Page 1

System

Heat Pump Indoor Unit

INSTALLATION MANUAL

LG

MODELS : SE/S3 Series

Type : ART COOL Mirror

IMPORTANT

• Please read this installation manual completely

before installing the product.

• Installation work must be performed in accordance

with the national wiring standards by authorized

personnel only.

• Please retain this installation manual for future

reference after reading it thoroughly.

ENGLISH ITALIANO ESPAÑOL FRANÇAIS DEUTSCH

Page 2

2 Indoor Unit

Artcool Deluxe Type Indoor Unit Installation Manual

TABLE OF CONTENTS

❏ Installation guide map

❏Four type "A" screws & plastic

anchors

❏Connecting cable

❏Pipes: Gas side

Liquid side

(Refer to Product Data)

❏Insulation materials

❏Additional drain pipe

❏Two type "B" screws

❏Level gauge

❏Screw driver

❏Electric drill

❏Hole core drill

❏Horizontal meter

❏Flaring tool set

❏Specified torque wrenches

(different depending on model No.)

❏Spanner.......Half union

❏A glass of water

❏Screw driver

❏Hexagonal wrench

❏Gas-leak detector

❏Vacuum pump

❏Gauge manifold

❏Owner's manual

❏Thermometer

❏Holder Remote Controller

Installation Parts ....................3

Safety Precautions.................4

Installation

Selection of the best location

................................................7

Piping Method........................8

Drain Piping .........................12

Wiring Connection...............13

Installation of Remote

Controller..............................14

Installation Requirements

Required Parts Required Tools

Page 3

Installation Manual 3

Installation Parts

ENGLISH

Installation Plate

Installation Plate

Type "A" screws and plastic anchorsType "A" screws and plastic anchors

Installation plate

Type 1

Type 1 Type 2

Type 2

Installation Parts

Page 4

4 Indoor Unit

Safety Precautions

Safety Precautions

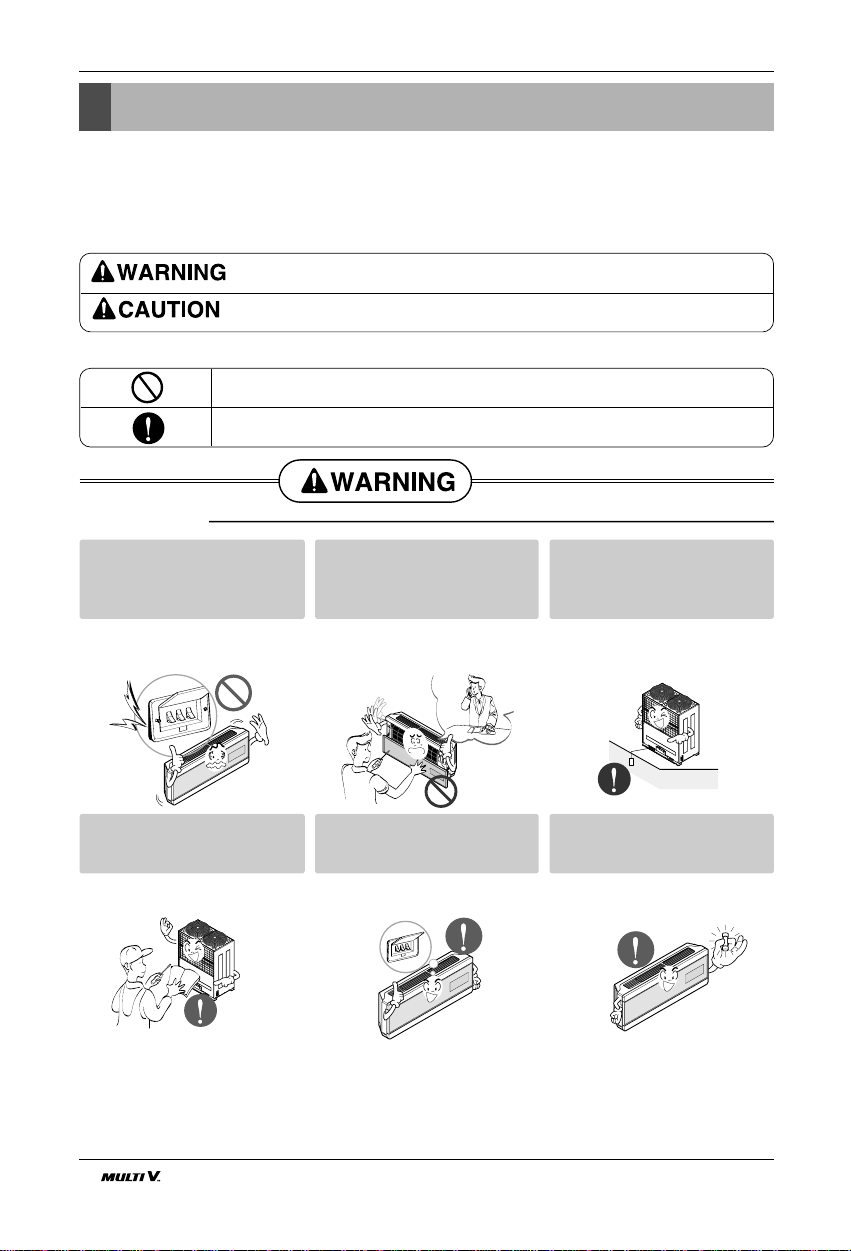

To prevent injury to the user or other people and property damage, the following instructions must be followed.

■ Be sure to read before installing the air conditioner.

■ Be sure to observe the cautions specified here as they include important items related to safety.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the

following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

Do not use a defective or underrated circuit breaker. Use this

appliance on a dedicated circuit.

• There is risk of fire or electric shock.

For electrical work, contact the

dealer, seller, a qualified electrician, or an Authorized Service

Center.

• Do not disassemble or repair the

product. There is risk of fire or electric shock.

Always ground the product.

• There is risk of fire or electric shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may

cause fire or electric shock

Use the correctly rated breaker

or fuse.

• There is risk of fire or electric shock.

Page 5

Installation Manual 5

Safety Precautions

ENGLISH

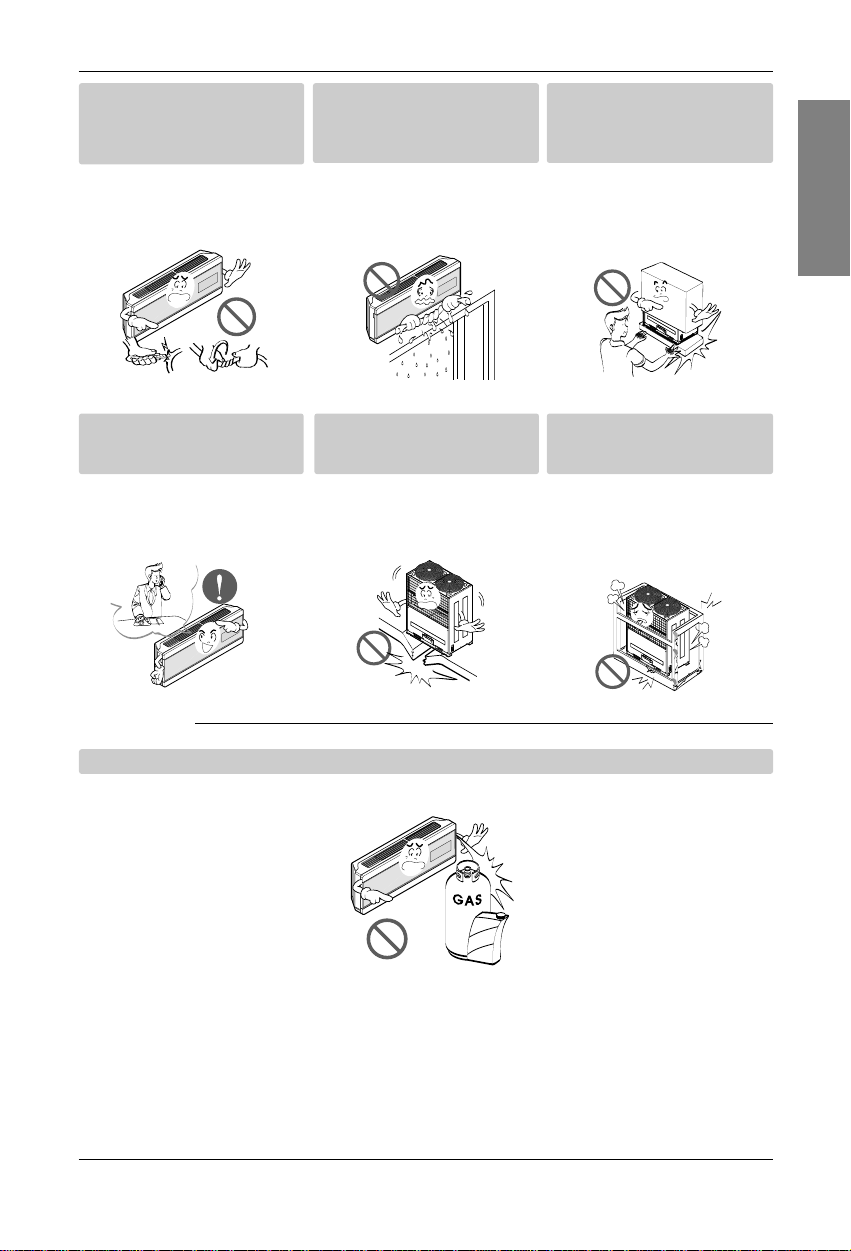

■ Operation

Do not modify or extend the

power cable.

• There is risk of fire or electric shock.

Do not let the air conditioner

run for a long time when the

humidity is very high and a door

or a window is left open.

• Moisture may condense and wet or

damage furniture.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury. Be

especially careful of the case edges

and the fins on the condenser and

evaporator.

For installation, always contact

the dealer or an Authorized

Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing property damage, product failure, and

personal injury.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

Gasolin

Page 6

6 Indoor Unit

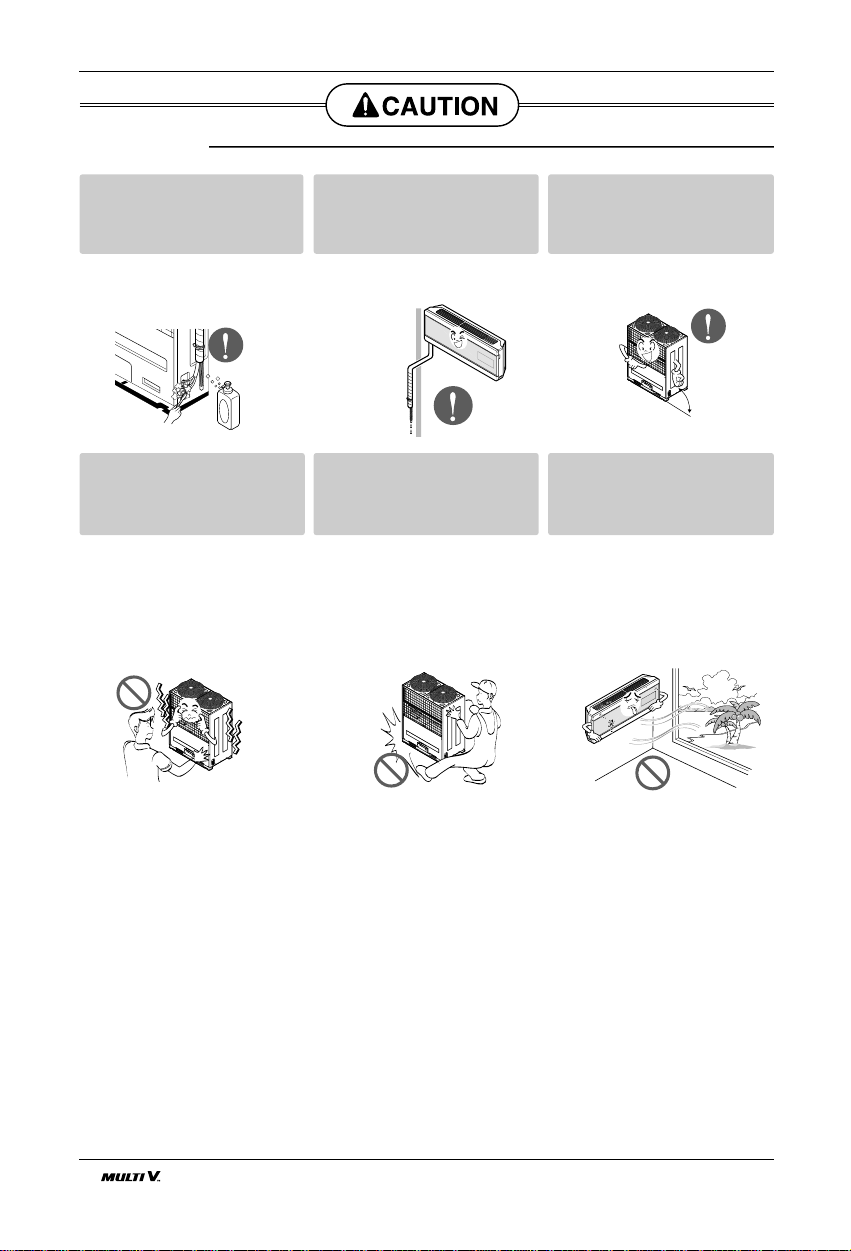

Safety Precautions

Always check for gas (refrigerant) leakage after installation or

repair of product.

• Low refrigerant levels may cause

failure of product.

Install the drain hose to ensure

that water is drained away properly.

• A bad connection may cause water

leakage.

Keep level even when installing

the product.

• To avoid vibration or water leakage.

Do not install the product where

the noise or hot air from the outdoor unit could damage the

neighborhoods.

• It may cause a problem for your

neighbors.

Use two or more people to lift

and transport the product.

• Avoid personal injury.

Do not install the product where

it will be exposed to sea wind

(salt spray) directly.

• It may cause corrosion on the product.

Corrosion, particularly on the condenser and evaporator fins, could

cause product malfunction or inefficient

operation.

■ Installation

90˚

Page 7

Installation Manual 7

Installation

ENGLISH

Read completely, then follow step by step.

Installation

Selection of the best location

CAUTION : In case that the unit is installed near the sea, the installation parts

may be corroded by salt. The installation parts (and the unit) should be taken

appropriate anti-corrosion measures.

• There should not be any heat source or steam

near the unit.

• There should not be any obstacles to prevent the

air circulation.

• A place where air circulation in the room will be

good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the

wall, ceiling, fence, or other obstacles.

The mounting wall should be strong and solid

enough to protect it from the vibration.

Mount the installation plate on the wall with four

Type "A" screws.

(If mounting the unit on the concrete wall, consider using anchor bolts.)

• Always mount the Installation plate horizontally

by aligning the marking-off line by means of the

thread and a level.

More than 10 cm

More than 50 cm

More than 2.3m

More than 50 cm

Chassis

Hook

Installation Plate

Type “A”

Type 2

(SE chassis)

Type 1

(S3 chassis)

Installation Plate

The lower left and the right side of Installation Plate

(S3 chassis)

Type 1

155mm

Ø70mm

306mm

Left rear piping Right rear piping

Installation plate

78mm

155mm

Ø70mm

Type 2

(SE chassis)

110mm

Ø70mm

85mm

Left rear piping Right rear piping

Installation plate

65mm

110mm

Ø70mm

Page 8

8 Indoor Unit

Installation

Piping Method

■ Preparing the indoor unit's piping and drain hose for

installation through the wall.

■ Remove the plastic tubing retainer(see illustration

below) and pull the tubing and drain hose away from

chassis.

■ Replace the plastic tubing holder in the original position.

1. Route the indoor tubing and the drain hose in the

direction of rear left.

2. Insert the connecting cable into the indoor unit

from the outdoor unit through the piping hole.

■ Do not connect the cable to the indoor unit.

■ Make a small loop with the cable for easy connection

later.

3. Tape the tubing, drain hose and the connecting

cable. Be sure that the drain hose is located at the

lowest side of the bundle. Locating at the upper

side can cause drain pan to overflow inside the

unit.

: If the drain hose is routed inside the room,

insulate the hose with an insulation material* so that dripping from "sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

4. Indoor unit installation

■ Hook the indoor unit onto the upper portion of the

installation plate.(Engage the two hooks of the rear

top of the indoor unit with the upper edge of the

installation plate.) Ensure that the hooks are properly

seated on the installation plate by moving it left and

right.

Press the lower left and right sides of the unit against

the installation plate until the hooks engage into their

slots(clicking sound).

NOTICE

For right rear piping

• Drill the piping hole with a ø70mm hole core drill.

Drill the piping hole at either the right or the left

with the hole slightly slanted to the outdoor side.

Drill a Hole in the Wall

5-7mm

(3/16"~5/16")

Indoor

WALL

Outdoor

Tape

Connecting

pipe

Drain hose

Connecting cable

Drain hose

Connecting

cable

Drain hose

Page 9

Installation Manual 9

Installation

ENGLISH

5. Connecting the pipings to the indoor unit and drain

hose to drain pipe.

■ Align the center of the pipings and sufficiently tighten

the flare nut by hand.

■ Tighten the flare nut with a wrench.

■ Mount the clamp on the boss with a type "B"

screw.(optional)

■ When extending the drain hose at the indoor

unit, install the drain pipe.

6. Wrap the insulation material around the connecting portion.

■ Overlap the connection pipe insulation material

and the indoor unit pipe insulation material. Bind

them together with vinyl tape so that there is no

gap.

■ Wrap the area which accommodates the rear piping housing section with vinyl tape.

■ Bundle the piping and drain hose together by

wrapping them with vinyl tape over the range with-

in which they fit into the rear piping housing section.

1. Route the indoor tubing and the drain hose to the

required piping hole position.

2. Insert the piping, drain hose and the connecting

cable into the piping hole.

For left rear piping

GAS LIQUID

Ø12.7[5.5kg.m] Ø6.35[1.8kg.m]

Ø15.88[6.6kg.m] Ø9.52[4.2kg.m]

Pipe Size[Torque]

Indoor unit tubing

Flare nut Pipings

Spanner (fixed)

Flare nut

Torque

wrench

Indoor

unit tubing

Connection

pipe

Connection

pipe

Vinyl tape

(wide)

Connecting cable

Wrap with vinyl tape

Vinyl tape(narrow)

Pipe

Drain hose

Wrap with vinyl tape

Vinyl tape(wide)

Indoor

unit pipe

Pipe

Type "B" screw

Clamp

Boss

Drain hose

Drain pipe

Indoor unit

drain hose

Adhesive

Vinyl tape(narrow)

Plastic bands

Insulation material

Connecting cable

Drain pipe

Page 10

10 Indoor Unit

Installation

3. Insert the connecting cable into the indoor unit.

■ Don't connect the cable to the indoor unit.

■ Make a small loop with the cable for easy connec-

tion later.

4. Tape the drain hose and the connecting cable.

• Connecting cable

5. Indoor unit installation

■ Hang the indoor unit from the hooks at the top of

the installation plate.

■ Insert the spacer etc. between the indoor unit and

the installation plate and separate the bottom of

the indoor unit from the wall.

6. Connecting the pipings to the indoor unit and

the drain hose to drain pipe.

■ Align the center of the pipings and sufficiently

tighten the flare nut by hand.

■ Tighten the flare nut with a wrench.

■ When extending the drain hose at the indoor unit,

install the drain pipe.

7. Wrap the insulation material around the connecting portion.

■ Overlap the connection pipe heat insulation and

the indoor unit pipe heat insulation material. Bind

them together with vinyl tape so that there is no

gap.

■ Wrap the area which accommodates the rear pip-

ing housing section with vinyl tape.

Vinyl tape

Adhesive

Drain hose

Indoor unit drain hose

(narrow)

Plastic bands

Insulation material

Vinyl tape

(narrow)

Connection

pipe

Connecting

cable

Indoor

unit piping

Pipe

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor unit tubing

Flare nut Pipings

Torque

wrench

Indoor

unit tubing

Spanner (fixed)

Connection

pipe

Flare nut

Installation plate

Spacer

Indoor unit

8cm

GAS LIQUID

Ø12.7[5.5kg.m] Ø6.35[1.8kg.m]

Ø15.88[6.6kg.m] Ø9.52[4.2kg.m]

Pipe Size[Torque]

Page 11

Installation Manual 11

Installation

ENGLISH

■ Bundle the piping and drain hose together by

wrapping them with cloth tape over the range

within which they fit into the rear piping housing

section.

8. Reroute the pipings and the drain hose across

the back of the chassis.

9. Set the pipings and the drain hose to the back of

the chassis with the tubing holder.

■ Hook the edge of tubing holder to tap on chassis

and push the bottom of tubing holder to be

engaged at the bottom of chassis.

10. Indoor unit installation

■ Remove the spacer.

■ Ensure that the hooks are properly seated on the

installation plate by moving it left and right.

Press the lower left and right sides of the unit

against the installation plate until the hooks engage

into their slots(clicking sound).

Drain hose

Vinyl tape

(narrow)

Pipe

Wrap with

vinyl tape(wide)

Piping for

passage through

piping hole

Tubing holder

Drain hose

Connecting

cable

Installation Information (For left piping)

• Good case

For left piping. Follow the instruction below.

■

Press on the upper side of clamp. ( )

■

Unfold the tubing to downward slowly. ( )

CAUTION

Page 12

12 Indoor Unit

Installation

Drain Piping

1. To remove the front panel from the indoor unit,

remove the front panel from the indoor unit

cabinet.

■ Set the air direction louvers up-and-down to the

position(horizontally) by hand.

■ Remove the securing screws that retain the front

panel. Pull the lower left and right sides of the grille

toward you and lift it off.

2. To check the drainage.

■ Pour a glass of water on the evaporator.

■ Ensure the water flows through the drain hose of

the indoor unit without any leakage and goes out

the drain exit.

■

The drain hose should point downward for easy drain

flow.

• Bad case

■

Following bending type from right to left could cause

problem of pipe damage.

CAUTION

Air

filter

Inlet Grille

Front panel

Type 1

Type 2

Connecting area

drain hose

Leakage

checking

Type 1

Type 2

Downward slope

Do not raise

Accumulated

drain water

Tip of drain hose

dipped in water

Air

Waving

Water

leakage

Water

leakage

Ditch

Less than

50mm gap

Water

leakage

■ Do not make drain piping.

Page 13

ENGLISH

Installation Manual 13

Installation

CAUTION:

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power circuit specifically for the air conditioner. As for the

method of wiring, be guided by the circuit diagram posted on the inside of control cover.

2) The screw which fasten the wiring in the casing of electrical fittings are liable to come loose from

vibrations to which the unit is subjected during the course of transportation. Check them and

make sure that they are all tightly fastened. (If they are loose, it could cause burn-out of the

wires.)

3) Specification of power source.

4) Confirm that electrical capacity is sufficient.

5) See to that the starting voltage is maintained at more than 90 percent of the rated voltage marked

on the name plate.

6) Confirm that the cable thickness is as specified in the power source specification.

(Particularly note the relation between cable length and thickness.)

7) In a wet or moist area, always install an earth leakage circuit breaker.

8) The following would be caused by voltage drop.

• Vibration of a magnetic switch, which will damage the contact point, fuse breaking, disturbance of the

normal function of the overload.

9) The means for disconnection from a power supply shall be incorporated in the fixed wiring and

have an air gap contact separation of at least 3mm in each active(phase) conductors.

Wiring Connection

Connect the wires to the terminals on the control

board individually according to the outdoor unit

connection.

• Ensure that the color of the wires of outdoor unit

and the terminal No. are the same as those of

indoor unit respectively.

Terminal Block Indoor

1(L) 2(N) 3 4

INDOOR POWER INPUT

Terminal Block Outdoor

ABC D Vcc

Connecting cable

Page 14

14 Indoor Unit

Installation

1. Remove the battery cover from the remote

controller.

• Slide the cover according to the arrow

direction.

2. Insert the two batteries.

• Be sure that the (+) and (-) directions are

correct.

• Be sure that both batteries are new.

3. Re-attach the cover.

• Slide it back into position.

HOW TO MOUNT ONTO A WALL

HOW TO INSERT BATTERIES

• Do not use rechargeable batteries,

such batteries differ from standard

dry cells in shape, dimensions, and

performance.

• Romove the batteries from the

remote controller if the air conditioner is not going to be used for some

long time.

Installation of Remote Controller

Page 15

Installation Manual 15

Installation

ENGLISH

Remote controller

box body

Cord clamp

(accessory)

Lever carefully

the box open

using a screw

driver, etc.

Front case

The lower part

Face of wall

Under plate

Screw (accessory)

• Separate the under plate from Remote

controller box.

• Attach insulator to under plate.

• Fix the under plate on the wall

•

Fix the cord clamps on the wall by ø 3 tapping screws (accessory).

•

Fix the remote controller cord.

WIRED REMOTE CONTROLLER INSTALLATION

DISASSEMBLING

ELECTRICAL WIRING

Wire and make sure that teminal

numbers are matched on unit side and

remote controller side.

The maximum length of the cord is 100m.

If the length of the cord exceeds 50m,

use a wire size greater than 0.5mm

2

.

Remote controller

(Main board)

CN REMO

• Although the room temperature sensor is in the indoor unit, the remote controller should be installed in such

places away from direct sunlight and high humidity.

Installation of the remote controller

• Select places that are not splashed with water.

• Select controller position after receiving customer approval.

• The room temperature sensor is built in the indoor unit.

• This remote controller equipped with liquid crystal display. If this position is higher or lower, display is difficult

to see.(The standard height is 1.2 ~1.5m high)

Routing of the remote controller cord

• Keep the remote controller cord away from the refrigerant piping and the drain piping.

• To protect the remote controller cord from electrical noise, place the cord at least 5cm away from other

power cables. (audio equipment. television set, etc.)

• If the remote controller cord is secured to the wall, provide a trap at the top of the cord to prevent water

droplets from running.

Installation of Remote Control

Page 16

16 Indoor Unit

Installation

You can choose the RPM(or air volume) of indoor

motor according to the height of ceiling to supply the

comfortable atmosphere to consumers.

Procedure

1. Choose the selectable position in the table after

measuring the height of ceiling.

2. In the case of changing the height as "high" or "low",

open the rear cover of the wired remote-controller.

3. Move the slide switch to the set position.

4. Close the rear cover and check if it works nomally.

2) Adjusting air volume to the height of ceiling

TH

R14H

SW TH

REMO

MAIN

2TH

OP7

R18H

R17H

OP6

LO

STAND

SW HIGH

HI

R03S

C070

R04S

R02S

R01S

OP3

OP2 OP1

R19H

R11H

R13H R12H

OP5R16H OP4

R15H

CO1H

Lo

Hi

STAND

Slide switch for ceiling height

Slide switch for 2 Thermistor

Standard

(Default)

Low ceiling

High Ceiling

Ceiling height Mode of slide switch Change of air volume Remark

more than 4.0m High Ceiling Increasing

3.2~4.0m Standard -

less than 3.2m Low Ceiling Decreasing

Maunfactured in stan-

dard mode

1) Two Thermistor System

(1) Open the rear cover of the wired remote-controller to

set the mode.

(2) Select one of three selectable modes as follows.

• Position 1:

The room temperature is controlled by the thermistor

of the main body.

• Position 2:

The room themperature is controlled by the thermistor of the wired remote-controller, control the temperature according to the position of wired remote-controller.

• Position 3:

The room temperature is controlled by lower temperature between the temperature of main body and of

remote-controller sensor.

(3) Move the slide switch to set position.

(4) Close the rear cover and check if it works normally.

TH

R14H

SW TH

REMO

MAIN

2TH

OP7

R18H

R17H

OP6

LO

STAND

SW HIGH

HI

R03S

C070

R04S

R02S

R01S

OP3

OP2 OP1

R19H

R11H

R13H R12H

OP5R16H OP4

R15H

CO1H

REMO

Room T emp. sensor

2TH

MAIN

Position 2

Position 1

Position 3

Slide switch for ceiling height

Slide switch for 2 Thermistor

Optional operation

CAUTION :

• Select the position after counselling with a customer.

In case of cooling mode, room temperature is controlled by the main body sensor.

• To control the room temperature by a wired remote controller, install the remote

controller (room temp. sensor) to sense the temperature more accurately.

• Maunfactured in the position 3.

Page 17

P/No.: 3828A20873F

Printed in Korea

After reading this manual, keep it in a place easily accessible to the user for future reference.

Loading...

Loading...