Page 1

SERVICE MANUAL

Room Air Conditioner

MODEL : LS-P0760CL/P0760HL LS-P0820C

LS-P0960CL/P0960HL

LS-S0960CL/S0960HL LS-S1120C

LS-S1260CL/S1260HL

LS-S1420CL LS-S1421CL

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY

PRECAUTIONS” IN THIS MANUAL.

Page 2

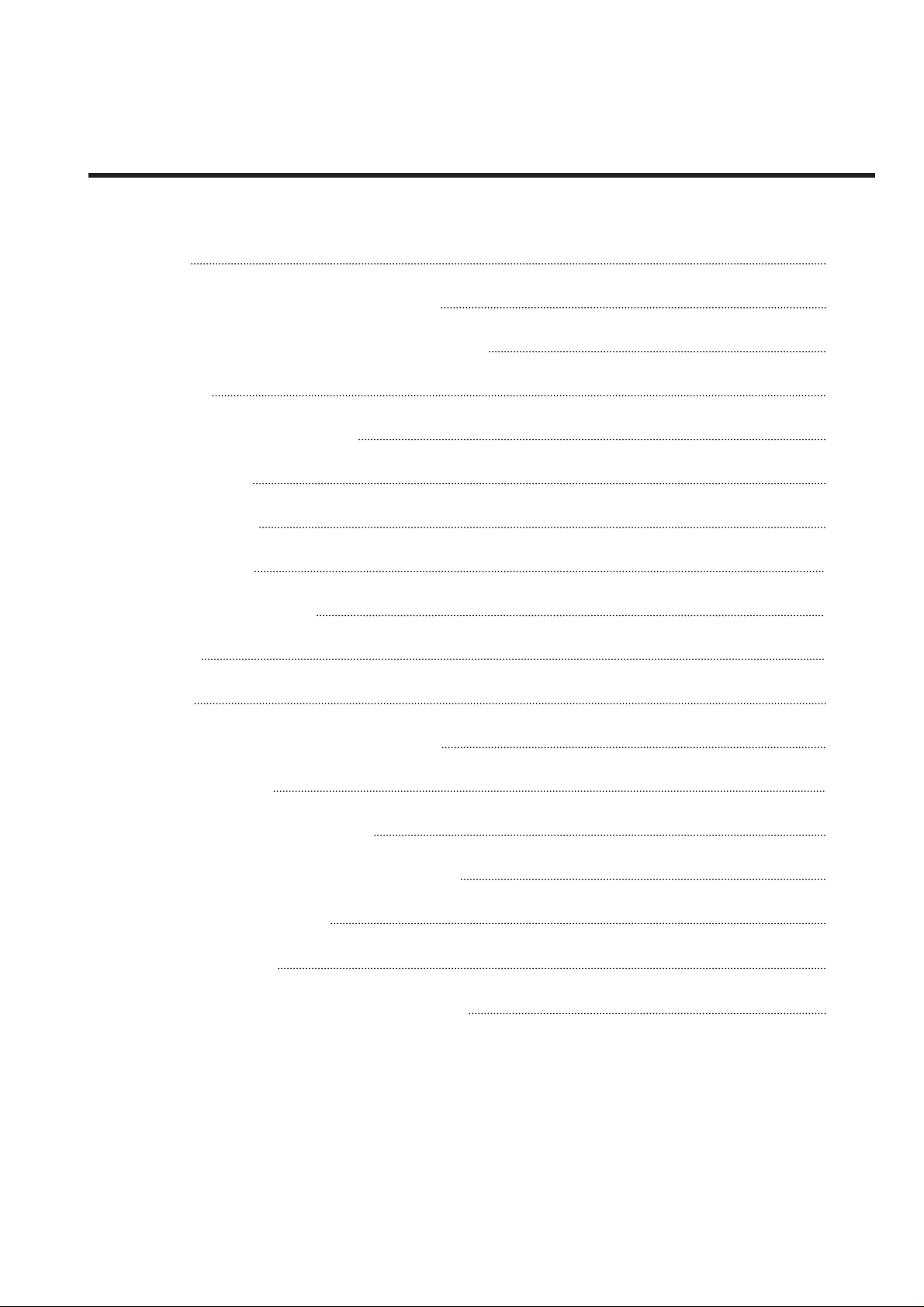

Contents

Functions 3

Product Specifications (Cooling Only) 5

Product Specifications (Cooling & Heating) 7

Dimensions 8

Refrigeration Cycle Diagram 10

Wiring Diagram 11

Operation Details 13

Display Function 21

Self-Diagnosis Function 21

Installation 22

Operation 41

Disassembly of the parts (Indoor Unit) 43

2-way, 3-way Valve 46

Cycle Trouble Shooting Guide 53

Electronic Parts Trouble Shooting Guide 54

Electronic Control device 59

Schematic Diagram 63

Exploded View & Replacement Parts List 67

ƒ¡2ƒ¡

Page 3

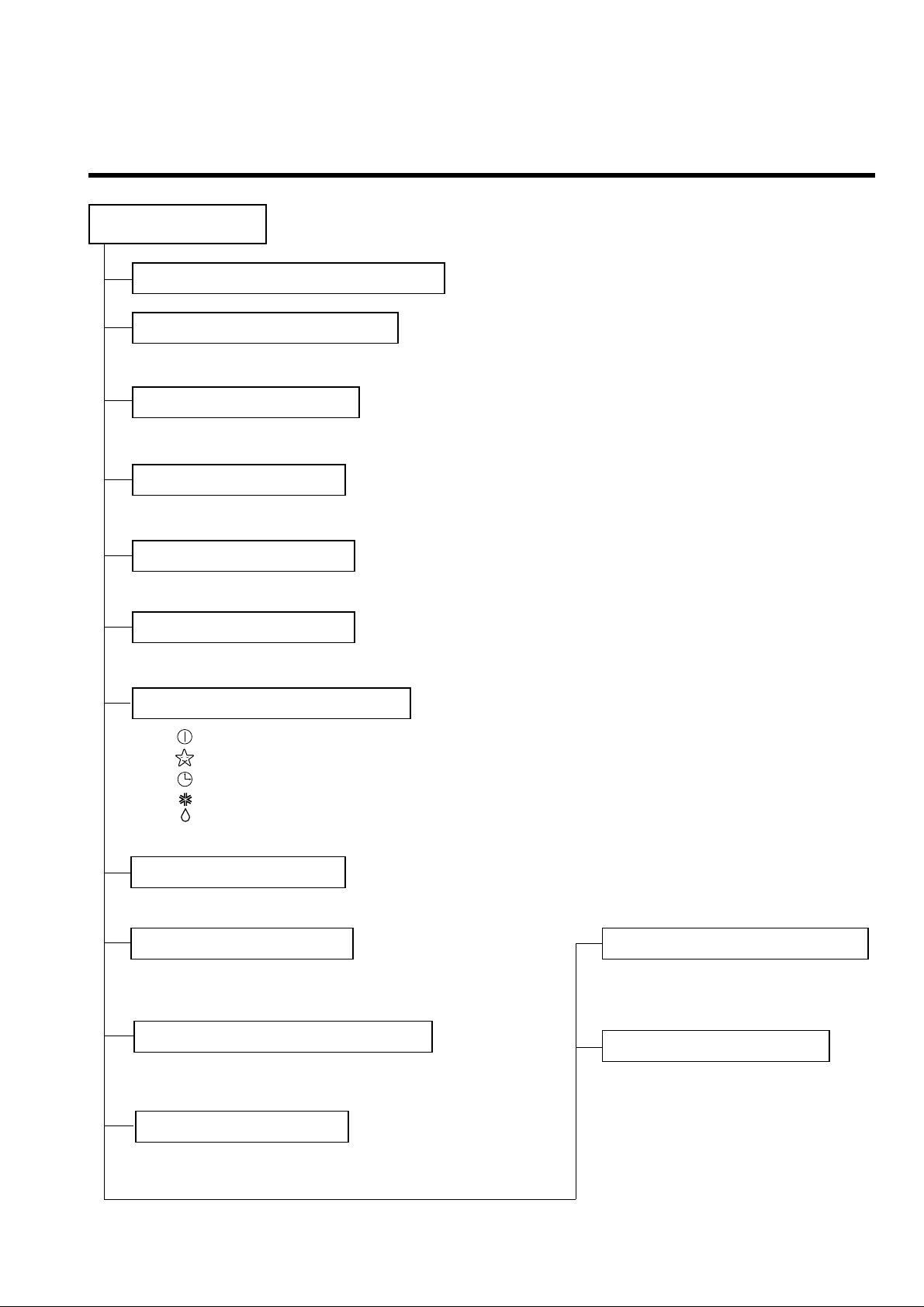

Functions

ƒU Room temperature sensor. (THERMISTOR)

ƒU Maintains the room temperature in accordance with the Setting Temp.

ƒU Indoor fan is delayed for 5 sec at the starting.

ƒU Restarting is inhibited for approx. 3 minutes.

ƒU High, Med, Low

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Deice Mode (for Heating Model)

OUTDOOR --- Lights up in compressor operation (for Cooling Model)

ƒU Intermittent operation of fan at low speed.

ƒU The fan is switched to low(Cooling), med(Heating) speed.

ƒU The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

ƒU The fan is switched to intermittent or irregular operation

ƒU

The fan speed is automatically switched from high to low speed.

ƒU The louver can be set at the desired position or swing

up and down automatically.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

ƒU Both the indoor and outdoor fan

stops during deicing.

ƒU The indoor fan stops until the

evaporator piping temperature

will be reached at 28¡ .

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

ƒ¡3ƒ¡

Deice (defrost) control (Heating)

Hot-start Control (Heating)

Page 4

ƒ¡4ƒ¡

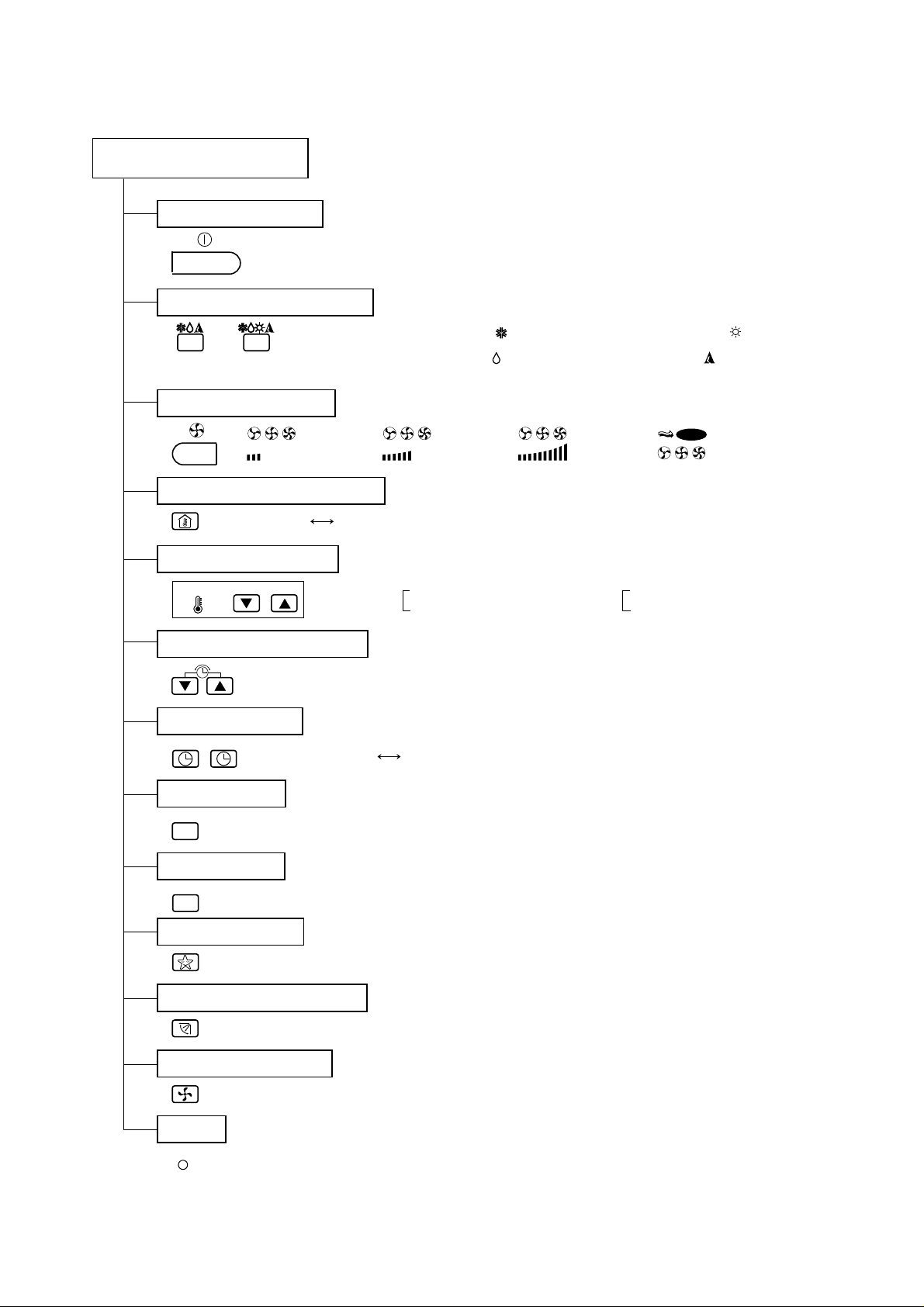

Remote Controller

Operation ON/OFF

Reset

Operation Mode Selection

Fan Speed Selection

Room Temperature Display

Temperature Setting

Setting the Time or Time

Timer Selection

Timer Setting

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

(Low) (Med) (High) (CHAOS)

Cooling Operation Mode.( )

Soft Dry Operation Mode.( ) Auto Operation Mode.( )

Heating Operation Mode.( )

CHAO

S

ON

OFF

SET

CANCEL

Fan Operation Mode

RESET

: High:39°C LOW:11°C

: Cooling

Down to 20°C

Up to 30°C

: Heating

Down to 16°C

Up to 30°C

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF.

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Cooling Model Only

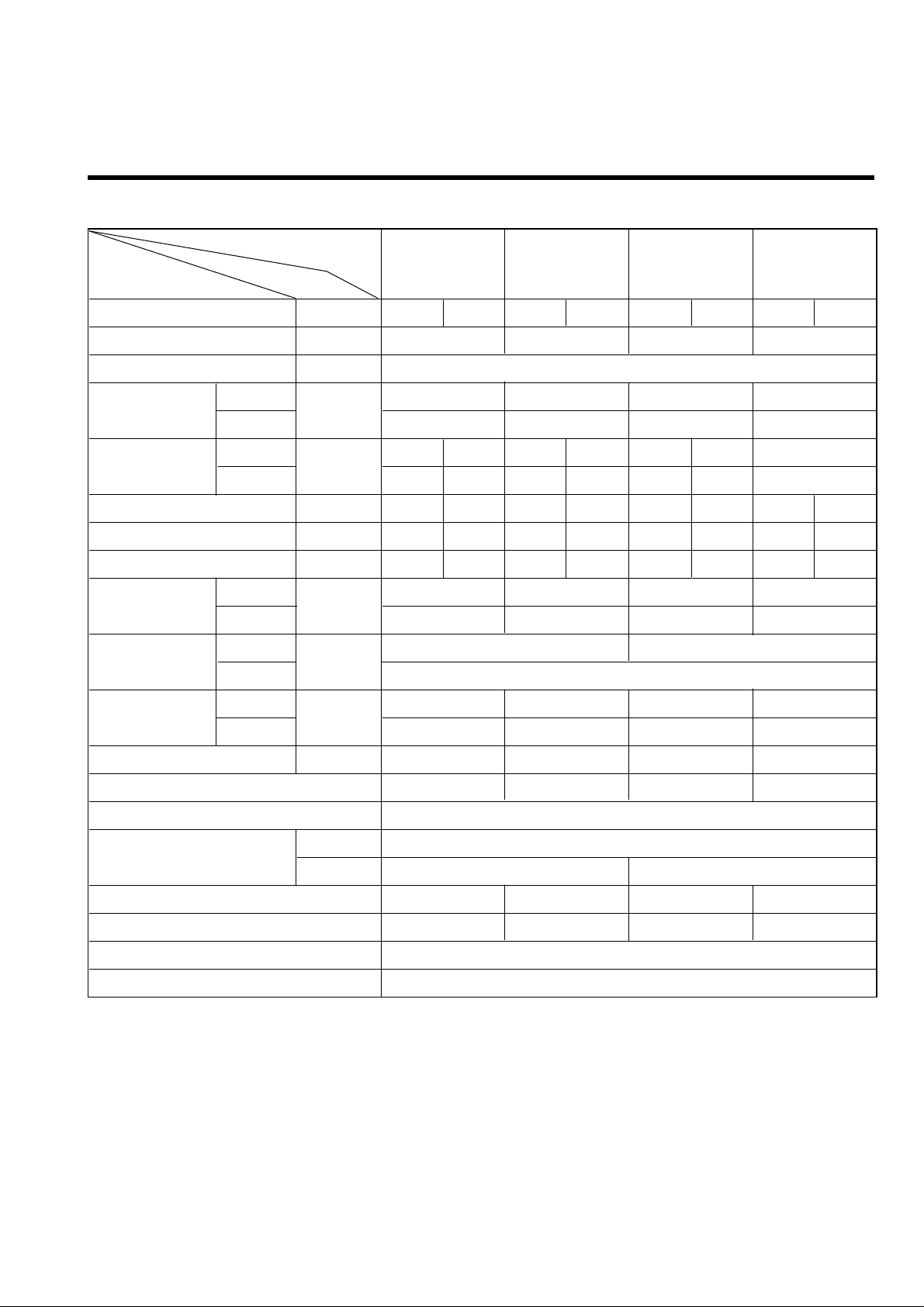

Page 5

ƒ¡5ƒ¡

Product Specifications (Cooling Only)

Model Name

Item Unit

Cooling Capacity BTU/h 7,200 7,300 8,400 8,500 8,800 9,000 12,000 12,000

Moisture Removal §⁄/h 1.0 1.2 1.2 1.2

Power Source §j, V, Hz 1§j220-240V, 50Hz

Indoor 4.6 5.3 7.3 8.9

Outdoor 25 25 25 25

Indoor 35 36 37 38 36 37 38

Outdoor 46 47 47 48 47 48 49

Input W 690 715 890 900 730 750 1,180 1,180

Running Current A 3.2 3.2 4.0 3.9 3.4 3.3 5.8 5.4

E.E.R. BTU/h-W 10.4 10.2 9.44 9.44 12.0 12.0 10.17 10.17

Indoor 8 8 10 15

Outdoor 25 25 25 25

Indoor 790¡¿230¡¿142 880¡¿302¡¿183

Outdoor 660¡¿540¡¿260

Indoor 7 7 9.5 9.5

Outdoor 29 29 29 30

Refrigerant (R-22) g 560 490 780 700

Airflow Direction Control (Up & Down) § § § §

Remocon Type L.C.D Wireless

Liquid 1/4" (6.35)

Gas 3/8" (9.52) 1/2"(12.7)

Sleeping Operation § § § §

Drain Hose § § § §

Connecting Cable 1.0mm

2

Power Cord 1.0mm

2

Air Circulation

Noise Level

m3/min

dB (A)¡ 3

Service Valve

Motor Output

Dimensions

(W¡¿H¡¿D)

Net. Weight

W

mm

kg

LS-P0760CL LS-P0960CL LS-S0960CL LS-S1260CL

SPEC. AT 220/240V

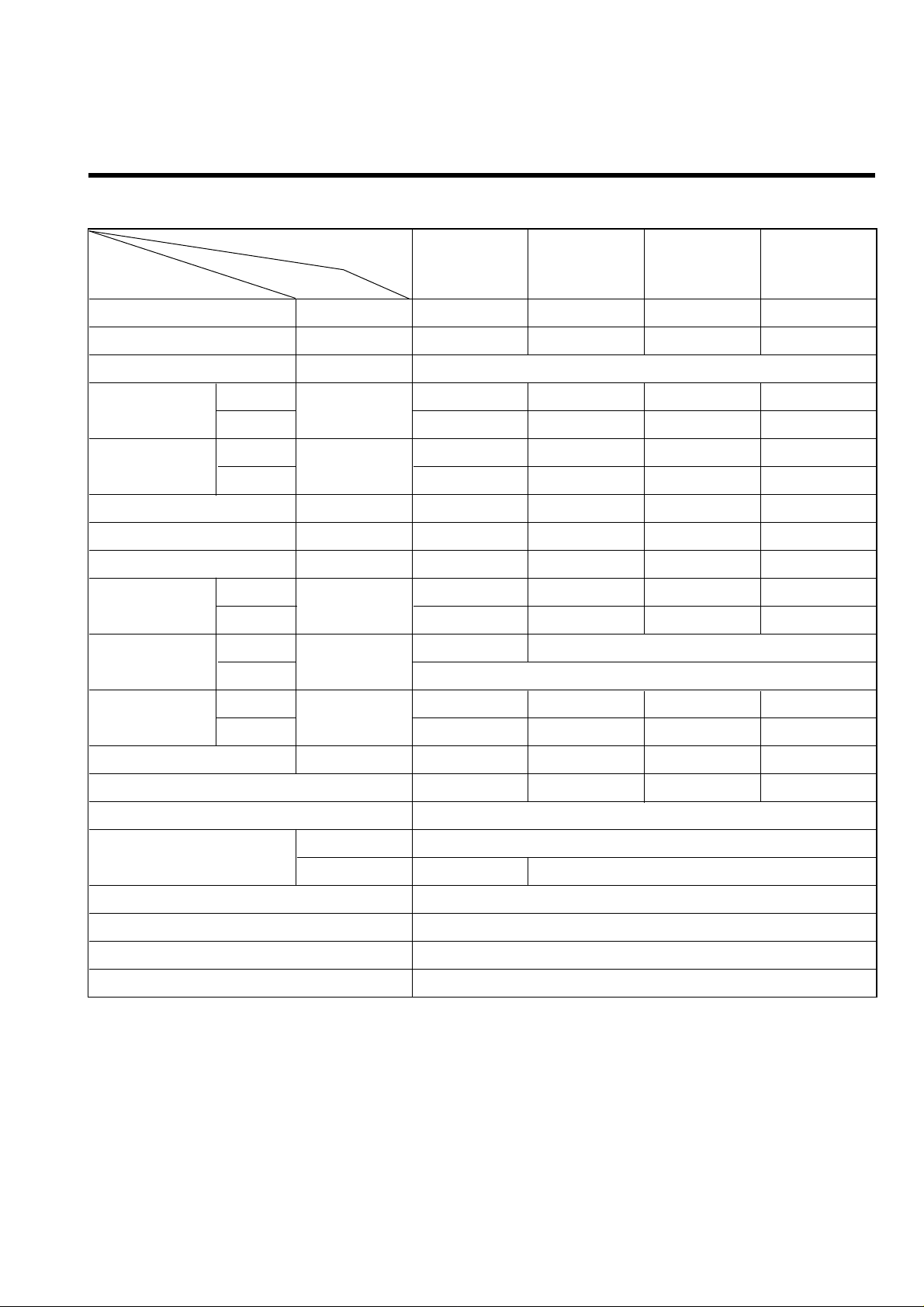

Page 6

ƒ¡6ƒ¡

Model Name

Item Unit

Cooling Capacity BTU/h(kcal/h) 7,500(1,900) 11,000(2,772) 13,300(3,350) 14,000(3,550)

Moisture Removal §⁄/h 1.2 2.3 2.3 2.5

Power Source §j, V, Hz 1Ø, 220~V, 60Hz

Indoor 5.5 9.0 9.0 10.1

Outdoor 23 24 24 27

Indoor 36 39 39 39

Outdoor 47 49 49 50

Input W 710 1,050 1,378 1,500

Running Current A 3.3 4.9 6.3 6.9

E.E.R. BTU/h-W 10.6 10.5 9.7 9.3

Indoor 4.5 19.8 19.8 19.8

Outdoor 20 30 30 35

Indoor 790¡¿230¡¿142 880¡¿302¡¿183

Outdoor 660¡¿540¡¿260

Indoor 6 9.5 9.5 9.5

Outdoor 29 31.5 33.5 31.5

Refrigerant (R-22) g 600 710 980 750

Airflow Direction Control (Up & Down) § § § §

Remocon Type L.C.D Wireless

Liquid 1/4" (6.35)

Gas 3/8" (9.52) 1/2" (12.7)

Sleeping Operation §

Drain Hose §

Connecting Cable 1.0mm

2

Power Cord 1.0mm

2

Air Circulation

Noise Level

m3/min

dB (A)¡ 3

Service Valve

Motor Output

Dimensions

(W¡¿H¡¿D)

Net. Weight

W

mm

kg

LS-P0820CL LS-S1120CL LS-S1420CL LS-S1421CL

SPEC. AT 220V

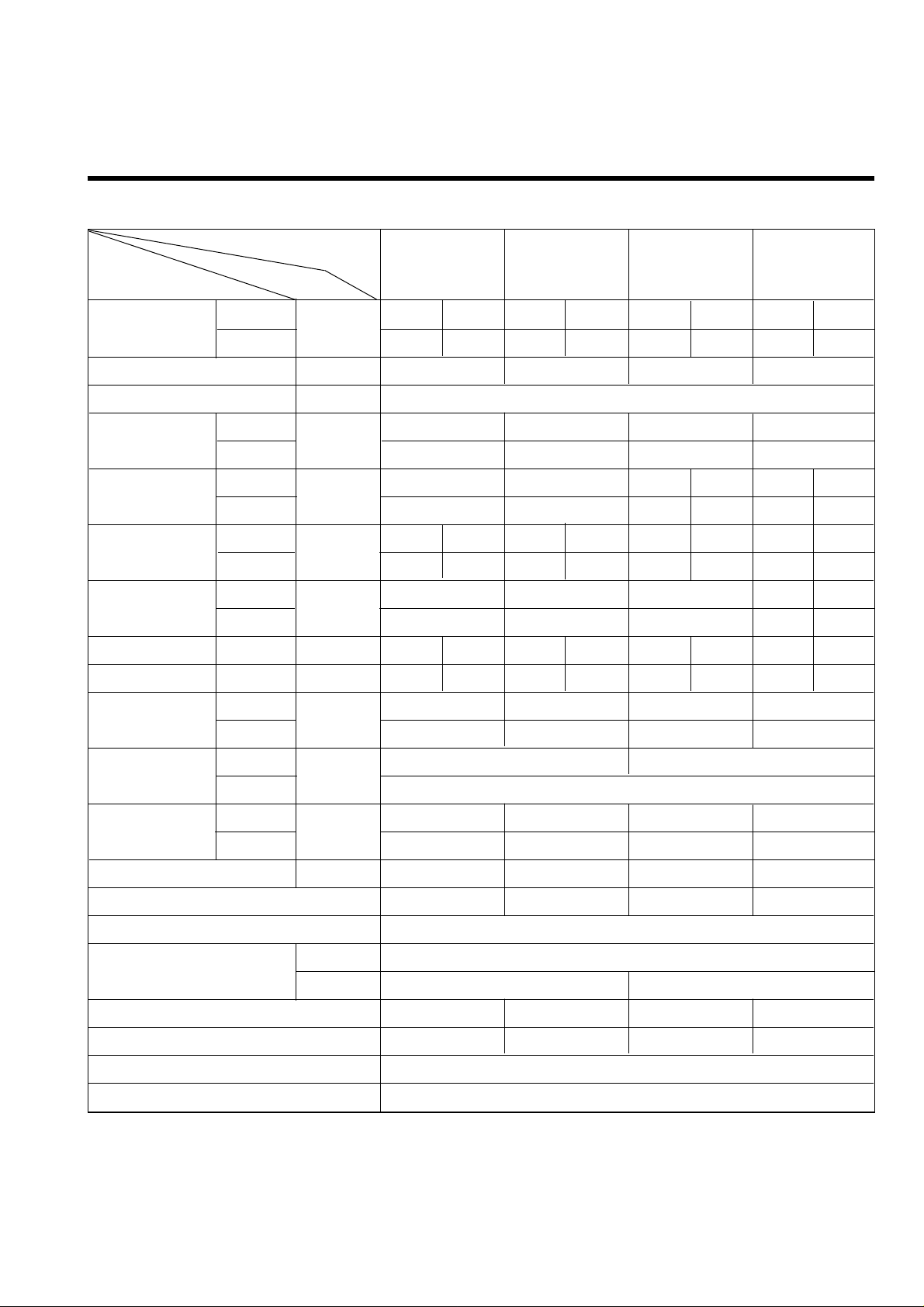

Page 7

ƒ¡7ƒ¡

Product Specifications (Cooling & Heating)

Model Name

Item Unit

Cooling 7,000 7,000 8,400 8,500 9,400 9,500 11,700 12,000

Heating 7,300 7,500 9,400 9,500 10,200 10,500 12,600 13,000

Moisture Removal §⁄/h 1.3 1.17 1.2 1.2

Power Source §j, V, Hz 1§j220-240V, 50Hz

Indoor 5.3 6.3 7.6 8.9

Outdoor 24 25 25 25

Indoor 36 38 36 37 37 38

Outdoor 47 49 47 48 48 49

Cooling 710 720 910 940 940 950 1,210 1,250

Heating 730 740 940 990 900 950 1,160 1,230

Cooling 3.1 4.5 4.5 6.4 6.2

Heating 3.3 4.5 4.5 6.2 6.0

E.E.R. Cooling BTU/h¡⁄w 9.86 9.7 9.23 9.0 10.0 10.0 9.7 9.6

C.O.P Heating W/W 2.93 2.97 2.93 2.81 3.32 3.2 3.2 3.1

Indoor 8 8 10 15

Outdoor 25 25 25 25

Indoor 790¡¿230¡¿142 880¡¿302¡¿183

Outdoor 660¡¿540¡¿260

Indoor 7 7 9.5 9.5

Outdoor 30 31 31 33

Refrigerant (R-22) g 600 540 1,020 1,150

Airflow Direction Control (Up & Down) § § § §

Remocon Type L.C.D Wireless

Liquid 1/4" (6.35)

Gas 3/8" (9.52) 1/2"(12.7)

Sleeping Operation § § § §

Drain Hose § § § §

Connecting Cable 1.0mm

2

Power Cord 1.0mm

2

Air Circulation

Noise Level

Input

Running

Current

Capacity BTU/h

Service Valve

Motor Output

Dimensions

(W¡¿H¡¿D)

Net. Weight

m3/min

dB (A)¡ 3

W

A

W

mm

kg

LS-P0760HL LS-P0960HL LS-S0960HL LS-S1260HL

SPEC. AT 220/240V

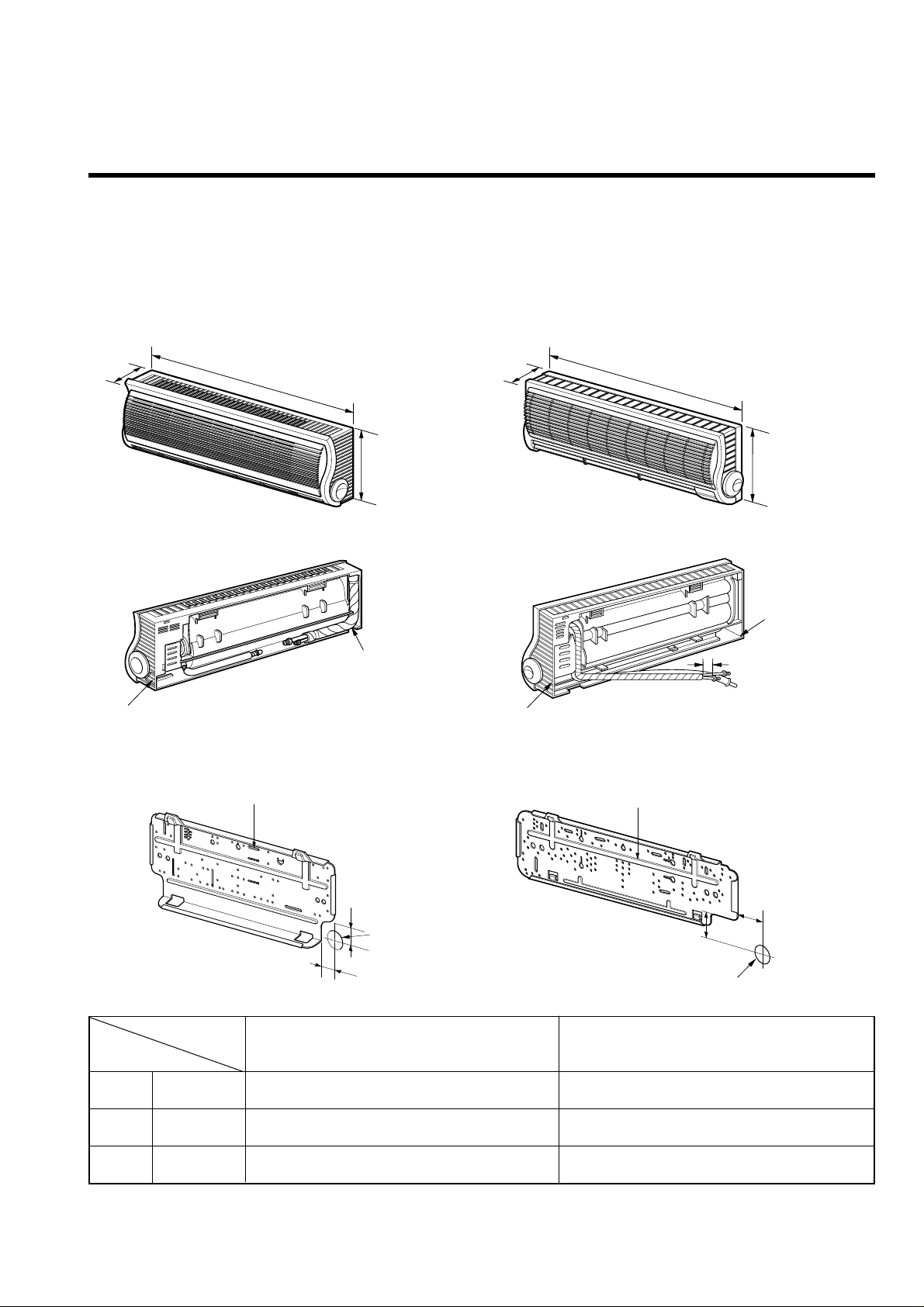

Page 8

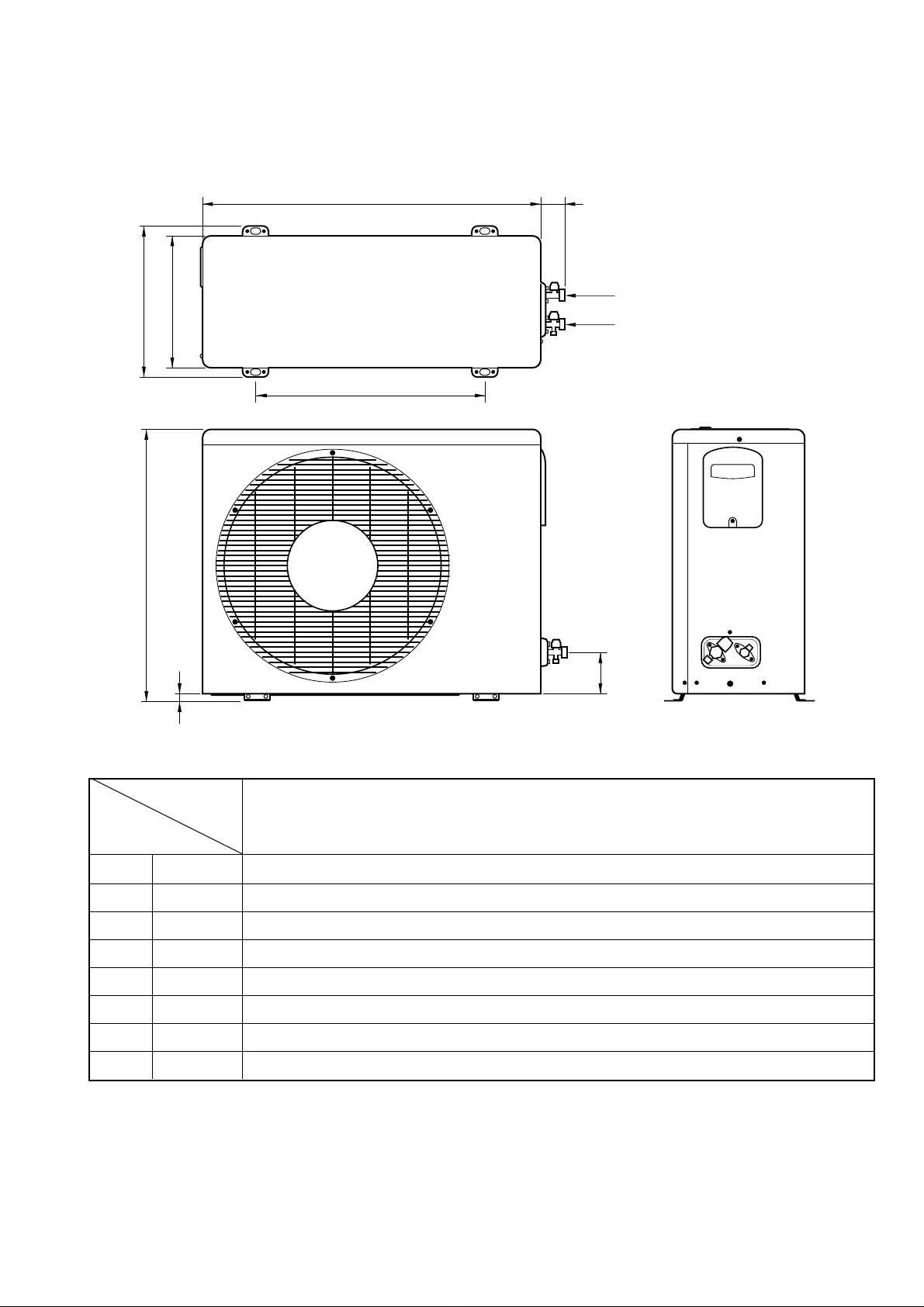

Dimensions

(1) Indoor Unit

ƒ¡8ƒ¡

W

D

H

Installation plate

45

70

Hole for piping

50

Tubing hole cover

Tubing hole cover

W

D

H

Installation plate

Hole for piping

Tubing hole cover

Tubing hole cover

20

50

MODEL

DIM

W mm 790 880

H mm 230 302

D mm 142 183

LS-P0760CL/P0760HL/P0820CL

LS-P0960CL/P0960HL

LS-S0960CL/S0960HL/S1120CL

LS-S1260CL/S1260HL/S1420CL/S1421CL

LS-P0760CL/P0760HL

LS-P0820CL

LS-P0960CL/P0960HL

LS-S0960CL/S0960HL

LS-S1120CL

LS-S1260CL/S1260HL

LS-S1420CL/S1421CL

Page 9

(2) Outdoor Unit

W L2

L3

L1

D

H

L4

L5

Liquid side (2-way valve)

Gas side (3-way valve)

MODEL

DIM

W mm 660

H mm 540

D mm 260

L1 mm 297

L2 mm 66

L3 mm 447

L4 mm 17

L5 mm 82

LS-P0760CL/P0760HL, LS-P0820CL, LS-P0960CL/P0960HL

LS-S0960CL/S0960HL, LS-S1120CL, LS-S1260CL/S1260HL

LS-S1420CL, LS-S1421CL

ƒ¡9ƒ¡

Page 10

Refrigeration Cycle Diagram

ƒ¡10ƒ¡

Pipe size(Diameter:§j)

MAX. Max

MODEL Piping length Elevation

Gas Liquid

(m) (m)

LS-P0760CL/P0760HL

LS-P0820CL 3/8" 1/4" 7 5

LS-P0960CL/P0960HL

LS-S0960CL/S0960HL

LS-S1120CL

LS-S1260CL/S1260HL

LS-S1420CL/S1421CL

1/2" 1/4" 7 5

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

LIQUID SIDE

2-WAY VALVE

GAS SIDE

3-WAY VALVE

CAPILLARY TUBE

ACCUMU

LATOR

COMPRESSOR

HEAT

EXCHANGE

(CONDENSOR)

REVERSING

VALVE

(Heating Model Only)

COOLING

HEATING

Page 11

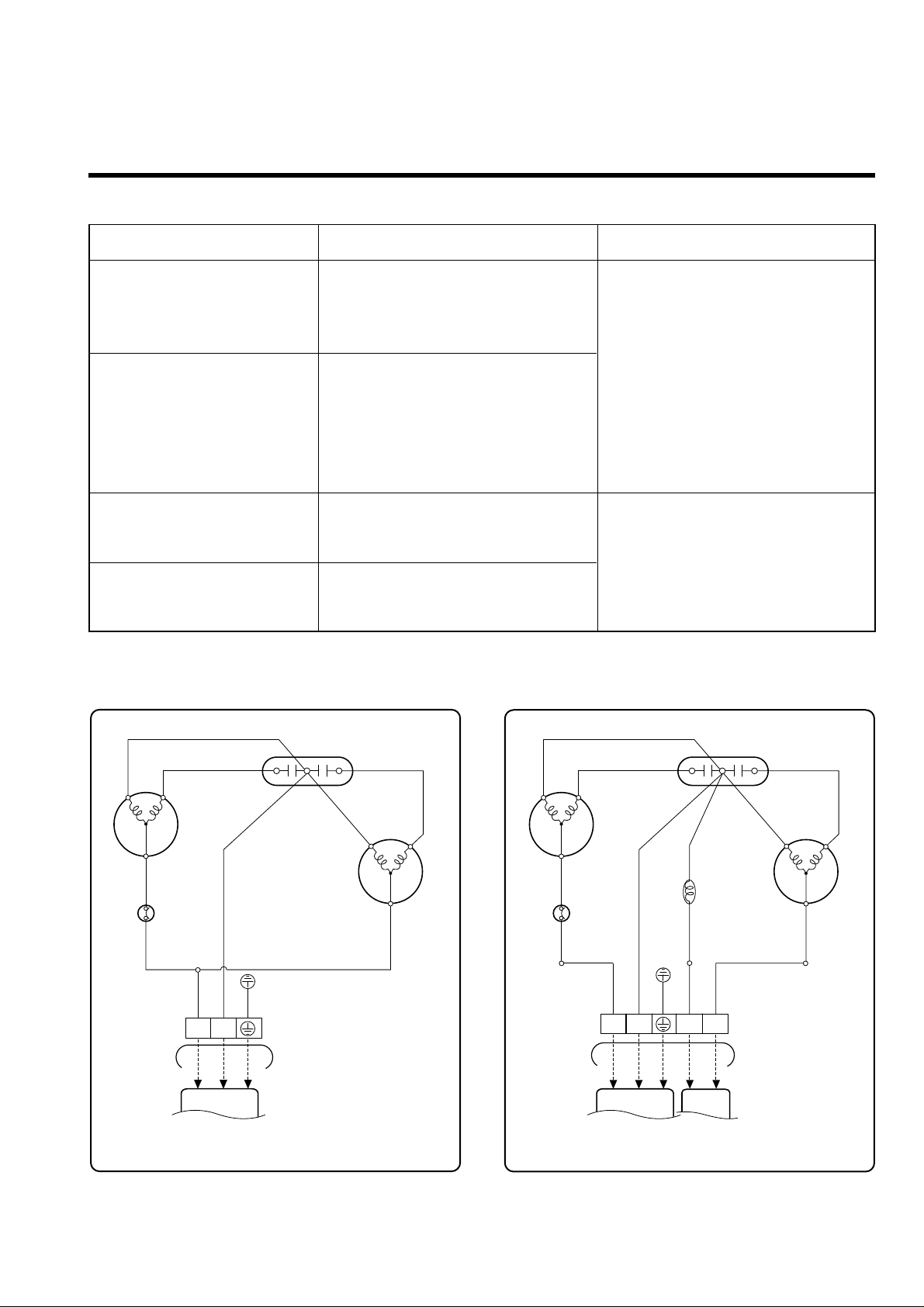

Wiring Diagram

ƒ¡11ƒ¡

F

CH

BL

R S

C

COMP

FAN

MOTOR

BL

CAPACITOR

RD

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM

RD

BR

OLP

BR

YL

PILLAR

TERMINAL

BL

3854AR2262F

1(L) 2(N)

1

GN/YL

BL

BR

BLACK

GN/YL

BL

BR

F

CH

BL

R S

C

COMP

FAN

MOTOR

BL

CAPACITOR

RD

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM

RD

BR

OLP

YL

PILLAR

TERMINAL

BL

3854AR2262E

1(L) 2(N)

GN/YL

1

GN/YL

BL

BR

3 4

BK

BK

2

RD

BL

BR

REVERSING

VALVE

RD

BK

3

BR

BLACK GRAY

MODEL INDOOR UNIT OUTDOOR UNIT

LS-P0760CL

LS-P0820CL

LS-P0960CL

LS-S0960CL

LS-S1120CL

LS-S1260CL

LS-S1420CL

LS-S1421CL

LS-P0760HL

LS-P0960HL

LS-S0960HL

LS-S1260HL

¤Ø

¤Œ

¤º

¤

¤

¤Ł

¤ ¤Ł

Page 12

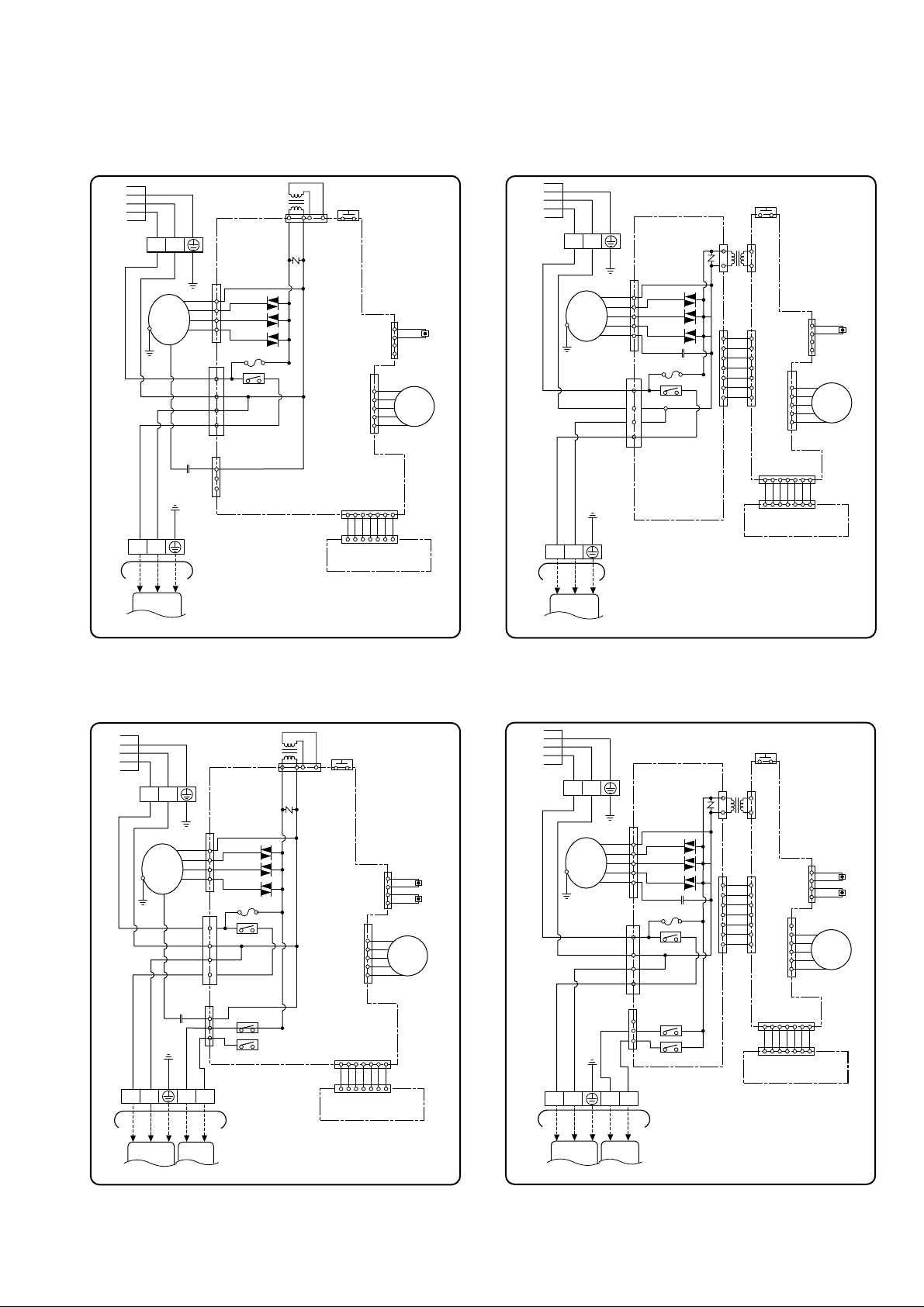

ƒ¡12ƒ¡

BLACK

BL

BR

GN/YL

BR BL

GN/YL

GN/YL

POWER

BR BL

BL

OR

BR

YL

CN-FAN

SSR-L

SSR-M

SSR-H

CN-TRANS

CN-TH

CN-UP/DOWN

CN-DISP

THERMISTOR

MAIN PCB

ASM

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

3854AR2262D

GN/YL

TO OUTDOOR UNIT

PILLAR

TERMINAL

CN-4WAY

CN-POWER

RY-COMP

FUSE T2A

2

1

3

4

BR BL

TRANS

FORMER

FORCED

OPERATION

SWITCH

SH-CAPA

RD

MOTOR

1(L)

2(N)

STEP

MOTOR

RD

1(L) 2(N)

BLACK

BL

BR

GN/YL

BR BL

GN/YL

GN/YL

POWER

BR BL

BL

OR

BR

YL

RD

CN-FAN

SSR-L

SSR-M

SSR-H

SH-CAPA

AC PCB

ASM

CN-TRANS

CN-TH

CN-AC/DC

CN-UP/DOWN

CN-DISP

THERMISTOR

DC PCB

ASM

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

3854AR2262B

GN/YL

TO OUTDOOR UNIT

PILLAR

TERMINAL

RY-COMP

FUSE T2A

2

1

3

4

BR BL

TRANS

FORMER

FORCED

OPERATION

SWITCH

MOTOR

STEP

MOTOR

1(L)2(N)

1(L)

2(N)

¤Ø ¤Œ

BLACK

BL

BR

RD

BK

GN/YL

GRAY

BR BL

GN/YL

GN/YL

POWER

BR BL

BL

OR

BR

YL

CN-FAN

SSR-L

SSR-M

SSR-H

CN-TRANS

CN-TH

CN-UP/DOWN

CN-DISP

THERMISTOR

MAIN PCB

ASM

INDOOR WIRING DIAGRAM

3854AR2262C

GN/YL

BK RD

TO OUTDOOR UNIT

RY-FAN

PILLAR

TERMINAL

RY-4WAY

CN-4WAY

CN-POWER

RY-COMP

FUSE T2A

2

1

3

4

BR

BL

TRANS

FORMER

FORCED

OPERATION

SWITCH

SH-CAPA

RD

MOTOR

STEP

MOTOR

DISPLAY PCB ASM

RD

1(L) 2(L)

1(L)

2(N)

3 4

BLACK

BL

BR

RD

BK

GN/YL

GRAY

BR BL

GN/YL

GN/YL

POWER

BR BL

BL

OR

BR

YL

RD

CN-FAN

SSR-L

SSR-M

SSR-H

SH-CAPA

AC PCB

ASM

CN-TRANS

CN-TH

CN-AC/DC

CN-UP/DOWN

CN-DISP

THERMISTOR

DC PCB

ASM

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

3854AR2262A

GN/YL

TO OUTDOOR UNIT

RY-FAN

PILLAR

TERMINAL

RY-4WAY

CN-POWER

RY-COMP

FUSE T2A

2

1

3

4

BR BL

TRANS

FORMER

FORCED

OPERATION

SWITCH

MOTOR

STEP

MOTOR

BK RD

CN-4WAY

1(L) 2(L)

1(L)

2(N)

43

¤º ¤

Page 13

Operation Details

(1) The function of main control

1. Time Delay Safety Control

ƒU3min¡ƒ The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

ƒU2sec¡ƒ The indoor fan is ceased for 2sec. to prevent relay noise.

(Protection of fan relay and micro chip)

ƒU30sec¡ƒThe 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode.

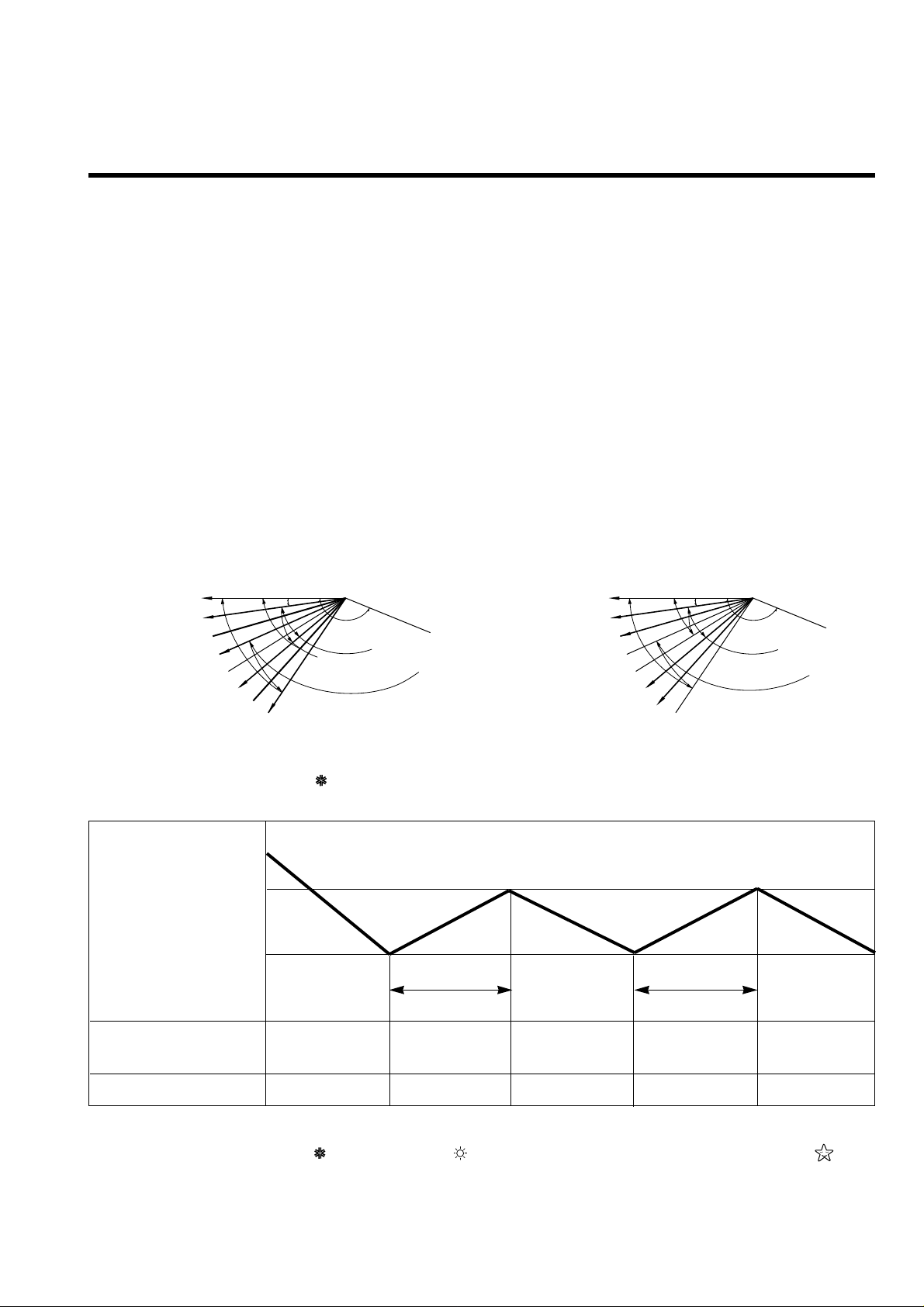

2. Airflow Direction Control

ƒU This function is to swing the louver up and down automatically and to set it at the desired position.

ƒU The procedure is as the following.

1st ; Press the ON/OFF Button to operate the product.

2nd ; Press the Airflow Direction Control Button to swing the louver up and down automatically.

3rd ; Repress the Airflow Direction Control Button to set the louver as the desired position.

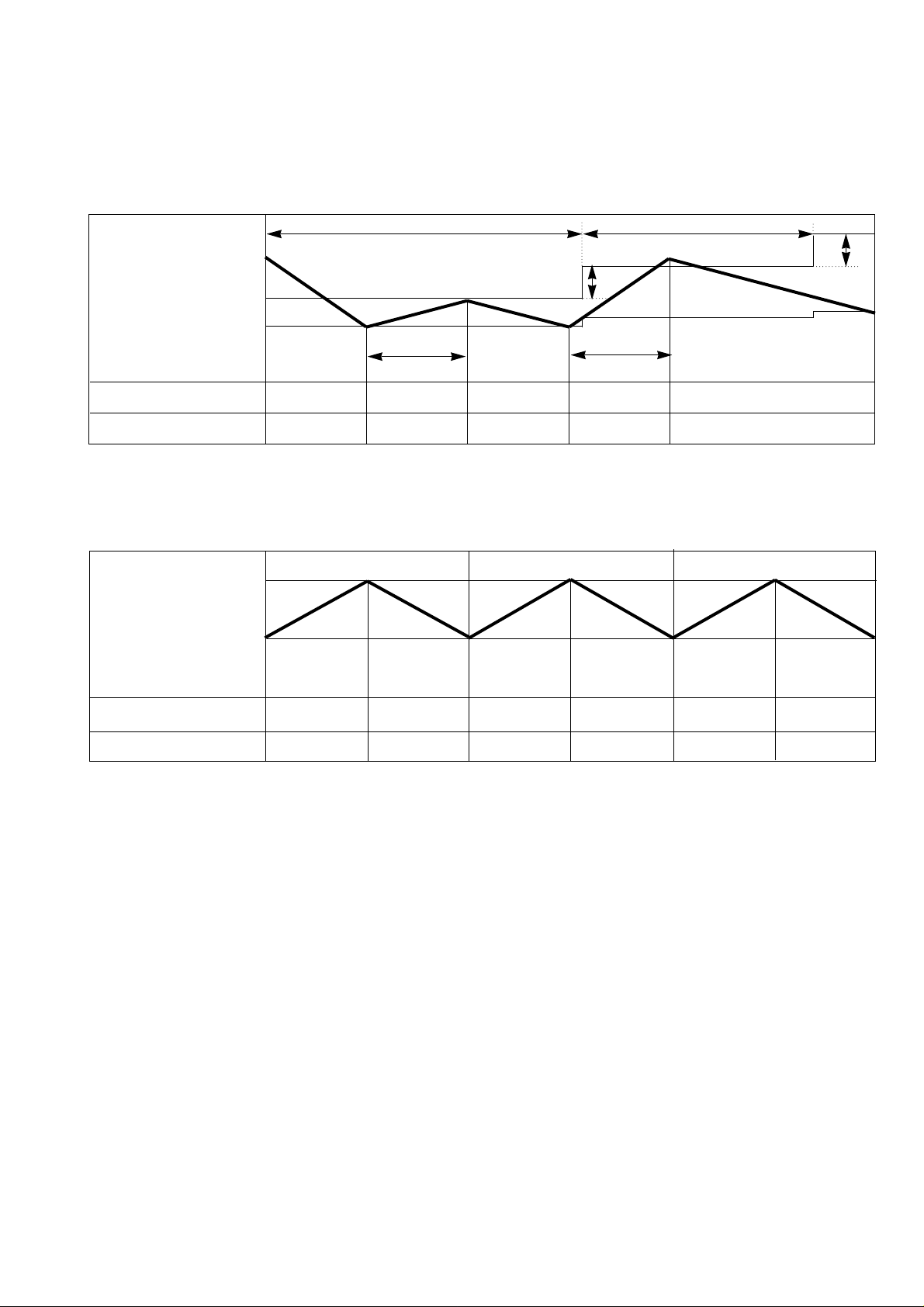

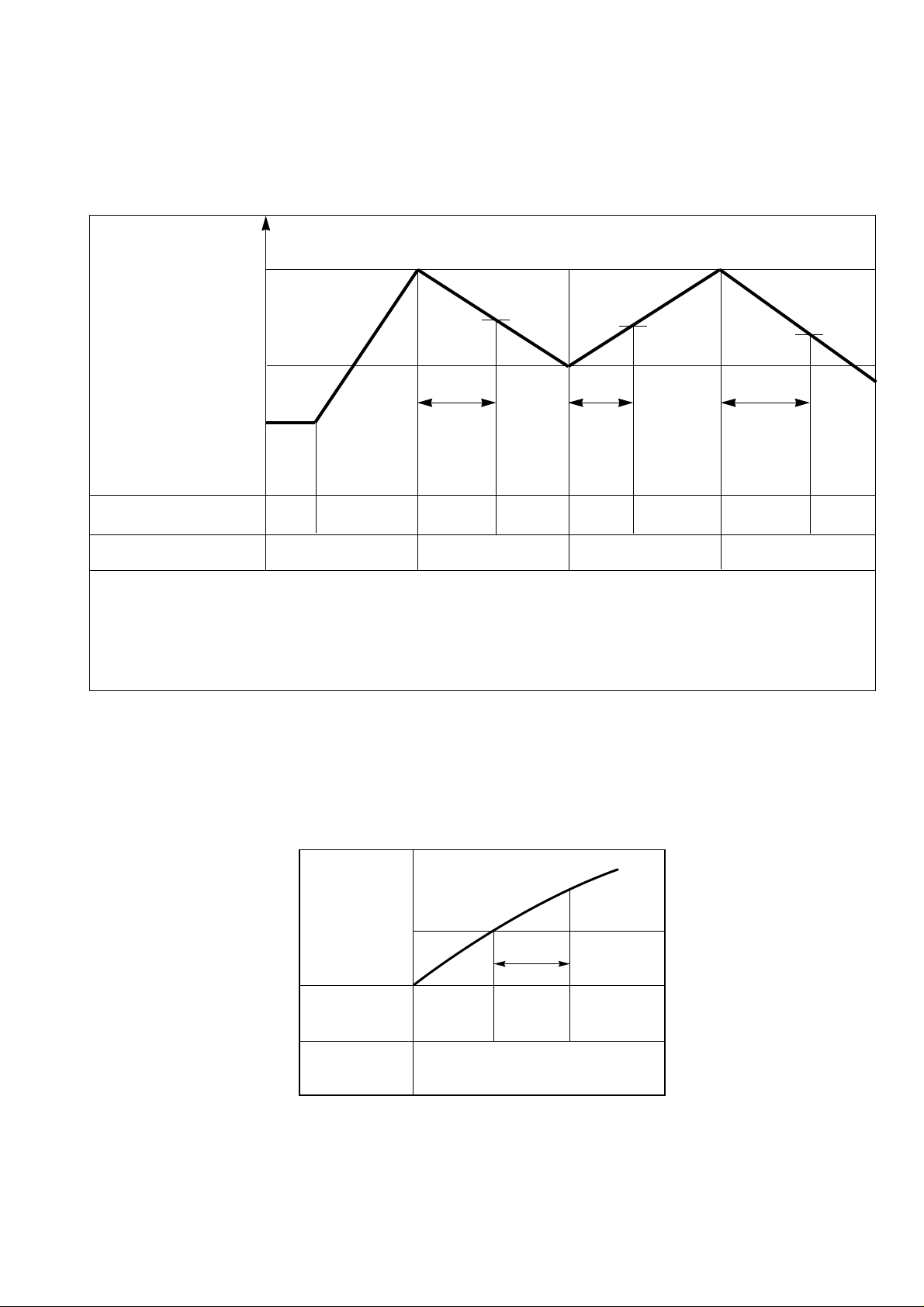

3. Cooling Mode Operation

ƒU When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote

controller and the operation diagram is as following

4. Cooling or Heating Mode with Sleep Mode Auto Operation

ƒU When selecting the Cooling( ) or the Heating( ) combined with the Sleep Mode Auto Operation( ), the

operation diagram is as following.

ƒ¡13ƒ¡

Horizontal 0

1

2

3

4

5

6

7

8

Setting point:

Setting range for:

(Close)

7°

110°

Cooling

Approx. 28°

Heating

Approx. 28°

Cooling

Heating

Heating

Cooling

Horizontal 0

1

2

3

4

5

6

7

8

Setting point:

Setting range for:

(Close)

8°

150°

Cooling

Approx. 32°

Heating

Approx. 32°

Cooling

Heating

Heating

Cooling

LS-S0960CL/S0960HL, LS-S1120CL

LS-S1260CL/S1260HL

LS-S1420CL, LS-S1421CL

LS-P0760CL/P0760HL, LS-P0820CL

LS-P0960CL/P0960HL

Intake Air temp.

COMP. ON

(SET TEMP.+0.5¡ )

COMP. OFF

(SET TEMP. -0.5¡ ) More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

¢”

¢”

Page 14

¡Æ Cooling Mode with the Sleep Mode

ƒU The setting temperature will be raised by 1¡ 30minutes later and by 2¡ 1 hour later.

ƒU The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

¡Æ Heating Mode with the Sleep Mode.

ƒU The operation will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

ƒ¡14ƒ¡

Intake Air temp.

COMP. ON

(SET TEMP.+0.5¡ )

COMP. OFF

(SET TEMP. -0.5¡ ) Morethan More than

3 minutes 3 minutes

INDOOR FAN Low Low Low Low Low

COMPRESSOR ON OFF ON OFF ON

Delay 3 minutes

30 minutes 30 minutes

1¡

1¡

Setting Temp. +3¡

(Compressor OFF)

Setting Temp.

(Compressor ON)

Indoor Fan Med. Med. Med. Med. Med. Med.

Compressor ON OFF ON OFF ON OFF

¢”

¢”

¢”

¢”

Page 15

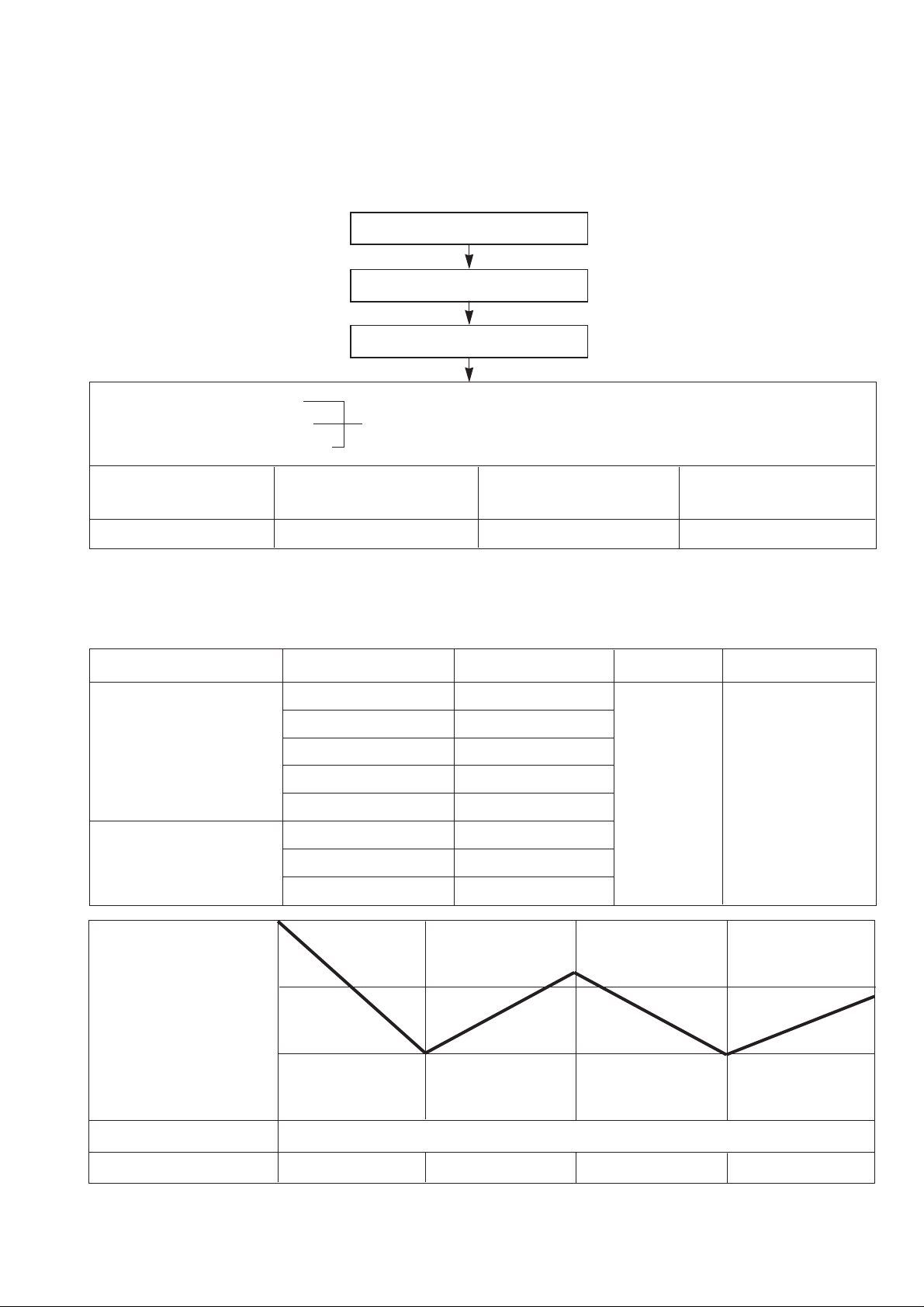

5. Auto Operation

ƒU The operation procedure is as following.

ƒNIf initial mode is decided, that mode is continued without the room temperature changing.

ƒƒUU

Auto Operation for Cooling.

ƒ¡15ƒ¡

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

Operation mode

Indoor fan speed are automatically decided by Fuzzy rule.

Setting temperature

Intake-air

temperature

Operation Mode Heating Soft Dry Cooling

Operation Condition Intake-air Temperature Setting temperature Fan speed Air Direction Control

Over 26°C 25°C

Over 24°C~below 26°C Intake air -1.0°C

Over 22°C~below 24°C Intake air -0.5°C

Over 20°C~below 22°C Intake air temperature

below 20°C 20°C

Over 20°C~below 30°C Fuzzy control

below 20°C 20°C

Over 30°C 30°C

below 21¡

below

24¡

~

Over 24¡

Over

21¡

When Auto Operation

initial start

When Switch to

Auto Operation

Controlled

by Fuzzy logic

1/f rhythm

Intake-Air temp

Setting Temp. +0.5°C

(Compressor OFF)

Setting Temp.-0.5°C

(Compressor ON)

Indoor Fan

Compressor ON OFF ON OFF

Fuzzy Speed

¢”

¢”

Page 16

ƒƒUU

Auto Operation for Soft Dry.

The Setting temperature will be set to the same that of the current intake-air temperature.

- Compressor ON temperature; Setting temperature +1°C

- Compressor OFF temperature; Setting temperature -0.5°C

ƒƒUU

Auto Operation for Heating.

ƒ¡16ƒ¡

Intake Air temp. below 20°C over 20°C~below 21°C

Setting temp. 20°C Intake air Temperature +0.5°C

21°C

20°C

20°C

Intake-Air temp.

Setting temp.

20.5°C

21°C

Page 17

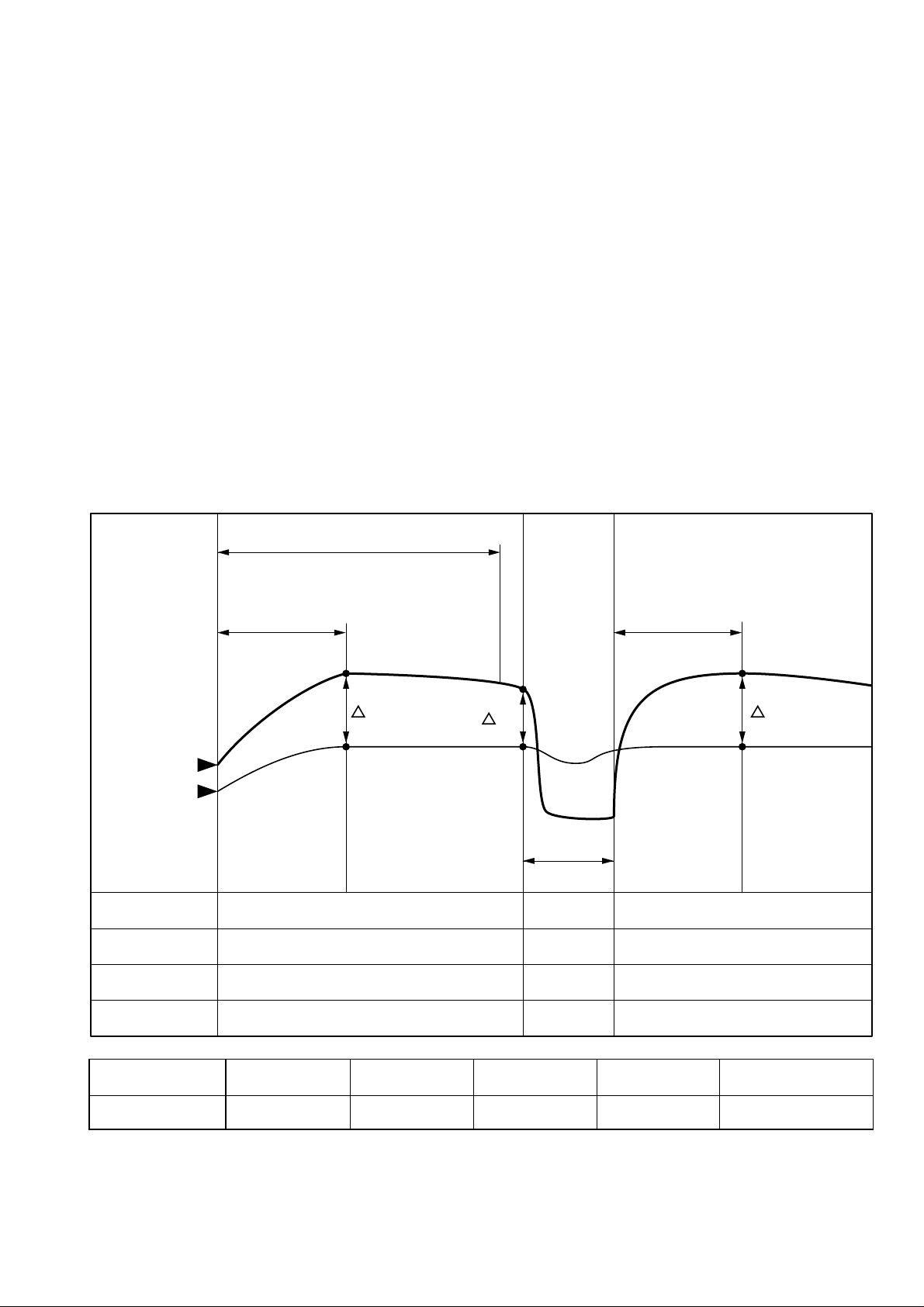

6. Natural Wind by CHAOS logic

There are common rules in the irregular changes amid the breeze of highlands and valleys, the sound of

streams, the songs of birds in the forest and brain waves of relaxation.

Mmm... the breath-taking and touchy feeling of wind from the deep mountains and dark valleys.

Through analysis in its chaos simulator, Goldstar has successfully created such a feeling of freshness and

serenity by analyzing the frequency of natural wind.

Generally natural wind has the following character (frequency-Magnitude), for example dark vally, sea, mountain wind.

So as to make a similar Natural wind function, Indoor fan speed is shifted to high from low or reversely in

according to the CHAOS logic.

ƒ¡17ƒ¡

Magnitude

frequency(Hz)

natural wind function

Page 18

7. Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as

following.

8. Hot-Start Control

ƒU The indoor fan stops until the evaporator piping temperature will be reached at 28¡ . (BY TEMPERATURE)

ƒU The operation diagram is as following.

ƒ¡18ƒ¡

Intake Air temp.

Setting temp.+3¡

(Compressor OFF)

Setting temp.

(Compressor ON)

INDOOR FAN Low OFF Low Low OFF

COMPRESSOR ON OFF ON OFF

ƒU A point; The indoor pipe temperature to be 35°C

The indoor fan operates minimum 10sec. even if falls lower than 35°C

ƒU B point; The indoor pipe temperature to be 35°C

The indoor fan operates minimum 10sec. even if falls lower than 35°C

Selecting fan

speed

HOT

START

OFF

Selecting fan

speed

minimum

10sec.

A A

minimum

10sec.

minimum

10sec.

B

¢”

¢”

PIPING

TEMP 28°C

60 sec.

COMPRESSOR

INDOOR

FAN

LOWOFF

SELECTING

FAN SPEED

ON

(HOT-START BY TEMPERATURE)

Page 19

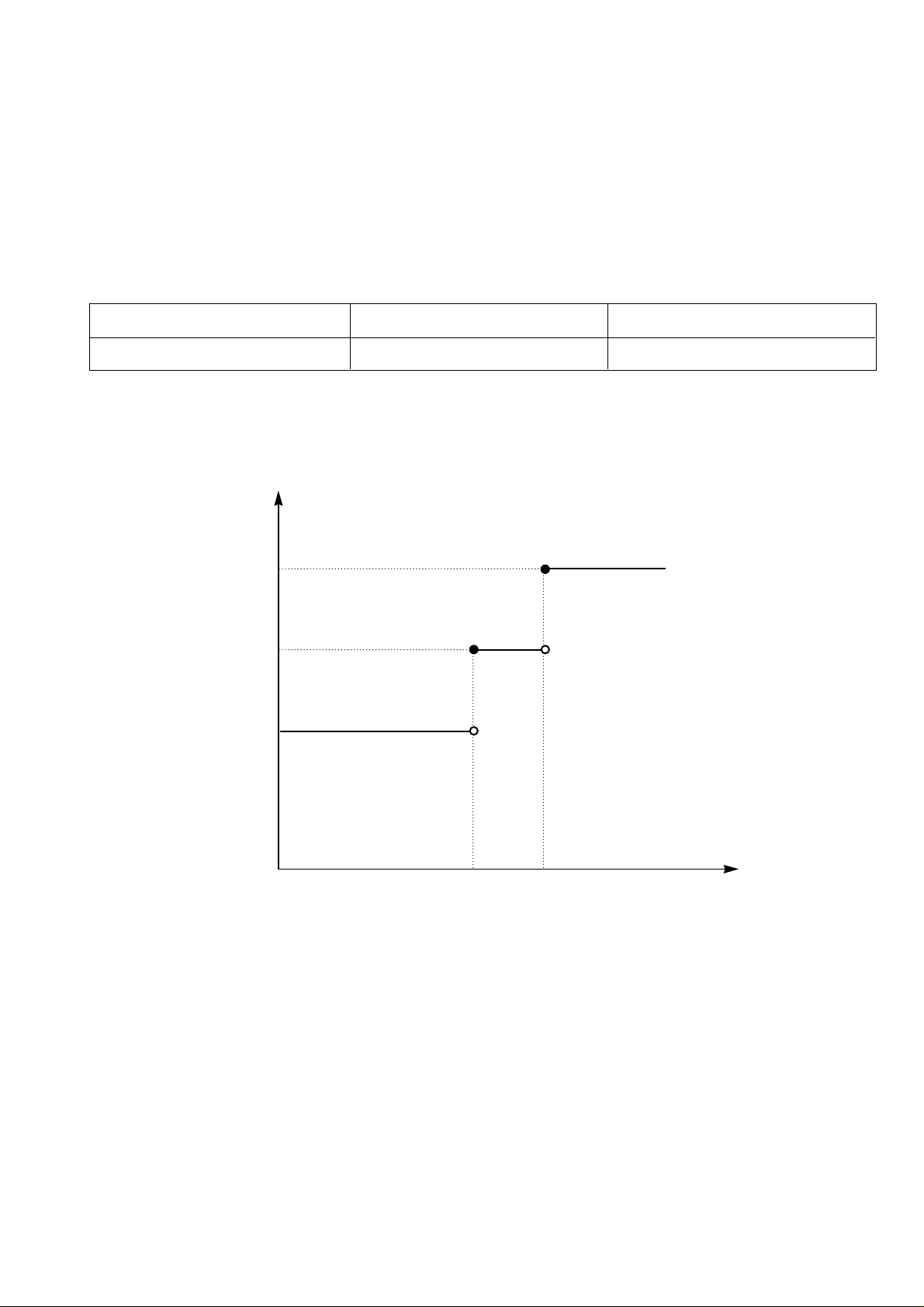

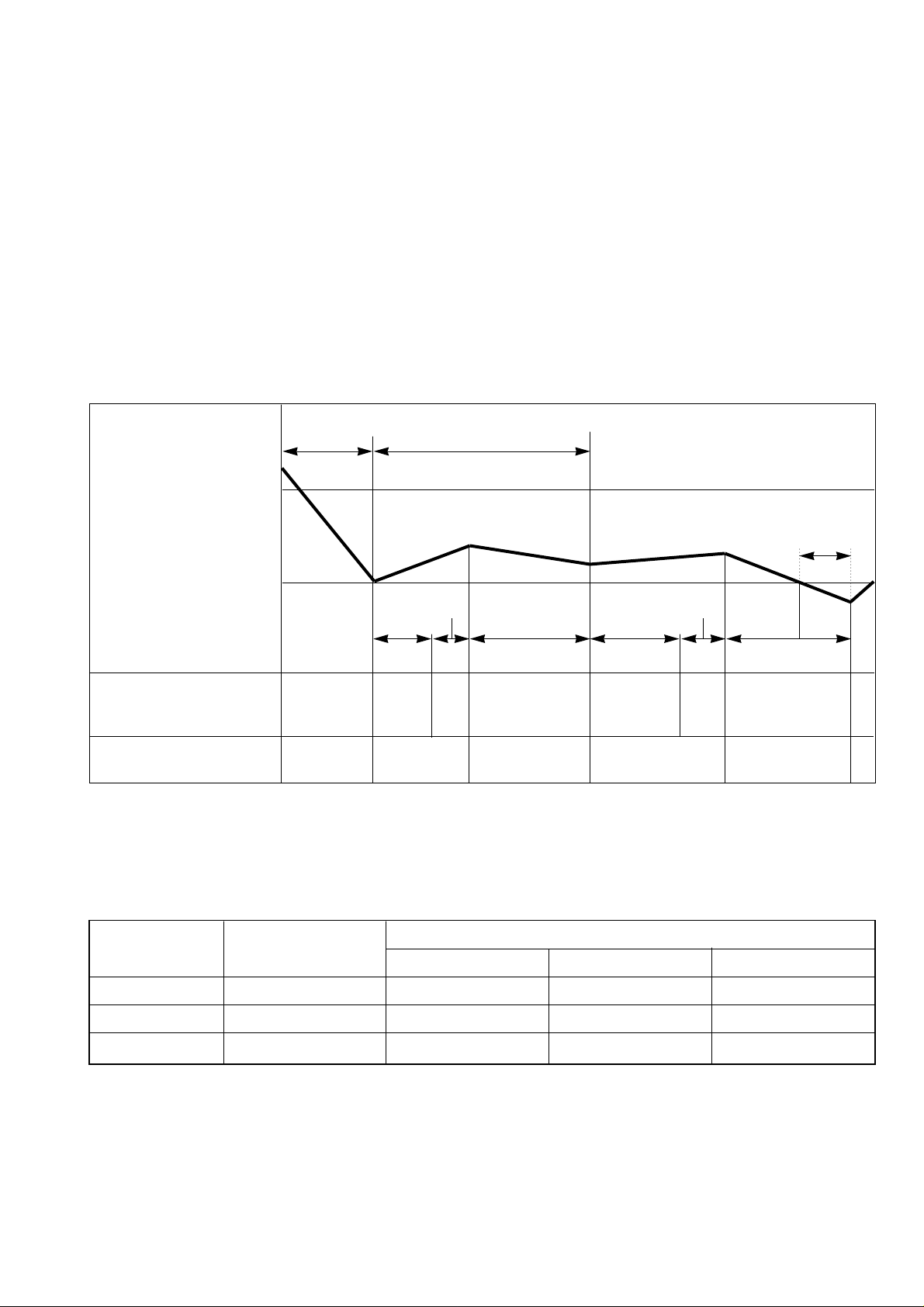

9. Deice Control

ƒU Deicing operation is controlled by timer and sensing the indoor pipe temperature.

ƒU Deicing operation checks the indoor pipe temperature and Intake-air temperature at 25 minutes and 60 min-

utes on starting of heating operation, and discriminates by temperature difference.

ƒU When the heating operation passed 25 minutes, the temperature (¡ T1=TE1–TR1) is checked and memorized

with checking the indoor pipe temperture (TE1) and the indoor Intake-air temperature (TR1).

ƒU When the heating operation passed 60 minutes, deicing operation checks the indoor pipe temperature (TE2)

and the indoor Intake-air temperature (TR2), and checks the temperature difference (¡ T2=TE2–TR2) and the

temperature difference ¡ Td(=¡ T1–¡ T2) of ¡ T1, ¡ T2.

If the temperature difference (¡ Td) become more than the option temperature, deicing operation starts.

ƒU At that time, deicing operation time is decided.

ƒU The deicing operation time stops after deicing operation started.

ƒU If deicing operation start, above heating operation time is reset, so if deicing operation is finished, the heating

operation time is recounted.

ƒU The deicinig time and the operation diagram are as following.

ƒ¡19ƒ¡

60 minutes

Heating

25 MINS

Heating

TE1

TR1

TE2

TR2

TR1

TE1

Heating

25 MINS

Deicing

Pipe Temp.

Intake Air

Temp.

T1

T2

T1

TEMP °C

INDOOR FAN

OUTDOOR FAN

COMPRESSOR

4WAY VALVE

ON

ON

ON

ON

OFF

OFF

ON

OFF

ON After HOT-START finished

ON

ON

ON

Td (=T1– T2) Over 3.5°C 3.0~3.5°C 2.5~3.0°C 2.0~2.5°C below 2.0°C

Deicing Time 12mins 11mins 10mins 9mins Heating Operation

Page 20

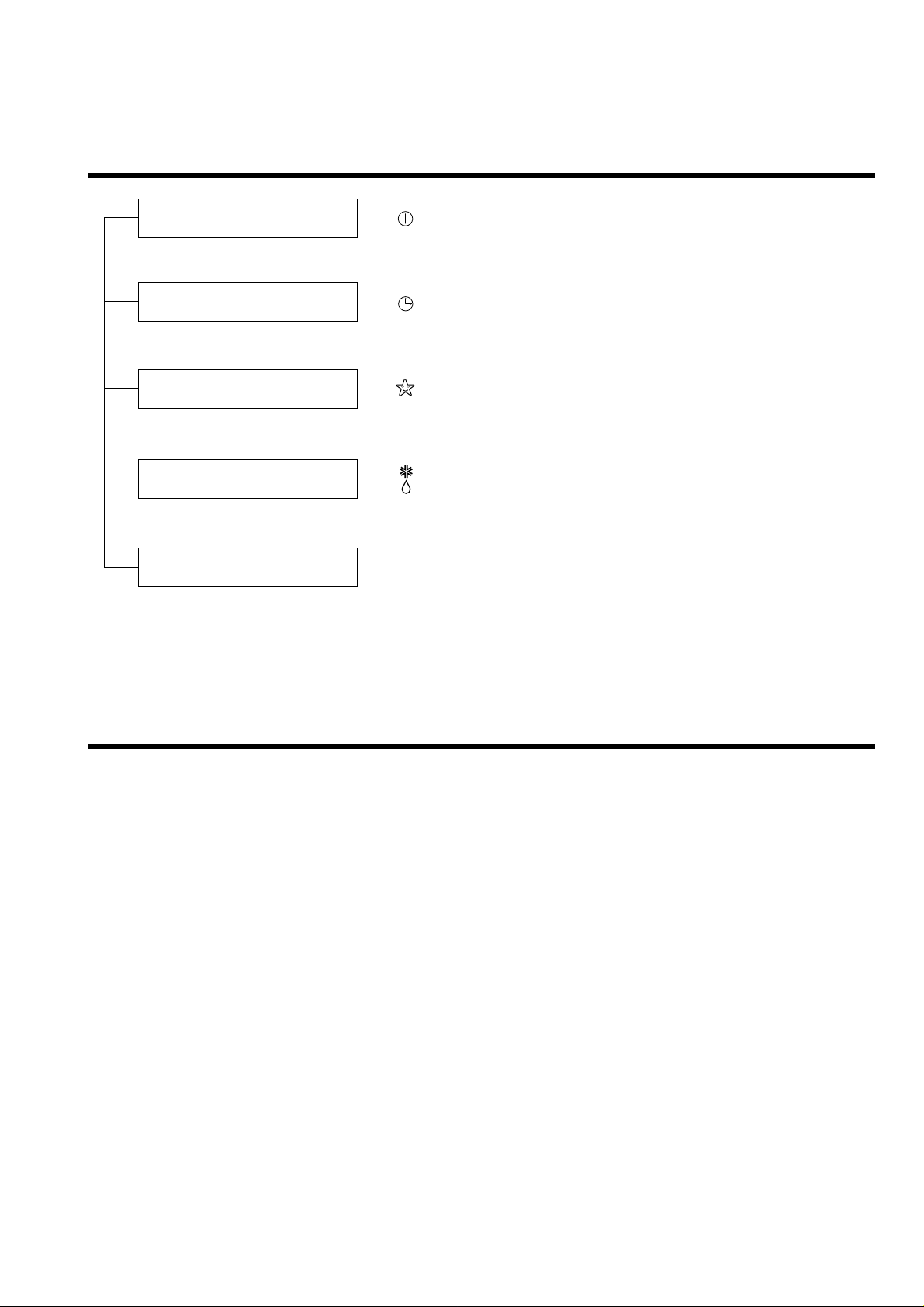

10. Soft Dry Operation.

ƒU During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 1¡ , the compres-

sor OFF temperature is the setting temperature minus 0.5¡

ƒU When the room temperature rises over the compressor ON temperature, the operation mode is switched to the

cooling mode.

ƒU When the room temperature falls between the compressor ON temperature and OFF temperature, the opera-

tion mode is switched to the Soft Dry Operation.

In this temperature range, 10min. Dry Operation, 5.5min operation OFF, 1.5min. only fan operation repeat. During 10min Dry operation, even if the room temperature falls below compressor OFF temperature, 10min(MAX)

Compressor ON from starting of Dry operation which includes 4 min. Compressor ON operation below the

comperssor OFF temperature.

ƒU In micom dehumidify mode, control of fan speed is as following.

11. Forced operation

ƒU If you lose wireless remote controller, you can operate the unit with forced operation switch.

ƒU The standand conditions are as following.

ƒ¡20ƒ¡

ROOM TEMP.

SETTING TEMP.+1°C

(COMP. ON)

SETTING TEMP.

(COMP. OFF)

INDOOR FAN OFF

LOW

LOW OFF LOW LOW

COMPRESSOR ON OFF ON OFF ON

Selecting

fan speed

2 minutes

5.5 minutes

maximum

4 minutes

1 minutes

1.5 minutes

10 minutes

maximum

10minutes

Operation

Cooling

Dry operation

Heat pump Model

Room Temp¡ˆ 24°C 21°C ¡´Room Temp£…24°C Room Temp £…21°C

Operation Mode Cooling Cooling Soft Dry Heating

FAN Speed High High Low High

Setting Temp. 24°C 24°C Room Temp. 22°C

Cooling Model

¢”

¢”

Page 21

Display Function

• Cooling, Soft Dry, Heating

• Timer Mode

• Sleep Mode

• Hot-start, Deice

Self-diagnosis Function

1. Protection of the evaporator pipe from frosting

If the temperature of the indoor pipe is below 0°C after 7 mins from starting the compressor, the compressor

and the outdoor fan is stopped, and then after 3 mins delay of the compressor and the temperature of the

indoor pipe is over 7°C, the compressor and the outdoor fan is reoperated.

2. Thermistor Cut Off or Short

Cut Off/Short : Blinks on and off the operation mode LED. (0.5 sec ON/3 sec OFF)

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Deice Indicator

: Heating Model only

Compressor On Indicator

: Cooling Model only OUTDOOR

ƒ¡21ƒ¡

Page 22

Installation

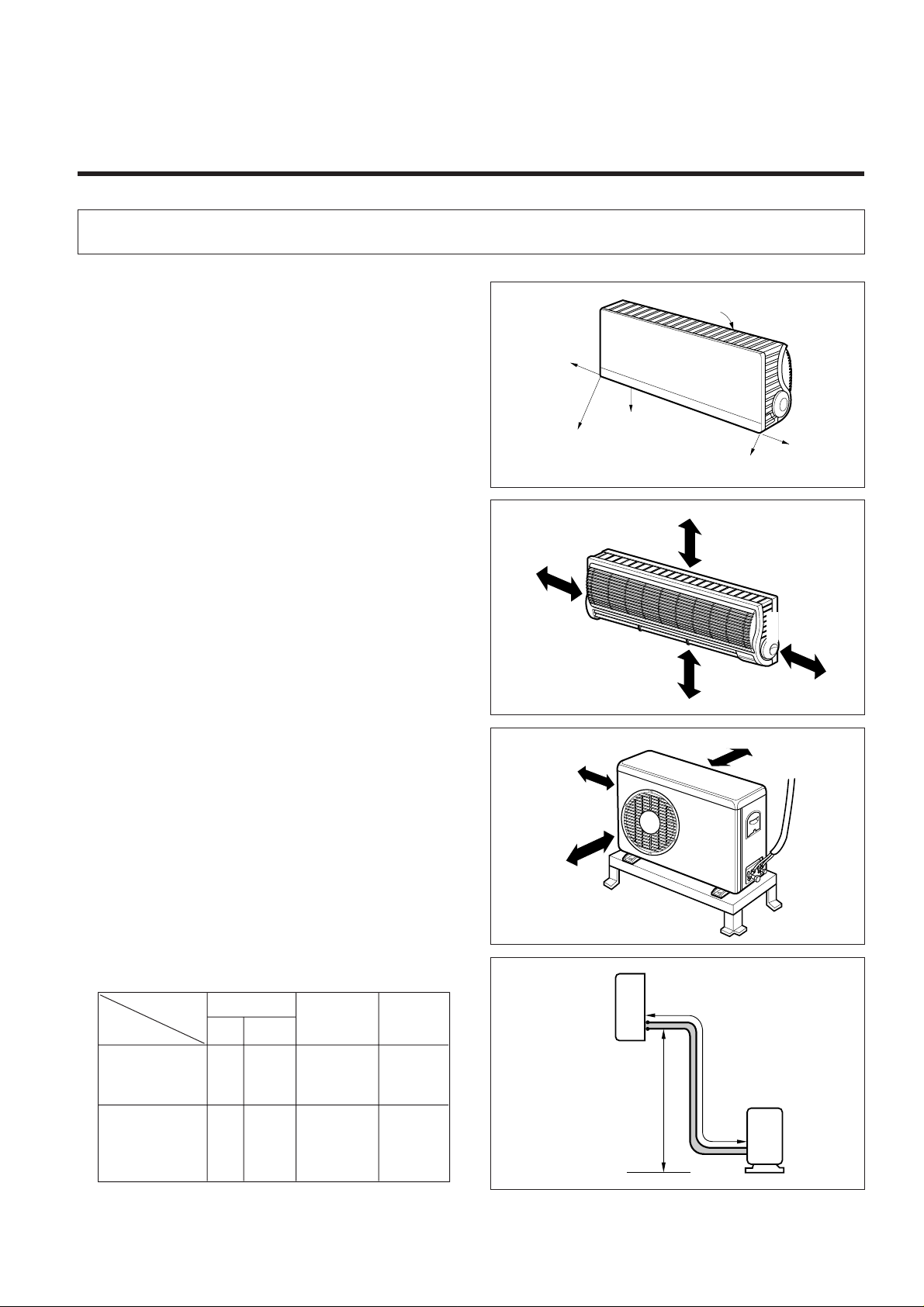

1) Selection of the best location

1. Indoor unit.

• There should not be any heat source or steam near

the unit.

• There should not be any obstacles to prevent the air

circulation.

• A place where air circulation in the room will be

good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the

wall, ceiling, fence, or other obstacles.

2. Outdoor unit.

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat radiation from the condenser is not restricted.

• There should not be any animals or plants which

could affected by hot air discharged.

• Ensure the spaces indicated by arrows from the

wall, ceiling, fence, or other obstacles.

3. Piping length and the elevation.

Ringt

Rear right

Down right

Rear left

left

Front

Pipe size Max. piping Max.

GAS LIQUID A(m) B(m)

3/8" 1/4" 7 5

1/2" 1/4" 7 5

1. Installation of indoor, Outdoor unit

ƒ¡22ƒ¡

LS-P0760CL/P0760HL

LS-P0820CL

LS-P0960CL/P0960HL

LS-S0960CL/S0960HL

LS-S1120CL

LS-S1260CL/S1260HL

LS-S1420CL/S1421CL

length elevation

More than

5cm

More than 5cm

More than

5cm

More than eye-level

More than

10cm

More than

70cm

Indoor unit

More than

10cm

A

B

Outdoor unit

Page 23

2) Indoor unit installation

The mounting wall should be strong and solid enough

to prevent it from the vibration.

1. Mount the installation plate on the wall with

four Type "A" screws.

• Always mount the installation plate horizontally by

aligning the marking-off line with using the thread

and a level.

LS-P0760CL/P0760HL, LS-P0820CL

LS-P0960CL/P0960HL

• To remove the installation plate, pull the two '¡ '

marked portion of bottom of chassis and pull the

installation plate out of chassis.

2. Drill the piping hole with 70mm dia. Hole-core

drill.

• Line according to the arrows marked on lower the

left and the right side of the installation plate.

The meeting point of the extended line is the center

of the hole.

• Drill the piping hole at either the right or the left and

the hole should be slightly slant to the outdoor side.

Installation Plate

Thread

Marking-off line

Weight

Type “A” screw

Left rear piping

ø70mm

ø70mm

50mm

20mm

20mm

80mm

LS-P0760CL/P0760HL, LS-P0820CL

LS-P0960CL/P0960HL

Right rear piping

WALL

5~7mm

Indoor Outdoor

LS-S0960CL/S0960HL, LS-S1120CL

LS-S1260CL/S1260HL, LS-S1420CL, LS-S1421CL

Left rear piping Right rear piping

Center Center

ø70mm ø70mm

The lower left and right side of installation Plate

ƒ¡23ƒ¡

££…… ££

æ

Page 24

1) Preparation of pipings

1. Cut the pipes and the cable.

• Use the accessory piping kit or the pipes purchased

locally.

• Measure the distance between the indoor and the

outdoor unit.

• Cut the pipes a little longer than measured distance.

• Cut the cable 1.5m longer than the length of pipe.

2. Remove burrs.

• Remove burrs from cut edges of pipes.

• Turn the pipe end toward down to avoid the metal

powder entering the pipe.

Caution:

If burrs are not removed, they may cause a gas leakage.

3. Flaring the pipes.

• Insert the flare nuts, mounted on the connection

ports of both indoor and outdoor unit, onto the copper pipes. Some refrigerant gas may leak, when the

flare nuts are removed from the indoor unit, as

some gas is charged to prevent the inside of the

pipe from rusting.

• Fit the copper pipe end into the Bar of flare tool

about 0.5~1.0mm higher. (See illustration).

• Flare the pipe ends.

4. Tape the flaring portion to protect it from the

dust or damages.

90°

Pipe cutter

Slanted Rough

"A";§j12.7mm(3/8")¡ 0.5mm

"A";§j9.52mm(

1

/2")¡ 1.0mm

"A";§j6.35mm(

1

/4")¡ 1.0mm

When properly flared, the internal surface flare

will evenly shine and be of even thickness. Since

the flare part comes into contact with the connectors, carefully check the flare finish.

= Improper flaring =

Inclined Surface

damaged

Cracked Uneven

thickness

2. Piping and Drainage of indoor unit

ƒ¡24ƒ¡

Pipe

Reamer

Point down

Bar

Copper pipe

Yoke

Bar

A

Handle

Cone

Page 25

2) Connection of pipings

(LS-S0960CL/S0960HL, LS-S1120CL, LS-S1260CL/S1260HL, LS-S1420CL, LS-S1421CL)

1. Remove the indoor tubing with Drain hose to the hole.

• Remove tubing holder and pull the tubing out of the chassis.

2. Refix the tubing holder into original position.

Tubing holder

Press1

Pull2

To remove the holder,

press the bottom of the

chassis near the holder

upwards and pull the tab

out of its hole.

For right rear piping

ƒ¡25ƒ¡

3. Route the tubing and the drain hose straight

backwards(see figure).

4. Insert the connecting cable into the indoor unit

through the piping hole.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection later.

5. Tape the tubing, drain hose and the connecting

cable.

Outdoor

Piping

Indoor

Connecting cable

Taping

Indoor/outdoor

connecting cable

Connecting

cable

Gas side piping

Liquid side piping

Drain hose

Page 26

6. Indoor unit installation.

• Hook the indoor unit onto the upper portion of installation plate. (Engage the two hooks of the rear top

of the indoor unit with the upper edge of the installation plate.)

Ensure the hooks are properly seated on the installation plate by moving it in left and right.

7. Connecting the pipings to the indoor unit

• Align the center of the pipings and sufficiently tighten the flare nut with fingers.

• Finally, tighten the flare nut with torque wrench until

the wrench clicks.

Wrench tightening the flare nut with forque wrench,

ensure the direction for tightening follows the arrows

on the wrench.

8. Wrap the insulation material around the con-

necting portion.

Connecting

cable

Drain hose

Press the lower left and right side of the unit

against the installation Plate until the hooks

engages with their slots(sound click).

Indoor unit tubing

Flare nut Pipings

Torque wrench

Spanner

Pipe Size Torque

Liquid Side(1/4") 1.8Kg¡⁄m

Gas Side(1/2") 5.5Kg¡⁄m

ƒ¡26ƒ¡

Plastic Bands Insulation material

Wrap the insulation material around the connecting portion.

Page 27

3. Route the indoor tubing with the drain

hose to the piping hole as desired

position.

Outdoor

Piping

Indoor

Connecting cable

ƒ¡27ƒ¡

Tubing holder

Press1

Pull2

To remove the holder,

press the bottom of the

chassis near the holder

upwards and pull the tab

out of its hole.

For the left pipings

4. Insert the pipings and the connecting cable

into the piping hole.

5. Insert the connecting cable into the indoor unit.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection later.

6. Tape the tubing, drain hose and the connecting

cable.

Taping

Indoor/outdoor

connecting cable

Connecting

cable

Gas side piping

Liquid side piping

Drain hose

Page 28

7. Indoor unit installation.

• Hook the indoor unit onto the upper portion of installation plate. (Engage the two hooks of the rear top

of the indoor unit with the upper edge of the installation plate.)

Ensure the hooks are properly seated on the installation plate by moving it in left and right.

8. Connecting the pipings to the indoor unit

• Align the center of the pipings and sufficiently tighten the flare nut with fingers.

• Finally, tighten the flare nut with torque wrench until

the wrench clicks.

Wrench tightening the flare nut with forque wrench,

ensure the direction for tightening follows the arrows

on the wrench.

9. Wrap the insulation material around the con-

necting portion.

Plastic Bands Insulation material

Wrap the insulation material around the connecting portion.

ƒ¡28ƒ¡

Connecting

cable

Drain hose

Press the lower left and right side of the unit

against the installation Plate until the hooks

engages with their slots(sound click).

Indoor unit tubing

Flare nut Pipings

Torque wrench

Spanner

Pipe Size Torque

Liquid Side(1/4") 1.8Kg¡⁄m

Gas Side(1/2") 5.5Kg¡⁄m

Gas Side(5/8") 6.5Kg¡⁄m

Page 29

10.Set the pipings and the connecting cable to the

back of the chassis with the tubing holder.

11. Indoor unit installation.

• Hook the indoor unit onto the upper portion of installation plate. (Engage the two hooks of the rear top

of the indoor unit with the upper edge of the installation plate.)

Ensure the hooks are properly seated on the installation plate by moving it in left and right.

Tubing holder

Taping

Piping

Drain hose

Hook

1

Push

2

Press the lower left and right side of the unit

against the installation Plate until the hooks

engages with their slots(sound click).

ƒ¡29ƒ¡

Connecting

cable

Drain hose

Page 30

2) Connection of Pipings

1. Remove the installation plate

• Pull the two '¡' marked portion of bottom of the chassis and pull the installation plate out of chassis.

2. Route the drain hose and the indoor tubing.

3. Insert the pipings, the connecting cables and

the drain pipe throught the piping hole on the

wall.

4. Connect the pipings and the indoor tubing, and

drain hose and drain pipe.

• Don't connect the cable to the indoor unit.

• Wrap the insulation material around the connecting

portion.

• Glue up the connection portion of drain hose and

drain pipe.

ƒ¡30ƒ¡

For right rear piping

Pipe Size Torque

Liquid Side (1/4") 1.8kg·m

Gas Side (3/8") 4.2kg·m

(LS-P0760CL/P0760HL, LS-P0820CL, LS-P0960CL/P0960HL)

Installation plate

pull

pull

Outdoor

Piping

Indoor

Connecting cable & Drain pipe

Indoor unit tubing

Spanner

Plastic Bands Insulation material

Drain Hose

Flare nut Pipings

Torque wrench

Drain Pipe

Adhevsive

Page 31

ƒ¡31ƒ¡

5. Bend the tubing as shown in the figure and

bind the pipings, the connecting cables and the

drain hose altogether.

• Make a small loop for easy connection later.

6. Wrap the tubing, the drain hose and the connecting cable

7. Indoor unit installation

• Hook the indoor unit onto the upper position of installation plate. (Engage the two hooks of the rear top of

the indoor unit with the upper edge of the installation

plate.)

Insure the hooks are properly seated on the installation plate by moving it in left and right.

CAUTION : Take care to arrange the pipings, drain

hose and cables as the feature 6 page for

inserting it into the indoor unit and mount

the indoor unit on the installation plate.

Connecting cable

Drain hose

Press the lower left and right side of the unit

against the Installation Plate until the hooks

engages with their slots (sound click).

Gas side piping

Liquid side piping

Drain hose

Connecting

cable

Loop

Tape

Page 32

ƒ¡32ƒ¡

3. Insert the connecting cables, the drain pipe

and connecting pipings throught the piping

hole on the wall.

4. Connect connecting pipings and indoor tubing,

and the drain hose and the drain pipe and

place the drain pipe into the chassis.

• Don't connect the cableto the indoor unit.

• Make a small loop for easy connection later.

• Glue up the connection portion of drain hose and

drain pipe.

5. Bend the drain hose as shown in the figure and

bind the drain hose, the pipings and the connecting cables altogether.

Outdoor

Indoor

Connecting Cable

Drain Pipe

Drain Hose

Connecting Piping

For left rear pipings

Pipe Size Torque

Liquid Side (1/4") 1.8kg·m

Gas Side (3/8") 4.2kg·m

Indoor unit tubing

Flare nut Pipings

Spanner

Drain Hose

Torque wrench

Drain Pipe

Adhevsive

Loop

Page 33

ƒ¡33ƒ¡

6. Wrap the insulation material around the connecting portion.

CAUTION : Take care to arrange the pipings, drain

hose and cables as the feature 6 page for

inserting it into the indoor unit and mount

the indoor unit on the installation plate.

7. Wrap the tubing, the drain hose and the connecting cable with tape.

8. Indoor unit installation

• Hook the indoor unit onto the upper position of installation plate. (Engage the two hooks of the rear top of

the indoor unit with the upper edge of the installation

plate.)

Insure the hooks are properly seated on the installation plate by moving it in left and right.

Indoor/outdoor

connecting cable

Taping

Gas side piping

Liquid side piping

Drain hose

Connecting

cable

Press the lower left and right side of the unit

against the Installation Plate until the hooks

engages with their slots (sound click).

Plastic Bands Insulation material

Wrap the insulation material around the connecting portion.

Connecting cable

Drain hose

Page 34

1) Connecting the piping to the Oudoor

unit.

1. Align the center of the pipings and sufficiently

tighten the flare nut with fingers.

2. Finally, tighten the flare nut with torque wrench

until the wrench clicks.

• When tightening the flare nut with touque wrench,

ensure the direction for tightening follows the arrow

on the wrench.

2) Connecting of the cable

1. Remove the cover control from the unit by

lossening the screw.

Connect the wires to the terminals onthe con-

trol board individually as the following.

1) Cooling only type

2. Secure the cable onto the control board with

the holder (clamper).

3. Refix the cover control to the original position

with the screw.

ƒNThe connecting cable for installation of indoor and

outdoor unit must be approved by TüV standard or

equivalent.

Pipe Size Torque

Liquid Side(1/4") 1.8Kg¡⁄m

Gas Side(3/8") 4.2Kg¡⁄m

Gas Side(1/2") 5.5Kg¡⁄m

Outdoor unit

Liquid side piping

(Smaller Dia)

Gas side

piping

(Bigger Dia)

Torque wrench

Terminal block

(Pillar terminal)

Outdoor unit

Over 5mm

Holder for

connecting

cable

Connecting

cable

Cover control

BROWN BLUE

GREEN/YELLOW

1(L) 2(N)

BLACK GRAY

1(L) 2(N) 3 4

BLACK GRAY

BROWN BLUE G/Y BLACK RED

Terminals on the outdoor unit

Terminals on the indoor unit

Terminals on the outdoor unit

1(L) 2(N)

1(L) 2(N) 3 4

Terminals on the indoor unit

BROWN BLUE G/Y BLACK RED

Color of Wires

2) Cooling & Heating type

Color of Wires

Color of Wires

3. Connecting Pipings and the cable to Outdoor unit

ƒ¡34ƒ¡

Page 35

1) Checking the Drainage

1. Remove the Grille from the cabinet.

• Set the up-and-down air direction louver to open

position(horizontally) by finger pressure.

• Remove the screw caps and the securing screws.

• To remove the Grille, pull lower the left and right

side of the grille toward you (slightly tilted) and lift it

straight upward.

2. Check the drainage.

• Pour a glass of water on the evaporator.

• Ensure if water flows drain hose of indoor unit.

Pull the right and the left side.

Screw

Screw cap

Evaporator

4. Checking the Drainage and Connecting the cable to Indoor unit

ƒ¡35ƒ¡

Page 36

2) Connect the cable to the indoor unit

1. Connect the wires to the terminals on the con-

trol board individually according to the outdoor

unit connection.

• Ensure the color of wires of outdoor unit and the ter-

minal No.s are the same to the indoor's respectively.

1) Cooling only type

• Secure the cable onto the control board with the

holder(clamper).

2. Attach the Grille onto the cabinet

• Grasp lower the left and right side of the Grille and

engage two tabs on the top in side edge of the grille

with two slots on the cabinet's top front edge.

• press the grille toward the cabinet until it will be

back into place.

• Secure the grille to the cabinet with two screws.

Connecting

cable

ƒ¡36ƒ¡

BROWN BLUE

GREEN/YELLOW

1(L) 2(N)

BLACK GRAY

1(L) 2(N) 3 4

BLACK GRAY

BROWN BLUE G/Y BLACK RED

Terminals on the outdoor unit

Terminals on the indoor unit

Terminals on the outdoor unit

1(L) 2(N)

1(L) 2(N) 3 4

Terminals on the indoor unit

BROWN BLUE G/Y BLACK RED

Color of Wires

2) Cooling & Heating type

Color of Wires

Color of Wires

Page 37

3) Form the pipings

1. Wrap the connecting portion of indoor unit with

the lnsulation material and secure it with two

plastic Bands (for the right pipings).

• If you want to connect an additional drain hose, the

end of the drain-outlet should keep distance from

the ground.(Do not dip it into water, and fix it on the

wall to avoid swinging in the wind.)

2. Tape the pipings, drain hose and Connecting

Cable from down to up.

3. Form the pipings gathered by taping along the

exterior wall and fix it onto the wall by saddle

or equivalent.

2. Tape the pipings and Connecting Cable from

down to up.

3. Form the pipings gathered by taping along the

exterior wall and the Trap is required to prevent

the room from entering the water.

4. Fix the pipings onto the wall by saddle or

equivalent.

Seal a small opening

around the pipings with

aum type sealer.

Taping

Drain

hose

Pipings

Connecting

cable

Plastic Band

Trap is required to prevent the electrical

parts from entering the water.

In case of the Oudoor unit to be installed

below the Indoor unit

In case of the Outdoor unit to be installed

upper position of the Indoor unit

ƒ¡37ƒ¡

Seal a small opening

around the pipings with

gum type sealer.

Trap

Page 38

1) Air purging

The air which contains a moisture is remaining in the

refrigeration cycle may cause a malfunction on the

compressor.

1. Remove the caps from the 2-way and 3-way

valves.

2. Remove the service-port cap from the 3-way valve.

3. To open the valve, turn the valve stem of 2-way

valve counter-clockwise approx. 90° and hold it

there for five seconds, then close it.

4. Check a gas-leakage of the connection portion of

the pipings.

• For the left pipings, refer page 26.

• For more details, refer page 45(2-way 3-way valve).

ƒNCAUTION:

Do not leak the gas in the air during Air purging

with vacumm pump as possible as you can.

2-way valve

(Open)

3-way valve

(Close)

Terminal block

(pillar terminal)

Cover control

To indoor unit

Liquid side

Gas side

Cap

Hexagonal wrench

Service port cap

5. To open 2-way valve again, turn the valve stem

counter-clockwise until it stops.

6. To purge the air, push the pin on the service port

of 3-way valve for three seconds with a hexagonal

wrench and set it free for one minute.

ƒU Repeat the operation three times.

ƒU Re-tighten the connecting portion with wrench.

No leakage found

Result

leakage found

leakage ceased

leakage ceased

leakage persists

¤

¤

¤

¤

Repair

5. Air Purging

ƒ¡38ƒ¡

7. Set the both 2-way and 3-way valves to open position with the hexagonal wrench for the unit operation.

Page 39

8. Checking a gas leakage.

(1)Connect the manifold gauge to the service port of

3-way valve.

Measure the pressure.

(2)Keep it for 5-10 minutes.

Ensure if the pressure indicated on the gauge is

as same as that of measured at first time.

Chiuso

Indoor unit

Liquid side

Closed

Closed

CLOSE

CLOSE

Outdoor unit

Gas side

NOTE:

The additional gas for air purging has been charged in the outdoor unit.

However, if the flare connections have not been done correctly and there gas leaks, a gas cylinder and the

charge set will be needed.

ƒNCAUTION:

Do not leak the gas in the air during Air purging with vacumm pump as possible as you can.

ƒ¡39ƒ¡

Page 40

1) Connection of power supply

1. Connect the power supply cord to independent

power supply.

2. Prepare the remote control.

• Insert two batteries provided.

Remove the cover from the back of the remote control.

• Slide the cover according to the arrow directon.

• Insert the two batteries.

(Two "R03" or "AAA" dry-cell batteries or equivalent).

• Be sure that the (+) and (-) directions are correct.

• Be sure that both batteries are new.

Re-attach the cover.

• Slide it back into position.

3. Operate the unit at cooling operation mode for

fitteen minutes or more.

• Anchor the outdoor unit with a bolt and nut (ø10cm)

tightly and horizontally on a concrete or rigid mount.

• When installing on the wall, roof or rooftop, anchor

the mounting base securely with a nail or wire

assuming the influence of wind and earthquake.

• In the case when the vibration of the unit is con-

veyed to the house, settle the unit with an antivibration rubber.

2) Evaluation of the performance

1. Measure the temperature of the intake and discharge air.

2. Ensure the difference between the intake temperature and the discharge one is more than

8°C.

Tubing connection

discharge air

Settlement of Outdoor Unit

6. Test running

ƒ¡40ƒ¡

Page 41

Operation

(1) Name and Function-Remote Control (Cooling Models)

Signal transmitter.

Transmits the signals

to the room air conditioner.

ƒ¡41ƒ¡

Remote Controller

1

2

6

7

10

11

13

14

12

9

3

4

5

8

TIME TIME

ON OFF

a.m.

p.m.

a.m.

p.m.

Hr.

ON

OFF

SET

CANCEL

RESET

ROOM AIR CONDITIONER

REMOTE CONTROL

15

CHAO

S

°

C

L

H

⁄A Operation Display

Displays the operation conditions.

⁄B Start/Stop Button

Operation start when this button is pressed, and

stops when the button is pressed again.

⁄C Operation Mode Selection Button

Used to select the type of operation mode.

ƒUCooling Operation Mode.

ƒUSoft Dry Operation Mode.

ƒUAuto Operation Mode.

⁄D Sleep Mode Auto Button

For Sleep Mode Auto Operation.

⁄E ON Timer Button

Used to set the time of starting operation.

⁄F Timer Set Button

Press to set the timer operation.

⁄G Timer CANCEL Button

Press to cancel the timer operation.

⁄H Indoor Fan Speed Selector

⁄I OFF Timer Button

Used to set the time of stopping operation.

⁄J Time Setting Button

⁄K Room Temperature Setting Button

Used to adjust the temperature.

⁄L Room Temperature

⁄M Airflow Direction Control Button

Press to set the desired airflow direction.

⁄N Reset Button

⁄O Fan Operation Button.

Used to operate the indoor fan only.

Page 42

(2) Name and Function-Remote Control (Heat Pump Models)

Signal transmitter.

Transmits the signals

to the room air conditioner.

ƒ¡42ƒ¡

Remote Controller

⁄A Operation Display

Displays the operation conditions.

⁄B Start/Stop Button

Operation start when this button is pressed, and

stops when the button is pressed again.

⁄C Operation Mode Selection Button

Used to select the type of operation mode.

ƒUCooling Operation Mode.

ƒUSoft Dry Operation Mode.

ƒUHeating Operation Mode.

ƒUAuto Operation Mode.

⁄D Sleep Mode Auto Button

For Sleep Mode Auto Operation.

⁄E ON Timer Button

Used to set the time of starting operation.

⁄F Timer Set Button

Press to set the timer operation.

⁄G Timer CANCEL Button

Press to cancel the timer operation.

⁄H Indoor Fan Speed Selector

⁄I OFF Timer Button

Used to set the time of stopping operation.

⁄J Time Setting Button

⁄K Room Temperature Setting Button

Used to adjust the temperature.

⁄L Room Temperature

⁄M Airflow Direction Control Button

Press to set the desired airflow direction.

⁄N Reset Button

CHAO

TIME TIME

ON OFF

a.m.

p.m.

8

5

ON

4

3

OFF

9

S

H

L

°

C

a.m.

p.m.

Hr.

1

2

SET

CANCEL

6

7

10

11

12

14

RESET

ROOM AIR CONDITIONER

REMOTE CONTROL

13

Page 43

Disassembly of the parts (Indoor unit)

Warning :

Disconnect the unit from power supply before making

any checks.

Be sure the power switch is set to “OFF”.

To remove the Grille from the Chassis.

• Set the up-and-down air discharge louver to open

position (horizontally) by finger pressure.

• Open the screw caps upward and remove the

securing screws.

• To remove the Grille, pull the lower left and right

side of the grille toward you (Slightly tilted) and lift it

straight upward.

1. To remove the sensor, housing connect, earth

conductor & step motor conductor with sensor

holder, Motor, Evaporator & P.C.B.

Up-and-down air direction louver

Screw

Screw cap

ƒ¡43ƒ¡

Page 44

2. To remove the Control Box.

• Remove 2 or 4 securing screws.

• Pull the control box out from the chassis

carefully.

3. To remove the Discharge Grille.

• Remove the securing screw.

• Pull the discharge grille out from the chassis

carefully.

4. To remove the Evaporator.

ƒ¡44ƒ¡

Page 45

• Unhook the tab on the left inside edge of the

chassis by pressing it outwards and at the same

time, slightly pull the evaporator until the tab is

clear of the end-plate.

• Remove the evaporator from the chassis

carefully.

• Unhook the tab on the right inside of the chassis

at the same time, slightly pull the evaporator

toward you until the tab is clear of the slot.

5. To remove the Cross-Flow Fan.

• Loosen the screw securing the cross-flow fan to

the fan motor (do not remove).

• Pull the left end of the cros-flow fan with the selfaligning bearing out the groove.

• Remove the cross-flow fan by sliding it out from

the shaft of fan motor.

6. To remove the Fan Motor.

• Pick it up from the groove. (Do not remove a

black rubber as a spacer).

Tab

Pull

Evaporator

End Plate

evaporator

Evaporator

Pull

Tab

Fan motor

Screw

Cross-flow fan

Cross-flow fan

Bearing

ƒ¡45ƒ¡

Page 46

2-way, 3-way Valve

2-way Valve (Liquid Side) 3-way Valve (Gas Side)

Shaft position Shaft position Service port

Closed Closed Closed

(with valve cap) (with valve cap) (with cap)

Open Closed Open

(counter-clockwise) (clockwise) (push-pin or with

vacumm pump)

Open Open Closed

(with valve cap) (with valve cap) (with cap)

Closed Open Open

(clockwise) (counter-clockwise) (connected manifold

gauge)

Open Open Open

(with charging

cylinder)

Open Open Open

(with charging

cylinder)

Open Open "

Open Open "

Works

Shipping

Air purging

(Installation)

Operation

Pumping down

(Transfering)

Evacuation

(Servicing)

Gas charging

(Servicing)

Pressure check

(Servicing)

Gas releasing

(Servicing)

1.

2.

3.

4.

5.

6.

Valve cap

Open position

Closed position

Pin

Service

port

Service

port cap

To outdoor unit

Flare nut

To

piping

connection

To outdoor unit

Hexagonal wrench (4mm)

Open position

Closed position

To

piping

connection

Flare nut

ƒ¡46ƒ¡

Page 47

1. Air purging

Required tools : hexagonal wrench, adjustable

wrench, torque wrenches, wrench to

hold the joints, and gas leak

detector.

The additional gas for air purging has been charged

in the outdoor unit.

However, if the flare connections have not been done

correctly and there gas leaks, a gas cylinder and the

charge set will be needed.

The air in the indoor unit and in the piping must be

purged. If air remains in the refrigeration pipes, it will

affect the compressor, reduce to cooling capacity, and

could lead to a malfunction.

• Procedure

(1) Recheck the piping connections.

(2) Open the valve stem of the 2-way valve

counterclockwise approximately 90°, wait 10

seconds, and then set it to closed position.

– Be sure to use a hexagonal wrench to operate

the valve stem.

(3) Check for gas leakage.

– Check the flare connections for gas leakage.

(4) Purge the air from the system.

– Set the 2-way valve to the open position and

remove the cap from the 3-way valve’s service

port.

– Using the hexagonal wrench to press the valve

core pin, discharge for three seconds and then

wait for one minute. Repeat this three times.

(5) Use torque wrench to tighten the service port

nut to a torque of 1.8kg.cm.

(6) Set the 3-way valve to the back seat.

(7) Mount the valve stem nuts to the 2-way and 3-

way valves.

(8) Check for gas leakage.

– At this time, especially check for gas leakage

from the 2-way and 3-way valve’s stem nuts,

and from the service port nut.

Caution

If gas leakage are discovered in step (3) above,

take the following mesures :

If the gas leaks stop when the piping connections

are tightened further, continue working from step (4).

If the gas leaks do not stop when the connections

are retightened, repair the location of the leak,

discharge all of the gas through the service port,

and then recharge with the specified amount of

gas from a gas cylinder.

Service port unt.

Be sure, using a torque wrench to tighten the service port nut (after using the service port), so that it prevents the

gas leakage from the refrigeration cycle.

* CAUTION : Do not leak the gas in the air during Air purging.

Liquid side

Outdoor unit

3-way

valve

Gas side

Indoor unit

2-way

valve

Open

Clsed

ƒ¡47ƒ¡

Page 48

2. Pumping down

• Procedure

(1) Confirm that both the 2-way and 3-way valves

are set to the open position.

– Remove the valve stem caps and confirm that

the valve stems are in the raised position.

– Be sure to use a hexagonal wrench to operate

the valve stems.

(2) Operate the unit for 10 to 15 minutes.

(3) Stop operation and wait for 3 minutes, then

connect the charge set to the service port of

the 3-way valve.

– Connect the charge hose with the push pin to

the service port.

(4) Air purging of the charge hose.

– Open the low-pressure valve on the charge set

slightly to air purge from the charge hose.

(5) Set the 2-way valve to the closed position.

(6) Operate the air conditioner at the cooling

cycle and stop it when the gauge indicates

1kg/cm2g.

(7) Immediately set the 3-way valve to the closed

position.

– Do this quickly so that the gauge ends up

indicating 3 to 5kg/cm2g.

(8) Disconnect the charge set, and mount the 2-

way and 3-way valve’s stem nuts and the

service port nut.

– Use torque wrench to tighten the service port

nut to a torque of 1.8 kg.m.

– Be sure to check for gas leakage.

Lo

Closed

Purge the air

Outdoor unit

Indoor unit

Liquid side

Gas side

CLOSE

Open

2-Way

valve

3-Way

valve

CLOSE

ƒ¡48ƒ¡

Page 49

1) Re-air purging

(Re-installation)

• Procedure

(1) Confirm that both the 2-way valve and the 3-

way valve are set to the closed position.

(2) Connect the charge set and a gas cylinder to

the service port of the 3-way valve.

– Leave the valve on the gas cylinder closed.

(3) Air purging.

– Open the valves on the gas cylinder and the

charge set. Purge the air by loosening the flare

nut on the 2-way valve approximately 45° for 3

seconds then closing it for 1 minute; repeat 3

times.

– After purging the air, use a torque wrench to

tighten the flare nut on the 2-way valve.

(4) Check for gas leakage.

– Check the flare connections for gas leakage.

(5) Discharge the refrigerant.

– Close the valve on the gas cylinder and

discharge the refrigerant until the gauge

indicates 3 to 5 kg/cm2g.

(6) Disconnect the charge set and the gas

cylinder, and set the 2-way and 3-way valves

to the open position.

– Be sure to use a hexagonal wrench to operate

the valve stems.

(7) Mount the valve stem nuts and the service

port nut.

– Use torque wrench to tighten the service port

nut to a torque of 1.8 kg.m.

– Be sure to check for gas leakage.

* CAUTION:

Do not leak the gas in the air during Air

Purging.

Lo

Closed

OPEN

Closed

Gas cylinder

R22

Outdoor unit

Indoor unit

Liquid side

Gas side

CLOSE

2-Way

valve

3-Way

valve

ƒ¡49ƒ¡

Page 50

2) Balance refrigerant of the 2-way, 3-way valves

(Gas leakage)

• Procedure

(1) Confirm that both the 2-way and 3-way valves

are set to the back seat.

(2) Connect the charge set to the 3-way valve’s

port.

– Leave the valve on the charge set closed.

– Connect the charge hose with the push pin to

the service port.

(3) Open the valve (Lo side) on the charge set

and discharge the refrigerant until the gauge

indicates 0 kg/cm2G.

– If there is no air in the refrigerant cycle (the

pressure when the air conditioner is not

running is higher than 1 kg/cm2G), discharge

the refrigerant until the gauge indicates 0.5 to 1

kg/cm2G. if this is the case, it will not be

necessary to apply a evacuatin.

– Discharge the refrigerant gradually; if it is

discharged too suddenly, the refrigeration oil

will also be discharged.

Lo

Open

Open

3-Way

valve

2-Way

valve

Gas side

CLOSEOPEN

Outdoor unit

Liquid side

Indoor unit

ƒ¡50ƒ¡

Page 51

3. Evacuation

(All amount of refrigerant leaked)

• Procedure

(1) Connect the vacuum pump to the charge set’s

center hose

(2) Evacuation for approximately one hour.

– Confirm that the gauge needle has moved

toward -76 cmHg (vacuum of 4 mmHg or less).

(3) Close the valve (Lo side) on the charge set,

turn off the vacuum pump, and confirm that

the gauge needle does not move (approximately 5 minutes after turning off the vacuum

pump).

(4) Disconnect the charge hose from the vacuum

pump.

– Vacuum pump oil.

If the vacuum pump oil becomes dirty or

depleted, replenish as needed.

Lo

Open

Open

Vacuum pump

2-Way

valve

Outdoor unit

Liquid side

Indoor unit

Gas side

3-Way

valve

CLOSE

OPEN

ƒ¡51ƒ¡

Page 52

4. Gas Charging

(After Evacuation)

• Procedure

(1) Connect the charge hose to the charging

cylinder.

– Connect the charge hose which you dis-

connected from the vacuum pump to the valve

at the bottom of the cylinder.

– If you are using a gas cylinder, also use a scale

and revers the cylinder so that the system can

be charged with liquid.

(2) Purge the air from the charge hose.

– Open the valve at the bottom of the cylinder

and press the check valve on the charge set to

purge the air. (Be careful of the liquid

refrigerant). The procedure is the same if

using a gas cylinder.

(3) Open the valve (Lo side on the charge set and

charge the system with liquid refrigerant.

– If the system can not be charged with the

specified amount of refrigerant, it can be

charged with a little at a time (approximately

150g each time) while operating the air

conditioner in the cooling cycle; however, one

time is not sufficient, wait approximately 1

minute and then repeat the procedure

(pumping down-pin).

(4) Immediately disconnect the charge hose from

the 3-way valve’s service port.

– Stopping partway will allow the gas to be

discharged.

– If the system has been charged with liquid

refrigerant while operating the air conditioner

turn off the air conditioner before disconnecting

the hose.

(5) Mount the valve stem nuts and the service

port nut.

– Use torque wrench to tighten the service port

nut to a torque of 1.8 kg.m.

– Be sure to check for gas leakage.

\

This is different from previous procedures.

Because you are charging with liquid refrigerant

from the gas side, absolutely do not attempt to

charge with larger amounts of liquid refrigerant

while operating the air conditioner.

ƒ¡52ƒ¡

Charging

cylinder

Indoor unit

Check valve

(1)

OPEN

Lo

Liquid side

Gas side

CLOSE

2-Way

valve

3-Way

valve

Open

Open

Outdoor unit

Page 53

Cycle Trouble Shooting Guide

Trouble analysis

1. Check temperature difference between intake and discharge air and operating current.

Temp. Difference

Temp. difference : approx. 0°C

Current : less than 80% of

rated current

Temp. difference : approx. 8°C

Current : less than 80% of

rated current

Temp. difference : less than 8°C

Current : over the reated

current

Temp. difference : over 8°C

Operating Current

All amount of refrigerant leaked out

Check refrigeration cycle

Refrigerant leakege

Clog of refrigeration cycle

Defective compressor

Excessive amount of refrigerant

Normal

Notice :

Temperature difference between intake and discharge air depends on room air humidity. When the room air

humidity is relativery higher, temperature difference is smaller. When the room air humidity is relatively lower

temperature difference is larger.

2. Check temperature and pressure of refrigeration cycle.

Notice :

1. The suction pressure is usually 4.5~6.0 kg/cm2G at normal condition.

2. The temperature can be measured by attaching the thermometer to the low pressure tubing and wrap it with

putty.

Suction pressure Temperature

(Compared with (Compared with Cause of Trouble Description

the normal value) the normal valve)

Defective compressor Current is low

Defective 4-way reverse valve

Excessive amount of High pressure does not quickly

Normal refrigerant rise at the beginning of

operation

Insufficient amount of Current is low

Lower Higher refrigerant (Leakage)

Clogging Current is low

High

Higher

ƒ¡53ƒ¡

Page 54

Electronic Parts Trouble Shooting Guide

: The unit does not operate

Possible Trouble 1

ƒ¡54ƒ¡

YES

YES

YES

NO

YES

Is the trans input power

AC240V?

Is the trans output power

about AC14V?

Is output voltage of IC2

DC12V?

Check the fuse, check

the wiring diagram.

Is output voltage of

IC3 DC5V?

Is the reset circuit

all right?

Exchange Main P.C.B ASM

YES

NO

Check the main P.C.B

patten.

NO

Exchange IC2

NO

Exchange IC 3

NO

Check and exchange IC4

YES

Exchange the trans.

Is shorted the

trans output?

NO

Page 55

Possible Trouble 2

: Fan dose not operate

ƒ¡55ƒ¡

NO

YES

YES

NO

Is it the DRY Mode?

Is it the HOT Mode?

Is the IC8 O.K?

Check the FAN Motor and

Connector (CN-AC/DC)

Check the SSR-L, M, H

YES

Is the each SSR

all right?

YES

NO

NO

Adjust setting temp

Does the temperature

set all right?

NO

Adjust setting temp

Does the temperature

set all right?

NO

YES

Check the FAN Motor

and Connector

Does the deice

LED 4 light?

NO

YES

YES

Exchange the IC8

Exchange the defect

SSR

Page 56

YES

YES

NO

YES

Is the IC7 O.K?

Is the voltage of

CN-UP/DOWN NO

1,2 DC12V?

Is the battery

consumption O.K?

Exchange receiver asm

YES

YES

Is DC5V between

1 and 7of CN-DISP

Is the connection

of CN-DISP all right?

NO

NO

NO

Exchange the IC7

Check the step motor and

Connector(CN-UP/DOWN)

NO

Check the P.C.B of DC12V

pattern

Exchange the battery

Check the P.C.B

pattern

Connect CN-DISP

exactly

Possible Trouble 3

: Up/Down Air direction louver does not operate

Possible Trouble 4

: Remotoe controller does not operate

ƒ¡56ƒ¡

Page 57

YES

NO

NO

Does 4way operate?

Check Voltage of IC8 1pin

(DC 5V?)

P.C.B pattern Check

YES

Check and Exchange

IC8, RY-4WAY

Check and Exchange

IC8

Possible Trouble 5

: Ineffective Heating

ƒ¡57ƒ¡

Page 58

Possible Trouble 6

: It does not operate forced operation.

ƒ¡58ƒ¡

P.C.B pattern Check

YES

Is the F/OP. KEY OK?

NO

Exchange the F/OP, KEY

Page 59

(7) DISPLAY P. C. B ASM : LS-S0960CL/S0960HL, LS-S1120CL,

LS-S1260CL/S1260HL, LS-S1420CL, LS-S1421CL

(8) Display P. C. B. ASM : LS-P0760CL/P0760HL, LS-P0820CL

LS-P0960CL/P0960HL

PRE-AMP

CN3

1

P.C.B 6046AQ3015A

ASM 6047AQ3014

LED1(DP) LED2(S) LED3(PS) LED4(DI)

A B

ƒ¡62ƒ¡

P.C.B 6046AQ3015A

ASM 6047AQ3014

LD1 LD2 LD3 LD4

REMOCON

RECIVER

1 CN-MAIN 7

Page 60

Exploded View & Replacement Parts List

1. Indoor Unit

• LS-S0960CL/S0960HL, LS-S1120CL, LS-S1260CL/S1260HL, LS-S1420CL,

LS-S1421CL

ƒ¡67ƒ¡

10

26

28

34

29

27

31

32

33

35

19

22

18

20

21

15

14

24

23

25

30

11

12

9

8

3

5 6

7

4 1

2

13

17

16

36

Page 61

• LS-P0760CL/P0760HL, LS-P0820CL, LS-P0960CL/P0960HL

ƒ¡68ƒ¡

25

24

26

22

20

21

23

9

12

11

8

7 6

4

2 1

5

3

16

15

14

17

18

19

27

13

10

29

30

32

28

31

Page 62

Parts List (LS-S0960CL/S0960HL, LS-S1260CL/S1260HL)

Q/TY

LS-S0960CL LS-S1260CL LS-S0960HL LS-S1260HL

1 1H00843A PLATE INSTALLING 1 1 1 1

2 3H03651A HOLDER, TUBE 1 1 1 1

3 2HO2441 MOTOR, BLOWER 1C 1E 1C 1E R

4 2H02440 CHASSIS ASM 1A 1G 1A 1G R

5 3H03652A COVER, TUBE 1 1 1 1

6 2H02426A CROSS FLOW FAN 1 1 1 1 R

7 3H02821A BEARING ASM 1 1 1 1 R

8 3H03711 EVAPORATOR 1C 1A 1C 1A

9 2H02449A TUBING ASM 1 1 1 1

10 6711AR1386 LCD REMOCON ASM 1C 1C 1D 1D R

11 3A00375D SOCKET FLARE 1 1 1 1

12 3H01420A SOCKET FLARE 1 1 1 1

13 4781AR1220A CONTROLLER ASM 1 1

4781AR1216B 1 1

14 3H02255S POWER CORD ASM 1 1 1 1 R

15 4780AR1013A CONTROL BOARD 1 1 1 1

16 6171AQ2147 POWER, TRANS 1A 1A 1A 1A R

17 4H03048 PILLAR TERMINAL 1A 1A 1C 1C R

18 4H03048A PILLAR TERMINAL 1 1 1 1 R

19 6047AQ3014 DISPLAY PCB ASM 1A 1A 1A 1A R

20 6871AQ2157 MAIN PCB ASM(D.C) 1B 1B 1A 1A R

21 6871AQ2156 MAIN PCB ASM(A.C) 1B 1B 1A 1A R

22 3Q35099 THERMISTOR ASM 1E 1E 1A 1A R

23 3H03716A GEAR CASE ASM 1 1 1 1 R

24 2H01721E DRAIN HOSE ASM 1 1 1 1

25 1H00866 DISCHARGE GRILLE ASM 1E 1E 1E 1E

26 3H02857A LOCK DOOR ASM 1 1 1 1

27 3H03718B BRACKET-R ASM 1 1 1 1

28 3H03719B BRACKET-L ASM 1 1 1 1

29 1H00830 INLET GRILLE 1L 1L 1L 1L

30 1H00867 FRONT GRILLE ASM 1R 1R 1S 1S R

31 3H03601A VANE-1 1 1 1 1 R

32 3H03602B VANE-2 1 1 1 1 R

33 3H03650B CAP SCREW 3 3 3 3

34 2H02422A AIR FILTER 2 2 2 2 R

35 3H03585 CONTROL COVER 1C 1C 1N 1N

36 4640AR3086A SCREEN, WIRE 1 1 1 1

ƒ¡69ƒ¡

NO PART NO. PART NAME

REMARKS

Page 63

Parts List (LS-S1120CL, LS-S1420CL, LS-S1421CL)

ƒ¡70ƒ¡

Q/TY

LS-S1120CL LS-S1420CL LS-S1421CL

1 1H00843A PLATE INSTALLING 1 1 1

2 3H03651A HOLDER, TUBE 1 1 1

3 2HO2441 MOTOR, BLOWER 1F 1F 1K R

4 2H02440 CHASSIS ASM 1A 1A 1A R

5 3H03652A COVER, TUBE 1 1 1

6 2H02426A CROSS FLOW FAN 1 1 1 R

7 3H02821A BEARING ASM 1 1 1 R

8 3H03711 EVAPORATOR 1A 1A 1A

9 2H02449A TUBING ASM 1 1 1

10 6711AR1386 LCD REMOCON ASM 1C 1C 1C R

11 3A00375D SOCKET FLARE 1 1 1

12 3H01420A SOCKET FLARE 1 1 1

13 4781AR1216B CONTROLLER ASM 1 1 1

14 3H02255S POWER CORD ASM 1 1 1 R

15 4780AR1013A CONTROL BOARD 1 1 1

16 6171AQ2147 POWER, TRANS 1A 1A 1A R

17 4H03048 PILLAR TERMINAL 1A 1A 1A R

18 4H03048A PILLAR TERMINAL 1 1 1 R

19 6047AQ3014 DISPLAY PCB ASM 1A 1A 1A R

20 6047AQ2157 MAIN PCB ASM(D.C) 1B 1B 1B R

21 6047AQ2156 MAIN PCB ASM(A.C) 1B 1B 1B R

22 3Q35099 THERMISTOR ASM 1E 1E 1E R

23 3H03716A GEAR CASE ASM 1 1 1 R

24 2H01721E DRAIN HOSE ASM 1 1 1

25 1H00866 DISCHARGE GRILLE ASM 1E 1E 1E

26 3H02857A LOCK DOOR ASM 1 1 1

27 3H03718B BRACKET-R ASM 1 1 1

28 3H03719B BRACKET-L ASM 1 1 1

29 1H00830 INLET GRILLE 1L 1L 1L

30 1H00867 FRONT GRILLE ASM 1R 1R 1R R

31 3H03601A VANE-1 1 1 1 R

32 3H03602B VANE-2 1 1 1 R

33 3H03650A CAP SCREW 3 3 3

34 2H02422A AIR FILTER 2 2 2 R

35 3H03585 CONTROL COVER 1C 1C 1C

36 4640AR3086A SCREEN, WIRE

NO PART NO. PART NAME

REMARKS

Page 64

Parts List (LS-P0760CL/P0760HL, LS-P0820CL, LS-P0960CL/P0960HL)

Q/TY

LS-P0760CL LS-P0820CL LS-P0960CL LS-P0760HL LS-P0960HL

1 3300AR1008A PLATE INSTALLING 1 1 1 1 1

2 4930AR3015A HOLDER TUBE 1 1 1 1 1

3 4680AR2033 MOTOR, BLOWER 1E 1B 1D 1E 1D R

4 3141AR2032 CHASSIS ASM 1D 1D 1D 1D 1D R

5 3140AR3003 CHASSIS SIDE 2D 2D 2D 2D 2D

6 5835AR2034A BLOWER ASS'Y 1 1 1 1 1 R

7 3H02821A BEARING ASM 1 1 1 1 1 R

8 5421AR2035 EVAPORATOR ASS'Y 1D 1B 1D 1D 1H

9 5211AR2042A TUBE ASS'Y 1 1 1 1 1

10 6711AR1386 LCD REMOCON ASM 1C 1C 1C 1D 1D R

11 3A00375D SOCKET FLARE 1 1 1 1 1

12 4010AR3071A SOCKET FLARE 1 1 1 1 1

13 4781AR2263 CONTROLLER ASS'Y 1D 1D 1D

4781AR2097 1H

4781AR2360 1B

14 3H02255 POWER CORD ASS'Y 1U 1S 1U 1U 1T R

15 4994AR1007A CONTROL BOARD 1 1 1 1 1

16 6171AQ2147 POWER TRANS 1B 1B 1B 1B 1B R

17 6047AQ3029 DISPLAY P .C.B ASS'Y 1B 1B 1B 1B 1B R

18 6871AQ2155 MAIN P.C.B ASS'Y 1B 1B 1B 1E 1A R

19 3Q35099 THERMISTOR ASM 1A 1A 1A 1A 1A R

20 2H01803B STEP MOTOR ASM 1 1 1 1 1 R

21 5250AR2044A DRAIN HOSE ASS'Y 1 1 1 1 1

22 5991AR3142 VANE ASS'Y 1A 1A 1A 1A 1A

23 5009AR1080

DISCHARGE GRILLE ASM

1F 1F 1F 1F 1F

24 3530AR1006 INLET GRILLE 1H 1H 1H 1H 1H

25 3531AR1081 FRONT GRILLE ASS'Y 1Q 1Q 1Q 1R 1R R

26 5230AR2003A AIR FILTER 2 2 2 2 2 R

27 3H01487A SH CAPACITOR 1 1 1 1 1

28 4H03048A PILLAR TERMINAL 1 1 1 1 1

29 4933AR3352 CONNECTOR ASS'Y 1A 1A 1A 1A 1A

30 4933AR3353 CONNECTOR ASS'Y 1A 1A 1A 1B 1B

31 4H03048 PILLAR TERMINAL 1A 1A 1A 1C 1C

32 3700AR3072B STEEL NET 1 1 1 1 1

NO PART NO. PART NAME

REMARKS

ƒ¡71ƒ¡

Page 65

2. Outdoor Unit

25

4

4-2

3

2

27

29

1

28

18

17

26

9

10

8

7

14

15

20

21

30

5

12

13

22

24

6

4-1

31

16

33

19

34

32

ƒ¡72ƒ¡

Page 66

Parts List (LS-P0760CL/P0960CL, LS-S0960CL/S1260CL)

Q'TY

LS-P0760CL LS-P0960CL LS-S0960CL LS-S1260CL

1 2H02435B BASE PAN WELD ASM 1 1 1 1

2 1H00838A MOUNT , MOTOR 1 1 1 1

3 1H00853 MOTOR, FAN 1D 1D 1D 1D R

4 1H00643A FAN 1 1 1 1 R

4-1 1WPA0600014 PLAIN WASHER 1 1 1 1

4-2 4H02861A FAN NUT 1 1 1 1

5 2H02383B SUPPORT, VALVE 1 1 1 1

6 5403AR2046 CONDENSOR ASM 1A 1A 1A 1A

7 5417AR2256 COMPRESSOR 1A R

1H00408 1M 1N 1M

8 4H00982A ANTI-VIBRATION BUSH 3 3 3 3

9 1NHA0801206 HEXAGON NUTS 3 3 3 3

10 4H00972D WASHER 3 3 3

4H01811C 3

12 2H02479 SERVICE VALVE(1/4") 1B 1B 1B 1B R

13 2H01890 SERVICE VALVE(1/2") 1H 1H R

2A00393 SERVICE VALVE(3/8") 1F 1F

14 6750-CL005A OVER LOAD PROTECTOR 1 R