Page 1

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : NF-99LA

MODEL : LN-15A10

Page 2

- 2 -

CONTENTS

Contents .................................................................................................. 2

Safety Precautions ..................................................................................3

Servicing Precautions ............................................................................ 4

Adjustment Instruction ............................................................................6

Troubleshooting .......................................................................................8

Exploded View ...................................................................................... 10

Exploded View Parts List.......................................................................11

Replacement Parts List ........................................................................ 12

SVC. Sheet .................................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate

high impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5

!1.5KV: 14-19 inch, 26!1.5KV: 19-21 inch,

29.0

!1.5KV: 25-29 inch, 30.0 ! 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc.,

to be sure the set is safe to operate without damage of

electrical shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

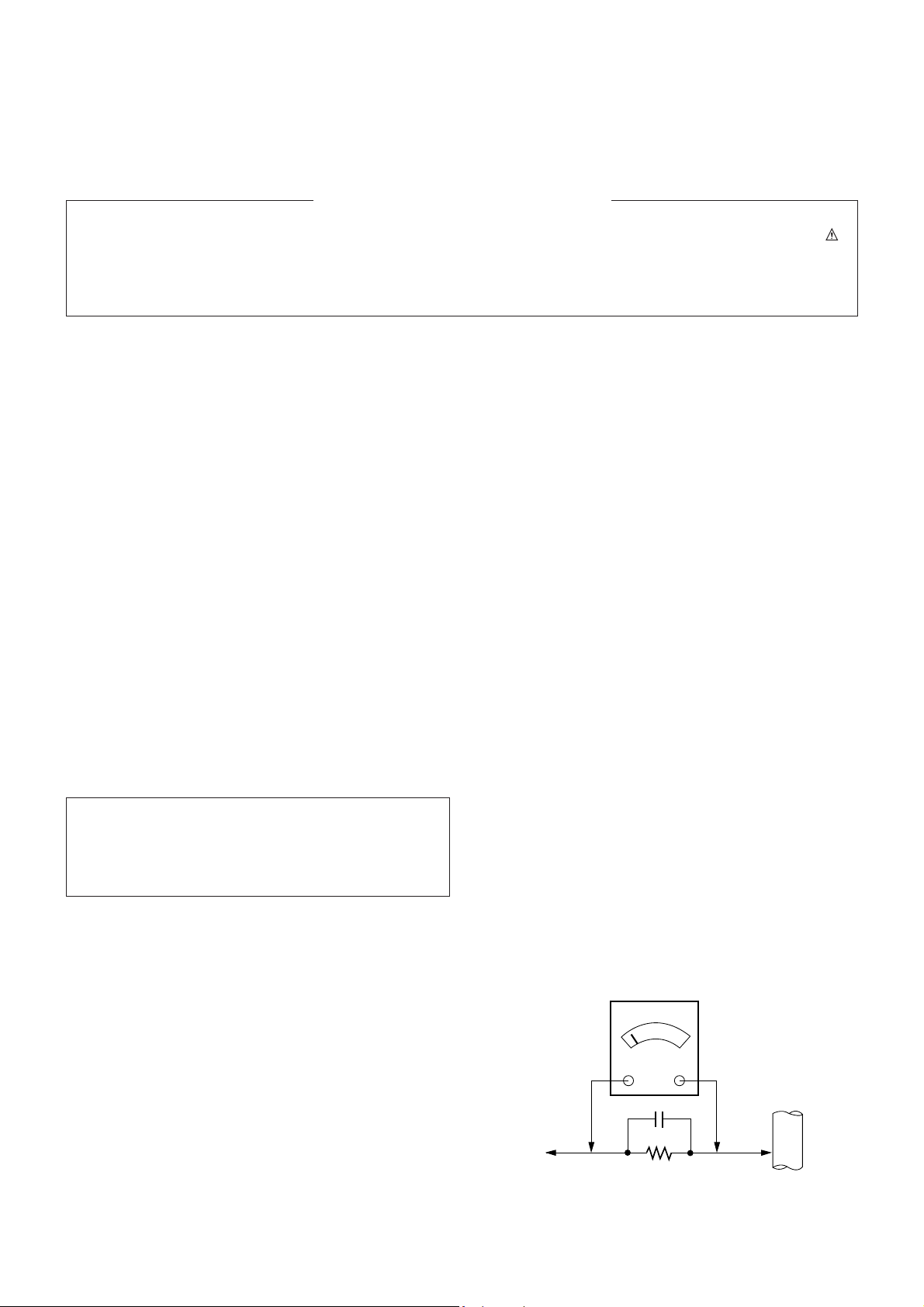

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the

High Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the

replacement tube must be the same type tube as specified in

the Replacement Parts List.

IMPORTANT SAFETY NOTICE

0.15uF

AC Volt-meter

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 4

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS

on page 3 of this publication.

NOTE:

If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug

or other electrical connection.

c.

Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first connecting

one end of an insulated clip lead to the degaussing or kine

aquadag grounding system shield at the point where the

picture tube socket ground lead is connected, and then (b)

touch the other end of the insulated clip lead to the picture

tube anode button, using an insulating handle to avoid

personal contact with high voltage.

4. Do not spray chemicals on or near this receiver or any of its

assemblies.

5. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator; 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%-99%

strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication

of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which receivers covered by this service manual might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test receiver

positive lead.

Always remove the test receiver ground lead last.

9.

Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to

any heatsink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called

Electrostatically Sensitive (ES) Devices.

Examples of

typical ES devices are integrated circuits and some fieldeffect

transistors and semicounductor "chip" components. The

following techniques should be used to help reduce the

incidence of component damage caused by static by static

electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed to prevent potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as "anti-static" can

generate electrical charges sufficent to demage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a repalcement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the ieads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

CAUTION:Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such

as the bruching together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintan tip

temperature within the range or 500

cF to 600cF.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thorohly clean the surfaces to be soldered. Use a mall

wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500cF to 600cF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuiboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500cF to 600cF)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

SERVICING PRECAUTIONS

Page 5

- 5 -

c. Qulckly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it

there only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess

or splashed solder with a small wire-bristle brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following

technique should be used to remove and replace the IC. When

working with boards using the familiar round hole, use the

standard technique as outlined in parapraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit boare.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the "U" with long nose pliers to insure metal to metal

contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicula y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them

and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board

to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board.

The following guidelines and procedures should be followed

whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely

necessary).

2. carefully scratch away the solder resist and acrylic coating

(if used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped end

of the good copper pattern. Solder the overlapped area and

clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involoves the installation of a jumper wire on the component

side of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of

the nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so

the it does not touch components or sharp edges.

Page 6

- 6 -

1. Application Object

This instruction is for the application to the LCD TV.

2. Notes

(1) This set uses an adapter, so connect the adapter and the

set correctly before adjustment.

(2) The adjustment must be performed under the correct

sequence.

(3) The adjustment must be performed in the circumstance of

25!5cC of temperature and 65!10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220V, 60Hz in

adjusting.

(5) The set must be operated for 30 minutes preliminarily

before adjustment if there is no specific designation.

[ ‘Heat Run’ must be performed with the full white signal or TV

noise signal in the internal part of the set.

[ The time for ‘Heat Run’ can be changed owing to production

plan.

3. TV Mode Adjustment

Before entering into the adjustment mode set the TV up with

the MENU button as below.

Contrast 85

Brightness 100

Saturation 50

Tint 0

3-1. White Balance Adjustment

3-1-1. Required Test Equipment

(1) A Remote Control

(2) A Color Analyzer for LCD : CA-110

(3) A TV Signal Generator : Pattern of 64 (128) tones or Ch. 13

in the company.

3-1-2. Preparation for Adjustment

(1) This adjustment should be performed 30 minutes later

after ‘Heat Run’.

(2) This adjustment should be performed in a darkroom or in

the simmilar condition.

3-1-3. Low Light Adjustment

(1) Seletc Ch.13 in the company.

(2) Enter into the adjustment mode with the ADJ button.

(3) Select the Sub-bright and stop adjusting at the moment

when Gray 0 and 1 aren’t distinguished.

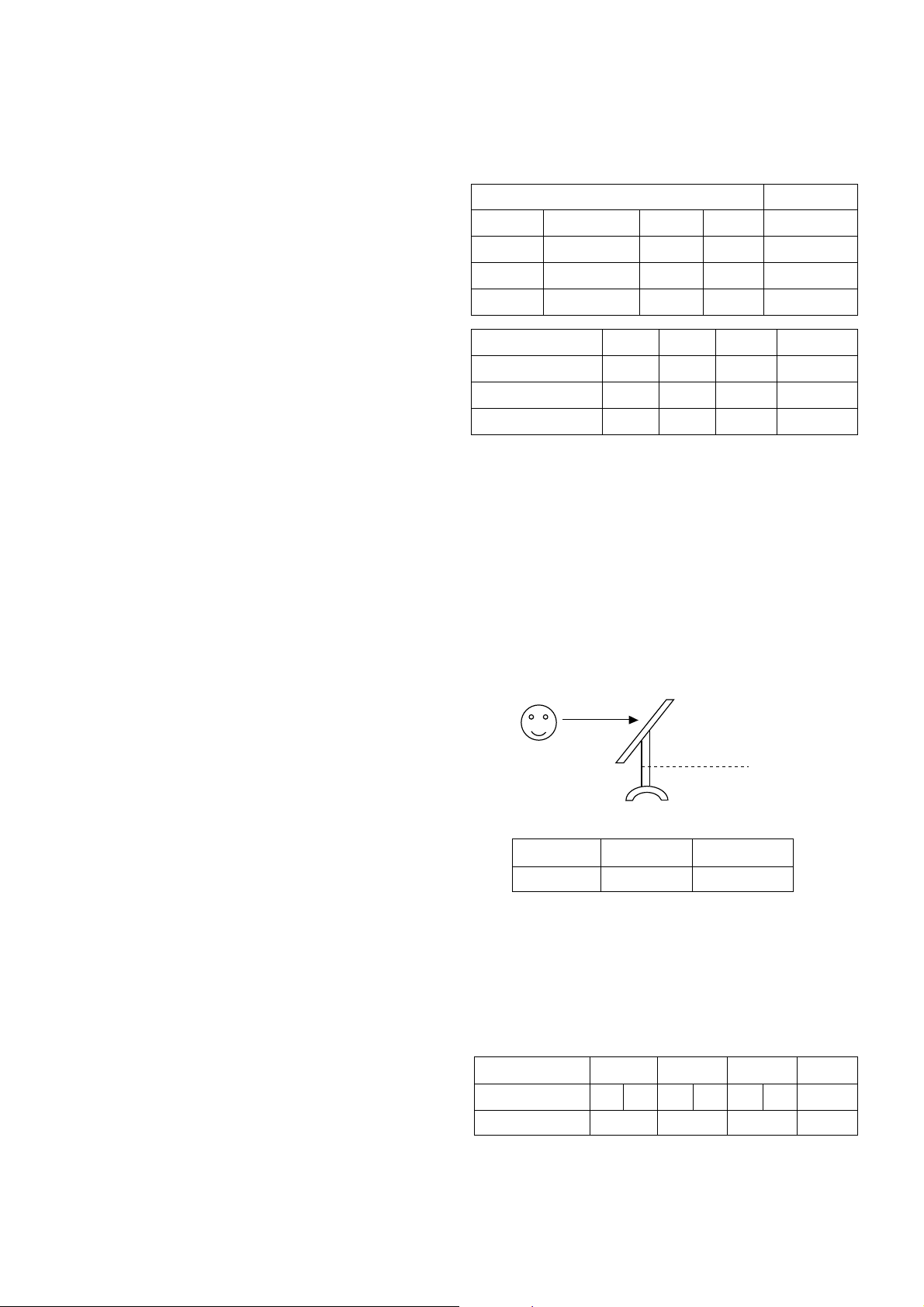

4. PC Input Mode Adjustment

4-1. Required Test Equipment

(1) A pattern generator being in proportion to VG819 ; Pattern

of 64 tones

(2) A remote control

4-2. Preparation for Adjustment

(1) Perform ‘Heat Run’ for more than 30 minutes in white

pattern.

(2) Connect the signal of pattern generator with LCD TV.

(3) Lean the set 45° backward. (Adjustment is easy.)

(4) Set the PC mode menu as below.

4-3. White Adjustment

(1) Approve the signal of 64 tones of XGA(1024 * 768).

(2) Select all the gain of R, B and G with using ADJ of remote

control.

(3) After making 62 tones, 63 tones and 64 tones not

distinguished with using each signal of R, G and B, finish

adjusting at the moment when the signal 62, 63 and 64 is

distinguished.

ADJUSTMENT INSTRUCTION

IC

VPC3230D

VPC3230D

VPC3230D

Name

BR

ACC_Sat

Tint

Default

0

2930

0

Unit-Decimal

Adj. Mode

No.304

No.236~237

No.248

IIC Type

IIC 0x52/7:0/

IIC 0x30/11:0/

Fp 0xDC

Low Light(Black)

3 x

3 y

Brightness:[cd/m^2]

Blue

0.14

0.10

Green

0.30

0.60

White

0.32

0.34

150[cd/m^2]

Red

0.63

0.34

45°

Initial Value

Contrast

70

Brightness

100

R

0.63 0.34

0x02

G

0.30 0.60

0x03

B

0.14 0.10

0x04

Error

! 0.03

Register

Color Coordinates(x,y)

AD9884

Page 7

- 7 -

4-4. Position of Mode Adjustment

Timing of Mode Table * H[dot]/V[line]

Mode

H_Total

H_Display

H_Blanking

H_Sync

H Polarity

H_Bp

H_Fp

H-Freq[KHz]

/Clk[MHz]

V_Total

V_Display

V_Blanking

V_Sync

V Polarity

V_Bp

V_Fp

VGA-60

800

640

160

96

NEG.

48

16

31.469

25.175

525

480

45

2

NEG

33

10

VGA-67

864

640

224

64

NEG.

96

64

35.0

30.24

525

480

45

3

NEG

39

3

VGA-72

832

656

176

40

NEG.

120

16

37.861

31.5

520

496

24

3

NEG

20

1

VGA-75

840

640

200

64

NEG.

120

16

37.5

31.5

500

480

20

3

NEG

16

1

VGA-85

832

640

192

56

NEG.

80

56

43.269

36.0

509

480

29

3

NEG

25

1

TEXT-70

900

720

180

108

NEG.

54

18

31.469

28.324

449

400

49

2

POS

34

13

SVGA-56

1024

800

224

72

POS

128

24

35.156

36.0

625

600

25

2

POS

22

1

SVGA-60

1056

800

256

128

POS

88

40

37.879

40.0

628

600

28

4

POS

23

1

SVGA-72

1040

800

240

120

POS

64

56

48.077

50.0

666

600

66

6

POS

23

37

Mode

H_Total

H_Display

H_Blanking

H_Sync

H Polarity

H_Bp

H_Fp

H-Freq[KHz]

/Clk[MHz]

V_Total

V_Display

V_Blanking

V_Sync

V Polarity

V_Bp

V_Fp

SVGA-75

1056

800

256

80

POS

160

16

46.875

49.5

625

600

25

3

POS

21

1

SVGA-85

1048

800

248

64

POS

152

32

53.674

56.25

631

600

31

3

POS

27

1

XGA-60

1344

1024

320

136

NEG

136

160

48.363

65.0

806

768

38

6

NEG

29

3

XGA-70

1328

1024

304

136

NEG

144

24

56.476

75.0

806

768

38

6

NEG

29

3

XGA-75

1312

1024

288

96

POS

176

16

60.23

78.75

800

768

32

3

POS

28

1

MAC-75

1152

832

320

64

NEG

224

32

49.725

57.283

667

624

43

3

NWG

39

1

Page 8

9 No sound Defective Reset IC of IC603 1) Check volume and speaker

- Speaker Defective MSP3400D of IC601 - Sound comes out only when being inputted into Audio

- Earphone L/R

2) Check after replacing IC603

3) Replace IC601

10 Video color beat noise Earphone shield case being touched

Check the mould of shield and JA401, Replace shield case

Soldering IC901 and IC501 Re-soldering

1 Soft touch doesn’t Defective speaker wire 1) Make some space between the speaker wire and

function properly and inverter wire the Soft touch Board by sticking the speaker wire

to the guide hole of the cabinet.

2) Arrange working state of A1. Tape in the inverter wire

and correct working state of the Shield case.

2 Soft touch doesn’t 1) Broken components and 1) Check Soft touch with eyes

function soldering of them Check and repair soldering

2) P101 connector error 2) Check and repair the P101 connector

3 No screen Input error of inverter connector 1) Bend the pin legs of P802 connector -> recheck them

2) Check and repair the IC806 SI4925

P501 and Pin 41 connector 1) Check and fix P501 connector

being slipped out 2) Check and fix the components at P501 LCD module

and at main board.

3) Check Pin41 and check and repair rubber packing

Cracked components and 1) Check and repair tuner board and main board

soldering at tuner board 2) Solder Q301, Q801 and R810

4 Dark screen 1) Defective LCD lamp 1) Replace the inverter

2) Defective inverter 2) Replace the LCD lamp

5 Broken OSD display Defective the font rom of IC502 Replace the font rom of IC502

- 8 -

TROUBLESHOOTING

1. General Features

2. PC Mode

No. Symptom Cause Check Point

No. Symptom Cause Check Point

Check Point

6 Screen noise Clock or phase being 1) Resettig is needed according to the video card of each

not able to be adjusted PC

2) Horizontal noise : adjust phase until no horizontal

noise occurres

3) Vertical noise : adjust clock in menu until no vertical

noise occurres

7 Screen position error Screen position error Adjust horizontal and vertical position until the screen

horizontally or vertically displayes normally

8 Color beat noise Soldering AD converter Recheck adn repair AD9884

or making it short

3. TV and external input

No. Symptom Cause

Page 9

MEMO

- 9 -

Page 10

- 10 -

EXPLODED VIEW

300

120

121

174

112

550

540

500

521

400

541

430

440

420

310

JA401

JA402

A3

410

JA701

Page 11

- 11 -

112 6304VT1512A LCD MODULE,151X2-C2TH 15.1”

120 6400VA0017A SPEAKER,GENERAL T401SX-095K14 LG C&D 8 OHM 1.0

121 4950V00010A METAL,HOLDER SPK SBHG

174 6410VUH003A POWER CORD,PS204-001 VOLEX UL/CSA 1800MM

300 3091V00226D CABINET ASSY,LN-15A10 ZENITH

310 5020V00360A BUTTON,CONTROL 8KEY ABS LN-15A1

400 3809V00168D BACK COVER ASSY

410 4950V00025A METAL,STAND ASSY

420 4950V00006A METAL,STAND SECC

430 4930V00103B HOLDER,STAND

440 3550V00081A BASE,COVER

500 6871VMM363C PCB ASSY,MAIN NF99LA US

521 4950V00009A FRAME ASSY,REAR METAL

540 6633VA0003A INVERTER ASSY,12VOLT 500VOLT

541 4814V00143B CASE,INVERTER SHIELD

550 6871VSM480A PCB ASSY,CTL NF99LA LN-15A1

A3 6634VBW002C ADAPTER,AC-DC AC110VOLT DC12VOLT UL/CSA/JAPAN

JA401 6613V00008D JACK ASSY,PMJ014D E/P(ST)+S-VH

JA402 6613V00004J JACK ASSY,PJ6054J A/V I/O 3P U

JA701 6630VGA001B CONNECTOR,68114-1522 MOLEX-KOR 15PIN

EXPLODED VIEW PARTS LIST

No.

PART NO.

DESCRIPTION

Page 12

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

Q708

Q709

Q711

Q712

Q713

Q714

Q715

Q720

Q721

Q722

Q723

Q725

Q726

Q727

Q728

Q801

Q900

D101

D102

D701

D702

D801

D802

D803

D804

ZD101

ZD102

ZD103

ZD104

ZD105

ZD106

ZD107

ZD108

ZD109

ZD170

ZD171

ZD172

ZD173

ZD174

ZD175

ZD176

ZD177

ZD178

ZD179

ZD180

ZD181

ZD182

0TR388009BB

0TR388009BB

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR102009AG

0TR102009AG

0TR102009AG

0TR102009AG

0TR102009AG

0TR102009AG

0TR102009AG

0TR102009AG

0TR387500AA

0TR387500AA

0DD181009AB

0DD181009AB

0DD247109AA

0DD247109AA

0DR190309AA

0DR190309AA

0DD181009AB

0DD181009AB

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

0DZ511109AA

KTC3880-Y TP KEC SOT23 CHIP

KTC3880-Y TP KEC SOT23 CHIP

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP KRC102S SOT-23 TP KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

SWITCHING,CHIP KDS181 85V 300MA KEC

SWITCHING,CHIP KDS181 85V 300MA KEC

DETECTOR,1S2471

DETECTOR,1S2471

RECTIFIER,MBRS190T3 TP MOTOROLA 403A-0

RECTIFIER,MBRS190T3 TP MOTOROLA 403A-0

SWITCHING,CHIP KDS181 85V 300MA KEC

SWITCHING,CHIP KDS181 85V 300MA KEC

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

LOCA. NO PART NO DESCRIPTION

IC101

IC102

IC104

IC105

IC301

IC401

IC402

IC501

IC502

IC601

IC602

IC603

IC604

IC605

IC606

IC607

IC608

IC701

IC702

IC801

IC808

IC901

IC503

IC802

IC803

IC804

IC805

IC806

IC807

Q100

Q101

Q102

Q301

Q302

Q303

Q304

Q501

Q601

Q602

Q702

Q703

Q704

Q705

Q706

Q707

0IZZVC0007E

0IKE704200J

0IAL241600B

0IPH740800F

0IKE780900N

0IAD988400A

0ISH323422A

0IAR300000A

0IZZVA0007G

0IIT344000B

0IKE780800J

0IKE704200J

0IPH705200C

0IPH705200C

0ISH092100A

0ISH092100A

0IKE780500Q

0ISG747410A

0ISG747410A

0ITC786000A

0IKE780500Q

0IIT323000A

0TF492509AA

0TF993609AA

0TF941009AA

0TF993609AA

0TF941009AA

0TF492509AA

0TF492509AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR387500AA

0TR387500AA

0TR388009BB

0TR388009BB

0TR388009BB

0TR388009BB

0TR388009BB

0TR388009BB

M37274EASP 52S DIP 52 BK US

KIA7042AF SOT-89 TP 4.2V VOLTA

AT24C16-10PC 8D EEPROM 16K

74HC08D SO-14 TP QUAD 2-INPUT

KIA7809AP 3 ST REGULATOR .

AD9884 100P MQFP BK A/D CONVER

PQ3RF23 4P(TO-220) 3.3V REGUL

AL300 160P PQFP BK LCD MONITOR

M27C512 28 BK US

MSP3440G QA 80QFP TP AUDIO MUL

KIA7808API 3P ST REGULATOR

KIA7042AF SOT-89 TP 4.2V VOLTA

TDA7052A 8P,DIP BK 1W AUDIO AM

TDA7052A 8P,DIP BK 1W AUDIO AM

PQ09RF21 4P 9V S/W REGULATOR

PQ09RF21 4P 9V S/W REGULATOR

KIA7805API 3P TO-220 ST REGULATOR 5V

M74HC74M1R 14P,SOP TP DUAL DTY

M74HC74M1R 14P,SOP TP DUAL DTY

SI786 28SSOP TP DUAL-OUTPUT PO

KIA7805API 3P TO-220 ST REGULATOR 5V

VPC3230D 80P PQFP BK COMB FILT

FET,SI4925DY TP TEMIC 30V 6.1A SO

FET,SI9936DY TP TEMIC 30V 5A SO-8

FET,SI9410DY TP TEMIC 30V 7A SO-8

FET,SI9936DY TP TEMIC 30V 5A SO-8

FET,SI9410DY TP TEMIC 30V 7A SO-8

FET,SI4925DY TP TEMIC 30V 6.1A SO

FET,SI4925DY TP TEMIC 30V 6.1A SO

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SA1504S(ASY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

CHIP 2SC3875S(ALY) KEC

KTC3880-Y TP KEC SOT23 CHIP

KTC3880-Y TP KEC SOT23 CHIP

KTC3880-Y TP KEC SOT23 CHIP

KTC3880-Y TP KEC SOT23 CHIP

KTC3880-Y TP KEC SOT23 CHIP

KTC3880-Y TP KEC SOT23 CHIP

IC

TRANSISTOR

- 12 -

RUN DATE : 2000.5.23

DIODE

Page 13

- 13 -

LOCA. NO PART NO DESCRIPTION

ZD183

ZD184

ZD301

ZD700

C102

C114

C115

C175

C176

C177

C178

C301

C302

C304

C308

C310

C312

C314

C320

C405

C527

C601

C602

C603

C605

C606

C608

C609

C612

C615

C625

C631

C632

C635

C637

C641

C642

C650

C801

C802

C804

C807

C809

C810

C811

C812

C813

C814

C817

C820

0DZ511109AA

0DZ511109AA

0DZ330009DF

0DZ511109AA

0CE1053K618

0CE1053K616

0CE4763F618

0CE1063F618

0CE1063F618

0CE1063F618

0CE4753K618

0CE4763F618

0CE4763F618

0CE227DF618

0CE227DF618

0CE106DK618

0CE1074F618

0CE227DF618

0CE1063F618

0CE477DF618

0CE687DD618

0CE4763F618

0CE4763F618

0CE1063F618

0CE1063F618

0CE3353K618

0CE4743K618

0CE4743K618

0CE1063F618

0CE1063F618

0CE4763F618

0CE1074F618

0CE1074F618

181-007H

181-007H

181-007H

181-007H

0CE4763F618

0CE1074F618

0CE1074F618

0CE4753K618

0CE4753K618

0CE1074F618

0CE227DF618

0CE687DD618

0CE227DF618

0CE1074F618

0CE476DK618

0CE227DF618

0CE337DF618

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

ZENER,MTZJ33B TP ROHM-K DO34 0.5W 33

ZENER,DTZ5.1BTT11(CHIP) TP ROHM

1UF SRE 50V M

1UF SRE 50V M

47UF SRE 16V M

10UF SRE 16V M

10UF SRE 16V M

10UF SRE 16V M

4.7UF SRE 50V M

47UF SRE 16V M

47UF SRE 16V M

220UF STD 16V M

220UF STD 16V M

10UF STD 50V M

100UF SRA 16V M

220UF STD 16V M

10UF SRE 16V M

470UF STD 16V M

680UF STD 10V M

47UF SRE 16V M

47UF SRE 16V M

10UF SRE 16V M

10UF SRE 16V M

3.3UF SRE 50V M

0.4700UF SRE 50V M

0.4700UF SRE 50V M

10UF SRE 16V M

10UF SRE 16V M

47UF SRE 16V M

100UF SRA 16V M

100UF SRA 16V M

MPE ECQ-V1H474JL3(TR), 50V 0.4

MPE ECQ-V1H474JL3(TR), 50V 0.4

MPE ECQ-V1H474JL3(TR), 50V 0.4

MPE ECQ-V1H474JL3(TR), 50V 0.4

47UF SRE 16V M

100UF SRA 16V M

100UF SRA 16V M

4.7UF SRE 50V M

4.7UF SRE 50V M

100UF SRA 16V M

220UF STD 16V M

680UF STD 10V M

220UF STD 16V M

100UF SRA 16V M

47UF STD 50V M

220UF STD 16V M

330UF STD 16V M

LOCA. NO PART NO DESCRIPTION

C823

C908

C910

C912

C943

C944

C945

C946

F801

JA401

JA402

JA801

L300

L301

L302

L401

L402

L403

L501

L502

L503

L504

L505

L506

L507

L508

L601

L602

L603

L801

L804

L806

L900

L901

LA501

LA502

LA503

LA504

LA505

LA506

L101

L701

L802

L803

L805

L902

0CE1074F618

0CE1063F618

0CE1063F618

0CE1063F618

0CE1053K616

0CE1053K616

0CE1053K616

0CE1053K616

131-096K

6613V00008D

6613V00004J

6612VAH001B

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001E

6210TCE001G

6210TCE001E

6210TCE001E

6210TCE001A

6210TCE001E

6210TCE001G

6210TCE001E

6210TCE001E

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE001G

6210TCE002A

6210TCE002A

6210TCE002A

6210TCE002A

6210TCE002A

6210TCE002A

0LA0152K119

0LA0222K119

6140VB0004A

6140VB0004B

6140VB0004B

0LA0152K119

100UF SRA 16V M

10UF SRE 16V M

10UF SRE 16V M

10UF SRE 16V M

1UF SRE 50V M

1UF SRE 50V M

1UF SRE 50V M

1UF SRE 50V M

FUSE,NON TIME DELAY 135% 2,000MA 125V

JACK ASSY,PMJ014D E/P(ST)+S-VH

JACK ASSY,PJ6054J A/V I/O 3P U

JACK,AC/DC POWER HEC3900-010110

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HB-1M2012-800JT

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HB-1M2012-800JT

CORE(CIRC),BEAD HB-1M2012-800JT

CORE(CIRC),BEAD HB-1S2012-080JT

CORE(CIRC),BEAD HB-1M2012-800JT

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HB-1M2012-800JT

CORE(CIRC),BEAD HB-1M2012-800JT

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HH-1M3216-501

CORE(CIRC),BEAD HB-4M3216-800JT

CORE(CIRC),BEAD HB-4M3216-800JT

CORE(CIRC),BEAD HB-4M3216-800JT

CORE(CIRC),BEAD HB-4M3216-800JT

CORE(CIRC),BEAD HB-4M3216-800JT

CORE(CIRC),BEAD HB-4M3216-800JT

INDUCTOR,15UH K

INDUCTOR,22UH K

COIL,CHOKE 9.5UH 1UEWPHY 13.5TURN YL-9N

COIL,CHOKE 26UH 1UEWPHY 22.5TURN YL-9N

COIL,CHOKE 26UH 1UEWPHY 22.5TURN YL-9N

INDUCTOR,15UH K

FUSE & JACK

CORE

CAPACITOR

COIL & TRANSFORMER

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 14

- 14 -

LOCA. NO PART NO DESCRIPTION

L903

T801

R321

R605

R607

R617

R618

RA501

RA503

RA505

RA507

RA509

RA511

X101

X601

X901

JA701

LD1

PA001

SP701

TU301

X501

A1

A2

A3

0LA0152K119

6170VTCA30A

0RS0561K607

0RD1200H609

0RD1200H609

0RS0681K607

0RS0681K607

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

156-A01P

156-A02M

6202VDB007B

6630VGA001B

0DL112100AB

6726VV0006D

6908VB0001A

6700VNF003E

6204V00001J

3828VA0131F

6710V00044T

6634VBW002C

INDUCTOR,15UH K

TRANSFORMER,CONVERTER[COIL] EPC 13-Z 320UH

5.60 2W 5%

120 1/2W 5%

120 1/2W 5%

6.80 2W 5%

6.80 2W 5%

MNR-14-E0A-J-101 R OHM 100 OH

MNR-14-E0A-J-101 R OHM 100 OH

MNR-14-E0A-J-101 R OHM 100 OH

MNR-14-E0A-J-101 R OHM 100 OH

MNR-14-E0A-J-101 R OHM 100 OH

MNR-14-E0A-J-101 R OHM 100 OH

CRYSTAL,HC49U RADIAL 8.000MHZ 30

CRYSTAL,HC49U RADIAL 18.432MHZ 30P

CRYSTAL,HC49U RADIAL 20.250MHZ 3

CONNECTOR,68114-1522 MOLEX-KOR 15PIN

LED,DL-11S2GN1 OPTO

PRE-AMP,TSOP4838ON1 TEMIC 38.0KHZ HOLD

BUZZER,PKM13EPY-4002 MURATA 4000HZ 70

TUNER,TAUG-H006P LG PRECISION CO., L

OSCILLATOR,OSC-SCO060 RADIAL 14.318

MANUAL,OWNERS NF99LA LN-15A10 ZENITH EN

REMOTE CONTROLLER,NF99LA LN-15A10

ADAPTER,AC-DC AC110VOLT DC12VOLT UL/CSA/J

LOCA. NO PART NO DESCRIPTION

MISCELLANEOUS

ACCESSORIES

RESISTOR

CRYSTAL

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 15

- 12 -

June, 2000

P/NO : 3828VD0066S Printed in Korea

Page 16

PRINTED CIRCUIT BOARD

MAIN(TOP)

CTL(TOP)

CTL(BOTTOM)

TUNER(TOP)

TUNER(BOTTOM)

MAIN(BOTTOM)

BLOCK DIAGRAM

Tuner & IF

- 6700VNF003C

Audio

Processor

- MSP3400C

Ext- L

Micro-Controller

- M 37274

Audio-Amp

TDA7052A

L

LCD

< 6-bits >

Video

Decorder

- VPC3230D

Video Scaler

- AL300

Computer

Signal

- D-Sub

R/G/B

H/V

D-R/G/B,

H / V -Sync,

Den, Clock

From

Computer

EPROM

For OSD

CVBS

Audio-Amp

TDA7052A

R

Ext- R

SIF

For MNT Application

LM151X2

1H/1V

A to D Converter

- AD9884

For MNT Application

For PC Input

- Contrast

- Brightness

- Color

Ext_Video

Ext_Y/C

OSD FB/R/G/B

DVD Y/Pb/Pr

For TV

. Contrast

. Brightness

. Color

. Tint

CVBS For Caption

Page 17

VIDEO

AUDIO

Y

C

Loading...

Loading...