Page 1

- 1-1 -

[CONTENTS]

❍ SECTION 1. GENERAL

• SERVICING PRECAUTIONS

.....................................................................................................

1-2

• ESD PRECAUTIONS

.................................................................................................................

1-4

• SPECIFICATION

........................................................................................................................

1-5

❍ SECTION 2. TROUBLESHOOTING

• ADJUSTMENTS

.........................................................................................................................

2-1

• TROUBLESHOOTING ............................................................................................................... 2-2

• WAVEFORMS OF MAJOR CHECK POINT............................................................................. 2-11

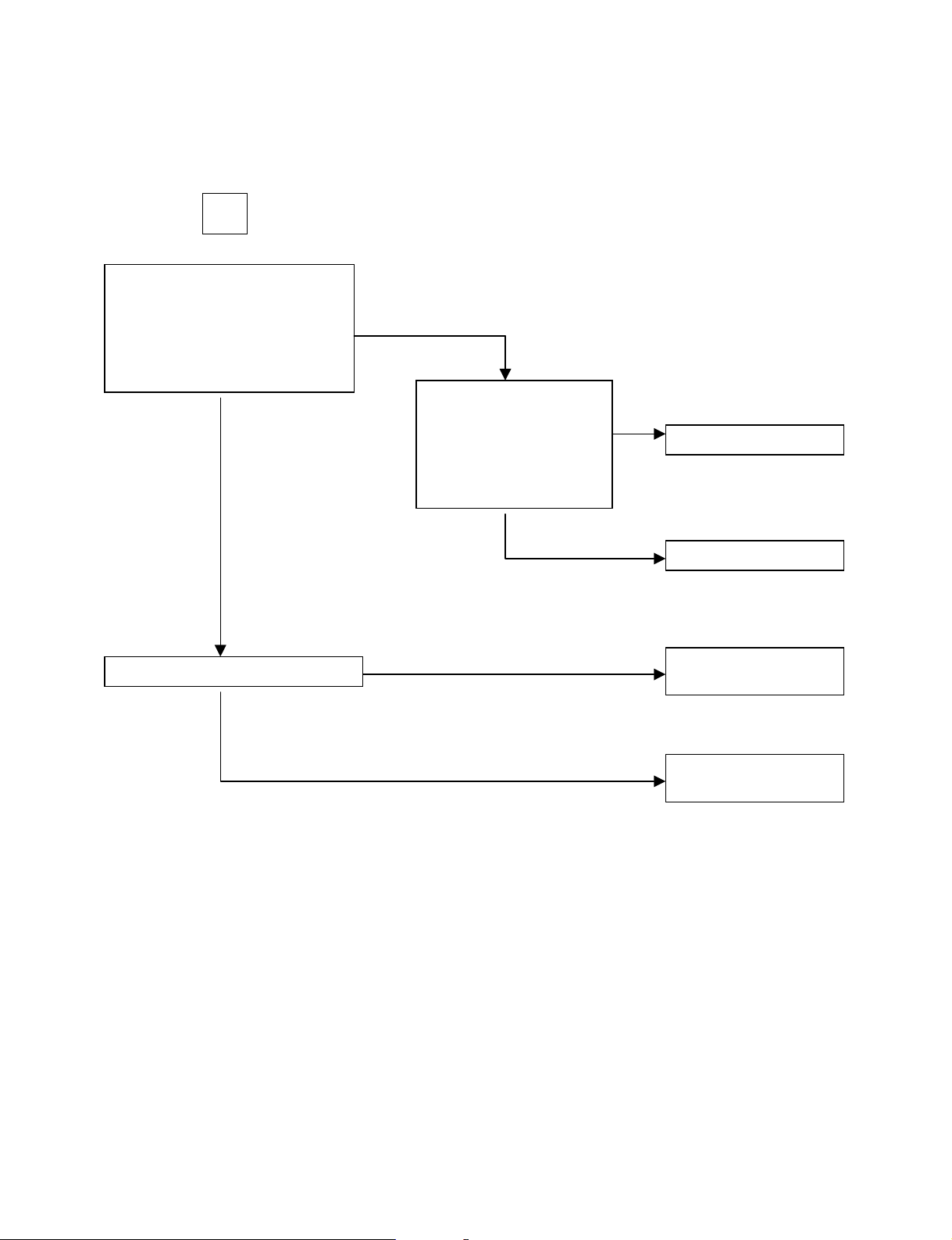

• BLOCK DIAGRAM

....................................................................................................................

2-21

• SCHEMATIC DIAGRAMS

........................................................................................................

2-23

• WIREING DIAGRAM ................................................................................................................ 2-29

• PRINTED CIRCUIT DIAGRAMS .............................................................................................. 2-31

• INTERNAL BLOCK DIAGRAM OF ICs .................................................................................... 2-38

❍ SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION

...................................................................................

3-1

❍ SECTION 4. SPEAKER PART

• SPEAKER PART

........................................................................................................................

4-1

❍ SECTION 5. REPLACEMENT PARTS LIST

• REPLACEMENT PARTS LIST

....................................................................................................

5-1

Page 2

❏ SERVICING PRECAUTIONS

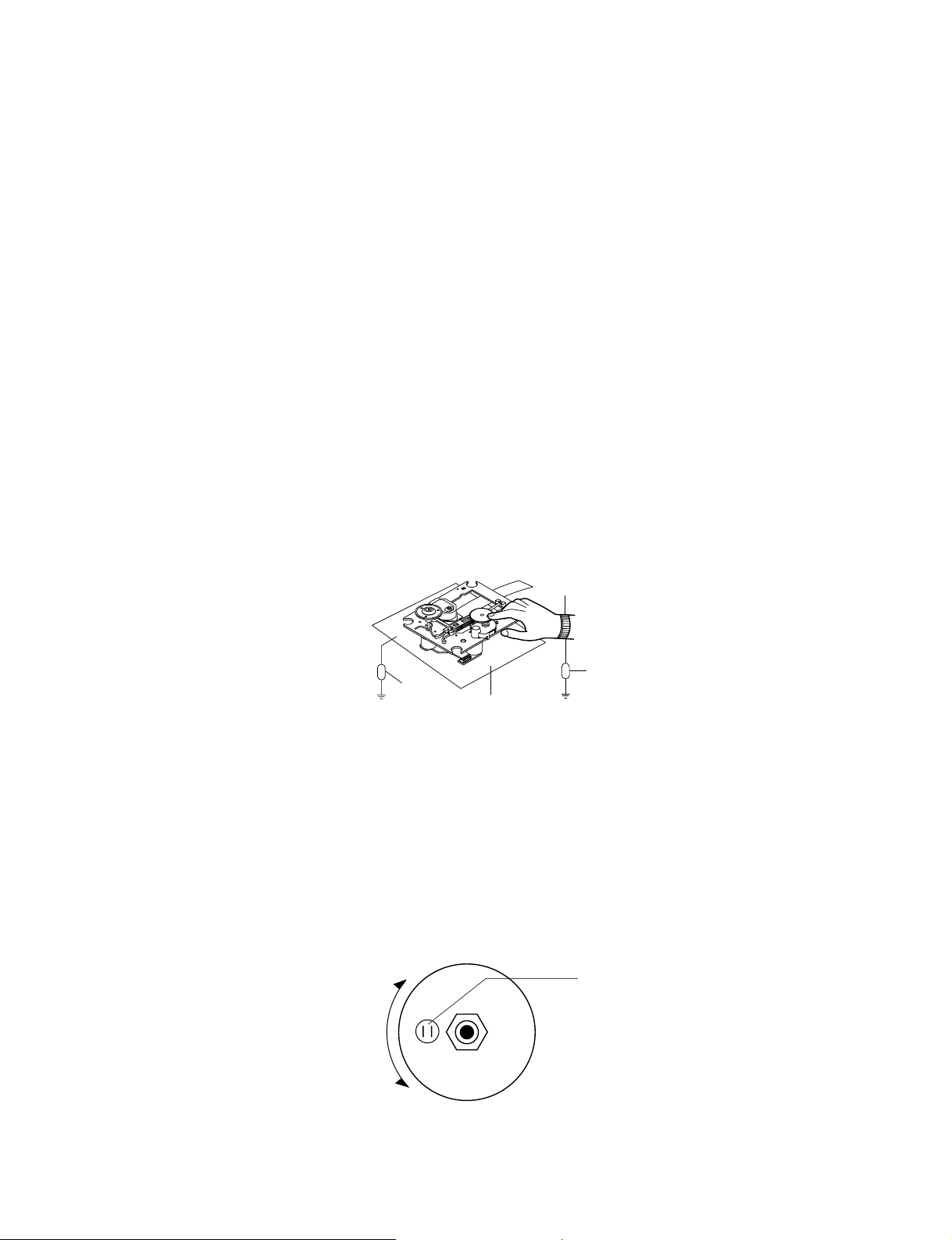

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a

cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do

not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of

this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

- 1-2 -

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Pressure

Pressure

Cotton swab

Conductive Sheet

SECTION 1. GENERAL

Page 3

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These

components are sensitive to, and easily affected by, static electricity. If such static electricity is high

voltage, components can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must

be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

CLEARING MALFUNCTION

You can reset your unit to initial status if malfunction occur(button malfunction, display, etc.).

Using a pointed good conductor(such as driver), simply short the RESET jump wire on the inside of the

volume knob for more than 3 seconds.

If you reset your unit, you must reenter all its settings(stations, clock, timer)

NOTE: 1. To operate the RESET jump wire, pull the volume rotary knob and release it.

2. If you wish to operate the RESET jump wire, it is necessary to unplug the power cord.

- 1-3 -

Armband

Conductive

Sheet

Resistor

(1 Mohm)

Resistor

(1 Mohm)

VOLUME KNOB

UP

DOWN

VOLUME

RESET jump wire

Page 4

❐ ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are ready

to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ESD device).

[CAUTION. GRAPHIC SYMBOLS]

- 1-4 -

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL

TRIANGLE, IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE

OF UNINSULATED “DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO

ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION IN SERVICE LITERATURE.

Page 5

❏ SPECIFICATIONS

- 1-5 -

SECTION SPECIFICATION

General Power supply Refer to the back panel of the unit

Power consumption 65W

Extemal dimensions(W X H X D)

161 X 255 X 268mm

CD Frequency Response 40 -18000Hz

Signal-to-noise ratio 70dB

Dynamic range 70dB

Tuning Range 87.5 -108.0MHz

Intermediate Frequency 10.7 MHz

FM Signal-to-noise ratio 60/55dB

Frequency Response 60 - 10000Hz

Tuning Range 522 - 1611kHz or 530 - 1610kHz

AM Intermediate Frequency 450kHz

Signal-to-noise ratio 35dB

Frequency Response 100 -1800 Hz

AMP Output Power 30W + 30W

T.H.D 0.15%

Frequency Response 40-25000Hz

Signal-to-noise ratio 80dB

TAPE Tape Speed 4.75cm/sec

Wow Flutter 0.25% (MTT-111,JIS-WTD)

F.F/REW Time 120sec(C-60)

Frequency Response 250-8000Hz

Signal-to-noise ratio 43dB

Channel Separation 50dB(P/B)/45dB(R/P)

Erase Ratio 55dB (MTT-5511)

Speaker MODEL LXS-M335

Type 2 Way 2 Speaker

Impedance 6Ω

Frequency Response 80-20000Hz

Sound Pressure Level 87dB/W(1m)

Rated Input Power 30W

Max.Input Power 60W

Net Dimension(W X H X D) 160 X 248 X 200mm

NOTE : Specification are subject to change without notice in the course of product improvement.

TUNER

Page 6

- 1-6 -

MEMO

Page 7

- 2-1 -

TAPE DECK ADJUSTMENT

1. AZIMUTH ADJUSTMENT

Figure 1. Azimuth Adjustment Connection Diagram

CH1 CH2

Speaker Out

Playback Mode

Head

Test Tape

MTT-114

L ch

R ch

GND

Dual-trace

synchroscope

Electronic

Voltmeter

L out

R out

Unit

❏ ADJUSTMENTS

This set has been aligned at the factory and normally will not require further adjustment. As a result, it is not

recommended that any attempt is made to modificate any circuit. If any parts are replaced or if anyone tampers

with the adjustment, realignment may be necessary.

IMPORTANT

1. Check Power-source voltage.

2. Set the function switch to band being aligned.

3. Turn volume control to minimum unless otherwise noted.

4. Connect low side of signal source and output indicator to chassis ground unless otherwise specified.

5. Keep the signal input as low as possible to avoid AGC and AC action.

Deck Mode Test Tape Test Point Adjustment Adjust for

Palyback MTT-114 Speaker Out

DECK Screw

Maximum

Azimuth Screw

SECTION 2. ELECTRICAL SECTION

Page 8

- 2-2 -

❏ TROUBLESHOOTING

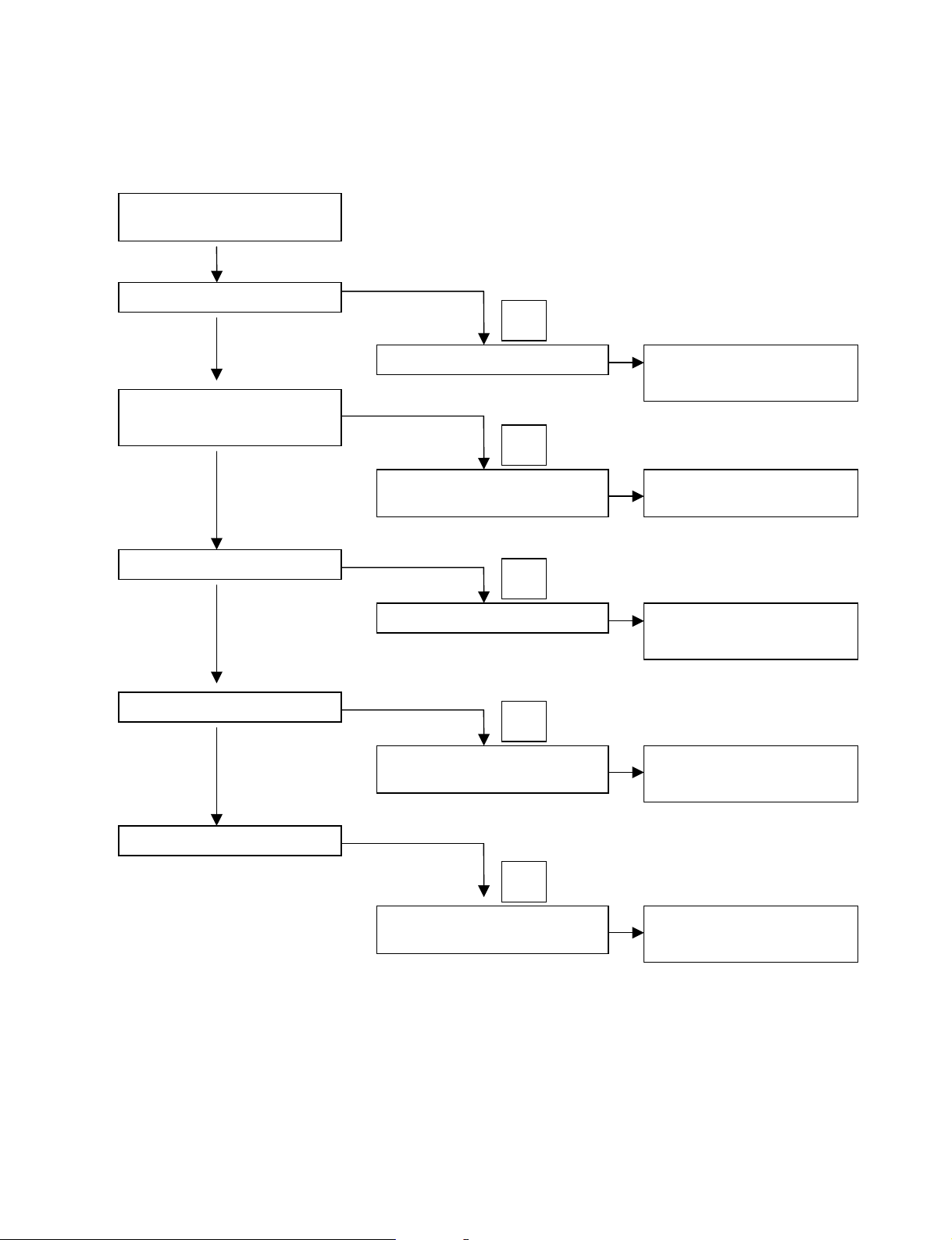

• CD PART

TURN ON CD

OPEN CLOSE CHECK

CONNECTOR CHECK ( PN508,PN507 )

CHECK POWER SUPPLY CIRCUIT( PN508 )

CHECK MICOM INTERFACE CIRCUIT( PN507 )

CHECK MICOM INTERFACE CIRCUIT( PN507 )

CONNECTOR CHECK(PN501,PN503)

CHECK PICKUP MOVEMENT

CHECK BA5810FP (IC503)

CHECK MN6627933CG (IC501)

CHECK AN22004 (IC502)

CONNECTOR CHECK (PN508)

CONNECTOR CHECK

( PN508,PN507,PN503,PN501 )

“ READING ”

DISPLAY CHECK

READING OK CHECK

IF PLAY, AUDIO

OUTPUT CHECK

OK

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

Page 9

- 2-3 -

DEFECTIVE MAIN

POEWR SUPPLY

DEFECTIVE MICOM

DEFECTIVE IC503

DEFECTIVE MICOM

MECHANISM

• OPEN CLOSE NG

CONNECTOR LOCKING CHECK ( PN508,PN507 )

CHECK POWER SUPPLY CIRCUIT( PN508

,PN507) PN 508 PIN 8 = 6.2V, PIN 7 = 5V

PN507 PIN 1 = 5V

CHECK VOLTAGE CHANGE OF OPEN CLOSE,

AND BTLMUTE VOLTAGE(= 5V)

(PN507 PIN 12:OPEN, 13:CLOSE, 14:BTLMUTE)

CHECK VOLTAGE CHANGE LO+, LO- OF IC503

(PN507, PIN OPEN:12, CLOSE:13)

NO

NO

NO

NO

YES

YES

YES

Page 10

- 2-4 -

• “ READING ” DISPLAY CHECK (= ONLY “CD “DISPLAY)

CONNECTOR LOCKING CHECK

(PN508,PN507,PN503,PN501 )

CHECK VOLTAGE THE PIN 2 OF

IC505 PIN2 : 3.3V

CHECK RESET SIGNAL OF PN507

PN507 PIN7 : 5V

CHECK MICOM INTERFACE

CIRCUIT( PN507 )

PN507 PIN 6,8,9,10 SIGNAL CHECK

(6: STAT, 8: MDATA, 9:MCLK, 10:MLD)

CHECK THE WAVE FORM #1

CHECK POWER SUPPLY

PORT( PN508 ,PN507)

PN508 PIN 8 = 6.2V, PIN 7 = 5V

PN507 PIN 1 = 5V

DEFECTIVE CONNECTOR OR

MAIN POWER SUPPLAY

DEFECTIVE IC505

DEFECTIVE MICOM OR

CONNECTOR

DEFECTIVE MICOM OR

CONNECTOR

DEFECTIVE IC501

NO

NO

NO

NO

NO

YES

YES

YES

YESYES

Page 11

- 2-5 -

• READING OK CHECK (= “NO DISC” DISPLAY)

AAAA

BBBB

CCCC

DDDD

EEEE

CONNECTOR LOCKING

CHECK(PN501,PN503)

DOES LENSE MOVE ?

(= UP & DOWN)

DOES SLED MOVE ?

CHECK PN503 PIN 3,4( SL+,SL-)

CHECK PN501 PIN 13,16

( FA-, FA+)

DEFECTIVE PICKUP OR

IC503 OR IC501 OR IC502

DEFECTIVE PICKUP OR

IC503 OR IC501

DEFECTIVE PICKUP OR

IC502

DEFECTIVE PICKUP OR

IC503

DEFECTIVE PICKUP OR

IC503 OR IC501 OR IC502

CHECK PN503 PIN 10( LD )

CHECK PN503 PIN

5,6( SP+,SP-)

CHECK PN501 PIN 14,15

(TA- ,TA+)

DOES LASER LIGHT ?

DOES SPINDLE ROTATE ?

IS READING OK ?

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YESYES

YES

YES

YES

Page 12

- 2-6 -

• READING OK CHECK #A (= “NO DISC” DISPLAY)

AAAA

DOES SL+ WAVEFORM

APPEAR AT ( IC503 PIN14 AND

PN503 PIN3) WAVEFORM #2

SLED MOTOR WAVE

DOES SLIN WAVEFORM

APPEAR AT ( IC503 PIN 5)

WAVEFORM #2 SLED

DRIVE WAVE

DEFECTIVE IC501

DEFECTIVE IC503

CHECK PN503 CONNECTOR LINE

DEFECTIVE PN503

CONNECTOR

DEFECTIVE PICKUP

SLED MOTOR

NO

NO

NO

NO

NO

YES

YES

Page 13

- 2-7 -

• READING OK CHECK #B (= “NO DISC” DISPLAY)

BBBB

DOES FA+ WAVEFORM

APPEAR AT ( IC503 PIN15 AND

PN501 PIN16) WAVEFORM #3

FOCUS COIL DRIVE WAVE

DOES FAIN- WAVEFORM

APPEAR AT ( IC503 PIN 26)

WAVEFORM #3 FOCUS

DRIVE WAVE

DEFECTIVE IC501

DEFECTIVE IC503

CHECK PN501 CONNECTOR LINE

DEFECTIVE PN501

CONNECTOR

DEFECTIVE PICKUP

FOCUS ACTUATOR

NO

NO

NO

NO

NO

YES

Page 14

- 2-8 -

• READING OK CHECK #C (= “NO DISC” DISPLAY)

CCCC

IS ?V APPLIED TO PIN10 OF PN501

LASER SUPPLY VOLTAGE CHECK

IS 3.3 V APPLIED TO

PIN3 OF IC502

RF IC SUPPLY VOLTAGE

CHECK

IS 2.0 V PIN2 OF IC502

LASER CONTROL

VOLTAGE CHECK

DEFECTIVE IC505

DEFECTIVE IC502

CHECK PN501 CONNECTOR LINE

DEFECTIVE Q501 OR

D502

DEFECTIVE PN501

CONNECTOR

DEFECTIVE PICKUP

LASER PART

NO

NO

NO

NO

NO

NO

YES

YES

Page 15

- 2-9 -

• READING OK CHECK #D (= “NO DISC” DISPLAY)

DDDD

CHECK PN503 CONNECTOR LINE

DEFECTIVE IC501

DEFECTIVE IC503

DEFECTIVE PN503

CONNECTOR

DEFECTIVE PICKUP

“SPINDLE MOTOR

NO

NO

NO

NO

NO

YES

YES

DOES SPIN WAVEFORM

APPEAR AT

( IC503 PIN 6)

WAVEFORM #4

SPINDLE DRIVE WAVE

DOES SP+ WAVEFORM APPEAR

AT ( IC503 PIN12 AND PN503 PIN6)

WAVEFORM #4

SPINDLE MOTOR DRIVE WAVE

Page 16

- 2-10 -

• READING OK CHECK #E (= “NO DISC” DISPLAY)

EEEE

DOES TA+ WAVEFORM APPEAR

AT ( IC503 PIN17 AND PN503 PIN15)

WAVEFORM #5

TRACKING COIL DRIVE WAVE

DOES TAIN- WAVEFORM

APPEAR AT

( IC503 PIN 23) WAVEFORM

#5 TRACKING DRIVE WAVE

DEFECTIVE IC501

DEFECTIVE IC503

CHECK PN503 CONNECTOR LINE

DOES ARF SIGNAL APPEAR?

(IC502 PORT 8)

WAVEFORM #6

DOES FE, TE SIGNAL APPEAR?

(IC502 PORT FE:23, TE:21)

WAVEFORM #6

DEFECTIVE IC501

DEFECTIVE PN503

CONNECTOR

DEFECTIVE PICKUP OR

IC502

DEFECTIVE PICKUP OR

IC502

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Page 17

- 2-11 -

❏ WAVEFORMS OF MAKOR CHECK POINT

#1 . MICOM INTERFACE WAVEFORM

(PN507 pin6, 8, 9, 1 0) during normal play

#2. SLED DRIVE AND MOTOR WAVEFORM

(IC503 pin5, 1 4) when focus search

#3. FOCUS DRIVE AND MOTOR WAVEFORM

(TP56 1 , IC503 pin 1 5)

- When focus search failed or there is no

disc on tray

- There is disc on tray and focus search

success

Page 18

- 2-12 -

#4. SPINDLE DRIVE AND MOTOR WAVEFORM

(IC503 pin6, 1 2) when TOC reading

#5. TRACK DRIVE AND MOTOR WAVEFORM

(TP560, IC503 pin23) during normal play

#6. RF, TRACKING AND FOCUS ERROR WAVEFORM

(IC502 pin8, 2 1 , 23) during normal play

Page 19

- 2-13 -

❏ AUDIO PART

VKK PART

Does DC - 27V appear at

PN601 pin .

Check the pattern of FRONT

PCB ASS’Y

Check the DC -34V of C928(-)

Check the DC -27V of

ZD 902(-)

Check the DC -27V of

Q901 “E”

Check the PATTERN

Replace the D936

Replace the ZD902

Replace the Q901

YES

YES

YES

YES

NO

NO

NO

NO

P-SENS PART

Does +5V appear at ZD901?

Check the pattern of

IC301 pin .

Check the waveform

of D937 (+).

Replace ZD901.

Replace the D937

YES

YES

NO

NO

26

16

Page 20

- 2-14 -

POWER CIRCUIT

Check the Fuse

Check the DC output

of C923(+)

Check the DC 12V

Output of IC901

Check the DC 6.2V

output of IC902

Check the DC 12V

Output of IC903

Check the 5.6V of Q604 “C”

(CD FUNCTION)

END

Replace the Fuse

CHECK THE AC VOLTAGE

OF CN901

pin

5, 6

Check the DC VOLTAGE of

D939(+)

Replace the Q501

Replace the D925, D926,

D927, D928

Replace the IC902

Check DC VOLTAGE OF

D930(+)

Check the “LOW” of

IC501 pin8

Check the “High” of Q605“B”

Replace the Q604

Replace the IC902

Replace the Transformer

Replace the D939

Replace the D930

Replace the IC501

Check the “High” of

IC501 pin4

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

Page 21

- 2-15 -

AUDIO ABNORMAL

Check the signal output of

IC701 pin3, 4

Check the signal input of IC701

pin8, 12

Check the DC +9V of IC601

pin1

Check the “High” of Q705 “B”

Check the “High” of

IC701 pin10

Check the power of IC701

Check the connecting to

SPEAKER

YES

YES

YES

NO

NO

NO

MUTING CIRCUIT (MUTE)

Dose “High” appear at

Q701, Q751“B”

check the “Low” of Q701,

Q751, “C”

MUTE

Check the “High” of PN601 pin12

Check the “High” of

the IC301 pin2

Replace the Q703

Replace the TR

Refer to IC 301

Troubleshooting

YES

YES

YES

NO

NO

NO

Page 22

- 2-16 -

FUNCTION MODE AUDIO ABNORMAL

TAPE

Check the signal input

of IC601 pin6, 23

Refer to “IC201 Troubleshooting”

AUX

Chekc the signal input of IC601,

pin

5, 24

Check the signal input of JK601

Check the signal input of IC601

pin

3, 26

Check the signal input of CN603 pin6, 8

Check the signal input of IC601 pin4, 25

Refer to “TUNER PACK Troubleshooting”

CD

TUNER

Page 23

- 2-17 -

Refer to “IC301

Troubleshooting”

IC301 TROUBLESHOOTING

IC601 TROUBLESHOOTING

Check the power supplying IC301

pin

17, 46, 72, 90?

Refer to “Power Circuit Troubleshooting”

Check the P-SENS

Replace the X301

Check the RESET circuit

Refer to “Power Circuit Troubleshooting”

Check the Data of IC301 pin9, 10

(CD ➞ TAPE FUNCTION)

Replace the

IC601

Check the pattern

Check the P-SENS “High” of IC301 pin26

Check the oscillation of X301

When power supplying to IC301 pin12.

(Low ➞ High)

Replace the IC301

Check the power supplying

to IC601 pin1

Check the CLK Data of IC601 pin14, 15

Check the IC601 FUNCTION SELECTOR

END

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Page 24

- 2-18 -

TUNER PACK TROUBLESHOOTING

Check the PLL- of CE, DI, DO, CLK

Is the normal ?

END

CE: Chip Enable

DI: Data Input(from u-com)

DO: Data Output(to u-com)

CLK: Tuner mode clock

Replace the TUNER PACK

YES

NO

TUNER PACK POWER TROUBLESHOOTING

Check the +9V of OPN602 pin2

Check the +DC C670

Check the pattern

Refer to “Power circuit

Troubleshooting”

Check the GND of PN602 pin4, 10

END

YES

YES

YES

NO

NO

PLAY

Check the VCC supplying to IC201 pin4

Refer to “Power Circuit

Troubleshooting”

Check the Deck Mecha

Replace the Deck

Mecha.

Replace the IC201

Check the signal output of IC201 pin3, 6

Check the “LOW” of Q201, Q251, “B”

YES

YES

YES

NO

NO

NO

Page 25

- 2-19 -

REC (Q252, Q202 ON / R273, R223 HIGH)

Check signal supplied to IC203 pin2, 8 ?

Check the output of IC203 pin3, 7

Check the “voltage” of L201 pin5

Refer to “power circuit Troubleshooting”

Check the power

supplying to C227(+)

Check the oscillation

of Q204, “E”

Check the signal of

R212, R262

Check the Pattern

Check the Vcc power of IC203 Pin6

Check the oscillation of L201 pin 1, 3

Replace the DECK

Check the “Low” of Q202,

Q252 “B”

Replace the Q202, Q252

Check the “Low” of

IC501 pin9

Refer to

“Power Circuit

Troubleshooting”

Check the 0.6V of

Q205 “B”

Replace the L201

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

Page 26

- 2-20 -

MEMO

Page 27

- 2-37 -

• CD MAIN P.C. BOARD (SOLDER SIDE)

Page 28

- 2-38 -

❏ INTERNAL BLOCK DIAGRAM OF ICs

■ KIA6225P/S (IC201)

BIPOLAR LINEAR INTEGRATED CIRCUIT

Page 29

- 2-39 -

• Internal circuit configuration

■ BA3126N (IC202)

2-channel head switch for radio cassette recoreders

■ BA3308 (IC203)

Dual preamplifier with ALC

Page 30

- 2-40 -

■ LC78645E (IC501)

Digital Servo Block Diagrams

• Overview

The focus servo circuit performs analog/digital conversion on FE(the focus error signal), while the tracking

and sled servo circuits do so on TE(the tracking error signal), then they each pass that result through an

equalizer, perform digital/analog conversion, and output it, At the spindle servo, based on the EFM signal

during CLV control or the FG signal during CAV control, the calculated value passes through an equalizer,

undergoes digital/analog conversion, and is output.

■ BU2090F (IC501)

-12 -bit, Serial IN, parallel OUT driver

Control circuit

12-bit shift register

Latch

VSS

2

1

3

4

5

6

7

8

DATA

CLOCK

Q0

Q1

Q2

Q3

Q4

16

15

14

13

12

11

10

9

VDD

Q11

Q10

Q9

Q8

Q7

Q6

Q5

Output buffer

(open drain)

Page 31

- 2-41 -

■ FAN8039BD3 (IC502)

5-CH Motor Driver

NO Symbol Description NO Symbol Description

1 DO1- CH1 Drive Output (-) 15 GND2 Power Ground1 (CH 2,3,5)

2 DO1+ CH1 Drive Output (+) 16 DO5+ CH5 Drive Output (+)

3 IN1 CH1 Drive Input 17 DO5- CH5 Drive Output(-)

4 REGVCC Regulator Supply Voltage 18 DO3- CH3 Drive Output(-)

5 REB Regulator Output 19 DO3+ CH3 Drive Output (+)

6 REO Regulator Feedback Input 20 IN3 CH3 Drive Input

7 RESX Regulator Reset 21 VCC1 Supply Voltage1(CH2,CH3,CH5)

8 GND1 Signal Ground 22 PS Power Save

9 CTL CH5 Motor Speed Control 23 VREF Bias Voltage

10 FWD CH5 Forward Input 24 VCC Supply Voltage(CH1,CH4)

11 REV CH5 Reverse Input 25 IN4 CH4 Drive Input

12 IN2 CH2 Drive Input 26 DO4+ CH4 Drive Output (+)

13 DO2+ CH2 Drive Output (+) 27 DO4- CH4 Drive Output (-)

14 DO2- CH2 Drive Output (-) 28 GND3 Power Ground2 (CH 1,4)

•

PIN Definitions

Page 32

- 2-42 -

MEMO

Page 33

- 4-1 -

MODEL: LXS-M335

857

865

854

858

859856

864

852

863

851

861

862

850

853

855

LOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

850 3701RM0078A NET ASSEMBLY SPK LXS-M335 SP-8505

851 3720RMF042A PANEL,FRONT FRONT LX-330, RESIN:GREY , L.

852 4930RM0012A HOLDER HOLDER PIEZO FE-386E

853 6400FSMG01A SPEAKER,FULLRANGE CW-125B30L-6 SAMMI FULL-RANGE

854 4766RM0028A FELT 1.0T BLACK LXS-330, FOR PIEZO

855 4766RM0012A FELT Audio FE-196E BLACK WOOFER

856 4766RM0027A FELT 1.0T BLACK LXS-330, FOR DUCT

857 3091RMW083A CABINET ASSEMBLY SPK LXS-M335 DE-1878-31

858 6852SCK004A CORD,A/V FE-M100E , 0.16 * 18/2C (CORD

859 3610RM0009A FOOT LXS-330, EVA(BLACK) PHI15X1T,

861 353M075E SCREW,DRAWING H1 D3.5 L19.0 MSWR3/FNM HEXAGO

862 4930RM0003B HOLDER NET (FE-J220, DECO WF)

863 353M025F SCREW TAPTITE, 3X8 FZMY

864 353M050C SCREW BH 3.5X16 FBK

865 4930RM0024A HOLDER LXS-330, RUBBER HOLDER NET, L.

SECTION 4. SPEAKER SECTION

RUN DATE : 16-SEP-2003

Page 34

- 4-2 -

MEMO

Page 35

BLOCK DIAGRAM

2-21 2-22

Page 36

SCHEMATIC DIAGRAMS

• MAIN SCHEMATIC DIAGRAM

NOTE: Warning

Parts that are shaded are critical With respect

to risk of fire or electrical shock.

NOTE:

1. Shaded(

with specified part number.

2. Voltages are DC-measured with a digital voltmefer

during Play mode.

■) parts are critical for safety.Replace only

2-23 2-24

Page 37

FRONT/POWER SCHEMATIC DIAGRAM

NOTE: Warning

Parts that are shaded are critical With respect

to risk of fire or electrical shock.

NOTE:

1. Shaded(■) parts are critical for safety.Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmefer

during Play mode.

2-25 2-26

Page 38

• CDP SCHEMATIC DIAGRAM

2-27 2-28

Page 39

WIRING DIAGRAM

2-29 2-30

Page 40

PRINTED CIRCUIT DIAGRAMS

• MAIN/TUNER P.C. BOARD(SOLDER SIDE)

2-31 2-32

Page 41

• MAIN/TUNER P.C. BOARD(COMPONENT SIDE)

2-33 2-34

Page 42

• FRONT/POWER P.C. BOARD (SOLDER SIDE) • FRONT/POWER P.C. BOARD (COMPONENT SIDE)

NOTE: Warning

Parts that are shaded are critical With respect

to risk of fire or electrical shock.

NOTE: Warning

Parts that are shaded are critical With respect

to risk of fire or electrical shock.

2-35 2-36

Page 43

351

459

301

A47

310

TUNER

A46

A41

A26

257

255

A00

302

303

305

A43

459

285

273

284

286

271

250

277

280

279

278

260

274

272

275

276

SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION

NOTE) Refer to “SECTION 5 REPLACEMENT

PARTS LIST” in order to look for the

part number of each part.

3-1 3-2

Page 44

• CD MECHANISM

001

429

430

430

012

430

012

430

018

014

013

017

020

011

015

431

012

430

012

429

026

004

002

003

A01

A03

A02

LOCA.NO. PART NO DESCRIPTION SPECIFICATION

A26 6721RJ0323A DECK ASSEMBLY,AUDIO CDP(CDM-300) CKD-HZ

A01 4861RH0004A CLAMP ASSEMBLY DISC (CDM-300)

A02 4405RHD009A MECHANISM ASSEMBLY MAIN LOADING CDP (CDM-300)

A03 6717RCA001A PICK UP ASSY KSM-213VSCM SONY FRONT LOADING

001 3300R-0547B PLATE CLAMP (CDM-300)

002 524-012AAAA COVER CLAMP MAGNET (030X018X5T)

003 4860R-0016A CLAMP DISC (CDM-300)

004 4930R-0171A HOLDER CLAMP

011 3040R-0073A BASE P/U (CDM-300)

012 5040R-0073A RUBBER DAMPER CDM-300(BK)

013 4400R-0006A BELT LOADING

014 4470R-0055A GEAR PULLEY

015 6871RC2016A PWB(PCB) ASSEMBLY,CD LOADING (CDM-300)

017 4470R-0056A GEAR LOADING

018 4974R-0023A GUIDE UP/DOWN

020 3040R-0072A BASE MAIN (CDM-300)

026 3390R-0005A TRAY DISC

429 1SZZR-0012A SCREW, B-TITE

430 6756SBX001A CD MECHANISM PARTS SCREW 2.6X10X10XFZMY CDM-H813

431 1SZZH-1007B SCREW,DRAWING + D2.0 6MM SWRCH16A/ZNBK 4MM 1

3-3 3-4

Loading...

Loading...