LG LSXS26466 Series, LSXS26366 Series, LSXS26386 Series, LSXS26326 Series, LSXC22386 Service Manual

...

REFRIGERATOR

SERVICE MANUAL

CAUTION

PLEASE READ CAREFULLY THE SAFETY PRECAUTIONS OF THIS MANUAL

BEFORE CHECKING OR OPERATING THE REFRIGERATOR.

MODELS:

LSXS26466

LSXS26386

LSXS26366

LSXS26326

*

*

*

*

CONTENTSCONTENTS

SAFETY PRECAUTIONS ................................................................................................ ............................ 3

1. SPECIFICATIONS .......................................................................................... .......................................... 4

2. PARTS IDENTIFICATION ......................................................................... ............................................... 5

3. DISASSEMBLY ................................................................................................. ....................................... 6

1. Door Alignment.......................................................................................................................................... 6

2. Install Water Filter...................................................................................................................................... 7

3. Refrigerator Shelves.................................................................................................................................. 7

4. Icemaker.................................................................................................................................................... 8

4. HOW TO DISASSEMBLY AND ASSEMBLY................................................ ............................................ 9

1. Removing and Replacing Refrigerator door.............................................................................................. 9

2. Handle Removal........................................................................................................................................ 10

3. Redd S/W.................................................................................................................................................. 11

4. Removing and Replacing Refrigerator and Freezer Led’s........................................................................ 11

5. Fan Shroud Grille....................................................................................................................................... 12

6. Water Valve Tubes Assembly Method....................................................................................................... 13

7. Way Valve Service..................................................................................................................................... 14

8. Dispenser .................................................................................................................................................. 15

9. Disassembly of Fan Motor ………………………………………………………………………………………. 17

5. MICOM FUNCTION ................................................................................................ ................................. 18

6. ICEMAKER AND DISPENSER WORKING PRINCIPLES AND REPAIR................................................ 26

1. Working Principles..................................................................................................................................... 26

2. Function on Icemaker................................................................................................................................ 27

3. Ice maker Troubleshooting........................................................................................................................ 30

4. Icemaker Circuit........................................................................................................................................ 31

7. CIRCUIT DIAGRAM................................................................................... ............................................... 32

8. TROUBLE DIAGNOSIS.......................................................... .................................................................. 33

9. PCB ………………………………………………………………………………………………………….......... 55

10. TROUBLESHOOTING WITH ERROR DISPLAY ……………………………………………………....…… 56

11. TROUBLESHOOTING WITHOUT ERROR DISPLAY ……………………………………………………… 74

12. EXPLODED VIEW .................................................................................................................................106

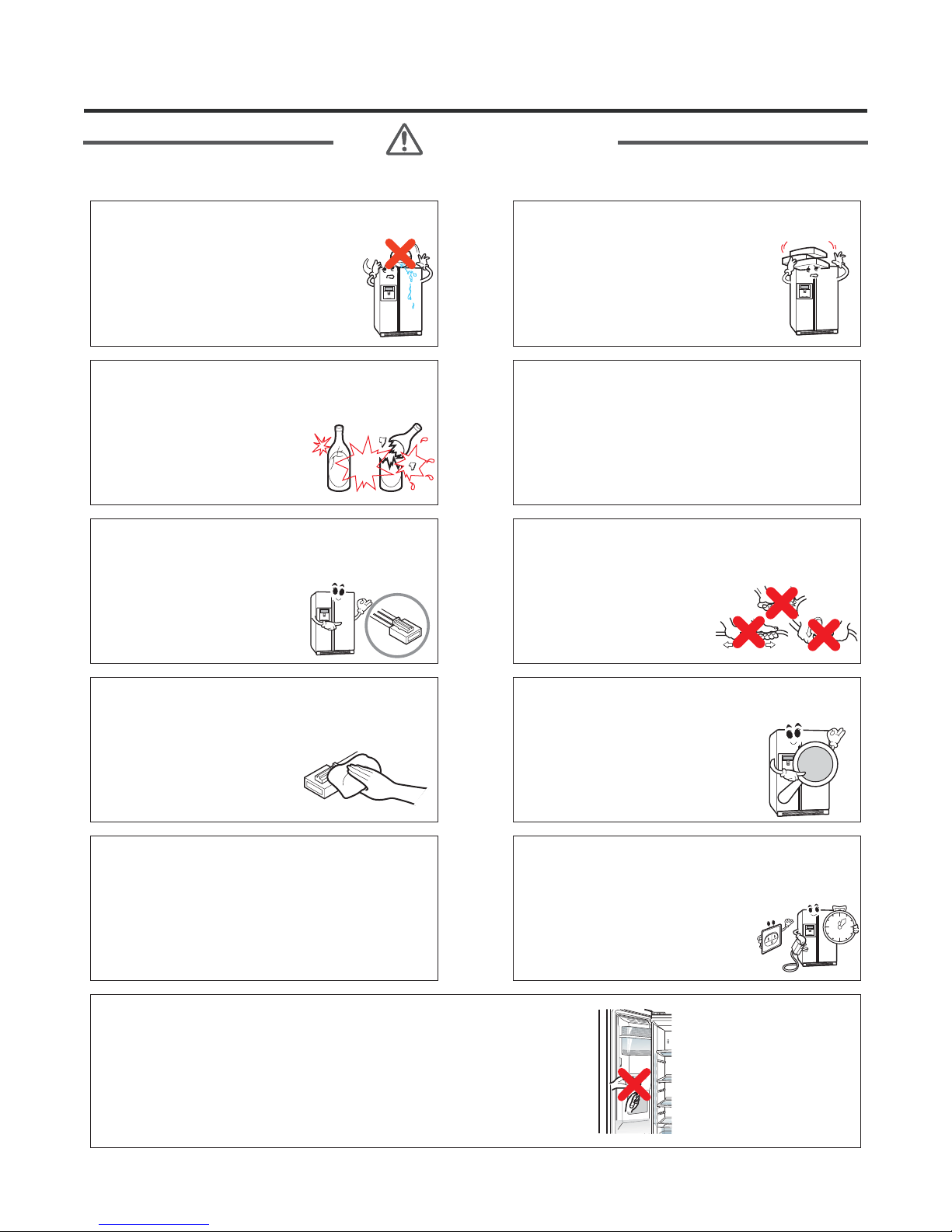

Safety Warning and Cautions

Chapter 1 Safety Warning and Cautions

► Observing cautions for safety can prevent accidents and dangers.

► Cautions are classified into Warning and Caution and the meanings are as follows

WARNING

WARNING indicates the possibility of serious injury or death if the

instructions are not followed.

CAUTION

Caution indicates a hazardous situation with the possibility of product

damage or personal injury if the instructions are not followed

WARNING

Be cautious of electric shock.

Control board (PWB Main and Sub)

uses power supply of about 120 VAC.

Be sure the plug and cord are not

pressed by the rear side of the

refrigerator.

Damage to power plugs

could result in fire or

electric shock.

Do not allow consumers to directly

repair, disassemble, or modify the

refrigerator.

Harm, electric shock,

or fire could occur.

Plug the refrigerator into a

dedicated circuit.

Plugging in too many appliances

can result in fire or problems with

the operation of your refrigerator.

Safety Warning and Cautions

WARNING

If grounding is required, be sure to

consult an electrician.

The refrigerator

must be plugged in

to a properly rated

and grounded

outlet. If you are

not sure of your

voltage or ground,

consult a qualified

and licensed

electrician.

Copper

plate

Grounding nut

Grounding wire

More than

75cm

Do not store medications or

biohazardous products requiring

precise temperature control.

Do not use the refrigerator to store

papers, electronic storage media,

or similar items.

The refrigerator is

for storing food.

This is a consumer

household

appliance and not a

precision device.

Do not store poisonous,

flammable, or explosive chemicals

in the refrigerator.

There is danger of

explosion and fire.

If storing or disposing of the

refrigerator, remove the doors

to eliminate the possibility of

children playing in it.

Children may

become entrapped in

the refrigerator.

Unplug the refrigerator for

cleaning or repair. Be sure your

hands are dry when handling the

power cord or plug.

Electric shock or

harm may occur.

Be sure the plug and socket are

clean and the connection is tight.

Dust or incomplete

connection may

result in fire.

Firstly take power socket out for

Electric shock may occur.

When dusts etc are stained to the

pin part of the power socket,

cleanly wipe out them.

Fire may occur.

4

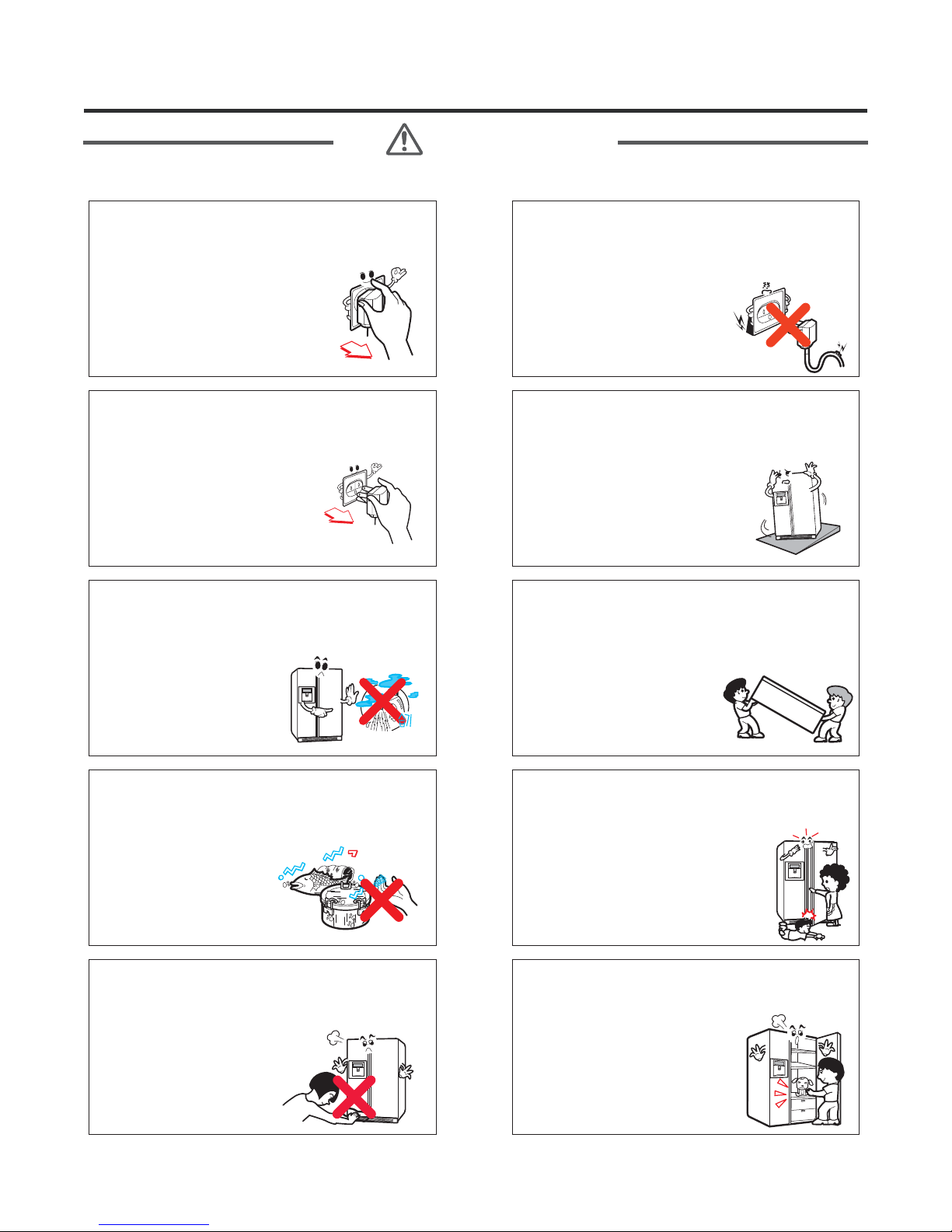

Safety Warning and Cautions

WARNING

Do not alter the power cord.

Replace it only with an exact factory

replacement part.

Electric shock or

fire may occur

due to electrical

damage of power

cables.

Do not hang or swing from the

refrigerator doors.

Do not allow children to

play with the refrigerator.

The refrigerator may turn

over. Hands and fingers

may be pinched.

Do not install the refrigerator next

to a stove or other sources of heat.

There is danger of fire.

Do not place heavy objects on the

refrigerator.

Falling objects when

opening or closing doors

may cause injury.

Do not use flammables near a

refrigerator.

There is danger of fire.

When a gas leak occurs, do not

unplug the refrigerator. Open the

doors for ventilation.

There is danger of

burning due to

explosion and

sparking.

Do not clean the refrigerator by

spraying water inside or outside.

It may result in

product damage,

fire, or electric

shock.

If the refrigerator is submerged or otherwise inundated

with water, have it checked by an authorized servicer.

Electric shock or fire may occur.

This refrigerator is designed for

use as a consumer home

appliance only.

It is not a precision

device for storing

medication or valuables.

Do not install the

refrigerator in a vehicle,

aircraft, maritime vessel,

or other than in a home

environment.

Safety Warning and Cautions

WARNING

Do put the vessel that flower base,

cup, cosmetics or drugs, etc

are contained on the

refrigerator.

Fire or electric shock may occur, or

injury due to dropping may occur.

Do not put glass bottles or other

sealed containers in the freezer.

They may burst, leaving

glass fragments in the food

and possibly causing injury.

Secure the cord behind the

refrigerator.

Do not allow the cord to

hang where it can be

pinched, damaged, or rolled

over by the refrigerator.

Do not accumulate objects on a

refrigerator or do not keep

foods in random method.

Dropping of objects when opening

or closing the door may cause

physical injury.

Be sure to use rated parts for

replacement of electric parts.

Use factory replacement parts.

Pull the plug out by the plug body;

do not pull the wire to disconnect

the cord.

Damage to power cords

may cause fire or electric

shock.

Keep electrical parts and

connections free from dust and

contamination.

There is danger of fire

from shorting or arcing.

Do not let moisture drop onto

electrical parts.

If there is a problem in this area, replace the

parts or tape the wires to prevent

contamination and degradation.

Do not put your hands, fingers, tools, or other

objects into the icemaker, crusher, or discharge

outlet. Do not check the operation of the ice

dispenser or crusher in this manner.

You may damage your product, fingers, or tools.

Be sure replacement parts are an

exact fit.

Replacement parts should look

and fit exactly like the original

parts and have the same electric

rating.

If you unplug the refrigerator or

turn off the power, wait 5 minutes

before plugging it back in

or turning the power on.

Rapid cycling of the compressor

could cause failure.

Safety Warning and Cautions

WARNING

power plugs catching with the end

of plugs without catching cords.

Fire may occur due to electric

shock or short-circuit.

Unplug the refrigerator if it is

going to be unused for an

extended period.

Remove all food items,

wipe down the inside of

the refrigerator, dry it

thoroughly, and prop the

doors open to allow air

circulation.

Do not install the refrigerator in a

place where it is subject to

splashing and excess moisture.

Deterioration of insulation

may cause electrical

leakage.

Do not use power cords or power

plugs when they are damaged or

holes of power plugs are loose.

Fire may occur due to

electric shock or

short-circuit.

Be sure the floor will support the

weight of the refrigerator.

If the refrigerator is not installed

at a firm, level location, the

doors and icemaker may not

operate properly.

To carry the refrigerator, use the

handles at the top of the back, and

beneath the edge of the front.

Using these handles will

ensure safety and reduce

the possibility of injury.

Do not touch foods, containers, or

the inside of the freezer

compartment with wet hands.

Your hands may stick

to the cold items. It

could cause frost bite.

Do not stick your hands or fingers

under the bottom of the

refrigerator.

Watch out for sharp

edges.

Be careful to avoid pinching hands

or feet when opening the doors.

Do not put live animals in the

refrigerator.

Product Standards

Effective inner

capacity

Outer dimension ( W X D X H )

Product weight (lb)

Rated consumption power of motor

Heater

Cooling method

Temperature control

Defrost

F-Room

R-Room

Freezing cycle

Electrical parts

srandard

F-Room

F-Room

F-Room

Method

Start

End

EvaPoration

Type of heat shield

Fixed Shelf

Drawer

Fixed Shelf

Shelf(Movable, Folding)

Egg container

Vegetable room

Compressor driving method

EvaPoration

Conderser

F-Room oil

Type of refrigerant

Capillary tube

Dryer (drying tube)

Parts related

with dewing

prevention

Capacitor

For

preventing

ice making

Overload protective device

F-Room fan motor

Fan motor for cooling condenser

Inside lamp at F-Room

Inside lamp at R-Room

Door switch (F-Room/R-Room)

Home bar door switch

Main Fuse

Power cord

Model

Total inner capacity(L)

F-Room

R-Room

Initial defrost

Defrost cycle

Rest time

Defrost sensor

Temp.fuse (rated/ operation

temperature)

Heater Sheath

Dispenser duct door heater

R-Room home bar heater

F-Room home bar heater

Dispenser heater

Comp’ Running

I/maker geared motor Running

Magic room Damper Heater

R-Room Damper Heater

Water Tank Heater

Water supply Heater

LSXS26466* LSXS26386* LSXS26366* LSXS26326*

738.66L (26.09 Cu.ft)

260.59L (9.20 Cu.ft)

478.07L (16.89 Cu.ft)

35 7/8" x 35 7/8" x 70 3/8"

298

105 ± 15%(W)

260 ± 10%(W)

Indirect cooling(F-Control)

MICOM(Outside)

MICOM(Outside)

Forced method

Auto

Auto

Forced method

Cyclo-Pentane

3

2

4

-

-

2

A Logic Inverter operation

Pin tube type

Forced convection method

Freol Alpha5 oil(175cc)

R134a(165g)

Φ 0.7/0.9

MOLECULAR SIEVE XH-9

4~5 hours (vary depending on condition)

9~11 hours (vary depending on condition)

3 Min

Returend to defrost function when reaching to 5℃

250V / 72℃

AC 115V / 260W

-

120V / 6.5W

-

DC 12V / 2.5W

AC 450V / 20 ㎌

AC 250V / 14 ㎌

-

DC 12V / 1W

-

DC 12V / 0.8W

MRA12325

DC 13V

DC 13V

DC 12V / 5W (1EA)

DC 12V / 5W (1EA)

250 V / 0.5 A

250 V / 0.5 A

250 V / 10 A

AC 125 V / 10 A

742.49L (26.22 Cu.ft)

260.59L (9.20 Cu.ft)

481.90L (17.02 Cu.ft)

R134a(175g)

Φ 0.75

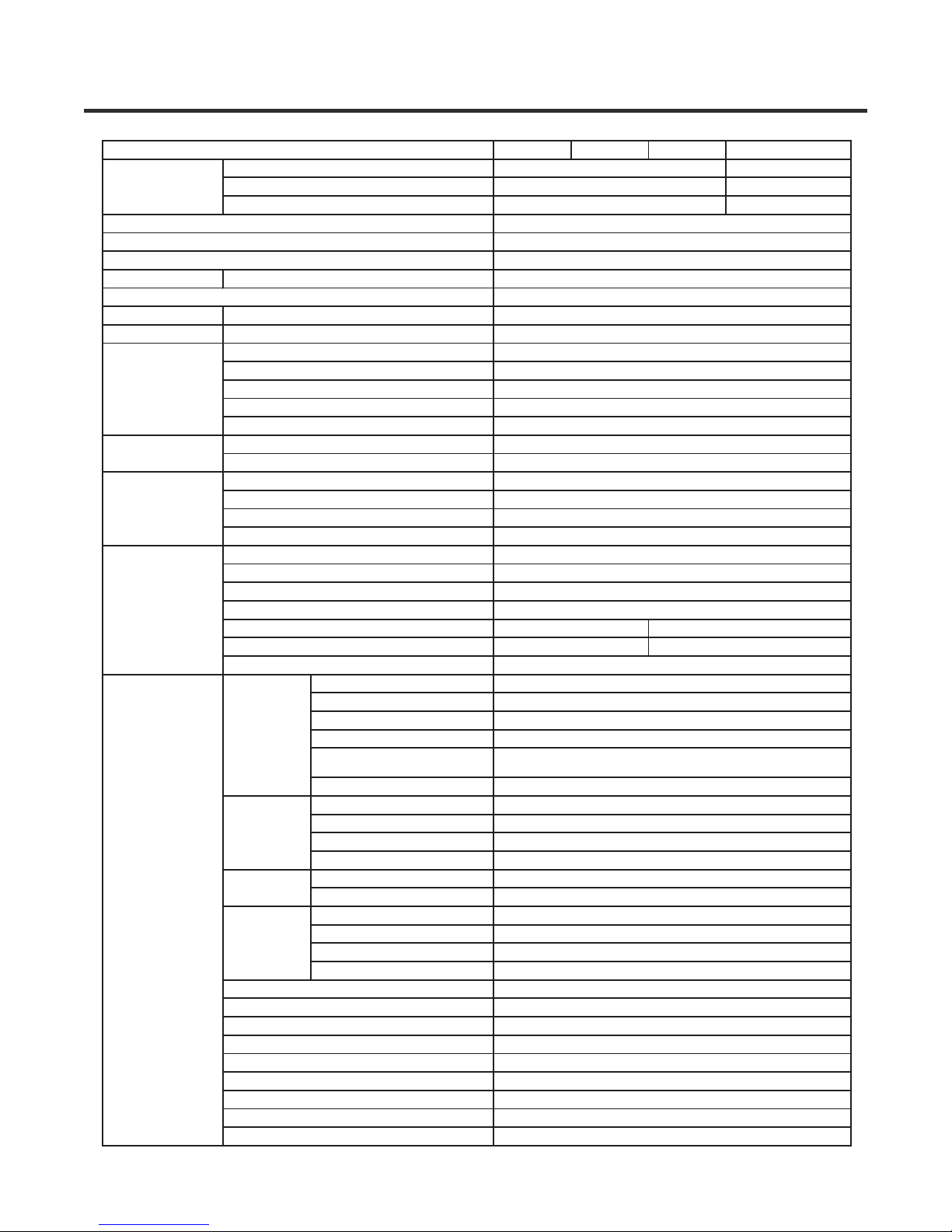

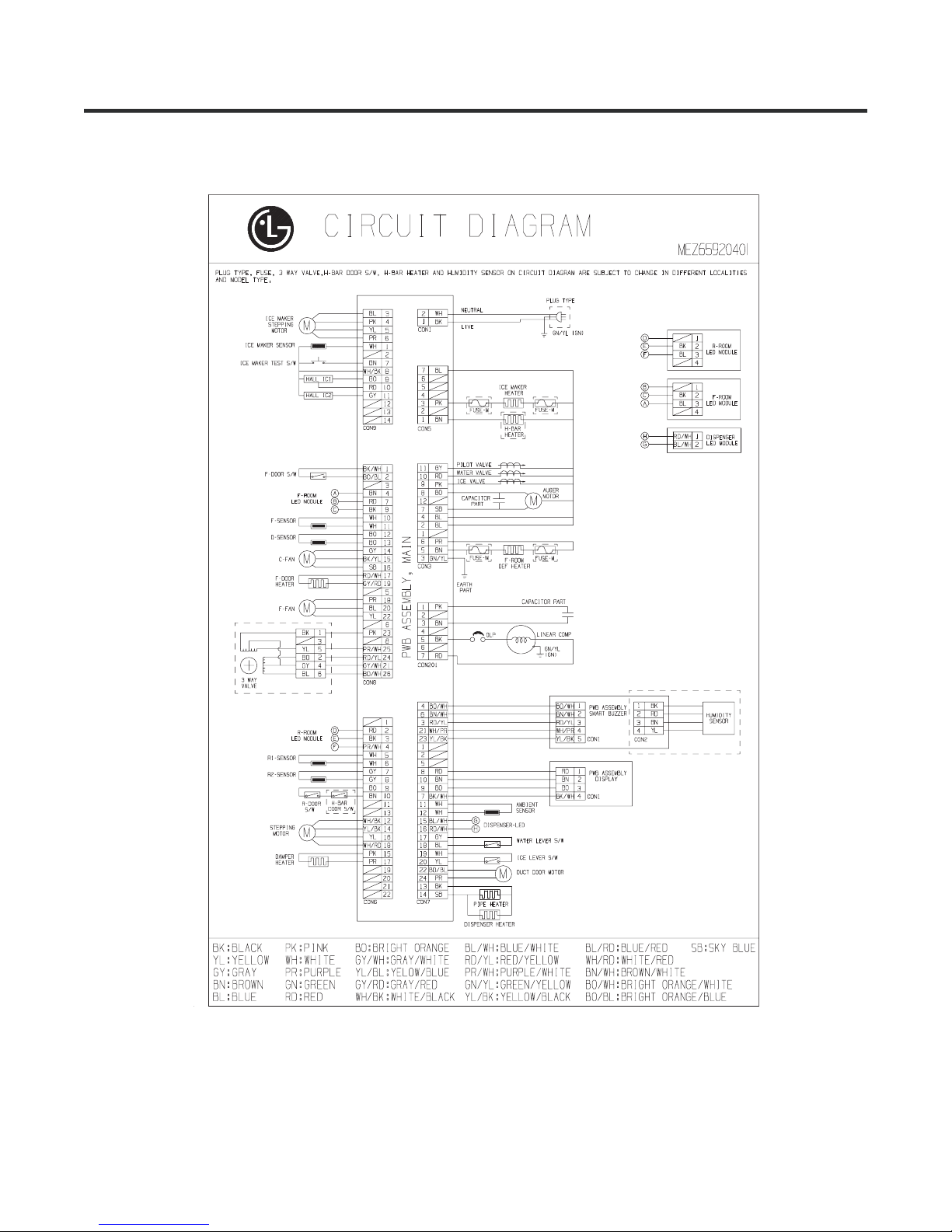

Circuit Diagram

Specifications

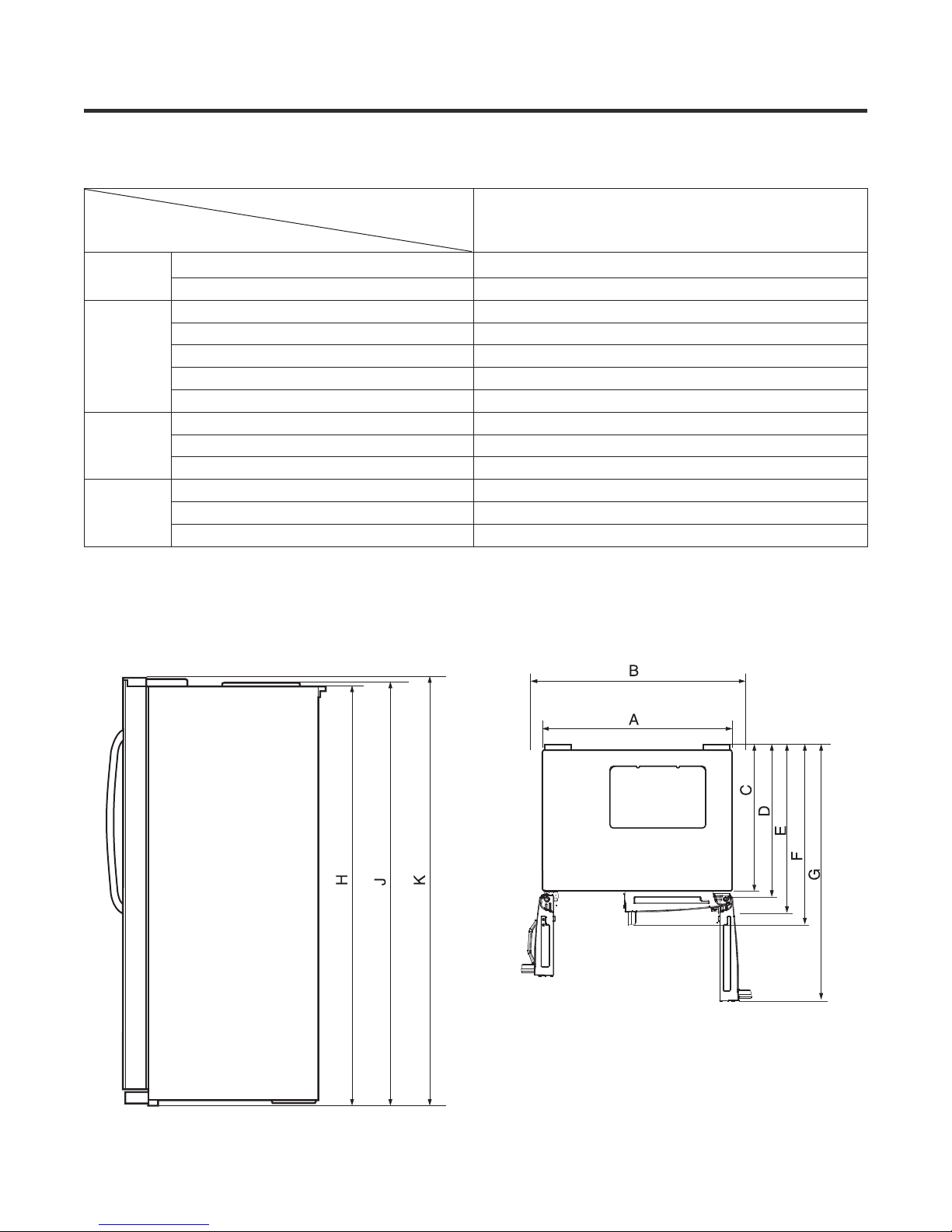

1. Specifications

Unit : inch (mm)

ltem

Width

Depth

Height

Minimum air

circulation

space

Model

Width (A)

When opening door by 90° (including handle) (B)

Case (including back handle) (C)

After disassembling door (including hinge, L) (D)

Including door (not including handle) (E)

Including handle (F)

When opening door by 90° (G)

Cabinet (H)

Including cover PWB (J)

Including door (K)

Top part

Side

Rear part

LSXS26466 LSXS26386

LSXS26366 LSXS26326

*/ *

* / *

35.9 (912)

39.6 (1005)

28 7 730.( )

31 5 800.( )

33 4 848.( )

35 9 912.( )

50 6 1285.( )

68 9 1750

69 3 1760.( )

70.3 (1785)

11.8 (300)

0.8 (20)

2.0 (50)

Front View

Top View

Appearance Size of Refrigerator and Name of Every Part

2. Main Name

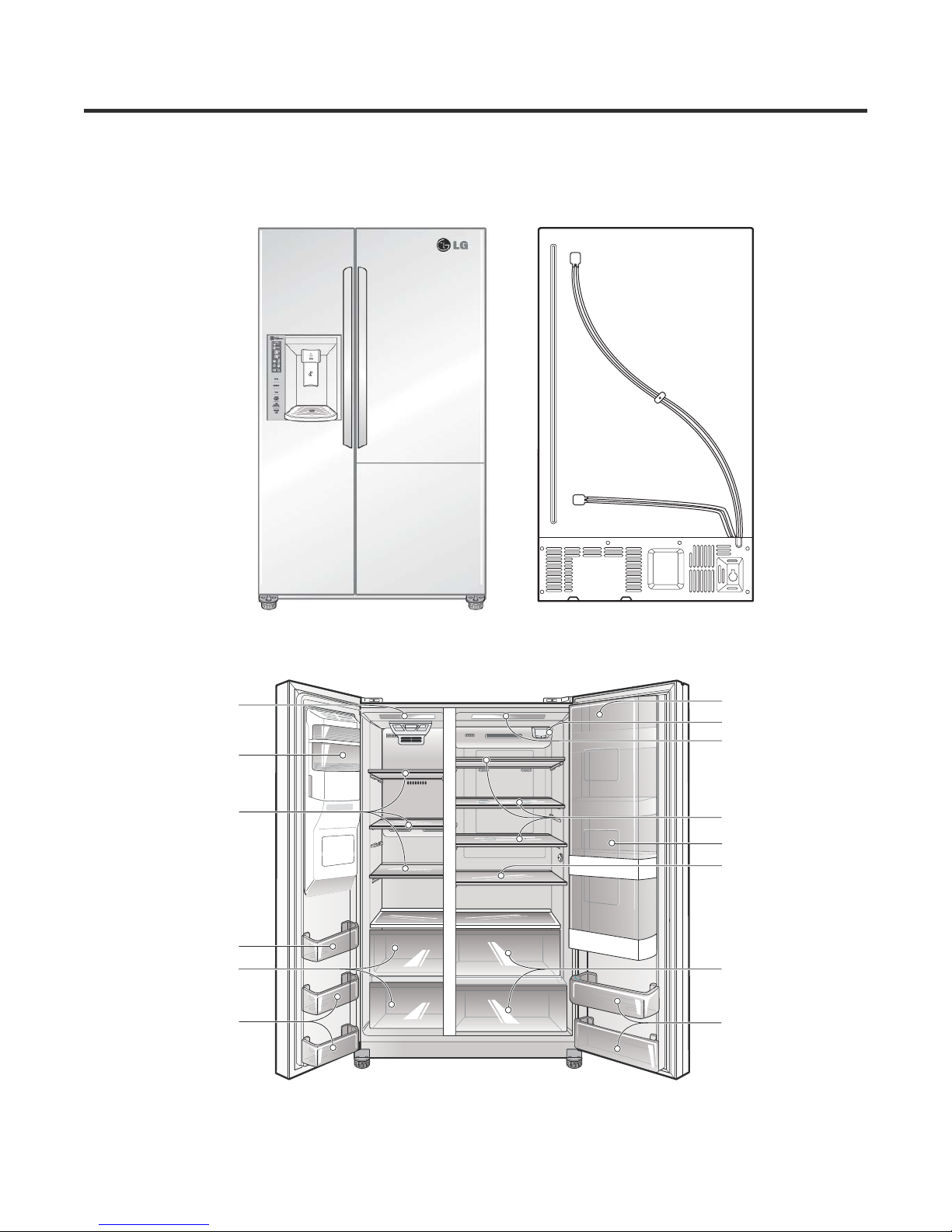

MODEL : LSXS26466 LSXS26386 LSXS26366*/ */ *

LED Lamp

Automatic

Icemaker

Shelf

Door Bin

Freezing Zone

Door Bin

Freezer

Compartment

Refrigerator

Compartment

Dairy Corner

Filter

LED Lamp

Shelf

Refreshment center

Shelf

Fresh zone

Door Bin

Appearance Size of Refrigerator and Name of Every Part

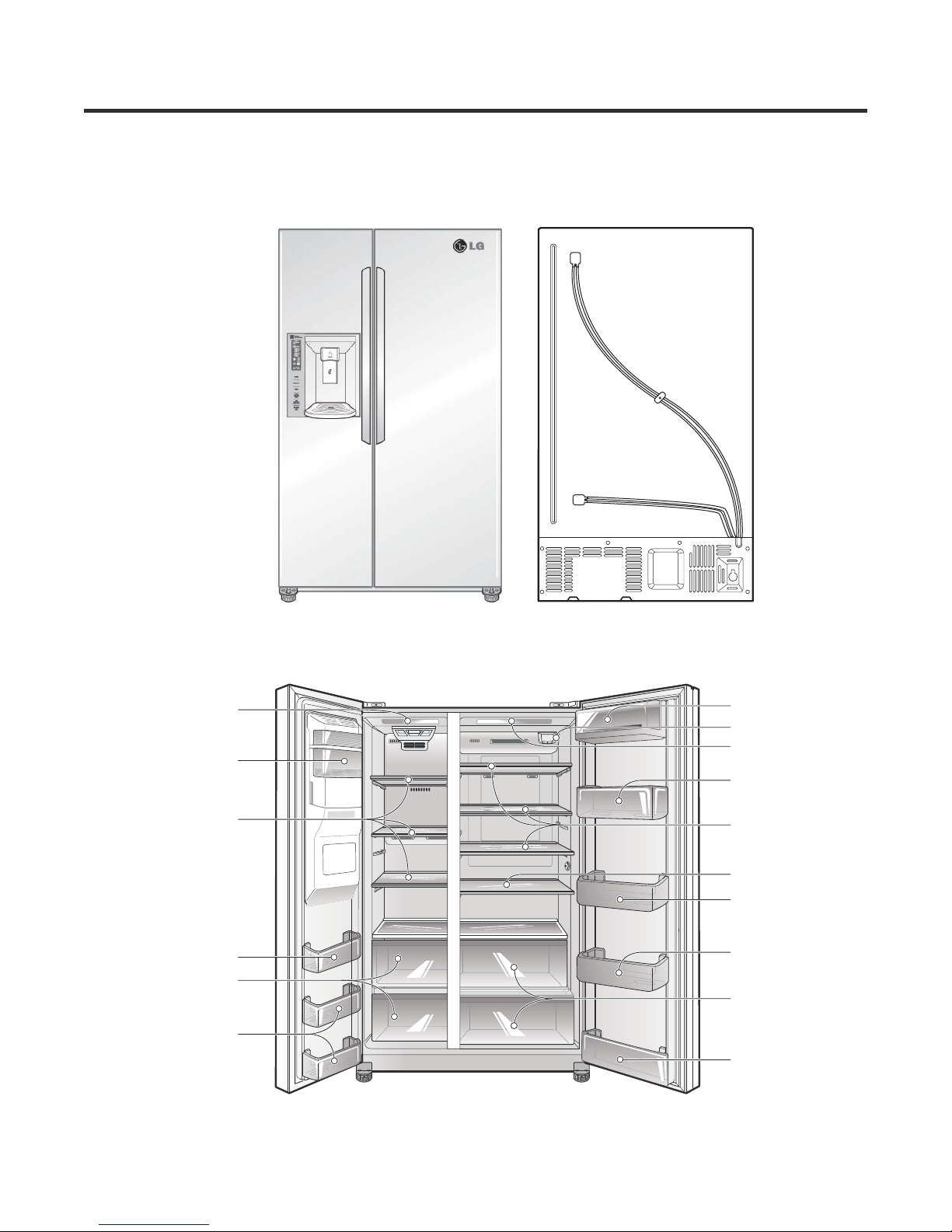

2. Main Name

MODEL : LSXS26326*

LED Lamp

Automatic

Icemaker

Shelf

Door Bin

Freezing Zone

Door Bin

Freezer

Compartment

Refrigerator

Compartment

Dairy Corner

Filter

LED Lamp

Door Bin

Shelf

Shelf

Door Bin

Door Bin

Fresh zone

Door Bin

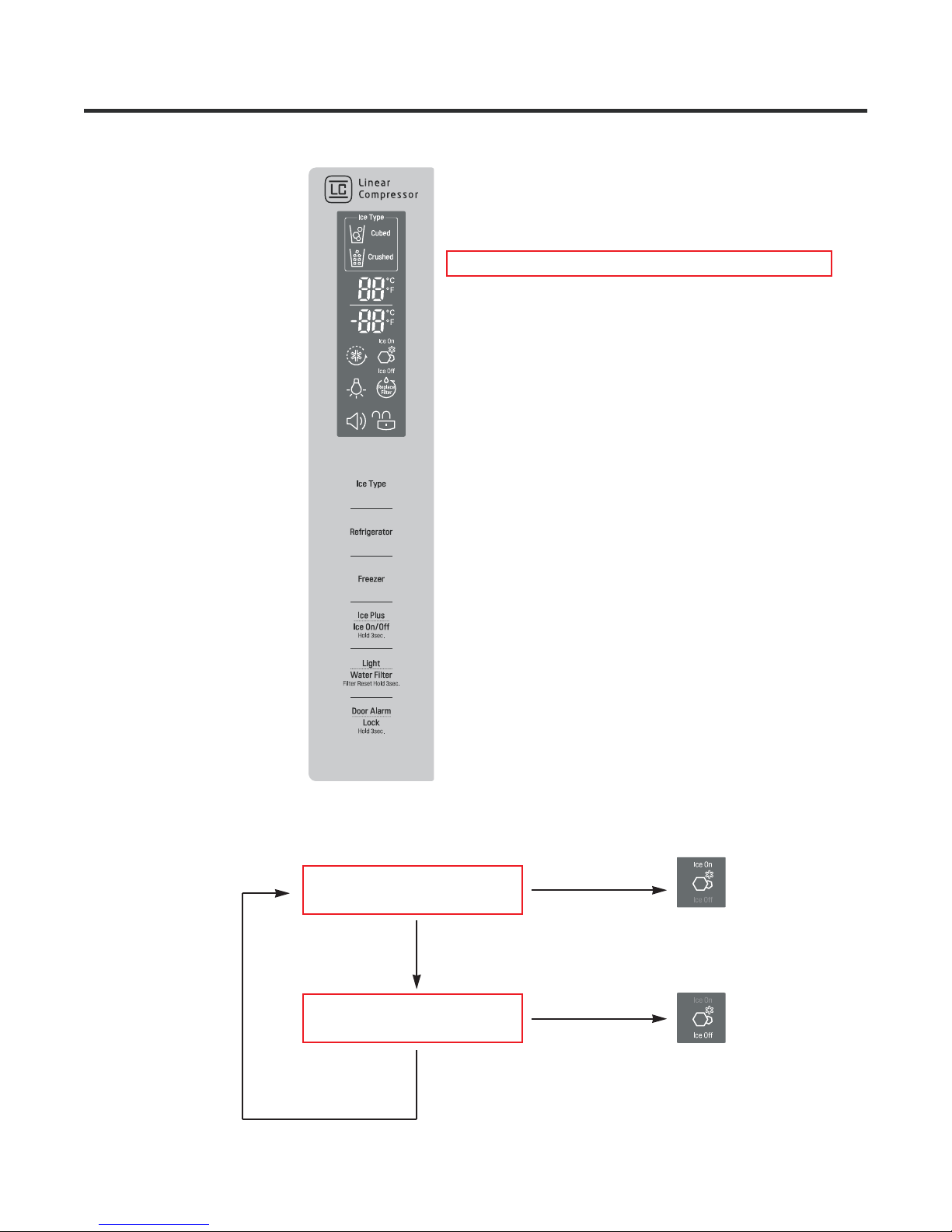

Micom Function

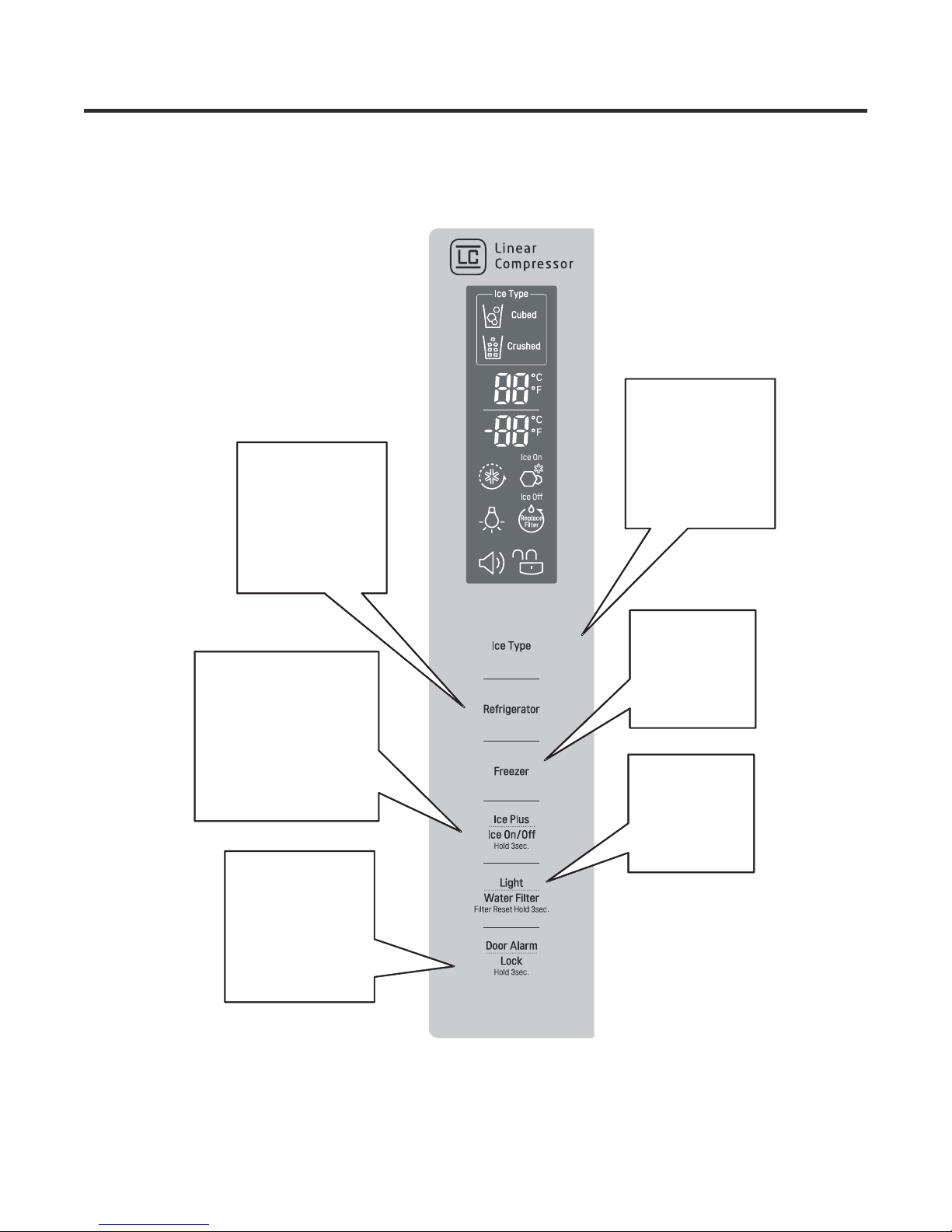

1. Operating Panel

MODEL : LSXS26466*

Ice Type

Refrigerator

Temperature

adjustment button

for refrigerator

compartment

Ice Plus

Ice on / off

Ice Plus

button(1sec)

Ice Making ON

OFF 3secs button

() )

/

Door Alarm

Dispenser

Selection Button

Freezer

Temperature

adjustment button

for freezer

compartment

Light /

Water Filter

Dispenser light

on/off button &

filter reset

button(3secs)

Door Alarm

Lock / Unlock

button(3secs)

Micom Function

1. Operating Panel

MODEL : LSXS26386 LSXS26366 LSXS26326** /*

Ice Type

Refrigerator

Temperature

adjustment button

for refrigerator

compartment

Ice Plus

Ice on / off

Ice Plus

button(1sec)

Ice Making ON

OFF 3secs button

() )

/

Door Alarm

Dispenser

Selection Button

Freezer

Temperature

adjustment button

for freezer

compartment

Light /

Water Filter

Dispenser light

on/off button &

filter reset

button(3secs)

Door Alarm

Lock / Unlock

button(3secs)

Micom Function

2. Function description

2-1. Funnction of Temperature Selection

Notch

Freezer -10 -2-3-4-6865432

Refrigeration 3637 35 34 33 46 45 44 43 42 41 40

Te mp

°F

°F

Power

Initiallly On

1st press

2nd press 3rd press 4th press 5th press 6th press 7th press 8th press 9th press

10th press 11th press

12th press

39

13th press

1

0

38

1. The actual inner temperature varies depending on the food status, as the indicated setting temperature is a target

temperature, not actual temperature within refrigerator.

2. Refrigeration function is weak in the initial time. Please adjust temperature as above after using refrigerator for minimum

2~3 days.

2-2. Automatic ice maker

The automatic icemaker can automatically makes 120~ 220 cubes per day. This quantity may vary by usage condition, including

ambient temperature, door opening, freezerload,and etc.

Icemaker stops making ice whentheice storage bin is full.

If you don’t want to have the automatic icemaker make ices, press and hold ICE ON/OFF button until the indicator lights on. If you

want to have icemaker makesicesagain, press and hold ICE ON/OFF button untiltheindicator lights off.

While ICE OFF indicator is on, Icemaker stops making ice. But you can dispense the ices until the ices run out from the ice

storage.Micom Function

2-3. When ice is not dispensedsmoothly

Ice is lumped together

• When ice is lumped together, take the ice lumps out of the ice storage bin, break them into small pieces, and then place them into

the ice storage bin again.

•

When the ice dispenser produces too small or lumped together ice, the amount of water supplied to the ice dispenser need to be

adjusted. Contact the service center.

• If ice is notusedfrequently, it maylump together.

Power failure

Ice may drop into the freezer compartment. Take the ice storage bin out and discardall the ice then dry it and place it back.After the

machine is powered again, thepreviousselection mode remains.

The unit is newly installed

It takes about 12 hoursfora newly installed refrigerator to make ice inthefreezer compartment.

2-4. Ice Plus

1. Ice Plus is function to improve cooling speed of the freezing room by consecutively operating compressors and freezing room

fan.

2. Ice Plus is releasedifpower failure occurs and then returns to theoriginalstatus.

3. Temperature setting isnot changed even if selecting the Ice Plus.

4. The change of temperature settingatthe freezing room or the cold storage roomisallowed with Ice Plus selected and processed.

5. The cold storage room operatesthestatus currently set with Ice Plus selected andprocessed.

6. If selecting the IcePlus,the Ice Plus function is released after continuouslyoperatingcompressor and freezing room fan.

7. If frost removal starting time is arrived during Ice Plus, Ice Plus operation is done only for the remaining time after completion of

frost removal when theIce Plus operation time passes 90minutes. If passing 90 minutes, IcePlus operation is done only for2 hours

after completion of frost removal.

8. If pressing Ice Plus button during frost removal, the Ice Plus LED is turned on but if pressing the Ice Plus, compressor operates

after the remaining time haspassed.

9. If selection Ice Plus within 7 minutes (delay for 7 minutes of compressor) after the compressor stops, compressor operates after

the remaining time has passed.

10. The freezing room fan motoroperatesat the high speed of RPM during operationofIce Plus.

11. During 21 hours after Pill Down Operation, F-Room is controlled at Maximum F-Notch normally and F-Fan operates normal

RPM.

12. The light of Ice Pluswouldbe turned off after Ice Plus.

13. Execute defrost immediately in case of defrost signal occurs in Ice Plus and defrosting time is included at execution time 21

hours.

14. If Ice Plus isstartedduring 2nd Load response operation, 2nd Load responseoperationwill be canceled.

15. If the button of Ice Plus in display is turned off, Ice Plus operation will be canceled. The compulsory operation of F notch in the

water tank’s preventing frost is priortothe one of Ice Plus.

Micom Function

2-5. Control of variable type of freezing room fan

1. To increase cooling speed and load response speed, MICOM variably controls freezing room fan motor at the high speed of

RPM and standard RPM.

2. MICOM only operates in the input of initial power or special freezing operation or load response operation for the high

speed of RPM and operates in the standard RPM in other general operation.

3. If opening doors of freezing / cold storage room or home bar while fan motor in the freezing room operates, the freezing

room fan motor normally operates (If being operated in the high speed of RPM, it converts operation to the standard RPM).

However, if opening doors of freezing room, the freezing room fan motor stops.

4. As for monitoring of BLDC fan motor error in the freezing room, MICOM immediately stops the fan motor by determining that

the BLDC fan motor is locked or poor if there would be position signal for more than 65 seconds at the BLDC motor.

Then it displays failure (refer to failure diagnosis function table) at the display part of refrigerator, performs re-operation in the

cycle of 30 minutes. If normal operation is performed, poor status is released and refrigerator returns to the initial status

(reset).

2-6. Control of M/C room fan motor

1. The M/C room fan motor performs ON/OFF control by linking with the COMP.

2. It controls at the single RPM without varying RPM.

3. Failure sensing method is same with freezing fan motor.(refer to failure diagnosis function table for failure display).

2-7. Door opening alarm

1. Buzzer generates alarm sound if doors are not closed even when more than a minute consecutively has passed with doors

of freezing / cold storage room or home bar opened.

2. Buzzer rings three times in the interval of 0.5 second after the first one-minute has passed after doors are opened and then

repeats three times of On/Off alarm in the cycle of every 30 seconds.

3. If all the doors of freezing / cold storage room or home bar are closed during door open alarm, alarm is immediately

released.

Doors of freezing /

cold storage room

or home bar

BUZZER

2-8 Ringing of button selection buzzer

1. If pressing the front display button, “Ding ~ “ sound rings.

2-9. Ringing of compulsory operation, compulsory frost removal buzzer

1. If pressing the test button in the main PCB, “Phi ~ “ sound rings.

2. In selecting compulsory operation, alarm sound is repeated and completed in the cycle of On for 0.2 second and Off for 1.8

second three times.

3. In selecting compulsory frost removal, alarm sound is repeated and completed in the cycle of On for 0.2 second , Off for 0.2

second, On for 0.2 second and Off for 1.4 second three times.

Micom Function

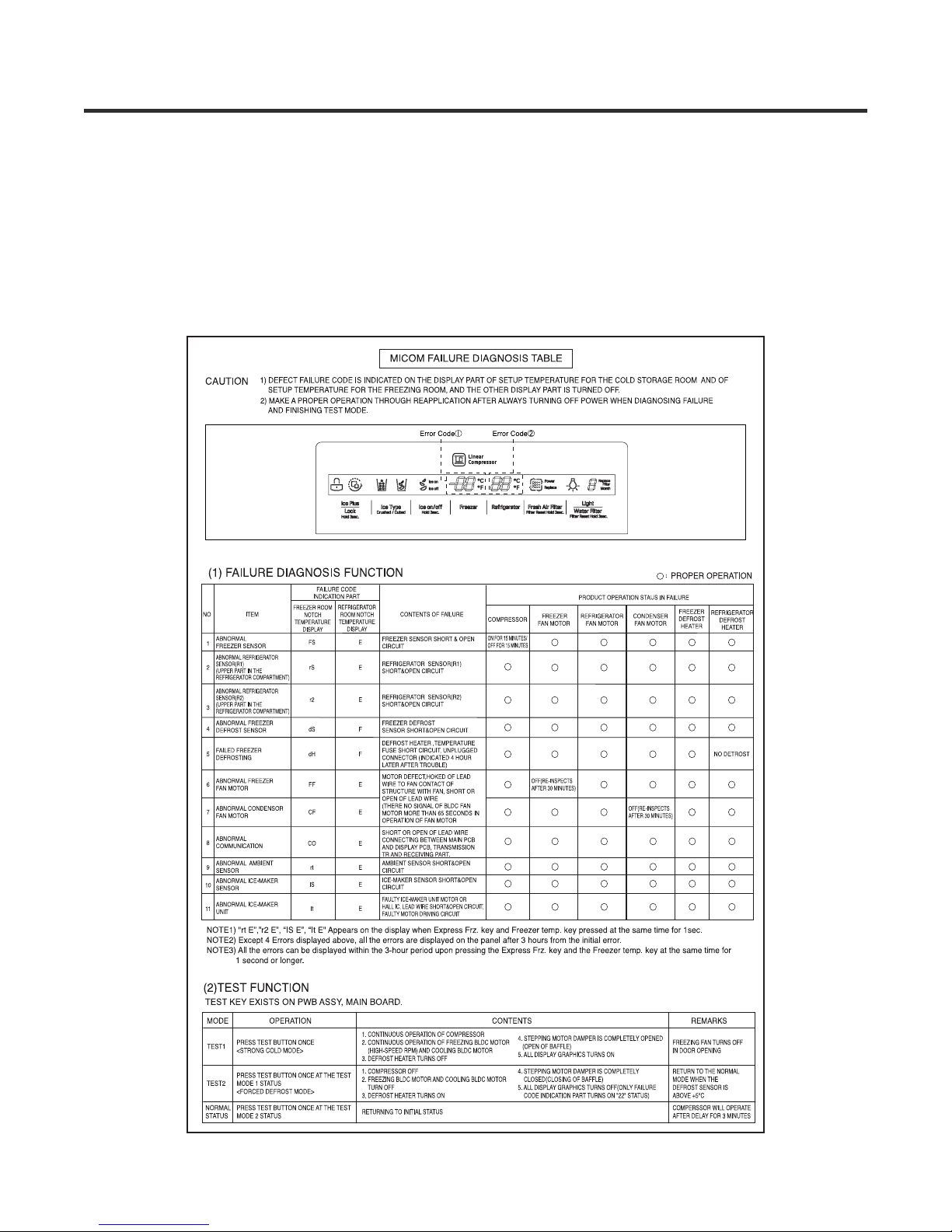

2-10. Function of Trouble Diagnosis(88-LED)

1. Failure diagnosis function is function to facilitate service when nonconforming matters affecting performance of product

during use of product.

2. In occurrence of failure, pressing the function adjustment button does not perform function and only alarm sound (“Ding~”)

rings.

3. If nonconforming matters occurred are released during display of failure code, MICOM returns to the original state (Reset).

4. Failure code is displayed on the display part of setting temperature for the freezing room and the display part of setting

temperature for the cold storage room of LED, which are placed at the display part of a refrigerator. All the LED graphics other

than a failure code are turned off

Micom Function

2-11. Test Function

1. Test function is function to find out any failed part in the failure status or check function of PWB and the product.

2. The test button is placed on the main PCB (test switch) of the refrigerator. The refrigerator ends the test mode after Max.

2 hours irrespective of modes and returns to normal status (reset).

3. The function control button is not detected during test mode.

4. When ending test mode, take out power cords and insert them again so as to become normal status.

5. If defect such as sensor failure during test mode is detected, release Test Mode to display failure code.

6. Test Mode is not performed even if pressing the test button during display of failure code.

MODE OPERATION CONTENTS REMARKS

TEST1

TEST2

NORMAL

STATUS

PRESS THEST

BUTTON ONCE

<STRONG COLD

MODE>

PRESS TEST

BUTTON ONCE AT

THE TEST MODE 1

STATUS

<FORCED DEFROST

MODE>

PRESS TEST

BUTTON ONCE AT

THE TEST MODE 2

STATUS

1.CONTINUOUS OPERATION OF COMPRESSOR

2.CONTINUOUS OPERATION OF FREEZING

BLDC MOTOR (HIGH-SPEED RPM) AND

COOLING BLDC MOTOR

3.DEFROST HEATER TURNS OFF

1.COMPRESSOR OFF

2.FREEZING BLDC MOTOR AND COOLING BLDC

MOTOR TURN OFF

3.DEFROST HEATER TURNS ON

RETRUING TO INITIAL STATUS COMPERSSOR WILL OPERATE

4.STEPPING MOTOR DAMPER IS

COMPLETELY OPENED

(OPEN OF BAFFLE)

5.ALL DISPLAY GRAPHICS TURNS ON

4.STEPPING MOTOR DAMPER IS

COMPLETELY CLOSED(CLOSING OF

BAFFLE)

5.ALL DISPLAY GRAPHICS TURNS

OFF(ONLY FAILURE CODE INDICATION

PART TURNS ON “22”STATUS)

FREEZING FAN TURNS OFF IN DOOR

OPENING.

RETURNS TO THE NORMAL MODE

WHEN THE DEFROST SENSOR IS

ABOVE +5°C

AFTER DELAY FOR 3 MINUTES

2-12. Functions performed when Ice Dispenser and Water Dispenser are mounted

1. This is function to dispense ice and water outside without opening doors.

2. If pressing the Dispenser Pressing Switch after selecting ice (cube ice, Crushed ice) or water, relevant ice and water come

out. However, when selecting ice, the duct door is opened by electric Motor (duct door, Motor) if pressing the Dispenser

Pressing Switch. The duct door is closed after it remains for 5 seconds in open status if pressing and then releasing the

Dispenser Pressing Switch.

3. Function to dispense ice and water out stops in the F-door open status.

4. If there is no OFF signal for 3 minutes after pressing the Dispenser Pressing Switch after selecting ice (cube ice, crushed

ice) or water, the refrigerator automatically turns off both gear motor and solenoid (cube, water).

However, the Motor (duct door) stops when 5 seconds pass after turning off. (This is for preventing coil-short due to heating of

solenoid.)

5. Dispenser Lamp On/Off Function

If pressing the Dispenser Pressing Switch after selecting ice (cube ice, crushed ice) or water, the lamp on the dispenser part

turns on and if releasing it, turns off.

6. Crushed Ice/Cube Select Function

1) This is function to operate the refrigerator as Crushed Ice/Cube function on the function control part depending on user s

selection. If pressing the Select Dispenser button, display and selection are done.

2) For the initial Power On, Crushed ice is automatically selected.

3) If pressing the Press Switch when ices are generated in the ice bank for selecting Crushed Ice, the refrigerator operates the

gear motor so that crushed ices are supplied outside.

4) If pressing the Press Switch when ices are generated in the ice bank for selecting Cube Ice, the refrigerator operates the

gear motor so that Cube ices are supplied outside.

Micom Function

2-13 Ice on / off function

Press Ice on/off Button to select Ice Making on or off.

Ice on Mode in factory default setting.

Ice on

Ice on / off BUTTON

Ice off

Ice on / off BUTTON

Icemaker and dispenser working principles and repair

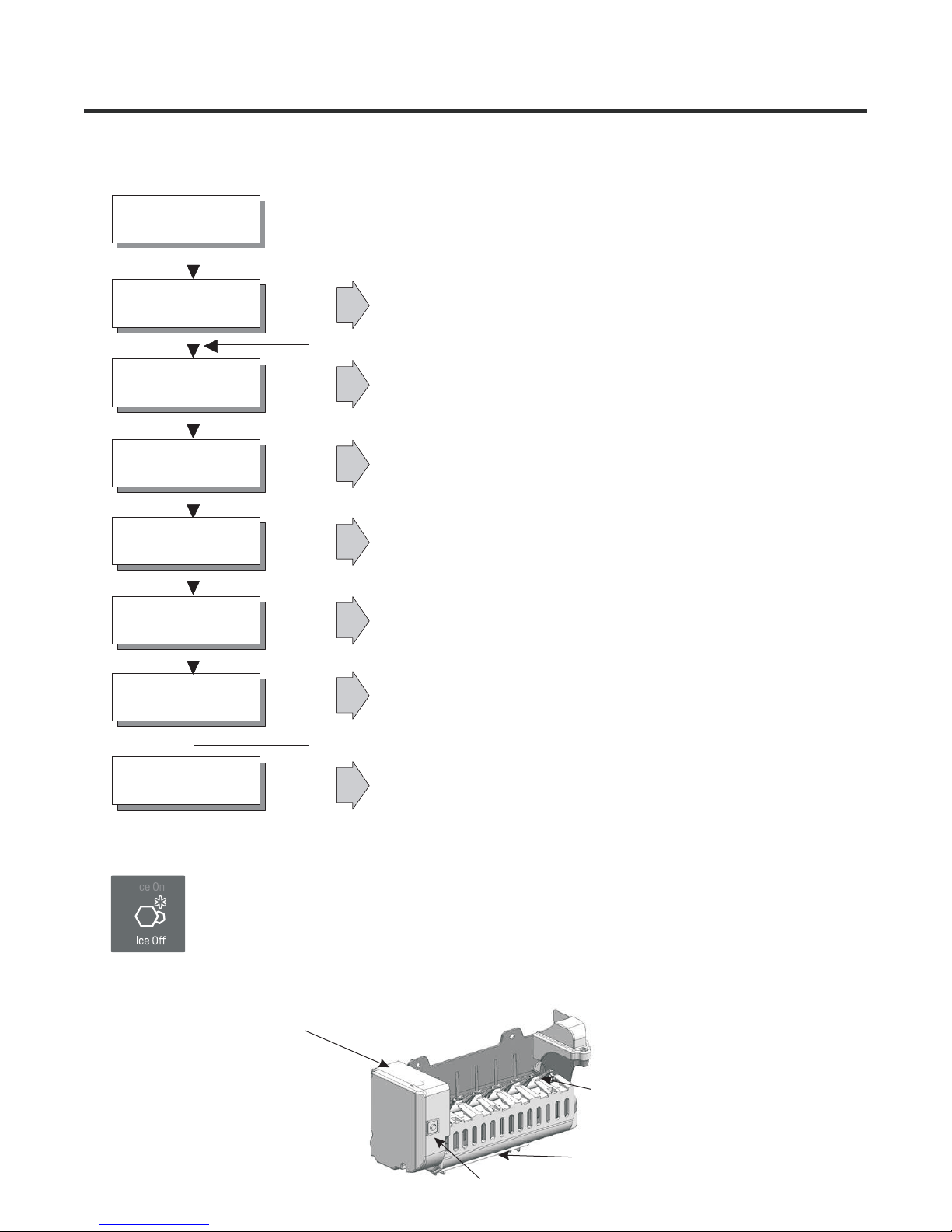

1. OPERATION PRINCIPLE

1-1. Operation Principle of Icemaker

Power On

Start Position

Icemaking

Mode

Checking full

ice Mode

Harvest

Mode

Fill Water

Park Position

• Adjusts EJECTOR to

Waits until water becomes cold after starting the

•

Start Position with power on.

icemaking operation.

• Check if the ice bin is full.

• Runs MOTOR to drop ice from the tray into the ICE

BIN.

• Performs after supplying water by

Ice Making Mode

operating the SOLENOID in ICE VALVE.

With the detect lever, checks if the ICE BIN is full.

•

Test Mode

• ICE-MAKING STATUS INDICATOR Shows Ice-making status. While the indicator lights on, Icemaker

stops making ice.

• Press and hold the ICE ON/OFF button on display for 3sec. to stop or restart making ice.

While ICE OFF indicator is on, Icemaker stops making ice. But you can dispense the ices until the ices run out from the ice

storage.

Icemaker

• To operate LINE and SERVICE, press and hold the

Test Button

for 3 seconds. The icemaker will run through 3 stages:

Harvest Fill Icemaking.→→

EJECTOR

Feeler Arm

Test Button

Icemaker and dispenser working principles and repair

2. Function TEST

1. Before you carry out the test mode, check whether the water is frozen in the icemaker completely. If the test is

CAUTION!

performed while the water is not frozen in the icemaker, The water may overflow after test and it will cause other serious

problem.

2. This is a forced operation for TEST, Service, cleaning, etc. It is operated by pressing and holding the Test Button for 3

seconds.

3. The test works only in the Icemaking Mode. (This test works when the ejector and stainless lever is at the their original

position.)It cannot be entered from the Harvest or Fill mode.

4. After water is supplied, the mormally CYCLE is followed : Icemaking Checking full ice Harvest Fill Water

Park Position

→→→→

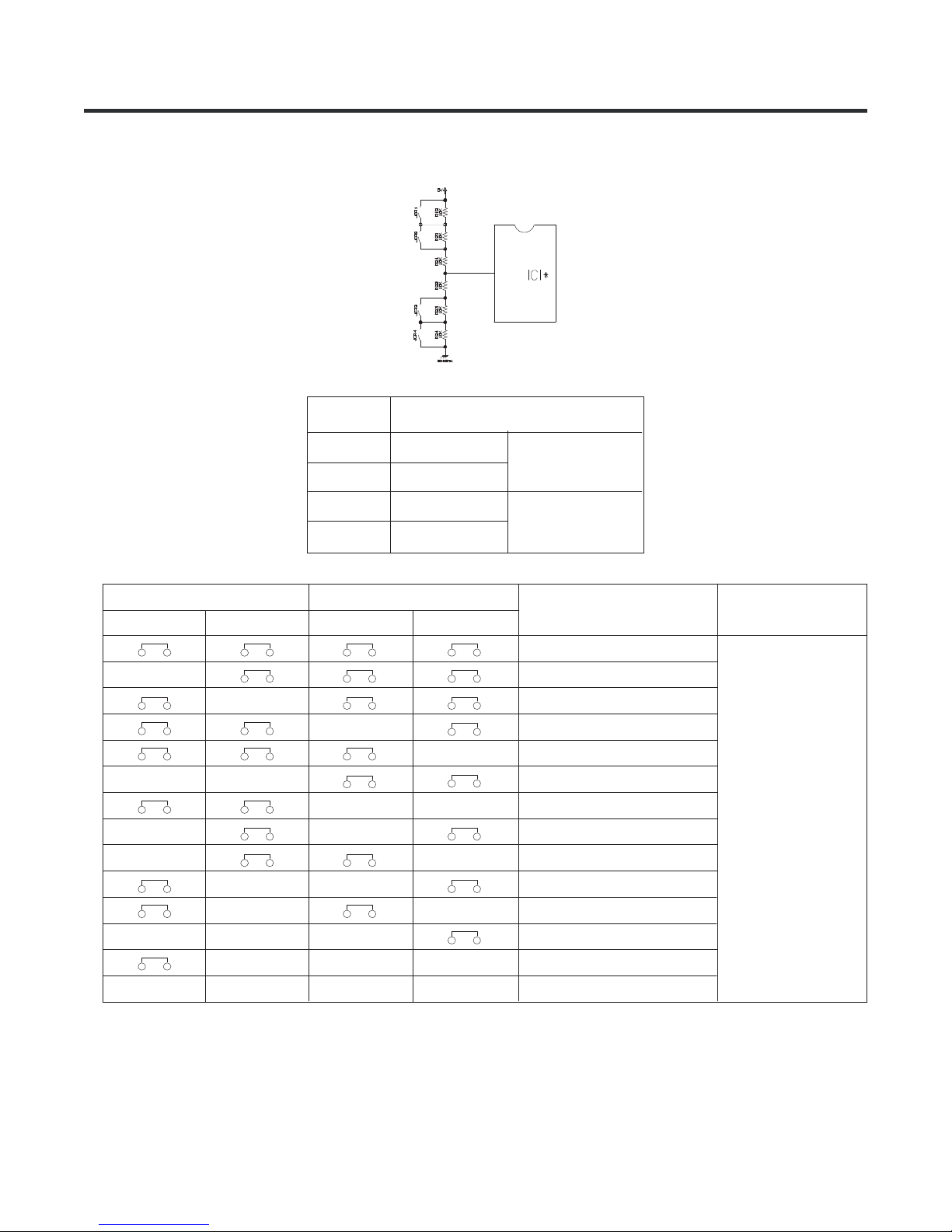

Micom Circuit description

1. Refrigerator undercool/overcool compensation circuit

Temperature compensation from cut

JCR1

JCR2

JCR3

JCR4

Undercool compensation

JCR3 JCR4

CUT

CUT

CUT CUT

CUT CUT

CUT CUT

CUT

CUT CUT

CUT CUT

CUT CUT

CUT

CUT

Overcool compensation

JCR1 JCR2

CUT

CUT

CUT

CUT

CUT

+1

+1

-1

-1

CUT

CUT

CUT

CUT

+2

-2

Refrigerator temperature

compensation

0 (Factory default)

-1

-1

+1

+1

-2

+2

0

0

0

0

-1

+1

0

Remarks

Above option circuit compensates the refrigerator temperature by simply cutting the circuit during the service.

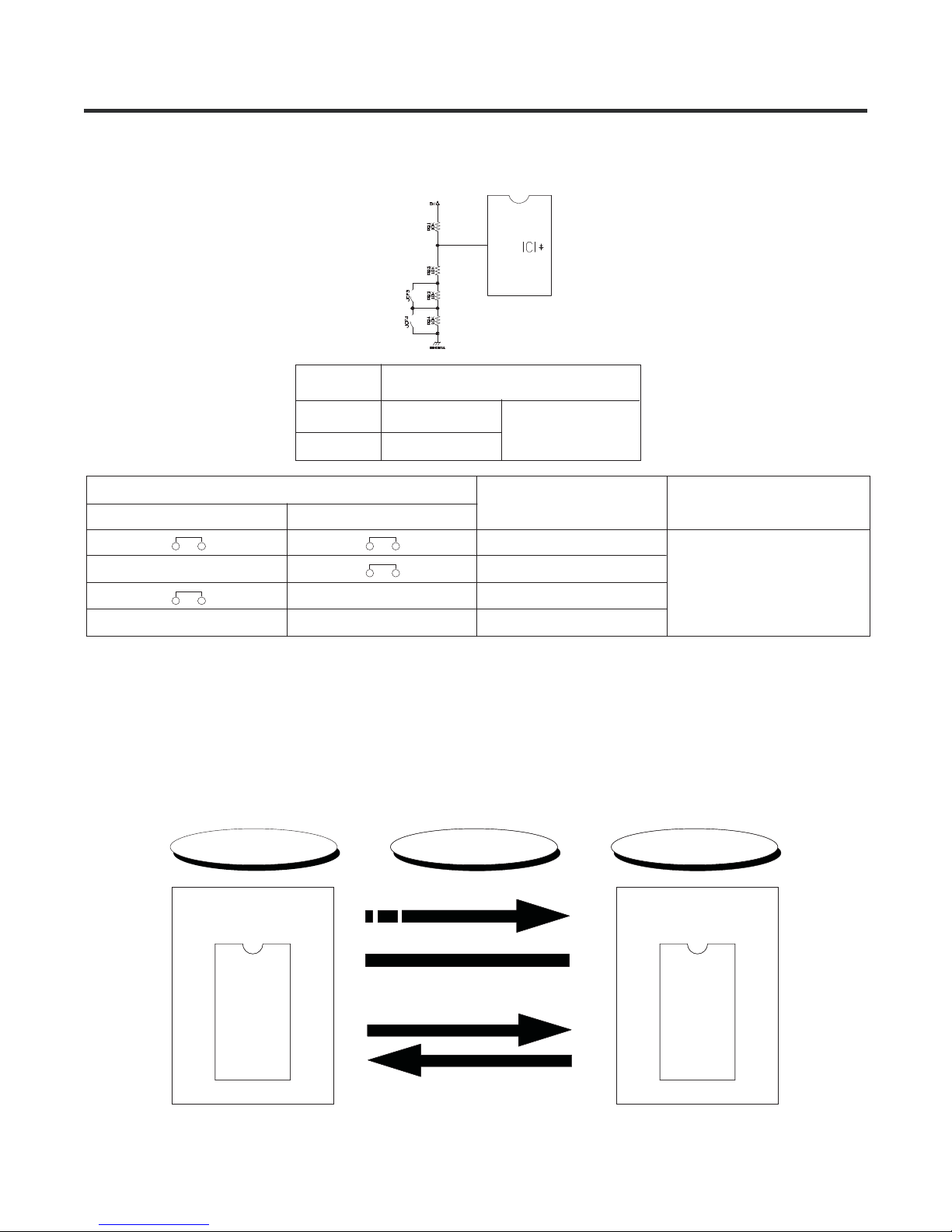

Micom Circuit description

2. Freezer undercool compensation circuit

Temperature compensation from cut

JCF 3

JCF 4

Undercool compensa tion

JCF3 JCF4

CUT

CUT

CUT

►Above option circuit compensates the freezer temperature by simply cutting the circuit during the service.

CUT

-1

-1

-2

Freezer temperature

compensa tion

0(Factorydefault)

-1

-1

-2

Remarks

2-1. Communication circuit and connecting L/wire between main PCB and display PCB

As the communication circuit, the following circuit exchanges information required between main MICOM of main PCB and

MICOM exclusively for LED for LED control of display PCB.

Sending/Receiving L/wire is required with DC12V required to operate the display PCB.

Communication error occurs when the information exchange between main MICOM of main PCB and MICOM exclusively

for LED for LED control of display PCB is disconnected for more than 30 seconds

Main PCB Display PCB

L/Wire FD/H(4wires)

Main MICOM

DC 12V

MICOM exclusively

for LCD

GND

Send (Error condition)

Receive (NO TCH condition)

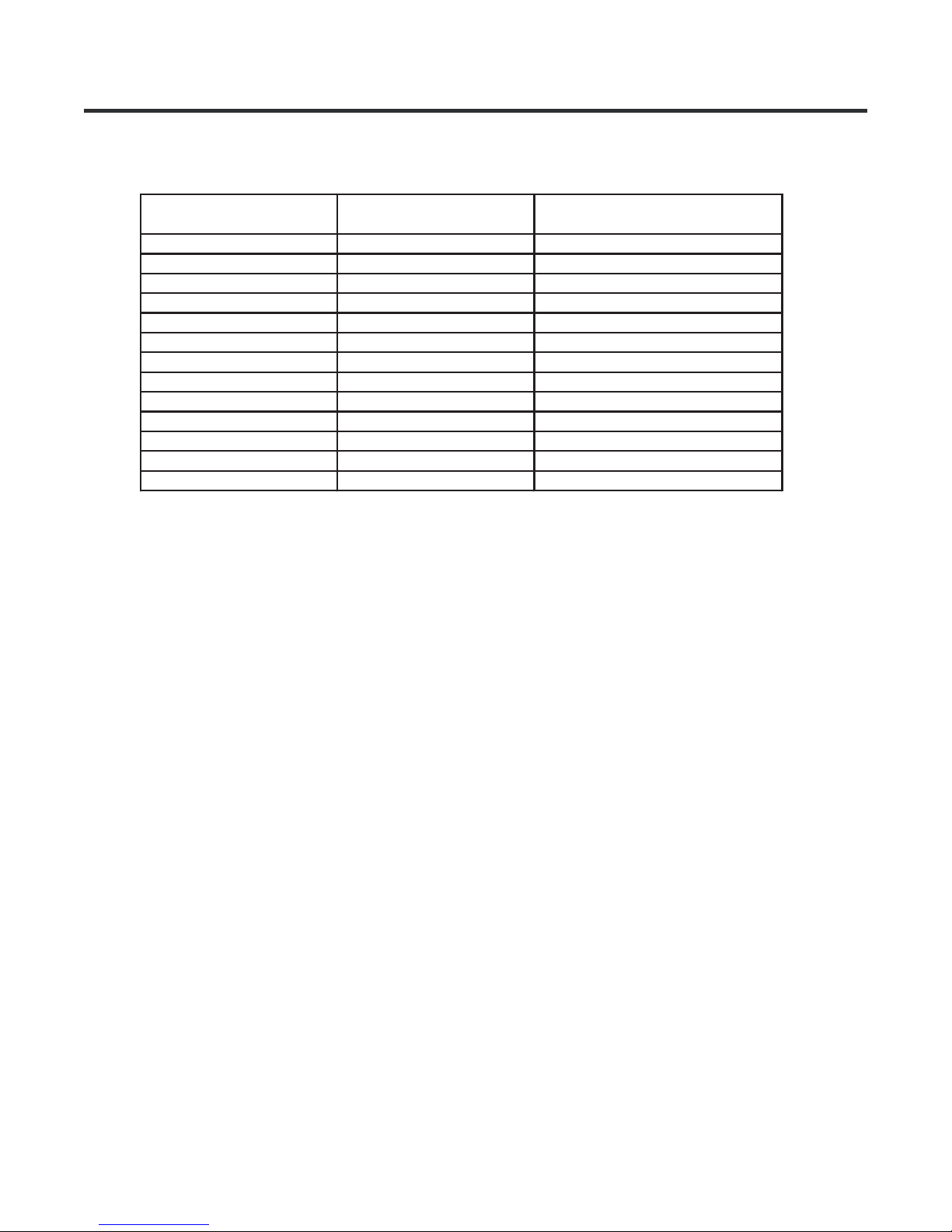

Micom Circuit description

3. Table of sensor resistance characteristics

Measured temperature Freezer sensor

-20 22.3kΩ 77kΩ

-15 16.9kΩ 60kΩ

-10 13kΩ 47.3kΩ

-5 10.1kΩ 38.4kΩ

0 7.8kΩ 30kΩ

+5 6.2kΩ 24.1kΩ

+10 4.9kΩ 19.5kΩ

+15 3.9kΩ 15.9kΩ

+20 3.1kΩ 13kΩ

+25 2.5kΩ 11kΩ

+30 2kΩ 8.9kΩ

+40 1.4kΩ 6.2kΩ

+50 0.8kΩ 4.3kΩ

Refrigerator sensor 1, 2, defrost

sensor, external sensor

Loading...

Loading...