LG LRSPC2051BM Owner’s Manual

WARNINGS AND PRECAUTIONS FOR SAFETY

Please observe the following safety precautions in order to

use safely and correctly the refrigerator and to prevent

accident and danger during repair.

1.13e care of an electric shock. Disconnect power cord

from wall outlet and wait for more than three minutes

before replacing PWB parts. Shut off the power

whenever replacing and repairing electric components.

2, When connecting power cord, please wait for more than

five minutes after power cord was disconnected from the

wall outlet.

3. Please check if the power plug is pressed down by the

refrigerator against the wall. If the power plug was

damaged, it may cause fire or electric shock.

4. If the wall outlet is over loaded, it may cause fire. Please

use its own individual electrical outlet for the refrigerator.

5. Please make sure the outlet is propedy earthed,

particularly in wet or damp area.

6. Use standard electrical components when replacing

them.

7, Make sure the hook is correctly engaged.

Remove dust and foreign materials from the housing

and connecting parts.

8. Do not fray, damage, machine, heavily bend, pull out,

or twist the power cord.

Please check the evidence of moisture intrusion in the

electrical components. Replace the parts or mask it

with insulation tapes if moisture intrusion was

confirmed.

10. Do not touch the icemaker with hands or tools to

confirm the operation of geared motor.

11. Do not let the customers repair, disassemble, and

reconstruct the refrigerator for themselves. It may

cause accident, electdc shock, or fire.

12. Do not store flammable materials such as ether,

benzene, alcohol, chemicals, gas, or medicine in the

refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals,

etc., or container with full of water on the top of the

refrigerator.

14. Do not put glass bottles with full of water into the

freezer. The contents shall freeze and break the glass

bottles.

15. When you scrap the refrigerator, plesse disconnect the

door gasket first and scrap it where children are not

accessible.

-3-

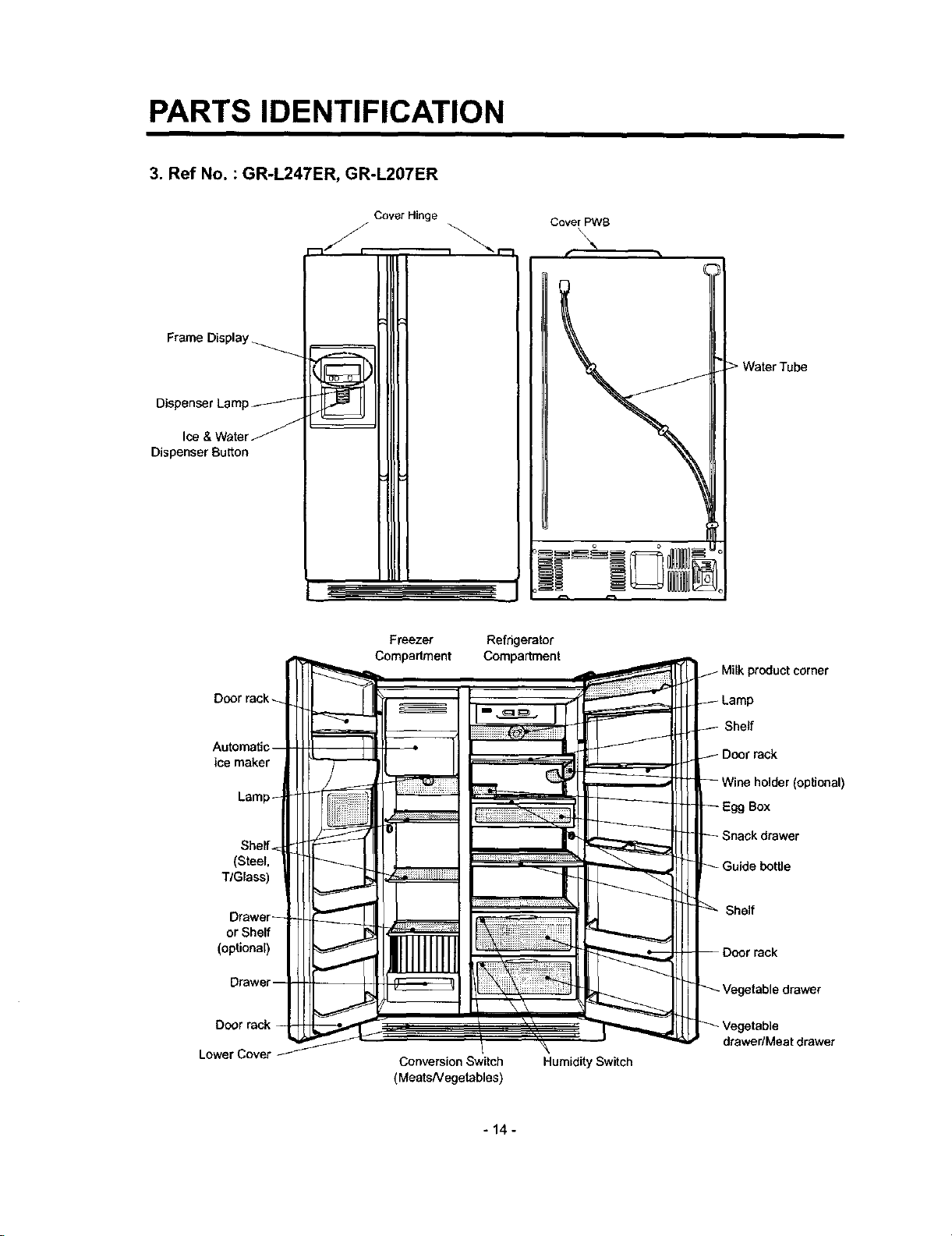

PARTS IDENTIFICATION

3. Ref No. : GR-L247ER, GR-L207ER

Dispenser Lain

Dispenser Button

Cover Hinge

Freezer Refrigerator

Compartment Compartment

CoverPWB

\

> Water Tube

o o

_ El! II_l_

Automatic

ice maker

Lamp-

Sheff.

(Steel.

T/Glass)

or Shelf

(optional)

Door

Lower Cover

Conversion Switch

(MeatsNegetables)

Shelf

Door rack

(optional)

Box

Shelf

r rack

drawer/Meat drawer

Humidity Switch

-14-

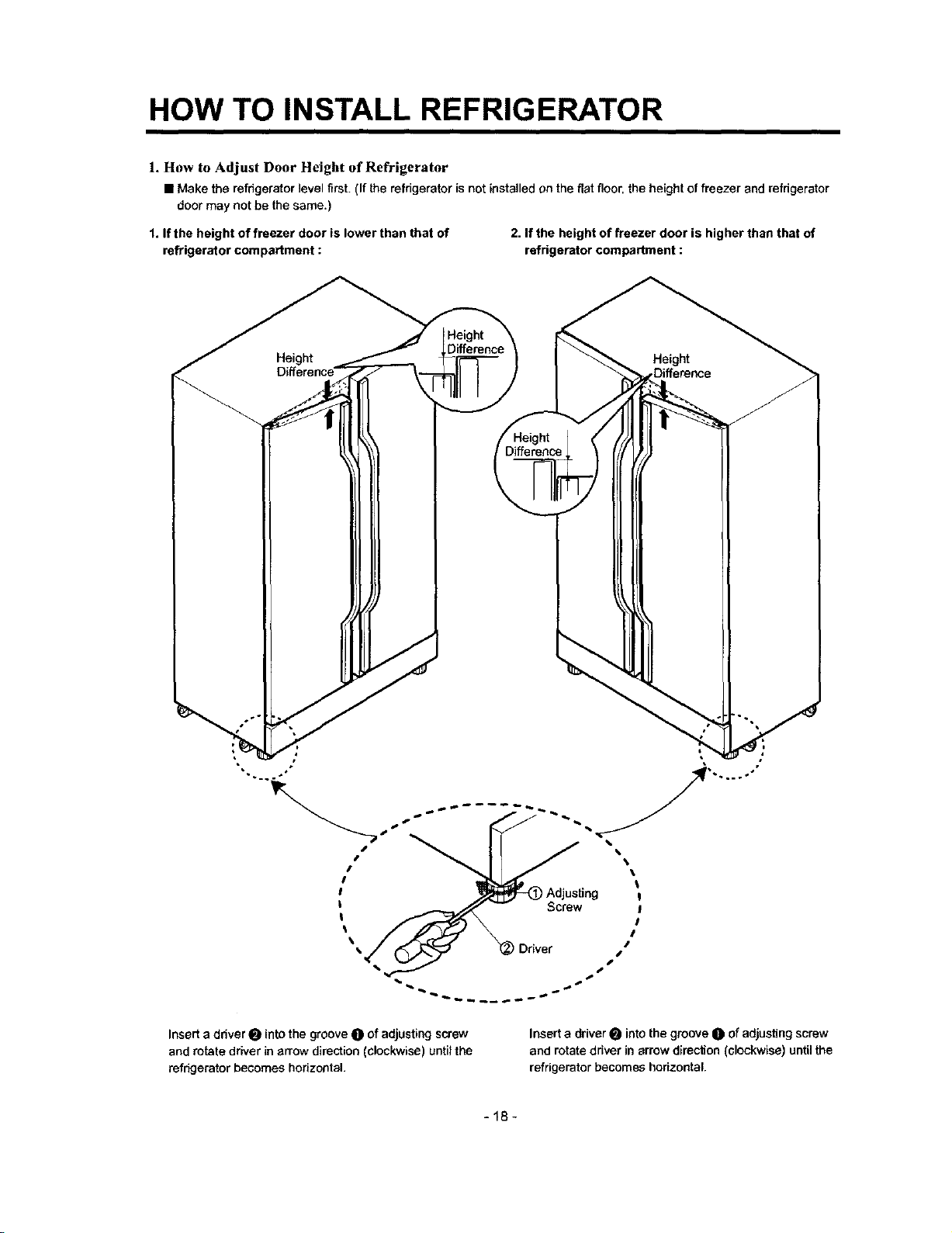

HOW TO INSTALL REFRIGERATOR

1. How to Adjust Door Height of Refrigerator

• Make the refrigerator levelfirst. (If the refrigerator is not installed on the flatfloor, the heightof freezer end refrigerator

door may not be the same.)

1. If the height of freezer door is lower than that of

refrigerator compartment :

2. If the height of freezer door is higher than that of

refrigerator compartment :

Height

Difference

Insert a driver _ into the groove 0 of adjusting screw

and rotate driver in arrow direction (clockwise) until the

refrigerator becomes horizontal.

Insert a driver _ into the groove O of adjusting screw

and rotate driver in arrow direction (clockwise) until the

refrigerator becomes horizontal.

-18-

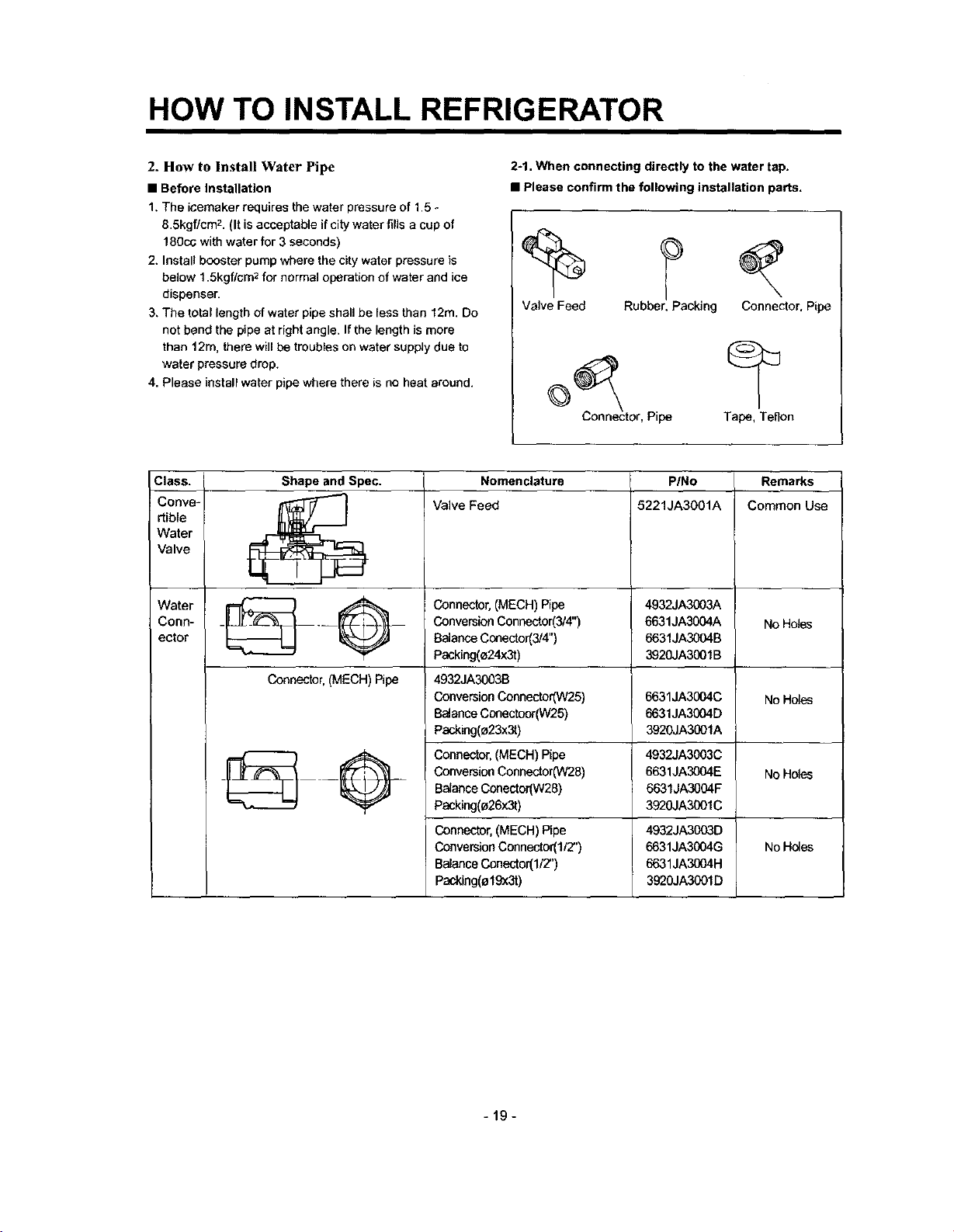

HOW TO INSTALL REFRIGERATOR

2. How to Install Water Pipe

• Before Installation

1. The icemaker requires the water pressure of 1.5 o

8.5kgf/cm 2. (It is acceptable if city water fills a cup of

180c_ with water for 3 seconds)

2. Install booster pump where the city water pressure is

below 1.5kgf/cm; for normal operation of water and ice

dispenser.

3, The total length of water pipe shall be less than 12m. Do

not bend the pipe at right angle. If the length is more

than 12m, there will be troubles on water supply due to

water pressure drop.

4. Please install water pipe where there is no heat around.

Class.

Conve-

_ible

Water

Valve

Water

Conn-

ector

Shape and Spec.

.-®

Connector,(MECH)Pipe

Valve Feed

Connector,(MECH)Pipe

ConversionConnector(3/4")

BalanceCenector(3/4")

Packing(e24x3t)

4932JA30038

ConversionConnector(W25)

BalanceConectoor(W25)

Packing(_23x3t)

Connector,(MECH)Pipe

ConversionConnector(W28)

BalanceConector(W28)

Packing(_26x3t)

Connector,(MECH)Pipe

ConversionConnector(112")

BalanceConector(l/Z')

Packing(_19x3t)

2-1. When connecting directly to the water tap.

• Please confirm the following installation parts,

Valve Feed Rubber. Packing Connector, Pipe

Nomenclature

_ Co_nnec_or, Pipe

P/No

5221JA3001A

4932JA3003A

6631JA3004A

6631JA3004B

3920JA3001B

6631JA3004C

6631JA3004D

3920JA3001A

4932JA3003C

6631JA3004E

6631JA3004F

3920JA3001C

4932JA3003D

6631JA3004G

6631JA3004H

3920JA3001D

Tape, Teflon

Remarks

Common U_

No Holes

No Holes

No Hales

NoH_es

-19-

HOW TO INSTALL REFRIGERATOR

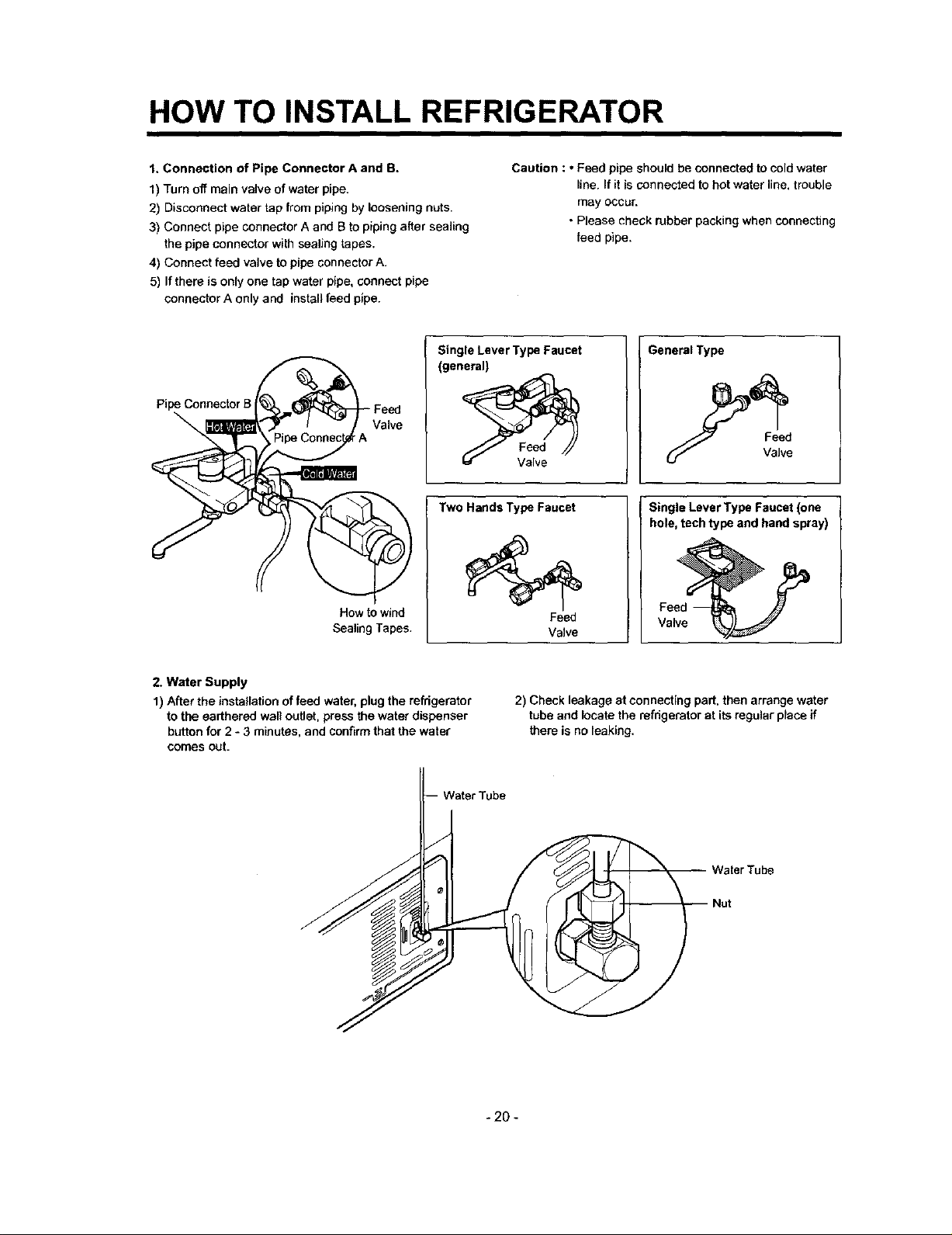

1. Connection of Pipe Connector A and B.

1) Turn off main valve of water pipe.

2) Disconnect water tap from piping by loosening nuts.

3) Connect pipe connector A and B to piping after sealing

the pipe connector with sealing tapes.

4) Connect feed valve to pipe connector A.

5) If there is only one tap water pipe, connect pipe

connector A only and install feed pipe.

Single Lever Type Faucet

(general)

Pipe Connector B

\ Valve

\

Two Hands Type Faucet

How to wind

Sealing Tapes.

Caution : • Feed pipe should be connected to cold water

line. If it is connected to hot water line, trouble

may occur.

• Please check rubber packing when connecting

feed pipe.

General Type

Single Lever Type Faucet (one

hole, tech type and hand spray)

Feed

Valve

Feed

Valve

2. Water Supply

1) After the installation of feed water, plug the refrigerator

to the earthered well outlet, press the water dispenser

button for 2 - 3 minutes, and confirm that the water

comes Out.

Water Tube

2) Check leakage at connecfing part, then arrange water

tube and locate the refrigerator at its regular place if

them is no leaking.

Water Tube

-20-

HOW TO INSTALL REFRIGERATOR

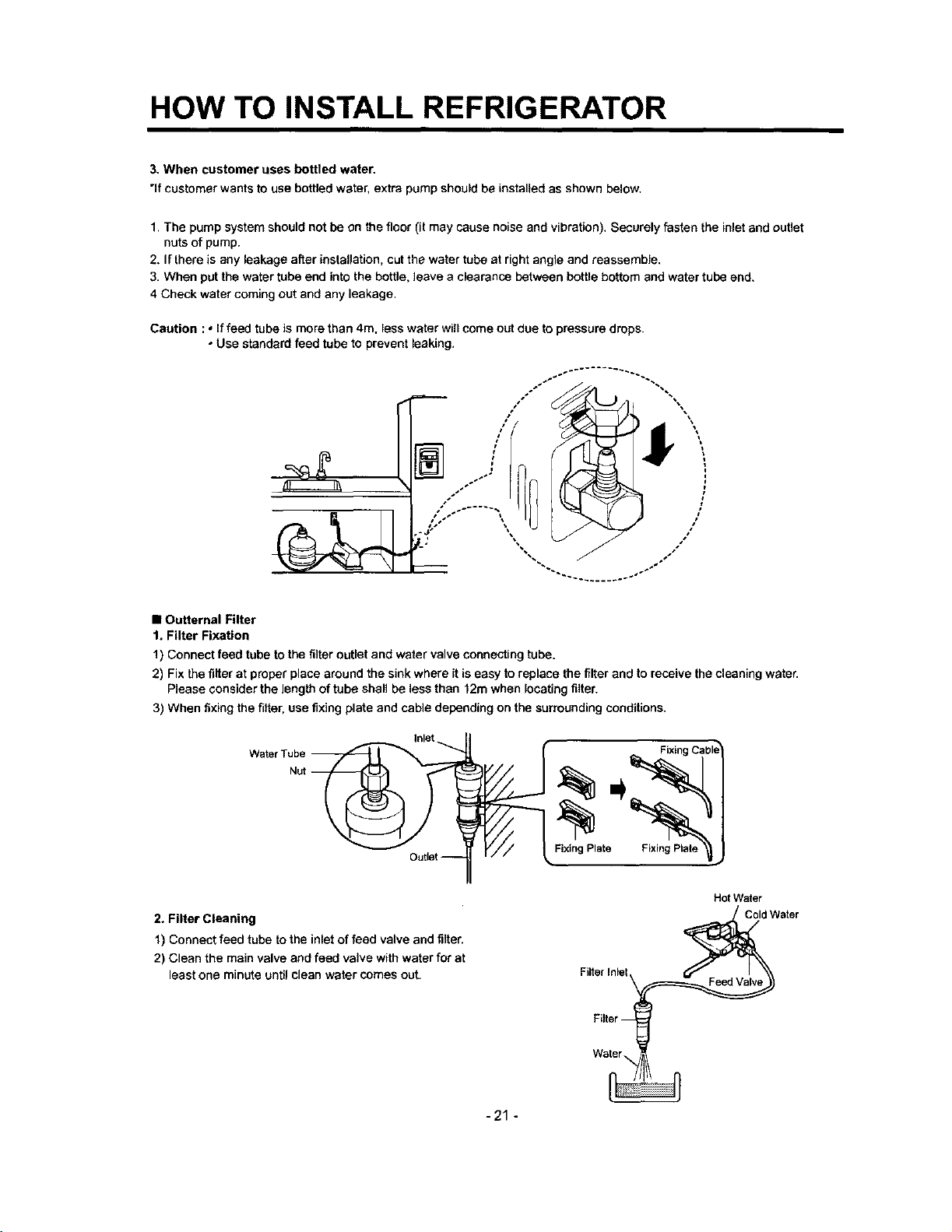

3. When customer uses bottled water.

"If customer wants to use bottled water, extra pump should be installed as shown below.

1. The pump system should not be on the floor (it may cause noise and vibration). Securely fasten the inlet and outlet

nuts of pump.

2. If there is any leakage after installation, cut the water tube at right angle and reassemble.

3. When put the water tube end into the bottle, leave a clearance between bottle bottom and water tube end.

4 Check water coming out and any leakage.

Caution :, If feed tube is more than 4m. less water will come out doe to pressure drops.

• Outternal Filter

t. Filter Fixation

1) Connect feed tube to the filter outlet and water valve connecting tube.

2) Fix the rifler at proper place around the sink where it is easy to replace the filter and to receive the cleaning water.

3) When fixing the filter, use fixing plate and cable depending on the surrounding conditions.

• Use standard feed tube to prevent leaking.

Please consider the length of tube shaft be less than 12m when locating filter.

Water Tube

Fixing CaDI_

2. Filter Cleaning

1) Connect feed tube to the inlet of feed valve and filter.

2) Clean the main valve and feed valve with water for at

least one minute until clean water comes out.

-21 -

FixingPlate

Filter Inlet

Water..

Fixing Plate

HotWater

Cold Water

Feed Valve

HOW TO INSTALL REFRIGERATOR

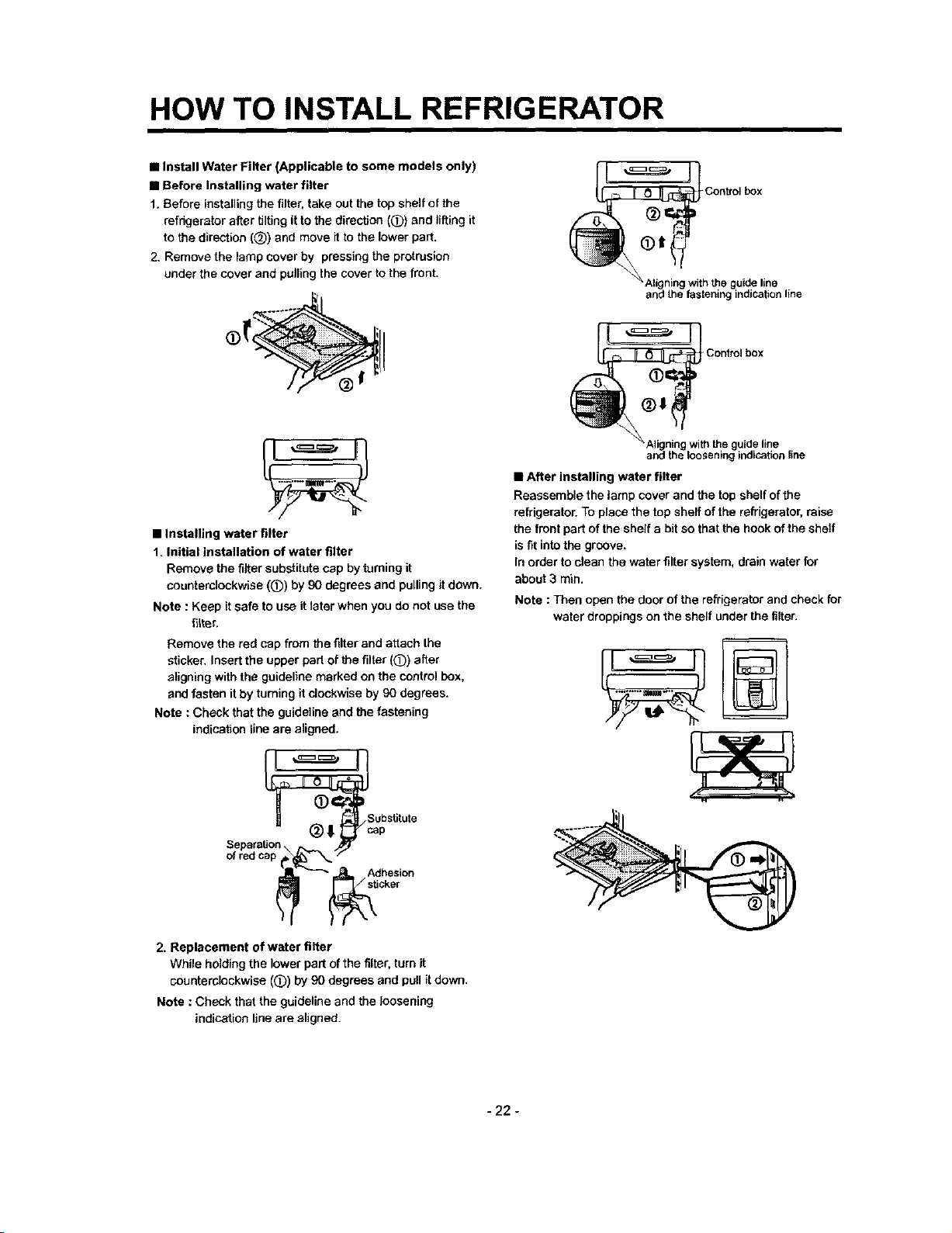

• Install Water Fitter (Applicable to some models only)

• Before Installing water filter

1. Before installing the filter, take out the top shelf of the

refrigerator after tilting it to the direction (O) and lifting it

to the direction (_)) and move it to the lower part.

2, Remove the lamp cover by pressing the protrusion

under the cover and pulling the cover to the front.

• After installing water filter

Reassemble the lamp cover and the top shelf of the

refi'EJeretor.To place the top shelf of the refrigerator, raise

• Installing water filter

1. Initial installation of water filter

Remove the filler substitute cap by turning it

counterclockwise ((_) by 90 degrees end pulling it down.

Note : Keep it safe to use it later when you do not use the

filte_

Remove the red cap from the filler and attach the

sticker, Insert the upper part of the filter (O) after

aligning with the guideline marked on the control box,

and fasten it by turning it clockwise by 90 degrees.

Note : Check that the guideline and the fastening

indication line ere aligned.

the front part of the shelf a bit so that the hook of the shelf

is fit into the groove.

In order to clean the water filter system, drain water for

about 3 min.

Note : Then open the door of the refrigerator and check for

water droppings on the shelf under the tilter.

Control box

and the fastening indication line

-Controlbox

ningwiththe guide line

the loosening indicationline

J ubstitute

cap

°n ---.

2. Replacement of water filter

While holding the lower part of the filter, turn it

counterclockwise ((_) by 90 degrees and pull II down.

Note : Check that the guideline end the loosening

indication line are aligned.

- 22 -

HOW TO INSTALL REFRIGERATOR

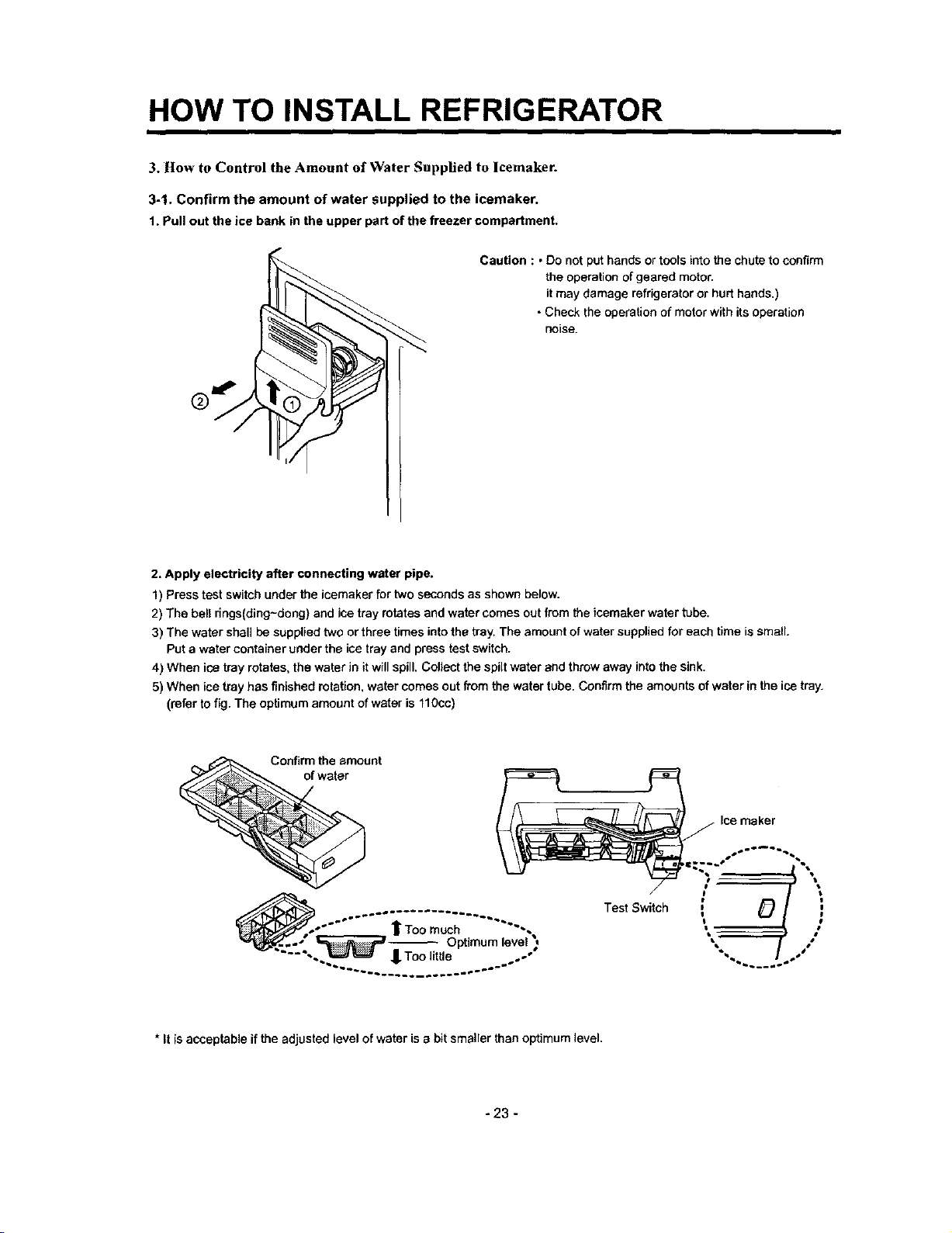

3. How to Control the Amount of'Water Supplied to Icemaker.

3-1. Confirm the amount of water supplied to the icemaker.

1. Pull out the ice bank in the upper part of the freezer compartment.

Caution : • Do not put hands or tools into the chute to confirm

the operation of geared motor.

it may damage refrigerator or hurt hands.)

• Check the operation of motor with its operation

noise.

2. Apply electricity after connecting water pipe.

1) Press test switch under the icemaker for two seconds as shown below.

2) The bell tings(ding-dong) and ice tray rotates and water comes out from the icemaker water tube,

3) The water shall be supplied two or three times into the tray, The amount of water supplied for each time is small.

Put a water container under the ice tray and press test switch.

4) When ice tray rotates, the water in it will spill. Collect the spilt water and throw away into the sink.

5) When ice tray has finished rotation, water comes out fTom the water tube. Confirm the amounts of water in the ice tray.

(refer to fig. The opSmum amount of water is 110cc)

Confirm theamount

ofwater

Ice maker

Test Switch

* It [sacceptable if the adjusted level of water is a bit smaller than optimum level.

- 23 -

HOW TO INSTALL REFRIGERATOR

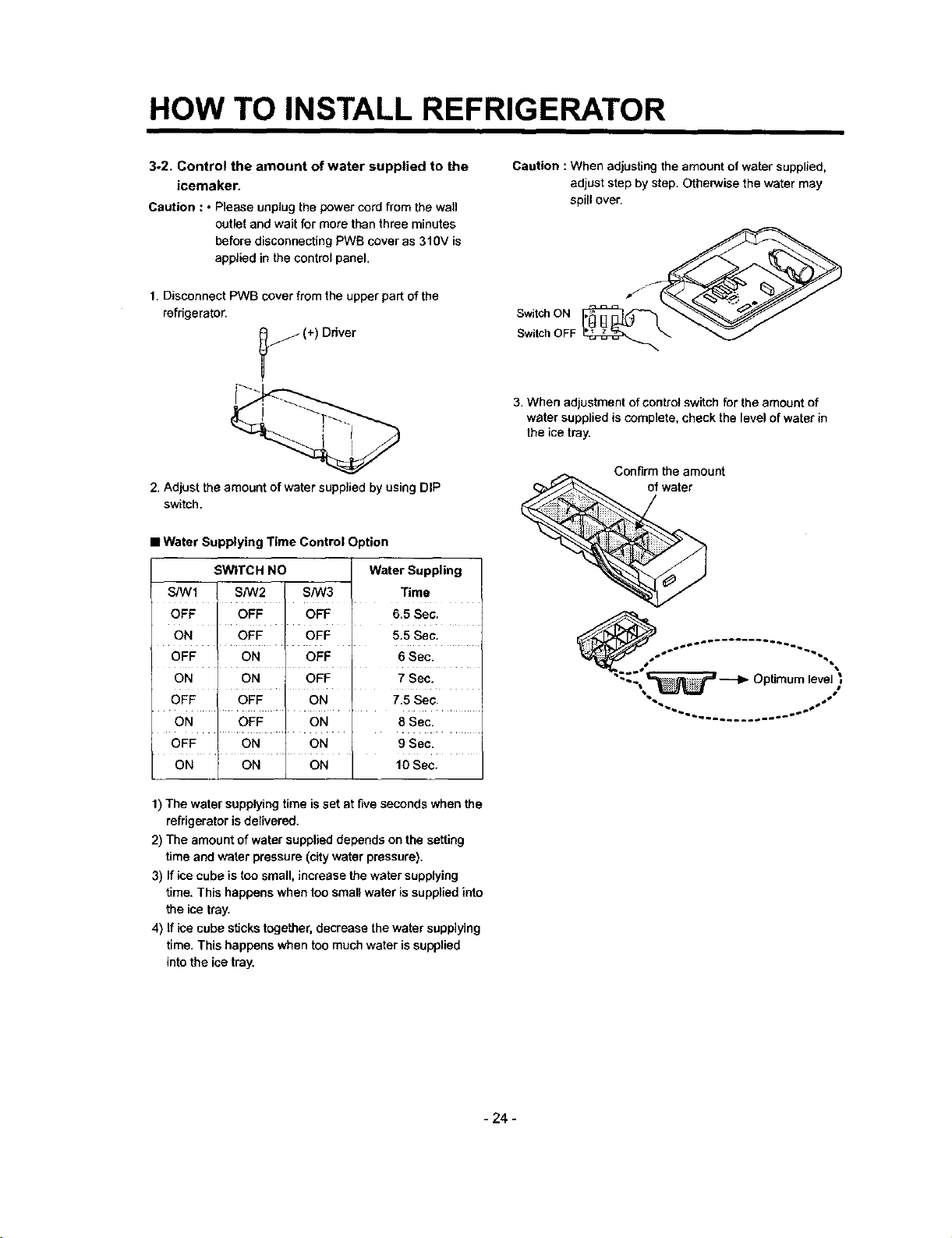

3-2. Control the amount of water supplied to the

icemaker.

Caution : • Please unplug the power cord from the wall

outlet and wait for more than three micutes

before disconnecting PWB cover as 310V is

applied in the control panel.

1. Disconnect PWB cover from the upper part of the

refrigerator.

(+) Ddver

2. Adjust the amount of water supplied by using DIP

switch.

• Water Supplying Time Control (_

SWITCH NO

S/W1 S/W2 SAN3

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON 8 Sec.

oFF ON ON 9 Sec.

ON ON ON 10 Sec.

_tion

Water Suppling

Time

6.5 Sea,

5.5 Sec.

6 Sec.

7set.

7.sSec.

Caution : When adjusting the amount of water supplied,

adjust step by step. Otherwise the water may

spill over.

Switch ON __

Switch OFF

3. When adjustment of control switch for the amount of

water supplied is complete, check the level of water in

the ice tray.

Confirm the amount

of water

::: _---_ Optimum level

1) The water supplying time is set at five seconds when the

refrigerator is delivered.

2) The amount of water supplied depends on the setting

time and water pressure (city water pressure).

3) If ice cube is too small, increase the water supplying

time. This happens when too small water is supplied into

the ice tray.

4) If ice cube sticks together, decrease the water supplying

time. This happens when too much water is supplied

into the ice tray.

- 24 -

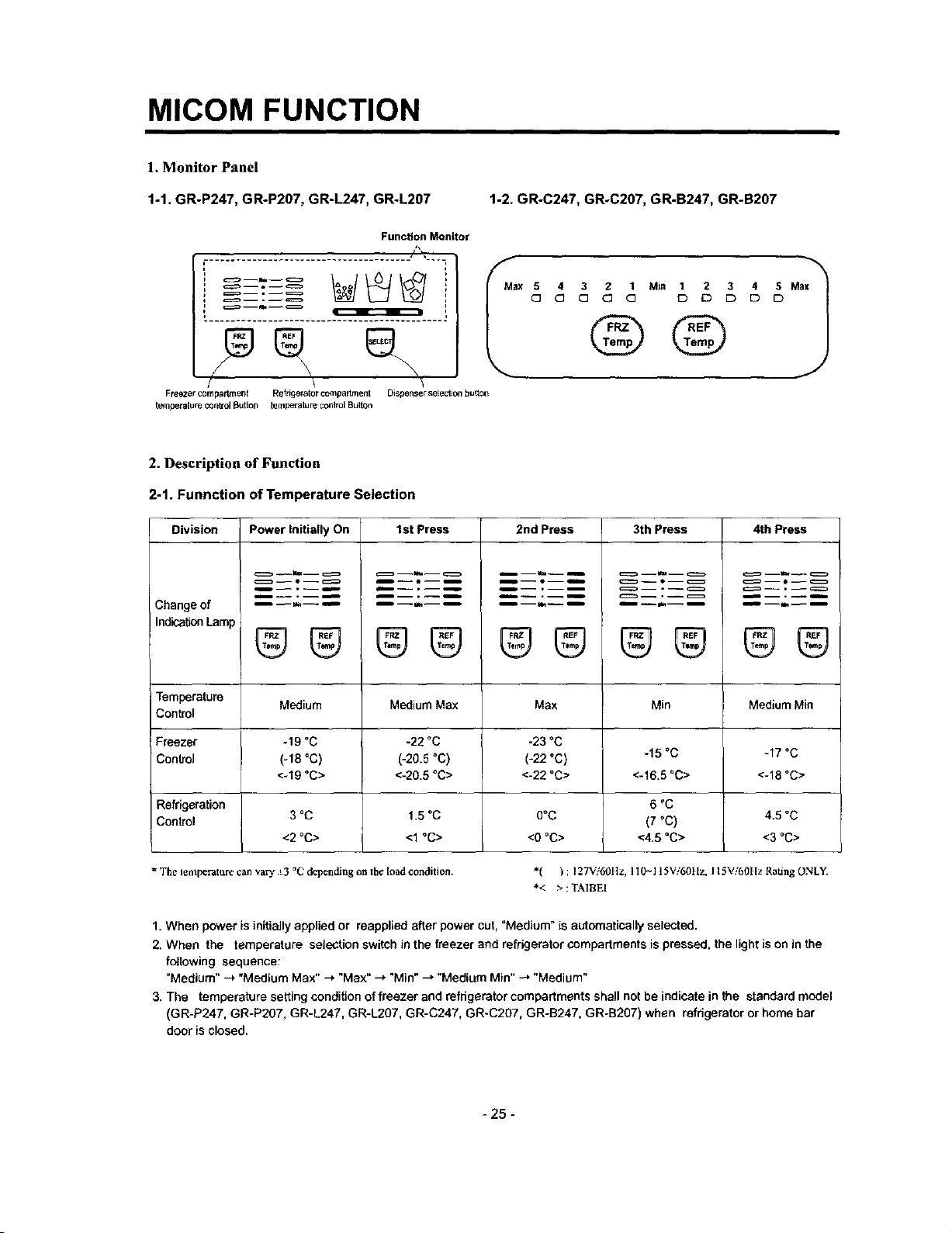

MICOM FUNCTION

I, Monitor Panel

1-1. GR-P247, GR-P207, GR-L247, GR-L207 1-2. GR-C247, GR-C207, GR-B247, GR-B207

Function Monitor

C] (:30 O (3 D D D D

Freezer corn ar_nent Refrigerator compartment Dispensersete_onbuttcn

tempera[we Control Buttol_ temperature con#ol Button

2. Description of Function

2-1. Funnction of Temperature Selection

Division

Change of

IndicatJonLamp

Temperature

Control

Freezer

Con_oi

Refrigeration

Con#ol

"The lemperatm_ can vary. !:3 °C depending on the load condition. *( '1: 12TVi60Hz, 110_115Vi60IIz, I 15Vi601-lz Rating ONLY.

1. When power is initially applied or reapplied after power cut, "Medium" is automatically selected.

2. When the temperature selection switch in the freezer and refrigerator compartments is pressed, the light is on in the

following sequence:

"Medium" --_"Medium Max" -, "Max" --* "Min" _" "Medium Min" _ "Medium"

3. The temperature setting condition of freezer and refdgerator compartments shall not be indicate in the standard model

(GR-P247, GR-P207, GR-L247, GR-L207, GR-C247, GR-C207, GR-B247, GR-B207) when refhgerator or home bar

door is closed,

Power Initially On

Medium

-19 °C

(-18 =C)

<-19 °C>

3 °C

_2 °C>

1st Press 2nd Press 3th Press 4th Press

n i--t--i n m,-- e-- ,m_, i _--e--_ i _--o--_,

I--i--i

@@

Medium Max

-22*C

(-20.5°C)

<-20.5 °C>

1.5°C

<1 °C>

i

i--

,il --s_-- ,i_

@@

Max

-23 °C

(-22 °C)

<-22 °C>

0"C

<0 °C>

*< >:TAIBEI

m --o_1-- u

@@

Min

-15 °C

<-16.5 °C>

6 °C

(7 *C)

= >

<4.5 C

i --)--i

Medium Min

-17 °C

<-18 °C>

4.5 °C

<3 °C>

- 25 -

MICOM FUNCTION

2-2. Automatic ice maker

• The automatic ice maker can automatically make 8 pieces of ice cube at a time. 80 pieces a day, But these quantities may

be varied according to various conditions including how many times the refrigerator door opens and closes.

• Ice making stops when the ice storage bin is full.

• If you don't want to use automatic ice-maker, change the ice-maker switch to ON-OFF.

If you want to use automatic ice-maker again, change the switch to OFF-ON

NOTE : It is normal that a noise is produced when ice made is dropped into the ice storage bin.

2-3. When ice maker does not operate smoothly

Ice is lumped together

• When ice is lumped together, take the ice lumps out of the ice storage bin, break them into small pieces, and then place

them into the ice storage bin again,

• When the ice maker produces too small or lumped together ice, the amount of water supplied to the ice maker need to

adjusted. Contact the service center.

:,_If ice is not used frequently, it may lump together,

Power failure

- Ice may drop into the freezer compartment, Take the ice storage bin out and discard all the ice then dry it and place it

back. Alter the machine is powered again, crushed ice will be automatically selected.

The unit is newly installed

• It takes about 12 hours for a newly installed refrigerator to make ice in the freezer compartment.

- 26 -

MICOM FUNCTION

2,,4. Control of variable type of freezing room fan

I. To increase cooling speed and load response speed, MICOM variably controls freezing room fan motor at the high speed

of RPM and standard RPM.

2. MICOM only operates in the input of initial power or special freezing operation or load response operation for the high

speed of RPM and operates in the standard RPM in other general operation.

3. If opening doors of freezing / cold storage room or home bar while fan motor in the freezing room operates, the freezing

room fan motor normally operates (If being operated in the high speed of RPM, it converts operation to the standard

RPM). However, if opening doors of freezing room or home bar, the freezing room fan motor stops.

4. As for monitoring of BLDC fan motor error in the freezing room, MICOM immediately stops the fan motor by determining

that the BLDC fan motor is locked or poor if there would be position signal for more than 65 seconds at the BLDC motor.

Then it displays failure (refer to failure diagnosis function table) at the display part of refrigerator, performs re-operation in

the cycle of 30 minutes. If normal operation is performed, poor status is released and refrigerator returns to the initial

status (reset).

2-5. Control of M/C room fan motor

I. The M/C room fan motor performs ON/OFF control by linking with the COMP.

2. It controls at the single RPM without varying RPM.

3. Failure sensing method is same as in fan motor of freezing fan motor (refer to failure diagnosis function table for failure

display).

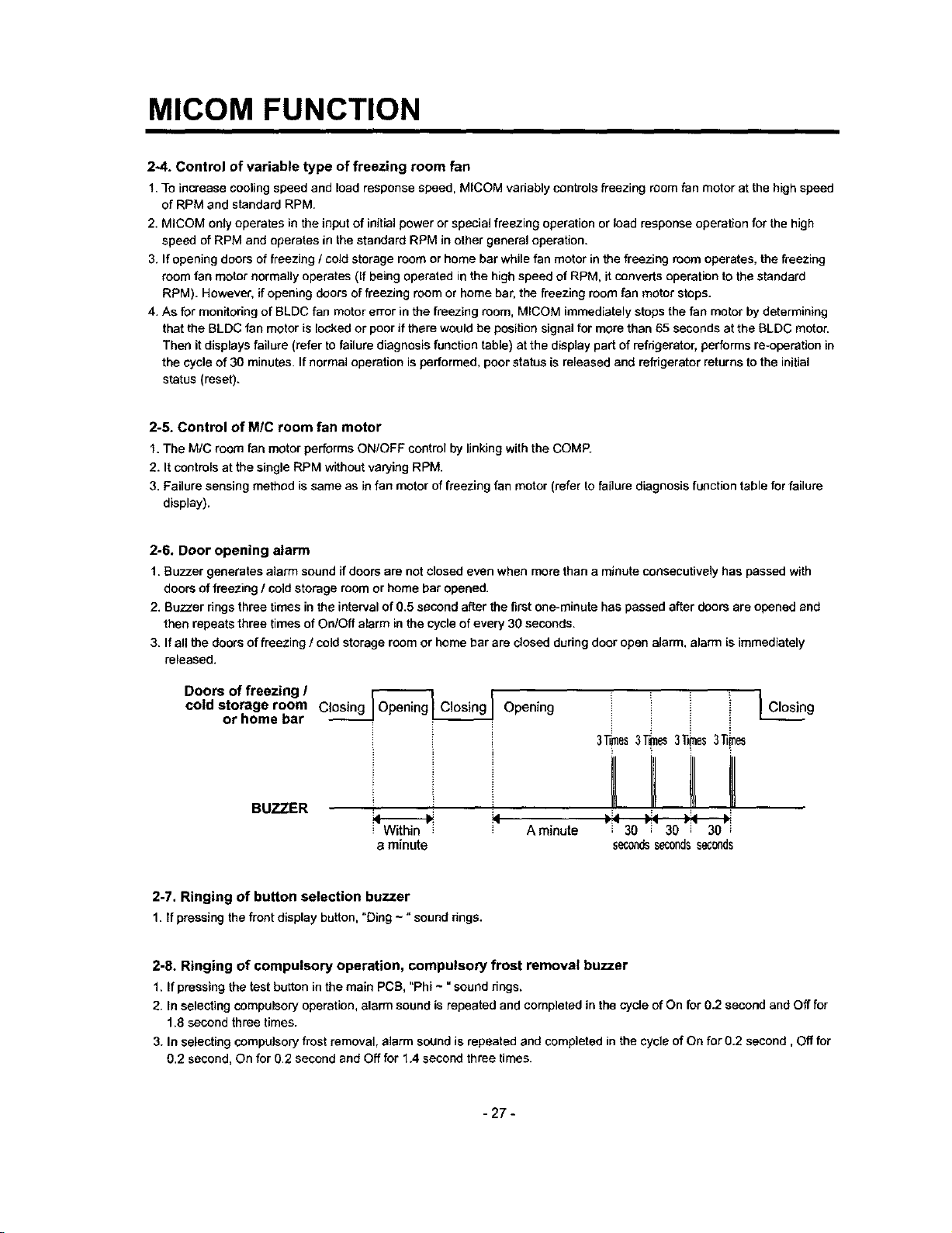

2-6. Door opening alarm

1. Buzzer generates alarm sound if doors are not closed even when more than a minute consecutively has passed with

doors of freezing / cold storage room or home bar opened.

2, Buzzer rings three times in the interval of 0.5 second after the first one-minute has passed after deers are opened and

then repeats three times of On/Off alarm in the cycle of every 30 seconds.

3. If all the doors of freezing / cold storage room or home bar are dosed during door open alarm, alarm is immediately

released.

Doors of freezing /

cold storage room Closing

or home bar

__ _ Opening

Closing

3T_es 3Ta_es 3_mes 3_mes

BUZZER

i Within _ i A minute

a minute

i 30")" 30 i 30 1

secondssecondsseconds

2-7. Ringing of button selection buzzer

1. If pressing the front display button,"Ding~ "sound dngs.

2-8. Ringing of compulsory operation, compulsory frost removal buzzer

1. If pressing the test button in the main PCB, "Phi ~ =sound rings.

2. In selecting compulsory operation, alarm sound is repeated and completed in the cycle of On for 0.2 second and Off for

1.8 second three times.

3. In selecting compulsory frost removal, alarm sound is repeated and completed in the cycle of On for 0.2 second, Off for

0.2 second, On for 0.2 second and Off for 1.4 second three times.

- 27 -

MICOM FUNCTION

2-9. Frost removal function

1. Frost removal is performed whenever total operation time of compressor becomes 7 ~ 7.5 hour.

2. in providing initial power (or returning power failure), frost removal stads whenever total operation time of compressor

becomes 4 - 4.5 hour.

3. Frost removal is completed if temperature of a frost removal sensor becomes more than 5°C after starting frost removal.

Poor frost removal is not displaced if it does not arrive at 5°C even if two hours have passed after starting frost removal.

4. No removal isdone if frost removal sensor becomes poor (snapping or shod-circuit).

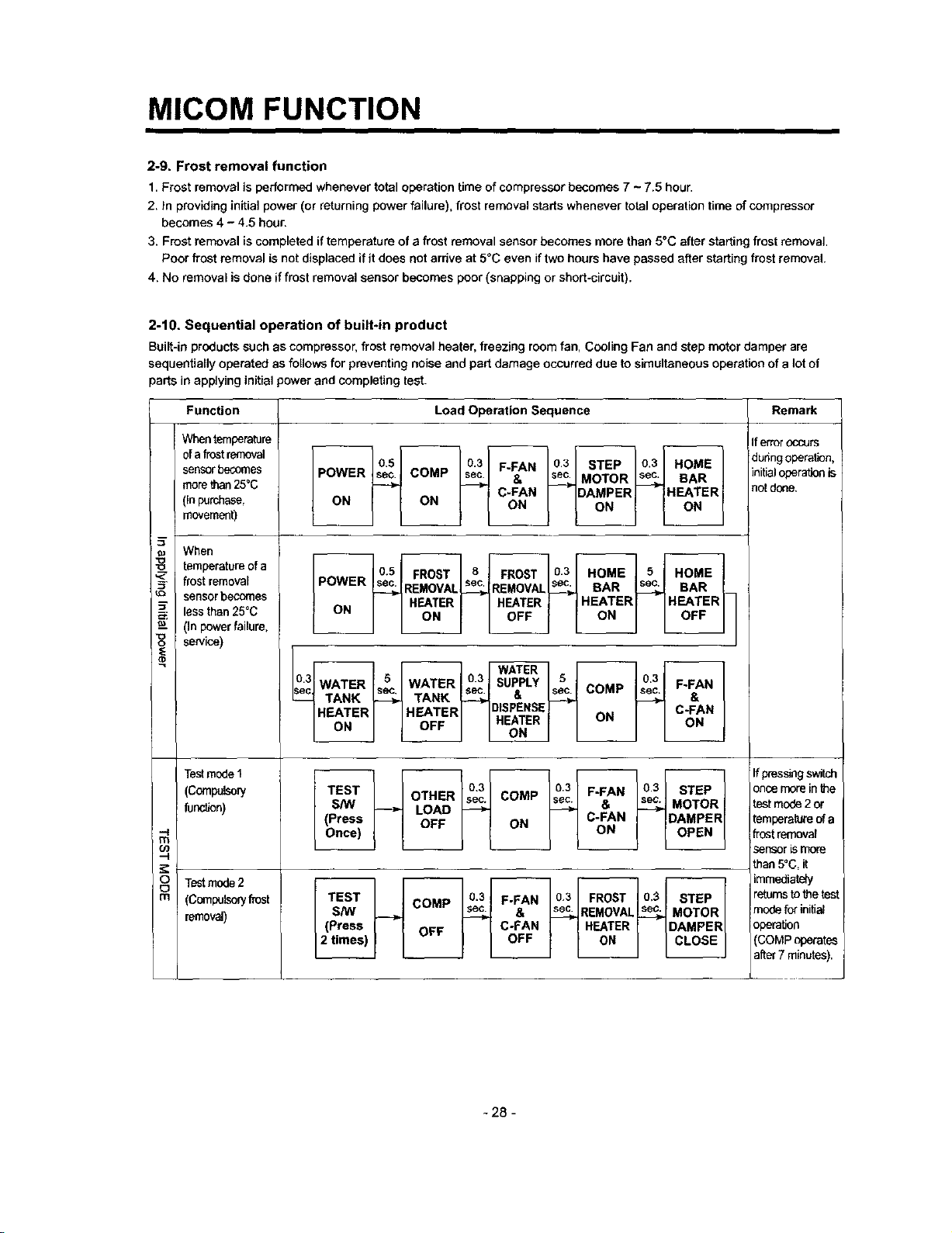

2-10. Sequential operation of built-in product

Built-in productS such as compressor, frost removal heater, freezing room fan, Cooling Fan and step motor damper are

sequentially operated as follow_ for preventing noise and part damage occurred due to simultaneous operation of a lot of

parts in applying initial power and completing test.

Function

Whentemperature

ofa frostremoval

sensor becomes

more than 25°C

(in purchase,

movement)

When

_ temperature of a

,<

3" frost removal

sensorbecomes

-_ less than 25°C

_-- (In power failure,

"_ service)

Testmode1

(Compulsory

function)

im

o)

-t

o Testmode 2

m (Compulsory frost

removal)

Load Operation Sequence

Iferroroccurs

POWER sec. COMP sec. &

0.5 0.3 F-FAN

ON ON ON

-- 0.3 ST_Ep 0.3 _

C-FAN

sec. MOTOR Isec.'J BAR I

duringoperation,

initial operationis

not done.

L J

POWER sec. REMOVAL=sec. REMOVAL

0.3 WATER 5 WATER 0.3 SUPPLY 5 0.3

--sec' TANK -_ TANK _ &

0.5 FROST 8 FROST

ON HEATER HEATER

ON OFF

S_C. Sec.

WATER

.EATERo.LH #RO'SPE"SE.EATE.o.

If pressing switch

TEST

S/W

(Press

Once)

TEST

S/W

(Press

2 times) I

OTHER sec. COMP .

OFF oN

COMP 0.3 F-FAN

sec. &

OFF C-FAN

OFF

once more in i_e

test mode 2 or

temperature of a

frostremoval

sensor _Smore

than 5°C=it

immediately

returnsto the test

mode for initial

operation

(COMP operates

after7 minutes).

Remark

- 28 -

MICOM FUNCTION

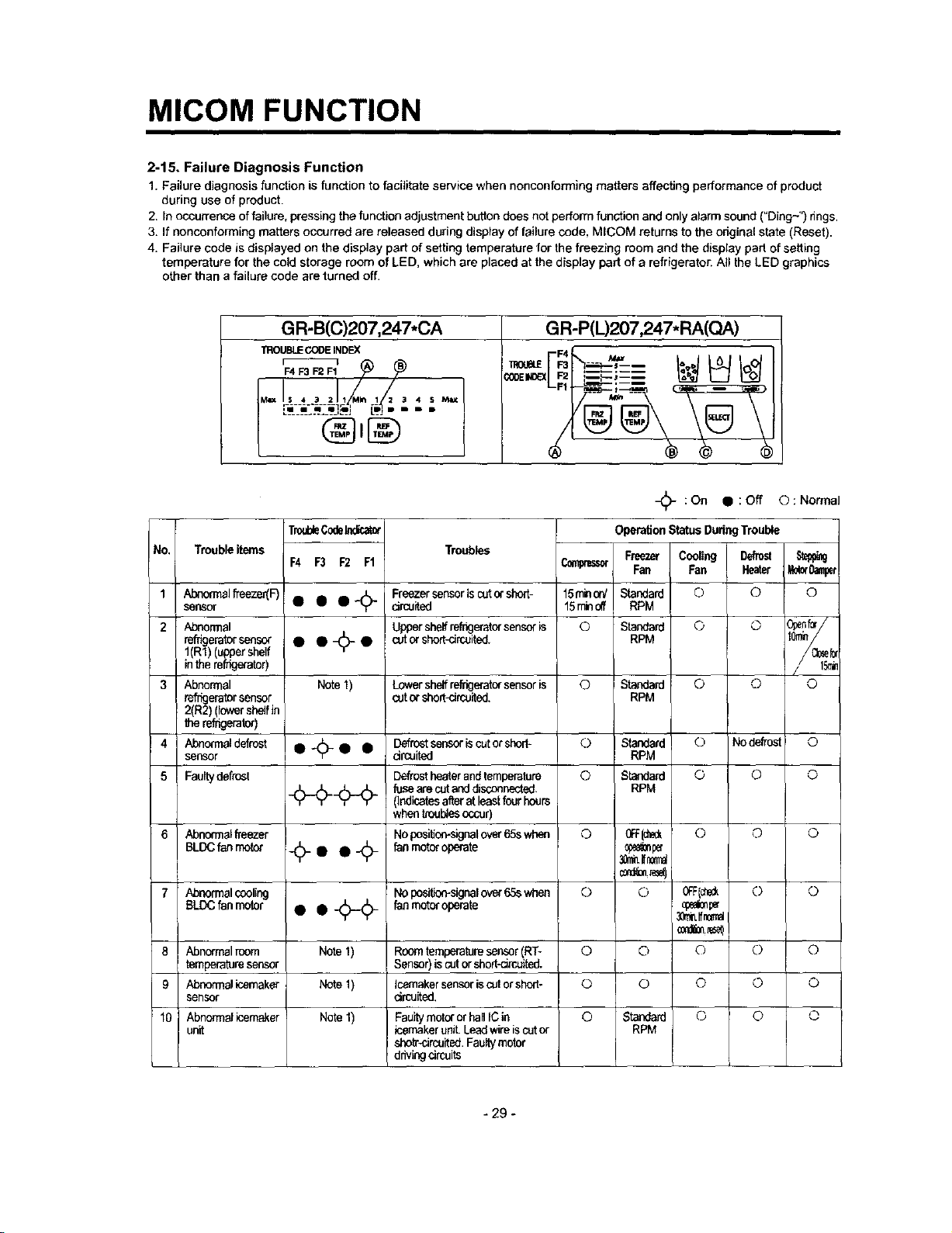

2-15. Failure Diagnosis Function

1. Failure diagnosis function is function to facilitate service when nonconforming matters affecting performance of product

during use of product.

2. In occurrence of failure, pressing the function adjustment button does not perform function and only alarm sound ("Ding~") rings.

3. If nonconforming matters occurred are released during display of failure code, MICOM returns to the edginal state (Reset).

4. Failure code is displayed on the display part of setting temperature for the freezing room and the display pad of setting

temperature for the cold storage room of LED, which are placed at the display pert of a refrigerator. All the LED graphics

other than a failure code are turned off.

GR-B(C)207,247*CA

TROUBLECODEINDEX

GR-P(L)207,247*RA(QA)

/

Mix

_)- :On Off © Normal

TroubleCode_icatot

Troubleitems Troubles

1

Abnormalfreezer{F) • • •J-L Freezersensoriscutorshod- 15m_oe./ Standard ©

sensor -"r#- circuited 15reinoff RPM

Abnormal Uppershelf refrigeratorsensor is © Standard CD

refdgeretor sensor • • _- • cut or shod-circuited. RPM

1(R1) uppershelf

n therefrigerator)

3 Note 1) Lowershelf refrigeratorsensor is © Standard ©

Abnormal

re;_"eratorsensor

2(R;_)(lowersha_fin

the reffigerato0

4

Abnormsldefrost

sensor

5

Fau_ defrost

Abnormalfreezer

BLDCfanmotor

F4 F3 1:2 FI

T

o oo

C_" Fan Fan

cat or short-circuited. RPM

Defrostsensoriscut orshort- 0 Standard O Nodefrost ©

drcuited RPM

Defrostheaterandtemperature © Standard © © ©

fuse are cut anddisconnected. RPM

(Indicates afterat least fourhours

whentroublesoccur)

Nopcsitiou-signalover 65swhen O Or'F{_I_ O O O

fan motoroperate 0p_

OperationStatus DuringTrouble

3Or__reTrd

© 0

© ©

Abnormal cuolin9

BLDC fan motor

8 Abnormal morn

temperaturesensor

9 Abnormal icemaker

serlser

10 Abnorrnalicemaker

unit

Note 1)

Note 1)

Note 1)

NOposition-signalover 65swhen C) (D OFF{ct_ 0 0

fan motor operate 0prel=r_

Roomtemperature sensor RT- 0 © © 0 ©

Sensor iscutor short_ircuiled.

Icemekersensoriscut or short- © O © © ©

circuited,

Fauity motoror hall ICin 0 Standard © © ©

icernakerunit. Leadwireiscutor RPM

shotr-circuited.Faulty motor

drivingcircuits

3_eb.lfremal

- 29 -

MICOM FUNCTION

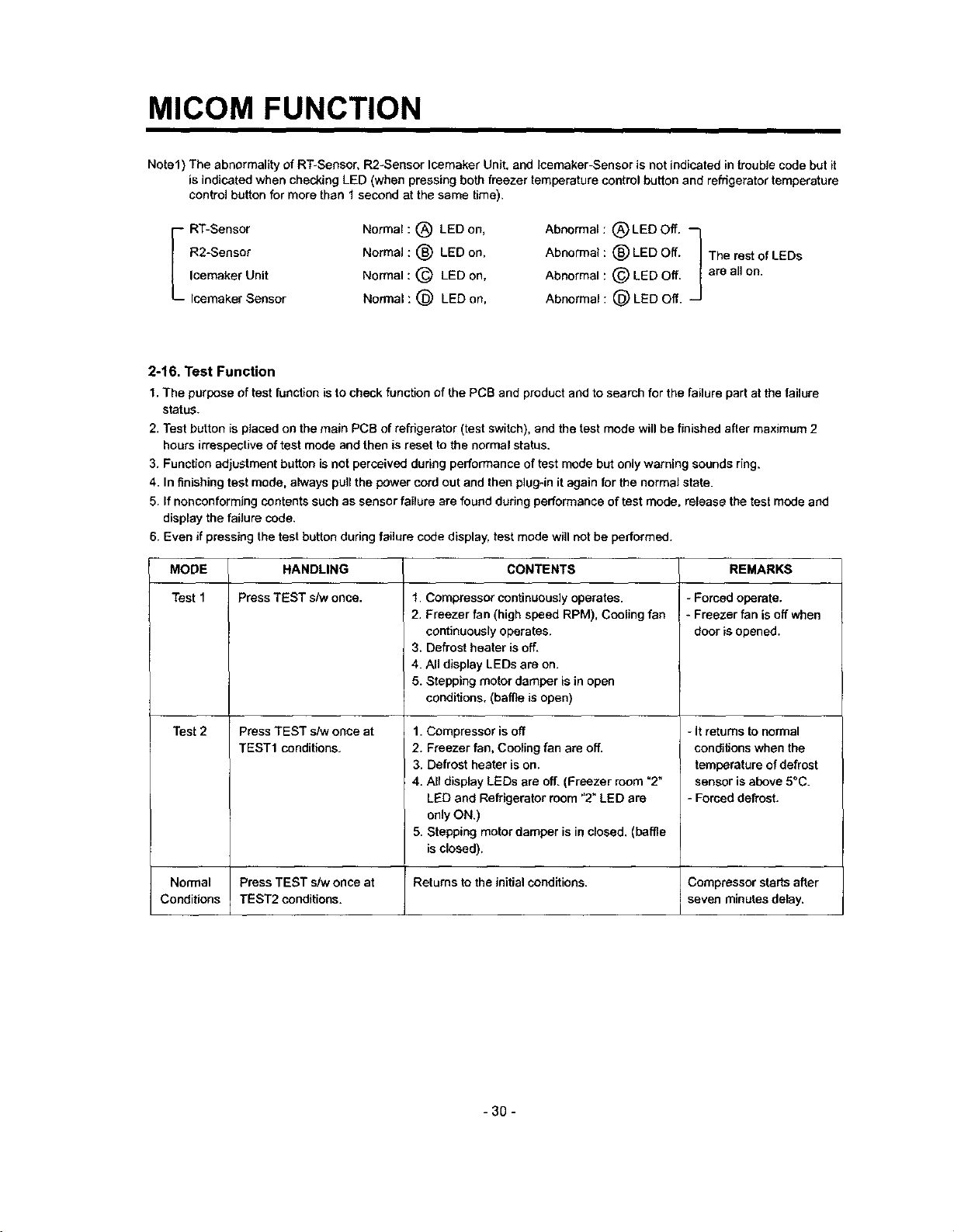

Note1) The abnormality of RT-Sensor, R2-Sensor Icemaker Unit, and Icemaker_Sensor is not indicated in trouble code but it

is indicated when checking LED (when preasing both freezer temperature control button and refrigerator temperature

control button for more than 1 second at the same time).

i RT-Sensor

R2-Sensor

2-16. Test Function

1. The purpose of test function is to check function of the PCB and product and to search for the failure part at the failure

status.

2, Test button is placed on the main PCB of refrigerator (test switch), and the test mode will be finished after maximum 2

hours irrespective of test mode and then is reset to the normal status.

3. FuncUon adjustment button is not perceived during performance of test mode but only warning sounds ring.

4. In finishing test mode, always pull the power cord out and then plug-in it again for the normal state.

5. If nonconforming contents such as sensor failure are found during performance of test mode, release the test mode and

display the failure code.

6. Even if pressing the test button dudng failure code display, test mode will not be pedormed.

MODE

Test 1

HANDLING

Press TEST s/w once.

Normal : (_) LED on,

Normal : (_) LED on,

Normal : (_ LED on,

Normal : (_) LED on,

1. Compressor continuously operates.

2. Freezer fan (high speed RPM), Cooling fan

continuously operates.

3. Defrost heater is off.

4. All display LEDs are on.

5. Stepping motor damper is in open

conditions. (baffle is open)

Abnormal : (_) LED Off. --_

Abnormal : (_) LED Off. |

Abnormal: (_) LED Off. |

Abnormal : (_) LED Off. -j

CONTENTS REMARKS

The rest of LEDs

are all on.

- Forced operate.

- Freezer fan is off when

door is opened.

Test2

Normal Press TEST s/w once at Returns to the initial conditions. Compressor starts after

Conditions TEST2 conditions, seven minutes delay.

PressTEST s/w onceat

TEST1 conditions.

1. Compressor is off

2. Freezer fan, Cooling fan are off.

3. Defrost heater is on.

4. All display LEDs are off. (Freezer room =2"

LED and Refrigerator room "2" LED are

only ON.)

5. Stepping motor damper is in closed. (baffle

isclosed).

- It returns to normal

condi_ons when the

temperature of defrost

sensor is above 5°C.

- Forced defrost.

-30-

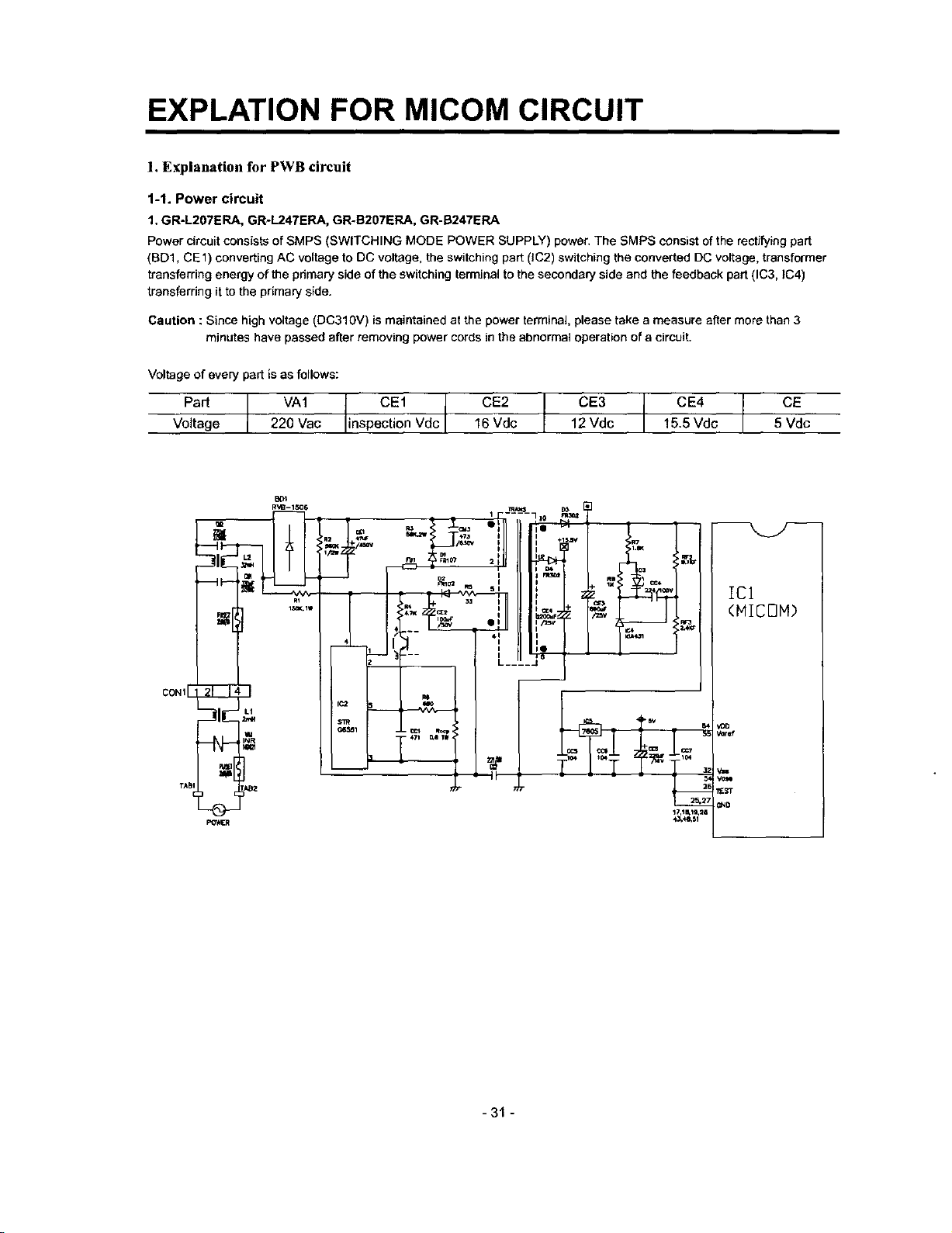

EXPLATION FOR MICOM CIRCUIT

1. Explanation for PWB circuit

1-1. Power circuit

1. GR-L207ERA, GR-L247ERA, GR-B207ERA, GR-B247ERA

Power circuit consists of SMPS (SWITCHING MODE POWER SUPPLY) power. The SMPS consist of the rectifying part

(BD1, CE1) converting AC voltage to DC voltage, the switching part (IC2) switching the converted DC voltage, transformer

transferring energy of the pdmary side of the switching terminal to the secondary side and the feedback part (IC3, IC4)

transferring it to the primary side.

Caution : Since high voltage (DC310V) is maintained at the power terminal, please take a measure after more than 3

minutes have passed after removing power cords in the abnormal operation of a circuit.

Voltage of every part is as follows:

Voltage [ r1220 Vac /inspection Vdc 16 Vdc 12 Vdc 15.5 Vdc 5 Vdc

B4}1

R'_B-I_O 6

--_ T= _. : Illi=_1/ ,.._;;=._'_

- I = - _, Sl + cev

= - ['----110 m3_

.

_ 2

i +

ICl

(MICOM)

CONI[j_

J_:_ "_It!j,jI [" 1

;,___ L--_

_ref

_ST

_D

-31-

EXPLATION FOR MICOM CIRCUIT

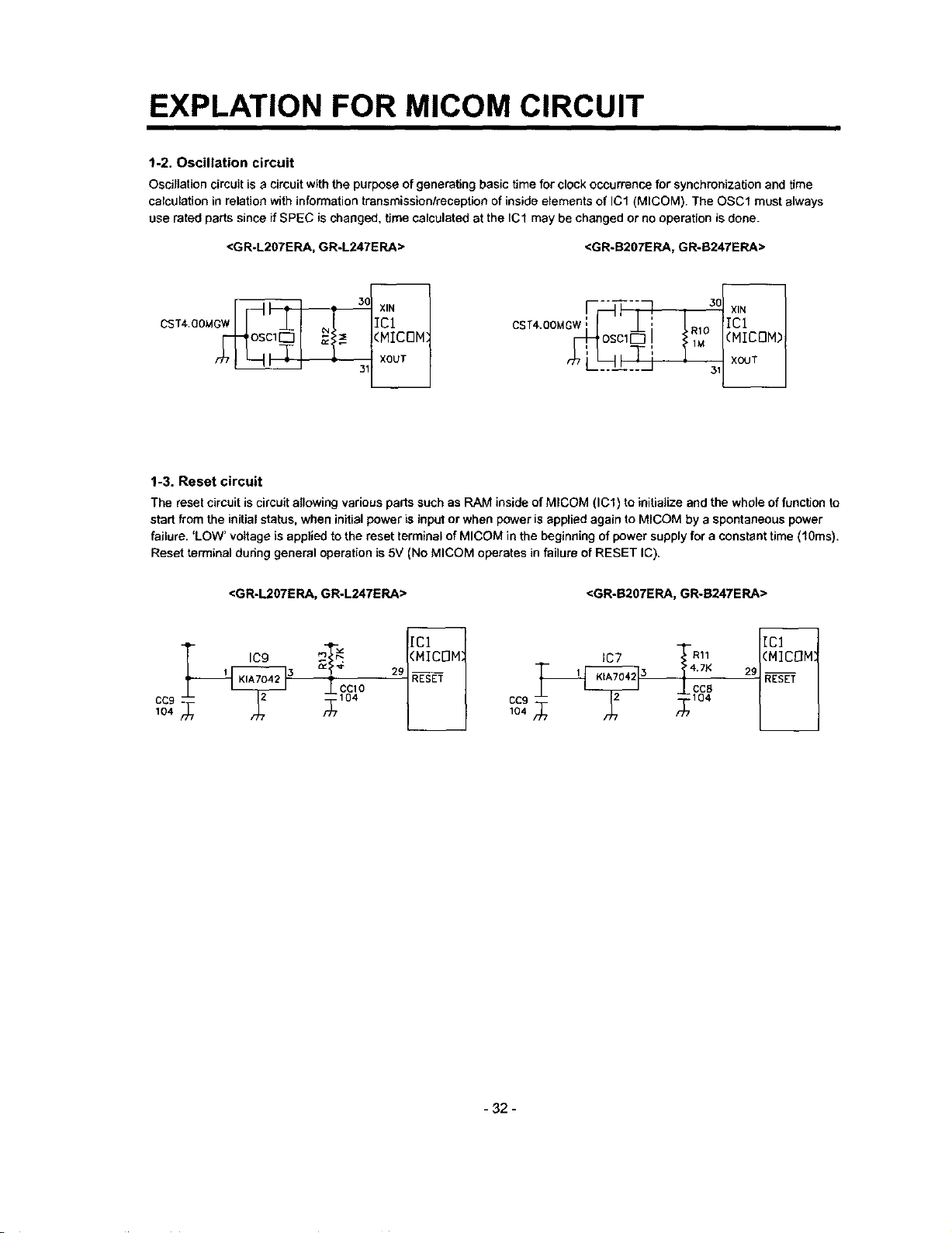

1-2. Oscillation circuit

Oscillation circuit is a circuit with the purpose of generating basic time for clock occurrence for synchronization and time

calculation in relation with information transmissionlreception of inside elements of IC1 (MICOM) The OSC1 must always

use rated parts since if SPEC is changed, time calculated at the ICl may be changed or no operation is done.

<GR.L207ERA, GR-L247ERA> <GR-B207ERA, GR-B247ERA>

CST4.OO_IGWI ;I i

r-MosclE]

CST4.0OUGW: I J_ ;

r_ osclr_ I

1M

t R1030_

L_Lt__1T'i

3,[___._j

1-3. Reset circuit

The reset circuit is circuit allowing various parts such as RAM inside of MICOM (IC1) to initialize and the whole of function to

start from the initial status, when initial power is inp_ or when power is applied again to MICOM by a spontaneous power

failure. 'LOW' voltage is applied to the reset terminal of MICOM in the beginning of power supply for a constant time (10ms).

Reset terminal dudng general operation is 5V (No MICOM operates in failure of RESET IC).

<GR-L207ERA, GR-L247ERA> <GR-B207ERA, GR-B247ERA>

T Icg IC7

CC9 f_104 f_7104

104 104

3 29 1 3 29

_ 4.7K

CC1O CC8

CC9 2

- 32 -

EXPLATION FOR MICOM CIRCUIT

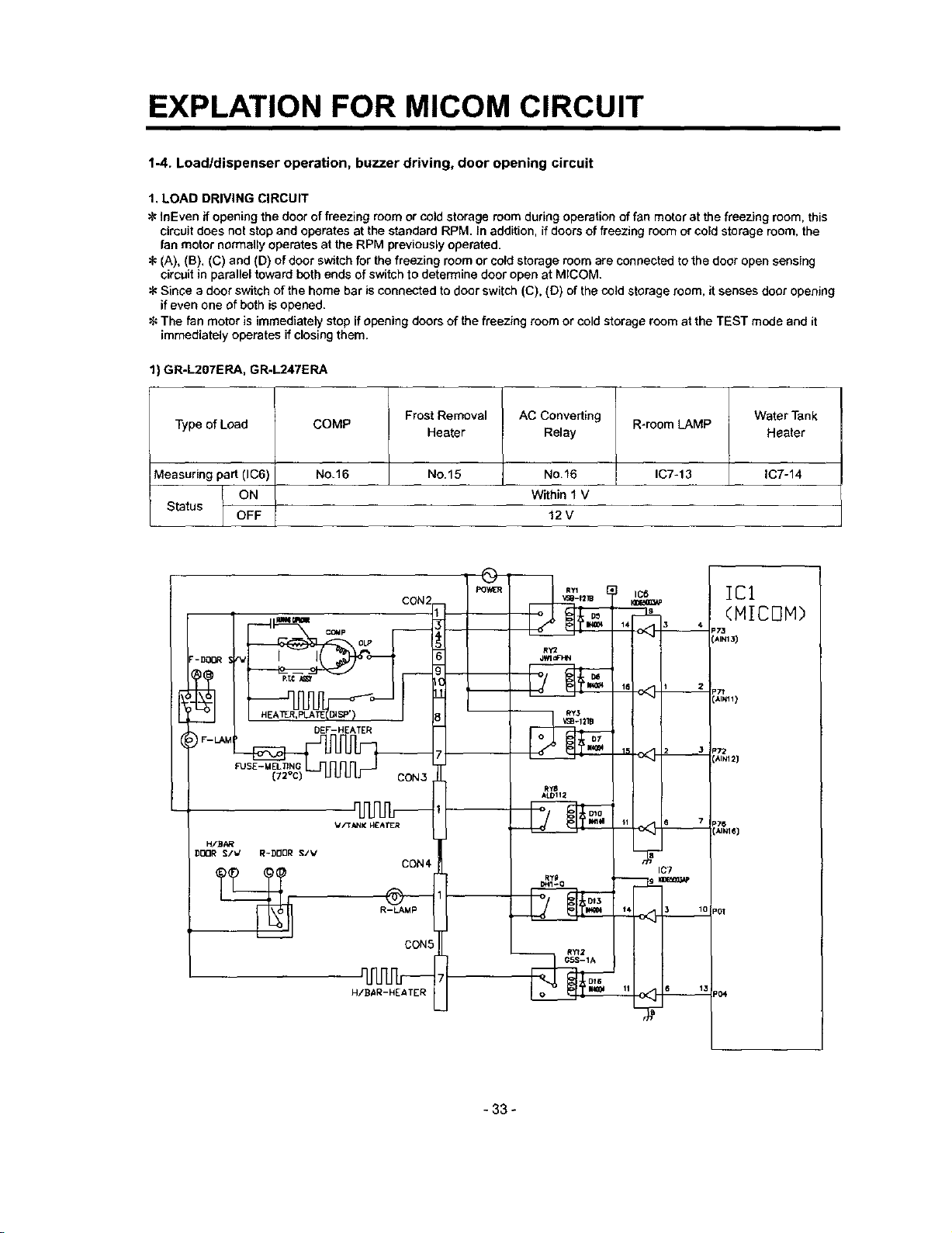

1-4. Load/dispenser operation, buzzer driving, door opening circuit

1. LOAD DRIVING CIRCUIT

faEven if opening the door of freezing room or cold storage room during operation offan motor at the freezing room, this

circuit does not stop and operates at the standard RPM. In addition, if doors of freezing room or cold storage room, the

fan motor normally operates at the RPM previously operated.

(A), (B), (C) and {D) of door switch for the freezing room or cold storage room are connected tothe door open sensing

circuit in parallel toward both ends of switch to determine door open at MICOM.

Since a door switch of the home bar is connected to door switch (C), (D) of the cold storage room, it senses door opening

if even one of both isopened_

The fan motor is immediately stop if opening doors of the freezing room or cold storage room at the TEST mode and it

immediately operates if closing them.

1) GR-L207ERA, GR.L247ERA

Type of Load

_4easudng part (IC6)

Status I ON

"- II[XlR V

,)F-_M_

H/BAR

DI_]R _/V R-DOOR S/V

COMP

No.16

CON;

DEF-HEATER

UUUIf CON

W/TANK HEATER

CON4

R-LAMp

Frost Removal

Heater

No.15

-- RY3

AC Converting

Relay

No_16

Within 1 V

12V

RY2

JWlOF_

Ry_

ALDll2

i_1. 0 '

R-room LAMP

IC7-13

14 3 4

111 1 2

2 3

IC7

ICI

(MICOM)

P73

i

P_

_76

AINI_)

I01

Water Tank

Heater

IC7-14

CON_

CR._21A

Dr6

304

-33-

EXPLATION FOR MICOM CIRCUIT

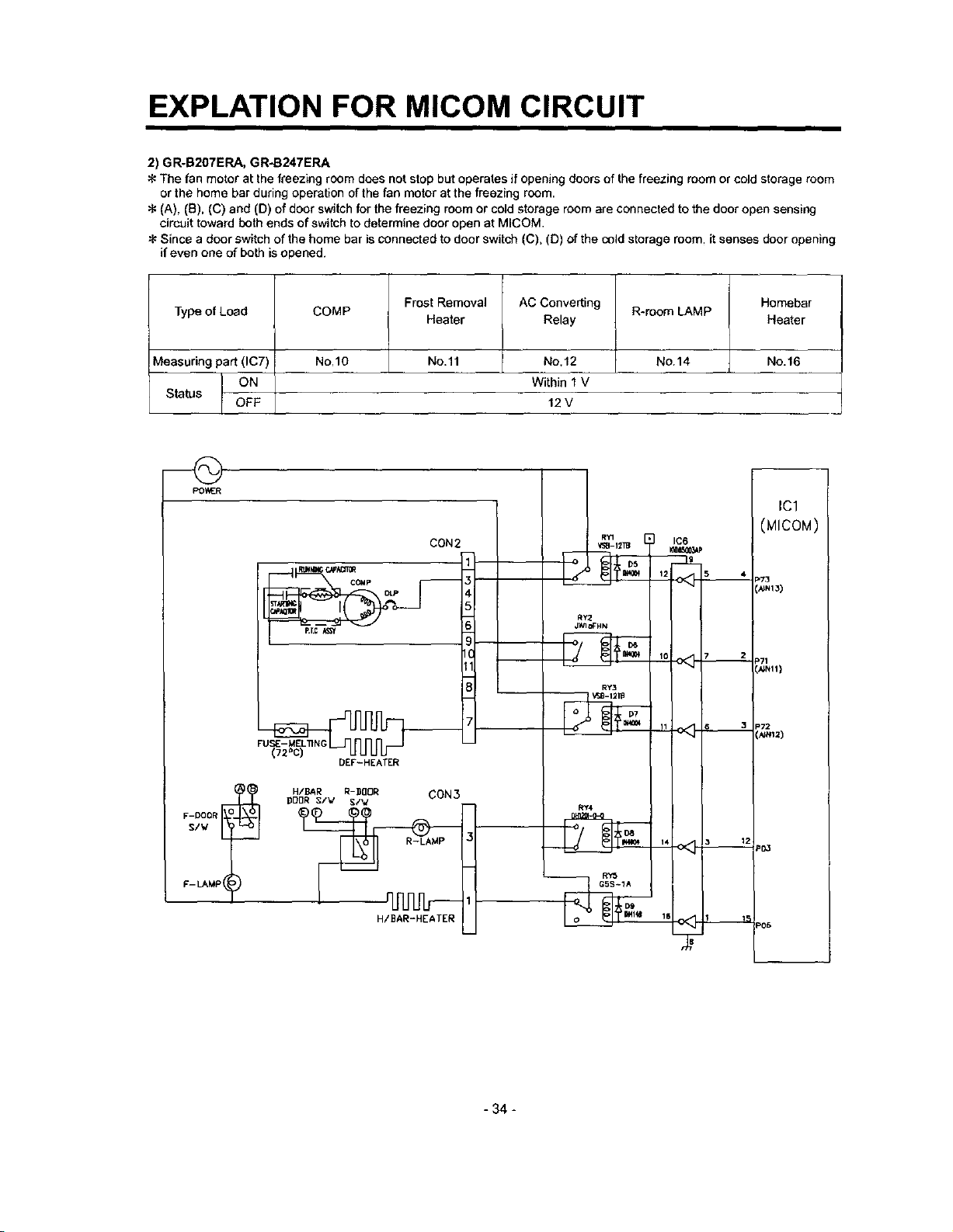

2) GR-B207ERA, GR-B247ERA

The fan motor at the freezing room does not stop but operates if opening doors of the freezing room or cold storage room

or the home bar during operation of the fan motor at the freezing room.

(A), (B). (C) and (D) of door switch for the freezing room or cold storage room are connected to the door open sensing

circuit toward both ends of switch to determine door open at MICOM.

Since a door switch of the home bar is connected to door switch (C), (D) of the cold storage room. it senses door opening

if even one of both isopened.

Type of Load

Measuring part (IC7)

Status Oo_FNF

POWER

FU_--MEL_NC

COMP Frost Removal AC Converting R-room LAMP Homebar

Heater Relay Heater

No,lO No.ll No.12 NO.14 No.16

Within 1 V

12V

MICOM)

CON2

COMP OLP P73

P.I_ _ R_Y2OFHN

p71

(_Nll1

P72

DEF-HEATER

IC1

!

F-LAMP

DOOR S/V _/_

H/]_R R-D00R CON3

p06

-34-

EXPLATION FOR MICOM CIRCUIT

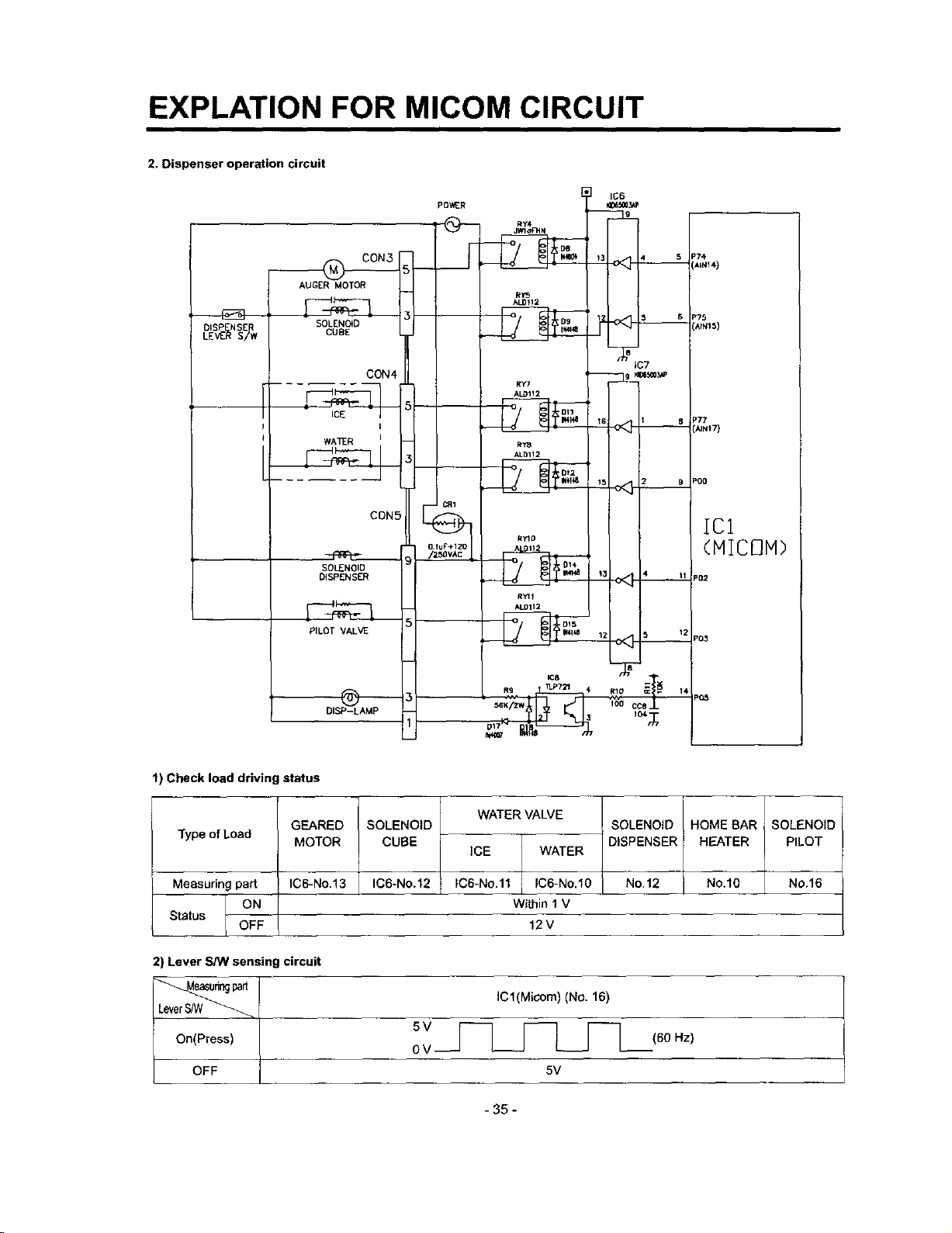

2. Dispenser operation circuit

AUGER MOTOR

DISPENSE CUBE

LEVERS_RW SOLENOID

ICE

WATER

SOLENOID

DISPENSER

PILOT VALVE

CON4

CON[

PO_R

JW1OP_N

RY_

ALD!12

Ry4

R'n

Ak_ll2

R_

ALD112

R_O

A 11

R_¢11

ALD112

] IC6

13 4 5

Dt2

Dig

_74

:AIN14)

P75

p77

p,iN_7)

POO

IC1

(MICOM)

P02

P_

t) Check load driving status

Type of Load

Measuring part

GEARED

MOTOR

IC6-No.13

Status 0[_ F

2) Lever S/W sensing circuit

On(Press)

OFF

@

DISP-LAMP

SOLENOID

CUBE

IC6-No.12

_K/ZW 104

1__ _721 4 g10 _ _ 14

WATER VALVE

ICE WATER

SOLENOID

DISPENSER

IC6-No.ll IC6-No,10

Within 1 V

12V

ICl(Micom) (No. 16)

5V

- 35 -

No.12

P_

HOME BAR

HEATER

No.10

SOLENOID

PILOT

NO.16

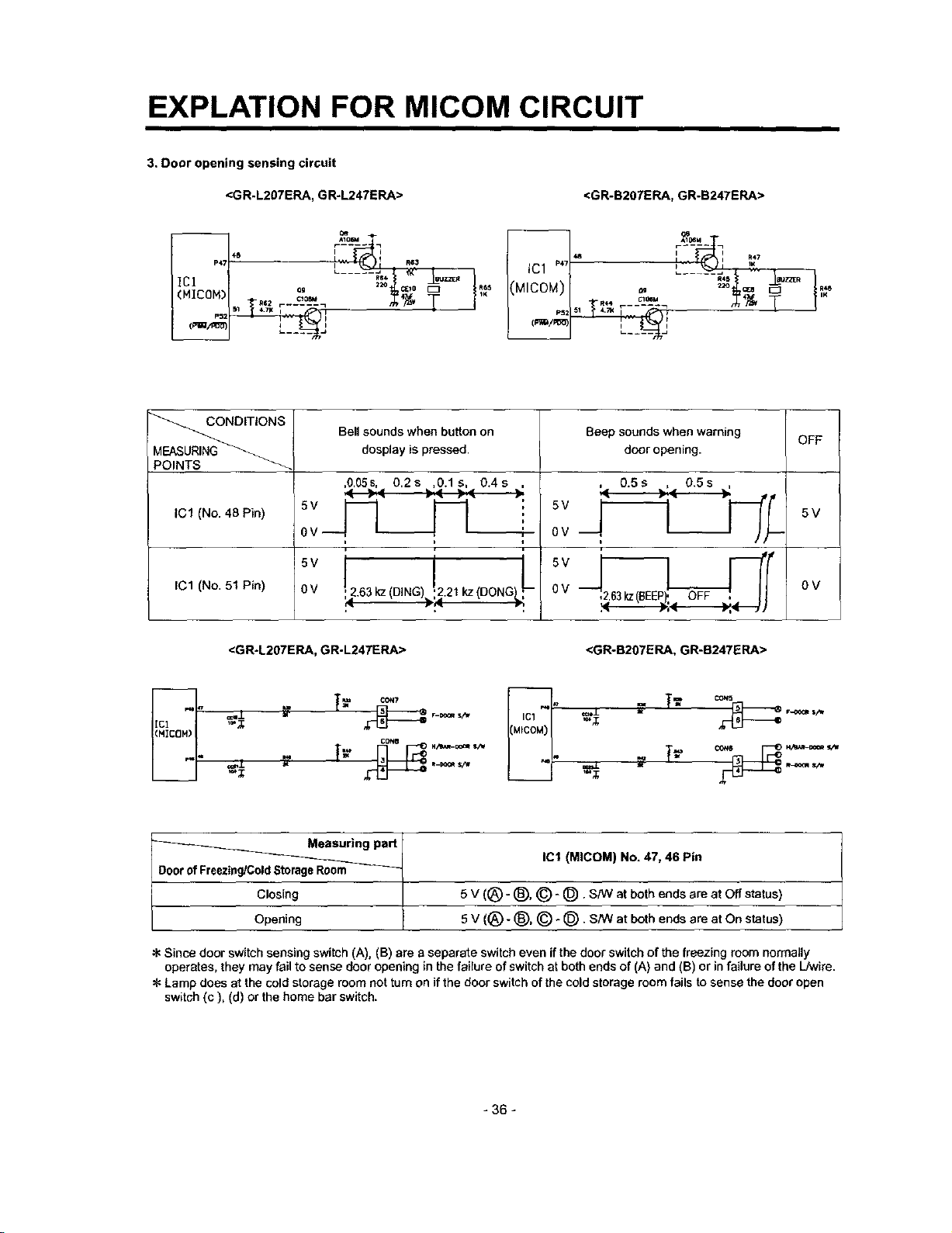

EXPLATION FOR MICOM CIRCUIT

3, Door opening sensing circuit

<GR.L207ERA, GR-L247ERA> <GR-B207ERA, GR-B247ERA>

rA.I°_ n

i .... i

.. f RII3

..... H4

I("Ic0")I

I I R47

ii b IK

..... R4 5

_....._DITtON S

MEASURING_

POINTS _-_

IC1 (No. 48 Pin)

IC1 (No. 51 Pin)

,_GR*L207ERA, GR-L247ERA> <GR-B207ERA, GR-B247ERA>

Door ofFreezing/Cold Storage Room --_

Closing

Opening

,vM" "i i"

OV -"-'4 L --4---

OV .63kz (DING)_ .21 kz (DONG

Measuring part

Bell sounds when button on

dosplay is pressed•

,£._, O.2s ,0.1_, O.4s ,

5 V (_) - (_), (_ - _). S/W at both ends ere at Off status)

5 V (_)- (_, (_) * _). S/W at both ends are at On status)

Beep sounds when warning r_= I

door opening.

OV

0V 0V

IC1 (MICOM) No. 47, 46 Pin

Since door switch sensing switch (A), (B) are a separate switch even if the door switch of the freezing room normally

operates, they may fail to sense door opening in the failure of switch at both ends of (A) and (B) or in failure of the L/wire.

Lamp does at the cold storage room not turn on if the door switch of the cold storage room fails to sense the door open

switch (c), (d) or the home bar switch.

- 36 °

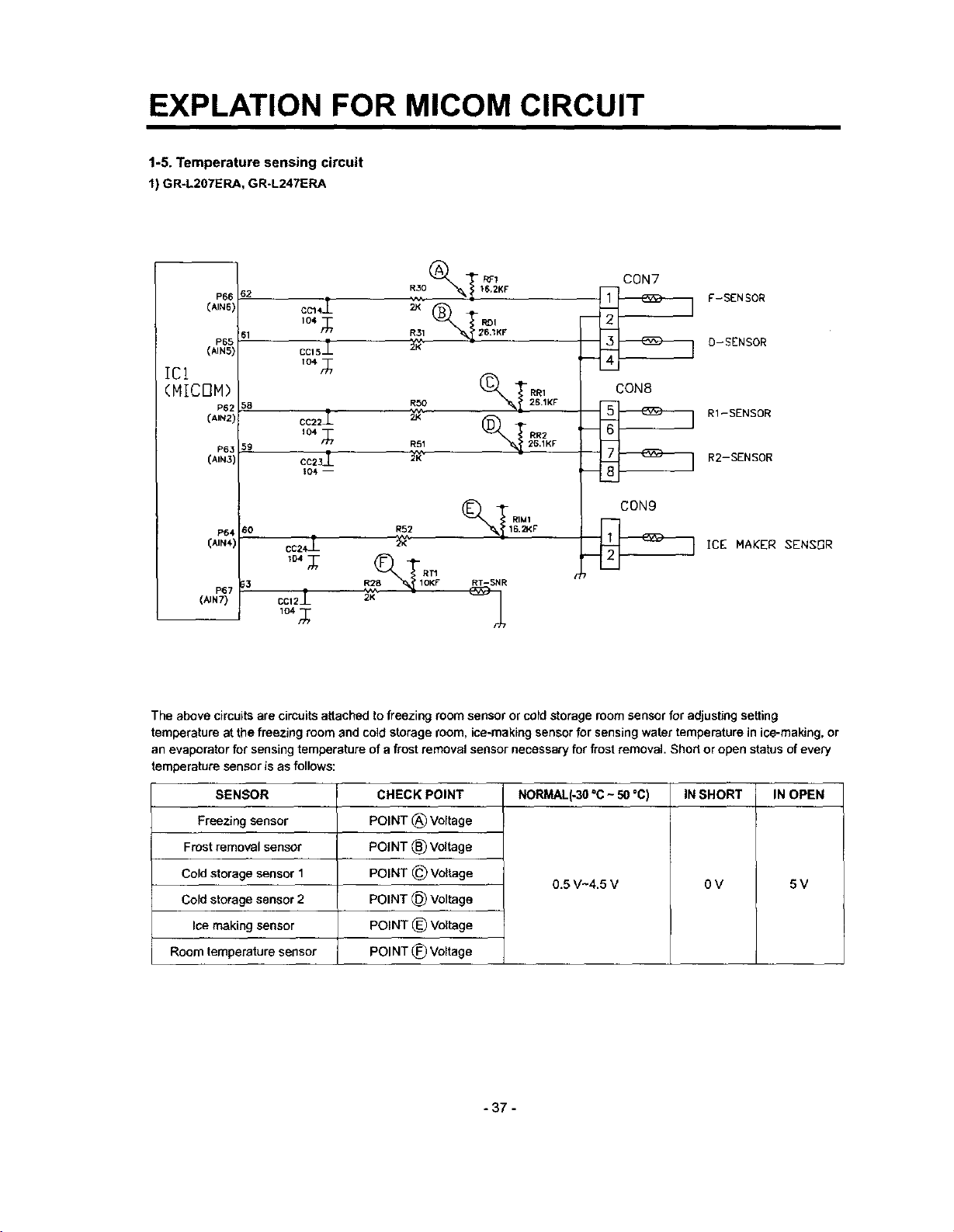

EXPLATION FOR MICOM CIRCUIT

1-5. Temperature sensing circuit

1) GR-L207ERA, GR-L247ERA

P66

(AIN6)

CON7

P65

(AIN5)

D-SENSOR

F-SENSOR

IC!

(M[CIqM)

P62

(AtN2)

59

P64

6O

R52 16.Z'_F

RIM1

o:=j_

P67

(AIN7)

104

The above circuits are circuits attached to freezing room sensor or cold storage room sensor for adjusting setting

temperature at the freezing room and cold storage room, ice-making sensor for sensing water temperature in ise-making, or

an evaporator for sensing temperature of a frost removal sensor necessary for frost removal. Short or open status of eveP/

temperature sensor is as follows:

SENSOR

Freezing sensor

Frost removal sensor

Cold storage sensor 1

Cold storage sensor 2

Ice making sensor

Room temperature sensor

R 1OKF RT-SNR

CHECK POINT

POINT (_ Voltage =

POINT (_ Voltage

POINT @ Voltage

POINT (_) Voltage

POINT (_) Voltage

POINT (_ Voltage

NORMAL(-30 °C ~ 50 °C) IN SHORT IN OPEN

0.5 V-4.5 V 0V 5V

CON8

_ R1-SENSOR

R2-SENSOR

CON9

ICE MAKER SENSOR

- 37 -

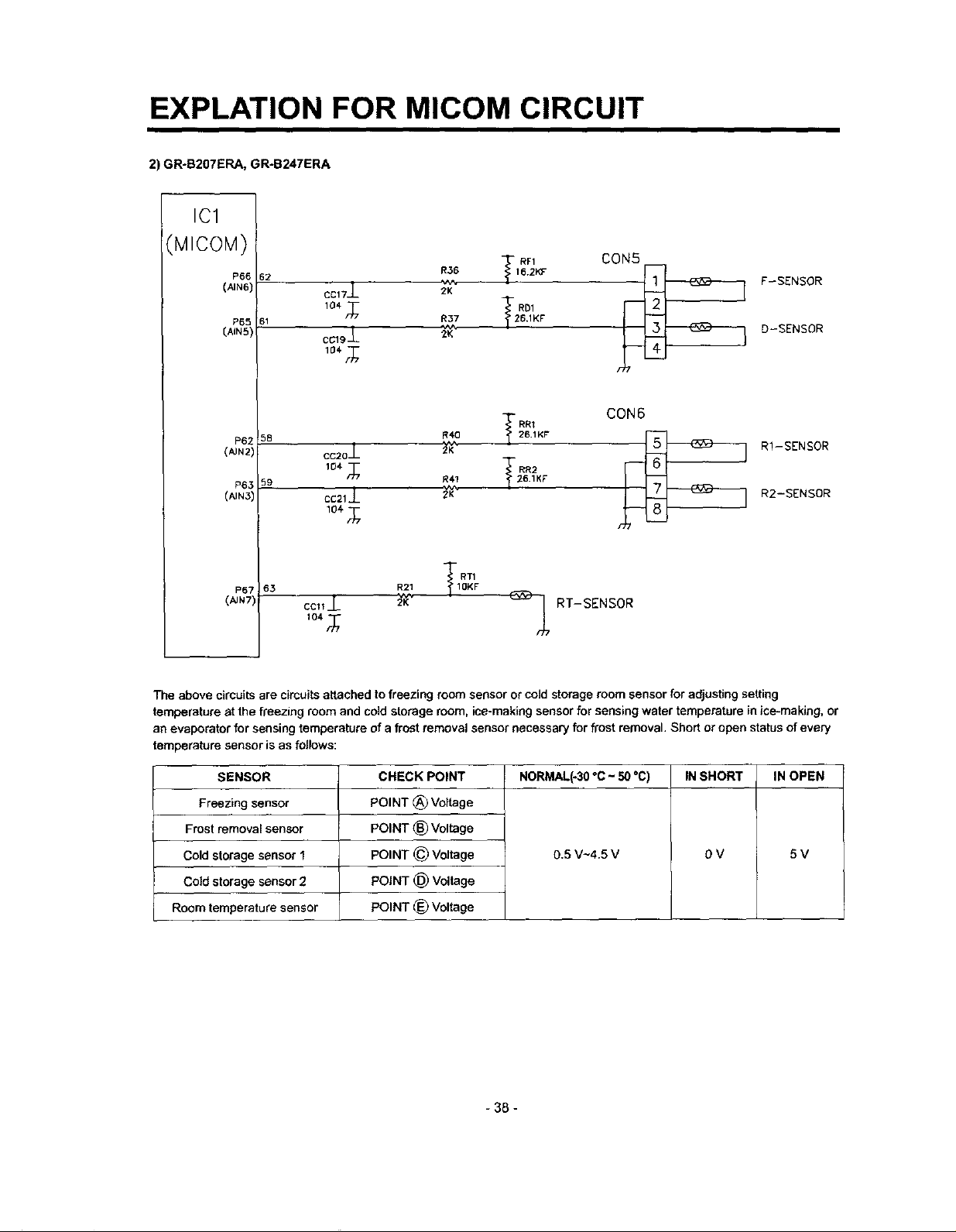

EXPLATION FOR MICOM CIRCUIT

2) GR-B207ERA, GR-B247ERA

IC1

"MICOM)

P66

(AINS]

P65

(AIN5

62

CC17] 2K

CC19 _K

104/._

R36 16,2_

R37 26.1KF

RF1

CON5

D-SENSOR

F-SENSOR

CON6

RT1

T RRtR413 26.1KF

/

_ R!-SENSOR

R2-SENSOR

58

P6;

(AJN2

P6;

59

CC20_- "_

104m_ _> RR2

R41 26.1KF

(AIN3)

104-

63

P67

(AJN7)

cc))ilo4,_ _ _,> RT-SENSOR

The above circuits are circuits attached to freezing room sensor or cold storage room sensor for adjusting setting

temperature at the freezing room and cold storage room, ice-making sensor for sensing water temperature in ice-making, or

an evaporator for sensing temperature of a frost removal sensor necessary for frost removal. Short or open status of every

temperature sensor is as follows:

R21 IOKF

SENSOR

Freezing sensor

Frost removal sensor

Cold storage sensor 1

Cold storage sensor 2

Room temperature sensor

CHECK POINT

POINT _ Voltage

POINT _) Voltage

POINT (_ Voltage

POINT @ Voltage

POINT _) Voltage

NORMAL(o30 *C ~ 50 °C) IN SHORT IN OPEN

0.5 V~4.5 V OV 5v

- 38 -

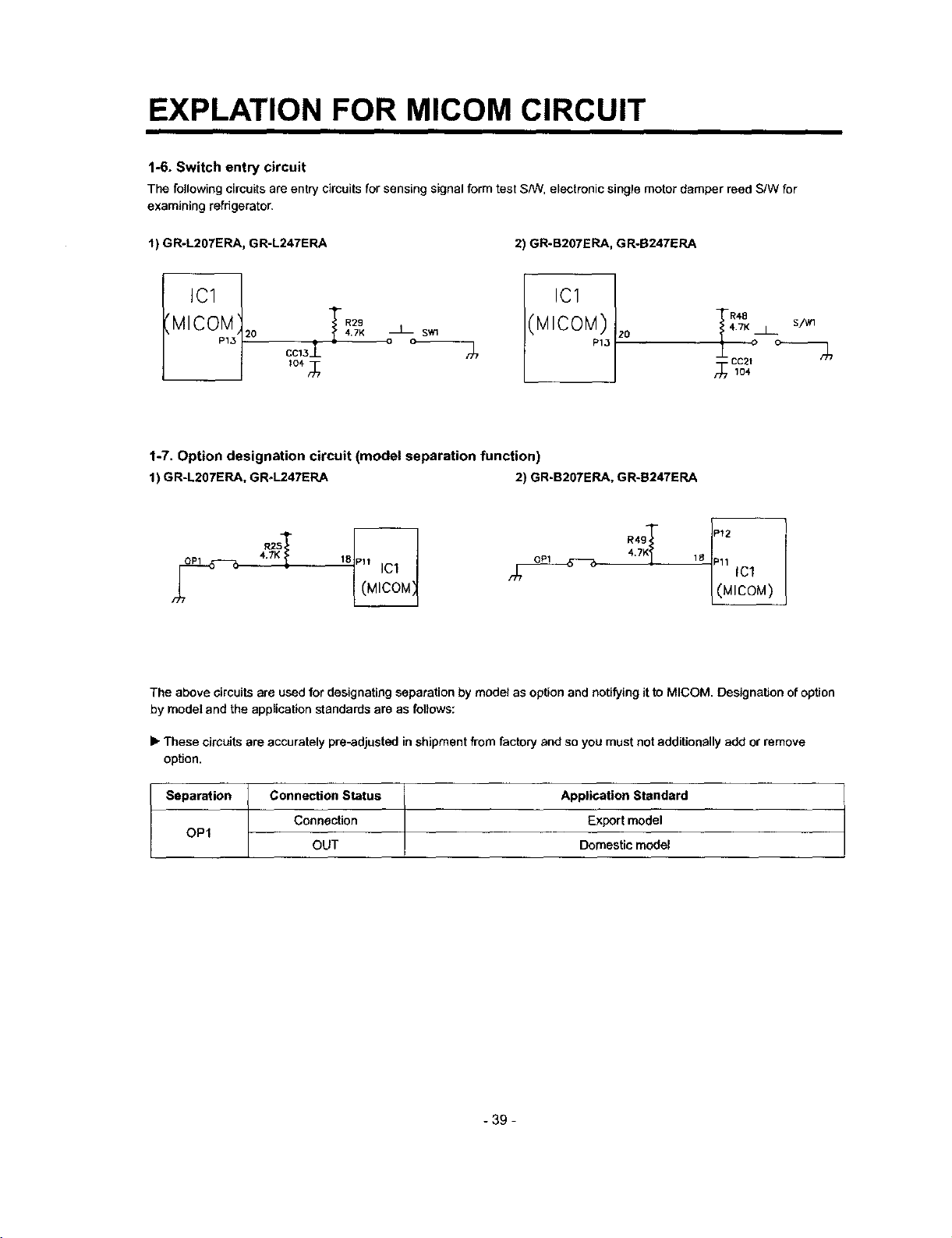

EXPLATION FOR MICOM CIRCUIT

1-6. Switch entry circuit

The following circuits are entry circuits for sensing signal form test S/W. electronic single motor damper reed S/W for

examining refrigerator.

1) GR-L207ERA, GR-L247ERA 2) GR-B207ERA, GR-B247ERA

SWl

1-7. Option designation circuit (model separation function)

1) GR-L207ERA, GR-L247ERA 2) GR-B207ERA, GR-B247ERA

ICl

(MICOM)

The above circuits are used for designating separation by model as option and notifying it to MICOM. Designation of option

by modal and the application standards are as follows:

b- These circuits are accurately pre-adjusted in shipment from factory and so you must not additionally add or remove

option.

Separation

OP1

Connection Status Application Standard

Connection Export model

OUT Domestic model

- 39 -

EXPLATION FOR MICOM CIRCUIT

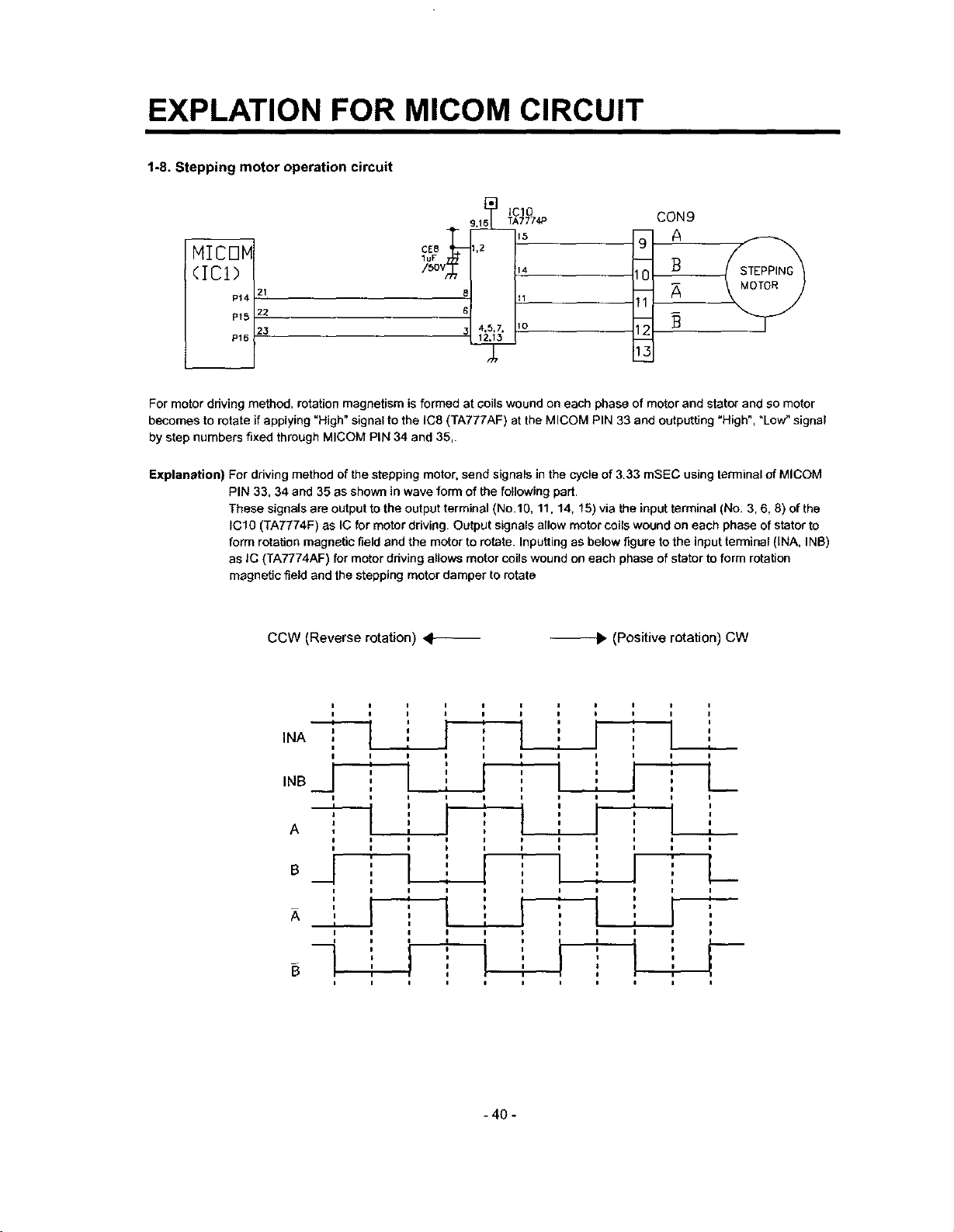

1-8. Stepping motor operation circuit

I tclO

TA7774P C0 N9

9,16

MIC[]_

<ICI)

21

P14

22

P15

23

P16

For motor driving method, rotation magnetism is formed at coils wound on each phase of motor and stator and so motor

becomes to rotate if applying "High" signal to the IC8 (TA777AF) at the MICOM PIN 33 and outputting "High", "Low" signal

by step numbers fixed through MICOM PIN 34 and 35,.

Explanation) For driving method of the stopping motor, send signals in the cycle of 3.33 mSEC using terminal of MICOM

PIN 33, 34 and 35 as shown in wave form of the following part.

These signals are output to the output terminal (No.1O, 11.14, 15) via the input terminal (No. 3, 5, 8) of the

ICl 0 (TA7774F) as IC for motor driving. Output signals allow motor coils wound on each phase of stator to

form rotation magnetic field and the motor to rotate, inputting as below figure to the input terminal (INA, INB)

as IC (TA7774AF) for motor ddving allows motor coils wound on each phase of stator to form rotation

magnetic field and the stepping motor damper to rotate

CE8 1,2

luF

/so

3 4.5

15 9 A

,4 10 B

1 -

'o 12 £

L-'i

STEPPING

CCW (Reverse rotation) ,-- --lb. (Positive rotation) CW

i I i I i I I i i

I I i I I I i i I

INA

I

INB

I I I I I I I I I I

I I

i I i I I i I

i I I I i Ii i i i

'ii ! i

. ,-q_j_J--'q_

i I I i i i I i

I I i I i

I I I I I I I I I

..... , L__i-

g

- 40 -

EXPLATION FOR MICOM CIRCUIT

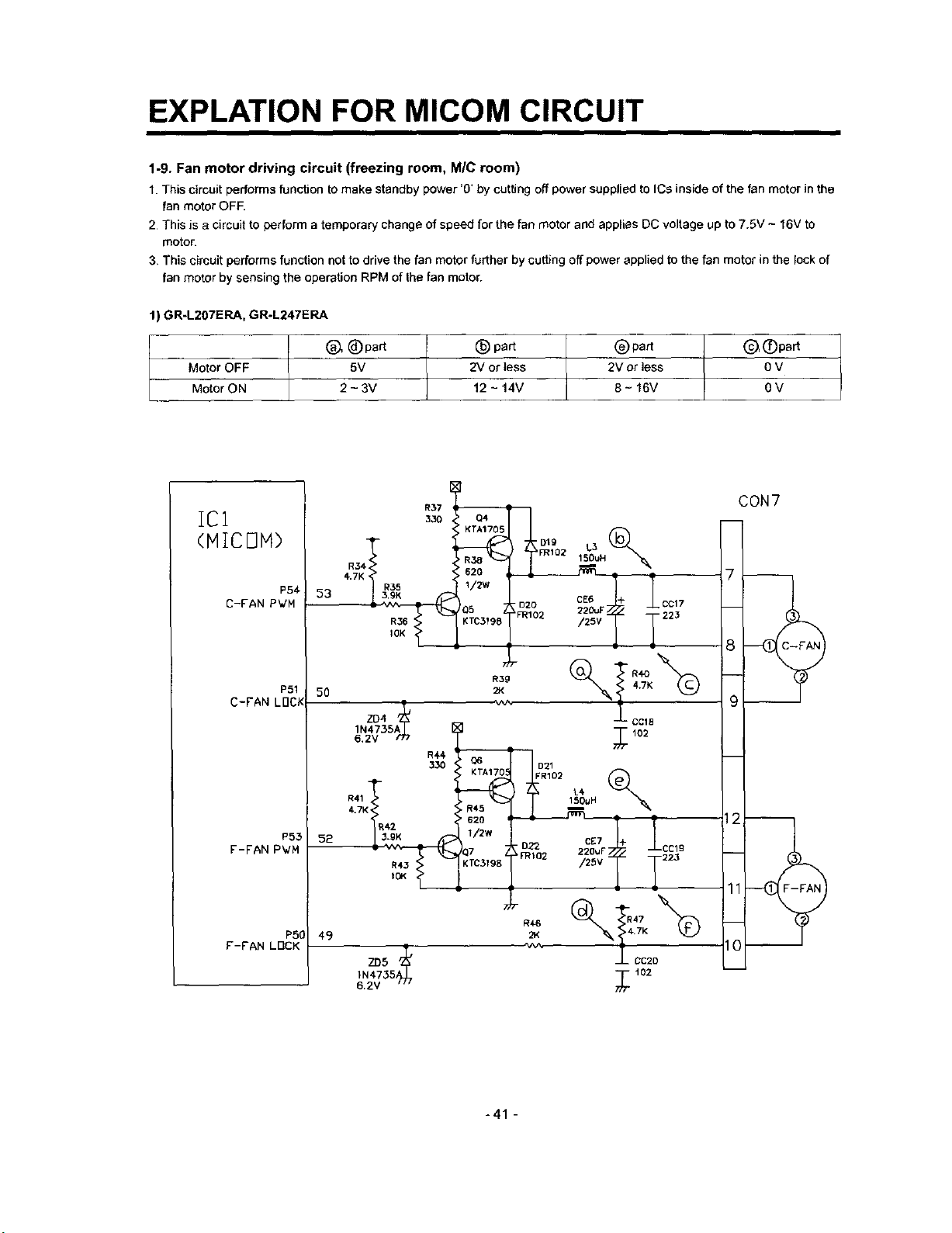

1-9. Fan motor driving circuit (freezing room, M/C room)

1. This circuit performs function to make standby power '0' by cutting off power supplied to ICs inside of the fan motor in the

fan motor OFF.

2 This is a circuit to perform a temporary change of speed for the fan motor and applies DC voltage up to 7.5V - 16V to

motor.

3. This circuit performs function not to drive the fan motor further by cutting off power applied to the fan motor in the lock of

fan motor by sensing the operation RPM of the fan motor.

1) GR-L207ERA, GR-L247ERA

@ @part

Motor OFF 5V

Motor ON 2 - 3V

IOl

(MICOM)

C-FAN PVM

P5,$

P51

C-FAN LOCK

P53

F-FAN PWM

4.7K •

53

5O

4.7K

52 3.gK

R41 _

ZD4

1N4735A

6.2V

R42

R43

R37

330

R44

33O

_)pa_ (e_part (_J_)pa_

2V orless 2V orIess 0 V

12 ~ 14V 8- 16V 0V

CON7

- D19 L3

_'FRI02 150oH

7

" D20 i CC17

=FRlO2 /25V T 223

22_F

CE6 @

8

R3g

2K

I 14

g 'o2 %

- D22 CE7220uF _--CC19

_'FRI02 /25V ? T 223

4.7K

a°

CC1B

102

9

11

F-FAN LOCK

PSO

49

tN4735

6.2V

_ .7K

R¢6 %_€47

--L CC2O

10

102

-41 -

EXPLATION FOR MICOM CIRCUIT

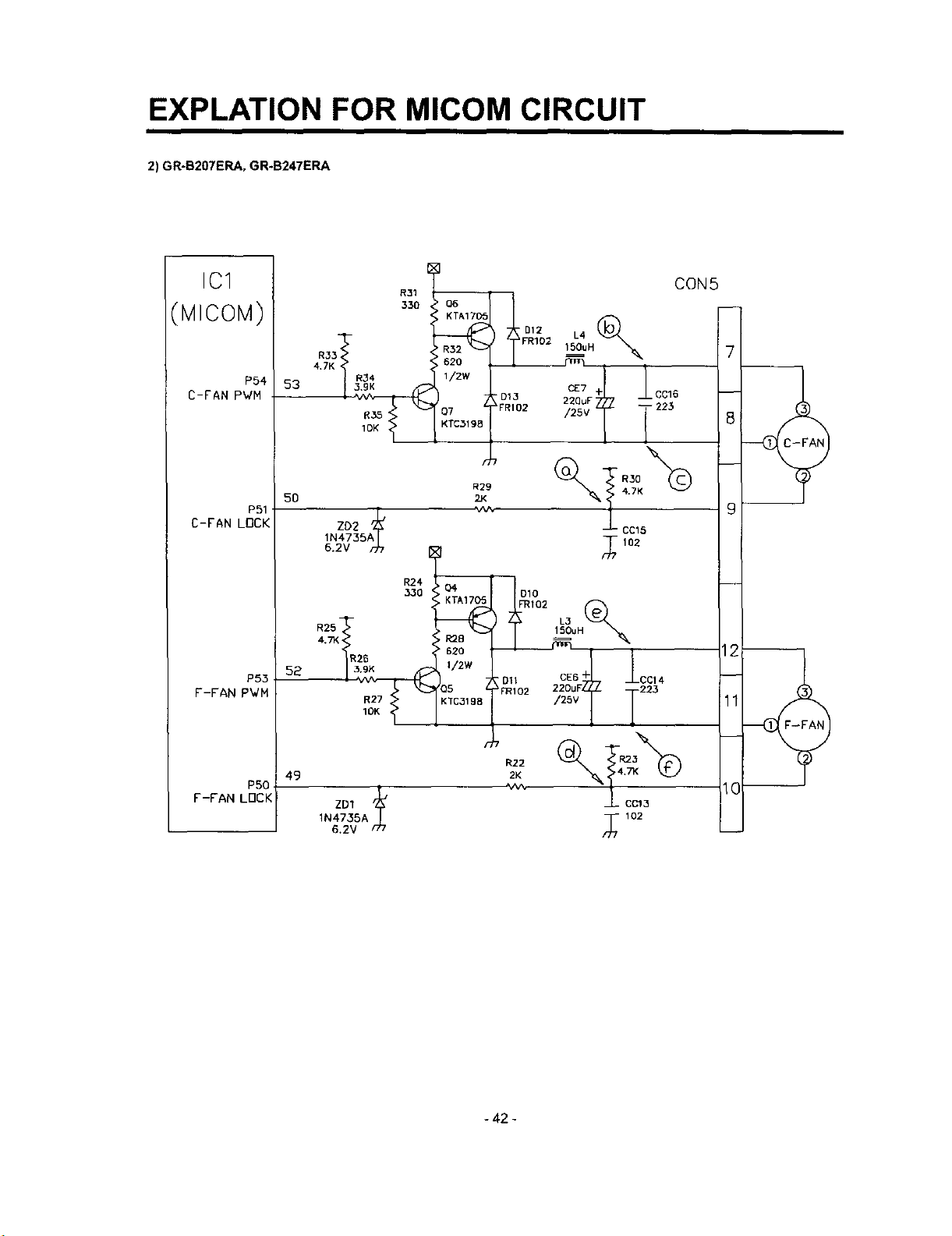

2) GR-B207ERA, GR-B247ERA

IC1

(MICOM)

C-FAN P_/M

C-FAN LOCK

F-FAN pX#M

P54

P51

P53

4.7K R34

53 3,9K

5O

1N4735A

ZC,2

6.2V

4,7K

R2B

R2_I

3.9K

R3,5

R31

33,0

R24

330

KTA1705

620

°[°&_8

R29

2K

_o.-\

FRI02 /'25V T

CE6 + LCC14

_102

CON5

%

7

g

F-FAN LOCK

P50

2K •

_4v_

- 42 -

_- CC13

1(

102

EXPLATION FOR MICOM CIRCUIT

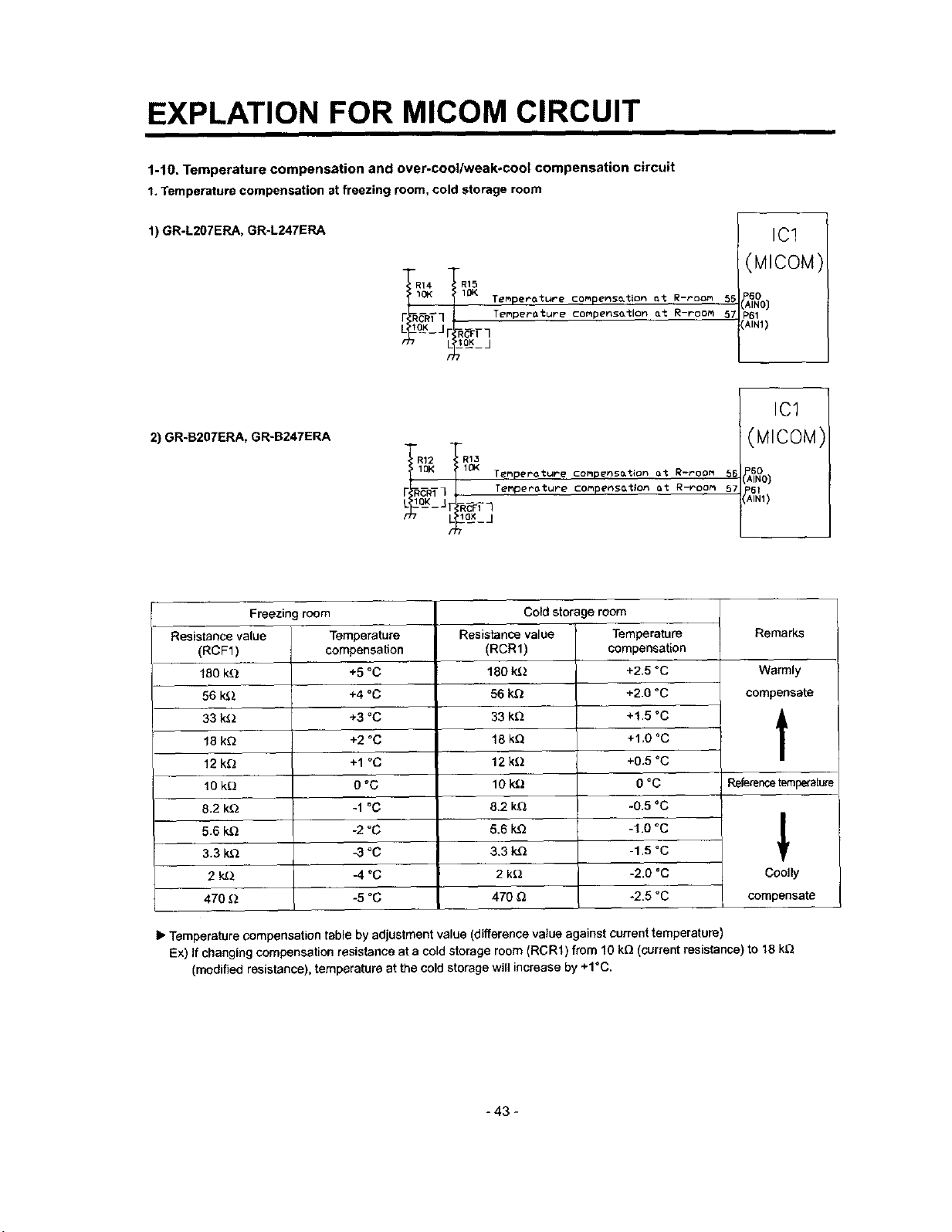

1-10. Temperature compensation and over-cool/weak.cool compensation circuit

1. Temperature compensation at freezing room, cold storage room

1) GR-L207ERA, GR-L247ERA

2) GR-B207ERA, GR-B247ERA

Freezing room Cold storageroom

Resistance value

(RCF1)

180 k£

56 k{2

33 k_2

18 k_

12 k_

10 kQ

8.2 kQ

5.6 k_

3.3 k_2

2 _2

470_2

Temperature

compensation

+5 °C

+4 °C

+3 °C

+2 °C

+1 oC

0 °C

-1 °C

_2oC

_3oC

-4 °C

-5 °C

1OK lPK Temperature cot_penso.tton e,l: R-root_ 5E

F RC-RT] Temper¢ture cor_pens(x±lon_1 R-room 57

L _O_K_JF RC-FT]

I_14 115

_R 12 I R13

m Lr__ J

0K_J

10K lf3K T_Mperoture conp¢ns_tion ot R-roo_ 56

CRT_ TeMpeP_tuPe Compensation _t R-Poo_ 57

Resistance value

(RCR1)

180 k_;_

56 k_

33 kQ

18 kQ

12 ki2

10 k_

8.2 k_

5.6 k-Q

3,3 k.Q

2 k[_

470 Q

Temperature

compensation

+2.5 °C

+2.0 °C

+1.5 °C

+1.0 °C

+0.5 "C

O°C

-0.5 °C

-1.0 °C

-1.5 °C

-2.0 °C

-2.5 °C

] ,,

ICI

,coM

_INO)

P61

IAIN )

IC1

(MICOM

6O

(_lNO)

PSt

(AINI)

Rema_s

Warmly

compensa_

Referencetemperature

Coolly

compensate

1_Temperature compensation table by adjustment value (difference value against current temperature)

Ex) If changing compensation resistance at a cold storage room (RCRt) from 10 k_ (current resistance) to 18 kQ

(modified resistance), temperature at the cold storage will increase by +1°C.

- 43 -

Loading...

Loading...