LG LS243HLV, LS363HLV, LA090HYV1, LA120HYV1, LC427HV User Manual

...

HOME COMFORT & LIGHT

COMMERCIAL SYSTEMS

2017

ABOUT LG

DUCT-FREE SYSTEMS:

A NEW WAY TO THINK

ABOUT AIR CONDITIONING

For truly personalized comfort in all rooms,

consider an LG Duct-Free Split air conditioning

system. LG air conditioning systems make

it easier to provide customized cooling and

heating in every room without any bulky

window units or costly ductwork, and with

several indoor unit designs sure to match any

décor, LG air conditioning systems can be right

for every job.

LG air conditioning systems

are THE smart alternative to

traditional air conditioning.

°

72

°

76

°

70

74

°

About LG Electronics USA

LG Electronics USA, Inc., based in Englewood Cliffs, NJ, is the North American subsidiary of LG

Electronics, Inc., a $49 billion global force and technology leader in consumer electronics, home

®

appliances and mobile communications. LG Electronics, a proud ENERGY STAR

for ve consecutive years, sells a range of stylish and innovative home entertainment products, mobile

phones, home appliances, commercial displays, air conditioning systems and solar energy solutions in

the United States, all under LG’s “Life’s Good” marketing theme. For more news and information on LG

Electronics, please visit www.LG.com.

Partner of the Year

LG Electronics USA Air Conditioning Technologies

The LG Electronics USA Commercial Air Conditioning business is based in Alpharetta, GA.

LG is a leading player in the global air conditioning market, manufacturing both commercial

and residential air conditioners and providing total sustainability and building management

solutions. From consumer and individual units to industrial and specialized air conditioning

systems, LG provides a wide range of products for heating, ventilating and air conditioning.

For more information, please visit www.lghvac.com.

Our Commitment to You:

QUALITY

TRAINING

PERFORMANCE

INNOVATION

LG air conditioning systems reect our commitment to building high-quality

products. Operating several state-of-the-art research & development facilities

across the globe, LG invests heavily to ensure we are combining the best

technologies with the best ideas.

With several LG training academies throughout the United States and even more

regional partner academies, LG makes it easy to learn about LG systems and

product applications.

LG makes a wide range of products with powerful cooling and heating

capabilities while maintaining industry-leading efciencies and enjoyable, quiet

operation for the end user.

LG has built smart technology to enhance the user’s experience as well as the

technician’s experience during routine maintenance or service. Our continued

efforts to look for the most innovative ideas in HVAC as well as our commitment

to building green technologies ensures that we will continue to bring to market

smarter, sustainable products.

LG Air Conditioning Technologies

1 2

TABLE OF CONTENTS

TABLE OF CONTENTS

INTRODUCTION

About LG

LG Advantages

Training & Recognition

Installation Best Practices

Key Features

SINGLE ZONE SYSTEMS

Wall Mounted

- ART COOL™ Gallery

- ART COOL™ Mirror

- ART COOL™ Premier

- Extended Piping

- High Efficiency

- Mega 208/230V

- Mega 115V

Ceiling Mounted

Low Static Ducted

High Static Ducted

MULTI ZONE SYSTEMS

1

5

7

8

9

11

12

13

15

16

17

17

18

19

20

Outdoor Units

Indoor Units

Multi F MAX Piping Accessories

Multi Zone Combination Tables

ACCESSORIES

Controls

Indoor Accessories

Outdoor Accessories

Air Technologies

REFERENCE TABLES

Controls & Accessories Compatibility

ENERGY STAR

Model Number Nomenclature

LG Air Conditioning Technologies

3 4

®

Systems

23

25

29

30

69

70

70

70

71

73

74

0.3µm

.3µm

Indoor Unit /

Evaporator

Conduit for

Refrigerant Lines &

Wiring

Outdoor Unit / Condenser

LG ADVANTAGES LG ADVANTAGES

°

ROOM-BY-ROOM CONTROL

With a controller for each indoor unit, LG air conditioning

systems offer precise temperature settings in each zone

while maximizing energy savings by heating or cooling only

the zones in use.

72

70

°

72

Whenever, wherever and no matter how many air conditioners

you have, the LG Smart AC module and LG Smart ThinQ® let you

°

°

74

easily access and control your air conditioner from your mobile

phone.

SMART AC & LG SMART THINQ®

1

QUIET OPERATION

LG DFS systems operate at low sound levels, thanks to LG’s

unique low-vibration compressor, skew fan and brushless direct

current (BLDC) motor technology that eliminates unnecessary

noise and allows for smooth operation.

TECHNOLOGY

Inverter variable-speed outdoor units are measurably quieter

and use less energy than conventional air conditioners. Unlike

conventional air conditioners that cycle on and off, an inverter

compressor ramps up or down to match the capacity and

maintain comfort levels.

Indoor Unit

40

Bird Calls

17

dB

LG AC Indoor Unit

as low as 17 dB

Art Cool Premier

(Sleep Mode)

Temperature

DESIRED

TEMP

dB

Noise Level Comparison (dB)

Energy

Saving

50

dB

Conversation

at Home

Energy

Saving

Conventional AC

LG Inverter

Energy

Saving

60

dB

Conversation

in Restaurant

70

dB

Vacuum

Cleaner

Energy

Saving

EASY INSTALLATION &

NO DUCTWORK

LG Duct-Free Systems are designed for easier and more

efcient installation. They require little to no ductwork, and

most indoor units can mount on any wall. Installation requires

only a small hole to be drilled in the wall. Smaller indoor and

outdoor units ensure space-saving convenience. Moreover,

long refrigerant piping lengths allow for extra installation and

design flexibility.

AIR QUALITY

3M Micro Protection Filters reduce dust and microscopic particles

including pollen, pet dander and odors while primary filters are

antifungal and washable, reducing operation costs. Indoor units

also self-clean the coil to protect against mold growth.

Diagram of a Single Zone System

Self-Cleaning Indoor Coil

The interior of the air conditioner is maintained by

drying off the heat exchanger, eliminating unwanted

mold and odors.

3M Micro Protection Filter, a high air ow lter

with low noise, collects harmful microscopic

substances including pollen and ne dust.

Air Filter

This primary lter captures dust size over 10μm.

LG Air Conditioning Technologies

5 6

Time

1. Smart AC and LG Smart ThinQ® are available only for select models. See product details for full compatibility

TRAINING & RECOGNITION INSTALLATION BEST PRACTICES

For jobs small to large, look for opportunities to use LG systems everywhere! Explore the many applications of LG single and

multi zone systems: whole home renovations, older system replacements, home additions, energy savings opportunities, hot or

cold zones … and many, many more!

Paramount to the success of an LG air conditioning system is proper sizing and installation. With the proper installation per

factory guidelines found in the installation manual, LG systems offer signicant advantages over traditional air conditioning

systems, like increased energy efciency, customizable design aesthetics and comfort control: and room by room.

Training

The LG US Air Conditioning division is headquartered near Atlanta in Alpharetta, GA, along with a full training academy.

Additional training academies are located in California, Texas and New Jersey. Since 2008, our academies have trained

thousands on the advantages of LG air conditioning systems, and even more have been trained through LG’s online training

modules. Classes are taught by world-class trainers with years of experience in ductless technology, and topics cover

everything from installation to service for the full range of LG air conditioning products.

For HVAC professionals, LG offers online instruction via our Learning Management System and classroom training at our training

academies strategically placed throughout the country. Training is open to all contractors; ask your LG Electronics authorized

distributor for details.

For more information and to nd out how you can be part of the next training class near you, visit lg.learnernation.com.

Service Tools

As part of our commitment to innovation, LG has developed innovative ways to enhance the service technician’s experience

during routine maintenance or service with these tools:

• LG SIMS (Smart Inverter Monitoring System) connects to select outdoor units and allows technicians to

troubleshoot accurately by interfacing directly with the unit and following step-by-step troubleshooting guidelines via

a free smartphone app developed by LG factory engineers.

• LG Telepresence connects technicians in the eld directly to LG Technical Assistance representatives via a live video

feed through the technician’s smartphone, allowing you to bring LG technical support with you to any jobsite.

Unit Placement (Indoor & Outdoor)

• Leave appropriate clearances on all sides for all

indoor and outdoor units to allow for proper

airow and for service access

• Include space for drainage to ensure condensate

ows properly out of the unit

• Units should be properly anchored to prevent

unnecessary vibrations

Additionally for indoor units:

• Keep unit away from any indoor steam or

excessive heat

• No obstacles should be placed around unit

• Do not install near a doorway

• Condensation drain should be routed away

from the unit

Piping

• Use only the correct line sizes as determined by

the indoor unit

• Use only copper refrigerant piping

• Insulate both refrigerant lines independently

of each other

• Flare connections using a 45-degree flaring tool

• Consider Flaretite fittings for all connections and

torque flares to specs

• Do not exceed the maximum pipe length or install

less than the required minimum

• Do not make vertical loops in the refrigerant piping

• Support pipe runs from sagging or bending

Wiring

• Use wire that fulfills or exceeds the minimum

wire requirements:

• Multi F MAX to BD unit: 16-4

• All other wiring: 18-4

• L1 and L2 are polarity sensitive on all models

• Indoor units are 208/230 volts (or 115 volt on the Mega HXV)

• Terminal 3 is 115 volts

• Never use wire nuts or splices in wiring

• Use non-insulated spade connectors on all terminal connections

• Use a JIS screwdriver on terminal block to avoid

stripping out the screws

• Only a dedicated electrical circuit is allowed

• Always ground indoor and outdoor unit

• Only connect 1 end of the shielded cable if using shielded wire

*NOTE*

All wiring must comply with applicable local and national codes.

Charging

• Leak test with dry nitrogen to at least 550 p.s.i.

• Never use anything but soap bubbles designed for

HVAC leak testing

• Use only an approved evacuation hose for proper evacuation

and leak testing

• If possible, remove cores from system prior to starting evacuation

• Start with fresh vacuum pump oil and evacuate to

less than 500 microns

• If refrigerant is added, use an electronic scale and

weigh in the precise amount

• Open service valves prior to energizing the unit

TAKE YOUR BUSINESS TO NEW LEVELS

The LG Excellence Contractor Program provides training and recognition for contractors

who install LG Home Comfort Solutions and Light Commercial Systems, helping to set you

apart from your competitors. Along with great incentives and recognition, the LG Excellence

Contractor Program provides an enhanced warranty, a website listing with LG Excellence

Installation and Service Tools:

• Quality Flaring Tool

• Digital Refrigerant Charging Scale

• Torque Wrench

• JIS Screwdriver

• Micron Gauge

• Vacuum Pump

• High-Quality Multimeter

designation on the LG contractor locator, consumer lead referrals and advertising materials.

To nd out how to put these tools to work for you, visit lghvac.com/excellence.

LG Air Conditioning Technologies

7 8

t

ic

SINGLE ZONE

KEY FEATURES

STYLISH DESIGN

LG air conditioning systems come in a variety of indoor units, including the Art Cool Gallery,

which includes a panel that works like a customizable picture frame. For Single Zone and

Multi F systems, mix and match from several different designs and capacities to match load

demands appropriately while maintaining the aesthetic of any décor.

OPTIMIZED AIRFLOW

Jet Cool / Jet Heat Mode operates the unit at a high speed for

up to 30 minutes to quickly cool or heat a room.

Swirl Wind / Chaos Wind allows for customized

louver and fan speed operation to create a stronger,

wider airow for reduced temperature stratication

and to provide more natural air circulation.

SINGLE ZONE SYSTEMS

Lineup

kBtu 9 12 15 18 24 30 36 42

ART COOL™

Gallery

LA090HVP LA120HVP

ART COOL™

Mirror

LA090HSV4 LA120HSV4 LA180HSV4 LA240HSV3

ART COOL

Premier

LA090HYV1 LA120HYV1 LA150HYV2 LA180HYV2 LA240HYV1

LA180HYV1

Wall Mounted

Extended

Piping

Auto Operation adjusts the temperature and fan speed

automatically to match the user’s preference from three levels

of comfort.

DEHUMIDIFYING MODE

Uses sensors in the indoor unit

to accurately measure room

temperature and control humidity by

adjusting the set point and fan speed.

DEFROST CONTROL

AUTO SLEEP MODE

Automatically increases the

temperature setting 2˚F twice

in 30 minute increments.

The indoor unit shuts off when

the timer setting is reached.

GOLD FIN

Gold Fin™ Coating is an

anticorrosion coating to help

protect your system from corrosive

elements, allowing the coil to

maintain excellent heat transfer

properties for an extended time.

Art Cool

directional airow for more natural and effective air

circulation.

Removes frost from the outdoor coil

when ambient outdoor temperatures

are low and simultaneously shuts

down the indoor fan to prevent

cold air from being blown into the

controlled space.

Gallery 3D Airflow uniquely provides three-

AUTO RESTART

Automatically restarts the

system after a power failure.

Restart

in 3 min

Ceiling

Ducted

Mounted

High Efciency

Mega

208/230V

Mega 115V

Ceiling

Cassette

High Static

Low Static

LS090HSV4 LS120HSV4 LS180HSV4

LS090HEV1 LS120HEV1 LS180HEV1 LS240HEV1

LS090HXV LS120HXV

LC097HV4 LC127HV4 LC187HV LC247HV LC367HV LC427HV

LD097HV4 LD127HV4

LS243HLV LS303HLV LS363HLV

LH247HV LH367HV

LG Air Conditioning Technologies

9 10

SINGLE ZONE

ART COOL GALLERY

Specication

Capacity

Power

Operating Range

Dimensions

Weight

Unit Data

Sound Pressure

Piping

Warranty Warranty (Parts, Comp)

Controller Supplied

Indoor Unit LAN090HVP LAN120HVP

Outdoor Unit LAU090HVP LAU120HVP

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Heating Capacity Range Btu/h

Max Heating Capacity at 17˚F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Cooling Operation Range °F DB

Optional Wind Bafe

IDU Operation Range Cooling °F WB

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airow (Max/H/M/L) CFM

Dehumidication pts/hr

Compressor Type

Refrigerant Type

Indoor (H/M/L) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/f t

Drain (OD, ID) in

4

6

Digital Airflow Control

The airflow can be controlled to ensure maximum comfort and convenience.

Normal Jet Cool Sleep Mode

Unit LA090HVP LA120HVP

4,436 ~ 11,942 4,436 ~ 13,648

4,436 ~ 14,330 4,436 ~ 17,060

208/230-1-60 208/230-1-60

208/230-1-60 208/230-1-60

No. x AWG

ZLABGP01A (0˚F) ZLABGP01A (0˚F)

23-5/8x23-5/8x5-3/4 23-5/8x23-5/8x5-3/4

30-5/16x21-1/2x11-5/16 30-5/16x21-1/2x11-5/16

370/335/311/247 370/346/311/247

AKB73635606 AKB73635606

9,000 11,200

10,800 13,300

10,960 13,500

16, 12.5 16, 12

8.2 8.2

0.72 0.93

0.85 1.25

10, 15 10, 15

4 x 18 4 x 18

7.3/8.1 7.3/8.1

14 ~ 65 14 ~ 65

14 ~ 118 14 ~ 118

53 ~ 75 53 ~ 75

60 ~ 86 60 ~ 86

64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86

31/34 31/34

78/82 78/82

2.54 3.17

Rotary Rotary

R410A R410A

42/36/32 42/36/32

45 45

1/4 1/4

3/8 3/8

9.8/49.2 9.8/49.2

22.9 22.9

24.6 24.6

0.22 0.22

27/32, 5/8 27/32, 5/8

5, 7 5, 7

LA090HVP

LA120HVP

ART COOL MIRROR

Specication Unit

1,2

Capacity

Power

Operating Range

Dimensions

Weight

Unit Data

Sound Pressure

Piping

Warranty

Controller

Indoor Unit

Outdoor Unit

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

Max Heating Capacity at -4°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Cooling Operation Range °F DB

Optional Wind Baffle

IDU Operation Range Cooling °F WB

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airflow (Max/H/M/L) CFM

Dehumidification pts/hr

Compressor Type

Refrigerant Type

Indoor (H/M/L/SL) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/ft

Drain (OD, ID) in

Warranty (Parts, Comp)

Supplied

4

6

No. x AWG

LA090HSV4

LA120HSV4

LA180HSV4

LA240HSV3

LA090HSV4 LA120HSV4 LA180HSV4 LA240HSV3

LAN090HSV4 LAN120HSV4 LAN180HSV4 LAN240HSV3

LSU090HSV4 LSU120HSV4 LSU180HSV4 LAU240HSV3

9,000 11,200 18,200 22,000

1,023 ~ 12,625 1,023 ~ 13,785 3,070 ~ 29,515 3,070 ~ 30,030

10,800 13,300 22,000 27,600

1,023 ~ 17,061 1,023 ~ 22,178 3,070 ~ 38,898 3,070 ~ 38,898

11,080 13,500 22,340 28,020

9,570 11,670 19,300 24,220

8,310 10,140 16,760 21,030

21.5, 13.3 21.5, 12.5 20.5, 12.6 20.0, 10.8

10.8 11 9.7 10.0

208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

0.68 0.90 1.45 2.04

0.70 1.00 1.76 2.67

10, 15 10, 15 19, 25 19, 25

4 x 18 4 x 18 4 x 18 4 x 18

8.7/8.7 8.7/8.7 15.4/15.4 15.4/15.4

-4 ~ 65 -4 ~ 65 -4 ~ 65 -4 ~ 65

14 ~ 118 14 ~ 118 14 ~ 118 14 ~ 118

ZLABGP01A (0˚F) ZLABGP01A (0˚F) ZLABGP02A (0˚F) ZLABGP02A (0˚F)

53 ~ 75 53 ~ 75 53 ~ 75 53 ~ 75

60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

64 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

34-13/16 x 11-1/4 x 8-1/16 34-13/16 x 11-1/4 x 8-1/16 40-9/16 x 12-13/16 x 9-11/16 40-9/16 x 12-13/16 x 9-11/16

30-5/16 x 21-1/2 x 11-5/16 30-5/16 x 21-1/2 x 11-5/16 34-1/4 x 31-1/2 x 12-19/32 34-1/4 x 31-1/2 x 12-19/32

24/29 24/29 32/39 32/39

75/79 75/79 121/131 121/131

423/353/272/191 423/353/272/191 735/622/509/399 735/622/509/399

2.30 2.30 5.5 5.5

Rotary Rotary Twin Rotary Twin Rotary

R410A R410A R410A R410A

38/33/23/19 39/33/23/19 45/40/35/29 45/40/35/29

45 45 53 53

1/4 1/4 3/8 3/8

3/8 3/8 5/8 5/8

6.6/65.6 6.6/65.6 9.84/98.4 9.84/98.4

32.8 32.8 49.2 49.2

41 41 24.6 24.6

0.22 0.22 0.38 0.38

27/32, 5/8 27/32, 5/8 27/32, 5/8 27/32, 5/8

5, 7 5, 7 5, 7 5, 7

AKB73835317 AKB73835317 AKB73835317 AKB73835320

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

Customizable Picture Frame

With LG’s revolutionary Art Cool Gallery, you can change

the look of your air conditioner to whatever you want,

whenever you want.

LG Air Conditioning Technologies

11 12

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

SINGLE ZONE

ART COOL PREMIER With LGRED° Powerful Heating Technology

LA090HYV1

LA120HYV1

Associated with models: LA090HYV1,

LA120HYV1, LA150HYV2 and LA180HYV2

Units with industry leading LGRED° Powerful Heating Technology

provide more than 100% of the rated heating capacity performance

down to 5°F and continuous heating performance down to -13°F.

For more information, visit lgredheat.com.

Specification Unit LA090HYV1 LA120HYV1 LA150HYV2 LA180HYV2

Capacity

Power

Operating Range

Dimensions

Weight

Unit Data

Sound Pressure

Piping

Warranty Warranty (Parts, Comp)

Controller Supplied

Indoor Unit LAN090HYV1 LAN120HYV1 LAN150HYV2 LAN180HYV2

Outdoor Unit LAU090HYV1 LAU120HYV1 LAU150HYV2 LAU180HYV2

Rated Cooling Capacity

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

Max Heating Capacity at -13°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring4No. x AWG

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Cooling Operation Range °F DB

Optional Wind Bafe

IDU Operation Range Cooling °F WB

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airow (Max/H/M/L) CFM

Dehumidification pts/hr

Compressor Type

Refrigerant Type

Indoor (H/M/L/SL) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/ft

Drain (OD, ID) in

6

Btu/h

9,000 11,000 15,000 18,200

1,023 ~ 12,966 1,023 ~ 13,785 3,070 ~ 21,000 3,070 ~ 29,515

11,000 12,000 18,000 22,000

1,023 ~ 20,472 1,023 ~ 22,178 3,070 ~ 25,200 3,070 ~ 32,000

11,940 14,650 21,430 27,400

11,220 13,720 18,950 24,360

7,920 9,520 14,660 19,120

27.5, 15.65 25.5, 13.75 24.0, 13.48 22.0, 12.5

12 12 12.5 12.0

208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

0.58 0.8 1.11 1.46

0.71 0.75 1.39 1.79

11.2, 15 11.2, 15 19.0, 25 19.0, 25

4 x 18 4 x 18 4 x 18 4 x 18

8.7/8.7 8.7/8.7 15.0/15.0 15.0/15.0

-13 ~ 65 -13 ~ 65 -13~65 -13~65

14~118 14~118 14~118 14~118

ZLABGP01A (0˚F) ZLABGP01A (0˚F) ZLABGP02A (0˚F) ZLABGP02A (0˚F)

53 ~ 75 53 ~ 75 53 ~ 75 53 ~ 75

60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

64 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

34-7/16x11-5/8x9-1/4 34-7/16x11-5/8x9-1/4 42-15/16x12-31/32x9-25/32 42-15/16x12-31/32x9-25/32

30-5/16x21-1/2x11-5/16 30-5/16x21-1/2x11-5/16 34-1/4 x 31-1/2 x 12-19/32 34-1/4 x 31-1/2 x 12-19/32

24/30 24/30 34/38 34/38

77/82 77/82 122/131 122/131

547/494/417/283 547/494/417/283 742/565/424/318 777/565/424/318

3.20 3.60 3.80 4.60

Twin Rotary Twin Rotary Twin Rotary Twin Rotary

R410A R410A R410A R410A

42/36/25/17 42/36/25/17 47/42/37/29 47/42/37/29

45 45 57 57

1/4 1/4 3/8 3/8

3/8 3/8 5/8 5/8

6.6/65.6 6.6/65.6 9.8/98.4 9.8/98.4

32.8 32.8 65.6 65.6

41 41 24.6 24.6

0.22 0.22 0.38 0.38

27/32, 5/8 27/32, 5/8 27/32, 5/8 27/32, 5/8

5, 7 5, 7 5, 7 5, 7

AKB73835320 AKB73835320 AKB74955602 AKB74955602

LA150HYV2

LA180HYV2

ART COOL PREMIER

LA180HYV1 LA240HYV1

Specification Unit LA180HYV1 LA240HYV1

Capacity

Power

Operating Range

Dimensions

Weight

Unit Data

Sound Pressure

Piping

Warranty Warranty (Parts, Comp)

Controller Supplied

Indoor Unit LAN180HYV1 LAN240HYV1

Outdoor Unit LAU180HYV1 LAU240 HYV1

Rated Cooling Capacity

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

Max Heating Capacity at -13°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Cooling Operation Range °F DB

Optional Wind Bafe

IDU Operation Range Cooling °F WB

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airflow (Max/H/M/L) CFM

Dehumidification pts/hr

Compressor Type

Refrigerant Type

Indoor (H/M/L/SL) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/f t

Drain (OD, ID) in

4

6

Btu/h

No. x AWG

18,200 22,000

3,070 ~ 29,515 3,070 ~ 30,000

22,000 27,000

3,070 ~ 30,709 3,070 ~ 35,200

22,340 27,410

19,300 23,690

14,060 17,250

24, 13.48 22, 12.5

13 12.3

208-230, 1, 60 208-230, 1, 60

208-230, 1, 60 208-230, 1, 60

1.35 1.76

1.69 2.19

19, 25 19, 25

4 x 18 4 x 18

15.3/15.3 15.3/15.3

-13 ~ 65 -13 ~ 65

14 ~ 118 14 ~ 118

ZLABGP02A (0˚F) ZLABGP02A (0˚F)

53 ~ 75 53 ~ 75

60 ~ 86 60 ~ 86

64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86

42-15/16 x 12-31/32 x 9-25/32 42-15/16 x 12-31/32 x 9-25/32

34-1/4 × 31-1/2 × 12-19/32 34-1/4 × 31-1/2 × 12-19/32

34/38 34/38

122/131 122/131

742/565/424/318 777/565/424/318

3.80 4.70

Twin Rotary Twin Rotary

R-410A R-410A

47/42/37/29 47/42/37/29

57 57

3/8 3/8

5/8 5/8

9.8/98.4 9.8/98.4

65.6 65.6

24.6 24.6

0.38 0.38

27/32, 5/8 27/32, 5/8

5, 7 5, 7

AKB74835304 AKB74835304

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

LG Air Conditioning Technologies

13 14

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

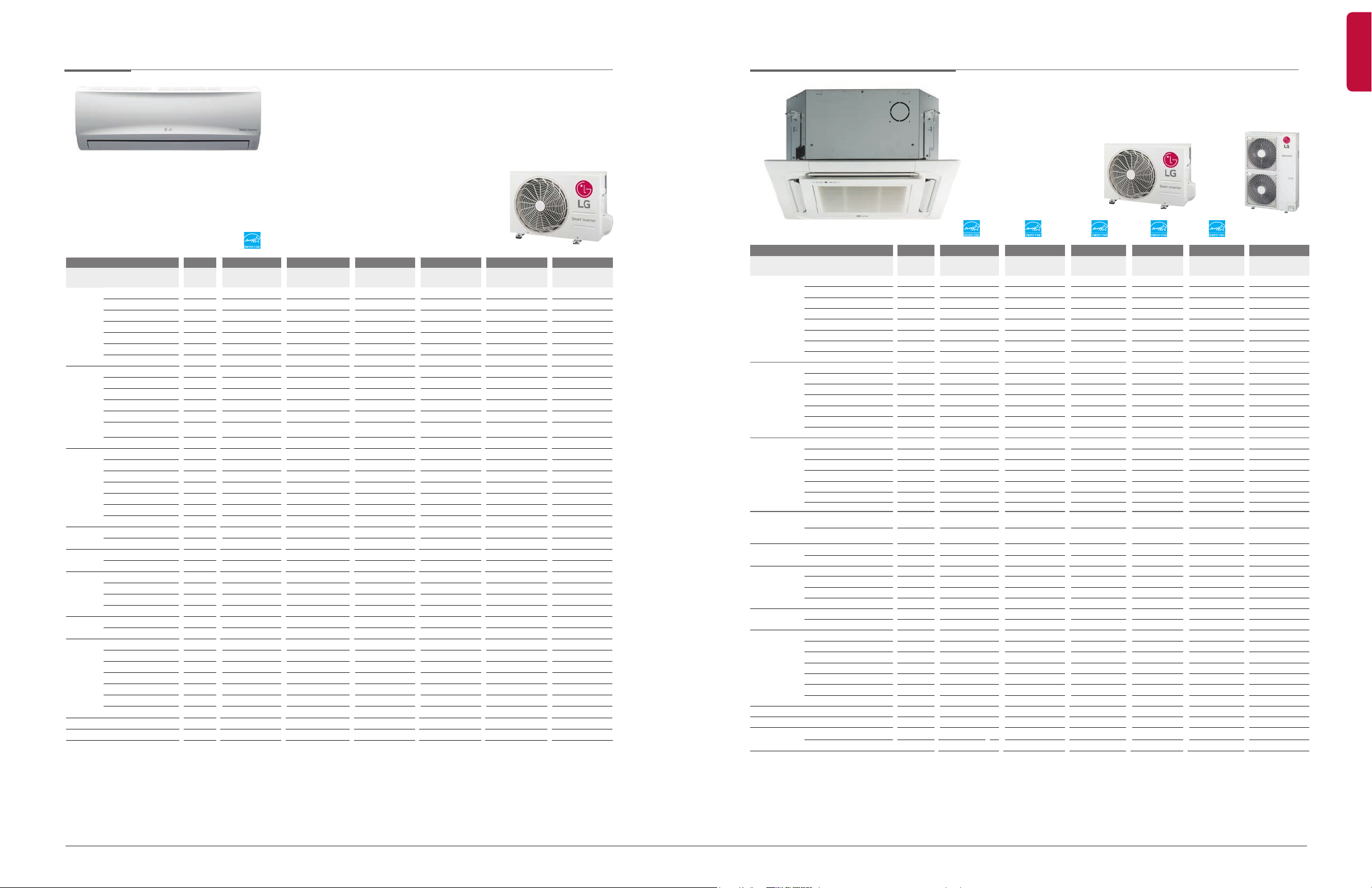

SINGLE ZONE

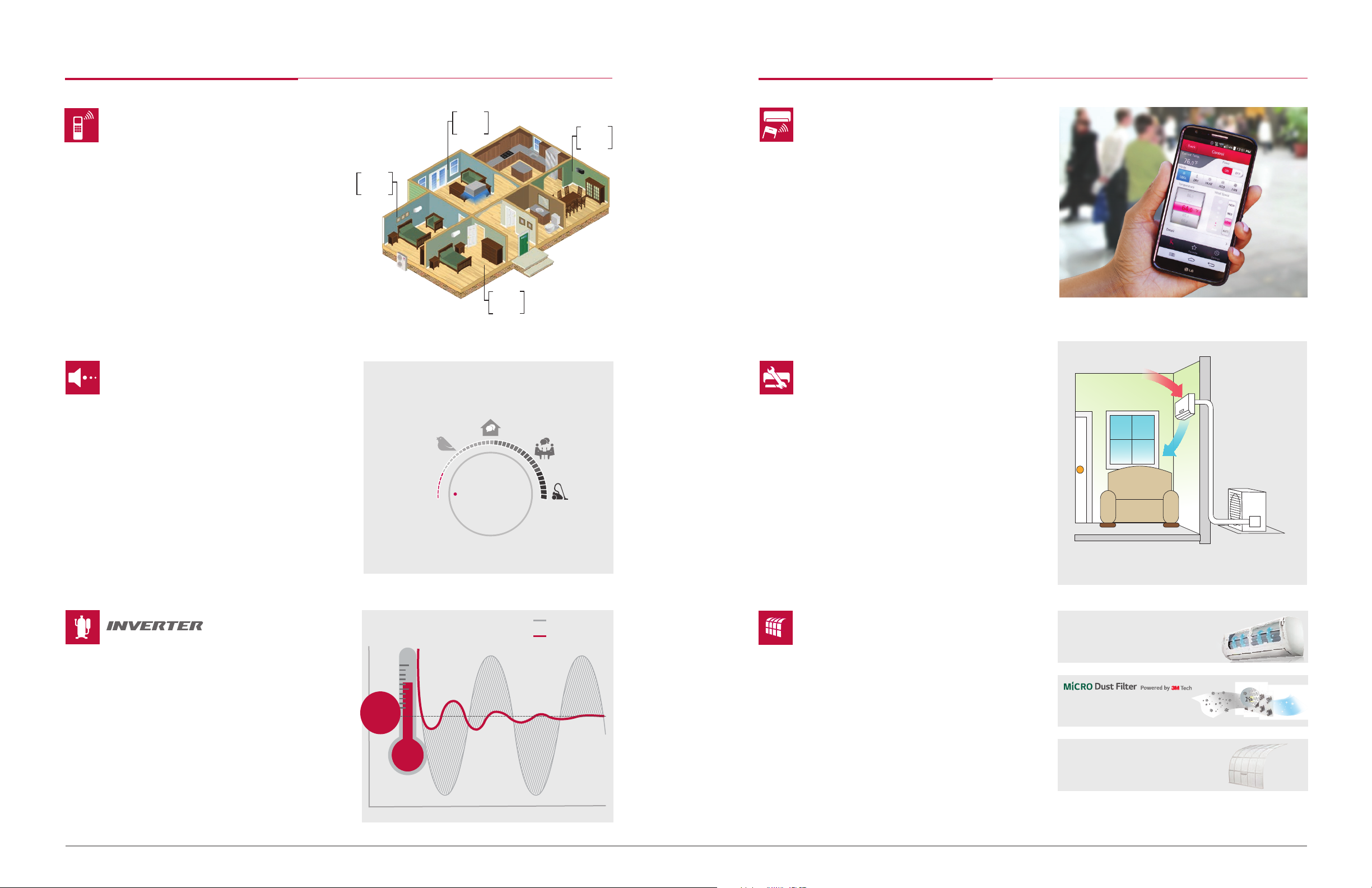

EXTENDED PIPING with Smart ThinQ® Technology

LS243HLV / LS303HLV / LS363HLV

Units with LG SmartThinQ® technology built in take the efciency

and convenience of LG systems to new heights by allowing you to

control them wireless from anywhere via a free smartphone app.

Specification Unit

Indoor Unit

Outdoor Unit

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Heating Capacity Range Btu/h

Capacity

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

Max Heating Capacity at -4°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Power

Heating Power Input kW

MCA, MOCP A

Recommended Fuse A

Power/Communication Wiring

4

No. x AWG

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Operating Range

Cooling Operation Range °F DB

Optional Wind Bafe

IDU Operation Range Cooling °F WB

6

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

Dimensions

Weight

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airow (Max/H/M/L) CFM

Unit Data

Dehumidification pts/hr

Compressor Type

Refrigerant Type

Sound Pressure

Indoor (H/M/L/SL) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Piping

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/ft

Drain (OD, ID) in

Warranty Warranty (Parts, Comp)

Controller Supplied

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification..

LS243HLV LS303HLV LS363HLV

LSN243HLV LSN303HLV LSN363HLV

LSU243HLV LSU303HLV LSU363HLV

22,000 30,000 33,000

3,070 ~ 29,515 3,070 ~ 34,000 3,070 ~ 34,000

27,000 32,000 35,200

3,070 ~ 38,898 3,070 ~ 38,898 3,070 ~ 38,898

27,410 32,490 35,740

23,690 28,080 30,890

20,580 24,390 26,820

21.5, 12.5 19.0, 10.0 17.5, 8.18

11 10.0 10

208/230-1-60 208/230-1-60 208/230-1-60

208/230-1-60 208/230-1-60 208/230-1-60

1.76 3.00 4.04

2.38 3.10 3.84

19, 30 19, 30 19, 30

25 25 25

4 x 18 4 x 18 4 x 18

14.85/14.85 14.85/14.85 14.85/14.85

-4 ~ 65 -4 ~ 65 -4 ~ 65

14 ~ 118 14 ~ 118 14 ~ 118

ZLABGP02A (0˚F) ZLABGP02A (0˚F) ZLABGP02A (0˚F)

53 ~ 75 53 ~ 75 53 ~ 75

60 ~ 86 60 ~ 86 60 ~ 86

64 ~ 86 64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86 60 ~ 86

46-7/8 x 13-5/8 x 10-7/16 46-7/8 x 13-5/8 x 10-7/16 46-7/8 x 13-5/8 x 10-7/16

34-1/4 x 31-1/2 x 12-19/32 34-1/4 x 31-1/2 x 12-19/32 34-1/4 x 31-1/2 x 12-19/32

40/46 40/46 40/46

125/133 125/133 125/133

953/848/706/530 953/848/706/530 953/848/706/530

5.5 5.9 6.6

Twin Rotary Twin Rotary Twin Rotary

R410A R410A R410A

49/44/40/37 49/44/40/37 49/44/40/37

55 55 55

3/8 3/8 3/8

5/8 5/8 5/8

9.84/164 9.84/164 9.84/164

98.4 98.4 98.4

24.6 24.6 24.6

0.38 0.38 0.38

27/32, 5/8 27/32, 5/8 27/32, 5/8

5, 7 5, 7 5, 7

AKB74955602 AKB74955602 AKB74955602

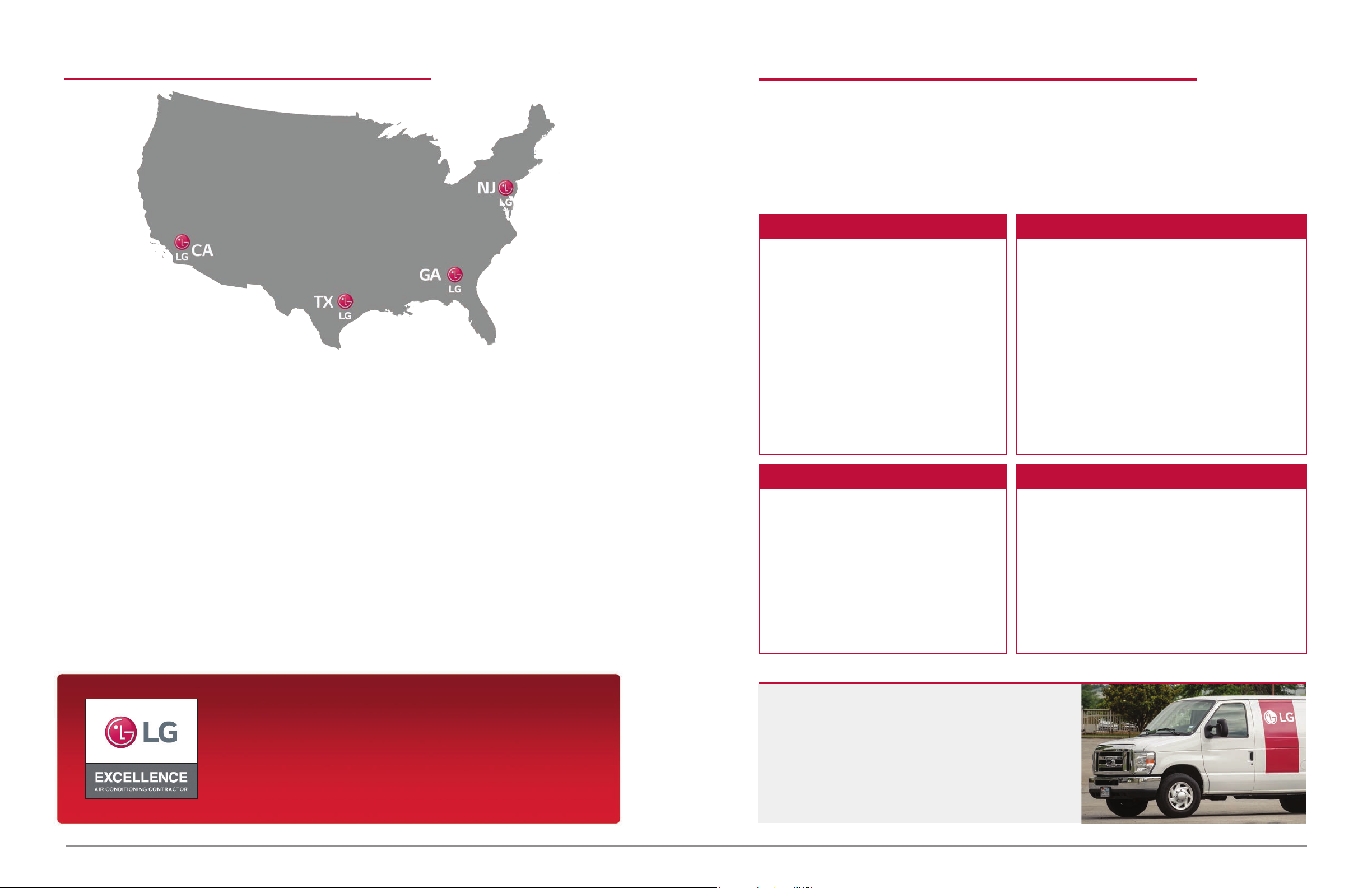

HIGH EFFICIENCY

LS090HSV4 / LS120HSV4 / LS180HSV4

Specification Unit

Indoor Unit

Outdoor Unit

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Capacity

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

Max Heating Capacity at -4°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Power

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring

4

No. x AWG

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Operating Range

Cooling Operation Range °F DB

Optional Wind Baffle

IDU Operation Range Cooling °F WB

6

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

Dimensions

Weight

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airflow (Max/H/M/L) CFM

Unit Data

Dehumidification pts/hr

Compressor Type

Refrigerant Type

Sound Pressure

Indoor (H/M/L/SL) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Piping

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/ft

Drain (OD, ID) in

Warranty

Controller

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

Warranty (Parts, Comp)

Supplied

LS090HSV4 LS120HSV4 LS180HSV4

LSN090HSV4 LSN120HSV4 LSN180HSV4

LSU090HSV4 LSU120HSV4 LSU180HSV4

9,000 11,200 18,200

1,023 ~12,625 1,023 ~ 13,785 3,070 ~ 29,515

10,800 13,300 22,000

1,023 ~ 17,061 1,023 ~ 22,178 3,070 ~ 38,898

11,080 13,500 22,340

9,570 11,670 19,300

8,310 10,140 16,760

21.5, 13.3 21.5, 12.5 20.5, 12.6

10.8 11 9.7

208/230-1-60 208/230-1-60 208/230-1-60

208/230-1-60 208/230-1-60 208/230-1-60

0.68 0.90 1.45

0.70 1.00 1.76

10, 15 10, 15 19, 25

4 x 18 4 x 18 4 x 18

8.7/8.7 8.7/8.7 15.4/15.4

-4 ~ 65 -4 ~ 65 -4 ~ 65

14 ~ 118 14 ~ 118 14 ~ 118

ZLABGP01A (0˚F) ZL ABGP01A (0˚F) ZLABGP02A (0˚F)

53 ~ 75 53 ~ 75 53 ~ 75

60 ~ 86 60 ~ 86 60 ~ 86

64 ~ 86 64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86 60 ~ 86

34-13/16 x 11-1/4 x 8-1/4 34-13/16 x 11-1/4 x 8-1/4 40-9/16 x 12-13/16 x 9-13/16

30-5/16 x 21-1/2 x 11-5/16 30-5/16 x 21-1/2 x 11-5/16 34-1/4 x 31-1/2 x 12-19/32

20/26 20/26 31/36

75/79 75/79 121/131

423/353/272/191 423/353/272/191 735/622/509/399

2.30 2.30 5.50

Rotary Rotary Twin Rotary

R410A R410A R410A

38/33/23/19 39/33/23/19 45/40/35/29

45 45 53

1/4 1/4 3/8

3/8 3/8 5/8

6.6/65.6 6.6/65.6 9.84/98.4

32.8 32.8 49.2

41 41 24.6

0.22 0.22 0.38

27/32, 5/8 27/32, 5/8 27/32, 5/8

5, 7 5, 7 5, 7

AKB73835317 AKB73835317 AKB73835317

LG Air Conditioning Technologies

15 16

SINGLE ZONE

MEGA

LS090HEV1

LS090HXV

LS120HEV1

LS120HXV

LS180HEV1

LS240HEV1

Specication Unit LS090HEV1 LS090HXV LS120HEV1 LS120HXV LS180HEV1 LS240HEV1

Capacity

Power

Operating

Range

Dimensions

Weight

Unit Data

Sound

Pressure

Piping

Warranty Warranty (Parts, Comp) 5, 7 5, 7 5, 7 5, 7 5, 7 5, 7

Controller Supplied AKB73835318 AKB73456121 AKB73835318 AKB73456121 AKB73835318 AKB73835318

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Due to our commitment to continued innovation, some specifications may be changed without notification.

Indoor Unit LSN090HEV1 LSN090HXV LSN120HEV1 LSN120HXV LSN180HEV1 LSN240HEV1

Outdoor Unit LSU090HEV1 LSU090HXV LSU120HEV1 LSU120HXV LSU180HEV1 LSU240HEV1

Rated Cooling Capacity Btu/h 8,500 8,500 12,000 12,000 17,000 22,000

Cooling Capacity Range Btu/h 3,070 ~ 9,500 1,023 ~ 13,785 3,070 ~ 13,780 1,023 ~ 13,785 3,685 ~ 18,493 3,685 ~ 24,000

Rated Heating Capacity Btu/h 9,000 10,900 12,000 13,000 19,000 22,000

Heating Capacity Range Btu/h 3,070 ~ 10,500 1,023 ~ 22,178 3,070 ~ 13,780 1,023 ~ 22,178 3,685 ~ 22,997 3,685 ~ 24,226

ax Heating Capacity at 17°F

M

SEER, EER 19.0, 12.5 17.0, 12.01 17.0, 10.52 17.0, 10.5 18.0, 10.97 17.0, 10.76

HSPF 9.0 9.0 9.2 9.0 9.0 9.0

Voltage (IDU) V, Ø, Hz 208/230-1-60 115-1-60 208/230-1-60 115-1-60 208/230-1-60 208/230-1-60

Voltage (ODU) V, Ø, Hz 208/230-1-60 115-1-60 208/230-1-60 115-1-60 208/230-1-60 208/230-1-60

Cooling Power Input kW 0.68 0.71 1.14 1.14 1.55 2.04

Heating Power Input kW 0.78 0.88 0.98 1.09 1.59 1.94

MCA, MOCP A 10, 15 13.5, 20 10, 15 13.5, 20 12, 20 15, 20

Power/Communication

4

Wiring

Rated Amps Cool/Heat A 7.5/7.5 10.4/10.4

Heating Operation Range °F WB 14 ~ 65 14 ~ 65 14 ~ 65 14 ~ 65 14 ~ 65 14 ~ 65

Cooling Operation Range °F DB 14 ~ 118 14 ~ 118 14 ~ 118 14 ~ 118 14 ~ 118 14 ~ 118

Optional Wind Bafe

IDU Operation Range Cooling °F WB 53 ~ 75 53 ~ 75 53 ~ 75 53 ~ 75 53 ~ 75 53 ~ 75

IDU Operation Range Heating °F DB 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

Setpoint Range Cooling °F 64 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86

Setpoint Range Heating °F 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

IDU Dimensions (WxHxD) in 29-3/4 x 10-7/16 x 7-1/4 34-27/32 x 11-1/4 x 8-9/32 34-13/16 x 11-1/4 x 8-1/4 34-27/32 x 11-1/4 x 8-9/32 40-9/16 x 12-13/16 x 9-13/16 40-9/16 x 12-13/16 x 9-13/16

ODU Dimensions (WxHxD) in 28-1/4 x 19-1/2 x 9-1/16 28-1/4 x 19-1/2 x 9-1/16 28-1/4 x 19-1/2 x 9-1/16 28-1/4 x 19-1/2 x 9-1/16 30-5/16 x 21-1/2 x 11-5/16 34-1/4 x 25-13/16 x 12-19/32

IDU Weight (Net/Shipping) lbs 17/20 23/26 23/28 23/26 28/33 28/34

ODU Weight (Net/Shipping) lbs 62/67 67/79 62/67 67/79 76/81 95/104

Airow (Max/H/M/L) CFM 318/276/226/177 335/272/212/124 424/353/272/212 335/272/212/124 629/512/441/353 689/600/494/388

Dehumidification pts/hr 2.12 2.30 2.76 2.80 3.39 4.88

Compressor Type Rotar y Rot ary Rota ry Rotary Twin Rotary Twin Rotary

Refrigerant Type R410A R410A R410A R410A R410A R410A

Indoor (H/M/L/SL) dB(A) 39/33/25/19 39/33/23/19 39/33/25/19

Outdoor Max dB(A) 47 47 47 47 51 53

Liquid Line in 1/4 1/4 1/4 1/4 1/4 1/4

Suction Line in 3/8 3/8 3/8 3/8 1/2 5/8

Pipe Length (Min/Max) ft 9.8/49.2 6.6/49.2 9.8/49.2 6.6/49.2 9.8/65.6 9.8/65.6

Max Pipe Elevation ft 22.9 22.9 22.9 22.9 32.8 32.8

Precharge Pipe Length ft 24.6 24.6 24.6 24.6 24.6 24.6

Additional Refrigerant oz/f t 0.22 0.22 0.22 0.22 0.33 0.33

Drain (OD, ID) in 27/32, 5/8 27/32, 5/8 27/32, 5/8 27/32, 5/8 27/32, 5/8 27/32, 5/8

6

Btu/h 9,140 11,070 12,180 13,200 19,290 22,340

No. x AWG 4 x 18 4 x 18 4 x 18 4 x 18 4 x 18 4 x 18

7.5/7.5 10.4/10.4 9.61/9.41 11.52/11.08

No No No No No No

39/33/23/19 42/40/35/29 45/40/35/29

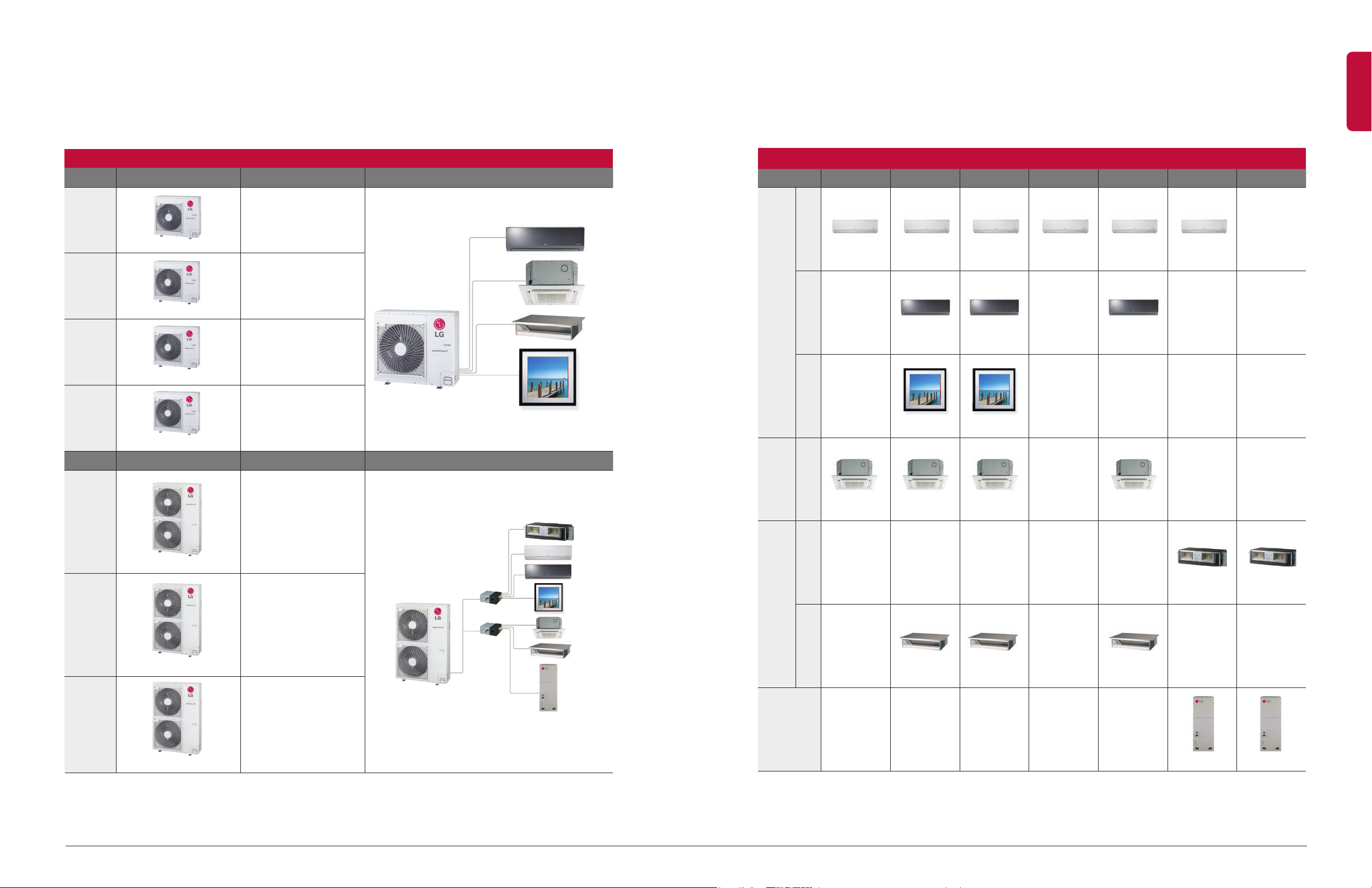

CEILING MOUNTED

33-1/16 x 11-11/

32 x 33-1/16

37-13/32 x

54-11/32 x 13

LC247HV

LC097HV4

LC127HV4

LC187HV

Specification Unit

Capacity

Power

Operating Range

Dimensions

Weight

Unit Data

Sound Pressure

Piping

Warranty Warranty (Parts, Comp)

Controller Supplied

Accessories

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

Indoor Unit

Outdoor Unit

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring4No. x AWG

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Cooling Operation Range °F DB

Optional Wind Bafe

IDU Operation Range Cooling °F WB

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airow (H/M/L) CFM

Dehumidication pts/hr

Compressor Type

Refrigerant Type

Indoor (H/M/L) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/ft

Drain (OD, ID) in

Grille

Grille Weight (Net/Shipping)

6

lbs 7/9 7/9 11/20 11/20 11/20 11/20

LC097HV4 LC127HV4 LC187HV LC247HV LC367HV LC427HV

LCN097HV4 LCN127HV4 LCN187HV LCN247HV LCN367HV LCN427HV

LUU097HV LUU127HV LUU187HV LUU247HV LUU367HV LUU427HV

9,000 11, 100 18,000 24,000 36,000 42,000

3,600 ~ 9,900 3,400 ~ 12,400 9,500 ~ 19,800 9,700 ~ 26 ,700 14,000 ~ 42,000 17,100 ~ 47,100

11,000 14,000 20,000 27,000 40,000 47,000

4,400 ~ 12,100 2,800 ~ 15,500 9,300 ~ 22,000 10,900 ~ 30,000 14,500 ~ 45,000 17,100 ~ 52,600

9,350 11 ,9 00 14, 330 21,343 30 ,3 11 34,6 81

8,250 10, 500 11, 27 1 2 0,778 29,250 33 ,351

20.2, 13.65 19.4,12.6 2 0, 15 .0 17.0, 12.6 19.0, 13.5 17. 0, 10 .3

10. 5 10. 4 10.1 9.7 9.5 8.6

208-230, 1, 60 208-230, 1, 60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

208-230, 1, 60 208-230, 1, 60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

0.66 0.88 1.26 1.91 2.97 4.07

0.83 1.19 1.50 2.60 3.20 4.05

11.9, 15 12.3, 15 18.1, 30 18.1, 30 24.5, 40 24.5, 40

4 x 18 4 x 18 4 x 18 4 x 18 4 x 18 4 x 18

9.65/9.65 10.05/10.05 14.7/14.7 15.1/15.1 20.2/20.8 20.2/20.8

-4 ~ 64 -4 ~ 64 0 ~ 64 0 ~ 64 0 ~ 64 0 ~ 64

0 ~ 118 0 ~ 118 5 ~ 118 5 ~ 118 5 ~ 118 5 ~ 118

ZLABGP01A (-4˚F) ZLABGP01A (-4˚F) ZLABGP04A (0˚F) ZL ABGP04A (0˚F) ZLABGP04A x 2 (0˚F) ZLABGP04A x 2 (0˚F)

57 ~ 77 57 - 77 57 ~ 77 57 ~ 77 57 ~ 77 57 ~ 77

59 ~ 81 59 ~ 81 59 ~ 81 59 ~ 81 59 ~ 81 59 ~ 81

65 ~ 86 65 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86 64 ~ 86

61 ~ 86 61 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86 60 ~ 86

22-7/16 x 8-7/16 x

22-7/16

30-5/16 x 21-15/32 x

11-11/32

31/37 31/37 46 / 55 46 / 55 55 / 65 55 / 65

82/89 82/89 133 / 148 133 / 148 203 / 227 203 / 227

300/265/230 335/283/247 565/494/424 600/530/459 1,060/989/918 1,060/989/918

1.60 2.47 5.10 5.10 7.70 7.70

Twin Rotary Twin Rotary Twin Rotary Twin Rotary Twin Rotary Twin Rotary

R-410A R-410A R410A R410A R410A R410A

36/33/30 38/35/32 38/36/34 38/36/34 46/44/43 46/44/43

51 52 52 52 54 54

1/4 1/4 3/8 3/8 3/8 3/8

3/8 3/8 5/8 5/8 5/8 5/8

9.8/66 9.8/66 6.6/164 6.6/164 6.6/246.1 6.6/246.1

49.2 49.2 98.4 98.4 98.4 98.4

24.6 24.6 24.6 24.6 24.6 24.6

0.22 0.22 0.43 0.43 0.43 0.43

1.25, 1 1.25, 1 1.25/1 1.25/1 1.25/1 1.25/1

5, 7 5, 7 5, 7 5, 7 5, 7 5, 7

PQWRHDF0 PQWRHDF0 PQWRHDF0 PQWRHDF0 PQWRHDF0 PQWRHDF0

PT-QCHW0/PT-UQC PT-QCHW0/PT-UQC PT-UMC1B/PT-UMC1 PT-UMC1B/PT-UMC1 PT-UMC1B/PT-UMC1 PT-UMC1B/PT-UMC1

22-7/16 x 8-7/16 x 22-7/16

30-5/16 x 21-15/32 x

11-11/32

33-1/16 x 8-1/

32 x 33-1/16

37-13/32 x

32-27/32 x 13

33-1/16 x 8-1/

32 x 33-1/16

37-13/32 x

32-27/32 x 13

LC367HV

LC427HV

33-1/16 x 11-11/

32 x 33-1/16

37-13/32 x

54-11/32 x 13

LG Air Conditioning Technologies

17 18

LOW STATIC DUCTED HIGH STATIC DUCTED

Specification Unit

Indoor Unit

Outdoor Unit

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Capacity

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Power

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring

4

No. x AWG

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Operating Range

Cooling Operation Range °F DB

Optional Wind Baffle

IDU Operation Range Cooling °F WB

6

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

Dimensions

Weight

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airflow (Max/H/M/L) CFM

Unit Data

Dehumidification pts/hr

Compressor Type

Refrigerant Type

in wg 0.20 0.20

Sound Pressure

Max External Static Pressure

Indoor (H/M/L) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Piping

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/ft

Drain (OD, ID) in

Warranty Warranty (Parts, Comp)

Controller Supplied

LD097HV4

LD127HV4

LD097HV4 LD127HV4

LDN097HV4 LDN127HV4

LUU097HV LUU127HV

9,000 11,600

3,600 ~ 9,900 4,640 ~ 12,760

14,000 16,000

5,600 ~ 15,400 6,400 ~ 17,600

11,900 13,600

10,500 12,000

18.5, 12.7 19.6, 12.9

10.3 10.5

208-230, 1, 60 208-230, 1, 60

208-230, 1, 60 208-230, 1, 60

0.71 0.90

1.43 1.29

11.9, 15 12.3, 15

4 x 18 4 x 18

9.65/9.65 10.05/10.05

-4 ~ 64 -4 ~ 64

0 ~ 118 0 ~ 118

ZLABGP01A (-4˚F) ZLABGP01A (-4˚F)

57 ~ 77 57 ~ 77

59 ~ 81 59 ~ 81

65 ~ 86 65 ~ 86

61 ~ 86 61 ~ 86

27-9/16 x 7-15/32 x 27-9/16 35-7/16 x 7-15/32 x 27-9/16

30-5/16 x 21-15/32 x 11-11/32 30-5/16 x 21-15/32 x 11-11/32

39/46 51/60

82/89 82/89

318 / 247 / 194 353 / 300 / 247

1.50 2.28

Twin Rotary Twin Rotary

R-410A R-410A

30 / 26 / 23 31 / 28 / 27

51 52

1/4 1/4

3/8 3/8

9.8/66 9.8/66

49.2 49.2

24.6 24.6

0.22 0.22

1.25/1 1.25/1

5, 7 5, 7

PQRCVCL0QW PQRCVCL0QW

Specification Unit

Indoor Unit

Outdoor Unit

Rated Cooling Capacity Btu/h

Cooling Capacity Range Btu/h

Rated Heating Capacity Btu/h

Capacity

Heating Capacity Range Btu/h

Max Heating Capacity at 17°F Btu/h

Max Heating Capacity at 5°F Btu/h

SEER, EER

HSPF

Voltage (IDU) V, Ø, Hz

Voltage (ODU) V, Ø, Hz

Cooling Power Input kW

Power

Heating Power Input kW

MCA, MOCP A

Power/Communication Wiring

4

No. x AWG

Rated Amps Cool/Heat A

Heating Operation Range °F WB

Operating Range

Cooling Operation Range °F DB

Optional Wind Baffle

IDU Operation Range Cooling °F WB

6

IDU Operation Range Heating °F DB

Setpoint Range Cooling °F

Setpoint Range Heating °F

Dimensions

Weight

IDU Dimensions (WxHxD) in

ODU Dimensions (WxHxD) in

IDU Weight (Net/Shipping) lbs

ODU Weight (Net/Shipping) lbs

Airflow (Max/H/M/L) CFM

Dehumidification pts/hr

Unit Data

Compressor Type

Refrigerant Type

in wg 0.78 0.60

Sound Pressure

Max External Static Pressure

Indoor (H/M/L) dB(A)

Outdoor Max dB(A)

Liquid Line in

Suction Line in

Pipe Length (Min/Max) ft

Piping

Max Pipe Elevation ft

Precharge Pipe Length ft

Additional Refrigerant oz/f t

Drain (OD, ID) in

Warranty Warranty (Parts, Comp)

Controller Supplied

LH247HV

LH367HV

LH247HV LH367HV

LHN247HV LHN367HV

LUU247HV LUU367HV

24,000 36,000

9,700 ~ 26,700 16,000 ~ 41,400

27,000 40,000

10,900 ~ 30,000 17,500 ~ 48,000

20,257 32,332

19,556 31,200

17.0, 12.0 17.6, 12.1

10.0 9.2

208/230-1-60 208/230-1-60

208/230-1-60 208/230-1-60

2.00 2.91

2.28 3.36

18.1, 30 24.5, 40

4 x 18 4 x 18

15.1/15.1 20.8/21.4

0 ~ 64 0 ~ 64

5 ~ 118 5 ~ 118

ZLABGP04A (0˚F) ZLABGP04A x 2 (0˚F)

57 ~ 77 57 ~ 77

59 ~ 81 59 ~ 81

64 ~ 86 64 ~ 86

60 ~ 86 60 ~ 86

46-17/32 x 11-23/32 x 17-23/32 48-7/16 x 14-31/32 x 23-7/32

37-13/32 x 32-27/32 x 13 37-13/32 x 54-11/32 x 13

73 / 95 125 / 139

133 / 146 203 / 227

688/618/530 1,130/953/706

7.00 10.60

Twin Rotary Twin Rotary

R410A R410A

38/36/35 39/38/37

52 54

3/8 3/8

5/8 5/8

6.6/164 6.6/246.1

98.4 98.4

24.6 24.6

0.43 0.43

1.25/1 1.25/1

5, 7 5, 7

PQRCVCL0QW PQRCVCL0QW

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

LG Air Conditioning Technologies

19 20

Note:

1. Rated capacity at 0 ft. above sea level with 25 ft. of refrigerant line and a 0 ft. level difference between outdoor and indoor unit.

2. Rated cooling capacity obtained with air entering the indoor unit at 80˚F dry bulb (DB) and 67˚F wet bulb (WB) and outdoor ambient conditions of 95˚F dry bulb (DB) and 75˚F wet bulb (WB).

Rated heating capacity obtained with air entering the indoor unit at 70˚F dry bulb (DB) and 60˚F wet bulb (WB) and outdoor ambient conditions of 47˚F dry bulb (DB) and 43˚F wet bulb (WB).

For capacity information, see engineering manual capacity tables.

3. Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745 and are the same in both cooling and heating mode. These values can increase due to ambient conditions during operation.

4. All power/communication wiring minimum 4-conductor, stranded, shielded, and must comply with applicable local and national codes.

5. Piping lengths are equivalent.

6. Installation of an optional Low Ambient Wind Baffle Kit will allow operation down to 0˚F in cooling mode for applicable outdoor units.

7. Due to our commitment to continued innovation, some specifications may be changed without notification.

MULTI ZONEMULTI ZONE

MULTI ZONE

Lineup

OUTDOOR UNITS

kBtu Multi F Maximum Indoor Units Combination Sample

18

LMU18CHV

24

LMU24CHV

30

LMU30CHV

2

3

4

MULTI ZONE

Lineup

INDOOR UNITS

Type 7 kBtu 9 kBtu 12 kBtu 15 kBtu 18 kBtu 24 kBtu 36 kBtu

High Efficiency

LMN078HVT LSN090HSV4 LSN120HSV4 LMN158HVT LSN180HSV4 LMN248HVT

Art Cool Mirror

Wall Mounted Unit

LAN090HSV4 LAN120HSV4 LAN180HSV4

36

LMU36CHV

kBtu Multi F MAX Maximum Indoor Units Combination Sample

48

LMU480HV

54

LMU540HV

60

4

8

8

8

Cassette

Ceiling Mounted

Ceiling Concealed Duct

Art Cool Gallery

4-Way Cassette

LMCN077HV LCN097HV4 LCN127HV4 LMCN185HV

High Static Pressure

Low Static Pressure

LMAN097HVP LMAN127HVP

LDN097HV4 LDN127HV4 LMDN186HV

LMHN240HV LMHN360HV

Vertical AHU

LMU600HV

LG Air Conditioning Technologies

21 22

LMVN240HV LMVN360HV

Loading...

Loading...