Page 1

Room Air Conditioner

SERVICE MANUAL

CAUTION

- BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

- ONLY FOR AUTHORIZED SERVICE.

MODEL: LP6000ER

LP7000R

WEBSITE http://biz.LGservice.com

E-MAIL http://www.LGEservice.com/techsup.html

Page 2

—2—

1. PREFACE

1.1 SAFETY PRECAUTIONS................................2

1.2 INSULATION RESISTANCE TEST.................2

1.3 SPECIFICATIONS...........................................3

1.4 FEATURES......................................................4

1.5 CONTROL LOCATIONS .................................4

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS....................................5

2.1.1 FRONT GRILLE .....................................5

2.1.2 TOP COVER ..........................................5

2.1.3 CABINET................................................5

2.1.4 CONTROL BOX .....................................5

2.2 AIR HANDLING PARTS ..................................6

2.2.1 AIR GUIDE AND CROSS FLOW FAN...6

2.2.2 FAN AND SHROUD ...............................6

2.2.3 INDOOR FAN MOTOR...........................7

2.2.4 AIR GUIDE LOWER...............................7

2.3 ELECTRICAL PARTS......................................7

2.3.1 OVERLOAD PROTECTOR....................7

2.3.2 COMPRESSOR......................................7

2.3.3 CAPACITOR...........................................8

2.3.4 POWER CORD ......................................8

2.3.5 OUTDOOR MOTOR...............................9

2.4 REFRIGERATION CYCLE..............................9

2.4.1 CONDENSER.........................................9

2.4.2 EVAPORATOR.......................................9

2.4.3 CAPILLARY TUBE.................................9

3.

INSTALLATION

3.1 HOW TO INSTALL THE UNIT.......................12

3.2 CHECKING INSTALLATION.........................12

3.3 WINDOW REQUIREMENTS.........................12

3.4 INSTALLATION KITS CONTENTS ...............12

3.5 SUGGESTED TOOL REQUIREMENTS .......13

3.6 HOW TO INSTALL ........................................13

3.7 REMOVAL FROM WINDOW.........................16

4.

TROUBLESHOOTING GUIDE

4.1 OUTSIDE DIMENSIONS...............................16

4.2 PIPING SYSTEM...........................................17

4.3 TROUBLESHOOTING GUIDE......................18

5. SCHEMATIC DIAGRAM

5.1 CIRCUIT DIAGRAM ......................................27

5.2 ELECTRONIC CONTROL DEVICE...............28

5.3

COMPONENTS LOCATION(FOR AC P.C.B ASM)

...

29

5.4

COMPONENTS LOCATION(FOR DC P.C.B ASM)

..29

6. EXPLODED VIEW..................................30

7. REPLACEMENT PARTS LIST........31

1. PREFACE

This

SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the ROTARY SWITCH

or POWER SWITCH to OFF and unplug the power

cord.

2. Observe the original lead dress.

If a short circuit is found, replace all parts which

have been overheated or damaged by the short

circuit.

3. After servicing the unit, make an insulation resistance test to protect the customer from being

exposed to shock hazards.

1.2

INSULATION RESISTANCE TEST

1.Unplug the power cord and connect a jumper

between 2 pins (black and white).

2. The grounding conductor (green) is to be open.

3. Measure the resistance value with an ohm meter

between the jumpered lead and each exposed

metallic part on the equipment at all the positions

(except OFF) of the ROTARY SWITCH.

4. The value should be over 1MΩ.

CONTENTS

Page 3

—3—

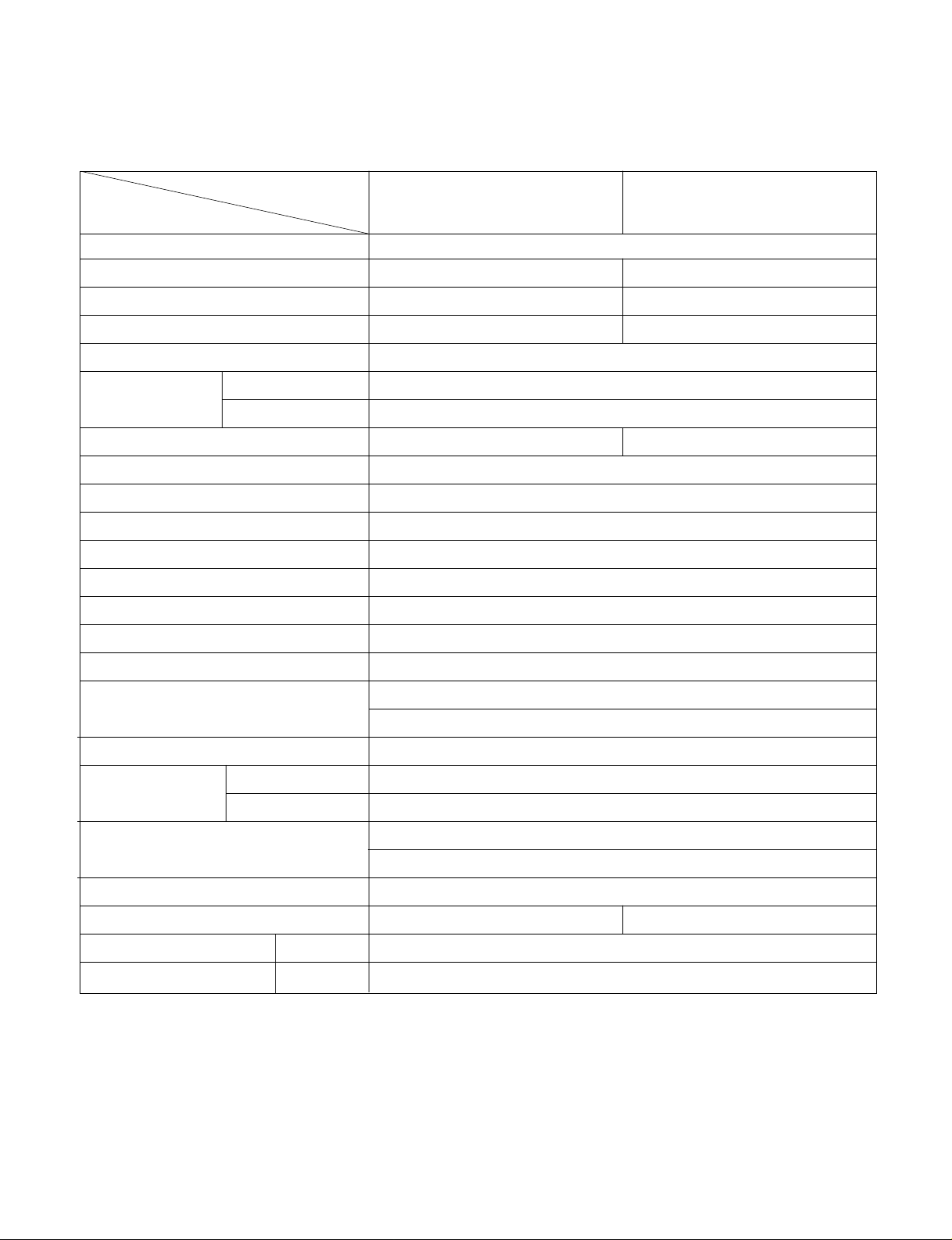

POWER SUPPLY

COOLING CAPACITY (Btu/h)

INPUT (W)

RUNNING CURRENT (A)

E.E.R (BTU/W.h)

INDOOR (°C)

OUTDOOR (°C)

REFRIGERANT (R-22) CHARGE

EVAPORATOR

CONDENSER

FAN, INDOOR

FAN, OUTDOOR

FAN SPEEDS, FAN/COOLING

FAN MOTOR

OPERATION CONTROL

ROOM TEMP. CONTROL

AIR DIRECTION CONTROL

CONSTRUCTION

PROTECTOR

COMPRESSOR

FAN MOTOR

POWER CORD

DRAIN SYSTEM

NET WEIGHT (lbs/kg)

OUTSIDE DIMENSION (inch)

(WxHxD) (mm)

115V, 60Hz

6,000 7,000

560 700

5.2 6.5

10.7 10.0

26.7(DB)* 19.4(WB)**

35(DB)* 23.9(WB)**

435g(15.3 oz) 350g(12.3 oz)

2ROW9STACKS,SLITFINTYPE

2 ROW 14 STACKS, LOUVER FIN TYPE

CROSS FLOW FAN

AXIAL FAN

3/3

4POLES

REMOTE CONTROLLER

THERMISTOR

VERTICAL LOUVER (RIGHT & LEFT)

HORIZONTAL LOUVER (UP & DOWN)

TOP-DOWN CHASSIS

OVERLOAD PROTECTOR

INTERNAL THERMAL PROTECTOR

3 WIRE WITH GROUNDING

ATTACHMENT PLUG (CORD-CONNECTED TYPE)

DRAIN PIPE SPLASHED BY FAN SLINGER

55/25 57/26

235/8 x12x181/32

600x305x458

LP6000ER LP7000R

MODELS

ITEMS

OPERATING

CONDITION

1.3 SPECIFICATIONS

1.3.1 FOR LP6000ER/LP7000R

* DB:Dry Bulb

**

WB:Wet Bulb

Page 4

—4—

1.4 FEATURES

• Designed for COOLING ONLY.

• Powerful and quiet cooling.

• Simple installation and service.

• Low air-intake, top cool-air discharge.

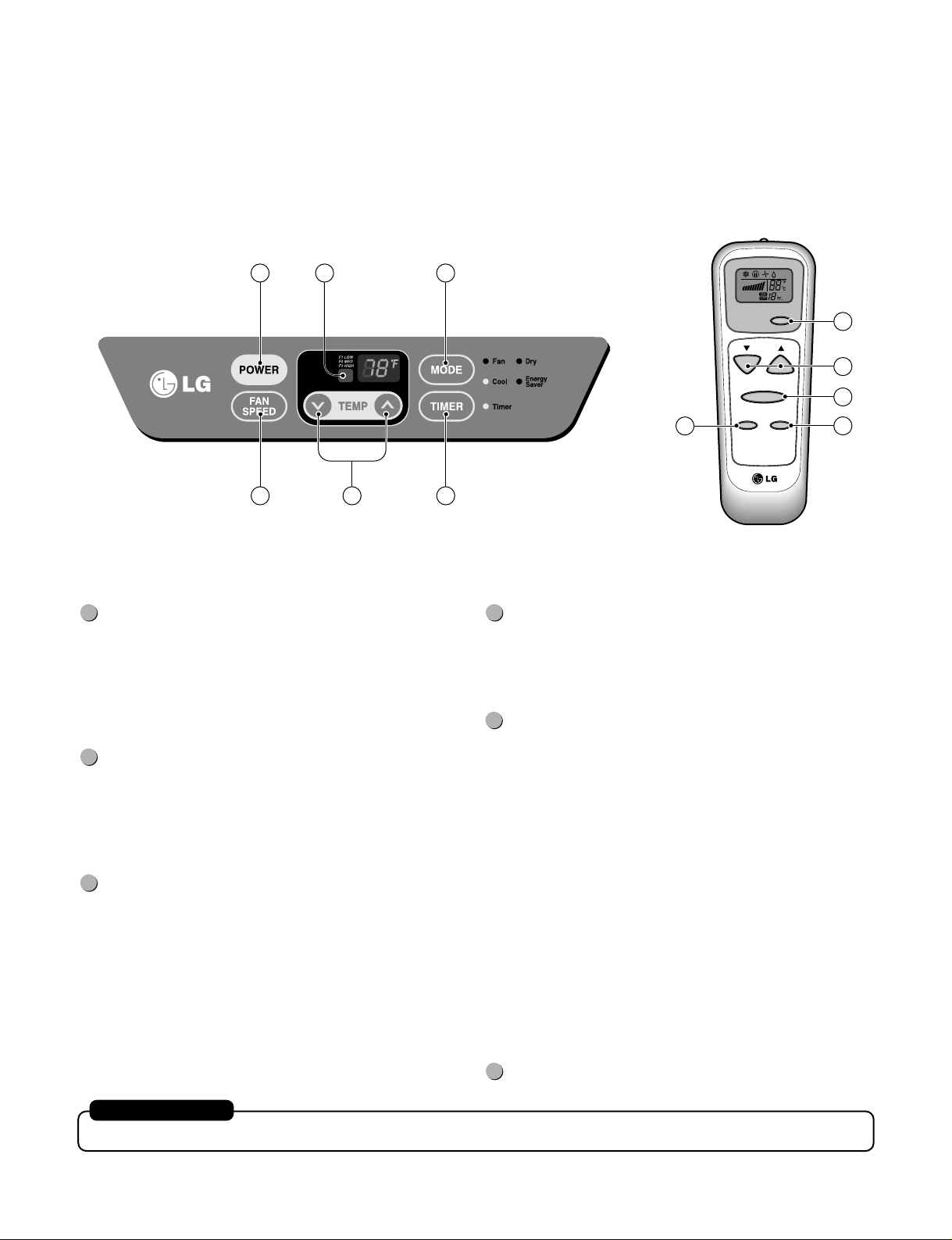

1.5 CONTROL LOCATIONS

• Built-in adjustable THERMISTOR

• Washable one-touch filter

• Compact size

• Reliable and efficient rotary compressor.

Timer

Air

Purifier

AIR

PURIFIER

Power

Temp

Timer Mode

Auto

Swing

Fan Speed

1

5

2

4

3

52 4

31 6

Precaution: The Remote Control unit will not function properly if bright light strikes the sensor window of the air

conditioner or if there are obstacles between the Remote Control unit and the air conditioner.

POWER

• To turn the air conditioner ON, push this button. To

turn the air conditioner OFF, push the button again.

• This button takes priority over any other button.

• When you first turn it on, the unit is in cool mode,

high fan speed, temperature setting at 72˚F.

TEMPERATURE SETTING

• Use this button to automatically control the

temperature of the room.

The temperature can be set within a range of 60°F

to 86°F by increments of 1°F.

MODE

- Every time you push this button, it will cycle through

COOL, ENERGY SAVER, FAN and DRY.

- ENERGY SAVER

• The fan stops when the compressor stops cooling.

Approximately every 3 minutes the fan will turn on

and the unit will check the room air to determine if

cooling is needed.

FAN SPEED

• Every time you push this button, it advances the

setting as follows: {High(F3) → Low(F1) → Med(F2)

→ High(F3)}

TIMER

- SHUT-OFF TIME

• You will usually use shut-off time while you sleep.

• With unit running, use Timer to set number of hours

until shut-off.

• For your sleeping comfort, once Time is set, the

Temperature setting will raise 2°F after 30 min, and

2°F after another 30 min.

• Every time you push Timer button, it advances the

Timer setting as follows: 1 Hour → 2 Hours → etc. →

12 Hours maximum.

- START TIME

• While unit not running, use timer to set number of

hours before unit starts.

• Every time you push Timer button, it advances the

Timer setting as follows: 1 Hour → 2 Hours → etc. →

12 Hours maximum.

REMOTE CONTROL SENSOR

6

5

4

3

2

1

AUTO RESTART

When power is restored after an electrical power failure, the unit will begin to run at its last setting.

Page 5

2. DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Unplug the unit from source of power.

2. Remove the 2 screws securing the front

Grille.(See Figure 1)

3. Push the grille up from the bottom and pull the

top of the grille way from the cabinet to lift the

top tabs out of their slots.(See Figure 2)

4. Disconnect display connector.

2.1.2 TOP COVER

1. Disconnect the unit from the power source.

2. Remove the front grille.(Refer to section 2.1.1)

3. Remove curtains on both side.

4. Remove 5 screws that secure the top cover to

the cabinet.(See Figure 3)

2.1.3 CABINET

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to section 2.1.1)

3. Remove the top cover. (Refer to section 2.1.2)

4. Remove 4 screws that secure the cabinet to the

base pan. (See Figure 4)

5. Remove the cabinet.

6. Re-install by referring to the procedures above.

2.1.4 CONTROL BOX

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the screw that fastens the power cord.

4. Remove the grounding screw from the

evaporator channel and remove the thermistor

from the evaporator fin.

5. Remove the 2 screws that fasten the control

box cover and open the control box cover.(See

Figure 5)

6. Remove the housing that connects motor and

wires come form compressor.

7. Remove the screw that secures the control box

and base pan.

8. Remove the 2 screws that secure the control

box and motor mount.(See Figure 6)

9. Move the control box upward.

—5—

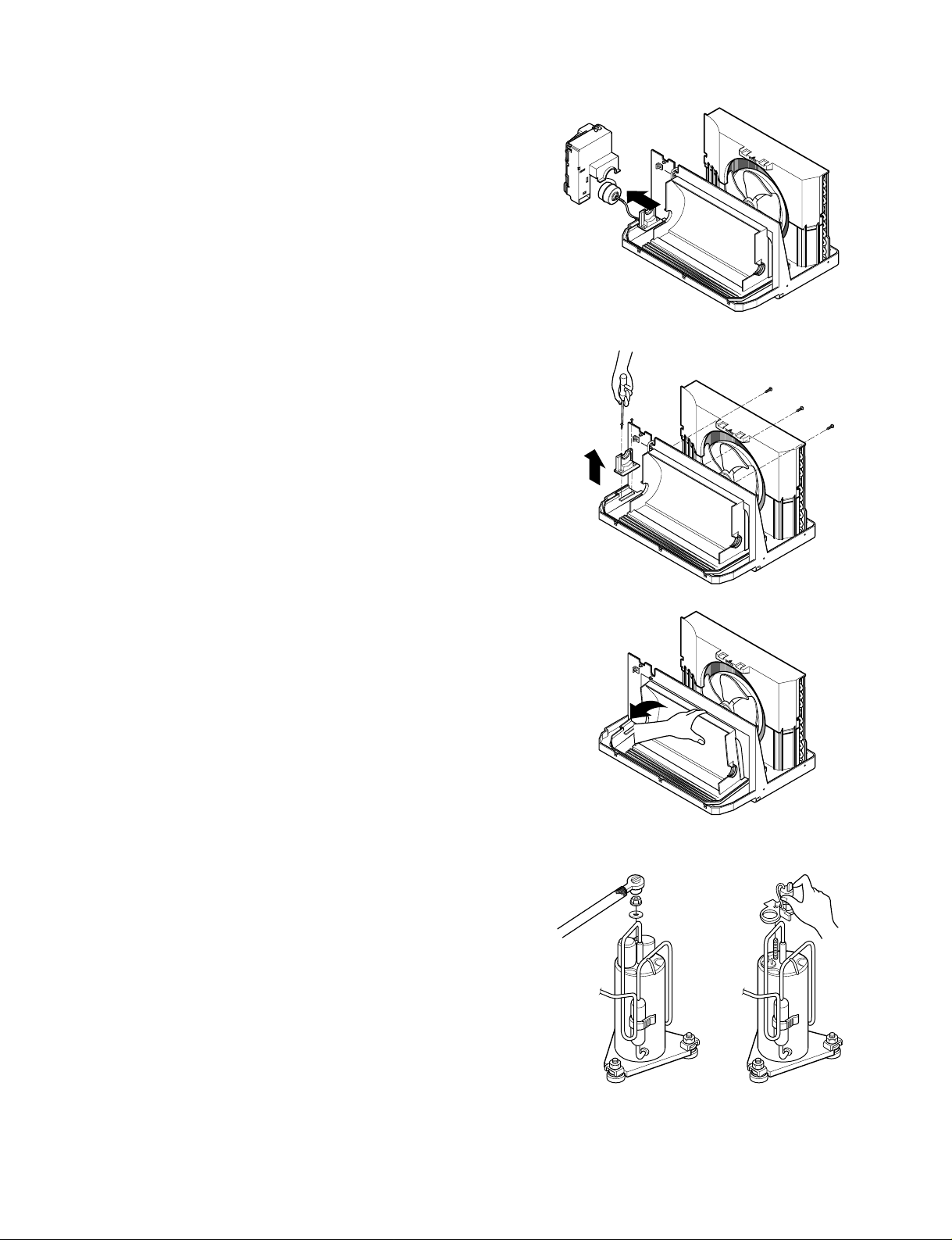

Figure 1

Figure 2

Figure 4

Figure 6

Figure 3

Figure 5

Page 6

—6—

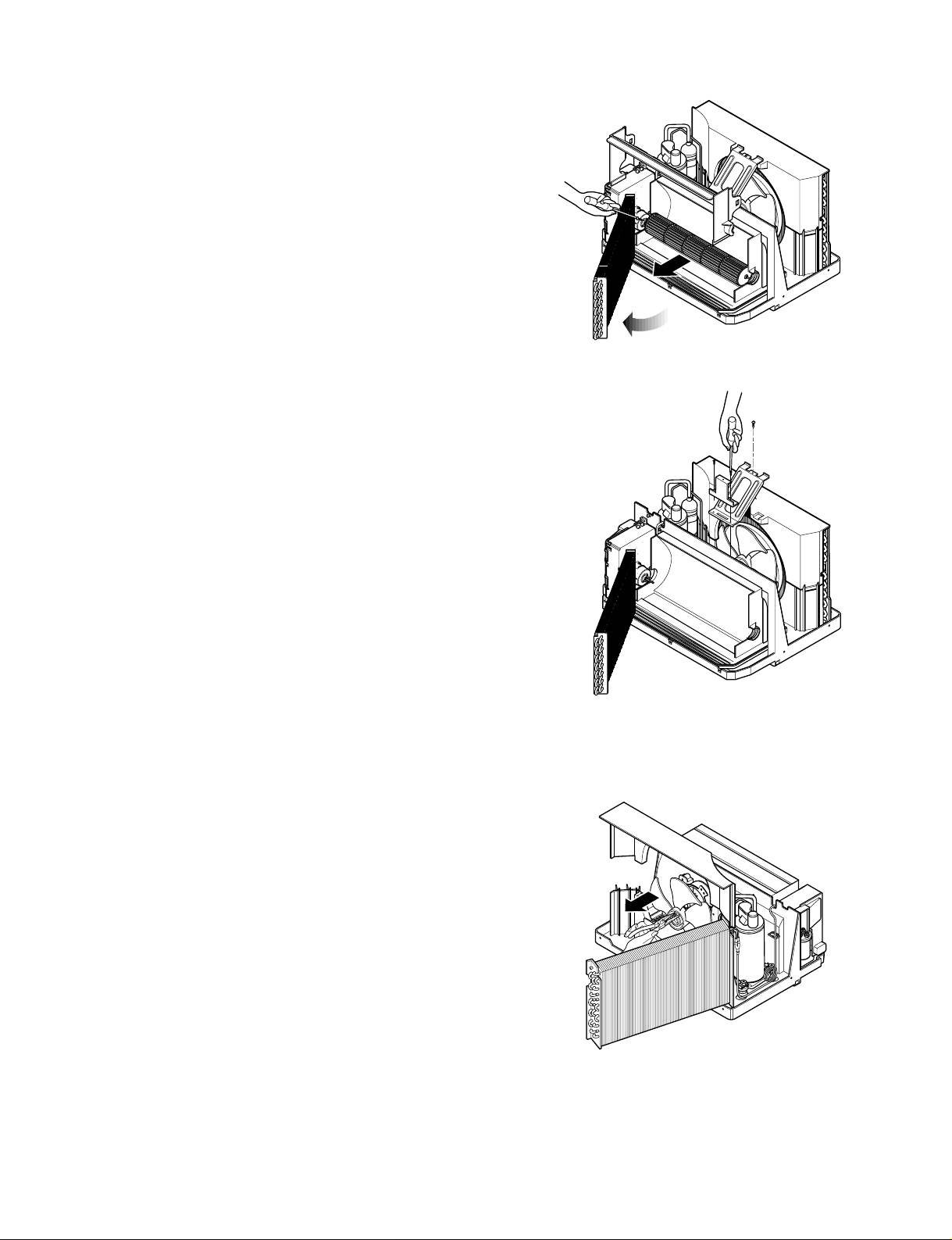

2.2 AIR HANDLING PARTS

2.2.1 AIR GUIDE UPPER AND CROSS

FLOW FAN

1. Disconnect the unit from the power source.

2. Remove the front grille.

(Refer to Section 2.1.1)

3. Remove the top cover. (Refer to Section 2.1.2)

4. Remove the cabinet. (Refer to Section 2.1.3)

5. Remove the control box. (Refer to Section

2.1.4)

6. Move the evaporator forward, pulling it upward

slightly.

7. Pull the air guide upper and remove it.(See

Figure 7)

8. Loosen the bolt securing the cross flow fan to

the motor (do not remove).

9. Pull the cross flow fan and remove it.

10. Re-install by referring to the procedures

above.

2.2.2 FAN AND SHROUD

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the top cover. (Refer to Section 2.1.2)

4. Remove the cabinet. (Refer to Section 2.1.3)

5. Remove 3 screws which the fasten the brace

and the bracket. (See Figure 8)

6. Remove the brace and the bracket.

7. Remove 4 screws which fasten the condenser

channel, shroud and base pan.

8. Move the shroud upward and remove it.

9. Move the condenser forward, pulling it slightly

upward .

10. Remove the clamp with a hand plier which

secures the fan.(See Figure 9)

11. Remove the fan.

14. Re-install by referring to the procedures

above.

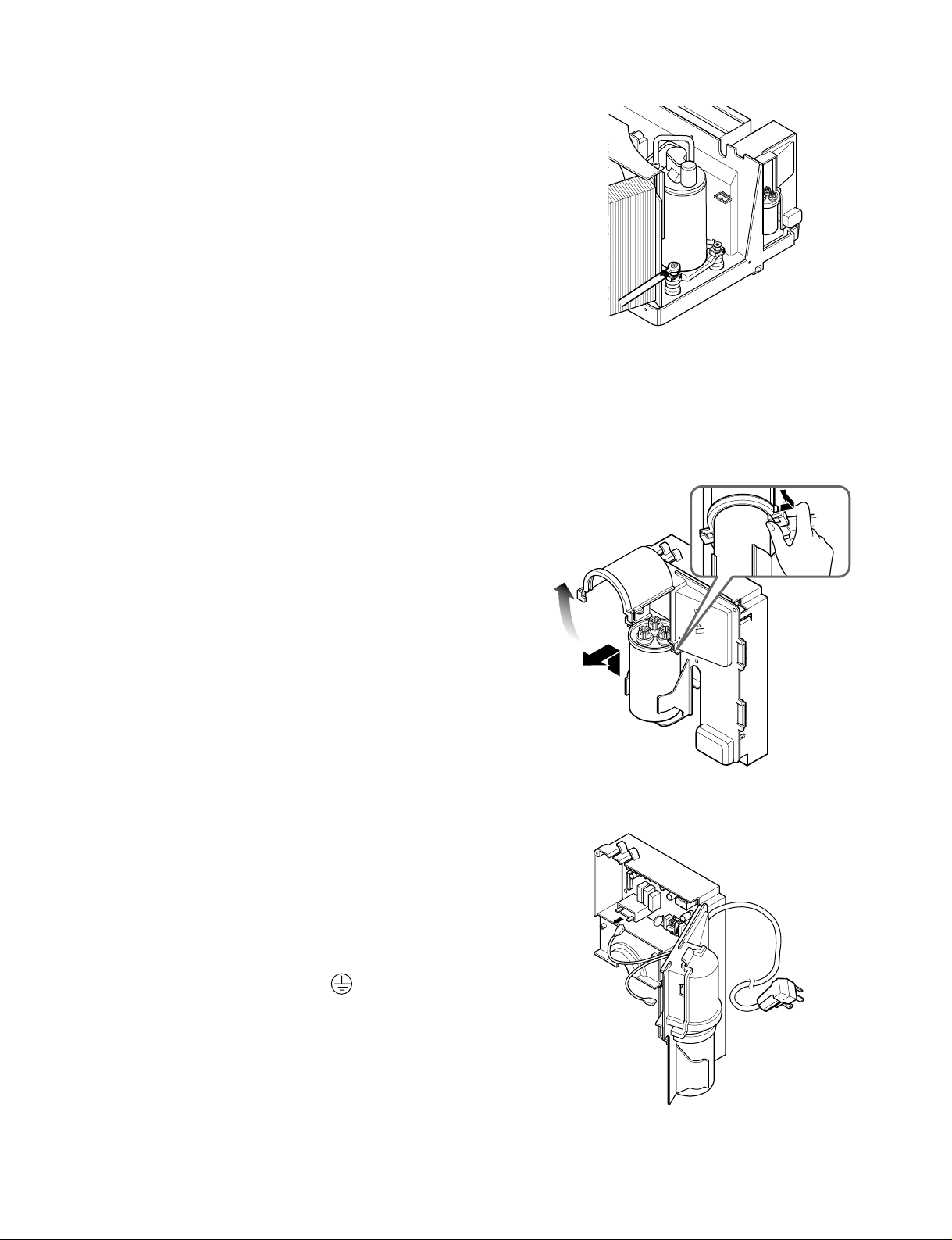

Figure 7

Figure 8

Figure 9

Page 7

—7—

2.2.3 INDOOR FAN MOTOR

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the control box.

(Refer to Section 2.1.4)

4. Remove the air guide upper and cross flow fan.

(Refer to Section 2.2.1)

5. Remove the motor.(See Figure 10)

6. Re-install by referring to the procedures above.

2.2.4 AIR GUIDE LOWER

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the top cover. (Refer to Section 2.1.2)

4. Remove the control box.

(Refer to Section 2.1.4)

5. Remove the air guide upper and cross flow fan.

(Refer to Section 2.2.1)

6.

Remove the motor. (Refer to

Section

2.2.3)

7.

Remove 2 screws which fasten the mount motor

and remove mount motor. (

See Figure 11

)

8. Remove the fan and shroud.(Refer to Section

2.2.2)

9. Remove 3 screws that secure the air guide to

the base pan. (See Figure 11)

10. Pull the airguide toward youself. (See Figure

12)

11. Re-install by referring to the procedures above.

2.3 ELECTRICAL PARTS

2.3.1 OVERLOAD PROTECTOR

1. Remove the front grille, top cover and cabinet.

(Refer to Section 2.1)

2. Remove the nut which fastens the terminal

cover.

3. Remove the terminal cover.

4. Remove all the leads from the overload

protector.

5. Remove the overload protector.

6. Re-install the components by referring to the

removal procedure above.

(See Figure 13 and 14)

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Page 8

—8—

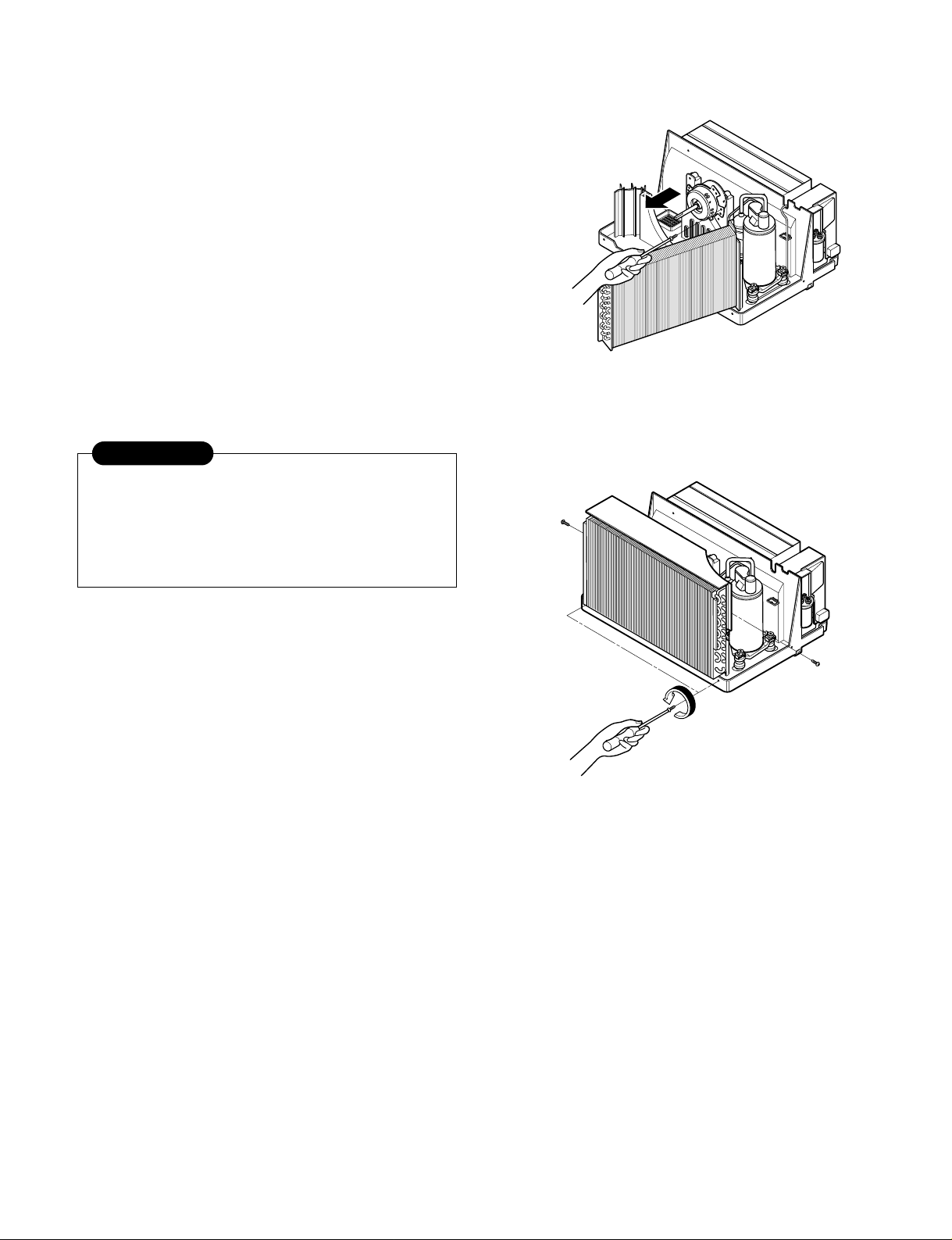

2.3.2 COMPRESSOR

1. Remove the front grille, top cover and cabinet.

(Refer to Section 2.1)

2. Discharge the refrigerant system using a

FreonTMRecovery System.

If there is no valve to attach the recovery

system, install one (such as a Watco A-1)

before venting the FreonTM. Leave the valve in

place after servicing the system.

3. Remove the overload protector. (Refer to

section 2.3.1)

4. After purging the unit completely, unbraze the

suction and discharge tubes at the compressor

connections.

5. Remove the 3 nuts and the 3 washers that

fasten the compressor.(See Figure 15)

6. Remove the compressor.

7. Re-install the components by referring to the

removal procedure, above.

2.3.3 CAPACITOR

1. Remove the front grille. (Refer to Section 2.1.1)

2. Open the capacitor cover. (See Figure 16)

3. Remove all the leads of capacitor terminals.

4. Re-install the components by referring to the

removal procedure above.

2.3.4 POWER CORD

1. Remove the control box.(Refer to section 2.1.4)

2. Open the control box cover.

3. Disconnect two leads from the capactitor and

relay.

4. Remove a screw securing the clip with cord to

the control box.

5. Pull out the power cord.

6. Re-install by referring to procedures above.(Use

only one ground-marked hole for ground

connection.)

7. If the supply cord of this appliance is damaged,

it must be replaced by the special cord.

(The special cord means the cord that has the

same specification marked on the supply cord

attached at the unit.)

Figure 15

Figure 16

Figure 17

Page 9

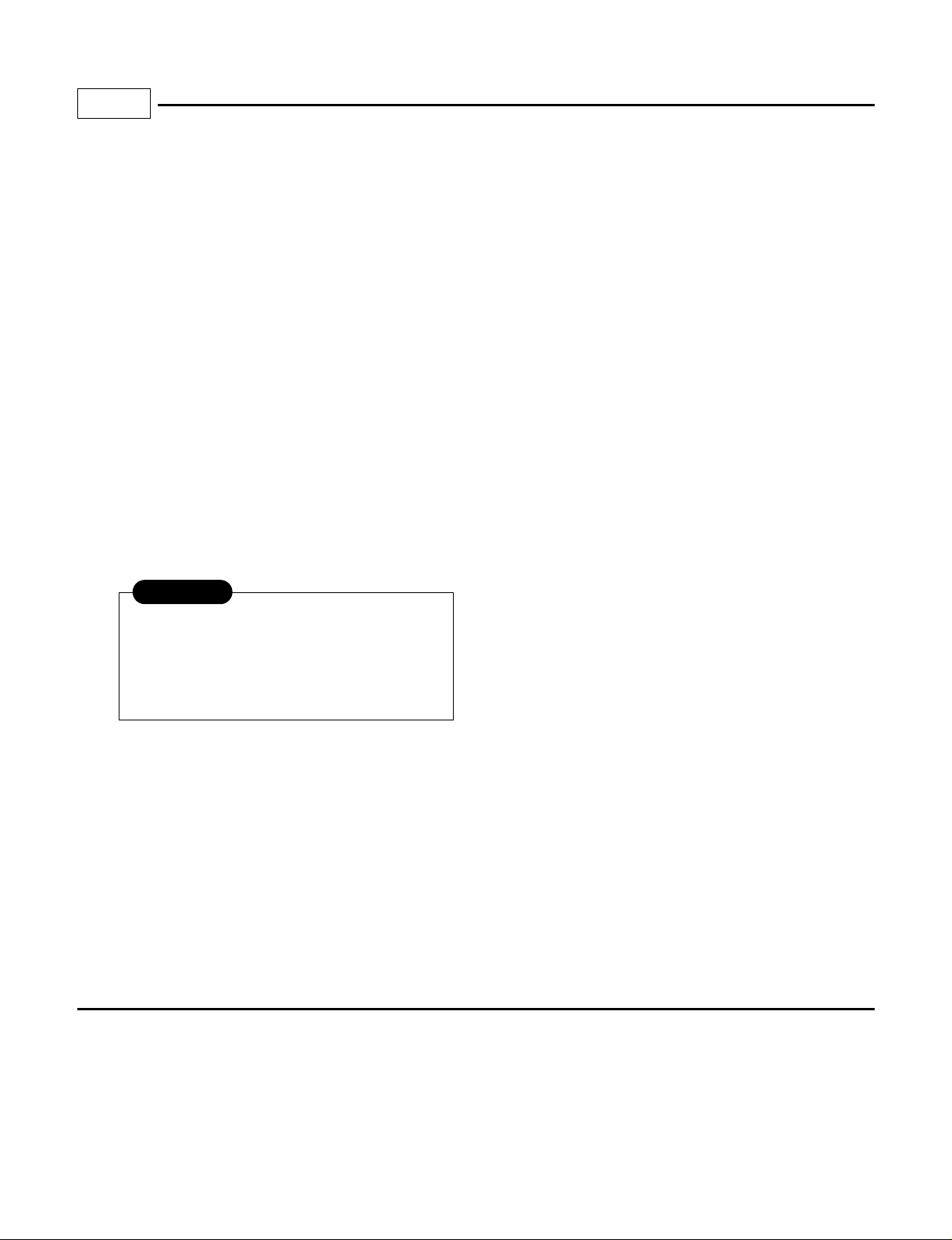

2.3.5 OUTDOOR MOTOR

1. Remove the front grille. (Refer to section 2.1.1)

2. Remote the top cover. (Refer to section 2.1.2)

3. Remove the cabinet. (Refer to section 2.1.3)

4. Remove the fan and shroud. (Refer to section

2.2.2)

5. Remove the 3 screws which fasten the motor from

the mount motor. (See Figure 18)

6. Open the capacitor cover(Refer to section 2.3.3)

7. Disconnect the outdoor motor housing.

8. Remove the motor.

9. Re-install the components by referring to the

removal procedure, above.

2.4 REFRIGERANT CYCLE

2.4.1 CONDENSER

1. Remove the front grille.(Refer to Section 2.1.1)

2. Remove the top cover. (Refer to Section 2.1.2)

3. Remove the cabinet. (Refer to Section 2.1.3)

4. Remove the shroud. (Refer to Section 2.2.2)

5. Discharge the refrigerant by using a refrigerant

recovery system.

6. After discharging the refrigerant completely,

unbraze the interconnecting tube at the

condenser connections.

7. Remove the condenser.

8. Re-install by referring to the procedures above.

2.4.2 EVAPORATOR

1. Remove the front grille.(Refer to Section 2.1.1)

2. Remove the top cover.(Refer to Section 2.1.2)

3. Remove the cabinet.(Refer to Section 2.1.3)

4. Remove the control box.(Refer to Section 2.1.4)

5. Discharge the refrigerant by using a refrigerant

recovery system.

6. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

7. Remove the evaporator.

8. Re-install by referring to the procedures above.

—9—

Figure 18

Figure 19

Discharge the refrigerant system using a

FreonTMRecovery System.

If there is no valve to attach the recovery

system, install one (such as a WATCO A-1)

before venting the FreonTM. Leave the valve in

place after servicing the system.

CAUTION

2.4.3 CAPILLARY TUBE

1. Remove the front grille.(Refer to Section 2.1.1)

2. Remove the top cover.(Refer to Section 2.1.2)

3. Remove the cabinet.(Refer to Section 2.1.3)

4. Remove the control box.(Refer to Section 2.1.4)

5. Discharge the refrigerant by using a refrigerant

recovery system.

6. After discharging the refrigerant completely,

unbraze the interconnecting tube of the capillary

tube.

7. Remove the capillary tube.

8. Re-install by referring to the procedures above.

Page 10

—10—

— Replacement of the refrigerant.

1. When replacing the refrigerant, be sure to

discharge the refrigerant system using a Freon

TM

recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the FreonTM. Leave the valve in place after

servicing the system.

2. After discharging the unit completely, remove the

desired component, and unbraze the pinch-off

tubes.

3. Braze service valves into the pinch-off tube ports,

leaving the valves open.

4. Braze the pinch-off tubes with Service valves.

5. Evacuate as follows.

1) Connect the vacuum pump, as illustrated figure

20A.

2) Start the vacuum pump, slowly open manifold

valves A and B with two full turns

counterclockwise and leave the valves open.

The vacuum pump is now pulling through valves

A and B up to valve C by means of the manifold

and entire system.

3) Operate the vacuum pump for 20 to 30 minutes,

until 600 microns of vacuum is obtained. Close

valves A and B, and observe vacuum gauge for

a few minutes. A rise in pressure would

indicate a possible leak or moisture remaining in

the system. With valves A and B closed, stop

the vacuum pump.

4) Remove the hose from the vacuum pump and

place it on the charging cylinder. See figure

20B.

Open valve C.

Discharge the line at the manifold connection.

5) The system is now ready for final charging.

6. Recharge as follows :

1) Refrigeration cycle systems are charged from

the High-side. If the total charge cannot be put

in the High-side, the balance will be put in the

suction line through the access valve which you

installed as the system was opened.

2) Connect the charging cylinder as shown in figure

20B.

With valve C open, discharge the hose at the

manifold connection.

3) Open valve A and allow the proper charge to

enter the system. Valve B is still closed.

4) If more charge is required, the high-side will not

take it. Close valve A.

5) With the unit running, open valve B and add the

balance of the charge.

a. Do not add the liquid refrigerant to the Low-

side.

b. Watch the Low-side gauge; allow pressure to

rise to 30 lbs.

c. Turn off valve B and allow pressure to drop.

d. Repeat steps b. and c. until the balance of the

charge is in the system.

6) When satisfied the unit is operating correctly,

use the pinch-off tool with the unit still running

and clamp on to the pinch-off tube. Using a tube

cutter, cut the pinch-off tube about 2 inches from

the pinch-off tool. Use sil-fos solder and solder

pinch-off tube closed. Turn off the unit, allow it to

set for a while, and then test the leakage of the

pinch-off connection.

NOTES

If high vacuum equipment is used, just crack

valves A and B for a few minutes, then open

slowly with the two full turns counterclockwise.

This will keep oil from foaming and being

drawn into the vacuum pump.

CAUTION

Page 11

—11—

Equipment needed: Vacuum pump, Charging cylinder, Manifold gauge, Brazing equipment. Pin-off tool capable

of making a vapor-proof seal, Leak detector, Tubing cutter, Hand Tools to remove components, Service valve.

A

COMPOUND GAUGE

EVAPORATOR

(LOW PRESSURE SIDE)

COMPRESSOR

CAPILLARY TUBE

CONDENSER

(HIGH PRESSURE SIDE)

SEE INSETS

BELOW

MANIFOLD

GAUGE

B

A

B

EXTERNAL

VACUUM PUMP

A

CHARGING

CYLINDER

LOW

HI

B

C

Figure 20A-Pulling Vacuum

Figure 20B-Charging

Page 12

—12—

3. INSTALLATION

3.1 HOW TO INSTALL THE UNIT

1. To prevent vibration and noise, make sure the

unit is installed securely and firmly.

2. Install the unit where the sunlight does not shine

directly on the unit.

3. The outside of the cabinet must extend outward

and there should be no obstacles, such as a

fence or wall, within 20" from the back of the

cabinet because it will prevent heat radiation of

the condenser.

Restriction of outside air will greatly reduce the

cooling efficiency of the air conditioner.

CAUTION: All side louvers of the cabinet must

remain exposed to the outside of the structure.

4. Install the unit a little slanted so the back is

slightly lower than the front (about 1/4").

This will force condensed water to flow to the

outside.

5. Install the unit with the bottom about 30"~60"

above the floor level.

3.2 CHECK OF INSTALLATION

The setting conditions must be checked prior to

initial starting.

The undermentioned items are especially important

checking points when the installation is finished.

1. Grounding wire (Green or Green and Yellow) is

provided in the power cord. The green wire must

be grounded.

2. Connect to a single-outlet 15A circuit.

(or 21A circuit for Electric Heater Model)

3. To avoid vibration or noise, make sure the air

conditioner is installed securely.

4 Avoid placing furniture or draperies in front of the

air inlet and outlet.

3.3 WINDOW REQUIREMENTS

NOTE: All supporting parts should be secured to

firm wood, masonry, or metal.

1. This unit is designed for installation in standard

double hung windows with actual opening widths

from 26" to 39 3/8".

2. The top and bottom window sash must open

sufficiently to allow a clear vertical opening of

12" from the bottom.

About 1/4"

30"~60"

Awning

Cooled air

Fence

Over 20"

Heat

radiation

26"(660mm) to

39

3

/8"(1000mm)

12"(305mm) min.

Inner sill

Offset

Window

Sill

Exterior

Interior wall

Sash

Figure 21

Figure 22

Page 13

—13—

3.4 INSTALLATION KITS CONTENTS

3.5 SUGGESTED TOOL REQUIREMENTS

3.6 HOW TO INSTALL

Carefully remove air conditioner from carton, check for

possible shipping damage. Pick a location which will

allow you to blow the cold air into the area you want.

Windows used for installation must be strong enough to

support the weight of the air conditioner. Good

installation with special attention to the proper position

of the unit will lessen the chance that service will be

needed.

When cooling more than one room, installation location

is very important. To cool your rooms, cold air must be

blown from the air conditioner in a straight path.

If air conditioner is blocked by a storm window frame,

see Step 7 and 8 on Page 14 before beginning to

install.

1. Cut the FOAM STRIP (ITEM G) to fit the

underside of the window sash. Open the window,

peel off the backing and attach the FOAM STRIP

as shown in Figure 23.

2. Mark center line with pencil on the center of the

inner sill, as shown in Figure 24.

A

B

F

E

C

D

G

H

CENTER LINE

INNER SILL

INDOOR

FOAM STRIP

(ITEM G)

ITEM NAME OF PARTS Q'TY

A SUPPORT, BRACKET 1

B LEVELING BOLT 1

C LEVELING BOLT 1

D SCREW: 5/8" 2

E SCREW: 5/8" 5

F FOAM SEAL 1

G FOAM STRIP 1

H L BRACKET 1

SCREWDRIVER(Phillips and Flathead), RULER, KNIFE, HAMMER, PENCIL, LEVEL

Figure 23

Figure 24

To avoid the possibility of personal injury, unplug

power to unit before installing or servicing.

CAUTION

Page 14

—14—

3. Install support bracket on window. See Figure 25.

Install leveling bolt up through bottom side of

support bracket. You can choose a short bolt

(ITEM C) or a long one (ITEM B) according to

window type. Also, you should select the position

of hole on bracket.

Position bracket on sill 1 inch (25.4mm) to left of

center line of window (See Figure 25).

Fasten bracket loosely to sill with screws (ITEM D)

provided.

Adjust leveling bolt so that the air conditioner will

be installed with a very slight tilt (about 1/4")

downward toward the outside for proper drainage.

Tighten bracket screws.

4. INSTALL THE AIR CONDITIONER IN THE

WINDOW

• Carefully lift the air conditioner and slide it into the

open window. Be careful not to hurt waist in this

operation.

• Use the two hand grips on top sides of unit to lift

unit.

• Make sure that support bracket is inserted in the

pocket under base fan, and that curtain frame guide

is stopped by stopper on the support bracket as

shown in Figure 28.

NOTE: When unit is properly centered and pushed

outward to correct bracket location, you will feel unit

drop securely in place on the support bracket. Hold

unit firmly during this procedure.

• Lower top window sash all the way down so that

sash sits firmly in top channel of unit and

expandable curtain frames.

SCREW SCREW

(ITEM D)(ITEM D)

CLOSE-UP VIEW

OF SUPPORT BRACKET

(ITEM A)

SCREW

(ITEM D)

LEVELING BOLT LEVELING BOLT

(ITEM B or C)(ITEM B or C)

LEVELING BOLT

(ITEM B or C)

ADJUSTMENT SLOT

CENTER LINE CENTER LINE

OF WINDOWOF WINDOW

CENTER LINE

OF WINDOW

OUTDOORINDOOR

INNER SILL

SCREW

LEVELING

BOLT

OUTER SILL

SUPPORT

BRACKET

ABOUT 1/4"

OUTDOORINDOOR

LEVELING BOLT

SUPPORT

BRACKET

STOPPER

SUPPORT

BRACKET

POCKET

HAND GRIP

WINDOW SASH

INDOOR

SECTION

INNER SILL

OUTER SILL

OUTDOOR

SECTION

TOP CHANNEL

CURTAIN

Figure 25

Figure 26

Figure 28

Figure 27

Failure to securely install support bracket may result

in unit falling from window if window sash is raised

after unit is installed. This could result in personal

injury.

CAUTION

During the following step, hold unit firmly until

window sash is lowered to top channel behind

curtain frames. Personal injury or property damage

may result if unit falls from window.

CAUTION

INNER

WINDOW

SILL

1"(25.4mm)

OUTER

WINDOW

SILL

CLOSE-UP VIEW

CLOSE-UP VIEW

OF SUPPORT BRACKET

OF SUPPORT BRACKET

(ITEM A)

(ITEM A)

CENTER LINE

Page 15

—15—

5. SECURE THE CURTAIN FRAMES

Expand the curtain frames and secure them using 5

screws (ITEM E) as shown in Figure 29.

When curtain frame opens or closes, you may feel a

slight resistance. This is normal.

6. FOAM SEAL AND WINDOW LOCK

• Cut the foam seal (ITEM F) to the window width.

Stuff the foam seal between the glass and the

window to prevent air and insects from getting into

the room, as shown in Figure 29.

• Install the L bracket to prevent window from being

raised which may result in unit falling.

NOTE: If window sash has a metal surface. use

sheet metal screws instead of the provided wood

screws. Obtain sheet metal screws at local hardware

store.

7. IF AIR CONDITIONER IS BLOCKED BY STORM

WINDOW FRAME

• If storm window presents interference, fasten a

2"(51mm) wide wood strip to the inner window sill

across the full width of the sill. The wood strip

should be thick enough to raise the height of the

window sill so that unit can be installed without

interference from the the storm window frame. See

Figure 30.

Top of wood strip should be approximately

3/4"(19mm) higher than the storm window frame to

help condensation to drain properly to the outside.

• Install a second wood strip (approximately

6"(152mm) long by 11/2"(38mm) wide and same

thickness as first strip) in the center of the outer sill

flush against the back of the inner sill. (Figure 30)

8. INSTALLATION FOR OTHER TYPE WINDOWS.

• Dimensions and geometry of windows are different

depending on their manufacturing. Check your

window and refer to FIG.31 to install the support

bracket firmly.

ITEM E

L BRACKETL BRACKET

FOAM SEAL

(ITEM F)

FOAM SEAL

(ITEM F)

INNER

SILL

WOOD STRIP MOUNTED

ON TOP OF INNER SILL

3/4"(19mm)

CLEARANCE

1 1/2" min.

(38mm)

STORM

WINDOW

FRAME

OUTDOORINDOOR

When storm window

frame is located on outer sill

OUTER

SILL

WOOD STRIPWOOD STRIP

FOR SUPPORT FOR SUPPORT

BRACKETBRACKET

WOOD STRIP

FOR SUPPORT

BRACKET

Figure 29

Figure 30

Figure 31

Failure to securely install support bracket may

result in unit falling from window if window sash is

raised after unit is installed. This could result in

personal injury.

CAUTION

(a) When window frame is located on inner sill.

WINDOW FRAME

WINDOW FRAME

• Install a wood strip (window width long and

window frame height high) on the inner sill.

WOOD STRIP

INNER

SILL

OUTER

SILL

OUTER

SILL

SASH WINDOW

19/32"(15mm)

(b) When the window frame is higher than

19/32"(15mm)

• Install a wood strip (about 4"(102mm) long) on

the outdoor sill to raise support bracket.

WOOD STRIP

INNER

SILL

Page 16

2

2

F

C

3

G

A

B

RIGHT SIDE

HORIZONTAL

LINE

D

305(12")

600(23 5/8")

458(18

1

/32")

172(6

25

/32") 60(2 3/8")

255(10")

—16—

4. TROUBLESHOOTING GUIDE

4.1 OUTSIDE DIMENSIONS

3.7 REMOVAL FROM WINDOW

• Turn off and unplug the air conditioner.

• Unscrew the side screws that you installed in Step

5. 6.

• Close the curtain frame and remove foam seal and

L bracket from the windows.

• Keep a firm grip on the air conditioner raise the

sash.

• Lift the air conditioner from the window and

remove the foam strip from between the windows.

• Remove the support bracket from window frame.

NOTE: When cooling season is over, unit is

removed from window for cleaning and storage.

There may still be some condensation water in the

basepan. Remove the unit carefully to avoid water

being spilled out on floor. Always store unit flat on its

base. Do not stand on end. Be sure to remove

support bracket, L bracket, and foam seal from

window and save. Window will not close if support

bracket remains installed.

Figure 32

Figure 33

Page 17

—17—

CAPILLARY TUBE

COMPRESSOR

INDOOR MOTOR

EVAPORATOR COIL

CONDENSER COIL

CROSS FLOW FAN

FAN

OUT MOTOR

4.2 PIPING SYSTEM

Following is a brief description of the important components and their functions in the refrigeration system.

Refer to Figure 35 to follow the refrigeration cycle and the flow of the refrigerant in the cooling cycle.

(LIQUID REFRIGERANT)

CAPILLARY TUBE

OUTSIDE COOLING

AIR FOR REFRIGERANT

PASS THROUGH

SUCTION LINE

COOL LOW PRESSURE VAPOR

COOLED

AIR

COMPLETE LIQUID

BOIL OFF POINT

LIQUID

PRESSURE

DROP

ROOM AIR HEAT LOAD

VAPOR INLET

HOT

DISCHARGED

AIR

LIQUID OUTLET

HIGH PRESSURE VAPOR

LIQUID REFRIGERANT

LOW PRESSURE VAPOR

ROOM AIR CONITIONER

EVAPORATOR COILS CONDENSER COILS

CYCLE OF REFRIGERATION

MOTOR

COMPRESSOR

OIL

Figure 35

Figure 34

Page 18

—18—

4.3 TROUBLESHOOTING GUIDE

In general, possible trouble is classified within one of two possible categories.

The first is designated Starting Failure and is caused from an electrical defect, while the other is ineffective Air

Conditioning caused by a defect in the refrigeration circuit or improper application.

Unit runs but cools poorly.

Ineffective Cooling

Check outdoor coil

(heat exchanger) & the fan

operation.

Check gas leakage.

Repair gas leak.

Replace the unit if it

is beyond repair.

Satisfactory operation with

temperature difference of

inlet & outlet air ;

44~50°F(7~10°C)

Check heat load

increase.

Clean condenser.

Not on separate circuit.

Check inside gas

pressure.

Adjust refrigerant charge.

Malfunction of compressor.

Replace compressor.

Check cold air circulation

for smooth flow.

Dirty indoor coil

(Heat exchanger)

Correct above trouble

Check clogging in refrigeration circuit.

Repair clogging in refrigeration circuit.

Obstruction at air outlet

Clogged air filter.

Malfunction of fan

Page 19

—19—

Fails to Start

Check circuit breaker

and fuse.

Check of control switch.

Only the fan fails to start.

Improper wiring.

Defect of fan motor

capacitor.

Irregular motor resistance

(

).

Irregular motor insulation

(

).

Replace fan motor.

Regular but fails to start.

Replace compressor

(locking of rotor, metal).

Improper thermistor setting.

Loose terminal connection.

Improper wiring.

Irregular motor resistance ( )

Irregular motor insulation ( )

Replace compressor

(Motor damaged)

Drop of power voltage.

Capacitor check.

Replacement

Only the compressor fails to

start.

Defect of compressor

capacitor.

Check power source.

Check control switch

setting.

Page 20

—20—

• Check the Fuse.

• Check the wiring diagram.

Is the Trans input power

AC 115V?

Is the Trans output power

about AC 14V?

Is the Trans. output shorted?

Is output Voltage of IC02D

DC 5V?

Is the voltage No.18 of Micom

DC 5V?

Exchange AC PCB Ass'y.

Is the

connection between

AC and DC

all right?

Is the reset circuit all right?

(The No.14 of

Micom is 5V.)

• Check the Fuse.

• Check the wiring diagram.

• Check the Main

PCB pattern.

• Exchange the Trans.

• Exchange IC02D.

• Exchange IC01A, C02A.

• Connect connector

exactly.

• Check the PCB

pattern.

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

YES

■ ELECTRICAL PARTS TROUBLESHOOTING GUIDE: LP6000ER/LP7000R

Possible Trouble 1 The unit does not operate.

Page 21

—21—

Possible Trouble 2 The compressor does not operate.

Possible Trouble 3 The compressor always operate.

Is setting

Temp. set lower than Room

Temp.-1°F?

Is the voltage No.10

of IC01M 0V?

• Exchange IC01M.

• Select the setting Temp. to lower Number.

• Wait 3 Minutes.

Does the

compressor activate

after 3 minutes?

• Exchange MAIN

PCB Ass'y.

Is the voltage N0.9 of

IC01M DC 12V?

• Check the RY-COMP.

• Check the wiring

Diagram.

NO

NO

NO

YES

YES

YES

YES

Is the wire connection of

RY-COMP all right?

• Check the RY-COMP.

• Connect LEAD Wire to

RY-COMP again.

NO

YES

NO

Page 22

—22—

Possible Trouble 4 FAN does not operate.

Possible Trouble 5

The function of Energy Saver does not operate.

• Exchange IC01M.

• Exchange IC01M.

Is the voltage NO.1 or 2 or 4

of IC01M DC 12V?

Is the voltage NO.16 or 15 or 13

of IC01M 0V?

• Check the RY-Hi or

RY-Med or RY-Lo.

•

Check the wiring diagram.

NO

NO

YES

YES

NO

NO

YES

YES

Has the mode

key been pushed once more

after cool mode?

Is the voltage No.3 of

CN-AC/DC of AC PCB

Ass'y DC 5V?

• Reference to

OWNER'S MANUAL.

• Set the mode key to

Energy Saver mode.

• Check the Energy

Saver mode key.

• Check the pattern of

AC & DC PCB.

Page 23

—23—

Possible Trouble 6 Remote controller does not operate.

Possible Trouble 7 It displays abnormally on DC PCB Ass’y.

NO

NO

NO

NO

YES

YES

YES

Is the IC01G all right?

Is the connection of

CN-AC/DC

all right?

• Exchange the DC

PCB Ass'y.

• Exchange IC01G.

• Exchange IC03G

(Q01G, Q02G, Q03G

for Deluxe Model).

• Connect connector

to

CN-AC/DC

exactly.

Does the IC03G

(Q01G, Q02G, Q03G for Deluxe Model)

operate normally on DC

PCB Ass'y?

• Check the PCB pattern.

Is the voltage of Battery

about over 2.3V?

• Exchange Receiver Ass'y.

Is the connection of

CN-AC/DC

all right?

Is the voltage No.10

of CN-AC/DC on DC PCB

Ass'y DC 5V?

• Exchange the battery.

• Check the PCB pattern.

• Connect connector to

CN-AC/DC

completely.

NO

NO

NO

YES

YES

YES

Page 24

—24—

Possible Trouble 8 It displays abnormally on DC PCB Ass’y.

NO

NO

NO

NO

YES

YES

YES

Are the IC01G and IC02G

all right?

Is the connection of

CN-AC/DC all right?

• Exchange the DC

PCB Ass'y.

• Exchange IC01G,

IC02G.

• Exchange IC03G.

• Connect connector

to CN-AC/DC exactly.

Does the IC03G

operate normally on AC

PCB Ass'y?

Page 25

—25—

NAME PLATE RATING MINIMUM MAXIMUM

115V ±10% 103.5V 126.5V

ROOM AIR CONDITIONER VOLTAGE LIMITS

COMPLAINT CAUSE REMEDY

Check voltage at outlet. Correct if voltage is missing.

Check voltage to connector of CN-PWR and 3 port of

comp-relay. If none, check power supply cord.

Replace cord if circuit is open.

Connect wire. Refer to wiring diagram for terminal

identification. Repair or replace loose terminal.

Test capacitor.

Replace if not within ±10% of manufacturer's rating.

Replace if shorted, open, or damaged.

Fan blade hitting shroud or blower wheel hitting

scroll. Realign assembly.

Units using slinger ring for condenser fan must have

1

/4to5/16inch clearance to the base. If it hits the

base, shim up the bottom of the fan motor with

mounting screw(s).

Check fan motor bearings; if motor shaft will not

rotate, replace the motor.

Check voltage. If not within limits, call an electrician.

Test capacitor.

Check bearings. Does the fan blade rotate freely?

If not, replace fan motor.

Pay attention to any change from high speed to

low speed. If the speed does not change, replace the

motor.

If cracked, out of balance, or partially missing,

replace it.

If cracked, out of balance, or partially missing,

replace it.

Tighten it.

If knocking sounds continue when running or loose,

replace the motor. If the motor hums or noise

appears to be internal while running, replace motor.

Check voltage.

If not within limits, call an electrician.

Check the wire connections, if loose, repair or

replace the terminal. If wires are off, refer to wiring

diagram for identification, and replace. Check wire

locations. If not per wiring diagram, correct.

No power

Power supply cord

Wire disconnected or

connection loose

Capacitor (Discharge

capacitor before testing.)

Will not rotate

Revolves on overload.

Fan

Cross flow fan

Loose clamper

Worn bearings

Voltage

Wiring

Fan motor will not run.

Fan motor runs

intermittently

Fan motor noise.

Compressor will not run,

but fan motor runs.

Page 26

—26—

COMPLAINT CAUSE REMEDY

Check the status the setting temperature if not lower

than room temperature, please decrease the setting

temperature.

Check continuity of the thermostat. Replace

thermostat if circuit is open.

Check the capacitor.

Replace if not within ±10% of manufacturers rating.

Replace if shorted, open, or damaged.

Check for compressor for open circuit or ground. If

open or grounded, replace the compressor.

Check the compressor overload, if externally

mounted. Replace if open. (If the compressor

temperature is high, remove the overload, cool it,

and retest.)

Check the voltage.

If not within limits, call an electrician.

Check overload, if externally mounted.

Replace if open. (If the compressor temperature is

high, remove the overload, cool, and retest.)

If not running, determine the cause. Replace if

required.

Remove the cabinet. inspect the interior surface of

the condenser; if restricted, clean carefully with a

vacuum cleaner (do not damage fins) or brush.

Clean the interior base before reassembling.

If condenser fins are closed over a large area on the

coil surface, head pressures will increase, causing

the compressor to overload. Straighten the fins or

replace the coil.

Test capacitor.

Check the terminals. If loose, repair or replace.

Check the system for a restriction.

If restricted, clean or replace.

Close if open.

Determine if the unit is properly sized for the area to

be cooled.

Check the set screw or clamp. If loose or missing,

correct. If the blower or fan is hitting air guide,

rearrange the air handling parts.

Remove the cabinet carefully and rearrange tubing

not to contact cabinet, compressor, shroud, and

barrier.

Thermistor

Capacitor (Discharge

capacitor before servicing.)

Compressor

Overload

Voltage

Overload

Fan motor

Condenser air flow

restriction

Condenser fins (damaged)

Capacitor

Wiring

Refrigerating system

Air filter

Exhaust damper door

Unit undersized

Cross flow fan or fan

Copper tubing

Compressor will not run,

but fan motor runs.

Compressor cycles on

overload.

Compressor cycles on

overload.

Compressor cycles on

overload.

Insufficient cooling or

heating

Excessive noise

Page 27

5. SCHEMATIC DIAGRAM

5.1 CIRCUIT DIAGRAM

■

MODEL : LP6000ER/LP7000R

—27—

OR

BR YL

OUTDOOR

FAN

MOTOR

1

6

8

7

5

3

2

4

S: Service Parts

N: Non Service Parts

LP6000ER LP7000R

PART NO.

4681A20088A

4681A20089A

6120AR2359V 0CZZA20001W

2520UABC2JA 2520UAEC2CB

6750U3L001A 6750U-L060A

6871A20342A

6871A20343A

6323A20004E

INDOOR MOTOR ASSY

OUTDOOR MOTOR ASSY

CAPACITOR

COMPRESSOR

OVERLOAD PROTECTOR

DC PCB ASSEMBLY

AC PCB ASSEMBLY

THERMISTOR

1

2

3

4

5

6

7

8

1

1

1

1

1

1

1

1

S

S

S

S

S

S

S

S

LOCATION

NO.

DESCRIPTION

RE-

MARKS

Q'TY

PER SET

Page 28

—28—

5.2 ELECTRONIC CONTROL DEVICE

■ MODEL: LP6000ER/LP7000R

O

7805

I

12V

+

5V

5V

F

C

CAPACITOR

C05D

STO2D-200

HIGH VOLTAGE GND(DC)

EN

BP

MAIN

POWER

MOTOR

FAN

OUTDOOR

TVR 14561

COMP

1

1

3

FUSE

250V/T2A

4

CN-OUT

RY-COMP

G4A-1A-E-LG

(14271)

HERM

11

FAN

C

CAPACITOR

33

CN-PWR

YW396-03AV

ZNR01J

40mH/1A

NF01J

275V

100nM

100nM

275V

4.7uF

450V

C01D

R03D

1/4W

300K

SCK102

5D2

S

266P

IC01D

TNY

SD01D

CN-AC/DC

D01D~D04D

C01J

C02J

1

NTC

SPARE

CN-AC/DC

1

INDOOR

MOTOR

FAN

1

1

2

2

7

9

7

9

135

135

1

1

RY-HI

RY-MED

RY-LOW

CN-MOTOR

YW396-09AV

3

3

2

2

3

3

SW1

PIPE-TH

1

1

3

3

2

2

SMW200-03(YL)

SMW200-03(WH)

CN-HVB

CN-12V

99

12

10

11

4

3

2

5V

12V

RY-MED

RY-HI

2

12V

3

4

121011

7

8

RY-COMP

RY-LOW

12V

OP1

8

7

ROOM-TH

3

3

2

2

1

1

SMW200-03(RD)

CN-TH2

SMW200-03(BL)

CN-TH1

5

66

5

5V

-4002

C08D

220

10V

ZBF503D

UG2D

S/TRANS

R01D

1/8W

ZD01D

472nM

400V

C05D

470/35V

TLP181BL

IC03D

C04D

1

4

104/50V

C02D

3.6mH(2.0mH)

4

3

1

2

11V

39

50V

103

C07D

R02D

1/8W

20K

C06D

25V

330

681/50V

C03D

D02D

L1

IC02D

103

C09D

50V

Q01T

2SC5343

R03T

12K

R02T

1K

R01T

4.7K

50V

0.01

C01T

143

5V

ULN2004A

IC01G

7

845

6

150

R07G

5V

10

9

R06G

R05G

R04G

13

11

12

150

150

150

1

2

R03G

R02G

R01G

16

15

150

150

150

C02F

0.001

R03F

10K

f

b

f

b

c

AIR PURIFIER

E/SAVER

FAN

TIMER

DRY

88 SEGMENT

c

1

d

g

8

4

7

6

e

g

dfe

d

g

e

c

COOL

PURIFIER

D03G

SW03G

AIR

TIMER

SW02G

D02G

10

Digit1

9

3

a

b

a

5

Digit0

a

FAN

D01G

SW01G

MICOM

Osc out

TMP87CH47U

VDD

RECEIVER

14

3

C06D

50V

+

10V

220

0.01

5V

Vout

BZ01E

PKM13EPY

C02L

10V

220

R02E

20

GND

12V

+

5V

IC01M

Vcc

ULN2004A

9

16

15

128

OR1H

1%

R21H

5V

12.1K

OR2H

131211

456107

1%

R22H

12.1K

HVB

Receiver

LED out3

Buzzer

R01E

1K

C01L

680pF

50V

R01L

1K

35

LED out1

LED out2

34

LED out0

3736

KEY1

FILTER

38

KEY0

39

313233

272829

30

ION

HI

MED

R01P

5V

20K

VAref

Pipe TH

Option1

Option2

Room TH

21

242526

SYNC

4WAY

LOW

23

COMP

22 1920 18

VSS

17

5V

12.1K

6.2K

1%

1%

R04H

5V

R02H

R01B

1M

OSC01B

RT8.00MG

Digit3 (Scan3)

Digit0 (Scan0)

Digit2 (Scan2)

Digit1 (Scan1)

44

SEG-f

4240

SEG-g

41

SEG-d

SEG-e

43

SEG-c

SEG-a

SEG-b

1235674

C01F

0.001

R01F

10K

R05P

10K

Digit4 (Scan4)

Osc in

/Reset

121416 15

TEST

13

SDA

SCL

8

9

10

11

Q02G

TEMP UP

D07G

SW07G SW05G

TEMP DOWN

D05G D06GD04G

SW04G

MODE

SW06G

ON/OFF

A101S

Q01G

A101S

Q04G

A101S

Q03G

A101S

A2

GND

A1

423

SCL

SDA

WP

576

R04P

1K

50V

C01A

0.01

5V

3.6V

1uF

10V

C02A

+

2

1

3

IC01A

S7136

R01A

20K

Non Auto Restart

EEPROM

A0

24LC01BT

C01P

25V

0.01

1

Vcc

8

Model

Auto Restart

R02P

20K

R03P

20K

X

5V

O

EEPROM

OX

R04P

+

1N4007

HVB

+

+

Page 29

—29—

5.3 COMPONENTS LOCATION(FOR AC P.C.B ASM)

■ MODEL: LP-6000ER/LP7000R

LOW

GND

GND

5V

PIPE TH

ROOM TH

COMP

12V

HI

HVB

MED

F/C

CN-12V

C05D

C03D

D07D

C04D

SMPS

CN-MOTOR

CO7D

L1

R01D

R02D

C06D

CN-TH2

CN-HVB

C08D

J01

PCB P/N0 6870A90129A

PCB ASM P/NO 6871A20343

C01D

NTC

SD01D

R03D

D04D

IC01D

D01D

D03D

D02D

C02J

RY-MED

250V/T3.15A( )

250V/T2A( )

RY-LOW

CN-PWR

IC03D

C02D

ZD01D

C01J

FUSE

ZNR01J

RY-HI

OP1

IC02D

C09D

J03

J02

J04

3

RY-COMP

4

CN-AC-DC

1

12

CN-OUT

88 SEGMENT

JP16

IC01A

CN-AC/DC

JP08

JP05

JP27

C02A

OSC01B

JP03

JP04

JP02

C05D

JP06

JP07

JP25

FAN

BZ01E

JP11

JP23

JP10

JP09

POWER

SW01G

SW06G

TEMP DOWN

D01G

JP13

D05G

JP12

JP01

SW05G

JP15

D06G

C02L

RECEIVER

AIR PURIFIER

JP22

JP21

SW04G

TEMP UP

D07G

TIMR

JP14

SW07G

MODE

SW02G

D04G

LED3

D02G

TIMER

AIR PURIFIER

COOL

JP29

JP20

JP19

FAN

LED1

D03G

LED2

SW03G

DRY

LED4

E/SAVER

JP28

LED6

:6871A20342

PCB P/No:6870A90128A

PCB ASSEMBLY P/No

LED5

5.4 COMPONENTS LOCATION(FOR DC P.C.B ASM)

■ MODEL: LP-6000ER/LP7000R

Page 30

6. EXPLODED VIEW

■ Model: LP6000ER/LP7000R

—30—

354210

249950

352381

149980

130910

359011

135500

152302

135501268716

237900

137215

238310

135312

554030

559011

552111

264110

263230

268715

135503

152303

147581

147582

135301

346810

148000

349600

352380

35211A

352115

567502

554160

550140

130410

135502

352113

546810

Page 31

—31—

7. REPLACEMENT PARTS LIST

• MODEL: LP6000ER/LP7000R

R: Service Parts

N: Non Service Parts

DESCRIPTION

PART NO.

REMARK

LP6000ER LP7000R

LOCATION

NO

.

130410 BASE ASS'Y, SINGLE 3041A20041A R

130910 CABINET ASS'Y 3091A20017B R

135301 FRONT GRILLE 3530A10153A R

135303 INLET GRILLE 3530A10158A R

135312 FRONT GRILL ASS'Y 3531A20168C 3531A20168B R

135500 TOP COVER 3550A20202B R

135501 COVER DISPLAY 3550A20200A R

135502 COVER, CONTROL BOX 3550A20201A R

135503 COVER, CAPACITOR 3550A20209A R

137215 CONTROL PANEL ASS'Y 3721A20133C 3721A20133B R

147581

DISCHARGE GRILLE(HORIZONTAL LOUVER)

3530A20078A R

147582 VERTICAL LOUVER 4758A30037A / 4758A30037B R

148000 BRACE 4800A20004A R

149980 SHROUD 4998A20002A R

152302 AIR FILTER ASS'Y 5230A20031A R

237900 WINDOW DISPLAY 3790A20065A R

238310 ESCUTCHEON 3831A20055C 3831A20055B R

249950 CONTROL BOX ASS'Y 4995A20277A 4995A20277B R

263230 THERMISTOR ASS'Y 6323A20004E R

264110 POWER CORD ASS'Y 6411A20011W R

268715 MAIN PCB ASS'Y(AC) 6871A20343A R

268716 DISPLAY PCB ASS'Y(DC) 6871A20342A R

346810 INDOOR MOTOR ASS'Y 4681A20088A R

349600 MOUNT MOTOR 4960A20045A R

35211A SUCTION TUBE ASS'Y 5211A20831A R

352113 TUBE ASS'Y, DISCHARGE 5211A20832A R

352115 TUBE ASS'Y EVAPORATOR 5211A20834A 5211A20834B R

352380 AIR GUIDE LOWER 5238A20022A R

352381 AIR GUIDE UPPER 5238A20021A R

354210 EVAPORATOR ASS'Y 5421A20137B R

359011 CROSS FLOW FAN 5901A20020A R

546810 OUTDOOR MOTOR ASS'Y 4681A20089A R

550140 ISOLATOR, COMP 5040AR4195A R

552111 TUBE ASS'Y, CONDENSER OUT 5211A20879A 5211A20879B R

554030 CONDENSER ASS'Y 5403A20117A 5403A20117B R

554160 COMPRESSOR 2520UABC2JA 2520UAEC2CB R

559011 FAN 5900A20006A R

567502 OVERLOAD PROTECTOR 6750U3L001A 6750U-L060A R

W0CZZ CAPACITOR 6120AR2359V 0CZZA20001W R

Page 32

—32—

MEMO

Page 33

—33—

MEMO

Page 34

P/No : 3828A20190H

February, 2003

Printed in Korea

Loading...

Loading...