Page 1

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

REFRIGERATOR

SERVICE MANUAL

http://biz.lgservice.com

MODEL : LRTBC1825T

LRTBC2025T

COLOR: TITANIUM

Page 2

SAFETY PRECAUTIONS....................................................................................................................................................... 2

SERVICING PRECAUTIONS.................................................................................................................................................. 3

SPECIFICATIONS................................................................................................................................................................... 4

PARTS IDENTIFICATION....................................................................................................................................................... 5

DISASSEMBLY.................................................................................................................................................................... 6-7

DOOR................................................................................................................................................................................... 6

DOOR SWITCH.................................................................................................................................................................... 6

THERMOSTAT..................................................................................................................................................................... 6

FAN AND FAN MOTOR........................................................................................................................................................ 7

DEFROST CONTROL ASSEMBLY...................................................................................................................................... 7

LAMP.................................................................................................................................................................................... 7

CONTROL BOX-R................................................................................................................................................................ 7

ADJUSTMENT........................................................................................................................................................................ 8

COMPRESSOR.................................................................................................................................................................... 8

POSITIVE TEMPERATURE COEFFICIENT-STARTER....................................................................................................... 8

OVERLOAD PROTECTOR.................................................................................................................................................. 9

CIRCUIT DIAGRAM................................................................................................................................................................ 9

TROUBLESHOOTING..................................................................................................................................................... 10-15

COMPRESSOR AND ELECTRIC COMPONENTS ........................................................................................................... 10

POSITIVE TEMPERATURE COEFFICIENT AND OVERLOAD PROTECTOR................................................................. 11

DEFROST TIMER .............................................................................................................................................................. 11

OTHER ELECTRIC COMPONENTS ................................................................................................................................. 12

SERVICE DIAGNOSIS CHART.......................................................................................................................................... 13

REFRIGERATING CYCLE............................................................................................................................................ 14-15

OPERATION PRINCIPLE AND REPAIR METHOD OF ICE MAKER ............................................................................ 16-27

EXPLODED VIEW .......................................................................................................................................................... 28-31

REPLACEMENT PARTS LIST............................................................................................................................................ 32-

CONTENTS

- 2 -

Please read the following instructions before servicing your

refrigerator.

1. Check the refrigerator for current leakage.

2. To prevent electric shock, unplug before servicing.

3. Always check line voltage and amperage.

4. If you use any kind of appliance, check regular current,

voltage, and capacity.

5. Don't touch metal products in the freezer with wet

hands. This may cause frostbite.

6. Prevent water from following onto electric elements in

the mechanical parts.

7. Close the top door before opening the bottom door.

Otherwise, you might hit your head when you stand up.

8. When tilting the refrigerator, remove any materials on

the refrigerator, especially the thin plates (ex. Glass

shelf or books.)

9. When servicing the evaporator, wear cotton gloves.

This is to prevent injuries from the sharp evaporator

fins.

10. Leave the disassembly of the refrigerating cycle to a

specialized service center. The gas inside the circuit

may pollute the environment.

SAFETY PRECAUTIONS

Page 3

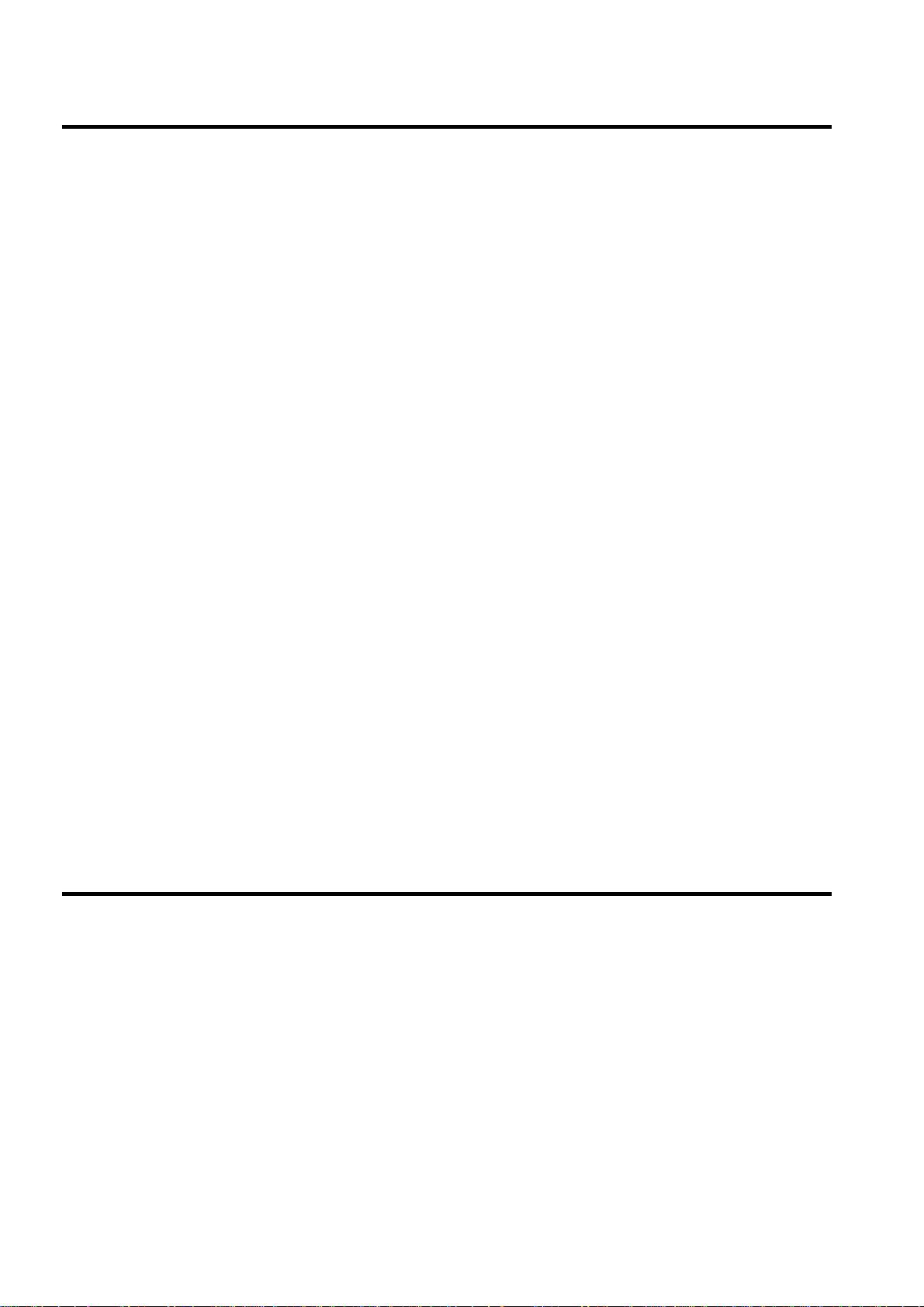

AIR RECHARGING IN COMPRESSOR

Test the refrigeration system connecting it electrically before

refilling operation. It is necessary to ascertain the function

of the motor-compressor and identify the defects

immediately. If defects have been found, empty the old

system of possible R-134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an complete extension with male Hansen and

at last, solder it to the same tube again. (Figure 2)

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during the heating the of the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm., -760 mm hg). In any

case it is advisable to keep the pump running for about 30

minutes. (Figure 3)

If considerable leakage occurs, it will be necessary to stop

the vacuum pump and to add a small quantity of Freon to

the system. If vacuum should not be obtained (pressure

gauge can't fall to 1 atmosphere), start the refrigeration

unit and find the leakage with special leak-finder. When the

defective soldering point is visible, repair it after opening

the extension tube valve and reestablishing the normal

outside pressure inside the group.

Because the melted alloy is sucked into the tubes and

blocks them, the pressure must be rebalanced when

vacuum is in the system when soldering. As soon as the

vacuum operation is over, add the quantity in grams of

R-134a to the refrigeration system. Remember that every

system has an exact quantity of R-134a that can be added

with a tolerance of ±5 grams. (Figure 4)

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and the refilling tube is

closed in order to keep the Freon for addition to the system.

(Figure 5)

In addition, check the graduated scale on the cylinder for

the quantity of R-134a to be added, for example, if we

have 750 grams of Freon in the cylinder and must add 140

grams to the group, this amount will be reached when

R-134a has dropped to 610 grams, remembering that the

indicator shows a lower limit of meniscus. Do this after

choosing the scale corresponding to the gas pressure

different scales reported as the same gas pressure

indicated by the pressure gauge on the top of the column.

To make R-134a flow into the system, open the valve

placed at the base of the cylinder connected to the filling

tube. The amount of Freon cannot be added to the system

all at once because it may cause a blocking of motorcompressor. Therefore, proceed by adding the original

quantity of about 20-30 grams and close the valve

immediately.

The pressure rises and the motor compressor must start

sucking the gas and lowering the pressure again. Open the

valve again, maintaining the same manner until reaching to

the quantity of R-134a established for the system being

charged. When the system is running, the suction pressure

must be stabilized between 0.30 to 0.6 (0.10 to 0.4)

atmosphere.

SERVICING PRECAUTIONS

- 3 -

POINT TO BE BROKEN

SERVICE TUBE EXTENSION

CHARGE TUBE

EXTENSION

FEMALE

HANSEN

MALE HANSEN

SOLDERING POINT

Figure 1 Figure 2

TO THE

VACUUM

PUMP

PRESSURE

GAUGE

Figure 3

TO THE R-134a CYLINDER

TO THE REFRIGERATION

SYSTEM

Figure 4

FILLING OR

CHARGE TUBE

VALVE TO BE OPENED

WHEN REFILLING

VALVE TO BE CLOSED

AFTER VACUUM

TO THE CHARGE

CYLINDER

TO THE REFRIGERATION

SYSTEM

TO THE

VACUUM

PUMP

Figure 5

Page 4

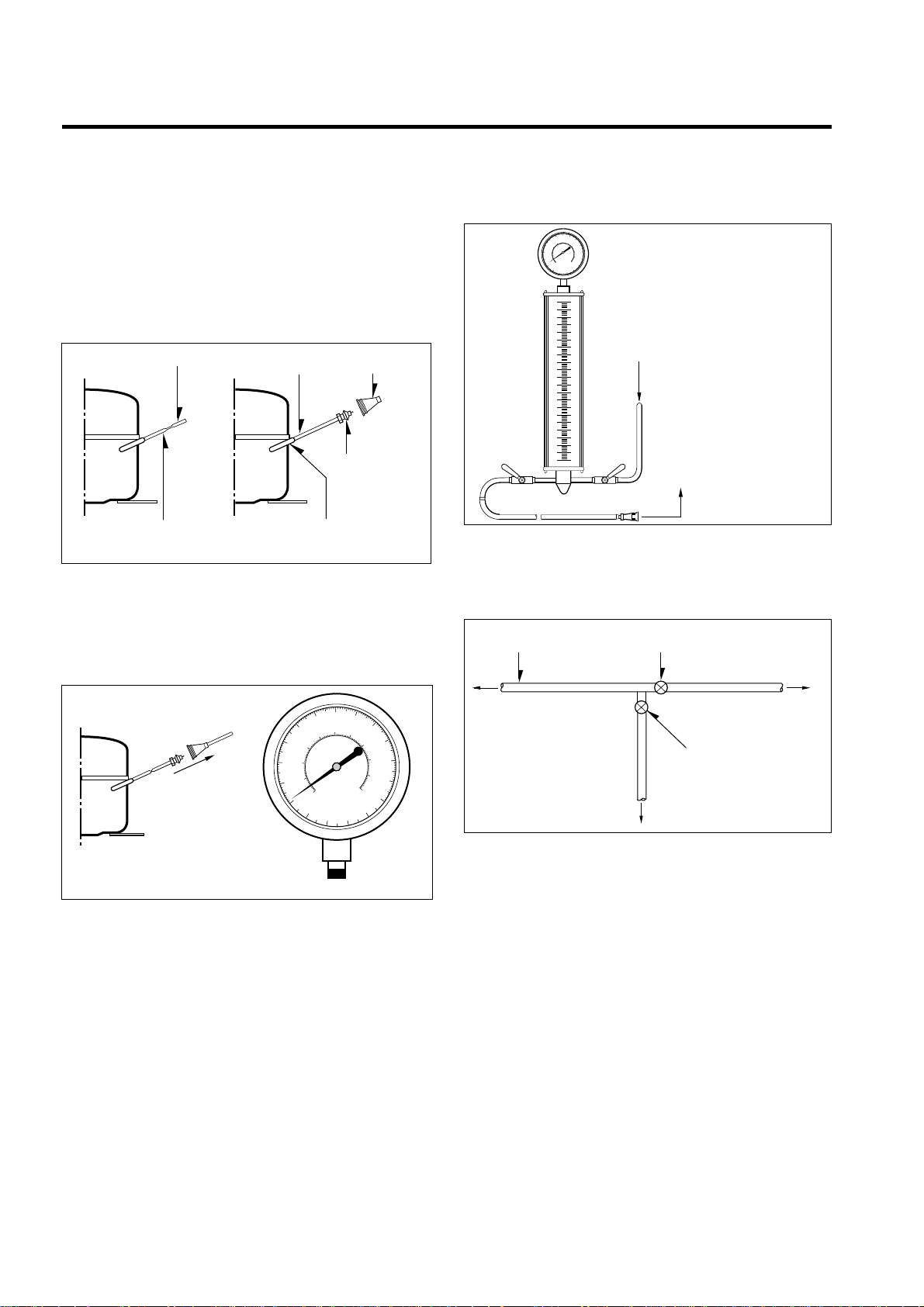

1. SPECIFICATIONS

- 4 -

ITEMS SPECIFICATIONS

DOOR DESIGN All Rounded

DIMENSIONS (mm)

754.5 X 735 X 1732 (W X D X H

)

NET WEIGHT (kg) 90

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Knob Dial

Full Automatic

DEFROSTING SYSTEM Heater Defrost

With a Timer

DOOR FINISH Vinyl Coated Metal

HANDLE TYPE Bar

INNER CASE ABS Resin

INSULATION Polyurethane Foam

ITEMS SPECIFICATIONS

VEGETABLE TRAY Transparent Drawer Type

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (155 g)

LUBRICATING OIL ISO10 (280 cc)

DEFROSTING DEVICE SHEATH HEATER

FREEZER 25 W

LAMP

REFRIGERATOR 40 W

1. Ref. No.: LRTBC1825T

ITEMS SPECIFICATIONS

DOOR DESIGN All Rounded

DIMENSIONS (mm)

754.5 X 788 X 1732 (W X D X H

)

NET WEIGHT (kg) 93

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Knob Dial

Full Automatic

DEFROSTING SYSTEM Heater Defrost

With a Timer

DOOR FINISH Vinyl Coated Metal

HANDLE TYPE Bar

INNER CASE ABS Resin

INSULATION Polyurethane Foam

ITEMS SPECIFICATIONS

VEGETABLE TRAY Transparent Drawer Type

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (155 g)

LUBRICATING OIL ISO10 (280 cc)

DEFROSTING DEVICE SHEATH HEATER

FREEZER 25 W

LAMP

REFRIGERATOR 40 W

2. Ref. No.: LRTBC2025T

Page 5

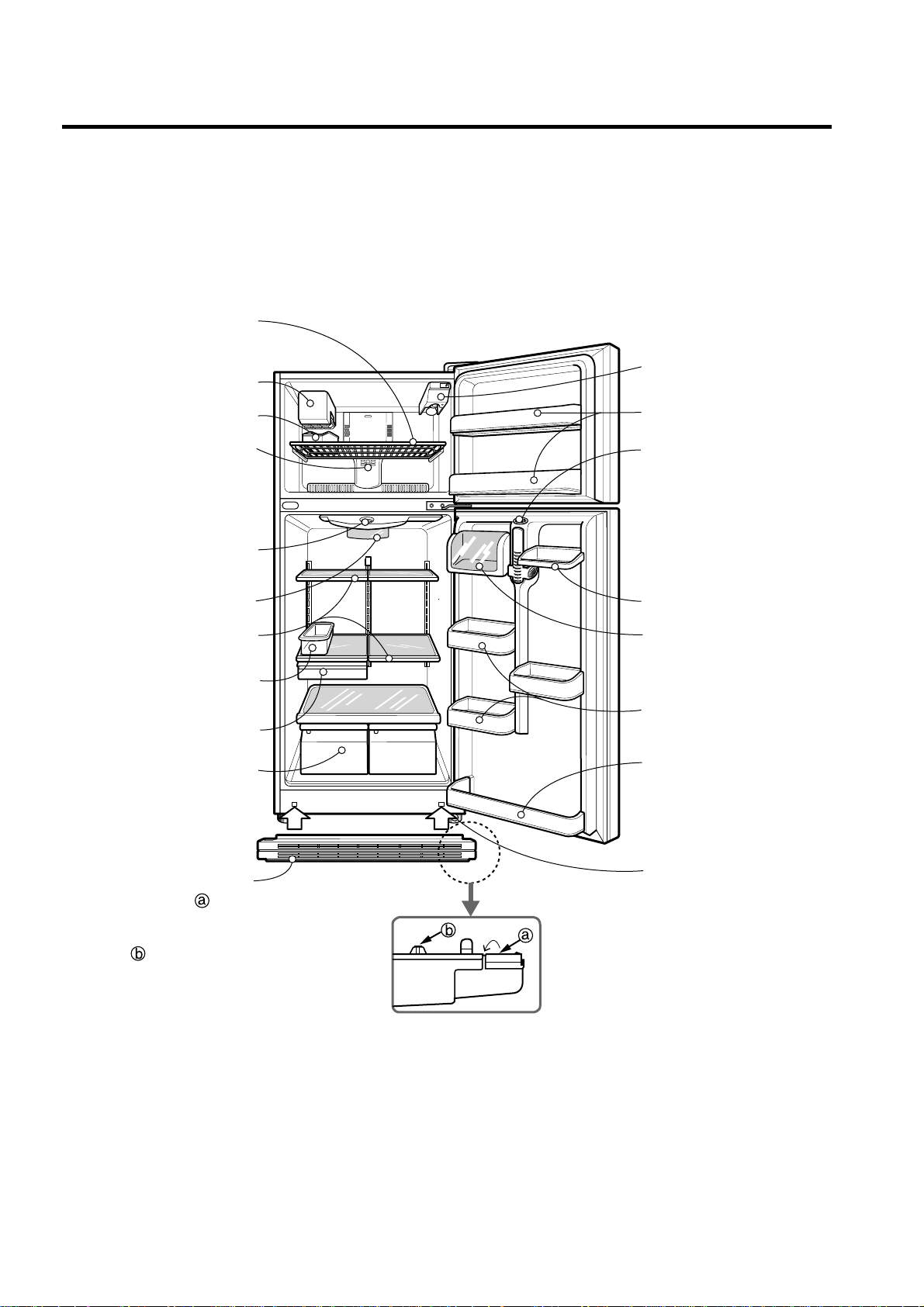

2. PARTS IDENTIFICATION

- 5 -

Automatic Ice Maker

Ice Cube Box

FREEZER

COMPARTMENT

REFRIGERATOR

COMPARTMENT

Freezer Temperature

Control Dial

Freezer Shelf

Door Cooling

On the refrigerator door,

the cold air passageway is

installed to supply

cold air to the doorside of

the refrigerator

compartment.

Temperature

Control Dial

Lamp

Shelves

Egg Box

(option)

Snack Corner

Crisper

Used to keep fruits

and vegetables

fresh and crisp.

Freezer Door Bin

Lamp

Refrigerator Door

Rack

Can Server

Adjustable

Door Bin

Leveling Screw

(Inside)

Dairy Corner

Base Grille

1. Bend down.

2. Push the grille toward the

refrigerator.

3. <Three protecting

parts> should be beneath

the bottom plate while

pushing the grille.

Page 6

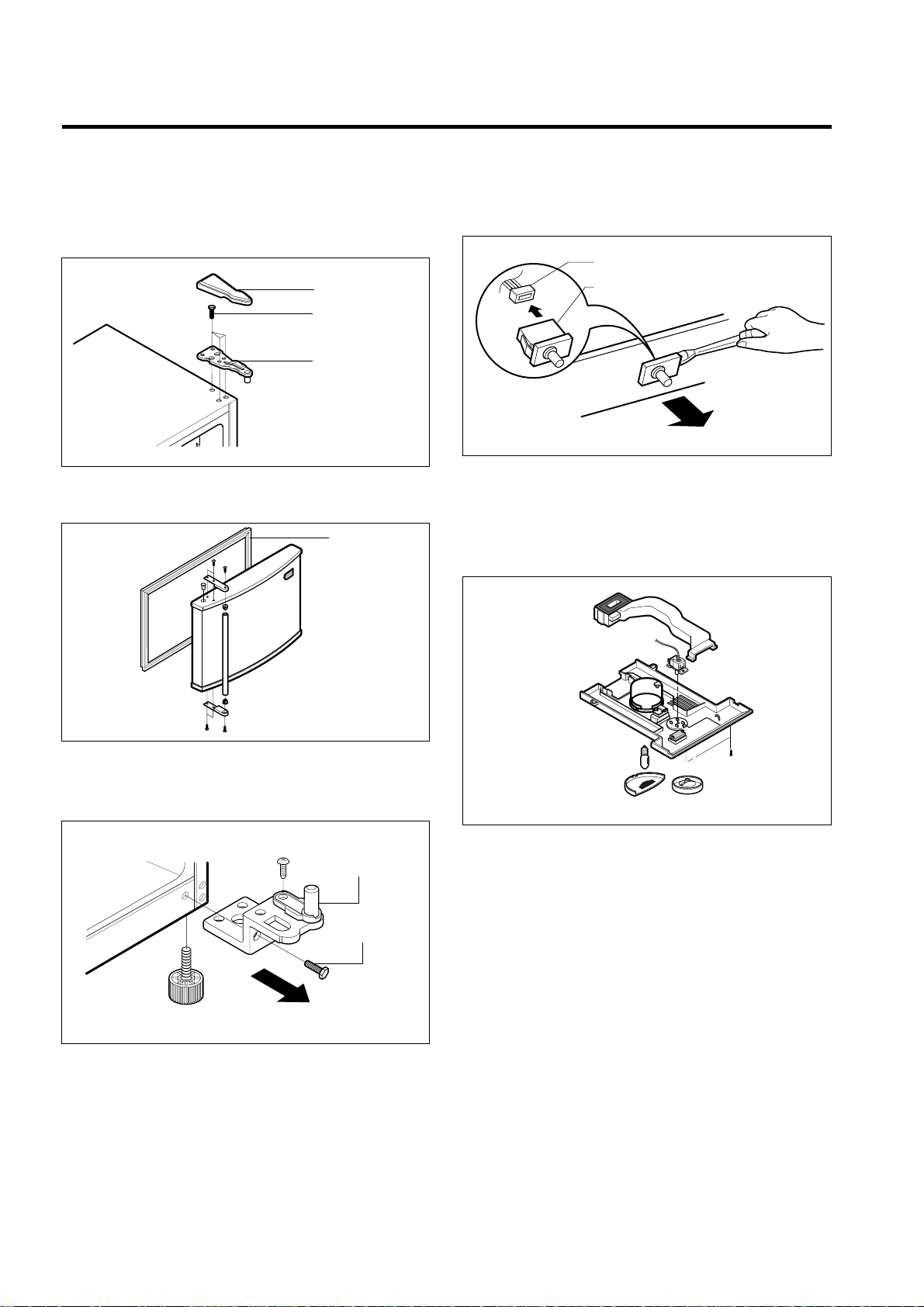

3-1 DOOR

● Freezer Door

1. Remove the hinge cover by pulling it upwards.

2. Loosen hexagonal bolts fixing the upper hinge to the

body and lift the freezer door.

3. Pull out the door gasket to remove from the door foam

assembly.

● Refrigerator Door

1. Loosen hexagonal bolts attaching the lower hinge to the

body to remove the refrigerator door only.

2. Pull out the door gasket to remove from the door foam

assembly.

3-2 DOOR SWITCH

1. To remove the door switch, pull out it with a slotted type

driver as shown in (figure 9).

2. Disconnect the lead wire from the switch.

3-3 THERMOSTAT

1. Remove Control Box-R by loosening 2 screws attached to

ceiling of Refrigerator compartment (Figure 10)

2. Separate the thermostat and dial knob F.

3. Remove the thermostat by disconnecting the lead wire.

3. DISASSEMBLY

- 6 -

BOLT

HINGE

HINGE COVER

Figure 6

GASKET

Figure 7

LOWER HINGE

BOLT

Figure 8

DOOR SWITCH

LEAD WIRE

Figure 9

Figure 10

Page 7

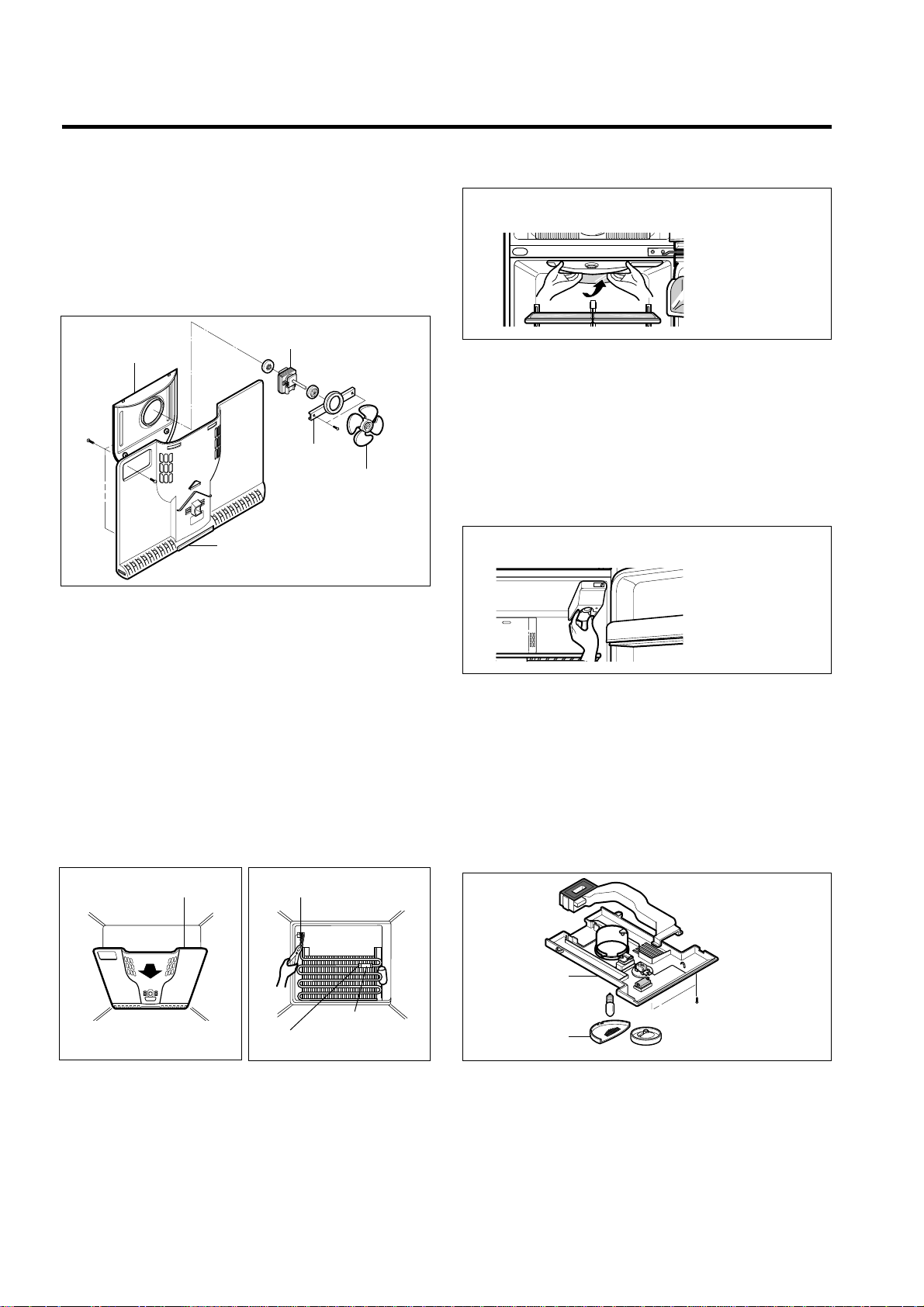

3-4 FAN AND FAN MOTOR

1. Remove the freezer shelf. (If your refrigerator have an

Ice Maker, disassemble the Ice maker first)

2. Remove the grille by pulling it out and by loosening a

screw.

3. Remove the Fan Motor assembly by loosening 4 screws

and disassemble the shroud.

4. Pull out the fan and separate the Fan Motor and Bracket.

3-5 DEFROST CONTROL ASSEMBLY

Defrost control assembly consists of Defrost Thermostat

and FUSE–M.

Defrost Thermostat functions to defrost automatically and it

is attached to metal side of the Evaporator and senses

Temp.

Fuse-M is a safety device for preventing over-heating of

the Heater when defrosting.

At the temperature of 77°C, it stops the emission of heat

from the Heater.

1. Pull out the grille assembly.

2. Separate the connector connected with the Defrost

Control assembly and replace the Defrost Control

assembly after cutting the Tie Wrap. (Figure 14)

3-6 LAMP

3-6-1 Refrigerator room lamp

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Release the hooks on both ends of the lamp shield and

pull the shield downward to remove it.

4. Turn the lamp counterclockwise.

5. Assemble in reverse order of disassembly. Replacement

bulb must be the same specification as original.

(Max 40 W)

3-6-2 Freezer room lamp

1. Unplug refrigerator or disconnect power.

2. Reach behind light shield to remove bulb.

3. Replace bulb with a 25-watt appliance bulb.

4. Plug in refrigerator or reconnect power.

3-7 CONTROL BOX-R

1. First, remove all shelves in the refrigerator and Control

Box-R by loosening 2 screws.

2. Remove the Control Box-R by pulling it downward.

3. Disconnect the lead wire on the right position and

seperate timer, themostat, Lamp socket, etc.

- 7 -

FAN

BRACKET

SHROUD

GRILLE

FAN MOTOR

Figure 12

SHROUD-F

Figure 13

DEF-THERMO

FUSE-M

HOLDER FUSE

Figure 14

REFRIGERATOR ROOM LAMP

Figure 16-1

Figure 16-2

CONTROL BOX

COVER LAMP

Figure 17

FREEZER ROOM LAMP

Page 8

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas evaporated from evaporator of the refrigerator, and

condenses this gas to high temperature and high pressure

gas, and then plays delivering role to condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are outside the

compressor. Since the compressor is manufactured to

tolerances of 1 micron, and is sealed in a dust - and

moisture - free environment, use extreme caution when

repairing it.

4-1-3 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) No Strike

If applying forcible power or strike (dropping or careless

handling), poor operation and noise may occur.

(3) Use proper electric components appropriate to the

Compressor.

(4) Note to Keep Compressor.

If Compressor gets wet in the rain and rust in the pin of

Hermetic Terminal, the result may be poor operation

and poor contact may cause.

(5) Be careful that dust, humidity, and welding flux don't

contaminate the compressor inside when replacing the

Compressor. Dust, humidity, and flux due to welding

which contaminates the cylinder may cause lockage

and noise.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic

material consisting of BaTiO

3.

(2) The higher the temperature is, the higher the resistance

value. These features are used as starting device for

the Motor.

4-2-2 Role of PTC-Starter

(1) PTC is attached to Hermetic Compressor used for

Refrigerator, Show Case, and starting Motor.

(2) Compressor for household refrigerator applies to

single-phase induction Motor.

For normal operation of the single-phase induction

motor, in the starting operation flows in both main coil

and sub-coil. After the starting is over, the current in

subcoil is cut off. The proper features of PTC play all

the above roles. So, PTC is used as a motor starting

device.

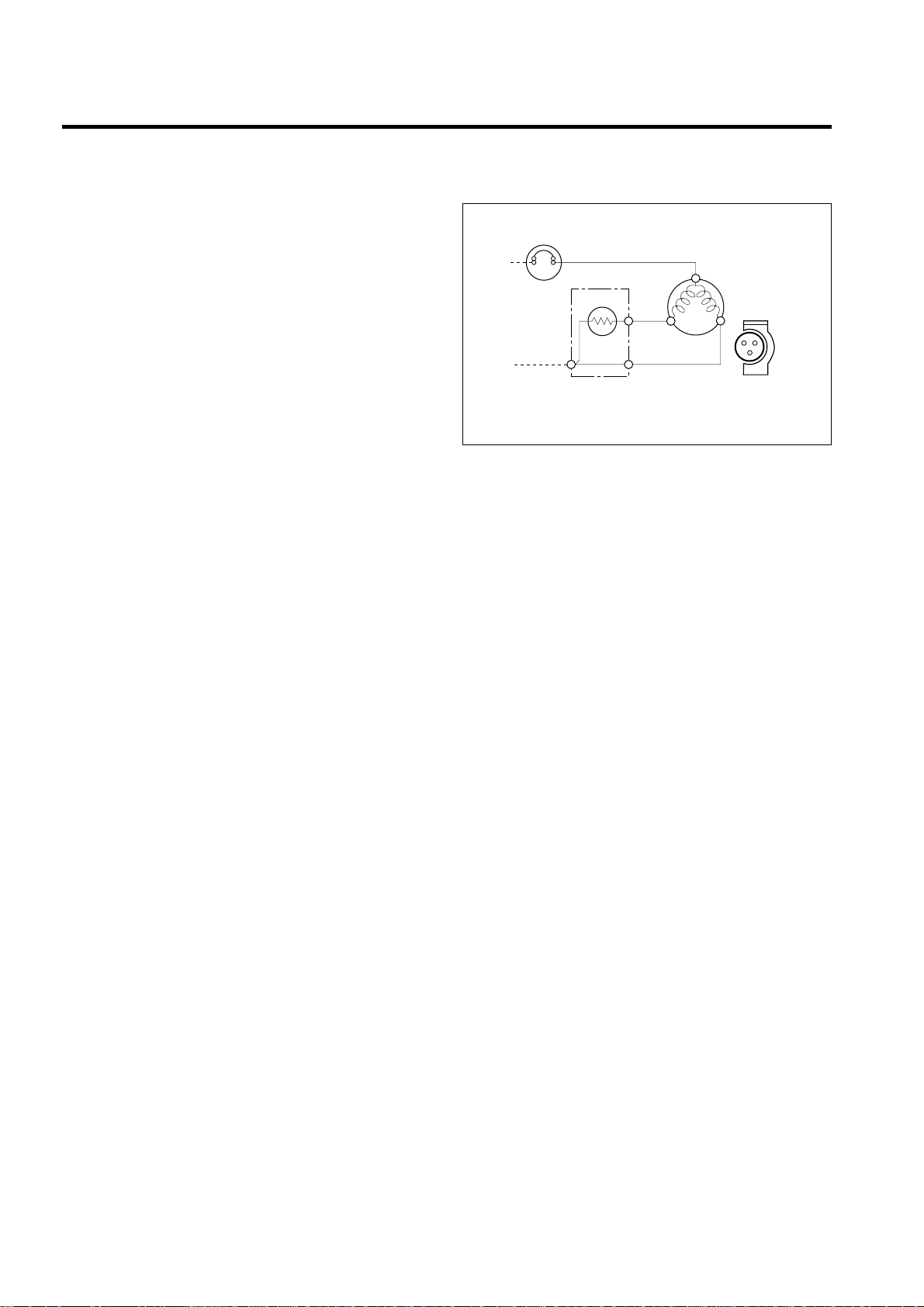

4-2-3 PTC-Applied Circuit Diagram

● According to Starting Method for the Motor

4-2-4 Motor Restarting and PTC Cooling

(1) For restarting after power off during normal

Compressor Motor operation, plug the power cord after

5 min. for pressure balance of Refrigerating Cycle and

PTC cooling.

(2) During normal operation of the Compressor Motor, PTC

elements generate heat continuously. Therefore,

if PTC isn't cooled for a while after the power has been

shut off, the motor will not restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the power is off during operation of Compressor and

the power is on before the PTC is cooled, (instant shutoff within 2 min. or unplugging and reconnecting), the

PTC isn't cooled and a resistance value grows. As a

result, current can't flow to the sub-coil, the Motor can't

operate, and the OLP operates by flowing over current

in only in the main-coil.

(2) While the OLP repeats on and off operation about 3-5

times, PTC is cooled and Compressor Motor performs

normal operation.

If OLP doesn't operate when PTC is not cooled,

Compressor Motor is worn away and causes circuitshort and fire. Therefore, always use a properly

attached OLP.

4-2-6 Note to Use PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not strike

Don't apply a forcible power or strike.

(3) Keep apart from any liquid.

If liquid, such as oil or water away enters the PTC,

PTC materials may fail due to insulation breakdown of

the material itself.

(4) Don't change PTC at your convenience.

Don't disassemble PTC and case. If the exterior to the

PTC-starter is damaged, resistance value is altered and

it may cause poor starting of the compressor motor

may cause.

(5) Use a properly attached PTC.

4. ADJUSTMENT

- 8 -

PTC STARTER

HERMETIC

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

3

6

5

S

PTC

OVERLOAD PROTECTOR(O.L.P)

RSIR

Figure 19

Page 9

4-3 OLP (OVERLOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by cutting the

current to the Motor if the temperature rises and

activates the bimetal spring in the OLP.

(2) When over-voltage flows to Compressor motor, the

Bimetal works by heating the heater inside the OLP,

and the OLP protects Motor by cutting off current which

flows to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Hermetic Compressor used

for the Refrigerator and prevents the Motor Coil from

being started in the Compressor.

(2) Do not turn the Adjust Screw of the OLP in any way for

normal operation of the OLP.

(Composition and connection diagram of OLP)

- 9 -

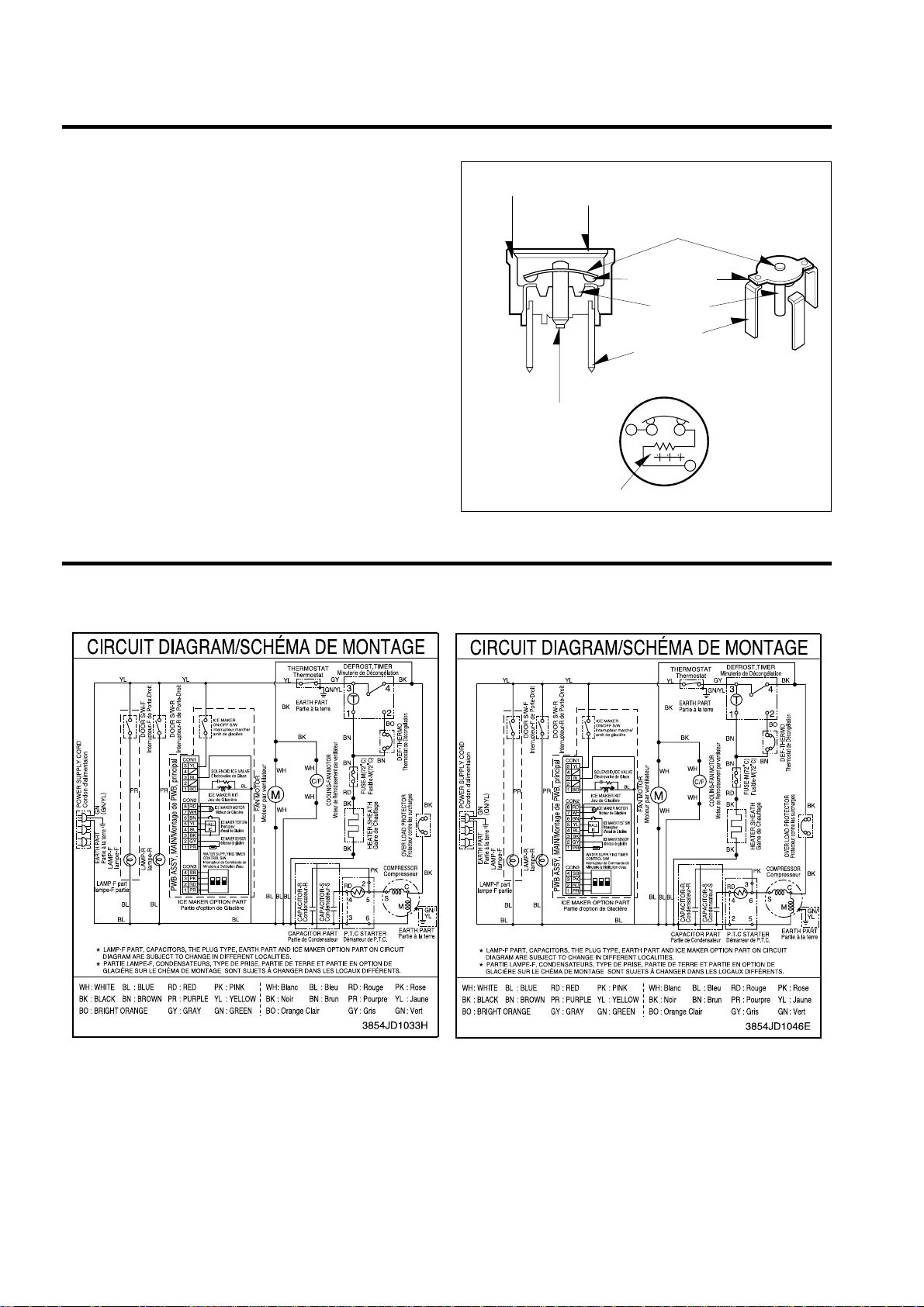

5. CIRCUIT DIAGRAM

CONTACTING

POINT

COVER

BIMETAL

CONTACTING

POINT

HEATER

TERMINALS

ADJUST

SCREW

HEATER

BIMETAL

Figure 21

Ref. No.: LRTBC1825T Ref. No.: LRTBC2025T

Page 10

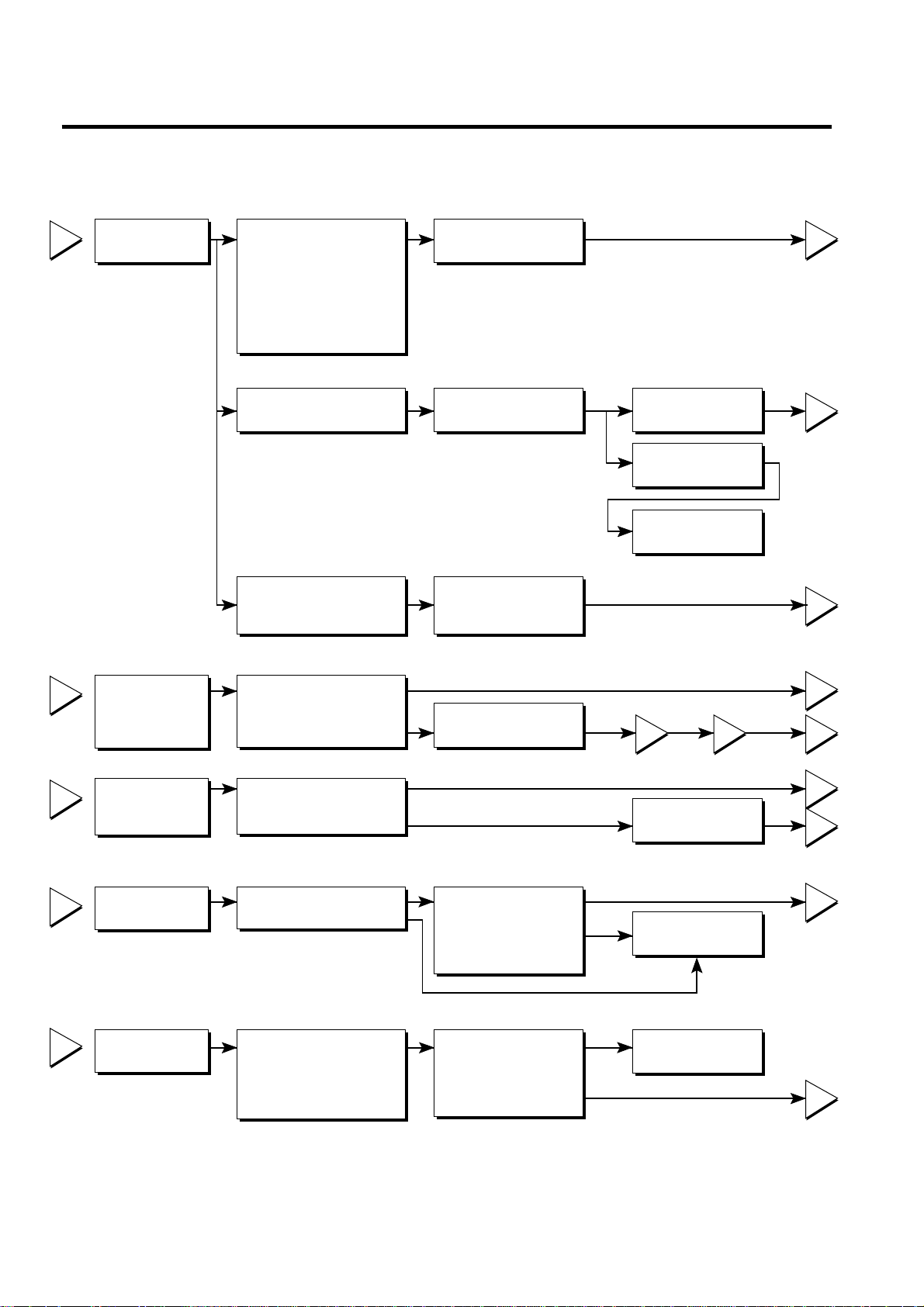

6. TROUBLESHOOTING

- 10 -

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

1

2

3

4

5

2

5

5

3

5

4

5

5

1

43

YES

YES

YES

YES

NO

NO

YES

YES

YES

NO

NO

NO

Power Source.

No Voltage.

(Rating Voltage

±10%)?

Replace OLP.

Reconnect.

Replace

PTC-Starter.

Replace OLP.

O.K.

Check connection

condition.

OLP disconnected?

Advise the customer

to use a regular

transformer.

Replace Compressor.

OLP works within

30 sec. in forcible OLP

operation by turning

instant power on and

off.

Components start in

the voltage of Rating

Voltage ±10%

below.

Applied voltage isn't

in the range of Rating

Voltage ±10%.

Remove the PTCStarter from the

Compressor and

measure the voltage

between Terminal C of

Compressor and

Terminals 5 or 6 of PTC.

Check the resistance

among M-C, S-C and

M-S in Motor

Compressor.

Check the resistance

of two terminals in

PTC-Starter.

Check if applying

a regular OLP.

Measure minimum

starting voltage after 5

min. for balancing cycle

pressure and cooling the

PTC.

Check the

resistance of

Motor

Compressor.

Check the

resistance of

PTC-Starter.

Check OLP.

Check

starting state.

Page 11

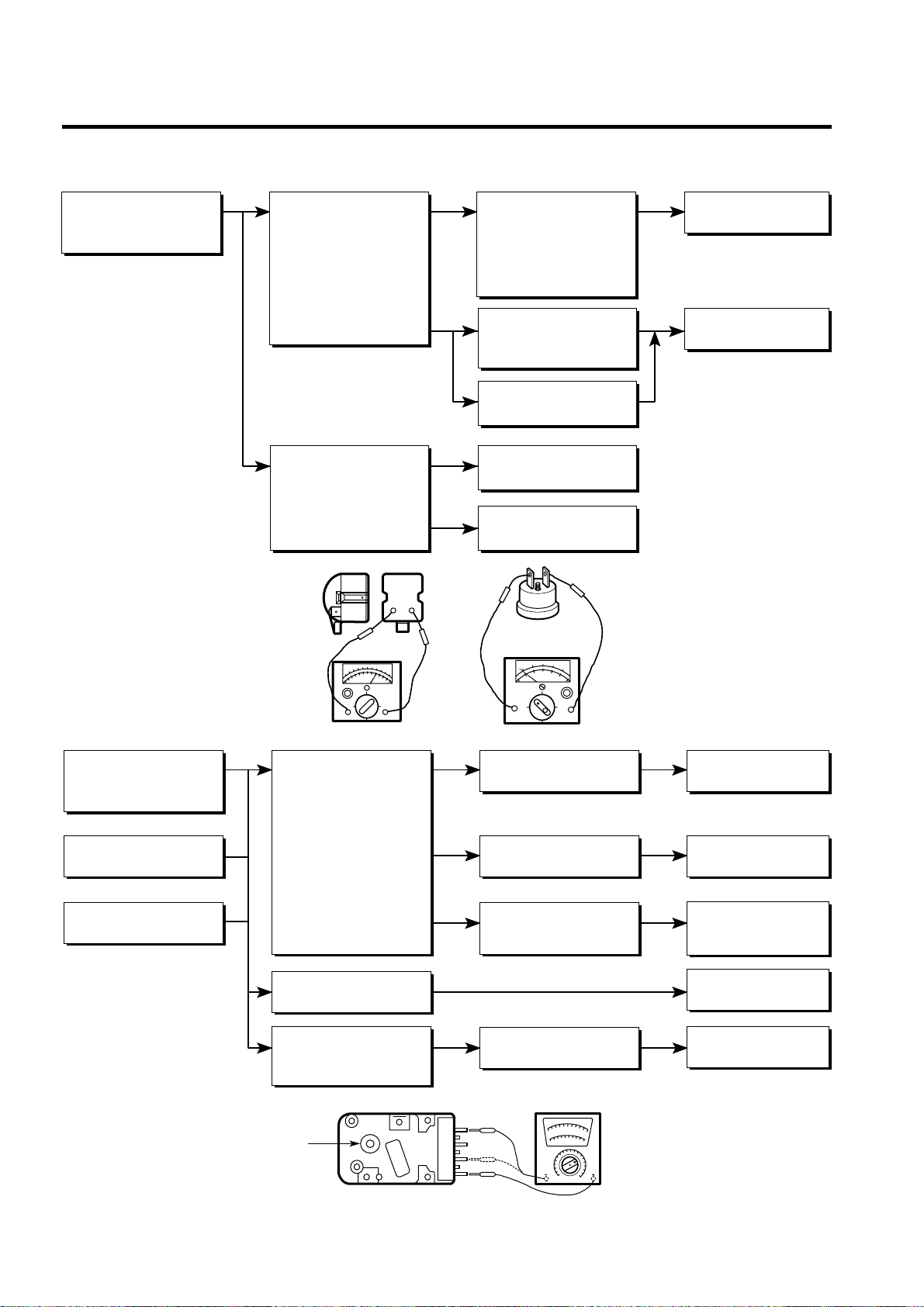

- 11 -

6-2 PTC AND OLP

65

YES

NO

NO

YES

NO

Cam Shaft

Normal operation of

Compressor is

impossible or poor.

Separate the PTCStarter from

Compressor and

measure the

resistance between

No. 5 and 6 of PTCStarter with a Tester or

Wheatstone Bridge.

(Figure 21)

Separate the OLP from

Compressor and check

the resistance value

between two terminals

of OLP with a Tester.

(Figure 22)

Observation value is

220V/50Hz : 22Ω±30%

115V/60Hz : 6.8Ω±30%

240V/50Hz : 33Ω±30%

127, 220V/60Hz : 22Ω

±30%

The resistance value

is 0 or several

hundred Ω.

The value is ∞.

Check another

electric components.

Replace OLP.

Check another

electric components.

Replace PTCStarter

Figure 21

Figure 22

Figure 23

Normal operation of

the Defrost Timer is

impossible.

No defrosting.

Poor cooling.

Position the Cam Shaft to

the point of first click

sound and check the

current flowing between

terminals No. 1(brown)

and No. 2(bright orange).

Next, position the Cam

Shaft to the point of

second click sound and

check the current flowing

between terminals

No. 1 (brown) and

No. 4 (black)

(Figure 23).

Turn the Cam Shaft.

Shake about 3 times

with holding the Cam

Shaft and Body softly.

The resistance is ∞.

The resistance is

0Ω or variable.

The resistance is about

220V/50Hz : 20KΩ

115V/60Hz : 7.8KΩ

Loud click sound.

Replace the

Defrost Timer.

Replace the

Defrost Timer.

Replace the

Defrost Timer.

Check the another

electric components.

Replace the

Defrost Timer.

6-3 DEFROST TIMER

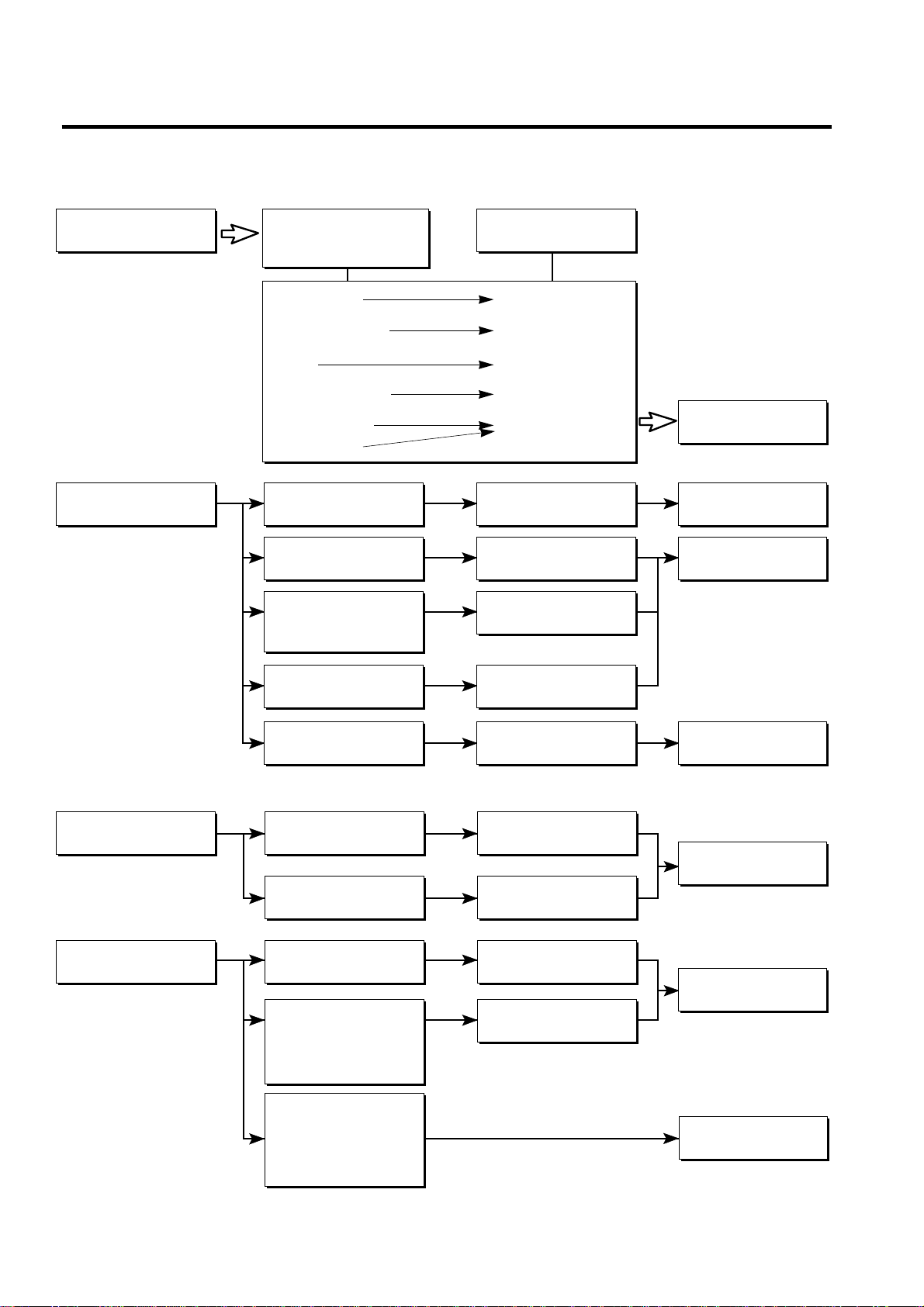

Page 12

- 12 -

▼ Cooling is impossible

Compressor

doesn't run.

Compressor runs

poorly.

Check a starting

voltage.

Check if current flows to

the following

components.

a. Thermostat

b. Starting devices

c. OLP

d. Compressor coil

e. Defrost Timer

f. Circuit parts

Low voltage.

Poor contacting and

gas leakage.

Shorted or broken.

Poor contacting

or shorted.

Coil shorted.

Poor contacting

or shorted.

Poor contacting

and broken.

Shorted.

Lack of capacity.

Coil of motor

Compressor.

Replace

the compressor.

Replace

indicated component.

Raise the voltage.

Replace

indicated component.

Cause

Check if current flows

to starting devices.

Check current flowing

in sub-coil of

Compressor.

Check capacity of OLP.

The items described

above are normal.

▼ Cooling ability is poor

Fan motor

doesn't run.

Much frost is built upon

the EVAPORATOR.

Poor contacting.

Coil is shorted.

Shorted.

Replace

indicated component.

Replace

indicated component.

Replace

indicated component.

Running is poor.

(Coil is shorted.)

Check current flowing

of the door S/W.

Check current flowing

in the Fan Motor.

Check the running

condition of Timer.

Check current flowing

of the following

components.

• Defrost Thermostat

• Fuse-M

Check current flowing

of the following

components.

• L-cord

• TE-Plate Heater

6-4 OTHER ELECTRIC COMPONENTS

Page 13

6-4 SERVICE DIAGNOSIS CHART

- 13 -

COMPLAINT POINTS TO BE CHECKED REMEDY

Cooling is • Is the power cord unplugged from the outlet? • Plug to the outlet.

impossible. • Check if the power S/W is set to OFF. • Set the switch to ON.

• Check if the fuse of power S/W is shorted. • Replace fuse.

• Measure the voltage of power outlet. • If voltage is low, correct wiring.

Cooling ability • Check if the set is placed close to wall. • Place the set with the space of about 10 cm (4 inches).

is poor. • Check if the set is placed close to stove, gas • Place the set apart from these heat

• cooker and direct rays. • appliances.

• Is the ambient temperature high or • Make the ambient temperature below.

• the room door closed?

• Check if put in is hot. • Put in foods after cooled down.

• Did you open the door of the set too often • Don't open the door too often and close

• or check if the door is closed up? • it firmly.

• Check if the Control is set to WARM. • Set the control to mid-position.

Foods in the • Is food placed in cooling air outlet? • Place foods in high temperature section.

Refrigerator • (Front Part)

are frozen. • Check if the Dial is set to COLD. • Set the dial to MID.

• Is the ambient temperature below 5°C? • Set the dial to WARM.

Dew or ice • Is liquid food stored? • Seal up liquid foods with wrap.

forms inside • Check if put in hot. • Put in foods after cooled down.

the set. • Did you open the door of the set too • Don't open the door too often and close

• often or check if the door is closed. • it firmly.

Dew forms • Check if ambient temperature and humidity • Wipe dew with a dry cloth. This occurrence

in the Exterior Case. of surroumcling air are high. • is solved naturally in low temperature and humidity.

• Is there gap in the door gasket? • Fill up the gap.

Abnormal • Is the set positioned in a firm and even place? • Adjust the Adjust Screw, and position

noise. • in the firm place.

• Are any unnecessary objects set • Remove the objects.

• in the back side of the set?

• Check if the Drip Tray is not firmly fixed. • Fix it firmly on the original position.

• Check if the cover of mechanical room • Place the cover at the original position.

• in below and front side is taken out.

Door does not • Check if the door packing is dirty • Clean the door packing.

close well. • with filth such as juice.

• Is the set positioned in a firm and even place? • Position in the firm place and level the

• Adjust Screw.

• Is too much food putted in the set? • Keep foods not to reach the door.

Ice and foods • Check if the inside of the set is dirty. • Clean the inside of the set.

smell unpleasant. • Did you keep fragrant foods without wrapping? • Wrap fragrant foods.

• It smells of plastic. • The new products smells of plastic, but it

• will go away after 1-2 weeks.

● In addition to the items described left, refer to the followings to solve the complaint.

Check if dew forms in

the freezer.

Replace the

Components of

defrosting circuit.

Check Refrigerating

Cycle.

Check the

Thermistor

Defrosting

is poor.

The cycle

is faulty.

Repair the cycle.

Replace the

Thermistor.

The operation of

the Thermistor is

poor.

Page 14

6-5 REFRIGERATING CYCLE

- 14 -

▼ Troubleshooting Chart

▼ Leakage Detection

● Observe discharging point of refrigerant which may be in the oil discharging part in the compressor and hole of evaporator.

YES

YES

Check if compressor

runs or not.

Check if frost

forms or not in

Evaporator.

Observe the discharged

amount of Refrigerant.

Inject refrigerant to compressor

and check cooling operation.

Clogged by dust. Gas leakage.

Faulty

Compressor.

Moisture Clog

Check if oil

leaks or not.

Frost formed normally

Normal amount

No or much amount

(Check the leakage point)

Frost formed normally

No frost

or forms

in inlet only

Check Compressor

PARTIAL Freezer Low flowing sound of A little higher • Refrigerant level is low due

LEAKAGE compartment and Refrigerant is heard and than ambient • to a leak.

Refrigerator don't frost forms in inlet only temperature. • Normal cooling is possible

cool normally. • when injecting of Refrigerant

• the regular amount.

WHOLE Freezer Flowing sound of refrigerant Equal to ambient • No discharging of Refrigerant.

LEAKAGE compartment and is not heard and frost isn't temperature. • Normal cooling is possible

Refrigerator don't formed. • when injecting of Refrigerant

cool normally. • the regular amount.

PARTIAL Freeze Flowing sound of refrigerant A little higher • Normal discharging of

CLOG compartment and is heard and frost forms than ambient • refrigerant.

Refrigerator don't in inlet only. temperature. • The capillary tube is faulty.

cool normally.

WHOLE

Freezer

Flowing sound of refrigerant Equal to ambient • Normal discharging of

CLOG

compartment and

is not heard and frost isn't temperature. • Refrigerant.

Refrigerator don't cool.

formed.

MOISTURE Cooling operation Flowing sound of refrigerant Lower than • Cooling operation restarts

CLOG stops periodically. is not heard and frost melts. ambient • when heating the inlet of

temperature • capillary tube.

COMP- Freezer and Low flowing sound of A little higher • Low pressure at high side

RESSION Refrigerator refrigerant is heard and ambient • of compressor due to low

don't cool. frost forms in inlet only. temperature. • refrigerant level.

NO COMP- No compressing Flowing sound of refrigerant Equal to ambient • No pressure of high pressure

RESSION operation. is not heard and no frost. temperature. • part in the compressor.

CAUSE

TEMPERATURE

OF THE

COMPRESSOR

REMARKS

STATE OF

THE SET

STATE OF THE

EVAPORATOR

LEAKAGE

CLOGGED BY DUST

DEFECTIVE

COMPRESSION

Page 15

- 15 -

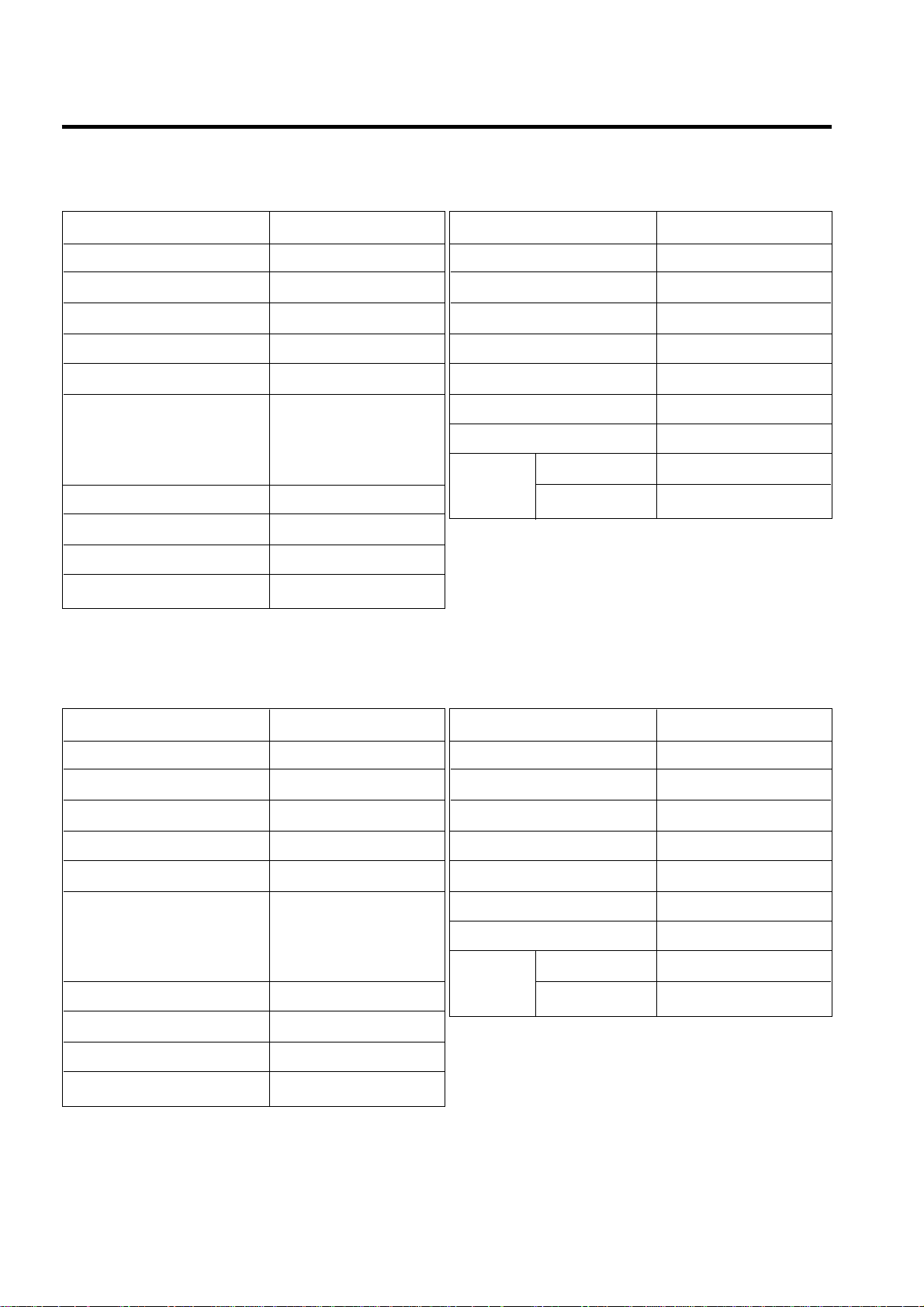

NO. ITEMS UNIT STANDARDS PURPOSES REMARKS

▼ General Control of Refrigerating Cycle

Pipe and

piping system

opening time

Welding

N

2 sealed

parts

Refrigeration

Cycle

Refrigerant

weighing

Drier

replacement

Leak check

1

2

3

4

5

6

7

Min.

Nitrogen

pressure

Confirm

N

2 leak

Min.

Torr

EA

EA

EA

EA

Pipe: within 1 hour.

Comp: within 10 minutes.

Drier: within 20 minutes.

Weld under Nitrogen

atmosphere.

(N

2 pressure:

0.1~0.2 kg/cm

2

)

Confirm air leaking sounds

when removing cap.

Sound: usable

No sound: not usable

More than 40 minutes

Below 0.03 (ref)

High and low pressure sides

are evacuated at the same

time for models above 200 l.

Use R-134a exclusive

manifold.

Use R-134a exclusive.

R-134a exclusive.

R-134a exclusive.

Use R-134a exclusively.

Weighing allowance: ±5g

Note: Winter: -5g

Summer: +5g

- Use R-134a exclusively for

R-134a refrigerator.

- Use R-12 exclusively for

R-12 refrigerator.

-

Replace drier whenever repairing

refrigerator cycle piping.

- Do not use soapy water for

check. It may be sucked

into the pipe by vacuum.

To protect

moisture

penetration.

To protect oxide

scale formation.

To protect

moisture

penetration.

To remove moisture.

To protect mixing

of mineral and

ester oils.

To protect R-12

refrigerant mixing.

"

"

Do not mix with

R-12 refrigerant.

To remove the

moisture from

pipe inside.

Defect

refrigerant leak

area.

The opening time should be reduced

to a half of the standards during rain

and rainy seasons (the penetration of

water into the pipe is dangerous).

- Refer to repair note in each part.

- R-134a refrigerant is more

susceptible to leaks than R-12 and

requires more care during welding.

-

Do not apply force to pipes before and

after welding to protect pipe from cracking.

- In case of evaporator parts, if it

doesn't make sound when removing

cap, blow dry air or N

2 gas for more

than 1 min and use the parts.

Note: Only applicable to the model

equipped with reverse flow

protect plate.

Vacuum efficiency can be improved

by operating compressor during

evacuation.

The bushing pipes for R-12 refrigerant

shall be melted when they are used for

R-134a refrigerant (causes of leak.)

- Do not weigh the refrigerant at too

hot or too cold an area.

(77°F[25°C] is adequate.)

-

Make Copper bombe (Device filling refrigerant)

Socket: 2SV Plug: 2PV R-134a

Note: Do not burn O-ring (bushing)

during welding.

- Check oil leak at refrigerant leak

area. Use electronic leak detector if

oil leak is not found.

- The electronic leak detector is very

sensitive to halogen gas in the air. It

also can detect R-141b in urethane.

Practice many times before using

this type of detector.

Evacuation

time

V acuum

degree

V acuum

V acuum

piping

Pipe

coupler

Outlet

(Socket)

Plug

Page 16

This manual describes function of models adhering Ice Maker.

7-1 OPERATION PRINCIPLE

7-1-1 Operation principle of Ice Maker

1. Turning the ice-making stop switch off stops ice-making function of the ice-maker and thus no ice is made .

2. Ice-making function stops at the time of selecting ice-making function and release of the ice-making function allows to

perform the initial control function again.

7.

OPERATION PRINCIPLE AND REPAIR METHOD OF ICE MAKER

- 16 -

•

Power Input

Initial Control

Icing Control

Ice-removing

Control

Water Supply

Control

Test Control

Keep a level of ice-removing tray with “initial control” inputting

power.

•

Wait until when water within ice-removing tray becomes cold

after starting ice-making operation.

•

Perform “ice-removing control” after supplying water to the iceremoving tray by operating solenoid of the ice valve.

•

As operation for the assembly line and service of refrigerator,

pressing a “I/Maker Test Switch” allows to operate in the order

of “initial ice-removing water supply” control step.

•

Perform “ice check operation” to ensure that ice is filled at an

ice bank by carrying out reverse turning and forward turning

the ice-removing motor. Perform “icing-removing operation for

dropping ices of ice-removing tray from the ice bank If ices

are not fully filled.

* Make sure the switch on the ice maker assy is turned “on”.

Page 17

7-2 Function of Ice maker

7-2-1 Initial control function

1. The level of the ice-removing tray (ice-removing container) after completing the MICOM initialization in the initial POWER

ON,returning to electricity failure and turning-off of ice-making stop switches. Namely, detection lever operates up and down.

2. The level of ice-removing container is detected with high / low output signal of hall sensor.

In another words, operation is performed in order to keep a level by operating ice-removing motor so that high or low voltage could be applied in the MICOM PIN.

3. No signal change of hall sensors until a minute after operating the ice-removing motor should be considered as failure. In

this case, stop the automatic ice-remover and then reset the ice-maker initialization if considered as normal after performing continuous check in a cycle of an hour.

4. Keeping of the ice-removing tray (ice-removing container) should be considered initial control is completed.

7-2-2 Water supply control function

1. Supply water into the ice-removing tray by operating the ice solenoid placed at the machine room of refrigerator using the

time check function if considered as the level is kept after performing a horizontal operation of the ice-making tray after

the ice-removing control (normal ice-removing control, ice-removing control of test function) is completed.

2. The quantity of water supply is determined by supplying water for a constant using the dip switch.

<Water Supply Quantity Table>

3. The change of the quantity of water supply setting may be done according to the changed time even after changing it

without powering off. In the change of dip switch during water supply, it is done according to the water supply time previously established and then done according to the additionally changed time from the next water supply.

7-2-3 Ice-making control function

1. Ice-making control is related with when considered as water within ice-making tray (ice container) turns into ice completely after completing water supply operation and performs ice-making completion operation by detecting temperature

of ice-making tray. (ice-making sensor is mounted on the bottom of the ice-making tray).

2. Ice-making control begins after completing water supply control or initial control.

3. It is considered that ice-making is completed if temperature of ice-making sensor arrives at -6°C after 60 minutes pass

from the time water is supplied to the ice-making tray.

4. It is considered that ice-making is completed if temperature of ice-making sensor arrives at below -7°C after 10 minutes

pass at the above status.

- 17 -

Remarks

The quantity of water supply may differ depending on

the setting status of the dip switch or on water pressure

as water supply method is of a pattern of direct connection to water cock.

* Make sure it is adjusted to meet the line indicating the

adequate amount of water supply.

Line indicating the

adequate amount

of water supply.

Adequate

water level.

Water supply control switch

* Adjust the water supply control switch to adjust the

amount of water being supplied.

SWITH

ON

SWITH

OFF

ON

SW1

123

SW2 SW3

SWITCH NO

SW1

SW2 SW3

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON

OFF ON ON

ON ON ON

TIME

10.5 sec

9 sec

10 sec

11 sec

12 sec

13 sec

14 sec

15 sec

Page 18

7-2-4 Ice-removing control function

1. Ice-removing control means operation to separate ice within ice-making tray ( ice-making container) after ice-making is

completed.

2. Step to check ices stored at the ice bank (container for storing ice) are fully filled. It is considered as they are fully filled if

signals of the hall sensor are at the On status (“high”) before 3.6seconds after rotating positively the ice-making motor. In

this case, the ice-making motor remains at the waiting status without performing ice-removing function.

Perform ice-detecting operation after rotating positively the ice-making motor in the cycle of an hour if the full ice status is

detected. Perform water supply control function after completing ice-removing function in the short of ices stored.

Reversely rotating the ice-removing motor in the storage of full ices and then let the motor stop at the position of the icemaking or waiting status.

3. Ice-removing control performs ice-removing operation immediately if ices stored at the ice bank (container for storing ice)

are not fully filled (the hall sensor are at the Off status (“low”) within 3.6seconds after rotating positively the ice-making

motor). In this case, it positively rotates (CW) the ice-removing motor and keeps the ice-making tray at the maximum distortion status and makes ices be separated from the ice-making tray. In this case, ice-detecting lever automatically operates lifting operation with ice-removing operation.

4. Ice-removing control positively rotates (CW) the ice-removing motor and stops it for a second as it considers as maximum

distortion point (ice-detecting axle = 160°) if the sensor signal changes from the Off status (“low”) to the On status (“high”)

after 3.6 seconds pass.

5. Ice-removing control positively rotates (CW) the ice-removing motor at the cycle of an hour if problems in ice-making

motor or hall sensor are found and performs initial operation or operates initialization of product if normal.

6. Ice-removing control stops for a second at the maximum distortion status of the ice-removing tray (container for storing

ice).

7. Step that the ice-removing tray stops for a second and then returns to the level. It returns to the level status returns to the

ice-removing tray by reversely rotating the ice-making motor.

8. The cycle of “water supply ➝ ice-making ➝ ice-removing ➝ returning to the level” if becoming the level status.

- 18 -

In the short of

ices stored

Output signal

of hall sensor

In full ices

stored

Output signal

of hall sensor

Operation of

ice-detecting axle

Ice-detection level 30°

Maximum distortion point

Ice-making

(original)

Lock

2±1 sec

9±3 sec

8±3 sec

Ice-detection Ice-removal lock

Lock

Level

status

Returning

to level

<Timing chart for ice-removal>

Page 19

7-2-5 Test Function

1. Function used compulsory operation for the purpose of performing operation test, service and cleaning. This test function

is performed if pressing the test switch mounted on the automatic ice-maker itself for 0.5 second or more.

2. The test button operates when the test function is not input but at the level status. It does not perform ice-removal control

and water supply control if ices are full during operation of test function

3. Pressing the test button for more than 0.5 seconds at the level the status immediately performs ice-removing operation

irrespective of the ice generation conditions of the ice-making tray.

Caution shall be exercised as water may overflow if operating the test function at the water status that ice-making is not

done. A cycle of water supply is performed at the level adjusting operation after ice-removing operation.

Therefore, the test button allows to check problems in ice-removing operation, level operation and water supply.

4. The test function operates in the normal cycle of ice-making ➝ ice-removal ➝ returning to the level ➝ water supply if

water supply is completed.

- 19 -

TEST S/W

* To check on the amount of water being supplied, press

the Test button. (Hold for 0.5 seconds)

Page 20

7-3 Failure diagnosis method of ice maker

- 20 -

No

Yes

No

No

Yes

Yes

DC power (5V,12V) is

normally output?

Defect of power terminal

• Check DC power (5V,12V)

Replacement of

MAIN PCB

Normally perform

ice-removing and returning to

the level if pressing TEST S/W

for more than 0.5

second?

Defect of ice-making sensor

Replacement of

ice-making sensor

Defect of ice-making kit

Replacement of

ice-making kit

Replacement of

MAIN PCB

Defect of ice-making KIT TEST S/W

Replacement of

ice-making kit

Replacement of

water supply valve

Defect of water supply

Water supply is

normal after the ice-making tray

and returning to the level with the

ice-removing motor?

Normal

• Check resistance values of

both ends of ice-making sensor

(Pin for PCB CON2 1,2 PIN)

• Ice-making sensor~Defect

between (PIN NO # 4 of IC1)

boards

• Both ends of TEST S/W

(# 3,6 pin of PCB CON2 3,6)

are at open status?

• TEST S/W ~ Defect between

boards (PIN NO #19 of IC1)

• Water supply valve conduct

current?

• Water supply pump normally

operates?

• Water supply line is normally

connected?

• Resistance values at both

ends of ice-removing motor

(# 7,8 pin of PCB CON2 7,8)

is 18°~22Ω ?

• Drive circuit of ice-removing

motor (IC5 and auxiliary

circuit) is normal?

• HALL IC~Defect between

(PIN NO # 20 of IC1) boards

• Be sure ice-removing and

returning to the level when

pressing the TEST S/W

Page 21

7-4 Explanation of ice maker circuits

7-4-1 Power circuit

The secondary party of transformer consists of power (12Vdc) for driving display and relay and power (5Vdc) supplying

power to MICOM and IC.

In this case, voltage at each part is as follows:

VA1 is parts for preventing over-voltage and noise and plays a role of protecting elements of the secondary part of transformer as the inside of element becomes short and is broken and power fuse is cut off when power of more than 175V is

applied.

7-4-2 Vibration circuit

Circuit used for synchronous clock generation for transmitting/receiving information of the inside logic elements of IC and

basic time generation for calculating time. Rated parts must be used as counting time is changed at the IC1 or the OSC1

does not operate if SPEC would be changed.

7-4-3 Reset circuit

The reset circuit is a circuit that initializes various parts such as RAM, etc inside of the MICOM (IC1) and starts the whole of

function from the initial status and ‘low’ voltage is applied for a constant time (10ms) at the reset terminal of the MICOM at

the start of power input.

The reset terminal is at 5V during general operation (the MICOM does not operate in the defect of the reset IC).

- 21 -

Part Both ends of VA1 Both ends of CE2 Both ends of CE3

Voltage 115Vac 12Vdc 5Vdc

Page 22

7-4-4 Load drive circuit

1. Load drive status check

- 22 -

Load Type Water Valve

Measurement Location A

Condition

ON 1V below

OFF 12V

Page 23

7-4-5 ICE MAKER drive/circuit

This circuit is a circuit used to embody functions such as ice-removing, full-ice detection, level noise, and ice-making temperature detection of ice-making tray (ice-making container).

- 23 -

Page 24

7-5 Main PWB Assembly and Parts List

7-5-1 MAIN PWB

- 24 -

Page 25

7-5-2 Replacement Part List

- 25 -

Page 26

7-6 PWB DIAGRAM

- 26 -

Page 27

- 27 -

Page 28

8. EXPLODED VIEW & REPLACEMENT PARTS LIST

- 28 -

▼ The parts of refrigerator and the shape of each part are subject to change in different localities.

▼ Capacitors and fuse are optional parts.

GR-T622, GR-T722

106A

104A

106A

401A

304A

103C

309A

318A

308A

314A

307A

312A

317A

310B

310A

103A

105A

301A

283B

282B

406B

103B

411A

328A

334B

323B

334A

315A

319A

329C

420A

319C

113D

113B

113C

410G

110A

410C

120B

409B

120C

158C

120A

145B

145A

282H

282E

282C

418A

281A

281B

Page 29

- 29 -

154A

151B

151C

151D

151A

147C*

147A*

151C

151D

170A

149A

330B

405C

404A

329A

405A

332A

110C

408A

409A

406A

158B

140D

140E

140B

140A*

141D

141E

141B

141A*

*

: Option

Page 30

- 30 -

241C

241A

241D

241C

241C

241B

205A

205A

243A

210A

233A

230A

203A

201A

231A

212A

244B

607A

607A

607A

244C

244B

1SZZ0A

244A

607A

244C

212G

1SZZ0A

281E

281E

211A

Handle Assembly,

Package

200A

Page 31

- 31 -

ICE MAKER PART

616E

623A

618A

616D

622A

620A

619A

605A

600A

603A

604A

5074AA

6923

601A

602A

603B

611A

Page 32

RUN-DATE: 02-07-26

BUYER NAME:LGEUS MODEL NAME:LRTBC1825T LG REFERENCE NO:GR-T622ATC.ATICLGX

COLOR:TITANIUM

- 32 -

S

AL

LOCA.NO

PART NO(LG) DESCRIPTION SPECIFICATION REMARK

6923 6923JB1001A MICOM ASSEMBLY

103A 3650JA2004U HANDLE,BACK

103B 3650JA2004V HANDLE,BACK

103C 3551JA2082D COVER ASSEMBLY,LOWER

104A 4441JA3001A CASTER ASSEMBLY

A 105A 5250JA2009A DRAIN,PIPE-Z

106A 4779JA2003B LEG ASSEMBLY,ADJUST

110A 6930JB1007C THERMOSTAT

110C 4940JD1007C KNOB,DAMPER

113B 4974JA2033A GUIDE,DUCT

113C 4970JA3016A SPRING,W

113D 4986JA2024A GASKET,DOOR

120A 4995JA1024K CONTROL BOX ASSEMBLY,R

120B 4994JD1037A CONTROL BOX,R

120C 4940JD1006E KNOB,DAMPER

140A 5027JA1041E SHELF ASSEMBLY,NET

140B 5027JA1029F SHELF ASSEMBLY,R

140D 5026JA2024E SHELF,NET

140E 5026JA2024F SHELF,NET

141A 5027JA1019Q SHELF ASSEMBLY,R

141B 5027JA1029F SHELF ASSEMBLY,R

141D 5026JA2020C SHELF,NET

141E 5026JA2020F SHELF,NET

145A 4930JA2032A HOLDER,SHELF

145B 4930JA2031A HOLDER,SHELF

149A 5026JA1108B SHELF ASSEMBLY,F

151A 3391JA1036G TRAY ASSEMBLY,VEGETABLE

151B 3391JA1036H TRAY ASSEMBLY,VEGETABLE

151C 4940JA2012A KNOB,DAMPER

151D 4940JA2011A KNOB,DAMPER

154A 3551JA1027D COVER ASSEMBLY,T/V

158B 4930JA1034A HOLDER,LAMP

158C 3550JA2096A COVER,LAMP

170A 3390JD1050G TRAY,MEAT

1SZZ0A 1TCG0403232

SCREW TAPPING,COUNTER SUNK HEAD

200A 3581JA1045Q DOOR ASSEMBLY,F

A 201A 5433JA0076F DOOR FOAM ASSEMBLY,F

203A 4987JA1024A GASKET ASSEMBLY,DOOR

205A 5004JD1110B BASKET,DOOR

210A 4620JA2011A STOPPER,DOOR

211A 3651JA2212A HANDLE ASSEMBLY,PACKAGE

212A 3650JA2053A HANDLE,F

Page 33

RUN-DATE: 02-07-26

BUYER NAME:LGEUS MODEL NAME:LRTBC1825T LG REFERENCE NO:GR-T622ATC.ATICLGX

COLOR:TITANIUM

- 33 -

S

AL

LOCA.NO

PART NO(LG) DESCRIPTION SPECIFICATION REMARK

212G 4140JD2001C NAME PLATE,P(H)

230A 3581JA8475C DOOR ASSEMBLY,R

A 231A 5433JA0077L DOOR FOAM ASSEMBLY,R

233A 4987JA1024B GASKET ASSEMBLY,DOOR

241A 5004JD1119A BASKET,DOOR

241B 5005JA1001B BASKET ASSEMBLY,DOOR

241C 5004JD1112B BASKET,DOOR

241D 5004JD1111B BASKET,DOOR

243A 4620JA3010B STOPPER,DOOR

244A 3650JA2054A HANDLE,R

244B 3650JA2055A HANDLE,DECO

244C 3650JA2056A HANDLE,DECO

281A 3550JA2132K COVER,HINGE

281B 4775JA2031B HINGE ASSEMBLY,U

281E 5006JA3054H CAP,HINGE

282B 4774JA2005A HINGE ASSEMBLY,C

282C 1WPZJA3007A WASHER,DRAWING

282E 5006JA2011U CAP,HINGE

282H 5006JA2020B CAP,HINGE

283B 4775JA2026A HINGE ASSEMBLY,L

301A 5421JA1032A EVAPORATOR ASSEMBLY

304A 3550JA1117A COVER,BACK-M/C

307A 2521C-B6282 COMPRESSOR,ASSEMBLY LA62LBCMC2 D DREF

A 308A 6748C-0004D P.T.C ASSEMBLY P6R8MD #250 MURATA

309A 6750C-0004M O.L.P 4TM414KFBYY-520

310A 3550JA2087A COVER,P.T.C

312A 5040JA3044A RUBBER,SEAT

314A 4620JA3009A STOPPER,COMP

315A 3103JA1015A COMP BASE ASSEMBLY,STD

317A 5851JA2003B DRIER

318A J719-00006A HOLDER,DRIER

319A 3390JA1115A TRAY,DRIP

319C 4974JA1046A GUIDE,FAN

323B 5403JA1026A CONDENSER ASSEMBLY,WIRE

327A 4J04328A RUBBER,DAMPING

328A 4J03020A RUBBER,DAMPING

329A J753-00011A FAN ASSEMBLY

329C 5901JA1005B FAN ASSEMBLY

330B 4998JA1010A SHROUD,F

332A 3531JA1018L GRILLE ASSEMBLY,FAN

334A 3550JA2095A COVER,PIPE

334B 5040JA3039A RUBBER,PIPE

Page 34

RUN-DATE: 02-07-26

BUYER NAME:LGEUS MODEL NAME:LRTBC1825T LG REFERENCE NO:GR-T622ATC.ATICLGX

COLOR:TITANIUM

- 34 -

S

AL

LOCA.NO

PART NO(LG) DESCRIPTION SPECIFICATION REMARK

401A 6615JB2003F CONTROLLER ASSEMBLY

404A 4681JB1011P MOTOR ASSEMBLY,REF FAN

405A 4810JA3007A BRACKET,MOTOR

A 405C J756-00008B RUBBER,MOTOR-N

406A 6600JB1005C SWITCH,[PUSH]

A 406B 6600JB1002K SWITCH,[PUSH]

408A 6621JB2005A SOCKET ASSEMBLY,LAMP

409A 6912JB2004F LAMP,[INCANDESCENT] 120V 25W

409B 6912JB2004C LAMP,[INCANDESCENT] 125V 40W

410C 6914JB2006G TIMER 120V

410G 0CBZJB2001E CAPACITOR,DRAWING 250VAC 12UF

411A 6411JB1013B POWER CORD ASSEMBLY

418A 5300JB1050R HEATER,SHEATH 115V 270W

420A 4681JB1013G MOTOR ASSEMBLY,REF FAN

5074AA 5074JA1023A BANK,ICE

600A 5989JA1004B ICE MAKER ASSEMBLY,KIT

601A 3390JA1118A TRAY,ICE

602A 4810JA1022A BRACKET,ICE MAKER

603A 3550JA3095A COVER,SENSOR

603B 5410JA3011A INSULATION,BACK

604A 4510JA3003A LEVER,ICE MAKER

605A 5988JA1001A ICE MAKER(MECH),UNIT

607A 4930JA3068A HOLDER,BRACKET

611A 3551JA2074A COVER ASSEMBLY,TRAY

616D 5210JA3005J TUBE,PE

616E 5210JA3021A TUBE,INJECT

618A 4810JA3036A BRACKET,COVER

619A 5220JA2009D VALVE,WATER

620A 1NZZJA3005A NUT,DRAWING

620A 1NZZJA3005A NUT,DRAWING

622A 5040JA3025A RUBBER,INJECT

623A 4770JA3001A BAND (MECH)

Page 35

RUN-DATE: 02-07-26

BUYER NAME:LGEUS MODEL NAME:LRTBC2025T LG REFERENCE NO:GR-T722ATC.ATICLGX

COLOR:TITANIUM

- 35 -

S

AL

LOCA.NO

PART NO(LG) DESCRIPTION SPECIFICATION REMARK

6923 6923JB1001A MICOM ASSEMBLY

103A 3650JA2004U HANDLE,BACK

103B 3650JA2004V HANDLE,BACK

103C 3551JA2082D COVER ASSEMBLY,LOWER

104A 4441JA3001A CASTER ASSEMBLY

A 105A 5250JA2009A DRAIN,PIPE-Z

106A 4779JA2003B LEG ASSEMBLY,ADJUST

110A 6930JB1007C THERMOSTAT

110C 4940JD1007C KNOB,DAMPER

113B 4974JA2033A GUIDE,DUCT

113C 4970JA3016A SPRING,W

113D 4986JA2024A GASKET,DOOR

120A 4995JA1022H CONTROL BOX ASSEMBLY,R

120B 4994JD1037B CONTROL BOX,R

120C 4940JD1006E KNOB,DAMPER

140A 5027JA1041J SHELF ASSEMBLY,NET

140B 5027JA1030E SHELF ASSEMBLY,R

140D 5026JA2016E SHELF,NET

140E 5026JA2016F SHELF,NET

141A 5027JA1019U SHELF ASSEMBLY,R

141B 5027JA1030E SHELF ASSEMBLY,R

141D 5026JA2012C SHELF,NET

141E 5026JA2012F SHELF,NET

145A 4930JA2032A HOLDER,SHELF

145B 4930JA2031A HOLDER,SHELF

147A 5074JA1008A TRAY,EGG

147C 3550JA1077A COVER,BANK

149A 5026JA1108A SHELF ASSEMBLY,F

151A 3391JA1036G TRAY ASSEMBLY,VEGETABLE

151B 3391JA1036H TRAY ASSEMBLY,VEGETABLE

151C 4940JA2012A KNOB,DAMPER

151D 4940JA2011A KNOB,DAMPER

154A 3551JA1027D COVER ASSEMBLY,T/V

158B 4930JA1034A HOLDER,LAMP

158C 3550JA2096A COVER,LAMP

170A 3390JD1050H TRAY,MEAT

1SZZ0A 1TCG0403232

SCREW TAPPING,COUNTER SUNK HEAD

200A 3581JA1045Q DOOR ASSEMBLY,F

A 201A 5433JA0076F DOOR FOAM ASSEMBLY,F

203A 4987JA1024A GASKET ASSEMBLY,DOOR

205A 5004JD1110B BASKET,DOOR

210A 4620JA2011A STOPPER,DOOR

Page 36

RUN-DATE: 02-07-26

BUYER NAME:LGEUS MODEL NAME:LRTBC2025T LG REFERENCE NO:GR-T722ATC.ATICLGX

COLOR:TITANIUM

- 36 -

S

AL

LOCA.NO

PART NO(LG) DESCRIPTION SPECIFICATION REMARK

211A 3651JA2212A HANDLE ASSEMBLY,PACKAGE

212A 3650JA2053A HANDLE,F

212G 4140JD2001C NAME PLATE,P(H)

230A 3581JA8475C DOOR ASSEMBLY,R

A 231A 5433JA0077L DOOR FOAM ASSEMBLY,R

233A 4987JA1024B GASKET ASSEMBLY,DOOR

241A 5004JD1119A BASKET,DOOR

241B 5005JA1001B BASKET ASSEMBLY,DOOR

241C 5004JD1112B BASKET,DOOR

241D 5004JD1111C BASKET,DOOR

243A 4620JA3010B STOPPER,DOOR

244A 3650JA2054A HANDLE,R

244B 3650JA2055A HANDLE,DECO

244C 3650JA2056A HANDLE,DECO

281A 3550JA2132K COVER,HINGE

281B 4775JA2031B HINGE ASSEMBLY,U

281E 5006JA3054H CAP,HINGE

282B 4774JA2005A HINGE ASSEMBLY,C

282C 1WPZJA3007A WASHER,DRAWING

282E 5006JA2011U CAP,HINGE

282H 5006JA2020B CAP,HINGE

283B 4775JA2026A HINGE ASSEMBLY,L

301A 5421JA1032A EVAPORATOR ASSEMBLY

304A 3550JA1117A COVER,BACK-M/C

307A 2521JA1006C COMPRESSOR,ASSEMBLY

308A 6748JA3001A P.T.C

309A 6750JA3001A O.L.P

310A 3550JA2158A COVER,P.T.C

310B 4620JA3014A STOPPER,CORD

312A 5040JA3044A BUSHING,SEAT

314A 4620JA3009A STOPPER,COMP

315A 3103JA1015B COMP BASE ASSEMBLY,STD

317A 5851JA2003B DRIER

318A J719-00006A HOLDER,DRIER

319A 3390JA1115A TRAY,DRIP

319C 4974JA1046A GUIDE,FAN

323B 5403JA1026A CONDENSER ASSEMBLY,WIRE

328A 4J03020A BUSHING,DAMPING

329A J753-00011A FAN ASSEMBLY

329C 5901JA1005B FAN ASSEMBLY

330B 4998JA1010A SHROUD,F

332A 3531JA1018L GRILLE ASSEMBLY,FAN

Page 37

RUN-DATE: 02-07-26

BUYER NAME:LGEUS MODEL NAME:LRTBC2025T LG REFERENCE NO:GR-T722ATC.ATICLGX

COLOR:TITANIUM

- 37 -

S

AL

LOCA.NO

PART NO(LG) DESCRIPTION SPECIFICATION REMARK

334A 3550JA2095A COVER,PIPE

334B 5040JA3039A BUSHING,PIPE

401A 6615JB2003F CONTROLLER ASSEMBLY

404A 4681JB1011P MOTOR ASSEMBLY,REF FAN

405A 4810JA3007A BRACKET,MOTOR

A 405C J756-00008B BUSHING,MOTOR-N

406A 6600JB1005C SWITCH,[PUSH]

A 406B 6600JB1002K SWITCH,[PUSH]

408A 6621JB2005A SOCKET ASSEMBLY,LAMP

409A 6912JB2004F LAMP,[INCANDESCENT] 120V 25W

409B 6912JB2004C LAMP,[INCANDESCENT] 125V 40W

410C 6914JB2006G TIMER 120V

410G 0CBZJB2001E CAPACITOR,DRAWING 250VAC 12UF

411A 6411JB1013B POWER CORD ASSEMBLY

418A 5300JB1050R HEATER,SHEATH 115V 270W

420A 4680JB1029A MOTOR ASSEMBLY,REF FAN 115V/60HZ

5074AA 5074JA1023A BANK,ICE

600A 5989JA1004B ICE MAKER ASSEMBLY,KIT

601A 3390JA1118A TRAY,ICE

602A 4810JA1022A BRACKET,ICE MAKER

603A 3550JA3095A COVER,SENSOR

603B 5410JA3011A INSULATION,BACK

604A 4510JA3003A LEVER,ICE MAKER

605A 5988JA1001A ICE MAKER(MECH),UNIT

607A 4930JA3068A HOLDER,BRACKET

611A 3551JA2074A COVER ASSEMBLY,TRAY

616D 5210JA3005J TUBE,PE

616E 5210JA3021A TUBE,INJECT

618A 4810JA3036A BRACKET,COVER

619A 5220JA2009D VALVE,WATER

620A 1NZZJA3005A NUT,DRAWING

620A 1NZZJA3005A NUT,DRAWING

622A 5040JA3025A BUSHING,INJECT

623A 4770JA3001A BAND (MECH)

Page 38

P/No. 3828JD8332Y JUL., 2002 Printed in Korea

Loading...

Loading...