LG LRSPC2331T Owner’s Manual

WARNINGS AND PRECAUTIONS FOR SAFETY

Please observe the following safety precautions in order to

use safely and correctly the refrigerator and to prevent

accident and danger dudng repair.

1. Be care of an electric shock. Disconnect power cord

from wall outlet and wait for more than three minutes

before replacing PWB parts. Shut off the bower

whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than

five minutes after power cord was disconnected from the

wall outlet.

3. Please check if the power plug is pressed down by the

refrigerator against the wall. If the power plug was

damaged, it may cause fire or electde shock.

4. Ifthe wall outlet is over loaded, it may cause fire. Please

use its own individual electrical outlet for the refrigerator.

5. Please make sure the outlet is properly earthed,

parficulady in wet or damp area.

6. Use standard electrical components when replacing

them.

7. Makesure the hook iscorrectlyengaged.

Remove dust and fore=gnmaterials from the housing

andconnecting parts.

8. Do not fray, damage, machine, heavily bend, pull out,

or twist the power cord.

9. Please check the evidence of moisture intrusion in the

electrical components. Replace the parts or mask it

with insulation tapes if moisture intrusion was

confirmed.

10. Do not touch the icamaker with hands or tools to

confirm the operation of geared motor,

11. Do not let the customers repair, disassemble, and

reconstruct the refrigerator for themselves. It may

cause accident, electric shock, or fire.

12. Do not store flammable materials such as ether,

benzene, alcohol, chemicals, gas, or medicine in the

refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals.

etc., or container with full of water on the top of the

refrigerator.

14. Do not put glass bottles with full of water into the

freezer. The contents shall freeze and break the glass

bottles.

15. When you scrap the refrigerator, please disconnect the

door gasket first and scrap it where children are not

accessible.

-3-

SPECIFICATIONS

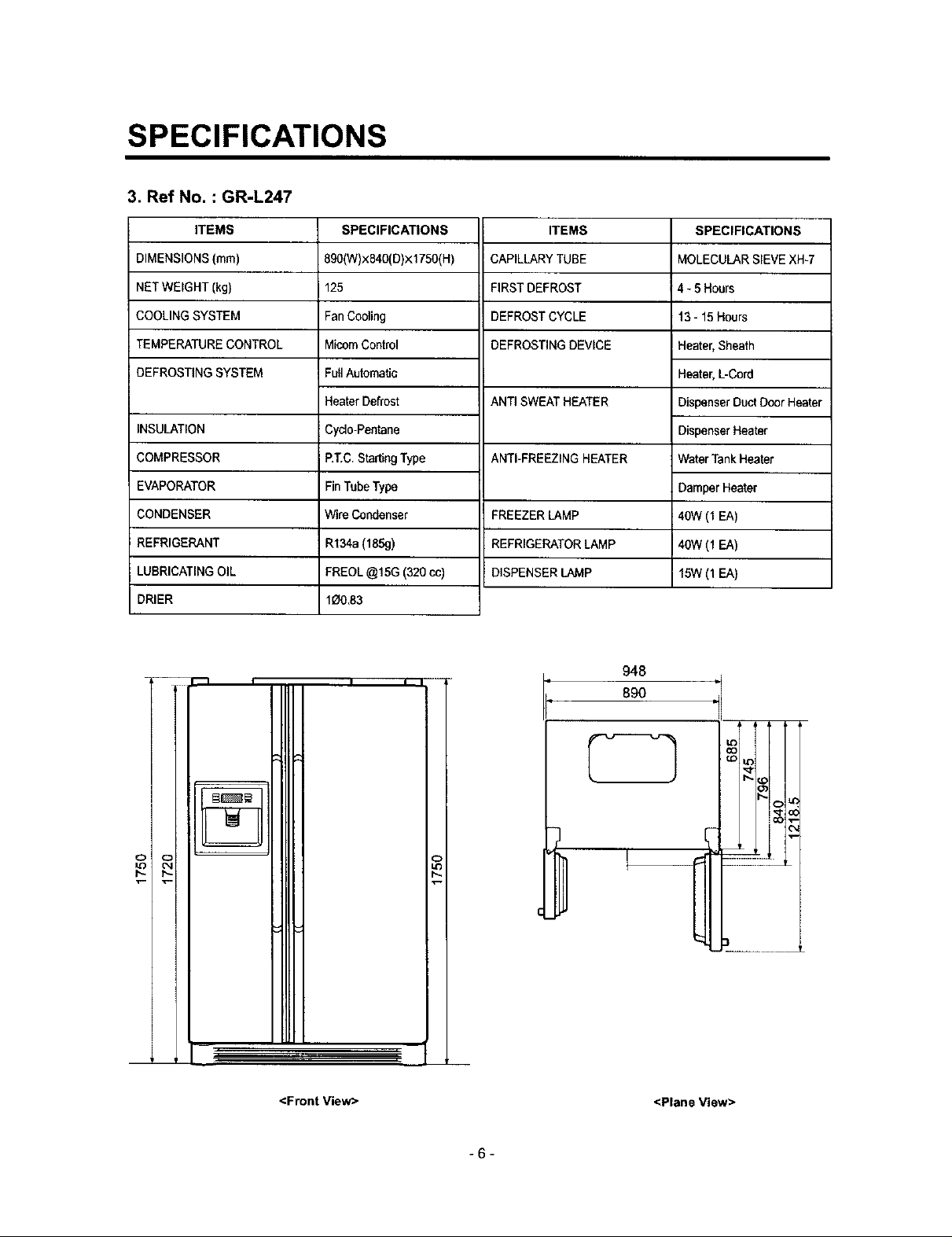

3. Ref No. : GR-L247

ITEMS

DIMENSIONS (ram)

NET WEIGHT (kg)

COOLING SYSTEM

TEMPERATURE CONTROL

DEFROSTING SYSTEM

INSULATION

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

LUBRICATING OIL

DRIER

"_ I I I

SPECIFICATIONS

890(W)x840(D)X1750(H)

125

Fan Cooling

MieamControl

FullAutomatic

Heater Defrost

Cyclo-Pentane

P.T.C.Starting Type

FinTube Type

Wire Condenser

R134a (1859)

FREOL @15G (320 ec)

1_0,83

ITEMS

CAPILLARY TUBE

FIRST DEFROST

DEFROST CYCLE

DEFROSTING DEVICE

ANTI SWEAT HEATER

ANTI-FREEZING HEATER

FREEZER LAMP

REFRIGERATOR LAMP

DISPENSER LAMP

SPECIFICATIONS

MOLECULAR SIEVE XH-7

4 - 5 Hours

13 - 15Hours

Heater, Sheath

Heater,L-Cord

Dispenser Duct Door Heater

Dispenser Heater

Water Tank Heater

Damper Heater

40W (1 EA)

40W (1 EA)

15W (1 EA)

948

890

<Front View>

O

<Plane View>

-6-

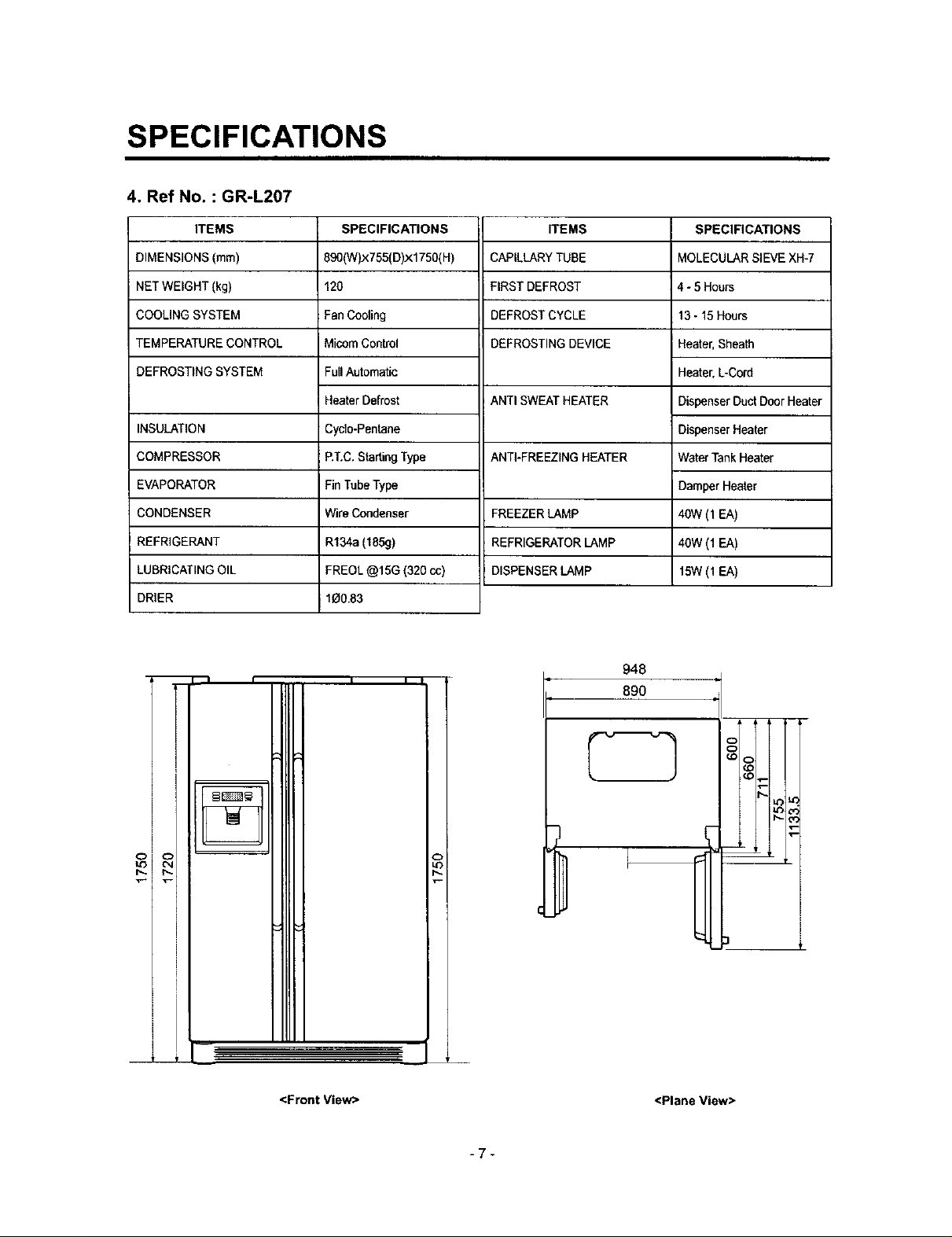

SPECIFICATIONS

4, Ref No. : GR-L207

ITEMS

DIMENSIONS (ram)

NET WEIGHT (kg)

COOLING SYSTEM

TEMPERATURE CONTROL

DEFROSTING SYSTEM

INSULATION

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

LUBRICATING OIL

DRIER

SPECIFICATIONS

890(W)x755( D)x1750(H)

120

Fan Cooling

Micom Control

Full Automatic

Heater Defrost

Cydo-Pentane

P.T.C.Starting Type

Fin Tube Type

Wire Condenser

R134a (185g)

FREOL @15G (320 cc)

100,83

I

ITEMS

CAPILLARY TUBE

FIRST DEFROST

DEFROST CYCLE

DEFROSTING DEVICE

ANTI SWEAT HEATER

ANTI-FREEZING HEATER

FREEZER LAMP

REFRIGERATOR LAMP

DISPENSER LAMP

SPECIFICATIONS

MOLECULAR SIEVE XN-7

4 - 5 Hours

13 - 15Hours

Heater, Sheath

Heater, L-Cord

Dispenser Duct Door Heater

DispenserHeater

Water Tank Heater

Damper Heater

40W (1 EA)

40W (1 EA)

15W(t EA)

948

890

!

J

i

LO ¢-q

J

E

i

I

Q

i

t

O

LO

T-

i

i

!

]

<Front View> <Plane View>

O

(.O

Lt3

L

)

-7-

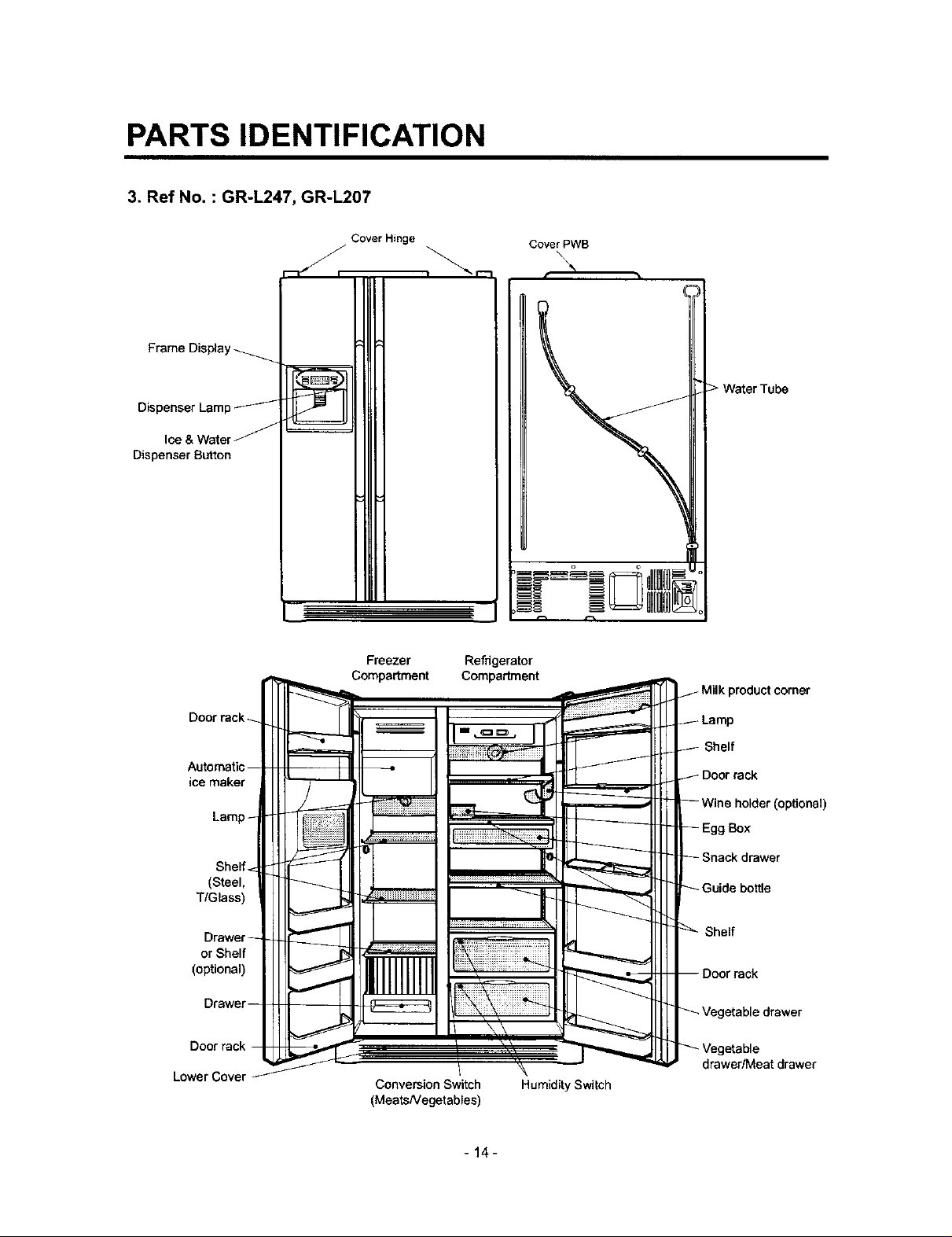

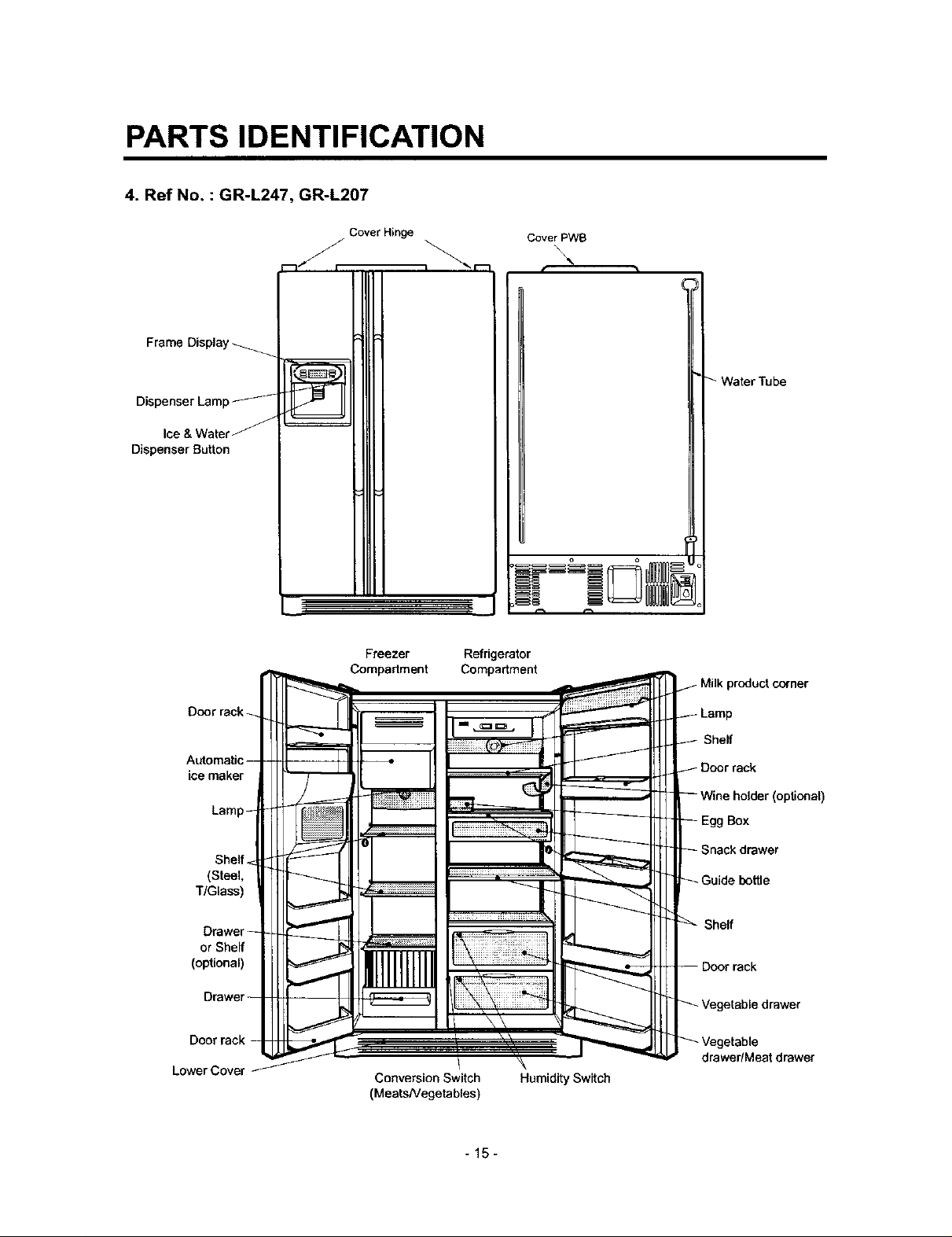

PARTS IDENTIFICATION

3. Ref No. : GR-L247, GR-L207

Dispenser

Dispenser Bu_ton

Cover Hinge

/

Freezer Refrigerator

Compartment Compartment

Cover PWB

\

Automatic

ice maker

Lamp-

(Steel,

T/Glass)

Drawer -

or Shelf

(optional)

Door rack -

Lower Cover

Conversion Switch

(MeatsNegetables)

Ioptional)

Box

Shelf

etable drawer

etable

drawer/Meat drawer

Humidity Switch

- 14-

PARTS IDENTIFICATION

4. Ref No. : GR-L247, GR-L207

Frame Display _-_

Dispenser Lam

Dispenser Button

Cover Hinge

0 I

Freezer Refrigerator

Compartment Compartment

Cover PWB

\\

Water Tube

ice maker

Shelf.

(Steel,

T/Glass)

Drawer

or Shelf

(optional)

Door rack

Lower Cover

Conversion Switch

(MeatsNegetables)

Sheff

(optional)

Box

Shelf

Door rack

drawer/Meat drawer

Humidity Switch

-15-

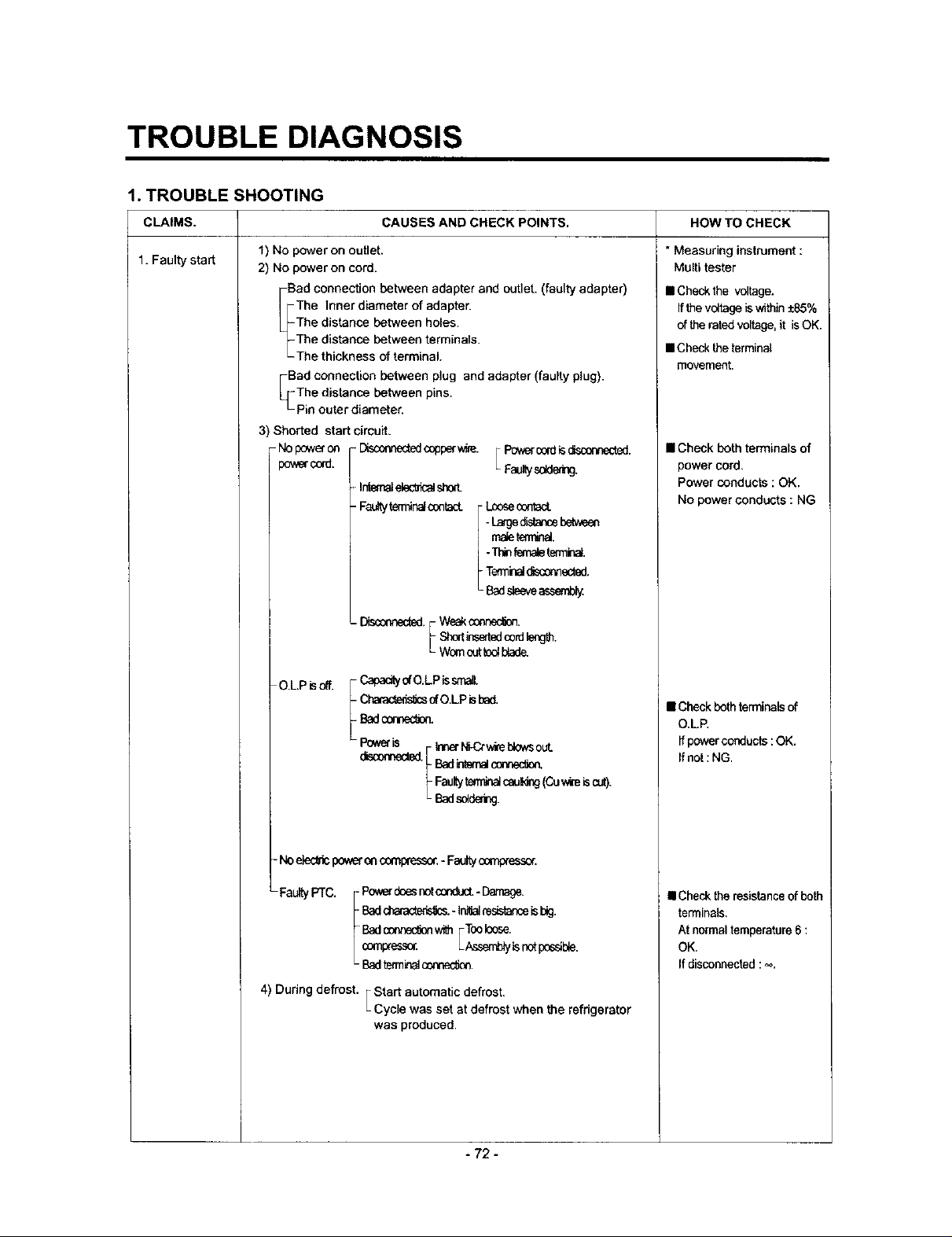

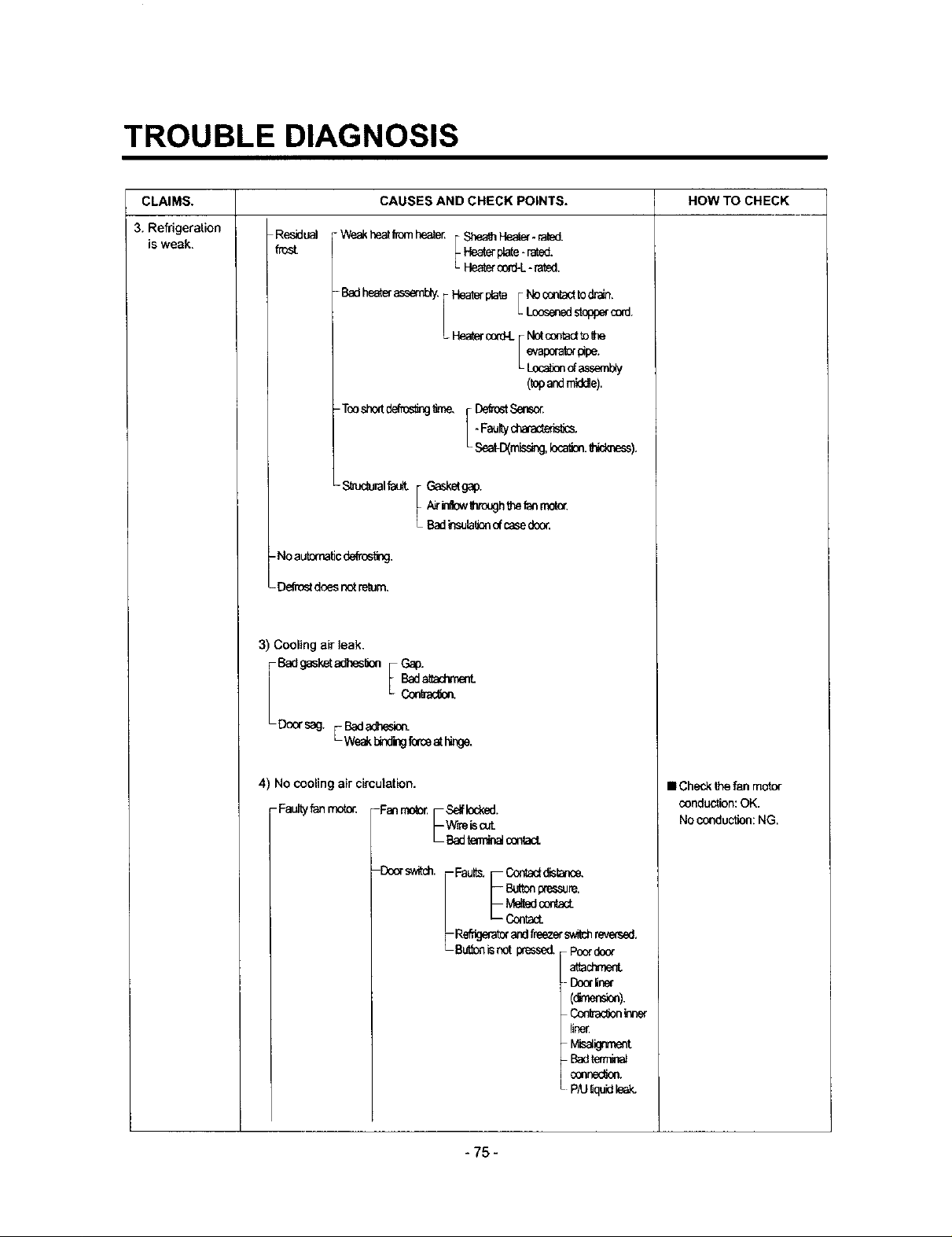

TROUBLE DIAGNOSIS

1. TROUBLE SHOOTING

CAUSES AND CHECK POINTS. HOW TO CHECKCLAIMS.

1.Faulty start

1) No power on outlet.

2) No power on cord.

Bad connection between adapter and outlet. (faulty adapter)

The thnerdiameter of adapter.

-The distance between holes.

The distance between terminals.

-The thickness of terminal.

Bad connection between plug and adapter (faulty plug).

The distance between pins.

Pin outer diameter.

3) Shorted start circuit.

Nogeweron -Dlsconnactedcopperwire. rpowrcordlsdlsconnected.

powercord. LFaulty,_der_.

I_err_l elsc_icalshofL

- Fo_tyterminatcontacL -Lcosecontact

-Laged'_tancebe_een

mdeterminal,

-1]in femalsterminal,

-Termiqaldisconnected.

-Bad_eveasse_b_

-Dlscoenact_.FWeakconnac_on.

_ Sho_tlssatedcord_.

L Womout_odbtade.

O.L.Pmoil.

Capa:ilyofO.LPissrr_l.

-Cha'acte_is_csofO.LPisba_

_Badcennec_on.

-Po_s InnarI_wim blowsout

_,sconnect_l.

Badintemalco_ecti_.

Faultyterminah::au_ng(Cuvaeiscut).

•Badsoldeing.

* Measuring instrument :

Multi tester

• Check the voltage.

Ifthe voltage iswithin _+85%

of the rated voltage, it isOK.

• Check the terminal

movement.

• Check both terminals of

power cord.

Power conducts : OK.

No power conducts : NG

• Check beth terminals of

O.LE

If power conducts : OK.

If not :NG.

- Noelectricpowerco oompress_.-Faultycompress_.

- FaultyPTC.

Powerdcesnotconduol.-Damage.

Bad_. - Ini_ resistancelsbig.

Bedc_aec_ withFTOObose.

compressor. LAssen'_isnotpossible.

•Bedterminalccon_oa.

4) Duringdefrost. FStart automatic defrost,

L

Cycle was set at defrost when the refrigerator

was produced.

- 72 -

• Check the resistance of both

terminals,

At normal temperature6 :

OK.

If disconnected : _.

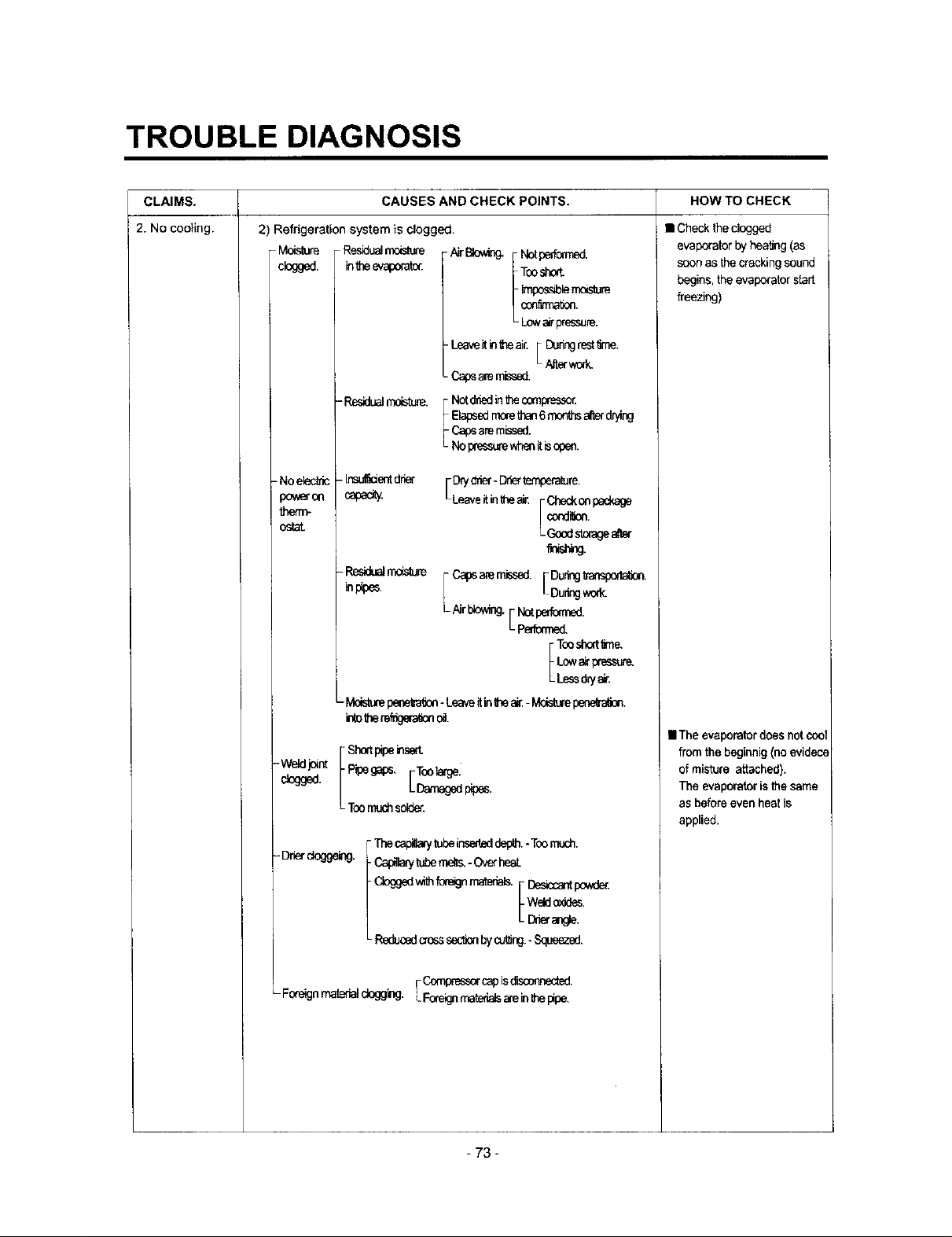

TROUBLE DIAGNOSIS

CLAIMS. CAUSES AND CHECK POINTS. HOW TO CHECK

2. No cooling.

2) Refrigeration system is clogged.

Moisture

clogged.

Residual

_theevamrat_

- Residualmoisture.- Notdriedinthecompresso_

-No_

poweron

' -Insul_ent drier

capadty.

IJlerm-

ostat

-Residualmo_ure

inpipes.

-Moislure_ -Leavaitinthe_ - Moisturepene_a_n.

i_othe_Ta_on ol.

Sho_p_t

-W_joint F_oegaps,rToolarge.

clogged. L[3_rnagedpipos.

Toomu_ sold_

-Tlle ¢api_alylube_ depth.-Toomuah.

-D_ do.oil. _be_-Overheat

Ck_edwithf_ge matedaJs.Oes_,:_powd_

i

Reducedmosssec_n byc_ng. - Squeezed.

- .AirBlow_9- Notpedom,_l.

Tooshod.

-Impos_e mois_m

(:onfin_.

Lowar pressure.

- Leaveit intheair, _ Dun_ rest _',e.

L,_en_K

- Capsam missed,

Elapsedmorethan6monO_Biterd_ng

- Capsaremissed.

- Nopressurewhenitisopen.

[ D_ drier- Driertemperature.

Leaveitintheai_ _ onpackage

omdiiion.

.Goedsto,_eafar

r_r_ng.

-calm m_sed.FDumg_,r_,

• Ouli_ work.

L P_I_l.

Toa sl_me.

Lowairpres,,_re,

.Lessd=yai-,

-Weldogde&

-I:_era_le,

• Check the clogged

evaporator byheating (as

soon as the cracking sound

begins, the evapo,'ator start

freezing)

• The evaporator does not coo

from the beginnig (no evidec,

of misture attached).

The evaporator is the same

as before even heatis

applied.

Foraigema_al dogging. LFore_ matarialsareinthei_Pe,

Fcompressor_ isdsoo_cted.

- 73 -

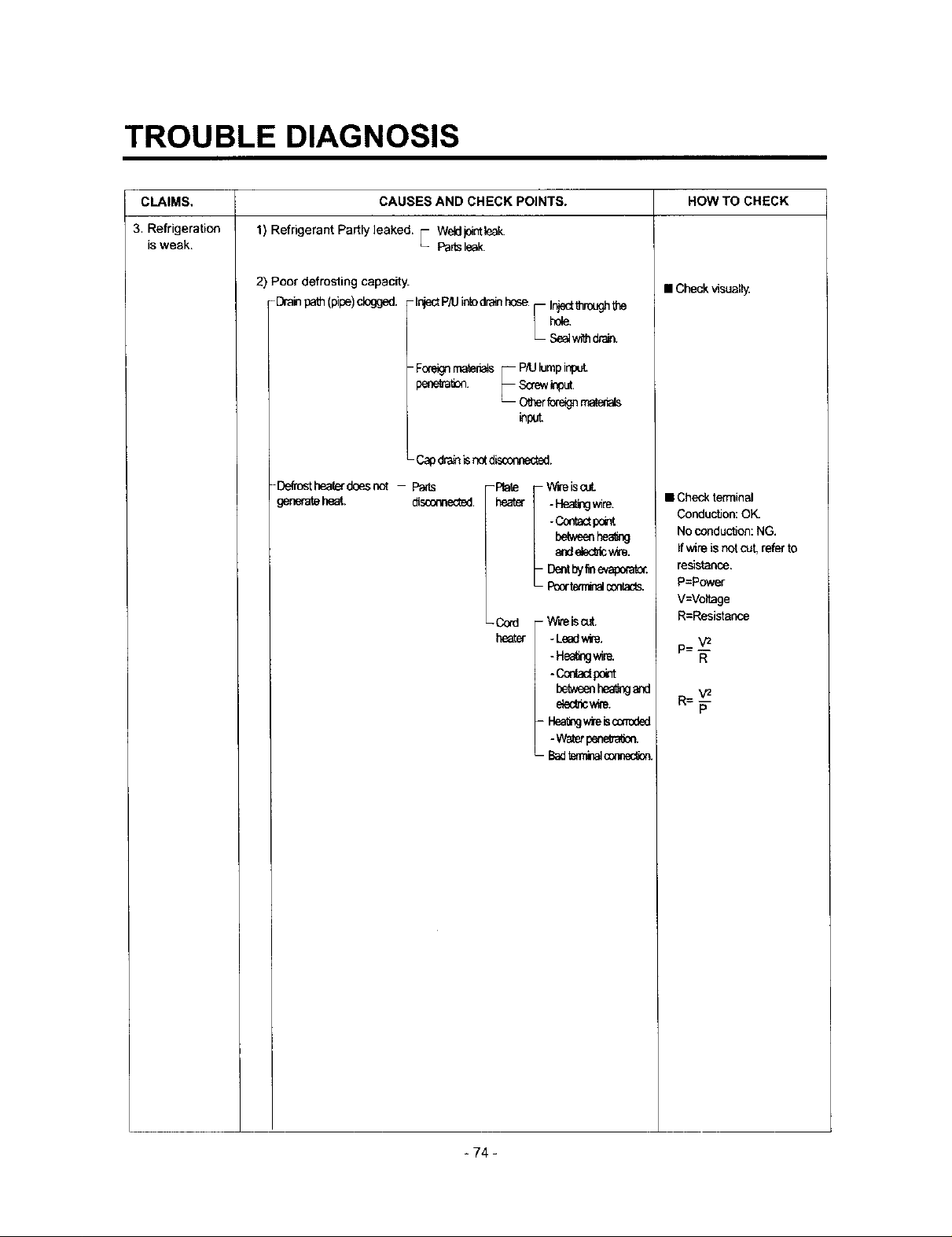

TROUBLE DIAGNOSIS

CLAIMS,

3. Refrigeration

is weak.

CAUSES AND CHECK POINTS.

1) Refrigerant Partly leaked. [- Weldjcintleak

2) Poor defrosting capacity.

Drainpath(pipe)ck:_ged, -Inject P/U intodrainhese._ InjectIJ_oughthe

L

Partsleak.

hole.

-- Sealw_ drein.

- Fore_ rr_terials-- PM lumpinput.

pene_on -- So_wq_ut

inp_

Capdr'_nisnotdisconcected.

-Defros[heaterdoesnot Pads

generateheat. disconnected.

-Rate

heater

Wireiscut.

- HeaUngwire.

be_e_hea_ng

andelec_ic'_re.

- Dentby_ evaporate.

- I:_orternmalcontadis.

-Cord - W_iscut

heater - Leadwire.

-Hea_gw_e.

-Cmtactpo_t

= betweenhea_g a_d

eiec_icwim.

- He_ngwre_c_0de_

-Water_.

I- Badtemina_conned_on.

HOWTO CHECK

• Check visually.

• Check terminal

ConductJon: OK.

No conduction:NG.

ifwire is not cut, refer to

resistance,

P=Power

V=Voltage

R=Resistance

p=__

R

R=__

P

- 74 -

TROUBLE DIAGNOSIS

CLAIMS.

3. Refrigeration

is weak.

ReskJual

frost

-WeakheatfromI'eate_ FSheathi-lealer, raled.

-Badhe_te-ass_rnbly,L Heaterp_ate [ No contacttodrain,

- Tcosho_tdefr_ _ne, [- Faulty_.

-S_uc_ralfaull [ Gasketgap,

- Noautomat d6_o6_j.

- D_'ro_ dcos nolmtum,

3) Cooling air leak.

CAUSES AND CHECK POINTS. HOW TO CHECK

t-H_e-rated

LHeateroold-L- latnd.

Lc_ened stoppe-cord

Heatermrd-L F NCtc&qtacltothe

LI_oca_Jmofassembly

(topandmidale).

Defrost,Sense.

- Seat_(rn_s_g,bca_m._).

L A__fbwU_:x_jh_e fanmotor.

Badinsulationofcasedoo_

- [_:_',_. B,_la_,_n.

[W_k _di_ f_ at_ree.

4) NOcooling air circulation.

-Faultyfanmo_r. -Faumo_ FSelf_ked.

[-W_ is c_L

m _1 _v_nal conlact

[_r s_t_.

i

• Check the fan motor

conduction: OK.

Noconduction:NG,

-Faults, Con_ct distance,

-- Buttonpie&sure.

Meltedconlad_

-- Contact.

- Rm_era_ a'd freezerm,@_ m_m_l.

-Bul_o_lisnot pressed. Poordool

attachment.

- DoorIin_

C,en_-ac_ninner

line_

M_nment

Badterrnin_

cconec_n.

P/Uliquidleak,

- 75-

Loading...

Loading...