LG LRSPC2661T Owner’s Manual

WARNINGS AND PRECAUTIONS FOR SAFETY

Please observe the following safety precautions inorder to

use safely and correctly the refrigerator and to prevent

accident and danger during repair.

1. Be care of an electric shock. Disconnect power cord

from wall outlet and wait for more than three minutes

before replacing PWB parts. Shut off the power

whenever replacing and repairing electde components.

2. When connecting power cord, please wait for more than

five minutes after power cord was disconnected from the

wall outlet.

3. Please check if the power plug is pressed down by the

refrigerator against the wall tf the power plug was

damaged, it may cause fire or electric shock.

4. ff the wall outlet is over loaded, it may cause fire. Please

use its own individual electrical outlet for the refrigerator.

5. Please make sure theoutletispropedy earthed,

particularlyin wet or damp area.

6, Use standard electrical components when replacing

them.

7. Make sure the hook is correctly engaged.

Remove dust and foreign matedals from the housing

and connecting parts.

8. Do notfray. damage, machine, heavily bend, pullout,

or twist the power cord.

Please check the evidence of moisture intrusion in the

electrical components. Replace the parts or mask it

with insulation tapes if moisture intrusion was

confirmed.

10. Do not touch the icomaker with hands or tools to

confirm the operation of geared motor.

11. Do not let the customers repair, disassemble, and

reconst_ct the refdgerator for themselves. It may

cause accident, electTic shock, or fire.

12. Do not store flammable materials such as ether,

benzene, alcohol, chemicals, gas, or medicine in the

refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals,

etc., or container with full of water on the top of the

refrigerator.

14. Do not put glass bottles with full of water into the

freezer. The contents shall freeze and break the glass

bottles.

15. When you scrap the refrigerator, please disconnect the

door gasket first and scrap it where children are not

accessible.

-3-

SPECIFICATIONS

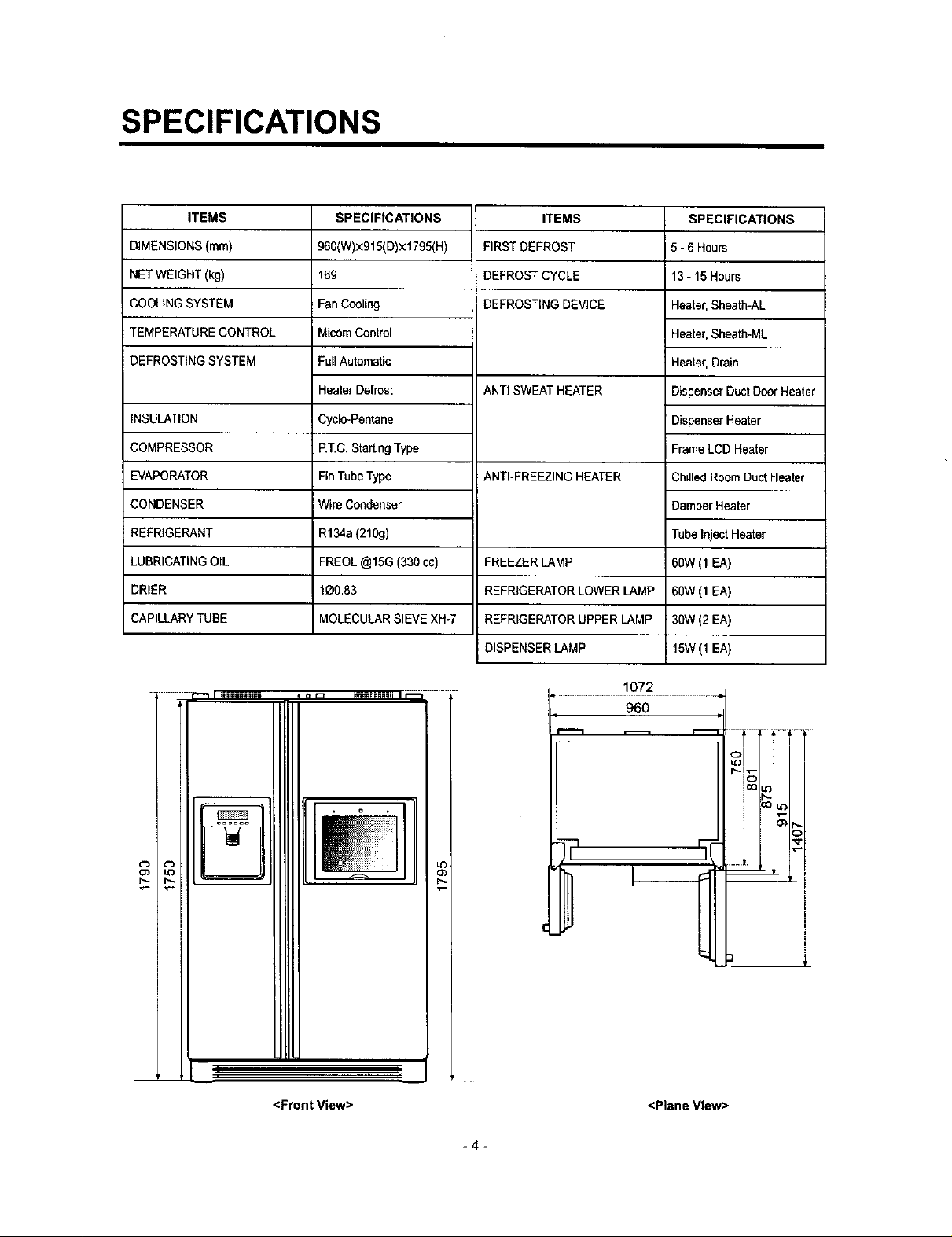

ITEMS

DIMENSIONS (ram)

NET WEIGHT (kg)

COOLING SYSTEM

TEMPERATURE CONTROL

DEFROSTING SYSTEM

INSULATION

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

LUBRICATING OIL

DRIER

CAPILLARY TUBE

SPECIFICATIONS

960(W)x915(D)×1795(H)

169

Fan Cooling

MicomControl

FullAutomatic

Heater Defrost

Cyclo-Pentane

P,T.C,Starting Type

Fin Tube Type

Wire Condenser

R134a (210g)

FREOL @15G (330 cc)

1_0.83

MOLECULAR SIEVE XH-7

ITEMS

FIRST DEFROST

DEFROST CYCLE

DEFROSTING DEVICE

ANTI SWEAT HEATER

ANTI-FREEZING HEATER

FREEZER LAMP

REFRIGERATOR LOWER LAMP

REFRIGERATOR UPPER LAMP

DISPENSER LAMP

SPECIFICATIONS

5 - 6 Hours

13- 15 Hours

Heater, Sheeth-AL

Heater, Sheatb-ML

Heater, Drain

DispenserDuctDoor Heater

DispenserHeater

Frame LCD Heater

Chilled Room DuctHeater

Damper Heater

Tube Inject Heater

60W (1 EA)

60W (1 EA)

30W (2 EA)

i 15W(1 EA)

<Front View>

1072

<Plane View>

L

i

!

I

i

-4-

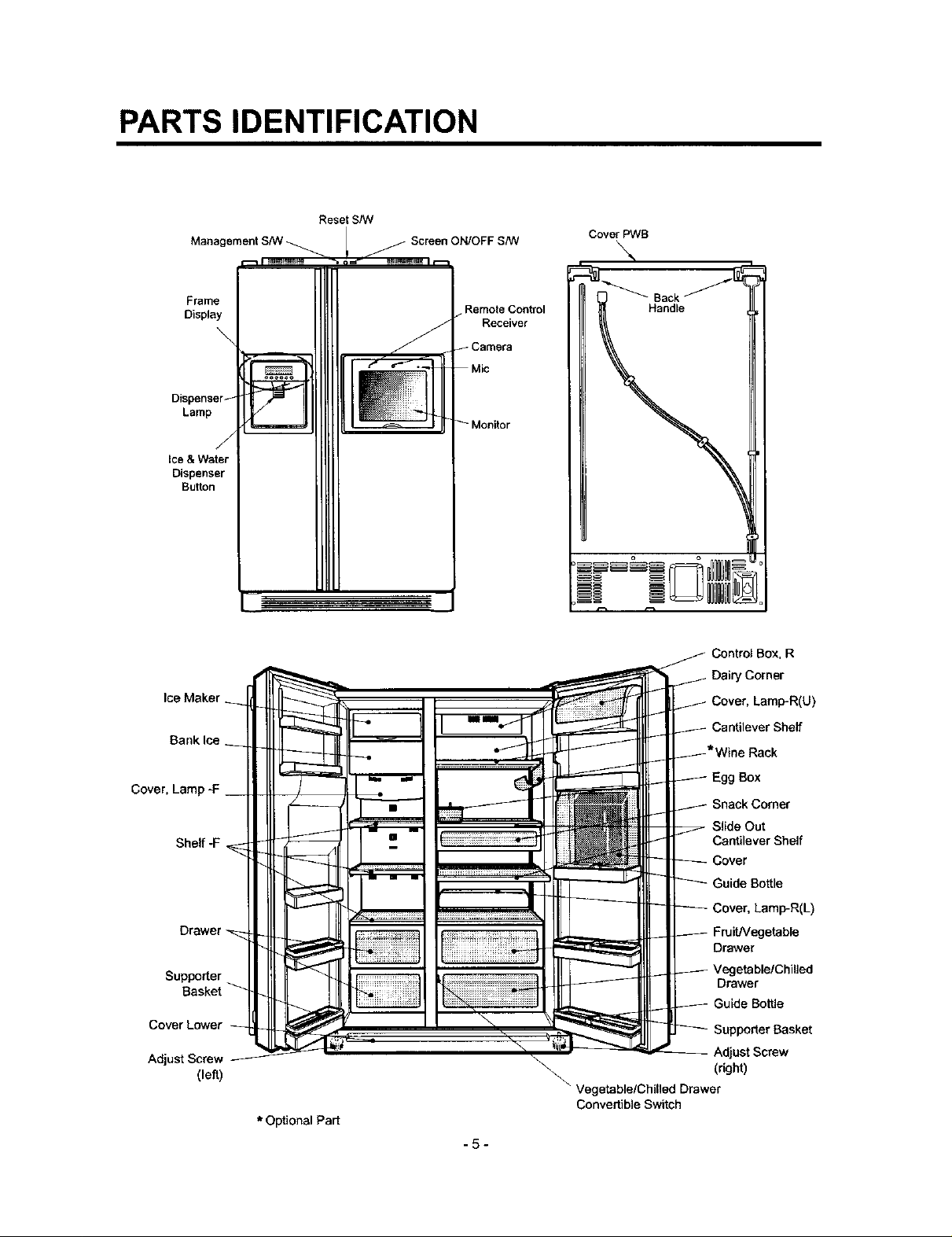

PARTS IDENTIFICATION

Manag

Frame

Display

Lamp

Ice &Water

Dispenser

Button

Banklce

Reset S/W

Cover PWB

RemoteControl

Receiver

Camera

Control Box, R

Dairy Corner

Cover, Lamp-R(U)

Cantilever Shelf

Cover,

Shelf-F

Supporter

Cover Lower

Adjust Screw

Basket

(left)

* Optional Part

Egg Box

Snack Comer

Slide Out

Cantilever Shelf

Cover

Guide Bottle

Cover, Lamp-R(L)

FruiUVegetable

Drawer

Drawer

Bottle

AdjustScrew

(right)

\\

Vegetable/Chilled Drawer

Convertible Switch

.5-

HOW TO INSTALL REFRIGERATOR

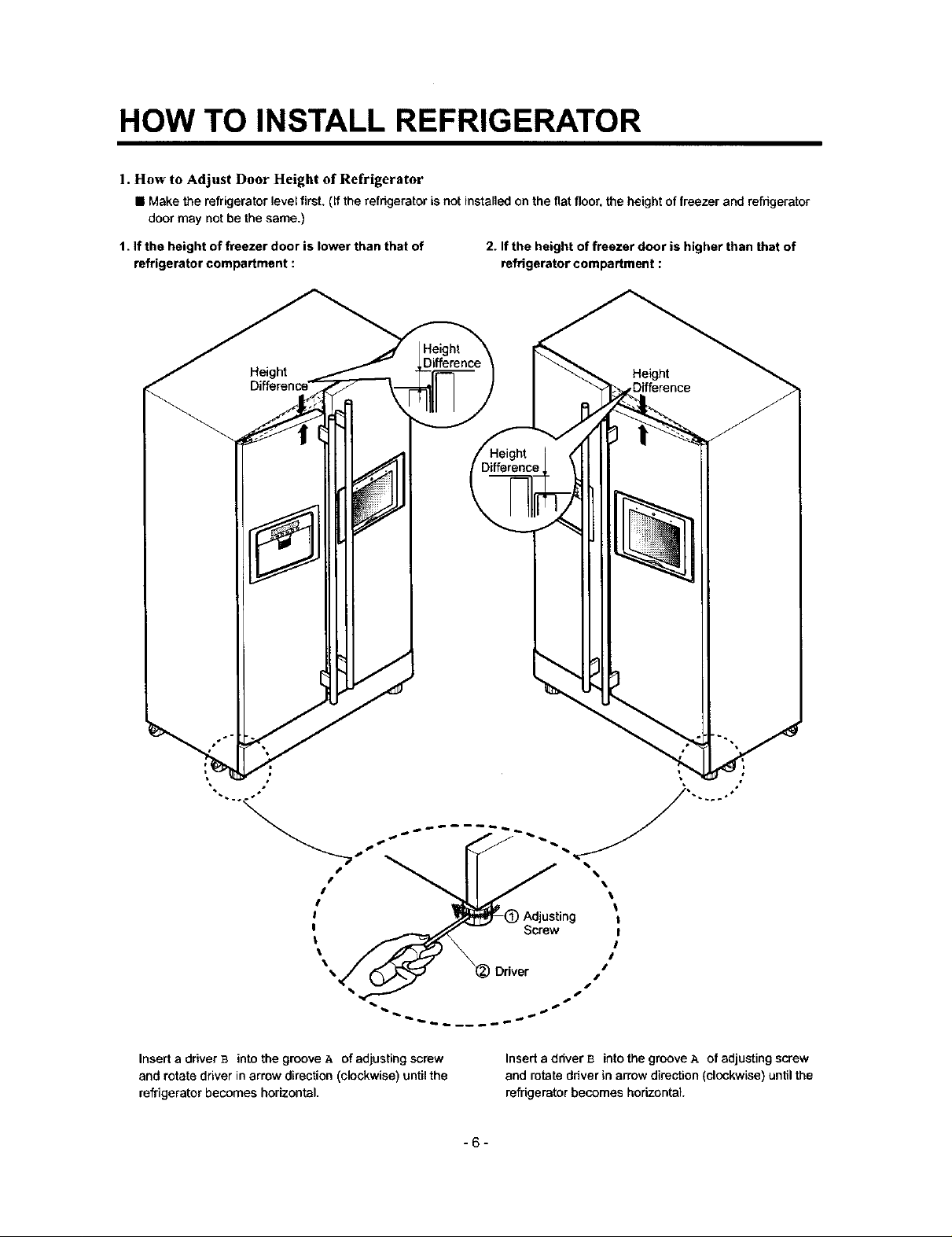

1. How to Adjust Door Height of Refrigerator

• Make the refrigerator level first. (ff the refrigerator is not installed on the fiat floor, the height of freezer and refrigerator

door may not be the same.)

1. If the height of freezer door is lower than that of

refrigerator compartment :

2. If the height of freezer door is higher than that of

refrigerator compartment :

Insert a driver B into the groove A of edjusting screw

and rotate driver in arrow direction (clockwise) until the

refrigerator becomes horizontal.

Insert a ddver B into the groove A of adjusting screw

and rotate driver in arrow direction (clockwise) until the

refrigerator becomes horizontal.

-6-

HOW TO INSTALL REFRIGERATOR

2. How to Install Water Pipe

• Before Installation

t. The icemaker requires the water pressure of 1.5 -

8.5kgf/cm 2. (It is acceptable if city water fills a cup of

180cc with water for 10 seconds)

2. Install booster pump where the city water pressure is

below 1.5kgf/cr_- for normal operation of water and ice

dispenser.

3. The total length of water pipe shall be less than 12rn. Do

not bend the pipe at right angle. If the length is more

than 12m. there will be troubles on water supply due to

water pressure drop.

4. Please install water pipe where there is no heat around.

5. Be sure that the filter does not sterilize.

6. The life span of water filter depends on the use

conditions. But the filter is generally replaced in every

six months. Install filter where replacement can be easily

performed,

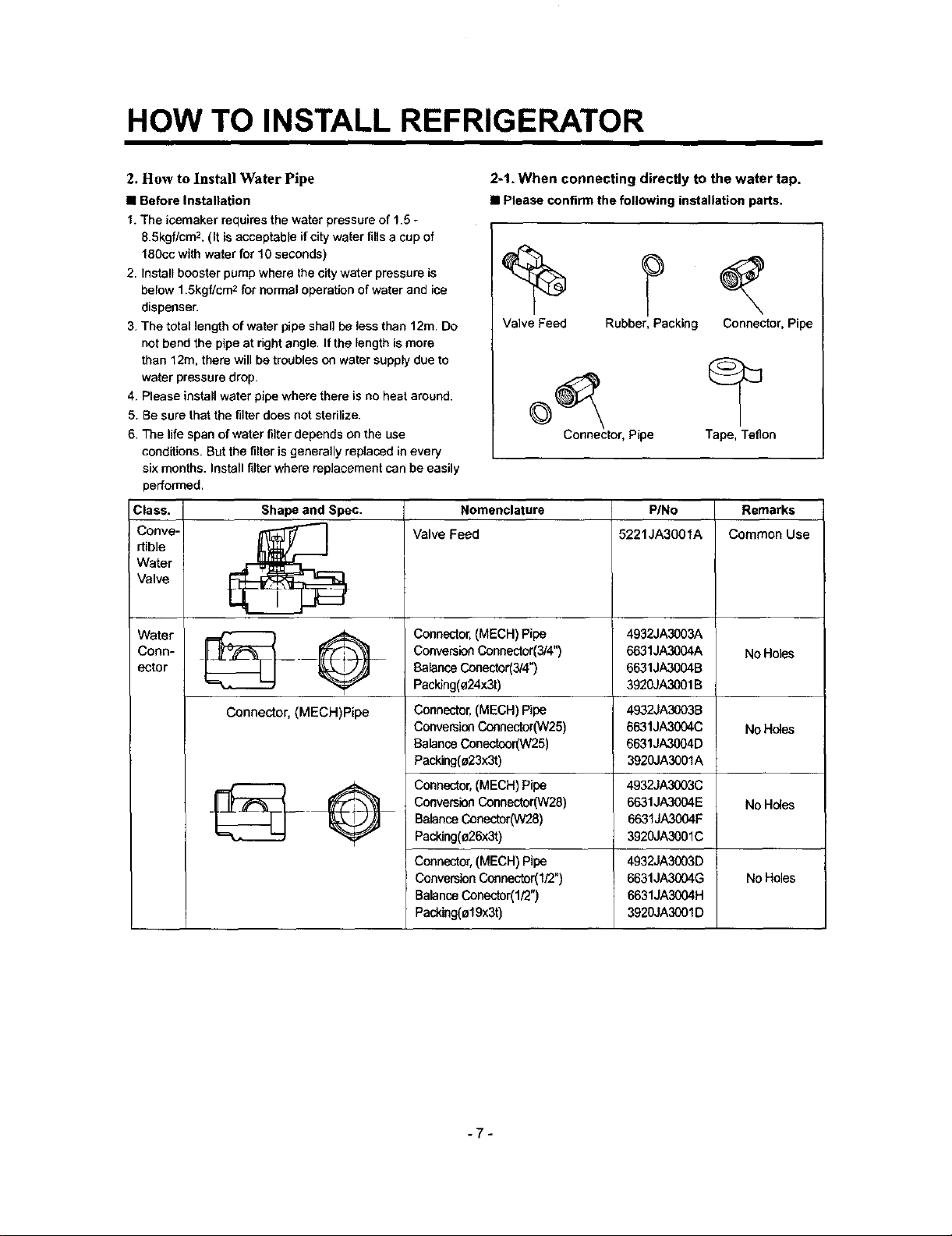

Class. Shape and Spec. Nomenclature PINo Remarks

Conve- _.[_"_ Valve Feed 5221JA3001A Common Use

rtible

Water

Valve

2-1. When connecting directly to the water tap.

• Please confirm the following installation parts.

Valve Feed Rubber, Packing Connector, Pipe

Connector, Pipe Tape, Teflon

Connector,(MECH)Pipe

Conn- _____ 6631JA3004A No Holes

ector 6631JA3004B

Water _ Q 4932JA3003A

Connector, (MECH)Pipe

ConversionConnector(3/4")

BalanceConector(3/4")

Packing(o24x3t)

Connector,(MECH) Pipe

ConversionCeenector(W25)

BalanceConectcor(W25)

Packing(a23x3t)

Connector,(MECH)Pipe

ConversionConnector(W28)

BalanceConector(W28)

Packing(e26x3t)

Connector,(MECH)Pipe

ConversionConnector(I/2")

BalanceConector(1/2")

Packing(ol9x3t)

3920JA3001 B

4932JA3003B

6631JA3004C

No Holes

6631JA3004D

3920JA3001A

4932JA3(X)3C

6631JA3004E No Holes

6631JA3004F

3920JA3001C

4932JA3003D

6631JA3004G

No Holes

6631JA3004H

3920JA3001D

-7-

HOW TO INSTALL REFRIGERATOR

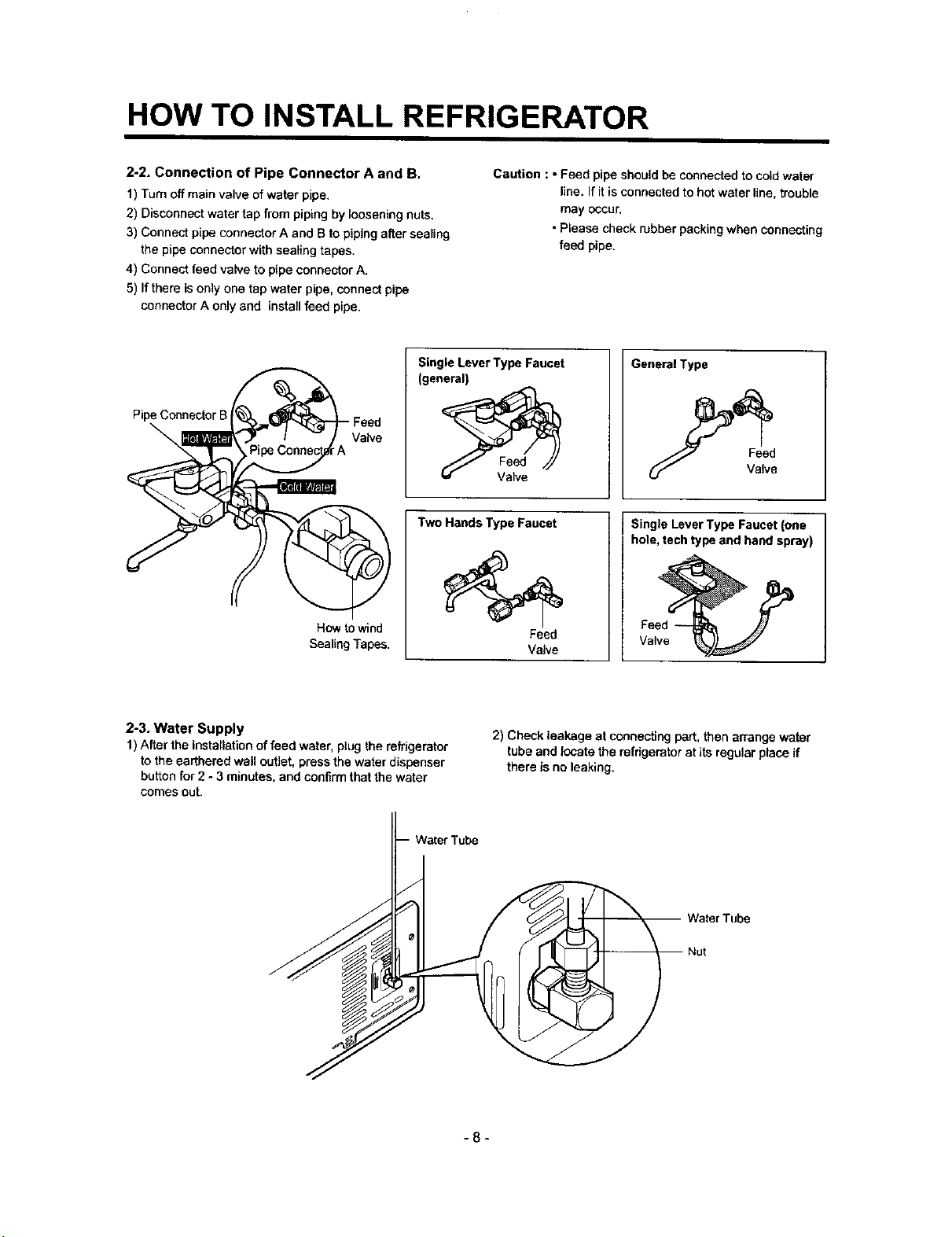

2-2. Connection of Pipe Connector A and B.

1) Turn off main valve of water pipe.

2) Disconnect water tap from piping by loosening nuts.

3) Connect pipe connector A and B to piping alter sealing

the pipe connector with sealing tapes.

4) Connect feed valve to pipe connector A.

5) Ifthere isonly one tap water pipe, connect pipe

connector A only and install feed pipe.

Single Lever Type Faucet

(general)

Pipe Connector B Feed

\

A

Two Hands Type Faucet

How towind

SealingTapes.

Caution : oFeed pipe should be connected to cold water

line. If it is connected to hot water line, trouble

may occur.

• Please check rubber packing when connecting

feed pipe.

Gene_lType

Feed

Valve

Single LeverTypeFaucet(one

hole, techtypeand hand spray)

Feed

Valve

Valve

2-3. Water Supply

1) After the installation of feed water, plug the refrigerator

to the earthered wall outlet, press the water dispenser

button for 2 - 3 minutes, and confirm that the water

comes out.

2) Check leakage at connecting part, then arrange water

tube and locate the refrigerator at its regular place if

there is no leaking.

-8-

HOW TO INSTALL REFRIGERATOR

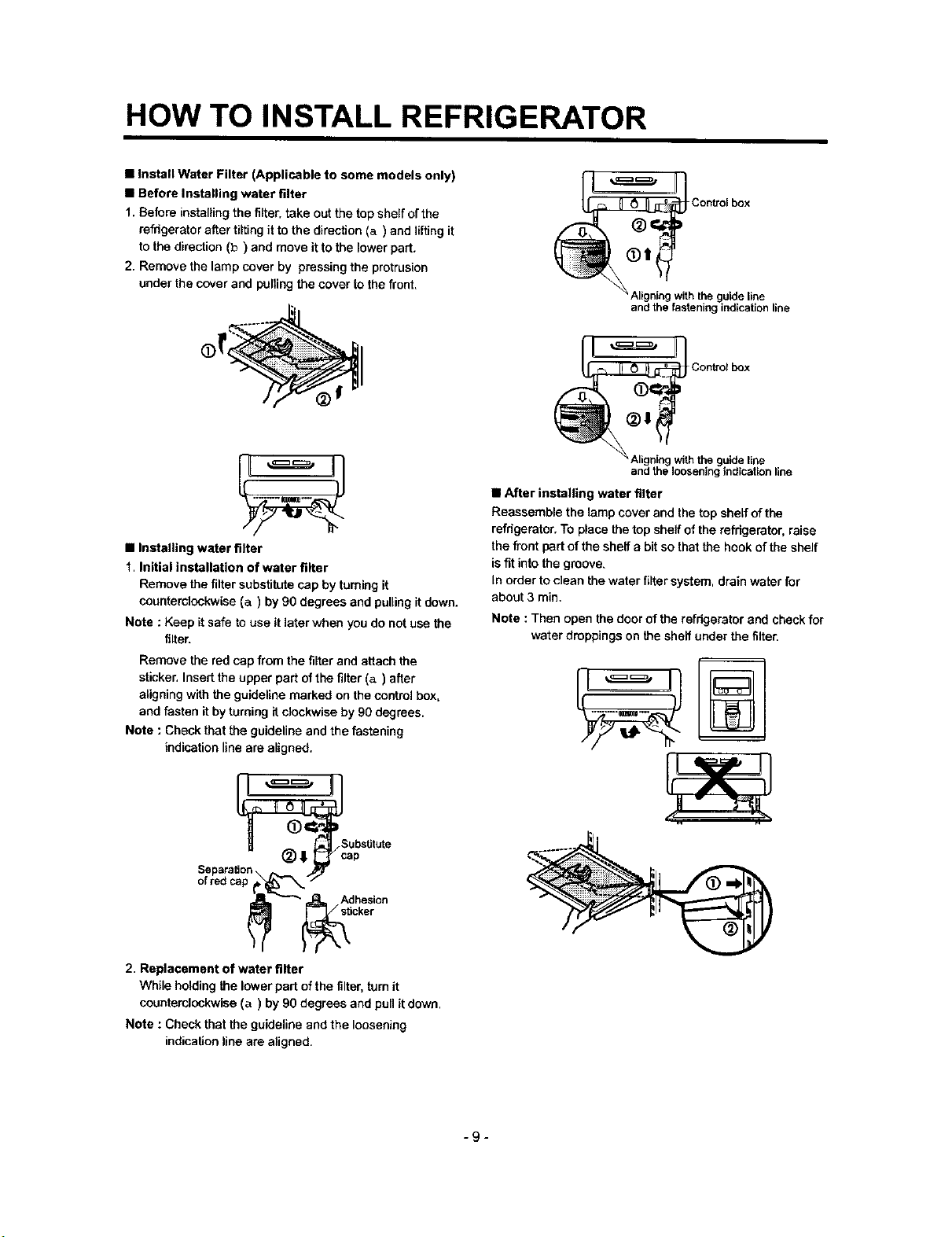

• Install Water Filter (Applicable to some models only)

• Before Installing water filter

1. Before installing the filter, take out the top shelf ofthe

refrigerator after tilting it to the direction (a) and lifting it

to the direction (b) and move it to the lower part.

2. Remove the lamp cover by pressing the protrusion

under the cover and pufiing the cover to the front.

O_i ;ontrolbox

• After installing water filter

Reassemble the lamp cover and the top shelf of the

refrigerator. To place the top sheff of the refrigerator, raise

• Installing water filter

1. Initial installation of water filter

Remove the filter substitute cap by turning it

counterclockwise (a) by 90 degrees and pulling it down.

Note : Keep it safe to use it later when you do not use the

filter.

Remove the red cap from the filter and attach the

sticker, Insert the upper part of the filter (a) after

aligning with the guideline marked on the control box,

and fasten it by turning it clockwise by 90 degrees.

Note : Check that the guideline and the fastening

indication line are aligned.

the front part of the shelf a bit so that the hook of the shelf

is fit into the groove.

In order to clean the water filter system, drain water for

about 3 min.

Note : Then open the door of the refrigerator and check for

water droppings on the shelf under the filter.

Control box

and the fastening indication line

guide line

JI

" " " the guide line

andthe loosening indication line

_ubstitute

_=_= Adhesion

_ _icker

2. Replacement of water filter

While holding the lower part of the filter, turn it

counterclockwise (a) by 90 degrees and pull it down.

Note : Check that the guideline and the loosening

indication line are aligned.

-9-

HOW TO INSTALL REFRIGERATOR

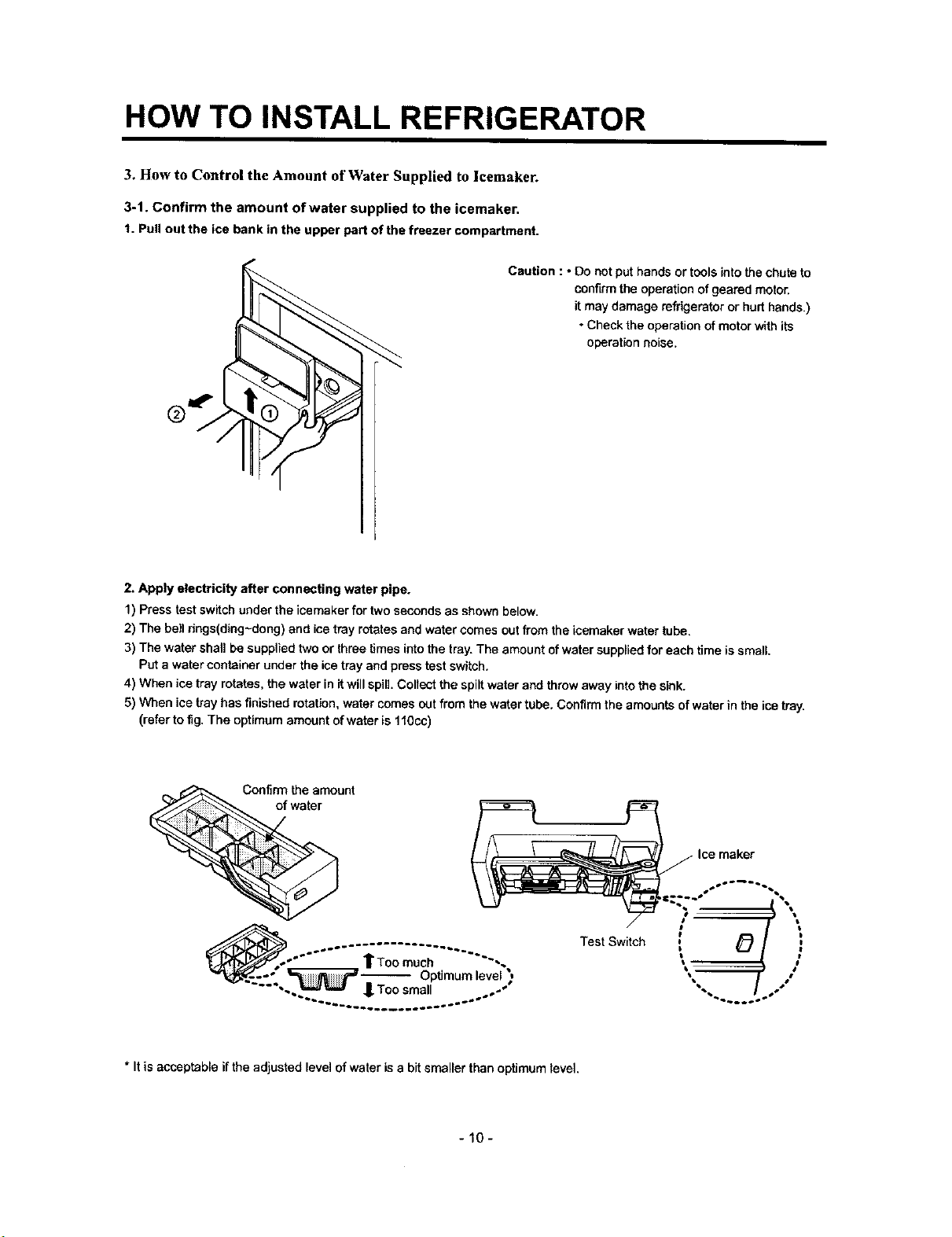

3. How to Control the Amount of Water Supplied to icemaker.

3-1. Confirm the amount of water supplied to the icemaker.

t. Pullout the ice bank in the upper pert of the freezer compartment.

Caution : * Do not put hands or tools into the chute to

confirm the operation of geared motor.

it may damage refrigerator or hurt hands.)

• Check the operation of motor with its

operation noise.

2. Apply electricity after connecting water pipe.

1) Press test switch under the icemaker for two seconds as shown below.

2) The bell rings(ding-dong) and ice tray rotates and water comes out from the icemaker water tube.

3) The water shall be supplied two or three times into the tray. The amount of water supplied for each time is small

Put a water container under the ice tray and press test switch.

4) When ice tray rotates, the water in it will spill. Collect the spilt water and throw away into the sink.

5) When ice tray has finished rotation, water comes out from the water tube. Confirm the amounts of water in the ice tray.

(refer to fig. The optimum amount of water is 110cc)

Confirm the amount

of water

Ice maker

Test Switch

i '

* It is acceptableifthe adjusted levelofwater isa bit smaller than optimumlevel.

-10-

HOW TO INSTALL REFRIGERATOR

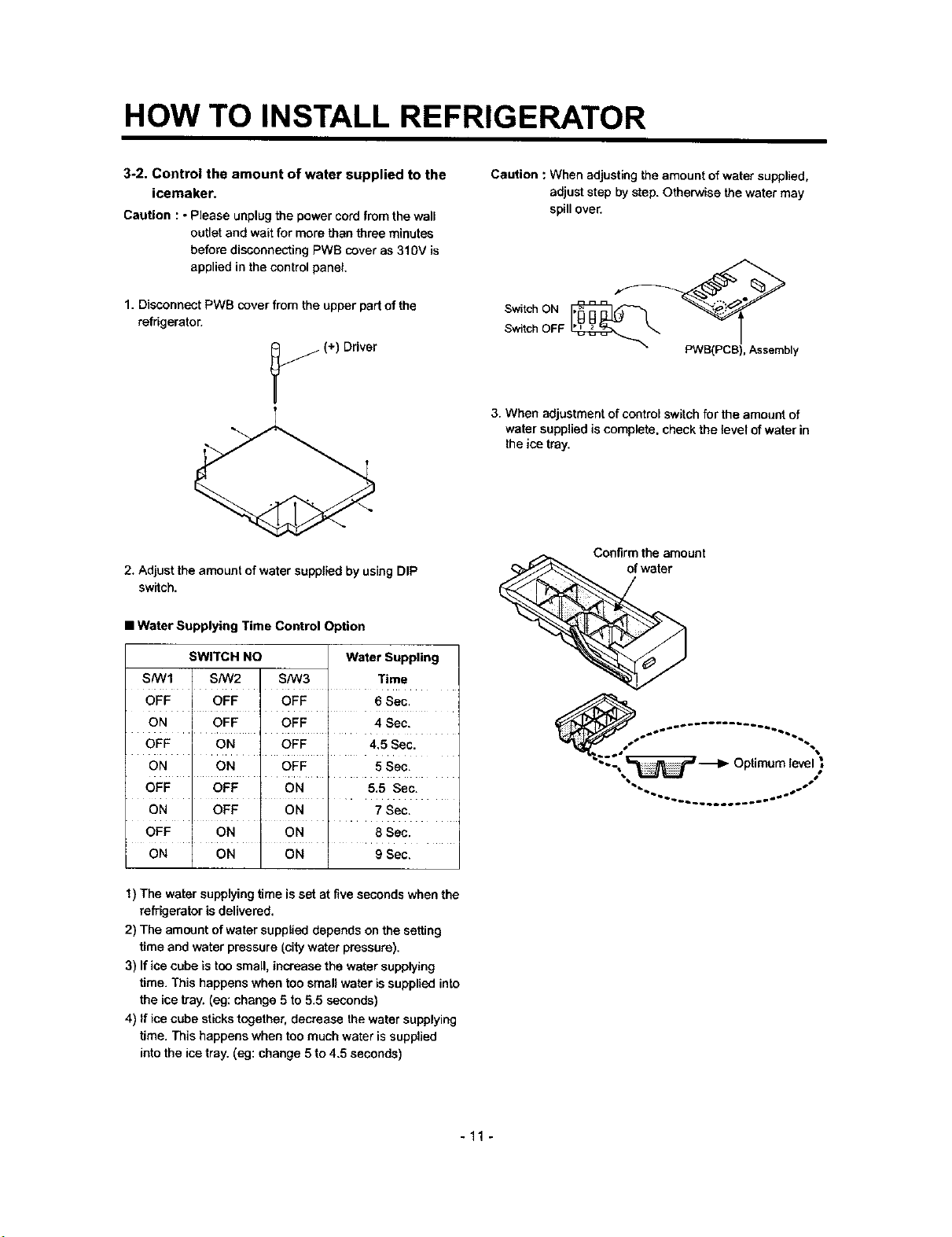

3-2. Control the amount of water supplied to the

icemaker.

Caution : • Please unplugthe powercordfrom thewall

outletand waitfor more than three minutes

before disconnectingPWS coveras 310V is

appliedin thecontrolpanel,

1. Disconnect PWB cover from the upper part of the

refrigerator.

j(+) Driver

2, Adjust the amountof water suppliedby usingDIP

switch.

• Water Supplying Time Control Option

Caution : When adjusting the amount of water supplied,

adjust step by step. Otherwise the water may

spill over.

Switch ON

Switch OFF

PWB(PCB), Assembly

3. When adjustment of control switch for the amount of

water supplied is complete, check the level of water in

the ice tray.

Confirm the amount

of water

SWITCH NO Water Suppling

S/W1 SNV2 S/W3 Time

OFF OFF OFF 6 Sec.

ON OFF OFF 4 Sec.

OFF ON OFF 4.5 Sec.

ON ON OFF 5 Sec.

OFF OFF ON 5.5 Sec.

ON OFF ON 7 Sec.

OFF .... ON ON ..... 8Sec.

ON ON ON g Sec.

1) The water supplying time is set at five seconds when the

refrigerator is delivered.

2) The amount of water supplied depends on the setting

time and water pressure (city water pressure).

3) If ice cube is too small, increase the water supplying

time. This happens when too small water is supplied into

the ice tray. (eg: change 5 to 5.5 seconds)

4) If ice cube sticks together, decrease the water supplying

time. This happens when too much water is supplied

into the ice tray. (eg: change 5 to 4.5 seconds)

Optimumle ,"

"'_b_ _o_ SS

-11 -

ICEMAKERANDDISPENSEROPERATIONPRINCIPLEANDREPAIRMETHOD

2°4. Ice Ejection Control Function

1. This is to eject ice from ice maker cube mould after ice making is completed.

2. if Hall IC signal is on within 3.6 seconds after ice ejection motor rotates in normal direction, it does not proceed ice

ejection but waits, If the ice bank is full ice ejection motor rotates in normal direction in every hour to check the condition

of ice bank. If the ice bank is not full, the water supply control starts after completion of ice ejection control. If the ice bank

is full, ice ejection motor rotates in reverse direction and sops under ice making or waiting conditions.

3. if ice bank isnot full, ice ejection starts. The cube mould tilts to the maximum and ice is separated from the mould and ice

checking lever raises.

4. Ice ejection motor stops for 1 second if Hall IC signal changes from OFF (low) to ON (high) after 3.6 seconds when ice

ejecSon motor rotates in normal direction. If there is no change in Hall IC signals within 1 minute after ice e}ection motor

operates, ice ejection motor stops as ice ejection motor or hall IC is out of order.

5. If ice ejection motor or Hall IC is abnormal, ice ejection motor rotates in normal direction to exercise initial operation. It

resets the ice maker if ice ejection motor or Halt IC is normal.

6. The mould stops for 1 second at maximum tilted conditions.

7. The mould returns to horizontal conditions as ice ejection motor rotates in reverse direction.

8. When the mould becomes horizontal, the cycle starts to repeat:

Water Supply ..* Ice Making * Ice Ejection .._Mould Returns to Horizontal

Maximum tilting

point

r Bank is

HALL IC

OUTPUT

SIGNALS

Bank is "_

HALL IC

OUTPUT

SIGNALS

I ICE CHECKING

o ' ' =-)'/'

i i i

i1_ I I i

OFF

ON

ICECHECKING LEVEL 30° i I

i p / I i t

t t t i i

-8' O" 10" 32' 41" 53" 68" 80'

Lock Ice making Ice Checking

(o_n_ i:,_nt)

2±1 sec = I

<Timing Chart During Ice Ejection>

• , r

, ,,

.... L .... J__J.

9:_3 sec

8+-3sac IL

I I

160" 170'

IceEjection Lock

L

- 22 -

ICEMAKERANDDISPENSEROPERATIONPRINCIPLEANDREPAIRMETHOD

2-5 Test Function

1. It is to force the operation during operation test, service, and cleaning. The test switch is mounted under the automatic

ice maker. The test function starts when the test switch is pressed for more than 0.5 second.

2. Test button does not work during ice ejection and water supply. It works when it is in the horizontal conditions. If mould is

full of ice during test function operation, ice ejection control and water supply control do not work.

3. When test switch is pressed for more than 0.5 second in the horizontal conditions, ice ejection starts irrespect of the

mould conditions. Water shall be splashed it test switch is pressed before the water in the mould freezes. Water shall be

supplied while the mould returns to the horizontal conditions after ice ejection. Therefore the problems of ice ejection,

returning to the horizontal conditions, and water supply can be checked by test switch. When test function performs

normally, buzzer sounds and water supply shall carry out. Check it for repair if buzzer does not sound.

4. When water supply is completed, the cycle operates normally as follows: Ice making • Ice ejection • Returning to

horizontal conditions , Water supply

5. Remove ice from the ice maker cube mould and press test switch when ice maker cube mould isfull of ice as ice ejection

and water supply control de not work when cube mould is full of ice.

2-6. Other functions relating to freezer compartment door opening

1, When freezer door is open, ice dispenser steps in order to reduce noise and ice drop.

2. When freezer door is open during ice ejection and cube mould returning to horizontal condition, ice ejection and cube

mould level return proceed.

3. When freezer door is open, geared motor and cube ice solenoid immediately stop and duct door solenoid stops after 5

seconds.

4. Water dispenser stops in order to protect water drop when freezer door is open.

5. Test function operates normally irrespect of refogearator cempadment door opening.

- 23 -

ICEMAKERANDDISPENSEROPERATIONPRINCIPLEANDREPAIRMETHOD

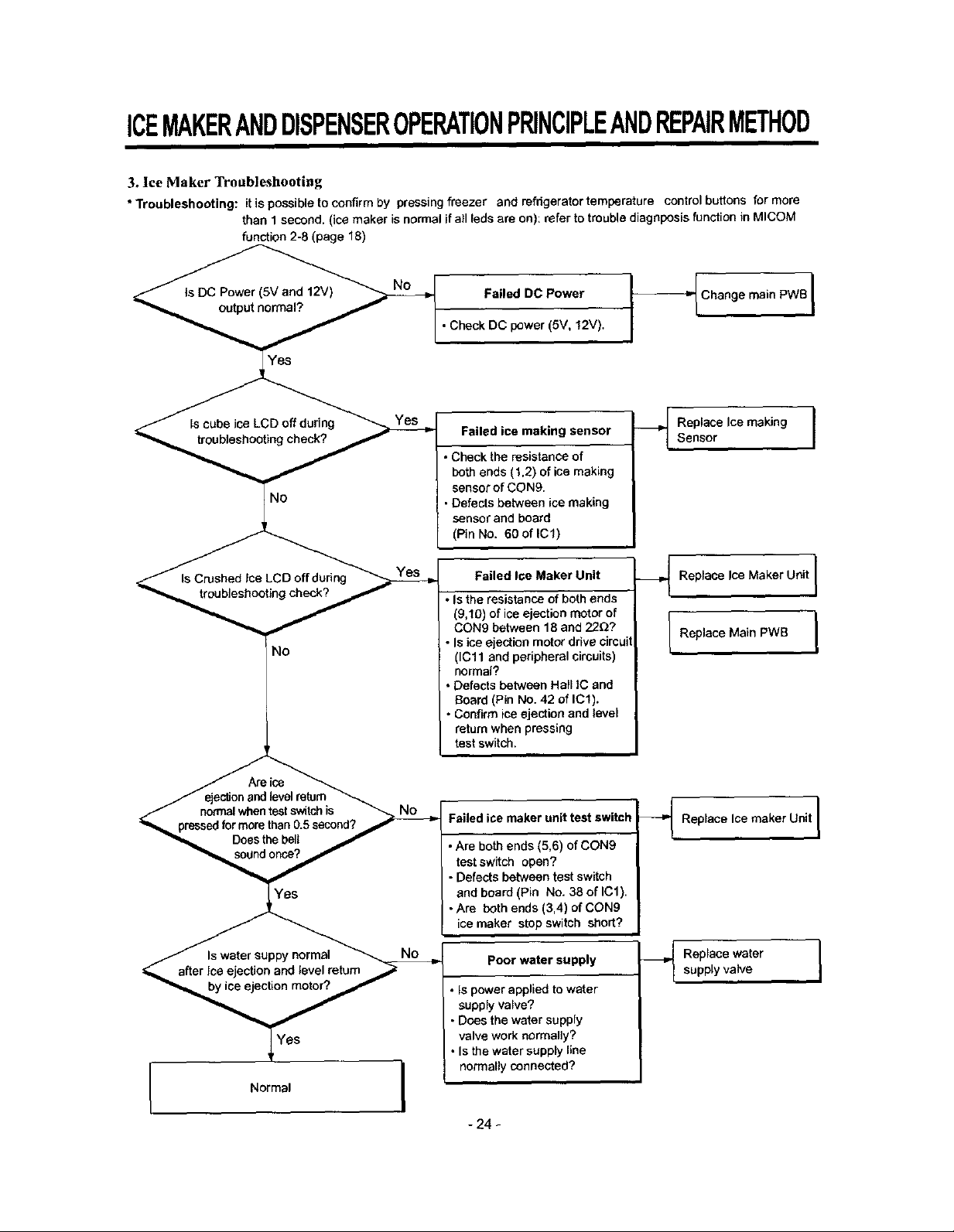

3. Ice Maker Troubleshooting

• Troubleshooting: itis possibletoconfirmby pressingfreezer and refrigerator temperature controlbuttons for more

than 1second.(icemaker is normalifall [edeare on): referto troublediagnposisfunction in MICOM

function 2-8 (page 18)

Failed DC Power

•Check DC power (5V, 12V).

Failed ice making sensor

• Check the resistance of

both ends (1,2) of ice making

sensor of CON9.

• Defects between ice making

sensor and board

(Pin No. 60oflCl)

Failed Ioe Maker Unit

• Isthe resistance of both ends

(9,10) of ice ejection motor of

CON9 between 18 and 22D?

No

r

• Is ice ejection motor drive circuit

(ICll and peripheral circuits)

normal?

• Defects between Hall IC and

Board (Pin No. 42 of IC1).

• Confirm ice ejection and level

return when pressing

test switch.

_ Chang e main PWB

Replace Ice making ]

Sensor

_._ Replace Ice Maker Unit [

I Replace Main PWB I

/ ejesb_nand level return

/ normalwhen test switch is

"_ pressedfor mere than 0.5 second? /

Does the bell /

Normal

Failed ice maker unit test switch

• Are both ends (5,6) of CON9

test switch open?

• Defects between test switch

and board (Pin No. 38 of IC1).

• Are both ends (3,4) of CON9

ice maker stop switch short?

Poor water supply

• Is power applied to water

supply valve?

• Does the water supply

valve work normally?

• Is the water supply line

normally connected?

- 24 -

_ Replace Ice maker Unit I

Replacewatersupplyvalve I

ICEMAKERANDDISPENSEROPERATIONPRINCIPLEANDREPAIRMETHOD

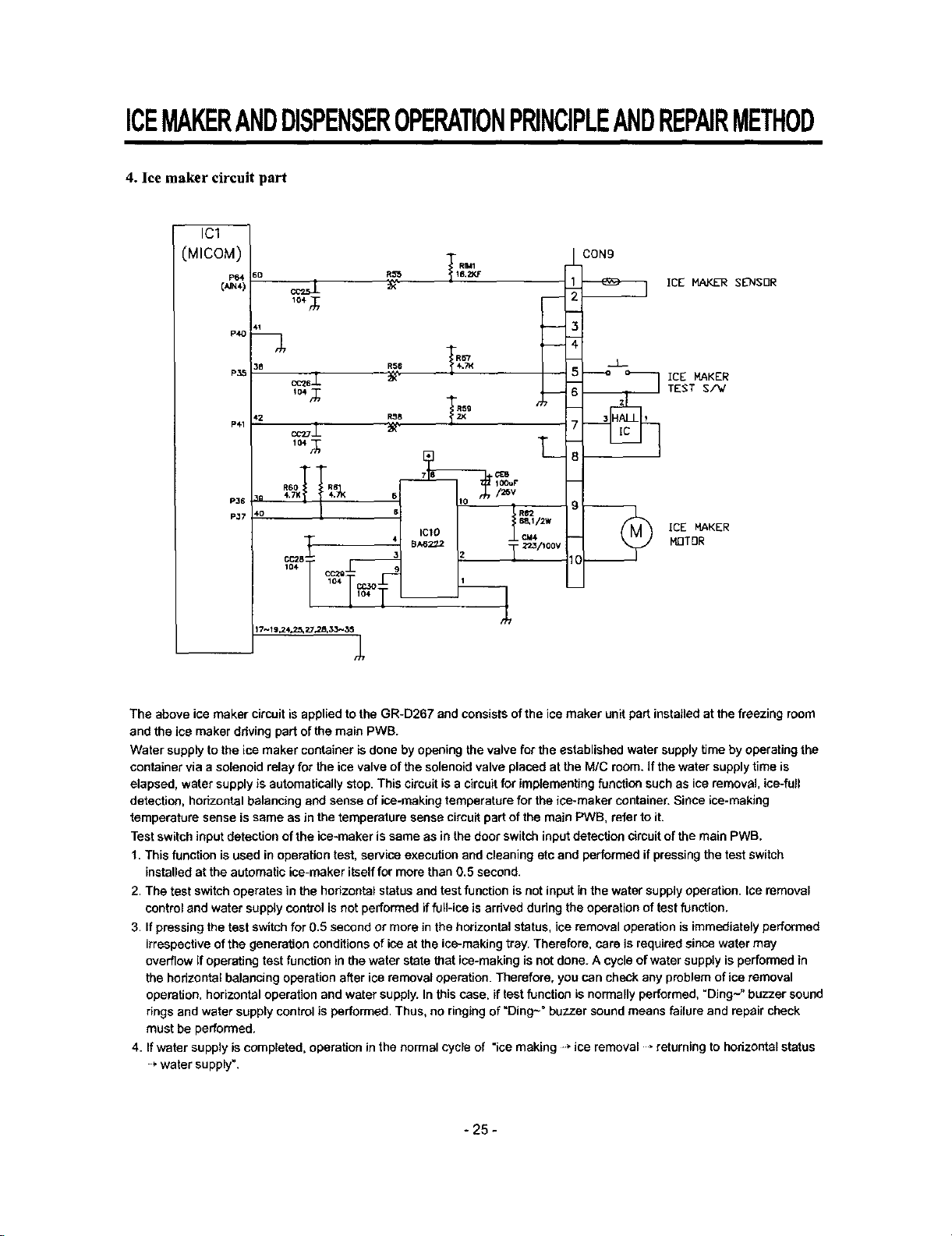

4. Ice maker circuit part

IC1

(MICOM)

P64

[,,,,_4)

P41

CON9

ICE MAKER

MOTOR

The above ice maker circuit is applied to the GR-D267 and consists of the ice maker unit pert installed at the freezing room

and the ice maker ddving part of the main PWB.

Water supply to the ice maker container is done by opening the valve for the established water supply time by operating the

container via a solenoid relay for the ice valve of the solenoid valve placed at the M/C room. If the water supply time is

elapsed, water supply is automatically stop. This circuit is a circuit for implementing function such as ice removal, ice-full

detection, horizontal balancing end sense of ice-making temperature for the ice*maker container. Since ice-making

temperature sense is same as Jnthe temperature sense circuit part of the main PWB, refer to it.

Test switch input detection of the ice-maker is same as in the door switch input detection circuit of the main PWB.

1. This function is used in operation test, service execution and cleaning etc and performed if pressing the test switch

installed at the automatic ice-maker itself for more than 0.5 second.

2. The test switch operates in the horizontal status and test function is not input in the water supply operation. Ice removal

control and water supply control is not performed if full-ice is arrived during the operation of test function.

3. If pressing the test switch for 0.5 second or more in the horizontal status, ice removal operation is immediately performed

irrespective of the generation conditions of ice at the ice*making tray. Therefore, care is required since water may

overflow if operating test function in the water state that ice-making is not done. A cycle of water supply is performed in

the horizontal balancing operation after ice removal operation. Therefore, you can check any problem of ice removal

operation, horizontal operation and water supply. In this case. if test function is normally performed, "Ding~" buzzer sound

rings and water supply control is performed. Thus, no ringing of"Ding~" buzzer sound means failure and repair check

must be performed.

4. If water supply is completed, operation in the normal cycle of "ice making -_ ice removal , returning to hodzontst status

* water supply".

- 25 -

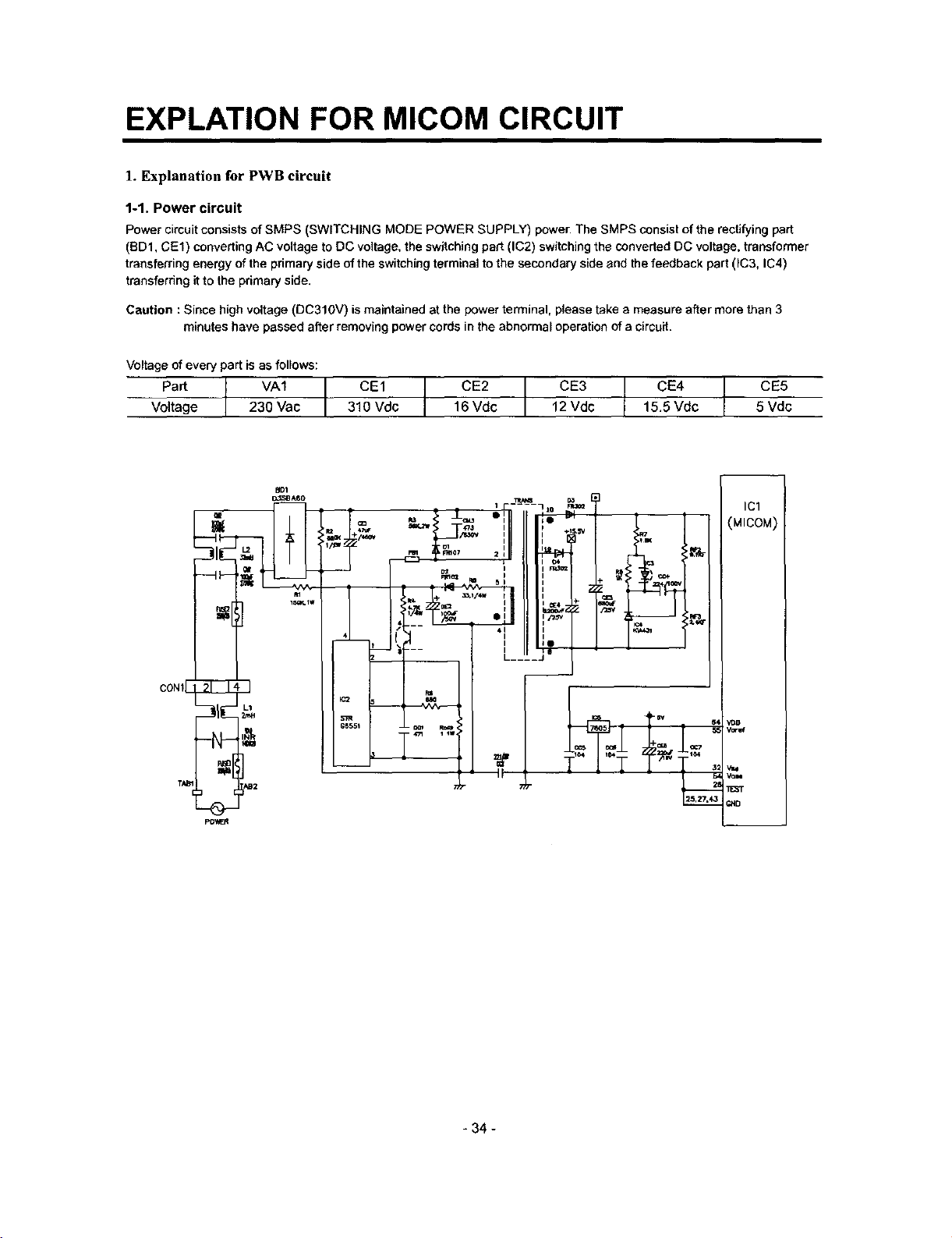

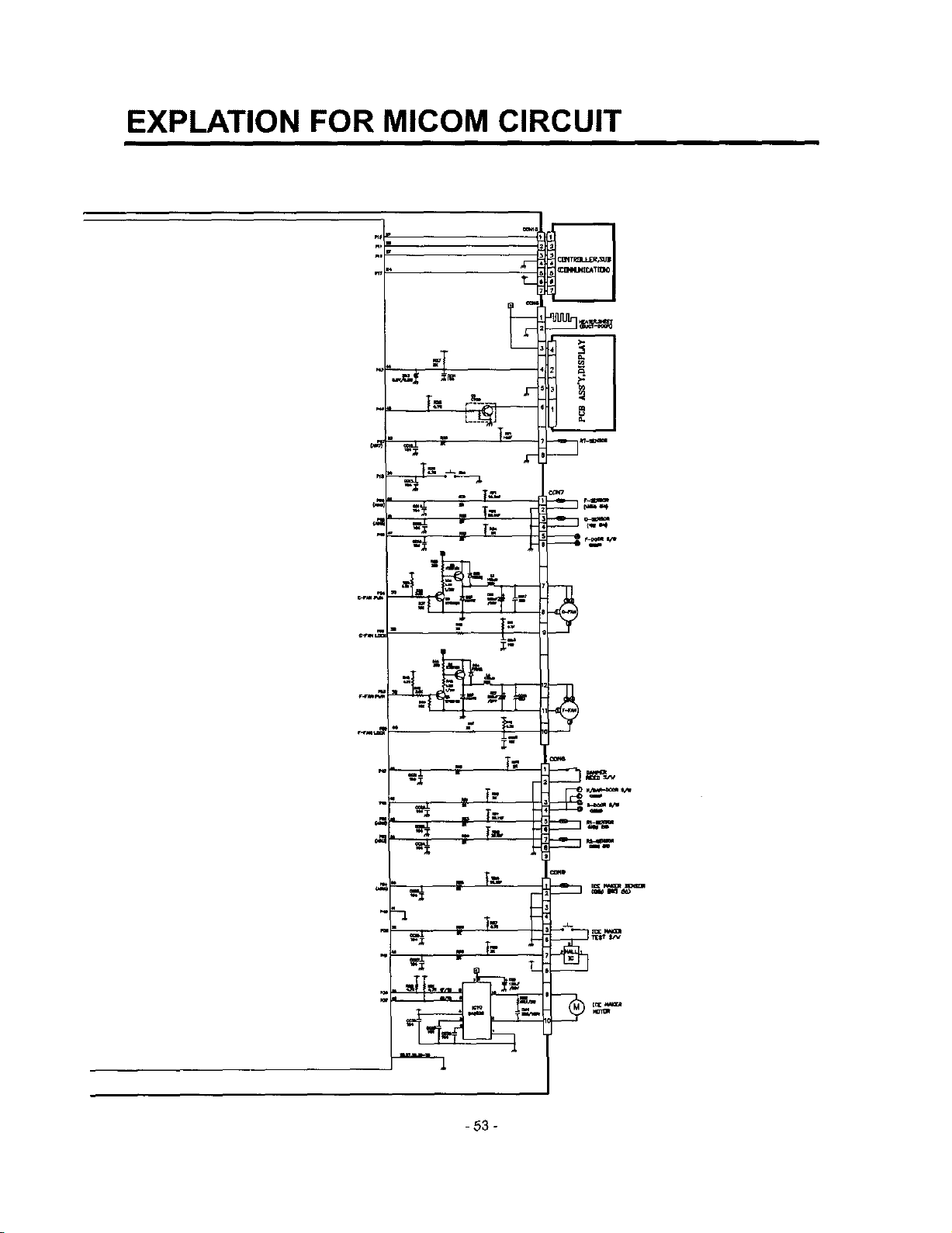

EXPLATION FOR MICOM CIRCUIT

1. Explanation for PWB circuit

1-1. Power circuit

Power circuit consists of SMPS (SWITCHING MODE POWER SUPPLY) power. The SMPS consist of the rectifying part

(BDI, CE1) converting AC voltage to DC voltage, the switching part (IC2) switching the converted DC voltage, transformer

transferring energy of the primary side of the switching terminal to the secondary side and the feedback part (IC3. IC4)

transferring itto the primary side.

Caution : Since high voltage (DC310V) is maintained at the power terminal, please take a measure after more than 3

minutes have passed after removing power cords in the abnormal operation of a circuit.

Voltage of every part is as follows:

Voltage 230 Vac 310 Vdc 16 Vdc 12 Vdc 15.5 Vdc 5 Vdc

CONf

- 34 -

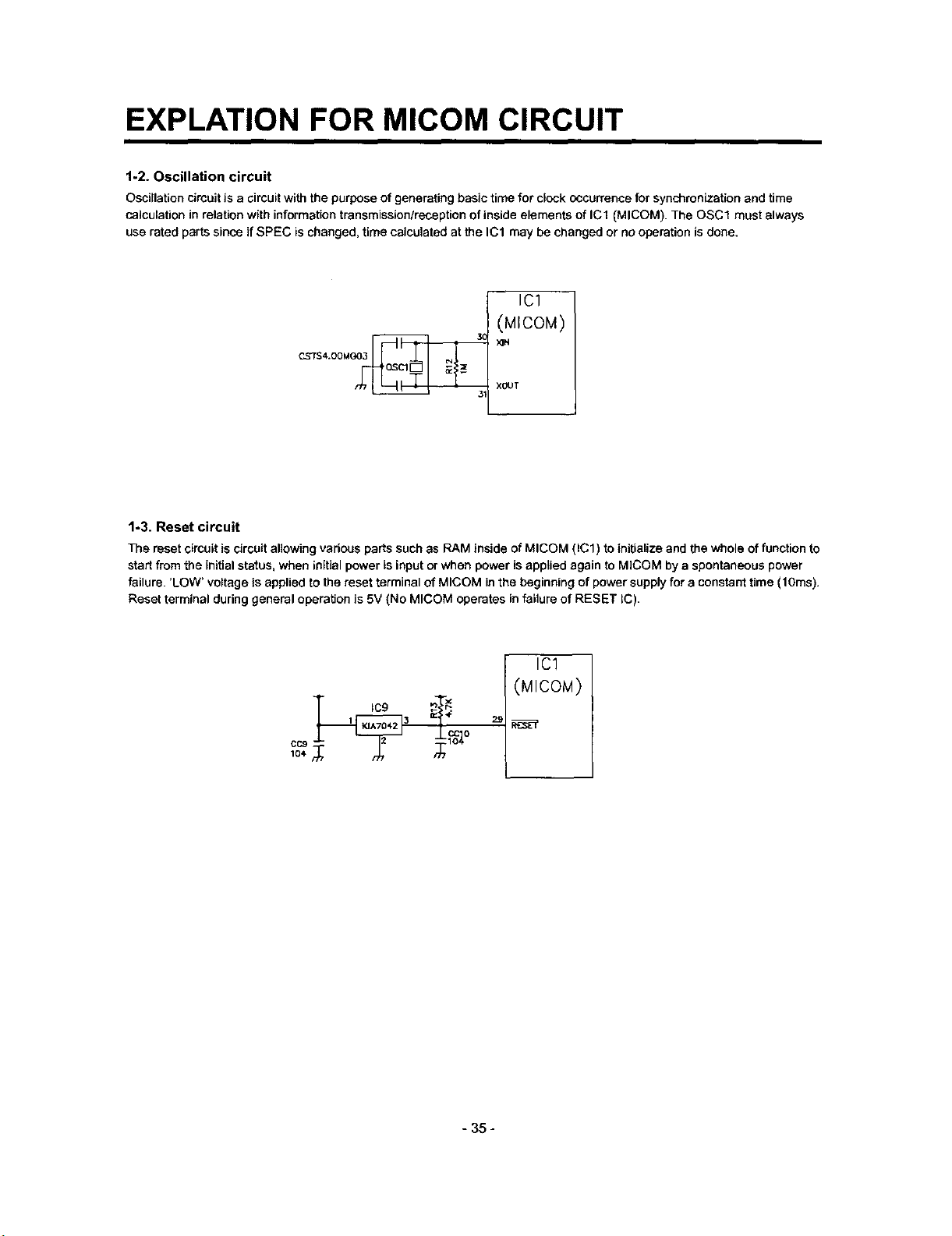

EXPLATION FOR MICOM CIRCUIT

1-2. Oscillation circuit

Oscillation circuit is a circuit with the purpose of generating basic time for clock occurrence for synchronization and time

calculation in relation with information transmission/reception of inside elements of IC1 (MICOM). The OSCl must always

use rated parts since if SPEC is changed, time calculated at the IC1 may be changed or no operation is done.

ICl

(MICOM)

CS7S4 00MGO_

1-3. Reset circuit

The reset circuit is circuit allowing various parts such as RAM inside of MICOM (ICl) to initialize and the whole of function to

start from the initial status, when initial power is input or when power is applied again to MICOM by a spontaneous power

failure. 'LOW' voltage is applied to the reset terminal of MICOM in the beginning of power supply for a constant time (t Ores).

Reset terminal during general operation is 5V (No MICOM operates in failure of RESET IC).

xeur

IC1

(MICOM)

1 IC9 3 _ #

- 35 -

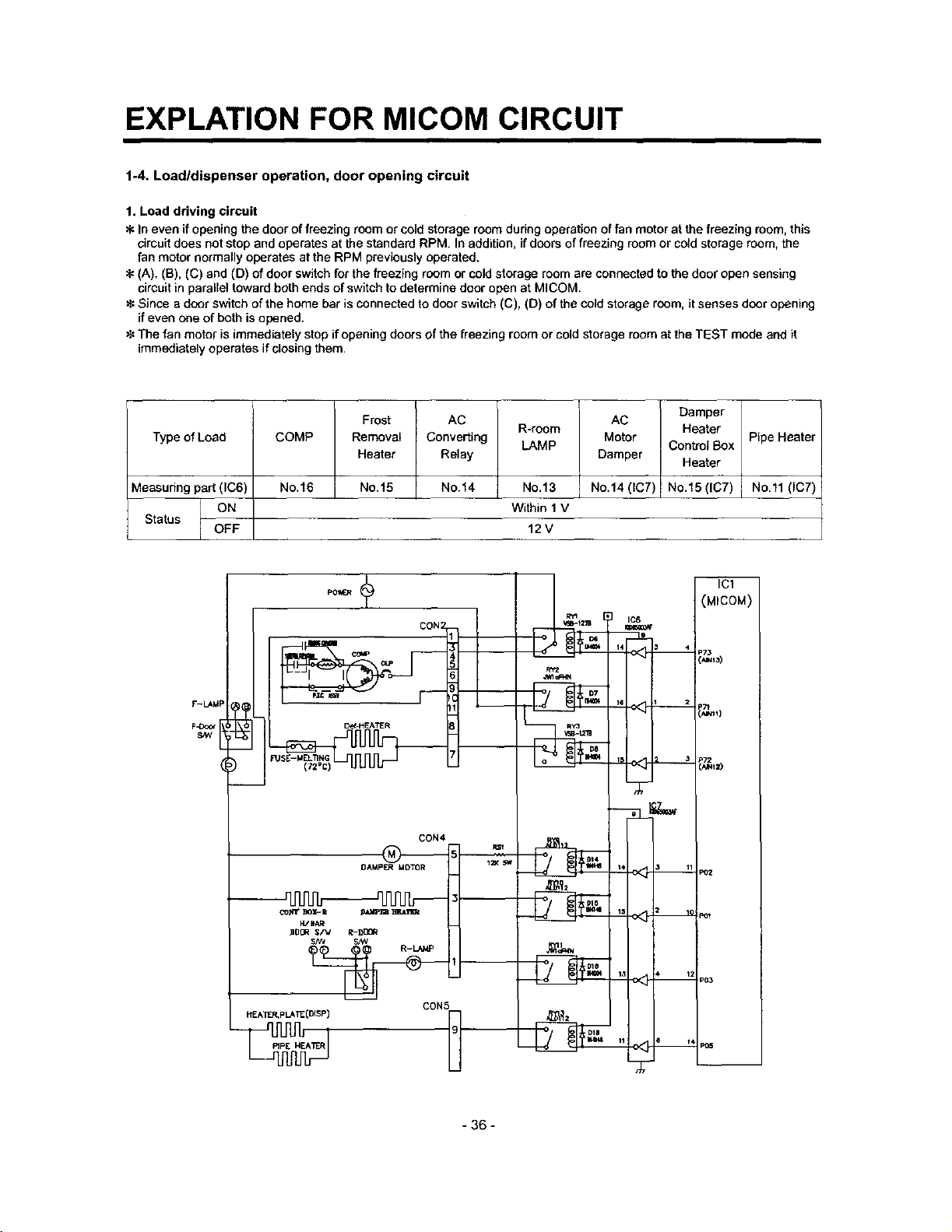

EXPLATION FOR MICOM CIRCUIT

1-4. Load/dispenser operation, door opening circuit

1. Load driving circuit

In even if opening the door of freezing room or cold storage room during operation of fan motor at the freezing room, this

circuit does not stop and operates at the standard RPM. In addition, if doors of freezing room or cold storage room, the

fan motor normally operates at the RPM previously operated.

(A). (B), (C) and (D) of door switch for the freezing room or cold storage room are connected to the door open sensing

circuit in parallel toward both ends of switch to determine door open at MICOM.

_€Since a door switch of the home bar is connected to door switch (C), (D) of the cold storage room, it senses door opening

if even one of both is opened.

The fan motor is immediately stop if opening doors of the freezing room or cold storage room at the TEST mode and it

immediately operates if closing them.

Type of Load

vleasudng part (IC6)

Status OFF

F-LAkIP

Frost

COMP

Removal

Heater

No.16

No.15

_@

FUSE- M_oNC_ _ L._

)

AC

Converting

Relay

No.14

CON4

R-room

LAMP

No.13

Within 1 V

12V

AC

Motor

Damper

No.14 (IC7)

14 _ 4

IIS 1 2

Damper

Heater

Control Box

Heater

No.15 (IC7)

ICI

(MICOM)

=73

_Tt

i_11)

'_'112)

Pipe Heater

No.ll (IC7)

DAMP_ MO1"OR

_-_'1 _ _-I1 _ _Tl_t

ZDCR $/V R-DDQR

_g_2

PeTZ

DIS

P6_

P03

CON5

DIB

I

- 36 -

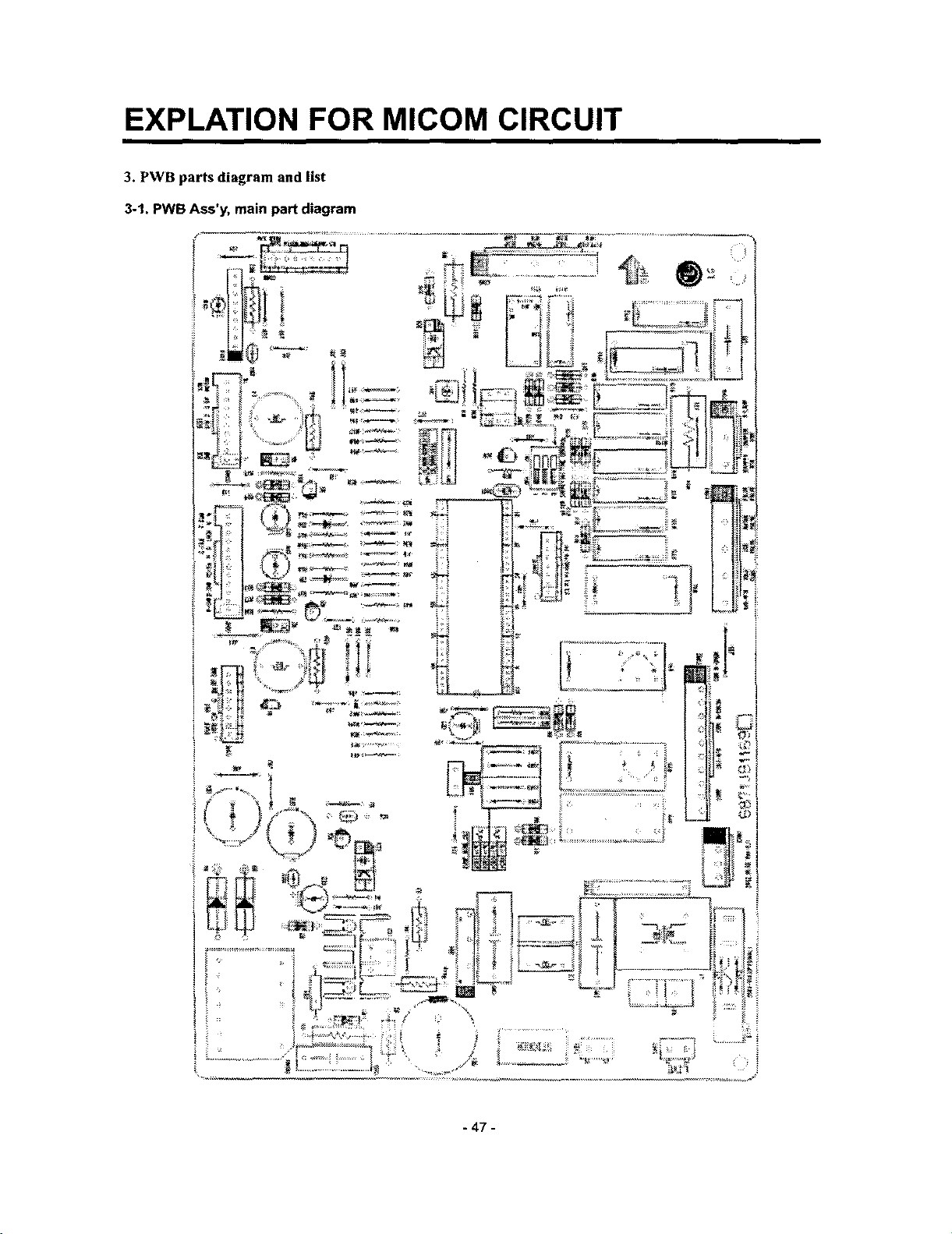

EXPLATION FOR MICOM CIRCUIT

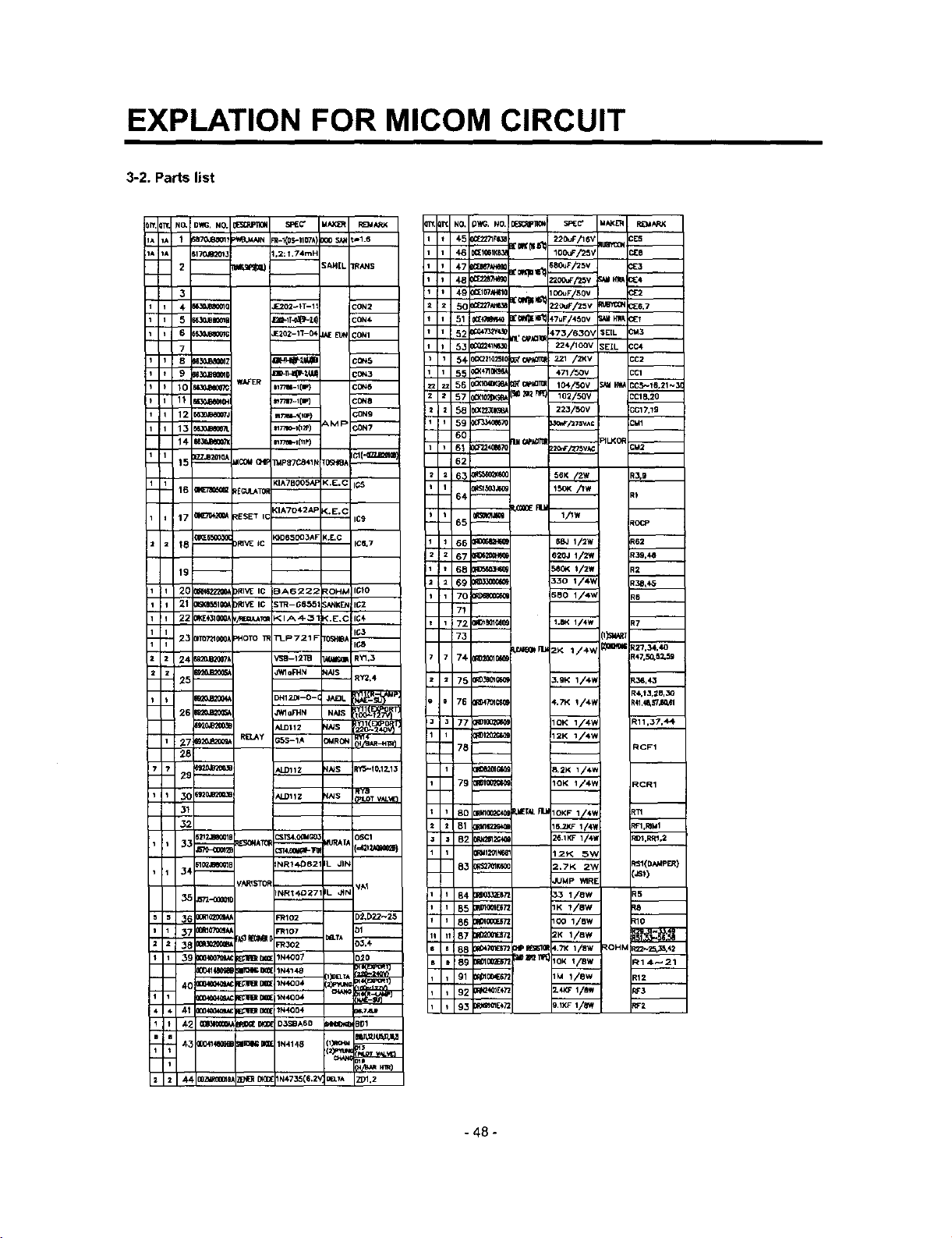

3. PWB parts diagram and list

3-1, PWB Ass'y, main part diagram

- 47 -

EXPLATION FOR MICOM CIRCUIT

3-2. Parts list

NO. DWG, NO. _ SREC' =IAX;I_ RE_ARK

1 ;BTOJBO01? _:_B.MNN R.I_tIOTA) _00 SA_ t_1.6

M70JOr2013 2: ?.74mH

2 _ _AH[L 1R,,LNS

3

_ Z3OJB_010 E202_IT-11 b'ON2

• 30JB_Cma [2nF+T_,_-lt) CON+

6- }$30jg_Q_G i£302-1T-0_ ._E_ CONI

7

_0 s63o,am=0 =_-_t4_ co_3

15 IZZJB2Ot__ _COU OtP B4pagCa41N r0S_9_ Icl{'0Z_sml

16 _ ,tg{;tJ_TOH

17 0(_R't_ _ESET IC IC9

18 -- 3RI_4_ +C IC_,7

WAFER mT_-Ilr) C0N6

_,_dB_07J mT_l-t(im} _C0N9

KIA7BOOSAP K+E.C

<IA7042AP <+E,(

19--

ITt NO+ O'h_, NO. _i_St_JF]_(_ SF4[C" dAKL'11 RI_4,t_K

+5 :[2271F¢3_ ;'_KOII_ 220uF/16V UE'R_ CE5

46 :I_tKLX_ 100uF/25V CIEB

48 _;'_o _ocuF/25v _1 _ c_4

_ 49 _t_lO t'Oeqllll_ oouFi50v C_2

z 5_ _t_._ !20uF/zsv _ CE6,7

51 0CE_R_ r_e_E_*_iF7uF/460v _tH_E?

_ :_241N8]_ 224,/1QOV ;EIL CC4

1 _4, 0C_21Q2510 _C_I]_ _21 /2KV CC2

_ 55 _<+____ +71/.',ov CCl

2 58 _(22.301(_ 223/50V ;C17,1g

1 59 O_P_670 3¢_'/_7swc CMI

6O

62

-- 64--

1 65 _ 1/IW tocP

66 _ SB_ 1/2W t6Z

z 67 _1t0_ 620J 1/2W 139.4_

+ 6B E 560(4 t/2w E2

6g _ 330 I/4W t38,43

1 70 m 5BO 1/4W le

73 [l_'_T

7 74 _1_01_ _47,50,5_59

75 m_m_ 3,9K 1/4W 136,4,3

_4,t3,21P,_

_0 '_21MB_D36: ALD11Z N_ RY_

3_

32

12_2.aooole CsTS4.OO_,___ MURAt^

tl0_,Jl_l_B =NRt_B2 IL_ JIN

_R_ST_

37 )ORlO_ 3(107 O1

_8 _ _/_/_ _R302 aa.TA D3,4

,*I11BItJ_l_; IN400+

4_ _ _ _ D3S_A6O _ BD1

,43 30m141_4_ ;II_'I_ IN4148 1_ mJ_li'l_'tt

_400_Ol_/ _ B_( N47_5(6.2' _._A ZD1,2

tF*ILOTVAL_E

osc1

J_ 77 R_I0_G_ 1OK 1/+V_ _11,37,4_

_'-78i--__ RCF1

79

80 Rm_ _T_ RtJ__ I_

B1 MI_O _ t+'1,mUl

B2 N2Sl_ 26.1KF 1/4_ _01.RRI,2

NI201k_ 12_<; _

_tK60 2._K 2"_, _:SI(DAMPER)

-- :.s_)

84 B_2ES,_ 33 1/8W _5

_5 R51g_4{57_ 1K 1/8w _8

86 _0too_z 1<:o 1/sw _10

It 87 _ 2K 1/8W

_188 ;4;_72 PIPRE_5]_ 4,7K 1/8W ROHM _'_2_42

91 1_1004E672 1M 1/OW R12

- 48 -

1OK 1/4_, _CR1

JUMp WlRE

EXPLATION FOR MICOM CIRCUIT

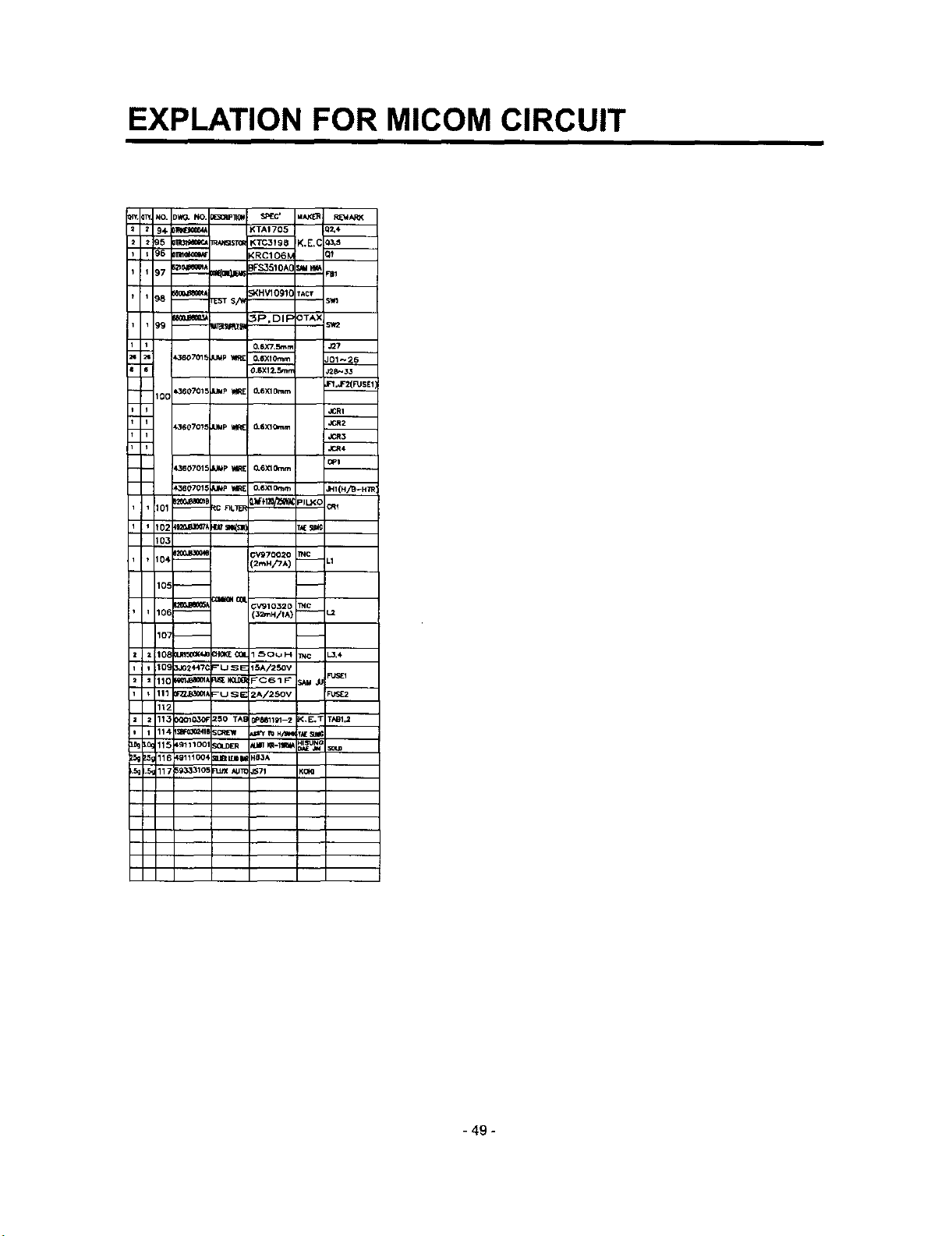

94 _ ;<TAt 705 i0_4

95 _ _ <TC31S_ K.E,( 13.s

96 _ ,'RC106_ _--

97 _eeem/:o_=R,IZa pFS3510A( s._4_ _1

98 ooo.18_Bo_Jr_ST S,i_ ;KHV1091C TACt ;Vn

99 _--m_ _P,DIFOTAX =_r2

k380701_ = M_? _1 O,6XlOmm _-_26

100 )360701_ JUMp WIRE O,6XlOmm F_'JF'2(FUSE_1

k360707_ JUMp _ O-SXlOmm

1_60701= JUmp IA_ O.6XlO_m

_360701_ J_ v,_[ O.6XlOt_m I41{H/B-H]_

102 _o_1oo7_ I_!Is= ) T_

103

104 _ 3v97o02o TNC

0.6X7,Smrr J_7

0.6X12.Sm.1

JCRI

,_R4

OPt

!,_HiTA) -- .1

106 -- 12mH/t^) -- -_

10_ 3J024471 _USE 15A/250V

112

lt3 :_0103_ _50 TA_ 78811_1-2 _.E,T TAB1.1

11_ 4_111004 IIBI_ Hg3A

- 49 -

EXPLATION FOR MICOM CIRCUIT

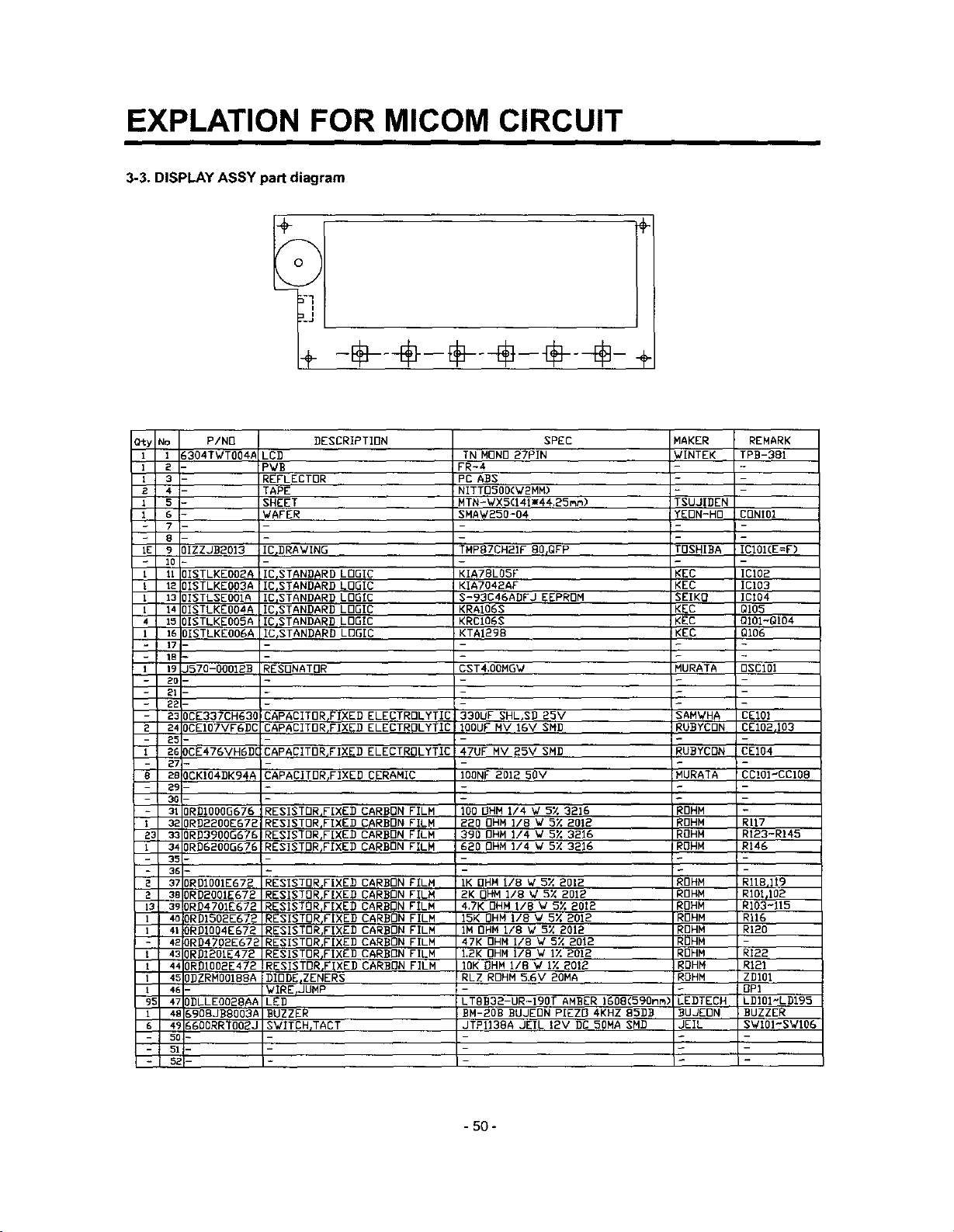

3-3. DISPLAY ASSY part diagram

O_y NO P/NO

t 1 _304TWTOO4#

12

13

2 4

1

7

- 8

IE 9 )IZZJBBOI3

10

I 11 ]ISTLKEOOBA

I 12 IISTLKEOO3A

I 13 )ISTLSEOOIA

I 14 )ISTLKEOOAA

4 15 )ISTLKEOOGA

I 16 ]ISTLKEOOGA

17

- 18

I 19 J570-OOOIBB

20 -

21

22

- 23 DCE337CH630

2 24 OCEIO7VFGDC

- 25-

1 26 DCE476VHGDC

- 27 -

8 2B OCKIO4DK94A

29 -

30 -

- 310RDIOOOG676

1 320RDBBOOE672

Z3 330RB3900G676

l 340RD6200G676

35 -

- 36 -

2 370RD100IE672

2 3BORDBOOIE672

13 390RD4701EG72

I 4o ORDIGOBE672

1 410RBIOO4E672

- 4_ ORD4702E672

t 430RDIBOlE472

1 4A ORDlOO2E472

1 4_ OBZRMOO1BBA

I 4E-

95 47 ODLLEOO28AA

t 4t _908JBBOO3A

6 4_ _600RRTOO_J

5CI-

51-

5zI-

LED TN MONO 27PIN

PWB FR-4

REFLECTOR PC ABS

TAPE NITTOGOD(WBMM)

SHEET MTN-WX5(141mA4.25mm)

WAFER SHAW250-04

IC_BRAWING TNP87CHBIF BO_QFP

_IC_STANDARD LOGIC

lIE,STANDARD LOGIC

ICISTANDARB LOGIC

ICjSTANDARD LOGIC

ICISTANDARB LOGIC

IC_STANDARB LOGIC

RESONATOR CST4,0OMGW MURATA 0SC101

CAPACITORFIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR_FIXEB ELECTROLYTIC

CAPACITDR_FIXED CERAMIC

RESISTOR_FIXEB CARBON FILM

RESISTOR_FIXED CARBON FILM

RESISTOR,FIXEB CARBON FILM

RESISTORIFIXED CARBON FILM

RESIBTORrFIXEB CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR_FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXES CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

DIODE_ZENERS

WIRErJUMP

LEg

BUZZER

SWITCH,TACT

DESCRIPTION SPEC

KIA78LO5F KEC ICI02

KIA7042AF KEC ICI03

S-93C46ABFJ EEPROM SEIKO ICt04

KRAI06S KEC QI05

KRCI06S KEC QIOI~QI04

KTAIBg8 KEC QI06

330UF SHL,SD 25V SAMWHA CEIOI

IOOUF NV IGV SMD RUBYCBN CEIO2rI03

47UF MV 25V SMD RUBYCDN CEI04

IODNF 2012 50V MURATA CCI01"CCIOB

100 OHM 114 W 5X 3216 _OHM

220 OHM I/8 W 5% 201B _OHN RII7

390 OHM I/4 W 5X 3216 !OHM RI23-R145

620 OHM 114 W 5% 3216 ROHM R146

IK OHM rib W 5% 2012 ROHM RIlB,]i9

2K OHM 118 W 5X 201B ROHM RIOI_IO2

4,7K OHM IIB W5% 2012 ROHM R103-115

15K OHM I/8 W 5% 201B RDHM R116

IM OHM I/8 V 5X 2012 _OHM RIB0

47K OHM i/8 V 5X 2012 RDHM -

I.BK OHM lib W i% 2012 ROHM RI22

IOK OHM 11B W IX 201_ ROHM R121

RLZ ROHM 5.6V 20MA ROHM ZBI01

.- - OPt

iLTBB32-UR-lBOT AMBER IGOB(590nm) LEDTECH LDIOI-LDI95

OH-BOB BUJEON PIEZO 4KHZ B5BB BUJEON :BUZZER

JTPII38A JEIL 12V DG 50MA SMD JEIL SWIOI'SWI06

MAKER REMARK

WINTEK TPB-381

TSUJIBEN

YEON-HO CONIOI

TOSHIBA ICI01(E=F)

-50 -

EXPLATION FOR MICOM CIRCUIT

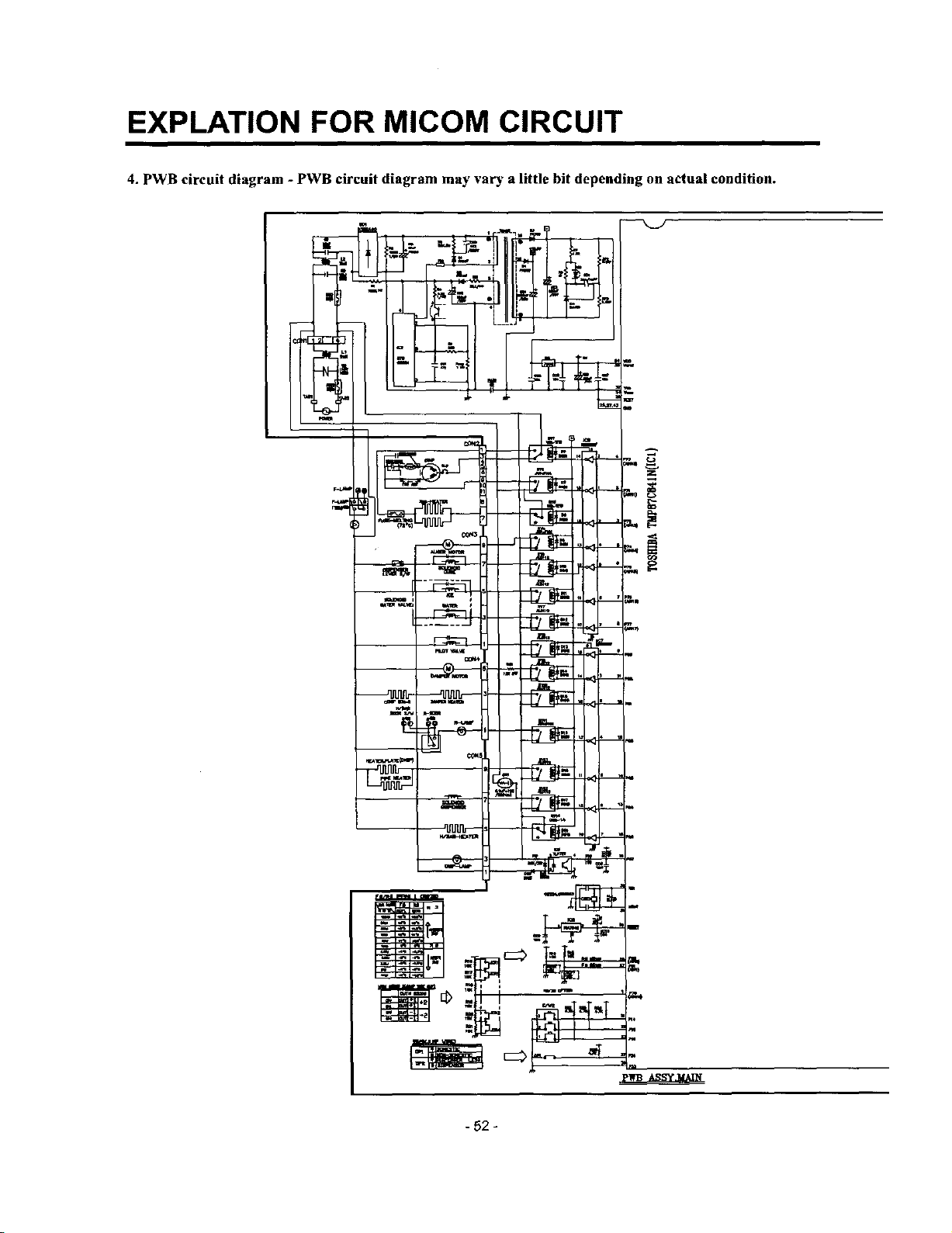

4. PWB circuit diagram - PWB circuit diagram may vary a little bit depending on actual condition.

- 52 -

EXPLATION FOR MICOM CIRCUIT

)

T

T_

=-. T=

.. . T=,.

- 53 -

v

_ mm

E

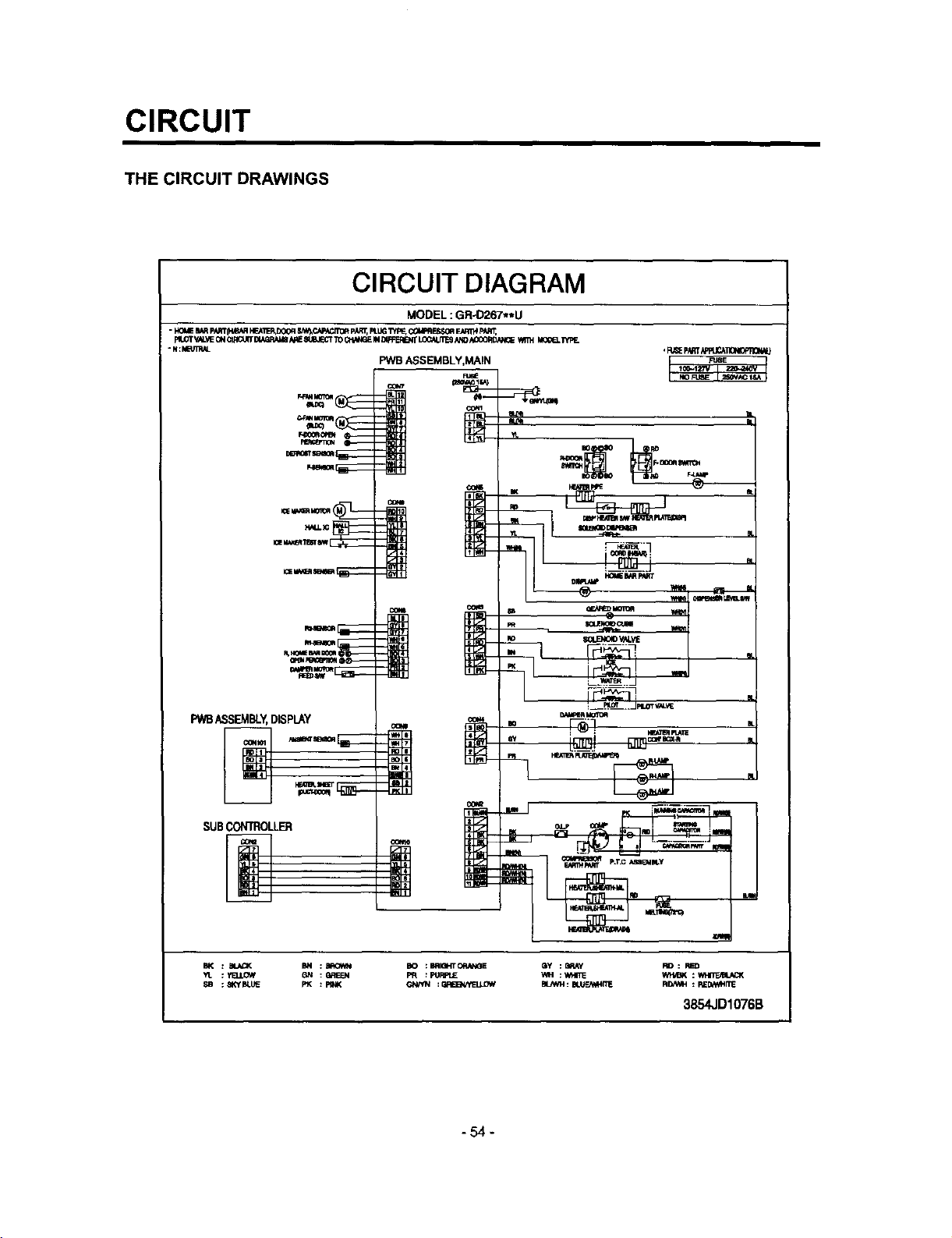

CIRCUIT

THE CIRCUIT DRAWINGS

CIRCUIT DIAGRAM

- I.!O_ e_/tpA_IW&_ FrcA_R,DOOFI_N_,CA=_.JT0_pAIT_,PI.UGWI=E,C_FIFJ_ E_qrtH pAR'_,

Ft.OTV_._EONQ;_C_IITDIA_qAt_&qESl_MEC'TTOCf,IiV_EIND_RIE_T _/_O ACCORDANQE_ M0_I_ 'i'YPF_

* N:HBrf_qL

PWB._SEMBLY,MAIN

MODEL : GR-D267**U

m_

PWBASSEMBLY,DISPLAY

SUBCONTROLLER

BK : _._'( M :BROW_ BO :BRIOpITOf_,_IE QY :E_Y RD: RED

Yr. : YELI.OW 13N : _qEEN PR : PUI=P.JE WH : wHr_ Wt'b_K : _

_B ;_O'I_UE P'_ :PINK GN/W_ :61R_/yLqJJ_W BlaW_:BI.UF2_ITE FIB/VAH:RE_Nt,.41TE

3854JD1076B

-54-

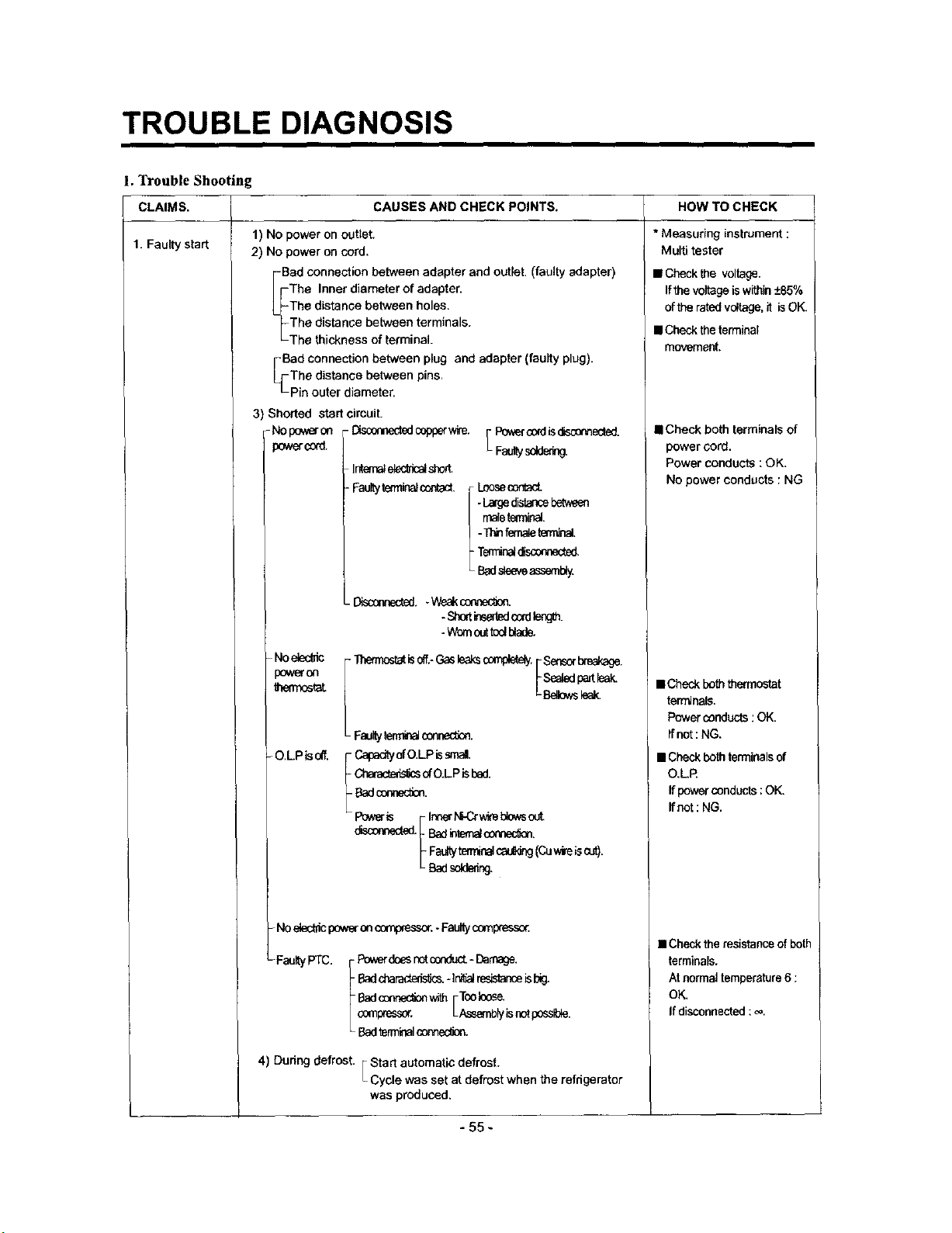

TROUBLE DIAGNOSIS

1.3¥ouble Shooting

CAUSES AND CHECK POINTS. HOW TO CHECKCLAIMS.

1. Faulty start

1) No power on outlet.

2) No power on cord.

Bad connection between adapter and outlet. (faulty adapter)

The Inner diameter of adapter.

The distance between holes.

The distanse between terminals.

The thickness of terminal.

Bad connection between plug and adapter (faulty plug).

The distance between pins,

Pie outer diameter,

3) Shorted start circuit.

Nopeweron -Disconnededcopperwire. [Pr_c_dgolsca'm_.

_wer_:_. _Fa_ys_

INemal_Ncat sh_,

-Faulty terminalcontact, [ Loosecont_t.

/ -La_d_,_r_ebe_v_

[ malete_ninal.

_ -Thin_role _rrr_nal.

Temlir_ olscer_ected.

L Badslseveasseml_y

._.. Weakconnec_

-Short_sat_dc0at_mgth.

- Wornout t_l btade.

- Noe_c_ic

)ower co

thennoatat

- O.L.PIS oil,

_tat is_.- Gas_aks completely.FSealedpartleak.

LBellowsleak.

I Sensorbreakage.

L FI_llty [e_ COt_(_Otl.

f CapadtyofO.LPissinai,

Characte_s_sofO.LP ls 13ed.

Badconne_on.

Po_ F InnertCCr wi_eblowsout

* Measuring instrument :

Multi tester

• Checkthe voltage.

Ifthevoitageiswithin+85%

ofthe ratedvoltage,it isOK.

• Checktheterminal

movement.

• Check both terminals of

power cord.

Power conducts : OK.

No power conducts : NG

• Checkboththermostat

terminals.

Powerconducts:OK.

Ifnot:NG.

• Check both terminals of

O.L.R

If power conducts ; OK,

ffnot: NG.

_ Fa_'tyterminalcau_,ing(Cuwireiscut).

L Badsoldering,

-NO electncpower on c_%o_.ssor.-Faultycompresso_

- FaultyPTC. Powerdoesnct(z_c_ - Damage.

-Badcharact_si_.-Ini_ reslstan_isbig.

Badcennec_nwith[TcoIoos_

compressor. Assemblyisnctpossble.

Badterminal_.

4) During defrost. FStart automaticdefrost.

L

Cycle wasset at defrost when the refrigerator

was produced,

- 55 -

• Check the resistance of both

terminals.

At normal temperature6 :

OK.

If disconnected : _.

Loading...

Loading...