LG LS-M3021AL, LS-M3060AL, LS-M3060HL, LS-M3060CL, LS-M3060BL Service Manual

...

Room Air Conditioner

SERVICE MANUAL

CAUTION

-BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

-ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODELS : LS-M3021CL/AL

LS-M3060HL/CL/AL/BL

LS-M3061HL/CL/BL/AL

LS-M3063CL

LS-M3064HL/CL/DL/EL/DM/EM

LS-M3221HL/CL/BL/AL

LS-N3621CL/AL

LS-N3660HL/CL/AL/BL

LS-N3661HL/CL/AL/BL

LS-N3664EL

LS-N3821HL/CL/BL/AL

LS-M306LCL/LDL

LS-M306LHL/LEL

LS-C366NLD0

LS-H366NLD0/NMD0

LS-N3621BL/HL

LS-C366NLA0

LS-C366NLB0

WEBSITE http://biz.LGservice.com

E-MAIL http://www.LGEservice.com/techsup.html

-2-

Contents

Functions

.................................................................................................................................3

Product Specifications

..........................................................................................................5

Dimensions

..............................................................................................................................8

Refrigeration Cycle Diagram

................................................................................................11

Pipe Length and the Elevation.............................................................................................12

Wiring Diagram

......................................................................................................................13

Operation Details

..................................................................................................................15

Display Function

...................................................................................................................22

Self-diagnosis Function

........................................................................................................22

Installation

.............................................................................................................................23

Operation

...............................................................................................................................39

Disassembly of the parts (Indoor Unit)

...............................................................................41

3-way Valve

............................................................................................................................49

Cycle Troubleshooting Guide

...............................................................................................54

Electronic Parts Troubleshooting Guide

.............................................................................55

Electronic Control Device

.....................................................................................................61

Schematic Diagram

...............................................................................................................64

Exploded View and Replacement Parts List

.......................................................................72

-3-

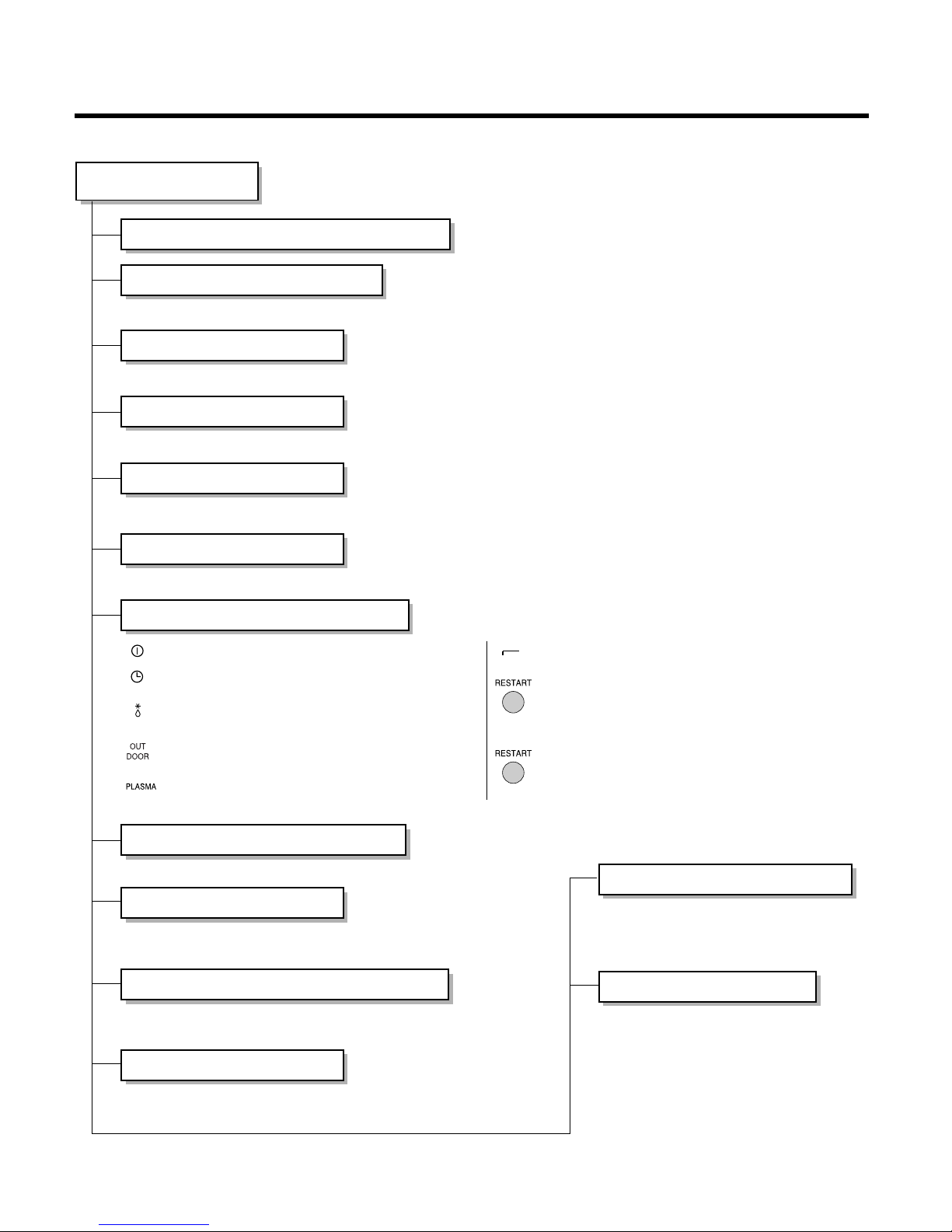

Functions

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 sec at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

• Both the indoor and outdoor fan

stops during deicing.

• The indoor fan stops until the

evaporator piping temperature will be

reached at 28°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

Deice (defrost) control (Heating)

Hot-start Control (Heating)

On/Off : Lights up during the system operation.

: Lights up during Timer operation or

Sleep mode.

Defrost Mode : Lights up during Defrost Mode or Hot

Start operation. (Heat pump model only)

: Lights up during outdoor unit operation.

(Cooling model only)

Plasma Mode : Lights up during plasma-purification

operation.(option)

Auto Restart Mode : Lights up during if Restart Button

is pressed.

Auto Restart Button : In failure of electric power, if the

button is pressed the unit runs as

previous setting operation when

power returns.

Forced Operation Button

: Operation starts, when this button

is pressed and stops when you

press the button again.

Outdoor unit

operation

Timer or

Sleep Mode

-4-

Healthy Dehumidification Operation Mode.

( )

Remote Controller

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

JET COOL

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Fan Operation Mode

Horizontal Airflow Direction Control Button(Option)

Room, Temperature Display

Setting the Time or Timer

PLASMA(Option)/NEGATIVE ION(Option)

ON OFF

SET

PLASMA

CANCEL

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High:39°C Low:11°C)

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C

Up to 30°C

Heating

Down to 16°C

Up to 30°C

-5-

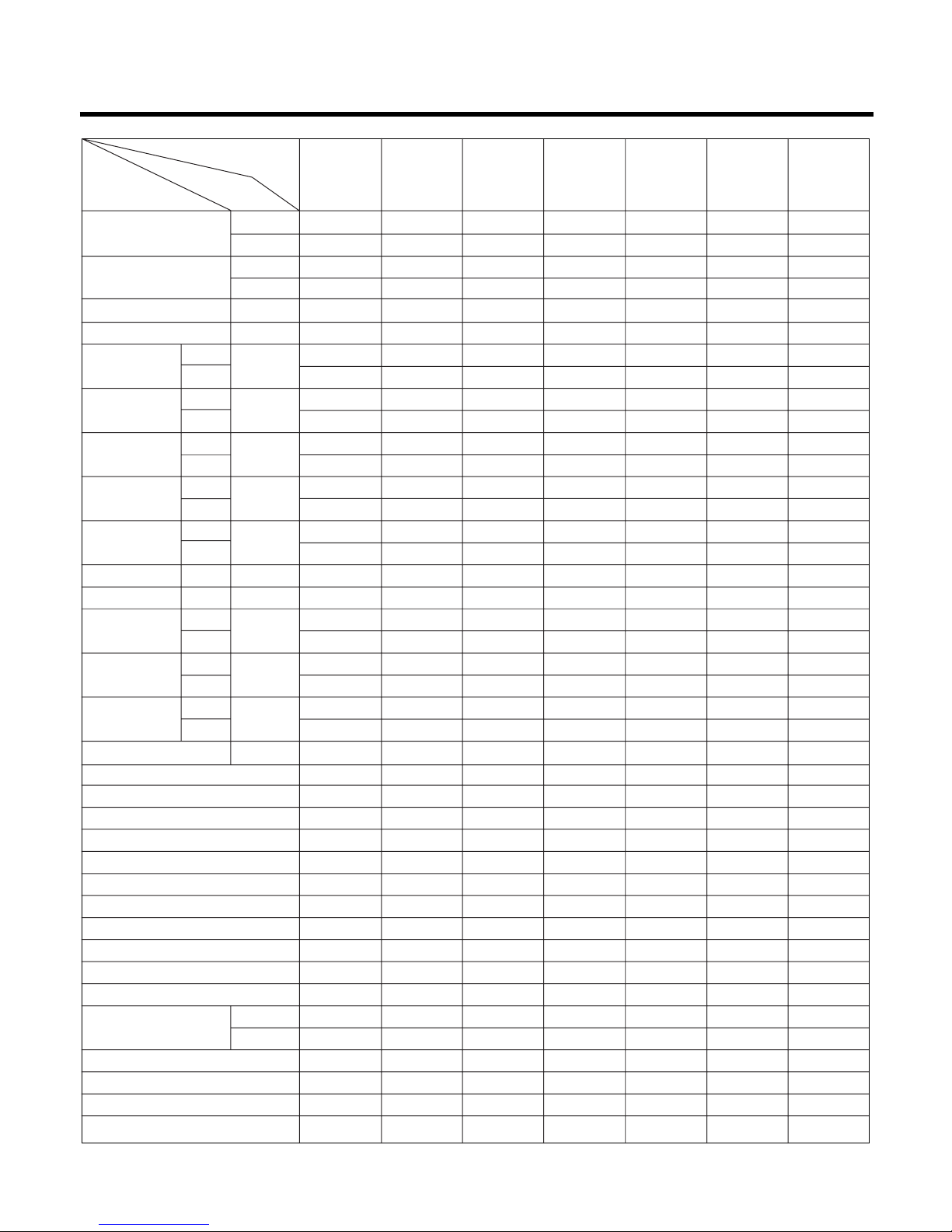

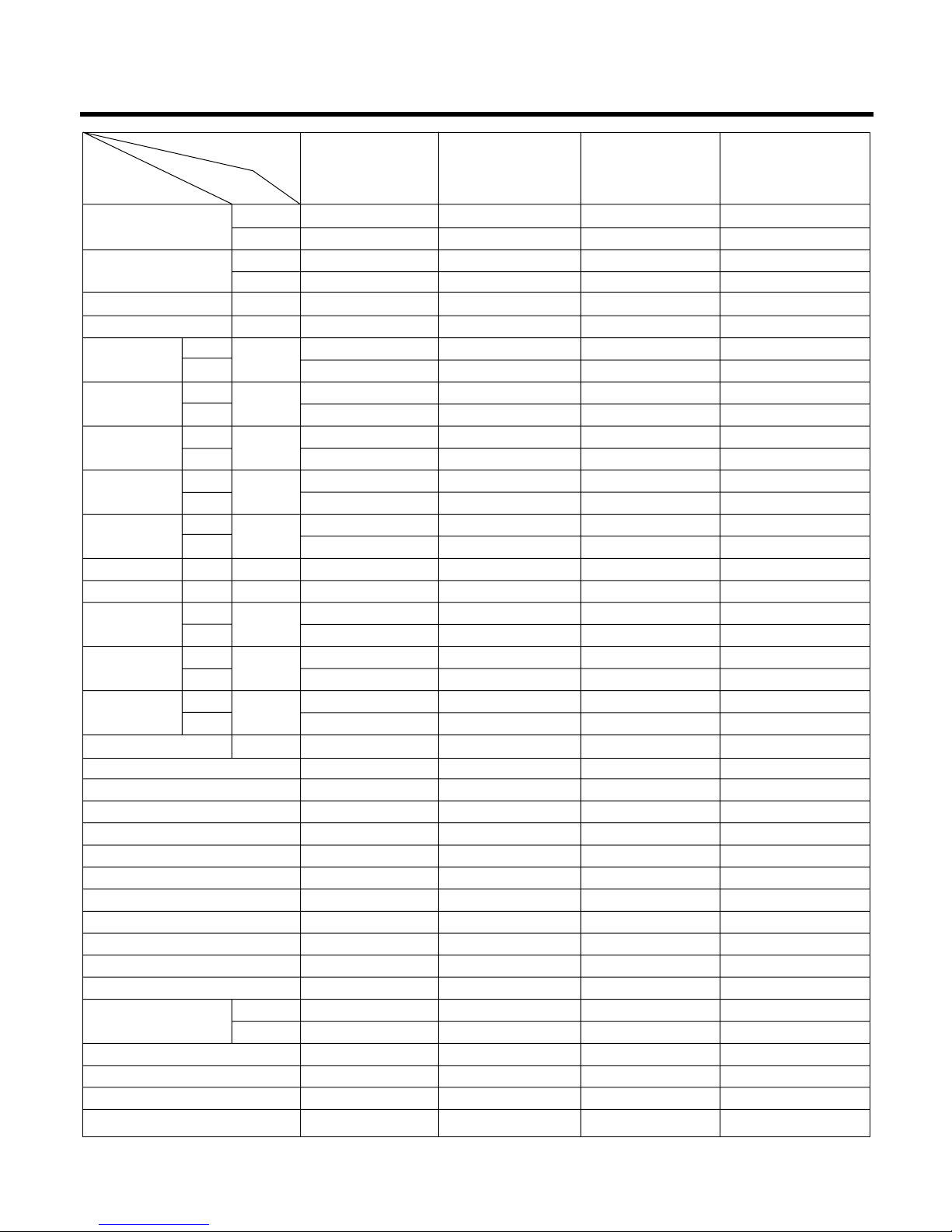

Product Specifications (30K, 32K)

Cooling Capacity

BTU/h(kcal/h)

W

Heating Capacity

BTU/h(kcal/h)

W

Moisture Removal l/h

Power Source Ø,V,Hz

Air Circulation m3/min

Noise Level dB(A)±3

Input W

Runnig Current A

Starting Current A

E.E.R. BTU/h-W

C.O.P W/W

Motor Output W

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control (Up & Down)

Airflow Direction Control (Right & Left)

Negative lon

Air Purifying Filter

Deicer

Hot Start

Chaos Wind

Micom Dry

Timer

Self Diagnosis

Remocon type

Service valve

Sleeping Operation

Drain Hose

Connecting Cable

Power Cord

28,000(7,056) 28,000(7,056) 28,000(7,056) 28,000 28,000(7,056)

8,205 8,205/9,377 8,205 8,205 8,205/9,377 8,205 8,205

29,000(7,308) 29,000(7,308) - - - -

8,498/9,377 8,498/9,377 8,498 - - - -

3.8 3.8 3.8 3.8 3.8 3.8 3.8

1ø,220-240V, 50Hz 1ø,220-240V, 50Hz 1ø,220-240V, 50Hz 1ø,220-240V, 50Hz 1ø,220-240V, 50Hz

21 21 21 21 21 21 21

58 58 58 58 58 58 58

46 46 46 46 46 46 46

58 58 58 58 58 58 58

3,200 3,200/3,350 3,200 3,200 3,200/3,350 3,200 3,200

3,100 3,100/3,350 3,100 - - - -

15.5 15.5/16.0 15.5 15.5 15.5/16.0 15.5 15.5

15 15/16.0 15 - - - -

85 85 43 85 85 85 85

85 85 43 - - - -

8.75 8.75/9.55 8.75 8.75 8.75/9.55 8.75 8.75

2.74 2.74/2.80 2.74 - - - -

47 47 47 47 47 47 47

80 80 80 80 80 80 80

1,259 x 349 x 205 1,259 x 349 x 205 1,259 x 349 x 205 1,259 x 349 x 205 1,259 x 349 x 205 1,259 x 349 x 205 1,259 x 349 x 205

870 x 800 x 320 870 x 800 x 320 870 x 800 x 320 870 x 800 x 320 870 x 800 x 320 870 x 800 x 320 870 x 800 x 320

20 20 20 20 20 20 20

72 72 72 71 71 71 71

2,100 2,100 2,100/2,550 1,950 1,950/2,420 2,550 1,950

YES YES YES YES YES YES YES

NO NO/YES NO(YES) NO NO/YES NO(YES) NO(YES)

NO NO NO NO NO NO NO

NO(OPTION) YES YES NO(OPTION) YES YES YES

YES YES YES NO NO NO NO

YES YES YES NO NO NO NO

YES YES YES YES YES YES YES

YES YES YES YES YES YES YES

24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF

YES YES YES YES YES YES YES

L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless

3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52)

5/8"(15.88) 5/8"(15.88) 5/8"(15.88) 5/8"(15.88) 5/8"(15.88) 5/8"(15.88) 5/8"(15.88)

YES YES YES YES YES YES YES

YES YES YES YES YES YES YES

0.75mm

2

0.75mm

2

0.75mm

2

0.75mm20.75mm20.75mm

2

0.75mm

2

2.5mm

2

2.5mm

2

2.5mm

2

2.5mm

2

2.5mm

2

2.5mm

2

2.5mm

2

Model Name

Unit

Indoor

Outdoor

Indoor

Outdoor

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Dimensions

(WxHxD)

Item

LS-M3061HL/BL

LS-M3221HL/BL

LS-M306LHL

LS-M306LEL

LS-M3060HL

LS-M3060BL

LS-M3064HL

(LS-M3064EL)

LS-M3064EM

LS-M306LCL

LS-M306LDL

LS-M3060CL

LS-M3060AL

LS-M3061CL/AL

LS-M3221CL/AL

LS-M3021CL/AL

LS-M3064CL

(LS-M3064DL)

LS-M3064DM

LS-M3063CL

28,000(7,056)/

32,000(8,064)

29,000(7,308)/

32,000(8,064)

1ø,220-240V, 50Hz/

1ø,220V, 60Hz

1ø,220-240V, 50Hz/

1ø,220V, 60Hz

28,000(7,056)/

32,000(8,064)

-6-

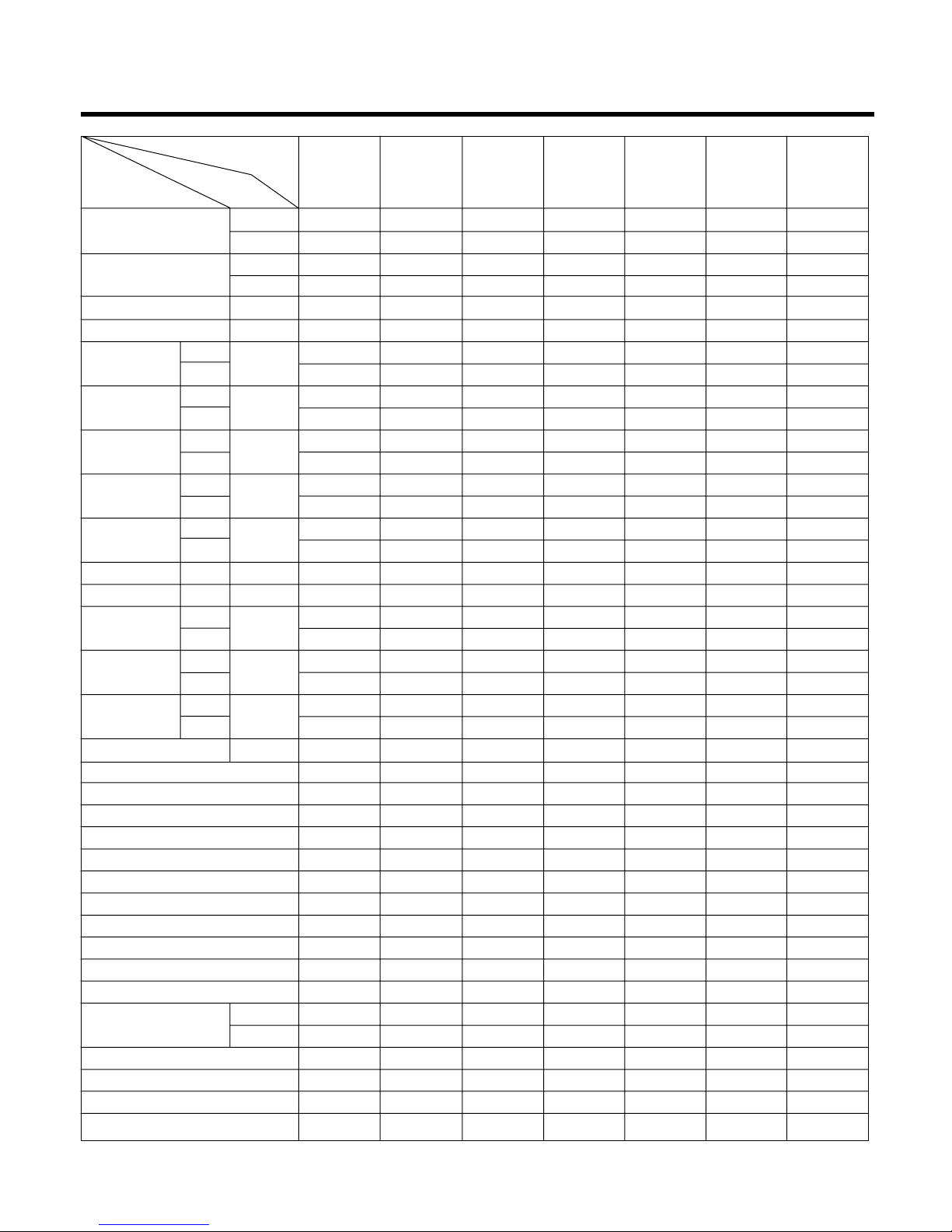

Cooling Capacity

BTU/h(kcal/h)

W

Heating Capacity

BTU/h(kcal/h)

W

Moisture Removal l/h

Power Source Ø,V,Hz

Air Circulation m3/min

Noise Level dB(A)±3

Input W

Runnig Current A

Starting Current A

E.E.R. BTU/h-W

C.O.P W/W

Motor Output W

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control (Up & Down)

Airflow Direction Control (Right & Left)

Negative lon

Air Purifying Filter

Deicer

Hot Start

Chaos Wind

Micom Dry

Timer

Self Diagnosis

Remocon type

Service valve

Sleeping Operation

Drain Hose

Connecting Cable

Power Cord

36,000(9,073) 36,000(9,073) 36,000(9,073) 36,000(9,073) 38,000(9,557) 38,000(9,577) 36,000(9,073)

10,549 10,549 10,549 10,549 11,135 11,135 10,549

36,000(9,073) 36,000(9,073) - - 3,800(9,577) - -

10,549 10,549 - - 11,135 - -

4.2 4.2 4.2 4.2 4.2 4.2 4.2

1ø,220-240V, 50Hz 1ø,220-240V, 50Hz 1ø,220-240V, 50Hz 1ø,220-240V, 50Hz 1ø,220-240V, 60Hz 1ø,220-240V, 60Hz 1ø,220-240V, 60Hz

26 26 26 26 26 26 26

58 58 58 58 58 58 58

47 47 47 47 47 47 47

58 58 58 58 58 58 58

4,300 4,300 4,300 4,300 3,970 3,970 3,970

4,300 4,300 - - 3,970 - -

22 22 22 22 19 19 19

22 22 - - 19 - -

113 113 113 113 91 91 91

113 113 - - 91 - -

8.37 8.37 8.37 8.37 9.23 9.23 9.23

2.45 2.45 - - 2.45 - -

65 65 65 65 38 38 38

50 50 50 50 30 30 30

1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205

790 x 965 x 320 790 x 965 x 320 790 x 965 x 320 790 x 965 x 320 790 x 965 x 320 790 x 965 x 320 790 x 965 x 320

25 25 25 25 25 25 25

80 80 80 80 80 80 80

2,100 2,100 2,100 1,950 1,950 1,950 1,950

YES YES YES YES YES YES YES

NO YES NO YES YES YES YES

NO NO NO NO NO NO NO

NO(OPTIONAL) YES NO(OPTIONAL) YES YES YES YES

YES YES NO NO YES NO NO

YES YES NO NO YES NO NO

YES YES YES YES YES YES YES

YES YES YES YES YES YES YES

24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF

YES YES YES YES YES YES YES

L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless

3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52) 3/8"(9.52)

3/4"(19.05) 3/4"(19.05) 3/4"(19.05) 3/4"(19.05) 3/4"(19.05) 3/4"(19.05) 3/4"(19.05)

YES YES YES YES YES YES YES

YES YES YES YES YES YES YES

0.75mm

2

0.75mm20.75mm

2

0.75mm20.75mm

2

0.75mm20.75mm

2

5.5mm

2

5.5mm

2

5.5mm

2

5.5mm

2

5.5mm

2

5.5mm

2

5.5mm

2

Model Name

Unit

Indoor

Outdoor

Indoor

Outdoor

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Dimensions

(WxHxD)

Item

LS-N3661HL/BL

LS-N3664EL

LS-N3660HL

LS-N3660BL

LS-N3660CL

LS-N3660AL

LS-N3661CL

LS-N3661AL

LS-N3821HL

LS-N3821BL

LS-N3821CL

LS-N3821AL

LS-N3621CL/AL

Product Specifications (36K, 38K)

-7-

Product Specifications (36K)

Cooling Capacity

BTU/h(kcal/h)

W

Heating Capacity

BTU/h(kcal/h)

W

Moisture Removal l/h

Power Source Ø,V,Hz

Air Circulation m3/min

Noise Level dB(A)

±3

Input W

Runnig Current A

Starting Current A

E.E.R. BTU/h-W

C.O.P W/W

Motor Output W

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control (Up & Down)

Airflow Direction Control (Right & Left)

Negative lon

Air Purifying Filter

Deicer

Hot Start

Chaos Wind

Micom Dry

Timer

Self Diagnosis

Remocon type

Service valve

Sleeping Operation

Drain Hose

Connecting Cable

Power Cord

36,000(9,073) 36,000(9,073) 36,000(9,073) 35,000(8,817)

10549 10549 10549 10254

36,000(9,073) - 36,000(9,073) 35,000(8,817)

10549 - 10549 10254

4.2 4.2 4.2 4.2

1ø, 220-240V, 50Hz 1ø, 220-240V, 50Hz 1ø, 220-240V, 50Hz 1ø, 220-240V, 50Hz

26 26 26 26

58 58 58 58

47 47 47 47

58 58 58 58

3970 4200 4200 4200

3970 - 3900 3900

19.0 19.0 19.0 19.0

19.0 - 18.0 18.0

91 91 113 113

91 - 113 113

9.23 9.23 8.37 8.33

2.41 - 2.45 2.63

65 65 65 65

50 50 50 50

1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205 1,499 x 349 x 205

790 x 965 x 320 790 x 965 x 320 790 x 965 x 320 790 x 965 x 320

25 25 25 25

80 80 80 80

3250 3240 3220 3220

YES YES YES YES

NO NO YES YES

NO NO NO NO

NO(OPTIONAL) NO(OPTIONAL) YES YES

NO NO YES YES

NO NO YES YES

YES YES YES YES

YES YES YES YES

24hr ON/OFF 24hr ON/OFF 24hr ON/OFF 24hr ON/OFF

YES YES YES YES

L.C.D Wireless L.C.D Wireless L.C.D Wireless L.C.D Wireless

3/8(9.52) 3/8(9.52) 3/8(9.52) 3/8(9.52)

3/4(19.05) 3/4(19.05) 3/4(19.05) 3/4(19.05)

YES YES YES YES

YES YES YES YES

0.75mm

2

0.75mm

2

0.75mm

2

0.75mm

2

5.5mm

2

5.5mm

2

5.5mm

2

5.5mm

2

Model Name

Unit

Indoor

Outdoor

Indoor

Outdoor

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Dimensions

(WxHxD)

Item

LS-N3621BL

LS-N3621HL

LS-C366NLD0

LS-C366NLA0

LS-C366NLB0

LS-H366NLD0 LS-H366NMD0

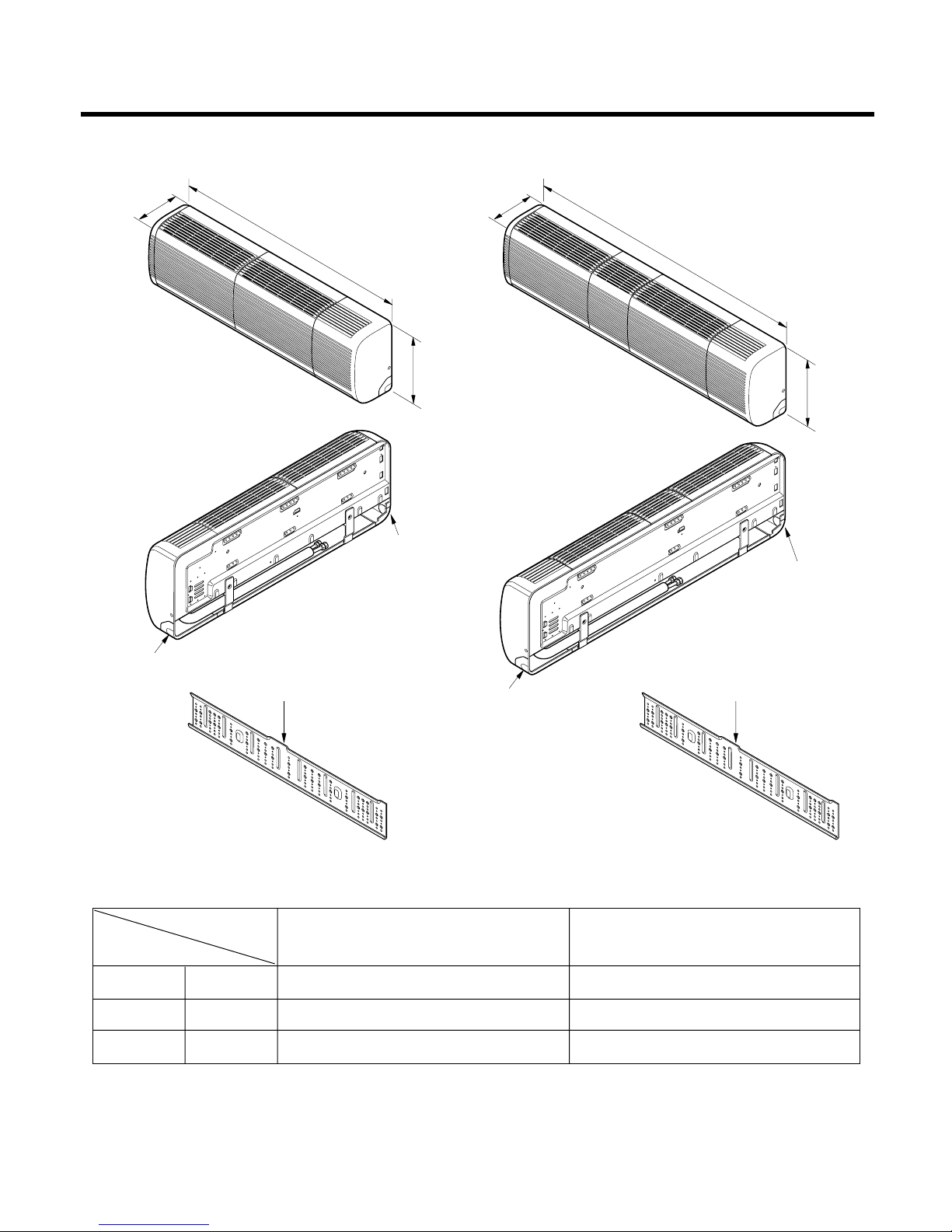

(1) Indoor Unit

-8-

Dimensions

Tubing hole cover

Tubing hole cover

Installation plate

D

W

H

W

H

Tubing hole cover

Tubing hole cover

Installation plate

D

W

H

Tubing hole cover

Tubing hole cover

Installation plate

D

W mm 1,259 1,499

H mm 349 349

D mm 205 205

Model

Dimension

SM CHASSIS SN CHASSIS

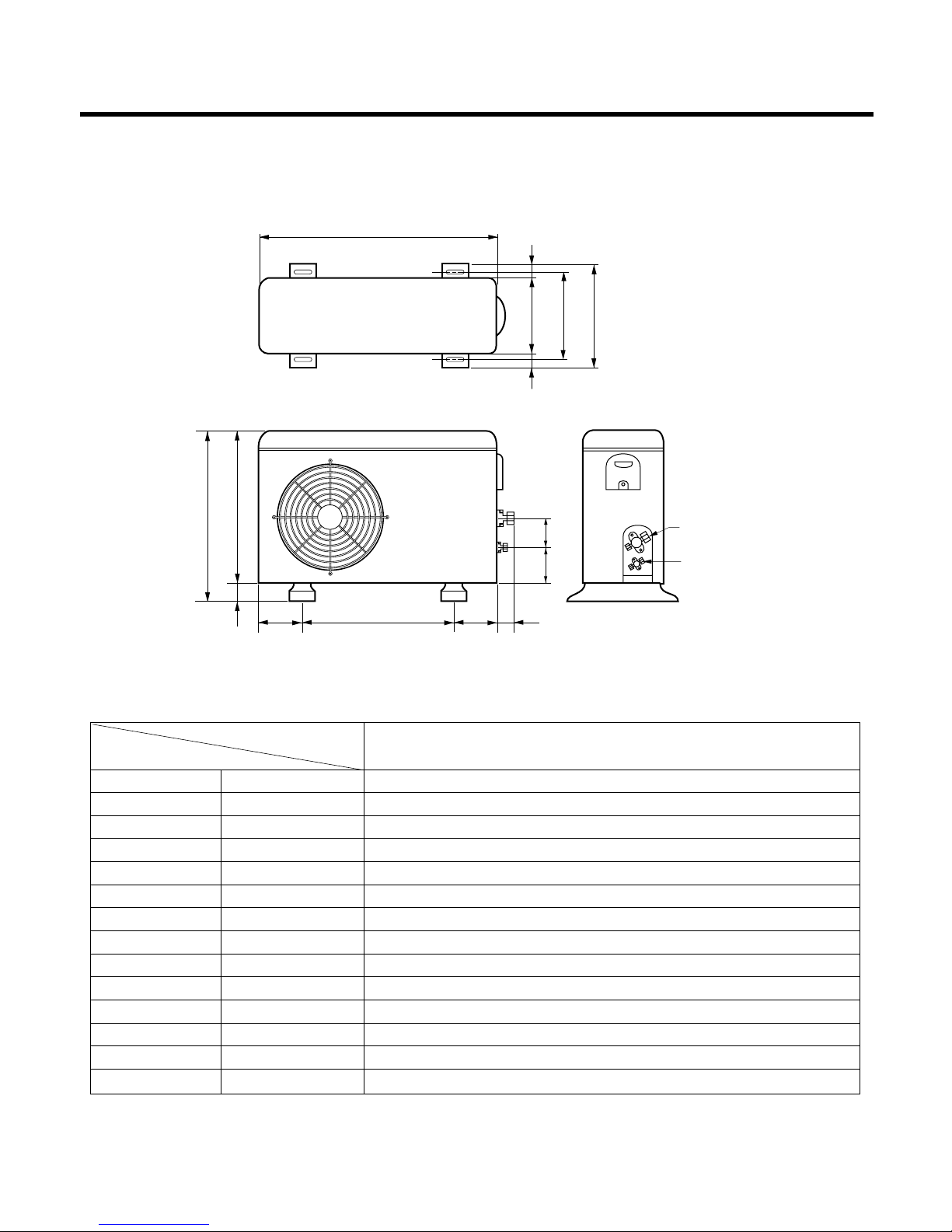

-9-

MODEL

DIM

-9-

W

L7 L6 L8 L9

D

L1

L2

L3

L10L11

L4L5

H

Gas side

3-way valve

Liquid side

3-way valve

W mm 870

H mm 800

D mm 320

L1 mm 370

L2 mm 340

L3 mm 25

L4 mm 775

L5 mm 25

L6 mm 546

L7 mm 162

L8 mm 162

L9 mm 54

L10 mm 74.5

L11 mm 79

30K, 32K SERIES

(2) Outdoor Unit

-10-

320

790

385

72

482

4-ø12Hole

249

71

145

500

145

10

334

354

10

265

440

925

965

130

40

80

292.5

(Air intake vent)

(Air intake vent)

(Air intake vent)

36K SERIES

-11-

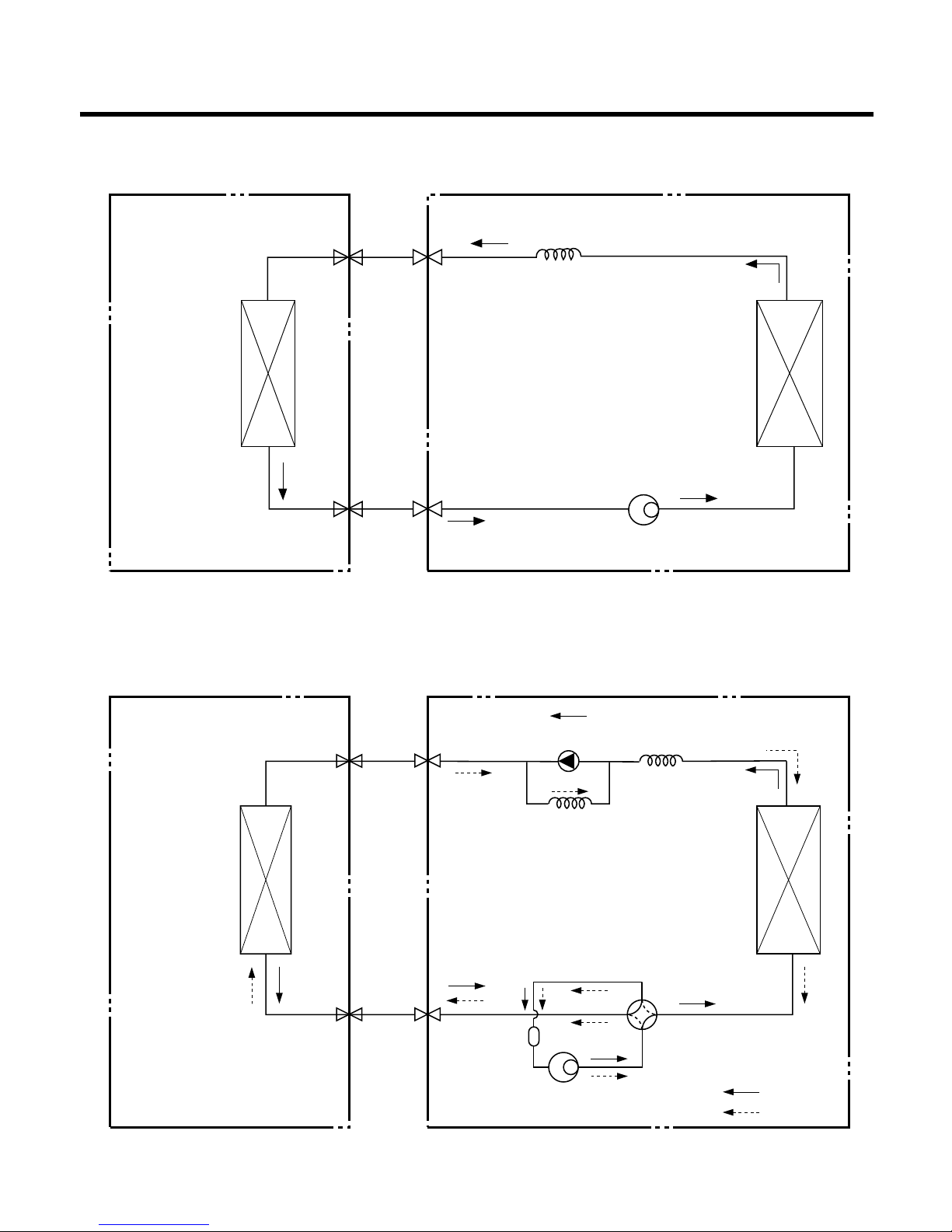

Refrigeration Cycle Diagram

INDOOR UNIT OUTDOOR UNIT

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

COMPRESSOR

ACCUMU

LATOR

GAS SIDE

GAS SIDE

3-WAY VALVE

LIQUID SIDE

LIQUID SIDE

3-WAY VALVE

CAPILLARY TUBE

CAPILLARY TUBE

CHECK VALVE

(Heating Model only)

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

(1) Cooling Only Models

(2) Cooling & Heating Models

-12-

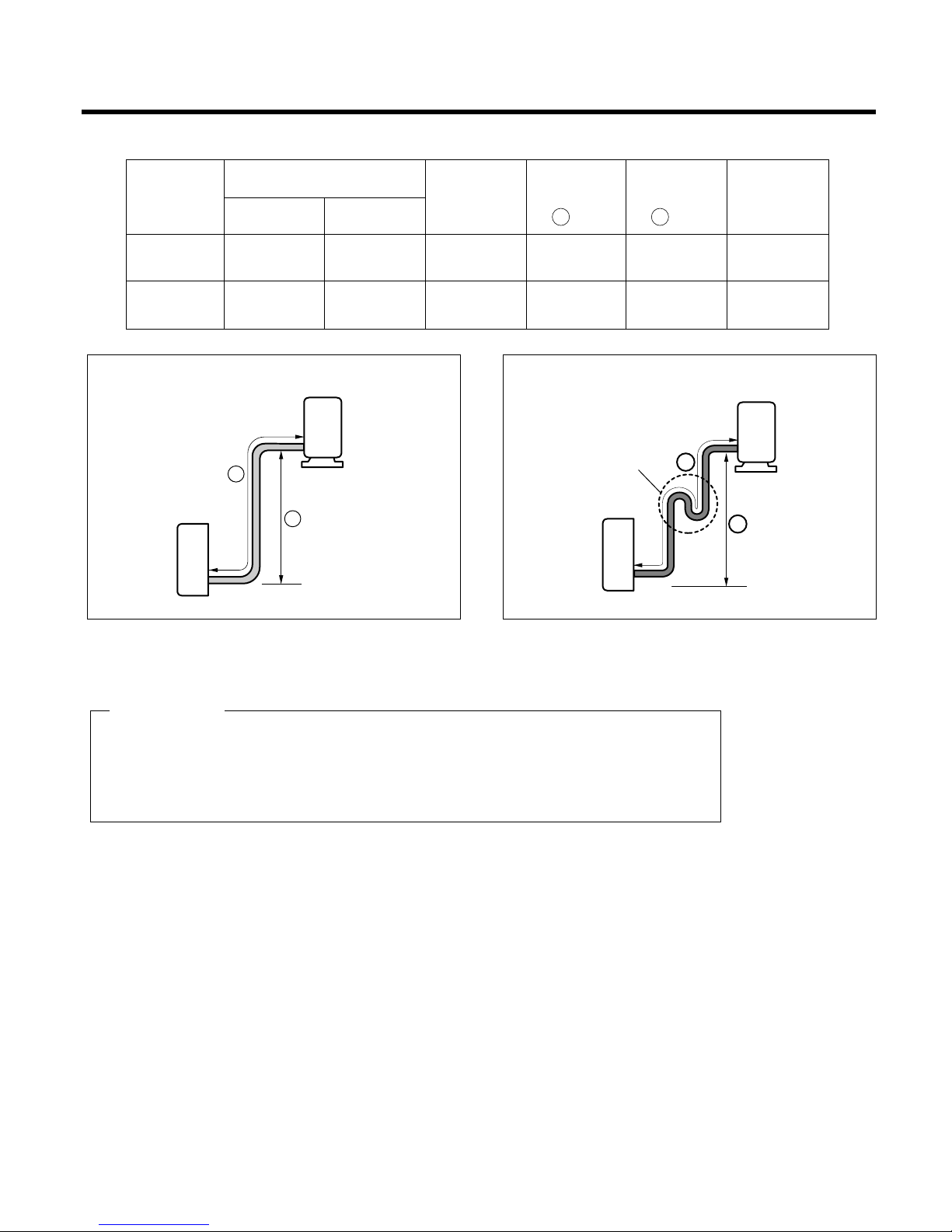

Pipe length and the elevation

* Capicity is based on standard length and maximum allowance length is the basis of

reliability.

* Oil trap should be installed per 5~7 meters.

CAUTION

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

In case more than 5m

30k/32k

5/8" 3/8" 7.5 15 30 30

(50Hz, 60Hz)

36k/38k

3/4" 3/8" 7.5 20 30 50

(50Hz, 60Hz)

Pipe Size

Capacity

(Btu/h)

GAS LIQUID

Additional

Refrigerant

(g/m)

Max.

Length

A (m)

Max.

Elevation

B (m)

Standard

Length

(m)

-13-

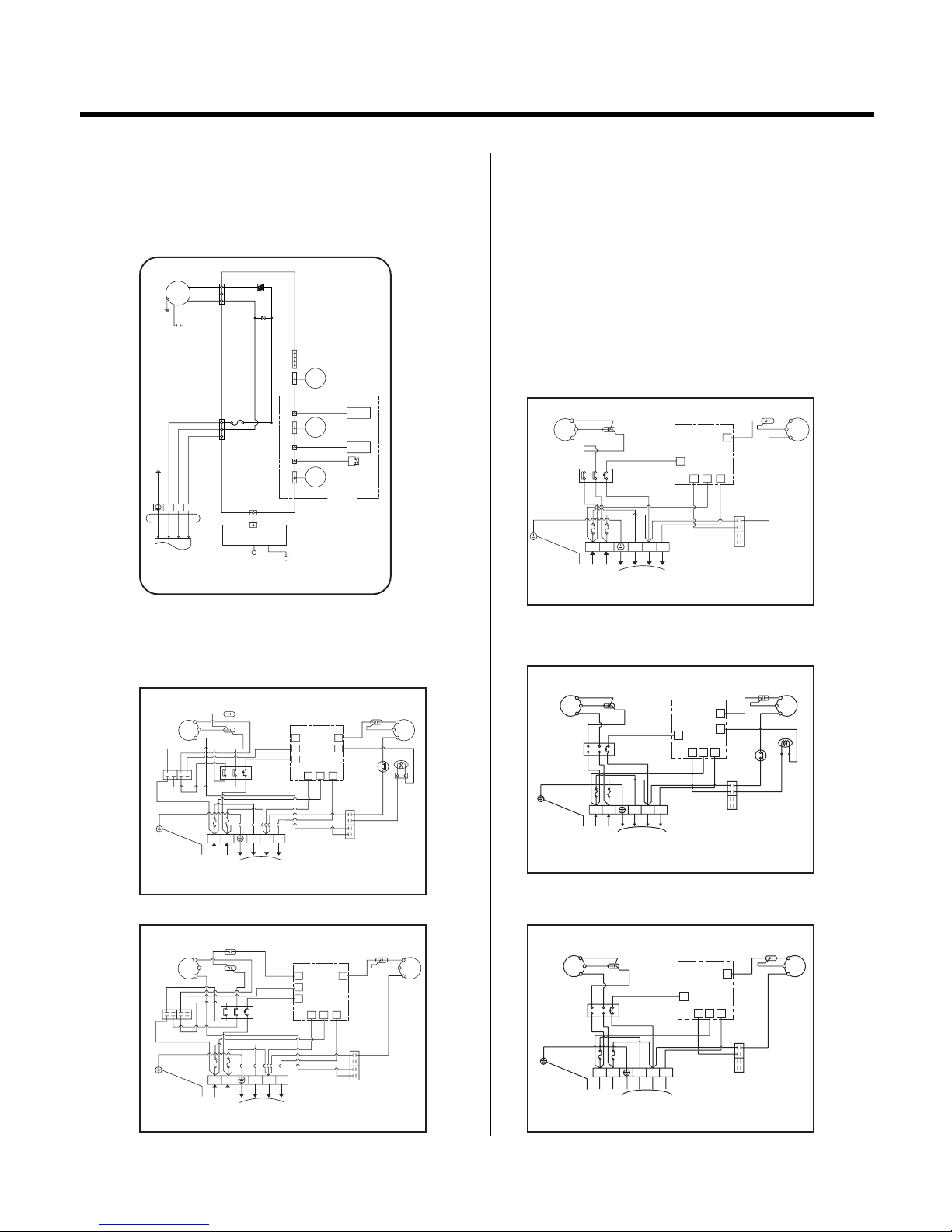

Wiring Diagram

3(L) 4(N)

START

CAPACITOR

BK

BL

RD

BR

R

S

COMP

RUNNING

CAPACITOR

BR

BR

BR

BR

BR

12

BL

1(L) 2(N)

TERMINAL BLOCK

BL

12

BK

BR

BL

BR

CN-

P2(N)

CN-COMP2

CN-COMP1

CN-FAN

OR

OR

BK

FAN

RY-CAPA

OUTDOOR PCB

CAPACITOR

YL

CNP1(L)

CN-

COMM

RD

BK

TERMINAL

BLOCK1

5

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

1

0

2

6

4

8

POWER

RELAY

TERMINAL

BLOCK 2

BR

BR

C

BK

OUTDOOR WIRING DIAGRAM

3854A20051B

OUTDOOR WIRING DIAGRAM

3854A20051D

OUTDOOR WIRING DIAGRAM

3854A20051F

OUTDOOR WIRING DIAGRAM

3854A20051G

BL

BL

BL

BR

OR

YL

FAN

BK

OR

CN-FAN

OUTDOOR PCB

RD

S

BL

RUNNING

C

BR

CN-CN-CN-

CN-COMP2

RD

P2(N)

COMM

P1(L)

BR

026

POWER

RELAY

148

CAPACITOR

R

COMP

2

BK

1

TERMINAL BLOCK1

TERMINAL BLOCK

5

4(N)3(L)

2(N)

1(L)

FUSE(5A)

FUSE(5A)

(COMM)

TO INDOOR UNIT

POWER INPUT

BR

CAPACITOR

BL

BK

BK

BL

BL

BR

YL

OR

FAN

OR

CAPACITOR

REVERSING

VALVE

BK

BK

SWITCH

HIGH PRESSURE

21

BK

OUTDOOR PCB

RUNNING

BL

S

C

COMP

BR

RD

R

CN-CN-

CN-COMP2

CN-

BR

RD

P2(N) P1(L)

COMM

RELAY

POWER

062

814

CAPACITOR

5

(COMM)

4(N)

TERMINAL BLOCK

1(L)

2(N)

FUSE(5A)

FUSE(5A)

3(L)

POWER INPUT

TO INDOOR UNIT

BR

TERMINAL BLOCK1

CN-4WAY

CN-FAN

3(L) 4(N)

START

CAPACITOR

BK

BL

RD

BR

R

S

COMP

RUNNING

CAPACITOR

BR

BR

BR

BR

BR

12

BL

1(L) 2(N)

TERMINAL BLOCK

BL

12

BK

BL

BR

CN-

P2(N)

CN-COMP2

CN-COMP1

CN-FAN

OR

OR

BK

REVERSING

VALVE

HIGH PRESSURE

S/W

BK

FAN

RY-CAPA

OUTDOOR PCB

CAPACITOR

YL

CN-4WAY

CN-

P1(L)

CN-

COMM

RD

BK

BK

TERMINAL

BLOCK1

5

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

1

0

2

6

4

8

POWER

RELAY

TERMINAL

BLOCK 2

BR

BR

C

BK

OUTDOOR WIRING DIAGRAM

3854A20051A

MOTOR

SH-CAPA.

YL

PILLAR

TERMINAL

AUTO RESTART

FORCED OPERATION

CN-DISP

CN-L/R CN-U/D CN-TH

THERMISTOR

STEP

MOTOR

(UP/DOWN)

STEP

MOTOR

(L/R)

H.V.B ASM

LIMITS S/W

Negative ion

OPTION

STEP

MOTOR

(L/R)

CN-L/R

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

3854A20065A

TO OUTDOOR UNIT

BL

3(L)

4(N) 5

BR

RD

GN/YL

BLRDBR

GN/YL

BR

FUSE

AC250V/T2A

TRIAC

OR

BK

ZNR

CN-POWER

CN-MOTOR

LS- M3060HL/CL/AL/BL, LS-M3061HL/CL/BL/AL

LS- M3064HL/CL/DL/DM/EM, LS-M3063CL

LS- M3221HL/CL/BL/AL, LS-M3021CL/AL

LS-M3064HL/EM, LS-M306LHL/LEL

LS-M3060HL, LS-M3061HL/BL,

LS-M3221HL/BL

LS-M3064CL/DL/DM, LS-M3063CL, LS-M306LCL/LDL

LS-M3060HL/BL, LS-M3061HL,

LS-M3221CL/AL, LS-M3021CL

LS-M3021AL, LS-M3061CL/AL

5

(COMM)

3(L) 4(N)

BL

RD

BR

R

S

COMP

RUNNING

CAPACITOR

BL

BL

BR

BL

1(L) 2(N)

TERMINAL BLOCK

BL

12

BK

BR

CN-

P2(N)

CN-COMP2

CN-FAN

OR

OR

FAN

OUTDOOR PCB

CAPACITOR

YL

CNP1(L)

CN-

COMM

RD

BK

TERMINAL BLOCK1

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

1

0

2

6

4

8

POWER

RELAY

BR

C

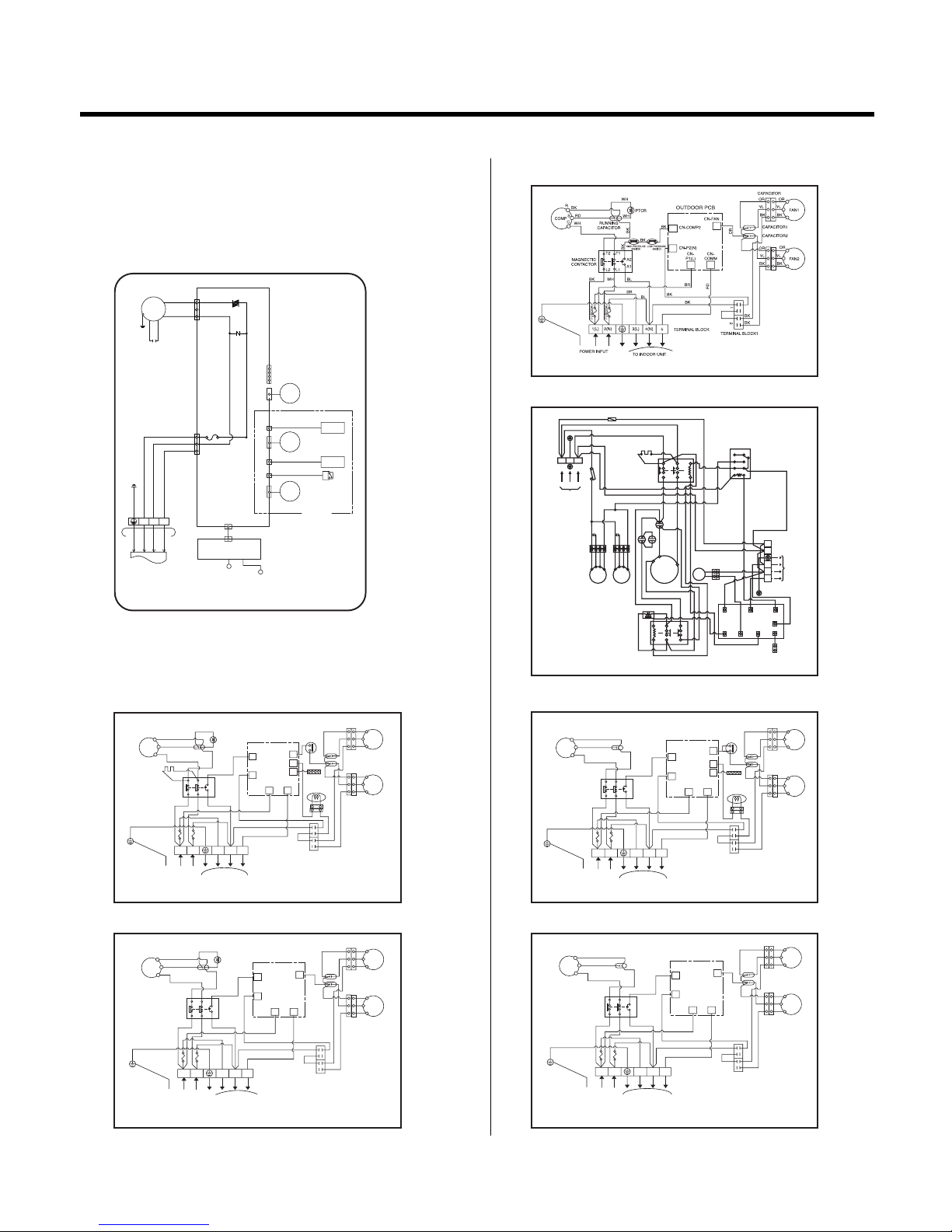

(2) Outdoor Unit

(Outdoor Unit - Continued)

• 30K, 32K

(1) Indoor Unit

-14-

MOTOR

SH-CAPA.

YL

PILLAR

TERMINAL

AUTO RESTART

FORCED OPERATION

CN-DISP

CN-L/R CN-U/D CN-TH

THERMISTOR

STEP

MOTOR

(UP/DOWN)

STEP

MOTOR

(L/R)

H.V.B ASM

LIMITS S/W

Negative ion

OPTION

STEP

MOTOR

(L/R)

CN-L/R

DISPLAY PCB ASM

INDOOR WIRING DIAGRAM

3854A20065A

TO OUTDOOR UNIT

BL

3(L)

4(N) 5

BR

RD

GN/YL

BLRDBR

GN/YL

BR

FUSE

AC250V/T2A

TRIAC

OR

BK

ZNR

CN-POWER

CN-MOTOR

LS-N3660HL/CL/AL/BL, LS-N3661HL/CL/AL/BL

LS-N3821HL/CL/BL/AL, LS-N3621CL/AL

LS-N3664EL/LS-N3621BL/LS-C366NLD0/LS-H366NLD0

LS-C366NLA0/LS-C366NLB0/LS-H366NMD0/LS-N3621HL

LS-N3660HL/BL, LS-N3661HL/BL, LS-H366NLD0

LS-N3821HL/BL, LS-N3621BL/HL

LS-N3664EL/LS-H366NMD0

LS-C366NLB0

LS-N3660CL, LS-N3661CL/AL, LS-C366NLD0, LS-C366NLA0

LS-N3821CL/AL, LS-N3621CL/AL

5

3(L) 4(N)

BK

RD

WH

WH

WH

R

S

COMP

RUNNING

CAPACITOR

BL

BL

BR

BR

BK

BK

BK

BK

WH

1(L) 2(N)

TERMINAL BLOCK

1

2

CN-P2(N)

CN-COMP2

CN-FAN

CN-4WAY

CN-TH

THERMISTOR

OR

OR

OROR

FAN1

OUTDOOR PCB

PTCR

MAGNECTIC

CONTACTOR

CRANK CASE

HEATER FOR COMP

CAPACITOR

YLYL

CN-

P1(L)

CN-

COMM

RD

BK BK

BK

BK

BK

BK

BK

BKBK

TERMINAL BLOCK1

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

T2 T1

L2 L1

A2

A1

BR

C

OUTDOOR WIRING DIAGRAM

3854A20051K

YL

FAN2

CAPACITOR1

CAPACITOR2

OR

YL

OR

REVERSING

VALVE

HIGH PRESS

SWITCH

OUTDOOR WIRING DIAGRAM

3854A20051L

OUTDOOR WIRING DIAGRAM

3854A20051M

5

3(L) 4(N)

BK

RD

WH

WH

WH

R

S

COMP

RUNNING

CAPACITOR

BL

BL

BR

BR

BK

BK

BK

BK

WH

1(L) 2(N)

TERMINAL BLOCK

1

2

CN-P2(N)

CN-COMP2

CN-FAN

OR

OROR

FAN1

OUTDOOR PCB

PTCR

MAGNECTIC

CONTACTOR

CAPACITOR

YLYL

CN-

P1(L)

CN-

COMM

RD

BK BK

BK

BK

BKBK

TERMINAL BLOCK1

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

T2 T1

L2 L1

A2

A1

BR

C

OUTDOOR WIRING DIAGRAM

3854A20051H

YL

FAN2

CAPACITOR1

CAPACITOR2

OR

YL

OR

5

3(L) 4(N)

BK

RD

WH

R

S

COMP

RUNNING

CAPACITOR

BL

BL

BR

BR

BK

BK

BK

BK

WH

1(L) 2(N)

TERMINAL BLOCK

1

2

CN-P2(N)

CN-COMP2

CN-FAN

OR

OROR

FAN1

OUTDOOR PCB

MAGNECTIC

CONTACTOR

CAPACITOR

YLYL

CN-

P1(L)

CN-

COMM

RD

BK BK

BK

BK

BKBK

TERMINAL BLOCK1

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

T2 T1

L2 L1

A2

A1

BR

C

OUTDOOR WIRING DIAGRAM

3854A20051J

YL

FAN2

CAPACITOR1

CAPACITOR2

OR

YL

OR

OUTDOOR WIRING DIAGRAM

3854A20051Z

78

1

TM

220-240V

1Ø, 50Hz

POWER SUPPLY

BK(BR)

63H2

52C

L1

L2

T1 T2

A2

A1

BK(BR)

52F1

12

34

56

WH

BK

BK

BK

BL

BR

WH

F1

BK(BR)

BK(BR)

WH(BL)

WH

Co

OR YLCoOR

FMo1

49FMo

CN-POWER2(N)

CN-POWER1(L)

CN-RYOIM CN-4WAY CN-COMP2

THERMISTOR

CN-TH

CN-COM

CN-FAN

FMo2

49FMo

20SV

YL

BKBK

BK

WH(BL)

BK(BR)

WH(BL)

BKBKBK

BL BK

BK

BKBK

WH

WH

BK

WH

YL

52S

BR

BL

BK

RD

GN/YL

PCB

Tmo

To indoor unit

WH(BL)

GN/YL

23

LN

1

2

3(L)

4(N)

5

CH1

BK

BK

BK

YL

BK

RD

BK

RD

REACTOR

R

C

S

CM

Cr

Cs

A2A1T3L3T2

L2

5

3(L) 4(N)

BK

RD

WH

R

S

COMP

RUNNING

CAPACITOR

BL

BL

BR

BR

BK

BK

BK

BK

WH

1(L) 2(N)

TERMINAL BLOCK

1

2

CN-P2(N)

CN-COMP2

CN-FAN

CN-4WAY

CN-TH

THERMISTOR

OR

OR

OROR

FAN1

OUTDOOR PCB

MAGNECTIC

CONTACTOR

CAPACITOR

YLYL

CN-

P1(L)

CN-

COMM

RD

BK BK

BK

BK

BK

BK

BK

BKBK

TERMINAL BLOCK1

TO INDOOR UNIT

POWER INPUT

FUSE(5A)

FUSE(5A)

T2 T1

L2 L1

A2

A1

BR

C

YL

FAN2

CAPACITOR1

CAPACITOR2

OR

YL

OR

REVERSING

VALVE

HIGH PRESS

SWITCH

(2) Outdoor Unit

• 36K, 38K

(1) Indoor Unit

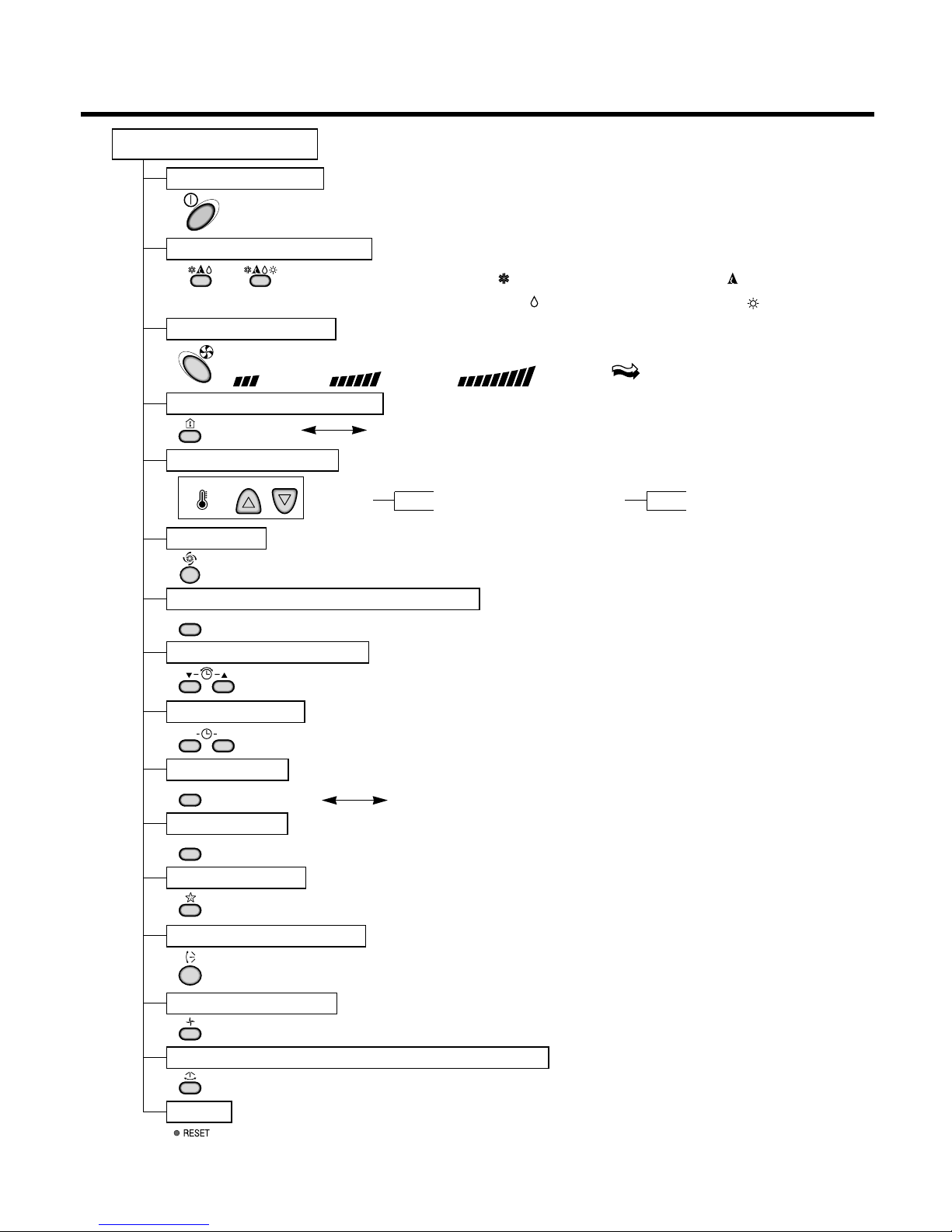

1. MAIN UNIT FUNCTION

• DISPLAY

1) C/O Model (high quality LCD remote controller supplied)

Op

eration

Indicato

r

• On while in appliance operation, off while in appliance pause

Ti

mer Indicator

• On while in timer mode (on/off) and in sleep timer mode, off when timer mode is completed or canceled.

Comp. Running Indicator

• While in appliance operation, on while in outdoor unit compressor running, off while in compressor off

P

lasma Indicator

• On while in plasma mode, off while plasma mode is canceled.

Auto restart Indicator

• On while auto restart mode, off while auto restart mode is canceled.

Auto restart

• In case the power comes on again after a power failure, Auto Restarting Operation is the function to operate

procedures automatically to the previous operating conditions.

If your want to use this operation, press the Auto Restart Button.

Power(Forced Operation)

• Operation starts, when this button is pressed and stops when you press the button again.

2) H/P Model (high quality LCD remote controller supplied)

Operation Indicator

• On while in appliance operation, off while in appliance pause

Timer Indicator

• On while in timer mode (on/off) and in sleep timer mode, off when timer mode is completed or canceled

D

efrost Indicator

• Off except when hot start during heating mode operation or while in defrost control.

P

lasm

a Indicator

• On while in plasma mode, off while plasma mode is canceled.

Auto restart Indicator

• On while auto restart mode, off while auto restart mode is canceled.

Auto restart

• In case the power comes on again after a power failure, Auto Restarting Operation is the function to operate

procedures automatically to the previous operating conditions.

If your want to use this operation, press the Auto Restart Button.

Power(Forced Operation)

• Operation starts, when this button is pressed and stops when you press the button again.

■ Cooling Mode Operation

•

When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp=> Setting Temp+0.5°C

Compressor OFF Temp => Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote controller. While in compressor

not running, operating with the low airflow speed regardless of the setting.

-15-

Operation Details

■

Healthy Dehumidification Mode

• When the dehumidification operation input by the remote controller is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp => 25°C

24°C ≤ Intake Air Temp < 26°C => Intake Air Temp-1°C

18°C ≤ Intake Air Temp < 24°C => Intake Air Temp-0.5°C

Intake Air Temp < 18°C=>18°C

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidification

operation and 4-min compressor off repeat

Compressor ON Temp. => Setting Temp+0.5°C

Compressor OFF Temp. => Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■

Heating Mode Operation

• When the intake air temp reaches +3°Cabove the setting temp, the compressor is turned off. When below the

setting temp, the compressor is turned on.

Compressor ON Temp. => Setting Temp.

Compressor OFF Temp. => Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 26®¨C , when above 28°C,it

operates with the low or setting airflow speed (while in sleep mode, with the medium airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C , when above 35°C,it

operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■

Defrost Control

• While in heating mode operation in order to protect the evaporator pipe of outdoor unit from freezing, reversed

to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• Defrost control is available 30 minutes later since heating mode operation started, and it will not polong over 6

minutes.

•

Deicing starts only when the outdoor pipe temperature falls below -6°C after 30 minutes passed from starting of

heating operating and more than 10 minutes operation of compressor.

• Deicing ends after 6 minutes passed from starting of deice operation or when the outdoor pipe temperature rises

over 12°C even if before 6 minutes.

■ Fuzzy Operation (C/O Model)

• According to the temperature set by Fuzzy rule, when the intake air temp is 0.5°C or more below the setting

temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is turned on.

Compressor ON Temp => Setting Temp+0.5°C

Compressor OFF Temp => Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

-16-

26°C ≤ Intake Air Temp => 25°C

24°C ≤ Intake Air Temp<26°C => Intake Air Temp+1°C

22°C ≤ Intake Air Temp<24°C => Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C => Intake Air Temp

Intake Air Temp<18°C=>18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature

■ Fuzzy Operation (H/P Model)

• When any of operation mode is not selected like the moment of the power on or when 3 hrs has passed since

the operation off, the operation mode is selected.

• When determining the operation mode, the compressor, the outdoor fan, and the 4 way valve are off and only

the indoor fan is operated for 15 seconds. Then an operation mode is selected according to the intake air temp

at that moment as follows.

24°C ≤ Inatake Air Temp => Fuzzy Operation for Cooling

21°C ≤ Inatake Air Temp<24°C => Fuzzy Operation for Dehumidification

Inatake Air Temp<21°C => Fuzzy Operation for Heating

• If any of the operation modes among cooling / dehumidification / heating mode operations is carried out for 10

sec or longer before Fuzzy operation, the mode before Fuzzy operation is operated.

1) Fuzzy Operation for Cooling

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is

turned on.

Compressor ON Temp => Setting Temp+0.5°C

Compressor OFF Temp => Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp => 25°C

24°C ≤ Intake Air Temp<26°C => Intake Air Temp+1°C

22°C ≤ Intake Air Temp<24°C => Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C => Intake Air Temp

Intake Air Temp < 18°C=>18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

2) Fuzzy Operation for Dehumidification

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is

turned on.

-17-

Compressor ON Temp => Setting Temp+0.5°C

Compressor OFF Temp => Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp => 25°C

24°C ≤ Intake Air Temp<26°C => Intake Air Temp+1°C

22°C ≤ Intake Air Temp<24°C => Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C => Intake Air Temp

Intake Air Temp < 18°C=>18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan repeats the low airflow speed or pause as in dehumidification operation.

3) Fuzzy Operation for Heating

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 3°C or more above the

setting temp, the compressor is turned off. When below the setting temp, the compressor is turned on.

Compressor ON Temp => Setting Temp

Compressor OFF Temp => Setting Temp + 3°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

20°C ≤ Intake Air Temp => Intake Air Temp + 0.5°C

Intake Air Temp < 20°C=>20°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is set to the high or the medium according to the

intake air temperature and the setting temperature.

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos by the input of the airflow speed selection key on the remote controller.

■ On-Timer Operation

• When the set time is reached after the time is input by the remote controller, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

■ Off-Timer Operation

• When the set time is reached after the time is input by the remote controller, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

-18-

■ Off-Timer <=> On-Timer Operation

• When the set time is reached after the on/off time is input by the remote controller, the on/off-timer operation is

carried out according to the set time.

■

Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote controller while in

appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature increas-

es by 1°C After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to the

low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to the

medium.

■ Chaos Swing Mode

• By the Chaos Swing key input, the vane automatically operates with the Chaos Swing or they are fixed to the

desired direction.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the airflow mode is operated for 2~15 sec randomly by the Chaos Simulation.”

■

Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (H/P Model)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the other

mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.”

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Auto Restarting Operation

• When the power is restored after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance automatically operates in the mode on the memory.

-19-

• Operation Mode that is kept on the memory

- State of Operation ON/OFF

- Operation Mode/Setting Temp/Selected Airflow Speed

- Sleep Timer Mode/Remaining Time of Sleep Timer (unit of hour)

■ Forced Operation ( C/O Model)

• To operate the appliance by force in case that the remote controller is lost, the forced operation button is on the

main unit of the appliance to operate the appliance in the standard conditions.

• Press the forced operation button, the forced operation is carried out.

• Press the forced operation button once again to stop operation.

• The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of air-

flow.

■ Forced Operation ( H/P Model)

• To operate the appliance by force in case that the remote controller is lost, the forced operation selection switch

is on the main unit of the appliance to operate the appliance in the standard conditions.

• Press the forced operation button, the forced operation is carried out.

• Press the forced operation button once again to stop operation.

• In the forced operation mode, the indoor fan is operated at low speed for around 15 sec and then the operation

condition is set according to the intake air temperature as follows.

24°C ≤ Intake Air Temp => Cooling Mode Operation, 22°C, High Speed

21°C ≤ Intake Air Temp < 24°C => Dehumidification Operation, 23°C, High Speed

Intake Air Temp < 21°C => Heating Mode Operation, 24°C, High Speed

■ Test Operation Control

• To check the condition of the installation when installing the appliance, the appliance is operated at cooling

mode, high speed of airflow, compressor-on for 18 min without controlling the room temperature.

• After supplying power to the main body, keep pressing the forced operation button for about 3 seconds.

• While in test operation, a key can be input by the remote controller.

When a key (operation start/stop, operation mode selection, airflow speed selection, temperature control, Jet

Cool) is input by the remote controller, the test operation is canceled and the appliance is operated according to

the setting by the remote controller.

■ Protection of the evaporator pipe from frosting

• In the temperrature of the indoor pipe is below 0°C after 7 minutes from starting the compressor, the compressor and outdoor fan are stopped, and 3 minutes delay of operating of the compressor, when the temperature of

the indoor pipe is over 7°C, the compressor and the outdoor fan are reoperated.

• Outdoor fan motor stops when indoor pipe temperature is blow 3°C and restarts at the pipe temperature above

6°C or after 90 seconds, if the pipe temperature does not rise to 6°C, outdoor fan motor runs continuously at

even below 3°C.

■ Buzzer Sounding Operation

• When the appliance-operation key is input by the remote controller, the short “beep-beep-” sounds.

• When the appliance-pause key is input by the remote controller, the long “beep—” sounds.

-20-

■ Air Cleaner Operation

• When an air cleaner function is selected during Air Conditioner operation

- Plasma air cleaner function will be operated while in any operation mode with selecting the function.

- The function is to be stopped while it is operating with selecting the function.

• When an air cleaner function is selected during operation off

- The function will be only operated.

• When inlet grille of air conditioner is opened during plasma operation, High Voltage Generator(H.V.B) is to be

stopped. When inlet grille of air conditioner is closed during plasma operation, High Voltage Generator(H.V.B)

will be operated again.

-21-

-22-

Display Function

Self-diagnosis Function

Signal Receptor

Receives the signals from the remote control.(Signal receiving sound: two short beeps or one long beep.)

Operation Indication Lamps

On/Off : Lights up during the system operation.

Timer or Sleep Mode : Lights up during Timer operation or Sleep mode.

Defrost Mode : Lights up during Defrost Mode or Hot

Start operation. (Heat pump model only)

Outdoor unit operation : Lights up during outdoor unit operation. (Cooling model only)

Plasma Mode : Lights up during plasma-purification operation.(option)

Auto Restart Mode : Lights up during if Restart Button is pressed.

Auto Restart Button : In failure of electric power, if the button is pressed the unit runs as previous

setting operation when power returns.

Forced Operation Button

: Operation starts, when this button is pressed and stops when you press the

button again.

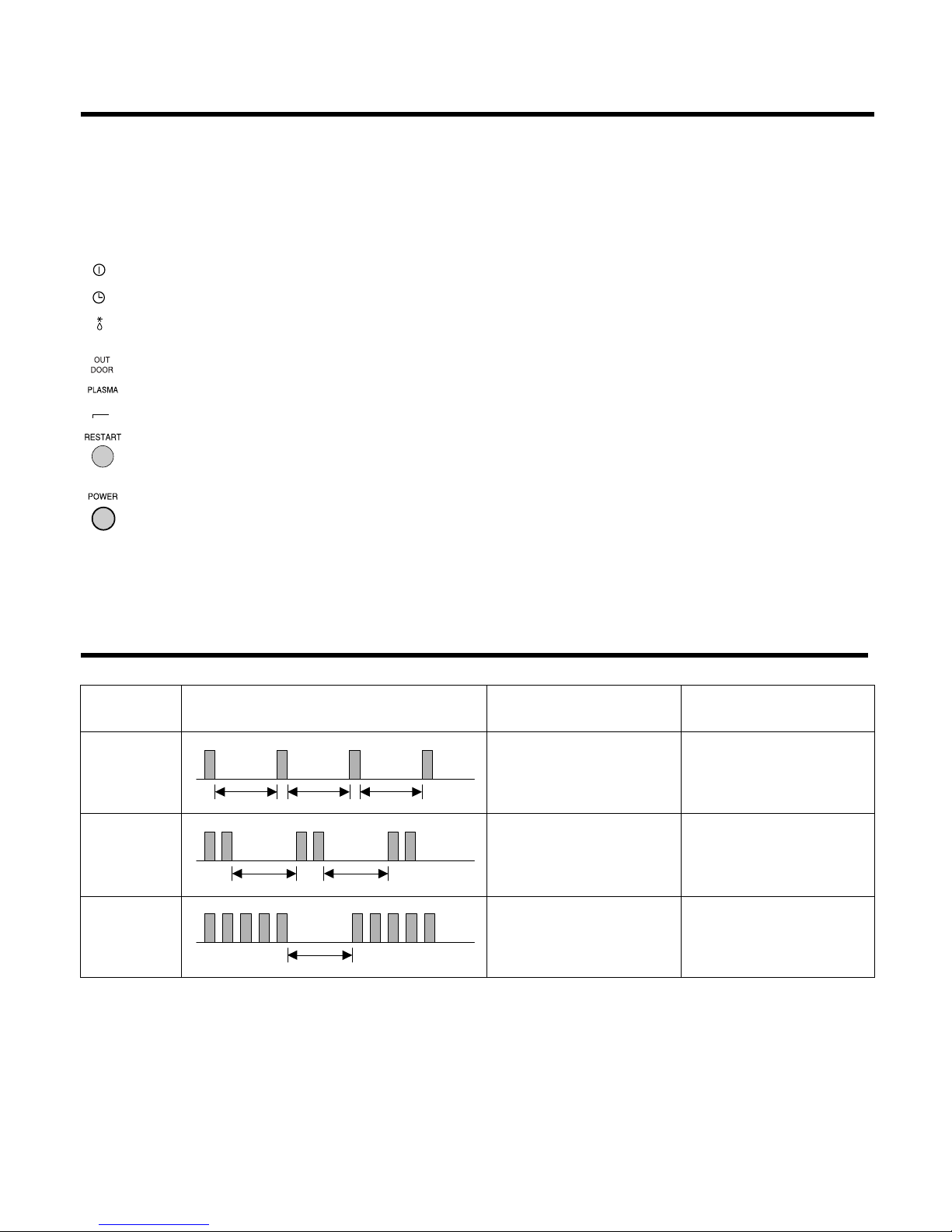

3sec 3sec 3sec

(once)

3sec 3sec

(twice)

3sec

(5times)

Error

Code

1

2

5

Error LED

(Indoor body operation LED)

Error contents

• Indoor room temperature

thermistor open/short

• Indoor pipe temperature

thermistor open/short.

• Outdoor pipe temperature

thermistor open/short.

• Poor communication.

• Indoor TH assy check

• Outdoor TH assy check

• Communication line/circuit

check

SVC check point

-23-

Installation

Read completely, then follow step by step.

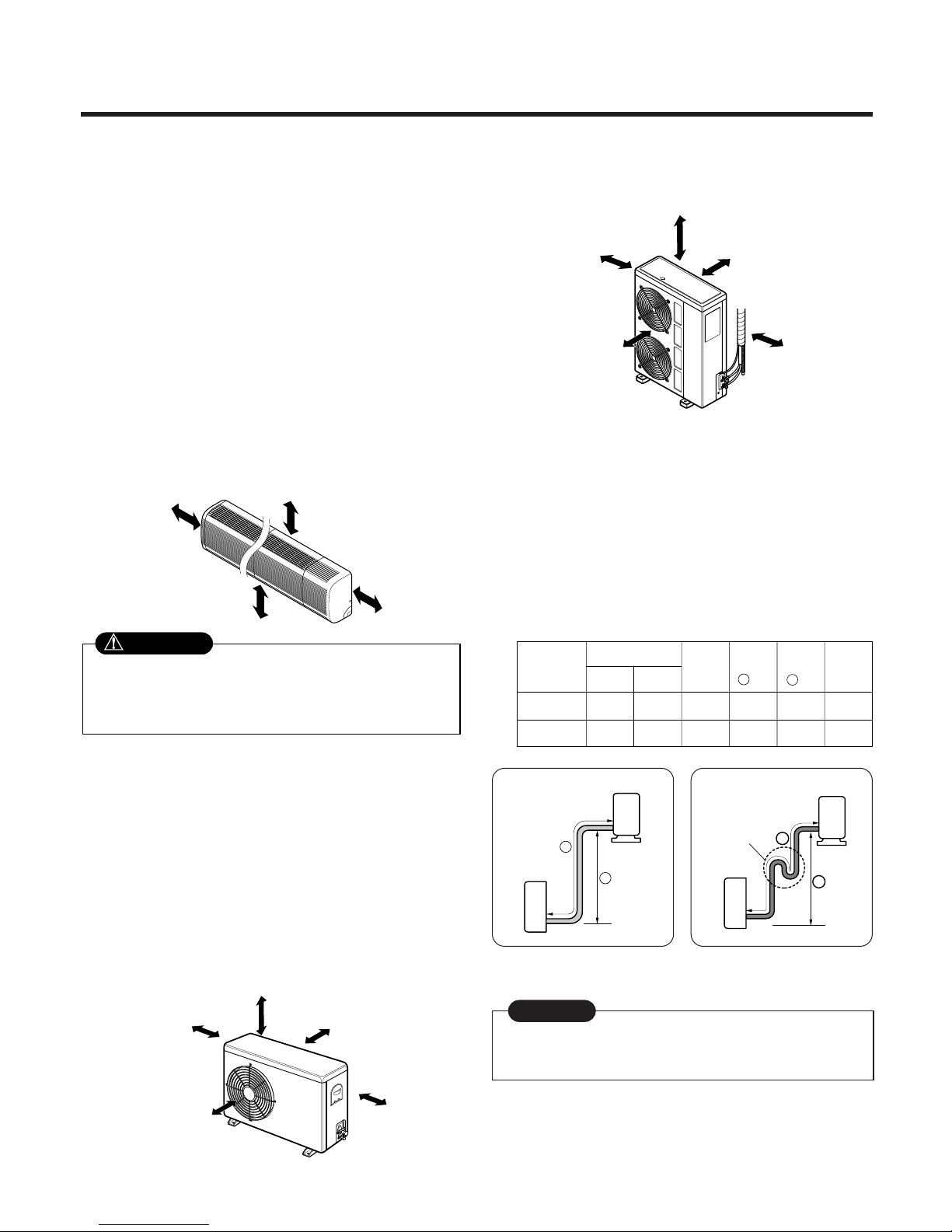

1. Installation of Indoor, Outdoor unit

1) Select the best location

1. Indoor unit

■ Do not have any heat or steam near the unit.

■ Select a place where there are no obstacles in

front of the unit.

■ Make sure that condensation drainage can be

conveniently routed away.

■ Do not install near a doorway.

■ Ensure that the space around the left and right of

the unit is more than 30cm. The unit should be

installed as high on the wall as possible, allowing

a minimum of 12cm from ceiling.

■ Use a stud finder to locate studs to prevent

unnecessary damage to the wall.

2. Outdoor unit

■ If an awning is built over the unit to prevent direct sun-

light or rain exposure, make sure that heat radiation

from the condenser is not restricted.

■ Ensure that the space around the back and sides is

more than 10cm. The front of the unit should have

more than 70cm of space.

■ Do not place animals and plants in the path of the

warm air.

■ Take the air conditioner weight into account and select

a place where noise and vibration are minimum.

■ Select a place so that the warm air and noise from the

air conditioner do not disturb neighbors.

■ Rooftop Installations:

If the outdoor unit is installed on a roof structure, be

sure to level the unit. Ensure the roof structure and

anchoring method are adequate for the unit location.

Consult local codes regarding rooftop mounting.

If the outdoor unit is installed on root structures or walls,

this may result in excessive noise and vibration, and

maybe also classed as non serviceable installation.

2) Piping length and elevation

More than 12cm

More than

30cm

More than

30cm

More than 2.3m

More than 10cm More than 10cm

More

than 60cm

More than 60cm

More than 70cm

More than 10cm More than 10cm

More

than 60cm

More than 60cm

More than 70cm

In case more than 5m

• Capacity is based on standard length and maximum

allowance length is on the basis of reliability.

• Oil trap should be installed every 5~7 meters.

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

CAUTION

Install the indoor unit on the wall where the height

from the floors more than 2.3 meters.

A minimum pipe run of 7.5 meters is required to minimise vibration & excessive noise.

CAUTION

30k, 32k 5/8" 3/8" 7.5 15 30 30

36k, 38k 3/4" 3/8" 7.5 20 30 50

Pipe Size

Capacity

(Btu/h)

GAS LIQUID

Max.

length

A (m)

Additional

Refrigerant

(g/m)

Max.

Elevation

B

(m)

Standard

Length

(m)

30K, 32K

36K, 38K

-24-

3) How to fix installation plate

The wall you select should be strong and solid enough to prevent

vibration

1. Mount the installation plate on the wall with four

type A screws. If mounting the unit on a concrete

wall, use anchor bolts.

Mount the installation plate horizontally by

aligning the centerline using a level.

2. Measure the wall and mark the centerline. It is also

important to use caution concerning the location

of the installation plate-routing of the wiring to

power outlets is through the walls typically.

Drilling the hole through the wall for piping connections must be done safely.

5-7mm

(0.2~0.3")

Indoor

WALL

Outdoor

Installation Plate

Type "A" screw

Right rear pipingLeft rear piping

ø

70mm195mm

115mm

115mm

180mm

Right rear piping

30K, 32K

36K, 38K

Left rear piping

50mm

ø

70mm180mm

115mm

4) Drill a hole in the wall

■ Drill the piping hole with a ø70mm hole core drill.

Drill the piping hole at either the right or the left

with the hole slightly slanted to the outdoor side.

-25-

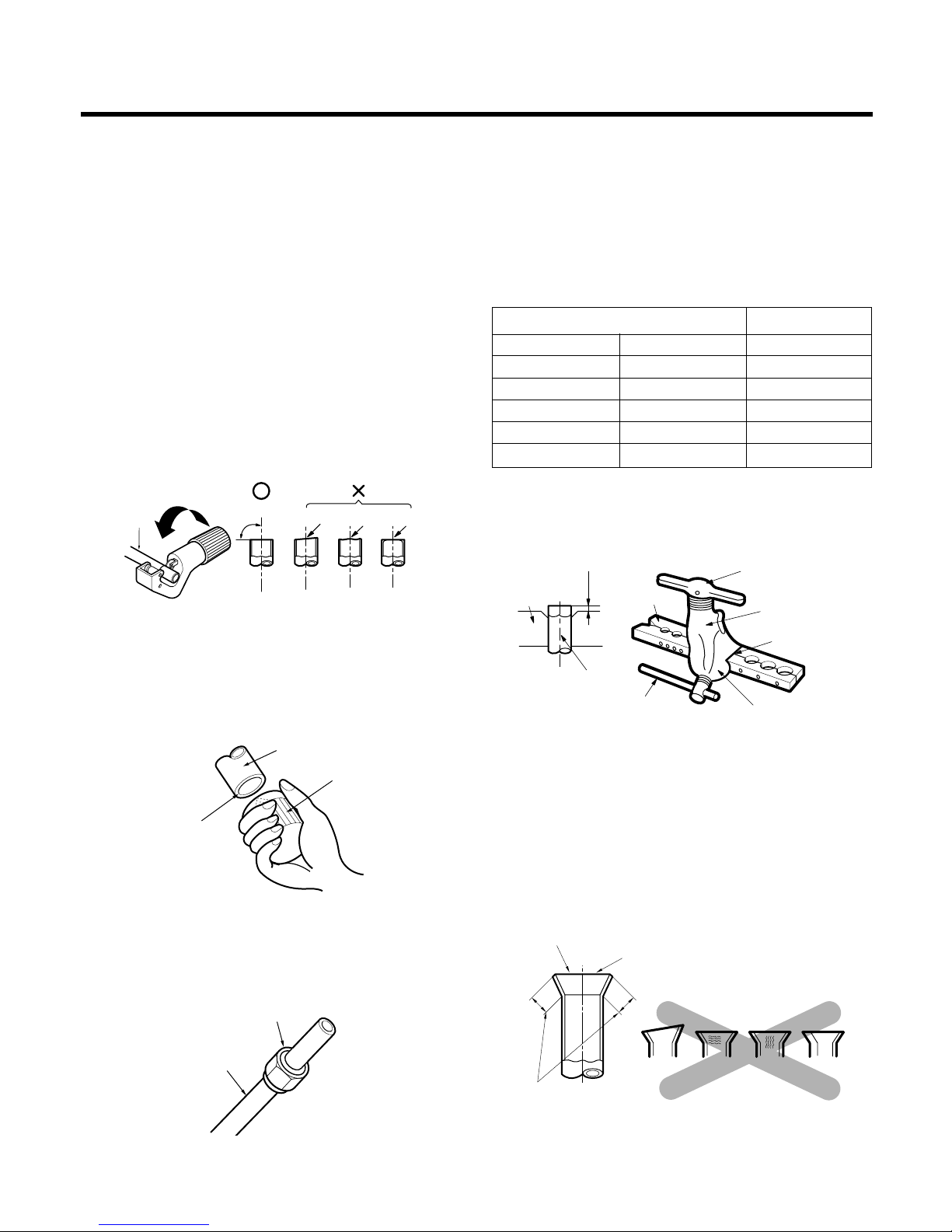

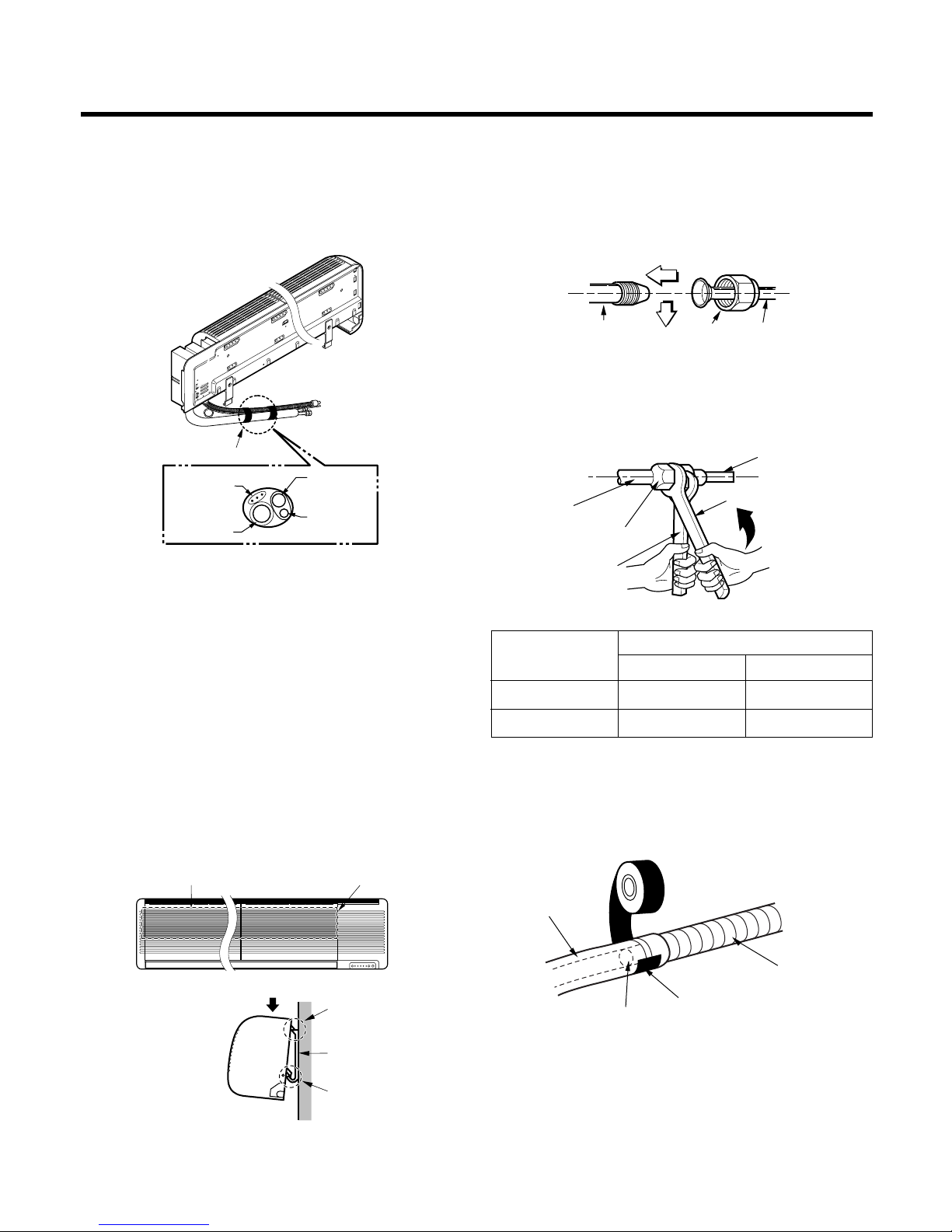

1) Flaring work

Main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the following procedure.

1. Cut the pipes and the cable.

■ Use the piping kit accessory or the pipes

purchased locally.

■ Measure the distance between the indoor and the

outdoor unit.

■ Cut the pipes a little longer than measured

distance.

■ Cut the cable 1.5m longer than the pipe length.

2. Burrs removal

■ Completely remove all burrs from the cut cross

section of pipe/tube.

■ Put the end of the copper tube/pipe in a downward direction as you remove burrs in order to

avoid dropping burrs into the tubing.

3. Putting nut on

■ Remove flare nuts attached to indoor and outdoor

unit, then put them on pipe/tube having completed burr removal.

(not possible to put them on after flaring work)

Copper

pipe

90°

Slanted Uneven Rough

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Pipe

Reamer

Point down

4. Flaring work

■ Carry out flaring work using flaring tool as shown

below.

Firmly hold copper pipe in a die in the dimension

shown in the table above.

5. Check

■ Compare the flared work with figure below.

■ If flare is noted to be defective, cut off the flared

section and do flaring work again.

mm inch mm

ø6.35 1/4 0 ~ 0.5

ø9.52 3/8 0 ~ 0.5

ø12.7 1/2 0 ~ 0.5

ø15.88 5/8 0 ~ 1.0

ø19.05 3/4 1.0 ~ 1.3

Outside diameter A

Flare nut

Copper tube

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

2. Flaring Work and Connection of Piping

-26-

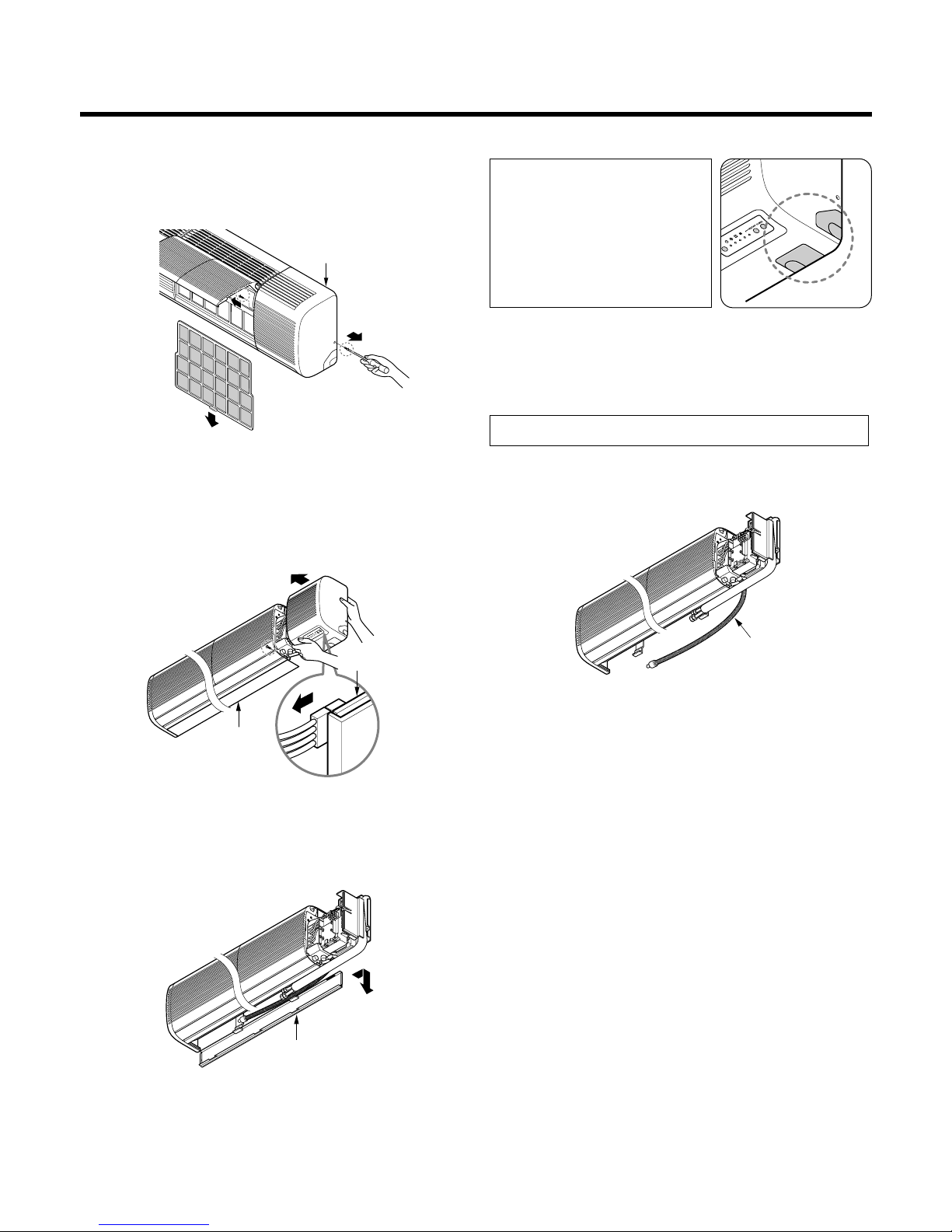

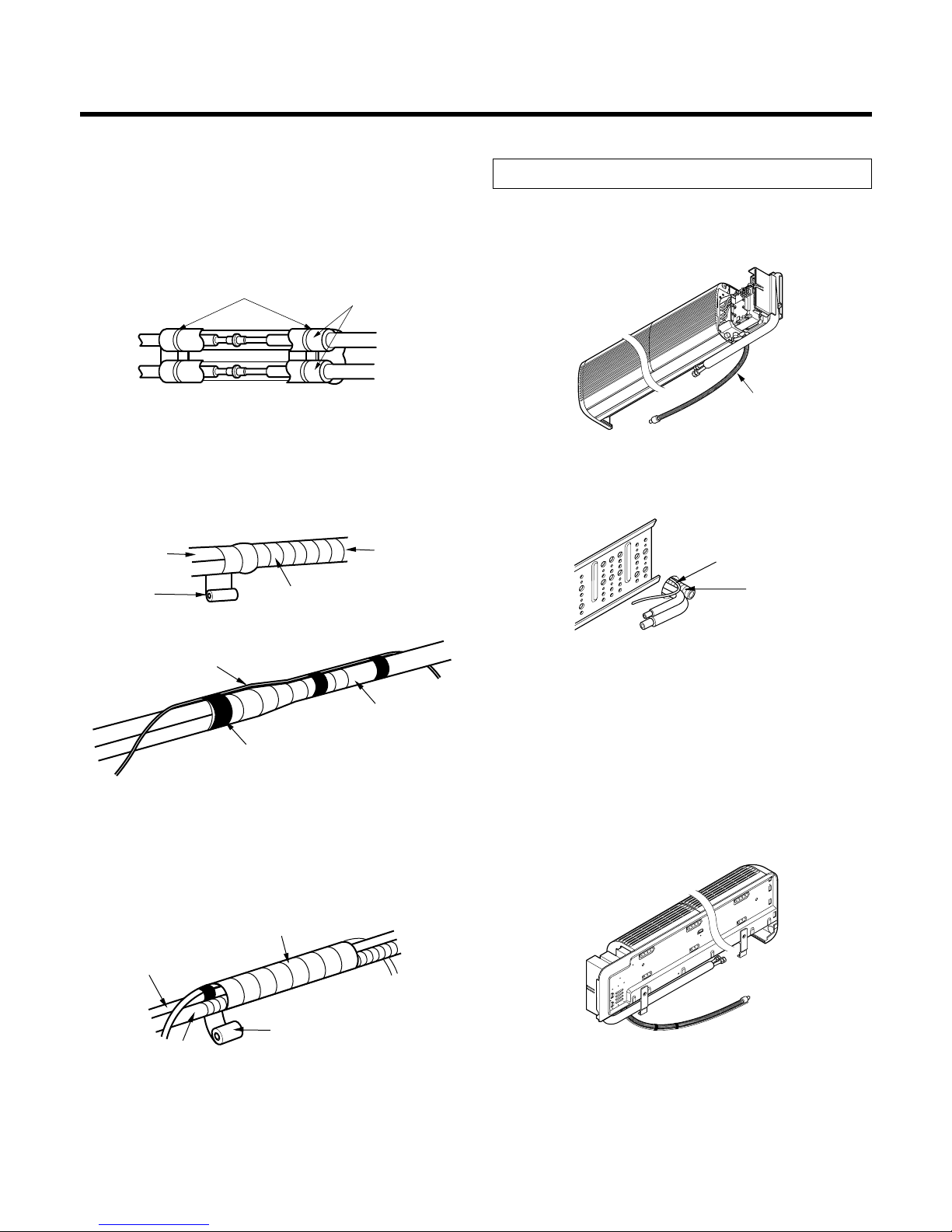

2) Connection of piping-Indoor

1. Remove the 2 screws of right side panel.

2. Remove the front right side panel by the arrow.

■ The connector can be disconnected by pulling it

while pressing the connector's hook.

■ Remove the 1 screw for fixing lower panel.

3. Remove the lower panel by the arrow.

■ Take care not to scratch the wall and mat to

drop.

1. Route the indoor tubing and the drain hose in the

direction of rear left.

2. Insert the connecting cable into the indoor unit

from the outdoor unit through the piping hole.

■ Do not connect the cable to the indoor unit.

■ Make a small loop with the cable for easy

connection later.

Right side panel

Drain hose

Main PCB

Lower panel

Lower panel

For left rear piping

CAUTION

When install, make sure that the

remaining parts must be

removed clearly so as not to

damage the piping and drain

hose, especially power cord and

connecting cable.

-27-

3. Tape the tubing, drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper side

can cause drain pan to overflow inside the unit.

3. Tape the tubing, drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper side

can cause drain pan to overflow inside the unit.

NOTE: If the drain hose is routed inside the room,

insulate the hose with an insulation material*

so that dripping from "sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is rec-

ommended.

4. Indoor unit installation

■ Hook the indoor unit onto the upper portion of the

installation plate.(Engage the three hooks of the

rear top and rear lower of the indoor unit with the

upper edge and lower edge of the installation

plate.) Ensure that the hooks are properly seated

on the installation plate by moving it left and right.

5. Connecting the pipings to the indoor unit and drain

hose to drain pipe.

■ Align the center of the pipings and sufficiently

tighten the flare nut by hand.

■ Tighten the flare nut with a wrench.

■ When extending the drain hose at the indoor unit,

install the drain pipe.

Connecting

cable

Loop

Gas side

piping

Liquid side

piping

Drain hose

Installation

plate

Three upper

hooks

Installation plate

Indoor unit

Three lower

hooks

Setting line

Indoor unit tubing Flare nut Pipings

Connection pipe

Flare nut

Indoor unit tubing

Torque wrench

Spanner (fixed)

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

Pipe Size[Torque]

Capacity

(Btu/h)

GAS LIQUID

30K, 32K 5/8"[6.6kg.m] 3/8"[4.2kg.m]

36K, 38K 3/4"[6.6kg.m] 3/8"[4.2kg.m]

-28-

6. Wrap the insulation material around the connecting

portion.

■

Overlap the connection pipe insulation material and

the indoor unit pipe insulation material. Bind them

together with vinyl tape so that there is no gap.

■ Wrap the area which accommodates the rear piping housing section with vinyl tape.

■ Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range within which they fit into the rear piping housing section.

1. Route the indoor tubing and the drain hose to the

required piping hole position.

2. Insert the piping, drain hose and the connecting

cable into the piping hole.

3. Insert the connecting cable into the indoor unit.

■ Don't connect the cable to the indoor unit.

■ Make a small loop with the cable for easy

connection later.

4. Tape the drain hose and the connecting cable.

• Connecting cable

Plastic bands

Insulation material

Drain hose

Drain pipe

Connecting cable

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

Wrap with vinyl tape

Drain hose

Pipe

Vinyl tape(wide)

For right rear piping

Loading...

Loading...