LG LP090CED-HED, LP120HED, LP120CED-HED, LP150CED-HE Schematic

LG

Packaged Terminal

Air Conditioner/Heat Pump

SERVICE MANUAL

LG

CAUTION

http://www.lgservice.com

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• FOR AUTHORIZED SERVICE ONLY.

—2—

1. PREFACE

1.1 SPECIFICATIONS ..........................................3

1.2 FEATURES AND BENEFITS..........................4

1.3 CONTROL LOCATIONS.................................6

1.4 ADDITIONAL CONTROLS..............................8

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS..................................10

2.1.1 FRONT GRILLE...................................10

2.1.2 CONTROL BOX...................................11

2.2 AIR HANDLING PARTS................................12

2.2.1 ELECTRIC HEATER

(Electric heater model only) .................11

2.2.2 CROSS FLOW FAN.............................12

2.2.3 AXIAL FAN...........................................13

2.2.4 SHROUD..............................................13

2.3 ELECTRICAL PARTS...................................14

2.3.1 OUTDOOR MOTOR ............................14

2.3.2 INDOOR MOTOR ................................14

2.3.3 COMPRESSOR...................................14

2.3.4 CAPACITOR........................................14

2.3.5 POWER CORD....................................14

2.3.6 P.C.B....................................................15

2.4 REFRIGERATION CYCLE............................15

2.4.1 CONDENSER......................................16

2.4.2 EVAPORATOR....................................16

2.4.3 CAPILLARY TUBE...............................16

3.

INSTALLATION

3.1 HOW TO INSTALL THE UNIT ......................17

3.2 SUGGESTED TOOL REQUIREMENTS.......19

3.2.1 PREPARATION OF SLEEVE ..............20

3.2.2 PREPARATION OF THE FRONT

GRILLE ................................................20

3.2.3 UNIT INSTALLATION..........................21

3.3 ELECTRICAL REQUIREMENTS..................22

3.3.1

ELECTRICAL DATA (FOR 230V/208 MODEL)........

22

3.3.2 ELECTRICAL SAFETY

............................

22

4.

FIELD INSTALLED ACCESSORIES

...

23

5.

FERFORMANCE DATA

.................................

39

6.

TROUBLESHOOTING GUIDE

6.1 OUTSIDE DIMENSIONS...............................44

6.2 PIPING SYSTEM ..........................................44

6.3 TROUBLESHOOTING GUIDE......................45

7. SCHEMATIC DIAGRAM.....................50

8. EXPLODED VIEW..................................52

9. REPLACEMENT PARTS LIST.......53

1. PREFACE

This

SERVICE MANUAL provides various service information, including the mechanical and electrical

parts, etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

CONTENTS

—3—

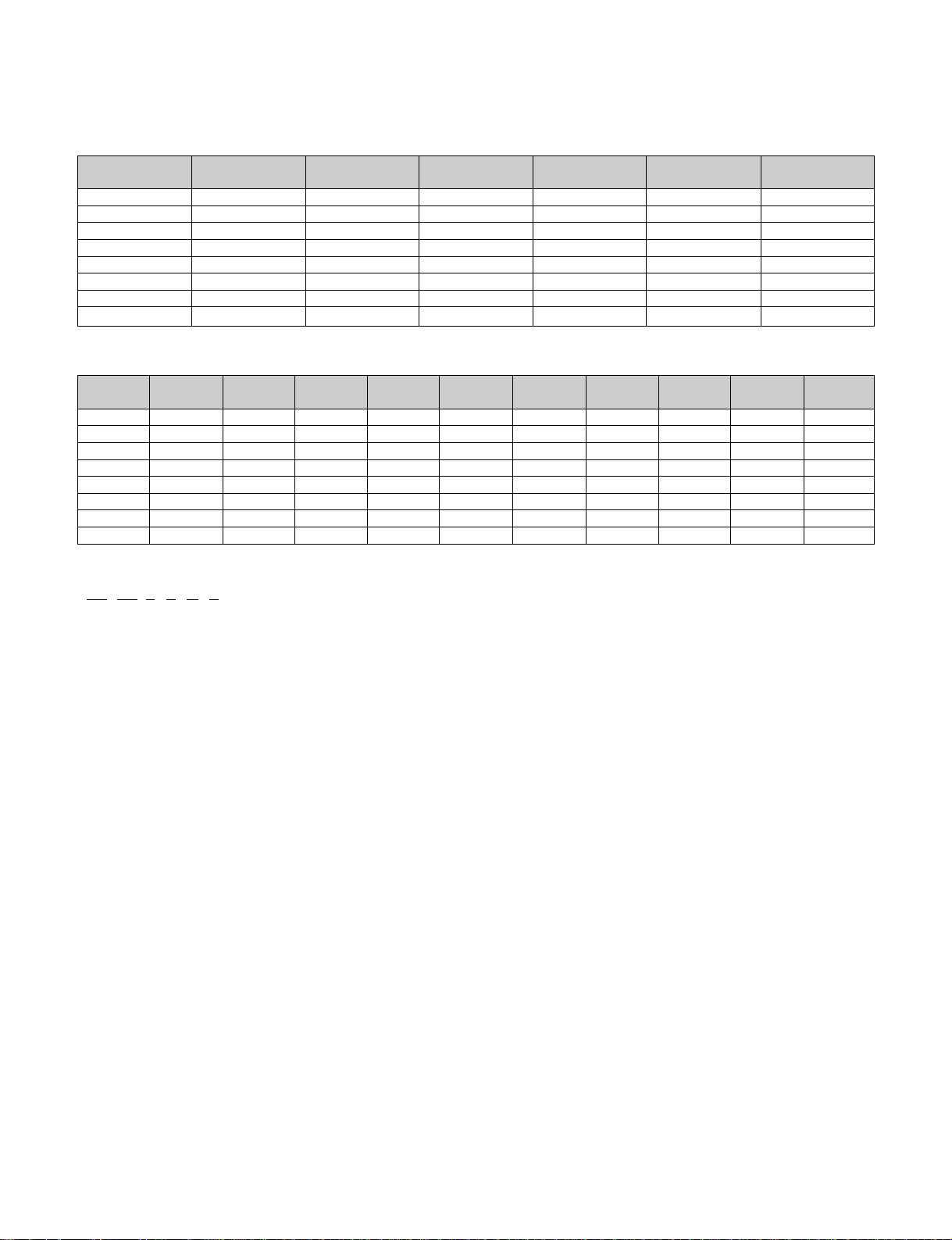

1.1 SPECIFICATIONS

LP070CEM 7,600/7,400 600/580 12.7/12.7 2.5kW E/Heater 2.7/2.9 20

LP090CEM 9,000/8,800 770/750 11.7/11.7 3.5kW E/Heater 3.5/3.8 20

LP120CEM 11,800/11,500 1,055/1,025 11.2/11.2 3.5kW E/Heater 4.8/5.2 20

LP150CEM 14,300/14,100 1,430/1,410 10.0/10.0 3.5kW E/Heater 6.5/7.1 20

LP070CED 7,600/7,400 600/580 12.7/12.7 2.5kW E/Heater 2.7/2.9 20

LP090CED 9,000/8,800 770/750 11.7/11.7 3.5kW E/Heater 3.5/3.8 20

LP120CED 11,800/11,500 1,055/1,025 11.2/11.2 3.5kW E/Heater 4.8/5.2 20

LP150CED 14,300/14,100 1,430/1,410 10.0/10.0 3.5kW E/Heater 6.5/7.1 20

Model Name Cooling (Btu/h) Cooling Watts (W) EER Electric Heat

Rated Amp,

Cooling

Mini Circuit

Protection (Amps)

Cooling/Electric Heater

LP070HEM 7,600/7,300 600/575 12.7/12.7 6,400/6,200 3.5/3.5 2.5kW E/Heater 535/520 2.7/2.9 2.4/2.6 20

LP090HEM 9,100/8,900 775/760 11.7/11.7 8,200/8,000 3.4/3.4 3.5kW E/Heater 705/690 3.7/3.9 3.2/3.5 20

LP120HEM 12,100/11,800 1,090/1,065 11.1/11.1 10,900/10,700 3.3/3.3 3.5kW E/Heater 970/950 5.0/5.4 4.4/4.8 20

LP150HEM 14,300/14,100 1,460/1,440 9.8/9.8 13,500/13,300 3.1/3.1 3.5kW E/Heater 1,275/1,255 6.7/7.3 5.8/6.3 20

LP070HED 7,600/7,300 600/575 12.7/12.7 6,400/6,200 3.5/3.5 2.5kW E/Heater 535/520 2.7/2.9 2.4/2.6 20

LP090HED 9,100/8,900 775/760 11.7/11.7 8,200/8,000 3.4/3.4 3.5kW E/Heater 705/690 3.7/3.9 3.2/3.5 20

LP120HED 12,100/11,800 1,090/1,065 11.1/11.1 10,900/10,700 3.3/3.3 3.5kW E/Heater 970/950 5.0/5.4 4.4/4.8 20

LP150HED 14,300/14,100 1,460/1,440 9.8/9.8 13,500/13,300 3.1/3.1 3.5kW E/Heater 1,275/1,255 6.5/7.3 5.8/6.3 20

Model Name

Cooling

(Btu/h)

Cooling

Watts (W)

EER

Reverse

Cycle (Btu/h)

COP Electric Heat

Rated Watts,

Heating

Rated Amp,

Cooling

Rated Amp,

Heating

Mini Circuit

Protection (Amps)

Cooling/Heat Pump/Electric

LP 12 0 C M 2

12 34 5 6 7 8

Digits 1,2 - LG Packaged Terminal Air Conditioner Digit 6 - Product Type

Digits 3,4 - Unit Cooling Capacity C = Air Conditoner

07 = 7,000 Btu/h H = Heat Pump

09 = 9,000 Btu/h Digit 7- Electric Heat

12 = 12,000 Btu/h E = Electric Heater

15 = 15,000 Btu/h Digit 8 - Electric Type

D = Manual Control

M = Electronic Control

1.2 FEATURES AND BENEFITS

The PTAC has many features, some of which are different than those found on conventional PTAC units. The servicer must be

familiar with these features in order to properly service the unit.

• IIR (Infinite Impulse Response)

The IIR function senses the temperature several times per second and makes micro-adjustments several times per

• Compressor Restart Delay

This feature extends the overall life of compressor by preventing the short-cycling of the air-conditioner. When the compressor

restarts, LG PTAC is designed to give a minimum of three minutes to have a time of equalizing the refrigerant pressures for

optimizing cycling.

• Fan-Only Setting - High/Low

The fan can run at HIGH or LOW speed without COOLING or HEATING to provide air circulation and ventilation.

• Indoor Fan Speed Selections - High/Low

The fan can run at HIGH or LOW speed for either COOLING or HEATING.

• Two Fan motors

The unit has two fan motors to provide quiet operation and maximum efficiency.

• LED Diagnostics

All units have this feature indicating the problem when the unit is not operating properly with easy-to-read diagnostics. For

example, 1 blink every 2 seconds indicates compressor failure.

—4—

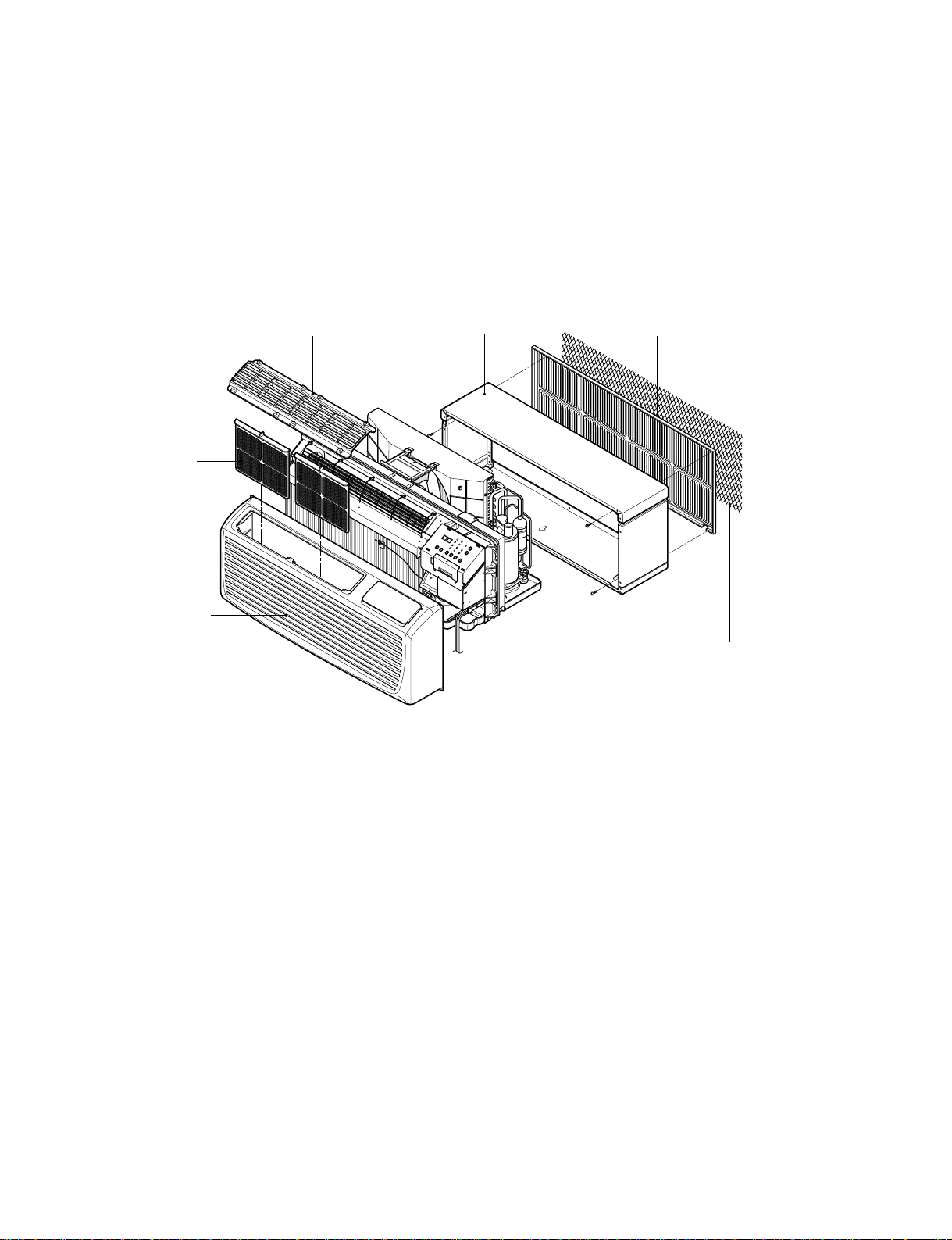

THE SLEEVE AND THE REAR GRILLE

(Available as an option)

REAR GRILLE

(Aluminum Rear Grille)

AIR FILTER

VERTICAL AIR DEFLECTOR

(Horizontal Louver)

SLEEVE ASSEMBLY

(Including Aluminum Rear Grille)

R

O

O

D

N

I

INLET GRILLE

(Air Intake)

EXPANDED METAL GRILLE

(Superior for a performance)

• Indoor Filters

The unit uses two indoor filters which slide in and cut easily. The filters may be cleaned by washing and brushing without

removing the front grille.

• Rotary Compressor

The unit uses a rotary compressor for quiet, reliable operation and long life.

• 2 Position Discharge Grille

The discharge grille can provide air flows upward at an angle of 40 off vertical or 15 degree off vertical. The angle is changed

by removing the front grille and 4 screws that fasten the discharge grille to the front grille and rotating the louvers to an

alternate position.

• Indoor Room Freeze Protection

When the unit senses the room temperature falls to less than 40° F the unit activates the fan motor and either the electric

resistance heater or the hydronic heater to prevent pipes or fixtures from freezing. This also overrides front desk control of the

unit mounted or wall mounted controls.

• Door Switch/Occupancy Sensor

The unit is capable of accommodating a field installed door switch and occupancy sensor to operate the energy management

feature. For additional information, refer to the unit operation section.

• Compressor Overload Protection

This feature prevents the damage of the compressor by sensing the indoor tube temperature in heating. If the indoor

temperature is over 130˚ F, the outdoor fan will be switched off and back on when the temperature drops below 120˚ F.

• Outdoor Air Temperature Switchover

This will effectively change the unit from heat pump mode to total electric resistance heat.

• Temperature limits

The unit is programmed to provide both heating and cooling temperature limits by dip switches on control panel from 50˚ F to

90˚ F. Temperature limits help to prevent overheating and overcooling and reduce energy costs.

• Condensate Drain Valve

The unit has a condensate drain valve to prevent water from collecting or freezing in the basepan.

• Quick Heater Recovery

The unit is designed to operate the electric heater to warm the room to the temperature set point as soon as heat pump cycle

is on in heating. This feature has an advantage of reducing the time to reach the set point and improving the temperature

increase for better comfort.

• Reverse Cycle Defrosting - (PTHDs only)

The unit will activate the reverse cycle defrost when the outdoor coil temperature has remained at a cold temperature to form

the ice on the coil.This ice will reduce airflow though the coil and will also reduce the efficiency of unit. The LG PTHP will

employ an active reverse cycle defrost function to melt the ice off the outdoor coil for insuring room comfort conditions and

savings from extended operation.

• High Temperature Heat Pump Operation Protection

The compressor will be switched off to prevent damage when the heat pump is operated in high outdoor temperatures.

• Remote Thermostat Control

Each unit is built to be operated from any standard 4 or 5 wire remote-mounted thermostat, if desired. The unit has a built-in

low voltage power source which can accommodate a large variety of thermostat choices-manual, auto changeover, or

programmable. A remote thermostat can also be added to any installed unit.

• Zone Sensor

Occupants enjoy ultimate comfort with consistent climate control. Attach an optional, inexpensive remote Zone Sensor to

exactly match the functions of the PTAC without disabling any features.

—5—

—6—

1.3 CONTROL LOCATIONS

• OPERATION

ELECTRIC HEATING MODEL COOLING ONLY MODEL

VENT

OPEN

VENT

CLOSE

TEMPERATURE CONTROL

Set the Thermostat control to the desired temperature

mark 5 (the mid-point is a good starting position). If the

room temperature is not satisfactory after a reasonable

time, adjust the control to a cooler or warmer setting, as

appropriate.

OPERATION MODE SELECTOR

OFF Turns air conditioner off.

LOW FAN Low speed fan operation without cooling.

HIGH FAN High speed fan operation without cooling.

LOW COOL Cooling with the low speed fan operation.

HIGH COOL Cooling with the high speed fan operation.

LOW HEAT Heating with the low speed fan operation.

HIGH HEAT Heating with the high speed fan operation.

• VENTILATION

The ventilation lever is located to the lower left side of the unit.

The ventilation lever must be in the CLOSE position in order

to maintain the best cooling conditions.

When fresh air is necessary in the room, set the ventilation

lever to the OPEN position.

The damper is opened and outdoor air is drawn into the room.

This will reduce the cooling or heating efficiency.

When the air conditioner has performed a cooling or

heating operation and is turned off or set to the fan

position, wait at least 3 minutes before resetting to the

cooling operation.

A slight heat odor may come from the unit when first

switching to HEAT after the cooling season is over.

This odor, caused by fine dust particles on the heater, will

disappear quickly. This is harmless.

CAUTION

NOTE

—7—

• ELECTRONIC CONTROLS

The controls will look like one of the following.

TEMP/TIME

MODE

HEATHEAT

E/SAVEE/SAVE

FANFAN

COOLCOOL

HIGHHIGH

LOWLOW TIMERTIMER

FAN TIMER

'

F

ON

OFFONOFF

REMOTE CONTROL SIGNAL

RECEIVER

POWER

MODE

-

Push this button to cycle through the modes from COOL → FAN

→ HEAT→ COOL.

- COOL

• Fan runs continually for normal cooling operation.

- ENERGY SAVER

• The fan stops when the compressor stops cooling.

Approximately every 3 minutes the fan will turn on and the unit

will check the room air temperature to determine if cooling is

needed.

- FAN

• Fan operation without heating or cooling.

TIMER

- SHUT-OFF TIME

• You will usually use shut-off time while you sleep.

• If unit is running, use Timer to set number of hours until shut-off.

• For your sleeping comfort, once Time is set, the Temperature setting will raise 2° F after 30 minutes, and once again

after another 30 minutes.

• Push Timer to cycle through the settings from 1 Hour → 2 Hours → ... → 12 Hours maximum.

TEMPERATURE SETTING

• Use this button to automatically control the

temperature of the room.

The temperature can be set within a range of

54° F to 86° F by increments of 1° F.

• The setting appears in the display.

FAN SPEED

• Every time you push this button, it cycles through the settings as follows:

{High → Low → High → Low}

• To turn the air conditioner ON, push this button.

To turn the air conditioner OFF, push the button

again.

• This button takes priority over any other button.

• At initial power-up, the unit defaults to COOL

mode, HIGH fan, 72˚ F.

F1 LOW

F2 HIGH

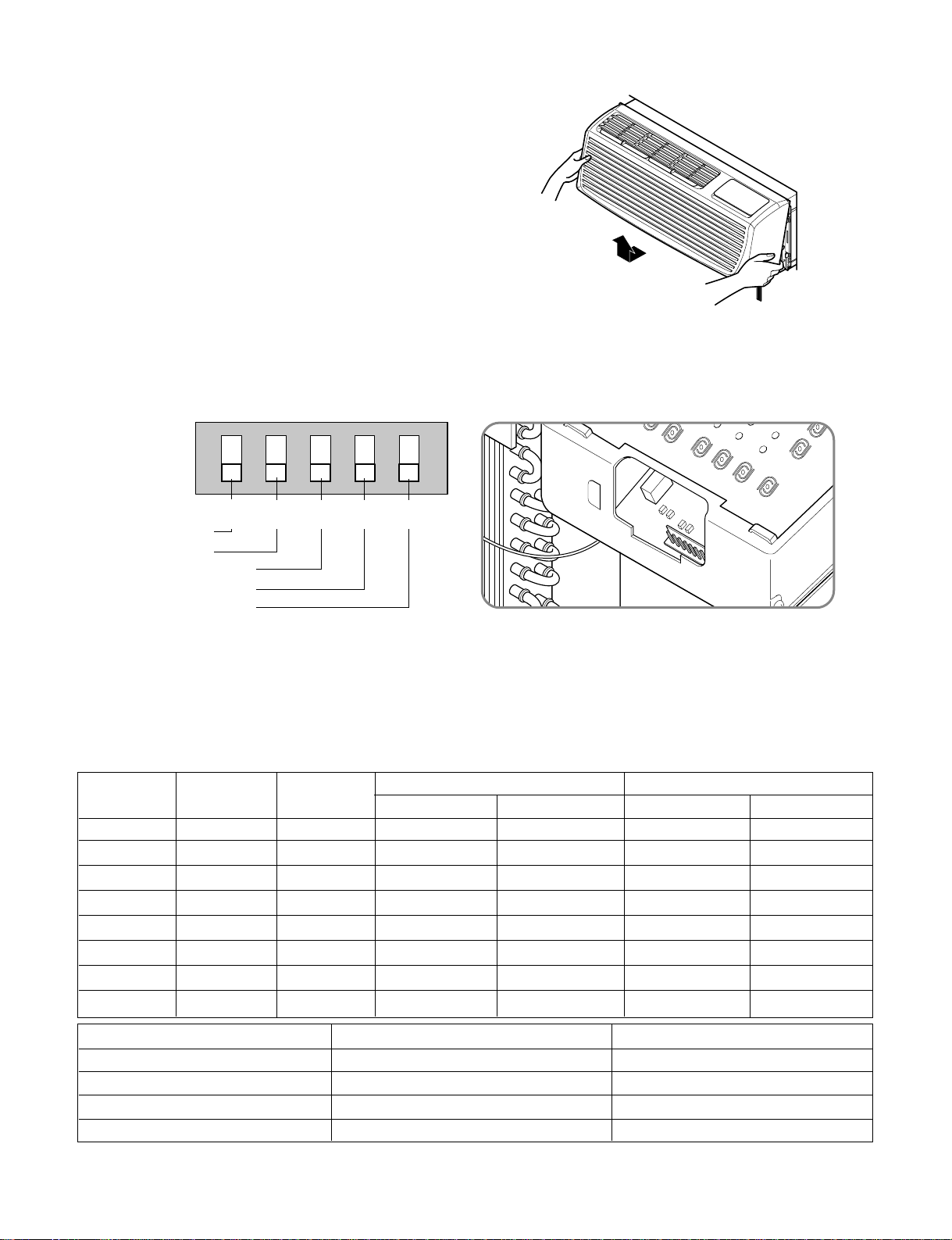

1.4 ADDITIONAL CONTROLS

• REMOVING THE FRONT GRILLE

Additional controls are available after removing the front

grille and option cover of control box.

To remove the front grille, pull out the bottom of front

grille and then lift up.

To replace the front grille, place the tabs over the top of

the unit and push the bottom of front grille until the clips

snap into place.

• ADDITIONAL CONTROLS

The additional controls are located behind the option cover of control box. The standard settings will be in the OFF position.

The authorized service man has to check switches and ensure the switches are in the desired position.

• TEMPERATURE LIMITING

Temperature Limiting can save money by limiting the lowest temperature for cooling and the highest temperature for heating.

The temperature limiting is controlled by dip switches #1 - #3.

This temperature limiting is not available with the Remote Wall Thermostat.

—8—

ON

ONREMOTE

OFF

ON ON ON

Remote/Local

Energy Saver

Temperature Limit 1

Temperature Limit 2

Temperature Limit 3

LOCALLOCAL

1

OFF

OFF

2

OFF

OFF

3

OFF

OFF

4

OFF

OFF

5

LOCAL

1

OFF2OFF3OFF4OFF

5

LOCALLOCAL

1

OFF

OFF

2

OFF

OFF

3

OFF

OFF

4

OFF

OFF

5

LOCAL

1

OFF2OFF3OFF4OFF

5

Temperature Temperature Temperature

Limit #1 Limit #2 Limit #3

OFF OFF OFF 54° F (12.2° C) 86° F (30.0° C)

ON OFF OFF 56° F (13.3° C)

OFF ON OFF 58° F (14.4° C)

ON ON OFF 60° F (15.5° C)

OFF

ON OFF ON 64° F (17.7° C)

OFF ON ON 66° F (18.9° C) 74° F (23.3° C)

ON ON ON 68° F (20.0° C) 72° F (22.2° C)

OFF ON 62° F (16.6° C)

#6

ON

ON

Cooling Operation

Heating Operation

Lowest Temp. Highest Temp. Lowest Temp. Highest Temp.

#7

86° F (30.0° C)

86° F (30.0° C)

86° F (30.0° C)

86° F (30.0° C)

86° F (30.0° C)

86° F (30.0° C)

86° F (30.0° C)

54° F (12.2° C)

54° F (12.2° C)

54° F (12.2° C)

54° F (12.2° C)

54° F (12.2° C)

54° F (12.2° C)

54° F (12.2° C)

54° F (12.2° C)

Unit Type

86° F (30.0° C)

84° F (28.9° C)

82° F (27.8° C)

80° F (26.7° C)

78° F (25.5° C)

76° F (24.4° C)

Cooling+Electric HeaterOFFOFF

Cooling OnlyONOFF

OFF

ON

Heat Pump Only

Cooling Only+Heat Pump

• REMOTE/LOCAL CONTROL

When remote/local switch #1 is on, it allow the unit to operate by the control of Remote Wall Thermostat.

The unit control by knobs are not available.

• ENERGY SAVER

The energy saver switch #2 is on. This switch is set at cycle fan to provide continuous fan operation in cool or heat modes.

When the switch is off the continuous fan allows continuous circulation of room air and make the more balanced temperature

of the room. When the switch is on the fan is on or off with the compressor or with the heater.

• FRONT DESK CONTROL

When the pair wire is connected to the connector LO and LI, the unit can be turned ON or OFF with a switch located at the

Front Desk Control panel. When the front desk switch is ON, the fan operate according to the condition of setting without

working compressor and heater. When the front desk switch is OFF, the unit can operate according to the setting of controls.

• REMOTE WALL THERMOSTAT

When the wires are connected, the unit will be controlled by a remote wall

thermostat.

The thermostat connections supply the 24 Volt AC. When you install the

digital/electronic thermostat, you must set it to the 24 Volt AC. See the

installation Instruction in this manual for the Remote Wall Thermostat.

—9—

GL GH O W Y R CLO LI

Front Desk Switch

LO LI GL GH O W Y R C

Low Fan

High Fan

Reversing V alve

Heater

Compressor

24 Volt-L

24 Volt-N

Wiring Schematic for

Remote Heat Pump

Wiring Schematic for

Straight Cool Unit.

Note: The following figures show wiring

schematics for heat pump and straight cool

units with electric heat, respectively.

Wire # AWG Maximum Length

#22

600 ft (180 m)

#20 900 ft (270 m)

#18 1500 ft (450 m)

#16 2000 ft (610 m)

—10—

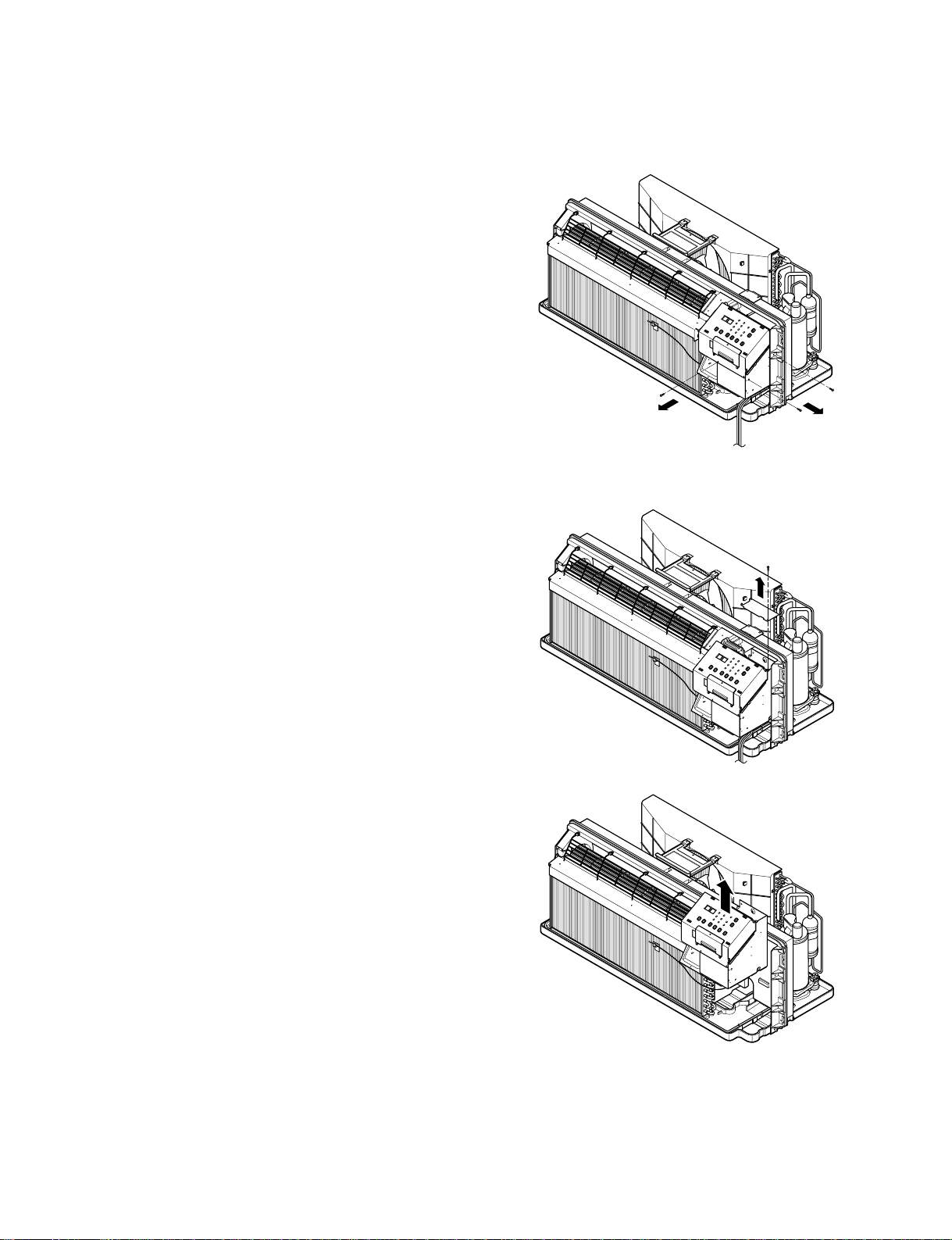

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

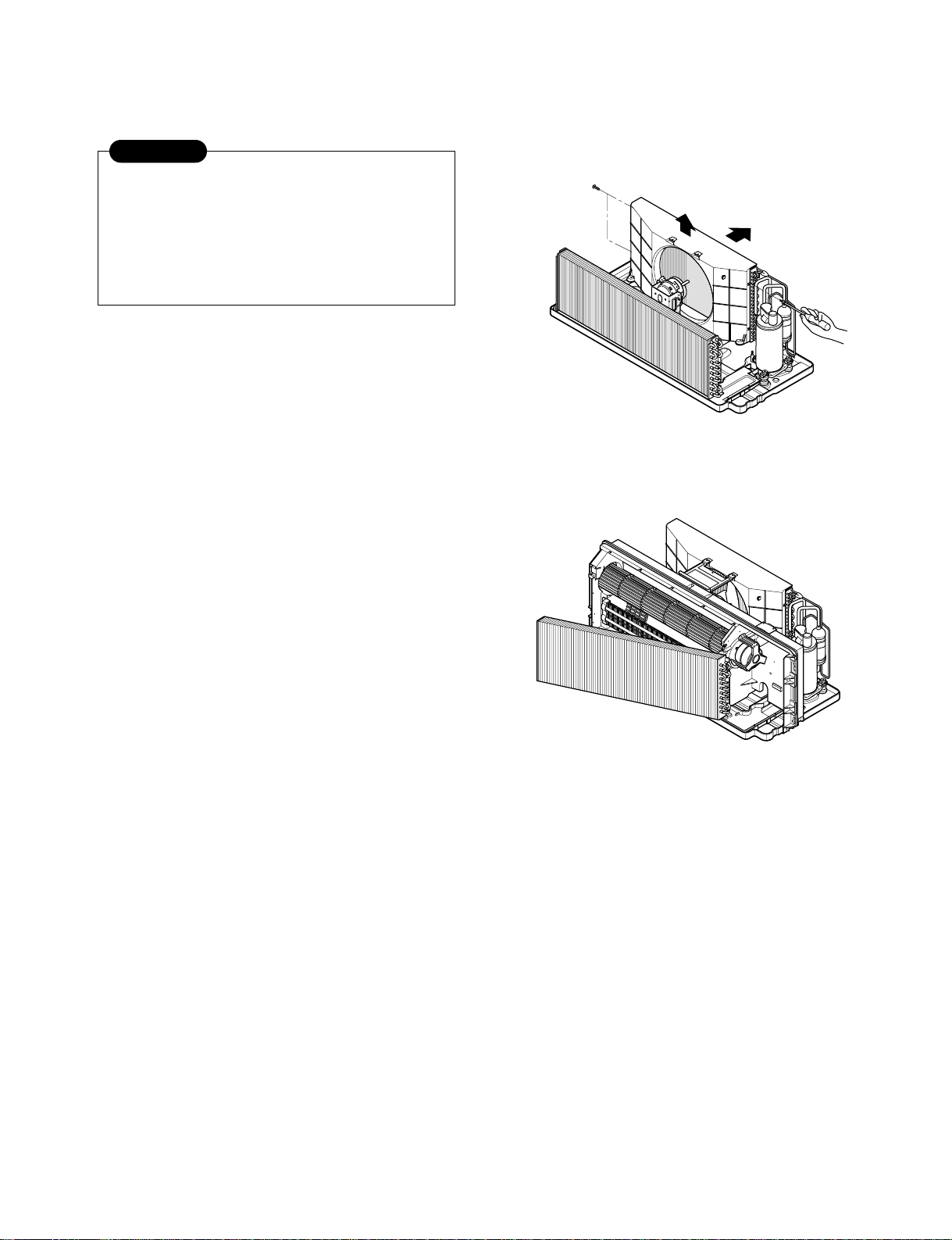

1. Remove the front grille. (See Figure 1)

2. To remove the front grille, pull out the bottom of

the front grille and then lift up.

Re-install the component by referring to the

removal procedure.

3. To replace the front grille, place the tabs over the

top of the unit and push the bottom of front grille

until the clips snap into place.

• This Room Air Conditioner (PTAC) discharges air

from the top of the unit through reversible, 2-position

discharge grille louvers. The unit is shipped from the

factory with the discharge grille louvers at an angle

of 40˚ off vertical. In the alternate position, the

louvers will be at an angle of 15˚ off vertical.

To adjust air direction, remove the front grille.

Remove the 4 screws that fasten the discharge grille

to the front grille.

Flip the discharge grille 180°, then reattach the

discharge grille to the front grille with 4 screws.

2. DISASSEMBLY INSTRUCTIONS

— Before the following disassembly, POWER SWITCH is set to OFF and disconnected the power cord.

Figure 1

40˚

15˚

Screws

—11—

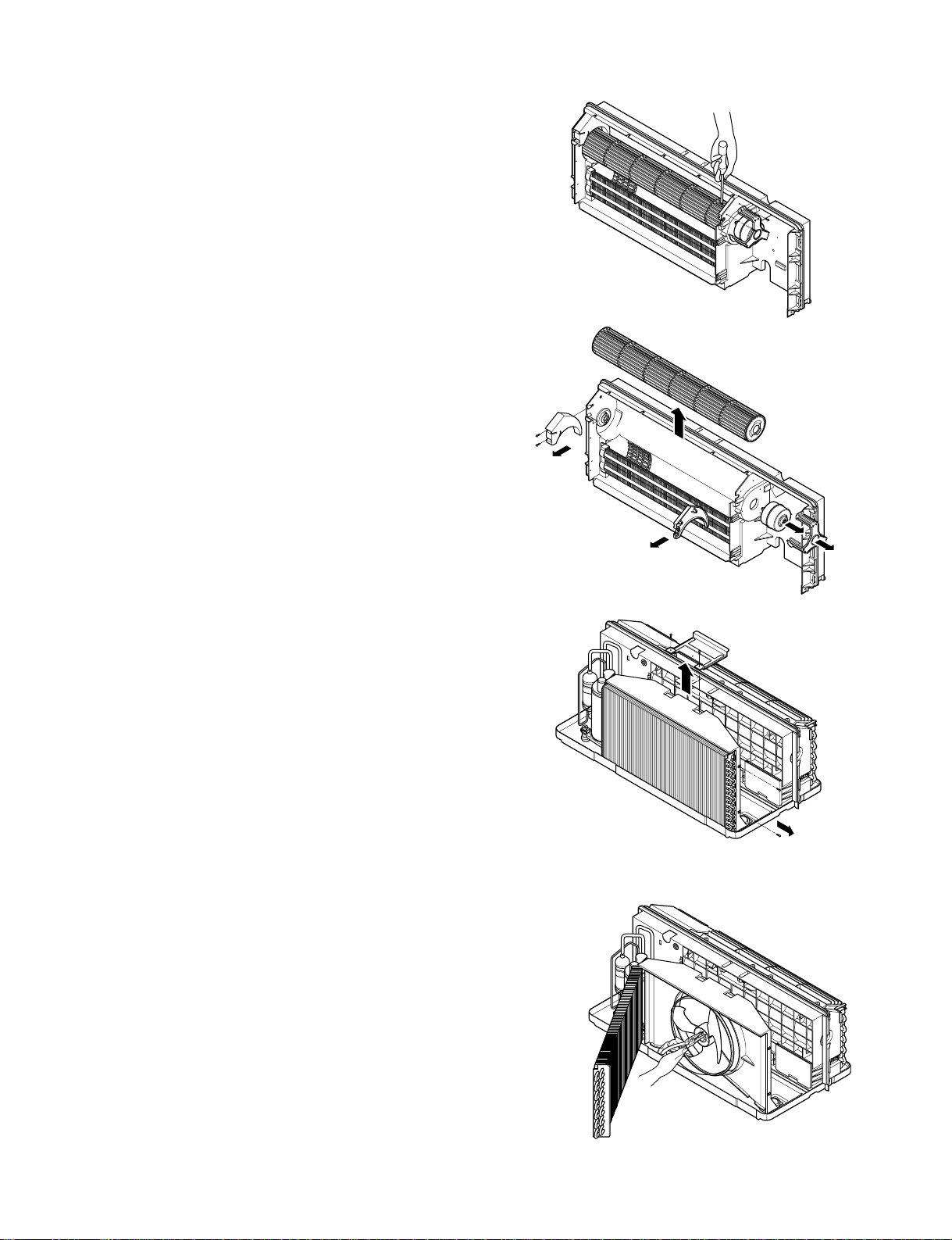

2.1.2 CONTROL BOX

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the two screws which fasten the control

box. (See Figure 2)

3. Pull the control box from the Air guide.

4. Remove the control box cover. (See Figure 3)

5. Disconnect wire housings on the control box.

6. Pull the control box assembly out from the unit.

(See Figure 4)

7. Re-install the components by referring to the

removal procedure.

Figure 2

Figure 3

Figure 4

Figure 8

—12—

2.2 AIR HANDLING PARTS

2.2.1 ELECTRIC HEATER

(ELECTRIC HEATER MODEL ONLY)

1. Remove the front grille.(Refer to section 2.1.1)

2. Remove the control box assembly.

(Refer to section 2.1.2)

3. Remove the 4 screws which fasten the Evaporator.

(See Figure 5)

4. Remove the top cover assembly, net steel, brace.

(See Figure 6)

5. Remove the 6 screws which fasten the Air-guide.

6. Pull the Air-guide assembly out from the unit.

(See Figure 7)

7. Remove the 2 screws which fasten the electric

heater in the left hand side.

8. Pull the electric heater towards left for a while and

then lift up vertically to disassemble it completely

from Air guide.

Figure 5

Figure 6

Figure 7

—13—

Figure 12

2.2.2 CROSS FLOW FAN

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the control box assembly.

(Refer to section 2.1.2)

3. Remove the Air-Guide Assembly from the unit.

(Refer to section 2.2.1)

4. Loosen the screw on the cross flow fan.

(See Figure 9)

5. Remove the 4 screws which fasten the indoor

motor and the earth wire. (See Figure 10)

6. Remove the supports on both sides.

7. Pull the cross flow fan out from the air-guide.

8. Re-install the components by referring to the

removal procedure.

2.2.3 AXIAL FAN

1. Remove the brace.

2. Remove the 4 screws which fasten the condenser

with the shroud and the basepan. (See Figure 11)

3. Remove the condenser sideways carefully.

4. Remove the clamp which secures the fan with

pliers.(See Figure 12)

5. Remove the axial fan.

6. Re-install the components by referring to the

removal procedure.

Figure 9

Figure 10

Figure 11

—14—

2.2.4 SHROUD

1. Remove the axial fan. (Refer to section 2.2.3)

2. Remove the 4 screws which fasten the condenser

with the shroud and the basepan. (See Figure 11)

3. Remove the shroud.

4. Re-install the component by referring to the

removal procedure.

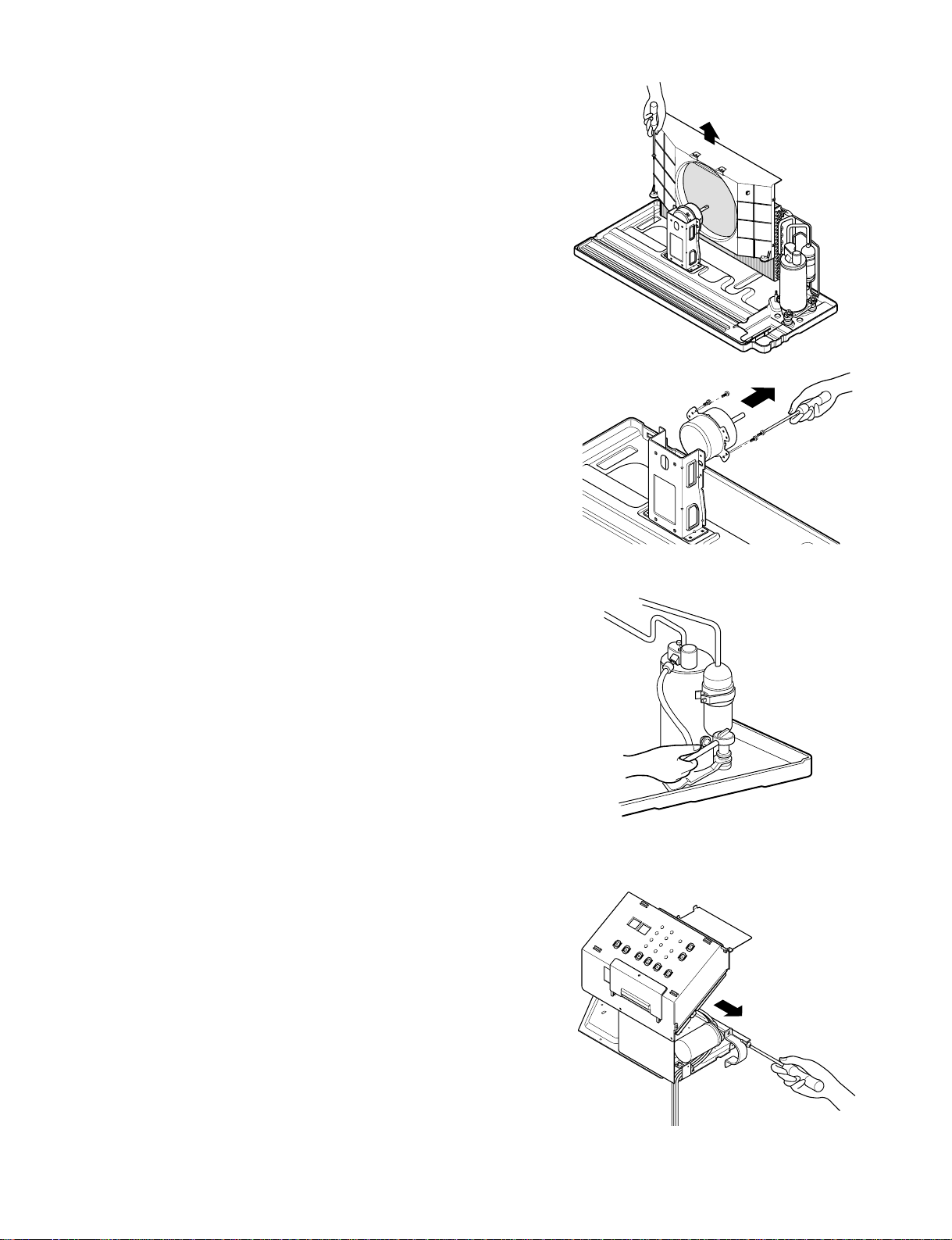

2.3. ELECTRICAL PARTS

2.3.1 OUTDOOR MOTOR

1. Remove the clamp cord and disconnect a wire

housing in control box. (Refer to section 2.1.2)

2. Remove the axial fan. (Refer to section 2.2.3)

3. Remove the 2 screws which fasten the motor.

(See Figure 12)

4. Remove the motor

5. Re-install the component by referring to the

removal procedure, above.

2.3.2 INDOOR MOTOR (Refer to section 2.2.2)

2.3.3 COMPRESSOR

1. Discharge the refrigerant system using a

refrigerant recovery system.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the refrigerant. Leave the valve in place after

servicing the system.

2. Disconnect the 3 leads from the compressor.

3. After purging the unit completely, unbraze the

suction and discharge tubes at the compressor

connections.

4. Remove the 3 nuts and the 3 washers which

fasten the compressor. (See Figure 15)

5. Remove the compressor.

6. Re-instill the components by referring to the

removal procedure, above.

2.3.4 CAPACITOR

1. Remove the control box. (Refer to section 2.1.2)

2. Remove 1 screw and disconnect the leads which

connected to the box type capacitor.

(See Figure 16)

3. Remove 1 screw and the clamp which fastens the

can-type capacitor.

4. Disconnect all the leads of capacitor terminals.

5. Re-install the components by referring to the

removal procedure, above.

Figure 13

Figure 14

Figure 15

Figure 16

—15—

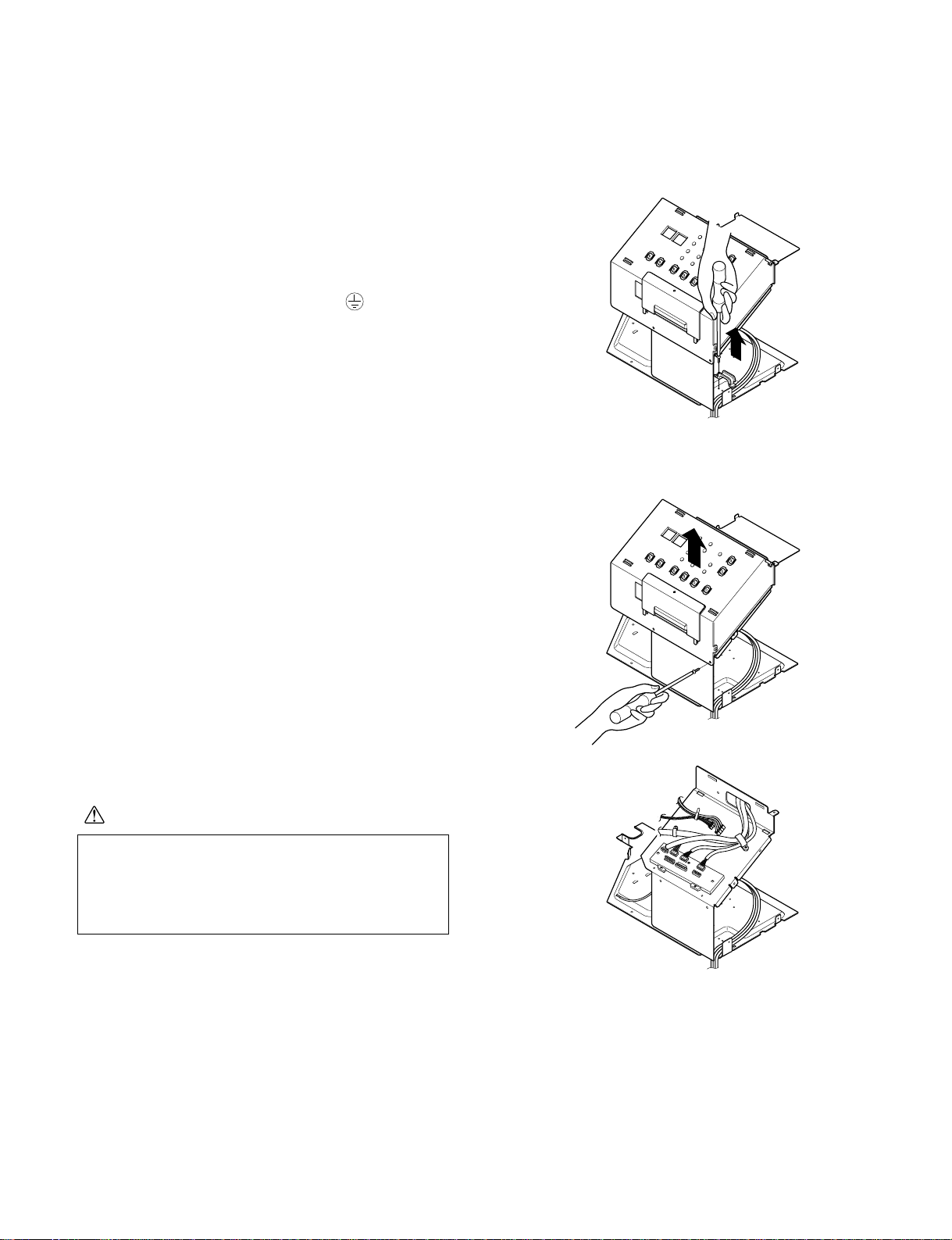

2.3.5 POWER CORD

1. Remove the control box. (Refer to section 2.1.2)

2. Disconnect the grounding screw from the control

box.

3. Disconnect 2 receptacles.

4. Remove a screw which fastens the clip cord.

5. Separate the power cord from the control box.

(See Figure 17)

6. Re-install the component by referring to the

removal procedure, above.

(Use only one ground-marked hole for ground

connection.)

7. If the supply cord of this appliance is damaged, it

must be replaced by an exact replacement part.

(The special cord means the cord which has the

same specification marked on the supply cord

fitted to the unit.)

2.3.6 P.C.B.

1. Remove the escutcheon.

2. Remove the two knobs.

3. Remove the 2 screws which fasten P.C.B. cover.

4. Disconnect all the leads which connected to the

P.C.B.

5. Remove the two screws which fasten the P.C.B.

board.

6. Re-install the components by referring to the

removal procedure, above.

WARNING

Figure 17

Figure 18

After servicing control box ,make sure that AC and DC

wires are separated and tied up properly.

The wires should also be pressed a little downwards to

prevent touching it to the display pcb.

—16—

2.4 REFRIGERATION CYCLE

2.4.1 CONDENSER

1. Remove the brace and the shroud.

(Refer to section 2.2.2)

2. Remove the 4 screws which fasten the shroud.

(Refer to section 2.2.2)

3. Push forward the shroud and remove the 2 screws

which fasten the condenser with the basepan.

4. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

5. Remove the condenser.

6. Re-install the components by referring to notes.

(See Figure 19)

2.4.2 EVAPORATOR

1. Remove the front grille. (Refer to section 2.1.1)

2. Discharge the refrigerant completely.

3. Remove the control box assembly.

(Refer to section 2.1.2)

4. Remove the 4 screws which fasten the evaporator

at the left side and the right side.

5. Move the evaporator sideward carefully and then

unbraze the interconnecting tube at the evaporator

connectors.

6. Remove the evaporator.

7. Re-install the components by referring to notes.

(See Figure 20)

2.4.3 CAPILLARY TUBE

1. After discharging the refrigerant completely,

unbraze the interconnecting tube at the capillary

tube.

2. Remove the capillary tube.

3. Re-install the components by referring to notes.

Figure 19

Figure 15

Discharge the refrigerant system using a

refrigerant recovery system.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before

venting the refrigerant. Leave the valve in place

after servicing the system.

CAUTION

Figure 20

—17—

— Replacement of the refrigeration cycle.

1. When replacing the refrigeration cycle, be sure to

discharge the refrigerant system using a

refrigerant recovery system.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the refrigerant. Leave the valve in place after

servicing the system.

2. After discharging the unit completely, remove the

desired component, and unbraze the pinch-off

tubes.

3. Solder service valves into the pinch-off tube ports,

leaving the valves open.

4. Solder the pinch-off tubes with service valves.

5. Evacuate as follows.

1) Connect the vacuum pump, as illustrated

Figure 16 A.

2) Start the vacuum pump, slowly open manifold

valves A and B with two full turns

counterclockwise and leave the valves closed.

The vacuum pump is now pulling through valves

A and B up to valve C by means of the manifold

and entire system.

3) Operate the vacuum pump for 20 to 30 minutes,

until 600 microns of vacuum are obtained. Close

valves A and B, and observe the vacuum gauge

for a few minutes. A rise in pressure would

indicate a possible leak or moisture remaining in

the system. With valves A and B closed, stop

the vacuum pump.

4)

Remove the hose from the vacuum pump and

place it on the charging cylinder. See Figure 16 B.

Open valve C.

Discharge the line at the manifold connection.

5) The system is now ready for final charging.

6. Recharge as follows :

1) Refrigeration cycle systems are charged from the

high-side. If the total charge cannot be put

in the high-side, the balance will be put in the

suction line through the access valve which you

installed as the system was opened.

2)

Connect the charging cylinder as shown in Figure

16B.

With valve C open, discharge the hose at the

manifold connection.

3) Open valve A and allow the proper charge to

enter the system. Valve B is still closed.

4) If more charge is required, the high-side will not

take it. Close valve A.

5) With the unit running, open valve B and add the

balance of the charge.

a. Do not add the liquid refrigerant to the low-

side.

b. Watch the low-side gauge; allow pressure to

rise to 30 lbs.

c. Turn off valve B and allow pressure to drop.

d. Repeat steps B and C until the balance of the

charge is in the system.

6) When satisfied the unit is operating correctly,

use the pinch-off tool with the unit still running

and clamp on to the pinch-off tube. Using a tube

cutter, cut the pinch-off tube about 2 inches from

the pinch-off tool. Use sil-fos solder and solder

pinch-off tube closed. Turn off the unit, allow it to

set for a while, and then test the leakage of the

pinch-off connection.

NOTES

If high vacuum equipment is used, just crack

valves A and B for a few minutes, then open

slowly with the two full turns counterclockwise.

This will keep oil from foaming and being

drawn into the vacuum pump.

CAUTION

Loading...

Loading...