Page 1

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

REFRIGERATOR

SERVICE MANUAL

models

LRTN19310

**

LRTN22310

**

Page 2

CONTENTS

SAFETY PRECAUTIONS ....................................................................................................................................................... 2

SPECIFICATIONS................................................................................................................................................................... 3

PARTS IDENTIFICATION....................................................................................................................................................... 4

DISASSEMBLY.................................................................................................................................................................... 5-6

DOOR................................................................................................................................................................................... 5

DOOR SWITCH.................................................................................................................................................................... 5

FAN AND FAN MOTOR........................................................................................................................................................ 6

DEFROST CONTROL ASSEMBLY...................................................................................................................................... 6

LAMP.................................................................................................................................................................................... 6

CONTROL BOX-REFRIGERATOR...................................................................................................................................... 6

ADJUSTMENT..................................................................................................................................................................... 7-8

COMPRESSOR.................................................................................................................................................................... 7

PTC-STARTER..................................................................................................................................................................... 7

OLP (OVERLOAD PROTECTOR) ....................................................................................................................................... 8

TO REMOVE THE COVER PTC...........................................................................................................................................8

CIRCUIT DIAGRAM................................................................................................................................................................ 9

TROUBLESHOOTING..................................................................................................................................................... 10-15

COMPRESSOR AND ELECTRICAL COMPONENTS ....................................................................................................... 10

PTC AND OLP.................................................................................................................................................................... 11

OTHER ELECTRICAL COMPONENTS ............................................................................................................................. 12

SERVICE DIAGNOSIS CHART.......................................................................................................................................... 13

REFRIGERATION CYCLE............................................................................................................................................ 14-15

DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ............................................................................................... 16-25

EXPLODED VIEW & REPLACEMENT PARTS LIST ......................................................................................................... 26-

SAFETY PRECAUTIONS

Please read the following instructions before servicing your

refrigerator.

1. Check the refrigerator for electrical faults.

2. To prevent electric shock, unplug before servicing.

3. Always check line voltage and amperage.

4. Use standard electrical components or cause your skin

to freeze and stick to the surfaces inside the freezer.

5. Don't touch metal products in the freezer with wet

hands. This may cause frostbite.

6. Prevent water from spiling onto electric elements or the

machine parts.

- 2 -

7. Close the top door before opening the bottom door.

Otherwise, you might hit your head when you stand up.

8. When tilting the refrigerator, remove any materials on

the refrigerator, especially the glass shelves and stored

food.

9. When servicing the evaporator, wear cotton gloves.

This is to prevent injuries from the sharp evaporator

fins.

10. Service on the refrigerator should be performed by a

qualified technician. Sealed system repair must be

performed by a CFC certified technician.

Page 3

1. SPECIFICATIONS

Ref. No.: 19Cuft / 22Cuft

ITEMS SPECIFICATIONS

DOOR DESIGN Slide Rounded

755 X 806

DIMENSIONS (mm)

NET WEIGHT (kg)

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM

DOOR FINISH VCM

HANDLE TYPE Bar

INNER CASE ABS Resin

INSULATION Polyurethane Foam

X 1664 (W X D X H

831

X 806 X 1715 (W X D X H

91 (19 cu.ft)

101 (22 cu.ft)

Full Automatic

Heater Defrost

) - 19 Cu.ft

) - 22 Cu.ft

ITEMS SPECIFICATIONS

VEGETABLE TRAY Opaque Drawer Type

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (155 g)

LUBRICATING OIL Freol@10G (310 cc)

DEFROSTING DEVICE SHEATH HEATER

LAMP REFRIGERATOR 60 W (1EA)

- 3 -

Page 4

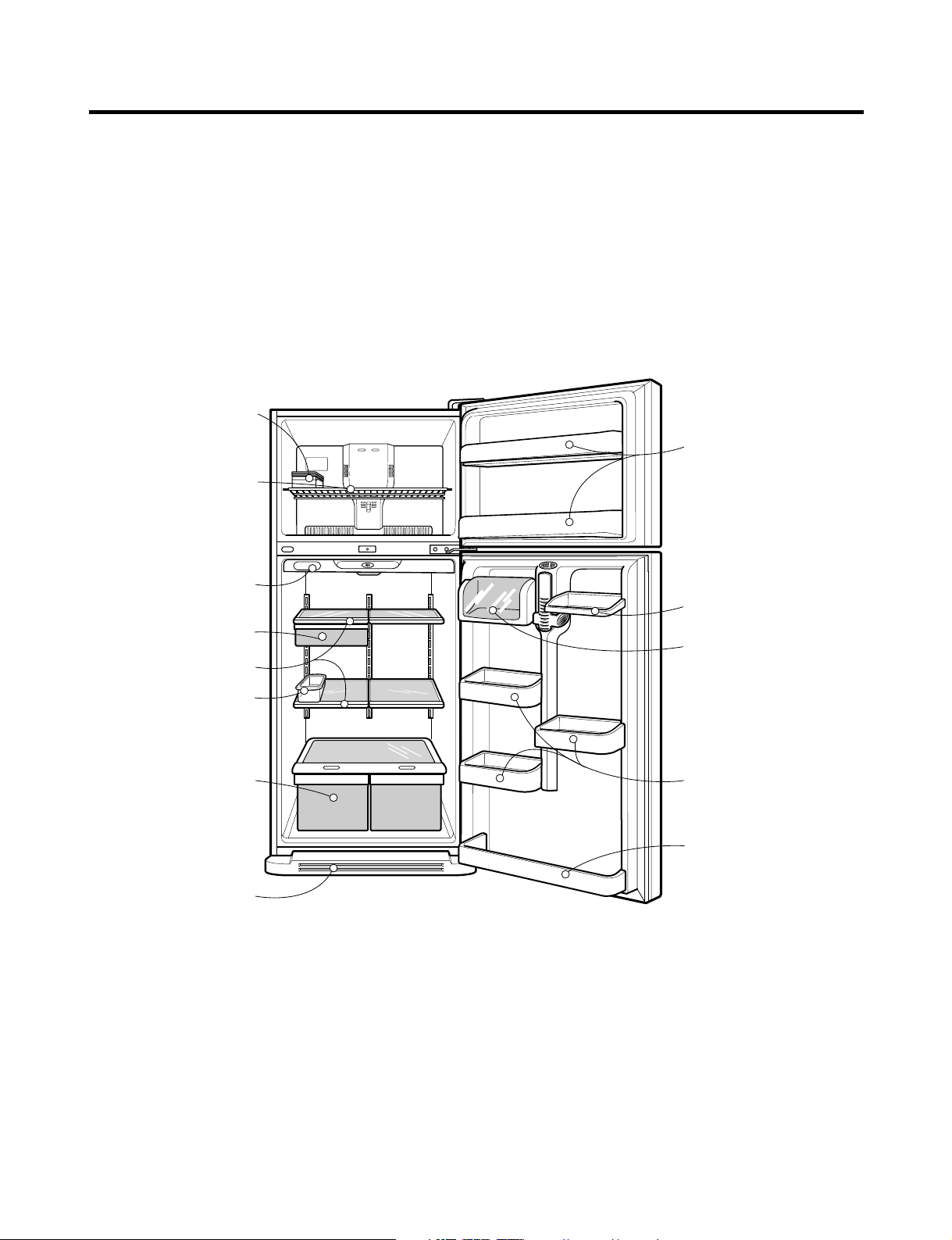

2. PARTS IDENTIFICATION

FREEZER

COMPARTMENT

REFRIGERATOR

COMPARTMENT

Ice Bin

Freezer Shelf

Digital Sensor

Control

Snack Corner

Shelves

Crisper

Keeps fruits

and vegetables

fresh and crisp.

Freezer Door Bin

Door Bin

Egg Tray

Refrigerator Door

Rack

Base Grille

Can Dispenser

Dairy Bin

- 4 -

Page 5

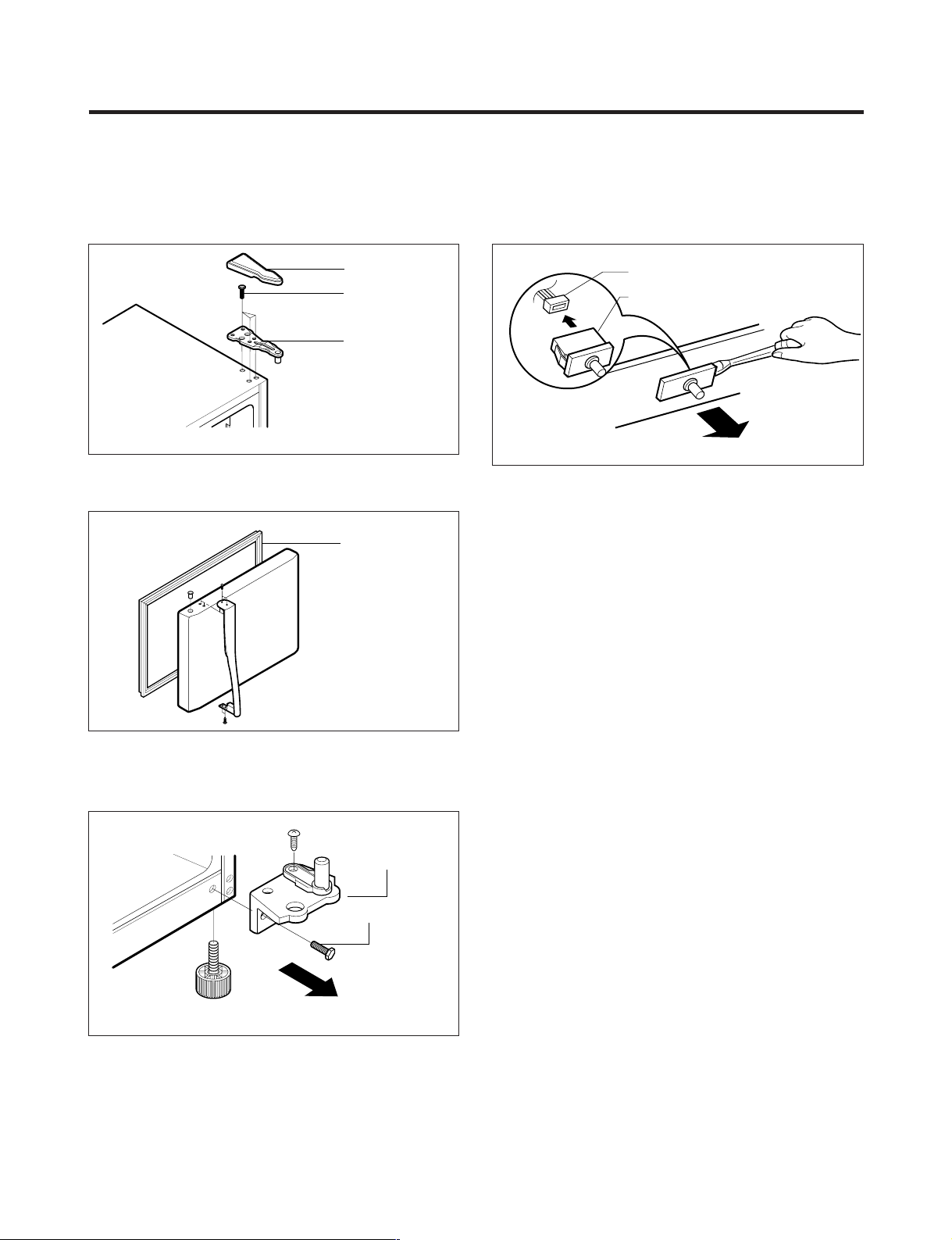

3. DISASSEMBLY

BOLT

HINGE

HINGE COVER

GASKET

LOWER HINGE

BOLT

DOOR SWITCH

LEAD WIRE

3-1 DOOR

● Freezer Door

1. Remove the hinge cover by pulling it upwards.

2. Loosen hexagonal bolts attaching the upper hinge to the

body and lift the freezer door.

Figure 1

3. Pull out the door gasket to remove from the door foam

assembly.

3-2 DOOR SWITCH

1. To remove the door switch, pry it out with a slotted-type

driver, as shown in (Figure 4).

2. Disconnect the lead wire from the switch.

Figure 4

Figure 2

● Refrigerator Door

1. Loosen hexagonal bolts attaching the lower hinge to the

body to remove the refrigerator door only.

Figure 3

2. Pull out the door gasket to remove from the door foam

assembly.

- 5 -

Page 6

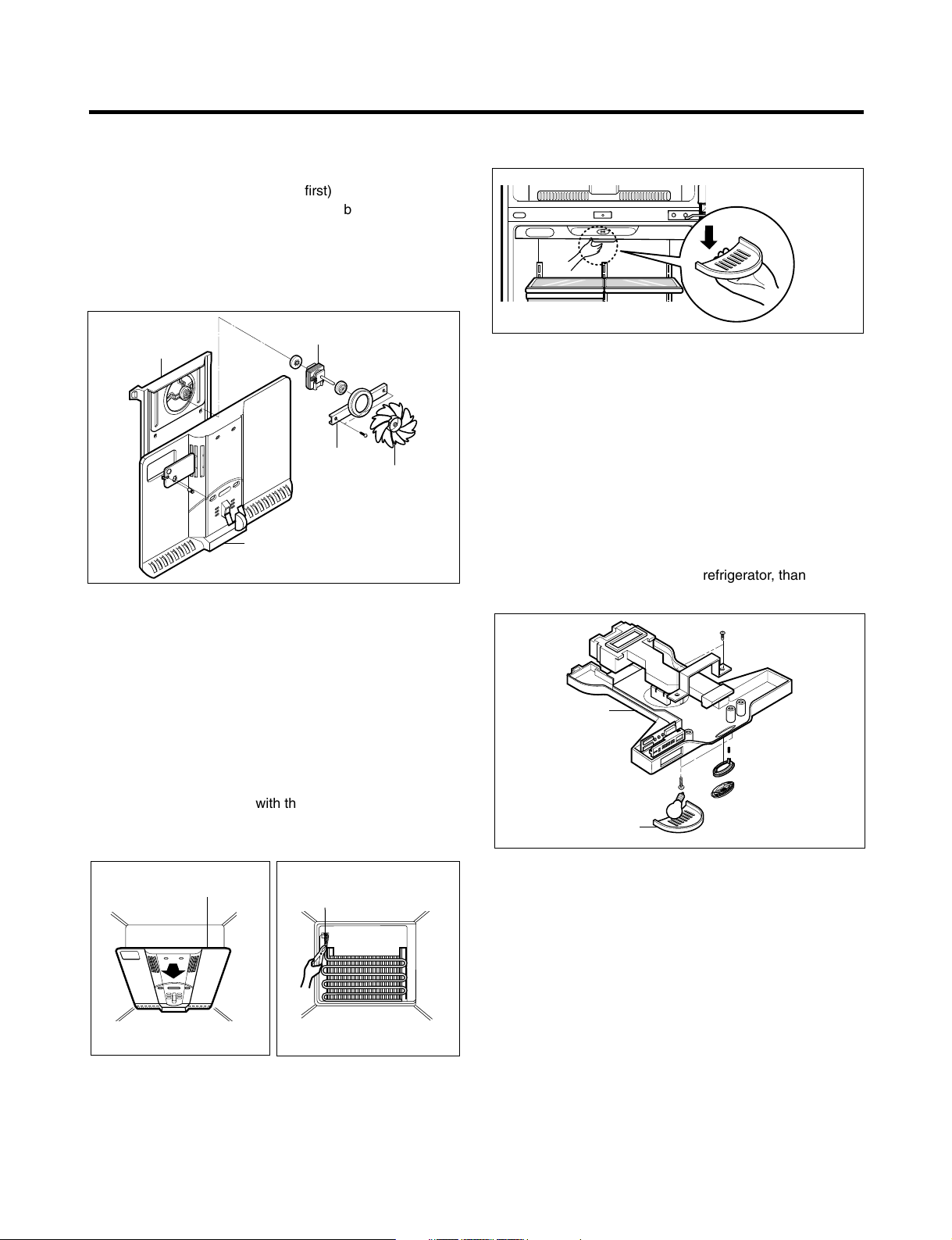

3-3 FAN AND FAN MOTOR

FAN

BRACKET

SHROUD

GRILLE

FAN MOTOR

GRILLE ASSEMBLY

DEFROST-CONTROL

ASSEMBLY

1. Remove the freezer shelf. (If your refrigerator has an

icemaker, remove the icemaker first)

2. Remove the grille by pulling it out and by loosening a

screw.

3. Remove the Fan Motor assembly by loosening 4 screws

and disassemble the shroud.

4. Pull out the fan and separate the Fan Motor and Bracket.

3-5 LAMP

Figure 8

3-5-1 Refrigerator Compartment Lamp

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Release the hooks on both ends of the lamp shield and

pull the shield downward to remove it.

4. Turn the lamp counterclockwise.

5. Assemble in reverse order of disassembly. Replacement

bulb must be the same specification as the original

(Max. 60 W-1EA).

3-4 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and

FUSE–M.

Defrost sensor functions to defrost automatically. It is

attached to metal side of the Evaporator and senses

Temperature. At the temperature of 162°F(72°C), it stops

the emission of heat from the Heater.

Fuse-M is a safety device for preventing over-heating of

the Heater when defrosting.

1. Pull out the grille assembly. (Figure 6)

2. Separate the connector with the Defrost Control

assembly and replace the Defrost Control assembly

after cutting the Tie Wrap. (Figure 7)

Figure 5

3-6 CONTROL BOX-REFRIGERATOR

1. First, remove all shelves in the refrigerator, than remove

the Refrigerator Control Box by loosening 2 screws.

CONTROL BOX

COVER LAMP

2. Remove the Refrigerator Control Box by pulling it

downward.

3. Disconnect the lead wire on the right position and

separate the lamp sockets.

Figure 9

Figure 6

Figure 7

- 6 -

Page 7

4. ADJUSTMENT

PTC STARTER

SEALED

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

3

6

5

2

S

PTC

OVERLOAD PROTECTOR

RSCR

N

L1

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use

extreme caution when repairing it.

4-1-3 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

Particular Compressor in your product.

(4) Keep Compressor dry.

If Compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result.

(5) When replacing the Compressor, be careful that dust,

humidity, and soldering flux don’t contaminate the inside

of the compressor. Dust, humidity, and solder flux

contaminate the cylinder and may cause noise or

improper operation even cause it to lock up.

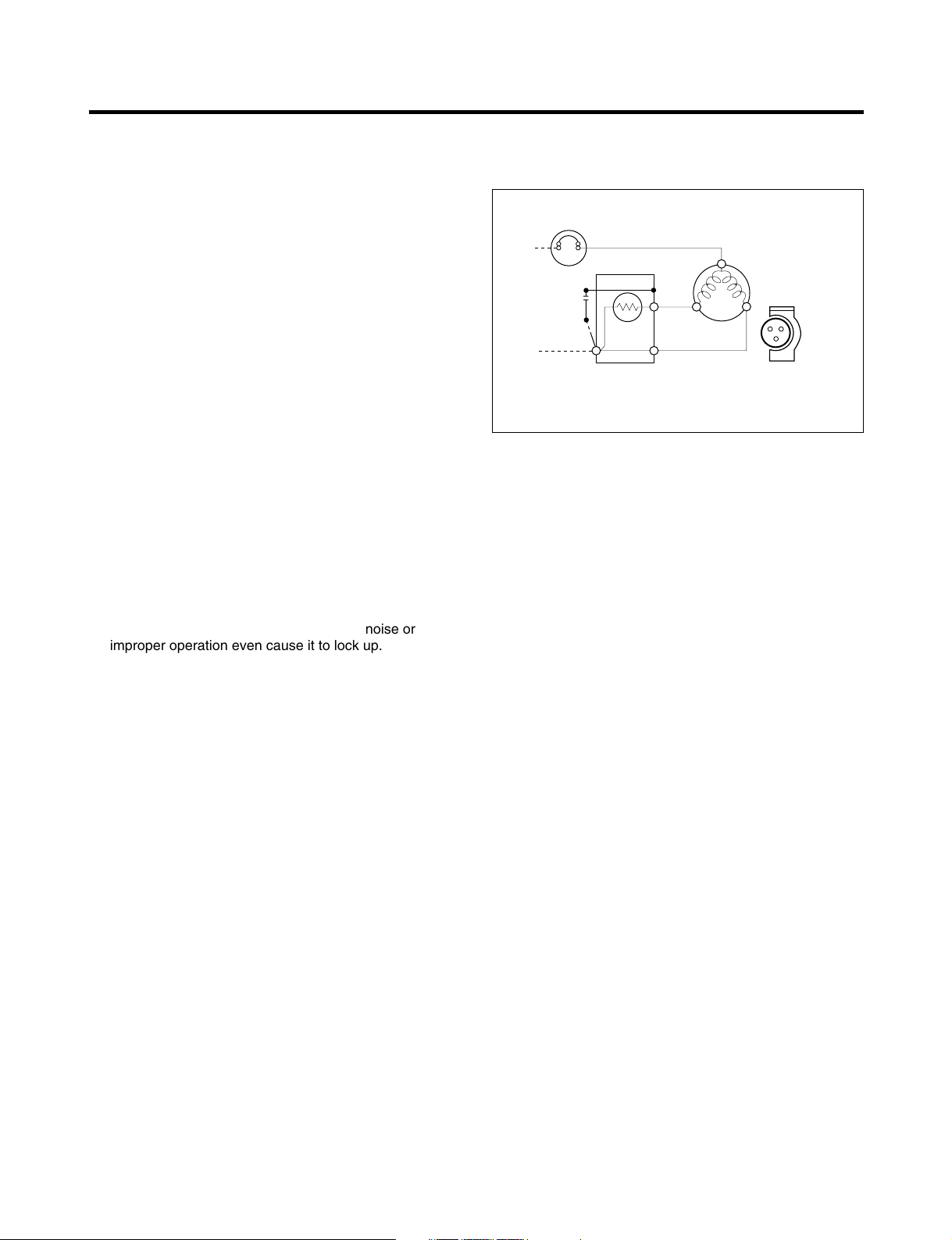

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic

material consisting of BaTiO

(2) The higher the temperature is, the higher the resistance

value. These features are used as a starting device for

the Motor.

4-2-2 Role of PTC-Starter

(1) The PTC is attached to the Sealed Compressor and is

used for starting the Motor.

(2) The compressor is a single-phase induction motor.

Durign the starting operation, the PTC allows current

flow to both the start winding and main winding.

3.

4-2-3 PTC-Applied Circuit Diagram

● Starting Method for the Motor

Figure 10

4-2-4 Motor Restarting and PTC Cooling

(1) It requires approximately 5 minutes for the pressure to

equalize before the compressor can start.

(2) The PTC device generates heat during operation.

Therefore, it must be allowed to cool before the

compressor can restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the compressor attempts to restart before the PTC

device is cooled, the PTC device will allow current to

flow only to the main winding.

(2) The OLP will open because of the over current

condition. This same process will continue (3 to 5

times) when the compressor attempts to restart until

the PTC device has cooled. The correct OLP must be

properly attached to prevent damage to the

compressor.

4-2-6 Note for Using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the PTC,

PTC materials may fail due to breakdown of their

insulating capabilities.

(4) If the exterior of the PTC is damaged, the resistance

value may be altered. This can cause damage to the

compressor and result in a no-start or hard-to-start

condition.

(5) Always use the PTC designed for the compressor and

make sure it is properly attached to the compressor.

- 7 -

Page 8

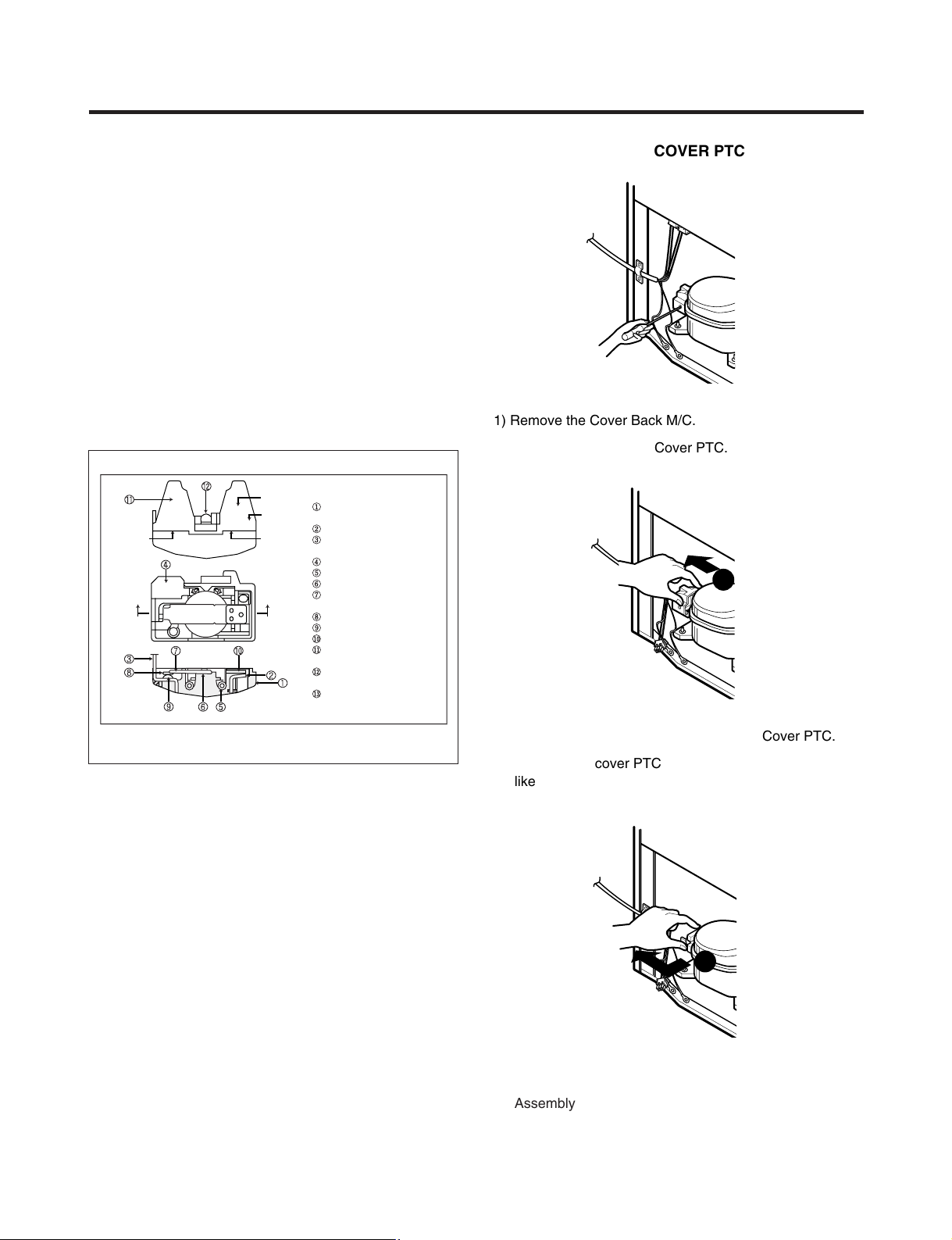

4-3 OLP (OVERLOAD PROTECTOR)

Part

Customer part

number

Lot code/

date code

330 FBYY -S1 BOX98

12345678

Physical

termination

part number

Electrical

characteristics

part number

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V -0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

Quick-connect terminal, brass,

conforms to UL 310, MEMA

DC-2, DIN 46344

(OVERLOAD PROTECTOR cross section)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by opening the

circuit to the Motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the Compressor motor, the

Bimetal works by heating the heater inside the OLP,

and the OLP protects the Motor by cutting off the

current flowing to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Sealed Compressor used

for the Refrigerator. It prevents the Motor Coil from

being started in the Compressor.

(2) For normal operation of the OLP, do not turn the Adjust

Screw of the OLP in any way.

4-4 TO REMOVE THE COVER PTC

1) Remove the Cover Back M/C.

(2) Remove the screw on Cover PTC.

1

Figure 11

(3) Remove two Housings on upper part of Cover PTC.

(4) Take out the cover PTC from upper to lower position

like .

2

(5) Turn 45° in the direction of and take it out.

(6) Assembly in reverse order of disassembly.

- 8 -

Page 9

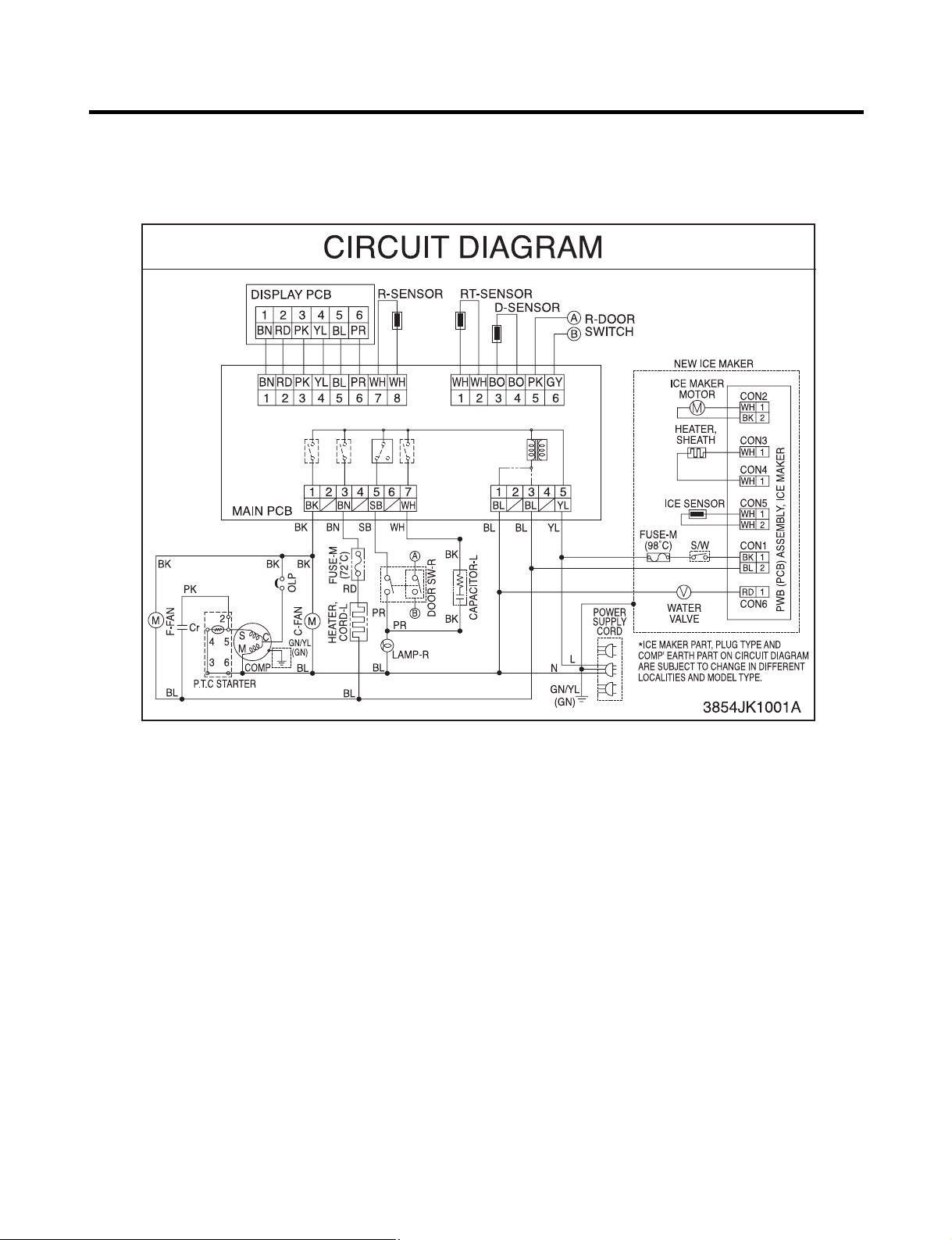

5. CIRCUIT DIAGRAM

GOOD MODEL

- 9 -

Page 10

6. TROUBLESHOOTING

Readings OK

Open or short

1

2

3

4

5

2

5

5

3

5

4

5

5

1

43

YES

YES

Readings OK

Readings OK

Open or short

Open or short

YES YES

NO

NO

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

Power Source.

Check

resistance of

Motor

Compressor.

Remove PTC-Starter

from Compressor and

measure voltage

between Terminal C of

Compressor and

Terminals 5 or 6 of PTC.

No Voltage.

Applied voltage isn't

in range of Rating

Voltage ±10%.

Check resistance

between M-C, S-C and

M-S in Motor

Compressor.

Check

resistance of

PTC-Starter.

Check resistance of

two terminals in

PTC-Starter.

Check OLP.

Check resistance of

two terminals in OLP.

(Reated Voltage

±10%)?

OLP disconnected?

Advise customer that

power supply needs to be

checked by an electrician.

Replace

Compressor.

Replace OLP.

Check connection

condition.

Reconnect.

Replace

PTC-Starter.

Replace OLP.

Check

starting state.

Check the power supply

under load.

(Compressor attempting

to re-start after being off

for 5 minutes).

Supply

voltage

rating with

±10%.

Did

compressor

start?

- 10 -

Compressor

is OK

Replace the

compressor

Page 11

6-2 PTC AND OLP

65

Shows continuity

Open

Normal operation of

Compressor is

impossible or poor.

Separate PTC-Starter

from Compressor and

measure resistance

between No. 5 and 6

of PTC-Starter with a

Tester.(Figure 12)

Separate OLP from

Compressor and check

resistance value

between two terminals

of OLP with a Tester.

(Figure 13)

Observation value is

115V/60Hz : 6.8Ω±30%

The resistance value

is 0Ω (short) or

∞ (open).

Check another

electric component.

Replace OLP.

Check another

electric component.

Replace PTCStarter

Figure 12

Figure 13

- 11 -

Page 12

6-3 OTHER ELECTRIC COMPONENTS

▼ Not cooling at all

Compressor

doesn't run.

▼ Poor cooling performance

Compressor runs

poorly.

Check for open short or

incorrect resistance readings

in the following components

a. Starting devices

b. OLP

c. Compressor coil

d. Wiring harness

Check a starting

voltage.

Check voltage at

starting devices.

Check current at

Compressor.

Cause

Short, open or broken.

Poor contact

or shorted.

Coil open or shorted.

Poor contact

or shorted.

Low voltage.

Poor or broken or

open contact.

Shorted.

Replace

indicated component.

Raise voltage.

Replace

indicated component.

Fan motor

doesn't run.

Heavy frost buildup on

EVAPORATOR.

Check rating of OLP.

Check wiring circuit.

Check Fan Motor.

Check current flow in

the following

components:

sensor

Fuse-M

Check current flow in

the Defrost Heater.

Lack of capacity.

Wire is open or

shorted.

Coil is shorted or

open.

Open.

Open.

Replace

indicated component.

Replace

indicated component.

Replace

Defrost Heater.

- 12 -

Page 13

6-4 SERVICE DIAGNOSIS CHART

COMPLAINT POINTS TO BE CHECKED REMEDY

No Cooling.

Cools poorly.

Foods in the

Refrigerator

are frozen.

Condensation or ice

forms inside

the unit.

Condensation forms

in the Exterior Case.

There is abnormal

noise.

• Is the power cord unplugged from the outlet?

• Check if the power Switch is set to OFF.

• Check if the fuse of the power Switch is shorted.

• Measure the voltage of the power outlet.

• Check if the unit is placed too close to the wall.

• Check if the unit is placed too close to the stove,

gas cooker, or in direct sunlight.

• Is the ambient temperature too high or

the room door closed?

• Check if food put in the refrigerator is hot.

• Did you open the door of the unit too often

or check if the door is sealed properly?

• Check if the Control is set to Warm position.

• Is food placed in the cooling air outlet?

• Check if the control is set to colder-position.

• Is the ambient temperature below 41°F(5°C)?

• Is liquid food sealed?

• Check if food put in the refrigerator is hot.

• Did you open the door of the unit too

often or check if the door is sealed properly?

• Check if the ambient temperature and humidity

of the surrounding air are high.

• Is there a gap in the door gasket?

• Is the unit positioned in a firm and even place?

• Are any unnecessary objects placed

in the back side of the unit?

• Check if the Drip Tray is not firmly fixed.

• Check if the cover of the compressor enclosure

in the lower front side is taken out.

• Plug into the outlet.

• Set the switch to ON.

• Replace the fuse.

• If the voltage is low, correct the wiring.

• Place the unit about 10 cm from the wall.

• Place the unit away from these heat sources.

• Lower the ambient temperature.

• Put in foods after they have cooled down.

• Don't open the door too often and close

it firmly.

• Set the control to Recommended-position.

• Place foods in the high-temperature section.

(front part)

• Set the control to Recommended-position.

• Set the control to Warm-position.

• Seal liquid foods with wrap.

• Put in foods after they have cooled down.

• Don't open the door too often and close

it firmly.

• Wipe moisture with a dry cloth. It will disappear

in low temperature and humidity.

• Fill up the gap.

• Adjust the Leveling Screw, and position

in a firm place.

• Remove the objects.

• Fix the Drip Tray firmly in the original position.

• Place the cover in its original position.

Door does not

close well.

Ice and foods

smell unpleasant

● Other possible problems:

Check if frost forms in

the freezer.

Check the

refrigeration system.

Check the

Thermistor.

• Check if the door gasket is dirty with

an item like juice.

• Is the refrigerator level?

• Is there too much food in the refrigerator?

• Check if the inside of the unit is dirty.

• Are foods with a strong odor unwrapped?

• The unit smells of plastic.

Not

defrosting.

The system

is faulty.

The operation of

the Thermistor is

incorrect.

• Clean the door gasket.

• Position in the firm place and level the

Leveling Screw.

• Make sure food stored in shelves does not prevent

the door from closing.

• Clean the inside of the unit.

• Wrap foods that have a strong odor.

• New products smell of plastic, but this

will go away after 1-2 weeks.

Check Components

of the defrosting

circuit.

Perform sealed

system repair.

Replace the

Thermistor.

- 13 -

Page 14

6-5 REFRIGERATING CYCLE

YES

YES

▼ Troubleshooting Chart

CAUSE

PARTIAL Freezer Low flowing sound of A little higher • Refrigerant level is low due

LEAKAGE compartment and Refrigerant is heard and than ambient • to a leak.

LEAKAGE

COMPLETE Freezer Flowing sound of refrigerant Equal to ambient • No discharging of Refrigerant.

LEAKAGE compartment and is not heard and frost isn't temperature. • Normal cooling is possible by

RESTRICTED BY DUST

PARTIAL Freezer Flowing sound of refrigerant A little higher • Normal discharging of the

RESTRICTION

WHOLE

RESTRICTION

MOISTURE Cooling operation Flowing sound of refrigerant Lower than • Cooling operation restarts

RESTRICTION

COMPRESSION

COMP- Freezer and Low flowing sound of A little higher • Low pressure at high side

DEFECTIVE

RESSION Refrigerator refrigerant is heard and ambient • of compressor due to low

STATE OF

THE UNIT

Refrigerator don't frost forms in inlet only. temperature. • Normal cooling is possible by

cool normally. • restoring the normal amount of

Refrigerator don't formed. • restoring the normal amount of

cool normally. • refrigerant and repairing the leak.

compartment and is heard and frost forms than ambient • refrigerant.

Refrigerator don't in inlet only. temperature. • The capillary tube is faulty.

cool normally.

Freezer

compartment and

Refrigerator don't cool.

stops periodically. is not heard and frost melts. ambient • when heating the inlet of the

don't cool. frost forms in inlet only. temperature. • refrigerant level.

STATE OF THE

EVAPORATOR

Flowing sound of refrigerant Equal to ambient • Normal discharging of the

is not heard and frost isn't temperature. • Refrigerant.

formed.

TEMPERATURE

OF THE

REMARKS

COMPRESSOR

• refrigerant and repairing the leak.

temperature. • capillary tube.

NO COMP- No compressing Flowing sound of refrigerant Equal to ambient • No pressure in the high

RESSION operation. is not heard and there is temperature. • pressure part of the

no frost. • compressor.

▼ Leakage Detection

● Observe the discharging point of the refrigerant, which may be in the oil discharging part of the compressor and in a hole

in the evaporator.

Check if compressor

runs.

Frost formed normally

Moisture Clog

Faulty

Compressor.

Check Compressor

Check if frost

forms in

Evaporator.

Normal amount

Clogged by dust. Gas leakage.

No frost

or frost forms

in inlet only

Observe the discharged

amount of Refrigerant.

Inject refrigerant in compressor

and check cooling operation.

Frost formed normally

Check if oil

leaks.

None or too much

(Find the leak and repair it)

- 14 -

Page 15

▼ General Control of Refrigerating Cycle

NO. ITEMS UNIT STANDARDS PURPOSES REMARKS

Pipe and

1

piping system

opening time

Welding

2

N

2

3

parts

Refrige-

4

ration

Cycle

sealed

Evacuation

time

Vacuum

degree

Vacuum

Vacuum

piping

Min.

Nitrogen

pressure

Confirm

N

2 leak

Min.

Torr

EA

EA

Pipe: within 1 hour.

Comp: within 10 minutes.

Drier: within 20 minutes.

Weld under Nitrogen

atmosphere.

(N

2 pressure:

0.1~0.2 kg/cm

2

)

Confirm the sound of

pressure relief when

removing the rubber cap.

Sound: usable

No sound: not usable

More than 40 minutes

Below 0.03 (ref)

High and low pressure sides

are evacuated at the same

time for models above 200 l.

Use R-134a manifold

exclusively.

To protect

moisture

penetration.

To protect oxide

scale formation.

To protect

moisture

penetration.

To remove moisture.

To protect mixing

of mineral and

ester oils.

The opening time should be reduced

to a half of the standards during rain

and rainy seasons (the penetration of

water into the pipe is dangerous).

- Refer to repair note in each part.

- R-134a refrigerant is more

susceptible to leaks than R-12 and

requires more care during welding.

-

Do not apply force to pipes before and

after welding to protect pipe from cracking.

- In case of evaporator parts, if it doesn't

make sound when removing rubber

cap, blow dry air or N

2 gas for more

than 1 min. and than use the parts.

Note: Only applicable to the model

equipped with reverse flow

protect plate.

Vacuum efficiency can be improved

by operating compressor during

evacuation.

The rubber pipes for R-12 refrigerant

will be melted when they are used for

R-134a refrigerant (causes of leak.)

Refrigerant

5

weighing

Drier

6

replacement

Leak check

7

Pipe

coupler

Outlet

(Socket)

Plug

EA

EA

Use R-134a manifold

exclusively.

R-134a manifold exclusively.

R-134a manifold exclusively.

Use R-134a exclusively.

Weighing allowance: ±5g

Note: Winter: -5g

Summer: +5g

- Use R-134a exclusively for

R-134a refrigerator.

-

Replace drier whenever repairing

refrigerator cycle piping.

- Do not use soapy water for

check. It may be sucked

into the pipe by a vacuum.

To protect R-12

refrigerant mixing.

To protect R-12

refrigerant mixing.

To protect R-12

refrigerant mixing.

Do not mix with

R-12 refrigerant.

To remove the

moisture from

pipe inside.

Defect in

refrigerant leak

area.

- Do not weigh the refrigerant at too

hot or too cold an area.

(77°F [25°C] is adequate.)

- Make Copper charging canister

(Device filling refrigerant)

Socket: 2SV Plug: 2PV R-134a

Note: Do not burn O-ring (bushing)

during welding.

- Check for an oil leak at the refrigerant

leak area. Use an electronic leak

detector if an oil leak is not found.

- The electronic leak detector is very

sensitive to halogen gas in the air. It

also can detect R-141b in urethane.

Practice many times before using this

type of detector to avoid false readings.

- 15 -

Page 16

7. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM

WARMER COLDER

12345

TEMPERATURE

ADJUST

7-1 FUNCTION

7-1-1 Function

1. When the appliance is plugged in, it is set to "3" for the Refrigerator.

You can adjust the Refrigerator control temperature by pressing the ADJUST button.

2. When the power is initially applied or restored after a power failure, it is automatically reset to "3".

7-1-2 Defrost Cycle

1. A defrost cycle will be initiated after 4 hours of accumulated compressor run time after the initial power up or a power

failure.

2. After the initial defrost, the defrost cycle is initiated after 7 hour of accumulated compressor run time.

3. The defrost cycle will be terminated once the defrost sensor reaches 50°F(10°C).

7-1-3 Electrical Parts Operates in Orders

Electrical parts such as COMP, defrost heater, freezer FAN, etc. operate in the following order to prevent noise and parts

damage. Several parts are started at the same time at initial power on and are turned off together when TEST is

completed.

OPERATING ORDERS

Temperature of Defrost

Sensor is 113°F(45°C) or

more (when unit is newly

Initial power on

purchased or when moved)

Temperature of defrost

sensor is lower than

113 °F(45°C) (when power

cuts, SERVICE)

POWER

ON

POWER

ON

in 1/2 second

in 1/2 second

in 1/2 second

COMP &

Freezer FAN

COMP &

Freezer FAN

ON

Defrost

heater ON

in 10 second

Defrost

heater OFF

ON

Reset to normal operation

from TEST MODE

Total load

OFF

in 7 minute

COMP &

Freezer FAN

ON

- 16 -

Page 17

7-1-4 Defect Diagnosis Function

WARMER COLDER

12345

TEMPERATURE

ADJUST

Defect code panel

1. Defect diagnosis functions are easy SVC when defects occur which can affect product performance.

2. When a defect occurs, the buttons will not operate; but the tones. such as "ding". will sound.

3. When the defect CODE removes the sign, it returns to normal operation (RESET).

4. The defect CODE shows on the refrigerator DISPLAY as temperature LED, and the other LED turns off.

- ERROR CODE on Refrigerator Temperature panel

NO ITEM

Refrigerator sensor

1

2

3

4

malfunctions

Defrost sensor

malfunctions

Room

Temperature

sensor

malfunctions

Defrosting

malfunctions

DEFECT SIGNS

R1 R2 R3 R4 R5

CONTENTS REMARKS

Open or short-circuited wire

Open or short-circuited wire

Open or short-circuited wire

2 hours after

defrosting starts,

the sensor is not

above 50°F(10°C)

Temperature FUSE cuts off,

HEATER cuts off, DRAIN is

clogged, HEATER starts,

RELAY malfunctions

:ON :OFF

Inspect

*

connecting wires

on each sensor

- 17 -

Page 18

7-1-5 TEST Mode

1. The Test mode allows checking the PCB and the function of the product as well as finding out the Defective part in case

of an error.

2. The test button is on the main PCB of the refrigerator (Test S/W). The test mode will be cleared in 2 hours regardless of

the type of test mode.

3. While in the test mode, the ADJUST button will not operate.

4. After exiting the test mode, be sure to reset by unplugging and then plugging in the appliance.

5. If an error (such as a sensor failure) is detected while in the test mode, the test mode is cleared and the error code is

displayed.

6. While an error code is displayed, the test mode will not be activated even if the test button is pushed.

MODE MANIPULATION CONTENTS REMARKS

TEST1

TEST2

Reset

Push the test button

once.

Push the test button

once while in

TEST MODE 1.

Push the test button

once while in

TEST MODE 2.

1. Continuous operation of the COMP

2. Continuous operation of the freezer fan

3. Defrosting Heater OFF

4. Every DISPLAY LED ON

1. COMP OFF

2. Freezer FAN OFF

3. Defrosting heater ON

4. 1, 3, 5 LED ON

Reset to the default setting

Reset if the

temperature of the

Defrosting sensor is

50°F(10°C) or more.

The compressor will

Start after a 7-minute

delay.

- 18 -

Page 19

7-2 PCB FUNCTION

7-2-1 Power Circuit

1. Power is supplied to the control board at pins 1 and 5 of connector #4.

- 19 -

Page 20

7-2-2 Load / Buzzer Drive & Open Door Detection Circuit

1. Load Drive Condition Check

To measure outputs of the control board, check voltages between the pins for the following components:

Circuit Pin Number Pin Number Output Voltage

Compressor Con1 pin1 Con4 pin1 115 VAC

Condenser fan Con1 pin1 Con4 pin1 115 VAC

Evaporator fan Con1 pin1 Con4 pin1 115 VAC

Defrost heater Con1 pin3 Con4 pin1 115 VAC

F,R-lamp Con1 pin5 Con4 pin1 115 VAC

NOTE: When the door of the freezer/refrigerator is left open for 7 minutes or longer, the lamp of the freezer/refrigerator turns

off automatically.

- 20 -

Page 21

2. Open Door Circuit (Door Monitor Circuit)

Freezer or Refrigerator Measurement between pins 5 and 6 at Con 3

Both Closed 0 volts

One door open 5 volts

- 21 -

Page 22

7-2-3 Temperature Sensor Circuit

Voltage supplied to each sensor wil range between 0.5 volts -22°F(-30°C) and 4.5 volts 122°F(50°C) depending upon the

temperature in the compartments. A measurement of 0 volts indicates a short in the sensor circuit. A measurement of 5

volts indicates an open in the sensor circuit.

- 22 -

Page 23

7-3 RESISTANCE SPECIFICATION OF SENSOR

TEMPERATURE RESISTANCE OF FREEZER RESISTANCE OF REFRIGERATOR

- 20 ˚C (-4 °F) 22.3 KΩ 77 KΩ

- 15 ˚C (5 °F) 16.9 KΩ 60 KΩ

- 10 ˚C (14 °F) 13.0 KΩ 47.3 KΩ

- 5 ˚C (23 °F) 10.1 KΩ 38.4 KΩ

0 ˚C (32 °F) 7.8 KΩ 30 KΩ

+ 5 ˚C (41 °F) 6.2 KΩ 24.1 KΩ

+ 10 ˚C (50 °F) 4.9 KΩ 19.5 KΩ

+ 15 ˚C (59 °F) 3.9 KΩ 15.9 KΩ

+ 20 ˚C (68 °F) 3.1 KΩ 13 KΩ

+ 25 ˚C (77 °F) 2.5 KΩ 11 K Ω

+ 30 ˚C (86 °F) 2.0 KΩ 8.9 KΩ

+ 40 ˚C (104 °F) 1.4 KΩ 6.2 KΩ

SENSOR & DEFROST SENSOR

+ 50 ˚C (122 °F) 0.8 KΩ 4.3 KΩ

• The resistance of the SENSOR has a ±5% common difference.

• Measure the resistance of the SENSOR after leaving it for over 3 minutes in the measuring temperature.

This delay is necessary due to sensor response speed.

• Measure the F-SENSOR, SUPER FROST SENSOR, R1, R2-SENSOR after disconnect CON5 of PWB ASSY, MAIN.

- 23 -

Page 24

Not defrosting

Not cold enough

Not Cooling

not operating

correctly

Electronic Display

COMPLAINT

7-4 TROUBLESHOOTING

1. Frosted up in

Freeer

4. Damper not opening or internal air flow blocked

5. Sensor not operating properly

6. Door not sealing

7. Evaporator Frosted up

1. Open in defrost circuit

2. Defrost sensor not operating correctly

3. Defrost drain clogged

8. Sealed System related problem

2. Display on

compressor is

operating

1. Condenser fan motor not operating

2. Condenser coils blocked

3. Evaporator fan motor not operating

operating

1. Display on but

compressor not

1. Compressor not operating

2. Open in compressor circuit

2. Partial or

abnormal display

1. Supply voltage not within specifications

2. Open in wiring harness from PWB board

3. Open in door monitor switch circuit

1. No Display at all

SYMPTOM POSSIBLE CAUSES SOLUTION

1. Supply voltage not within specifications

2. Open in wiring harness from PWB board

1. Check defrost heater and circuit using Test Key

2. Check sensor

3. Check drain

7. Check defrost circuit components

wiring, etc.

1. Check condenser fan motor and wiring circuit

2. Check air flow across condenser

3. Check evaporator fan motor and wiring circuit

4. Check damper motor circuit

5. Check refrigerator and freezer sensors

6. Check for proper door esal

1. Check supply voltage to refrigerator

2. Check for open on OLP, PTC, compressor,

1. Check for compressor operation by using the test

key on main circuit board

2. Check wiring and connectors to and from PWB

board

3. Check door monitor circuit

1. Check supply voltage to refrigerator

2. Check wiring and connectors to PWB board

- 24 -

Page 25

7-5 MAIN PWB ASSEMBLY AND PARTS LIST

7-5-1 Main PWB Assembly

- 25 -

Page 26

8. EXPLODED VIEW & REPLACEMENT PARTS LIST

106A

106A

315A

401A

304A

501A

411A

410G

501F

S01

309A

318A

308A

S07

314A

307A

312A

317A

S06

S09

310A

327A

103A

105A

301A

283E

103B

328A

145B

145A

282H

B02

S13

282B

406B

418A

281A

B01

281B

103C

305B

305B

305C

305C

B03

S19

S38

105F

S10 S10

B04

323B

329C

420A

319A

S08

319C

282E

S02

S05

S04

283B

S14

120A

S17

120B

113D

113B

113C

409B

158A

S16

113A

503C

503D

CASE PARTS

CAUTION: Use the part number to order part, not the position number.

- 26 -

Page 27

FREEZER PARTS

405C

404A

405A

S20

330B

S21

332A

149A

149B

284C

284A

329A

110D

S22

147B

125A

131A

CAUTION: Use the part number to order part, not the position number.

- 27 -

Page 28

REFRIGERATOR PARTS

128A

170A

141B

141C

141A

141B

141C

141A

141C

141A

141B

141B

141C

141A

141C

141A

141B

154A

167B

151A

155B

151A

151C

128B

CAUTION: Use the part number to order part, not the position number.

- 28 -

Page 29

DOOR PARTS

241C

241C

205D

233A

203A

200A

201A

231A

281D

281D

281E

281E

234B

244A*

S25*

S25*

244B*

S25*

212A*

S25*

S25*

S25*

210A

S26

210B

201A

281D

281E

244B*

212A*

607A*

607A*

244C*

243A

283F

231A

281D

281E

S27

244B*

244A*

607A*

607A*

244C*

230A

S25*

S25*

S25*

S25*

205D

241C

241A

241D

241B

CAUTION: Use the part number to order part, not the position number.

: on some models

*

- 29 -

Page 30

P/No. 3828JL8015A MAR., 2003 Printed in Korea

Loading...

Loading...