely and attach the wires firmly to

the terminal board connecting sections so the stress

of the wires is not applied to the sections.

Incomplete connecting and fixing could cause fire.

Check that the refrigerant gas do not leak after

installation is completed.

Be sure the installation area does not deteriorate

with age.

If the base collapses, the air conditioner could fall with it,

causing property damage, product failure and personal injury.

Perform the installation securely referring to the

installation manual.

Incomplete installation could cause a personal injury due to

fire, electric shock, the unit falling or a leakage of water.

Perform electrical work according to the installation

manual and be sure to use an exclusive circuit.

If the ca pacit y of the power circu it is insuffic ient or there is

incomplete electrical work, it could result in a fire or an electric

shock.

Attach the electrical part cover to the indoor unit and

the service panel to the outdoor unit securely.

If the electrical part cover if the indoor unit and/or the service

panel if the outdoor unit are not attached securely, it could result

in a fire or electric shock due to dust, water, etc.

Be sure to use the part provided or specified parts for

the installation work.

The use of defective parts could cause an injury or leakage of

water due to a fire, electric shock, the unit falling, etc.

Be cautious when unpacking and installing

the product.

Sharp edges could cause injury. Be especially careful of the

case edges and the fins on condenser and evaporator.

Do not modify or extend the power cable.

There is risk of fire or electric shock. Improper wiring or installation may cause fire or electric shock.

Use the correctly rated circuit breaker.

There is risk of fire or electric shock. There is risk of fire or electric shock.

Do not use a defective or under rated circuit breaker.

Use this appliance on a dedicated circuit.

There is risk of fire or electric shock.

Always install a dedicated circuit and breaker.

Always ground the product.

4

CAUTION

Perform the drainage/piping work securely

according to the installation manual.

If there is a defect in the drainage/p iping work, water

could drop from the unit and household goods could be

wet and damaged.

Always check for refrigerant R-22 leakage after

installing or repair of product.

Low refrigera nt R-22 levels may cause malfun ctionin g

of product.

Do not install the product where the noise or hot air

coming from the outdoor unit could harm your

neighbors.

It may cause problem to your neighb ors.

Do not install the product where it will be exposed to

sea wind (Salt spray) directly.

It may cause corro sion on p roduct. Corro sion,

particularly on the condenser and evaporator fins,

could cause product malfunction or in efficie nt operation.

Do not install the unit in a place where an

inflammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it

could cause an explosion.

Use two or more people to lift and transport the

product.

Avoid personal injury.

Keep the level of your airconditioner as mentioned

in manual to avoid vibration or water leakage.

ENGLISH

5

2. PRODUCT SPECIFICATION

2.1 PRODUCT DESCRIPTION:

Airconditioner is composed of evaporator unit and condensing unit. Evaporator

unit is positioned on top of condensing unit and connected with interconnection

pipes. Condenser section consists of compressor, propeller fan, fan motor and

condenser coil. And Evaporator section consists of evaporator coil, centrifugal

blower, blower motor and logical controller. Airconditioner is equipped with dual

independent Airconditioning cycle for reliability measures.

2.2 INSPECTION:

1. Check the damage after unit is unloaded, report promptly to the carrier, any

damage found to unit. Do not drop the unit.

2. Open the Packing carefully to check the unit in upright position.

3. Check the unit dents, paint damage, tube pinch offs, tube parts touching with

sheet metals, mechanical components and electrical wires connections.

4. Condensing unit is precharged with R-22 gas from factory. Ensure gas in

condensing unit before installation.

6

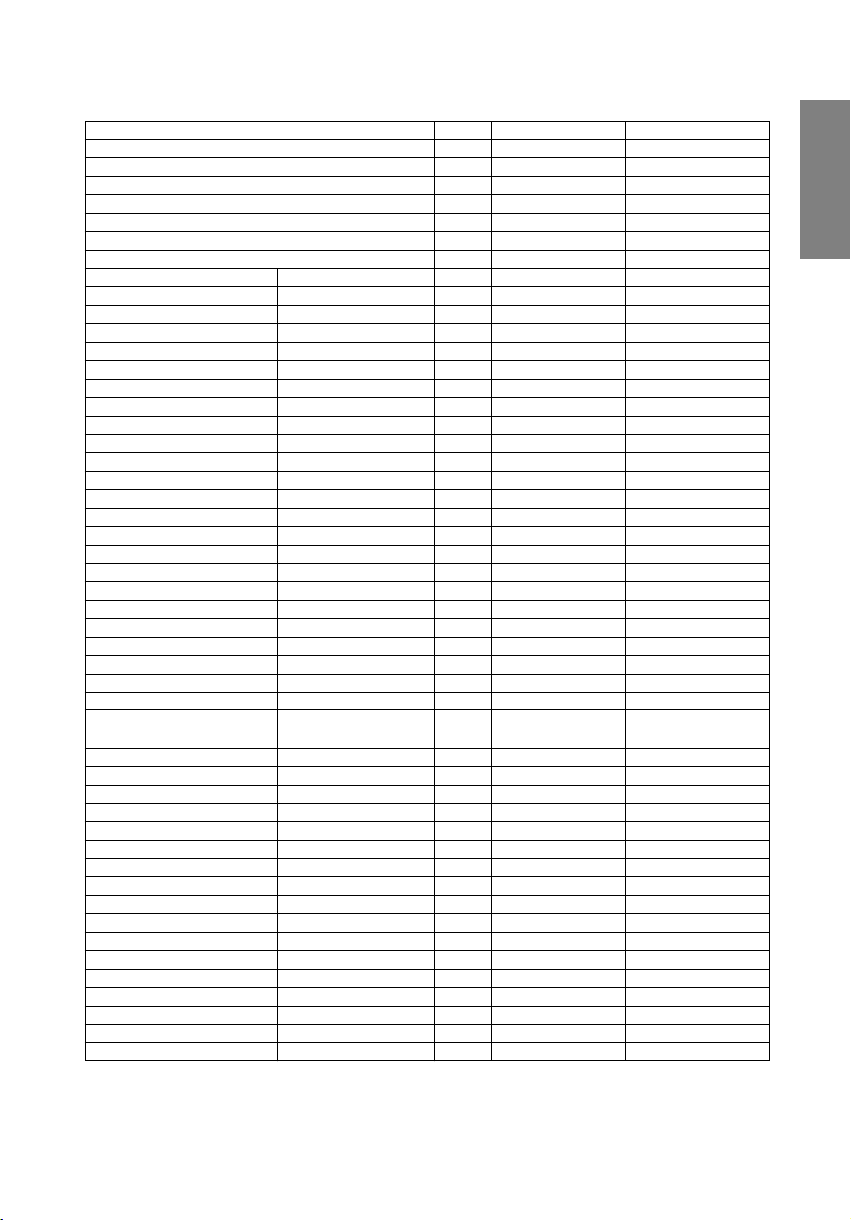

2.3 TECHNICAL SPECIFICATIONS

NOMINAL COOLING CAPACITY

TOTAL COOLING CAPACITY

SENSIBLE COOLING CAPACITY

LATENT COOLING CAPACITY

NO OF REFRIGERANT CIRCUITS

COMPRESSOR TYPE

EVAPORATOR FACE AREA

CONDENSER FACE AREA

INDOOR MOTOR TYPE

OUTDOOR MOTOR TYPE

BLOWER

FAN TYPE

CONNECTIONS CONDENSATE DRAIN SIZE

OVERALL DIMENSION-INDOOR (A)WIDTH

WEIGHT-INDOOR WEIGHT GROSS

OVERALL DIMENSION-OUTDOOR WIDTH

WEIGHT-OUTDOOR WEIGHT GROSS

DESCRIPTION

QTY

MAKE

MODEL

QTY

FIN DENSITY/ROWS

MATERIAL OF TUBE/FIN

QTY

FIN DENSITY/ROWS

MATERIAL OF TUBE/FIN

QUANTITY

POWER SUPPLY

SPEED

SHAFT DIAMETER

CLASS OF INSULATION

QUANTITY

POWER SUPPLY

SHAFT DIAMETER

CLASS OF INSULATION

FAN SPEED

TYPE

QTY

FAN MATERIAL

QTY

GAS OUTLET SIZE OD (nos)

LIQUID INLET SIZE,OD (nos)

(B)DEPTH

©HEIGHT

WEIGHT NET

DEPTH

HEIGHT

WEIGHT NET

UNITS LX-0356QC

TR 3.0

BTU/HR 18600 X 2

KCAL/HR 4650 X 2

KCAL/HR 4185 X 2

KCAL/HR 465 X 2

CFM 825 X 2AIRFLOW

NOS 2

NOS 2

Sq.M 0.223

NOS 2

FPI/No 14/2

Sq.M 0.272

NOS 2

FPI/No 14/3

NOS 2

RPM 960

mm 17

NOS 2

mm 12.7

RPM 880

NOS 2

NOS 2

mm 19

mm 12.7x2

mm 9.52x2

mm 665

mm 762

mm 938

KGS 90

KGS 85

mm 665

mm 550

mm 1080

KGS 110

KGS 105

Rotary

Hitachi

SH315CV-C7HU

Cu/Al-Precoat

Cu/Al-Precoat

INDUCTION MOTOR

230V-1PH-50Hz

B CLASS

INDUCTION MOTOR

230V-1PH-50Hz

B CLASS

CENTRIFUGAL,FORWARD

CURVE, DIDW

PROPELLER -AXIAL

Plastic

LX-0456QC

3.5

21000 X 2

5250 X 2

4725 X 2

525 X 2

960 X 2

2

Rotary

2

Hitachi

SH315CV-C7HU

0.223

2

14/3

Cu/Al-Precoat

0.272

2

14/3

Cu/Al-Precoat

INDUCTION MOTOR

2

230V-1PH-50Hz

1100

17

B CLASS

INDUCTION MOTOR

2

230V-1PH-50Hz

12.7

B CLASS

880

CENTRIFUGAL,FORWARD

CURVE, DIDW

2

PROPELLER -AXIAL

Plastic

2

19

12.7x2

9.52x2

665

762

938

92

87

665

550

1080

110

105

ENGLISH

7

3. INSTALLATION STANDARD

3.1 PRE-CHECK:

1. Remove the packing wooden base from indoor & outdoor unit.

2. Place the outdoor unit over mounting base (Concrete or I –beam) and

place antivibration pad and mount as per installation instructions.

3. Positioned the Indoor unit over Top of condensing unit and bolted indoor

with outdoor after fixing indoor to shelter cut-out portion.

4. Check there should not be any dents, dust in interconnecting piping.

5. Prepare inter connection pipe to connect indoor unit with outdoor unit as

per following.

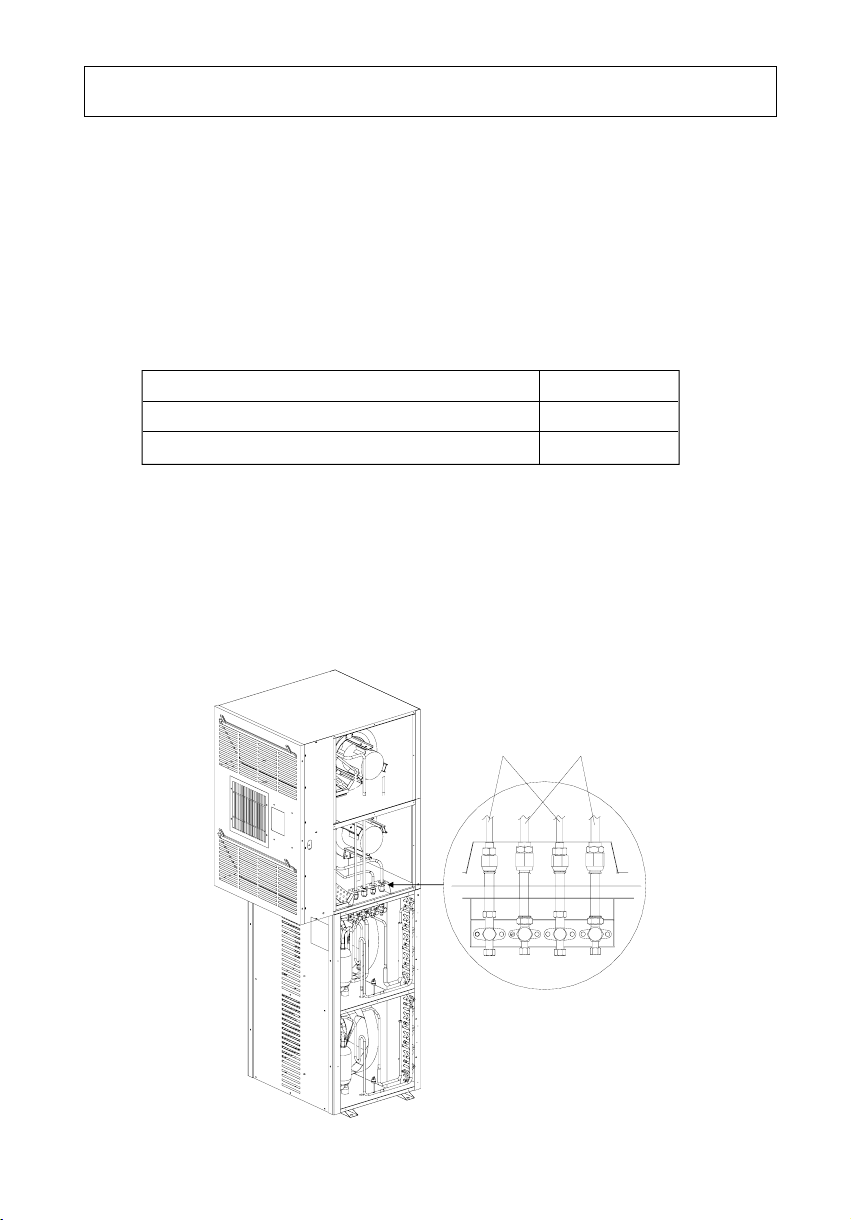

FLARED TYPE INTERCONNECTING PIPING SIZE X QTY.

SUCTION LINE INTERCONNECTING PIPING 1/2 inch X 2

LIQUID LINE INTER CONNECTING PIPING 3/8 inch X 2

6. Wrap Teflon tape in direction of thread to the connectors & service valve before

placing flared tubing.

7. Align the centre of the pipings (2 suctions & 2 liquids) and sufficiently tighten the

flare nut with fingers.

8. Finally tighten the flare nut with torque wrench until the wrench clicks (40~80kgf).

When tightening the flare nut with torque wrench, ensure the direction of

tightening follows the arrow of wrench.

Liquid

Interconnection

Suction

Interconnection

(A)

8

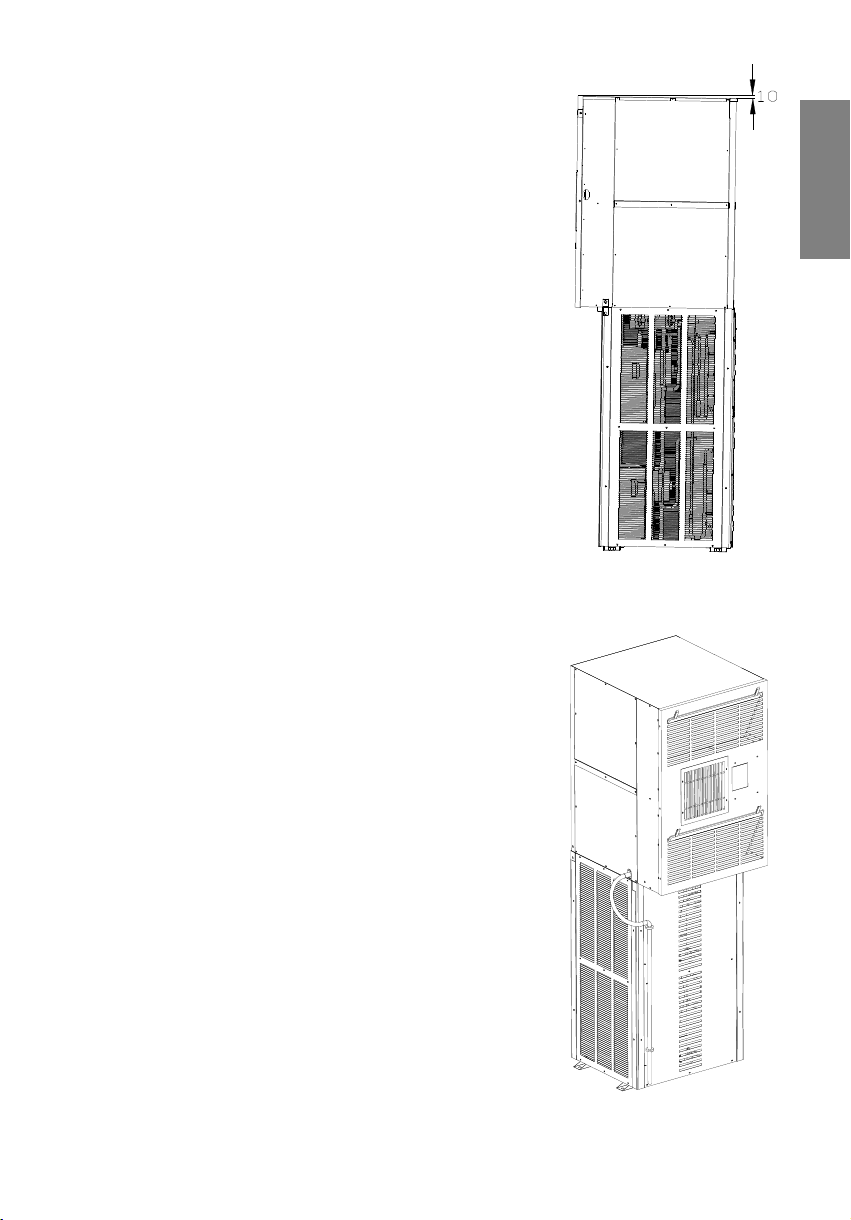

3.2. Levelling of Airconditioner

After placing the unit on Channel/concrete structure

maintain the levelling of unit towards rear side with

10mm slope so as to ensure free flow drainage.

Water seepage problem may happen due to improper

levelling of unit.

3.3. Shelter Cutout sealing

Angle flanges (4 nos) to be fixed with shelter wall after

installation. These flanges are to be fixed with shelter

wall after installation so as to prevent any leakage in

shelter. after fixing the flanges; apply silicon sealant

on edges of flanges to make complete leak free

cut-out. These are not the part of unit accessories.

ENGLISH

(B)

3.4. Condensate Drain pipe

1. Air conditioner is provided with one flexible drain

pipe, which shall be connected to metal Drain pipe

of unit & should be routed through gap between

shelter wall and condensing unit (see fig. C).

2. Do Not leave drain pipe open, your airconditioner

may suck condensate water and cause splitting of

water inside the shelter.

9

(C)

3.5. Air purging of inter connection & Indoor unit

The air which contains moisture remaining in the refrigeration cycle may cause

malfunction of compressor.

1. Confirm the both liquid valves& gas valves are set to closed position.

2. After connecting the piping, check the joints for gas leakage with gas leal

detector.

3. Remove the service port nut, and connect the gauge manifold and vacuum

pump to the service port by charge hose.

4. Vacuum the indoor unit & connecting pipes until the pressure in them lowers

to below 76 cmHg.

5. Remove the valve stem nuts. and fully open the stems of service valves with

hexagon wrench. & Tight the flare nuts of indoor & outdoor unit.

6. Purge the gas qty-80grams in each circuit to remove moist air contents.

7. Disconnect the charge hose and fit the nut to the service port.

(Tightening torque:1.8kg.m)

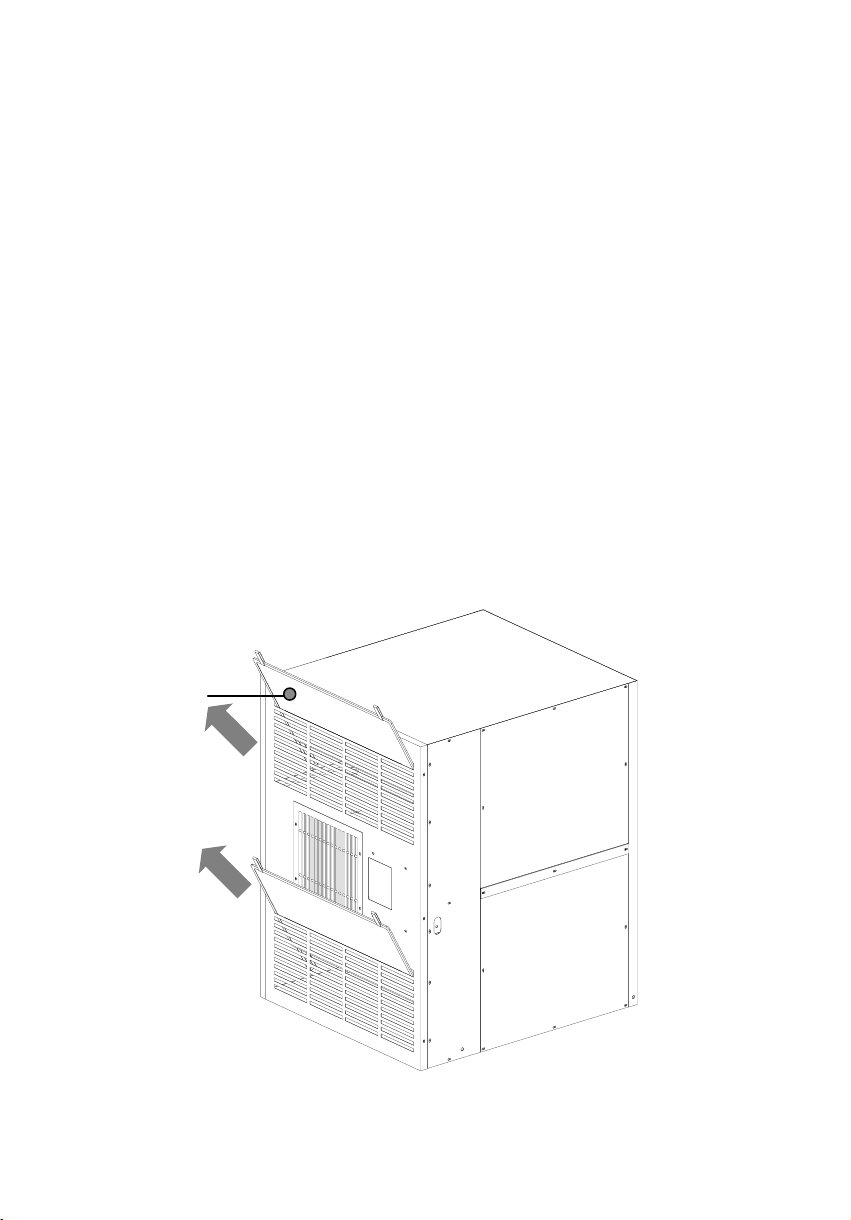

3.6. Filter Cleaning

The Airconditioner is equipped with fine air filter (2 nos.). The Air filter are at

front of unit shall be checked and cleaned every month or more often

if necessary.

Air-filter

10

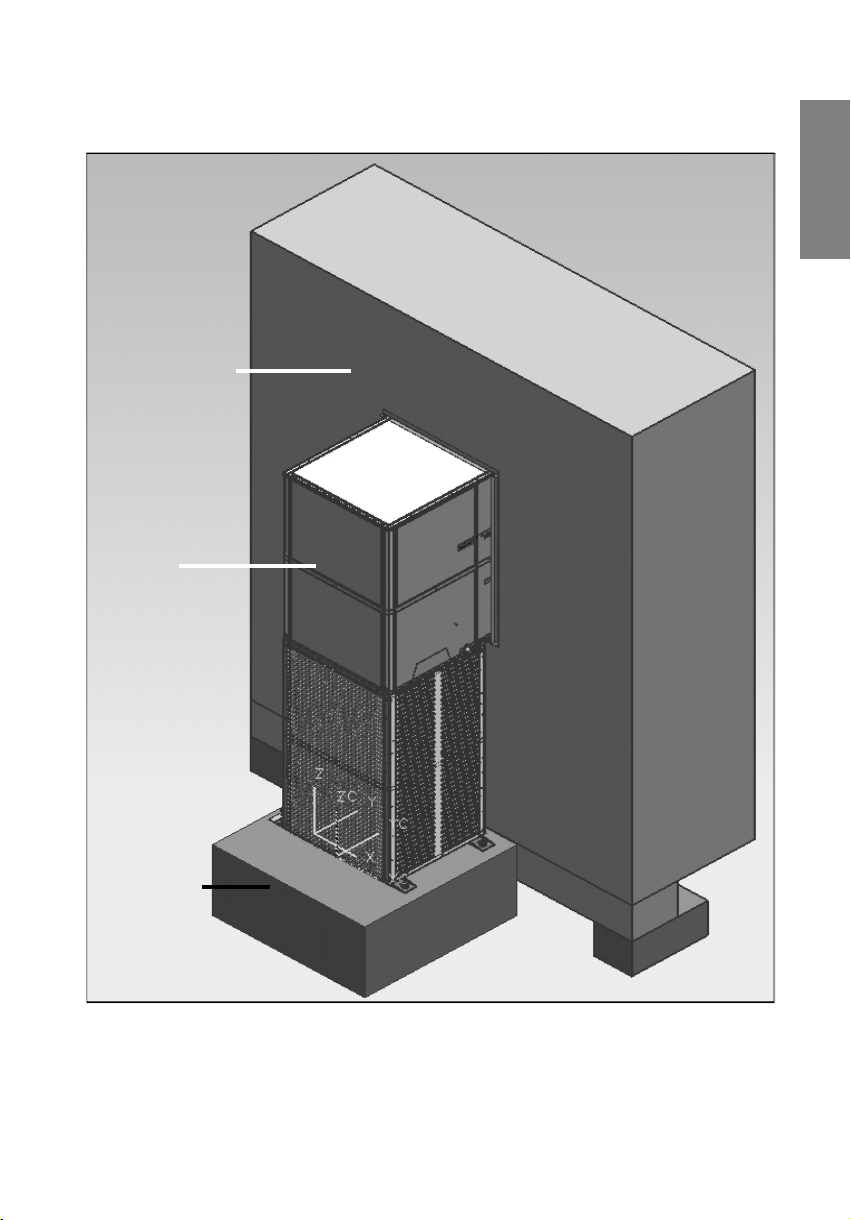

3.7. INSTALLATION DRAWING - CASE 1 :

CONCRETE BASEMOUNTING

SHELTER WALL

AC UNIT

ENGLISH

CONCRETE

BASE

11

Loading...

Loading...