Lg LSG4511BD Installation

INSTALLATION

13

INSTALLATION

Before Installing the Range

Make sure your range is properly installed and grounded by a qualified installer, according to the installation

instructions. Any adjustment and service should be performed only by qualified gas range installers or service

technicians.

In the Commonwealth of Massachusetts

•This product must be installed by a licensed plumber or gas fitter.

•When using ball type gas shut-off valves, they must be the T-handle type.

•When using a flexible gas connector, it must not exceed 3 feet in length.

Preparing for Installation

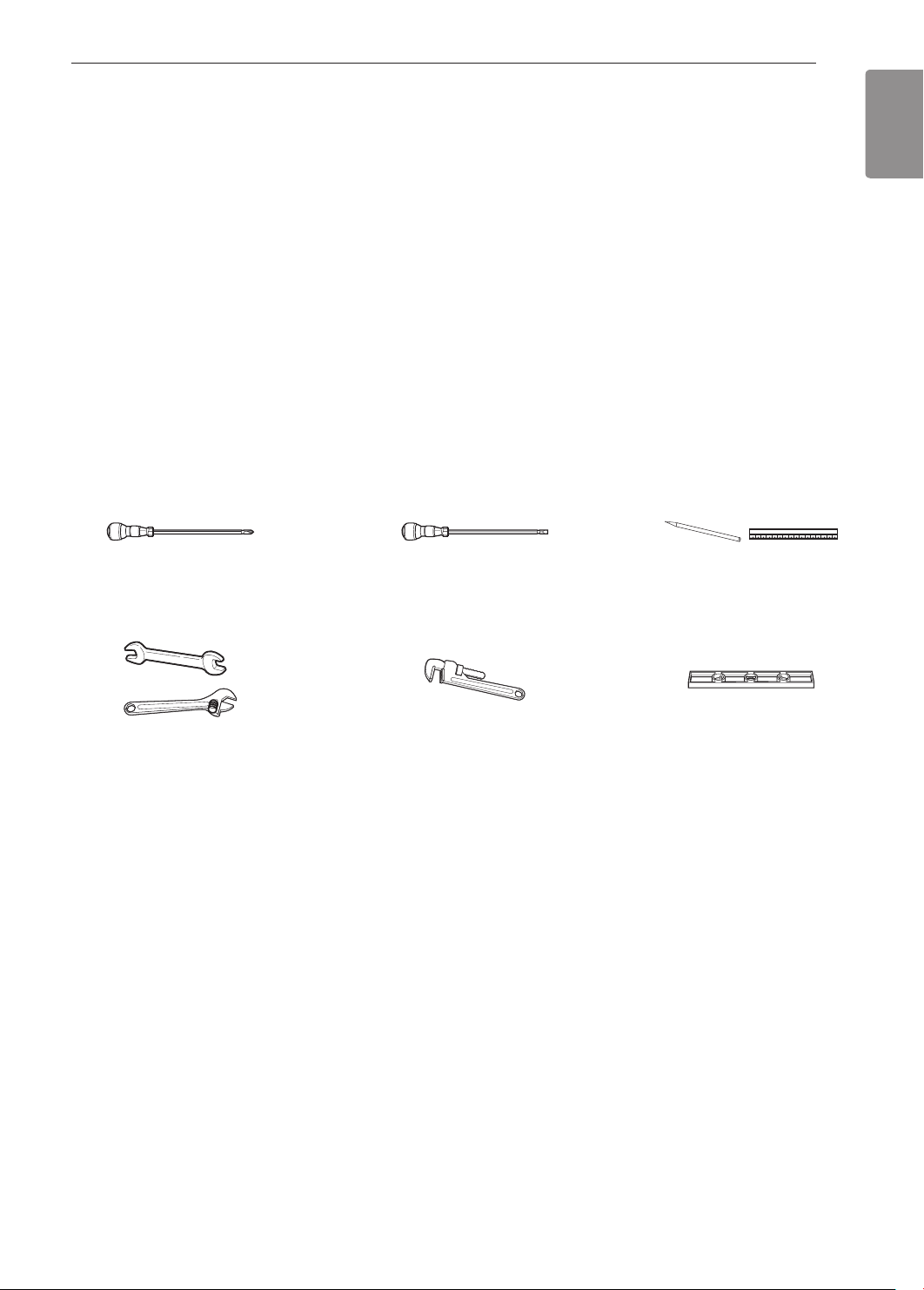

Tools Needed

Phillips screwdriver

Flat-blade screwdriver

Pencil and ruler

ENGLISH

Open-end or adjustable

wrench

Materials You May Need

•Gas line shut-off valve

•Pipe joint sealant that resists action of natural and LP gases

•Flexible metal appliance connector (

Never use an old connector when installing a new range.

•Flare union adapter for connection to gas supply line (

•Flare union adapter for connection to pressure regulator on range (

•Liquid leak detector or soapy water

•Lag bolt or

1

/2" O.D. sleeve anchor (for concrete floors only)

3

/4" or 1/2" NPT x 1/2" I.D.)

Pipe wrench (2)

(one for support)

3

/4" or 1/2" NPT x 1/2" I.D.)

1

/2" NPT x 1/2" I.D.)

Level

14

INSTALLATION

Installing the Range

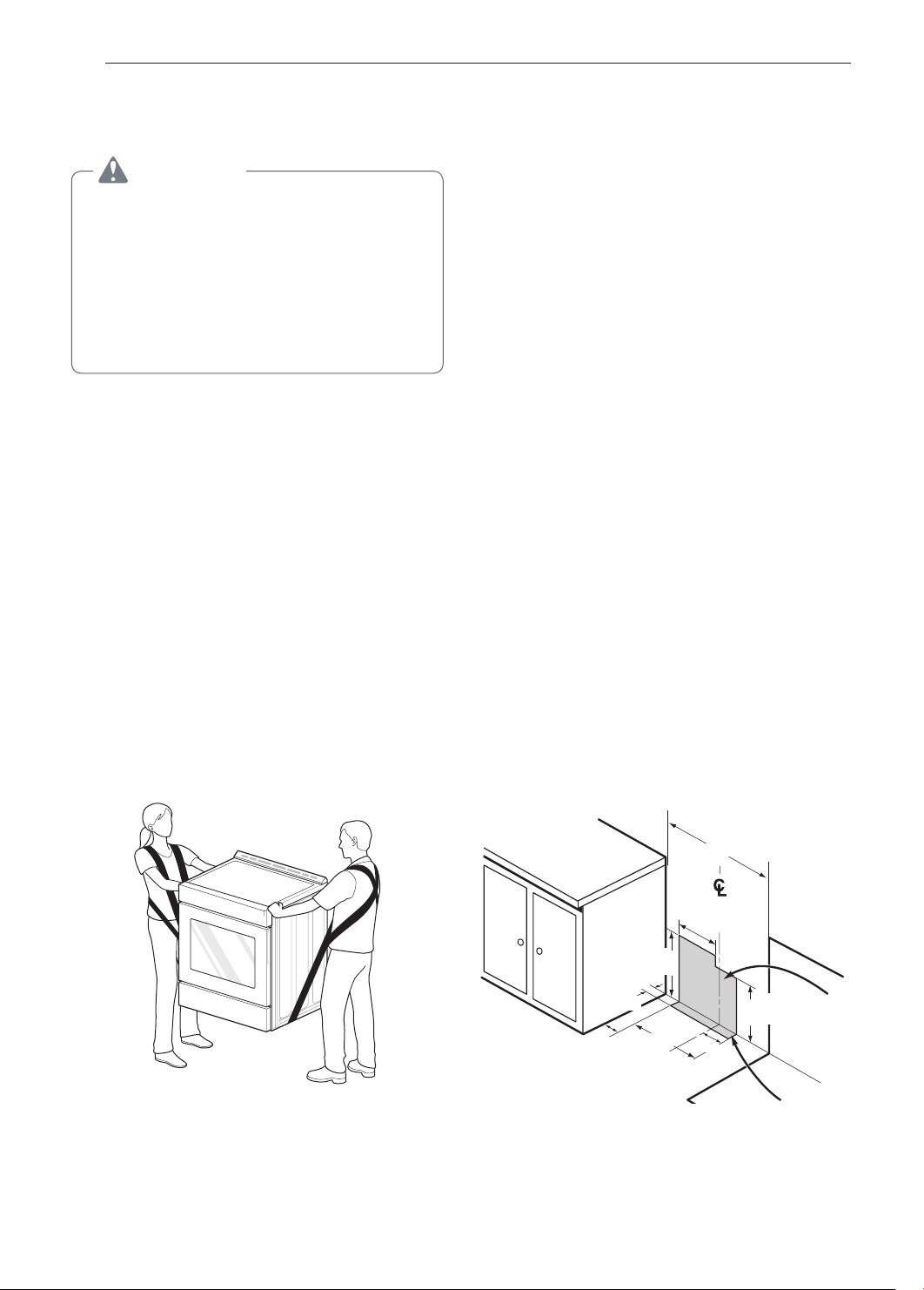

Unpacking and Moving the Range

CAUTION

•You should use two or more people to move

and install the range. (Excessive Weight

Hazard) Failure to do so can result in back or

other injury.

•Do not use the door handles to push or

pull the range during installation or when

moving the range out for cleaning or

service. Doing so can result in serious damage

to the door of the range.

Remove packing material, tape and any temporary

labels from your range before using. Do not remove

any warning-type labels, the model and serial number

label, or the Tech Sheet that is located on the back of

the range.

To remove any remaining tape or glue, rub the area

briskly with your thumb. Tape or glue residue can also

be easily removed by rubbing a small amount of liquid

dish soap over the adhesive with your fingers. Wipe

with warm water and dry.

Do not use sharp instruments, rubbing alcohol,

flammable fluids, or abrasive cleaners to remove tape

or glue. These products can damage the surface of

your range.

Your range is heavy and can be installed on soft

floor coverings such as cushioned vinyl or carpeting.

Use care when moving the range on this type of

flooring. Use a belt when moving the range to prevent

damaging the floor. Or slide the range onto cardboard

or plywood to avoid damaging the floor covering.

Choosing the Proper Location

Do not locate your range where it may be subject to

strong drafts. Any openings in the floor or wall behind

the range should be sealed. Make sure the openings

around the base of the range that supply fresh air

for combustion and ventilation are not blocked by

carpeting or woodwork.

Your range, like many other household units, is heavy

and can be installed on soft floor coverings such as

cushioned vinyl or carpeting. Use care when moving

the range on this type of flooring.

This appliance must not be installed with a ventilation

system that blows air downward toward the range.

This type of ventilation system may cause ignition and

combustion problems with the gas cooking appliance

resulting in personal injury or unintended operation.

When the floor covering ends at the front of the

range, the area that the range will be installed on

should be built up with plywood to the same level

or higher than the floor covering. This will allow the

range to be moved for cleaning and servicing, as well

as provide proper air flow to the range.

Also, make sure the floor covering can resist

temperatures of at least 167 °F (75 °C). See the

Installation Safety Instructions included in this

manual.

Make sure the wall coverings around your range

can resist the heat generated up to 194 °F (90 °C)

by the range. See the Installation Safety Instructions

included in this manual.

Gas Pipe and Electrical Outlet

Locations

(8.5 cm)

3"

(7.6 cm)

3

6/

11

13/

(30 cm)

"

16

17

15/

(45.6 cm)

16

16

"

"

30"

(76.2 cm)

7

14/

16

(20 cm)

5

"

14/

16

(15 cm)

"

(17 cm)

6

"

11/

16

INSTALLATION

15

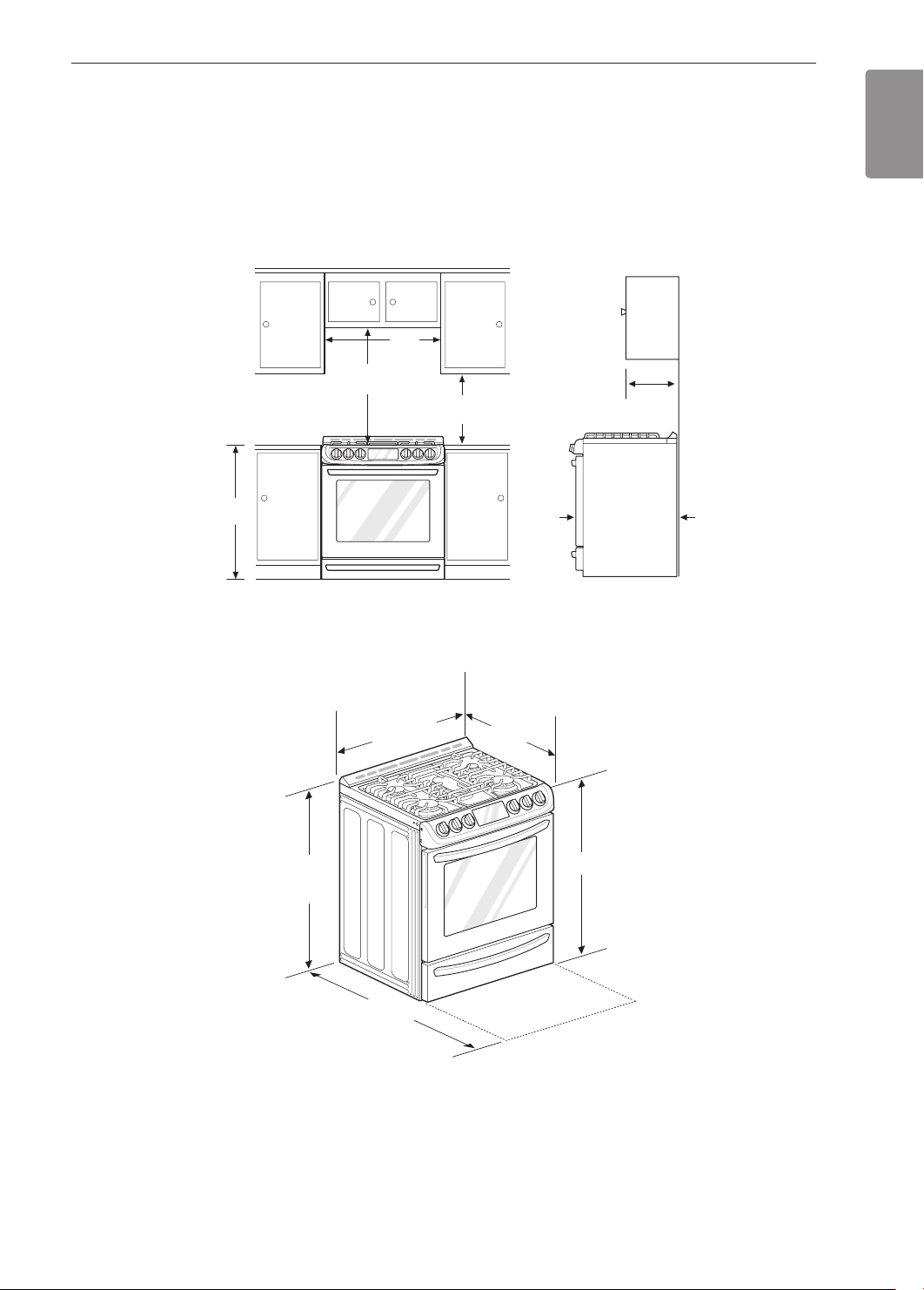

Dimensions and Clearances

Provide proper clearance between the range and adjacent combustible surfaces. These dimensions must be met

for safe use of your range. The location of the electrical outlet and pipe opening (see Gas Pipe and Electrical

Outlet Locations, page 14) may be adjusted to meet specific requirements. The range may be placed with 0"

clearance (flush) at the back wall.

Installation Clearances

Maximum

depth for

cabinets above

coutertops

Front edge of

/4"

the range side

panel forward

from cabinet

1

13"

0"

To cabinets

below

cooktop and

at the range

back

36"

(91.4 cm)

(76.2 cm)

30" (76.2 cm)

Minimum

30"

15"

(38.1 cm)

ENGLISH

Dimensions

Height

59

37

/64"

Depth with door open

43

7

29

/8"

(75.7 cm)

5

/32"

Depth with door closed

(includes door handle)

3

28

/4"

36

"

16

INSTALLATION

Installing the Anti-tip Device

Anti-tip

bracket

Screw must

enter wood or

concrete

The anti-tip bracket is packaged with an installation

template. The instructions include necessary

information to complete the installation. Read and

follow the range installation instruction sheet.

Wall plate

WARNING

•Range must be secured with an approved

anti-tip device.

•The range could be tipped by standing, sitting

or leaning on an open door if the range or

anti-tip device is not properly installed.

•After installing the anti-tip device, verify that it is

in place by carefully attempting to tilt the range

forward.

•This range has been designed to meet all

recognized industry tip standards for all normal

conditions.

•The installation of the anti-tip device must meet

all local codes for securing the appliance.

•The use of this device does not preclude tipping

of the range when not properly installed.

Optional Rear Filler

If the counter does not bridge the opening at the rear

wall the rear filler kit, that is provided with the slide in

range, will be needed.

Tighten the two lower screws on the rear

3

bracket. Insert one of the screws removed in

step 1 in the slot at each end of the rear filler.

Store the remaining two screws with these

4

instructions for future use.

Providing Adequate Gas

Supply

Your range is designed to operate at a pressure of

5" of water column on natural gas or 10" of water

column on LP.

Make sure you are supplying your range with the type

of gas for which it is configured.

This range is convertible for use on natural or LP gas.

When using this range on LP gas, conversion must

be made by a qualified LP installer before attempting

to operate the range.

For proper operation, the pressure of natural gas

supplied to the regulator must be between 5" and 13"

of water column.

For LP gas, the pressure supplied to the regulator

must be between 10" and 13" of water column. When

checking for correct operation of the regulator, the

inlet pressure must be at least 1" more than the

operating (manifold) pressure as given above.

The pressure regulator located at the inlet of the

range must remain in the supply line regardless of

which type of gas is being used.

A flexible metal appliance connector used to connect

the range to the gas supply line should have an I.D.

5

of

/8" and a maximum length of 5 feet. In Canada,

flexible connectors must be single wall metal

connectors less than 6 feet in length.

NOTE

If the countertop depth is greater than 25" there

will be a gap between the filler kit and the back

wall.

If the countertop depth is less than 24", the control

panel will not sit flush with the countertop.

Installing the Rear Filler

Using a screwdriver, remove the upper four

1

screws that attach the rear bracket and loosen

the lower two screws.

Place the rear filler on the rear bracket.

2

INSTALLATION

17

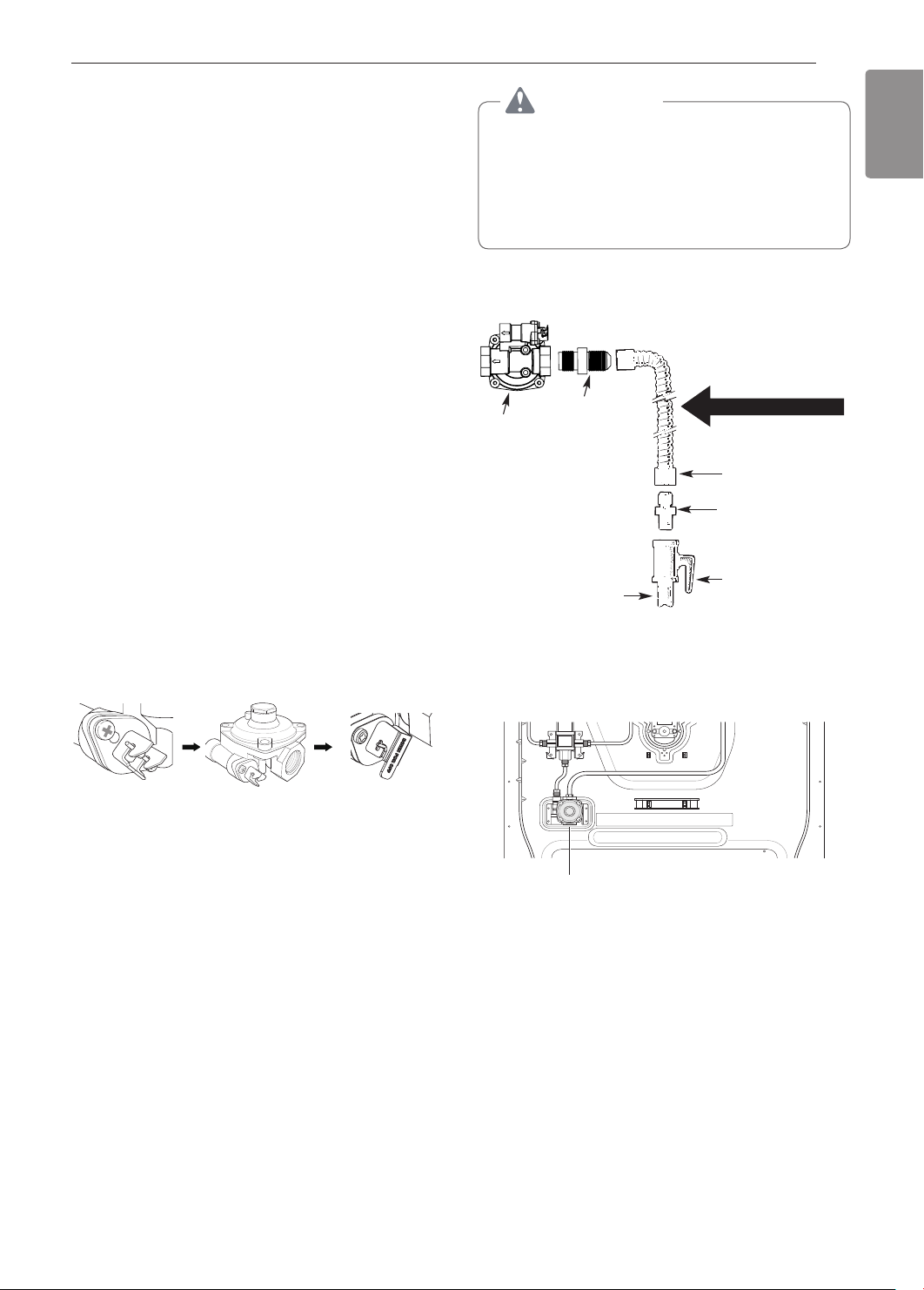

Connecting the Range to Gas

Shut off the range gas supply valve before removing

the old range and leave it off until the new hook-up

has been completed.

Because hard piping restricts movement of the range,

the use of a CSA International-certified flexible metal

appliance connector should be used unless local

codes require a hard-piped connection.

A manual valve shall be installed in an accessible

location in the gas piping external to the appliance

for the purpose of turning on or shutting off gas to the

appliance.

Never reuse an old connector when installing a new

range.

To protect against gas leaks, use a qualified pipe joint

sealant on all external threads.

Install a male 1/2" or 3/4" flare union adapter to the

1

NPT internal thread of the manual shut-off valve,

taking care to back-up the shut-off valve to keep

it from turning.

Install a male 1/2" flare union adapter to the 1/2"

2

NPT internal thread at the inlet of the pressure

regulator. Use a backup wrench on the pressure

regulator fitting to prevent damage.

WARNING

•Do not use a flame to check for gas leaks.

•Isolate the range from the gas supply system

by closing its individual shut-off valve during

any pressure testing of the gas supply system

at test pressures equal to or less than

(3.5 kPa).

Flexible Connector Hookup

1

Adapter

/2"

Pressure regulator

1

/2" or 3/4" Gas

pipe

Gas Flow into Range

Flex connector

(6 ft. max.)

Adapter

Gas shut-off

valve

1

/2" psig

ENGLISH

In an emergency situation or if you want to shut

off the gas supply, close the regulator valve by

positioning the lever as shown in the figure below.

Lever’s open

position

Connect a flexible metal appliance connector to

3

the adapter on the range. Position the range to

permit connection at the shut-off valve.

When all connections have been made, be sure

4

all range controls are in the Off position and turn

on the main gas supply valve. Gas leaks may

occur in your system and create a hazard. Gas

leaks may not be detected by smell alone.

Check all gas connection joints and fittings for

leaks with a non-corrosive leak detection fluid,

then wipe off.

Gas suppliers recommend you purchase and

install a UL approved gas detector. Install

and use in accordance with the installation

instructions.

Lever’s closed

position

Installer: Inform the consumer of the location of the gas

shutoff valve

Pressure Regulator Position

.

Pressure Regulator

18

INSTALLATION

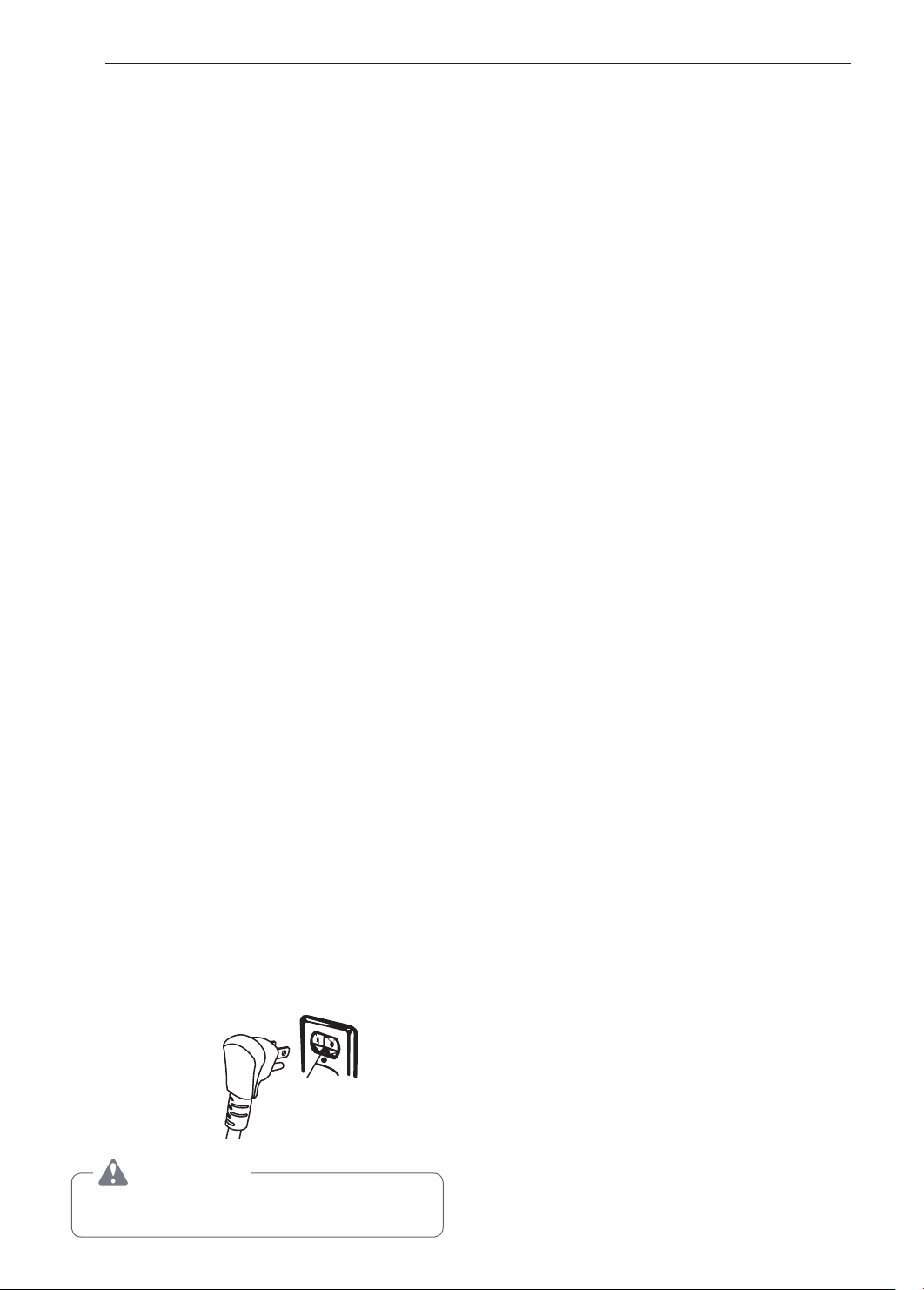

Electrical Connections

Electrical Requirements

120 Volt, 60 Hz, properly grounded dedicated circuit

protected by a 15 or 20 Amp circuit breaker, or slow

blow fuse.

If an external electrical source is utilized, the

appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70.

Grounding

IMPORTANT: FOR PERSONAL SAFETY, THIS

APPLIANCE MUST BE PROPERLY GROUNDED.

The power cord of this appliance is equipped with

a 3-prong (grounding) plug which mates with a

standard 3-prong grounding wall receptacle to

minimize the possibility of electric shock hazard from

this appliance.

The customer should have the wall receptacle and

circuit checked by a qualified electrician to make sure

the receptacle is properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD.

A word about GFCI’s – GFCI’s are not required or

recommended for gas range receptacles.

Ground Fault Circuit Interrupters (GFCI’s) are

devices that sense leakage of current in a circuit

and automatically switch off power when a threshold

leakage level is detected. These devices must

be manually reset by the consumer. The National

Electrical Code requires the use of GFCI’s in kitchen

receptacles installed to serve countertop surfaces.

Performance of the range will not be affected

if operated on a GFCI-protected circuit but the

occasional resetting of the circuit can become an

annoyance.

Do not use an adapter plug. Disconnecting of the

power cord places undue strain on the adapter

and leads to eventual failure of the adapter ground

terminal.

Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

The installation of appliances designed for mobile

home installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24

CFR, Part 3280 (formerly the Federal Standard

for Mobile Home Construction and Safety, Title

24, HUD, Part 280) or, when such standard is not

applicable, the Standard for Manufactured Home

Installations, latest edition (Manufactured Home Sites,

Communities and Set-Ups), ANSI A225.1, latest

edition, or with local codes. In Canada, mobile home

installation must be in accordance with the current

CAN/CSA Z240/MH Mobile Home Installation Code.

Sealing the Openings

Seal any openings in the wall and floor after electrical

and gas supplies are completed.

Preferred

Method

Ensure proper ground

exists before use

CAUTION

Have the circuit checked by a qualified electrician

to make sure the receptacle is properly grounded.

INSTALLATION

19

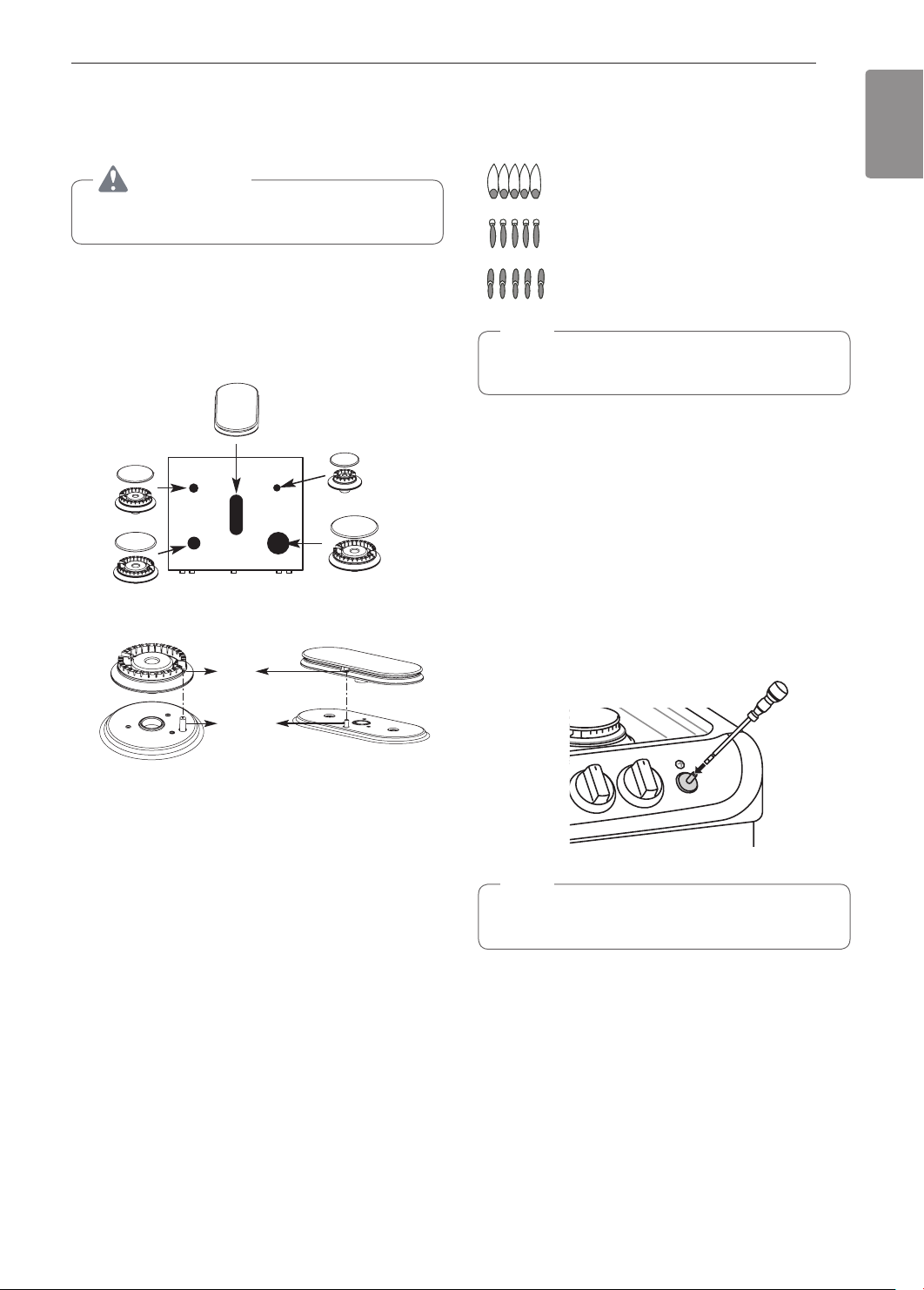

Assembling the Surface

Burners

CAUTION

Do not operate the burners without all parts in

place.

Place the burner caps and heads on the cooktop.

Make sure that the caps and heads are placed in the

correct locations. There is one small, one medium,

one large, one oval(center), and one extra large

burner head and cap.

Center Burner

Oval (Center) burner

head/cap assembly

Medium

burner

head

and cap

Large burner

head and cap

Front of range

Hole

Extra large burner

Small burner

head and

cap

head and cap

Quality of Flames

The combustion quality of the burner flames needs to

be confirmed visually.

A Yellow flames - Call for service.

B Yellow tips on outer cones - This

is normal for LP gas.

C Soft blue flames - This is normal

for natural gas.

NOTE

•With LP gas, some yellow tipping on outer

cones is normal.

Adjusting the Surface Burner to the

Low Flame (Simmer) Setting

Light all surface burners.

1

Turn the knob on the burner being adjusted to

2

Lo.

Remove the knob.

3

Insert a small, flat-blade screwdriver into the

4

valve shaft.

ENGLISH

Electrode

Make sure the hole in the burner head is positioned

over the electrode.

Checking Ignition of the

Surface Burners

Electric Ignition

Select a surface burner knob and simultaneously

push in and turn to the Lite position. You will hear

a clicking sound indicating proper operation of the

spark module.

Once the air has been purged from the supply lines

the burner should ignite within 4 seconds. After the

burner ignites, rotate the knob out of the Lite position.

Try each burner in succession until all burners have

been checked.

NOTE

Hold the valve shaft with one hand while turning

the screw to adjust with the other.

Replace the knob.

5

Test the flame stability.

6

Test 1: Turn the knob from Hi to Lo quickly. If the

flame goes out, increase the flame size and test

again.

Test 2: With the burner on a Lo setting, open

and close the oven door quickly. If the flame is

extinguished by the air currents created by the

door movement, increase the flame height and

test again.

Repeat steps 1-6 for each surface burner.

7

20

INSTALLATION

Checking Operation of Bake / Broil

Burners

To check ignition of the Bake burner, follow the steps

below:

Remove all packing materials from inside the

1

oven cavity.

Turn oven mode knob to select Bake. 350 °F

2

appears in the display.

Press Start.

3

It may take between 30 and 90 seconds for the

burner to start heating.

To check ignition of the Broil burner, follow the steps

below:

Turn oven mode knob to select Broil High. Hi

1

appears in the display.

Make sure the door is closed.

2

Press Start.

3

It may take between 30 and 90 seconds for the

burner to start heating.

NOTE

Do not try to light either the Bake or Broil burners

during a power outage. The range has an

electrical ignition system and cannot be used

without power.

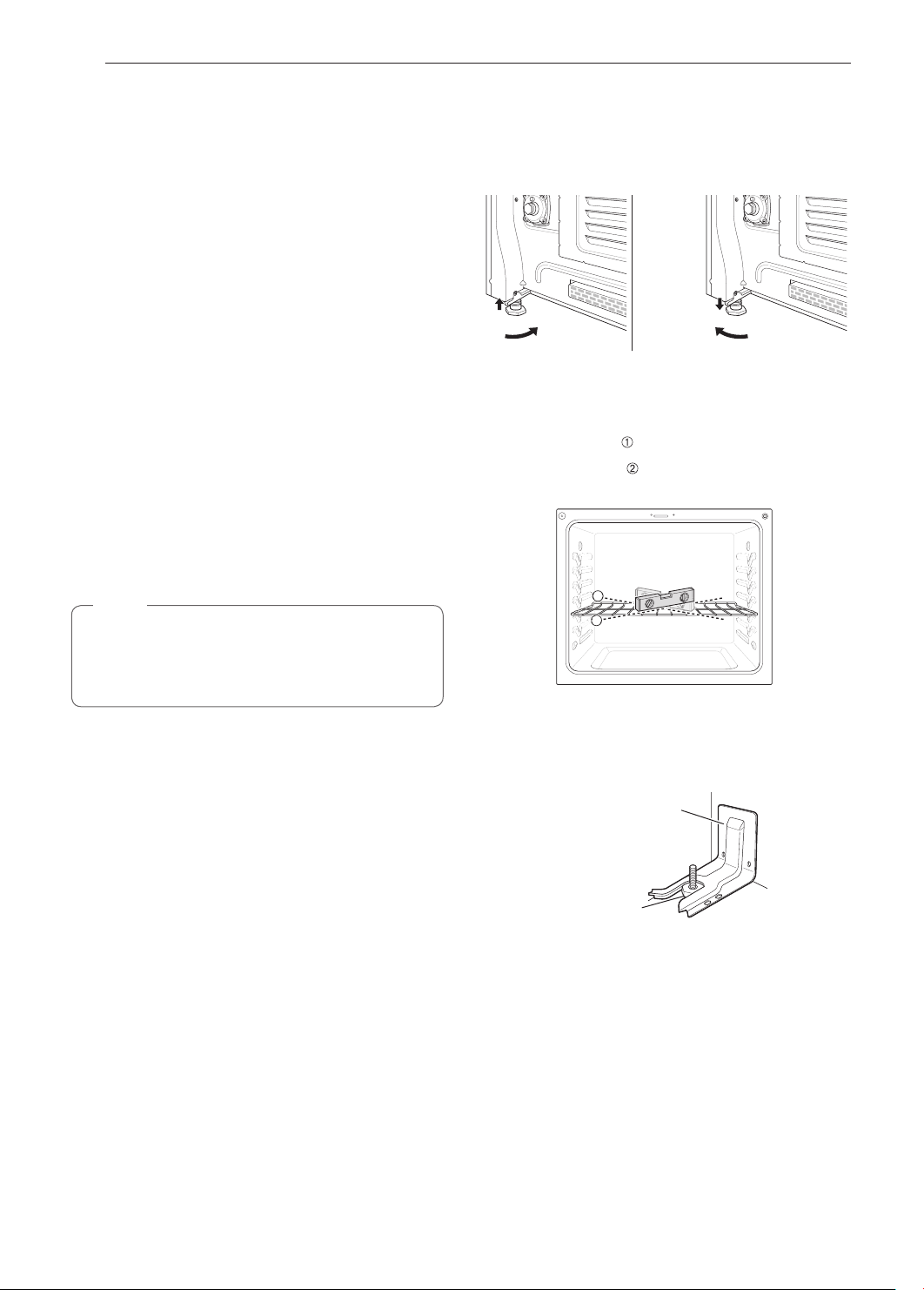

Leveling the Range

Level the range by adjusting the leveling legs.

Extending the legs slightly may also make it easier to

insert the rear leg into the anti-tip bracket.

Use a level to check your adjustments. Place the level

diagonally on the oven rack, and check each direction

for level.

First check direction

Then check direction

on the rack, adjust the leveling legs.

.

. If the level doesn’t show level

2

1

Adjusting Air Shutters (for LP

Conversions)

The range comes from the factory with the air

shutters adjusted for proper air flow for natural gas.

If converted to LP, follow the instructions provided in

the conversion kit to properly adjust the air shutters.

LP conversion must be performed by a qualified

technician.

Engaging the Anti-tip Device

Anti-tip

bracket

Leveling leg

Slide the range against the wall, making sure

1

the back leg slides into and engages the anti-tip

bracket.

Check for proper installation by grasping

2

the front edge of the cooktop and carefully

attempting to tilt the range forward.

OPERATION

21

OPERATION

Gas Surface Burners

Before Use

Read all instructions before using.

Make sure that all burners are properly placed.

Make sure that all grates are properly placed

before using the burner.

CAUTION

Do not operate the burner for an extended period

of time without cookware on the grate.

The finish on the grate may chip without cookware

to absorb the heat.

CAUTION

ENGLISH

WHAT TO DO IF YOU SMELL GAS

•Open windows.

•Do not try to light any appliance.

•Do not touch any electrical switch.

•Do not use any phone in your building.

•Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

•If you cannot reach your gas supplier, call the

fire department.

NOTE

Electric spark igniters from the burners cause

a clicking noise. All the spark igniters on the

cooktop will activate when igniting just one burner.

Make sure the burners and grates are cool before

touching them, or placing a pot holder, cleaning

cloth, or other materials on them.

Touching grates before they cool down may cause

burns.

Loading...

Loading...