Page 1

Website:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

COLOR MONITOR

SERVICE MANUAL

CHASSIS NO. : LM57B

MODEL: L1752T (L1752T-SFQ.AX**QP)

L1752T (L1752T-BFQ.AX**QP)

L1952T (L1952T-SFQ.AX**QP)

L1952T (L1952T-BFQ.AX**QP)

( ) **Same model for Service

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

*To apply the MSTAR Chip.

Page 2

CONTENTS

SPECIFICATIONS ................................................... 2

PRECAUTIONS ....................................................... 3

TIMING CHART ....................................................... 7

DISASSEMBLY ....................................................... 8

BLOCK DIAGRAM...................................................12

DISCRIPTION OF BLOCK DIAGRAM .................. 14

ADJUSTMENT ...................................................... 16

SPECIFICATIONS

1. LCD CHARACTERISTICS

Type : TFT Color LCD Module

Active Display Area : 17 inch - L1752T

Pixel Pitch : 0.264 (H) x 0.264 (V) - L1752T

Color Depth : 8bits, 16.2M colors

Size :

Electrical Interface : LVDS

Surface Treatment : Hard-coating(3H), Anti-Glare

Operating Mode :

Backlight Unit : 4-CCFL

2. OPTICAL CHARACTERISTICS

2-1. Viewing Angle by Contrast Ratio ≥ 10

Left : -60° min., -70°(Typ) Right : +60° min., +70°(Typ)

Top :+60° min., +75°(Typ) Bottom : -50° min., -65°(Typ)

: 19 inch - L1952T

: 0.294 (H) x 0.294 (V) - L1952T

358.5 (H) x 296.5 (V) x 17.0(D) - L1752T

:

396 (H) x 324 (V) x 17.5(D) - L1952T

Normally White, Transmissive mode

SERVICE OSD........................................................17

TROUBLESHOOTING GUIDE .............................. 18

WIRING DIAGRAM ............................................... 24

EXPLODED VIEW...................................................25

REPLACEMENT PARTS LIST ...............................27

SCHEMATIC DIAGRAM......................................... 32

4. Max. Resolution

D-sub Analog : 1280 x 1024@75Hz

Digital : 1280 x 1024@60Hz

5. POWER SUPPLY

5-1. Power : AC 100~240V, 50/60Hz , 0.6A

5-2. Power Consumption

MODE

POWER ON (NORMAL)

STAND-BY

SUSPEND

DPMS OFF

POWER S/W Off

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

-

VIDEO

POWER CONSUMPTION

ACTIVE

less than 33 W -L1752T

less than 37 W -L1952T

OFF

OFF

OFF

-

less than 1 W

less than 1 W

less than 1 W

less than 1 W

LED COLOR

BLUE

or GREEN

AMBER

AMBER

AMBER

OFF

2-2. Luminance :

2-3. Contrast Ratio : 1400:1 (DFC)

3. SIGNAL (Refer to the Timing Chart)

3-1. Sync Signal

• Type : Separate Sync, Digital, SOG

3-2. Video Input Signal

1) Type : R, G, B Analog

2) Voltage Level : 0~0.71 V

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467Vp-p

c) Color 15, 0 : 0.714Vp-p

3) Input Impedance : 75Ω

3-3. Operating Frequency

Horizontal : 30 ~ 83kHz

Vertical : 56 ~ 75Hz

230(min), 300(Typ) (Full White pattern, 0.70V) -6500K

:

150(min) (Full White pattern, 0.70V) -9300K

75%(min)

6. ENVIRONMENT

6-1. Operating Temperature : 10°C~35°C (50°F~95°F)

(Ambient)

6-2. Relative Humidity : 10%~80% (Non-condensing)

6-3. MTBF : 50,000 HRS with 90% Confidence

Lamp Life : 50,000 Hours(Min)

7. DIMENSIONS (with TILT/SWIVEL)

L1752T

Width : 364.5 mm (14.35'')

Depth : 180 mm (7.09'')

Height : 378.2 mm (14.89'')

L1952T

Width : 402 mm (15.83'')

Depth : 180 mm (7.09'')

Height : 407.5 mm (16.04'')

8. WEIGHT (with TILT/SWIVEL)

L1752T

Net. Weight : 3.5 kg (7.72 lbs)

Gross Weight : 4.6 kg (10.14 lbs)

L1952T

Net. Weight : 4.4 kg (9.70 lbs)

Gross Weight : 5.6 kg (12.35 lbs)

- 2 -

Page 3

PRECAUTION

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked on the schematic diagram and the

replacement parts list. It is essential that these critical

parts should be replaced with the manufacturer’s

specified parts to prevent electric shock, fire or other

hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the

original parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly

or electric shock as this will result in damage to the

screen.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or

inverter circuit, must disconnect the AC adapter

because high voltage appears at inverter circuit about

650Vrms.

• Handle with care wires or connectors of the inverter

circuit. If the wires are pressed cause short and may

burn or take fire.

Leakage Current Hot Check Circuit

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are

grounded through wrist band.

• Do not leave the module in high temperature and in

areas of high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

the module.

• If the surface of panel become dirty, please wipe it off

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

- 3 -

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this

service manual and its supplements and addenda, read

and follow the SAFETY PRECAUTIONS on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict

between the following servicing precautions and any of the

safety precautions on page 3 of this publication, always

follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit

board module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical

plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may

result in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an

appropriate high voltage meter or other voltage

measuring device (DVM, FETVOM, etc) equipped with

a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield

at the point where the picture tube socket ground lead

is connected, and then (b) touch the other end of the

insulated clip lead to the picture tube anode button,

using an insulating handle to avoid personal contact

with high voltage.

4. Do not spray chemicals on or near this receiver or any

of its assemblies.

5. Unless specified otherwise in this service manual,

clean electrical contacts only by applying the following

mixture to the contacts with a pipe cleaner, cottontipped stick or comparable non-abrasive applicator;

10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual,

lubrication of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks

with which receivers covered by this service manual

might be equipped.

7. Do not apply AC power to this instrument and/or any of

its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test

receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in

this service manual.

CAUTION: Do not connect the test fixture ground strap

to any heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES)

Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and

semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of

component damage caused by static by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed to prevent potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static type solder removal device.

Some solder removal devices not classified as "antistatic" can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ES

device.)

- 4 -

Page 5

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range or 500。F to 600。F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

mall wire-bristle (0.5 inch, or 1.25cm) brush with a

metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal

temperature.

(500。F to 600。F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500。F to 600。F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong)

through which the IC leads are inserted and then bent flat

against the circuit foil. When holes are the slotted type,

the following technique should be used to remove and

replace the IC. When working with boards using the

familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation

by gently prying up on the lead with the soldering iron

tip as the solder melts.

2. Draw away the melted solder with an anti-static

suction-type solder removal device (or with solder

braid) before removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle

brush. (It is not necessary to reapply acrylic coating to

the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board

and crimp the "U" with long nose pliers to insure metal

to metal contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close

as possible to diode body.

2. Bend the two remaining leads perpendicular y to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit

board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder

joints of the two "original" leads. If they are not shiny,

reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component

around notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components and the

circuit board to prevent excessive component

temperatures.

- 5 -

Page 6

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil

to the circuit board causing the foil to separate from or

"lift-off" the board. The following guidelines and

procedures should be followed whenever this condition is

encountered.

At IC Connections

To repair a defective copper pattern at IC connections use

the following procedure to install a jumper wire on the

copper pattern side of the circuit board. (Use this

technique only on IC connections).

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as

absolutely necessary).

2. carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small "U" in one end of a small gauge jumper

wire and carefully crimp it around the IC pin. Solder the

IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area and clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the

component side of the circuit board.

1. Remove the defective copper pattern with a sharp

knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire

opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead

of the nearest component on one side of the pattern

break to the lead of the nearest component on the

other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so the it does not touch components or sharp

edges.

- 6 -

Page 7

TIMING CHART

VIDEO

SYNC

B

C

E

A

D

MODE

1 H(Pixels) + 25.175 31.469 800 640 16 96 48 640 x 350

2 H(Pixels) - 28.321 31.468 900 720 18 108 54 720 X 400

3 H(Pixels) - 25.175 31.469 800 640 16 96 48 640 x 480

4 H(Pixels) - 31.5 37.5 840 640 16 64 120 640 x 480

5 H(Pixels) + 40.0 37.879 1056 800 40 128 88 800 x 600

6 H(Pixels) + 49.5 46.875 1056 800 16 80 160 800 x 600

7 H(Pixels) +/- 57.283 49.725 1152 832 32 64 224 832 x 624

8 H(Pixels) - 65.0 48.363 1344 1024 24 136 160 1024 x 768

9 H(Pixels) - 78.75 60.123 1312 1024 16 96 176 1024 x 768

10 H(Pixels) +/- 100.0 68.681 1456 1152 32 128 144 1152 x 870

11 H(Pixels) +/- 92.978 61.805 1504 1152 18 134 200 1152 x 900

12 H(Pixels) + 108.0 63.981 1688 1280 48 112 248 1280 x 1024

13 H(Pixels) + 135.0 79.976 1688 1280 16 144 248 1280 x 1024

H / V

V(Lines) - 70.09 449 350 37 2 60

V(Lines) + 70.08 449 400 12 2 35

V(Lines) - 59.94 525 480 10 2 33

V(Lines) - 75 500 480 1 3 16

V(Lines) + 60.317 628 600 1 4 23

V(Lines) + 75.0 625 600 1 3 21

V(Lines) +/- 74.55 667 624 1 3 39

V(Lines) - 60.0 806 768 3 6 29

V(Lines) - 75.029 800 768 1 3 28

V(Lines) +/- 75.062 915 870 3 3 39

V(Lines) +/- 65.96 937 900 2 4 31

V(Lines) + 60.02 1066 1024 1 3 38

V(Lines) + 75.035 1066 1024 1 3 38

Sync

Polarity

Dot

Clock

Frequency

Total

Period

( E )

Video

Active

Time ( A )

Sync

Duration

( D )

Front

Porch

( C )

Blanking

Time

( B )

Resolution

- 7 -

Page 8

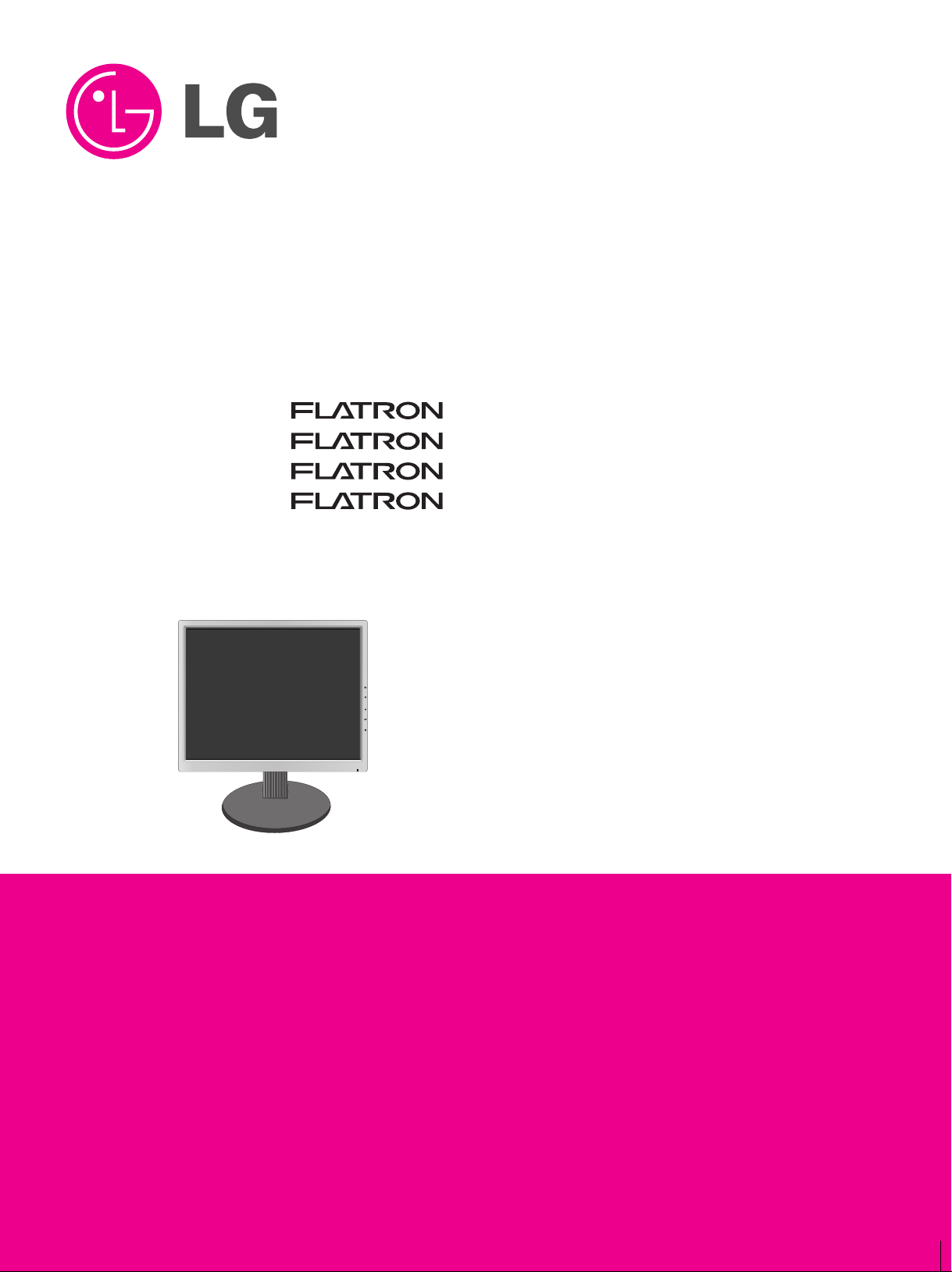

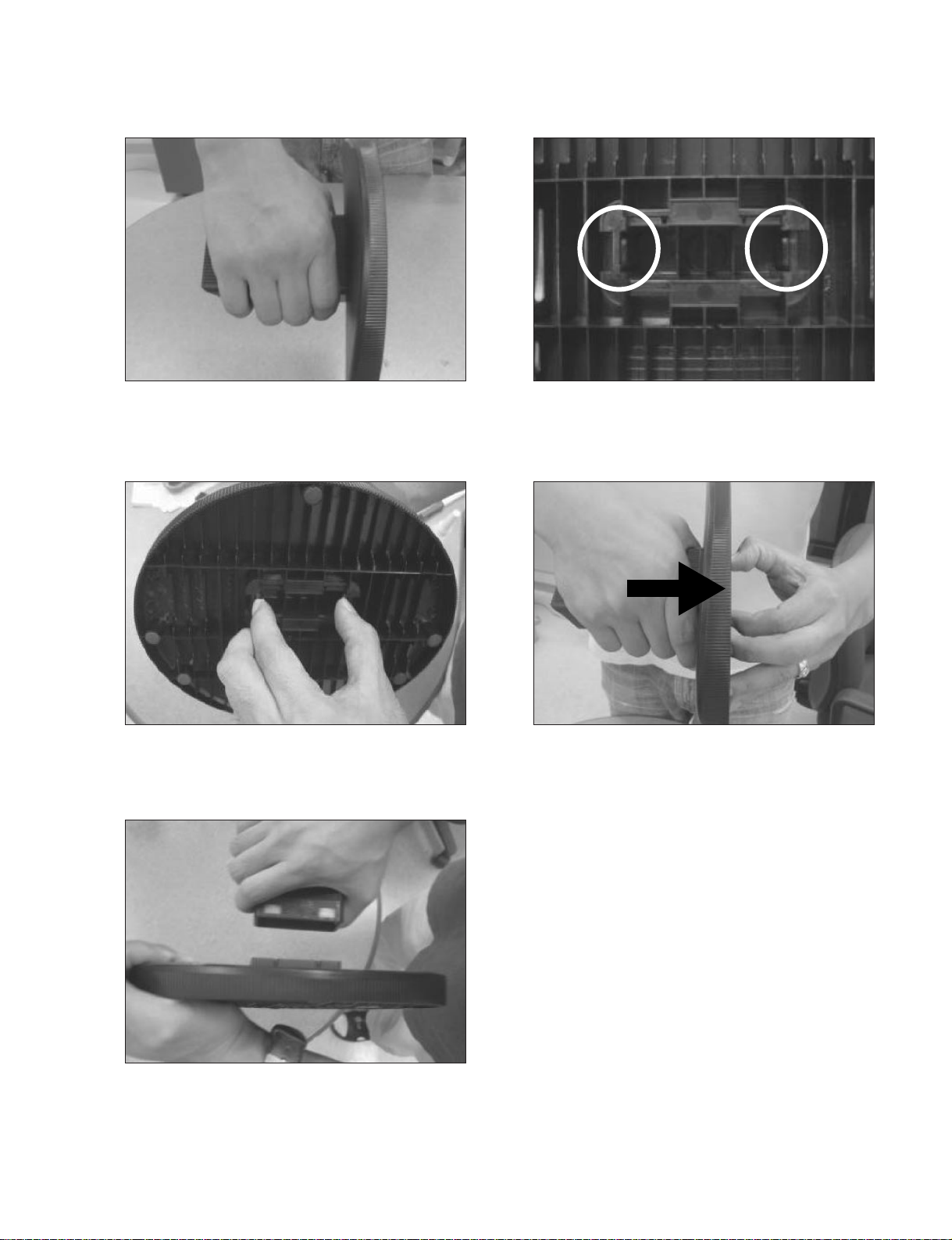

DISASSEMBLY-Set

# 1

# 3

Soft pad on the table.

# 2

Monitor on the pad.

# 4-1

# 4-2

Pull up the stand part.

Hold the head & stand base and then

Twist Stand until "Click".

# 5

Separate head & stand

- 8 -

Page 9

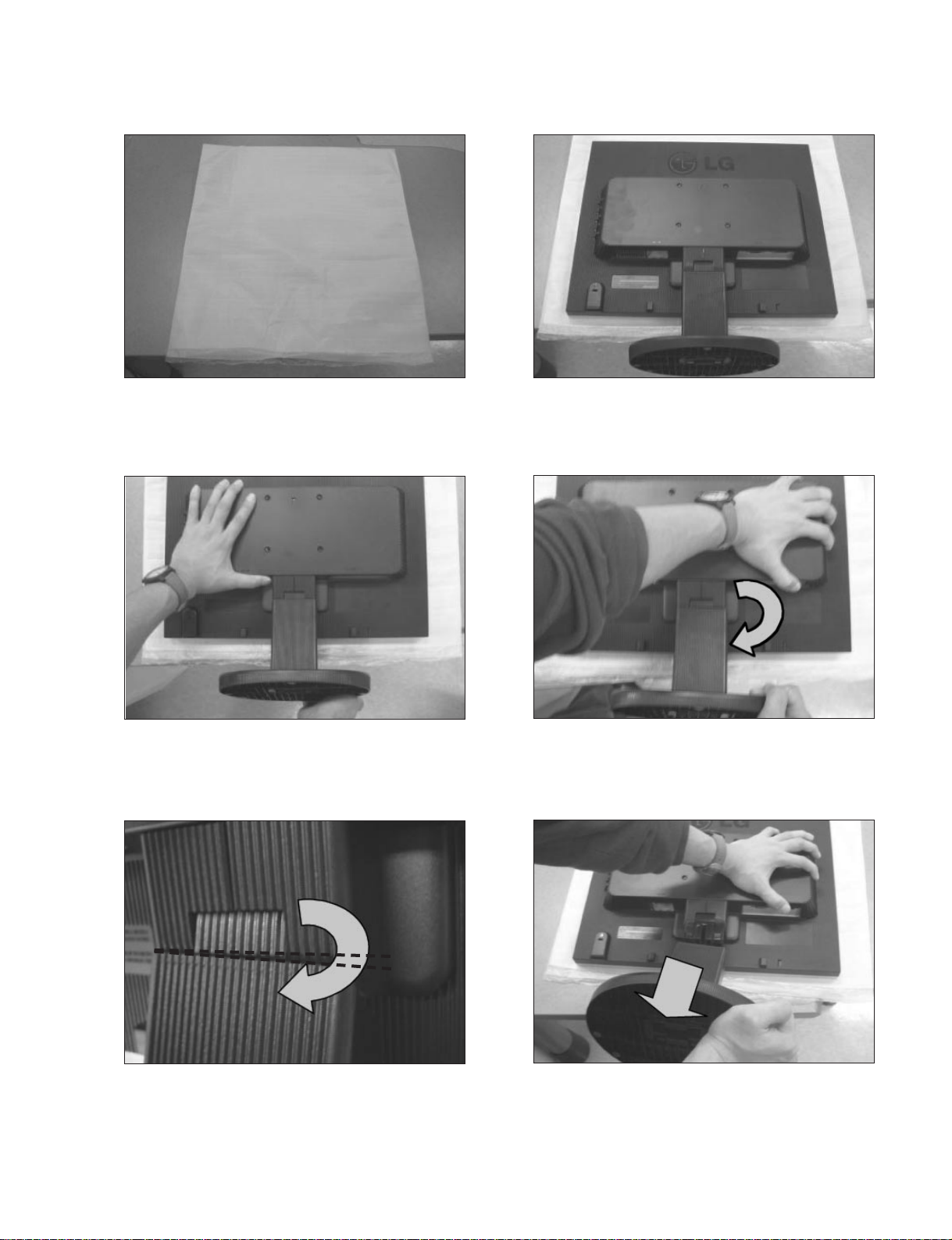

# 6

# 7

# 8

Remove the screws.

1. Pull the front cover upward.

2. Then, let the all latches are separated.(#3-1~3-2)

3. Put the front face down.

# 9

Disassemble back cover.

- 9 -

Page 10

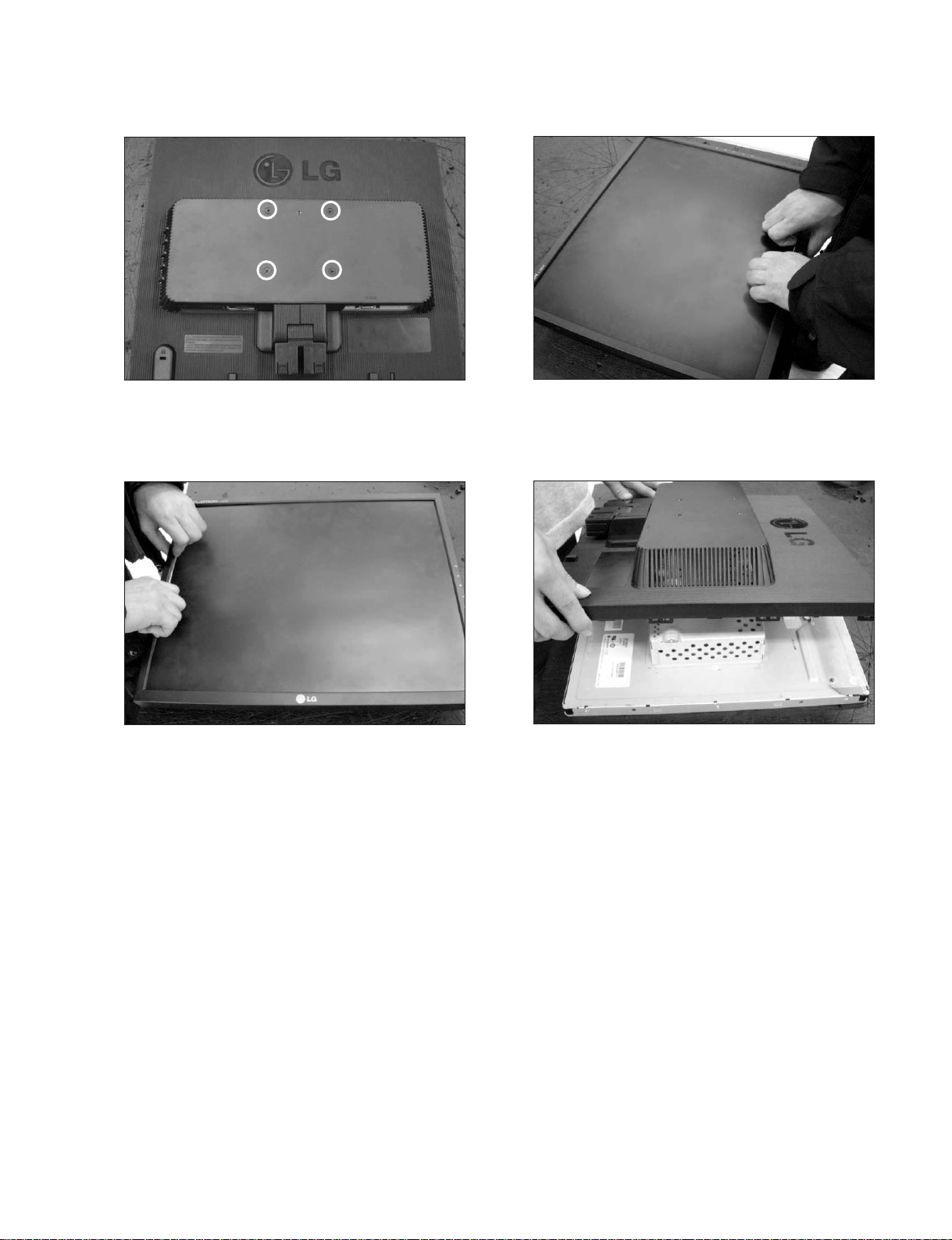

* In case of Latch 4.

DISASSEMBLY-Stand

# 1-1

Push the four latches on the bottom to the

outside and Separate Stand Body & Base.

(Reference the #1-2)

# 2 # 3

# 1-2

After finished repair, necessarily push 4ea

Latches to inside for restoration.

- 10 -

Page 11

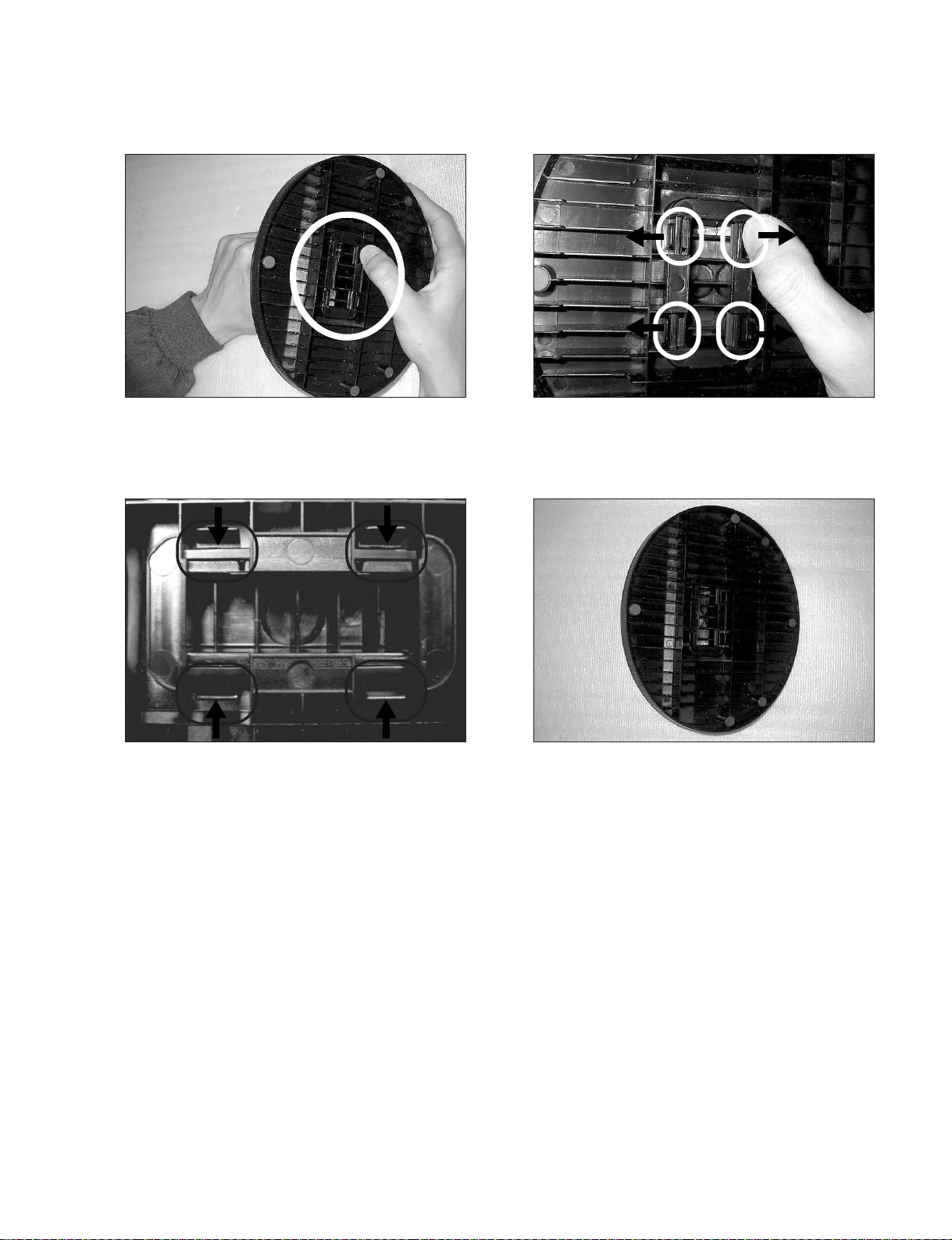

DISASSEMBLY-Stand

* In case of Latch 2.

# 1 # 2

Hold the stand body. Confirm two latch of right and left.

# 3

# 5

# 4

Push the latch to the inside. Push the base to the opposite direction.

Confirm the condition of separation.

- 11 -

Page 12

BLOCK DIAGRAM

LVDS

MStarACE

Line Buffer

Module

Vcc

5V

LVDS

Scaler

Tx

OSD

KEY

SSC

SDA

/SCL

EEPROM

(System)

Flash ROM

3.3V

3.3V

3.3V

1.8V

Regulator

ADC

TSUMx6AL

5V

3.3V

Analog (R/G/B)

TMDS Rx

Digital

D-SubDVI-D

MCU

Intel8032

1.8V

EEPROM

(EDID)

LIPS

5V

12V

Filter

5V

12V

12V

Inverter (4 lamps)

- 12 -

Page 13

BLOCK DIAGRAM-POWER

High

Over

Voltage

Protection

13V

P-ch

12V

Inverter

Inverter

Control

5V

LAMP

Trans

IC

Low

Lamp

Current

Feedback

N-ch

Drive Block

POWER INVERTER

5V

12V

Main Board

Module Vcc

Aux

Drive

Dimming (Lamp Current Control)

Inverter On/OFF (3.3V)

DC DC

(Scaler &

converter)

SMPS

Power

Control

Feedback

IC

Start

Line Filter

LN

- 13 -

Page 14

DESCRIPTION OF BLOCK DIAGRAM

1. Video Controller Part.

This part amplifies the level of video signal for the digital conversion and converts from the analog video signal to the

digital video signal using a pixel clock.

The pixel clock for each mode is generated by the PLL.

The range of the pixel clock is from 25MHz to 135MHz.

This part consists of the Scaler, ADC convertor, TMDS receiver and LVDS transmitter.

The Scaler gets the video signal converted analog to digital, interpolates input to 1280 X 1024 resolution signal and

outputs 8-bit R, G, B signal to transmitter.

2. Power Part.

This part consists of the one 3.3V, and one 1.8V regulators to convert power which is provided 5V in Power board.

12V is provided for inverter, 5V is provided for LCD panel.

Also, 5V is converted 3.3V and 1.8V by regulator. Converted power is provided for IC in the main board.

The inverter converts from DC12V to AC 700Vrms and operates back-light lamps of module.

3. MICOM Part.

This part is include video controller part. And this part consists of EEPROM IC which stores control data, Reset IC and

the Micom.

The Micom distinguishes polarity and frequency of the H/V sync are supplied from signal cable.

The controlled data of each modes is stored in EEPROM.

- 14 -

Page 15

LIPS Board Block Diagram

50 ~ 60Hz

LINE

100 ~ 240V

EMI

COMPONENTS

INPUT RECTIFIER

AND FILTER

PWM CONTROL

CIRCUIT

HVDC

SWITCHING

TRANSFORMER

PHOTO-COUPLER

ISOLATION

100KHz

OUTPUT RECTIFIER

AND FILTER

SIGNAL

COLLENT-

ION

12V

5V

GND

PRIMARY SECONDARY

INVERTER CIRCUIT

High V oltage12V

Operation description_LIPS

1. EMI components.

This part contains of EMI components to comply with global marketing EMI standards like FCC,VCCI CISPR, the

circuit included a line-filter, across line capacitor and of course the primary protection fuse.

2. Input rectifier and filter.

This part function is for transfer the input AC voltage to a DC voltage through a bridge rectifier and a bulk capacitor.

3. Energy Transfer.

This part function is for transfer the primary energy to secondary through a power transformer.

4. Output rectifier and filter.

This part function is to make a pulse width modulation control and to provide the driver signal to power switch, to

adjust the duty cycle during different AC input and output loading condition to achieve the dc output stabilized, and

also the over power protection is also monitor by this part.

5. Photo-Coupler isolation.

This part function is to feed back the DC output changing status through a photo transistor to primary controller to

achieve the stabilized DC output voltage.

6. Signal collection.

This part function is to collect the any change from the DC output and feed back to the primary through photo

transistor.

- 15 -

Page 16

ADJUSTMENT

Windows EDID V1.0 User Manual

Operating System: MS Windows 98, 2000, XP

Port Setup: Windows 98 => Don’t need setup

Windows 2000, XP => Need to Port Setup.

This program is available to LCD Monitor only.

1. Port Setup

a) Copy “UserPort.sys” file to

“c:\WINNT\system32\drivers” folder

b) Run Userport.exe

c) Remove all default number

d) Add 300-3FF

2. EDID Read & Write

1) Run WinEDID.exe

2) Edit Week of Manufacture, Year of Manufacture,

Serial Number

a) Input User Info Data

b) Click “Update” button

c) Click “ Write” button

e) Click Start button.

f) Click Exit button.

- 16 -

Page 17

SERVICE OSD

1) Turn off the power switch at the front side of the display.

2) Wait for about 5 seconds and press MENU, POWER switch with 1 second interval.

3) The SVC OSD menu contains additional menus that the User OSD menu as described below.

a) Auto Color : W/B balance and Automatically sets the gain and offset value.

b) NVRAM INIT : EEPROM initialize.(24C08)

c) CLEAR ETI : To initialize using time.

d) AGING : Select Aging mode(on/off).

e) R/G/B-9300K : Allows you to set the R/G/B-9300K value manually.

f) R/G/B-6500K : Allows you to set the R/G/B-6500K value manually.

g) R/G/B-Offset : Allows you to set the R/G/B-Offset value manually.(Analog Only)

h) R/G/B-Gain : Allows you to set the R/G/B-Gain value manually.(Analog Only)

i) MODULE : To select applied module.

Video Signal

Generator

Control Line

A

IBM

Compatible PC

PARALLEL PORT

Not used

RS232C

C

PARALLEL

Power inlet (required)

220

VGS

A

MONITOR

POWER

ST

V-SYNC

B

F

Power Select Switch

(110V/220V)

Power LED

E

ST Switch

V-Sync On/Off Switch

(Switch must be ON.)

5V

15

OFF ON

F

10

5

11

6

1

B

69

5

1

C

OFF

13

25

5V

4.7K

4.7K

74LS06

ON

5V

E

74LS06

4.7K

1

14

Figure 1. Cable Connection

- 17 -

Page 18

TROUBLESHOOTING GUIDE

NO POWER

(POWER INDICATOR OFF)

1. NO POWER

Check J403 Voltage

Pin5, Pin6 (5V)?

YES

Check

U301 Pin2 Voltage

(3.3V) ?

YES

Check Key Control

Connector Routine

Is U201

Pin75 (3.3V)

Voltage ?

YES

1

Check U201 Pin 96

Pulse

NO

NO

NO

NO

Check Power Board,

And Find Out a Short Point

as Opening

Each Power Line

Check 3.3V Line

(Open Check)

No Problem

Check 3.3V Line

Check X-TAL

1

U201-#96

YES

Check U201

Waveforms

- 18 -

Page 19

2. NO RASTER (OSD IS NOT DISPLAYED) – LIPS

NO RASTER

(OSD IS NOT DISPLAYED)

J403

PIN5, PIN6

5V?

YES

J403 PIN9

5V?

YES

J403 PIN10

5V?

YES

CHECK

PULSE AS

CONTACTING SCOPE

PROBE TO CAUTION LABEL.

(CONTACT PROBE TO

CAUTION LABEL.

CAN YOU SEE PULSE

AT YOUR

SCOPE?

NO

NO

NO

NO

CHECK POWER BOARD,

AND FIND OUT A SHORT

POINT AS OPENING EACH

POWER LINE

CHECK MICOM INV

ON/OFF PORT.

1. CONFIRM BRIGHTNESS

OSD CONTRL STATE.

2. CHECK MICOM DIM-ADJ

PORT

LIPS

YES

REPLACE CCFL LAMP

IN THE LCD MODULE

- 19 -

Page 20

3. NO RASTER (OSD IS NOT DISPLAYED) – MSTAR

NO RASTER

(OSD IS NOT DISPLAYED)

U201

PIN 16, 75

3.3V?

YES

U201

1

2

PIN96, 97

OSCILLATE AS

14.31MHZ?

YES

U201

PIN27 IS 48KHz H-SYNC?

PIN28 IS 60Hz V-SYNC?

IS PULSE APPEARED

AT SIGNAL PINS?

AT MODE 12?

YES

TROUBLE IN CABLE

OR LCD MODULE

NO

NO

NO

CHECK U301

1. CHECK C210, C211

SOLDERING CONDITION

2. CHECK X201

3. TROUBLE IN U201

CHECK CONNECTION

LINE FROM D-SUB TO

U201

Waveforms

1 2

U201-#96, 97 U201-#27 H-SYNC

- 20 -

2

U201-#28 V-SYNC

Page 21

TROUBLE IN DPM

4. TROUBLE IN DPM

3

CHECK

R442, R443

YES

CHECK

U201 PIN 27,28

SYNC PULSE ?

YES

TROUBLE IN U201

NO

NO

CHECK PC

PC IS NOT GOING

INTO DPM OFF MODE

CHECK H/V SYNC LINE

3

R442 H-Sync

Waveforms

3

R443 V-Sync

- 21 -

Page 22

NO POWER

(POWER INDICATOR OFF)

5. POWER

CHECK

Fuse F101 OK?

YES

CHECK

C101 Voltage

(AC110V->160Vdc

(AC220V->304Vdc

YES

CHECK

U101 Pin6 Waveform

(Square wave

Come out?)

YES

Check Q101 Drain

Waveform

YES

NO

NO

NO

NO

Trouble in Fuse (F101)

Check BD101

Check U101 Pin7 : 9~10V

Check D102

Trouble in Q101

Check D201, D202

Voltage

YES

CHECK 5V, 12V Line

NO

- 22 -

Trouble in D201, D202

Page 23

NO Raster

(Lamp Off)

6. Raster

CHECK

P201 Pin9

3.3V?

YES

Check U301 Pin3

5V?

YES

Check U301 Pin2 OVP,

Less than 1.8V

YES

Check U301 Pin10 CMP,

Less than 2.75V

NO

NO

NO

NO

Check Scaler Output

(Main Board)

Check Q301, Q302

Check the waveform of U301

Pin11, 12, 19, 20

Check the waveform of U301

Pin11, 12, 19, 20

If waveform is no problem

Check U303, U304

Drain waveform

YES

CHECK T301, T302

NO

- 23 -

Check Q303~Q308

Or Trouble in U303, U304

Page 24

WIRING DIAGRAM

11P

6P

3P

30P

6631900011H

6631T20023J

6631900109A

6631T20010E

- 24 -

Page 25

EXPLODED VIEW

030

170

160

190

180

020

200

130

120

100

150

110

050

080

070

140

040

090

010

060

- 25 -

Page 26

* Note: Safety mark

EXPLODED VIEW PARTS LIST

Ref. No.

010

020

030

040

050

060

070

080

Part No.

30919C0018L CABINET ASSEMBLY, L1752T BRAND 30909C0006 CABINET ASSY+SILVER+PCABS+DUAL

30919C0018M CABINET ASSEMBLY, L1752T BRAND 30909C0006 CABINET ASSY+BLACK+PCABS+DUAL

30919C0019J CABINET ASSEMBLY, L1952T BRAND 30909C0007 CABINET ASSY-SILVER-DUAL+PC ABS

30919C0019K CABINET ASSEMBLY, L1952T BRAND 30909C0007 CABINET ASSY-BLACK -DUAL+PC ABS

6304FLP278A

6304FLP312A

or 6304FLP337A

6304FLP310A

3809900177N BACK COVER ASSEMBLY, L1752T NON BACK COVER ASSY PC+ABS MODULE-LPL-DUAL

3809900178K BACK COVER ASSEMBLY, L1952T NON BACK COVER MODULE-LPL-DUAL

3043900041A TILT SWIVEL ASSEMBLY, LX52 35509K0241 STAND BASE ASSY

35509K0245A COVER, L1752S STAND BODY .

35509K0246A COVER, L1952S STAND BODY .

3520900038A INDICATOR, LED&PRE AMP LX52 PMMA NON LED LENS

49509K0266A METAL, SHIELD LX52 LAMP-L1752T

49509K0267A METAL, SHIELD L1952 LAMP

68719STA24C PWB(PCB) ASSEMBLY,SUB, SUB T.T LM57A LX52 KXRDQPT NT CKD CONTROLL-SILVER

68719ST086A

LCD(LIQUID CRYSTAL DISPLAY), LM170E01-TLB1 LG PHILPS TFT COLOR P5,645CH,300NITS,8MS,700/1,LPL NJ/KUMI,PB FREE,EGI,OKI S D-IC,EGI,

LCD(LIQUID CRYSTAL DISPLAY), LM190E03-TLB7 LG PHILPS TFT COLOR P4,645CH,300NITS,TN,8MS,LPL KUMI,PB FREE,EGI,NEC S D-IC,SXGA,LVDS

LCD(LIQUID CRYSTAL DISPLAY), LM190E03-TLBB LG PHILPS TFT COLOR DOT FREE OF LM190E03-TLB7,P4,645CH,300NITS,TN,8MS,LPL KUMI,PB FREE

LCD(LIQUID CRYSTAL DISPLAY), LM190E03-TLB5 LG PHILPS TFT COLOR P4,645CH,300NITS,TN,8MS,LPL KUMI,PB FREE,EGI,OKI S D-IC,SXGA,LVDS

PWB(PCB) ASSEMBLY,SUB, SUB T.T LM56A L1752/L1952BFQ .KXRDQPT CONTROL TOTAL NT CKD-BLACK

Description

090

100

110

120

130

140

150

160

170

180

190

200

0DLLT0089AA LED, LITEON LTL-1BEDJ-0C2 TP GREEN/YELLOW 19MCD

68719PT298A PWB(PCB) ASSEMBLY,POWER, POWER T.T LM57A L1752S KNRDQPT TOTAL

or 6709900027A SMPS,AC/DC, AIVP 100.0TO240.0 40W 50TO60HZ

33139L7033C MAIN TOTAL ASSEMBLY, L1752T-BFQ.KXRDQPT NT CKD TSUM56AWL BRAND LM57B-SILVER

3313917030A MAIN TOTAL ASSEMBLY, L1752T-BFQ.KXRDQPT NT CKD TSUM56AWL BRAND LM56A-BLACK

33139L9041C MAIN TOTAL ASSEMBLY, L1952T-BFQ.KXRDQPT NT CKD BRAND LM57B TSUM56AWL-SILVER

3313919008A

35509K0247A COVER, LX52 PIECE COVER VESA

49509S0034B METAL, SHIELD LX52 REAR SHIELD-DUAL

4940900022B KNOB, MAIN 5KEY LX52 TACK KNOB ADD SOURCE PRINTING

49509K0262A METAL, SUPPORT L1752 BRACKET

49509K0263A METAL, SUPPORT L1952S BRACKET

49519K0137A METAL ASSEMBLY, STAND HINGE ASSY 17 INCH

35509K0242A COVER, LX52 HINGE R

35509K0243A COVER, LX52 HINGE L

35509K0244A COVER, LX52 HINGE COVER BODY

64109UP002A POWER CORD, DTII-3P-11+DTII-3P-04 HONGCHANG UL/CSA 1870MM PLUG SILVER

6410TUW008A POWER CORD, LP31+LS13 LONGWELL UL/CSA 1870MM WALL CD/PB FREE BLACK-L1752T

MAIN TOTAL ASSEMBLY, L1952T-BFQ.KXRDQPT NT CKD TSUM56AWL BRAND 14-LANGUAGE LM57B-BLACK

6410TUW008B

POWER CORD, LP31+LS13 LONGWELL UL/CSA 1870MM WALL CD/PB FREE 85964 BLACK-L1952T

- 26 -

Page 27

REPLACEMENT PARTS LIST

CAUTION: BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

MAIN BOARD AND POWER BOARD PARTS ARE DIFFERENT.

* NOTE : S SAFETY Mark

AL ALTERNATIVE PARTS

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

MAIN BOARD

CAPACITORS

C101 0CZZ9ST017A AL EL CAPACITOR 100UF 450V 2

C102 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C103 0CZZ9ST014A AL EL CAPACITOR 33UF 50V 20%

C104 0CH5271K416 270PF 2012 50V 5% NP0 R/TP

C105 0CZZ9ST013A AL EL CAPACITOR 0.47UF 50V 2

C106 0CK222DK4DA 2200PF 2012 50V 5% COG R/TP

C107 0CK1040K945 "0.1UF D 50V 80%,-20% F(Y5V)"

C201 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C201 0CKZTTA002E EKR3A102K09FK5 SAMWHA 1KV 10

C202 0CZZ9ST021A AL EL CAPACITOR 1000UF 25V 2

C203 0CK473CH56A 0.047UF 1608 25V 10% R/TP X7

C203 0CZZ9ST020A AL EL CAPACITOR 680UF 25V 20

C204 0CK473CH56A 0.047UF 1608 25V 10% R/TP X7

C204 0CZZ9ST018A AL EL CAPACITOR 1000UF 16V 2

C205 0CK473CH56A 0.047UF 1608 25V 10% R/TP X7

C205 0CZZ9ST018A AL EL CAPACITOR 1000UF 16V 2

C206 0CK473CH56A 0.047UF 1608 25V 10% R/TP X7

C206 0CZZ9ST021A AL EL CAPACITOR 1000UF 25V 2

C207 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C207 0CZZ9ST019A AL EL CAPACITOR 470UF 25V 20

C208 0CK473CH56A 0.047UF 1608 25V 10% R/TP X7

C208 0CKZTTA002B 330PF 1KV K R TP5.0 TAPING .

C209 0CK473CH56A 0.047UF 1608 25V 10% R/TP X7

C210 0CC220CK41A 22PF 1608 50V 5% R/TP NP0

C210 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C211 0CC220CK41A 22PF 1608 50V 5% R/TP NP0

C213 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C215 0CE106CF638 "10UF SHL,SD 16V M FM5 TP 5"

C216 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C217 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C218 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C219 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C220 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C221 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C222 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C223 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C224 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C225 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C226 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C227 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C228 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C229 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C230 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C301 0CE107EF610 "100UF KMG,RD 16V 20% FL BULK"

C301 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C302 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y

C303 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y

C303 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C304 0CK105CD56A 1UF 1608 10V 10% R/TP X7R

C304 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C305 0CE107EF610 "100UF KMG,RD 16V 20% FL BULK"

C305 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C306 0CE107EF610 "100UF KMG,RD 16V 20% FL BULK"

C306 0CK224DH56A 0.22UF 2012 25V 10% R/TP X7R

C307 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C308 0CK105DH56A 1UF 2012 25V 10% X7R R/TP

C309 0CK224DH56A 0.22UF 2012 25V 10% R/TP X7R

C310 0CK105DH56A 1UF 2012 25V 10% X7R R/TP

C313 0CH2393K516 39000PF 50V 10% B(Y5P) 2012

C314 0CK152DK51A 1500PF 2012 50V 10% B(Y5P) R

C315 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C317 0CH5221K416 220PF 50V 5% NP0 2012 R/TP

C320 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C402 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C403 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C404 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C405 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C406 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C407 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C408 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y

C409 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y

C409 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C410 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C410 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C411 0CK105CD56A 1UF 1608 10V 10% R/TP X7R

C411 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C412 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C412 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C413 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C413 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C414 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C414 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C415 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C415 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C416 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C417 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C417 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C418 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C418 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C419 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C419 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C420 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C421 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C422 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C423 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C424 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(Y

C425 0CC680CK41A 68PF 1608 50V 5% R/TP NP0

C426 0CC680CK41A 68PF 1608 50V 5% R/TP NP0

C427 0CC680CK41A 68PF 1608 50V 5% R/TP NP0

C428 0CC680CK41A 68PF 1608 50V 5% R/TP NP0

CX101 0CZZ9ST025A FILM CAPACITOR 0.47UF 275V 1

CY101 0CZZ9ST024A "Y CAPACITOR 100PF 250V 10%,-"

CY102 0CZZ9ST024A "Y CAPACITOR 100PF 250V 10%,-"

CY104 0CZZ9ST023A "Y CAPACITOR 4700PF 250V 20%,"

- 27 -

Page 28

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

DIODEs

BD101 0DRTW00121A D2SB60-1121 TIWAN SEMI ST GB

D101 0DRGF00354A UF4007(GPP) GULF TAPING52 DO

D102 0DRGF00354A UF4007(GPP) GULF TAPING52 DO

D103 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D201 0DRNH00140A FCH10U15 NIHON INTER BULK TO

D202 0DRNH00130A FCH10U10 NIHON INTER BULK TO

D306 0DSGD00048A MM4148 GRANDE REEL TAPING LL

D401 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D402 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D403 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D404 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D405 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D405 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D406 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D406 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D407 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D407 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D408 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D408 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D409 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D410 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D411 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D412 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D413 0DD184009AA KDS184 TP KEC - 85V - - - 30

D416 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D417 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

D418 0DS226009AA KDS226 TP KEC - 80V - - 4NSE

ZD101 0DZ330009CC MTZJ3.3B TP ROHM-K DO34 - 3.

ZD301 0DZGD00128A ZMM5231B GRANDE REEL TAPING

ZD406 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD407 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD408 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD409 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD410 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD411 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD412 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD414 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ZD415 0DZ560009GB "BZT52C5V6S-(F),LF DIODES R/T"

ICs

U101 0IPMG78425A FAN7601 FAIRCHILD DIP-8P BUL

U201 0IPRP00705A FE2031-LF(TSUM56AWL) MSTAR 1

U201 0IPMG78424A "AZ431-A BCD 3P,TO-92 TAPING"

U202 0IZZ9H0187A 0IMMR00004B SST SOIC 8 PIN F

U203 0ISG240860B "M24C08WMN6T(P),LF SGS-THOMSO"

U301 0IPMGK2001B AIC1117A-33PYTR(BS33) AIC 3P

U301 0IPMG78426A OZL68GN O2MICRO 20P SOP BULK

U303 0IPMG00049A "AZ1117H-1.8TRE1(EH13A),LF BC"

U304 0IMMRSG036A "M24C02-WMN6T(P),LF SGS-THOMS"

COILs & COREs & FILTERs

L202 61409B0009A HL-1520S JEONGSAN 7.0UH 25%

FB101 6210TCE003G BRS3550B BO SUNG 3550MM RADI

LF101 6200J000154 13.0*710*23680 SAMWAH BULK L

TRANSISTOR

Q101 0TF760000AD SSS7N60B FAIRCHILD ST TO220F

Q201 0TR390409AE FAIRCHILD KST3904(LGEMTF) TP

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

Q301 0TR144009AI DTA144EK CHIP TP ROHM - Q302 0TR144009AH DTC144EK CHIP TP ROHM - Q303 0TRKE80046A 2N3904S KEC R/TP SOT23 60V 2

Q304 0TR390609DC 2N3906S-RTK KEC REEL TAPING

Q305 0TFDI80001A 2N7002 DIODES R/TP SOT23 60V

Q306 0TFDI80001A 2N7002 DIODES R/TP SOT23 60V

Q307 0TR390609DC 2N3906S-RTK KEC REEL TAPING

Q308 0TRKE80046A 2N3904S KEC R/TP SOT23 60V 2

Q401 0TR390609FA FAIRCHILD KST3906-MTF TP SOT

Q402 0TR390609FA FAIRCHILD KST3906-MTF TP SOT

U302 0TFVI80067A SI3865BDV(E3) VISHAY R/TP TS

U303 0TFAN00001A AP4511GD ADVANCED POWER ELEC

U304 0TFAN00001A AP4511GD ADVANCED POWER ELEC

RESISTORs

R101 0RJ4703G676 470K OHM 1/4 W 5% 3216 R/TP

R102 0RJ6801E472 6800 OHM 1/8 W 1% 2012 R/TP

R103 0RH1004D622 1M OHM 1 / 10 W 2012 5.00% D

R104 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R105 0RD0912Q609 91 OHM 1/4 W (3.4) 5% TA52

R106 0RH2201D622 2.2K OHM 1 / 10 W 2012 5.00%

R107 0RD8203A609 820K OHM 1/2 W(7.0) 5.00% TA

R108 0RD4702A609 47K OHM 1/2 W(7.0) 5.00% TA5

R109 0RX0560J609 0.56OHM 1 W 5% TA52

R110 0RX1003K607 100KOHM 2 W 5% TA62

R111 0RD0471Q609 4.70 1/4W(3 5% TA52

R112 0RJ1302E472 13K OHM 1/8 W 1% 2012 R/TP

R115 0RJ4703G676 470K OHM 1/4 W 5% 3216 R/TP

R116 0RJ4703G676 470K OHM 1/4 W 5% 3216 R/TP

R117 0RH2403D622 240K OHM 1 / 10 W 2012 5.00%

R118 0RH2403D622 240K OHM 1 / 10 W 2012 5.00%

R201 0RJ0562D677 56 OHM 1/10 W 5% 1608 R/TP

R202 0RJ0562D677 56 OHM 1/10 W 5% 1608 R/TP

R202 0RX0242K665 24 OHM 2 W 5% SF

R203 0RJ0562D677 56 OHM 1/10 W 5% 1608 R/TP

R204 0RJ0562D677 56 OHM 1/10 W 5% 1608 R/TP

R204 0RN3002F409 30K OHM 1/6 W 1.00% TA52

R205 0RJ1001D677 1K OHM 1/10 W 5% 1608 R/TP

R205 0RN2201F409 2.2K OHM 1/6 W 1.00% TA52

R206 0RJ0562D677 56 OHM 1/10 W 5% 1608 R/TP

R206 0RJ1601E472 1.6K OHM 1/8 W 1% 2012 R/TP

R207 0RJ0562D677 56 OHM 1/10 W 5% 1608 R/TP

R207 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R208 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R208 0RH6800D622 680 OHM 1 / 10 W 2012 5.00%

R209 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R209 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R211 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R211 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R212 0RJ3900D677 390 OHM 1/10 W 5% 1608 R/TP

R213 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R215 0RJ2002D677 20000 OHM 1/10 W 5% 1608 R/T

R216 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R217 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R218 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R219 0RJ1002D677 10K OHM 1/10 W 5% 1608 R/TP

R222 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R223 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R224 0RJ1503D677 150K OHM 1/10 W 5% 1608 R/TP

R225 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R226 0RJ0332D677 33 OHM 1/10 W 5% 1608 R/TP

- 28 -

Page 29

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

R227 0RJ0332D677 33 OHM 1/10 W 5% 1608 R/TP

R228 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R230 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R231 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R234 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R235 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R301 0RD1001Q609 1K OHM 1/4 W(3.4) 5.00% TA52

R302 0RJ5600D677 560 OHM 1/10 W 5% 1608 R/TP

R303 0RJ2202D677 22K OHM 1/10 W 5% 1608 R/TP

R303 0RH0222D622 22 OHM 1 / 10 W 2012 5.00% D

R304 0RD1002Q609 10K OHM 1/4 W(3.4) 5.00% TA5

R305 0RJ4702D677 47000 OHM 1/10 W 5% 1608 R/T

R306 0RX0220J668 0.22 OHM 1 W 5% SF15

R307 0RX0681K668 6.8 OHM 2 W 5% SF15

R308 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R309 0RN1502F409 15K OHM 1/6 W 1.00% TA52

R310 0RH1004D622 1M OHM 1 / 10 W 2012 5.00% D

R311 0RH1502D422 "15K , 1/10W 1% TP"

R313 0RJ6202E472 62K OHM 1/8 W 1% 2012 R/TP

R315 0RH2001D622 2K OHM 1 / 10 W 2012 5.00% D

R316 0RH2001D622 2K OHM 1 / 10 W 2012 5.00% D

R317 0RJ3303E472 330000 OHM 1/8 W 1% 2012 R/T

R318 0RJ1503E472 150K OHM 1/8 W 1% 2012 R/TP

R319 0RH1303D622 130K OHM 1 / 10 W 2012 5.00%

R320 0RH1502D422 "15K , 1/10W 1% TP"

R321 0RH1002D422 10K OHM 1/10 W 1% 2012 R/TP

R401 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R402 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R403 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R404 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R406 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R407 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R408 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R409 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R415 0RJ1200D677 120 OHM 1/10 W 5% 1608 R/TP

R416 0RJ1200D677 120 OHM 1/10 W 5% 1608 R/TP

R417 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R418 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R419 0RJ1000D677 100 OHM 1/10 W 5% 1608 R/TP

R420 0RJ2001D677 2K OHM 1/10 W 5% 1608 R/TP

R422 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R423 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R424 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R425 0RJ0122D677 12 OHM 1/10 W 5% 1608 R/TP

R426 0RJ0122D677 12 OHM 1/10 W 5% 1608 R/TP

R427 0RJ0122D677 12 OHM 1/10 W 5% 1608 R/TP

R428 0RJ0122D677 12 OHM 1/10 W 5% 1608 R/TP

R429 0RJ0122D677 12 OHM 1/10 W 5% 1608 R/TP

R430 0RJ0122D677 12 OHM 1/10 W 5% 1608 R/TP

R431 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R432 0RJ0222D677 22 OHM 1/10 W 5% 1608 R/TP

R433 0RJ4700D677 470 OHM 1/10 W 5% 1608 R/TP

R434 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R435 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R436 0RJ0332D677 33 OHM 1/10 W 5% 1608 R/TP

R437 0RJ0332D677 33 OHM 1/10 W 5% 1608 R/TP

R438 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R439 0RJ4701D677 4.7K OHM 1/10 W 5% 1608 R/TP

R440 0RJ0332D677 33 OHM 1/10 W 5% 1608 R/TP

R441 0RJ0000D677 0 OHM 1/10 W 5% 1608 R/TP

R442 0RJ0682D677 68 OHM 1/10 W 5% 1608 R/TP

R443 0RJ0682D677 68 OHM 1/10 W 5% 1608 R/TP

R444 0RJ0332D677 33 OHM 1/10 W 5% 1608 R/TP

R445 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R446 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

R448 0RJ0752D677 75 OHM 1/10 W 5% 1608 R/TP

OTHERs

F101 0FZZTTH001E TIME LAG HBC 2153.15MXE(LEAD

R201 971-0016 TIN HDC 0.60H NON NON

R306 971-0016 TIN HDC 0.60H NON NON

SC101 6620K00020A HUAJIE AC UL/CSA 3PPIN BLACK

T101 61709MC011A EER3016 430UH LX52 LIPS SMPS

T301 61709MC010A EFD-2124 95UH INVERTER TRANS

T302 61709MC010A EFD-2124 95UH INVERTER TRANS

TH101 6322A00035A 10D2-07 SEMITEC 10OHM 15% L1

X201 6212AA2004F HC-49U TXC 14.318 MHZ +/- 30

CONTROL BOARD

R1 0RD7501Q609 7.50K 1/4W(3 5% TA52

R2 0RD7501Q609 7.50K 1/4W(3 5% TA52

R3 0RD1801Q609 1.8K OHM 1/4 W(3.4) 5.00% TA

R4 0RD1201Q609 1.20K 1/4W(3 5% TA52

R5 0RD1201Q609 1.20K 1/4W(3 5% TA52

SW1 140-058E SKHV10910B LGEC NON 12V 20A

SW2 140-058E SKHV10910B LGEC NON 12V 20A

SW3 140-058E SKHV10910B LGEC NON 12V 20A

SW4 140-058E SKHV10910B LGEC NON 12V 20A

SW5 140-058E SKHV10910B LGEC NON 12V 20A

ZD401 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

ZD402 0DZ560009AG GDZJ5.6B TP GRANDE DO-34 500

LED1 0DLLT0089AA LITEON LTL-1BEDJ-0C2 TP GREE

POWER BOARD

CAPACITORS

C101 0CZZ9ST017A AL EL CAPACITOR 100UF 450V 2

C103 0CZZ9ST014A AL EL CAPACITOR 33UF 50V 20%

C104 0CH5271K416 270PF 2012 50V 5% NP0 R/TP

C105 0CZZ9ST013A AL EL CAPACITOR 0.47UF 50V 2

C106 0CK222DK4DA 2200PF 2012 50V 5% COG R/TP

C107 0CK1040K945 "0.1UF D 50V 80%,-20% F(Y5V)"

C201 0CKZTTA002E EKR3A102K09FK5 SAMWHA 1KV 10

C202 0CZZ9ST021A AL EL CAPACITOR 1000UF 25V 2

C203 0CZZ9ST020A AL EL CAPACITOR 680UF 25V 20

C204 0CZZ9ST018A AL EL CAPACITOR 1000UF 16V 2

C205 0CZZ9ST018A AL EL CAPACITOR 1000UF 16V 2

C206 0CZZ9ST021A AL EL CAPACITOR 1000UF 25V 2

C207 0CZZ9ST019A AL EL CAPACITOR 470UF 25V 20

C208 0CKZTTA002B 330PF 1KV K R TP5.0 TAPING .

C210 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C301 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C303 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C304 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C305 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C306 0CK224DH56A 0.22UF 2012 25V 10% R/TP X7R

C307 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C308 0CK105DH56A 1UF 2012 25V 10% X7R R/TP

C309 0CK224DH56A 0.22UF 2012 25V 10% R/TP X7R

C310 0CK105DH56A 1UF 2012 25V 10% X7R R/TP

C313 0CH2393K516 39000PF 50V 10% B(Y5P) 2012

C314 0CK152DK51A 1500PF 2012 50V 10% B(Y5P) R

- 29 -

Page 30

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C315 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C317 0CH5221K416 220PF 50V 5% NP0 2012 R/TP

C320 0CZZTCT006D C3216X7R1E225M TDK 25V 2.2UF

C402 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C403 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C404 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C405 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C406 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C407 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C409 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C410 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C411 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C412 0CK22201510 2200PF D 1KV 10% B(Y5P) R

C413 0CZZ9ST028A CERAMIC DISK 10PF 6KV 5% TR

C414 0CH2153K516 15000PF 50V 10% B(Y5P) 2012

C415 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C417 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C418 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

C419 0CH2222K516 2200PF 50V 10% B(Y5P) 2012 R

CX101 0CZZ9ST025A FILM CAPACITOR 0.47UF 275V 1

CY101 0CZZ9ST024A "Y CAPACITOR 100PF 250V 10%,-"

CY102 0CZZ9ST024A "Y CAPACITOR 100PF 250V 10%,-"

CY104 0CZZ9ST023A "Y CAPACITOR 4700PF 250V 20%,"

DIODEs

BD101 0DRTW00121A D2SB60-1121 TIWAN SEMI ST GB

D101 0DRDI00234A PR1007 DIODES TAPING52 DO41

D102 0DRDI00244A 1N4007/L DIODES TAPING52 DO4

D103 0DSGF00019A 1N4148 GULF TP DO35 100V 0.1

D201 0DRNH00140A FCH10U15 NIHON INTER BULK TO

D202 0DRNH00130A FCH10U10 NIHON INTER BULK TO

D306 0DSGD00048A MM4148 GRANDE REEL TAPING LL

D401 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D402 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D403 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D404 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D405 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D406 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D407 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

D408 0DSDI00038A "BAV99-(F),LF DIODES R/TP SOT"

ZD101 0DZ330009CC MTZJ3.3B TP ROHM-K DO34 - 3.

ZD301 0DZGD00128A ZMM5231B GRANDE REEL TAPING

TRANSISTORs & ICs

Q101 0TF760000AD SSS7N60B FAIRCHILD ST TO220F

Q301 0TR144009AI DTA144EK CHIP TP ROHM - Q302 0TR144009AH DTC144EK CHIP TP ROHM - Q303 0TRKE80046A 2N3904S KEC R/TP SOT23 60V 2

Q304 0TR390609DC 2N3906S-RTK KEC REEL TAPING

Q305 0TFDI80001A 2N7002 DIODES R/TP SOT23 60V

Q306 0TFDI80001A 2N7002 DIODES R/TP SOT23 60V

Q307 0TR390609DC 2N3906S-RTK KEC REEL TAPING

Q308 0TRKE80046A 2N3904S KEC R/TP SOT23 60V 2

U101 0IPMG78425A FAN7601 FAIRCHILD DIP-8P BUL

U201 0IPMG78424A "AZ431-A BCD 3P,TO-92 TAPING"

U301 0IPMG78426A OZL68GN O2MICRO 20P SOP BULK

U303 0TFAN00001A AP4511GD ADVANCED POWER ELEC

U304 0TFAN00001A AP4511GD ADVANCED POWER ELEC

PC201 0IPMG78432A "LTV-817M-V(C) LITEON 4P, WID"

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

RESISTORs

R101 0RJ4703G676 470K OHM 1/4 W 5% 3216 R/TP

R102 0RJ6801E472 6800 OHM 1/8 W 1% 2012 R/TP

R103 0RH1004D622 1M OHM 1 / 10 W 2012 5.00% D

R104 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R105 0RD0912Q609 91 OHM 1/4 W (3.4) 5% TA52

R106 0RH2201D622 2.2K OHM 1 / 10 W 2012 5.00%

R107 0RD8203A609 820K OHM 1/2 W(7.0) 5.00% TA

R108 0RD4702A609 47K OHM 1/2 W(7.0) 5.00% TA5

R109 0RX0560J609 0.56OHM 1 W 5% TA52

R110 0RX1003K607 100KOHM 2 W 5% TA62

R111 0RD0471Q609 4.70 1/4W(3 5% TA52

R112 0RJ1302E472 13K OHM 1/8 W 1% 2012 R/TP

R115 0RJ4703G676 470K OHM 1/4 W 5% 3216 R/TP

R116 0RJ4703G676 470K OHM 1/4 W 5% 3216 R/TP

R117 0RH2403D622 240K OHM 1 / 10 W 2012 5.00%

R118 0RH2403D622 240K OHM 1 / 10 W 2012 5.00%

R202 0RX0242K665 24 OHM 2 W 5% SF

R204 0RN3002F409 30K OHM 1/6 W 1.00% TA52

R205 0RN2201F409 2.2K OHM 1/6 W 1.00% TA52

R206 0RJ1601E472 1.6K OHM 1/8 W 1% 2012 R/TP

R207 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R208 0RH6800D622 680 OHM 1 / 10 W 2012 5.00%

R209 0RH1001D622 1K OHM 1 / 10 W 2012 5.00% D

R211 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R301 0RD1001Q609 1K OHM 1/4 W(3.4) 5.00% TA52

R303 0RH0222D622 22 OHM 1 / 10 W 2012 5.00% D

R304 0RD1002Q609 10K OHM 1/4 W(3.4) 5.00% TA5

R309 0RN1502F409 15K OHM 1/6 W 1.00% TA52

R310 0RH1004D622 1M OHM 1 / 10 W 2012 5.00% D

R311 0RH1502D422 "15K , 1/10W 1% TP"

R313 0RJ6202E472 62K OHM 1/8 W 1% 2012 R/TP

R315 0RH2001D622 2K OHM 1 / 10 W 2012 5.00% D

R316 0RH2001D622 2K OHM 1 / 10 W 2012 5.00% D

R317 0RJ3303E472 330000 OHM 1/8 W 1% 2012 R/T

R318 0RJ1503E472 150K OHM 1/8 W 1% 2012 R/TP

R319 0RH1303D622 130K OHM 1 / 10 W 2012 5.00%

R320 0RH1502D422 "15K , 1/10W 1% TP"

R321 0RH1002D422 10K OHM 1/10 W 1% 2012 R/TP

R401 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R402 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R403 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R404 0RJ1001G476 1K OHM 1/4 W 1% 3216 R/TP

R406 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R407 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R408 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

R409 0RJ3600E472 360 OHM 1/8 W 1% 2012 R/TP

TH101 6322A00035A 10D2-07 SEMITEC 10OHM 15% L1

TRANSFORMER

T101 61709MC011A EER3016 430UH LX52 LIPS SMPS

T301 61709MC010A EFD-2124 95UH INVERTER TRANS

T302 61709MC010A EFD-2124 95UH INVERTER TRANS

OTHERs

SC101 6620K00020A HUAJIE AC UL/CSA 3PPIN BLACK

F101 0FZZTTH001E TIME LAG HBC 2153.15MXE(LEAD

FB101 6210TCE003G BRS3550B BO SUNG 3550MM RADI

HS1 4920900021A EXTRUSION 10*20 16 LX52

HS2 4920900021A EXTRUSION 10*20 16 LX52

- 30 -

Page 31

DATE: 2006. 01. 26.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

HS3 4920900022A PLATE 7*60 16 LX52

HS4 4920900032A PLATE 20.5 *10.5 *12.0

L202 61409B0009A HL-1520S JEONGSAN 7.0UH 25%

LF101 6200J000154 13.0*710*23680 SAMWAH BULK L

P201 6602T20008K SMW200-11 YEONHO 11P 2.0MM L

P401 6630V90218A "35001WR YEONHO 2P 3.5MM DIP,"

P402 6630V90218A "35001WR YEONHO 2P 3.5MM DIP,"

P403 6630V90218A "35001WR YEONHO 2P 3.5MM DIP,"

P404 6630V90218A "35001WR YEONHO 2P 3.5MM DIP,"

J30 971-0016 TIN HDC 0.60H NON NON

J31 971-0016 TIN HDC 0.60H NON NON

- 31 -

Page 32

SCHEMATIC DIAGRAM

1. SCALER

- 32 -

Page 33

2. POWER & WAFER

- 33 -

Page 34

3. INVERTER

- 34 -

Page 35

4. POWER

- 35 -

Page 36

Jan. 2006

P/NO : 38289S0041W Printed in Korea

Loading...

Loading...