Page 1

10

INSTALLATION

INSTALLATION

Installation Overview

Please read the following installation instructions first after purchasing this product or transporting it to another

location.

Check and choose the

proper location

240 V or 208 V

Black White Red

Terminal

block

Conduit

connection

plate

Install anti-tip device Level the range Connect electric range

Plug in the power cord Engage the anti-tip device Test run

Product Specifications

The appearance and specifications listed in this manual may vary due to constant product improvements.

Oven Range Models LSE4613, LSE4611

Description Electric Slide In Oven Range

Electrical requirements

Exterior Dimensions

Height to cooking surface 36

Net weight 176 lb (80.0 kg)

Total capacity Total cap.: 6.2 cu. ft.

LSE4613 : 13.5 kW 120/240 VAC or 10.1 kW 120/208 VAC

LSE4611 : 12.6 kW 120/240 VAC or 9.5 kW 120/208 VAC

7

29

"

/

(W) x 37 7/

8

"

(H) x 26 1/

8

"

(D) (D with door closed)

2

75.7 cm (W) x 96 cm (H) x 67.3 cm (D) (D with door closed)

"

(91.4 cm)

Page 2

INSTALLATION

ENGLISH

11

Before Installing the Range

WARNING

Tip - Over Hazard

A child or adult can tip the range and

be killed. Verify the anti-tip bracket

has been installed. Ensure the

anti-tip bracket is engaged when the

range is moved.

Do not operate the range without the

anti-tip bracket in place. Failure to

follow these instructions can result

in death or serious burns to children

and adults.

To check that leveling leg is

inserted into anti-tip bracket,

grasp the top rear edge

of the range and carefully

attempt to tilt it forward.

Tools Needed

Anti-tip

bracket

Leveling

leg

If you did not receive an anti-tip bracket with your

purchase, call 1-800-243-0000 (1-888-542-2623 in

CANADA) to receive one at no cost.

WARNING

•The information in this manual should be

followed exactly. Failure to do so may result

in fire, electrical shock, property damage,

personal injury, or death.

•Wear gloves during the installation

procedure. Failure to do so can result in bodily

injury.

Phillips screwdriver

Level

Flat-blade screwdriver

Adjustable wrench

Parts Provided

Template (1) Anti-tip bracket kit (1)

Anchor sleeves (6) Lag bolts (6)

Rear ller (1)

1

/4" Nut driver

Drill

Pliers

Safety glasses

Parts not Provided

4-Wire cord or

3-Wire cord

(UL approved 40 or 50

AMP)

Tape measure

Strain relief

(For conduit

Installations only)

NOTE

•Observe all governing codes and ordinances.

•Have the installer show you the location of the circuit breaker or fuse. Mark it for easy reference.

•As when using any appliance generating heat, there are certain safety precautions you should follow.

•Be sure your range is installed and grounded properly by a qualified installer or service technician.

Gloves

Page 3

12

INSTALLATION

Installing the Range

Unpacking and Moving the Range

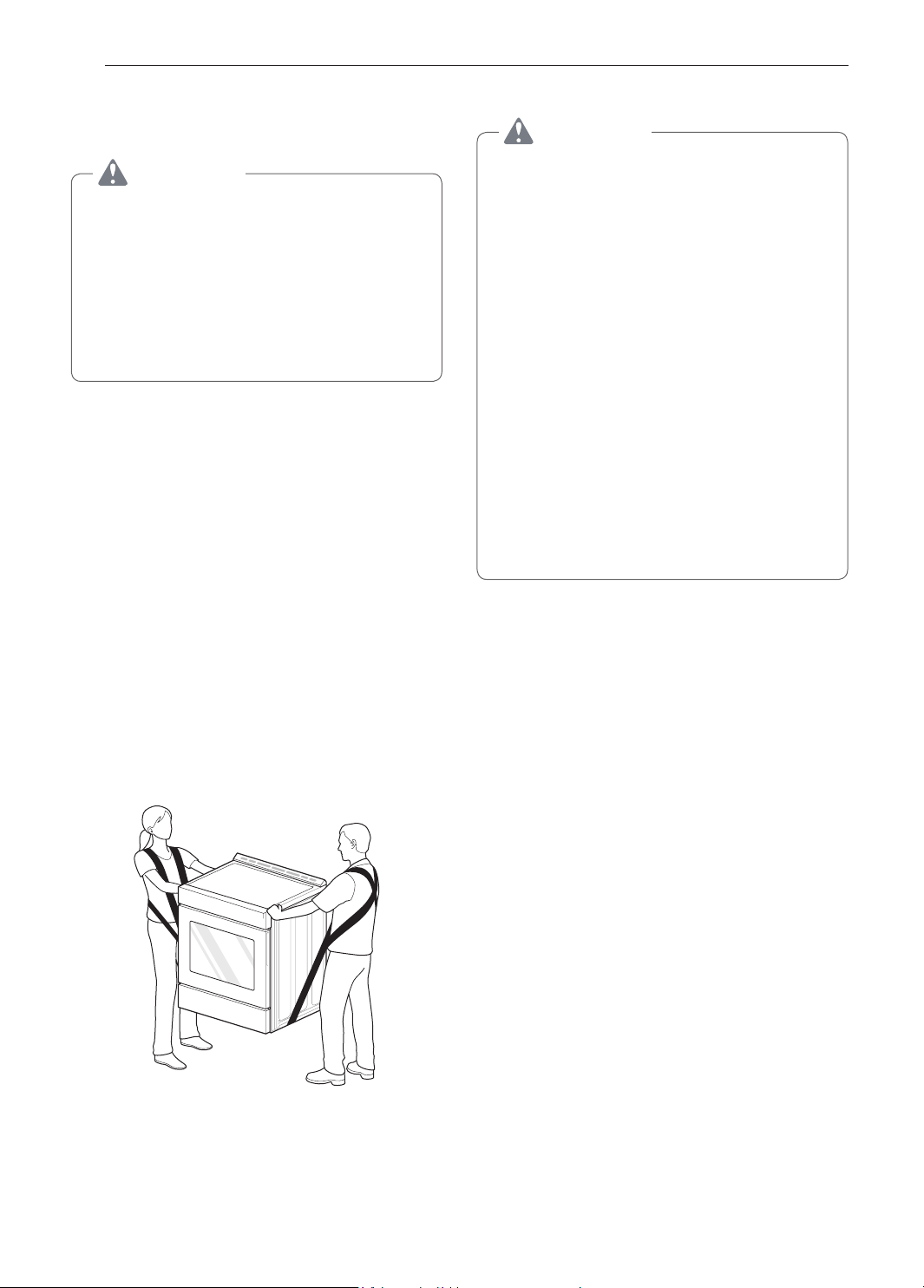

CAUTION

•You should use two or more people to move

and install the range. (Excessive Weight

Hazard) Failure to do so can result in back or

other injury.

•Do not use the door handles to push or

pull the range during installation or when

moving the range out for cleaning or

service. Doing so can result in serious damage

to the door of the range.

Remove packing material, tape and any temporary

labels from your range before using. Do not remove

any warning-type labels, the model and serial number

label, or the Tech Sheet that is located on the back of

the range.

To remove any remaining tape or glue, rub the area

briskly with your thumb. Tape or glue residue can also

be easily removed by rubbing a small amount of liquid

dish soap over the adhesive with your fingers. Wipe

with warm water and dry.

Do not use sharp instruments, rubbing alcohol,

flammable fluids, or abrasive cleaners to remove tape

or glue. These products can damage the surface of

your range.

Your range is heavy and can be installed on soft

floor coverings such as cushioned vinyl or carpeting.

Use care when moving the range on this type of

flooring. Use a belt when moving the range to prevent

damaging the floor. Or slide the range onto cardboard

or plywood to avoid damaging the floor covering.

Choosing the Proper Location

CAUTION

•Avoid placing cabinets above the range. To

minimize the hazard caused by reaching over

the open flames of operating burners, install a

ventilation hood over the range that projects

forward at least five inches beyond the front of

the cabinets.

•Make sure wall covering, countertop and

cabinets around the range can withstand

the heat (up to 194 °F) generated by the

range. Discoloration, delamination or melting

may occur. This range has been designed to

comply with the maximum allowable wood

cabinet temperature of 194 °F.

•Before installing the range in an area

covered with linoleum or other synthetic

floor covering, make sure the floor covering

can withstand temperatures of at least

200 °F (93 °C).

•Use an insulated pad or

plywood under the range if installing the

range over carpeting.

The range should always be plugged into its own

individual properly grounded electrical outlet. This

prevents overloading house wiring circuits which

could cause a fire hazard from overheated wires. It is

recommended that a separate circuit serving only this

appliance be provided.

Mobile Home - Additional Installation

Requirements

The installation of this range must conform to the

Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280 (formerly the

Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280), or when

such standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1/NFPA

501A or with local codes.

•When this range is installed in a mobile home, it

must be secured to the floor during transit. Any

method of securing the range is adequate as long

as it conforms to the standards listed above.

•A four-wire power supply cord or cable must be

used in a mobile home installation.

1

/4 in. (0.64 cm)

Page 4

INSTALLATION

ENGLISH

13

Dimensions and Clearances

NOTE

Save for the use of the local electrical inspector.

3" (7.6 cm)

A

Cabinet

opening

24"

36"

(91.4 cm)

29.8"

(75.7 cm)

(60.9 cm)

Cabinet

24"

(60.9 cm)

Acceptable

electrical

outlet area

4"

(10 cm)

25"

(63.5 cm)

36"

(91.4 cm)

15" (38 cm)

6"

(15.2 cm)

9"

(23 cm)

3" (7.6 cm)

Normal counter

top depth

Counter

top height

Wall

11" (28 cm)

(10 cm)

Center

4"

2.5" (6.3 cm)

5"

(13 cm)

(15.2 cm)

9"

(23 cm)

6"

2.5"

(6.3 cm)

A = 30" (76.2 cm) For U.S.A

= 30" (76.2 cm) ~ 31" (78.7 cm) For CANADA

15

"

/

For installation in Canada, a free-standing range is not to be installed closer than

(12 mm) from any

32

adjacent surface.

30"

(76.2 cm)

*30" (76.2 cm)

Minimum

**15"

(38.1 cm)

36"

(91.4 cm)

Minimum Dimensions

* 30" (76.2 cm) minimum clearance between the top of the cooking surface and the bottom of an unprotected

wood or metal cabinet; or 24" (60.9 cm) minimum when bottom of wood or metal cabinet is protected by not less

1

"

/

than

(6.4 cm) flame retardant millboard covered with not less than no. 28 MSG sheet steel, 0.015" (0.381 mm)

4

stainless steel, 0.024" (0.610 mm) aluminum or 0.020" (0.508 mm) copper.

** 15" (38.1 cm) minimum between countertop and adjacent cabinet bottom.

Page 5

14

INSTALLATION

Installing the Anti-tip Device

WARNING

Tip - Over Hazard

A child or adult can tip the range and

be killed. Verify the anti-tip bracket

has been installed. Ensure the anti-tip

bracket is engaged when the range

is moved. Do not operate the range

without the anti-tip bracket in place.

Failure to follow these instructions

can result in death or serious burns to

children and adults.

To check that leveling leg is

inserted into anti-tip bracket,

grasp the top rear edge

of the range and carefully

attempt to tilt it forward.

Screw must

enter wood or

concrete

Anti-tip

bracket

Anti-tip

bracket

Locate the anti-tip bracket using the template

An anti-tip bracket is packaged with the template.

The instructions include necessary information to

complete the installation. Read and follow the range

installation instruction sheet (template).

Leveling the Range

Level the range by adjusting the leveling legs with a

wrench. Extending the legs slightly may also make it

easier to insert the rear leg into the anti-tip bracket.

Leveling

leg

Wall plate

Use a level to check your adjustments. Place the level

diagonally on the oven rack, and check each direction

for level.

First check direction

Then check direction

.

. If the level doesn’t show level

on the rack, adjust the leveling legs with a wrench.

2

1

Connecting Electricity

Electrical Requirements

This appliance must be installed and grounded on a

branch circuit by a qualified technician in accordance

with the National Electrical code ANSI/NFPA NO. 70 latest edition.

All wiring should conform to Local and NEC codes.

This range requires a single-phase, 3 wire, A.C

120/208 V or 120/240 V 60 Hz electrical system. Use

only a 3-conductor or a 4-conductor UL- listed range

cord with closed-loop terminals, open-end spade

lugs with upturned ends or similar termination. Do not

install the power cord without a strain relief.

A range cord rated at 40 amps with 120/240

minimum volt range is required. If a 50 amp range

cord is used, it should be marked for use with 1

diameter connection openings. This appliance

may be connected by means of a conduit or power

cord. If a conduit is being used, go to page 17 for

3 wire conduit connections or 4 wire conduit

connections.

3

"

/

8

Page 6

INSTALLATION

ENGLISH

15

WARNING

•Allow 2 to 3 ft (61.0 cm to 91.4 cm) of slack

in the line so that the range can be moved if

servicing is ever necessary.

•The power supply cord and plug should

not be modified. If it will not fit the outlet,

have a proper outlet Installed by a qualified

electrician.

•Using an extension cord to connect the

power is prohibited. Connect the power

cord and plug directly.

•Electrical ground is required on this

appliance.

•Make sure that the power cord is not

pinched by the range or heavy objects.

Failure to do so can result in serious burns or

electrical shock.

Specified power-supply-cord kit rating

Diameter (inches)

Range rating, watts

Specified

rating of

power

120/240

volts

3-wire

8,750 16,500

16,501 22,500

120/208

volts

3-wire

7,801 12,500

12,501 18,500

supply-

cord kit,

amperes

40 or 50A

50

3, 4 - Wire electrical wall Receptacle

of Range

connection

Opening

Power

cord

3

"

/

1

8

"

1 3/

4

Conduit

"

1 1/

8

"

1 3/

8

Use the cord/conduit connection plate to install the

power cord or conduit. Leave the connection plate

as installed for power cord installations. Remove the

connection plate for conduit installations and use the

smaller 11/8 in. (2.8 cm) conduit hole instead of the

13/8 in. (3.5 cm) power cord hole.

1

/8"

(2.8 cm) Conduit

1

13/8"

(3.5 cm) Cord

Remove the conduit connection plate

For power cord installations, hook the strain relief

over the 1

3

/8 in. (3.5 cm) power cord hole located

below the rear of the oven. Insert the power cord

through the strain relief and tighten it.

Conduit

connection

plate

Power cord

3

Assembling power cord strain relief at the 1

/8" opening

For conduit installations, insert the conduit strain

relief in the 11/8 in. (2.8 cm) conduit hole. Then install

the conduit through the body of the strain relief and

fasten the strain relief with its ring.

4 Wire receptacle (14-50R)

3 Wire receptacle (10-50R)

Connecting the Power Cord

The rear access cover must be removed. Loosen the

two screws with a screwdriver. The terminal block will

then be accessible.

Access cover

Ring

Body

Assembling conduit cord strain relief at the 1

Cord/

Conduit

connection

plate

Conduit

1

/8" opening

Page 7

16

INSTALLATION

3-Wire Connection : Power Cord

WARNING

•The middle (neutral or ground) wire, which

is white, of a 3-wire power cord or a 3-wire

conduit has to be connected to the middle

post of the main terminal block. The

remaining two wires of the power cord or

conduit have to be connected to the outside

posts of the main terminal connection block.

Failure to do so can result in electrical shock,

severe personal injury or death.

Install the power cord as follows:

For power cord installations, hook the strain relief

over the power cord hole (1

of the oven. Insert the power cord through the strain

relief and tighten it.

Do not install the power cord without a strain

relief.

Remove the lower 3 screws from the terminal

1

block and retain them.

Insert the 3 screws through each power cord

2

terminal ring and into the lower terminals of

the terminal block. Make sure that the center

(neutral) wire, which is white, is connected to the

center lower position of the terminal block.

Tighten the 3 screws securely into the terminal

3

block. Do not remove the ground strap

connections.

3-wire connection

Black White Red

3

"

/

) located below the rear

8

4-Wire Connection : Power Cord

WARNING

•Only a 4-conductor power-supply cord

kit rated 120/240 volts, 50 amperes and

marked for use with ranges with closedloop connectors or opened spade lugs with

upturned ends shall be used.

The white middle (neutral) wire of the power

cord or 4-wire conduit has to be connected

to the middle post of the main terminal

block. The other two wires of the power

cord or conduit have to be connected to

the outside posts of the main terminal

connection block. The 4th ground wire

(green) must be connected to the frame of

the range with the ground screw. Failure

to do so can result in electrical shock, severe

personal injury or death.

Install the power cord as follows:

Do not install the power cord without a strain

relief.

Remove the lower 3 screws from the terminal

1

block and retain them.

Remove the ground screw and bend the end of

2

the ground strap up so the slot is over the hole

of the center screw removed in step 1.

Insert the ground screw into the power cord

3

ground wire (green) terminal ring and secure it to

the range frame.

Insert the 3 screws through each power cord

4

terminal ring and into the lower terminals of the

terminal block. Make sure that the white center

(neutral) wire is connected to the center lower

position of the terminal block.

Terminal

block

Conduit

connection plate

If screws are not tightened securely, it can result in

electrical spark and severe personal injury or death.

Tighten the 3 screws securely into the terminal

5

block. The center screw now attaches the bent

up ground strap to the block.

4-wire connection

Black White Red

Terminal

block

Ground

screw

If screws are not tightened securely, it can result in

electrical spark and severe personal injury or death.

Conduit

connection plate

Ground

strap

Bend strap up

and attach

Page 8

INSTALLATION

ENGLISH

17

3-Wire Connection: Conduit

Install the conduit as follows:

Remove the conduit connection plate from the rear of

the oven and rotate it. The conduit hole (1

be used.

First, prepare the conduit wires as shown below.

3-Wire

Conduit

connection

plate

Second, install the conduit strain relief.

For conduit installations, purchase a strain relief and

insert it in the 1

install the conduit through the body of the strain relief

and fasten the strain relief with its ring. Reinstall the

bracket.

For conduit connections:

If the wire in the conduit is copper it must be 8 or 10

AWG wiring.

If the wire in the conduit is aluminum it must be 6 or 8

AWG wiring.

Loosen the lower 3 screws from the terminal

1

block.

Insert the bare wire (white/neutral) end through

2

the center terminal block opening. Do not

remove the ground strap connections.

1

/8 in. (2.8 cm) conduit hole. Then

or

4-Wire

1

/8") must

Ground

wire

4-Wire Connection: Conduit

WARNING

•The white middle (neutral) wire of the power

cord or 4-wire conduit has to be connected

to the middle post of the main terminal

block. The other two wires of the power

cord or conduit have to be connected to

the outside posts of the main terminal

connection block. The 4th ground wire

(green) must be connected to the frame of

the range with the ground screw. Failure

to do so can result in electrical shock, severe

personal injury or death.

Follow the instructions for installing the conduit

1

under 3-Wire Connection: Conduit until the strain

relief and bracket are installed. Do not install the

conduit without a strain relief.

Loosen the 2 lower left and right screws from

2

the terminal block. Remove the lower 2 center

screws. Do not discard any screws.

Remove the ground screw and bend the end of

3

the ground strap up so the slot is over the hole

of the center screw removed in step 1.

Attach the ground (green) bare wire end to

4

the range frame and secure it in place with the

ground screw.

Insert the bare wire (white/neutral) end through the

5

center terminal block opening. The center screw

now attaches the bent up ground strap to the block.

Insert the two side bare wire ends into the left

6

and the right terminal block openings. Tighten

the 3 screws securely into the terminal block.

(approximately 35 - 50 IN-LB)

Insert the two side bare wire ends into the lower

3

left and the lower right terminal block openings.

Tighten the 3 screws securely into the terminal

block. (approximately 35 - 50 IN-LB)

3-wire connection

Black White Red

Terminal

block

Wire

ends

Conduit

connection plate

If screws are not tightened securely, it can result in

electrical spark and severe personal injury or death.

4-wire connection

Black White Red

Terminal

block

Ground

Wire

ends

Conduit

connection

plate

Ground

screw

If screws are not tightened securely, it can result in

electrical spark and severe personal injury or death.

Ground

wire

strap

Bend strap

up and

attach

Page 9

18

INSTALLATION

Engaging the Anti-tip Device

•Move the range close enough to the opening to

plug into the receptacle.

•Slide the range into position ensuring that the back

leg slides under the anti-tip bracket. The range

should sit flush against the back wall when properly

installed.

•Carefully attempt to tip the range forward to ensure

that the anti-tip bracket is engaged properly. If

properly installed, the anti-tip bracket will prevent

the range from being tipped. If the range can be

tipped, reinstall the range until the anti-tip bracket is

properly installed and the range will not tip forward.

•Turn on electrical power. Check the range for

proper operation.

Installing the Rear Filler

Using a screwdriver, remove the upper four

1

screws that attach the rear bracket and loosen

the lower two screws.

Place the rear filler on the rear bracket.

2

Tighten the two lower screws on the rear

3

bracket. Insert one of the screws removed in

step 1 in the slot at each end of the rear filler.

Store the remaining two screws with these

4

instructions for future use.

Test Run

Check if the range is properly installed and run a test

cycle.

Turn the oven mode knob to the Off position to

1

start test.

Turn each knob to the Hi position to check

2

that the surface heating elements are working

properly. The elements should glow red and

radiate heat, and they should cycle on and off

periodically even when the knob is in the Hi

position. This cycling prevents the glass-ceramic

from being cracked by thermal shock.

IMPORTANT : The Warming Zone does not

consume enough power to glow red.

Optional Rear Filler

If the counter does not bridge the opening at the rear

wall the rear filler kit, that is provided with the slide in

range, will be needed.

NOTE

If the countertop depth is greater than 25" there

will be a gap between the filler kit and the back

wall.

If the countertop depth is less than 24", the control

panel will not sit flush with the countertop.

*For Model : LSE4613

3

After checking all the surface heating elements,

check the locking system by pressing Clock

for three seconds. The oven door should lock

and the cooktop should not operate while the

Lockout function is turned on. Pressing Clock

for three seconds to disable Lockout.

Now check the oven's operation. Turn the oven

4

mode knob to select the Bake mode. 350 °F

appears in the display. Press Start.

The oven should finish preheating in 15 minutes,

5

and the convection fan should operate while the

oven is preheating.

After checking the oven's operation, turn the

6

temperature up to 450 °F and leave the oven on

for at least an hour to help remove any oil which

might cause smoke and odors when first using

the oven.

NOTE

Smoke may come out of the range when it is first

used.

Loading...

Loading...