Page 1

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

REFRIGERATOR

SERVICE MANUAL

MODELS:

LRFD22850ST

LRFD22850SW

LRFD22850TT

Page 2

CONTENTS

SAFETY PRECAUTIONS ....................................................................................................................................................... 2

SPECIFICATIONS................................................................................................................................................................... 3

PARTS IDENTIFICATION ....................................................................................................................................................... 4

DISASSEMBLY.................................................................................................................................................................... 5-7

DOOR................................................................................................................................................................................ 5-6

TO REMOVE THE DISPENSER ...........................................................................................................................................6

FAN AND FAN MOTOR........................................................................................................................................................ 7

DEFROST CONTROL ASSEMBLY...................................................................................................................................... 7

LAMP.................................................................................................................................................................................... 7

CONTROL BOX-REFRIGERATOR ...................................................................................................................................... 7

MULTI DUCT........................................................................................................................................................................ 7

ADJUSTMENT..................................................................................................................................................................... 8-9

COMPRESSOR.................................................................................................................................................................... 8

PTC-STARTER ..................................................................................................................................................................... 8

OLP (OVERLOAD PROTECTOR)........................................................................................................................................ 9

TO REMOVE THE COVER PTC...........................................................................................................................................9

CIRCUIT DIAGRAM.............................................................................................................................................................. 10

TROUBLESHOOTING..................................................................................................................................................... 11-16

COMPRESSOR AND ELECTRIC COMPONENTS............................................................................................................ 11

PTC AND OLP.................................................................................................................................................................... 12

OTHER ELECTRICAL COMPONENTS ............................................................................................................................. 13

SERVICE DIAGNOSIS CHART.......................................................................................................................................... 14

REFRIGERATION CYCLE............................................................................................................................................ 15-16

OPERATION PRINCIPLE & REPAIR METHOD OF ICEMAKER .................................................................................. 17-20

DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ............................................................................................... 21-43

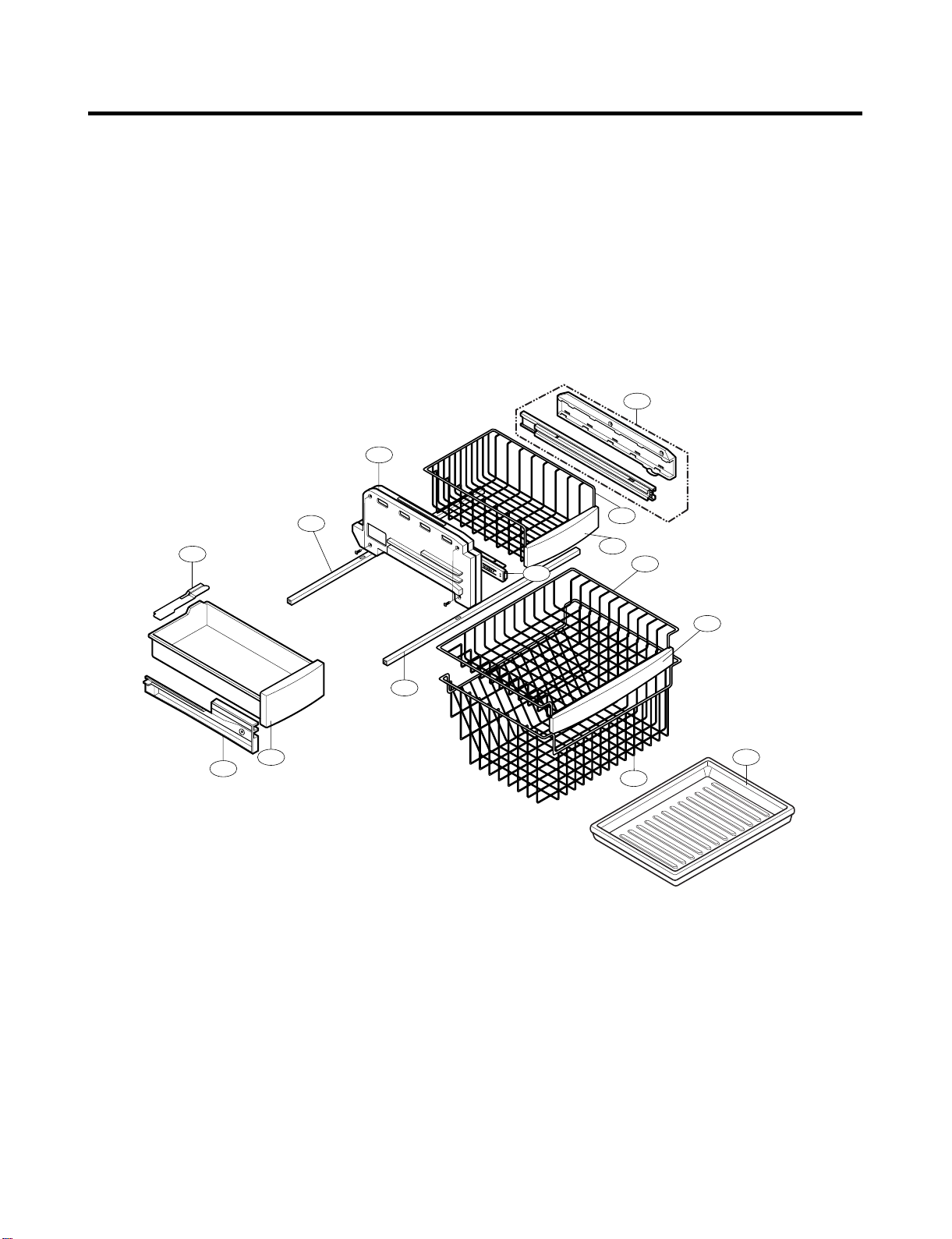

EXPLODED VIEW & REPLACEMENT PARTS LIST ..................................................................................................... 44-54

SAFETY PRECAUTIONS

Please read the following instructions before servicing your

refrigerator.

1. Check the refrigerator for current leakage.

2. To prevent electric shock, unplug before servicing.

3. Always check line voltage and amperage.

4. Use standard electrical components.

5. Don't touch metal products in the freezer with wet

hands. This may cause frostbite.

6. Prevent water from spiling onto electric elements or the

machine parts.

- 2 -

7. Before tilting the refrigerator, remove all materials from

on or in the refrigerator.

8. When servicing the evaporator, wear gloves to prevent

injuries from the sharp evaporator fins.

9. Service on the refrigerator should be performed by a

qualified technician. Sealed system repair must be

performed by a CFC certified technician.

Page 3

1. SPECIFICATIONS

22 cu. Ft. (22.4 cu. Ft.)

ITEMS SPECIFICATIONS

DOOR DESIGN Side Rounded

DIMENSIONS

NET WEIGHT

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

DEFROSTING SYSTEM

DOOR FINISH V CM, Sta inless

HANDLE TYPE Bar

INNER CASE ABS Resin

INSULATION Polyurethane Foam

W(836)x D(870)x H(1764) mm

W(32.91)x D(34.25)x H(69.45) in

128.4 Kg

283.29 pounds

Full Automatic

Heater Defrost

ITEMS SPECIFICATIONS

VEGETABLE TRAY Opaque Drawer Type

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (115 g)

LUBRICATING OIL ISO10 (220 ml)

DEFROSTING DEVICE SHEATH HEATER

REFRIGERATOR 60 W (2EA)

LAMP

FREEZER 60 W (1EA)

- 3 -

Page 4

2. PARTS IDENTIFICATION

- 4 -

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

I

A

Digital Sensor Control*

B

Refrigerator Light

C

Shelves

D

Chef Fresh

E

Can Dispenser

F

Optibin Crisper

Keeps fruits and vegetable fresh and crisper

G

Customcube Icemaker

H

Ice Bin

I

Full Widht Wire Basket

J

Wire Durabase

K

Filter (inside)*

L

Dairy Bin

M

Egg Box

N

Design-A-Door Bins

O

Freezer Light

P

Wire Basket

*On some models

Page 5

3. DISASSEMBLY

3-1 DOOR

Left Door

Disconnect water supply tube by pushing back

on the disconnect ring (3).

Loosen the cover screw (1).

Disconnect door switch wire (2).

Attach the tube on the door with door.

Pull out the tube (4).

Disconnect wire harness (5).

Loosen screws (6) and lift off the top hinge (7).

Place the door on a non-scratching surface with

the inside up.

Right Door

Loosen the cover screw (1).

Disconnect door switch wire (2).

Disconnect wire harness (4).

Remove the ground screw (8).

Loosen screws (6) and lift off the top hinge (7).

Place the door on a non-scratching surface with

the inside up.

2. Remove gasket bracket clips

There are two clips on each door. Start bracket removal

near one of the middle clips.

1) Pull gasket back to expose gasket bracket clip and

door frame.

2) Insert a flat tip screwdriver into seam between gasket

bracket and door frame and pry back until clips snaps

out.

3) Continue prying back along seam until all clips snap

out.

Door

Frame

Flat Tip

Screwdriver

3. Remove gasket

Pull gasket free from gasket channel on the three

remaining sides of door.

Gasket

Bracket Clip

Figure 3

Gasket

Bracket

Left

Figure 1

Door Gasket Removal

1. Remove door frame cover

Starting at top of cover and working down, snap cover

out and away from door.

Frame Cover

Handle

Right

Figure 2

Figure 4

Door Gasket Replacement

1. Insert gasket bracket clips

1) Insert gasket bracket edge beneath door frame edge.

2) Turn upper gasket bracket spring so that both spring

ends are in the door channel.

3) Push in clip until you hear it snap securely into place.

Gasket

Bracket Clip

Spring

Door

Frame

4) Push in remaining two clips until you hear each snap

securely into place.

Note: Make sure that no part of gasket bracket edge

protrudes from beneath door frame edge.

Correct Incorrect

Figure 5

- 5 -

Page 6

2. Insert gasket into channel

1) Snap gasket assembly into the door bracket.

<Inserting the Gasket Assembly into the Bracket Door>

Correct

Incorrect

Figure 6

3-2 TO REMOVE THE DISPENSER

1. Use fiat tip screwdriver to pry back hooks on botton

underside of cover dispenser.

Figure 9

2. Pry off cover dispenser.

2) Press gasket into channels on the three remaining

sides of door.

Figure 7

3. Replace door frame cover

Starting at top of cover and working down, snap cover

back into door.

Figure 10

Disconnect wire harness.

3. Replace cover dispenser in opposite manner and order

of removal.

Figure 8

- 6 -

Page 7

3-3 FAN AND FAN MOTOR

GRILLE ASSEMBLY

DEFROST-CONTROL

ASSEMBLY

CONTROL BOX

COVER LAMP

1. Remove the freezer shelf. (If your refrigerator has an

icemaker, remove the icemaker first)

2. Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

3. Remove the grille by removing one screw and pulling the

grille forward.

4. Remove the Fan Motor assembly by loosening 2 screws

and disassembling the shroud.

5. Pull out the fan and separate the Fan Motor and Bracket.

FAN MOTOR

BRACKET

MOTOR

3-5-1 Refrigerator Compartment Lamp

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Release the hooks on both ends of the lamp shield and

pull the shield downward to remove it.

4. Turn the lamp counterclockwise.

5. Assembly is the reverse of disassembly. Replacement

bulb must be the same specification as the original

(Max. 60 W2EA).

FAN

GRILLE

Figure 11

3-4 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and

FUSE–M.

The Defrost Sensor works to defrost automatically. It is

attached to the metal side of the Evaporator and senses its

temperature. At 72°C, it turns the Defrost Heater off.

Fuse-M is a safety device for preventing over-heating of

the Heater when defrosting.

1. Pull out the grille assembly. (Figure 12)

2. Separate the connector with the Defrost Control

assembly and replace the Defrost Control assembly

after cutting the Tie Wrap. (Figure 13)

Figure 15

3-5-2 Freezer Compartment Lamp

1. Unplug refrigerator or disconnect power.

2. Reach behind light shield to remove bulb.

3. Replace bulb with a 60-watt appliance bulb.

4. Plug in refrigerator or reconnect power.

3-6 CONTROL BOX-REFRIGERATOR

1. First, remove all shelves in the refrigerator, than remove

the Refrigerator control Box by loosening 2 screws.

Figure 16

2. Remove the Refrigerator Control Box by pulling it

downward.

3. Disconnect the lead wire on the right position and

separate the lamp sockets.

3-5 LAMP

Figure 12

Figure 13

Figure 14

3-7 MULTI DUCT

1. Remove the upper and

lower Caps by using a flat

screwdriver, and remove 2

screws. (Figure 17)

2. Disconnect the lead wire

on the bottom position.

Figure 17

- 7 -

Page 8

4. ADJUSTMENT

PTC STARTER

SEALED

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

2

5

6

3

S

PTC

N

L1

OVERLOAD PROTECTOR

Resistance Starter Capacitor Running

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use

extreme caution when repairing it.

4-1-3 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

Particular Compressor in your product.

(4) Keep Compressor dry.

If the Compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result.

(5) When replacing the Compressor, be careful that dust,

humidity, and soldering flux don’t contaminate the inside

of the compressor. Contamination in the cylinder may

cause noise, improper operation or even cause it to

lock up.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic

material consisting of BaTiO

(2) The higher the temperature is, the higher the resistance

value. These features are used as a starting device for

the Motor.

4-2-2 Role of PTC-Starter

(1) The PTC is attached to the Sealed Compressor and is

used for starting the Motor.

(2) The compressor is a single-phase induction motor.

Durign the starting operation, the PTC allows current

flow to both the start winding and main winding.

4-2-3 PTC-Applied Circuit Diagram

● Starting Method for the Motor

Figure 18

4-2-4 Motor Restarting and PTC Cooling

(1) It requires approximately 5 minutes for the pressure to

equalize before the compressor can restart.

(2) The PTC device generates heat during operation.

Therefore, it must be allowed to cool before the

compressor can restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the compressor attempts to restart before the PTC

device is cooled, the PTC device will allow current to

flow only to the main winding.

(2) The OLP will open because of the over current

condition. This same process will continue (3 to 5

times) when the compressor attempts to restart until

the PTC device has cooled. The correct OLP must be

properly attached to prevent damage to the

compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part

3.

number and model number. Using an incorrect part

could result in damage to the product, fire, injury, or

possibly death.

4-2-6 Note for Using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the PTC,

PTC materials may fail due to breakdown of their

insulating capabilities.

(4) If the exterior of the PTC is damaged, the resistance

value may be altered. This can cause damage to the

compressor and result in a no-start or hard-to-start

condition.

(5) Always use the PTC designed for the compressor and

make sure it is properly attached to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part

number and model number. Using an incorrect part

could result in damage to the product, fire, injury, or

possibly death.

- 8 -

Page 9

4-3 OLP (OVERLOAD PROTECTOR)

Part

Customer part

number

Lot code/

date code

330 FBYY -S1 BOX98

12345678

Physical

termination

part number

Electrical

characteristics

part number

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V -0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

(OVERLOAD PROTECTOR cross section)

1

2 3

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by opening the

circuit to the Motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the Compressor motor, the

Bimetal works by heating the heater inside the OLP,

and the OLP protects the Motor by cutting off the

current flowing to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Sealed Compressor used

for the Refrigerator. It prevents the Motor Coil from

being started in the Compressor.

(2) For normal operation of the OLP, do not turn the Adjust

Screw of the OLP in any way.

4-4 TO REMOVE THE COVER PTC

(1) Remove the Cover Back M/C.

(2) Disconnect two housing upper side of comp connected

in.

(3) Loosen two screws on comp base.

Figure 19

(4) Use a L-shaped flap tool to pry off the cover.

(5) Assembly in reverse order of disassembly.

- 9 -

Page 10

5. CIRCUIT DIAGRAM

- 10 -

5. CIRCUIT DIAGRAM

- 10 -

Page 11

6. TROUBLESHOOTING

1

2

3

4

5

2

5

5

3

5

1

43

YES

NO

YES

The range of resistance is between 1~50Ω(ok)

Open or short

YES

YES

NO

NO

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

Power Source.

Remove PTC-Starter

from Compressor and

measure voltage

between Terminal C of

Compressor and

Terminal 5 or 6 of PTC.

No Voltage.

Applied voltage isn't

in acceptable range.

(115V ±10%)

(Rated Voltage

±10%)?

OLP disconnected?

Advise customer that

power supply needs to be

checked by an electrician.

Replace OLP.

Check connection

condition.

Reconnect.

Check

resistance of

Motor

Compressor.

Check

resistance of

PTC-Starter.

Check resistance

between M-C, S-C and

M-S in Motor

Compressor.

Check resistance of

two terminals in

PTC-Starter.

Replace

Compressor.

Reference Page12.

Check OLP.

Check resistance of two

terminals in OLP.

Reference Page12.

Check

starting state.

Check the power supply

under load.

(Compressor attempting

to re-start after being off

for 5 minutes).

Supply

voltage rating

with ±10%.

Did

compressor

start?

Compressor

is OK

Replace the

compressor

- 11 -

Page 12

6-2 PTC AND OLP

65

Shows continuity

Open

Normal operation of

Compressor is

impossible or poor.

Separate PTC-Starter

from Compressor and

measure resistance

between No. 5 and 6

of PTC-Starter with a

Tester.

(Figure 20)

Separate OLP from

Compressor and check

resistance value

between two terminals

of OLP with a Tester.

(Figure 21)

Observation value is

115V/60Hz : 6.8Ω±30%

The resistance value

is 0Ω (short) or

∞ (open).

Check another

electric component.

Replace OLP.

Replace PTCStarter.

Figure 20

Figure 21

- 12 -

Page 13

6-3 OTHER ELECTRICAL COMPONENTS

▼ Not cooling at all

Compressor

doesn't run.

▼ Poor cooling performance

Compressor runs

poorly.

Check for open short or

incorrect resistance readings

in the following components

a. Starting devices

b. OLP

c. Compressor coil

d. Wiring harness

Check starting

voltage.

Check voltage at

starting devices.

Cause

Short, open, or broken.

Poor contact

or shorted.

Coil open or shorted.

Poor contact

or shorted.

Low voltage.

Poor or broken or

open contact.

Replace

indicated component.

Advise customer that

the Power supply

needs to be checked

by an electrician.

Replace

indicated component.

Fan motor

doesn't run.

Heavy frost buildup on

EVAPORATOR.

Check current flowing

in sub-coil of

Compressor.

Check rating of OLP.

Check wiring circuit.

Check Fan Motor.

Check current flow in

the following

components:

Sensor

Fuse-M

Check current flow in

the Defrost Heater.

Shorted.

Lack of capacity.

Wire is open or

shorted.

Coil is shorted

or open.

Open.

Open.

Replace

indicated component.

Replace

indicated component.

Replace

Defrost Heater.

- 13 -

Page 14

6-4 SERVICE DIAGNOSIS CHART

COMPLAINT POINTS TO BE CHECKED REMEDY

No Cooling.

Cools poorly.

Food in the

Refrigerator

is frozen.

Condensation or ice

forms inside

the unit.

Condensation forms

in the Exterior Case.

There is abnormal

noise.

• Is the power cord unplugged from the outlet?

• Check if the power switch is set to OFF.

• Check if the fuse of the power switch is shorted.

• Measure the voltage of the power outlet.

• Check if the unit is placed too close to the wall.

• Check if the unit is placed too close to the stove,

gas cooker, or in direct sunlight.

• Is the ambient temperature too high or

the room door closed?

• Check if food put in the refrigerator is hot.

• Did you open the door of the unit too often

or check if the door is sealed properly?

• Check if the Control is set to Warm position.

• Is food placed in the cooling air outlet?

• Check if the control is set to colder position.

• Is the ambient temperature below 41°F(5°C)?

• Is liquid food sealed?

• Check if food put in the refrigerator is hot.

• Did you open the door of the unit too

often or check if the door is sealed properly?

• Check if the ambient temperature and humidity

of the surrounding air are high.

• Is there a gap in the door gasket?

• Is the unit positioned in a firm and even place?

• Are any unnecessary objects placed

in the back side of the unit?

• Check if the Drip Tray is not firmly fixed.

• Check if the cover of the compressor enclosure

in the lower front side is taken out.

• Plug into the outlet.

• Set the switch to ON.

• Replace the fuse.

• If the voltage is low, correct the wiring.

• Place the unit about 4 inches (10 cm) from the wall.

• Place the unit away from these heat sources.

• Lower the ambient temperature.

• Put in foods after they have cooled down.

• Don't open the door too often and close

it firmly.

• Set the control to Recommended position.

• Place foods in the high-temperature section.

(front part)

• Set the control to Recommended position.

• Set the control to Warm position.

• Seal liquid foods with wrap.

• Put in foods after they have cooled down.

• Don't open the door too often and close

it firmly.

• Wipe moisture with a dry cloth. It will disappear

in low temperature and humidity.

• Fill up the gap.

• Adjust the Leveling Screw, and position the

refrigerator in a firm place.

• Remove the objects.

• Fix the Drip Tray firmly in the original position.

• Place the cover in its original position.

Door does not

close well.

Ice and foods

smell unpleasant.

● Other possible problems:

Check if frost forms in

the freezer.

Check the

refrigeration system.

Check the

Thermistor.

• Check if the door gasket is dirty with

an item like juice.

• Is the refrigerator level?

• Is there too much food in the refrigerator?

• Check if the inside of the unit is dirty.

• Are foods with a strong odor unwrapped?

• The unit smells of plastic.

Not

defrosting

The system

is faulty.

The operation of

the Thermistor is

incorrect.

• Clean the door gasket.

• Position in a firm place and level the

Leveling Screw.

• Make sure food stored in shelves does not prevent

the door from closing.

• Clean the inside of the unit.

• Wrap foods that have a strong odor.

• New products smell of plastic, but this

will go away after 1-2 weeks.

Check Components

of the defrosting

circuit.

Perform sealed

system repair.

Replace the

Thermistor.

- 14 -

Page 15

6-5 REFRIGERATION CYCLE

▼ Troubleshooting Chart

CAUSE

PARTIAL Freezer Low flowing sound of A little higher • Refrigerant level is low due

LEAKAGE compartment and Refrigerant is heard and than ambient • to a leak.

LEAKAGE

COMPLETE Freezer Flowing sound of refrigerant Equal to ambient • No discharging of Refrigerant.

LEAKAGE compartment and is not heard and frost isn't temperature. • Normal cooling is possible by

CLOGGED BY DUST

PARTIAL Freezer Flowing sound of refrigerant A little higher • Normal discharging of the

CLOG compartment and is heard and frost forms than ambient • refrigerant.

WHOLE

CLOG

MOISTURE Cooling operation Flowing sound of refrigerant Lower than • Cooling operation restarts

CLOG stops periodically. is not heard and frost melts. ambient • when heating the inlet of the

COMPRESSION

COMP- Freezer and Low flowing sound of A little higher • Low pressure at high side

DEFECTIVE

RESSION Refrigerator refrigerant is heard and than ambient • of compressor due to low

STATE OF

THE UNIT

Refrigerator don't frost forms in inlet only. temperature. • Normal cooling is possible by

cool normally. • restoring the normal amount of

Refrigerator don't formed. • restoring the normal amount of

cool normally. • refrigerant and repairing the leak.

Refrigerator don't in inlet only. temperature. • The capillary tube is faulty.

cool normally.

Freezer

compartment and

Refrigerator don't cool.

don't cool. frost forms in inlet only. temperature. • refrigerant level.

STATE OF THE

EVAPORATOR

Flowing sound of refrigerant Equal to ambient • Normal discharging of the

is not heard and frost isn't temperature. • Refrigerant.

formed.

TEMPERATURE

OF THE

REMARKS

COMPRESSOR

• refrigerant and repairing the leak.

temperature. • capillary tube.

NO COMP- No compressing Flowing sound of refrigerant Equal to ambient • No pressure in the high

RESSION operation. is not heard and there is temperature. • pressure part of the

no frost. • compressor.

- 15 -

Page 16

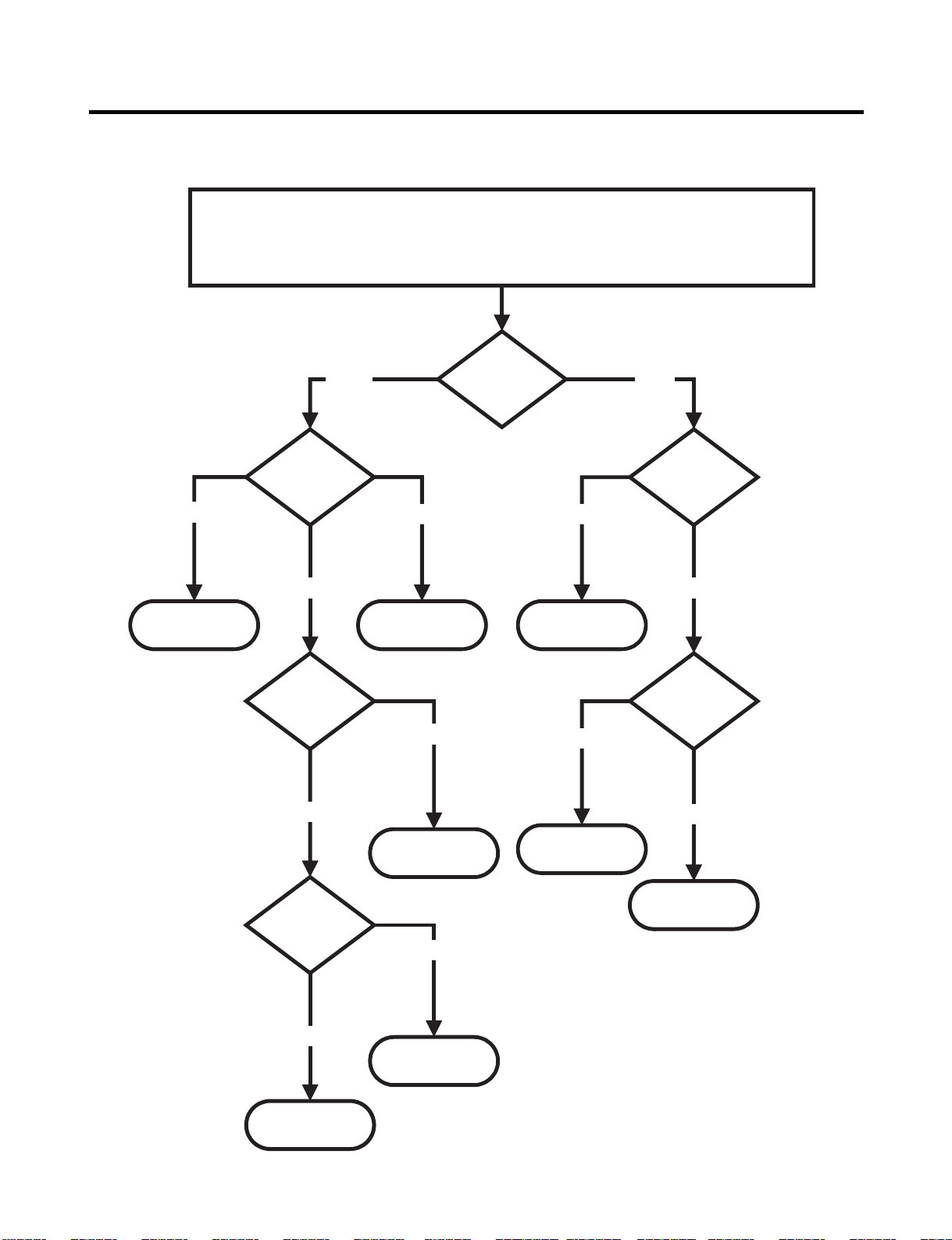

6-5-1 SEALED SYSTEM DIAGNOSIS

“Not Cooling” Complaint

All components operating, No airflow problems, Not frosted up as a defrost problem

problem has been isolated to sealed system area

Frost

Pattern?

Equalization

Test

Partial

Very Fast

Inefficient

Compressor

Partial

Restriction

Complete

Restriction

Equalization

Test

Condenser

Temperature

None

Very Fast

Very SlowVery Slow

Hotter than Normal

Air/Low Side

Leak

Loss of Change

Compressor Not

Pumping

Cap Tube

Sound

Room Temperature

Trace of Oil

Undercharge

Leak

Yes

No

Faint

Fast

None to Weak

(The equalization test is trying to restart a compressor using a start kit after it has been operating.)

- 16 -

Page 17

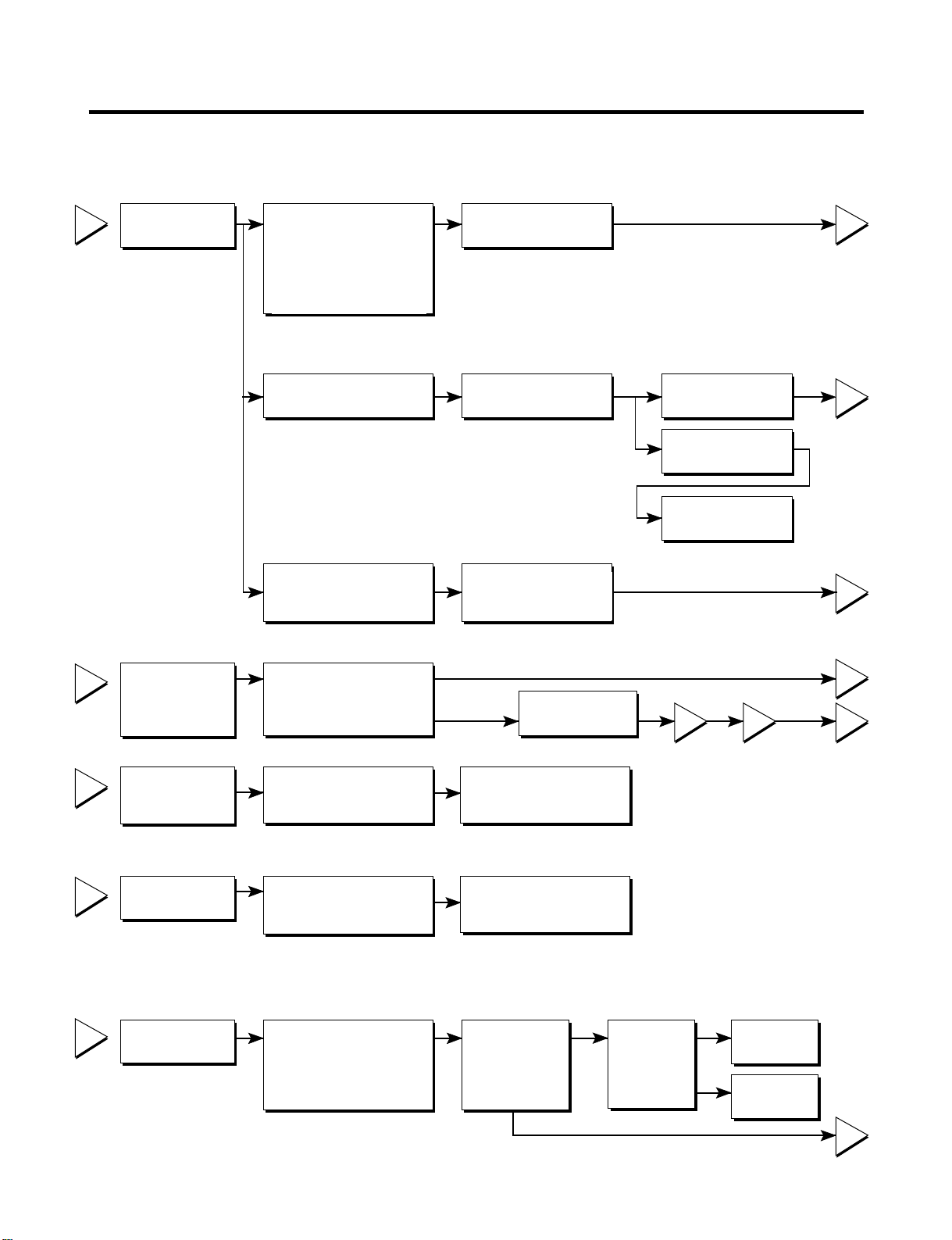

7. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER

• Adjusts EJECTOR to Start Position with power on.

Power On

Start Position

Ice Making

Mode

Harvest

Mode

Park Position

Fill

Test Mode

• Waits until water becomes cold after starting the

ice making operation.

• Runs MOTOR to drop ice from the tray into the ICE BIN.

• Performs Ice Making Mode after supplying water by operating

the SOLENOID in ICE VALVE.

• To operate LINE and SERVICE, press and hold the Fill Key

for 3 seconds. The ice maker will run through 3 stages:

Harvest Fill Icemaking.

• With the detect lever, checks if the ICE BIN is full.

Power (On/ Off) Switch

Fill Key

7-1 OPERATION PRINCIPLE

7-1-1 Operation Principle of IceMaker

1. Turning the Icemaker stop switch off (O) stops the ice making function.

2. Setting the Icemaker switch to OFF and then turning it back on will reset the icemaker control.

- 17 -

Page 18

7-2 ICE MAKER FUNCTIONS

Heater

on

off

on

0V

5V

off

30 sec.

10 sec.

Motor

Hall IC

Ice removing

completion point

2 ms

Ice making sensor temperature is 50°F(10˚C)

or more

Max. 18 minutes

After detect LEVER rises

7-2-1 Start Position

1. After POWER OFF or Power Outage, check the EJECTOR's position with MICOM initialization to restart.

2. How to check if it is in place:

- Check HIGH/LOW signals from HALL SENSOR in MICOM PIN.

3. Control Method to check if it is in place:

(1) EJECTOR is in place,

- It is an initialized control, so the mode can be changed to ice making control.

(2) EJECTOR isn't in place:

A. If EJECTOR is back in place within 2 minutes with the motor on, it is being initialized. If not, go to Step B.

B. If EJECTOR is back in place within 18 minutes after the heater turns from ON to OFF, it is being initialized. If not, it is

not functioning. Repeat Step B with Heater and Motor off.

7-2-2 Ice Making Mode

1. Ice Making refers to the freezing of supplied water in the ice trays. Complete freezing is assured by measuring the

temperature of the Tray with Ice-Making SENSOR.

2. Ice Making starts after completion of the water fill operation.

3. The Ice Making function is completed when the sensor reaches 19°F(-7°C), 60 to 240 minutes after starting.

4. If the temperature sensor is defective, the ice-making function will be completed in 4 hours.

NOTE : After Icemaker Power is ON, the Icemaker heater will be on for test for 9 sec.

7-2-3 Harvest Mode

1. Harvest (Ice removing) refers to the operation of dropping cubes into the ice bin from the tray when ice-making has

completed.

2. Harvest mode:

(1) The Heater is ON for 30 seconds, then the motor starts.

(2) After performing Step 1 (the Heater is turned OFF), the Ejector will be back in place wthin 18 minutes. (Hall SENSOR

sign = OV). Ice removal is then complete. Then the Ice Maker cycles to the Fill Mode. The water supply fails to start, it

is not functioning. Put the Heater and Motor in the off position. Restart every 2 hours. (Refer to fig.1)

NOTE : If the motor malfunctions and starts before the detect lever rises, MICOM regards the Ice-Removing phase as

completed. Water then starts flowing. To prevent this, MICOM doesn’t switch to water-supply mode, but restarts the iceremoving mode. If this happens 3 times, the motor is malfunctioning and you should stop the loads (Heater, Motor). Then

restart the Ice-Removing mode every 2 hours. (See Step 2 above.)

<fig1. Harvest mode Process>

- 18 -

Page 19

7-2-4 Fill / Park Position

1. Once a normal harvest mode has been completed, the water solenoid will be activated.

2. The amount of water is adjusted by pressing the Fill Key repeatedly. This changes the time allowed for fill as illustrated in

the table below.

<Water supply amount TABLE>

STAGE TIME TO SUPPLY INDICATIONS REMARKS

1

2

3

4

5

6 sec.

6.5 sec.

7 sec.

7.5 sec.

8 sec.

The water amount will vary depending

on the water control Switch setting, as

well as the water pressure of the

connected water line.

- 19 -

Page 20

7-2-5 Function TEST

1. This is a compulsory operation for TEST, SVC, cleaning, etc. It is operated by pressing and holding the Fill Key for 3 seconds.

2. The test works only in the Ice Making Mode. It cannot be entered from the Harvest or Fill mode. (If there is an ERROR, it

can only be checked in the TEST mode.)

3. Caution! If the test is performed before water in the Maker is frozen, the Ejector will pass through the water. When the Fill

mode begins (Stage 4), unless the water supply has been shut off, added water will overflow into the ice bin. If the control

doesn’t operate normally in the TEST mode, check and repair as needed.

4. After water is supplied, the normal CYCLE is followed: ice making → Harvest → Fill → Park Position.

5. Five seconds after Stage 5 is completed, the Ice Maker returns to MICOM control. The time needed to supply water

resets to the pre- test setting.

<Diagnosis TABLE>

STAGE ITEMS INDICATOR REMARKS

Five seconds after heater starts, heater will

1

2

HEATER

MOTOR

go off if temperature recorded by sensor is

10°C or lever is in up position.

Five seconds after heater starts, you can

confirm that motor is moving.

HALL IC I

3

4

5

6

(detection of

position)

VALVE

HALL IC II

(detection of full-

filled Ice)

Reset

Return to Status prior to

TEST MODE

You can confirm Hall Ic detection of position.

Two seconds after detection of initial

position, you can confirm that valve is on.

You can check whether hall is sensing Full

ice condition. (If there is a full-filled error, the

fifth LED is not on.)

Five seconds after fifth stage is completed,

the icemaker resets to initial status.

7-3 DEFECT DIAGNOSIS FUNCTION

7-3-1 ERROR CODES shown on Ice Maker water supply control panel

NO DIVISION INDICATOR CONTENTS REMARKS

1

2

Normal

Ice-Making

Sensor

malfunction

Mark time to

supply

None

Open or short-circuited wire

Display switch

operates properly

Make sure that the wire

on each sensor is

connected.

3

ERROR indicators in table can be checked only in TEST mode.

Ice Maker Kit

malfunction

When ejector blades don’t reach

park position over 18 minutes after

- 20 -

Harvest Mode starts.

Check

HALL IC/MOTOR/

HEATER/RELAY

Page 21

8. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM

LOCK CONTROL

Ex) In selecting

"LOCK"

Ex) In selecting

"LOCK" again

DISPENSER & BUTTON

LOCK

DISPENSER & BUTTON

In initial Power On

/ Filter RESET

Replace indicator

light on

Classification

Filter Status

Display

FILTER RESET

HOLD 3SECS

EXPRESS FRZ

Control range -6°F ~ 8°F

-21°C ~ -13°C

32°F ~ 47°F

0°C ~ 8°C

Control range

8-1 FUNCTION

8-1-1 Function

1. When the appliance is plugged in, it is set to 37°F for Refrigerator and 0°F for freezer.

You can adjust the Refrigerator and the Freezer control temperature by pressing the ADJUST button.

2. When the power is initially applied or restored after a power failure, it is automatically set to “37” & “0”.

8-1-2 How to Toggle the Display between °F & °C

1. The display temperature mode can be changed from °F to °C or °C to °F by pressing and holding the FRZ TEMP and the

REF TEMP keys at the same time for over one second.

2. The initial setting is °F. Whenever the mode is changed, the LED lights are changed.

8-1-3 Lock function (dispenser and display button lock)

1. When the refrigerator is first turned on, the buttons are not locked. The display panel shows the padlock

unlocked icon.

2. To lock the display, the dispenser, and the control panel, press

and hold the LOCK button for 3 seconds. The locked padlock

icon is displayed with the word "LOCK" printed beside it.

3. The LOCK button is the only control feature that remains active

in the locked state. The buzzer sound, other control buttons,

and the dispenser are deactivated.

4. To release from the locked state, press and hold the LOCK

button again for 3 seconds.

8-1-4 Filter condition display function

1. There is a replacement indicator light for the water

filter cartridge on the dispenser.

2. Water filter needs replacement once six months or

about 28,000 seconds of using water filter.

3. Water filter light and “FILTER RESET HOLD 3 SECS”

text turn on to tell you need to replace the filter soon.

4. After replace the filter, press and hold the lock button

more than 3 seconds.

Then water filter light and “FILTER RESET HOLD 3

SECS” text turn off with reset status.

8-1-5 Express freezing selection

Please select this function for quick freezing.

• Function is repeated following below whenever pressing Express FRZ button.

• Expressing freezer function automatically turns off after a fixed time passes.

- 21 -

Page 22

8-1-6 CONTROL OF FREEZER FAN MOTOR

Closed Open Closed Open

3 Times 3 Times 3 Times 3 Times

Closed

Within 1 min. 1 min.

30 sec 30 sec 30 sec

Freezer Door

or Refrigerator

Door

Buzzer

1. Freezer fan motor has high and standard speeds.

2. High speed is used at power-up, for express freezing, and when refrigerator is overloaded.

Standard speeds is used for general purposes.

3. To improve cooling speed, the RPM of the freezer fan motor change from normal speed to high.

4. High speed (2700RPM) : Initial power on or load corresponding operation, express freezing.

Normal speed (2400RPM) : General working conditions.

5. Fan motor stops when refrigerator or freezer door opens.

8-1-7 EXPRESS FREEZING

1. The purpose of this function is to intensify the cooling speed of freezer and to increase the amount of ice.

2. Whenever selection switch is pressed, selection/release, the LED will turn ON or OFF.

3. If there is a power outage and the refrigerator is powered on again, EXPRESS FREEZING will be canceled.

4. To activate this function, press the Express Freezing key and the LED will turn ON. This function will remain activated for

24 hrs. The first three hours the compressor and Freezer Fan will be ON. The next 21 hours the freezer will be controlled

at the lowest temperature. After 24 hours or if the Express Freezing key is pressed again, the freezer will return to its

previous temperature.

5. During the first 3 hours:

(1) Compressor and freezer fan (HIGH RPM) run continuously.

(2) If a defrost cycle begins during the first 90 minutes of Express Freezing, the Express Freeze cycle will complete its

cycle after defrosting has ended.

If the defrost cycle begins when Express Freeze has run for more than 90 minutes, Express Freeze will run for two

hours after the defrost is completed.

(3) If EXPRESS FREEZING is pressed during defrost, EXPRESS FREEZING LED is on but this function will start seven

minutes after defrost is completed and it shall operate for three hours.

(4) If EXPRESS FREEZING is selected within seven minutes after compressor has stopped, the compressor (compressor

delays seven minutes) shall start after the balance of the delay time.

(5) The fan motor in the freezer compartment runs at high speed during EXPRESS FREEZING .

6. For the rest of the 21 hours, the freezer will be controlled at the lowest temperature.

8-1-8 REFRIGERATOR LAMP AUTO OFF

1. To avoid heat damage caused by the lamp, it is turned off automatically when the refrigerator door is open for more than 7

minutes.

8-1-9 Alarm for Open Door

1. This feature sounds a buzzer when the freezer or refrigerator door is not closed within 1 minute after it is opened.

2. One minute after the door is opened, the buzzer sounds three times each for 1/2 seconds. These tones repeat every 30

seconds.

3. The alarm is cancelled when the freezer or the refrigerator is closed while the buzzer sounds.

- 22 -

Page 23

8-1-10 Buzzer Sound

When the button on the front Display is pushed, a Ding~ Dong~ sound is produced.

(Refer to the Buzzer Circuit 8-2-4 No. 3)

8-1-11 Defrosting (removing frost)

1. Defrosting starts each time the COMPRESSOR running time reaches 7 hours.

2. For initial power on or for restoring power, defrosting starts when the compressor running time reaches 4 hours.

3. Defrosting stops if the sensor temperature reaches 46.4°F(8°C) or more. If the sensor doesn’t reach 46.4°F(8°C) in

2 hours, the defrost mode is malfunctioning. (Refer to the defect diagnosis function, 8-1-14.)

4. Defrosting won’t function if its sensor is defective (wires are cut or short circuited)

8-1-12 Filter Replacement Indication

1. In 6 months after the UNIT (refrigerator) is power on, or after 28,000 seconds of dispenser use, the water filter Indicator

LED will be ON.

2. When the water filter indicator LED is illuminated, you should change the water filter. After this, you must press the water

filter button for three seconds and you will hear a ding-dong sound.

The LED will be OFF. This operation will indicate that the UNIT is reset to its initial conditions, so this process is restarted.

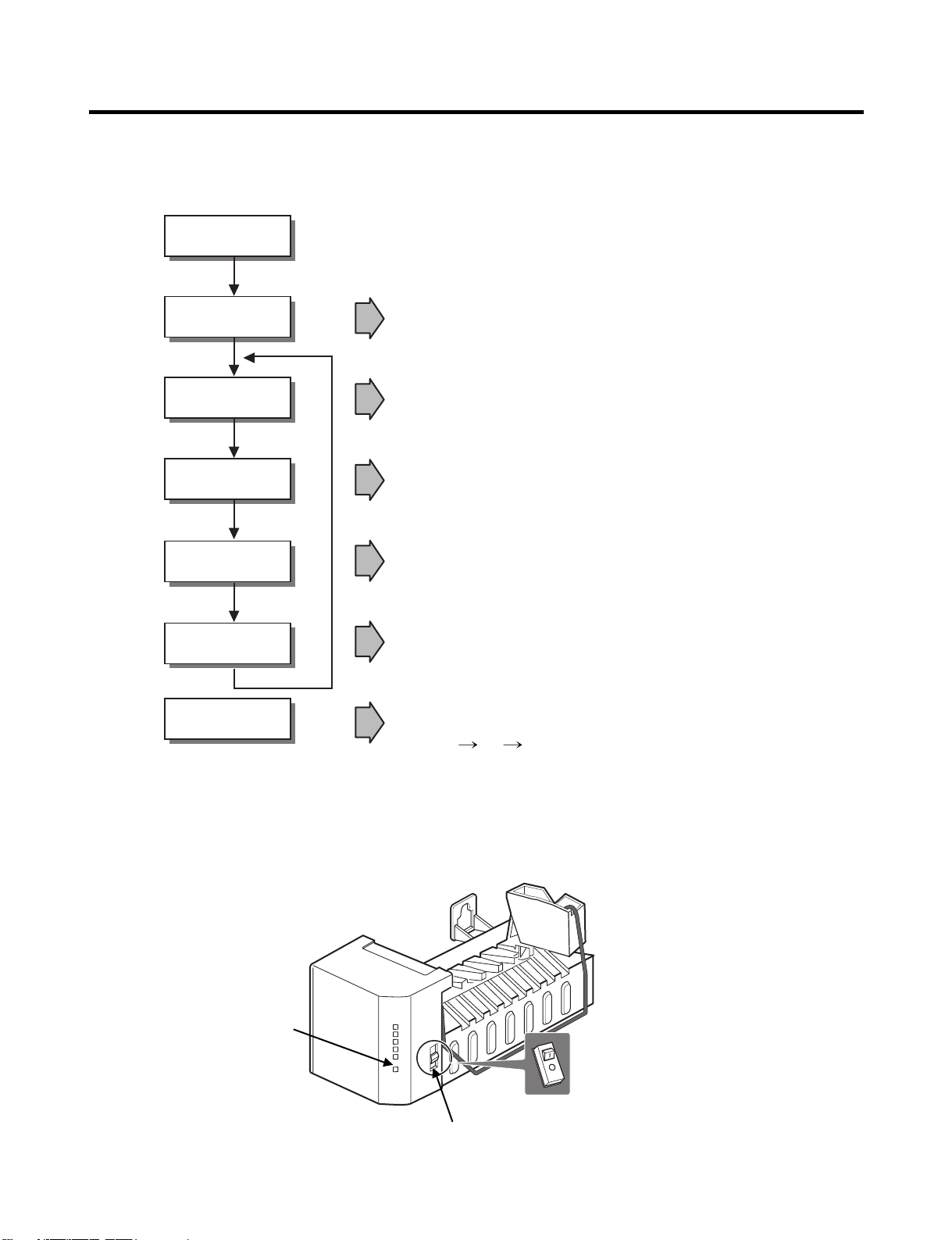

8-1-13 Electrical Parts Are Turned On Sequentially

Electrical parts such as COMP, defrosting heater, freezer FAN, etc. are turned on in the following order to prevent noise and

parts damage. Several parts are started at the same time at initial power on and are turned off together when TEST is

completed.

OPERATING ORDERS

Temperature of Defrosting

Sensor is 113°F(45°C) or

more (when unit is newly

Initial power on

purchased or when moved)

Temperature of defrosting

sensor is lower than

113 °F(45°C)

(when power cuts, SERVICE)

Reset to normal operation

from TEST MODE

POWER

in 1/2 second in 1/2 second

ON

POWER

in 1/2 second

ON

in 1/2 second in 1/2 second

COMP

COMP

ON

Defrosting

heater ON

ON

Total load

OFF

in 7 minute

COMP

ON

Freezer FAN

in 10 second

Freezer FAN

ON

in 1/2 second

ON

Defrosting

heater OFF

Freezer FAN

ON

- 23 -

Page 24

8-1-14 Defect Diagnosis Function

1. Automatic diagnosis makes servicing the refrigerator easy.

2. When a defect occurs, the buttons will not operate; but the tones. such as ding. will sound.

3. When the defect CODE removes the sign, it returns to normal operation (RESET).

4. The defect CODE shows on the Refrigerator and Freezer Display.

ERROR CODE on display panel

Note 1) Freezer room notch temperature display and refrigerator room notch temperature display (Failure code

indication part) are normally indicated in abnormal ambient sensor, and “Er” indicated on the amvient

temperature display.

✽ LED check function: If simultaneously pressing express freezer button and freezing temperature adjustment

button for a second, display LED graphics on. If releasing the button, the LED graphic

displays the previous status.

NO ITEM

Failure of freezer

1

sensor

Failure of

2

Refrigerator sensor

Failure of defrost

3

sensor

Failure of Room

Temperature

4

sensor

Failure of defrost

5

mode

Failure of BLDC

Fan Motor at

6

Freezing

Compartment.

ERROR CODE

Er

Er

Er

When Display check mode

Er

Er

FS

rS

dS

dH

FF

CONTENTS REMARKS

Cut or short circuit wire

Cut or short circuit wire

Inspect Connecting wires

Cut or short circuit wire

Cut or short circuit wire

When defrost sensor

doesn’t reach 46°F within 2

hours after starting defrost.

If there is no fan motor

signal for more than 65sec

in operation fan motor

Snapping of defrost heater

or Temperature fuse, pull-

out of connector (indicated

minimum 2 hours after

Poor motor, hooking to

wires of fan, contact of

structures to fan, snapping

or short circuit of Lead wires

on each sensor

failure occurs)

- 24 -

Page 25

8-1-15 TEST Mode

1. The Test mode allows checking the PCB and the function of the product as well as finding out the defective part in case of

an error.

2. The test mode is operated by pressing two buttons at Display panel.

3. While in the test mode, the function control button is not recognized, but the recognition tone (beep~) sounds.

4. After exiting the test mode, be sure to reset by unplugging and then plugging in the appliance.

5. If an error, such as a sensor failure, is detected while in the test mode, the test mode is cleared and the error code is

displayed.

6. While an error code is displayed, the test mode will not be activated.

MODE MANIPULATION CONTENTS REMARKS

TEST1

TEST2

TEST3

Reset

Push FREEZER

Key and LOCK KEY at the

same time for 3 seconds

OR Push TEST S/W(on

the main Board) once.

Push FREEZER

Key and LOCK KEY at the

same time for 3 seconds

in TEST MODE 1 OR

Push TEST S/W once in

TEST MODE 1

Push FREEZER

Key and LOCK KEY at the

same time for 3 seconds

in TEST MODE 2 OR

Push TEST S/W once in

TEST MODE 2

Push FREEZER

Key and LOCK KEY at the

same time for 3 seconds

in TEST MODE 3 OR

Push TEST S/W once in

TEST MODE 3

1) Continuous operation of the

COMPRESSOR and the Freezer fan

2) Stepping DAMPER OPEN

3) Defrosting HEATER OFF

4) DISPLAY LED all ON

1) Continuous operation of the

COMPRESSOR and the Freezer fan

2) Stepping DAMPER CLOSE

3) Defrosting HEATER OFF

4) DISPLAY LED shows no. 2

1) COMPRESSOR and the Freezer fan

OFF

2) Stepping DAMPER CLOSE

3) Defrosting HEATER ON

4) DISPLAY LED shows no. 3

Reset to the previously setting

Before TEST MODE.

Reset if the

Temperature of the

Defrosting Sensor is

46°F(8°C) or more.

The compressor will

Start after a 7-minute

Delay.

* Freezer Fan RPM Variable Check:

In case the freezer fan is in operation when the express freezer button and freezing temp. button. Control are pressed for

more than one second at the same time freezer fan RPM changes. (for example if high speed, to normal speed or if

normal speed, to high speed for 30 seconds)

After 30 seconds, it turns to its original RPM.

* Demonstration MODE:

1. When the Express Freezing Temp. Control button and the Refrigerator Temp. Control button are pushed and hold for 3 seconds

or longer, it converts to Demostration Mode.

2. The Display shows the Demo graphic.

3. In this status, all Loads are off (Compressor / Fan / Damper / Heater)

(Even is Demonstration Mode, the refrigerator Lamp automatic off function warks normally and can be demonstrated)

4. Exit the Demo mode and reset the Display by pressing the Express Freezing Temp. Control button and the Refrigerator Temp.

Control button for 3 seconds or longer.

- 25 -

Page 26

8-2 PCB FUNCTION

8-2-1 Power Circuit

The secondary part of the TRANSFORMER is composed of the power supply for the display, the BLDC FAN Motor drive

(15.5 V), the relay drive (12 Vdc) and the MICOM and IC (5 Vdc).

The voltage for each part is as follows:

VA1 is a part for preventing over voltage and noise. When 385V or higher power is applied, the inside elements are shortcircuited and broken, resulting in blowout of the fuse in order to protect the elements of the secondary part of the

TRANSFORMER.

PART VA 1 CE 3 CE 4 CE 5

VOLTAGE 115 Vac 12 Vdc 15.5 Vdc 5 V

- 26 -

6.8

100

Page 27

8-2-2 Oscillation Circuit

This circuit generates the base clock for calculating time and the synchro clock for transmitting data from and to the inside

logic elements of the IC1 (MICOM). Be sure to use specified replacement parts, since calculating time by the IC1 may be

changed. If changed, the OSC1 SPEC will not work.

8-2-3 Reset Circuit

The RESET circuit allows all the functions to start at the initial conditions by initializing various parts, including the RAM

inside the MICOM (IC1) when the power is initially supplied or the power supply to the MICOM is restored after a

momentary power failure. For the initial 10ms of power supply, LOW voltage is applied to the MICOM RESET terminal.

During a normal operation, 5V is applied to the RESET terminal. (If a malfunction occurs in the RESET IC, the MICOM will

not operate.)

- 27 -

Page 28

8-2-4 Load / Buzzer Drive & Open Door Detection Circuit

1. Load Drive Condition Check

LOAD TYPE

COMP

NO.13 NO.14 NO.16 NO.12 NO.15

1V or below

12V

DEFROSTING

HEATER

LAMP VALVE

FRENCH DOOR

HEATER 1, 2 /

DEW HEATER

Measurement Location (IC6)

Condition

ON

OFF

- 28 -

2.1 Fan motor driving circuit (freezing compartment fan)

1. This circuit makes standby power 0 by cutting off power supplied to ISs inside of the fan motor in the fan motor OFF.

2. This is a circuit to perform a temporary change of speed for the fan motor and applies DC voltage up to 7.5V ~ 16V to motor.

3. This circuit prevents over-driving the fan motor by cutting off power applied to the fan motor in the lock of fan motor by

sensing the operation RPM of the fan motor.

2. Motors driving circuit

CON1

POWER

ICE MAKER

RUNNING CAPACITOR

STARTING CAPACITOR

DEF-HEATER

LAMP-F

LAMP-R

WATER VALVE

FRENCH DOOR

HEATER

L1

5mH/4A

CM1

470nF

VA1

COMP

CON2

OLP

M

FUSE-M

com

nc

com

nc

com

nc

com

nc

CON3

275VAC

5

3

1

1

3

5

7

5

3

1

RY1

ALZ21B12

RY2

G5NB-1A

RY3

G5NB-1A

RY4

G5NB-1A

RY5

G5N-1A

RY6

G5N-1A

IC6

KID65003AP

D7

1N4004

9

4

13

3

14

6

11

1

16

10

P06

11

P05

14

P02

13

P03

I C 1

(MICOM)

2

15

5

12

8

12

P04

9

P07

PTC START

RC-FILTER

VALVE II

RC-FILTER

9

7

COOLING-FAN

A

B

DOOR S/W-F

C

D

DOOR S/W-R1&R2

M

M

Page 29

part part part

a b

MOTOR OFF 2V or less 0V 5V

MOTOR ON 13V~15V 0V 2V~3V

2.2 Cooling motor driving circuit (machine room)

c

1. This circuit makes standby power 0

by cutting off power supplied to ISs inside of the fan motor in the fan motor OFF.

2. This circuit prevents over-driving the fan motor by cutting off power applied to the fan motor in the lock of fan motor by

sensing the operation RPM of the fan motor.

Part part

a b

MOTOR OFF 2V or less 0V

MOTOR ON 13V~15V 0V

A

R46

4.7KJ

CC20*

102

CON4

4

5

6

3

4

1

C-FAN

I C 1

(MICOM)

P14

(PPG)

P11

(INT1)

R43

Q4

330J

KTB1151

R40

4.7KJ

R41

35

3.9KJ

R42*

10KJ

R44

1.5KJ

1/2W

Q5

KTC3198

32

RJ1*

R45

2KJ

D9

FR107

D8

FR107

1mH

L4

220uF

/25V

CE12

CC19*

223

- 29 -

Page 30

3. Open Door Detection Circuit Check

Measurement

Freezer/

Location

Refrigerator Door

Closed 5 V

Open 0 V

8-2-5 Temperature Sensor Circuit

7

1

2

(PIN NO.30 & PIN NO.37)

7

5

6

The upper CIRCUIT reads REFRIGERATOR temperature, FREEZER Temperature, and DEFROST-SENSOR temperature

for defrosting and the indoor temperature for compensating for the surrounding temperature into MICOM.

OPENING or SHORT state of each TEMPERATURE SENSOR are as follows:

SENSOR CHECK POINT NORMAL (-30¡C ~ 50¡C)

Freezer Sensor POINT Voltage

Refrigerator Sensor POINT Voltage

A

B

SHORT-CIRCUITED

OPEN

0.5 V ~ 4.5 V 0 V 5 V

Defrosting Sensor POINT Voltage

Room Temperature sensor

POINT Voltage

C

D

- 30 -

Page 31

8-2-6 Refrigeration Compartment Stepping Motor Damper Circuit

* The circuit shown below is the damper circuit to regulate the refrigerator temperature.

2

4

3

8-2-7 Dispenser Input

7

3

4

- 31 -

Page 32

8-2-8 Temperature Compensation & Overcooling/Undercooling Compensation Circuit

1. Refrigerator Temperature Compensation

Refrigerator

Resistance Temperature Remark

(RCR) Compensation

180 KΩ +2.5°C Compensation by

56 KΩ +2.0°C

33 KΩ +1.5°C

18 KΩ +1.0°C

12 KΩ +0.5°C

10 KΩ 0 °C

8.2 KΩ -0.5°C Compensation by

5.6 KΩ -1.0°C

3.3 KΩ -1.5°C

2 KΩ -2.0°C

470 Ω -2.5°C

2. The temperature compensation for refrigerator compartment is in the following table:

Revised resistance

Present resistance

470Ω change Up Up Up Up Up Up Up Up Up Up

2kΩ Down Change Up Up Up Up Up Up Up Up Up

3.3kΩ Down Down Change Up Up Up Up Up Up Up Up

5.6kΩ Down Down Down Change Up Up Up Up Up Up Up

8.2kΩ Down Down Down Down Change Up Up Up Up Up Up

Refrigerator 2.5°C2°C 1.5°C1°C 0.5°C No 0.5°C1°C 1.5°C2°C 2.5°C

(RCR) 10kΩ Down Down Down Down Down Change Up Up Up Up Up

12kΩ Down Down Down Down Down Down Change Up Up Up Up

18kΩ Down Down Down Down Down Down Down Change Up Up Up

33kΩ Down Down Down Down Down Down Down Down Change Up Up

56kΩ Down Down Down Down Down Down Down Down Down Change Up

180kΩ Down Down Down Down Down Down Down Down Down Down Change

470Ω 2kΩ 3.3kΩ 5.6kΩ 8.2kΩ 10kΩ 12kΩ 18kΩ 33kΩ 56kΩ 180kΩ

No 0.5°C1°C 1.5°C2°C 2.5°C3°C 3.5°C4°C 4.5°C5°C

0.5°C No 0.5°C1°C 1.5°C2°C 2.5°C3°C 3.5°C4°C 4.5°C

1°C 0.5°C No 0.5°C1°C 1.5°C2°C 2.5°C3°C 3.5°C4°C

1.5°C1°C 0.5°C No 0.5°C1°C 1.5°C2°C 2.5°C3°C 3.5°C

2°C 1.5°C1°C 0.5° No 0.5°C1°C 1.5°C2°C 2.5°C3°C

3°C 2.5°C2°C 1.5°C1°C 0.5°C No 0.5°C1°C 1.5°C2°C

3.5°C3°C 2.5°C2°C 1.5°C1°C 0.5°C No 0.5°C1°C 1.5°C

4°C 3.5°C3°C 2.5°C2°C 1.5°C1°C 0.5°C No 0.5°C1°C

4.5°C4°C 3.5°C3°C 2.5°C2°C 1.5°C1°C 0.5°C No 0.5°C

5°C 4.5°C4°C 3.5°C3°C 2.5°C2°C 1.5°C1°C 0.5°CNo

raising the

temperature

Standard Temperature

lowering the

temperature

➧ Table of Temperature Compensation by adjusting the

resistance (difference from the current temperature)

e.g., If the refrigerator compensation resistance

(RCR) is changed from 10K (the current resistance)

to 18K (the adjustment resistance), the temperature

of the refrigerator rises 33.8°F(+1°C).

NOTE: This circuit is designed to input the necessary temperature compensation values into the MICOM. This adjusts the

refrigerator temperature, which is different in each model.

- 32 -

Page 33

8-2-9 Key Button Input & Display Light-On Circuit

The circuit shown above determines whether a function control key on the operation display is pushed. It also turns on the

corresponding function indication LED Module SEVEN SEGMENT DISPLAY. The drive type is the scan type.

4

3

2

1

CON 6

- 33 -

Page 34

8-3 RESISTANCE SPECIFICATION OF SENSOR

TEMPERATURE

- 20 ˚C 22.3 KΩ 77 KΩ

- 15 ˚C 16.9 KΩ 60 KΩ

- 10 ˚C 13.0 KΩ 47.3 KΩ

- 5 ˚C 10.1 KΩ 38.4 KΩ

0 ˚C 7.8 KΩ 30 KΩ

+ 5 ˚C 6.2 KΩ 24.1 KΩ

+ 10 ˚C 4.9 KΩ 19.5 KΩ

+ 15 ˚C 3.9 KΩ 15.9 KΩ

+ 20 ˚C 3.1 KΩ 13 KΩ

+ 25 ˚C 2.5 KΩ 11 KΩ

+ 30 ˚C 2.0 KΩ 8.9 KΩ

+ 40 ˚C 1.4 KΩ 6.2 KΩ

+ 50 ˚C 0.8 KΩ 4.3 KΩ

RESISTANCE OF FREEZER

SENSOR

RESISTANCE OF REFRIGERATOR &

DEFROST SENSOR & ROOM SENSOR

• The resistance of the SENSOR has a ±5% common difference.

• Measure the resistance of the SENSOR after leaving it for over 3 minutes in the measuring temperature.

This delay is necessary due to sensor response speed.

• Measure the F-SENSOR, SUPER FROST SENSOR, R1, R2-SENSOR after disconnect CON5 of PWB ASSY, MAIN.

- 34 -

Page 35

COOLING is poor. NO COOLING. 1. If the COMPRESSOR USE TEST MODE1 COMPRESSOR locked or Replace COMPRESSOR.

is poor.

POWER SOURCE 1.

8-4 TROUBLESHOOTING

PROBLEM INDICATED BY CHECK CHECKING METHOD CAUSE SOLUTION

4. Door Line contact. Check the seal when Door liner damaged. Replace door liner.

the door is closed.

3. If SENSOR Check the resistance SENSOR RESISTANCE is Replace SENSOR.

is normal. sticking on the EVAPORATOR . is poor.

is normal. of the Refrigerator poor.

SENSOR.

TEMPERATURE is operates. (forced COOLING).

incorrect CONNECTING WIRE is poor. Refer to 8-2-4. 2 and check

2. If DEFROSTING Check the amount of frost DEFROSTING is poor. See DEFROSTING

FREEZER 1. If FAN MOTOR USE TEST MODE1 FAN MOTOR is poor. Replace the FAN MOTOR.

2. If refrigerant is leaking. Measure the amount of frost Refrigerant leakage. Replace the leaking part and

. sticking on EVAPORATOR replace any lost refrigerant.

and the surface temperature

of the condenser pipe.

DISPLAY operates the MAIN PWB CONNECTOR. is poor.

abnormally CONNECTOR. TRANS FUSE is open. Replace TRANS.

operate.

(forced COOLING).

If less than 7 minutes pass OLP, PTC is poor. Replace OLP, PTC.

after compressor shuts off, COMPRESSOR RELAY is Replace MAIN PWB.

don’t press the KEY and poor.

wait. THE CONNECTING WIRE Check the connection of the

2.

DISPLAY is off.

The whole DISPLAY

LED/SEVEN SEGMENT

DISPLAY LED/

SEVEN SEGMENT

2. If LAMP is dim. Check visually. Applied voltage error. Use boosting TRANS.

3. The connection of Check connection of CONNECTOR connection Reconnect CONNECTOR.

1. FREEZER/ Check if FREEZER/ POWER SOURCE is poor. Check outlet Voltage.

REFRIGERATOR. REFRIGERATOR DOOR IS

OPEN and check display.

is poor. black wire of the MAIN PWB

CONNECTOR (CON2).

blocked.

- 35 -

Page 36

DEFROSTING is NO DEFROSTING. 1. If HEATER emits heat. USE TEST MODE3 HEATER disconnection. Replace HEATER.

poor. (forced DEFROSTING).

COOLING is poor. If REFRIGERATOR 1. If FREEZER TEMPERATURE Check is FREEZER Make sure the

TEMPERATURE is normal. TEMPERATURE is too low. DOOR isattached.

is too low. 2. If amount of cool air from Make sure that the amount FAN MOTOR is poor. Replace FAN MOTOR.

PROBLEM INDICATED BY CHECK CHECKING METHOD CAUSE SOLUTION

3. If ice remains after Make sure that DEFROST Connection is poor. Reassemble the

DEFROSTING. SENSOR is connected. DEFROST-SENSOR.

Make sure that FREEZER /

REFRIGERATOR DOOR is closed.

DOOR does not close Reassemble DOOR.

properly. Replace GASKET.

blocked. Check HEATER PLATE

2. If DRAIN PIPE is Check DRAIN PIPE. DRAIN PIPE is blocked. Remove ice and impurities.

TEMPERATURE FUSE Replace TEMPERATURE

disconnection. FUSE.

DEFROST-SENSOR is poor. Replace DEFROST-SENSOR.

HEATER RELAY is poor. Replace RY2 of MAIN PWB.

Connection is poor. Check EVAPORATOR

3. Door Line contact. Check door seal when Door liner damaged. Replace Door liner.

check supplied on the EVA frozen. See DEFROSTING is poor.

REFRIGERATOR.

door is closed.

FAN MOTOR is and speed of cool air are Passage of cool air Remove impurities.

sufficient. sufficient by touching the is blocked.

resistance.

connection and wire of MAIN

PWB CONNECTOR.

- 36 -

Page 37

8-5 MAIN PWB ASSEMBLY AND PARTS LIST

8-5-1 Main PWB Assembly

- 37 -

Page 38

APPLICATION

8-5-2 Replacement Parts List

- 38 -

P/NO

No

1

6870JB8203A

2

6170JB2012B

6170JB2012C

3

4

6630AQ9106D

5

6630AQ9106E

6630AQ9106B

6

6630JB8004E

7

8

6630JB8004L

6630JB8004C

9

6630JB8004F

10

11

0IZZJB2054V

12

0ISK635100A

13

0IPMGNE001A

0IKE431000A

14

0IKE780500Z

15

16

0IKE650030B

0IKE704200A

17

18

0ITO777400A

6920ALZ001B

19

6920JB2003A

20

6920JB2003E

21

6920JB2009B

22

-

23

24

6212JB8001B

6102JB8001B

25

6102W5V007A

26

27

0DB360000AA

28

0DD400409AC

29

0DR107009AA

30

0DRSA00070A

31

0CE105BK638

32

0CE106EK638

33

0CE227BF638

34

0CE227BH638

35

-

36

0CE476BK638

37

0CE476ZV6E0

38

0CE687YH6E0

39

0CE687YJ618

40

0CK102DK96A

41

0CK1040K949

42

0CK104DK9BA

43

0CK22102510

44

0CK2230K949

45

0CK223DK96A

46

0CK4710K519

47

0CQ1041N509

48

0CK102DK96A

48

0CQ4732Y430

49

0CQ47418670

50

0LR1001M4F0

51

0RD1001G609

52

0RD1002G609

53

0RD2001G609

54

0RD3901G609

55

0RD4701G609

56

0RD5603H609

57

0RD2001G609

58

0RD4701G609

59

0RJ2701L622

60

0RH1002L622

61

0RH1004L622

62

0RH1001L622

63

0RH2001L622

64

0RH3300L622

65

0RH4701L622

66

0RD1000E672

67

0RD1501H609

68

0RJ0000E672

69

0RJ2401E472

70

0RJ6800E672

71

72

0RJ9101E472

73

0RJ1002E472

74

0RN1622G409

75

0RN2612G409

76

0RS0151J609

77

0RS0101J609

0RS5602K641

78

0RS3303J609

79

80

0TR319809AA

81

0TRKE00008A

82

0TRKE80016A

83

6200JB8004A

84

6200JB8007X

85

6210JB8001A

86

6600RRT001Z

87

0DZMR00029A

88

6854B50001A

89

0FZZJB3001A

1SBF0302418

90

91

4920JB3007A

92

93

49111004

94

59333105

95

9VWF0120000

DESCRIPTION

PWB(PCB)

TRANSFORMER,SMPS[COIL]

TRANSFORMER,SMPS[COIL]

CONNECTOR (CIRC),WAFER

CONNECTOR (CIRC),WAFER

CONNECTOR (CIRC),WAFER

CONNECTOR (CIRC),WAFER

CONNECTOR (CIRC),WAFER

CONNECTOR (CIRC),WAFER

CONNECTOR (CIRC),WAFER

IC,DRAWING

IC,POWER MANAGEMENT

IC,POWER MANAGEMENT

IC,KEC

IC,LINEAR

IC,KEC

IC,KEC

IC,DRAWING

RELAY

RELAY

RELAY

RELAY

RESONATOR,CERAMIC

VARISTOR

VARISTOR

DIODE,RECTIFIERS

DIODE,RECTIFIERS

DIODE,RECTIFIERS

DIODE,RECTIFIERS

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED ELECTROLYTIC

CAPACITOR,FIXED CERAMIC(HIGH DIELECTRIC)

CAPACITOR,FIXED CERAMIC(High dielectric)

CAPACITOR,FIXED CERAMIC(High dielectric)

CAPACITOR,FIXED CERAMIC(High dielectric)

CAPACITOR,FIXED CERAMIC(High dielectric)

CAPACITOR,FIXED CERAMIC(HIGH DIELECTRIC)

CAPACITOR,FIXED CERAMIC(High dielectric)

CAPACITOR,FIXED FILM

CAPACITOR,FIXED CERAMIC(HIGH DIELECTRIC)

CAPACITOR,FIXED FILM

CAPACITOR,FIXED FILM

INDUCTOR,RADIAL LEAD

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,FIXED CARBON FILM

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,FIXED CARBON FILM

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,METAL GLAZED(CHIP)

RESISTOR,FIXED METAL FILM

RESISTOR,FIXED METAL FILM

RESISTOR,FIXED METAL FILM

RESISTOR,FIXED METAL OXIDE FILM

RESISTOR,FIXED METAL OXIDE FILM

RESISTOR,FIXED METAL OXIDE FILM

RESISTOR,FIXED METAL OXIDE FILM

TRANSISTOR

TRANSISTOR,BIPOLARS

TRANSISTOR,BIPOLARS

FILTER(CIRC),EMC

FILTER(CIRC),EMC

FILTER(CIRC),EMC

SWITCH,TACT

DIODE,ZENERS

JUMP WIRE

FUSE,DRAWING

SCREW TAP TITE(S),BINDING HEAD

HEAT SINK

SOLDER,SOLDERING

FLUX

SOLDER(ROSIN WIRE) RS0

SPEC

BEST BRAVO-PJT

DL-PJT 2.9MH/20W

YW396-09AV

YW396-07AV

YW396-05AV

SMW250 YEONHO 6P 2.5MM STRAIGHT SN

SMW250 YEONHO 12P 2.5MM STRAIGHT SN

SMW250 YEONHO 4P 2.5MM STRAIGHT SN

SMW250 YEONHO 7P 2.5MM STRAIGHT SN

TMP87C846N 42P SDIP BK MASK BRAVO33-PJT BEST/BETTER

STR-G6351 5PIN BK SMPS 2,4PIN FORM

PS2561L1-1-V NEC 4P,DIP BK = TLP721F

KIA431 3 PIN TP - KIA7805PI 3DIP BK 5V 1A REFORM

KID65003AP 16P,SDIP BK DRIVE IC

KIA7042P KEC 3P BK RESET

TA7774AP 16,SDIP BK DRIVE,IC STEPPING MOTOR

ALZ12B12 NAIS 250VAC 16A 12VDC 1A NO VENTING

G5N-1A OMRON 250VAC 1.5A 12VDC 1A JAPAN

G5NB-1A-E(CHINA) OMRON 250VAC 5A 12VDC 1A NO VENTING

G5SB-14 OMRON 250VAC 5A 12VDC 1C NO VENTING

CSTS0400MG03 MURATA 4MHZ . TP -

INR14D621 ILJIN UL/VDE BK 620V

INR14D331K IL JIN UL/CSA/VDE BK

D3SBA60 BK SHINDENGEN - 600V 4A 80A - 10UA

RECT1N4004 TP

FR107 TP RECTRON DO41 1000V 1A 30A 500NSEC 5A

RL2 SANKEN BK NON 400V 2A 40A 50NSEC 10UA

1UF KME,RG,YX 50V 0.2 FM5 TP 5

10UF KMG 50V 20% FM5 TP 5

220UF KME TYPE 16V 20% FM5 TP 5

220UF KME,RG 25V 20% FM5 TP 5

47UF KME TYPE 50V 20% FM5 TP 5

47UF HE 450V 20% BULK SNAP IN

680UF RX 25V 20% BULK SNAP IN

680UF RX 35V 20% TP 5 FL

1NF 2012 50V 80%,-20% R/TP X7R

0.1UF D 50V 80%,-20% F(Y5V) TA52

0.1UF 2012 50V 80%,-20% R/TP JE

220P 2KV K B S

22NF 50V Z F TA52

22NF 2012 50V 80%,-20% R/TP X7R

470PF 50V K B TA52

0.1UF D 100V 10% PE TP5

1NF 2012 50V 80%,-20% R/TP X7R

47000PF S 630V 5% M/PE NI R

0.47UF D 275V 20% M/PP NI R

1000UH 20% R 6X12.5 BULK

1K OHM 1/4 W 5% TA52

10K OHM 1/4 W 5% TA52

2K OHM 1/4 W 5% TA52

3.9K OHM 1/4 W 5% TA52

4.7K OHM 1/4 W 5% TA52

560K OHM 1/2 W 5% TA52

2K OHM 1/4 W 5% TA52

4.7K OHM 1/4 W 5% TA52

2.7K OHM 1/8 W 5% 2012 R/TP

10KOHM 1/8 W 5% 2012 R/TP

1MOHM 1/8 W 5% 2012 R/TP

1K OHM 1 / 8 W 2012 5.00% D

2K OHM 1 / 8 W 5% 2012 R/TP

330 OHM 1/8 W 5% 2012 R/TP

4.7K OHM 1/8 W 5% 2012 R/TP

100 OHM 1/8 W 5% 2012 R/TP

1.5K OHM 1/2 W 5% TA52

0 OHM 1/8 W 5% 2012 R/TP

2.4K OHM 1/8 W 1% 2012 R/TP

680 OHM 1/8 W 5% 2012 R/TP

6.8K OHM 1/4 W 5% TA52RESISTOR,FIXED CARBON FILM 0RD6801G609

9.1K OHM 1/8 W 1% 2012 R/TP

10K OHM 1/8 W 1.00% 2012 R/TP

16.2K OHM 1/4 W 1.00% TA52

26.1K OHM 1/4 W 1.00% TA52

1.5 OHM 1 W 5.00% TA52

1 OHM 1 W 5% TA52

56K OHM 2 W 5.00% F20

330K OHM 1 W 5.00% TA52

KTC3198-TP-Y (KTC1815)KEC

KEC KTB1151 BK TO126 60V 5A

KEC KRC106S R/TP SOT23 50V 100MA

CV940050 TNC - UV11-05320 TNC BK 0.5A 320MH

BFS3510A0 SAMWHA TP52 BEAD FILTER

JTP1280A6 JEIL 12VDC 50MA 1N5232B MOTORORA TP DO34 0.5W 5.6V 81MA .PF

0.6MM 52MM TP TAPING SN

2A 250V - SLOW-BLOW LITTELFUSE,TRIAD

+ D3.0 L8.0 MSWR3/FZY

23.3*17*25 DRIVE IC STR R-S64,65,73 2PIN 1-SCREW 3MM NA HEESUNG METAL BAR SN 63% NA

JS-71 KOKI SANEI KOREA(KSK) SG;0.808 +/-0.003

D1.20

MAKER

DOO SAN

SAM IL

YEON HO

YEON HO

YEON HO

YEON HO

YEON HO

YEON HO

YEON HO

TOSHIBA

SANKEN

NEC

KEC

KEC

KEC

KEC

TOSHIBA

NAIS

OMRON

OMRON

OMRON

MURATA

IL JIN

IL JIN

SHINDENGEN

DELTA

DELTA

SANKEN

SAM WHA

SAM WHA

SAM WHA

SAM WHA

SAM WHA

SAM WHA

SAM WHA

SAM WHA

MURATA

SAM WHA

MURATA

SAM WHA

SAM WHA

MURATA

SAM WHA

SAM WHA

MURATA

SAM WHA

SAM WHA

TNC

SMART

SMART

SMART

SMART

SMART

SMART

SMART

SMART

ROHM

ROHM

ROHM

ROHM

ROHM

ROHM

ROHM

ROHM

SMART

ROHM

ROHM

ROHM

SMART

ROHM

ROHM

SMART

SMART

SMART

SMART

SMART

SMART

KEC

KEC

KEC

TNC

TNC

SAM WHA

JEIL

DEL TA

DAE A LEAD

SAM JU KYO YUK

HAENG SUNG

(IC2)

-

-

-

REMARK

T=1.6

TRANS

TRANS

CON1

CON2

CON3

CON4

CON5

CON6

CON7

IC1

IC2

IC3

IC4

IC5

IC6

IC7

IC8

RY1

RY5,RY6

RY2-4

-

OSC1

VA1

VA1

BD1

D7

D1,D2,D5,D6,D8,D9

D3,D4

CE10

CE6-CE9

CE5

CE11,CE12

CE2

CE1

CE3

CE4

CC17,CC20

CC3,CC4,CC6,CC7

CC5,CC10

CC2

CC8,CC9,CC11-15,CC18

CC1

CM4

CC20

CM3

CM1

L3,L4

R19

R29,R35,RCR1

R17,R20,R21,R22,R26,R27,R36

R34,R41

R18,R33,R40

R2

R45

R46

R21

R15,R28,R30,R42,R8

R13

R7

R23-R25,R38,R39

R31,R43

R14,R16,R37

R5

R32,R44

RJ1

RL2

R6

R4

RL1

RT1

RF1

RR1,RD1

ROCP

ROCP

R3

R1

Q3,Q5

Q2,Q4

Q1

L1

L2

FB1

SW1

ZD1

J03,J04,J06-J12,J15(10MM)

J13,J14(8MM)

J01,J02,J05(12.5MM)

FUSE1

(IC2)

-

-

-

Page 39

8-5-3 PWB Assembly, Display, And Parts List

- 39 -

Page 40

- 40 -

Page 41

8-5-4 Circuit Diagram of Display

- 41 -

Page 42

8-6 PWB DIAGRAM

8-6-1 PWB Main Assembly

- 42 -

POWER

ICE MAKER

LAMP-F

LAMP-R

CON1

RUNNING CAPACITOR

STARTING CAPACITOR

PTC START

DEF-HEATER

WATER VALVE

RC-FILTER

FRENCH DOOR

HEATER

VALVE II

RC-FILTER

9

7

COMP

M

COOLING-FAN

FUSE-M

nc

A

B

nc

DOOR S/W-F

nc

C

D

nc

DOOR S/W-R1&R2

M

M

BD1

CM2

470nF

275VAC

L2

32mH/0.5A

FUSE1

250V/2A

L1

5mH/4A

VA1

CM1

470nF

275VAC

D3SBA60

R2

560KJ

1/2W

R1

4

IC2

STR

G6551

2W

/450V

1

2

5

3

D1

FB1

FR107

D2

FR107

R4

CE2

6.8KJ

47uF

/50V

4

IC3-1

3

R6*

680J

CC1

471

R3

CE1

56KJ

47uF

TRANS

1

CM3

473

/630V

R5*

100J

Rocp

10

12

2

RL2

5

680uF

4

8

CC2

221

/2KV

5

3

CON2

OLP

1

1

com

3

com

5

com

com

ALZ21B12

G5NB-1A

G5NB-1A

G5NB-1A

RY1

RY2

RY3

RY4

RY5

G5N-1A

1N4004

D7

7

CON3

5

RY6

G5N-1A

3

1

OSC1

CSTS0400MG03

TEMP.COMPENSATION (REPLACING RCR1)

COLD-STORAGE ROOM

RESISTANCE OF

RCR1

180KJ

56KJ

33KJ

18KJ

12KJ

10KJ

8.2KJ

5.6KJ

3.3KJ

2KJ

470J

TEMP. COMPENSATION

+2.5 C

+2 C

+1.5 C

+1 C

+0.5 C

0 C

-0.5 C

-1 C

-1.5 C

-2 C

-2.5 C

NOTE

WARMER

FACTORY

COLDER

10KJ

RCR1

10KJ

CC6

104

R15*

D3

12V

RL2

+15.5V

D4

CE4

/35V

13

14

11

16

15

12

CE3

680uF

/25V

CC3

104

IC6

KID65003AP

1

KIA7042

R7*

1.8KJ

RL1*

9.1KF

IC3

CM4

R8*

103/100V

1KJ

RL2*

2.4KF

IC4

KIA431

IC5

5V

22

7805

CE5

CC4

220uF

104

/16V

9

4

3

6

1

2

5

8

R13*

IC7

R14*

3

2

VDD

Varef

42

CC5*

104

21

Vss

Vass

17

TEST

10

P06

11

P05

14

P02

13

P03

12

P04

9

P07

19

XIN

1MJ

20

XOUT

4.7KJ

18

RESET

CC7

104

27

P64

TOSHIBA TMP87CH46N(IC1)

1,2,3,4,5,8,14-16,29,30,35,40,41

Page 43

(PDO/PWM)

- 43 -

R31

Q2

330J

R33

4.7KJ

R34

6