LG GR-382R, LRTP1231xx, LRTP1231W Service Manual

SERVICE MANUAL

REFRIGERATOR

ATTENTION

Before start servicing, carefully read the safety instructions

in this manual

MODEL(S): GR-382R

LRTP1231W

Contents

Safety Precautions ----------------------------------------------- -------------------------------------- 1

Service Precautions ----------------------------------------------------------------------------------- 2-3

Specifications ------------------------------------------------------------------------------------------- 4

Feature Chart ------------------------------------------------------------------------------------------- 5

Circuit Diagram ------------------------------------------------------------------------------------------ 6-7

Cooling Systems ---------------------------------------------------------------------------------------- 8

Product Disassembly ---------------------------------------------------------------------------------- 9-11

Doors ------------------------------------------------------------- ----------------------------------------- 9

Door Switch ---------------------------------------------------------------------------------------------- 9

Electronic Control Display PCB ----------------------------------------------------------------- --- 9

Freezer Fan ---------------------------------------------------------------------------------------------- 10

Defrost Control ------------------------------------------------------------------------------------------ 10

Lamp ------------------------------------------------------------------------------------------------------- 10

Refrigerator Control Box ------------------------------------------------------------------------------ 11

Reversible Door --------------------------------------- --------------------------------------------------- 12-13

Adjustments ----------------------------------------------------------------------------------------------- 14-15

Compressor ---------------------------------------------------------------------- ------------------------ 14

PTC Starter----------------------------------------------------------------------------------------------- 14

Overload Protector (OLP) ---------------------------------------------------------------------------- 15

Troubleshooting ----------------------------------------------------------------------------------------- 16-21

Compressor & Electrical Components ------------------------------------------------------------ 16

PTC & OLP ------------------------------------ ---------------------------------------------------------- 17

Other Electrical Components ----------------------------------------------------------------------- 18

Service Diagnosis Chart ------------------------------------------------------------- ----------------- 19

Refrigerant Cycle --------------------------------------------------------------------------------------- 20-21

MICOM circuit & operation --------------------------------------------------------------------------- 22-39

Refrigerator Exploded View-------------------------------------------------------------------------- 40-41

Service Parts list----------------------------------------------------------------------------------------- 42-43

Safety Precautions.

Read the following inst ructions before servicing your refrigerator.

1. Unplug the refrigerator before

servicing.

2. Visually inspect for gas leakage or

short circuit.

3. If testing with the refrigerator

plugged in, wear rubber gloves to

avoid electric shock.

4. Do not touch frozen metal parts;

your hands could freeze to the

surface. This

5. Be sure that no water is dripping

may cause frostbite.

towards electrical or metal parts.

6. If you check the bottom part of the

refrigerator while the freezer

door is open, be careful standing

up. You

could bump your head.

7. When you tilt your refrigerator be

sure to take out all metal, glass, or

other loose

parts.

8. When servicing the evaporator,

wear cotton gloves to prevent cutting

by any of

the evaporator fins.

1

Service Precautions

Refrigerant Recharging

Test the compressor's operation before

recharging the refrigerant; this is very

important to detect failures and to

ensure the proper motor running, and

to identify failures immediately. If

failure has been detected, clean the

system from any other possible

R-134a residues by breaking the final

part of the compressor's service pipe

at it's thinnest part as shown in Fig. #1.

Replace the filter and any other part

that could be deteriorated. Unweld

and pull out the service pipe,

then place a new pipe extension with a

Hansen male connector and solder

the new pipe. See Fig. #2

0(absolute or -1 atm, -760 mm Hg.) It

is not recommend to run the vacuum

pump for more than 30 minutes. See

Figure 3.

In case there is a large leak and the

vacuum operation must stop,

you must add a small amount of

refrigerant to the system and check

with an electronic leak detector. If a

soldering failure is detected, open the

valve before soldering to equalize the

pressure and keep solder from being

blown out of the joint or sucked into

the piping.

It is necessary to open the valve

when soldering to allow the gases to

escape without forcing the molten

solder out of the joint. The extension

with the male Hansen connector

should be connected to a female type

connector to the vacuum pump's pipe.

See Fig. #3

System air evacuation starts as soon

as the pump begins to run. The

system must be kept under vacuum

until the low pressure gauge shows

As soon as the repair is completed,

charge the correct amount of

refrigerant into the system.

Remember that each system requires

a specific amount of refrigerant with a

tolerance of ±5 grams. See Figure 4.

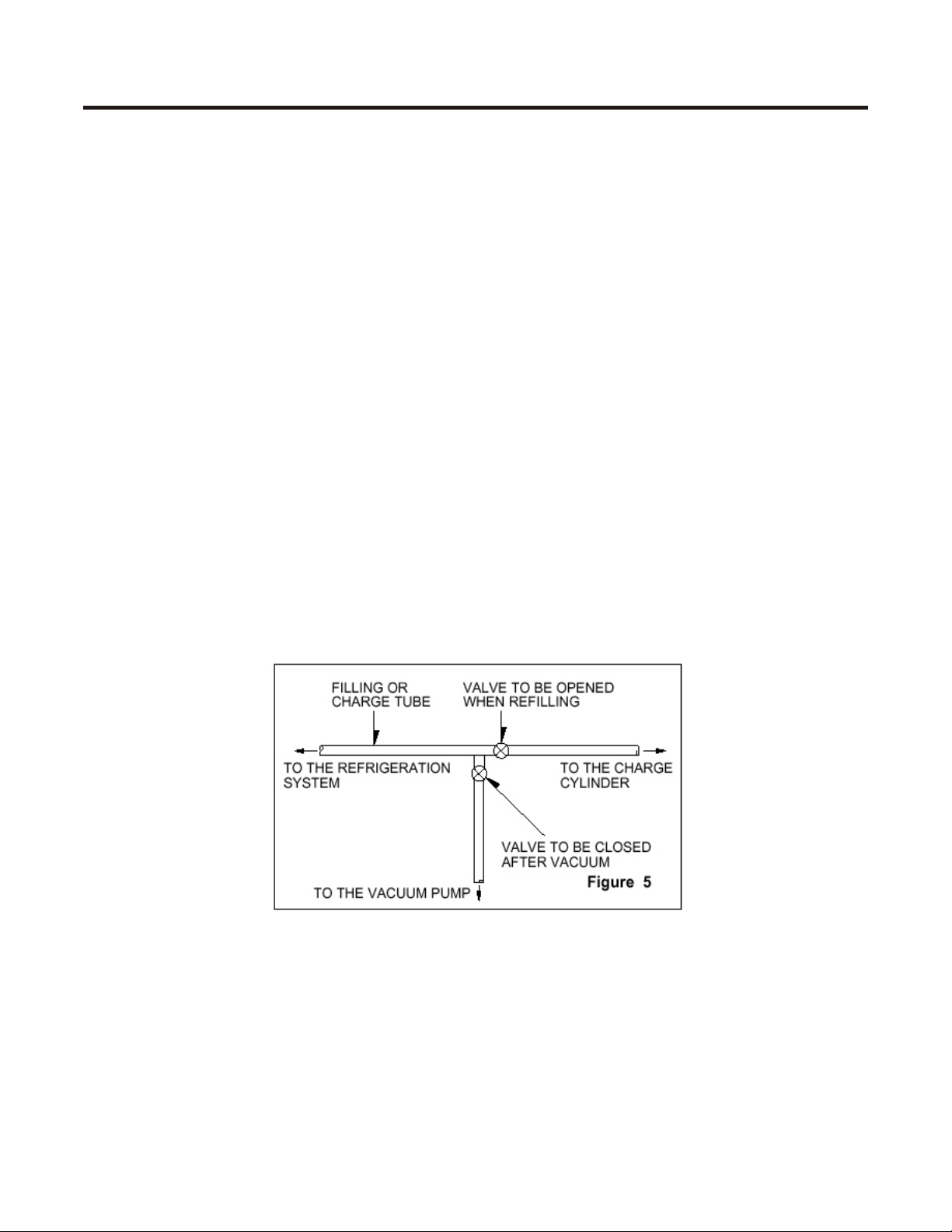

Before performing this operation (if

the vacuum pump and charging

cylinder are still attached to the

system) be sure the valve between

the pump and the cylinder is closed to

2

Service Precautions

keep refrigerant out of the system.

See Figure 5.

For gas charging, check the

graduated scale on the cylinder to see

the amount of refrigerant that it

contains and the amount that will be

pumped into the system. For

example, if you have 750 grams of

refrigerant in the cylinder and we

have to pump 165 grams to the

system, this amount will be reached

when the indicator reaches 585

grams; remember that the indicator

shows a lower level of meniscus.

Do this after choosing the scale

corresponding to the gas pressure

indicated on the pressure indicator

located on the upper part of the

column. To let R-134a flow into the

system, open the valve at the

recharging cylinder's base. The total

amount of refrigerant should not be

installed in one session, as it could

block the compressor. Install 20~30

grams at a time and close the valve.

The compressor will run and the

pressure will drop. Then open the

valve and install other 20~30 grams

of refrigerant. Repeat this procedure

until the entire amount has been

added to the system. Under operating

conditions, the system pressure

should stabilize between 0.3 and 0.6

atm.

3

Feature Chart

FREEZER

Temperature

Control

Shelf

Ice Trays

Twist´n Serve

REFRIGERATOR

Temperature

Control

Fresh Meat

Tray

Lamp

Shelves

(Plastic or Glass)

Deodorizer

(Absorbs

Odors)*

Multi Air Flow

Air flow distributor

Freezer

Door Baskets

Refrigerator

Door Baskets

Vegetable Tray

(Keeps fruits and

vegetables fresh)

MODEL(S): GR-382R

LRTP1231W

* This part is only included in model LRTP1231W

Magic Crisper

(Vegetable Tray cover

that control humidity)

5

Leveling

Screws

Graphic Circuit Diagram

Brown

Red

Pink

Yellow

Blue

Violeta

Whitte

White

White

White

Brown

Red

Red

Blue

Orange

Orange

Yellow

Blue

c

C

C

Brown

Red

Orange

Orange

Blue

Black

Switch

Violet

Yellow

Thermal Fuse

Defrost Resistance

Evaporator

Defrost Resistance

Fan

(Heater Cord)

Sensor

Lamp

Control

Sensor

Brown

Blue

Red

Blue

Sensor

CON2

Defrost and Temperature Electronic Control

CON1

Black

Yellow

Blue

Black

Fan

Motor

Blue

AC Current

Brown

Pink

Blue

Pink

Black

OLP

M

Running Capacitor

COMPRESSOR

7

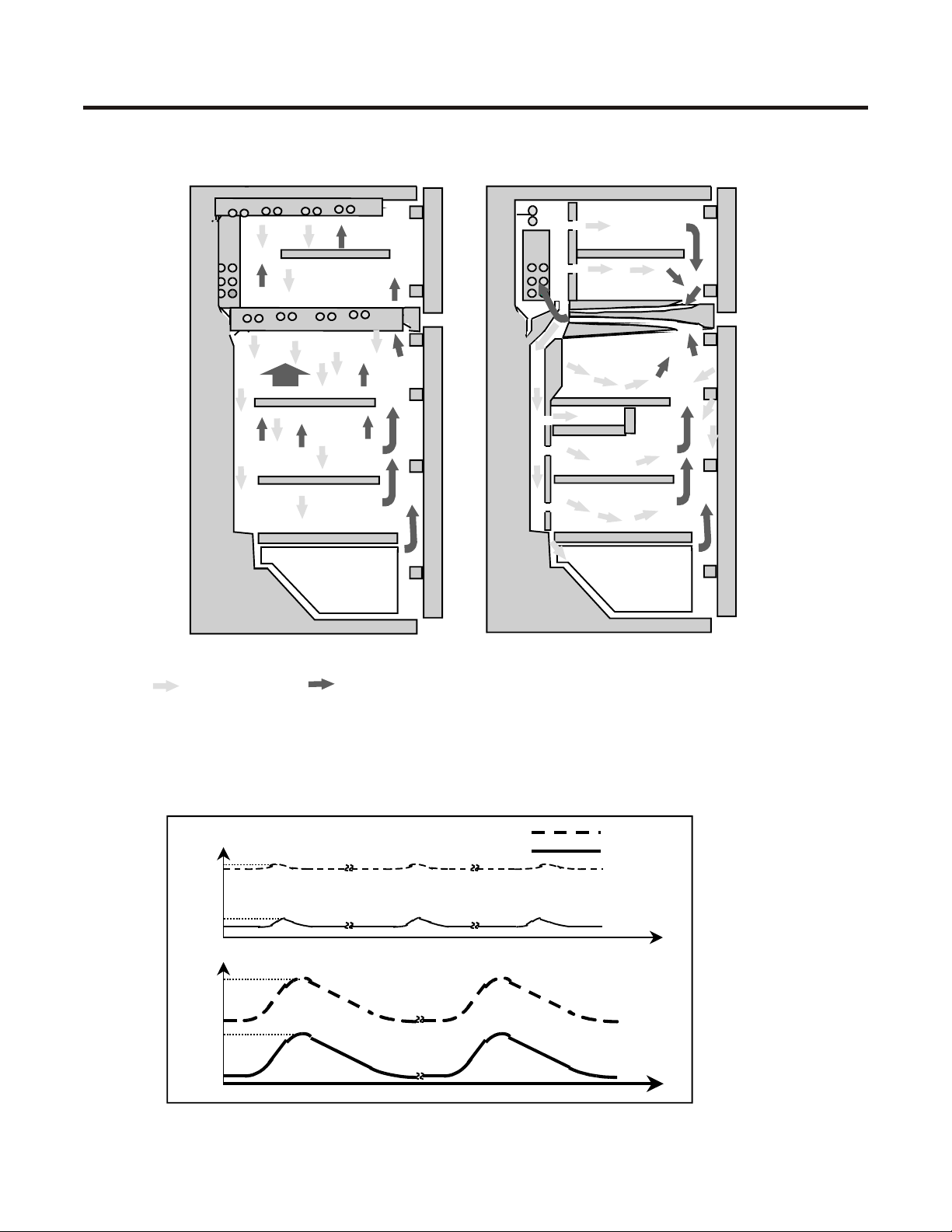

Cooling Systems

Direct System Indirect System

Important: Check that the air ducts are not

Cold Air

Temperature variation during defrosting time, depending upon the cooling system .

Temp.( ? )

4

3

-16

-18

Temp.( ? )

18

Warm Air

obstructed for a better cooling

performance.

Indirect System

Direct System

Refrigerator

Freezer

Tim

e

3

-3

-18

Tim

e

8

3. Product Disassemble.

Doors

Freezer Door

1. Remove hinge cover by pulling it

upwards.

2. Loosen the hexagonal bolts that

hold the upper hinge in place. See

Figure 1.

3. Remove door. See Figure 2.

Figure 1

Figure 2

4. Pull gasket to remove it. See

Figures 3 and 4.

2. Disconnect all switche's cables.

See Figure 8

Figure 7

Figure 8

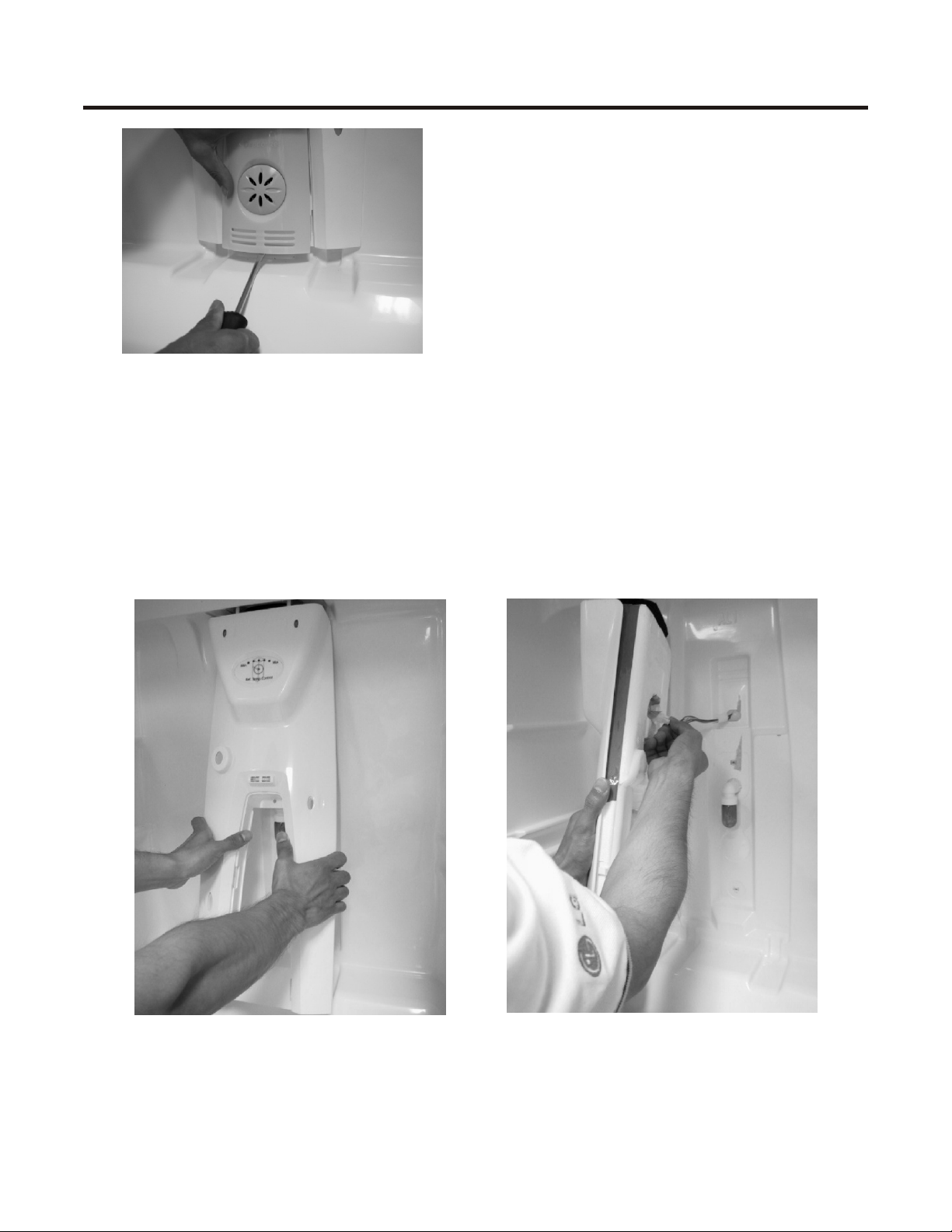

Control Circuit ( Display PWB)

1. Remove the lamp cover by

inserting a screwdriver in the lower

side's holes. See Figure 9.

2. Loosen and remove the 2 screws.

See Figure 10.

Figure 3

Figure 4

Refrigerator Door.

1. Loosen the hexagonal bolts that

hold the central hinge in place.

See Figure 5.

2. Remove refrigerator door. See

Figure 6.

3. Pull out the gasket to remove it

from the door. See Figure 4 from

Freezer door.

Figure 5

Figure 6

Door Switch

1. Pull out the door switch out using

a flat head screwdriver. See

Figure 7

Figure 9 Figure 10

3. Pull out the Control Box. See

Figure 11.

4. Disconnect the connector from the

cable terminal. See Figure 12.

5. Remove the EPS Multi air duct

(insulation) from the control box.

6. Detach the electronic control

(Display, PWB). See Figure 13.

Figure 11

Figure 12

9

Figure 13

Fan and Fan Motor.

1. Remove freezer shelf.

3. Remove the ice bin assembly by

pulling it to the right side, until it

snaps out.

4. Remove Grill Fan screw cover.

See Figure 14.

5. Loosen the screw. See Figure 15.

6. Pull out the fan cover. Figure 16.

Defrost Control Assembly

1. The defrost control assembly

consists of one thermistor and a

fuse that melts with heat.

2. The termistor's function is to

sense the compartment's

temperature and automatically

stop the defrost. The termistor is

located beside of the evaporator

bracket.

3. The melting fuse is a safety device

to prevent an overheating of the

defrosting resistance when it

operates.

4. The fuse melts at 162° F and the

resistance heater stops.

5. To replace this components,

please follow the steps mentioned

at Figure 18.

Figure 14

Figure 15

6. Unplug the connector.

7. Remove the fan holder shroud.

Figure 17.

8. Remove fan and loosen both

screws that hold the bracket.

9. Remove the motor bracket and the

rubber parts. Pull out the fan

motor. See Figure 17.

Figure 16

Figure 17

1. Figure 18. Unplug the connector plugged to

Lamp.

Refrigerator Compartment Lamp

1. Remove the lamp cover with

a screwdriver or a similar tool.

See Figure 19.

2. Remove the lamp by unscrewing it

counterclockwise and replace it

with the same specifications

(125V,20W). Part Number

6912JB2002J.

10

Figure 13

Figure 19

Refrigerator Control Box.

Remove the lamp cover as mentioned

before.

1. Loosen the screws.

2. Remove the entire control box.

See Figure 20.

3. Disconnect the control box

connector. See Figure 21.

Figure 20 Figure 21

11

4. Reversible Door

PRECAUTION

1. Before reversing the doors, remove all foods and accesories,

like shelves or trays, which are not attached to the doors.

2. Use a Philips screwdriver, bolt driver, torque wrench, or spanner to

tighten and loosen the bolt.

3. Be careful not to drop the refrigerator or door when assembling or

disassembling lower hinge or the Adjustable Screw Assembly.

4. Don´t lay the refrigerator down to work on it. It will cause

malfunction.

5. The doors may be reversed to provide left or right opening, depending upon the customer´s

preference.

HOW TO REPLACE THE DOOR OPENING LEFT TO RIGHT

(when converting from left-opening to right opening)

12

13 14

Loading...

Loading...