LG LS-J0761NM, LS-J0962NM Service Manual

MODEL : LS-J0761NL/NM/NN

LS-J0962NL/NM/NN/YL

LS-L1261NL/NM/NN

LS-K1860NL/NM/NN/YL

LS-K1861YL

LS-K18612L

Room Air Conditioner

SERVICE MANUAL

CAUTION

-BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

-ONLY FOR AUTHORIZED SERVICE PERSONNEL.

WEBSITE http://biz.LGservice.com

E-MAIL http://www.LGEservice.com/techsup.html

Contents

Functions

.................................................................................................................................

3

Product Specification (Cooling & Heating)

...........................................................................

6

Dimensions

..............................................................................................................................

7

Refrigeration Cycle Diagram

..................................................................................................

9

Wiring Diagram

......................................................................................................................

10

Operation Details

..................................................................................................................

12

Installation

.............................................................................................................................

27

Operation

...............................................................................................................................

41

Disassembly of the parts (Indoor Unit)

...............................................................................

43

2-way, 3-way Valve

.................................................................................................................

46

Cycle Troubleshooting Guide

...............................................................................................

53

Self-diagnosis function

.........................................................................................................

54

Electronic Parts Troubleshooting Guide

.............................................................................

56

Electronic Control Device

.....................................................................................................

67

Schematic Diagram

...............................................................................................................

73

Exploded View and Replacement Parts List

.......................................................................

78

-2-

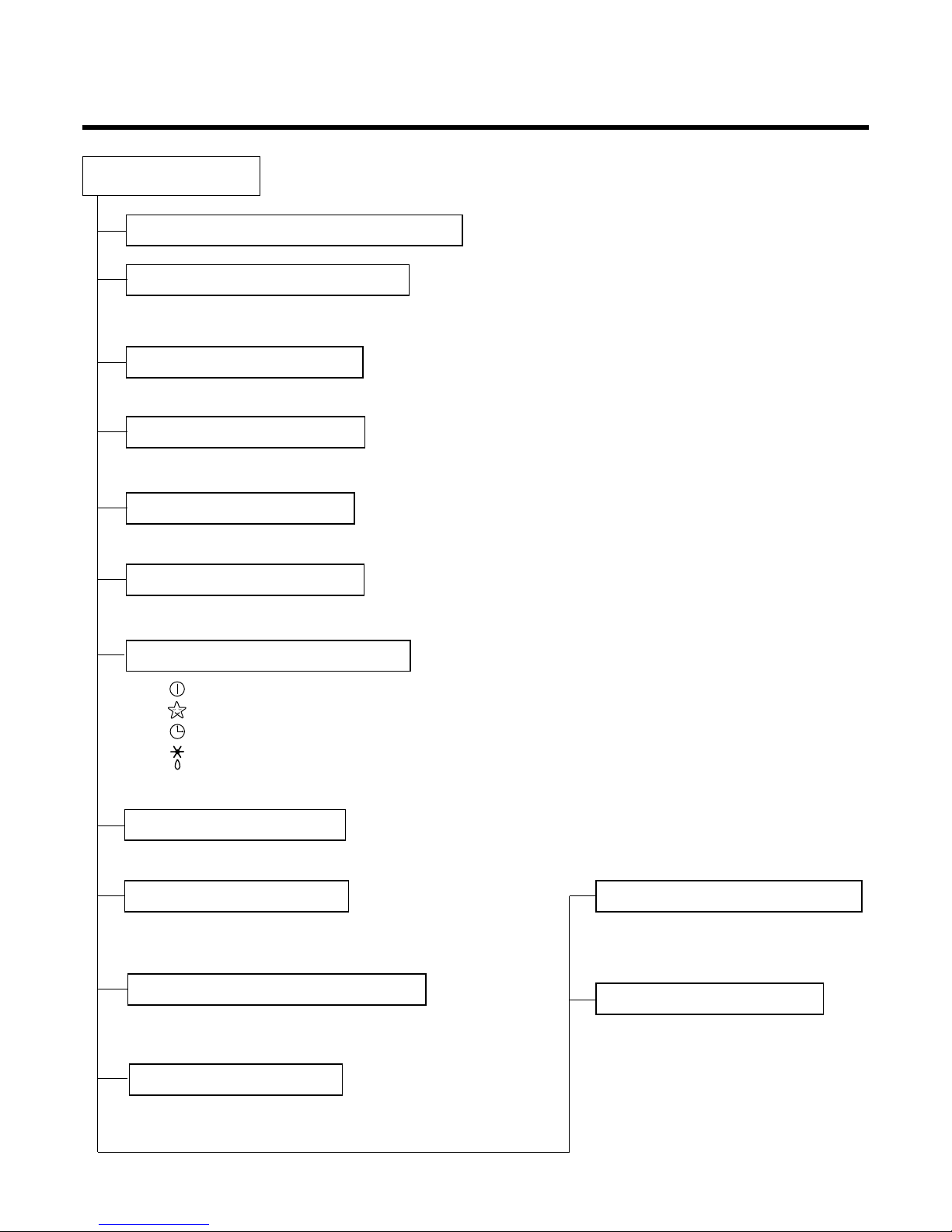

Functions

• Room temperature sensor. (Thermistor)

• Pipe temperature sensor. (Thermistor)

• Maintain the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 sec at the starting.

• Restarting is for approx. 2 minutes.

• Super High, High, Med, Low

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Defrost Mode (for Heating Model)

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), low(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting the Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

• Both the indoor and outdoor fan stops

during defrosting.

• The indoor fan stops until the

evaporator pipe temperature will be

reached at 30°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

-3-

Defrost(Deice) control (Heating)

Hot-start Control (Heating)

-4-

• If power is on, it will operate to chage capacitor (330µF/450WV) on controller and power relay will operate after about 2~5sec.

• If outdoor temp. is below 0°C, preheater is operating for 1~5min.

• At the initial, It will be operated compressor after 1min. for preheating.

• The active power filter is designed to correct power factor(cos θ) and to regulate DC link voltage.

• It will be operated PFC circuit when the compressor freq. is over 12Hz.

• If DC link voltage is not over DC 350V in 6 sec. in case of PFC on, it does not operating of compressor.

• The final operating freq. of comp. is set the lowest freq. that limited outdoor temp., discharge pipe temp.,

heat-sink temp., target freq., owing to CT.

• When the temp. of power module increases to 85°C, controller decreases Freq. of Comp.

• It will be changed the drive freq. of comp. according to temp. of indoor and outdoor.

• It will be changed the drive voltage of comp. according to operating frequency.

• It is only operated in the heating operation mode except defrosting operation.

• High speed

- Although fan motor speed is low, it will change high speed in case of below AC193V, over 45°C of out-

door temp., and over fc, fh of comp. Freq.

• Low speed

- Nomal mode and over AC270V

Outdoor Unit

Power relay control

Stand by control at low temp.

Active power filter control(PFC)

Comp. Freq. control

Overheatng. Protection(Power module)

Freq. speed control(up/down speed)

V/F control

Total current control (over current protection)

DC peak current control

4 way valve control

Outdoor fan motor control

Discharge pipe temp. control

-5-

Healthy Dehumidification Operation Mode.

( )

Remote Controller

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

Jet Cool

Timer Cancel

Sleep Operation

Airflow Direction Control

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Fan Operation Mode

Room, Temperature Display

Setting the Time or Timer

ON OFF

SET

CANCEL

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High: 30°C LOW : 18°C)

Down to 18°C

Up to 30°C

Cooling

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Down to 16°C

Up to 30°C

Heating

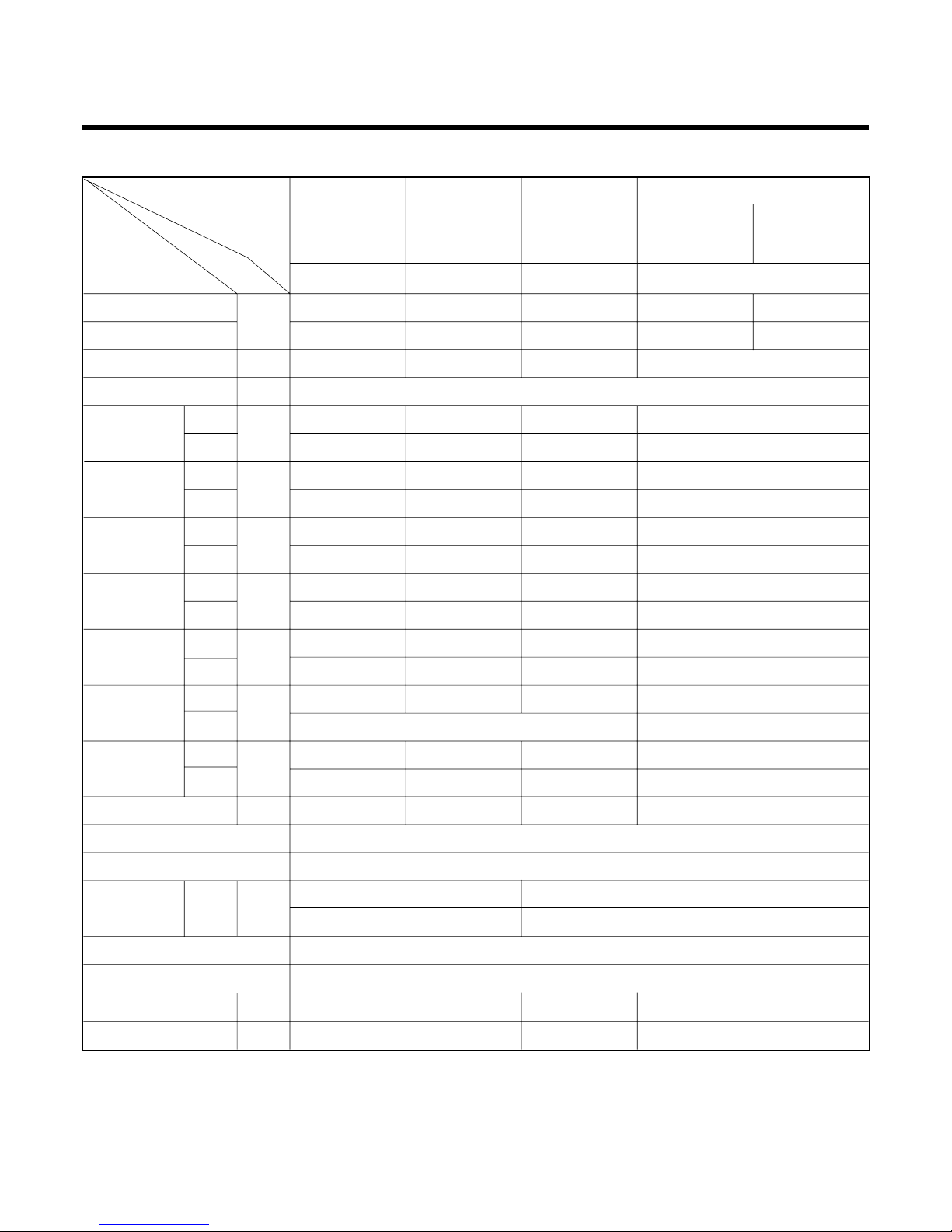

18K Series

LS-K1861YL

LS-K1860NL/YL

LS-K181N-1

LS-K18612L

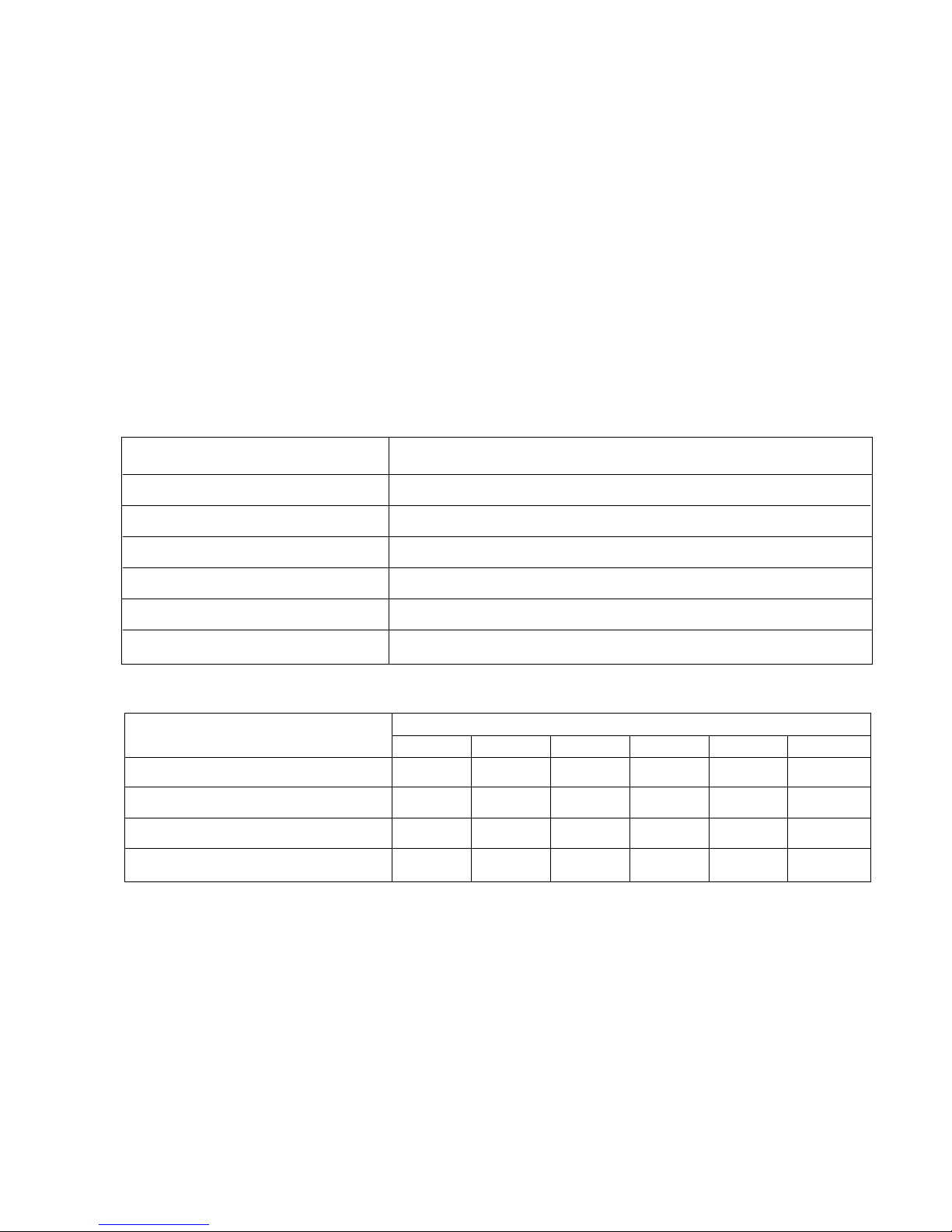

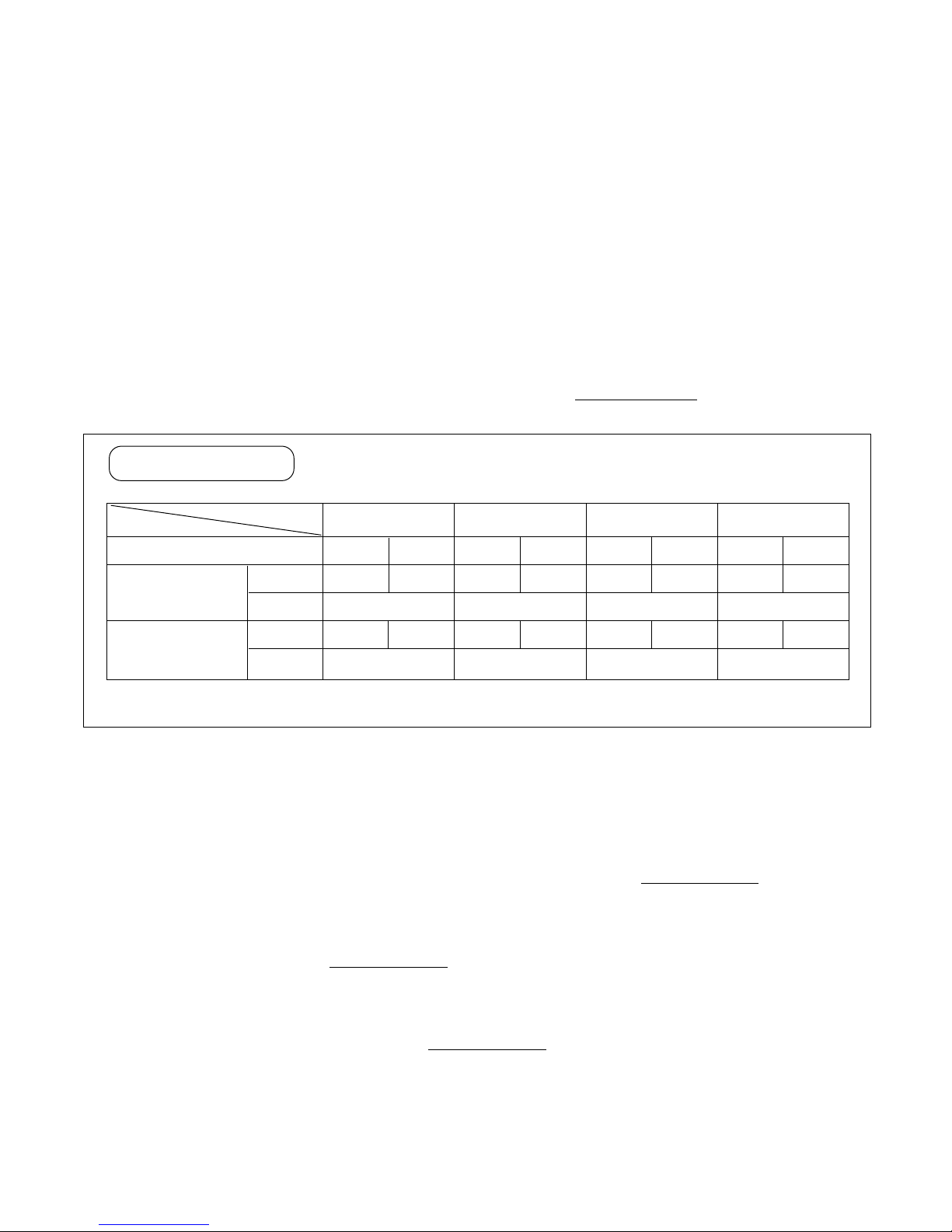

7K Series 9K Series 12K Series

Cooling Capacity Btu/h

Heating Capacity

Moisture Removal l/h

Power Source Ø, V, Hz

Air Circulation Indoor m3/min

Outdoor

Noise Level Indoor dB (A)±3

Outdoor

Input Cooling W

Heating

Running Cooling A

Current Heating

Motor Output Indoor W

Outdoor

Dimensions Indoor mm

(W x H x D) Outdoor

Net. Weight Indoor kg

Outdoor

Refrigerant (R22) g

Airflow Direction Control (Up & Down)

Remocon Type

Service Valve Liquid inch(mm)

Gas

Sleeping Operation

Drain Hose

Connecting Cable mm

2

Power Cord mm

2

at 230V at 230V at 230V at 230V

7,000(4,700-8,300) 9,000(5,200-9,700) 12,000(7,500-13,200) 18,000(11,000-19,800) 17,500(11,000-19,800)

9,000(5,000-10,000) 11,250(4,600-12,500) 14,400(8,300-15,900) 27,700(12,800-22,770) 19,700(12,800-22,770)

1 1.1 1.3 2.5

1Ø, 220-240V, 50Hz

5.6 6.5 8.6 12

25 25 25 42

33 36 39 42

50 50 51 56

740 1,070 1,280 2,000

980 1,300 1,580 2,200

3.3 4.8 5.8 9.0

4.4 6 7 9.5

7.5 7.5 13 20

35.8 35.8 35.8 62

802*262*165 802*262*165 888*287*170 1,080*314*181

801*555*262 870*655*320

779 15

33 35 41 54

530 650 980 1,250

O

L.C.D Wireless

1/4''(6.35) 1/4''(6.35)

3/8''(9.52) 1/2''(12.7)

O

O

1 1.5 2.5

1 1.5 2.5

-6-

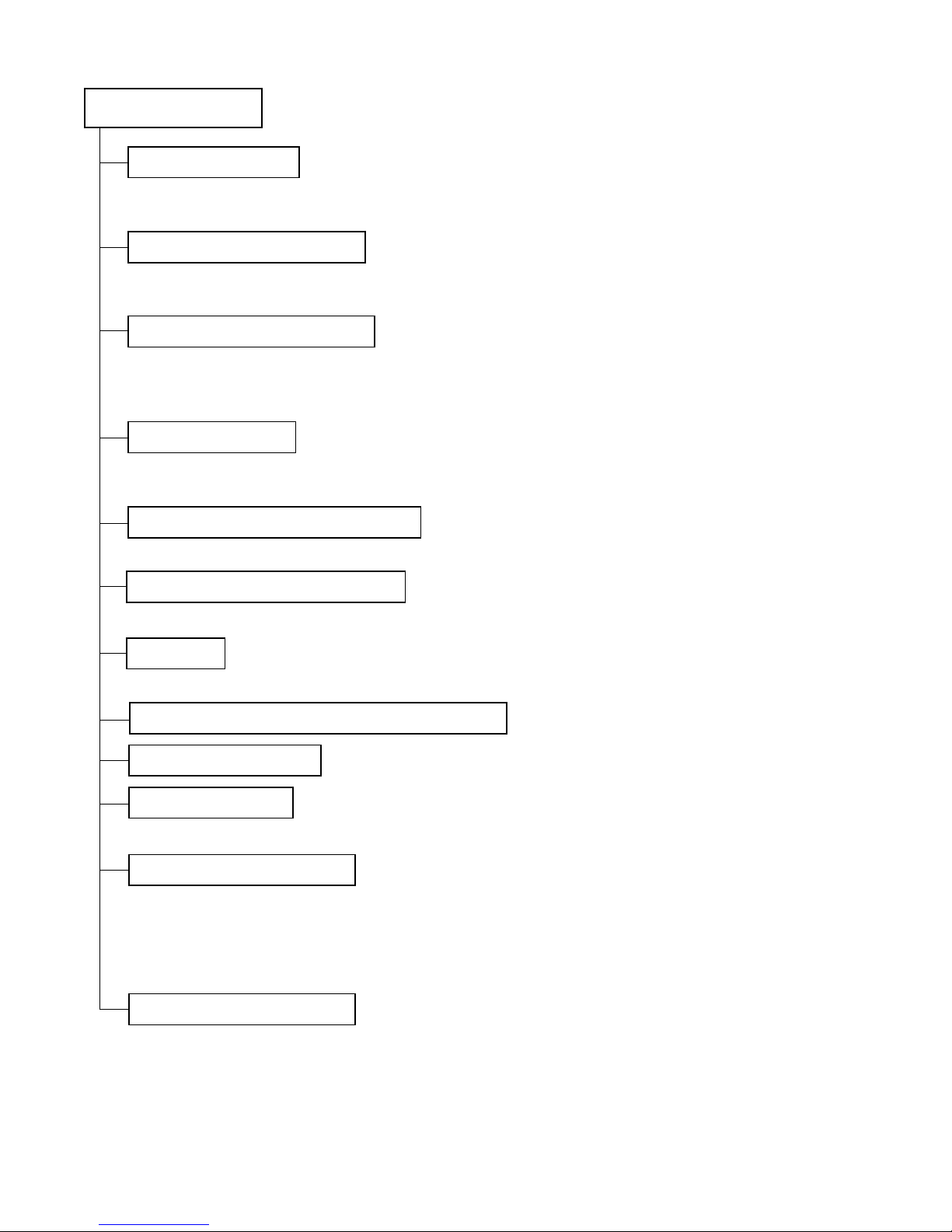

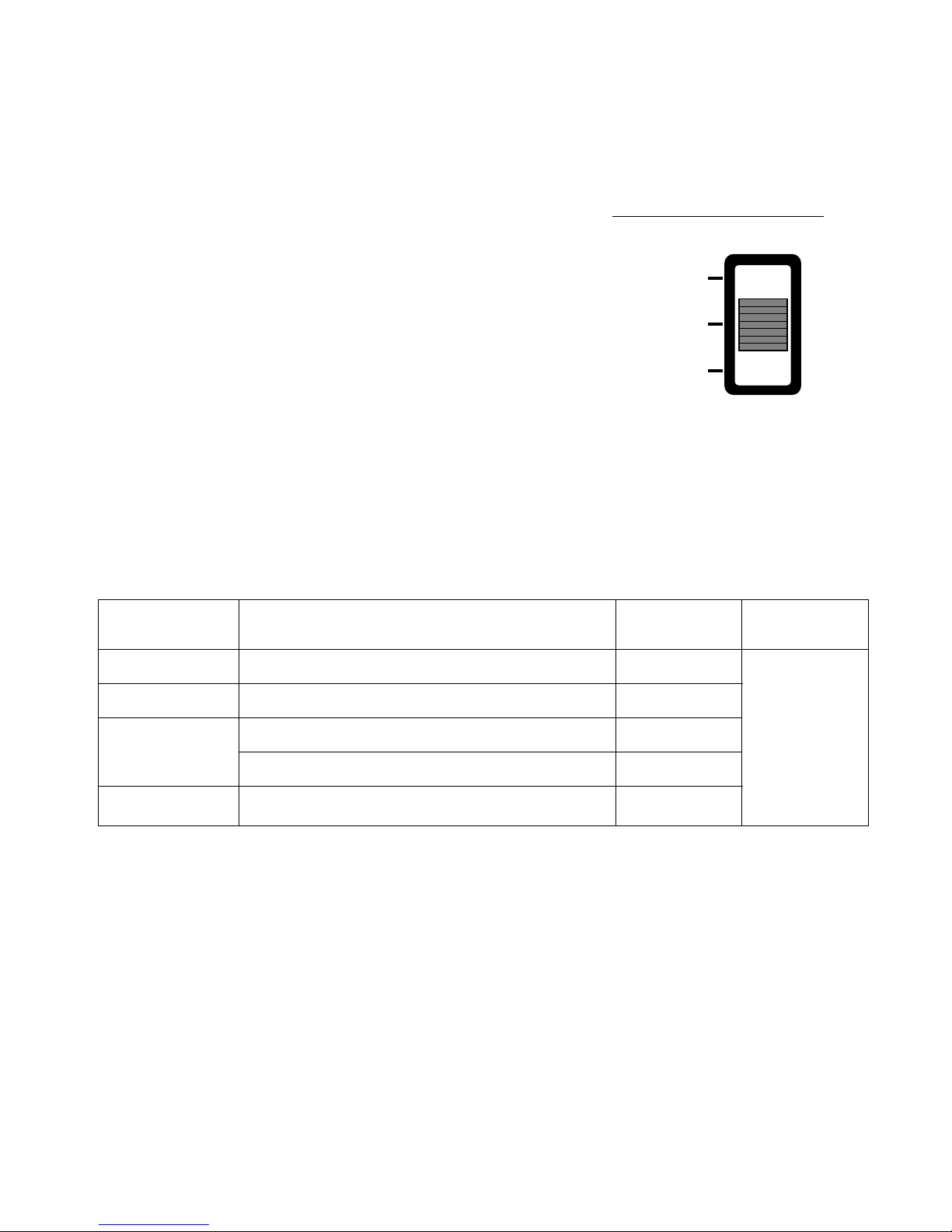

Product Specifications (Cooling & Heating)

Model Name

UnitItem

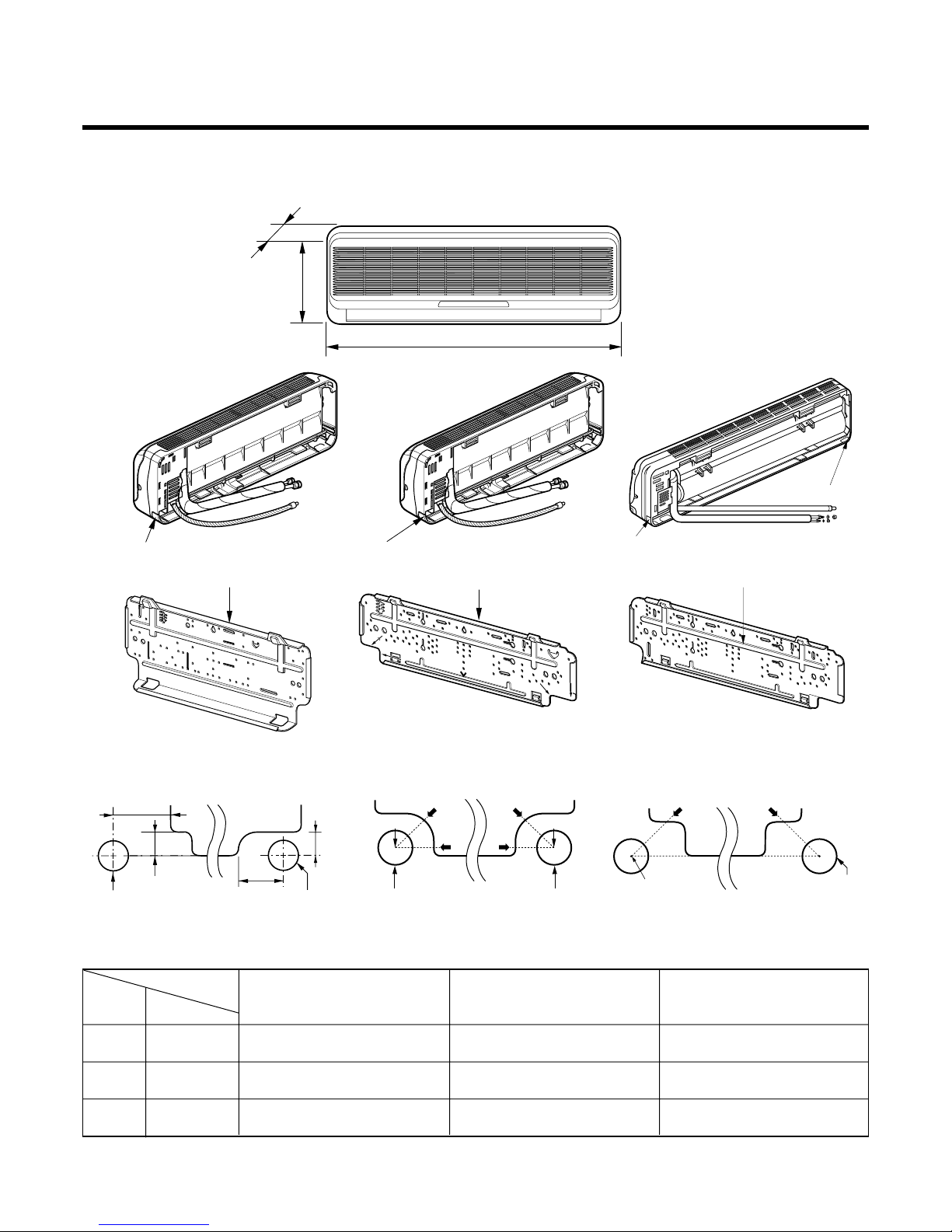

Dimensions

(1) Indoor Unit

-7-

Tubing hole cover

D

H

W

Installation plate

Tubing hole cover

Installation plate

Right rear piping

Left rear piping

ø70mm

ø70mm

50mm

20mm

20mm

80mm

ø70mm

A

A

A

A

Center

Right rear pipingLeft rear piping

Center

ø70mm

Tubing hole cover

Tubing hole cover

Installation plate

"D" "C"

Right rear pipingLeft rear piping

Hole center

ø70mm

MODEL

DIM Unit

W mm 802 888 1,080

H mm 262 287 314

D mm 165 170 181

7k, 9k Btu Series 12k Btu Series 18k Btu Series

(7k, 9k, 12k, 18k )

( 7k, 9k ) ( 12k ) ( 18k )

( 7k, 9k ) ( 12k ) ( 18k )

-8-

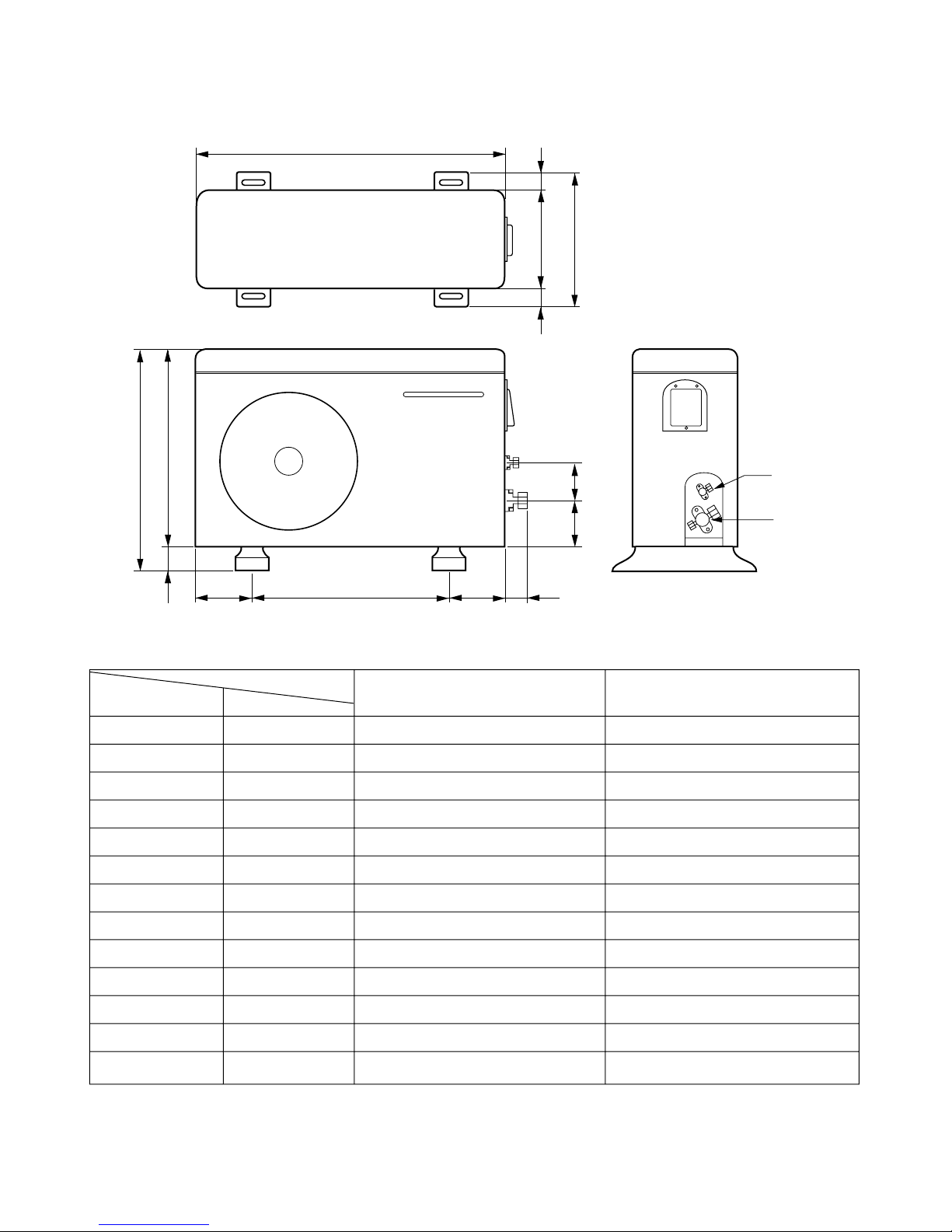

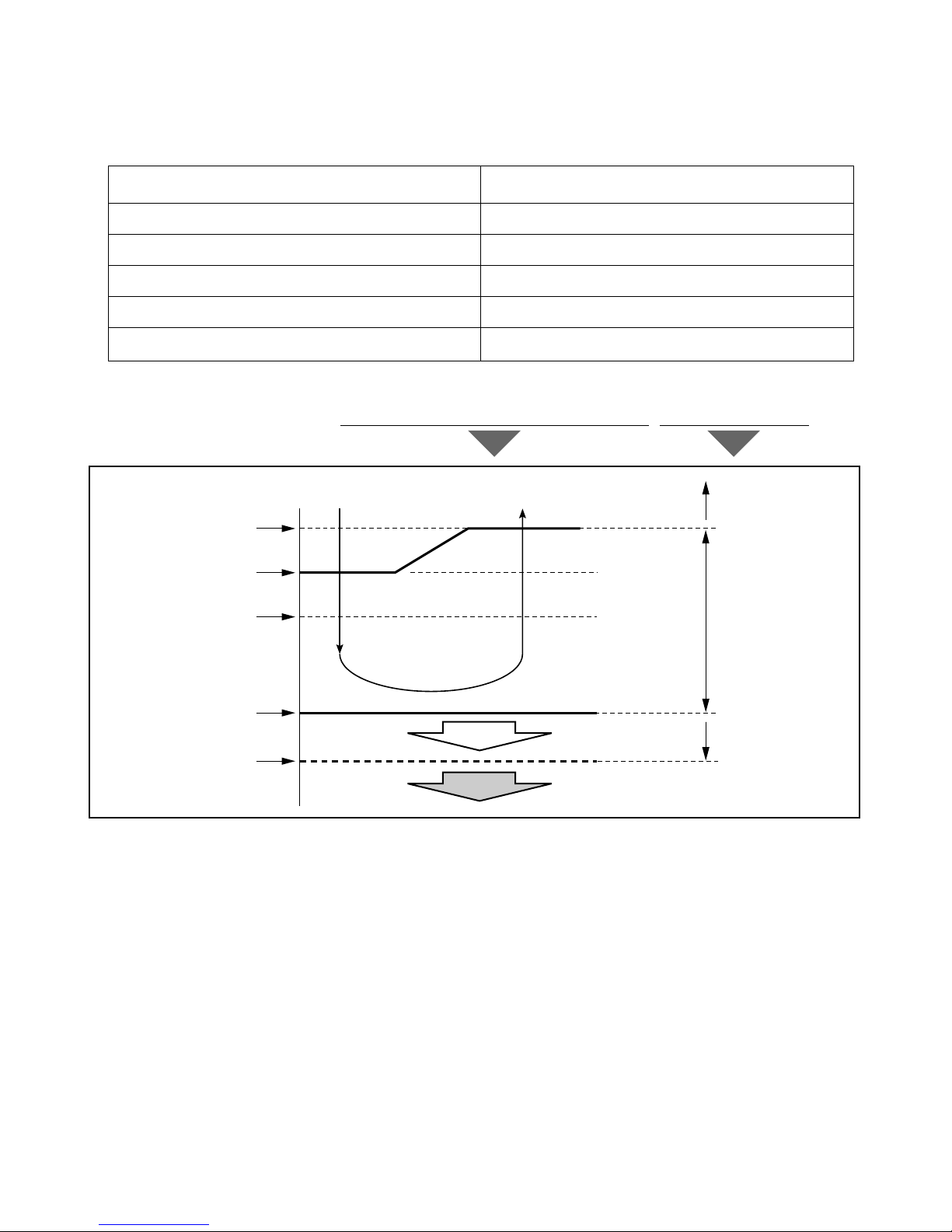

(2) Outdoor Unit

W

D

L1

L2

H

L3

L4

L5L6 L7 L8

L9

L10

Liquid side

2-way valve

Gas side

3-way valve

MODEL

7k, 9k, 12k Btu/h Series 18k Btu/h Series

DIM unit

W mm 801 870

H mm 555 655

D mm 262 320

L1 mm 339 370

L2 mm 37 25

L3 mm 543.6 630

L4 mm 11.4 25

L5 mm 591 546

L6 mm 105 162

L7 mm 105 162

L8 mm 72.5 54

L9 mm 86.4 79

L10 mm 77 74.5

Pipe size(Diameter:Ø)

MAX. Max

MODEL Piping length Elevation

Gas(inch) Liquid(inch)

(m) (m)

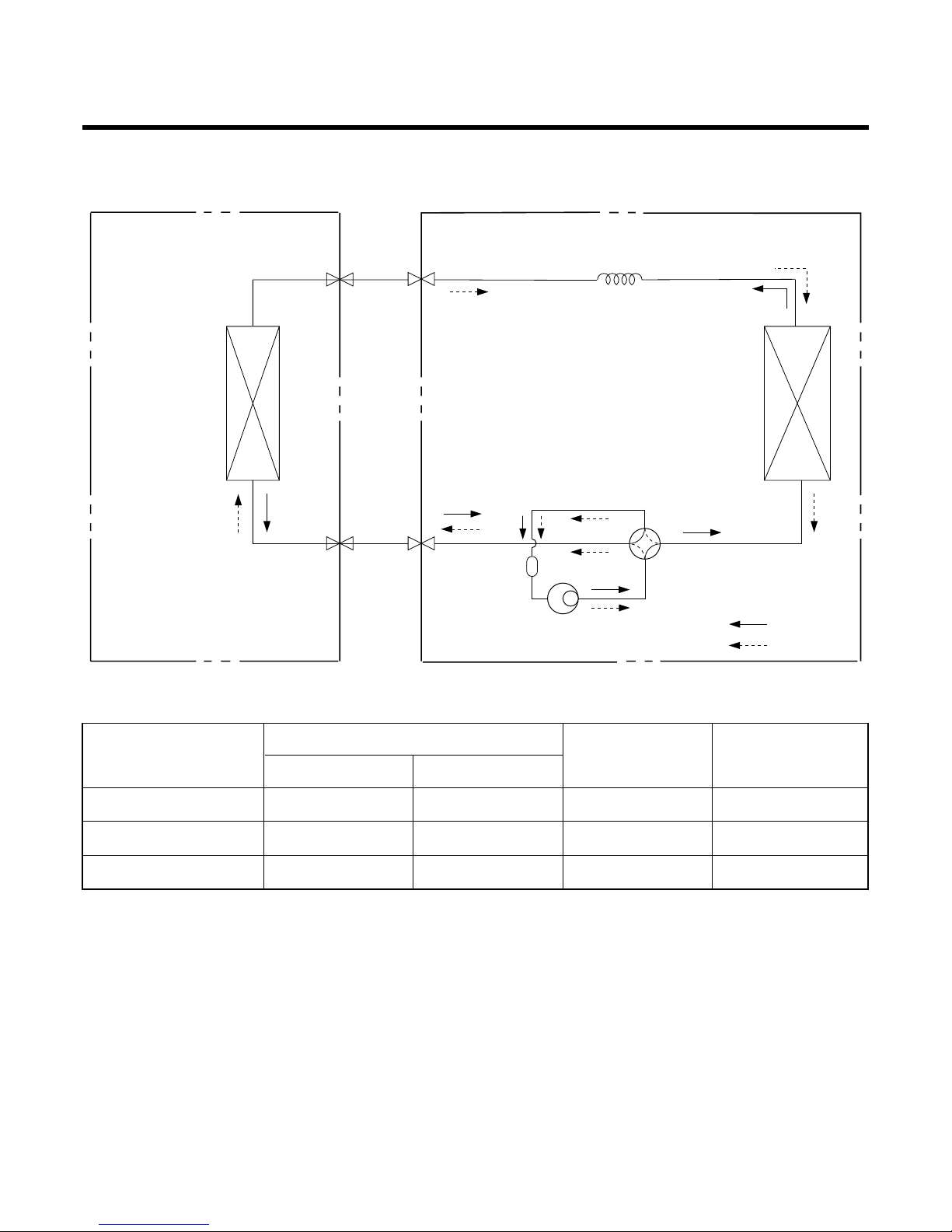

Refrigeration Cycle Diagram

-9-

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

ACCUMU

LATOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

CAPILLARY TUBE

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

7k, 9k Btu SERIES 3/8" 1/4" 15 7

12k Btu SERIES 1/2" 1/4" 15 7

18k Btu SERIES 1/2" 1/4" 30 15

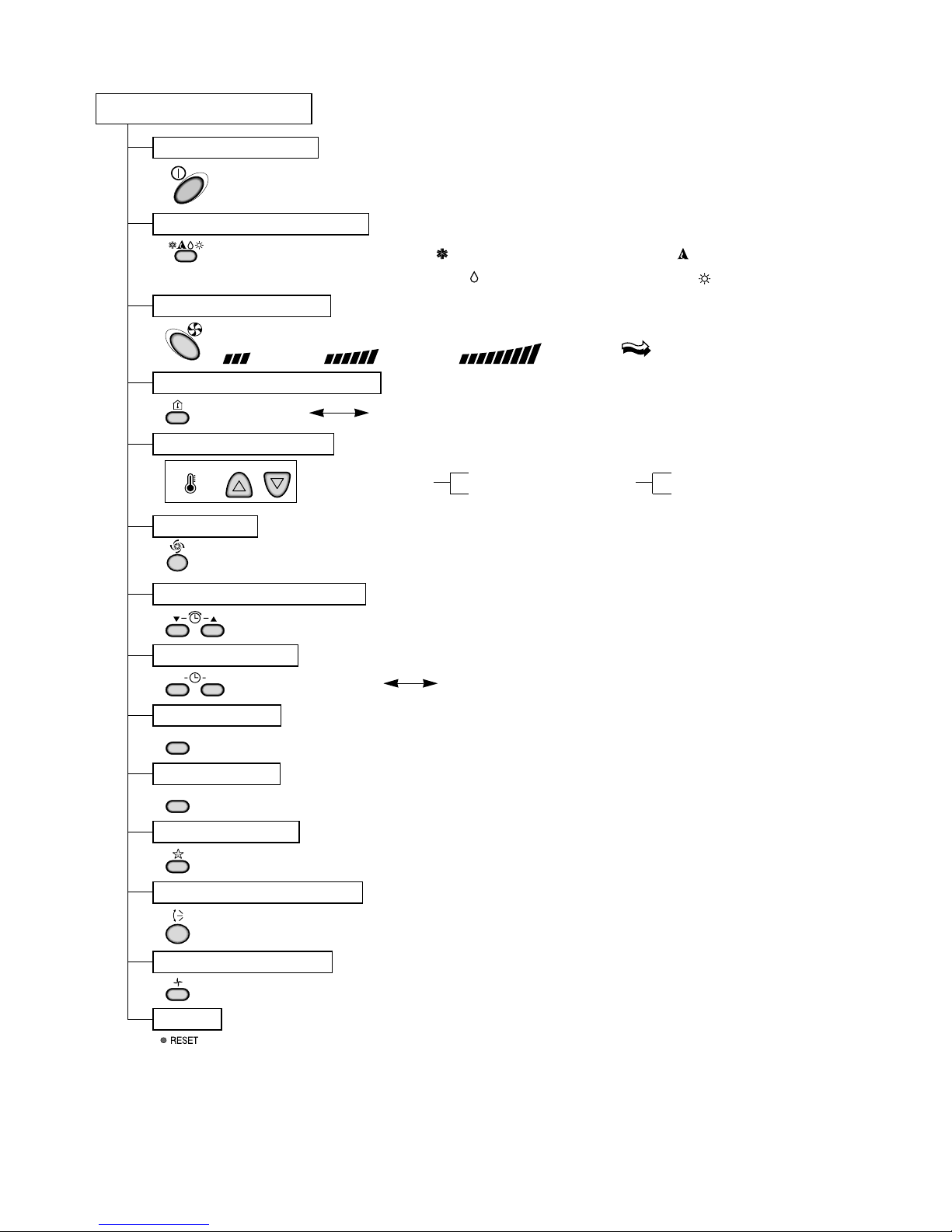

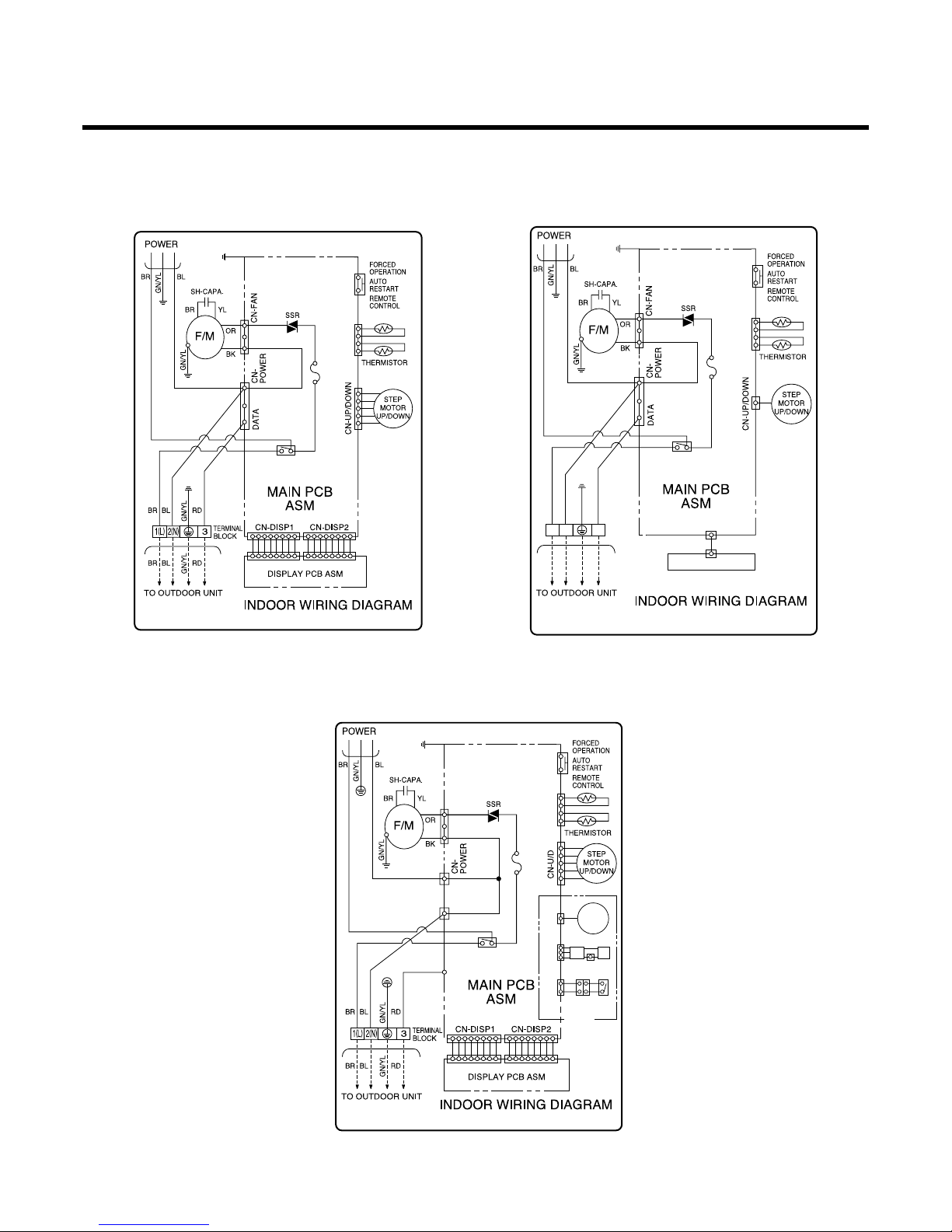

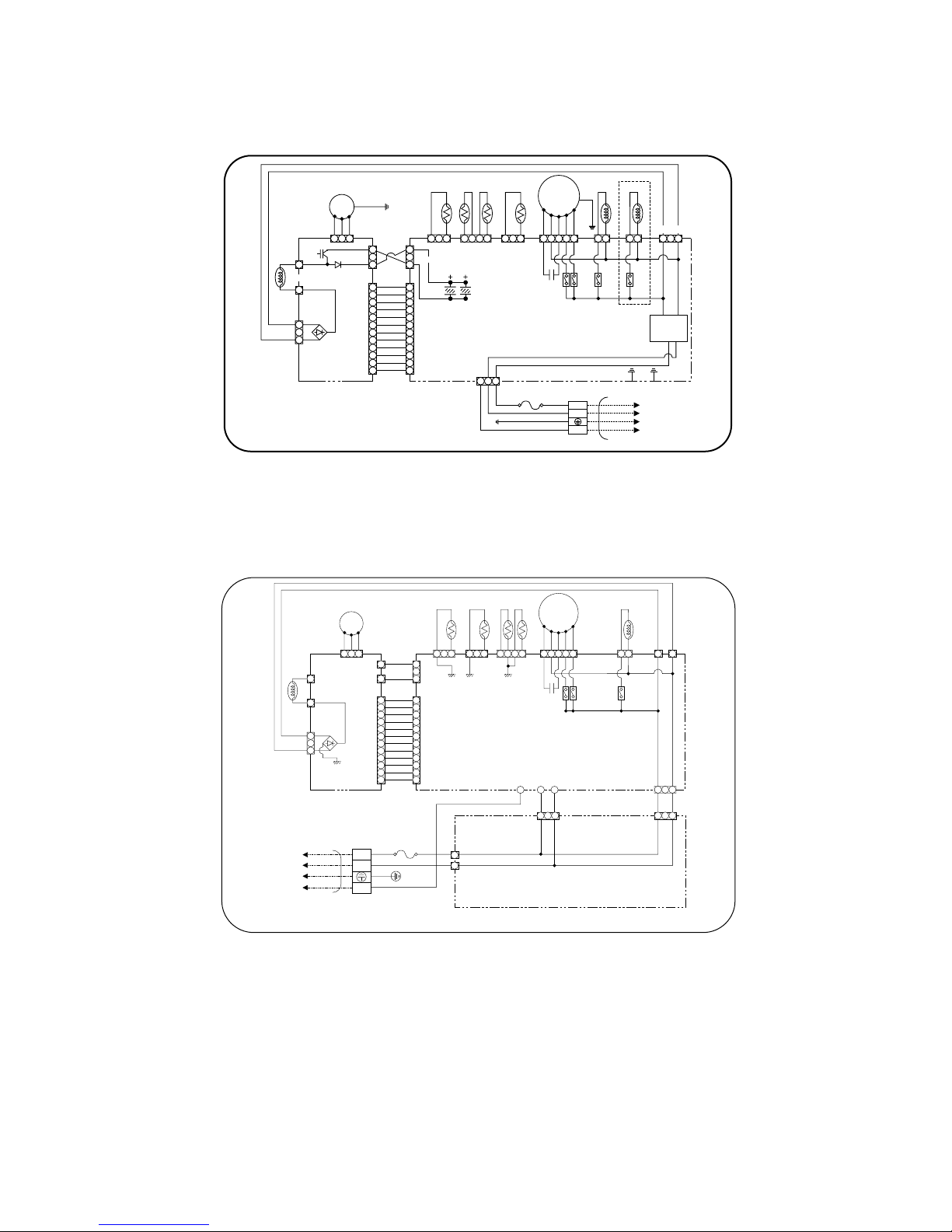

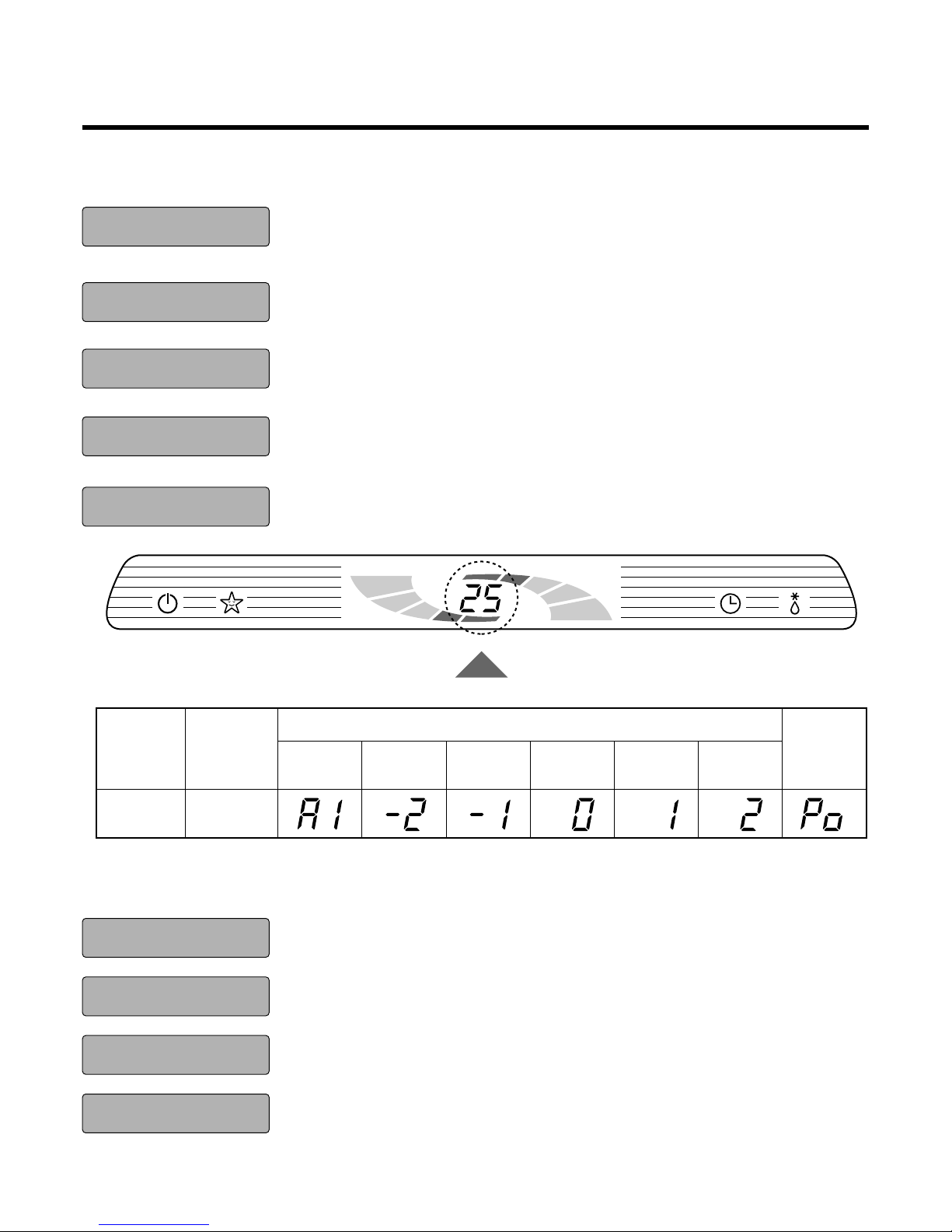

Wiring Diagram

-10-

SW01FCN-TH1

FUSE 2A,250V

P/NO:3854A90014E

RY-POWER

BK

SW01FCN-TH1

FUSE 2A, T250V

P/NO:3854A20080P

RY-POWER

BK

RD

BK BK

LIMIT

S/W

CN-L/R

STEP

MOTOR

H.V.B A/CL

OPTION

BK BK

BK BK

CN-MOTOR

CN-OUT

CN-DATA

SW01FCN-TH1

FUSE 2A,250V

P/NO:3854A20080A

RY-POWER

BK

CN-DISP1

DISPLAY PCB ASM

BRBRBL

BL

RD

RD

GN/YLGN/YL

TERMINAL

BLOCK

1(L

)

2(N

)

3

(1) Indoor Unit

LS-_NL Series (7, 9, 12K Btu) LS-_NM/NN Series (7, 9, 12K Btu)

LS-_NL/NM/NN Series (18K Btu)

LS-K18612L

-11-

CN-COMP

CN-POWER

CN-IPM

CN-OLPCN-TH1

TERMINAL

BLOCK

CN-4WAY1

RYLOW

RYHIGH

RY4WAY

RYHEAT

CN-HEAT

BR

BL

BR

BL

GN/YL

RD

BR

BR

BK BK

SPECIAL FUSE

(15A,250V)

BL

GN/YL

RD

BR

GN/YL

OR

YL BL BK

F/M

CN-AC

NOISE

FILTER

1(L

)

2(N

)

3

TO

INDOOR

UNIT

MAIN PWB ASM

OUTDOOR WIRING DIAGRAM

P/NO : 3854A20080B

(3854A90014G)

SUB PWB

CAPACITOR

CN-DC

CN-DC

CN-UVW

RD

YL

YL

YL

BL

BR

CN-AC

IGB T

C/COIL

COMP

GN/YL

RD BL YL

CN-COMP

CN-UVW

U

V

W

CN-PWR1

CN-PWR1

CN-DATA

CN-AC1

CN-AC2

CN-IPM

CN-TH2 CN-TH1 CN-4WAY

RYLOW

WCN3 WCN1 WCN2

RYHIGH

RY4WAY

CN-SUB1 CN-SUB2

3854A20080T

SUB

PWB

FILTER PWB ASM

MAIN PWB ASM

F/M

OUTDOOR WIRING DIAGRAM

CN-DC

CN-SUB

C/COIL

1(L

)

2(N

)

3

INDOOR

UNIT

SPECIAL FUSE

AC250V/20A

COMP

RD

BR

BR

TERMINAL

BLOCK

BL

GN/YL

RD

BR

BL

GN/YL

RD

BL

BL YL

BK

RD

BR BL BR BL

BR BL

BRORYL BL BK

(2) Outdoor Unit

LS-_NL/NM/NN Series (7, 9, 12K Btu)

(2) Outdoor Unit

LS-_NL/NM/NN Series (18K Btu), LS-K18612L

Operation Details

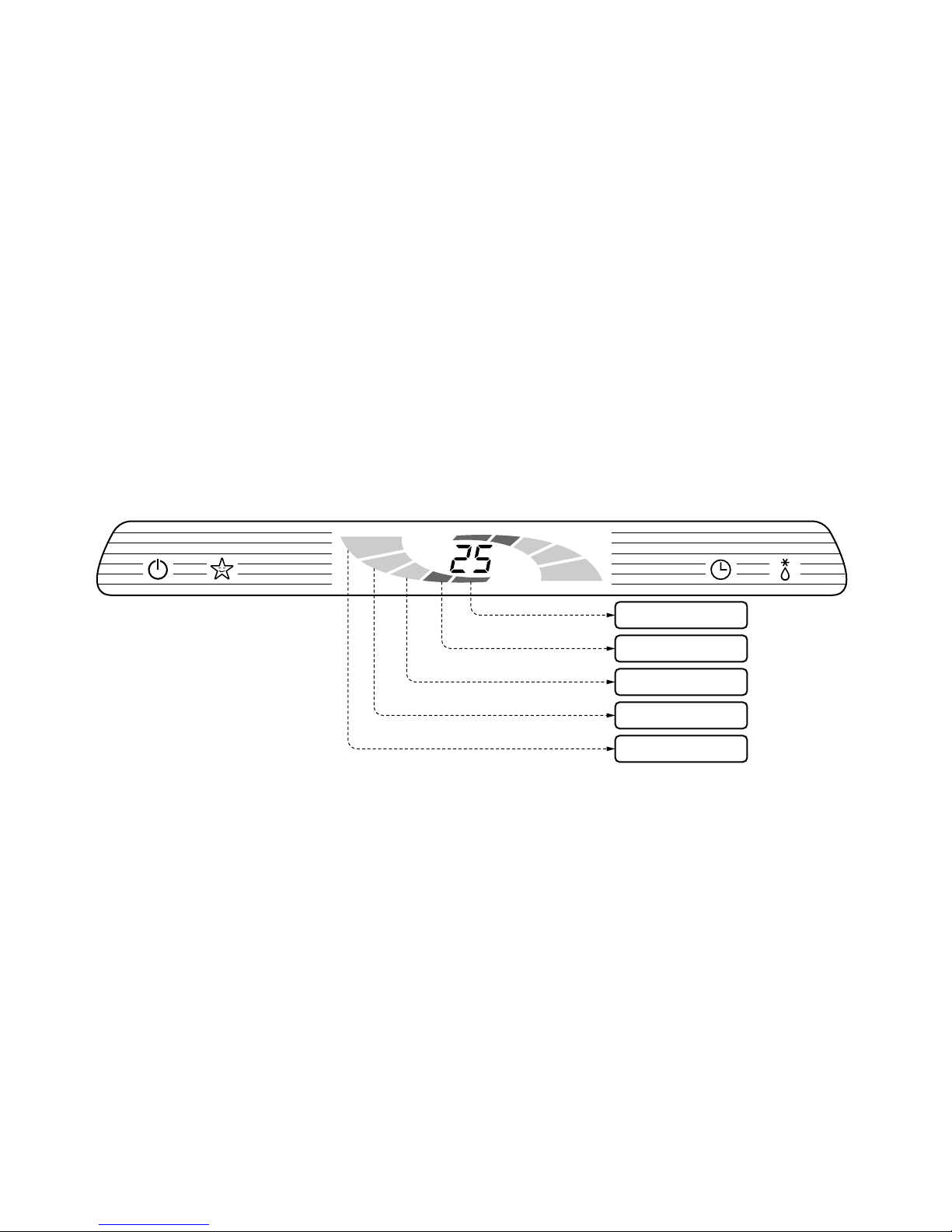

1. LED display of indoor unit

■ LS-_NL Series

■ LS-_NM/NN Series

-12-

A.I operation mode

Operation

Indicator

Shape of

display

Cooling

heating

dehumidifi-

cation

Setting

temp.

Standard Too hot Hot

Comfor-

table

Cold Too cold

Jet cool

Operation Indicator

Sleep Timer Indicator

Timer Indicator

Defrost Indicator

Setting Temp.

• On while in appliance operation, off while in appliance pause.

• Blinking(3sec off/0.5sec on) according to Error Code as long as the system mal-

functions.

• On while in sleep timer mode, off when sleep timer cancel or appliance operation

pause.

• On while in timer mode(on/off), off when timer mode is completed or canceled.

• Off except when hot start during heating mode operation or while in defrost control.

• Cooling/heating/dehumidification mode : setting temperature from remote control

• Fuzzy operation mode : fuzzy key data(5sec on) ➔ AI

Operation Indicator

Sleep Timer Indicator

Timer Indicator

Defrost Indicator

• On while in appliance operation, off while in appliance pause.

• Flashing while in disconnection or short in Thermistor. (3 sec off/0.5 sec on)

• On while in sleep timer mode, off when sleep timer cancel or appliance operation

pause.

• On while in timer mode(on/off), off when timer mode is completed or canceled.

• Off except when hot start during heating mode operation or while in defrost control.

■ How to operate the power display (LS-_NL Series)

• It must be displayed the power level that will be operating frequency of compressor.

• It indicates power levels that compressor operating frequency is controlled to depend on indoor and outdoor

conditions.

• It is displayed as below.

❐ Heat mode operation

- Power level 1: below Step 3 of COMP. operating frequency

- Power level 2: below Step 6 of COMP. operating frequency

- Power level 3: below Step 10 of COMP. operating frequency

- Power level 4: below Step 14 of COMP. operating frequency

- Power level 5: over Step 14 of COMP. operating frequency

❐ Operation mode except heat mode operation

- Power level 1: below Step 2 of COMP. operating frequency

- Power level 2: below Step 8 of COMP. operating frequency

- Power level 3: below Step 10 of COMP. operating frequency

- Power level 4: below Step 12 of COMP. operating frequency

- Power level 5: over Step 12 of COMP. operating frequency

-13-

Power Level 1

Power Level 2

Power Level 3

Power Level 4

Power Level 5

-14-

2. Protection of the evaporator pipe from frosting

• If the indoor pipe temperaure is below 0°C in 7 min. after the compressor operates without pause while in

cooling cycle operation mode,

➔ compressor, outdoor fan are turned off.

• When indoor pipe temp. is 7°C or higher after 2 min pause of compressor

➔ compressor, outdoor fan is turned on according to the condition of the room temperature.

3. Protection of the indoor fan from droplet formation (Enclosure

sweat and condensed disposal test)

• Control condition : The system operates standard operation without this condition as follows.

- Setting temperature <25°C

- Indoor fan speed ≤ low speed

- Outdoor temperature < 31°C

• Control method

- Operation frequency of compressor must be below ➃ (refer to the comp. Freq. table)

- The indoor fan operates at medium speed.

Comp. free

Comp. off

0˚C

7˚C

Indoor pipe

temp.

Comp. free

Comp. Step 4

3˚C

3°C

Indoor pipe

temp.

-15-

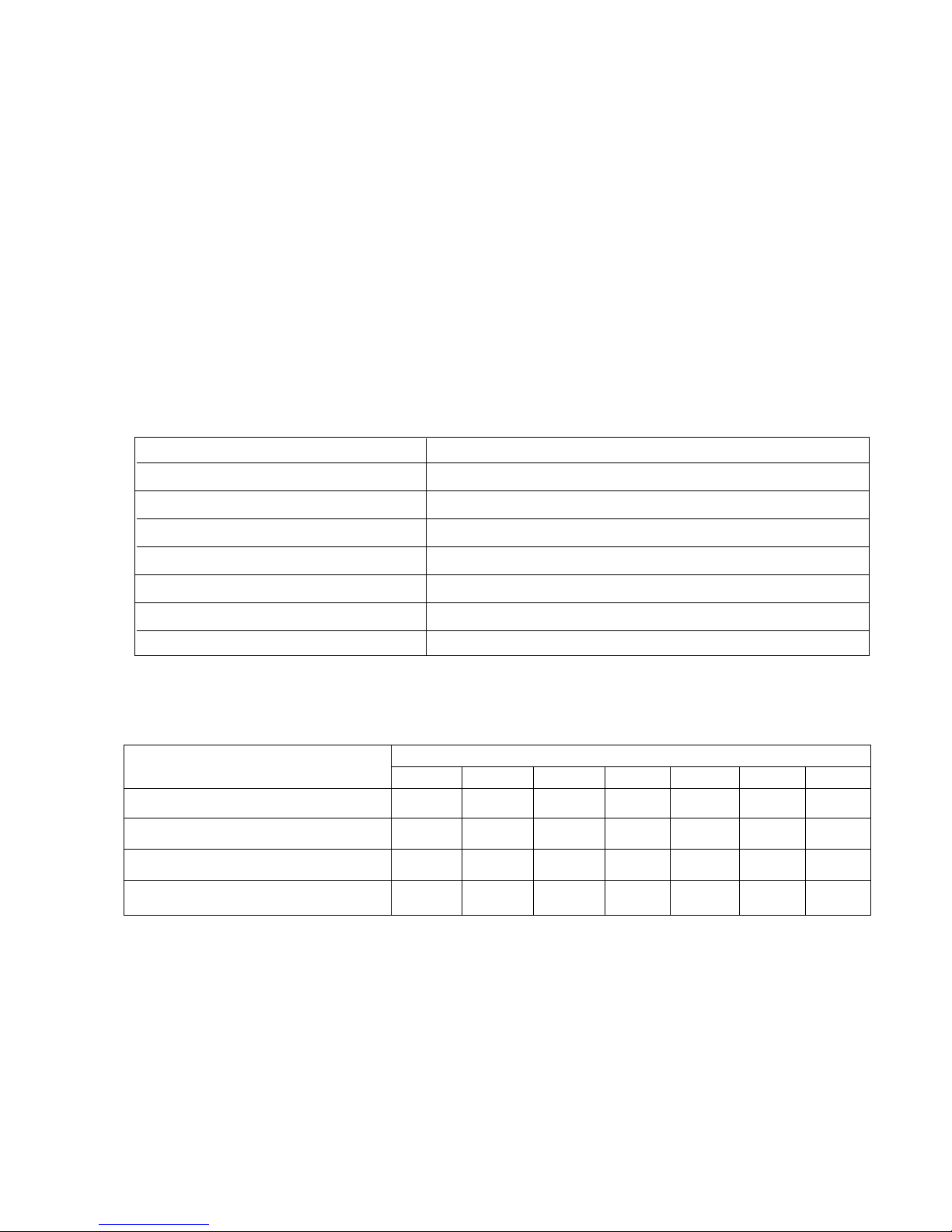

4. Cooling mode operation

• Operating frequency of compressor depend on the difference of the temperature.

(= intake air Temp.- Compressor off Temp.

• Compressor off temp.= setting temp. -0.5°C

on temp. = setting temp. +0.5°C

• If compressor operates at some operating frequency, the operating frequency of compressor cannot be

changed within 30 seconds.

• Condition of compressor turned off

- When intake air temperature stay at the temperature between setting temp.

-

0.5°C and setting temp.

-

1.0°C for 3 minutes continuously.

- When intake air temperature reaches below the temperature of setting temp.

-

1.0°C.

• Compressor 2 minutes delay

- The compressor can restart minimum 2 minutes later after compressor off.

Temp. differences

over 2.5°C

2.0~2.49°C

1.5~1.99°C

1.0~1.49°C

0.5~0.99°C

0.0~0.49°C

Comp. Operating frequency

Step 12

Step 10

Step 8

Step 4

Step 2

Step 1

[The operating freq. step of comp.]

[The targeting operating freq. of comp. each model]

Model

7K Btu Series

9K Btu Series

12K Btu Series

18K Btu Series

Comp. Operating frequency

40 47 54 64 74 85

45 53 72 86 95 110

35 47 51 58 62 67

35 47 57 66 71 96

Step 1 Step 2 Step 4 Step 8

(Fc)

Step 10 Step 12

-16-

5. Healthy Dehumidification mode operation

• When the dehumidification operation is set by the remote controller the intake air temperature is detected and

the setting temp. is automatically set according to the intake air temperature.

• Operating frequency of compressor and indoor fan speed.

Temp. differences

32°C ≤ intake air temp.

26°C ≤ intake air temp. < 32°C

24°C ≤ intake air temp.< 26°C

18°C < intake air temp. < 24°C

intake air temp. ≤ 18°C

Comp. Operating frequency

25°C

25°C

intake air temp. -1°C

intake air temp. -0.5°C

18°C

Cooling operation area

Dehumidification

operation area

After 3 min off

OFF instantly

Low

speed

Low

speed

After 5 min OFF

low speed

Setting

speed

+

1.0˚C

+

0.5˚C

Setting temp. +

0˚C

-

1.0˚C

-

2.0˚C

Operating frequency of compressor Indoor fan speed

Step 3

Step 2

Step 1

-17-

6. Heating mode operation

• Operating frequency of compressor depend on the difference of the temperature

(= compressor off temp. - intake air temp.)

• Compressor off temp. = setting temp.+3.0°C

on temp. = setting temp.

• If compressor operates at some operation frequency, the operating frequency of compressor cannot be

changed within 30 seconds.

• Condition of compressor turned off

- When intake air temperature reaches +3°C above the setting temperature.

• Condition of indoor fan turned off

- While in compressor on:indoor pipe temp. < 26°C

off: indoor pipe temp. < 37°C

• While in defrost control, between the indoor and outdoor fans are turned off.

• Compressor 2minutes delay

- After compressor off, the compressor can restart minimum 2 minutes later.

Temp. differences

over 3.0°C

2.5~3.0°C

2.0~2.49°C

1.5~1.99°C

1.0~1.49°C

0.5~0.99°C

0.0~0.49°C

Comp. Operating frequency

Step 19

Step 15

Step 13

Step 9

Step 5

Step 3

Step 1

[ The operating freq. step of comp]

[The targeting operating freq. of comp. each model]

Model

7K Btu Series

9K Btu Series

12K Btu Series

18K Btu Series

Comp. Operating frequency

42 47 56 67 80 86 90

42 56 68 82 95 103 110

41 49 57 64 72 76 83

41 47 53 58 67 71 76

Step 1 Step 3 Step 5 Step 9

Step 13(Fh)

Step 15 Step 19

-18-

7. Fuzzy mode operation

• When any of operation mode is not selected like the moment of the power on or when the unit turned off, the

operation mode is selected.

• When determining the operation mode, the compressor, outdoor fan are off and only the indoor fan is operated for 15seconds, then an operation mode is selected according to.

Basis of determining operating mode

Outdoor temp.

over 24°C

21~24°C

18~21°C

below 18°C

Operating Mode

Cooling

Healthy Dehumidification

intake air temp. ≥ 25°C …Dehumidification

intake air temp. < 25°C … Heating

Heating

7.1 Fuzzy operation for cooling

• According to the setting temperature selected by Fuzzy rule, the operating frequency of compressor is determined like cooling mode operation.

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temperature at that time.

• When the Fuzzy key(=setting temp. key) is input after the initial setting temperature is selected, the Fuzzy

key value and intake air temperature at that time are compared to select the setting temperature automatically

according to the fuzzy rule.

• While in Fuzzy operation, the air flow speed of the indoor fan is automatically operated by chaos logic.

at beginning

during opertion

Intake air temp.

over 26°C

18~26°C

below 18°C

18~30°C

below 18°C

over 30°C

Setting temp.

25°C

intake air temp. -05°C

18°C

Fuzzy rule

18°C Fuzzy rule

30°C Fuzzy rule

Fan speed

CHAOS airflow

-19-

7.2 Fuzzy operation for Heating

• According to the setting temperature selected by Fuzzy rule, the operating frequency of compressor is determined like heating mode operation.

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temperature at that time.

• When the Fuzzy key(=setting temp. key) is input after the initial setting temperature is selected, the Fuzzy key

value and intake air temperature at that time are compared to select the setting temperature automatically

according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically operated by CHAOS logic.

at beginning

during opertion

Outdoor temp.

over 26°C

0~5°C

-5~0°C

below -5°C

16~30°C

below 16°C

over 30°C

Setting temp.

intake air temp. +0.5°C

intake air temp. +1.0°C

intake air temp. +1.5°C

intake air temp. +2.0°C

Fuzzy rule

16°C Fuzzy rule

30°C Fuzzy rule

Fan speed

CHAOS airflow

7.3 Fuzzy operation for dehumidification

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temperature at that time.

• According to the setting temperature selected by Fuzzy rule, the operating frequency of compressor is determined like dehumidefication mode operation.

at beginning

during operation

Outdoor temp.

over 26°C

18~26°C

below 18°C

Setting temp.

25°C

intake air temp. -0.5°C

18°C

same as dehumidification mode

Fan speed

CHAOS airflow

-20-

8. Jet cool mode operation

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the

other mode operation(cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated super-high speed for 30 min. at cooling mode operation.

• In the Jet Cool mode, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode input while the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vane is reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

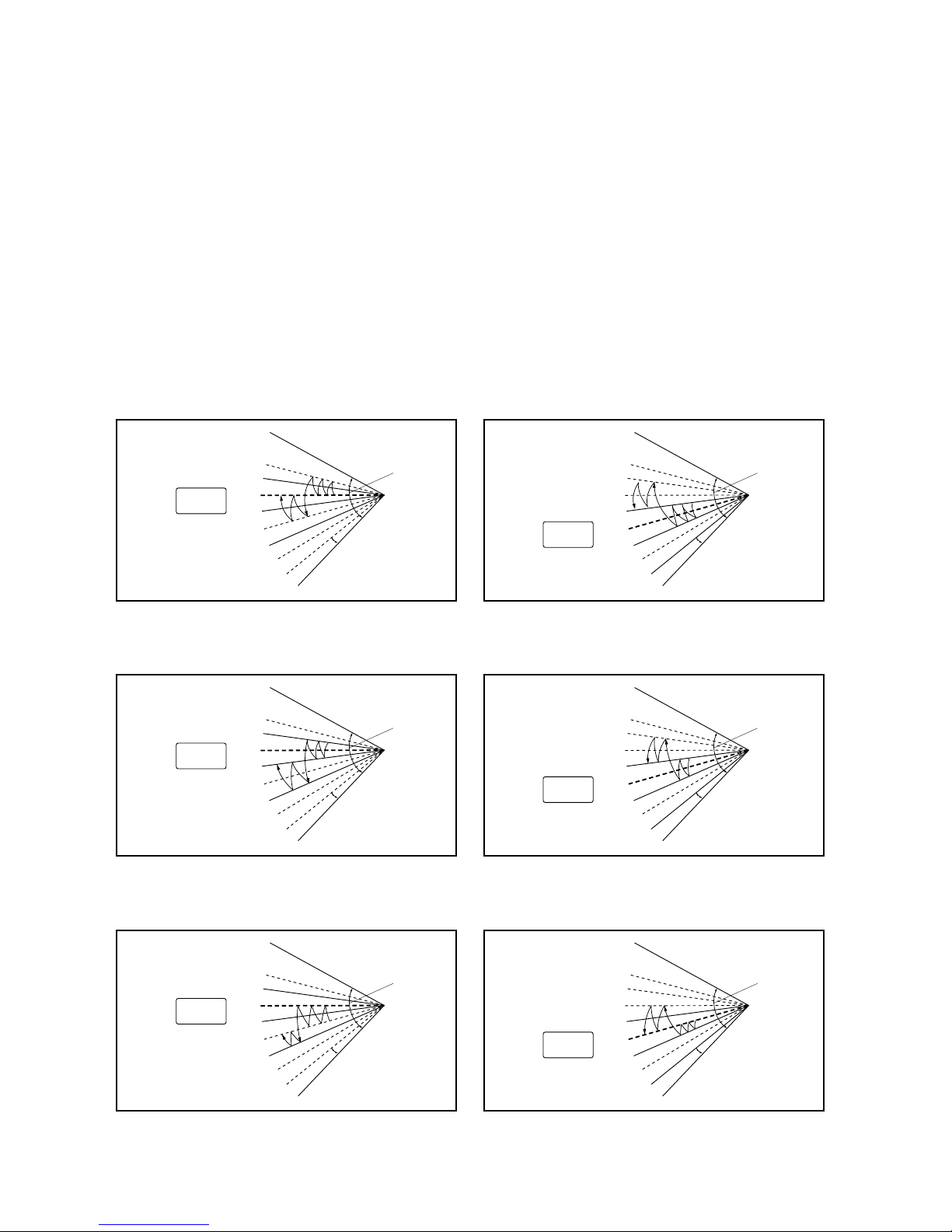

9. Swing mode

9.1 Chaos swing mode of not fuzzy mode operation

• By the Chaos swing key input, the upper/lower vane automatically operates with the Chaos swing or it is fixed

to the desired direction.

Closed

Open

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Mode 7

Beginning

of cooling

Mode 8

< Cooling Mode >

Chaos swing of 7K, 9K Btu Series

Chaos swing of 12K Btu Series

8°

135°

< Heating Mode >

Closed

Open

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Mode 7

Beginning

of heating

Mode 8

8°

135°

Closed

Open

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Mode 7

Beginning

of cooling

Mode 8

< Cooling Mode >

7°

125°

< Heating Mode >

Closed

Open

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Mode 7

Beginning

of heating

Mode 8

7°

125°

Chaos swing of 18K Btu Series

Closed

Open

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Mode 7

Beginning

of cooling

Mode 8

< Cooling Mode >

7°

125°

< Heating Mode >

Closed

Open

Mode 1

Mode 2

Mode 3

Mode 4

Mode 5

Mode 6

Mode 7

Beginning

of heating

Mode 8

7°

125°

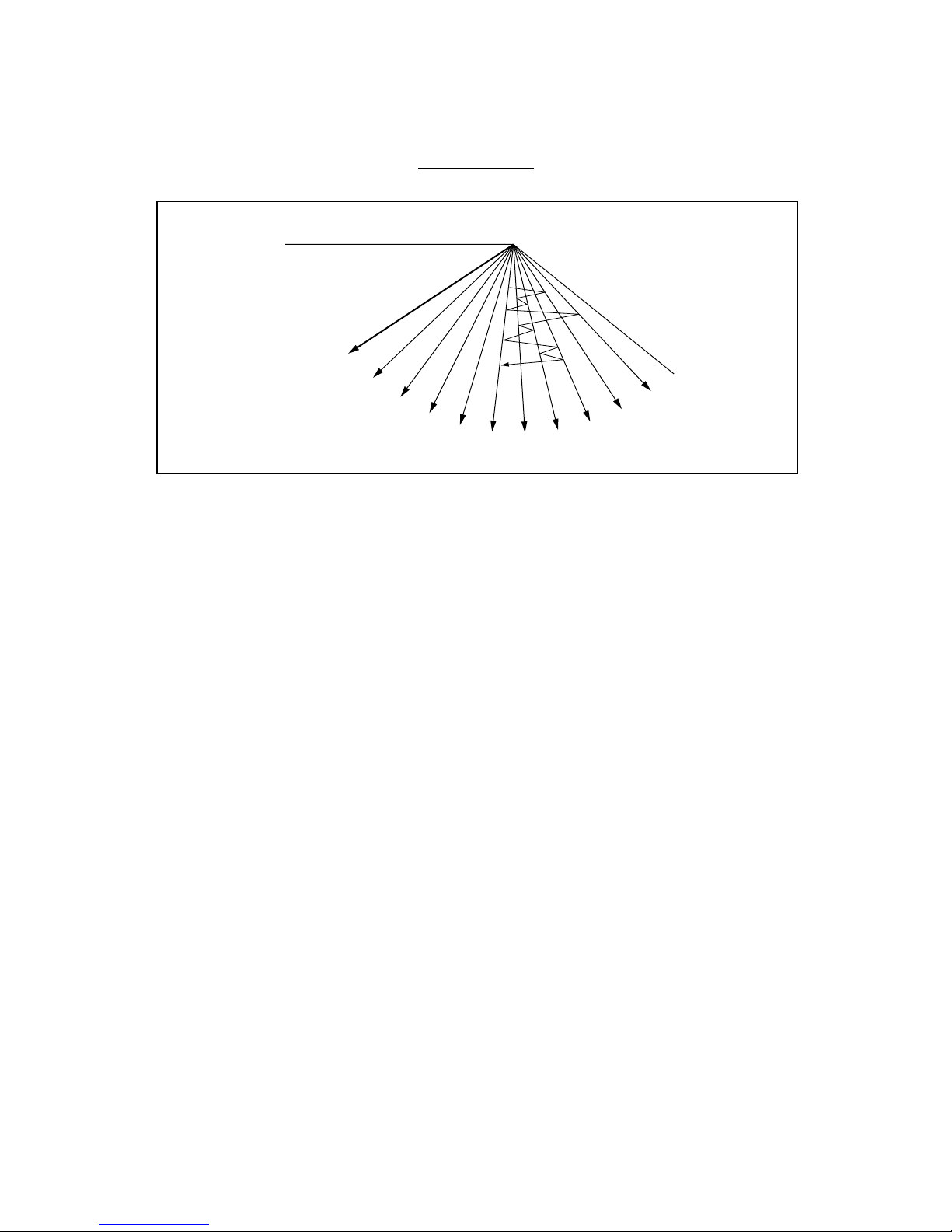

9.2 Auto swing of Fuzzy mode operation

• While in Fuzzy mode operation, Chaos swing is operated according to 1/f fluctuation.

1/f fluctuation

-21-

MODE00

(Open)

MODE01

MODE02

MODE03

MODE04

MODE05

MODE06

MODE08

MODE09

MODE10

MODE11

MODE12

MODE13

MODE14

MODE15

MODE16

MODE17

(

Closed

)

MODE07

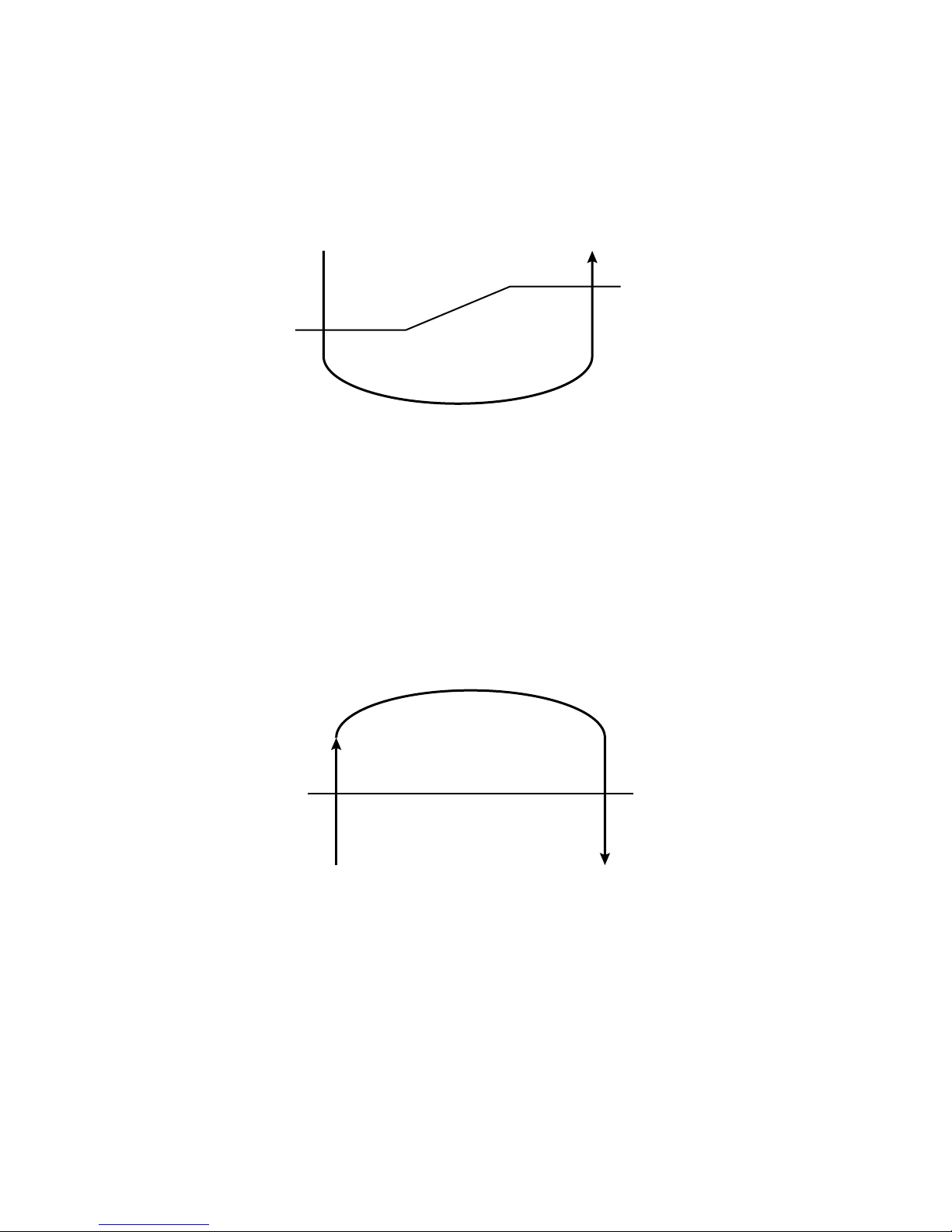

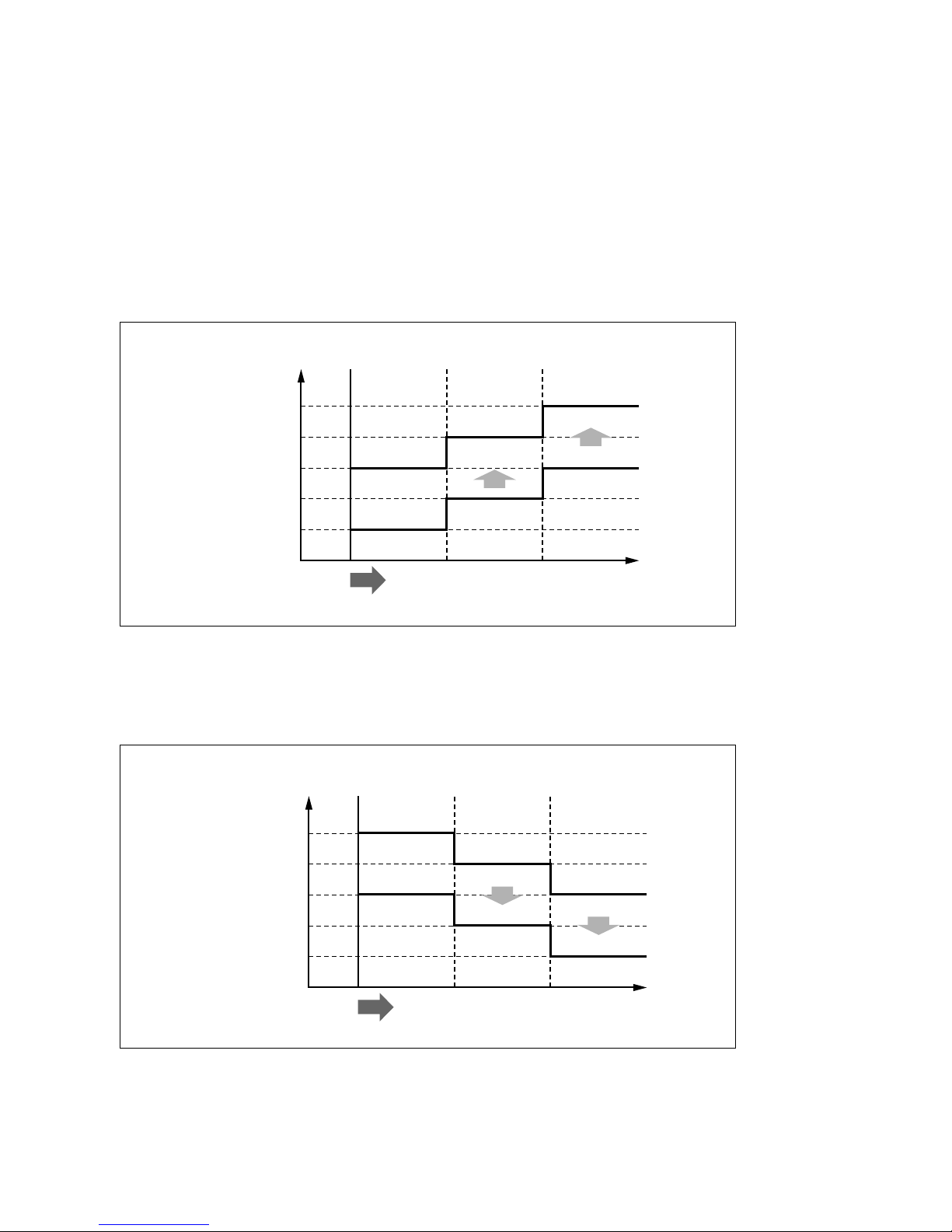

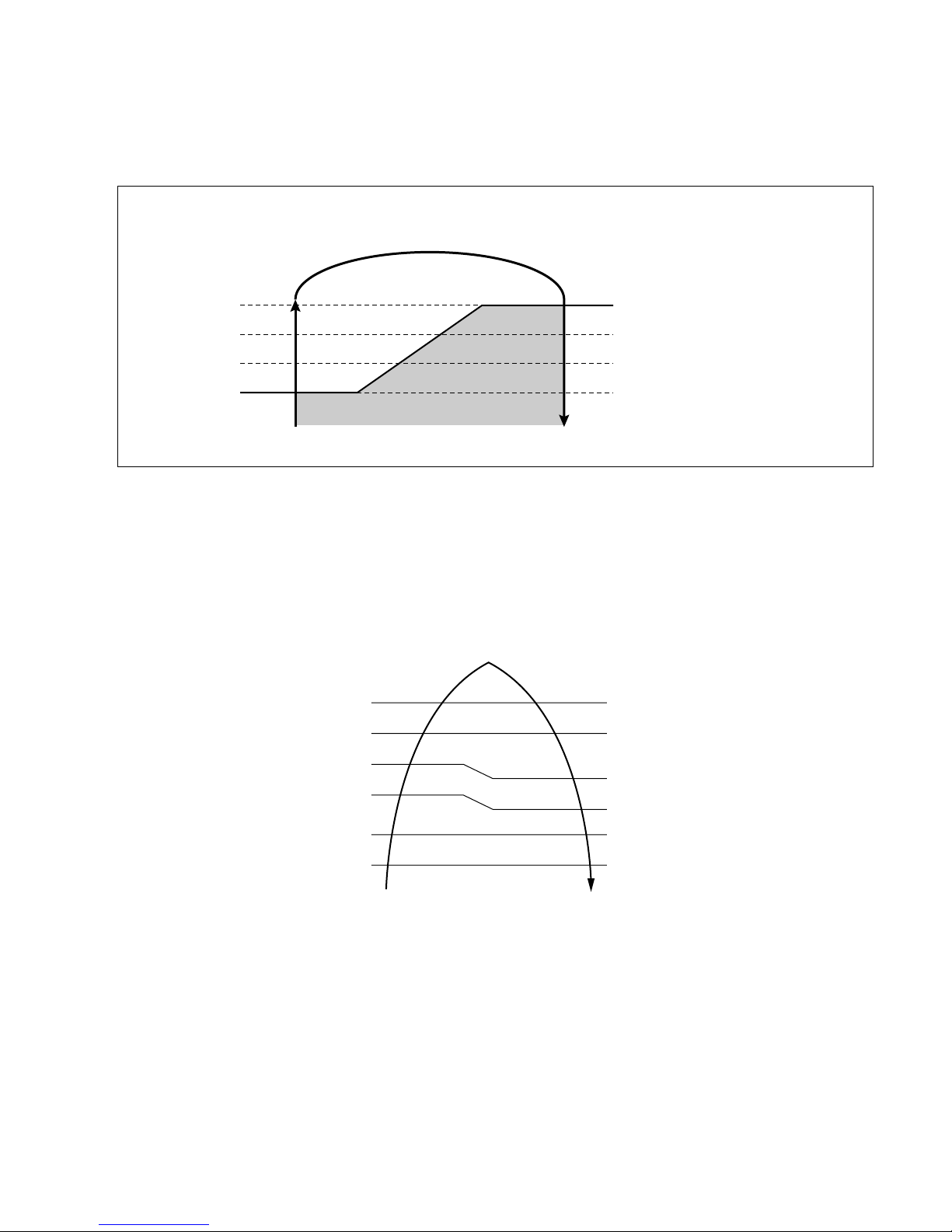

10.1 Sleep timer operation for cooling cycle

• While in cooling mode operation, 60 min. later since the start of the sleep timer, the setting temperature

increase by 0.5°C. After another 60min. elapse, it increases by 1°C again.

10.2 Sleep timer operation for heating cycle

• While in heating mode operation, 60 min. later since the start of the sleep timer, the setting temperature

decrease by 0.5°C. After another 60min. elapse, it decreases by 1°C again.

-22-

Setting temp. (˚C)

0.5˚C up

0.1˚C up

Cooling ON temp.

(Setting temp. +0.5˚C)

Cooling OFF temp.

(Setting temp. -0.5˚C)

1 2 Sleep time (hr

)

Setting temp. (˚C)

Heating ON temp.

(Setting temp)

Heating OFF temp.

(Setting temp. +3.0˚C)

1 2 Sleep time (hr

)

0.5˚C down

1.0˚C down

10. Sleep timer operation

• When the sleep time is reached after [1,2,3,4,5,6,7hr] is input by the remote control during the operation, the

operation of the appliance stops.

• When the appliance is on pause, the sleep timer mode cannot be input.

11. Auto restarting operation

• When the power is restarted after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance automatically operates in the mode on the memory.

• The slide switch on the indoor unit of the appliance should be on the AUTO RESTART position in order that

the Auto restarting operation is available.

• Operation mode that is kept on the memory

— State of operation ON/OFF

— Operation mode/setting temp./selected airflow speed

— Sleep timer mode/remaining time of sleep timer

12. Forced operation

• To operate the appliance by force in case that the remote control is lost, the forced operation selection switch

is on the main unit of the appliance to operate the appliance in the standard conditions.

• The operation condition is set according to the outdoor temp. and intake air temperature as follows.

-23-

Outdoor temp.

over 24°C

21~24°C

18~21°C

below 18°C

Setting temp.

22°C

23°C

23°C

24°C

24°C

Setting speed of

indoor fan

High speed

Operating Mode

Cooling

Healthy Dehumidification

Intake air temp. ≥ 25°C ➔ Dehumidification

Intake air temp. < 25°C ➔ Heating

Heating

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

Slide Switch of indoor unit

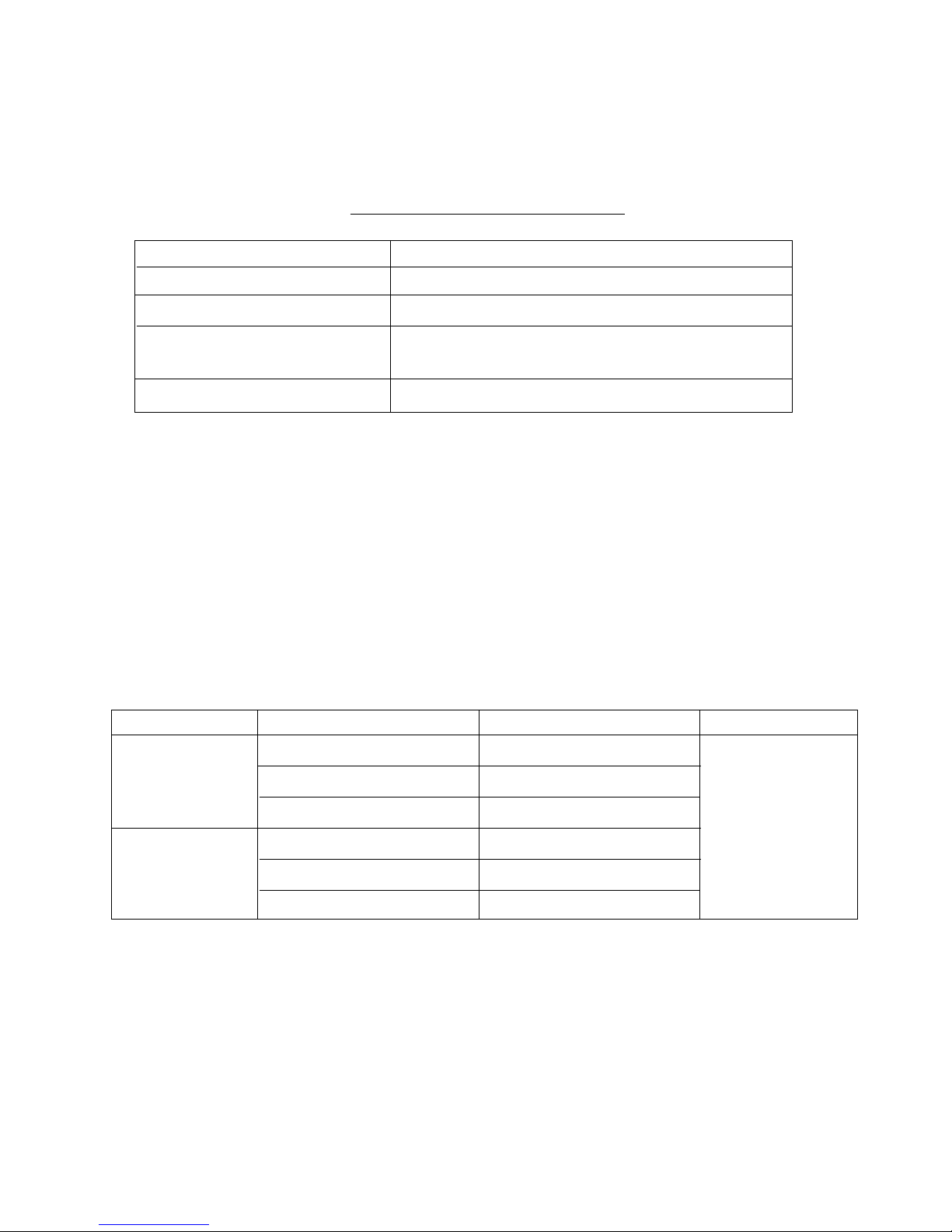

13. Power relay control

• Power relay turns on 1 second later after the power is input to the outdoor unit.

• Control sequence : power on

➔ PTC operating ➔ power relay on

14. Protection from total current control

■ CT1 control

• If the operating current reaches I1, the operating frequency of the compressor decrease.

• After decreasing the operating frequency by 1step, if operating current is below I1 for 24 seconds continuous-

ly, the operating frequency of compressor increase by 1step.

■ CT2 control

• If the operating current of the appliance reaches I2, the compressor stop instantly and 2 minutes later the

compressor restart again.

• If CT2 occurs twice within 1hour, the appliance turn off and display ERROR CODE 7.

-24-

Model

7K Btu Series 9K Btu Series 12K Btu Series 18K Btu Series

Cooling Heating

8.5A 10A

11.5A

8A 9.5A

11.5A

Cooling Heating

9A 10.5A

13.5A

8.5A 10A

13.5A

Cooling Heating

10.5A 12A

13.5A

10A 11.5A

13.5A

Cooling Heating

12.5A 14A

16A

12A 13.5A

16A

Operating mode

below 38°C

(outdoor temp.)

I1

I2

I1

I2

over 38°C

(outdoor temp.)

Condition

❇ I1:Current of operating frequency down

I2: Current of compressor cut off

cf. I1 is set the lowest level between intial value and in case dectection of dc paeak current.

Control table

15. Protection from DC Peak Current

■ DC Peak Current Error by a fault signal of IPM

• If the operating current of IPM reaches 35A ±3A, the compressor stop instantly.

• If DC PEAK occurs 3 times within 1 hour, the appliance turns off and display ERROR CODE 6.

■ DC Peak Current Error b y the compressor lock

• If the DC LINK voltage below DC 350V occurs 5 times within 1 hour while the compressor is operating, the

appliance turns off and display ERROR CODE 6.

■ DC Peak Current Error b y the Outdoor Fan Lock

• If it’s 5 times within 1 hour in case of the temperature of outdoor pipe TH is over 65°C while the compressor is

operating, the appliance turns off and display ERROR CODE 6.

16. Portection from overheating of power module

• If the temperature of the heat sink TH. reaches over Toff, the Compressor stop instantly.

• It will be limited the compressor operating frequency according to the heat sink TH.(refer to below FIG.)

• It will be blink 4 times, when the thermistor is open or short, also the temperature is over Toff.

17. Portection from overheating of compressor

• If the temperature of the discharge pipe of compressor reaches over 130°C or below -30°C the compressor

stop instantly.

• It will be limited the compressor operating frequency according to the compressor dome TH.(Refer to below

Fig.)

-25-

Comp. off

Comp. free

Fc-1

Fc-2

Target frequency

Toff (84°C)

Ton + 2°C (78°C)

Ton + 5°C (81°C)

Ton (76°C)

130°C

118°C

111°C

108°C

-13°C

-30°C

101°C

93°C

Fhmin

OFF

OFF

0Hz

Fc-2

Fc-1

Setting frequency

[The control graph from heat–sink TH]

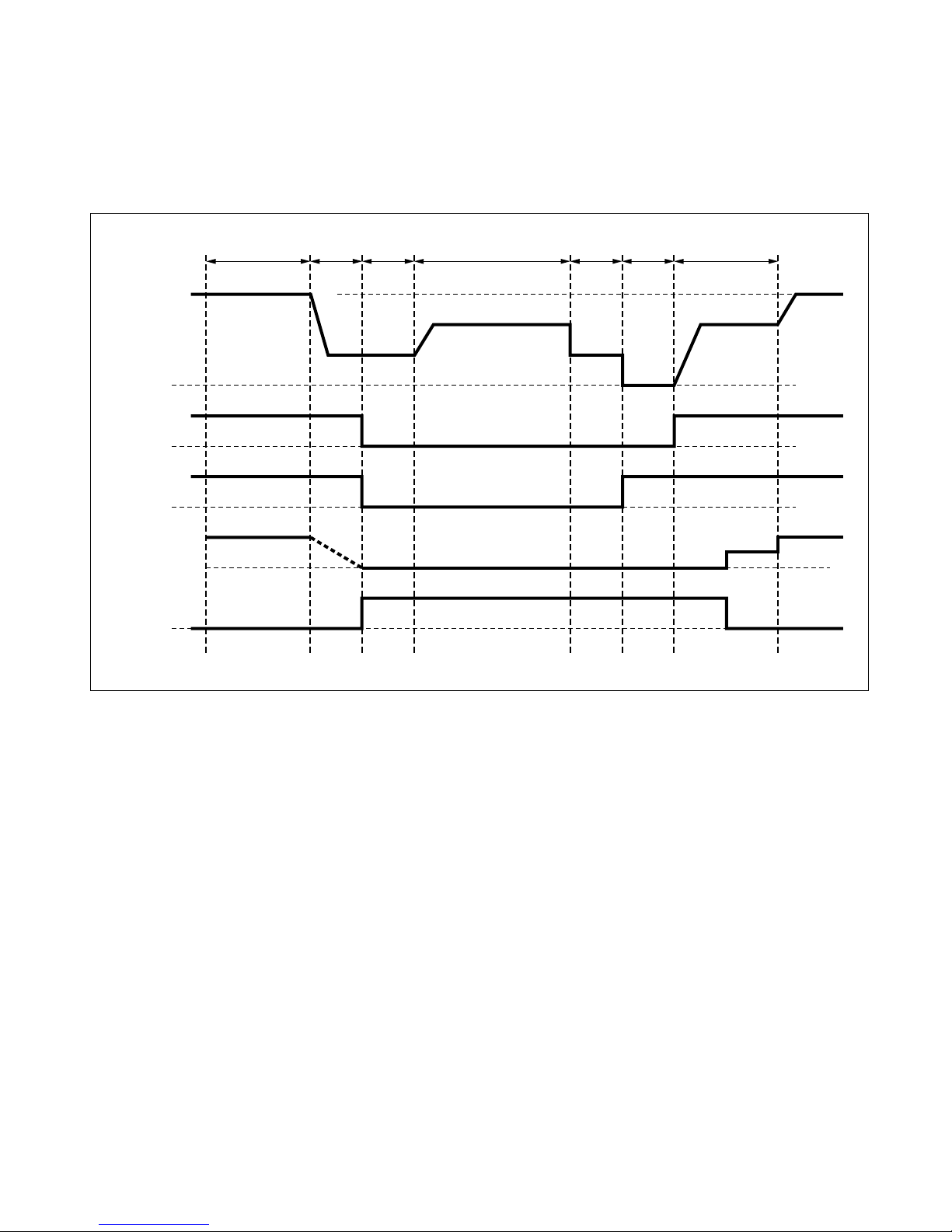

18 . Defrosting control

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from freezing,

reversed to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• Defrosting control is available 50 minutes later since heating cycle started and the pipe temperature of outdoor unit reaches below -6°C.

-26-

50 min

Setting frequency

Setting speed

Setting

speed

OFF OFF

ON

OFF

OFF(Cooling cycle)

Setting

frequency

30 sec

Fc-1 step

Operating

frequency

of compressor

4 Wa y valve

Outdoor fan

Indoor fan

Defrost LED

Fc-1

Fh+1

OFF

ON ON(Heating cycle)

ON ON

Low

(FhMAX-2 or

FhMAX-3)

30 sec 30 sec

8 min or

over 25˚C(120sec)

30 sec 1 min

Loading...

Loading...