LG LRTBC2025T Owner’s Manual

SERVICING PRECAUTIONS

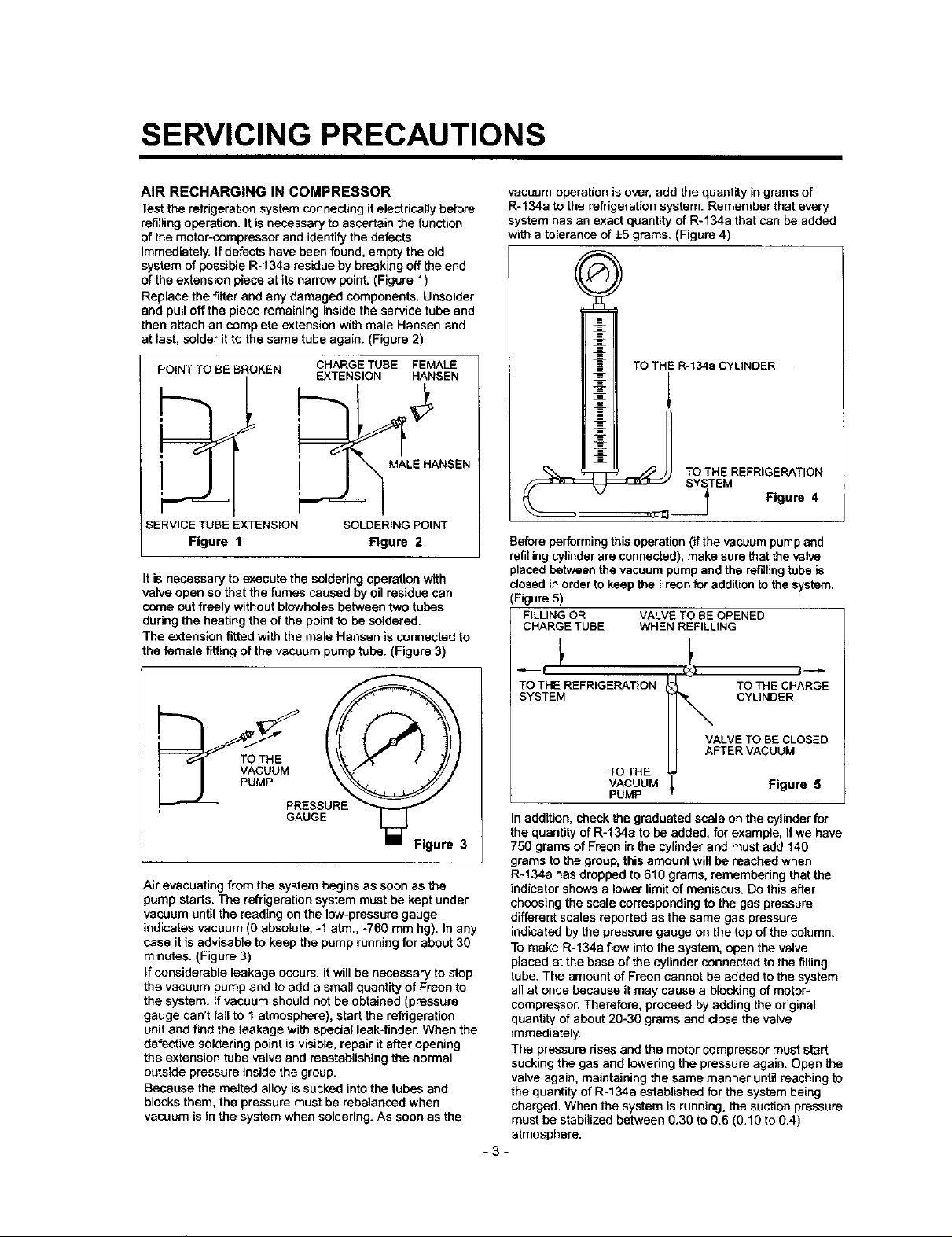

AIR RECHARGING IN COMPRESSOR

Test the refrigeration system connecting it electrically before

refilling operation. It is necessary to ascertain the function

of the motor-compressor and identify the defects

immediately. Ifdefects have been found, empty the old

system of possible R-134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an complete extension with male Hansen and

at last, solder itto the same tube again. (Figure 2)

POINT TO BE BROKEN CHARGE TUBE FEMALE

,_ MALE HANSEN

SERVICE TUBE EXTENSION SOLDERING POINT

Figure 1 Figure 2

EXTENSION HANSEN

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowhetes between two tubes

during the heating the of the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

vacuum operation is over, add the quantity in grams of

R-134a to the refrigeration system. Remember that every

system has an exact quantity of R-134a that can be added

with a tolerance of +5 grams. (Figure 4)

TO THE R-134a CYLINDER

_,, _ TO THE REFRIGERATION

SYITEM Figure 4

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and the refilling tube is

closed in order to keep the Freon for addition to the system.

(Figure 5)

FILLING OR VALVE TO BE OPENED

CHARGE TUBE WHEN REFILLING

GAUGE

Figure 3

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm., -760 mm hg). In any

case it is advisable to keep the pump running for about 30

minutes. (Figure 3)

If considerable leakage occurs, it will be necessary to stop

the vacuum pump and to add a small quantity of Freon to

the system. If vacuum should not be obtained (pressure

gauge can't fall to f atmosphere), start the refrigeration

unit and find the leakage with special leak-finder. When the

defective soldering point is visible, repair it after opening

the extension tube valve and reestablishing the normal

outside pressure inside the group.

Because the melted alloy is sucked into the tubes and

blocks them, the pressure must be rebalanced when

vacuum is in the system when soldering. As soon as the

TO THE REFRIGERATION TO THE CHARGE

SYSTEM CYLINDER

VALVE TO BE CLOSED

AFTER VACUUM

TO THE

VACUUM _ Figure 5

PUMP

In add:tion, check the graduated scale on the cylinder for

the quantity of R-134a to be added, for example, if we have

750 grams of Freon in the cylinder and must add 140

grams to the group, this amount will be reached when

R-134a has dropped to 610 grams, remembering that the

indicator shows a lower limit of meniscus. Do this after

choosing the scale corresponding to the gas pressure

different scales reported as the same gas pressure

indicated by the pressure gauge on the top of the column.

To make R-134a flow into the system, open the valve

placed at the base of the cylinder connected to the filling

tube. The amount of Freon cannot be added to the system

all at once because it may cause a blocking of motor-

compressor. Therefore, proceed by adding the original

quantity of about 20-30 grams and close the vane

immediately.

The pressure rises and the motor compressor must start

sucking the gas and lowering the pressure again. Open the

valve again, maintaining the same manner until reaching to

the quantity of R-134a established for the system being

charged. When the system is running, the suction pressure

must be stabilized between 0.30 to 0.6 (0.10 to 0.4)

atmosphere.

-3-

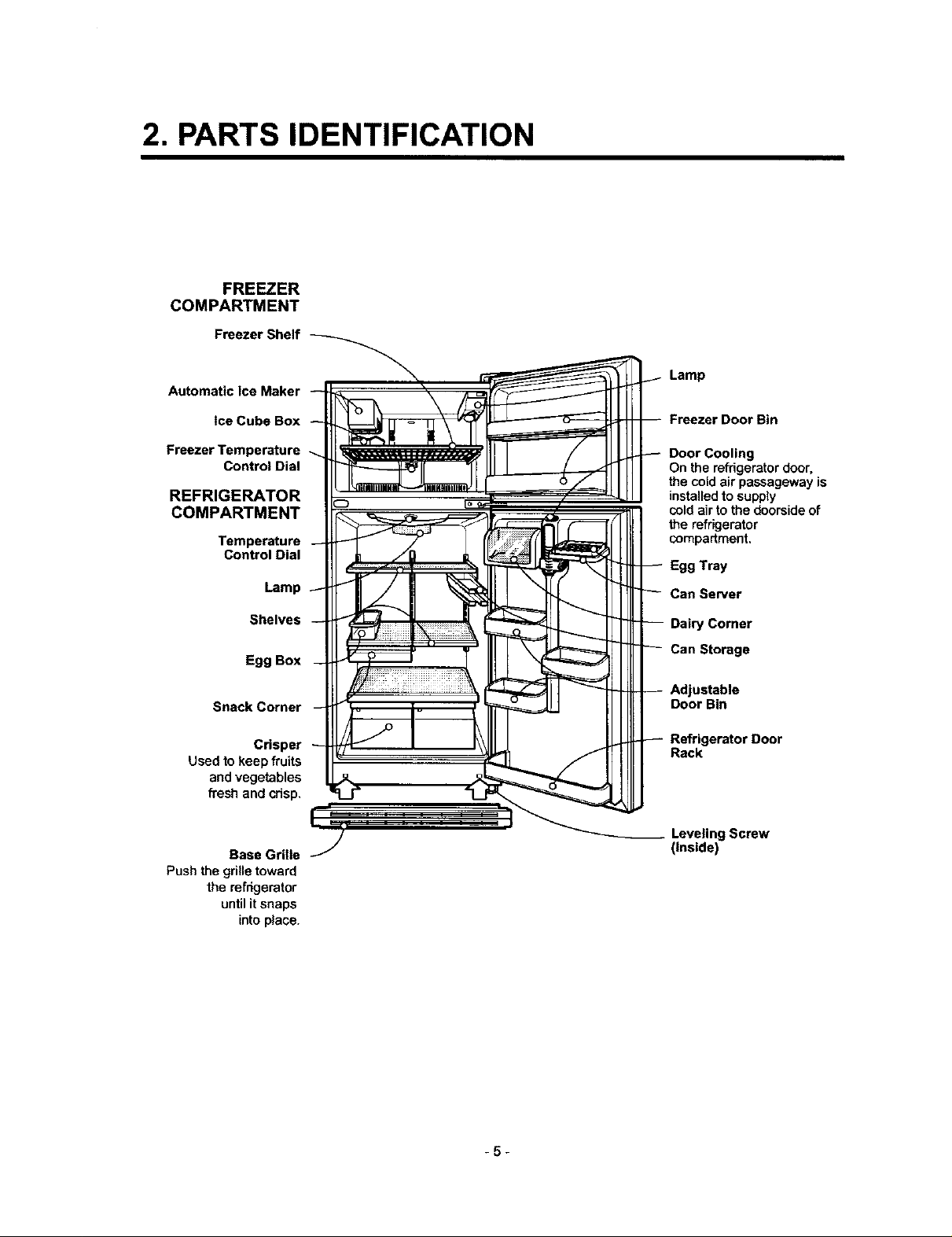

2. PARTS IDENTIFICATION

FREEZER

COMPARTMENT

Freezer Shelf

Automatic Ice Maker

tce Cube Box

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Temperature

Control Dial

Lamp

Shelves

Egg Box

Snack Corner

Crisper

Used to keep fruits

and vegetables

fresh and cdsp,

Lamp

Freezer Door Bin

Door Cooling

On the refrigeratordoor,

the cold air passageway is

installedto supply

coldair tothe doorsideof

the refrigerator

compartment.

Egg Tray

Can Server

Dairy Corner

Can Storage

Adjustable

Door Bin

Refrigerator Door

Rack

Base Grille

Push the grille toward

the refdgerator

until it snaps

into place.

Leveling Screw

(Inside)

-5-

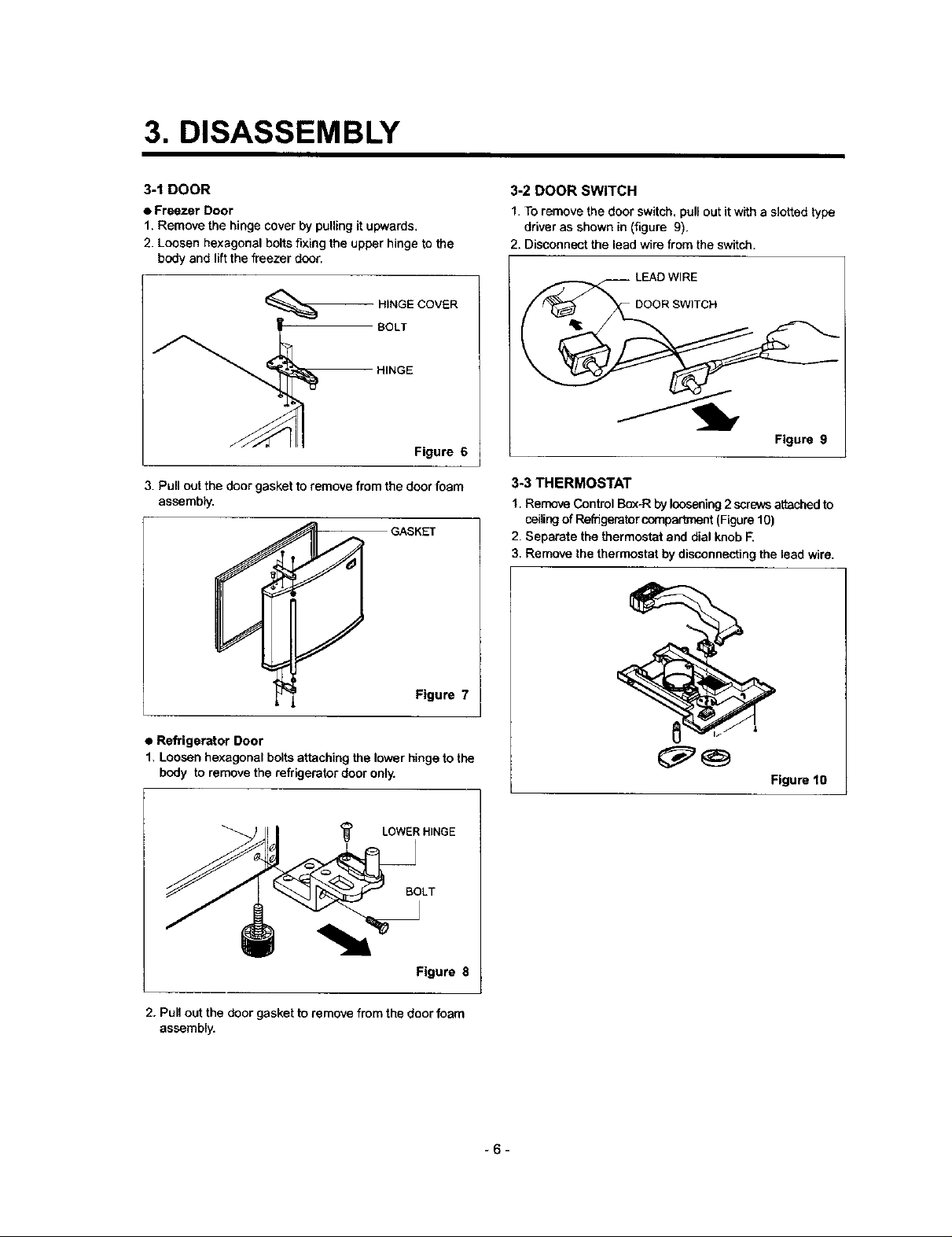

3. DISASSEMBLY

3-1 DOOR

• Freezer Door

1, Remove the hinge cover by pulling it upwards.

2. Loosen hexagonal bolts fixing the upper hinge to the

body and lift the freezer door.

HINGE COVER

HINGE

BOLT

Figure 6

3. Pull out the door gasket to remove from the door foam

assembly.

3-2 DOOR SWITCH

1. To remove the door switch, pull out it with a slotted type

driver as shown in (figure 9).

2. Disconnect the lead wire from the switch.

LEAD WIRE

DOOR SWITCH

Figure 9

3-3 THERMOSTAT

1. Remove Control Bc_-R by loosening 2 screws attached to

ceilingof Reffigerator comparb_ent (Figure 10)

Separate the thermostat and dial knob F.

Remove the thermostat by disconnecting the lead wire.

GASKET

Figure 7

• Refrigerator Door

1, Loosen hexagonal bolts attaching the lower hinge to the

body to remove the refrigerator door only.

<_ LOWER HINGE

BOLT

Figure 8

2. Pun out the door gasket to remove from the door foam

assembly.

Figure 10

-6-

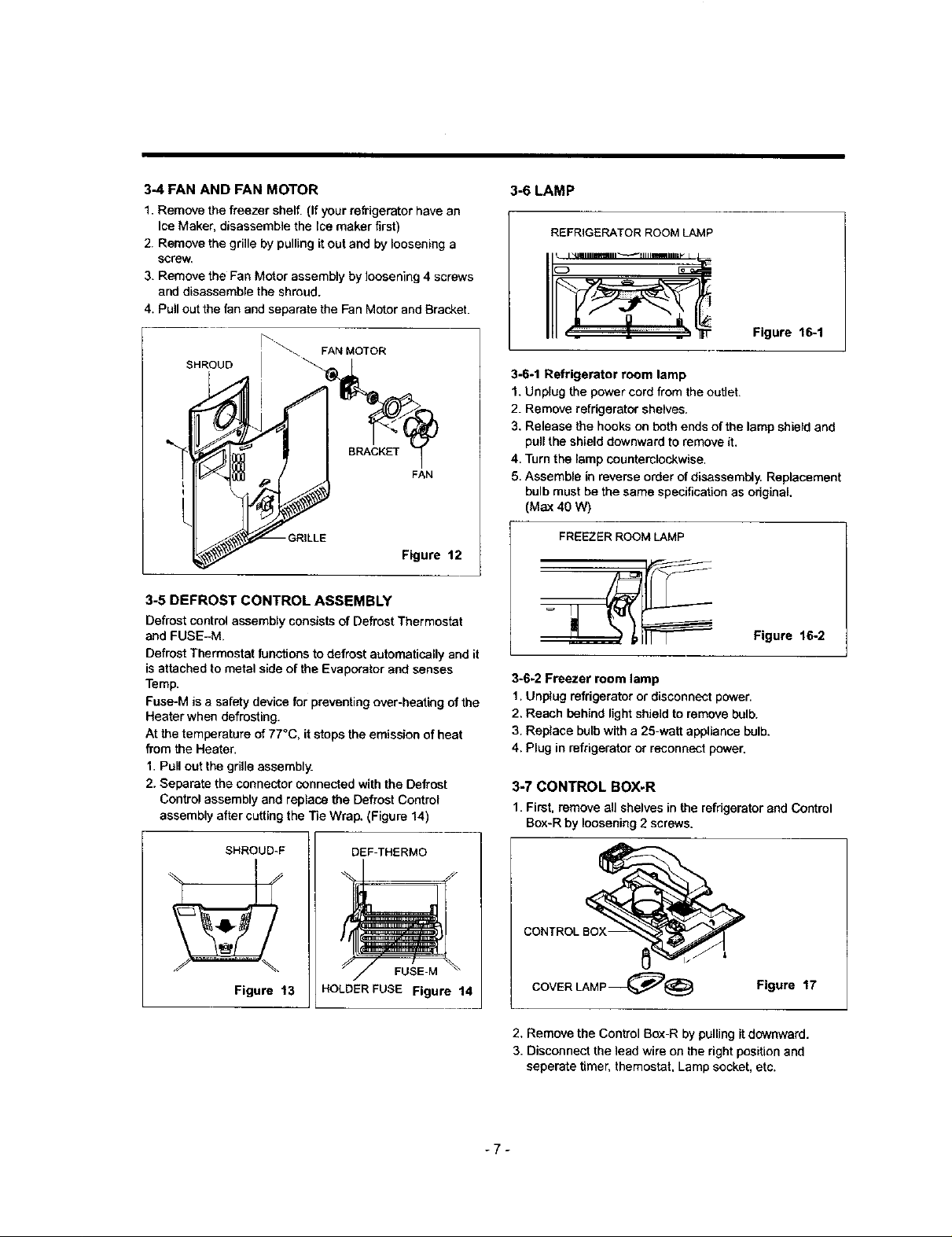

3-4 FAN AND FAN MOTOR

1. Remove the freezer shelf, (If your refrigerator have an

Ice Maker, disassemble the Ice maker first)

2. Remove the grille by pulling it out and by loosening a

screw,

3. Remove the Fan Motor assembly by loosening 4 screws

and disassemble the shroud.

4. Pull out the fan and separate the Fan Motor and Bracket.

3-6 LAMP

REFRIGERATOR ROOM LAMP

Figure 16-1

SHROUD

Figure 12

3-5 DEFROST CONTROL ASSEMBLY

Defrost control assembly consists of Defrost Thermostat

and FUSE-M.

Defrost Thermostat functions to defrost automatically and it

is attached to metal side of the Evaporator and senses

Temp.

Fuse-M is a safety device for preventing over-heating of the

Heater when defrosting.

At the temperature of 77°C, it stops the emission of heat

from the Heater.

1. Pull out the grille assembly.

2. Separate the connector connected with the Defrost

Control assembly and replace the Defrost Control

assembly after cutting the Tie Wrap. (Figure 14)

SHROUD-F

DEF-THERMO

3-6-1 Refrigerator room lamp

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Release the hooks on both ends of the lamp shield and

pull the shield downward to remove it.

4. Turn the lamp counterclockwise.

5. Assemble in reverse order of disassembly. Replacement

bulb must be the same specification as odginaL

(Max 40 W)

FREEZER ROOM LAMP

Figure 16-2

3-6-2 Freezer room lamp

1. Unplug refrigerator or disconnect power.

2, Reach behind light shield to remove bulb.

3. Replace bulb with a 25-watt appliance bulb,

4. Plug in refrigerator or reconnect power,

3-7 CONTROL BOX-R

1. First, remove all shelves in the refrigerator and Control

Bax-R by loosening 2 screws,

Figure 13

FUSE-M

HOLDERFUSE Figure 14

CONTROL BOX-

COVER LAMP_ Figure 17

2. Remove the Control Box-R by pulling it downward.

3. Disconnect the lead wire on the right position and

seperate timer, themostat, Lamp socket, etc.

-7-

4. ADJUSTMENT

_1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas evaporated from evaporator of the refrigerator, and

condenses this gas to high temperature and high pressure

gas, and then plays delivering role to condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are outside the

compressor. Since the compressor is manufactured to

tolerances of I micron, and is sealed in a dust - and

moisture - free environment, use extreme caution when

repairing it.

4-%3 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) No Strike

If applying forcible power or strike (dropping or careless

handling), poor operation and noise may occur.

(3) Use proper electric components appropriate to the

Compressor.

(4) Note to Keep Compressor,

If Compressor gets wet in the rain and rust in the pin of

Hermetic Terminal, the result may be poor operation

and poor contact may cause.

(5) Be careful that dust, humidity, and welding flux don't

contaminate the compressor inside when replacing the

Compressor. Dust, humidity, and flux due to welding

which contaminates the cylinder may cause leskage

and noise.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-centact

semiconductor starting device which uses ceramic

material consisting of BaTiO3.

(2) The higher the temperature is, the higher the resistance

value. These ,features are used as starting device for

the Motor,

4-2-2 Role of PTC-Starter

(1) PTC is attached to Hermetic Compressor used for

Refrigerator, Show Case, and starting Motor,

(2) Compressor for household refrigerator applies to

single-phase induction Motor.

For normal operation of the single-phase induction

motor, in the starting operation flows in both main coil

and sub-coil. After the starting is over, the current in

subcoil is cut off. The proper features of PTC play aft

the above roles. So, PTC is used as a motor starting

device.

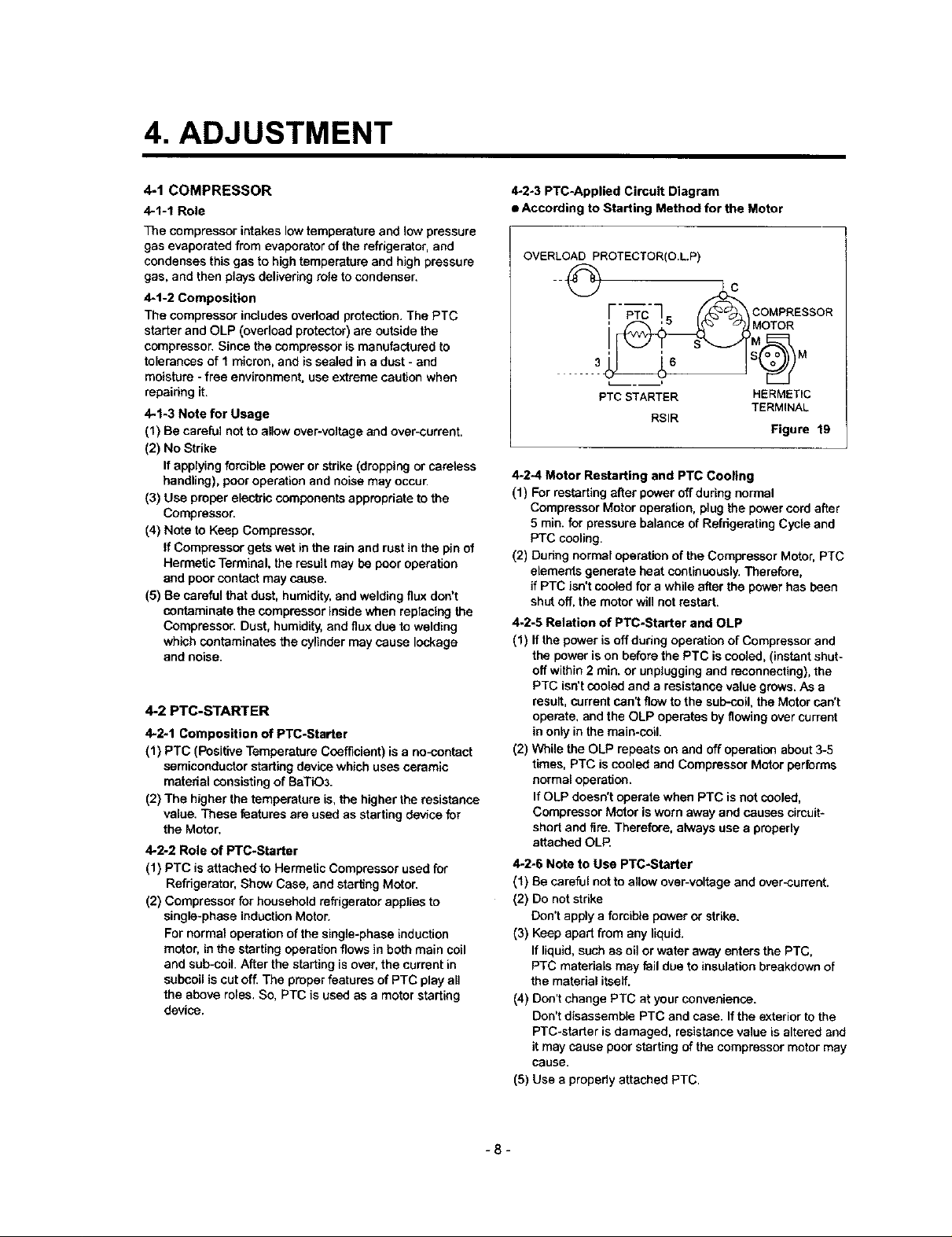

4-2°3 PTC-Applied Circuit Diagram

• According to Starting Method for the Motor

OVERLOAD PROTECTOR(O.L.P)

F- -c-q F COMPRESSOR

.....

PTC STARTER HERMETIC

RSIR

4*2*4 Motor Restarting and PTC Cooling

(1) For restarting after power off during normal

Compressor Motor operation, plug the power cord after

5 rain. for pressure balance of Refrigerating Cycle and

PTC cooling.

(2) During normal operation of the Compressor Motor, PTC

elements generate heat continuously. Therefore,

if PTC iso't cooled for a while after the power has been

shut oft, the motor will not restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the power is off during operation of Compressor and

the power is on before the PTC is cooled, (instant shut-

off within 2 rain. or unplugging and reconnecting), the

PTC isn't cooled and a resistance value grows. As a

result, current can't flow to the sub-ceil, the Motor can't

operate, and the OLP operates by flowing over current

in only in the main-cofi.

(2) While the OLP repeats on and off operation about 3-5

times, PTC is cooled and Compressor Motor performs

normal operation.

If OLP doesn't operate when PTC is not cooled,

Compressor Motor is worn away and causes cimuit*

short and fire. Therefore, always use a properly

attached OLR

4-2-6 Note to Use PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not strike

Don't apply a forcible power or strike.

(3) Keep apart from any liquid.

If liquid, such as oil or water away enters the PTC,

PTC materials may Faildue to insulation breakdown of

the materiel itself.

(4) Don't change PTC at your convenience.

Don't disassemble PTC and case. If the exterior to the

PTC-starter is damaged, resistance value is altered and

it may cause poor starting of the compressor motor may

cause.

(5) Use a propedy attached PTC.

TERMINAL

Figure 19

-8-

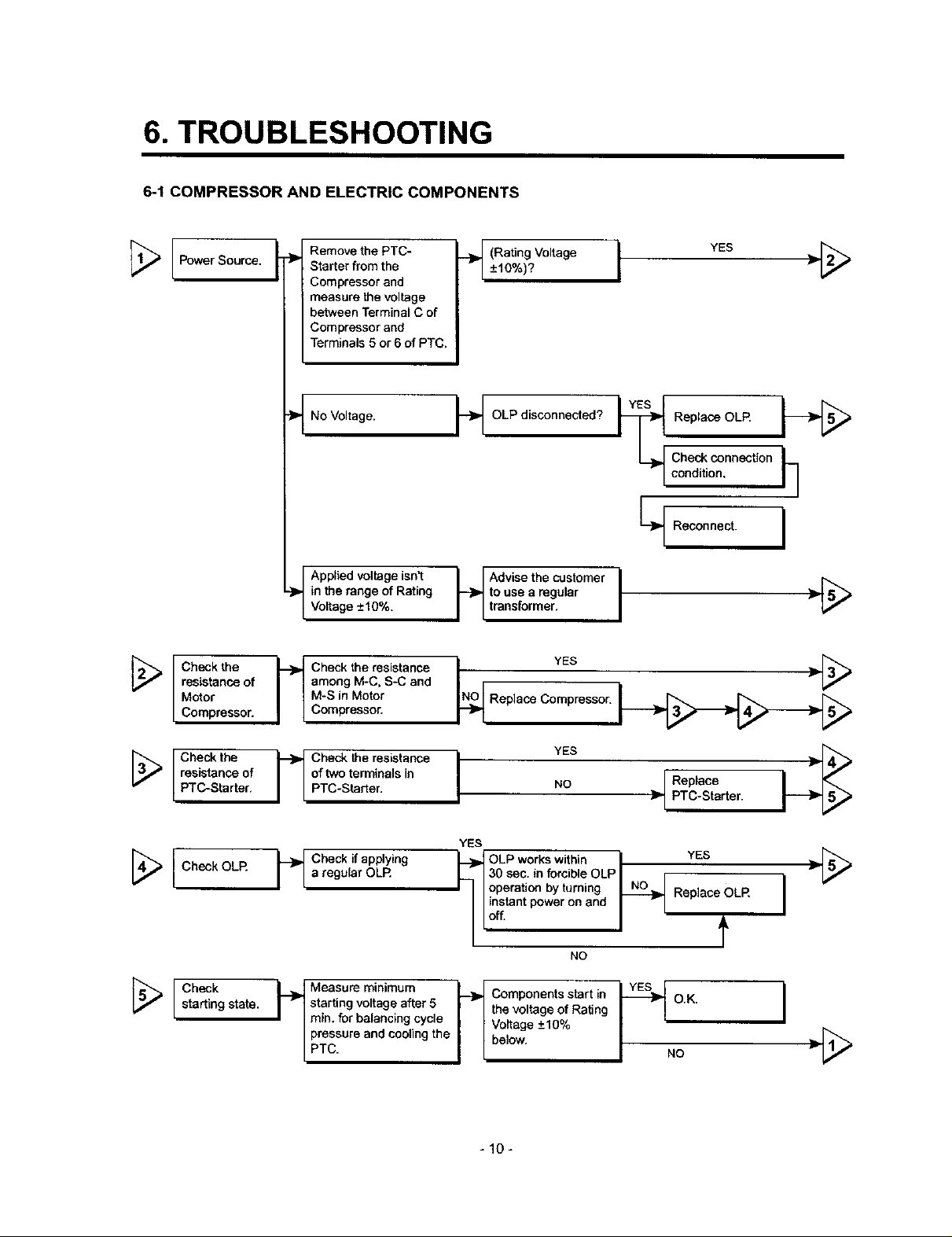

4-30LP (OVERLOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by catting the

current to the Motor if the temperature rises and

activates the bimetal spring in the OLP.

(2) When over-voltage flows to Compressor motor, the

Bimetat works by heating the heater inside the OLR

and the OLP protects Motor by catting off currant which

flows to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Hermetic Compressor used

for the Refrigerator and prevents the Motor Coil from

being started in the Compressor.

(2) Do not turn the Adjust Screw of the OLP in any way for

normal operation of the OLR

(Composition and connection diagram of OLP)

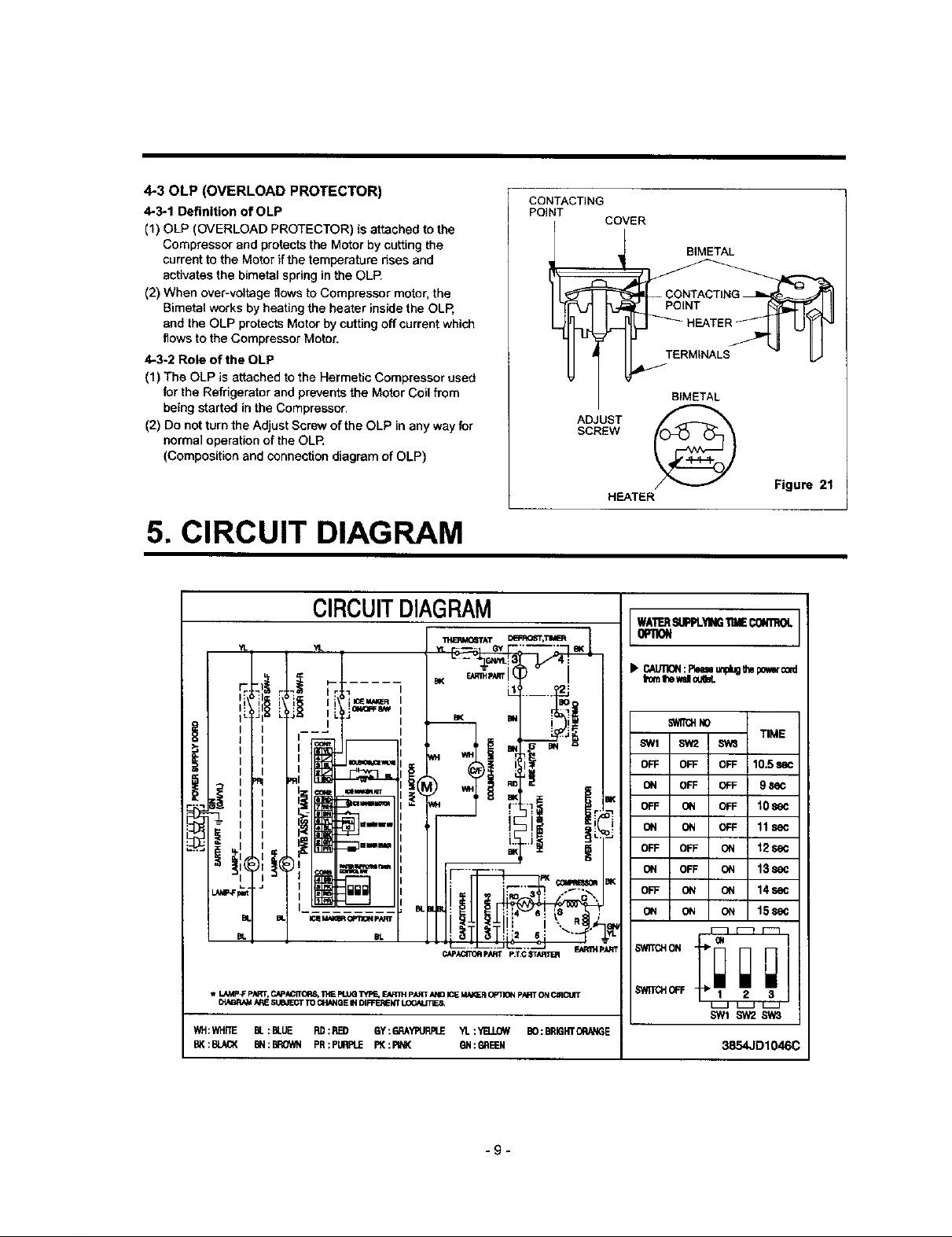

5. CIRCUIT DIAGRAM

CONTACTING

POINT

__BIMETAL

SCREW

ADJUST

COVER

HEATER

BIMETAL

Figure 21

-9-

10.5=

9se(

lOse

11se

t2se

13se

14s_

15se

SWn_H0FF 2 3

SWI SW2SW3

3854JD1046C

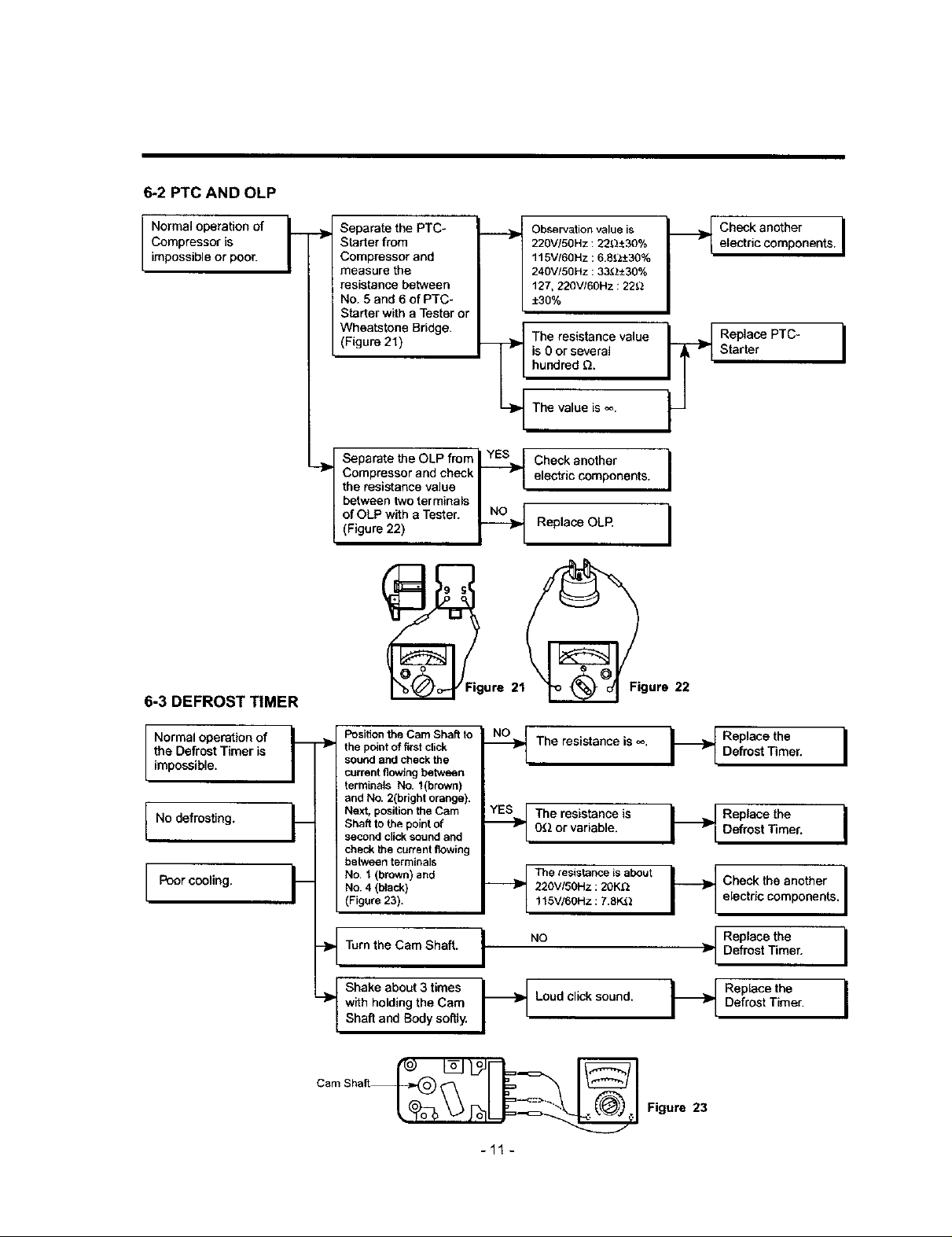

6. TROUBLESHOOTING

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

Power Source.

[_ heck the

resistance of

Motor

Compressor.

.._ Remove the PTC-

Starter from the

Compressor and

measure the voltage

between Terminal C of

Compressor and

Terminals 5 or 6 of PTC,

-_No Voltage.

/ Applied voltage isn't

-}P,_in the range of Rating

/ Voltage +-10%.

i_ heck the resistance

among M-C, S-C and

M-S in Motor

Compressor.

_}_ (Rating Voltage I+-10%)?

-_ OLP disconnected?

_ Replace OLR

L-_ Reconnect. I

to use a regular }_

H Advise the customer I [_

transformer.

Replace Compressor.

N_O YES }__

YES }l_[_

condition.

Check connection t_ 1

[_ Check the

[_ [ Check OLR

[_ [ sChartieCnkgstate.

resistance of

PTC-Starter,

--_ heck the resistance

of two terminals in

PTC-Starter.

_1 Check if applying I.__ OLP works within "I YES .[_

a regular OLR I-_ 130 sec. in forcible OLPI _ I

I

YES

I I Ioperation by turning _ Replace OLR

YES

NO }_ Replace

PTC-Starter.

I -'

NO

t_ Measure minimum I--_

starting voltage after 5 I r I

min. for baiencing cycle I I

pressure and cooling the _ I

PTC. I I

the voltage of Rating

Voltage +_10%

Componentsstartin I_ o.K. I

below. NO }1-[_

-10-

6-2 PTC AND OLP

Compressor is

I Normal operationof

impossibleor poor.

Sl_rter from

Compressor and

measure the

Separate the PTC-

resistance between

' No. 5 and 6 of PTC-

Starter with a Tester or

Wheatstone Bridge.

(Figure 21)

"_' Compressor and check I

the resistance value I I

between two terminals

Separate the OLP fmm_ YES_ _

of OLP with a Tester. NLN0_

(Figure 22)

(_Figure 21_igure 22

I ,

Observationvalue is

220V/5OHz: 22_:_30%

115V/6OHz ;6.8_.__+30%

240V/50Hz ;33(_±30%

127, 220V/60Hz : 22_

±30%

The resistance value

is 0 or several

hundred Q.

The value is _.

Check another

electric components.

Replace OLR

.._ Check another I

electric components. I

I

I

6-3 DEFROST TIMER

Normal operation of

the Defrost Timer is

impossible.

No defrosting.

Poorcooling.

"_ the point of first click

fl Position the Cam Shaft to

F Next, position the Cam

___ No. 1 (brown) and

sound and check the

current flowing between

terminals No. t(brown)

and No. 2(bright orange).

Shaft to the point of

second click sound and

check the current flowing

between terminals

No. 4 (black)

(Figure 23).

- Turn the Cam Shaft.

"-_ with holding the Cam

Shake about 3 times

Shaft and Body softly.

--_ The resistance is _o.

__The resistance is

__The resistance is about

OQ or variable.

220VISOHz:20K_

1t 5V/6OHz :7.8K3.2

I "°

Loud click sound.

-11 -

H

Figure 23

Replace the

Defrost Timer.

Defrost Timer.

Replace the I

Check the another I

electric components. I

Defrost Timer.

-I

Replace the I

Defrost Timer.

Replace the I

i

i

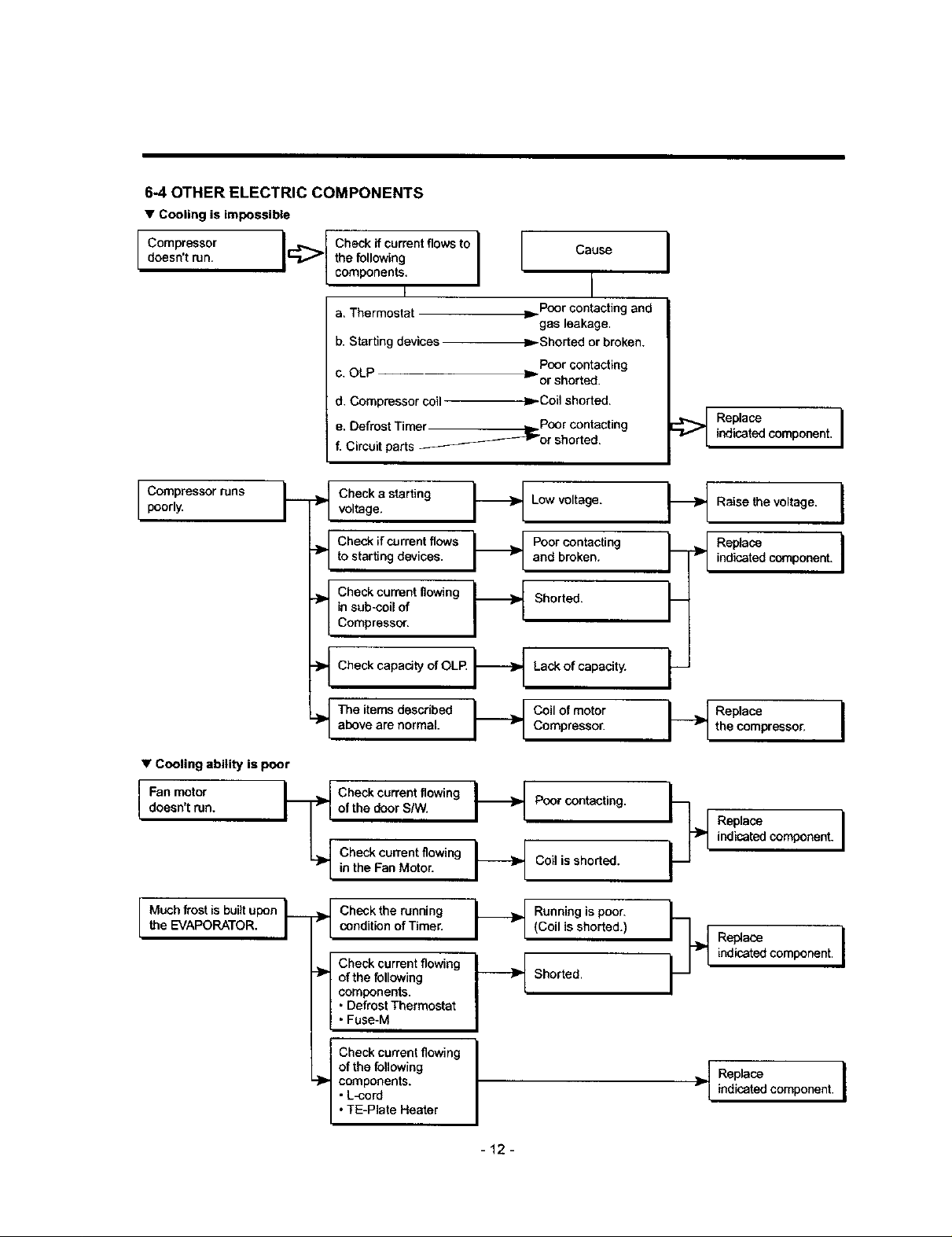

6-4 OTHER ELECTRIC COMPONENTS

• Cooling is impossible

doesn't ran. I:_

Compressor I

J Compressor runs

poorly.

Check ff cuwentflowsto

the following

component.

a. Thermostat

b. Starting devices

c. OLP _ orshorted.

d. Compressor coil

e. Defrost Timer _ Poor contacting

f. Circuit parts ____-_--_"or shorted.

_ heck a starting _{ Low voltage.voltage.

to starting devices, and broken.

.}_ Check if currant flows t._ Poor oontecting

in sub-coil of

_ heckcum_nt flo_ng ___ Shorted.

Compressor.

Cause

I

Poor contacting and

gas leakage.

,._Shorted or broken.

Poorsenta_ing

_Coilshorted.

I

I

_ Replace

indicated component. I

Raise the voltage. I

_'-- }_ iRndiP_t6_dcemp°ne_" I

• Cooling ability is poor

doesn't run.

I Fan motor

Much frost is built upon

the EVAPORATOR. I---

Check capacity of OLR

The items described

above are normal.

of the door S/W. Poor contacting.

Check current flowing _._

Check current flowing _ Coil is

in the Fan Motor.

Check the running _ Running is poor.

condition of Timer. I rl (Coil is shorted.)

Check current flowing I _l

components.

• Defrost Thermostat

of the following _ Shorted.

i • Fuse-M

Check current flowing I

of the following

components.

• L-cord

• TE-Piate Heater

_,_ oil of motorCompressor.

i I

I -I

I

Lack of capacity.

shorted.

_ Replece

the compressor. I

indicated component.

Replace I

indicated component.

Replace I

Replace

indicated component. I

-12-

Loading...

Loading...