Page 1

CAUTION

PLEASE READ CAREFULLY THE SAFETY PRECAUTIONS OF THIS MANUAL

BEFORE CHECKING OR OPERATING THE REFRIGERATOR.

REFRIGERATOR

SERVICE MANUAL

LRSC26944SW, LRSC26944TT

LRSC26930SW, LRSC26930TT

LRSC26922SW, LRSC26922TT

LRSC26920SW, LRSC26920TT

LRSC26911SW, LRSC26911TT

LRSC26910SW, LRSC26910TT

http://biz.lgservice.com

Page 2

WARNINGS AND PRECAUTIONS FOR SAFETY ................................................................................................................ 3

SPECIFICATIONS................................................................................................................................................................... 4

PARTS IDENTIFICATION....................................................................................................................................................... 8

HOW TO INSTALL THE REFRIGERATOR.......................................................................................................................... 12

HOW TO ADJUST DOOR HEIGHT.................................................................................................................................... 12

FILTER ............................................................................................................................................................................... 13

HOW TO CONTROL THE ICEMAKER WATER SUPPLY.................................................................................................. 14

MICOM FUNCTION .............................................................................................................................................................. 16

EXPLANATION OF MICOM CIRCUIT.................................................................................................................................. 30

EXPLANATION OF PWB CIRCUIT.....................................................................................................................................30

PWB PARTS DIAGRAM AND LIST.....................................................................................................................................46

PWB CIRCUIT DIAGRAM...................................................................................................................................................52

OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER ................................................................................... 54

OPERATION PRINCIPLE................................................................................................................................................... 54

CONTROL METHOD ACCORDING TO FUNCTIONS....................................................................................................... 55

DEFECT DIAGNOSIS FUNCTION..................................................................................................................................... 57

CIRCUIT................................................................................................................................................................................ 58

TROUBLE DIAGNOSIS........................................................................................................................................................ 61

TROUBLESHOOTING ....................................................................................................................................................... 61

FAULTS .............................................................................................................................................................................. 71

COOLING CYCLE HEAVY REPAIR................................................................................................................................... 88

HOW TO DEAL WITH CLAIMS.......................................................................................................................................... 95

HOW TO DISASSEMBLE AND ASSEMBLE..................................................................................................................... 100

DOOR............................................................................................................................................................................... 100

HANDLE........................................................................................................................................................................... 101

FAN SHROUD GRILLE.................................................................................................................................................... 102

ICEMAKER ASSEMBLY................................................................................................................................................... 102

DISPENSER..................................................................................................................................................................... 103

EXPLODED VIEW .............................................................................................................................................................. 105

REPLACEMENT PARTS LIST............................................................................................................................................ 119

CONTENTS

- 2 -

Page 3

Please observe the following safety precautions to use the

refrigerator safely and correctly and to prevent accident or

injury when servicing.

1. Be careful of an electric shock. Disconnect power cord

from wall outlet and wait for more than three minutes

before replacing PWB parts. Shut off the power

whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than

five minutes after power cord was disconnected from the

wall outlet.

3. Please check if the power plug is pressed by the

refrigerator against the wall. If the power plug was

damaged, it could cause fire or electric shock.

4. If the wall outlet is overloaded, it may cause a fire.

Please use a dedicated circuit for the refrigerator.

5. Please make sure the outlet is properly grounded.

Particularly in a wet or damp area.

6. Use standard electrical components.

7. Make sure hooks are correctly engaged.

Remove dust and foreign materials from the housing

and connecting parts.

8. Do not fray, damage, run over, kink, bend, pull out, or

twist the power cord.

9. Please check for evidence of moisture intrusion in the

electrical components. Replace the parts or mask with

insulation tape if moisture intrusion was confirmed.

10. Do not touch the icemaker with hands or tools to

confirm the operation of geared motor.

11. Do not suggest that customers repair their refrigerator

themselves. This work requires special tools and

knowledge. Non-professionals could cause fire, injury,

or damage to the product.

12. Do not store flammable materials such as ether,

benzene, alcohol, chemicals, gas, or medicine in the

refrigerator.

13. Do not put anything on top of the refrigerator,

especially something containing water, like a vase.

14. Do not put glass bottles with full of water into the

freezer. The contents will freeze and break the glass

bottles.

15. When you scrap or discard the refrigerator, remove the

doors and dispose of it where children are not likely to

play in or around it.

WARNINGS AND PRECAUTIONS FOR SAFETY

- 3 -

Page 4

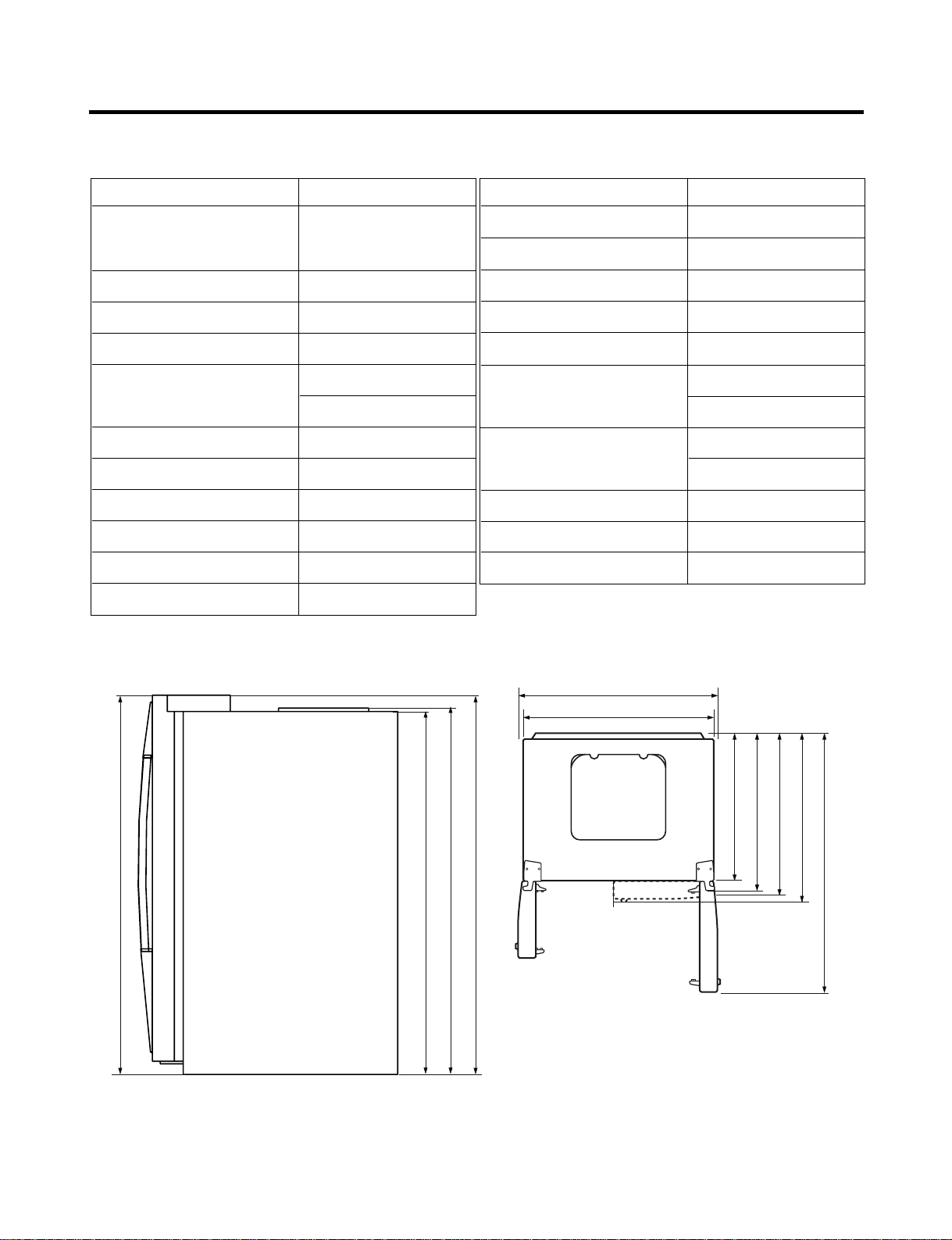

SPECIFICATIONS

- 4 -

ITEMS SPECIFICATIONS

DIMENSIONS 908 X 896 X 1771 mm

W

X

D X H (35

11

/16

X

35

5

/16

X

697

11

/16

in.)

NET WEIGHT 149 kg (328.5 lbs.)

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (185g) (6

1

/2 oz.)

LUBRICATING OIL FREOL @10G (320 cc)

ITEMS SPECIFICATIONS

DRIER MOLECULAR SIEVE XH-7

CAPILLARY TUBE ID Ø0.83

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI-SWEAT HEATER Dispenser Duct Door Heater

Dispenser Heater

ANTI-FREEZING HEATER Water Tank Heater

Damper Heater

FREEZER LAMP 40W (2 EA)

REFRIGERATOR LAMP 40W (4 EA)

DISPENSER LAMP 15W (1 EA)

Front View Top View

1. Ref No. : GR-L267AV(T)BA

in.)

16

/

11

1771 mm (69

1004 mm (391/2 in.)

11

908 mm (39

in.)

2

/

1

1741.5 mm (68

in.)

in.)

4

/

16

/

3

11

1771 mm (69

1746.5 mm (68

/16 in.)

in.)

in.)

in.)

2

8

8

/

/

1

/

5

5

724 mm (28

779 mm (30

829 mm (32

in.)

in.)

8

/

16

/

5

5

897 mm (35

1261 mm (49

Page 5

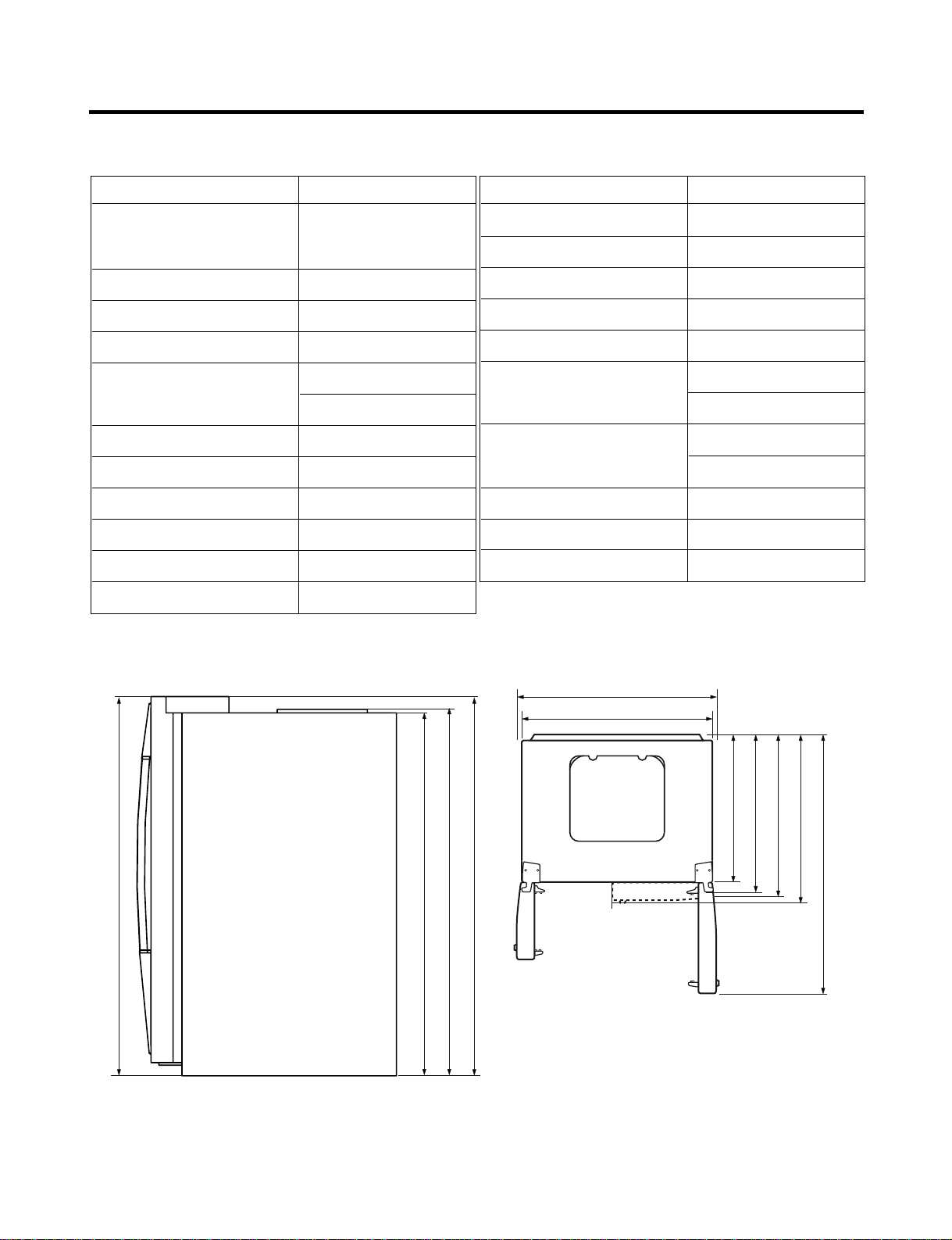

SPECIFICATIONS

- 5 -

724 mm (28

1

/

2

in.)

1004 mm (391/2 in.)

908 mm (39

11

/16 in.)

779 mm (30

5

/

8

in.)

829 mm (32

5

/

8

in.)

897 mm (35

5

/

16

in.)

1261 mm (49

5

/

8

in.)

1741.5 mm (68

1

/

2

in.)

1746.5 mm (68

3

/

4

in.)

1771 mm (69

11

/

16

in.)

1771 mm (69

11

/

16

in.)

2. Ref No. : GR-L267AV(T)FA

ITEMS SPECIFICATIONS

DIMENSIONS 908 X 896 X 1771 mm

W

X D X

H (35

11

/16X355/16X69711/16 in.)

NET WEIGHT 149 kg (328.5 lbs.)

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (185g) (6

1

/2 oz.)

LUBRICATING OIL FREOL @10G (320 cc)

ITEMS SPECIFICATIONS

DRIER MOLECULAR SIEVE XH-7

CAPILLARY TUBE ID Ø0.83

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI-SWEAT HEATER Dispenser Duct Door Heater

Dispenser Heater

ANTI-FREEZING HEATER Water Tank Heater

Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (4 EA)

DISPENSER LAMP 15W (1 EA)

Front View Top View

Page 6

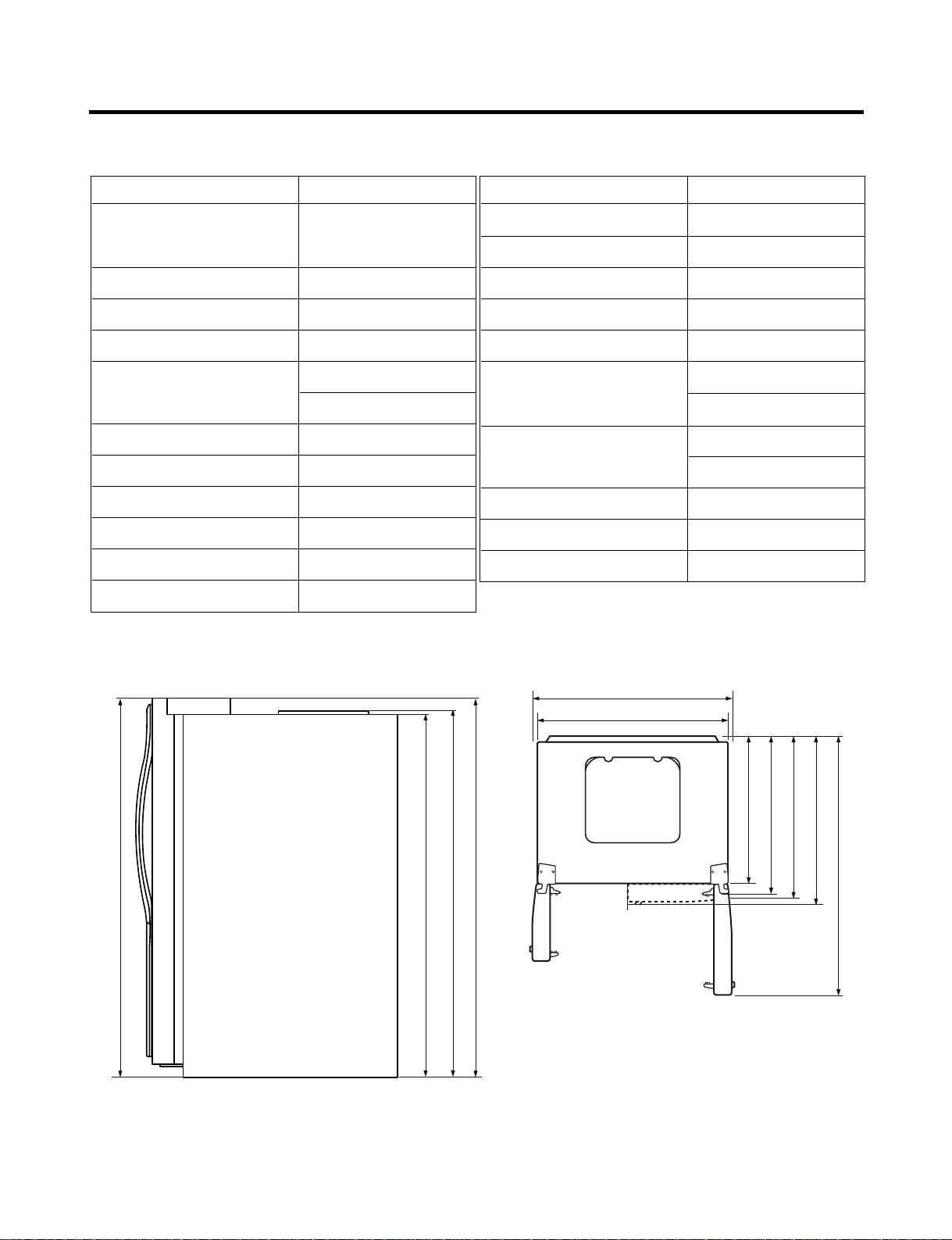

SPECIFICATIONS

- 6 -

ITEMS SPECIFICATIONS

DIMENSIONS 908 X 896 X 1771 mm

W

X D X

H (35

11

/16X355/16X69711/16 in.)

NET WEIGHT 149 kg (328.5 lbs.)

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (185g) (6

1

/2 oz.)

LUBRICATING OIL FREOL @10G (320 cc)

ITEMS SPECIFICATIONS

DRIER MOLECULAR SIEVE XH-7

CAPILLARY TUBE ID Ø0.83

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI-SWEAT HEATER Dispenser Duct Door Heater

Dispenser Heater

ANTI-FREEZING HEATER Water Tank Heater

Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (4 EA)

DISPENSER LAMP 15W (1 EA)

3. Ref No. : GR-L267AV(T)RA

Front View Top View

in.)

16

/

11

1771 mm (69

1004 mm (391/2 in.)

11

908 mm (39

in.)

2

/

1

1741.5 mm (68

in.)

in.)

4

/

16

/

3

11

1771 mm (69

1746.5 mm (68

/16 in.)

in.)

in.)

in.)

2

8

8

/

/

1

/

5

5

724 mm (28

779 mm (30

829 mm (32

in.)

in.)

8

/

16

/

5

5

897 mm (35

1261 mm (49

Page 7

SPECIFICATIONS

- 7 -

ITEMS SPECIFICATIONS

DIMENSIONS 908 X 896 X 1771 mm

W

X

D X H (35

11

/16

X

35

5

/16

X

697

11

/16

in.)

NET WEIGHT 149 kg (328.5 lbs.)

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM Full Automatic

Heater Defrost

INSULATION Cyclo-Pentane

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R134a (185g) (6

1

/2 oz.)

LUBRICATING OIL FREOL @10G (320 cc)

ITEMS SPECIFICATIONS

DRIER MOLECULAR SIEVE XH-7

CAPILLARY TUBE ID Ø0.83

FIRST DEFROST 4 - 5 Hours

DEFROST CYCLE 13 - 15 Hours

DEFROSTING DEVICE Heater, Sheath

ANTI-SWEAT HEATER Dispenser Duct Door Heater

Dispenser Heater

ANTI-FREEZING HEATER Water Tank Heater

Damper Heater

FREEZER LAMP 40W (1 EA)

REFRIGERATOR LAMP 40W (3 EA)

DISPENSER LAMP 15W (1 EA)

Front View Top View

4. Ref No. : GR-L267DV(T)R

in.)

16

/

11

1771 mm (69

1004 mm (391/2 in.)

11

908 mm (39

in.)

2

/

1

1741.5 mm (68

in.)

in.)

4

/

16

/

3

11

1771 mm (69

1746.5 mm (68

/16 in.)

in.)

in.)

in.)

2

8

8

/

/

1

/

5

5

724 mm (28

779 mm (30

829 mm (32

in.)

in.)

8

8

/

/

5

1

892 mm (35

1261 mm (49

Page 8

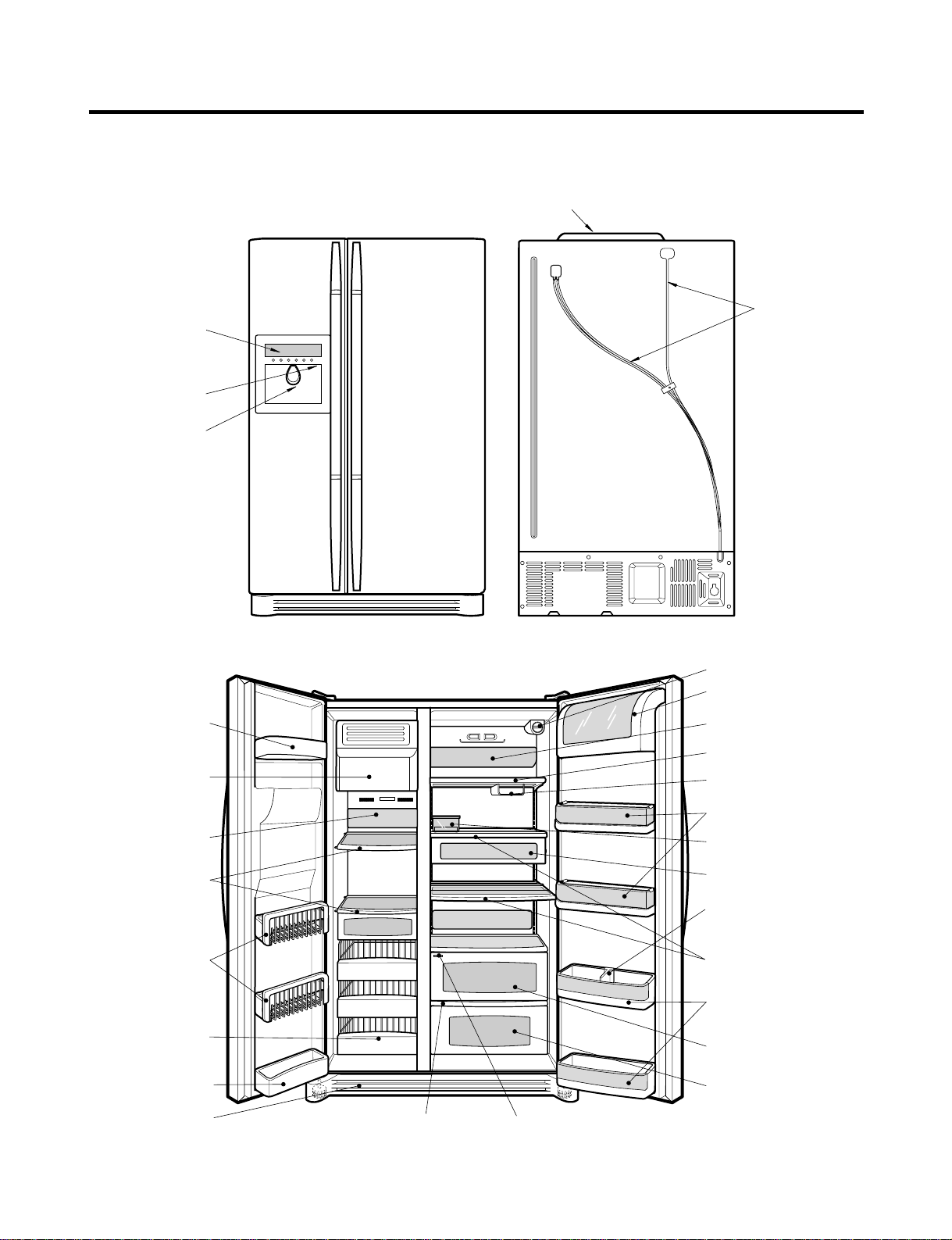

PARTS IDENTIFICATION

- 8 -

Humidity SwitchOptiChill Display

Lamp

Shelf

Egg Box

Snack Drawer

Vegetable Drawer

OptiChill

Door Rack

Shelf

Grab and Go

Can Server

Lamp

Lower Cover

Dairy Product Corner

Water Filter

Door Rack

Drawer

(Wire/Plastic)

Freezer

Compartment

Refrigerator

Compartment

Automatic

Icemaker

Door Rack

Shelf

Door Rack

Bottle Guide

Frame Display

Dispenser Lamp

Ice & Water

Dispenser Button

PWB Cover

Water Tubes

1. Ref No. : GR-L267AV(T)BA

Page 9

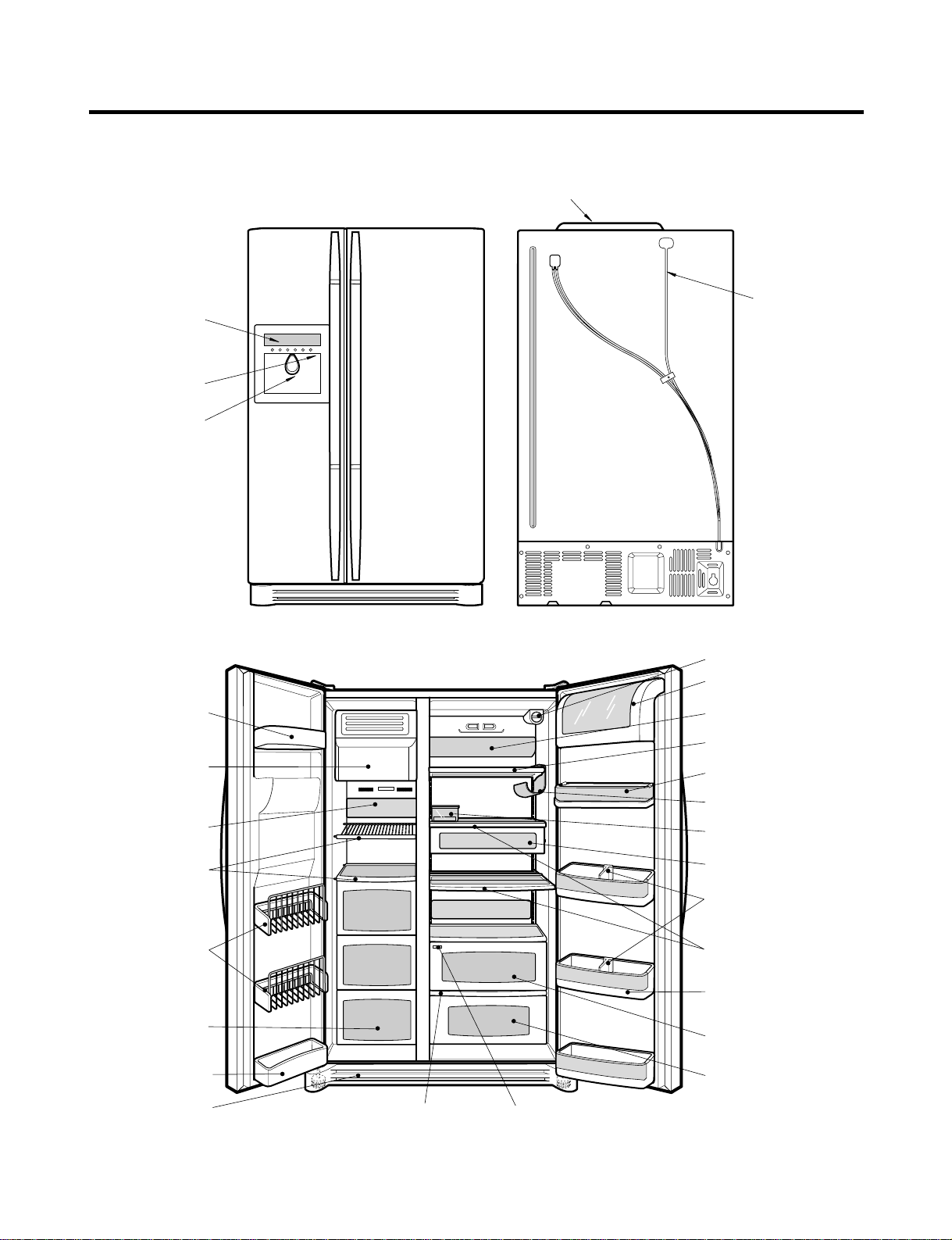

2. Ref No. : GR-L267AV(T)FA

PARTS IDENTIFICATION

- 9 -

Humidity Switch

Lamp

Shelf

Egg Box

Snack Drawer

Vegetable Drawer

OptiChill

Door Rack

Shelf

Grab and Go

Wine Holder

Lamp

Lower Cover

Dairy Product Corner

Door Rack

Drawer

(Wire/Plastic)

Freezer

Compartment

Refrigerator

Compartment

Automatic

Icemaker

Door Rack

Shelf

Bottle Guide

Frame Display

Dispenser Lamp

Ice & Water

Dispenser Button

OptiChill Display

Door Rack

Water Filter

PWB Cover

Water Tubes

Page 10

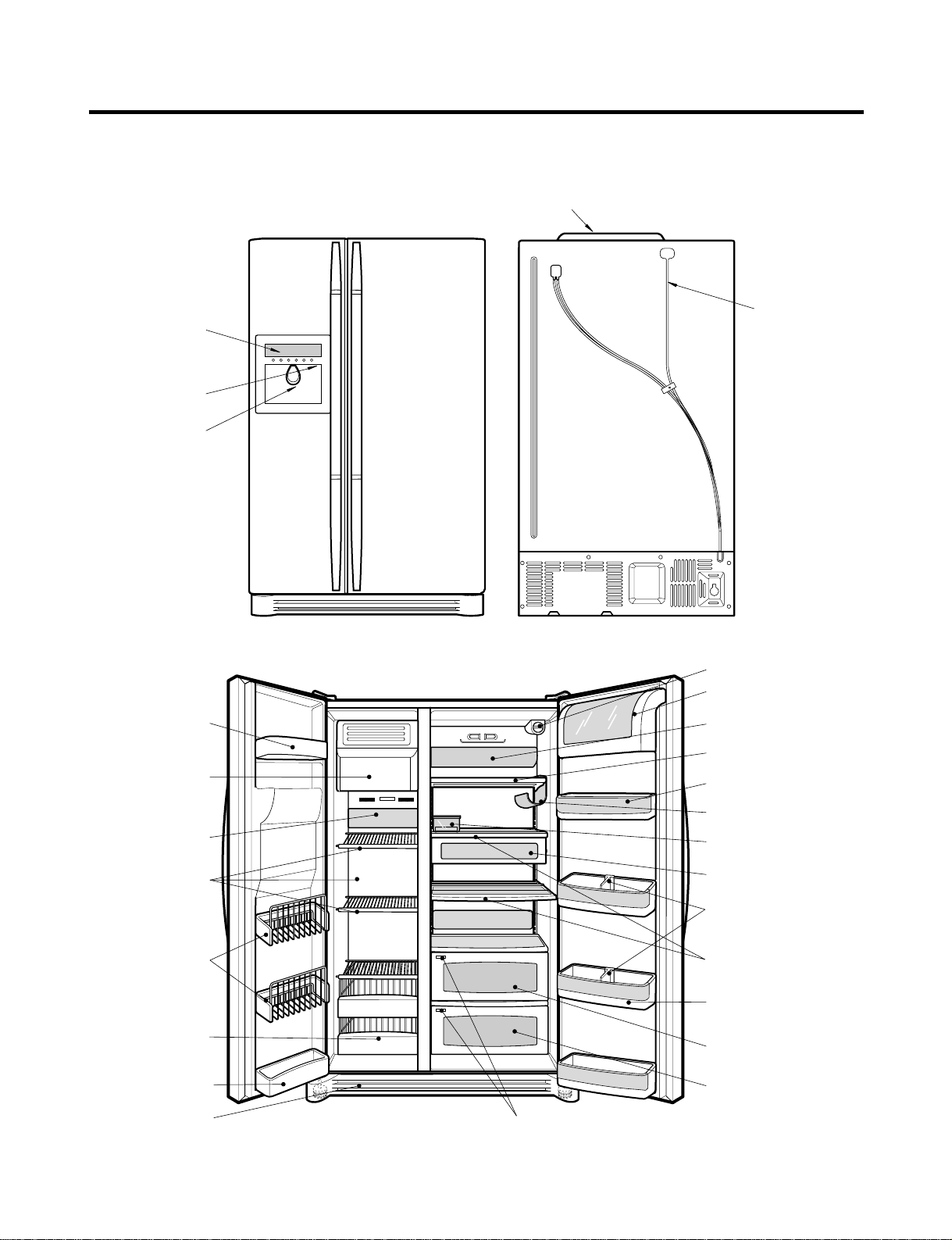

PARTS IDENTIFICATION

- 10 -

Humidity Switch

Lamp

Shelf

Egg Box

Snack Drawer

Vegetable Drawer

Vegetable Drawer

/Meat Drawer

Door Rack

Shelf

Door Rack

Wine Holder

Lamp

Lower Cover

Dairy Product Corner

Door Rack

Drawer

(Wire/Plastic)

Freezer

Compartment

Refrigerator

Compartment

Automatic

Icemaker

Door Rack

Shelf

Bottle Guide

Frame Display

Dispenser Lamp

Ice & Water

Dispenser Button

PWB Cover

Water Tubes

Door Rack

Water Filter

3. Ref No. : GR-L267AV(T)RA,

Page 11

4. Ref No. : GR-L267DV(T)R

PARTS IDENTIFICATION

- 11 -

Lamp

Shelf

Egg Box

Snack Drawer

Vegetable Drawer

Vegetable Drawer

/Meat Drawer

Door Rack

Shelf

Door Rack

Wine Holder

Lamp

Lower Cover

Dairy Product Corner

Door Rack

Drawer

(Wire/Plastic)

Freezer

Compartment

Refrigerator

Compartment

Automatic

Icemaker

Door Rack

Shelf

PWB Cover

Water Tubes

Door Rack

Water Filter

Humidity Switch

Bottle Guide

Frame Display

Dispenser Lamp

Ice & Water

Dispenser Button

Page 12

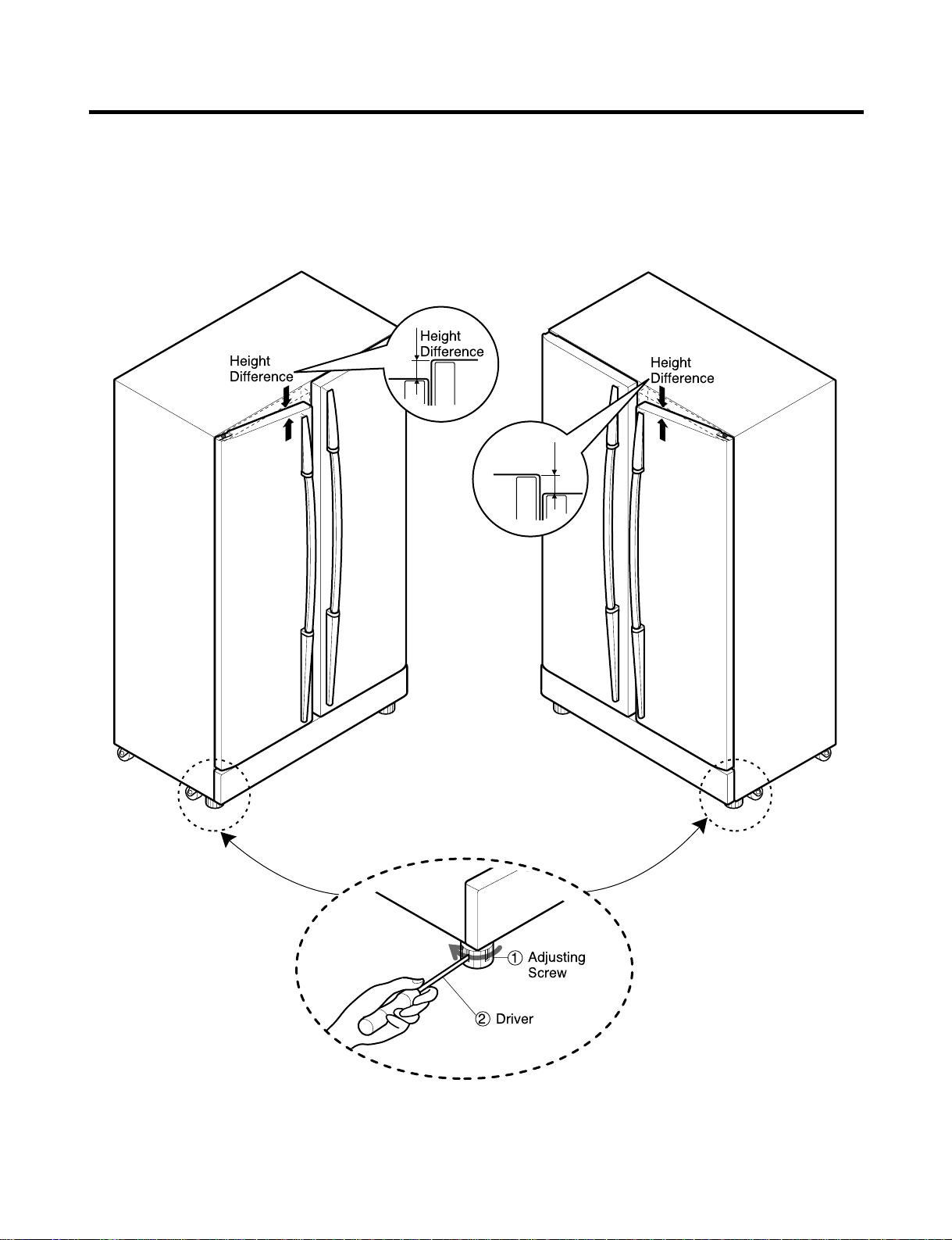

1. How to Adjust Door Height of Refrigerator

■ Make the refrigerator level first. (If the refrigerator is not installed on a flat floor, the height of freezer and refrigerator

door may not be the same.)

1. If the freezer door is lower than the refrigerator

door:

2. If the freezer door is higher than the refrigerator

door:

Insert a driver into the groove if the adjusting

screw and turn in the direction of the arrow (clockwise)

until the refrigerator is level.

Insert a driver into the groove if the adjusting

screw and turn in the direction of the arrow (clockwise)

until the refrigerator is level.

HOW TO INSTALL REFRIGERATOR

- 12 -

Adjusting

Screw

Driver

Height

Difference

Height

Difference

Height

Difference

Height

Difference

1

2

Page 13

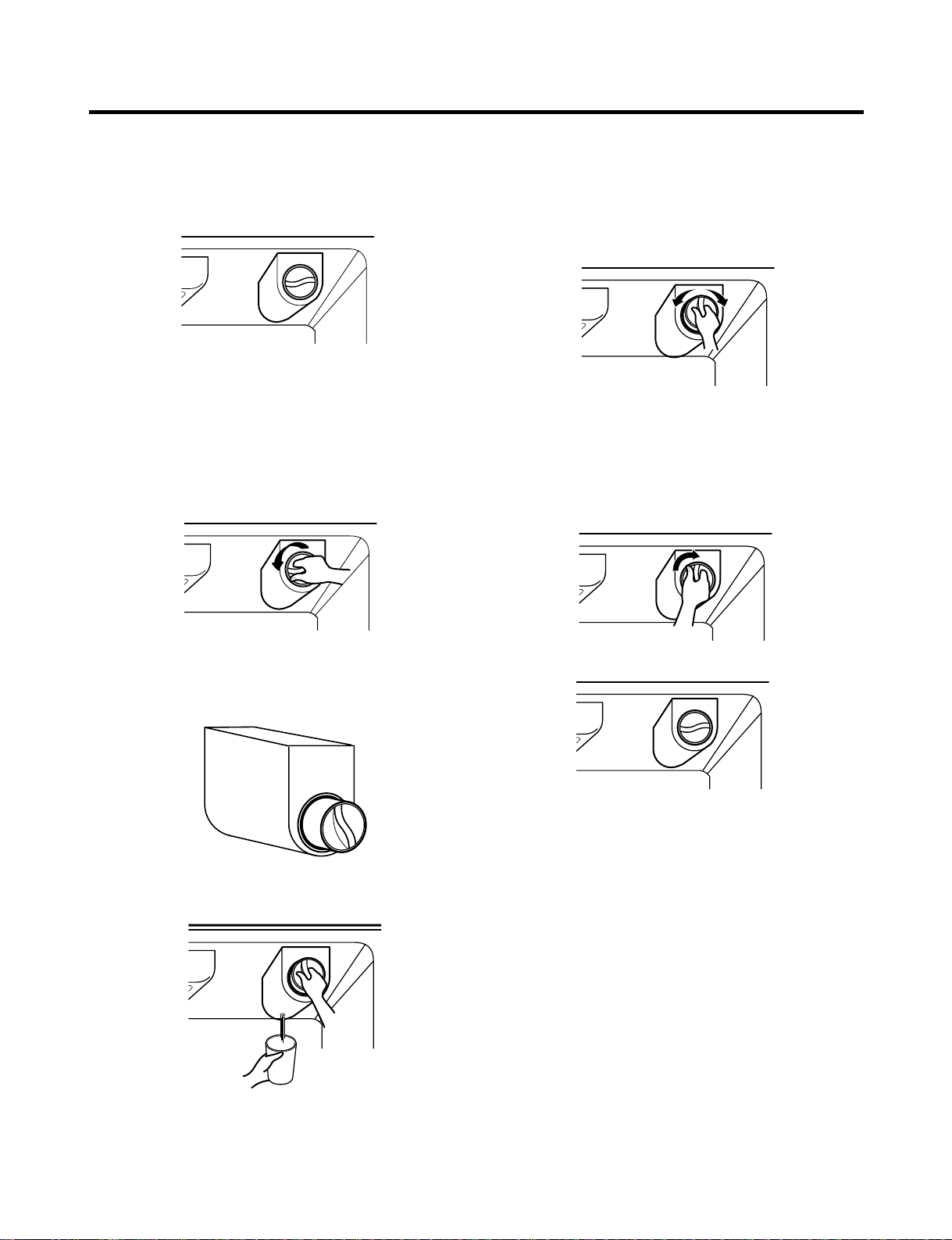

2. Filter

Replace the filter when the indicator light comes on or the

performance of the icemker or water dispenser decreases

noticeably.

After changing the water filter cartridge, reset the water

filter status display and indicator light by pressing and

holding the BUTTON for 3 seconds.(page 18)

1. Remove the old cartridge.

Twist the knob of the cartridge counter clockwise.

When the cartridge is removed, you will feel it click .

Pull out the cartridge.

NOTE: There will be some water(25cc) in the filter

cartridge. Some spilling may occur. Catch it in a

bowl or towel.

2. Replace with a new cartridge.

Take the new cartridge out of its packaging and remove

protective cover from the o-rings.

With cartridge knob in the vertical position, push the new

filter cartridge into the cover until it stops.

If you can’t turn the filter from side to side, it isn’t fully

inserted. Push it in firmly and twist it into place. You will

hear the snap when it clicks into place.

Using the handle, twist the cartridge clockwise about 1/4

turn.

3. Flush the Water System After Replacing Filter Dispense

water through the water dispenser for 3 minutes to

purge the system.

There may be a little air in the line, causing noise or

hissing. Run the water at the dispenser until the hissing

stops to purge the air from the system.

NOTE: - To purchase replacement water filter cartridges,

visit your local appliance dealer or part distributor.

- You can also visit our website :

www.lgappliances.com or call 1-877-714-7481.

HOW TO INSTALL REFRIGERATOR

- 13 -

Page 14

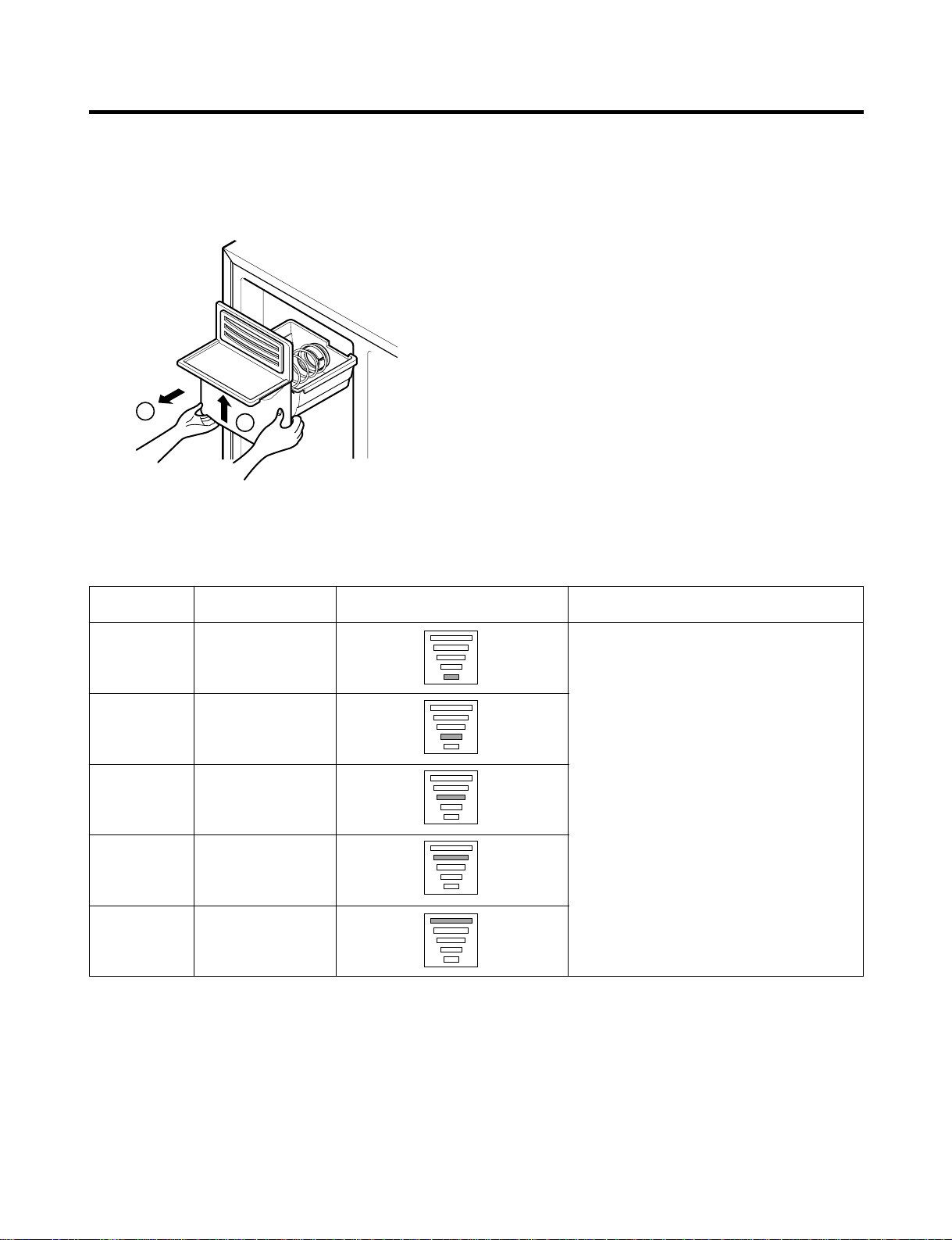

3. How to Control the Amount of Water Supplied to Icemaker.

3-1. Confirm the amount of water supplied to the icemaker.

1. Pull out the ice bin shelf in the upper part of the freezer compartment.

Caution : • Do not put hands or tools into the chute to confirm

the operation of geared motor.

It may damage the refrigerator or hurt your hands.

Water supply amount TABLE

HOW TO INSTALL REFRIGERATOR

- 14 -

2

1

ST AGE TIME TO SUPPL Y INDICA TIONS REMARKS

1

2

3

4

5

4 sec.

4.5 sec.

5 sec.

5.5 sec.

6 sec.

The water amount will vary depending

on the Water Control Switch setting as

well as the water pressure of the

connected water line.

Page 15

ww

WARNING

Personal Injury Hazard

Avoid contact with the moving parts of the ejector

mechanism, or with the heating element that releases

the cubes. DO NOT place fingers or hands on the

automatic icemaking mechanism while the refrigerator

is plugged in.

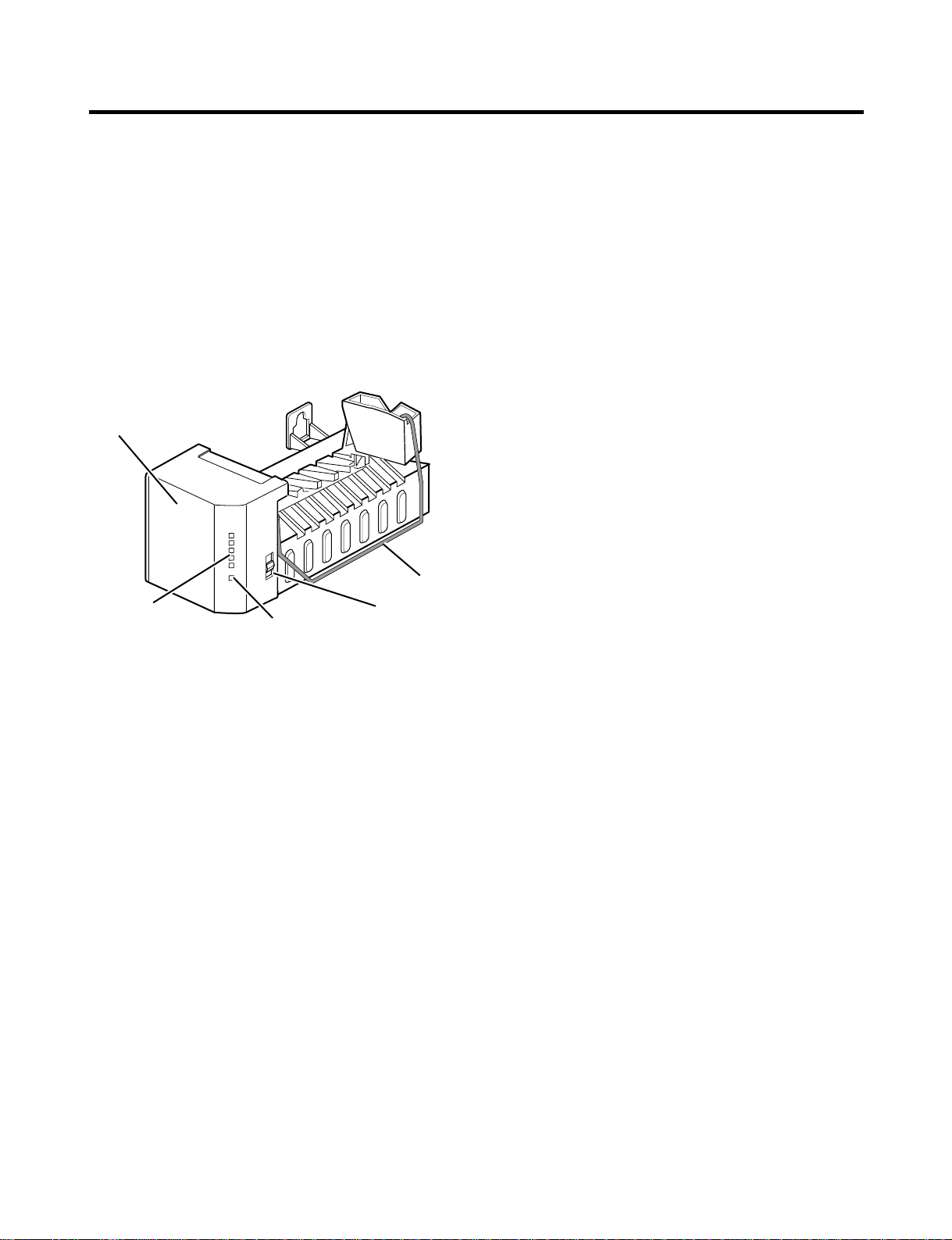

3-2. Operation instructions

A newly-installed refrigerator may take up to 24 hours

to begin making ice.

The icemaker will produce eight cubes per

cycle—approximately 120–150 cubes in a 24-hour period,

depending on freezer compartment temperature, room

temperature, number of door openings and other operating

conditions.

If the refrigerator is used before the water connection is

made to the icemaker, set the power switch to O (off).

When the refrigerator has been connected to the water

supply, set the power switch to I (on).

The icemaker will fill with water when it cools to freezing. A

newly-installed refrigerator may take up to 24 hours to

begin making ice cubes.

Throw away the first few batches of ice to allow the water

line to clear.

Be sure nothing interferes with the sweep of the feeler arm.

When the bin fills to the level of the feeler arm, the

icemaker will stop producing ice.

It is normal for several cubes to be stuck together.

If ice is not used frequently, old ice cubes will become

cloudy, taste stale, and shrink.

NOTE: If the cube size is smaller or larger than you

expected, you can regulate the size with the cube size

button. (nomally caused by variations in water pressure.)

Every time you press the cube size button, the indicator

light go up. The higher position light is on, the larger cubes

will be. (1st step is the next after the 5th step.)

3-3. When you should set the icemaker power

switch to O (off)

• When the water supply will be shut off for several hours.

• When the ice storage bin is removed for more than a

minute or two.

• When the refrigerator will not be used for several days.

3-4. Normal sounds you may hear

• The icemaker water valve will buzz as the icemaker fills

with water. If the power switch is in the I (on) position, it

will buzz even if it has not yet been hooked up to water.

To stop the buzzing, move the power switch to O (off).

NOTE: Keeping the power switch in the I (on) position

before the water line is connected can damage the

icemaker.

• You will hear the sound of cubes dropping into the bin

and water running in the pipes as the icemaker refills.

3-5. Preparing for Vacation

Set the icemaker power switch to O (off) and shut off the

water supply to the refrigerator.

If the ambient temperature will drop below freezing, have a

qualified servicer drain the water supply system (on some

models) to prevent serious property damage due to

flooding from ruptured water lines or connections.

HOW TO INSTALL REFRIGERATOR

- 15 -

Feeler Arm

Icemaker

Cube Size

Indicator Light

Water Supply

Control Switch

Power Switch

Page 16

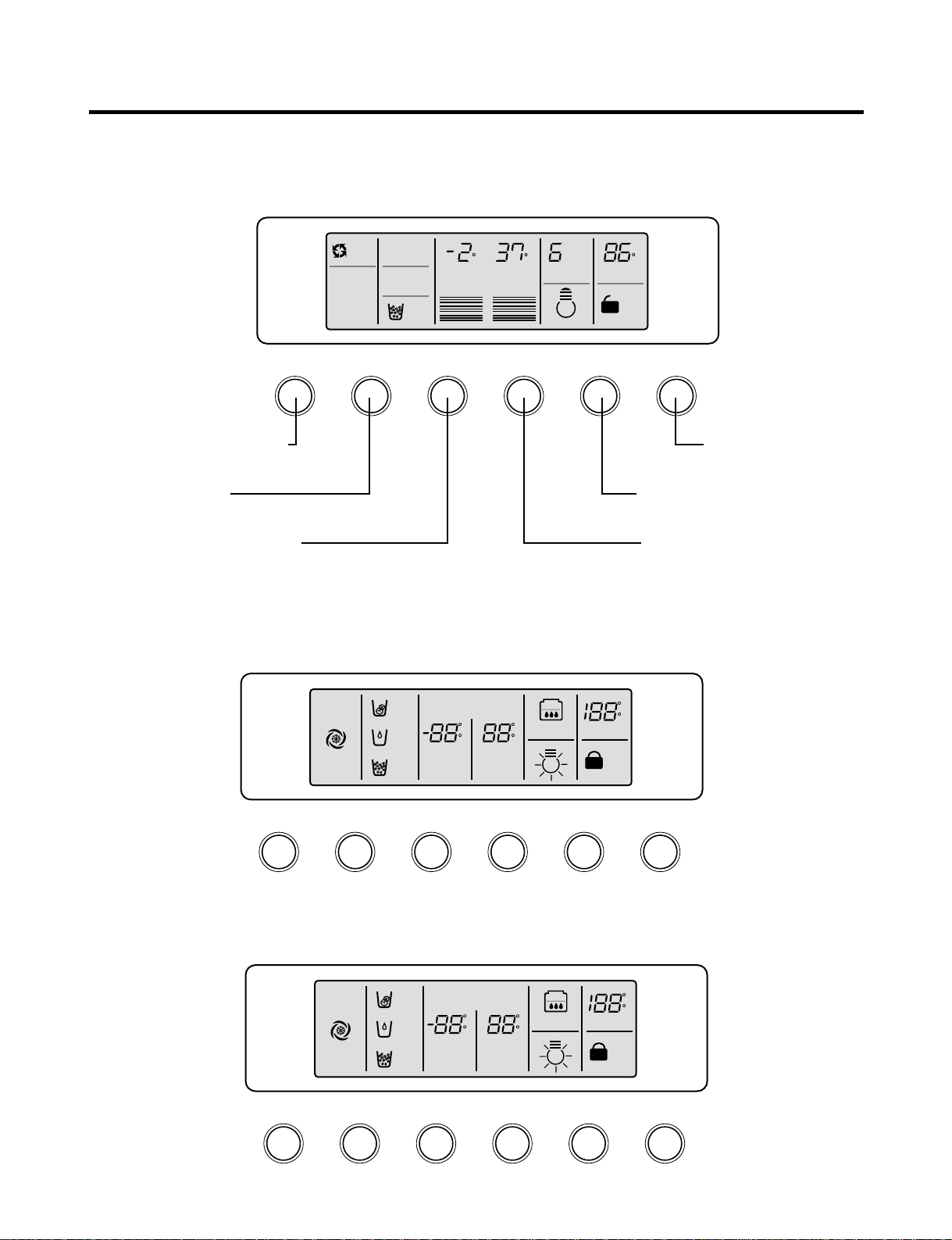

1. Monitor Panel

1-1. GR-L267AV(T)BA

1-2. GR-L267AV(T)FA

1-3. GR-L267AV(T)RA, GR-L267DV(T)R

MICOM FUNCTION

- 16 -

ICEBEAM

COOLING

OFF

CUBE

FILTER

MONTH

EXPRESS/JET FRZ DISPENSER FREEZER REFRIGERATOR FILTER/LIGHT LOOK

ROOM TEMP

DISPENSER & KEY

F

WATER

5

4

3

2

1

CRUSH

F F

3 SECS

Dispenser selection

button

Express Freezer/Jet Freezer

function selection button

Dispenser and Button

Lock button

Dispenser Lamp On/Off button/

Filter status display RESET button

Temperature adjustment button

for refrigerator compartment

Temperature adjustment button

for freezer compartment

EXPRESS

DIGITAL CONTROL

FRZ TEMP REF TEMP

JET

CUBE

FILTER RESET

HOLD 3SECS

EXPRESS/JET FRZ DISPENSER FREEZER

REFRIGERATOR

FILTER RESET/LIGHT

LOOK

ROOM TEMP

LOCK

DISPENSER & KEY

WATER

CRUSH

3 SECS

F

C

F

C

F

C

FILTER

ON

DIGITAL CONTROL

FRZ TEMP REF TEMP

OFF

CUBE

FILTER RESET

HOLD 3SECS

EXPRESS FRZ DISPENSER FREEZER

REFRIGERATOR

FILTER RESET/LIGHT

LOOK

ROOM TEMP

LOCK

DISPENSER & KEY

WATER

CRUSH

3 SECS

F

C

F

C

F

C

FILTER

Page 17

2. Description of Function

2-1-1. Function of Temperature Selection

* The temperature can vary ±3 °C depending on the load condition.

❉ Whenever pressing button, setting is repeated in the order of (Medium) ➝ (Medium Max) ➝ (Max) ➝ (Min) ➝

(Medium Min).

• The actual inner temperature varies depending on the food status, as the indicated setting temperature is a target

temperature, not actual temperature within refrigerator.

• Refrigeration function is weak in the initial time. Please adjust temperature as above after using refrigerator for minimum

2~3 days.

2-1-2. LCD Back Light Control (GR-L267AV(T)BA Model only)

1. In order to see the LCD display more easily, the backlight is turned on for one minute at the initial application of power, for

20 seconds when buttons are pressed, and when a door is opened and for 20 seconds after it is closed.

2. When any display button is pressed while the backlight is off, the buzzer sounds and the backlight is turned on, but the

button function is not performed. In other words, pressing any button turns on the backlight but does not cause any

function to be initiated.

3. If pressing the special freezing button and the freezing temperature adjustment button for more than a second, the back

light is turned on and all the graphics of LCD are turned on. If releasing the button, the LCD graphic is displayed in the

previous status and the back light is turned off (check LCD graphic and back light ON/OFF status).

2-1-3. Outside temperature display function

1. Outside temperature sensor at the right Hinge Cover - U of refrigerator senses ambient temperature and displays the

outside temperature in the upper of ROOM TEMP text on the display part.

2. Ambient temperature is displayed up to 16°F ~ 120°F and displayed as Lo for less than 15°F and as HI for more than

121°F. If the ambient temperature sensor fails, it is displayed as Er.

3. Since display temperature of outside temperature is temperature sensed by the ambient sensor in the upper hinge of the

refrigerator room, it may differ from the outside temperature display of other household electrical appliances.

MICOM FUNCTION

- 17 -

Division Power Initially On 1st Press 2st Press 3th Press 4th Press

Setting

temperature

Temperature

Control

Medium Medium Max Max Min Medium Min

Freezer Control

-2 °F -5 °F -8 °F 7 °F 4 °F

Refrigeration

37 °F 34 °F 32 °F 46 °F 41 °F

Control

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

Page 18

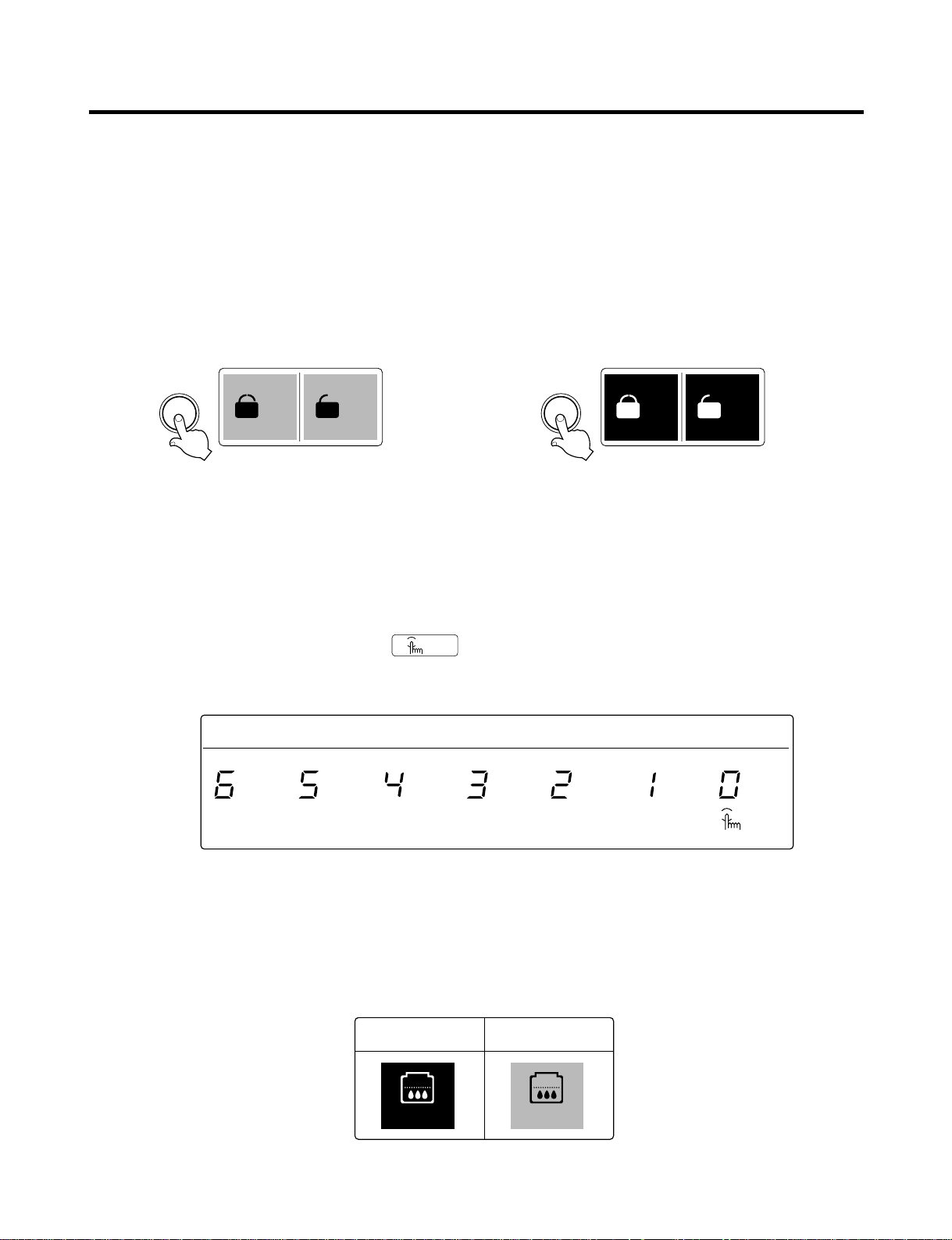

2-1-4. Lock function (dispenser and display button lock)

1. When the refrigerator is first powered up, the LOCK text on the display is turned off.

2. To lock the display, the dispenser, and the control panel, press and hold the LOCK button for more than 3 seconds. The

LOCK text on the display will be turned on.

3. The buzzer sound and control panel and dispenser function is not performed even if pressing display button other than

lock key in the lock status.

4. To unlock the controls, press and hold the lock button for more than 3 seconds. The LOCK text on the display will be

turned off.

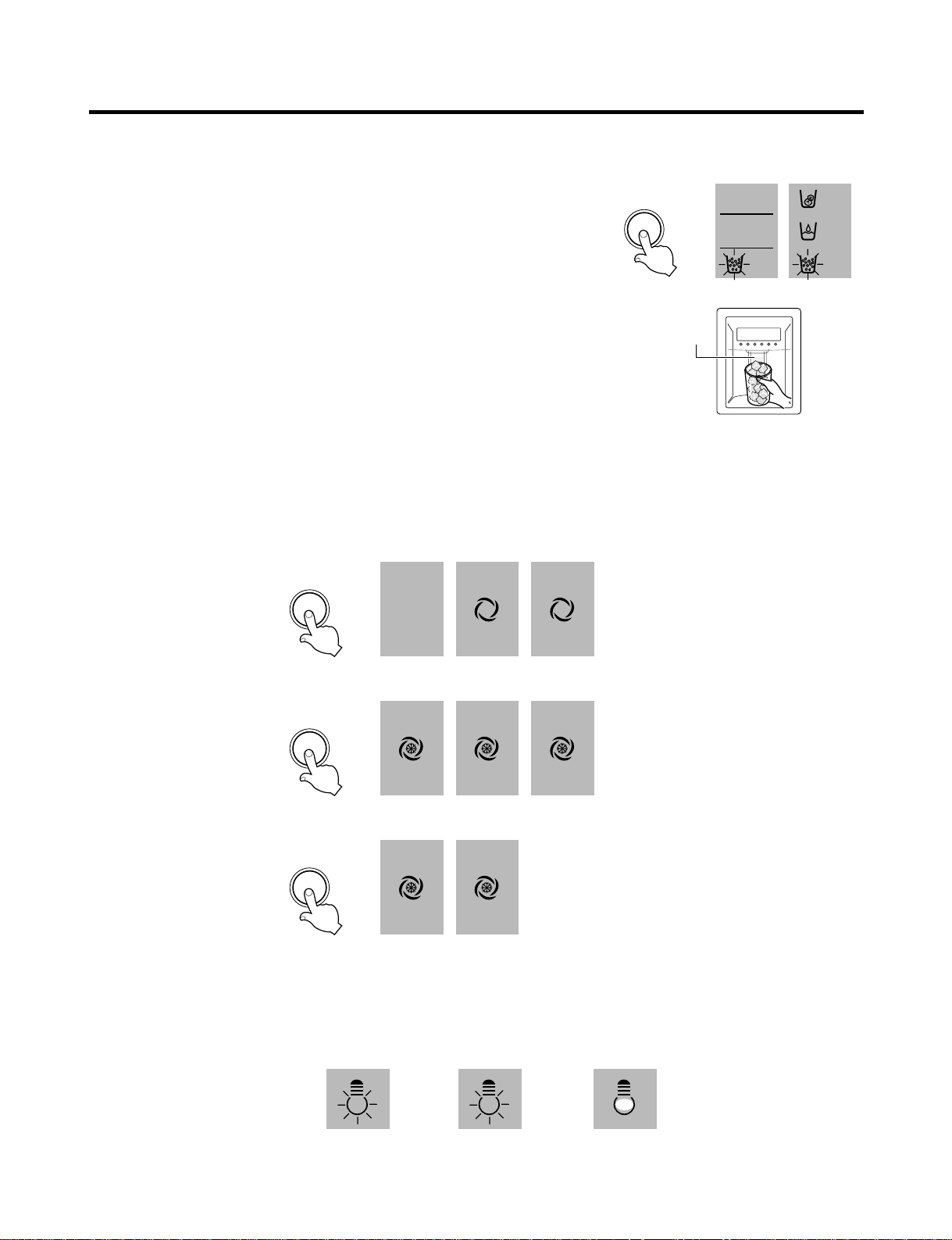

2-1-5. Filter condition display function

(1) LCD (GR-L267AV(T)BA Model)

1. As shown below, the display tells the months left in units of 30 days (or about 4,700 seconds of filter usage) before the

filter must be replaced. The timer is started at the initial power up of the refrigerator.

2. After 6 months have passed the filter change will appear on the display. It will show FILTER LIGHT 3 SECS.

3. After 6 months have passed, if the filter has been replaced or you wish to reset the indicator, press and hold the Filter

Light button for more than 3 seconds.

(2) LED (GR-L267AV(T)BA other Model)

1. There is a replacement indicator light for the water filter cartridge on the dispenser.

2. The water filter should be replaced every six months or about 28,000 seconds' filtering time.

3. The water filter light and FILTER RESET HOLD 3 SECS will show in the display to remind you to change the filter soon.

4. After replacing the filter, press and hold the lock button for more than 3 seconds. The FILTER RESET HOLD 3 SECS will

turn off.

MICOM FUNCTION

- 18 -

DISPENSER & KEY

3 SECS

LOCK

DISPENSER & KEY

3 SECS

LOCK CONTROL

DISPENSER & KEY

3 SECS

LOCK

DISPENSER & KEY

3 SECS

LOCK CONTROL

Ex) Select

LOCK

Ex) Select

LOCK again

Ex) Select

LOCK

Ex) Select

LOCK again

In initial

Power On

Classification

Filter Status

Display

Pass of

a month

Pass of

2 months

Pass of

3 months

Pass of

4 months

Pass of

5 months

Pass of

6 months

3 SECS

FILTER

MONTH

FILTER

MONTH

FILTER

MONTH

FILTER

MONTH

FILTER

MONTH

FILTER

MONTH

FILTER

MONTH

FILTER LIGHT

In initial Power On

/ Filter RESET

Replace indicator

light on

Classification

Filter Status

Display

FILTER

FILTER RESET

HOLD 3SECS

FILTER

LCD (GR-L267AV(T)BA Model) LED (GR-L267AV(T)BA other Model)

3 SECS

FILTER LIGHT

Page 19

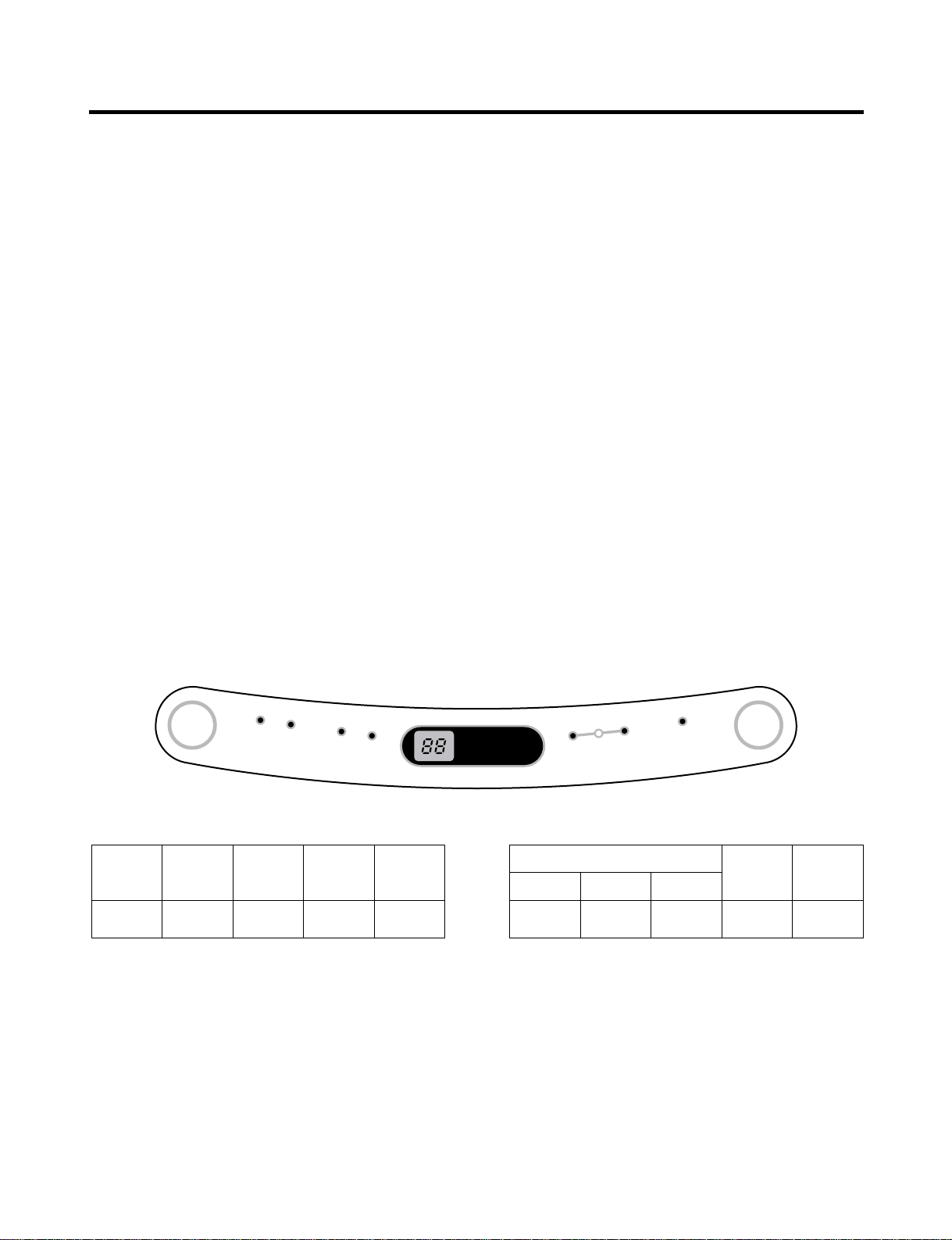

2-2. Dispenser use selection

You can select water or ice.

❉ Select water, crushed ice, or ice cubes by cycling through the selections when

pressing the DISPENSER button.

❉ Please press the push button lightly by catching and pushing in cup.

• You’ll hear a PLAP sound 5 seconds after ice is dispensed.

• That is the sound of the ice dispenser door flap being closed.

REFERENCE : Hold your cup in the dispenser for a few seconds after dispensing

ice or water to allow the last pieces of ice or drops of water to fall

into the cup.

2-3. Express freezing/JET freezing selection

Please select this function for prompt freezer.

• Function is repeated following below whenever pressing EXPRESS/JET FRZ button.

• The arrow mark graphic remains at the On status after flickering 4 times when selecting Special Refrigeration EXPRESS

FRZ or JET FRZ.

• EXPRESS FREEZE and JET FREEZE operate for a set time and then default to normal freezer operation.

2-4. Dispenser Light

• Dispenser switch or dispenser light button turn the dispenser light in the dispenser on and off.

• The dispenser light Function is repeated following below whenever pressing FILTER RESET/LIGHT button.

• If dispenser light continuously turns on more than 7 minutes with dispenser light button, the dispenser light turns off

automatically.

MICOM FUNCTION

- 19 -

DISPENSER

LCD LED

CUBE

WATER

CRUSH

CUBE

WATER

CRUSH

Pressing

Switch

LCD (GR-L267AV(T)BA Model)

LED (GR-L267AV(T)FA)

LED (GR-L267A(V)RA, GR-L267DV(T)R)

EXPRESS/JET FRZ

OFF

EXPRESS FRZ

JET FRZ

EXPRESS/JET FRZ

EXPRESS

JET

EXPRESS FRZ

ON

OFF

Dispenser Iight OFF

LCD

Dispenser Iight ON

LCD

Dispenser Iight ON/OFF

LED

CN

Page 20

2-5. Express freezing

1. EXPRESS FREEZING improves the cooling speed of the freezer by running the compressor and the freezer fan.

2. In the event of power failure, EXPRESS FREEZING is cancelled and the freezer defaults to normal operation.

3. The temperature setting is not changed when EXPRESS FREEZING is selected.

4. The freezer compartment and refrigerator temperature settings can be changed even when EXPRESS FREEZING is

selected and the cycle is underway.

5. The refrigerator compartment will operate at its usual setting even when EXPRESS FREEZING is selected or in progress.

6. If you select EXPRESS FREEZING, the refrigerator will default to its original setting at the end of the cycle.

7. If the defrost cycle is scheduled to come on while EXPRESS FREEZING is selected, EXPRESS FREEZING will operate

only for the time that is not used by the defrost setting.

8. If you press EXPRESS FREEZING during the defrost cycle, the EXPRESS FREEZING indicator will turn on but the cycle

will not run until the defrost cycle is completed.

9. If you press EXPRESS FREEZING within 7 minutes of the compressor’s last run cycle, the EXPRESS FREEZING cycle

will not begin until the 7 minute delay is complete.

10. The freezer fan runs at high speed when Express Freezing is selected.

2-6. Jet Freezing

1. Jet Freezing improves the cooling speed of the Jet Freezing Compartment by running the compressor and the Jet

Freezing Compartment fan.

2. If there is a power failure, the Jet Freezing cycle is released and the freezer defaults to its original setting.

3. Changed even if you select Jet Freezing.

4. If Jet Freezing is selected, the compressor (after the compressor delay time has passed) and the freezer fan will be

turned on. The temperature in the freezer will drop and the fan motor will be turned off for a set time, but the Jet Freezing

fan will run for no more than two hours. After that, the Jet Freezing function terminated and the freezer defaults to its

original setting.

5. To keep the fan motor from freezing, it is switched on for 10 seconds once an hour.

6. The fan motor of jet freezing box will not be detected as a failure. (dc 12v operation)

7. When checking the Jet Freezing function, the Jet Freezing Compartment fan motor is switched on for 1 minute if the

freezer adjustment button or the Express Freeze button is pressed for more than one second.

MICOM FUNCTION

- 20 -

Page 21

2-7. OptiChill Function

uu

GR-L267AV(T)BA Model

2-7-1. Temperature Control in OptiChill

1. The Optichill is positioned at the bottom of the refrigerator compartment. It allows the user to select a more specific

temperature based on the foods being stored, such as meat, fish, fruits and vegetables, etc.

2. The Optichill system consists of a sensor at the rear of the drawer, a damper, a fan motor between the Optichill

compartment and the freezer, a heater at the bottom of the Optichill compartment, and a temperatur adjustment display at

the top.

3. At initial power-up, the initial setting of the Optichill will be FRUIT VEGE. If only the refrigerator door is opened, the

Optichill LED will be ON.

4. Each time you press the SELECT button, the selection cycles through the settings in the order of FRUIT VEGE

(39°F)→CHILLED ROOM (30°F)→PARTIAL FREEZING (27°F)→WINE(50°F)→FRUIT VEGE (39°F). The display will show

the target temperature. If EXPRESS CHILL or THAW is selected, the selected temperature and NOTCH LED are not

shown, and the temperature can be adjusted.

5. The Optichill sensor detects the temperature and relays this information to the MICOM. Based on the temperature and

setting, The damper is opened or closed and the heater is on or off, as the conditions warrant.

6. If the Optichill damper hasn’t moved within an hour, it is automatically opened or closed and then returned to its previous

setting to keep it from freezing in one position.

7. In Display Check mode, the Optichill fan motor is turned on for one minute. To enter the Display Check mode, press and

hold both the Freezer Adjust button and the Express Freezing button for three seconds.

8. If the Optichill fan motor hasn’t run within an hour, it is automatically run for ten seconds once every hour to keep it from

freezing in one position.

MICOM FUNCTION

- 21 -

°F / SET TEMP

/ TIME REMAINING

MIN

WINE

3.0

1.5

0.5

EXPRESS

CHILL

THAW(lbs)

FRUIT

VEGE

CHILED

ROOM

PARTIAL

FREEZING

SELECT SELECT

HR

Display 27°F30°F39°F50°F

NOTCH

Partial

Freezing

Chilled

Room

Fruit

VEGE

Wine

12Hr 8Hr 4Hr 90Min 50°F

3.0lbs 1.5lbs

THAW

0.5lbs

Express

Chill

Function

Page 22

2-7-2. Thawing and Express chill function in OptiChill

1. When you press the SELECT button on the right, the THAW LED will light. The time for the selected function will be

shown. You can cycle through the options in this order: EXPRESS CHILL/THAW OFF→EXPRESS CHILL (90 Min.)→

THAW 0.5 lbs. (4 hours)→THAW 1.5 lbs. (8 hours)→THAW 3.5 lbs. (12 hours)→EXPRESS CHILL/THAW OFF. If

EXPRESS CHILL/THAW is selected, the NOTCH temperature in the Optichill will not be displayed.

2. If EXPRESS Chill is selected, the Optichill damper is opened and the fan motor is turned on. If the Optichill does not

reach the set temperature after no more than ninety minutes, the setting is released.

3. The Optichill will count down from 90 minutes and show the remaining time in minutes.

4. When the EXPRESS CHILL cycle ends (or is released), the setting defaults to FRUIT VEGE (39°F).

5. If a THAWING is selected, the Optichill damper is closed and the time and temperature will be set according to the

thawing function selected. The thawing function will be automatically terminated at the ned of the set time.

6. When in THAW mode, the sensor controls the heater to keep the set temperature.

7. When in THAW mode, the display counts down the remaining time in minutes.

8. When the THAW mode is released, the Optichill automatically defaults to CHILLED ROOM (30°F).

uu

GR-L267AV(T)FA Model

2-7-3. Temperature control in OptiChill

1. The Optichill is in the bottom of the refrigerator compartment and allows the user to select and adjust the temperature

based on the type food stored there. Selections include meat, fish, fruits and vegetables, etc. Storing foods at the proper

temperature allows them to be stored for longer periods.

2. The Optichill consists of a temperature sensor, a damper between the Optichill and the freezer, and a temperature

control/display at the top.

3. At initial power-up, the Optichill defaults to FRUIT VEGE. If the refrigerator door is opened, the Optichill LED will be on.

4. When you press the SELECT button on the left, the LED will light and indicate the setting. The time for the selected

function will be shown. You can cycle through the options in this order: FRUIT VEGE (39°F)→CHILLED ROOM→PARTIAL

FREEZING→FRUIT VEGE. The display will indicate the temperature for the selected setting.

5. The Optichill sensor detects the temperature and relays that information to the MICOM. When the set temperature is

reached, the Optichill damper is closed. If the temperature rises, the damper is opened to allow the temperature to fall

again.

6. If the Optichill damper hasn’t moved within an hour, it is automatically moved and returned to its original setting once

every hour to keep it from freezing in one position.

MICOM FUNCTION

- 22 -

Page 23

2-8. Control of variable type of freezing fan

1. To increase the cooling speed and load response speed, the MICOM switched the freezer compartment fan motor

between high and regular speeds.

2. The MICOM runs the freezer fan at high speed only at initial power-up, Express Freezing operation, or in response to a

high load. The fan runs at the regular speed in all other circumstances.

3. When you open the refrigerator door while the fan is running at high speed, the MICOM will switch the fan to regular

speed. If you open the freezer door or the home bar door, the fan is switched off.

4. If the MICOM determines the fan is obstructed (the blade cannot turn) it switches the fan off. When there is no fan rotation

signal for 115 seconds, the MICOM displays the error on the display. To restart the fan, clear the obstruction and turn the

power off and back on.

2-9. Control of cooling fan motor

1. The cooling fan is switched ON and OFF in conjunction with the compressor.

2. The cooling fan runs at a single speed.

3. Failure sensing method is same as in fan motor of freezing fan motor (refer to failure diagnosis function table for failure

display).

2-10. Door opening alarm

1. Buzzer generates alarm sound if doors are not closed even when more than a minute consecutively has passed with

doors of freezing/cold storage room or home bar opened.

2. If the doors are left open for more than one minute, the buzzer sounds three

1

/

2-second tones at thirty second intervals for

four times.

3. If all the doors of freezing/cold storage room or home bar are closed during door open alarm, alarm is immediately

released.

2-11. Ringing of button selection buzzer

1. The DING sounds if you press any button on the front display.

MICOM FUNCTION

- 23 -

Doors of freezing /

cold storage room

or home bar

BUZZER

Closing

Opening

Within

a minute

A minute

30

seconds30seconds30seconds

Opening

Closing Closing

3 Times 3 Times 3 Times 3 Times

Page 24

2-12. Automatic Defrost Signal

1. The beep will sound if you press the test button on the main PCB.

2. The regular cycle sounds three short beeps one second apart.

3. When you select the automatic defrost cycle, the alarm sounds three series of three short beeps one minute apart.

2-13. Defrost Function

1. Automatic defrost is performed whenever the compressor run time totals 71/2 hours.

2. At initial power-up, the defrost cycle will run when the total compressor runtime is 4

1

/2

hours.

3. Defrost is completed when the defrost sensor temperature rises above 41°F (5°C) during the defrost cycle. The defrost

cycle will terminate if the defrost sensor temperature does not achieve 41°F (5°C) within two hours.

4. The defrost cycle will not operate if the defrost sensor fails.

2-14. Refrigerator compartment lamp automatically off

• The refrigerator light is turned ON and OFF by the refrigerator door switch.

• If the refrigerator light is on for more than 7 minutes, it will be turned off automatically. It will operate normally if you close

the door and re-open it.

MICOM FUNCTION

- 24 -

Page 25

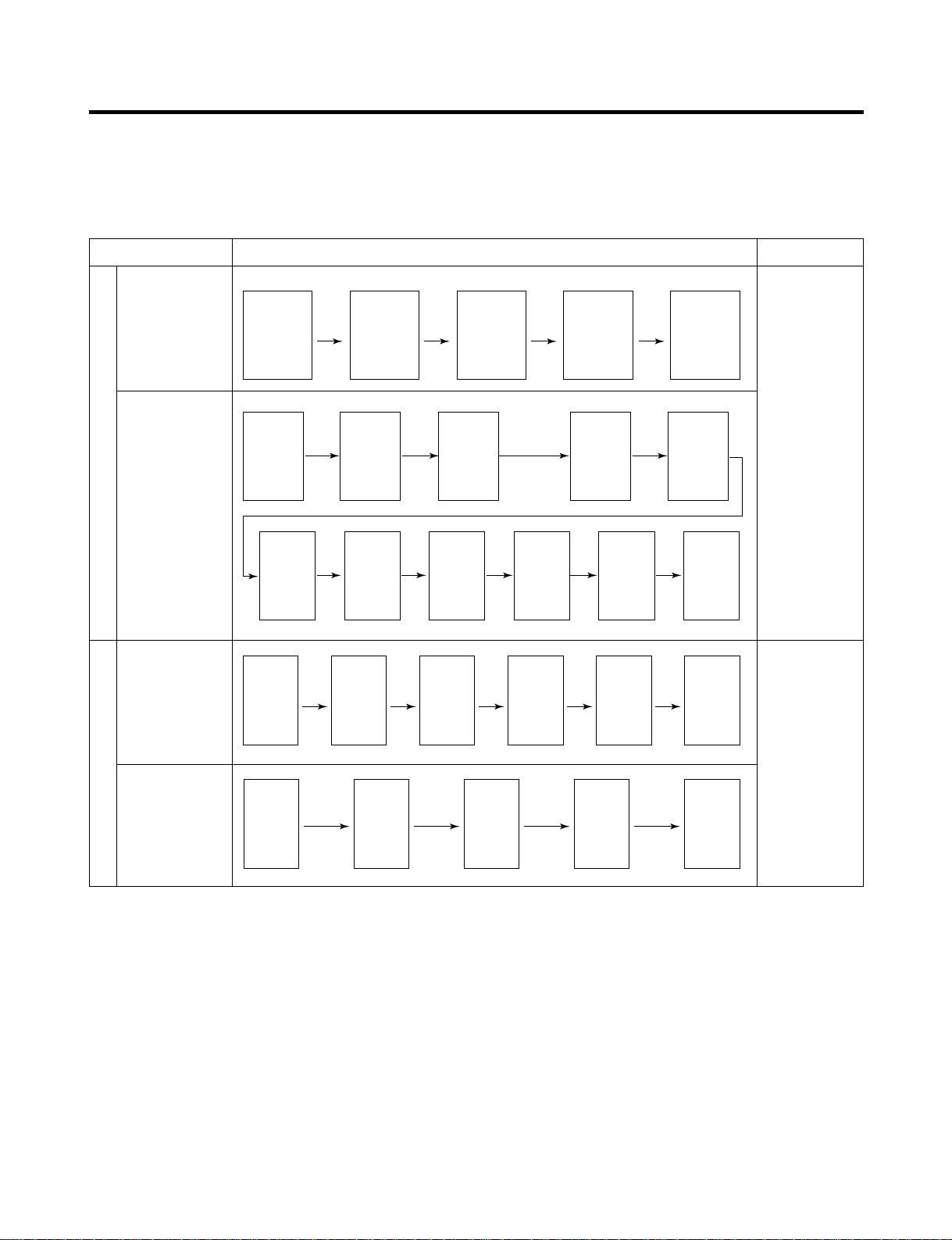

2-15. Sequential operation of built-in product

Electromechanical parts of the appliance, such as the compressor, defrost heater, freezer fan, cooling fan, and damper

motor, are operated sequentially as shown in the chart below to prevent noise and circuit overload from everything starting

at once.

MICOM FUNCTION

- 25 -

Function Load Operation Sequence Remark

In applying Initial power TEST MODE

When temperature

of a defrost sensor

becomes more

than 45°C

(In purchase,

movement)

If error occurs

during operation,

initial operation is

not done.

■

Sequence of

load operation

when closing

freezer and

refrigerator.

The refrigerator

will return to

normal operation

if you press the

test switch once

again while in

Test Mode 2 or if

the temperature

of the defrost

sensor surpasses

41°F (5°C). The

compressor will

run after the 7minute delay.

When

temperature of a

defrost sensor

becomes less

than 45°C

(In power failure,

service)

Test mode 1

(Compulsory

function)

Test mode 2

(Compulsory

defrost)

POWER

ON

COMP

ON

F-FAN

&

C-FAN

ON

R-STEP

MOTOR

DAMPER

ON

OPTICHILL

STEP

DAMPER

MOTOR

ON

DEFROST

HEATER

OFF

DEFROST

HEATER

ON

DAMPER

&

DUCT DOOR

&

OPTICHILL

HEATER ON

DAMPER

&

DUCT DOOR

&

OPTICHILL

HEATER OFF

0.3

sec.

6.0

sec.

0.3

sec.

0.3

sec.

0.3

sec.

POWER

ON

0.3

sec.

PIPE

&

DISP'

HEATER

OFF

0.3

sec.

COMP

ON

0.3

sec.

F-FAN

&

C-FAN

ON

0.3

sec.

R-STEP

MOTOR

DAMPER

ON

0.3

sec.

OPTICHILL

STEP

DAMPER

MOTOR

ON

PIPE

&

DISP'

HEATER

ON

TEST

SWITCH

(PRESS

Once)

OTHER

LOAD

OFF

COMP

ON

F-FAN

&

C-FAN

ON

R-STEP

MOTOR

DAMPER

ON

OPTICHILL

STEP

DAMPER

MOTOR

CLOSE

TEST

SWITCH

(PRESS

2 Times)

COMP

OFF

F-FAN

&

C-FAN

OFF

FROST

REMOVAL

HEATER

ON

R-STEP

MOTOR

DAMPER

CLOSE

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

0.3

sec.

Page 26

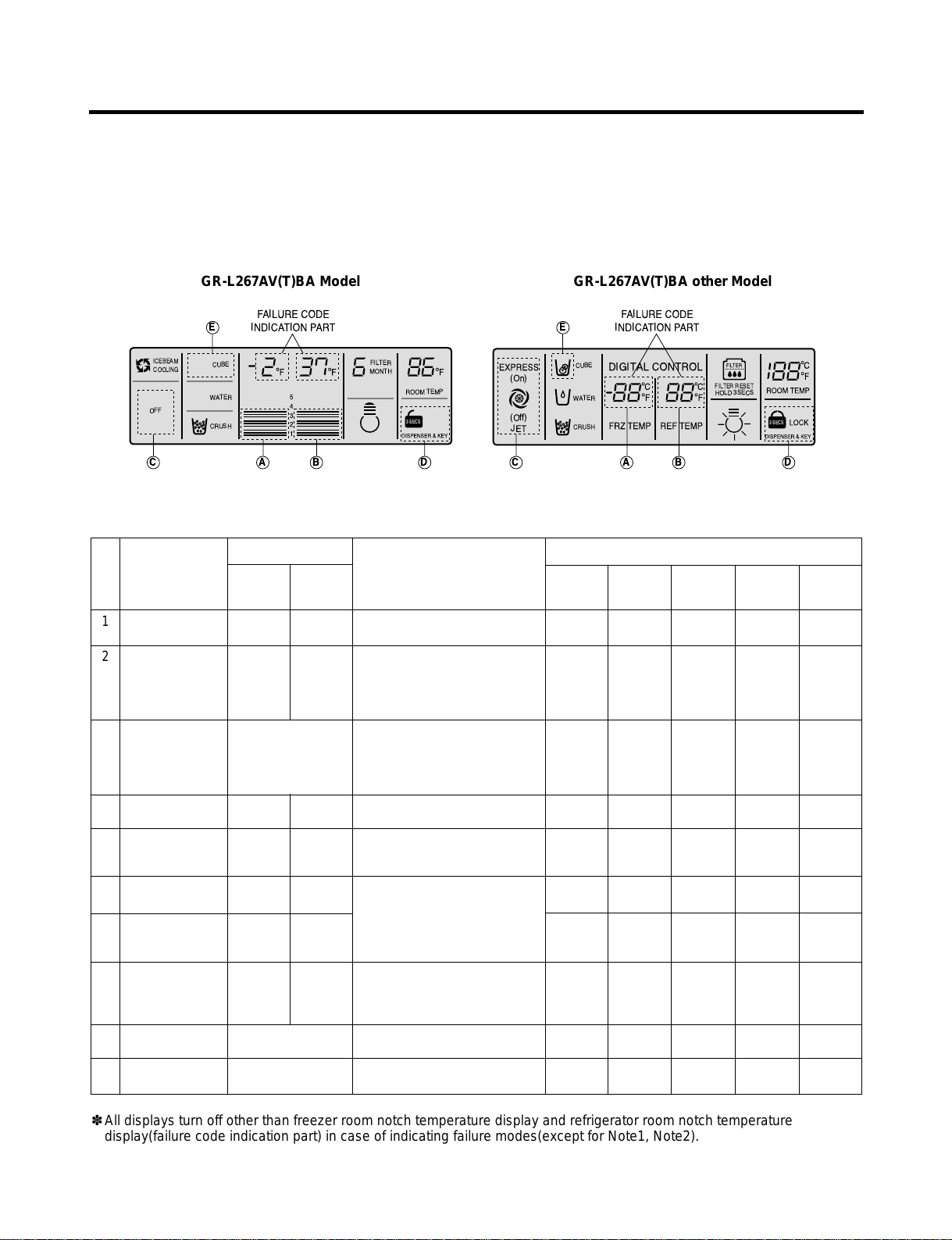

2-16. Failure Diagnosis Function

1. The failure diagnosis function makes servicing simpler by indicating the area of a failure while the product is in operation.

2. When the appliance enters the failure mode, pressing buttons has no effect on the operation of the appliance.

3. If the error clears itself, the MICOM will reset and the appliance will operate as usual.

4. The failure code will be displayed as indicated in the drawings below. All other graphics and displays will be turned off.

MICOM FUNCTION

- 26 -

ICEBEAM

COOLING

OFF

CUBE

FILTER

MONTH

ROOM TEMP

DISPENSER & KEY

F

WATER 5

4

3

2

1

CRUSH

F F

3 SECS

EXPRESS

(On)

DIGITAL CONTROL

FRZ TEMP REF TEMP

(Off)

JET

CUBE

FILTER RESET

HOLD 3SECS

ROOM TEMP

LOCK

DISPENSER & KEY

WATER

CRUSH

3 SECS

F

C

F

C

F

C

FILTER

C

E

A B D C

FAILURE CODE

INDICATION PART

E

A B D

FAILURE CODE

INDICATION PART

GR-L267AV(T)BA Model GR-L267AV(T)BA other Model

✽ All displays turn off other than freezer room notch temperature display and refrigerator room notch temperature

display(failure code indication part) in case of indicating failure modes(except for Note1, Note2).

1

2

3

4

5

6

7

8

9

10

Er FS

Er rS

Normal display

(Note 2)

Er dS

Er dH

Er FF

Er CF

Er CO

Normal display

(Note 1)

Normal display

(Note 2)

Failure code indication part

Freezer notch

temperature

display

Refrigerator notch

temperature

display

No. Item

Contents of failure

Freezing

BLDC motor

Compressor

Stepping

motor damper

Defrost

Heater

Cooling

BLDC motor

Product operation status in failure

Abnormal

freezer sensor

Abnormal refrigerator

sensor 1 (R1)

(Upper part in the

refrigerator

compartment)

Abnormal refrigerator

sensor 2 (R2)

(Middle part in the

refrigerator

compartment)

Abnormal defrost

sensor

Failed defrosting

Abnormal freezing

BLDC motor

Abnormal cooling

BLDC motor

Communication

Errors.

Abnormal

ambient sensor

Abnormal

Optichill sensor

Freezer sensor short circuit

Refrigerator sensor1 short circuit

Refrigerator sensor2 short circuit

Abnormal short circuit

Defrost heater, temperature fuse short

circuit, unplugged connector(indicated

4 hour later after trouble)

Motor defect, hooked of lead wire

to fan, contact of structures with

fan, short or open of lead

wire(there is no signal of BLDC

motor more than 115 seconds in

operation of fan motor)

Short or open of lead wire

connecting between main PCB

and display PCB, transmission tr

and receiving part

Ambient sensor short circuit

Optichill sensor short circuit

Standard

RPM

Standard

RPM

Standard

RPM

Standard

RPM

Standard

RPM

OFF

Standard

RPM

Standard

RPM

●●

●●

●●

●●

●●

●●

●●

●●

OFF

●●

●●

●●

ON for 15minutes /

OFF for 15minutes

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

No defrost

●●

●●

●●

●●

●●

●●

●●

Full opening for

10 minutes/

Full closing for

15 minutes

●●

●●

●●

●●

●●

●●

●●

●●

●●

: Proper operation

Page 27

Note1) The freezer and refrigerator temperature displays are also used to display error codes. The exception is that when

the ambient temperature sensor fails, it shows Er in the ambient temperature display. All other display elements will

function normally.

Note2) The R2 sensor, Optichill sensor, and water tank sensor are not indicated in the error codes, but you can see these

errors by entering the test mode by pressing and holding the Freezer Temperature and Super Freezer buttons

simultaneously.

R2-sensor (middle room)

Normal: LED or LCD graphic on the (C) part turns on

Abnormal: LED or LCD graphic on the (C) part turns off

Optichill sensor

Normal: LED or LCD graphic on the (D) part turns on

Abnormal: LED or LCD graphic on the (D) part turns off

Water tank sensor

Normal: LEDs or LCDs graphic on the (E) part turns on

Abnormal: LEDs or LCDs graphic on the (E) part turns off

✻ LCD (LED) check function: LCD (LED) Press and hold the Express Freeze button and the Freezer Temperature

adjustment button to check the display. This will turn on the backlight and all display elements.

Release the buttons and the display will return to its usual state.

MICOM FUNCTION

- 27 -

The other LED or

LCD Graphics

Turn On.

Page 28

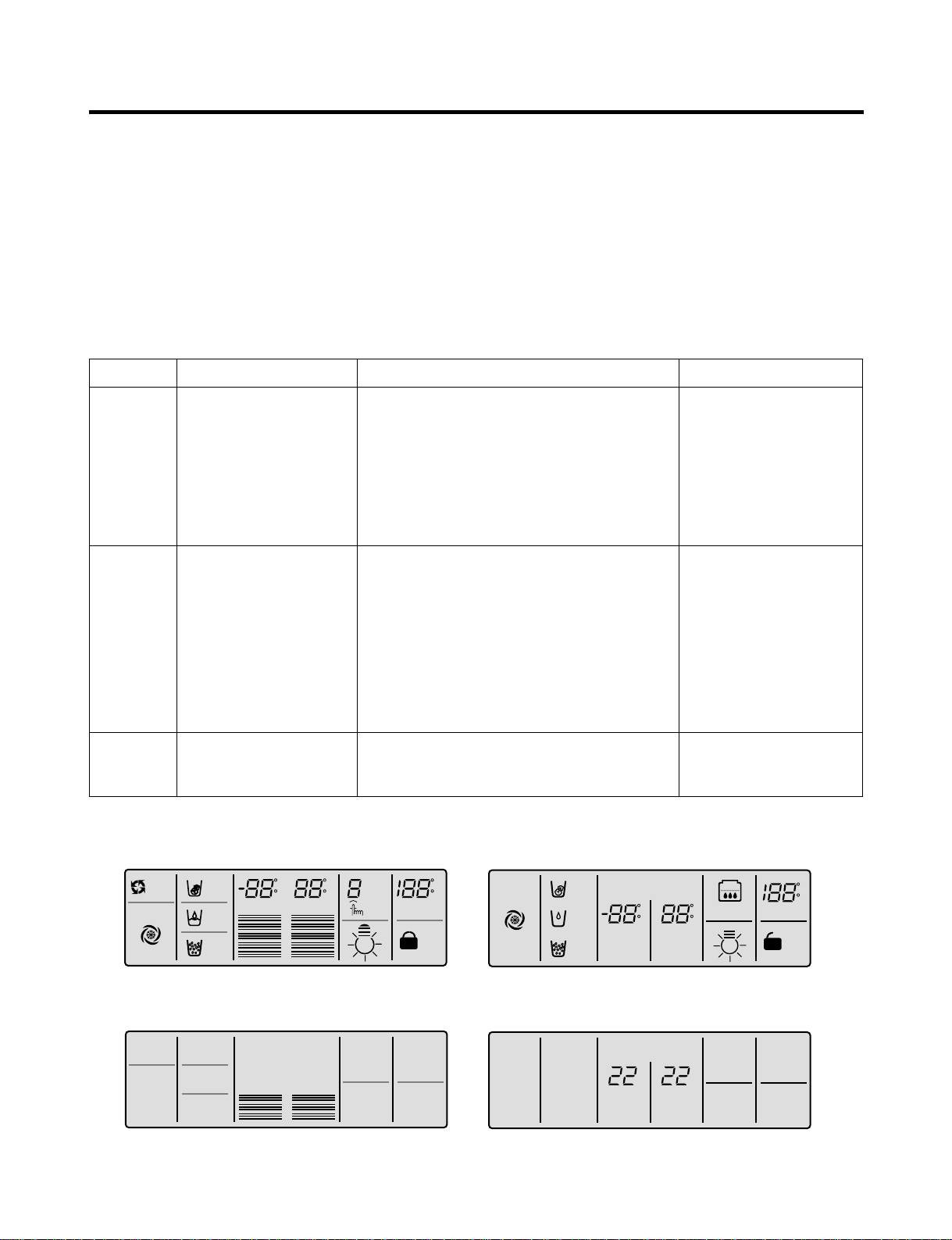

2-17. Test Function

1. The test function is a self-diagnostic system designed to detect problems early and to make diagnosis and repair easier

and quicker.

2. The test button is on the main PCB. Test mode can run for up to 2 hours and will then default to the normal operation

mode if not reset manually.

3. The function buttons are inoperable when the refrigerator is in test mode.

4. When you have finished using the test mode, reset the appliance manually by unplugging it for several seconds.

5. If nonconforming contents such as sensor failure are found during performance of test mode, release the test mode and

display the failure code.

6. The test button is inoperable if the display is showing failure codes. Reset the appliance manually to use the test button.

MICOM FUNCTION

- 28 -

Test 1

Test 2

Normal

Status

Mode Operation Contents Remarks

Press test button once

(strong cold mode)

Press test button once at

the test mode 1 status

(forced defrost mode)

Press test button once at

the test mode 2 status

1. Continuous operation of compressor

2. Continuous operation of freezing BLDC motor

(high-speed RPM) and cooling BLDC motor

3. Defrost heater turns off

4. Stepping motor damper is completely opened

(baffle open)

5. Optichill stepping motor damper is completely

closed.

6. All display LEDs or LCD graphics turn on.

1. Compressor OFF

2. Freezing BLDC motor and cooling BLDC

motor turn off

3. Defrost heater turns on

4. Stepping motor damper is completely closed

(baffle close)

5. Optichill stepping motor damper is completely

closed.

6. All display LEDs or LCD graphics turn off.

Except for (A), (B) LCD graphic.

Except for (A): 22 (B): 22 LEDs.

Return to the initial status.

Freezer fan is off when

door is open.

Return to the normal mode

when the defrost sensor is

above +5°C

Compressor will operate

after delay for 7 minutes

EXPRESS

DIGITAL CONTROL

FRZ TEMP REF TEMP

JET

CUBE

FILTER RESET

HOLD 3SECS

ROOM TEMP

LOCK

DISPENSER & KEY

WATER

CRUSH

3 SECS

F

C

F

C

F

C

FILTER

5

4

3

2

1

ICEBEAM

COOLING

CUBE

FILTER

MONTH

ON

ROOM TEMP

DISPENSER & KEY

WATER 5

4

3

2

1

CRUSH

3 SECS

EXPRESS FRZ

F

C

F

C

LOCK

F

C

JET

3 SECS

FILTER LIGHT

TEST MODE1 STATUS DISPLAY

TEST MODE2 STATUS DISPLAY

Page 29

2-18. Function of built-in ice and water dispenser.

1. This feature allows dispensing of ice and water without having to open the refrigerator door.

2. Select CUBES, CRUSHED ICE, or WATER. Then press the dispenser switch. The duct door is operated by a solenoid.

This door closes 5 seconds after ice is dispensed.

3. The dispenser does not work if the freezer door is open.

4. The dispenser will turn itself off after 3 minutes even if it does not receive an OFF signal. This prevents damage and

overheating of the motor. The duct door will close 5 seconds after ice is dispensed.

5. The dispenser lamp is turned on and off by the dispenser switch.

6. Selection of Cubes/Crushed/Water

1) Select Cubes/Crushed/Water using the selection button

2) The default at power-up is Cubes

3) The geared motor operates when Cubes or Crushed is selected.

7. Water Dispenser Function

1) Select Water using the selection button

2) The water line must be connected to the household water supply. The solenoid at the bottom right rear of the

refrigerator operates to supply water.

3) Press the dispenser switch to dispense water.

MICOM FUNCTION

- 29 -

Page 30

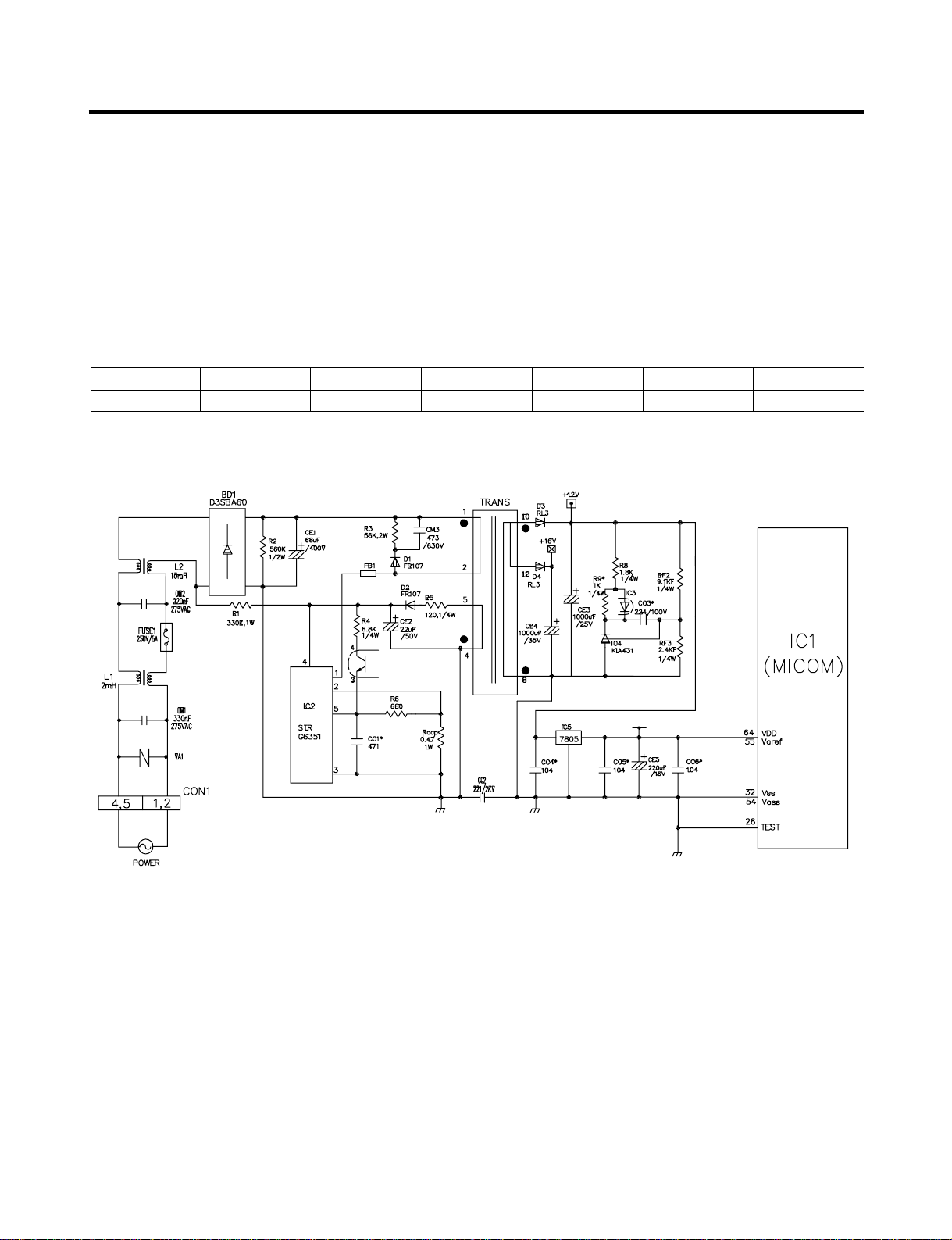

1. Explanation for PWB circuit

1-1. Power circuit

1. GR-L267

****

The power circuit includes a Switched Mode Power Supply (SMPS). It consists of a rectifier (BD1 and CE1) converting AC

to DC, a switch (IC2) switching the DC voltage, a transformer, and a feedback circuit (IC3 and IC4).

Caution : Since high voltage (160 Vdc) is maintained at the power terminal, wait at least 3 minutes after unplugging the

appliance to check the voltages to allow the current to dissipate.

Voltage of every part is as follows:

EXPLANATION FOR MICOM CIRCUIT

- 30 -

Part VA1 CE1 CE2 CE3 CE4 CE5

Voltage 120 Vac 160 Vdc 14 Vdc 12 Vdc 15.5 Vdc 5 Vdc

Page 31

1-2. Oscillation circuit

The oscillation circuit generates a basic clock signal for synchronization and time calculation related to the transmission of

data and calculations made by the MICOM (IC1). The oscillator (OSC1) must always be replaced with an exact rated part,

because if this spec is changes, the time calculations of the MICOM will be affected and it might not work at all.

1-3. Reset circuit

The RESET circuit allows various parts of the MICOM, such as RAM, defrosting, etc., to be restarted from the initial state

when power is interrupted or restored. A LOW signal applied to the reset terminal for 10 ms causes the MICOM to reset

itself. During normal operation, the voltage at the reset terminal is 5 Vdc. If the reset fails, the MICOM will not operate.

EXPLANATION FOR MICOM CIRCUIT

- 31 -

GR-L267

****

GR-L267

****

Page 32

1-4. Load/dispenser operation, door opening circuit

1. LOAD DRIVING CIRCUIT

✽ The fan operates at the regular speed even if the door of the refrigerator or freezer is opened. When the doors are closed,

the fan reverts to its original speed.

✽ (A), (B), (C), and (D) of door switch for the freezer or refrigerator are connected to the door open sensing circuit in parallel

toward both ends of switch to determine door open at MICOM.

✽ In the TEST mode, the fan will stop if any door is opened. It will resume operation when the door is closed.

1) GR-L267

****

EXPLANATION FOR MICOM CIRCUIT

- 32 -

REF

REF

Measuring part (IC6) IC6-14 IC6-10 IC7-16 IC6-13 IC6-11 IC6-12

Status

ON Within 1 V

OFF 12 V

Type of Load Compressor

Frost Removal

Heater

AC Converting

Relay

Refrigerator

LAMP

Dispensor

Heater

Magic room

Heater

Page 33

2. Dispenser operation circuit

1) Check load driving status

2) Lever Switch sensing circuit

EXPLANATION FOR MICOM CIRCUIT

- 33 -

Measuring part

Lever S/W

IC1(Micom) (No. 16)

On(Press)

OFF 5V

Measuring part IC7-15 IC7-14 IC7-13 IC7-12

Status

ON Within 1 V

OFF 12 V

Type of Load

GEARED

MOTOR

SOLENOID

CUBE

WATER VALVE

WATER

SOLENOID

DISPENSER

5 V

0 V

(60 Hz)

Page 34

3. Door opening sensing circuit

1) GR-L267

****

✽ Since door switches (A) and (B) are interconnected, if either fails, the other will not respond properly.

✽ If either switch fails, the light will not come on.

EXPLANATION FOR MICOM CIRCUIT

- 34 -

Closing 5 V ( A - B , C - D . Switch at both ends are at Off status)

Opening 5 V ( A - B , C - D . Switch at both ends are at On status)

Measuring part

IC1 (MICOM) No. 47, 46 Pin

Door of Freezer / Refrigerator

Page 35

1-5. Temperature sensing circuit

1) GR-L267

****

The circuits involving the freezer and refrigerator sensors controls the temperature in both the freezer and the refrigerator.

The Icemaker sensor detects when ice is made. The defrost sensor determines both the need for defrosting and the

efficiency of the defrost operation. See the table below for voltages and checkpoints.

EXPLANATION FOR MICOM CIRCUIT

- 35 -

SENSOR CHECK POINT

NORMAL(-30 °C ~ 50 °C) IN

SHORT IN OPEN

Freezing sensor POINT A Voltage

Defrost sensor POINT B Voltage

Refrigerator sensor 1 POINT C Voltage

Refrigerator sensor 2 POINT D Voltage 0.5 V~4.5 V 0 V 5 V

Room temperature sensor POINT E Voltage

Water tank sensor POINT F Voltage

Optichill sensor POINT G Voltage

ROOM-SENSOR

WATER TANK

-SENSOR

FRZ-SENSOR

DEFROST-

SENSOR

REF-UPPER-

SENSOR

REF-LOWER-

SENSOR

OPTICHILL-

SENSOR

Page 36

1-6. Switch entry circuit

The following circuits are sensing signal form the test switch, damper motor reed switch for testing and diagnosing the

refrigerator.

1) GR-L267

****

1-7. Option designation circuit (model separation function)

1) GR-L267

****

The circuits shown above vary according to which features are included on your particular model.

uThese circuits are preset at the factory and cannot be altered.

NOTE: The chart makes absolutely no sense. You have Optichill no matter which way the connection is set.

EXPLANATION FOR MICOM CIRCUIT

- 36 -

P34

37

R25

CC10

223

R24

48

P47

P46

47

Separation Connection Status Application Standard

Connection OptiChill exist

OP1

OUT OptiChill don’t exist

Page 37

1-8. Stepping motor operation circuit

The motor is driven by magnetism formed in the areas of the coils and the stator. Rotation begins when a HIGH signal is

applied to MICOM Pin 33 of IC10 (TA7774F). This causes an output of HIGH and LOW signals on MICOM pins 34 and 35.

Explanation) The stepping motor is driven by sending signals of 3.33 mSEC via MICOM pins 33, 34, and 35, as shown in

the chart below. These signals are output via terminals 10, 11, 14, and 15 via input terminals 3, 6, and 8 of

IC10 (TA7774F), the motor drive chip. The output signals allow the coils wound on each phase of the stator to

form a magnetic field, which causes rotation. Input to the terminals INA and INB of IC10 as shown in the chart

below drives the motor.

EXPLANATION FOR MICOM CIRCUIT

- 37 -

TA7774F

CON9

R56

R57 R58

INA

INB

A

B

A

B

CCW (Reverse rotation) (Positive rotation) CW

Page 38

1-9. Fan motor driving circuit (freezer, mechanical area)

1. The circuit cuts all power to the fan drive IC, resulting in a standby mode.

2. This circuit changes the speed of the fan motor by varying the DC voltage between 7.5 Vdc and 16 Vdc.

3. This circuit stops the fan motor by cutting off power to the fan when it senses a lock-up condition.

1) GR-L267

****

EXPLANATION FOR MICOM CIRCUIT

- 38 -

a , d part b part e part c , f part

Motor OFF 5V 2V or less 2V or less 0 V

Motor ON 2 ~ 3V 12 ~ 14V 8 ~ 16V 0 V

COMPRESSOR

-FAN PWM

COMPRESSOR

-FAN LOCK

FREEZER-FAN PWM

FREEZER-FAN LOCK

Page 39

1-10. Temperature compensation and temperature compensation circuit

1. Temperature compensation in freezer and refrigerator

1) GR-L267

****

u Temperature compensation table by adjustment value (difference value against current temperature)

Ex) If you change compensation resistance at a refrigerator (RCR1) from 10 kΩ (current resistance) to 18 kΩ (modified

resistance), the temperature at the cold storage will increase by +1°C[+1.8°F].

EXPLANATION FOR MICOM CIRCUIT

- 39 -

Temperature compensation at refrigerator

Temperature compensation at freezer

R16 R17

Freezer Refrigerator

Resistance value Temperature Resistance value Temperature Remarks

(RCF1) compensation (RCR1) compensation

180 kΩ +5 °C [+9°F] 180 kΩ +2.5 °C [+4.5°F] Warmer

56 kΩ +4 °C [+7.2°F] 56 kΩ +2.0 °C [+3.6°F]

33 kΩ +3 °C [+5.4°F] 33 kΩ +1.5 °C [+2.7°F]

18 kΩ +2 °C [+3.6°F] 18 kΩ +1.0 °C [+1.8°F]

12 kΩ +1 °C [+1.8°F] 12 kΩ +0.5 °C [+0.9°F]

10 kΩ 0 °C [0°F] 10 kΩ 0 °C [0°F]

Reference temperature

8.2 kΩ -1 °C [-1.8°F] 8.2 kΩ -0.5 °C [-0.9°F]

5.6 kΩ -2 °C [-3.6°F] 5.6 kΩ -1.0 °C [-1.8°F]

3.3 kΩ -3 °C [-5.4°F] 3.3 kΩ -1.5 °C [-2.7°F]

2 kΩ -4 °C [-7.2°F] 2 kΩ -2.0 °C [-3.6°F]

470 Ω -5 °C [-9°F] 470 Ω -2.5 °C [-4.5°F] Cooler

Page 40

u Temperature compensation table at the refrigerator is as follows:

u Temperature compensation at the freezer is performed the same as at the refrigerator. The value for the freezer is twice

that of the refrigerator.

u This circuit enters the necessary level of temperature compensation for adjusting the appliance. The method is the same

for every model in this appliance family.

EXPLANATION FOR MICOM CIRCUIT

- 40 -

470 Ω 2 kΩ 3.3 kΩ 5.6 kΩ 8.2 kΩ 10 kΩ 12 kΩ 18 kΩ 33 kΩ 56 kΩ 180 kΩ

No 0.5 °C1 °C 1.5 °C2 °C 2.5 °C3 °C 3.5 °C4 °C 4.5 °C5 °C

470Ω [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F] [4.5 °F] [5.4 °F] [6.3 °F] [7.2 °F] [8.1 °F] [9 °F]

change

Up Up Up Up Up Up Up Up Up Up

0.5 °C No 0.5 °C1 °C 1.5 °C2 °C 2.5 °C3 °C 3.5 °C4 °C 4.5 °C

2 kΩ [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F] [4.5 °F] [5.4 °F] [6.3 °F] [7.2 °F] [8.1 °F]

Down change

Up Up Up Up Up Up Up Up Up

1 °C 0.5 °C No 0.5 °C1 °C 1.5 °C2 °C 2.5 °C3 °C 3.5 °C4 °C

3.3 kΩ [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F] [4.5 °F] [5.4 °F] [6.3 °F] [7.2 °F]

Down

Down

change

Up Up Up Up Up Up Up Up

1.5 °C1 °C 0.5 °C No 0.5 °C1 °C 1.5 °C2 °C 2.5 °C3 °C 3.5 °C

5.6 kΩ [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F] [4.5 °F] [5.4 °F] [6.3 °F]

Down Down Down

change

Up Up Up Up Up Up Up

2 °C 1.5 °C1 °C 0.5 ° No 0.5 °C1 °C 1.5 °C2 °C 2.5 °C3 °C

8.2 kΩ [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F] [4.5 °F] [5.4 °F]

Refrigerator

Down Down Down

Drop

change

Up Up Up Up Up Up

(RCR1) 2.5 °C2 °C 1.5 °C1 °C 0.5 °C No 0.5 °C1 °C 1.5 °C2 °C 2.5 °C

10 kΩ [4.5 °F] [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F] [4.5 °F]

Down Down Down Down Down

change

Up Up Up Up Up

3 °C 2.5 °C2 °C 1.5 °C1 °C 0.5 °C No 0.5 °C1 °C 1.5 °C2 °C

12 kΩ [5.4 °F] [4.5 °F] [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F] [3.6 °F]

Down Down Down Down Down Down

change

Up Up Up Up

3.5 °C3 °C 2.5 °C2 °C 1.5 °C1 °C 0.5 °C No 0.5 °C1 °C 1.5 °C

18 kΩ [6.3 °F] [5.4 °F] [4.5 °F] [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F] [2.7 °F]

Down Down Down Down Down Down Down

change

Up Up Up

4 °C 3.5 °C3 °C 2.5 °C2 °C 1.5 °C1 °C 0.5 °C No 0.5 °C1 °C

33 kΩ [7.2 °F] [6.3 °F] [5.4 °F] [4.5 °F] [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F] [1.8 °F]

Down Down Down Down Down Down Down Down

change

Up Up

4.5 °C4 °C 3.5 °C3 °C 2.5 °C2 °C 1.5 °C1 °C 0.5 °C No 0.5 °C

56 kΩ [8.1 °F] [7.2 °F] [6.3 °F] [5.4 °F] [4.5 °F] [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F] [0.9 °F]

Down Down Down Down Down Down Down Down Down

change

Up

5 °C 4.5 °C4 °C 3.5 °C3 °C 2.5 °C2 °C 1.5 °C1 °C 0.5 °CNo

180 kΩ [9 °F] [8.1 °F] [7.2 °F] [6.3 °F] [5.4 °F] [4.5 °F] [3.6 °F] [2.7 °F] [1.8 °F] [0.9 °F]

Down Down Down Down Down Down Down Down Down Down

change

Modification

resistance

Current

resistance

Page 41

2. Compensation circuit for temperature at freezer

1) GR-L267

****

u This circuit allows adjustment of the set temperature for compensation by changing jumpers at locations JCR1~JCR4.

EXPLANATION FOR MICOM CIRCUIT

- 41 -

R18

R19

R20

R21

R22

R23

Compensation Compensation

for weak-cold for over-cold

Temperature compensation value

Remarks

JCR3 JCR4 JCR1 JCR2

at refrigerator

0 °C (In shipment from factory)

CUT -1 °C [-1.8 °F]

CUT -1 °C [-1.8 °F]

CUT +1 °C [+1.8 °F]

CUT +1 °C [+1.8 °F]

CUT CUT -2 °C [-3.6 °F]

CUT CUT +2 °C [+3.6 °F]

CUT CUT 0 °C [0 °F]

CUT CUT 0 °C [0 °F]

CUT CUT 0 °C [0 °F]

CUT CUT 0 °C [0 °F]

CUT CUT CUT -1 °C [-1.8 °F]

CUT CUT CUT +1 °C [+1.8 °F]

CUT CUT CUT CUT 0 °C [0 °F]

Temperature compensation in CUT

JCR1 +1 °C [+1.8 °F]

+2 °C [+3.6 °F]

JCR2 +1 °C [+1.8 °F]

JCR3 -1 °C [-1.8 °F]

-2 °C [-3.6 °F]

JCR4 -1 °C [-1.8 °F]

Page 42

1-11. Communication circuit and connection L/Wire between main PCB and display PCB

The following communication circuit is used for exchanging information between the main MICOM of the Main PCB and the

dedicated MICOM of the LED (LCD) Display PCB.

A bi-directional lead wire assembly between the two boards is required for the display to function properly.

Poor communication occurs if a continuous information exchange fail to continue for more than 2 minutes between main

MICOM of main PCB and LCD (LED) dedicated MICOM for LCD (LED) control of display PCB.

1) GR-L267

****

EXPLANATION FOR MICOM CIRCUIT

- 42 -

ICEBEAM

COOLING

OFF

CUBE

FILTER

MONTH

EXPRESS/JET FRZ DISPENSER FREEZER REFRIGERATOR FILTER/LIGHT LOOK

ROOM TEMP

DISPENSER & KEY

F

WATER 5

4

3

2

1

CRUSH

F F

3 SECS

PWB ASSEMBLY DISPLAY

Main MICOM LCD(LED) dedicated MICOM

DC 12V

GND

Transmission (error status)

Reception (notch status)

Main PCB L/Wire FD/H(4-wires) Display PCB

Page 43

2) Sensor resistance characteristics table

u Resistance value allowance of sensor is ±5%.

u When measuring the resistance value of the sensor, allow the temperature of that sensor to stabilize for at least 3 minutes

before measuring. This delay is necessary because of the sense speed relationship.

u Use a digital tester to measure the resistance. An analog tester has to great a margin of error.

u Resistance of the cold storage sensor 1 and 2 shall be measured with a digital tester after separating CON8 of the PWB

ASSEMBLY and the MAIN part.

u Resistance of the freezing sensor shall be measured with a digital tester after separating CON7 of the PWB ASSEMBLY

and the MAIN part.

EXPLANATION FOR MICOM CIRCUIT

- 43 -

Measuring T emperature (°C) Freezing Sensor

Cold storage sensor 1&2

Frost removal sensor, Outside sensor

-20 °C 22.3 kΩ 77 kΩ

-15 °C 16.9 kΩ 60 kΩ

-15 °C 13.0 kΩ 47.3 kΩ

-5 °C 10.1 kΩ 38.4 kΩ

0 °C 7.8 kΩ 30 kΩ

+5 °C 6.2 kΩ 24.1 kΩ

+10 °C 4.9 kΩ 19.5 kΩ

+15 °C 3.9 kΩ 15.9 kΩ

+20 °C 3.1 kΩ 13 kΩ

+25 °C 2.5 kΩ 11 kΩ

+30 °C 2.0 kΩ 8.9 kΩ

+40 °C 1.4 kΩ 6.2 kΩ

+50 °C 0.8 kΩ 4.3 kΩ

Page 44

1-12. OptiChill stepping MOTOR/Display

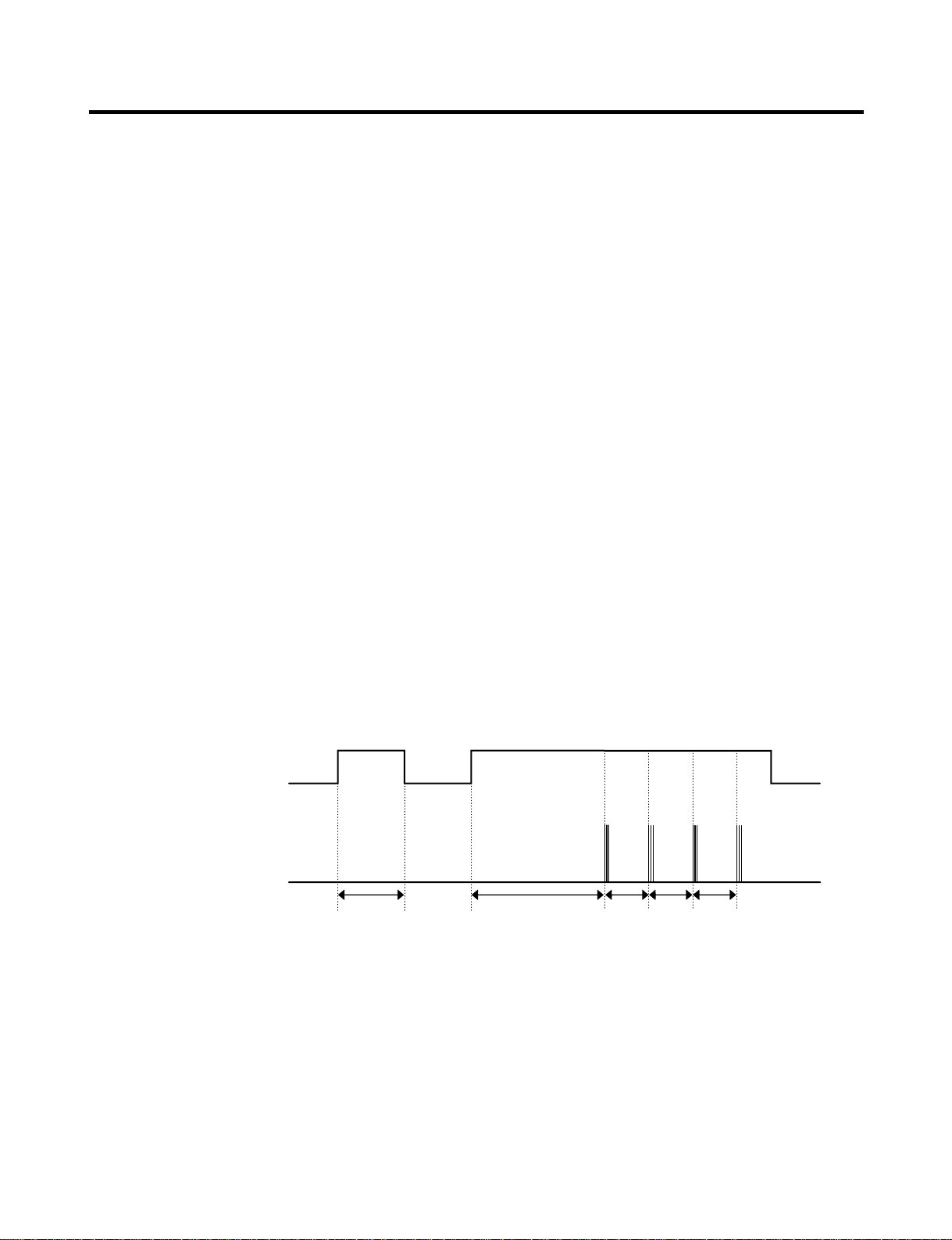

1) GR-L267AV(T)BA, GR-L267AV(T)FA MODEL

1-13. Jet freezing

1) GR-L267AV(T)BA, GR-L267AV(T)FA MODEL

EXPLANATION FOR MICOM CIRCUIT

- 44 -

DAMPER HEATER

OPTICHILL

OPTICHILL

STEPPING

MOTOR

OPTICHILL

SENSOR

PW B ASSEM BLY D ISPLA Y

JET/FREEZER

BOX FAN MOTOR

Page 45

2. PWB parts diagram and list

2-1. PWB Assembly, main part diagram

1. GR-L267

****

EXPLANATION FOR MICOM CIRCUIT

- 45 -

Page 46

2-2. Parts list

1. GR-L267

****

EXPLANATION FOR MICOM CIRCUIT

- 46 -

Page 47

EXPLANATION FOR MICOM CIRCUIT

- 47 -

Page 48

2-3. GR-L267AV(T)BA

1. DISPLAY ASSEMBLY part diagram

EXPLANATION FOR MICOM CIRCUIT

- 48 -

Page 49

2. DISPLAY circuit diagram

EXPLANATION FOR MICOM CIRCUIT

- 49 -

Page 50

2-4. GR-L267AV(T)FA, GR-L267AV(T)RA, GR-L267D(A)TR

1. DISPLAY ASSEMBLY part diagram

EXPLANATION FOR MICOM CIRCUIT

- 50 -

Page 51

2. DISPLAY circuit diagram

EXPLANATION FOR MICOM CIRCUIT

- 51 -

PW B ASSE M B LY DISPL AY

Page 52

3. PWB Circuit Diagram may vary according to model.

1. GR-L267

****

EXPLANATION FOR MICOM CIRCUIT

- 52 -

REF-

REF-

Page 53

EXPLANATION FOR MICOM CIRCUIT

- 53 -

ROOM-SENSOR

WATER TANK

-SENSOR

FREEZER-SENSOR

DEFROST-SENSOR

FRZ-DOOR SWITCH

JET FREEZER

BOX FAN MOTOR

PCB ASSE M B LY D ISPLAY

PCB A SSEM B LY D ISPL AY

REF-DOOR SWITCH

REF-UPPER-SENSOR

REF-LOWER-SENSOR

DAMPER HEATER

OPTICHILL

OPTICHILL

STEPPING

MOTOR

OPTICHILL

BOX FAN MOTOR

OPTICHILL SENSOR

Page 54

1. Operation Principle

1-1. Operation Principle of Icemaker

1. Turning the Icemaker stop switch off (O) stops the icemaking function.

2. Setting the Icemaker switch to OFF and then turning it back on will reset the icemaker control.

OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER

- 54 -

• Adjusts EJECTOR to Start Position with power on.

Power On

Start Position

Icemaking

Mode

Dump

Mode

Park Position

Fill

Test Mode

• Waits until water becomes cold after starting the

ice making operation.

• Runs MOTOR to drop ice from the tray to the ICE BIN.

• Performs Icemaking Mode after supplying water by operating

the SOLENOID in ICE VALVE.

• To operate LINE and SERVICE, press and hold the water supply

control switch for 3 seconds. The icemaker will run through

3 stages:

Dump Fill Icemaking.

• With the detect lever, checks if the ICE BIN is full.

Page 55

2. Control Method according to Functions

2-1. Start Position

1. After POWER OFF or Power Outage, check the EJECTOR's position with MICOM initialization to restart.

2. How to check if it is in place:

- Check HIGH/LOW signals from HALL SENSOR in MICOM PIN.

3. Control Method to check if it is in place:

(1) EJECTOR is in place,

- It is an initialized control, so the mode can be changed to ice making control.

(2) EJECTOR isn't in place:

A. If EJECTOR is back in place within 2 minutes with the motor on, it is being initialized. If not, go to Step B.

B. If EJECTOR is back in place within 18 minutes with the heater on (to control Heater on its OFF condition), it is being

initialized. If not, it is not functioning. Repeat Step B with Heater and Motor off.

2-2. Icemaking Mode

1. Icemaking control refers to the freezing of supplied water in the ice trays. Complete Icemaking operations by measuring

the temperature of the Tray with Icemaking SENSOR.

2. Icemaking starts after completing fulfilled ice control and initial control.

3. The Icemaking function is completed when the sensor reaches 19°F(-7°C), 60 to 240 minutes after starting.

4. If the temperature sensor is defective, the Icemaking function will be completed in 4 hours.

2-3. Harvest with Dump Mode

1. Harvest with Dump control refers to the operation of dropping cubes into the ice bin from the tray when Icemaking has

completed.

2. Harvest with Dump control mode:

(1) Operates Heater for 30 seconds; then operate MOTOR.

(2) After performing Step 1 (to control the Heater on its off condition), Ice-Removal control will be back in place wthin 18

minutes. (Hall SENSOR sign = OV). Ice removal is then complete. Then change the mode to the water supply control.

If this control phase fails to start, it is not functioning. Put the Heater and Motor in the off position. Restart every 2

hours. (Refer to fig.1)

NOTE : If the motor malfunctions and starts before the detect lever rises, MICOM regards the Ice-Removing phase as

completed. Water then starts flowing. To prevent this, MICOM doesn’t switch to water-supply mode, but restarts the iceremoving mode. If this happens 3 times, the motor is malfunctioning and you should stop the loads (Heater, Motor). Then

restart the Ice-Removing mode every 2 hours. (See Step 2 above.)

OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER

- 55 -

Heater

on

off

on

0V

5V

off

30 sec.

10 sec.

Motor

Hall IC

Ice removing

completion point

2 ms

Icemaking sensor temperature is 50°F(10˚C)

or more

Max. 18 minutes

After detect LEVER rises

Page 56

2-4. Fill / Park Position

1. When Ice-Removing control (Normal Ice-Removing control, Ice-Removing control for test) has completed, and the

EJECTOR is in place, this control operates the ICE SOLENOID by time check in the compressor enclosure of the