Page 1

ENGLISH

LG

Room Air Conditioner

INSTALLATION MANUAL

LG

http://www.lgservice.com

IMPORTANT

• Please read this instruction manual completely before

installing the product.

• When the power cord is damaged, replacement should be

performed by authorized personnel only.

• Installation work must be performed in accordance with

the national wiring standards by authorized personnel

only.

• Please retain this installation manual for future reference

after reading it thoroughly.

FRANÇAIS ESPAÑOL

Page 2

2 Room Air Conditioner

Room Air Conditioner Installation Manual

TABLE OF CONTENTS

Safety Precautions .........................3

Introduction .....................................9

Symbols Ued in This Manual ......9

Features .......................................9

Installation .....................................10

Installation Parts ........................10

Installation Tools ........................10

Installation Map..........................11

Confirm The Refrigerant ...........12

Select The Best Location .........13

Piping Length And Elevation.....14

How To Mount Installation Plate

..15

Drill a Hole In The Wall..............15

Flaring Work...............................16

Connecting The Piping..............17

Connection Of The Drain Hose

...22

Connection Of Piping -Outdoor

...22

Connection Of The Cable .........23

Checking The Drainage ............25

Forming The Piping ...................26

Air Purging .................................27

Air Purging With Vacuum Pump

..27

Charging.....................................29

Tes t R unn ing .................................30

❏ Installation plate

❏ Four type "A" screws

❏ Connecting cable

❏ Pipes: Suction line

Evaporator line

(Refer to page 13)

❏ Insulation materials

❏ Additional drain pipe

(

Outer Diameter

.........

15.5mm(0.61in))

❏ Two type "B" screws

Installation

Requirements

Required Parts Required Tools

❏ Level gauge

❏ Screwdriver

❏ Electric drill

❏ Hole core drill(ø70mm(2.76in))

❏ Flaring tool set

❏ Specified torque wrenches

4.2kg.m, 6.6kg.m

(different depending on model No.)

(Refer to page 17)

❏ Spanner .....................Half union

❏ Aglassofwater

❏ Screw driver

❏ Hexagonal

wrench(4mm(0.16in))

❏ Gas Leak Detector

❏ Vacuum pump

❏ Manifold Gauge

❏ Owner's manual

❏ Thermometer

❏ Remote Control Holder

Page 3

Installation Manual 3

ENGLISH

Safety Precautions

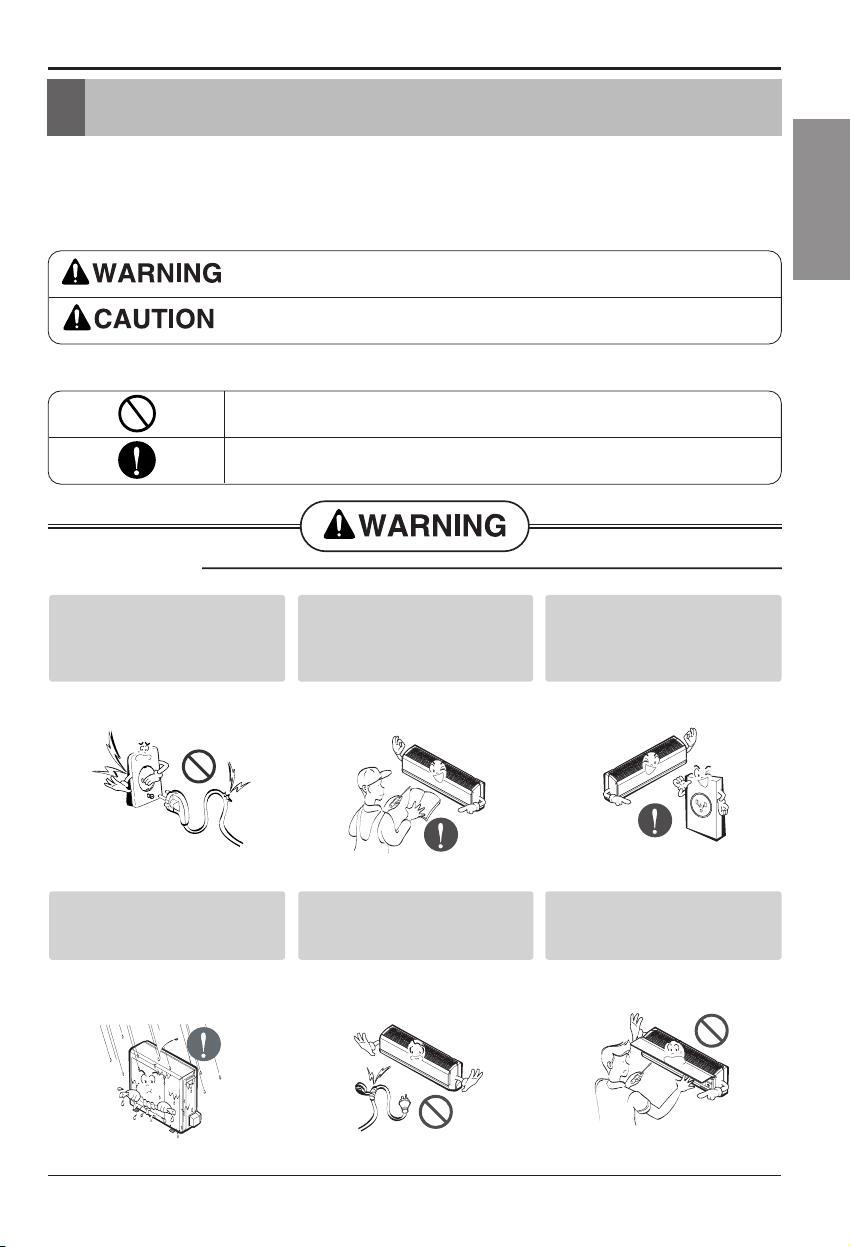

To prevent the injury of the user or other people and property damage, the following instructions

must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ The meanings of the symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Installation

Be sure not to do.

Be sure to follow the instruction.

Safety Precautions

Do not use damaged power

cords, plugs, or a loose socket.

• There is risk of fire or electric shock.

For electrical work, contact the

dealer, seller, a qualified

electrician, or an Authorized

Service Center.

• There is risk of fire or electric shock.

Always use the power plug and

socket with the ground terminal.

• There is risk of electric shock.

Install the panel and the cover of

control box securely.

• There is risk of fire or electric shock.

Do not modify or extend the

power cord.

• There is risk of fire or electric shock.

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric shock,

explosion or injury.

Page 4

4 Room Air Conditioner

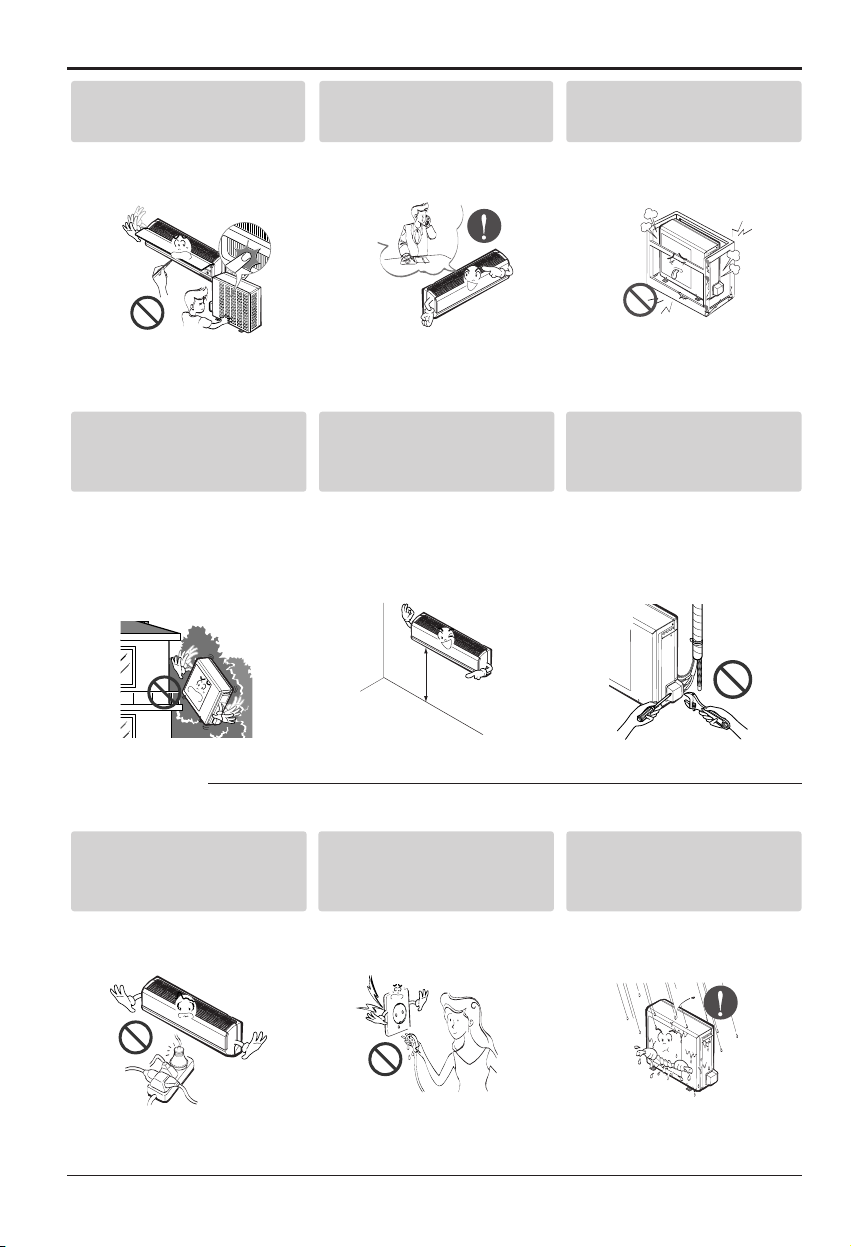

Safety Precautions

■ Operation

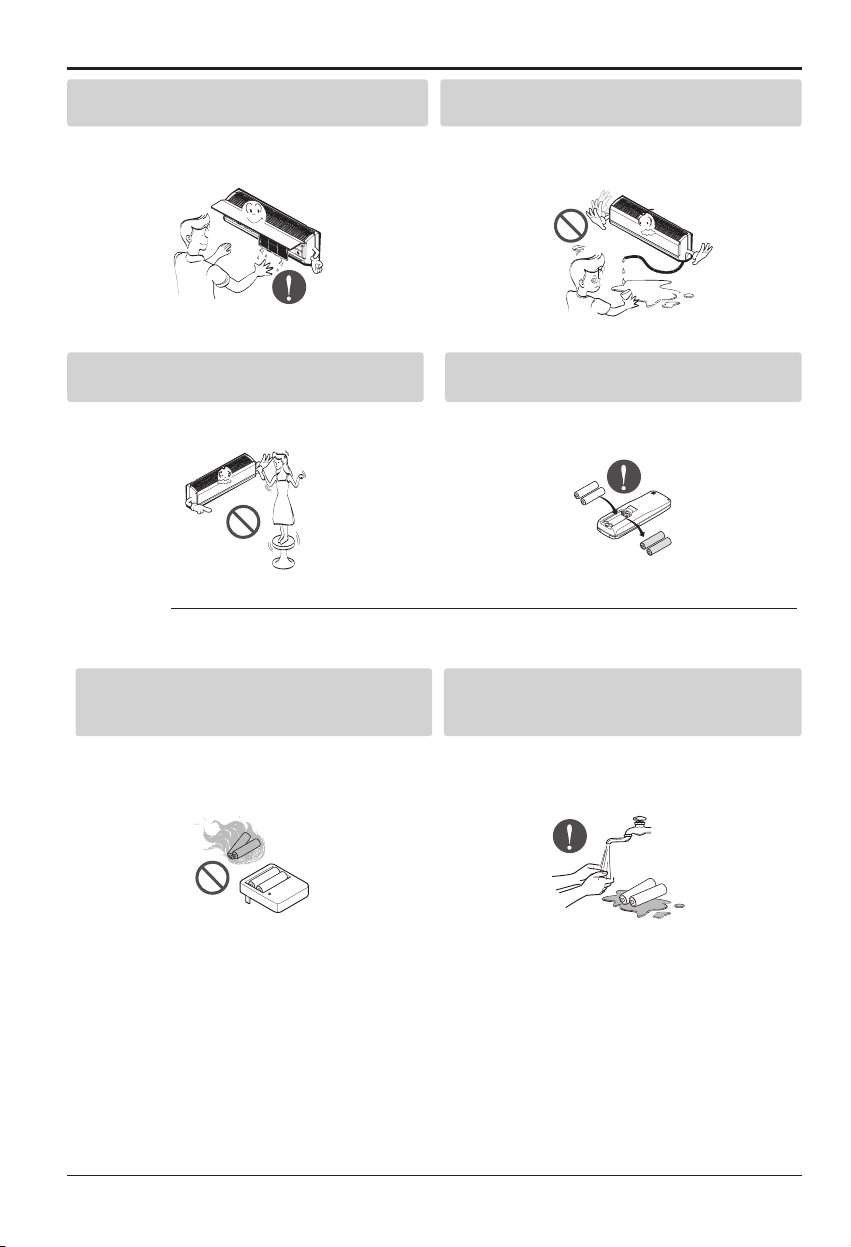

Be cautious when unpacking and

installing the product.

• Shape edges could cause injury. Be

especially careful of the sharp edges.

For installation, always contact

thedealeroranAuthorized

Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air

conditioner could fall with it, causing

property damage, product failure, and

personal injury.

Install the indoor unit on the wall

where the height from the floors

more then 8ft(2.4m)

• There are sharp moving parts that

could cause personal injury.

Do not handle the pipe by

yourself(customer)

• High-Pressure refrigent may cause

personal injury.

Use a dedicated outlet for this

appliance.

• There is risk of fire or electric shock.

Grasp the plug to remove the

cord from the outlet. Do not

touch it with wet hands.

• There is risk of fire or electric shock.

Do not allow water to run into

electric part.

• There is risk of fire, failure of the

product, and/or electric shock.

8ft(2.4m)

Page 5

Installation Manual 5

ENGLISH

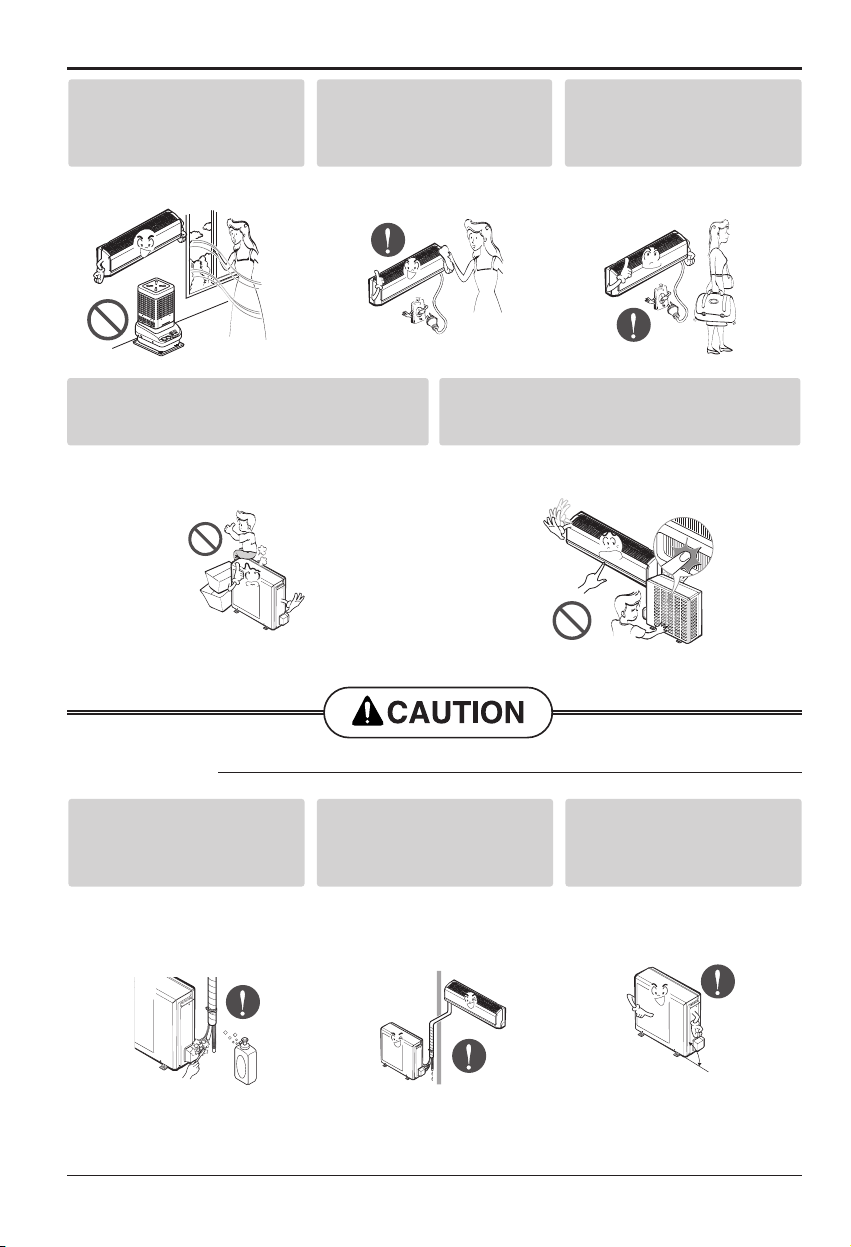

Safety Precautions

Do not place a heater or other

appliances near the power cable.

•

There is risk of fire, failure of the product,

and/or electric shock.

Do not let the air conditioner run

for a long time when the

humidity is very high and a door

or a window is left open.

• Moisture may condense and wet or

damage furnishings.

Do not store of use flammable

gas or combustibles near the air

conditioner.

• There is risk of fire or product failure.

Do not use the product in a

tightly closed space for a long

time.

• Oxygen deficiency could occur.

• Some ventilation by opeing window

is necessary for the fresh air.

When flammable gas leaks, turn off

the gas and open a window for

ventilation before turning the product

on. Do not use the telephone or turn

switches on or off.

• There is risk of explosion or fire.

Unplug the unit if strange

sounds odors or smoke comes

from it.

•

There is risk of fireproduct failure and/or

electric shock.

Stop operation and close any

window in storm or hurricane.

before the hurricane arrives.

• There is risk of property damage,

failure of product, or electric shock.

Do not open the inlet grill of the

product during operation. (Do

not touch the electrostatic filter,

if the unit is so equipped.)

• There is risk of physical injury, electric

shock, or product.

When the product is soaked

(flooded or submerged), contact

an Authorized Service Center.

• There is risk of electrical shock.

Thinner

Wax

Page 6

6 Room Air Conditioner

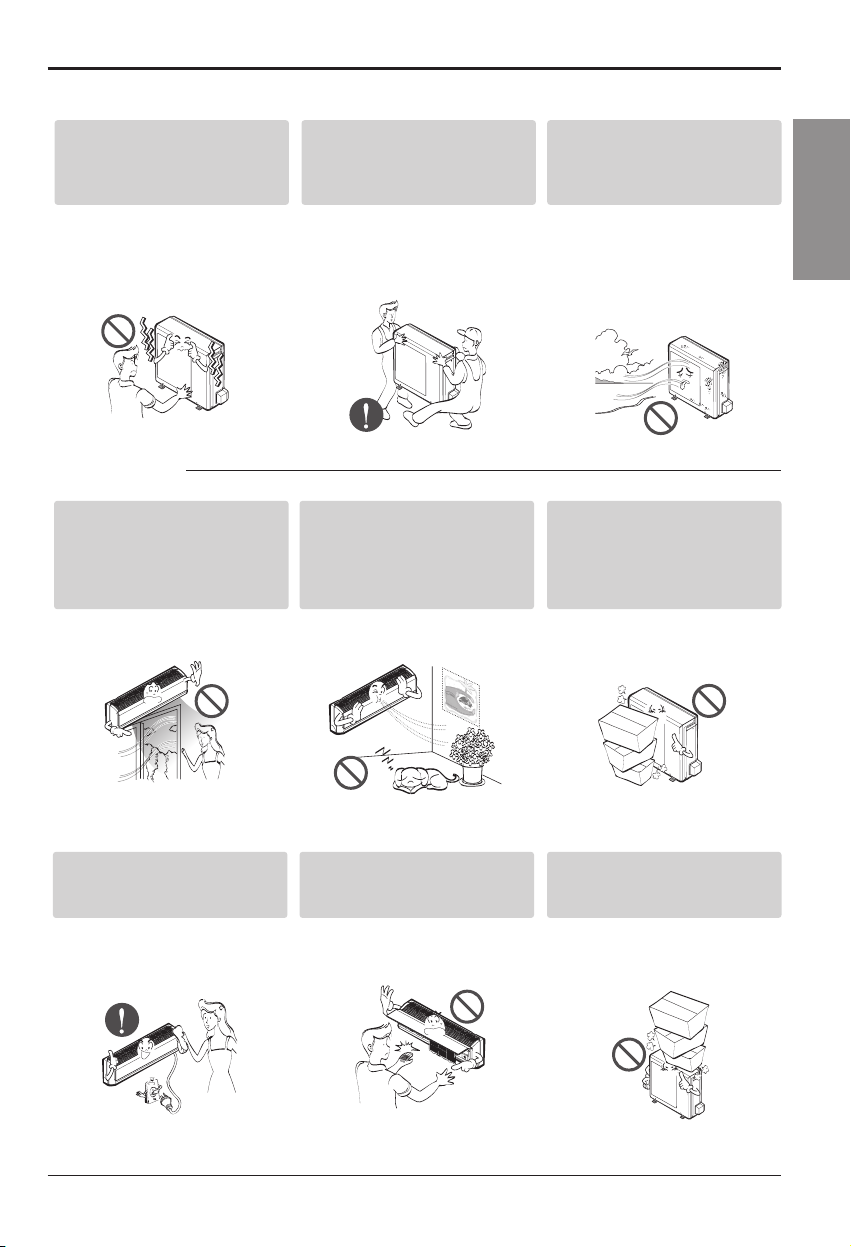

Safety Precautions

■ Installation

Always check for gas(refrigerant)

leakage after installation or

repair of product.

• Low refrigerant levels may cause

product failure.

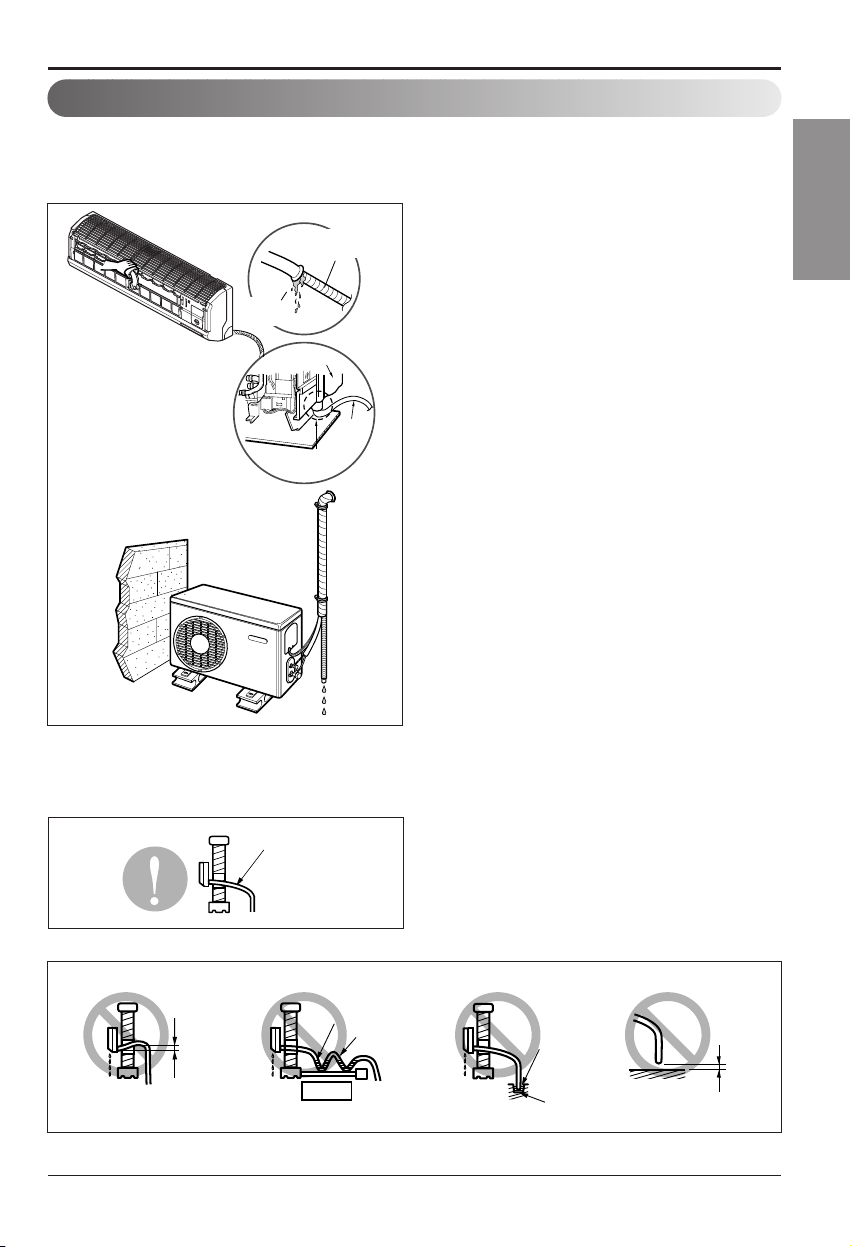

Install the drain hose to ensure

that water is drained away

properly.

• A bad connection may cause water

leakage.

Keep level even when installing

the product.

• To avoid vibration or water leakage.

Take care to ensure that nobody could step on or

fall onto the outdoor unit.

• There could result in personal injury and product damage.

Do not insert hands or other objects through the air

inlet or outlet while the air conditioner is plugged

in.

• There are sharp and moving parts that could cause

personal injury.

Ventilate the product from time to

time when operating it together

with a stove, etc.

• There is risk of fire or electrical shock.

Unplug the appliance before

performing cleaning or

maintenance.

• Thereisriskofelectricshock.

When the product is not be used

for a long time disconnect the

power supply plug or turn off the

breaker.

• There is risk of product damage or

failure, or unintended operation.

90˚

Page 7

Safety Precautions

Installation Manual 7

ENGLISH

■ Operation

Do not install the product where

the noise or hot air from the

outdoor unit could damage the

neighborhoods.

• It may cause a problem for your

neighbors.

Use two or more people to lift

and transport the air conditioner

• Avoid personal injury.

Do not install the product where

it will be exposed to sea wind

(salt spray) directly.

• It may cause corrosion in the product.

Corrosion, particularly on the

condenser and evaporator fins, could

cause product malfunction or

inefficient operation.

Do not direct airflow at room

occupants.

• This could damage your health.

Do not use the product for special

purposes, such as preserving

foods, works of art, etc. It is a

consumer air conditioner, not a

precision refrigeration system.

• There is risk of damage or loss of

property.

Do not block the inlet or outlet of

air flow.

• It may cause product failure.

Use a soft cloth to clean.

Do not use harsh detergents,

solvents, etc.

• There is risk of fire, electric shock

or damage to the plastic parts of the

product.

Do not touch the metal parts of

the product when removing the

air filter. They are very sharp!

• There is risk of personal injury.

Do not step on or put anything

on the product. (outdoor unit)

• There is risk of personal injury and

failure of product.

Page 8

8 Room Air Conditioner

Safety Precautions

■ Disuse

Always insert the filter securely. Clean the filter

every two weeks or more often if necessary.

• A dirty filter reduces the efficiency of the air conditioner and

could cause product malfunction or damage.

Do not drink the water drained from the unit.

• It is not sanitary and could cause serious health issues.

Do not recharge or disassemble the batteries. Do

not dispose of batteries in a fire.

• They may burn or explode.

If the liquid from the batteries gets onto your skin

or clothes, wash it well with clean water. Do not

use the remote if the batteries have leaked.

• The chemicals in batteries could cause burns or other

health hazards.

Use a firm stool or ladder when cleaning or

maintaining the air conditioner.

• Be careful and avoid personal injury.

Replace all the batteries in the remote.

• There is risk of fire or explosion.

Page 9

Installation Manual 9

ENGLISH

Introduction

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that may cause harm to

the air conditioner.

This symbol indicates special notes.

NOTICE

Introduction

Symbols Used In This Manual

Features

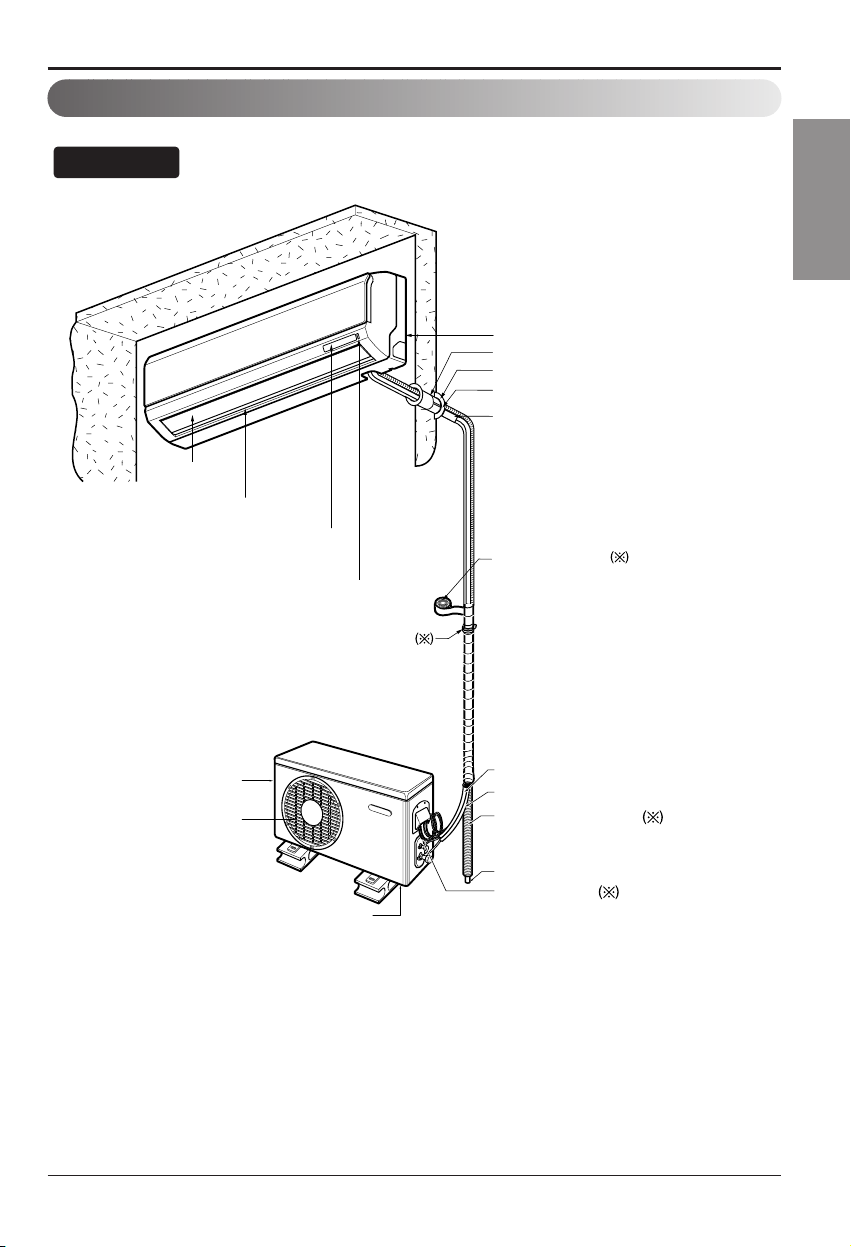

Air Intake Vents

Air Outlet Vents

Connecting

Wires

Piping

Drain Hose

Base Plate

Air Outlet

Vents

Air Intake

Vents

Piping

Connecting

Wires

Drain Hose

Signal Receptor

Base Plate

Front Panel

Air Inlet

Air Filter

Page 10

10 Room Air Conditioner

Installation

Type "A" screw and plastic anchor

Type "B" screw

Remote Control Holder

Installation plate

Figure FigureName

Screw driver

Electric Drill

Measuring Tape, Knife

Hole Core Drill

Spanner

Torque wrench

Ohmmeter

Hexagonal wrench

Ammeter

Gas Leak Detector

Thermometer,

Level

Flaring Tool Set

Name

Installation Parts

Installation Tools

Installation

Read carefully, and then follow step by step.

Page 11

Installation Manual 11

ENGLISH

Installation

Installation Map

Installation parts you should purchase.

Vertical Air deflector

Air Discarge

Forced Operation Button

Operation Indication Lamps/

Signal Receptor

Vinyl tape(Wide)

• Apply after carrying out a

drainage test.

• To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

Saddle

Gas side piping

Liquid side piping

Additional drain pipe

Drain Hose

Base Plate

Air Inlet Vents

Connecting cable

Installation Plate

Sleeve

Bushing-Sleeve

Putty(Gum Type Sealer)

Bend the pipe as closely

on the wall as possible,

but be careful that it

doesn't break.

NOTICE

NOTE: refrigerant line wall thickness must be at least 0.8 mm (0.031 inch)

Air Outlet Vents

Page 12

Installation

1. Check the quality label on the indoor and outdoor unit.

2. Make certain that the refrigerant is R-410A.

THIS PRODUCT CONTAINS R-410A REFRIGERANT

1) Different compressor oil

- R-410A(Polyol ester) / R-22(Mineral).

- Do not mix the existing mineral oil.

- Do not apply used pipe, tools and gauges covered with the existing mineral oil.

2) Absorption of moisture

-Compressor’s oil has the high absorption rate of moisture.

3) Composition

- R-410A(R32:R125=50:50wt%).

NOTE: Never mix with other refrigerants

4) High pressure.

- 1.6 times higher than R-22.

- High Pressure refrigerant may cause personal injury.

Do not handle the pipe by yourself (customer) High-pressure refrigerant may cause personal injury.

- manifold gauge ,charging and any piping tools must be dedicated to R-410A systems.

NOTICE

Confirm The Refrigerant

12 Room Air Conditioner

Boiling Pt.(

°C) Vapor pressure(25°C)(kg f/cnf) Vapor density(25°C)(kg/m2)

R-410A -51.4 15.9 64

R-22 -40.8 9.6 44.4

Example : Split type 12,000 Btu/h

120

100

100

80

93

89

84

76

60

40

20

0

R-410A

R-22

100%

70% 50% 30%

0%

100%70%50%30%0%

Page 13

Installation Manual 13

ENGLISH

Installation

Outdoor unit

1. If an awning is built over the unit to prevent

direct sunlight or rain exposure, make sure

that heat radiation from the condenser is not

restricted.

2. Ensure that the space around the back and

sides is more than 10cm(3.9in). The front of

the unit should have more than 70cm(27.6in)

of space.

3. Do not place animals and plants in the path

of the warm air.

4. Take the air conditioner weight into account

and select a place where noise and vibration

are minimum.

5. Select a place so that the warm air and noise

from the air conditioner do not disturb

neighbors.

Rooftop Installations

If the outdoor unit is installed on a roof structure, be sure to level the unit. Ensure the roof structure

and anchoring method are adequate for the unit location. Consult local codes regarding rooftop

mounting.

If the outdoor unit is installed on roof structures or walls, this may result in excessive noise and

vibration, and may be also classed as non serviceable installation.

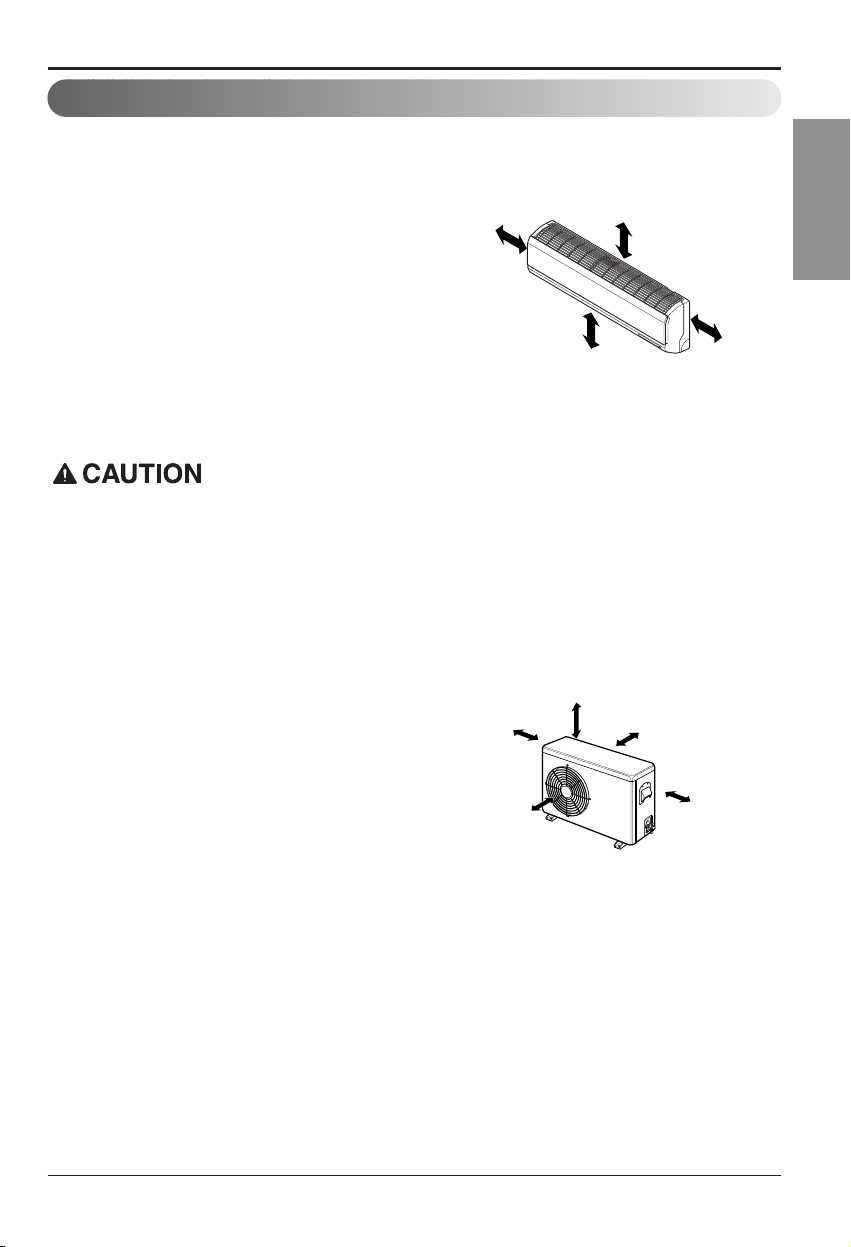

Indoor unit

1. Do not have any heat or steam near the unit.

2. Select a place where there are no obstacles

in front of the unit.

3. Make sure that condensation drainage can be

conveniently routed away.

4. Do not install near a doorway.

5. Ensure that the space around the left and

right of the unit is more than 30cm(11.8in).

Theunitshouldbeinstalledashighonthe

wall as possible, allowing a minimum of

12cm(4.7in) from ceiling.

6.Useastudfindertolocatestudstoprevent

unnecessary damage to the wall.

Select The Best Location

Install the indoor unit on the wall where the height from the floors more than 2.3meters(7.6ft).

A minimum pipe run of 7.5meters(24.6ft) is required to minimize vibration and excessive noise.

More than

12cm(4.7in)

More than

30cm(11.8in)

More than

30cm(11.8in)

More than 8ft(2.4m)

More than

10cm(3.9in)

More than

10cm(3.9in)

More than

60cm(23.6in)

More than

60cm(23.6in)

More than

70cm(27.6in)

Page 14

14 Room Air Conditioner

Installation

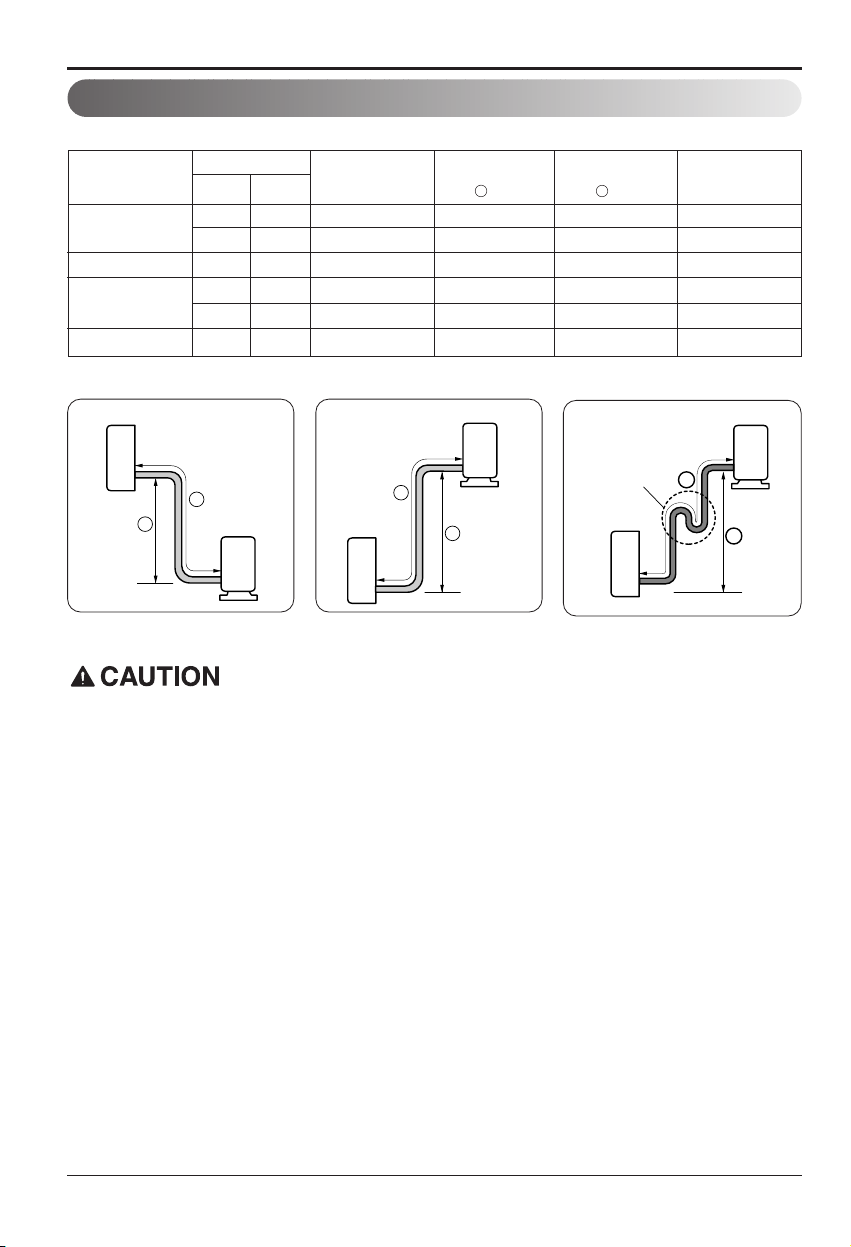

Piping Length And Elevation

• Capacity is based on standard length and maximum allowance length is on the basis of

reliability.

• Oil trap should be installed every 5~7meters (16.4~23.0ft).

Pipe Size

Capacity

(Btu/h)

Suction

Evap

Max.

length

A m(ft)

Additional Refrigerant

g/m(oz/ft)

Max.

Elevation

B m(ft)

Standard

Length

m(ft)

In case more than 5m(16.4ft)

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

9k

3/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

12k 1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

18k

1/2" 1/4" 7.5(25) 15(49) 30(98) 20(0.22)

5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

24k 5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

Page 15

Installation Manual 15

ENGLISH

Installation

The wall you select should be strong and solid

enough to prevent vibration

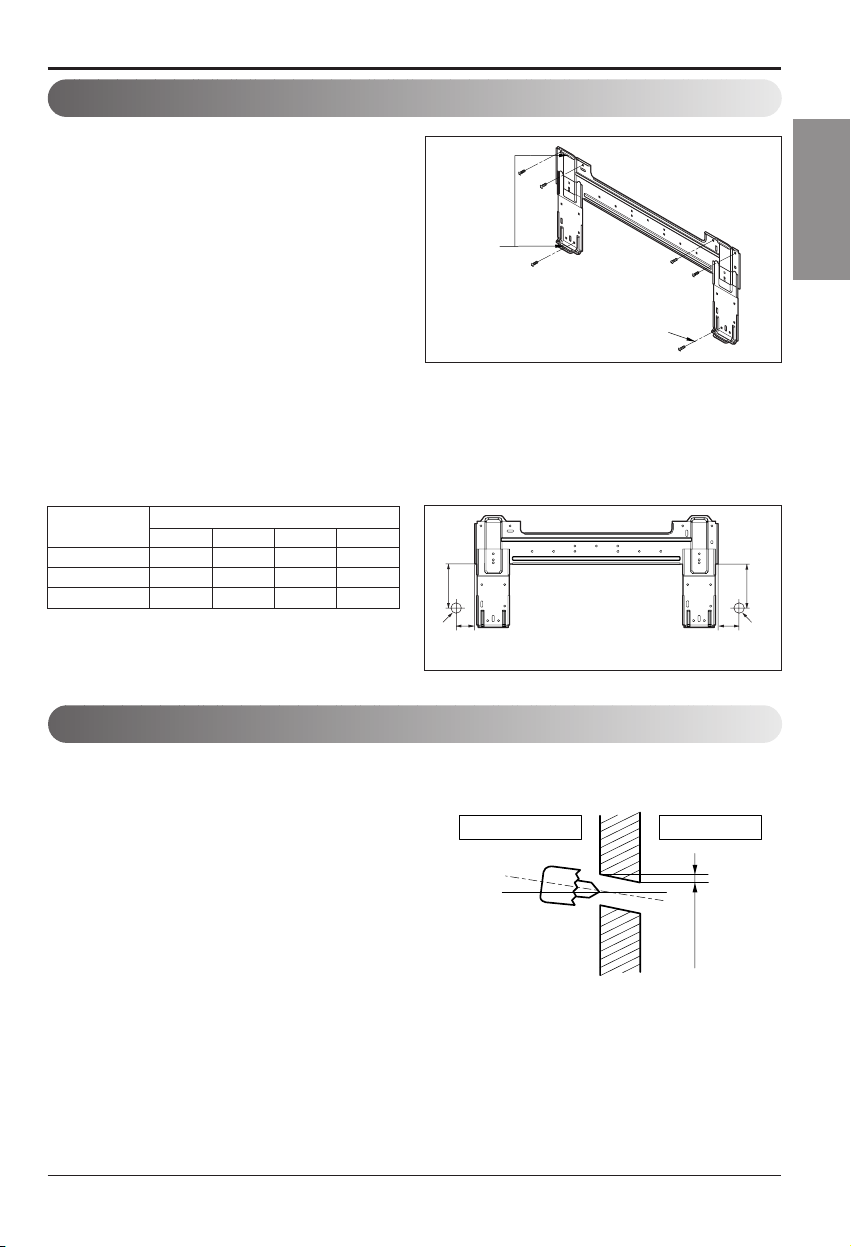

1. Mount the installation plate on the wall with

type "A" screws. If mounting the unit on a

concrete wall, use anchor bolts.

• Mount the installation plate horizontally by

aligningthecenterlineusingalevel.

2. Measure the wall and mark the centerline. It is also important to use caution concerning the

location of the installation plate-routing of the wiring to power outlets is through the walls typically.

Drilling the hole through the wall for piping connections must be done safely.

How To Mount Installation Plate

Chassis

Hook

Installation Plate

Type “A”

• Drill the piping hole with a ø70mm(2.76in)

hole core drill. Drill the piping hole at either

the right or the left with the hole slightly

slantedtotheoutdoorside.

Drill a Hole In The Wall

5-7mm

(0.2~0.3")

Indoor

WALL

Outdoor

ABCD

S4 50 105 59 105

SE 65 110 85 110

S5 95 122 235 122

CHASSIS

(Grade)

Distance (mm)

D

C

Ø70mm

Left rear piping Right rear piping

Installation plate

A

B

Ø70mm

Page 16

16 Room Air Conditioner

Installation

Flaring Work

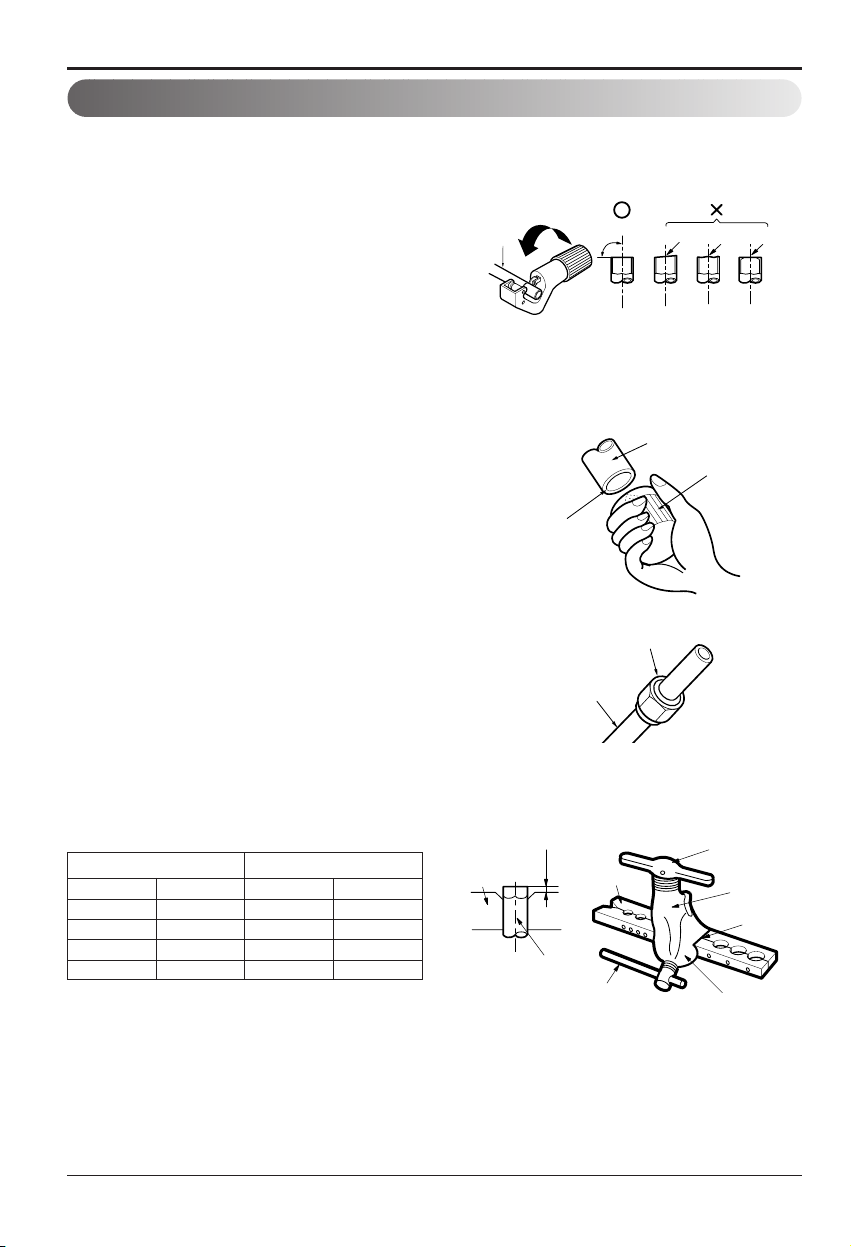

Cut the pipes and the cable.

1. Use the piping kit accessory or the pipes

purchased locally.

2. Measure the distance between the indoor and

the outdoor unit.

3. Cut the pipes a little longer than measured

distance.

4. Cut the cable 1.5m(59.1in) longer than the

pipe length.

Burrs removal

1. Completely remove all burrs from the cut cross

section of pipe/tube.

2. Put the end of the copper tube/pipe in a

downward direction as you remove burrs in

order to avoid dropping burrs into the tubing.

Putting nut on

• Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube having

completed burr removal.

(not possible to put them on after flaring work)

Flaring work

• Carry out flaring work using flaring tool as

shown below.

Main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the

following procedure.

mm inch mm inch

Ø6.35 1/4 0~0.5 0~0.020

Ø9.52 3/8 0~0.5 0~0.020

Ø12.7 1/2 0~0.5 0~0.020

Ø15.88 5/8 0~1.0 0~0.039

Outside diameter A

Copper

pipe

90¡

Slanted Uneven Rough

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Pipe

Reamer

Point down

Firmly hold copper pipe in a die in the

dimension shown in the table above.

Flare nut

Copper tube

Page 17

Installation Manual 17

ENGLISH

Installation

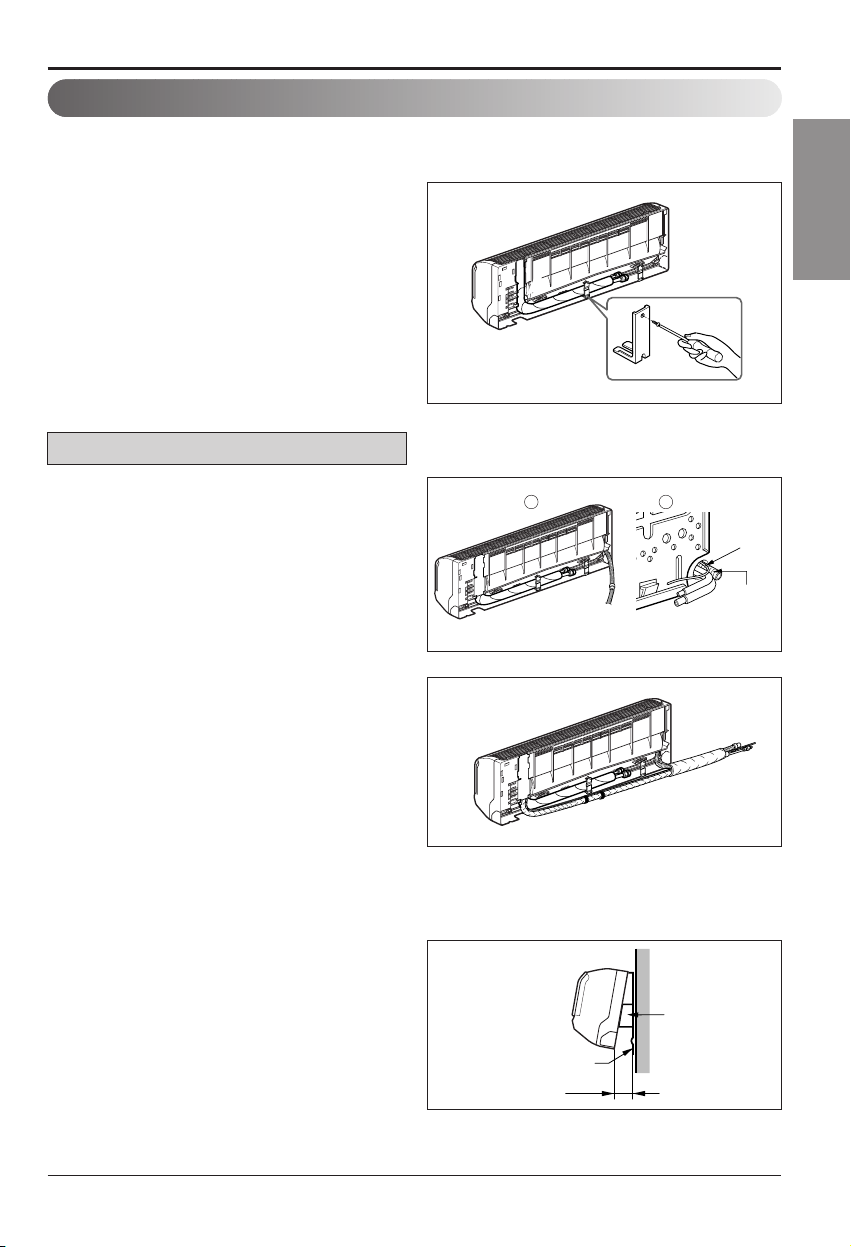

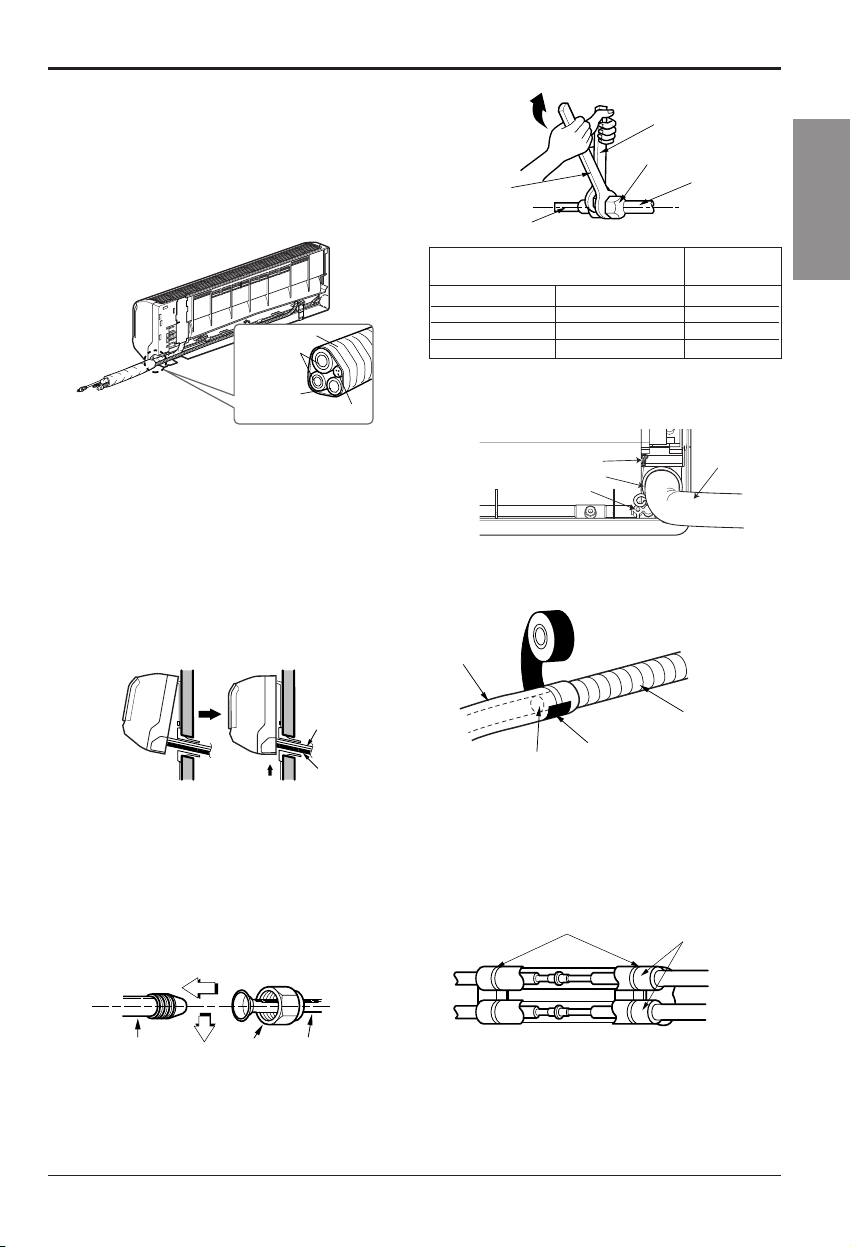

Indoor

1. Prepare the indoor unit's piping and drain hose for installation through the wall.

2. Remove the plastic tubing retainer(see the

illustration by) and pull the tubing and drain

hose away from chassis.

3. Replace only the plastic tubing holder 1, not

the holder 2 in the original position.

Route the indoor tubing and the drain hose in

the direction of rear left.

Insert the connecting cable into the indoor unit

from the outdoor unit through the piping hole.

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy

connection later.

Tape the tubing, drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper side

can cause drain pan to overflow inside the unit.

NOTE: If the drain hose is routed inside the room,

insulate the hose with an insulation material* so that

dripping from "sweating"(condensation) will not

damage furniture or floors.

*Foamed polyethylene or equivalent is

recommended.

Indoor unit installation

• Hook the indoor unit onto the upper portion of

the installation plate.(Engage the three hooks

of the rear top and rear lower of the indoor unit

with the upper edge and lower edge of the

installation plate.) Ensure that the hooks are

properly seated on the installation plate by

moving it left and right.

Connecting the Piping

For left rear piping

Connecting The Piping

1 2

Indoor unit

Installation plate

8cm

Spacer

Connecting

cable

Drain pipe

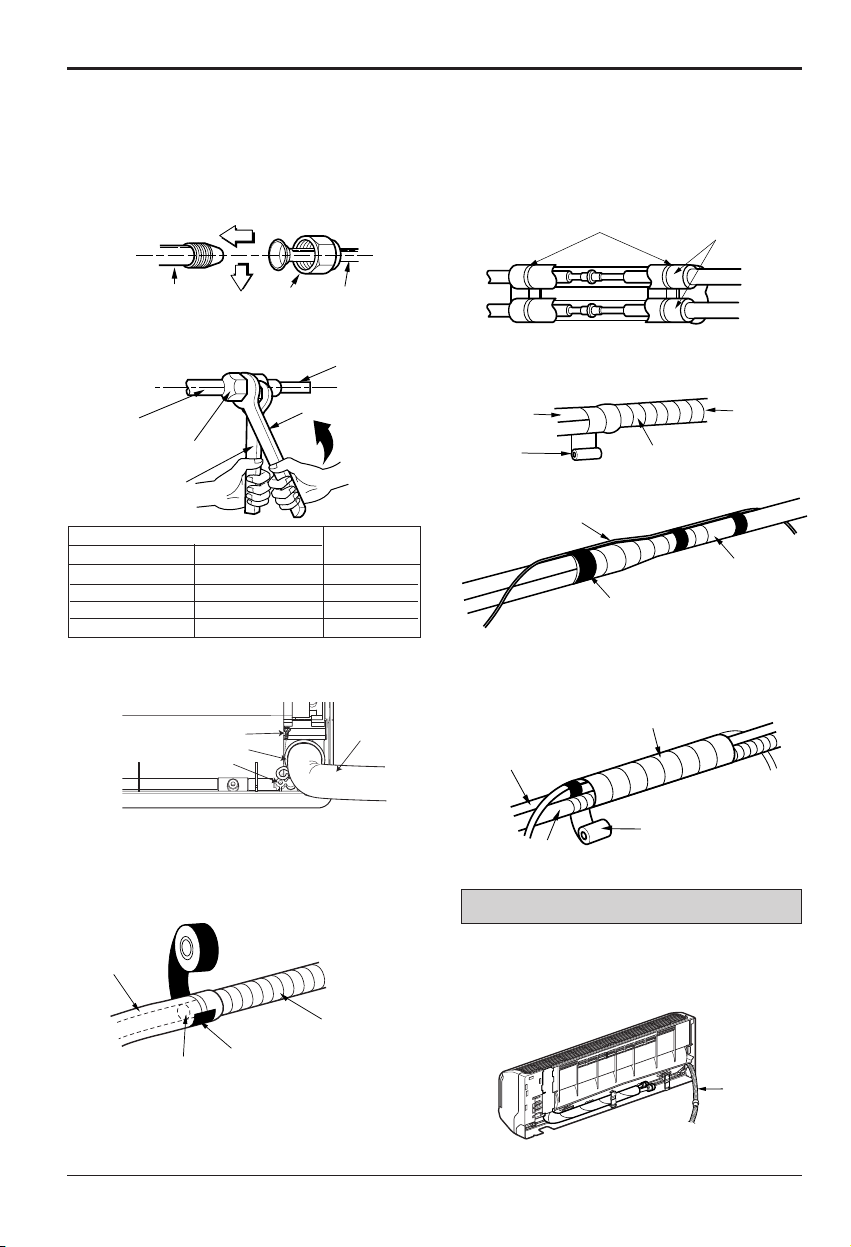

Page 18

18 Room Air Conditioner

Installation

Wrap the insulation material around the

connecting portion.

• Overlap the connection pipe insulation material

and the indoor unit pipe insulation material. Bind

them together with vinyl tape so that there is no

gap.

Route the indoor tubing and the drain hose to

the required piping hole position.

Plastic bands

Insulation material

Connection pipe

Flare nut

Indoor unit tubing

Torque wrench

Spanner (fixed)

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

• When extending the drain hose at the indoor unit,

install the drain pipe.

• Mount the clamp on the boss with a type "B"

screw.(SE-H/P: 9k, 12k C/O: 12k)

• Tighten the flare nut with a wrench.

• Wrap the area which accommodates the rear

piping housing section with vinyl tape.

For right rear piping

Connecting the pipings to the indoor unit

and drain hose to drain pipe.

• Put a couple drops of refrigerant oil on the face of

the flare before assembling taking care not to add

any contaminants.

• Align the center of the pipings and sufficiently

tighten the flare nut by hand.

Indoor unit tubing Flare nut Pipings

Drain hose

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Outside diameter

mm inch

Torque

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

• Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range

within which they fit into the rear piping housing

section.

Wrap with vinyl tape

Drain hose

Pipe

Vinyl tape(wide)

Type "B" screw

Clamp

Boss

Drain hose

Page 19

Installation Manual 19

ENGLISH

Installation

Insert the connecting cable into the indoor unit.

• Don't connect the cable to the indoor unit.

• Make a small loop with the cable for easy

connection later.

Tape the drain hose and the connecting cable.

• Connecting cable

Connecting the pipings to the indoor unit and

the drain hose to drain pipe.

• Put a couple drops of refrigerant oil on the face of

the flare before assembling taking care not to add

any contaminants

• Align the center of the pipings and sufficiently

tighten the flare nut by hand.

• Tighten the flare nut with a wrench.

Indoor unit tubing Flare nut Pipings

Torque wrench

Indoor unit tubing

Spanner (fixed)

Connection pipe

Flare nut

Indoor unit installation

• Hook the indoor unit onto the upper portion of

the installation plate.(Engage the three hooks of

the rear top and rear lower of the indoor unit with

the upper edge and lower edge of the installation

plate.) Ensure that the hooks are properly

seated on the installation plate by moving it left

and right.

Wrap the insulation material around the

connecting portion.

•

Overlap the connection pipe heat insulation and the

indoor unit pipe heat insulation material. Bind them

together with vinyl tape so that there is no gap.

Plastic bands

Insulation material

Vinyl tape

Adhesive

Drain hose

Indoor unit drain hose

(narrow)

• When extending the drain hose at the indoor unit,

install the drain pipe.

Connecting

pipe

Connecting cable

Tape

Drain hose

Drain hose

Connecting

cable

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Outside diameter Torque

• Mounttheclamponthebosswithatype"B"

screw.(SE-H/P: 9k, 12k C/O: 12k)

Type "B" screw

Clamp

Boss

Drain hose

Page 20

20 Room Air Conditioner

Installation

Reroute the pipings and the drain hose

across the back of the chassis.

Reroute the pipings and the drain hose

across the back of the chassis.

Drain hose

Vinyl tape(narrow)

Pipe

Wrap with

vinyl tape(wide)

• Bundle the piping and drain hose together by

wrapping them with cloth tape over the range within

which they fit into the rear piping housing section.

Piping for

passage through

piping hole

Drain hose

Connecting

cable

• Wrap the area which accommodates the rear

piping housing section with vinyl tape.

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Indoor

unit piping

Pipe

Vinyl tape

(wide)

Wrap with vinyl tape

Page 21

Installation Manual 21

ENGLISH

Installation

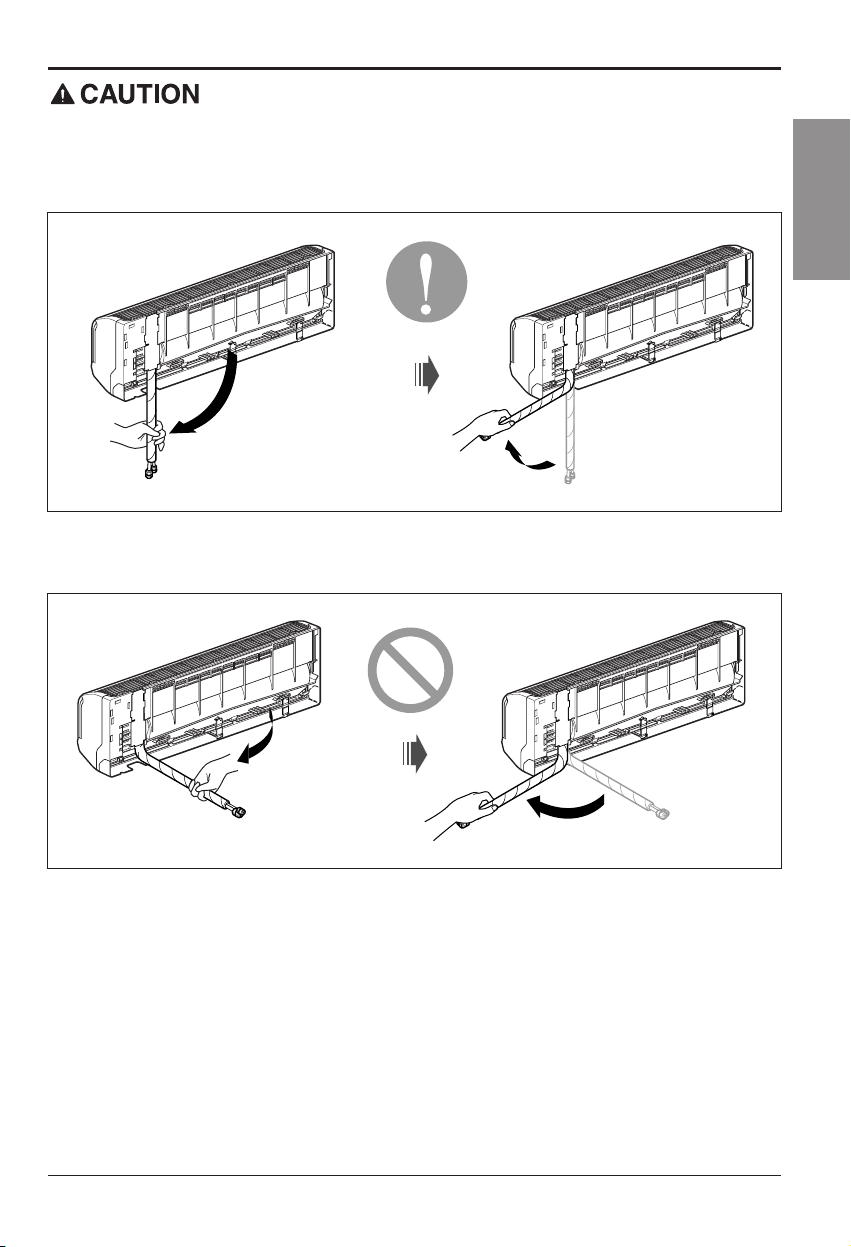

Installation Information. For left piping. Follow the instruction below.

Correct case

• Press on the upper side of clamp and unfold the tubing to downward slowly.

Incorrect case

• Following bending type from right to left may cause damage to the tubing.

Page 22

22 Room Air Conditioner

Installation

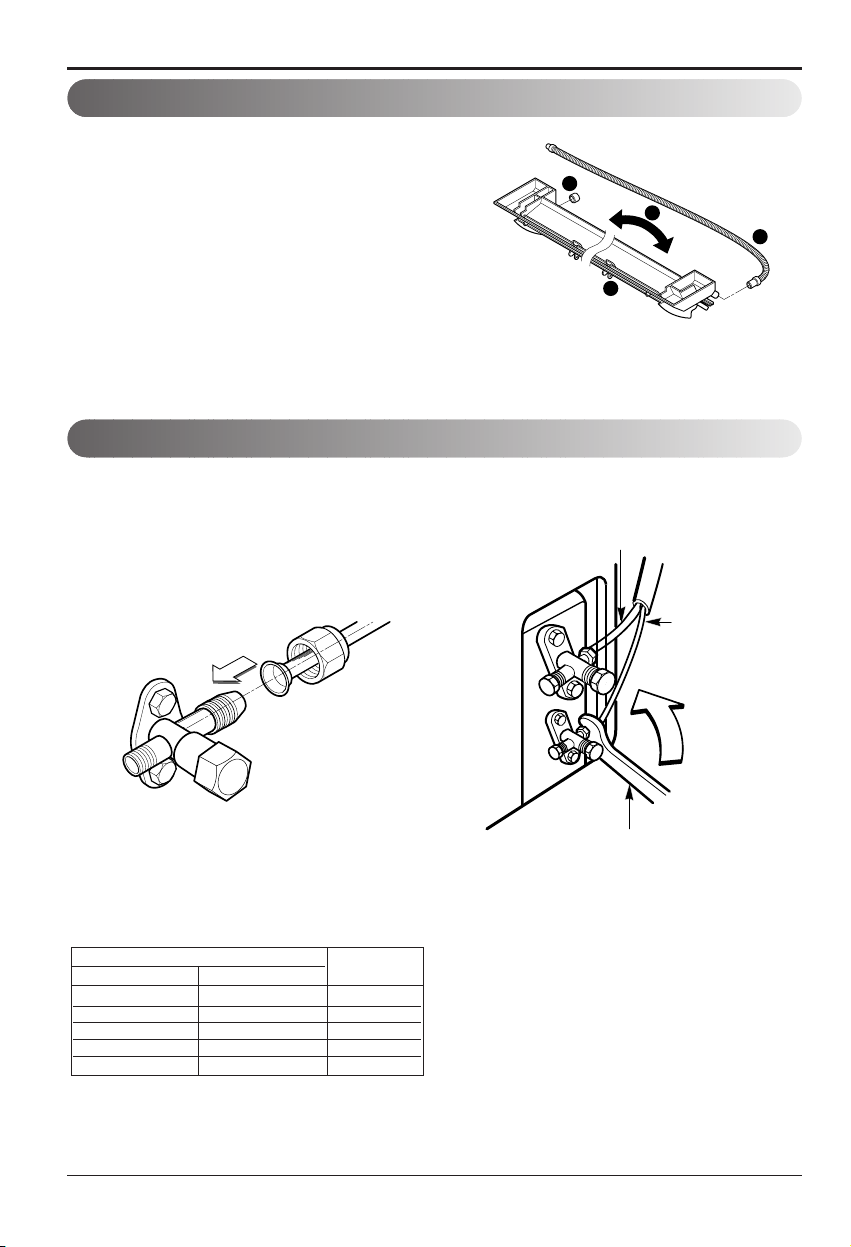

Put a couple drops of refrigerant oil on the face

of the flare before assembling taking care not to

add any contaminants.

Align the center of the pipings and sufficiently

tighten the flare nut by hand.

• The drain hose can be connected at two different

positions. Use the most convenient position and, if

necessary, exchange the position of the drain pan,

rubber cap and the drain hose.

➊ Drain pan

➋ Rubber cap

➌ Drain hose

➍ Exchange if necessary

• Remove the drain hose.

• Securely insert both the rubber plug and drain

hose into the drain outlets.

Be sure the rubber the cap is securely fastened so

that there is no leakage.

Finally, tighten the flare nut with torque wrench

until the wrench clicks.

• When tightening the flare nut with torque wrench,

ensure the direction for tightening follows the arrow

on the wrench.

Outdoor unit

Suction Line piping

(Bigger diameter)

Evaporator Line

piping

(Smaller

diameter)

Torque wrench

1

2

3

4

Connecting the PipingConnection Of The Drain Hose

Connecting the PipingConnection Of Piping -Outdoor

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter

mm inch

Torque

Page 23

Installation Manual 23

ENGLISH

Installation

Connecting the PipingConnection Of The Cable

1

Indoor Unit Outdoor Unit

2

3

4

1

2

3

4

5

6

G

To

branch

circuit

Ground

Power supply

a

L1

*

L2

Connecting cable(Low voltage)

b

Terminal

(4P)

Terminal

(6P)

Outdoor unit

Wiring Diagram

Terminal block

Over 5mm

(0.2")

Cover control

Conduit panel

Connecting

cable

Power supply

cord

*

L1 is neutral for 115V models.

1. Remove the cover control from the unit by

loosening the 3 screws.

2. Dismount caps on the conduit panel.

3. Temporarily mount the conduit tubes on the

conduit panel.

4. Properly connect both the power supply and

low voltage lines to the corresponding

terminals on the terminal block.

5. Ground the unit in accordance with local

codes.

6. Be sure to size each wire allowing several

inches longer than the required length for

wiring.

7. Use lock nuts to secure the conduit tubes.

1. shows field wiring.

2. Separately wire the high and low voltage line.

3. Use heat-proof electrical wiring capable of

withstanding temperatures up to 167°F.

4. Use outdoor and waterproof connection cable

rated more than 300V for the connection between

indoor and outdoor unit.

(For example, Type STOW)

• Be sure to comply with local codes while

running the wire from the indoor unit to the

outdoor unit(size of wire and wiring method,

etc).

• Everywiremustbeconnectedfirmly.

• No wire should be allowed to touch

refrigerant tubing, the compressor or any

moving parts.

Connector trade size for this unit is 1/2"

for instructions on connecting depending on

thewiretypeyouareusing.

WARNING

NOTE

Power Supply

Model

Powe r sour ce

9K 1ø, 115V 14 18 15A

12K 1ø, 115V 14 18 20A

18K 1ø, 230/208V 14 18 20A

24K 1ø, 230/208V 12 18 25A

AWG(MI N.)

Fuse or breaker

Capacity

NOTE

Page 24

24 Room Air Conditioner

Installation

After the confirmation of the above conditions, prepare the wiring as follows:

1)

Never fail to have an individual power circuit specifically for the air conditioner. As for

the method of wiring, be guided by the circuit diagram posted on the inside of control

cover.

2) The screw which fasten the wiring in the casing of electrical fittings are liable to

come loose from vibrations to which the unit is subjected during the course of

transportation. Check them and make sure that they are all tightly fastened. (If they

are loose, it could cause burn-out of the wires.)

3) Specification of power source.

4) Confirm that electrical capacity is sufficient.

5) Confirm that the starting voltage is maintained at more than 90 percent of the rated

voltage marked on the name plate.

6) Confirm that the cable thickness is as specified in the power source specification.

(Particularly note the relation between cable length and thickness.

7) Always install an GFCI circuit breaker in a wet or moist area.

8) The following would be caused by voltage drop.

• Vibration of a magnetic switch, which will damage the contact point, open fuse, disturbance of the

normal function of the overload.

9) The means for disconnection from a power supply shall be incorporated in the fixed

wiring and have an air gap contact separation of at least 3mm(0.12in) in each

active(phase) conductors.

CAUTION

Page 25

Installation Manual 25

ENGLISH

Installation

Checking The Drainage

• Pour a glass of water on the drain pan.

• Ensure the water flows through the drain hose of the indoor unit without any leakage and goes out the drain

exit.

Drain piping

• The drain hose should point downward for easy drain flow.

• Avoid these situations.

Drain pan

Drain

hose

Leakage

checking

Connecting area

drain hose

Leakage

checking

Downward slope

Water

leakage

Accumulated

drain water

Waving

Air

Do not raise

Water

leakage

Water

leakage

Tip of drain hose

dipped in water

Ditch

Less than

50mm gap

Page 26

26 Room Air Conditioner

Installation

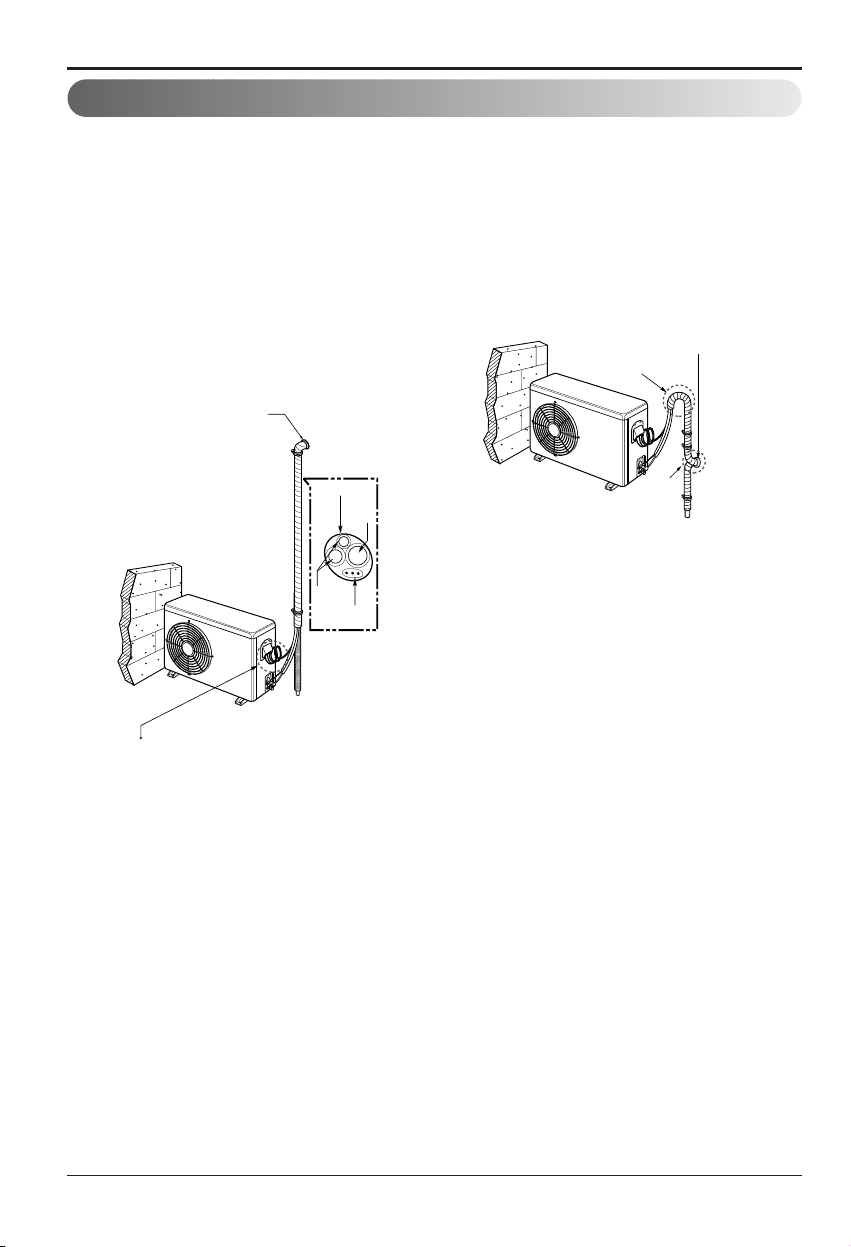

Forming The Piping

Form the piping by wrapping the connecting

portion of the indoor unit with insulation material

and secure it with two kinds of vinyl tapes.

• If you want to connect an additional drain hose, the

end of the drain outlet should be routed above the

ground. Secure the drain hose appropriately.

In cases where the outdoor unit is installed

below the indoor unit perform the following.

•

Tape the piping, drain hose and connecting cable

from down to up.

•

Secure the tapped piping along the exterior wall

using saddle or equivalent.

Taping

Drain

hose

Pipings

Connecting

cable

Trap is required to prevent water

from entering into electrical parts.

Seal small openings

around pipings with a

gum type sealer.

In cases where the Outdoor unit is installed

above the Indoor unit perform the following.

•

Tape the piping and connecting cable from down to

up.

•

Secure the taped piping along the exterior wall. Form

atraptopreventwaterenteringtheroom.

•

Fix the piping onto the wall by saddle or equivalent.

Seal a small opening

around the pipings

with gum type sealer.

Trap

Trap

Page 27

Installation Manual 27

ENGLISH

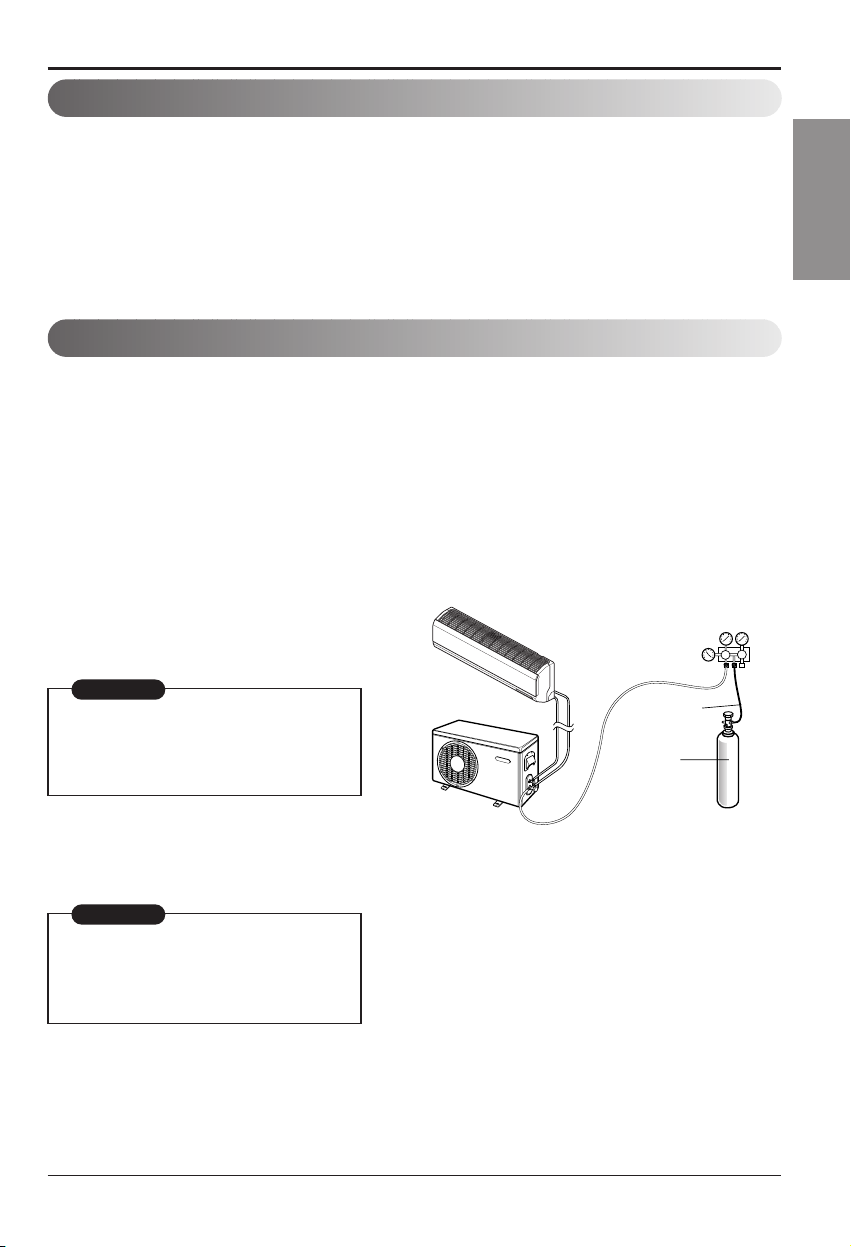

Air Purging

Air purging With Vacuum Pump

Lo Hi

Indoor unit

Outdoor unit

Manifold valve

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

Pressure

gauge

Air and moisture remaining in the refrigerant system have undesirable effects as indicated below.

• Pressure in the system rises.

• Operating current rises.

• Cooling(or heating) efficiency drops.

• Moisture in the refrigerant circuit may freeze and block capillary tubing.

• Water may lead to corrosion of parts in the refrigeration system.

Therefore, the indoor unit and tubing between the indoor and outdoor unit must be leak tested and evacuated

to remove any noncondensables and moisture from the system.

Preparation

• Check that each tubing(both liquid and gas side

tubes) between the indoor and outdoor units have

been properly connected and all wiring for the test

run has been completed. Remove the service

valve caps from both the gas and the liquid side

on the outdoor unit. Note that both the liquid and

the gas side service valves on the outdoor unit are

kept closed at this stage.

Leak test

• Connect the manifold valve(with pressure

gauges) and dry nitrogen gas cylinder to this

service port with charge hoses.

• Pressurize the system to no more than 150 P.S.I.G.

with dry nitrogen gas and close the cylinder valve

when the gauge reading reached 150 P.S.I.G. Next,

test for leaks with liquid soap.

• Do a leak test of all joints of the tubing(both indoor

and outdoor) and both gas and liquid side service

valves.

Bubbles indicate a leak. Be sure to wipe off the soap

with a clean cloth.

• After the system is found to be free of leaks, relieve

the nitrogen pressure by loosening the charge hose

connector at the nitrogen cylinder. When the system

pressure is reduced to normal, disconnect the hose

from the cylinder.

Be sure to use a manifold valve for air

purging. If it is not available, use a stop

valve for this purpose. The "Hi" knob of

the manifold valve must always be kept

close.

To avoid nitrogen entering the refrigerant system in

a liquid state, the top of the cylinder must be higher

than its bottom when you pressurize the system.

Usually, the cylinder is used in a vertical standing

position.

CAUTION

CAUTION

Installation

Page 28

28 Room Air Conditioner

Installation

Evacuation

• Connect the charge hose end described in the

preceding steps to the vacuum pump to

evacuate the tubing and indoor unit.

Confirm the "Lo" knob of the manifold valve is

open. Then, run the vacuum pump.

The operation time for evacuation varies with

tubing length and capacity of the pump. The

following table shows the time required for

evacuation.

• When the desired vacuum is reached, close the

"Lo" knob of the manifold valve and stop the

vacuum pump.

Finishing the job

• With a service valve wrench, turn the valve

stem of liquid side valve counter-clockwise to

fully open the valve.

• Turn the valve stem of gas side valve counterclockwise to fully open the valve.

• Loosen the charge hose connected to the gas

side service port slightly to release the pressure,

then remove the hose.

• Replace the flare nut and its bonnet on the gas

side service port and fasten the flare nut securely

with an adjustable wrench. This process is very

important to prevent leakage from the system.

• Replace the valve caps at both gas and liquid side

service valves and fasten them tight.

This completes air purging with a vacuum pump.

The air conditioner is now ready to test run.

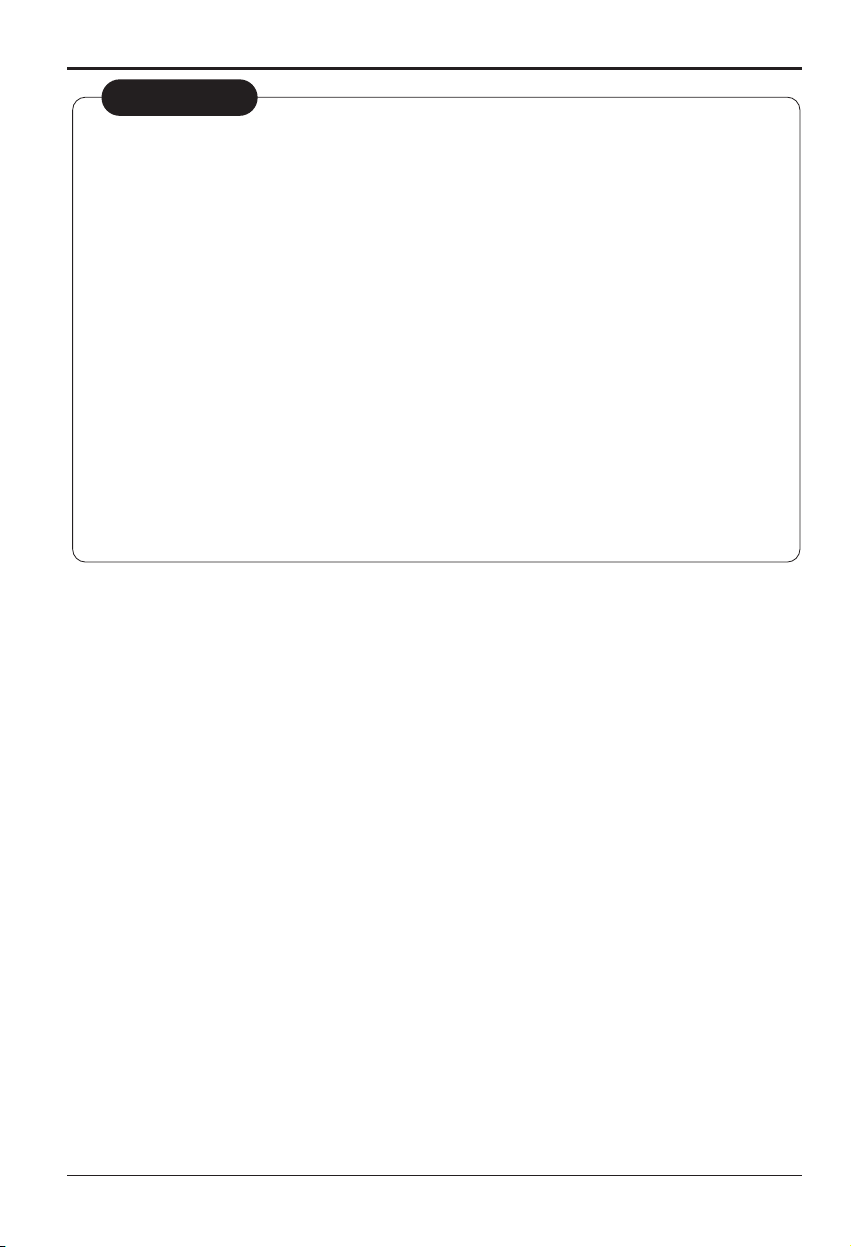

(1) Remove the caps from the gas side and

liquid side valves.

(2) Remove the service-port cap from the gas

side valve.

(3) To open the gas side valve turn the valve

stem counterclockwise approximately 90°,

wait for about 2~3 seconds, and close it.

(4) Apply a soap water or a liquid neutral

detergent on the indoor unit connection or

outdoor unit connections by a soft brush to

check for leakage of the connecting points

of the piping.

(5) If bubbles come out, the pipes have

leakage.

Soap water method

Suction Line

Evaporator Line

Cap

Hexagonal wrench

3-way valve

(Open)

3-way valve

(Close)

Required time for evacuation when 30 gal/h

vacuum pump is used

10 min. or more 15 min. or more

If tubing length is less

than 10m (33 ft)

if tubing length is longer

than 10m (33 ft)

Indoor unit

Outdoor unit

Lo Hi

Manifold valve

Vacuum pump

Pressure

gauge

Open

Close

Page 29

Installation Manual 29

ENGLISH

Installation

Charging

■ Each outdoor unit is factory charged (nameplate charge) for the evaporator as well as a 7.5m(25ft) line

set. Any time a line set is used either shorter or longer then the nominal 7.5m(25ft) line set length the

refrigerant charge has to be adjusted.

■ Whether the line set is made shorter or longer you must adjust the charge based on how many ft of tubing

are either added or removed based on 30g(0.32oz) of R-410A per meter(foot).

Example: A 30ft line set is used

5 additional ft X 0.22 ounce per foot= add 1.1 ounces of R-410A

Important:

If you are ever uncertain of the unit charge, reclaim, evacuate and weigh in the correct charge using the unit

nameplate charge adjusting for line sets longer or shorter than 7.5m(25ft).

Confirm the refrigerant R-410A. Use manifold gauge and hose for R-410A.

Pipe Size

Capacity

(Btu/h)

Suction

Evap

Max.

length

A m(ft)

Additional Refrigerant

g/m(oz/ft)

Max.

Elevation

B m(ft)

Standard

Length

m(ft)

9k

3/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

12k 1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

18k

1/2" 1/4" 7.5(25) 15(49) 30(98) 20(0.22)

5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

24k 5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

Page 30

30 Room Air Conditioner

Test Running

Outside ambient TEMP. The pressure of the gas side service valve

95°F(35°C)

8.5~9.5kg/cm2G(120~135 P.S.I.G.)

Settlement of outdoor unit

■

Anchor the outdoor unit with a bolt and

nut(ø10mm(0.39in) tightly and horizontally on a

concrete or rigid mount.

■

When installing on the wall, roof or rooftop, anchor

the mounting base securely with a nail or wire

assuming the influence of wind and earthquake.

■

In the case when the vibration of the unit is

conveyed to the hose, secure the unit with an antivibration rubber.

1.

Check that all tubing and wiring have been

properly connected.

2.

Check that the gas and liquid side service valves

are fully open.

Prepare remote control

1. Remove the battery cover

by pulling it according to the

arrow direction.

2. Insert new batteries making

sure that the (+) and (–)of

battery are installed correctly.

3. Reattach the cover by

pushing it back into position.

NOTE:

• Use 2 AAA(1.5volt) batteries. Do not use

rechargeable batteries.

• Remove the batteries from the remote control if

the system is not going to be used for a long

time.

Evaluation of the performance

Operate unit for 15~20 minutes, then check the

system refrigerant charge:

1.

Measure the pressure of the gas side service

valve.

2.

Measure the temperature of the intake and

discharge of air.

NOTE: If the actual pressure are higher than

shown, the system is most likely overcharged, and charge should be removed. If

the actual pressure are lower than shown,

the system is most likely undercharged, and

charge should be added.

The air conditioner is now ready for use.

Bolt

Tubing connection

This is performed when the unit is to be

relocated or the refrigerant circuit is

serviced.

Pump Down means collecting all refrigerant in

the outdoor unit without loss of refrigerant.

CAUTION:

Be sure to perform Pump Down procedure

with the unit cooling mode.

Pump Down Procedure

1. Connect a low-pressure gauge manifold hose

to the charge port on the gas side service

valve.

2. Open the gas side service valve halfway and

purge the air from the manifold hose using the

refrigerant gas.

3. Close the liquid side service valve(all the way

in).

4. Turn on the unit's operating switch and start

the cooling operation.

5. When the low-pressure gauge reading

becomes 1 to 0.5kg/cm2G(14.2 to 7.1

P.S.I.G.), fully close the gas side valve stem

and then quickly turn off the unit. At that time,

Pump Down has been completed and all

refrigerant will have been collected in the

outdoor unit.

PUMP DOWN

3. Ensure the difference between the intake

temperature and the discharge is more than

46.4°F(8°C) (Cooling) or (Heating).

4. For reference; the gas side pressure of optimum

condition is as below.(Cooling)

Discharge

temperature

Discharge air

Intake temperature

Test Running

Page 31

FRANÇAIS

Climatiseur

MANUEL D’INSTALLATION

IMPORTANT

• Veuillez lire au complet ce manuel d’instructions avant

installer le produit.

• Si le cordon d’alimentation est endommagé, son

remplacement ne doit être accompli que par du personnel

autorisé.

• Conformément aux standards nationaux sur le câblage,

l’installation ne doit être effectuée que par du personnel

autorisé.

• Après l’avoir lu au complet, veuillez conserver ce manuel

d’installation pour référence ultérieure.

Page 32

2 Climatiseur

Manuel d’installation du Climatiseur

TABLE DES MATIÈRES

❏

Plateau d’installation

❏

Quatre vis du type “A”

❏

Câble de branchement

❏

Tuyaux : Ligne de succion

..

5/8"

Ligne d’évaporation

.............

3/8"

(Voir page 13)

❏

Matériaux d’isolation

❏

Tuyau supplémentaire de

vidange (diamètre extérieur

15,5 mm(0.61in))

❏

Deux vis de type “B”

❏

Niveau

❏

Tournevis

❏

Perceuse électrique

❏

Pointe de perceuse

(ø70mm(2.76in))

❏

Ensemble outil d’évasement

❏

Clés torsiométriques

4,2 kg.m, 6,6 kg.m

(différentes selon le numéro du

modèle)

(Voir page 17)

❏

Clé ............................. anglaise

❏

Un verre d’eau

❏

Tournevis

❏

Clé hexagonale (4 mm(0.16in))

❏

Indicateur de fuite de gaz

❏

Pompeàvide

❏

Manomètre

❏

Manuel utilisateur

❏

Thermomètre

❏

Support télécommande

Conditions requises

pour l’installation

Composants nécessaires

Outils nécessaires

Mesuresdesécurité..................3

Introduction................................9

Symboles utilisés dans ce

manuel ....................................9

Caractéristiques......................9

Installation................................10

Pièces d’installation ..............10

Outils d’installation................10

Carte d’installation ................11

Vérifiez le gaz réfrigérant......12

Sélectionnez le meilleur

emplacement ........................13

Elévation et longueur des

tuyaux ...................................14

Comment fixer la plaque

d’installation ..........................15

Pratiquez un trou dans

le mur....................................15

Travail d’évasage ..................16

Raccordement de la

tuyauterie ..............................17

Connexion du tuyau de

drainage................................22

Connexion des canalisations

Externe .................................22

Raccordement des câbles ....23

Contrôle de la vidange..........25

Façonnage des tuyaux..........26

Vidange air............................27

Vidange air avec pompe

à vide ....................................27

Charge ..................................29

Test de fonctionnement ..........30

Verification ............................30

Page 33

Manuel d'installation 3

FRANÇAIS

Mesures de sécurité

Pour éviter des blessures à l'utilisateur ou à d'autres personnes ainsi que des dommages matériels,

vous devez suivre les instructions ci-dessous.

■ L’utilisation incorrecte de l’appareil due à la méconnaissance des instructions provoquera des

blessures ou des dommages, dont la gravité est indiquée au moyen des symboles suivants.

■ La signification des symboles utilisés dans ce guide est indiquée ci-dessous.

Ce symbole indique la possibilité de mort ou de blessures graves.

Ce symbole indique la possibilité de blessures ou de dommages

matériels uniquement.

AVERTISSEMENT

■ Installation

Veillez à ne pas faire.

Veillez à suivre cette instruction.

Mesures de sécurité

N'utilisez des câbles

électriques ou des fiches

endommagés, ni des prises

desserrées.

• Ceci risque de provoquer un

incendie ou un choc électrique.

Pour un travail électrique,

contactez le distributeur, le

vendeur, un électricien qualifié

ou un centre de service aprèsvente agréé.

• Autrement, vous risqueriez de

provoquer un incendie ou un

choc électrique.

Utilisez toujours une fiche

d'alimentation et une prise de

courant avec borne de mise à

la terre.

• Autrement, vous risqueriez de

provoquer un choc électrique.

Installez fermement le panneau

et le couvercle du tableau de

commande.

• Autrement vous risquerez de

provoquer un incendie ou un

choc électrique.

Ne modifiez ni prolongez le

cordon d'alimentation.

• Ceci risquerait de provoquer un

incendie ou un choc électrique.

N'installez, n'enlevez ni remettez

en place l'unité vous-même (si

vous êtes un client).

• Vous pourriez provoquer un

incendie, un choc électrique, une

explosion ou vous blesser.

AVERTISSEMENT

ATTENTION

Page 34

4 Climatiseur

Mesures de sécurité

■ Fonctionnement

Prenez soin lorsque vous

déballez et installez ce produit.

• Les bords aiguisés peuvent

provoquer des blessures. Faites

attention en particulier aux bords

aiguisés.

Contactez toujours le

revendeur ou un centre de

service aprèsventeagréé pour

effectuer l'installation.

• Autrement, vous pourriez

provoquer un incendie, un choc

électrique, une explosion ou vous

blesser.

N'installez pas le produit sur

un support d'installation

défectueux.

• Ceci peut provoquer des

blessures, un accident ou bien

endommager le produit.

Assurez-vous que la zone

d'installation n'est pas abîmée

par le temps.

• Si la base s'écroule, le

climatiseur pourrait tomber avec

elle, provoquant des dommages

matériels, une défaillance du

produit et des blessures.

Installez le group interne sur la

paroi ou' la hauteur á partir du

plancher est supérieure á 8ft(2.4

métres)

• Il y a des bords aiguisés et des

piéces mobiles gui pourraient

vous blesser.

Ne pas manipuler le tuyau vousmême (utilisateur).

• Le gaz réfrigérant à haute pression

peut provoquer des blessures.

8ft(2.4m)

Assurez-vous qu'on ne tire ni

n'endommage le cordon

d'alimentation en cours du

fonctionnement de l'unité.

• Ceci risquerait de provoquer un

incendie ou un choc électrique.

Ne placez aucun objet sur le

cordon d'alimentation.

• Ceci risquerait de provoquer un

incendie ou un choc électrique.

Ne mettez en marche ni arrêtez

le climatiseur en branchant ou

débranchant la fiche

d'alimentation.

• Ceci risquerait de provoquer un

incendie ou un choc électrique.

Page 35

Manuel d'installation 5

FRANÇAIS

Mesures de sécurité

Utilisé une prise de courant

dédiée pour cet appareil.

• Autrement, vous risqueriez de

provoquer un incendie ou un

choc électrique.

Saisissez la fiche pour retirer

le cordon de la prise de

courant. Ne touchez pas la

fiche avec les mains humides.

• Ceci risquerait de provoquer un

incendie ou un choc électrique.

Ne permettez pas que de l'eau

s'écoulesurlespièces

électriques.

• Ceci pourrait provoquer un

incendie, une défaillance de

l'appareil ou un choc électrique.

Ne placez pas de plinthes ou

d'autres appareils prèsdu

cordon d'alimentation.

• Ceci pourrait provoquer un

incendie, une défaillance de

l'appareil ou un choc électrique.

Ne permettez pas que de l'eau

s'écoulesurlespièces

électriques.

• Ceci pourrait provoquer un

incendie, une défaillance de

l'appareil ou un choc électrique.

N'emmagasinez ni utilisez de

substances inflammables ou

combustibles prèsdece

climatiseur.

• Ceci entraînerait un risque

d'incendie ou de défaillance du

produit.

N'utilisez pas ce produit dans

un espace fermé

hermétiquement pendant une

longue période de temps.

• Un manque d'oxygène pourrait

survenir.

S'ilyaunefuitedegaz

inflammable, fermez le robinet à gaz

et ouvrez une fenêtre pour ventiler

la pièce avant de mettre en marche

le climatiseur. N'utilisez le téléphone

ni déplacez les interrupteurs sur les

positions marche/arrêt.

• Ceci risquerait de provoquer une

explosion ou un incendie.

Si l'unité dégage des sons, des

odeurs ou de la fumée,

débranchez-la.

• Ceci pourrait provoquer un

incendie, une défaillance de

l'appareil ou un choc électrique.

Thinner

Wax

Page 36

6 Climatiseur

Mesures de sécurité

Arrêtez le climatiseur et fermez

la fenêtre en cas de tempête ou

d'ouragan. Si possible, retirez

le produit de la fenêtre avant

que l'ouragan n'arrive.

• Autrement, vous risqueriez de

provoquer des dommages

matériels, une défaillance du

produit ou un choc électrique.

N'ouvrez pas la grille d'entréed'air

du produit alors que celui-ci est en

fonctionnement. (Ne touchez pas

le filtre électrostatique, si l'unité en

est équipée.)

•

Autrement, vous risquerez de

subir des blessures physiques, un

choc électrique ou de provoquer

une défaillance du produit.

Contactez un centre de service

après-vente agréé si le produit

est trempé (rempli d'eau ou

submergé).

• Ceci risque de provoquer un

choc électrique.

Ventilezleproduitdetemps

en temps lorsque vous

l'utilisez simultanément avec

une poêle, etc.

• Autrement, vous risquerez de

provoquer un incendie ou un

choc électrique.

Débranchez l'appareil avant de

procéder à des opérations de

nettoyage ou de maintenance

du produit.

• Autrement, vous risquerez de

provoquer un choc électrique.

Si vous n'allez pas utiliser le

produit pendant une longue

période de temps, débranchez le

cordon d'alimentation ou mettez le

disjoncteur sur la position arrêt.

• Autrement, vous risquerez

d'endommager le produit, de

provoquer une défaillance de

celui-ci ou bien une mise en

marche involontaire de l'unité.

Assurez-vous que personne ne pourra marcher

ou tomber sur l'unité extérieure.

• Ceci pourrait provoquer des blessures personnelles

et endommager le produit.

N'insérez pas les mains ou d'autres objets à

travers l'entréeoulasortied'airlorsquele

climatiseur est branché.

• Il y a des bords aiguisés et des pièces mobiles qui

pourraient vous blesser.

Page 37

Mesures de sécurité

Manuel d'installation 7

FRANÇAIS

ATTENTION

■ Installation

Vérifiez toujours s'il y a des

fuites de gaz (frigorigène) suite

à l'installation ou à la

réparation du produit.

• Des niveaux de frigorigène trop

bas peuvent provoquer une

défaillance du produit.

Installez le raccord de drainage

de manière à assurer un

drainage approprié.

• Une mauvaise connexion peut

provoquer des fuites d'eau.

Maintenez le produit de niveau

lors de son installation.

• Ceci sert àéviter des vibrations

ou des fuites d'eau.

N'installez pas le produit à un

endroit où le bruit ou l'air chaud

dégagésdel'unité extérieure

pourraient déranger les voisins.

• Ceci peut provoquer des

problèmes à vos voisins.

Faites appel à deux ou

plusieurs personnes pour

enlever et transporter ce

climatiseur.

• Evitez des blessures.

N'installez pas ce produit à un

endroit où il serait exposé

directement au vent de la mer

(pulvérisation d'eau de mer).

•

Ceci peut produire de la corrosion sur

le produit. La corrosion,

particulièrement sur les ailettes du

condenseur et de l'évaporateur, peut

provoquer un dysfonctionnement ou un

fonctionnement inefficace du produit.

N'orientez pas le flux d'air vers

les occupants de la pièce (Ne

vous asseyez pas sous le

courant d'air).

• Ceci pourrait nuire à votre santé.

N'utilisez pas ce produit pour des

objectifs spéciaux tels que la

préservation d'aliments, d'oeuvres

d'art, etc. C'est un climatiseur

grand public, non pas un système

de refroidissement de précision.

• Il y a risque de dommage à la

propriété ou pertes matérielles.

Ne bloquez pas l'entréeoula

sortie du flux d'air.

• Ceci peut provoquer une

défaillance du produit.

■ Fonctionnement

90˚

Page 38

8 Climatiseur

Mesures de sécurité

Utilisez un chiffon doux pour le

nettoyage. N'employez pas de détergents

agressifs, de dissolvants, etc.

•

Ceci risquerait de provoquer un incendie,

un choc électrique ou des dommages

aux pièces plastiques du produit. Ne

touchez pas les pièces métalliques du

produit lorsque vous enlevez le filtre à air.

Elles sont trèsaiguisées!

• Vous risquez de subir des

blessures.

Ne marchez ni placez aucun

objet sur le produit (unité

extérieure).

• Ceci risquerait de provoquer des

blessures et une défaillance du

produit.

Insérez toujours fermement le filtre. Nettoyez le filtre

toutes les deux semaines ou plus souvent si besoin.

• Un filtre sale réduit l'efficacité du climatiseur et

pourrait provoquer un mauvais fonctionnement de

l'appareil ou l'endommager.

Ne buvez pas l'eau drainée du produit.

• Ceci n'est pas hygiénique et pourrait entraîner de

sérieux problèmes de santé.

■ Désuétude

Ne rechargez ni démontez les piles.

Ne placez pas les piles sur le feu.

• Elles peuvent brûler ou exploser.

Si le liquide des piles tombe sur votre peau ou vos

vêtements, lavez-les bien avec de l'eau propre.

N'utilisez pas la télécommande si les piles ont des fuites.

• Les substances chimiques des piles pourraient

produire des brûlures ou entraîner d'autres risques

pour la santé.

Utilisez une banquette ou une échelle solide lorsque

vous faites des opérations de nettoyage ou de

maintenance du produit.

• Faites attention et évitez des blessures. Remplacez

les piles vieilles de la télécommande par des piles

neuves du même type.

Replacez les piles de la télécommande.

• Il y a risque d’incendie, dommage du produit et/ou

choc électrique.

Page 39

Manuel d'installation 9

FRANÇAIS

Introduction

Ce symbole indique un risque de choc électrique.

Ce symbole signale des risques qui pourraient endommager

le climatiseur.

Ce symbole indique les remarques.

REMARQUE

Introduction

Symboles utilisés dans ce manuel

Caractéristiques

Grilles d’entrée d’air

Grilles de

sortie d’air

Câbles de

connexion

Tuyauterie

Raccord de

drainage

Plaque base

Grilles de sortie

d'air

Grilles d'entrée

d'air

Tuyauterie

Raccord de

drainage

Plaque base

Câbles de

connexion

Arrivée d’air

Filtre à air

Panneau avant

Récepteur de signal

Page 40

10 Climatiseur

Installation

Vis Type "A" et bride d’ancrage en plastique

Vis Type "B"

Support de la télécommande

Plaque d’installation

Figure Figure Nom

Tournevis

Perceuse électrique

Ruban de mesure, Couteau

Mèche

Clé de serrage

Clé de serrage

dynamométrique

Ohmmètre

Clé à six pans

Ampèremètre

Détecteur de fuite de gaz

Thermomètre,

Dispositif de nivellement

Ensemble d’outils

d’évasement

Nom

Pièces d’installation

Outils d’installation

Installation

Lisez-le avec soin et suivez les pas exactement.

Page 41

Manuel d'installation 11

FRANÇAIS

Installation

Carte d’installation

Installation parts you should purchase.

Vertical Air deflector

Air Discarge

Forced Operation Button

Operation Indication Lamps/

Signal Receptor

Vinyl tape (Wide)

• Apply after carrying out a

drainage test.

• To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

Saddle

Gas side piping (Optional Parts)

Liquid side piping (Optional Parts)

Additional drain pipe

Vinyl tape (Narrow)

Drain Hose

Base Plate

Air Outlet Vents

Air Inlet Vents

Connecting cable

(Optional Parts)

Installation plate

Sleeve

Bushing-Sleeve

Putty(Gum Type Sealer)

Bend the pipe as closely

on the wall as possible,

but be careful that it

doesn't break.

NOTICE

Page 42

12 Climatiseur

1. Vérifiez l’étiquette de qualitéàl’intérieur et à l’extérieur de l’appareil.

2. Assurez-vous qu’il s’agîtbiendugazréfrigérant R-410A.

Le gaz réfrigérant R-410A est différent du R-22.

1) Différentes huiles de compresseur.

- R-410A (Polyesther) / R-22 (minéral)

- Ne pas mélanger l’huile minérale existante

- Ne pas appliquer sur des tuyaux usés, sur des outils ou des jauges couvertes d’huile minérale.

2) Absorption de la moisissure.

-L’huile du compresseur possède une forte capacité d’absorption de la moisissure.

3) Mélange de 2 gaz réfrigérants.

- R-410A (R32 : R125 = 50 :50wt%)/R-22(100%).

- Ne pas utiliser le gaz réfrigérant existant R-22. La capacité chuteencasd’insertion de R-22

dans un système R-410A.

4) Haute pression.

- 1,6 fois supérieure qu’avec du R-22.

-Vérifiez que l’épaisseurdutuyausoitbiende0,8.

Ne pas manipuler le tuyau vous-même (utilisateur).

Le gaz réfrigérant à haute pression peut provoquer des blessures.Vérifiez qu’il s’agisse bien du gaz

réfrigérant R-410A. Utilisez une jauge, un manifold et un tuyau. Pour R-410.

REMARQUE

Vérifiez le gaz réfrigérant

Point d’ébullition(

°C)

Pression vapeur (25°C)(kg f/cnf) Densité vapeur(25°C)(kg/m2)

R-410A -51.4 15.9 64

R-22 -40.8 9.6 44.4

Example : Split type 12,000 Btu/h

120

100

100

80

93

89

84

76

60

40

20

0

R-410A

R-22

100%

70% 50% 30%

0%

100%70%50%30%0%

Page 43

Manuel d'installation 13

FRANÇAIS

Installation

Sélectionnez le meilleur emplacement

Lire attentivement ce qui suit, puis suivre chaque point.

Groupe externe

1.

En cas de construction d’un abri de protection des rayons du soleil et de la pluie, vérifiez que l’irradiation de chaleur du

condensateur ne soit pas limitée.

2.

Vérifiez que l’espace à l’arrière et sur les côtés soit supérieur à 10 cm(3.9in). La parte avant du groupe doit avoir plus de 70

cm(27.6in) d’espace.

3.

Ne gardez pas d’animaux ou de plantes dans le flux de l’air chaud.

4.

Prenez en considération le poids du conditionneur d’air et sélectionnez une position où le bruit et les vibrations sont au

minimum.

5.

Sélectionnez un emplacement de manière à ce que l’air chaud et le bruit du conditionneur d’air ne dérangent pas les voisins.

Installations sur le toit

Si le groupe externe est installé sur un toit, vérifiez que le groupe soit bien nivelé. Assurez-vous que la structure du

toit et que le système d’ancrage soient appropriés à l’emplacement du groupe. Consultez les règles locales en ce qui

concerne le montage sur les toits.

Si l'unité extérieure est installéesurlesstructuresderacineoulesmurs,cecipeutlerésultat dans le bruit et la

vibration excessif, et peut-être aussi classed comme non l'installation utilisable.

Plus de

10cm(3.9in)

Plus de

10cm(3.9in)

Plus de 60cm(23.6in)

Plus de 60cm(23.6in)

Plus de

70cm(27.6in)

Plus de 10cm

Plus de

5cm

Plus de 8ft(2.4m)

Plus de

5cm

Groupe Interne

1.

Evitez de la chaleur et de la vapeur à côté du groupe.

2.

Sélectionnez un emplacement où il n’yapasd’obstacles en face du groupe.

3.

Assurez-vous que la vidange de la condensation puisse être correctement placée.

4.

N’installez pas à côté d’une porte.

5.

Vérifiez que l’espace sur la droite et la gauche du groupe soit supérieur à 30 cm(11.8in). Le groupe doit être installé sur la

paroi le plus haut possible, en laissant un espace minimum de 12 cm(4.7in) du plafond.

6.

Utilisez un localisateur de goujons pour les localiser et éviter ainsi d’endommager inutilement la paroi.

Installez le groupe interne sur la paroi où la hauteur à partir du plancher est supérieure à 2,3 mètres(7.6ft).

Un morceau de 7,5 mètres (24,6 pi) (minimum) est nécessaire pour minimiser la vibration et le bruit excessif.

Page 44

14 Climatiseur

Installation

Elévation et longueur des tuyaux

Dans les cas qui dépassent 5 m(16.4ft)

Groupe externe

Groupe interne

A

B

Groupe externe

Groupe interne

A

B

A

Séparateur huile

B

Groupe externe

Groupe interne

Dimensions tuyau

Capacité

(Btu/h)

Succion Évaporation

Longueur maximale

A (m)

Réfrigérant

supplémentaire(g/m)

Elévation maximale

B (m)

Longueur standard

(m)

9k

3/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

12k 1/2" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

18k

1/2" 1/4" 7.5(25) 15(49) 30(98) 20(0.22)

5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

24k 5/8" 1/4" 7.5(25) 7.5(25) 15(49) 20(0.22)

• La capacité se base sur la longueur standard et la longueur maximale permise est calculéesurlabasedelafiabilité.

• Un séparateur d’huile doit être installé tous les 5-7 mètres(16.4~23.0ft).

Page 45

Manuel d'installation 15

FRANÇAIS

Installation

Comment fixer la plaque d’installation

Pratiquez un trou dans le mur

La paroi choisie doit être résistante et solide pour

prévenir des vibrations.

Monter le plateau d’installation sur la paroi avec

quatre vis du type A. Si le groupe est monté sur un

mur en ciment, utilisez des boulons d’ancrage.

■ Montez le plateau d’installation horizontalement

en alignant la ligne de centre en utilisant un

niveau.

Mesurez la paroi et marquez la ligne centrale. Il est important de faire très attention pour l’emplacement du

plateau d’installation, d’habitude les fils électriques passent à travers les parois. Les trous pratiquésdanslemur

pour le branchement des tuyaux doivent être effectués en faisant très attention.

5-7mm

(0.2~0.3")

Interne Externe

MUR

■ Pratiquez le trou pour le tuyau avec une pointe de

70 mm(2.76in). Percez le trou vers la gauche ou

vers la droite, avec le trou légèrement en descente

vers l’extérieur.

Plaque d'installation

Vis type "A"

Crochet de la

carcasse

ABCD

S4 50 105 59 105

SE 65 110 85 110

S5 95 122 235 122

BOITIER

(Classe)

Distance (mm)

D

C

Ø70mm

Tuyauterie arrière gauche Tuyauterie arrière droite

Plaque d'installation

B

A

Ø70mm

Page 46

16 Climatiseur

Installation

La cause principale des fuites de gaz, ce sont des défauts dans le travail d’évasement. Effectuer correctement

le travail d’évasement en suivant les instructions suivantes.

Couper le tuyau et le câble

1. Utiliser les éléments pour les tuyaux accessoires

ou les tuyaux achetés localement.

2. Mesurer la distance entre le groupe externe et le

groupe interne.

3. Couper les tuyaux à une longueur légèrement

supérieure à celle qui a été mesurée.

4. Couper le câble 1,5 m(59.1in) plus long que la

longueur du tuyau.

Enlever les bavures

1. Enlever complètement les bavures de la section

coupée du tuyau.

2. Diriger l’extrémité du tuyau en cuivre vers le bas

pour éviter la chute des bavures à l’intérieur des

tuyaux.

Insertion de l’écrou

1. Enlever les écrous évasésreliés aux groupes

interne et externe, puis les insérer sur le tuyau

après avoir terminé d’enlever les bavures. (On ne

peut pas les insérer après avoir terminé le travail

d’évasage.)

Tuyau de cuivre

90°

Incliné Impair Brut

Barre

Tuyau de cuivre

Manche de la borne

Flèche rouge

Cône

Borne

Manche

Barre

"A"

Tuyau

Alésoir

Pointe vers

le bas

Tra vail d’évasage

1. Utiliser l’outil d’évasage indiqué ci-dessous pour

effectuer ce travail.

Serrer le tuyau de cuivre dans une barre ou une

forme comme indiqué dans le tableau des

dimensions ci-dessus.

Ecrou évasé

Tuyau de cuivre

Diamètre extérieur

A

mm

Pouce

mm

ø6.35 1/4 0~0.5

ø9.52 3/8 0~0.5

ø12.7 1/2 0~0.5

ø15.88 5/8 0~1.0

Travail d’évasage

Page 47

Manuel d'installation 17

FRANÇAIS

Installation

Unité intérieure

1. Préparez la tuyauterie et le raccord de

drainage de l'unité intérieure pour l'installation

à travers le mur.

2. Enlevez le support de fixation plastique de la

tuyauterie (voir l'illustration tout à côté)et

tirez du tuyau et du raccord de drainage pour

les faire sortir du boîtier.

3. Remettez à sa place originale seulement le

support 1 des tuyaux en plastique et non pas

le support 2.

Raccordement de la tuyauterie

Faites passer les tuyaux internes et le tuyau

flexible de vidange en direction de l’arrière

gauche.

Pour les tuyaux arrière gauches

Installation groupe interne

■ Accrochez l'unité interne à la partie supérieure

de la plaque d'installation. (Enclenchez les trois

crochets supérieurs arrière et inférieurs arrière de

l'unité internedanslebordsupérieur et dans le

bord inférieur de la plaque d'installation).

Assurez-vous que les crochets soient

correctement logés dans la plaque d'installation

en la déplaçantversladroiteetverslagauche.

Remarque : Siletuyauflexibledevidangepasseà

l’intérieurdelapièce, isolez le tuyau avec du

matériel isolant* pour que les gouttes éventuelles de

condensation ne provoquent pas de dommages aux

meubles et au plancher.

* Nous suggérons du polyuréthanne expansé ou

équivalent.

Tuyau de

drainage

Câble de

connexion

1 2

Stecken Sie das Verbindungskabel vom Branchez

le câble de branchement à partir du groupe

externedanslegroupeinterneà travers le trou

pour les tuyaux.

■ Ne branchez pas le ce branchez pas le câble au

groupe interne.

■ Faites un petit noeud coulant avec le câble pour le

brancher facilement plus tard.

Regroupez les tuyaux, le tuyau flexible de vidange et

le câble. Vérifiez que le tuyau flexible de vidange

soit placé en position inférieure dans le groupe. Si

vous le mettiez en position supérieure, cela pourrait

provoquer un débordement à l’intérieur du groupe.

Unité intérieure

Entretoise

Plaque d'installation

8cm

Page 48

18 Climatiseur

Installation

Entourez la section de raccord de matériel isolant.

■ Superposez le matériel d’isolation du tuyau de

raccord et le matériel d’isolation du tuyau du

groupe interne. Combinez avec du ruban

vinylique pour qu’il n’yaitpasd’espace libre.

Faites passer les tuyaux internes et le tuyau

flexible de vidange dans la position demandée

par le trou pour les tuyaux.

Bandelettes en plastique.

Matériel isolant

Ruban vinylique (étroit)

Tuyau de raccord

Câble de branchement

Ruban vinylique (large)

Entourez avec

du ruban vinylique

Tuyau

groupe

interne

Tuyau

Tuyau de raccord

Ecrou évasé

Tuyaux groupe interne

Clé torsiométrique

Clé fixe

Ruban en vinyle (étroit)

Adhésif

Tuyau de

vidange

Tuyau flexible de

vidange groupe interne

■ Quand vous allongez le tuyau flexible de vidange

du groupe interne, installez le tuyau de vidange.

■ Montez le collier de serrage sur la portéeen

utilisant la vis du type “B”.

(SE-H/P: 9k, 12k C/O: 12k)

■ Serrez l’écrou évasé avec une clé.

■ Entourez avec du ruban vinylique la zone qui

accueille la section de logement arrière des

tuyaux.

■ Réunir les tuyaux et le tuyau flexible de vidange

en les entourant de ruban vinylique dans le

secteur où ils sont insérés dans le logement

arrière des tuyaux.

Pour les tuyaux arrière droits

Branchement des tuyaux au groupe interne et le

tuyau flexible de vidange au tuyau de vidange.

■ Versez deux gouttes d’huile réfrigérant sur la face

évaséeavantd’assembler en ayant soin de ne

pas ajouter des polluants.

■ Alignez le centre des tuyaux et serrez à la main

l’écrou évasé.

Tuyaux groupe

interne

Ecrou évasé Tuyaux

Raccord

de drainage

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Diamétre extérieur

mm pouces

To rq u e

kg.m

Crampon

Entreprenneur

Vis Type "B"

Raccord

de drainage

Entourer avec du

ruban vinylique

Tuyau

Tuyau flexible

de vidange

Ruban vinylique (large)

Page 49

Manuel d'installation 19

FRANÇAIS

Installation

Introduisez le câble de branchement dans le

groupe interne.

■ Ne branchez pas le câbleaugroupeinterne.

■ Faites un petit noeud coulant avec le câble pour

un branchement plus facile plus tard.

Entourez le tuyau flexible de vidange et le câble

de branchement.

• Câble de branchement

Tuyau de

raccordement

Câble de connexion

Ruban adhésif

Raccord de

drainage

Branchement des tuyaux au groupe interne et le

tuyau flexible de vidange au tuyau de vidange.

■ Versez deux gouttes d’huile réfrigérant sur la

face évasée avant d’assembler en ayant soin de

ne pas ajouter des polluants.

■ Alignez le centre des tuyaux et serrez à la main

l’écrou évasé.

■ Serrez l’écrou évasé avec une clé.

Tuyaux groupe

interne

Ecrou évasé Tuyaux

Installation du groupe interne

■

Accrochez l'unité interne à la partie supérieure de la

plaque d'installation. (Enclenchez les trois crochets

supérieurs arrière et inférieurs arrière de l'unité

internedanslebordsupérieur et dans le bord

inférieur de la plaque d'installation). Assurez-vous

que les crochets soient correctement logésdansla

plaque d'installation en la déplaçantversladroiteet

vers la gauche.