LG LRTB2021W, LRTB1821W Owner’s Manual

SERVICING PRECAUTIONS

AIR RECHARGING IN COMPRESSOR

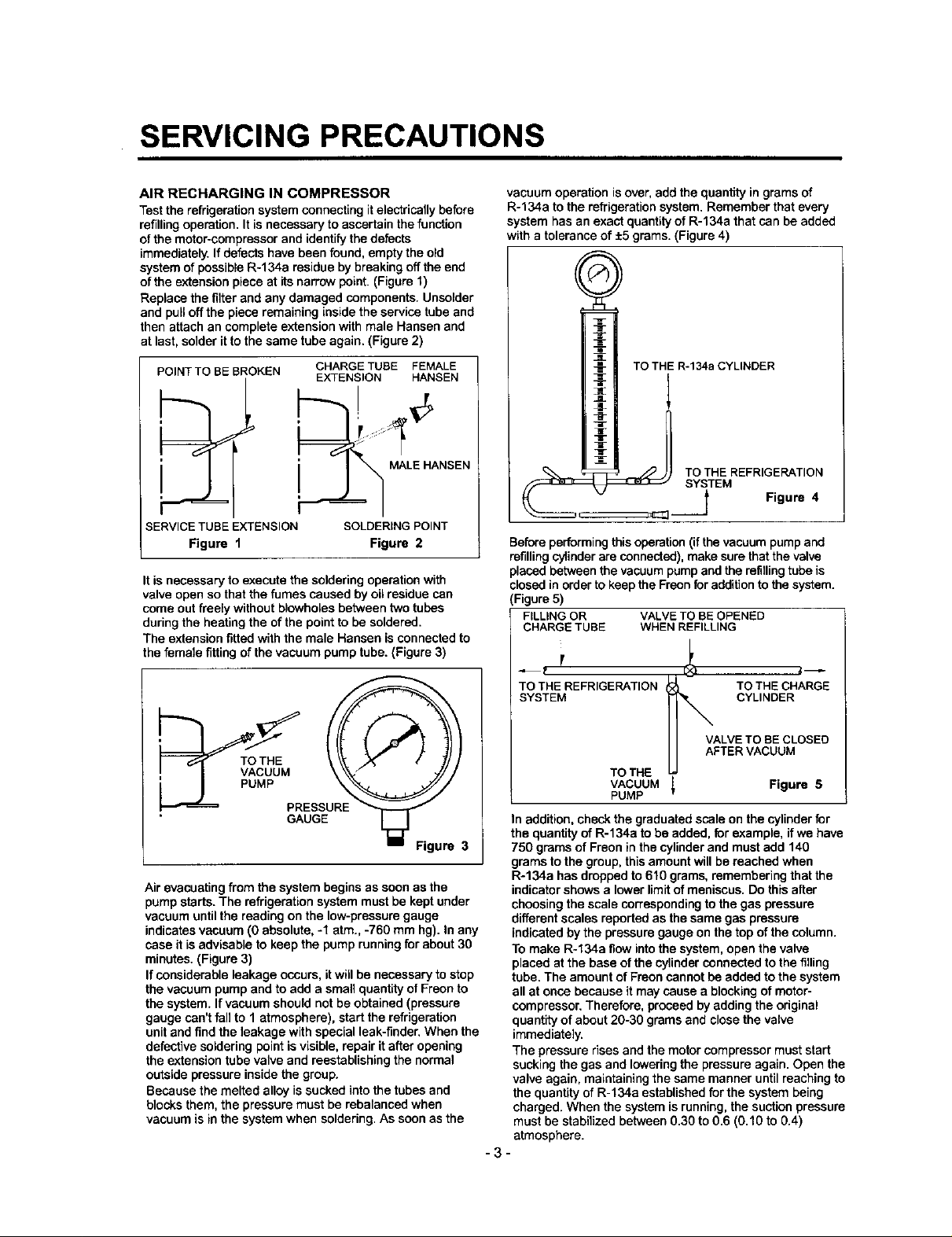

Test the refrigeration system connecting it electrically before

refilling operation. It is necessary to ascertain the function

of the motor-compressor and identify the defects

immediately. If defects have been found, empty the old

system of possible R-134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an complete extension with male Hanson and

at last, solder it to the same tube again. (Figure 2)

POINT TO BE BROKEN CHARGE TUBE FEMALE

'.J__ i MALE HANSEN

SERVICE TUBE EXTENSION SOLDERING POINT

Figure 1 Figure 2

EXTENSION HANSEN

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during the heating the of the point to be soldered.

The extension fitted with the male Hanson is connected to

the female fitting of the vacuum pump tube. (Figure 3)

vacuum operation is over, add the quantity in grams of

R-134a to the refrigeration system. Remember that every

system has an exact quantity of R-134a that can be added

with a tolerance of +5 grams. (Figure 4)

TO THE R-134a CYLINDER

:__ TO THE REFRIGERATION

SYSTEM

I Figure 4

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump end the refillingtube is

closed in order to keep the Frecn for addition to the system.

(Figure 5)

FILLING OR VALVE TO BEOPENED

CHARGE TUBE WHEN REFILLING

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 arm., -760 mm hg). In any

case it is advisable to keep the pump running for about 30

minutes. (Figure 3)

If considerable leakage occurs, itwill be necessary to stop

the vacuum pump and to add a small quantity of Freon to

the system. If vacuum should not be obtained (pressure

gauge can't fall to 1 atmosphere), start the refrigeration

unit and find the leakage with special leak-finder. When the

defective soldering point is visible, repair it after opening

the extension tube valve and reestablishing the normal

outside pressure inside the group.

Because the melted alloy is sucked into the tubes and

blocks them, the pressure must be rebalanced when

vacuum is in the system when soldering. As soon as the

TO THE REFRIGERATION TO THE CHARGE

SYSTEM CYLINDER

VALVE TO BE CLOSED

AFTER VACUUM

TO THE

VACUUM [ Figure 5

PUMP

T

In addition, check the graduated scale on the cylinder for

the quantity of R-134a to be added, for example, if we have

750 grams of Freon in the cylinder and must add 140

grams to the group, this amount will be reached when

R-134a has dropped to 610 grams, remembering that the

indicator shows a lower limit of meniscus. Do this after

choosing the scale corresponding to the gas pressure

different scales reported as the same gas pressure

indicated by the pressure gauge on the top of the column.

To make R-134a flow into the system, open the valve

placed at the base of the cylinder connected to the filling

tube. The amount of Fraon cannot be added to the system

all at once because it may cause a blocking of motor-

compressor. Therefore, proceed by adding the original

quantity of about 20-30 grams and close the valve

immediately.

The pressure rises and the motor compressor must start

sucking the gas and lowering the pressure again. Open the

valve again, maintaining the same manner until reaching to

the quantity of R-134a established for the system being

charged. When the system is running, the suction pressure

must be stabilized between 0.30 to 0.6 (0.10 to 0.4)

atmosphere.

"3-

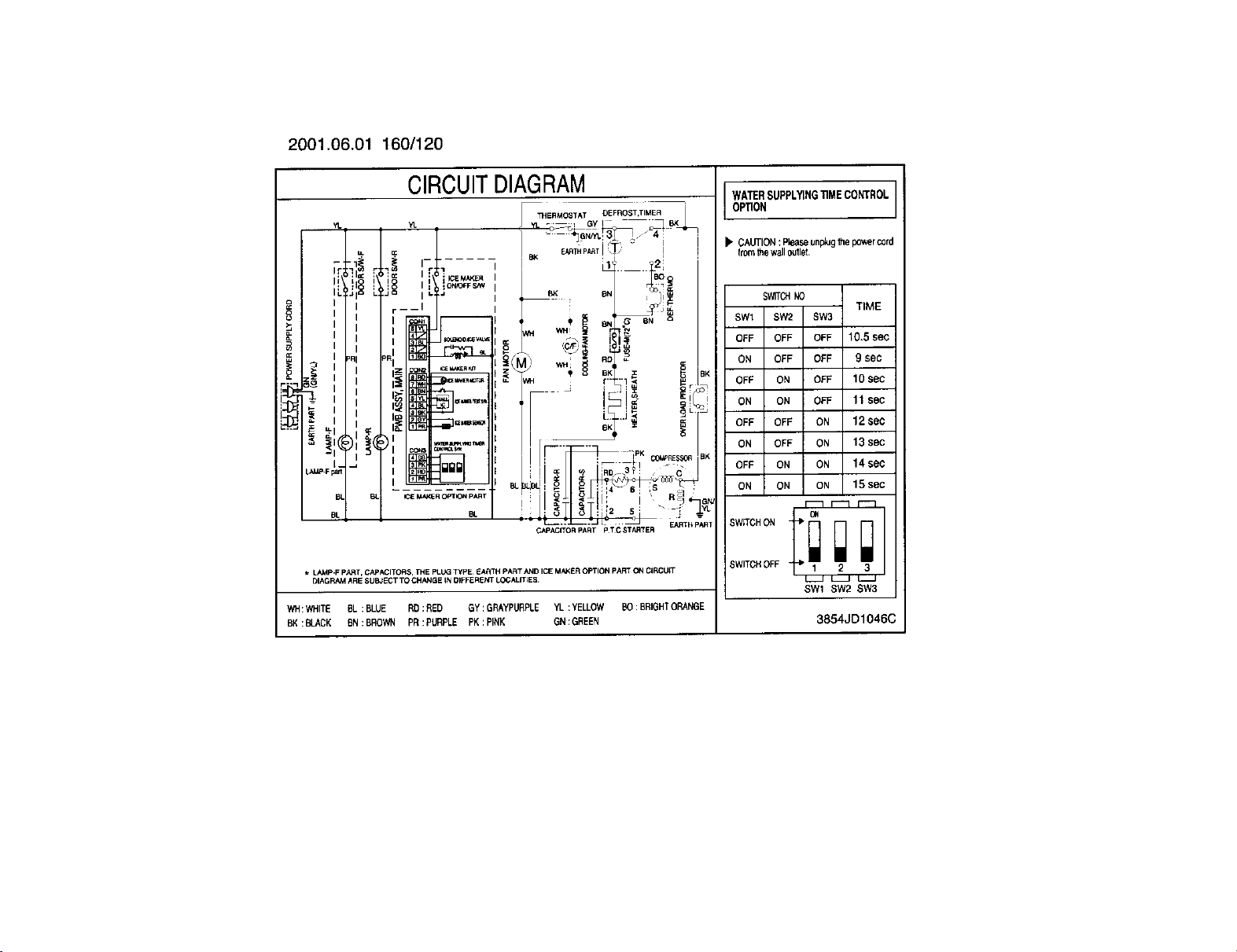

2001.06.01 160/120

CIRCUITDIAGRAM

YL YL

LL OC

;i__ ,_ '_i_

I!! h'_ := I I 'K:E_','XE.

=_ IL_'_ J_ ,._

>_ I

i Z i _ u<

1 n x "="_=

= _ll(_),___(,,ll[__1=. =-,......

LAMP-F paxt

BL _ ,_E _A_Q¢R OPTION P_T

OL BL

* LAMP-F pART, CAPACITORS, THE PLUG _pE, _AR_H pA_T AND ICE MAKER OPTION pART C_NCIRCUIT

WH:WHITE BL:BLUE RD:NED GY:GRAYPURPLE YL :YELLOW BO: BRIGHTORANGE

BK: BLACK _.N:BROWN PR ; PURPLE PK:PINK ON:GREEN

I i :_ _ON_O'FFSPN

r----I

-- I _ 8N G SN

_'_ERMOSTAT_} GYIDEFROST'TIMERj-_T 8K

',

I _ °" , ,_

_M) _ _ .D, e

II .... = ==

' I"__!i_ - '-;'_

L'_.!_-_-_,_i:__ _.t_,

;ApA_iTOR PART p T C STABTER

_LITtES

WATERSUPPLYINGTIMECONTROL

OPTION

)" CAUTION:Pleaseunp_Jgthepowercord

fromthewalloutlet.

S_TCHNO

SW1 SW2 SW3

OFF OFF OFF 10.5 sec

ON OFF OFF 9 sec

OFF ON OFF 10 sec

ON ON OFF 11 BOG

OFF OFF ON 12 sec

ON OFF ON 13 sec

OFF ON ON 14 sec

ON ON ON 15 sec

_ r-'3 r'-]

SWITCHOFF _" 1 2 3

SW1 SW2 SW3

TIME

o_

3854JD1046(

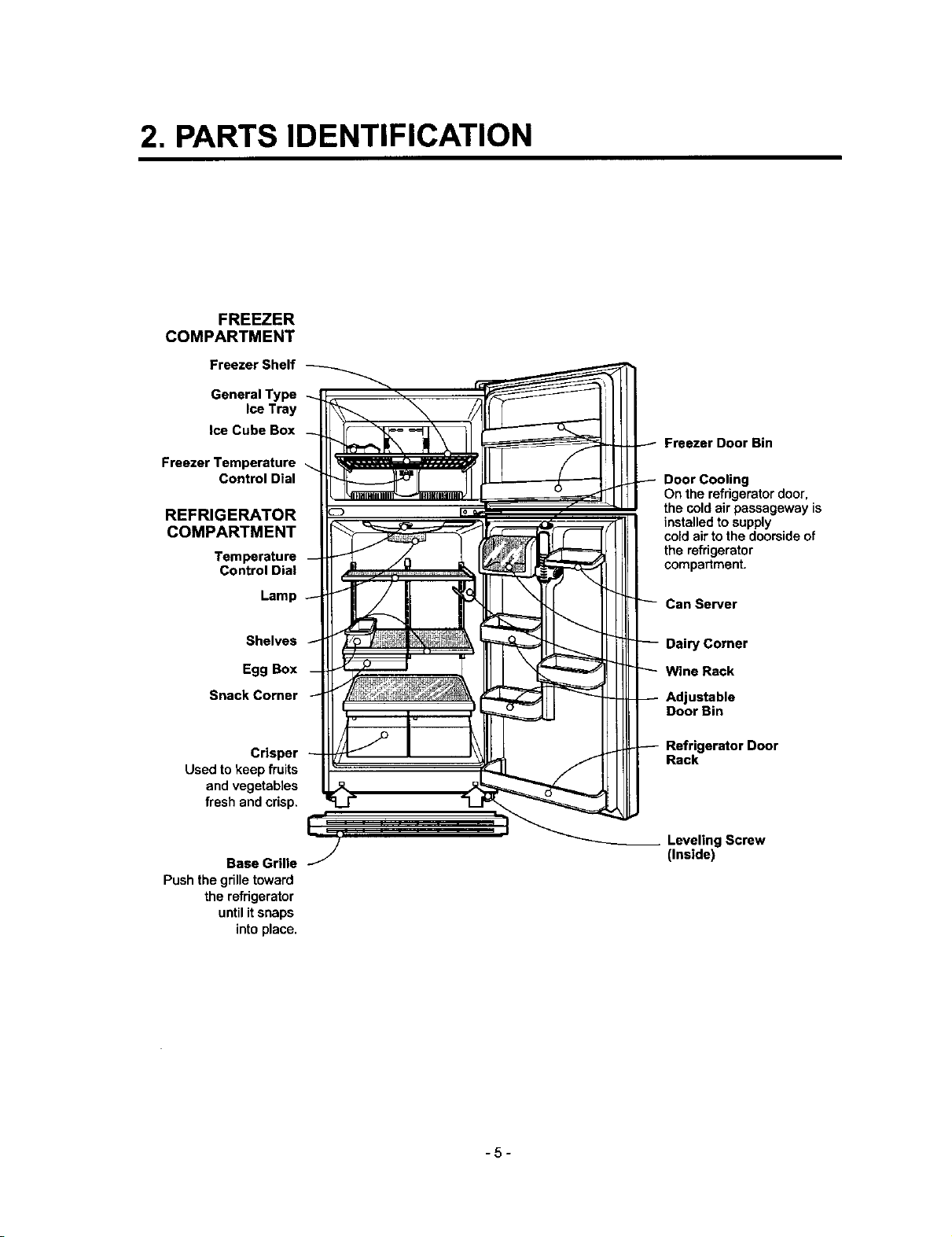

2. PARTS IDENTIFICATION

FREEZER

COMPARTMENT

Freezer Shelf

GeneralType

Ice Tray

Ice Cube Box

Freezer Temperature

Control Dial

REFRIGERATOR

COMPARTMENT

Temperature

Control Dial

Lamp

Freezer Door Bin

Door Cooling

On the refrigerator door,

the cold air passageway is

installed to supply

coldair tothe doorsideof

the refrigerator

compartment.

Can Server

Shelves

Egg Box

Snack Corner

Crisper

Used to keep fruits

and vegetables

fresh and crisp.

Base Grille

Pushthe grilletoward

the refrigerator

until it snaps

intoplace,

Dairy Corner

Wine Rack

Adjustable

Door Bin

Refrigerator Door

Rack

LevelingScrew

(Inside)

-5-

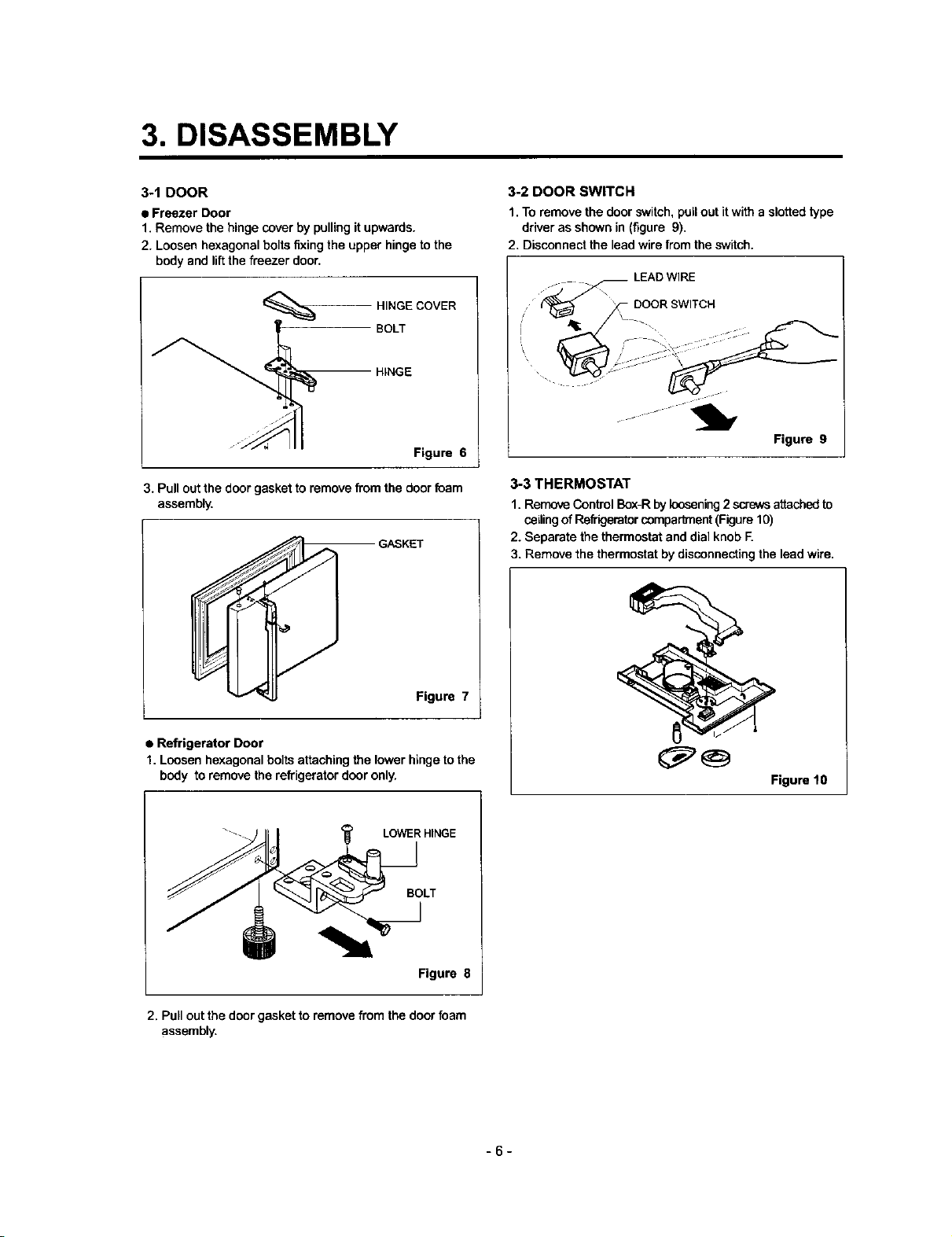

3. DISASSEMBLY

3-1 DOOR

• Freezer Door

1. Remove the hinge cover by pulling it upwards.

2. Loosen hexagonal bolts fixing the upper hinge to the

body and liftthe freezer door.

HINGE COVER

HINGE

BOLT

Figure 6

3. Pull out the door gasket to remove from the door foam

assembly,

GASKET

3-2 DOOR SWITCH

1. To remove the door switch, pull out it with a slotted type

driver as shown in (figure 9).

2. Disconnect the lead wire from the switch.

LEAD WIRE

_ DOOR SWITCH

:S 2:2

Figure 9

3-3 THERMOSTAT

1. Remove Control Box-R by loosening2 screws attached to

ceilingof Refi'igemtorcompad_ent (Figure 10)

2. Separate the thermostat and dial knob F.

3. Remove the thermostat by disconnecting the lead wire.

Figure 7

• Refrigerator Door

1. Loosen hexagonal bolts attaching the lower hinge to the

body to remove the refrigerator door only.

<_ LOWER HINGE

BOLT

__J

Figure 8

2. Pull out the door gasket to remove from the door foam

assembly.

Figure 10

-6-

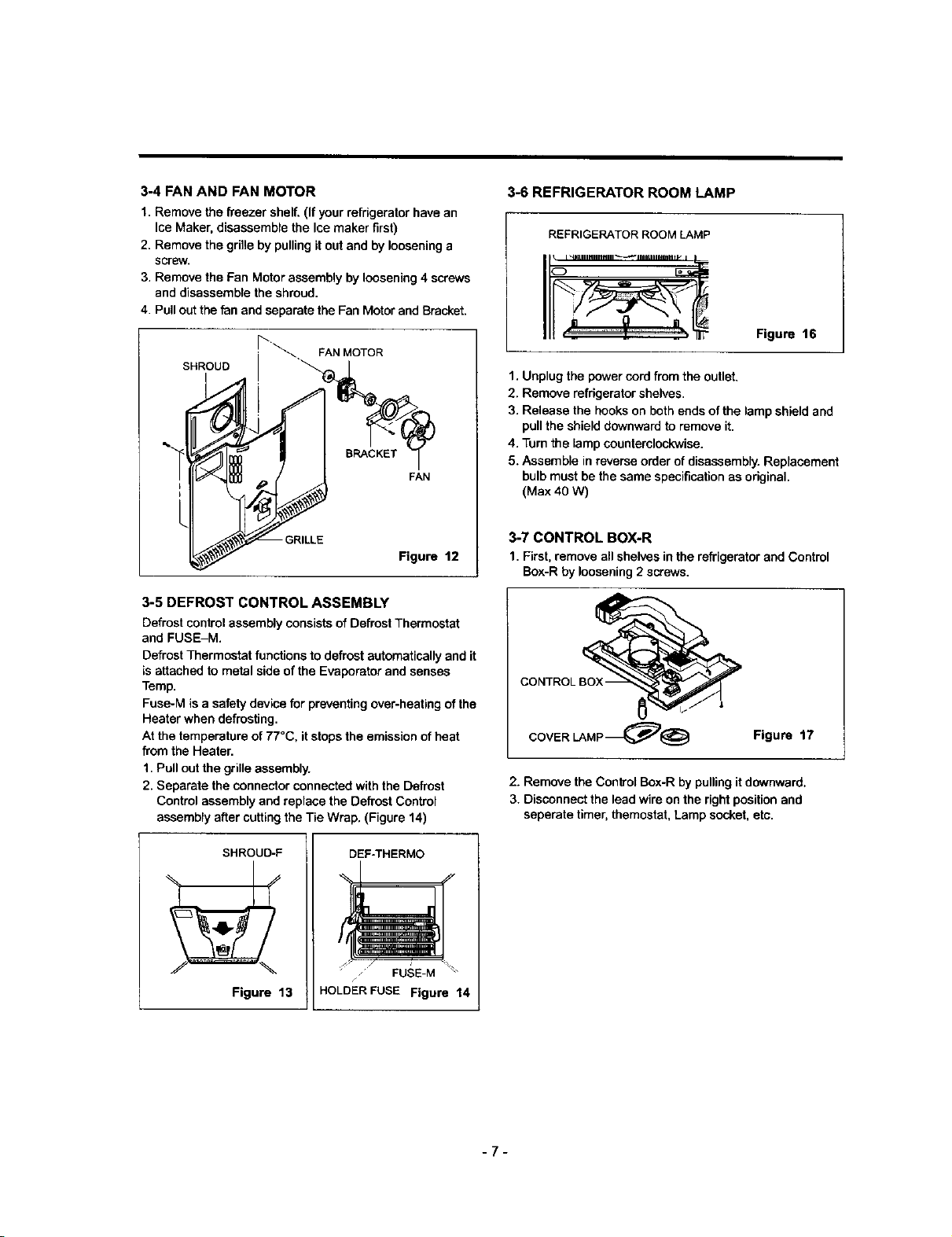

3-4 FAN AND FAN MOTOR

1. Remove the freezer shelf. (If your refrigerator have an

Ice Maker, disassemble the Ice maker first)

2. Remove the grille by pulling it out and by loosening a

screw.

3. Remove the Fan Motor assembly by loosening 4 screws

and disassemble the shroud.

4. Pull out the fan and separate the Fan Motor and Bracket.

_'_. FAN MOTOR

SHROUD

FAN

3-6 REFRIGERATOR ROOM LAMP

REFRIGERATOR ROOM LAMP

............................

Figure 16

1. Unplug the power cord from the outlet,

2. Remove refrigerator shelves.

3. Release the hooks on both ends of the lamp shield and

pull the shield downward to remove it.

4. Turn the lamp counterclockwise.

5. Assemble in reverse order of disassembly. Replacement

bulb must be the same specification as original.

(Max 40 W)

-GRILLE

Figure 12

3-5 DEFROST CONTROL ASSEMBLY

Defrost control assembly consists of Defrost Thermostat

and FUSE-M.

Defrost Thermostat functions to defrost automatically and it

is attached to metal side of the Evaporator and senses

Temp.

Fose-M is a safety device for preventing over-heafing of the

Heater when defrosting.

At the temperature of 77°C, it stops the emission of heat

from the Heater.

1. Pull out the grille assembly.

2. Separate the connector connected with the Defrost

Control assembly and replace the Defrost Control

assembly after cutting the Tie Wrap. (Figure 14)

SHROUD-F

Figure 13

DEF_HERMO

FUSE-M

HOLDER FUSE Figure 14

3-7 CONTROL BOX-R

1. First, remove all shelves in the refrigerator and Control

Box-R by loosening 2 screws.

A

COVER LAMP_@ Figure 17

2. Removethe Control Box-Rby pulling it downward.

3. Disconnectthe lead wireonthe rightpositionand

seperatetimer,themostat,Lampsocket,etc.

-7-

Loading...

Loading...