ENGLISH

SINGLE PA CKAGED AIR CONDITIONERS

INSTALLATION & MAINTENANCE INSTRUCTIONS

• Please read this instruction sheet completely before installing the product.

• Installation work must be performed in accordance with national wiring standards by authorized

personnel only.

P/No.: 3828A30038Z

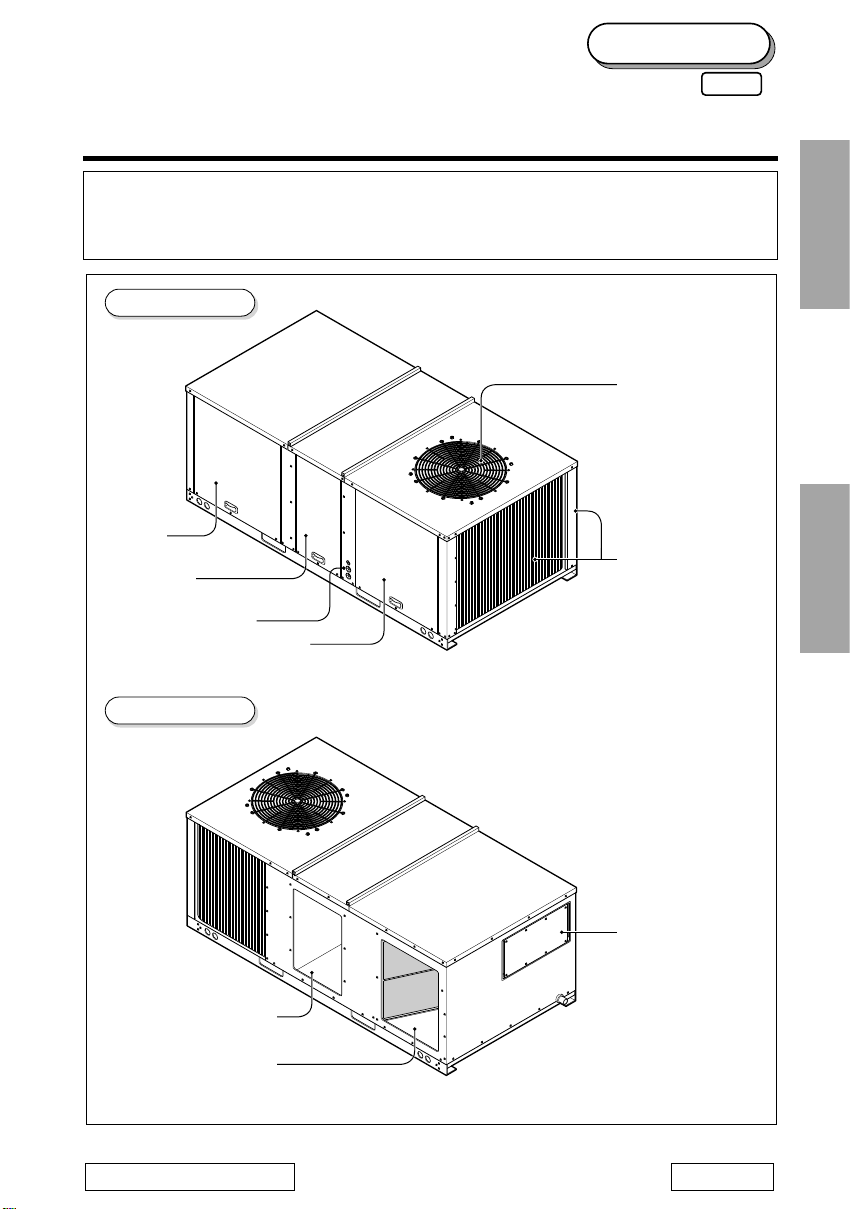

Air Outlet Vents

Filter

Access Panel

E/Heater

Access Panel

Unit Power Wires

Control and Compressor

Access Panel

Air Intake Vents

Refresh

Air Hood

Supply

(Side)

(Rear)

Return

Front View

Rear View

File Tab Position: 4 Rev. No.: 1

LK-IM-12

50Hz

ESPAÑOL

2

1.The following should be always observed for safety ...............................3

2. Dimensional Data ........................................................................................4

3. Installation of Unit .......................................................................................6

4. Ductwork ......................................................................................................7

5. Condensate Drain Piping ...........................................................................8

6. Filter Installation .........................................................................................8

7. Installation of remote controller ................................................................9

8. Electrical Wiring ........................................................................................10

9. Control Wiring ...........................................................................................13

10. Start-Up Pre-Start Quick Check List .....................................................15

11. Test Mode Procedure ..............................................................................16

12. Trial Run Mode ........................................................................................18

13. Evaporator Fan Adjustment ...................................................................19

14. Start-up ....................................................................................................20

15. Final installation Checklist and Maintenance ......................................22

TABLEOFCONTENTS

ENGLISH

3

1. The following should be always observed for safety

• Please report to or take consent by the supply authority before connecting to the system.

• Be sure to read "THE FOLLOWING SHOULD BE ALWAYS OBSERVED FOR SAFETY" before

installing the air conditioner.

• Be sure to observe the cautions specified here as they include important items related to safety.

• The indications and meanings are as follows.

• After reading this manual, be sure to keep it together with the owner's manual in a handy place .

Could lead to death, serious injury, etc.

Do not install it yourself (customer).

Perform the installationsecurely referring to the

installation manual.

Install the unitsecurely in a place which canbear the

weight of theunit.

Perform electrical workaccording to the installation

manual and besure to use an exclusive circuit.

Attach the electricalpart cover and service panel to

the unit securely.

Be sure touse the part provided or specifiedparts for

the installation work.

Check that the refrigerant gas do not leak after

installation is completed.

Bodily injury can result from high voltage electrical

components or fast moving fan drives. For protection

from these inherent hazards during installation and

servicing, the electrical supply must be disconnected. If

operating checks must be performed with the unit

operating, it is the technician's responsibility to

recognize these hazards and proceed safely.

UNIT CONTAINS ANHCFC (R-22) REFRIGERANT

Section 608 paragraphC of the 1990 Clean AirAct states:

Effective July 1,1992 it shall be unlawful forany person, in the

course of maintaining,servicing, repairing or disposing of anair

conditioning system, toknowingly vent or release any CFCor

HCFC refrigerant minimalreleases (air purges of refrigerant

hoses) associated withgood faith attempts to recapture or

recycle are exemptedfrom the ban on venting.

Use the specifiedwires to connect the unit andthe

field installed cutoff switch box securely and attach

the wires firmlyto the terminal so the stressof the

wires is notapplied to the sections.

• Incomplete installation could cause injury due to fire, electric shock

or leakageof water. Consultthe dealer fromwhom you purchased

the unitor special installer.

• Incomplete installationcould cause a personal injury due to

fire, electric shock,noisy operation or distortion.

• When installedin an insufficient strong place, noisy operation

and distortion couldoccur.

• Incomplete connectingand fixing could cause fire.

• If thecapacity of the power circuit is insufficient or there is incomplete

electrical work, itcould result in a fire or an electric shock.

• Theuse of defective parts could cause aninjury or leakage of

water due to a fire, electricshock etc.

• Ifthe electrical part cover panel are notattached securely, it

could resultin a fire orelectric shock due todust, water etc.

Could lead to serious injury in particular environments when operated incorrectly.

WARNING

WARNING

CAUTION

Having perfect vacuum process in the factory, our units don't have drier but have filter in the

refrigerantcircuit.IncaseofrechargingR-22gasinthefield,

"DRIER" must be installed on the liquid line which is connected

from discharge part of condenser to intake part of evaporator. Because the refrigerant circuit is

capable of containing water with imperfect vacuum.

The equipment does not contain surge protection. To prevent damage caused by surge, transients

appropriate measures should be taken.

CAUTION

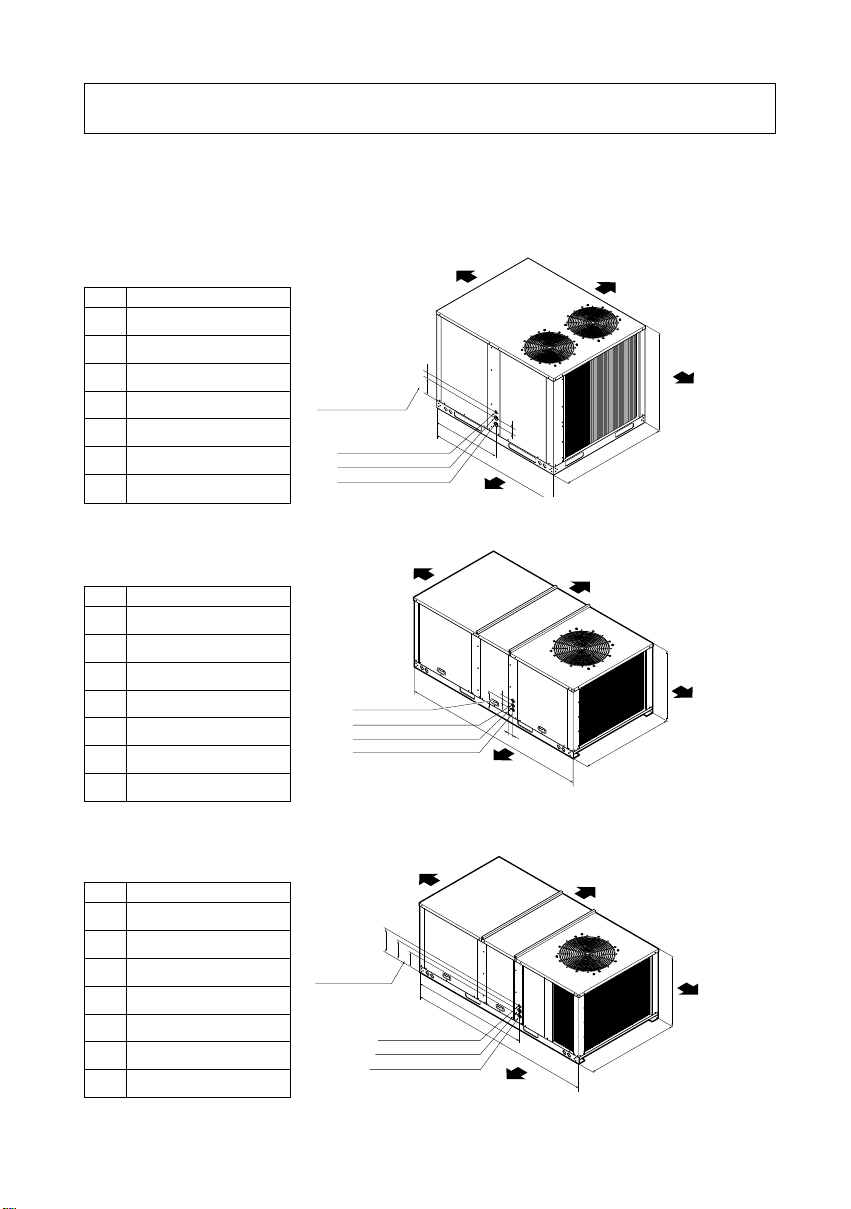

UNIT Dimensions (Figure 1A)

UNIT Dimensions (Figure 1B)

4

Single packaged cooling unit are designed for outdoor mounting with vertical condenser discharge. They

can be located either at ground level or on roof.

Each unit contains an operating charge of Refrigerant 22 as shipped.

E

G

F

Center Line of Hole

A

B

CLEARANCE 34"

CLEARANCE 16"(HORIZONTAL)

CLEARANCE 32"(DOWNFLOW)

CLEARANCE 34"

1" Dia. Hole Control Wires

1.5" Dia. Hole Power Wires

1.5" Dia. Hole Other Purpose

D

C

J

N

M

K

LL

1.5" Dia. Hole Power Wires

1.5" Dia. Hole Other Purpose

Center Line of Hole

1" Dia. Hole Control Wires

H

I

CLEARANCE 34"

CLEARANCE 16"

CLEARANCE 34"

CLEARANCE 46"

e

g

f

d

c

Center Line of Hole

a

b

CLEARANCE 34"

CLEARANCE 46"

CLEARANCE 16"(HORIZONTAL)

CLEARANCE 34"

1" Dia. Hole Control Wires

1.5" Dia. Hole Power Wires

1.5" Dia. Hole Other Purpose

Figure 1A

Figure 1B

Figure 1C

2. Dimensional Data

UNITS

LK-0580CC/0580HC/0680CH

A

B

C

D

E

F

G

41.93(1065)

43.70(1110)

50.39(1280)

29.49(749)

9.65(245)

2.36(60)

2.76(70)

UNITS

LK-0880CH/0880HH

H

I

J

K

L

M

N

35.04(890)

46.93(1159)

85.43(2170)

10.43(265)

2.76(70)

2.36(60)

3.54(90)

UNITS

LK-1080CH/1080HH

a

b

c

d

e

f

g

41.34(1050)

48.89(1242)

85.43(2170)

55.0(1397)

6.10(155)

8.46(215)

10.43(265)

UNIT Dimensions (Figure 1C)

Unit: inch(mm)

Unit: inch(mm)

ENGLISH

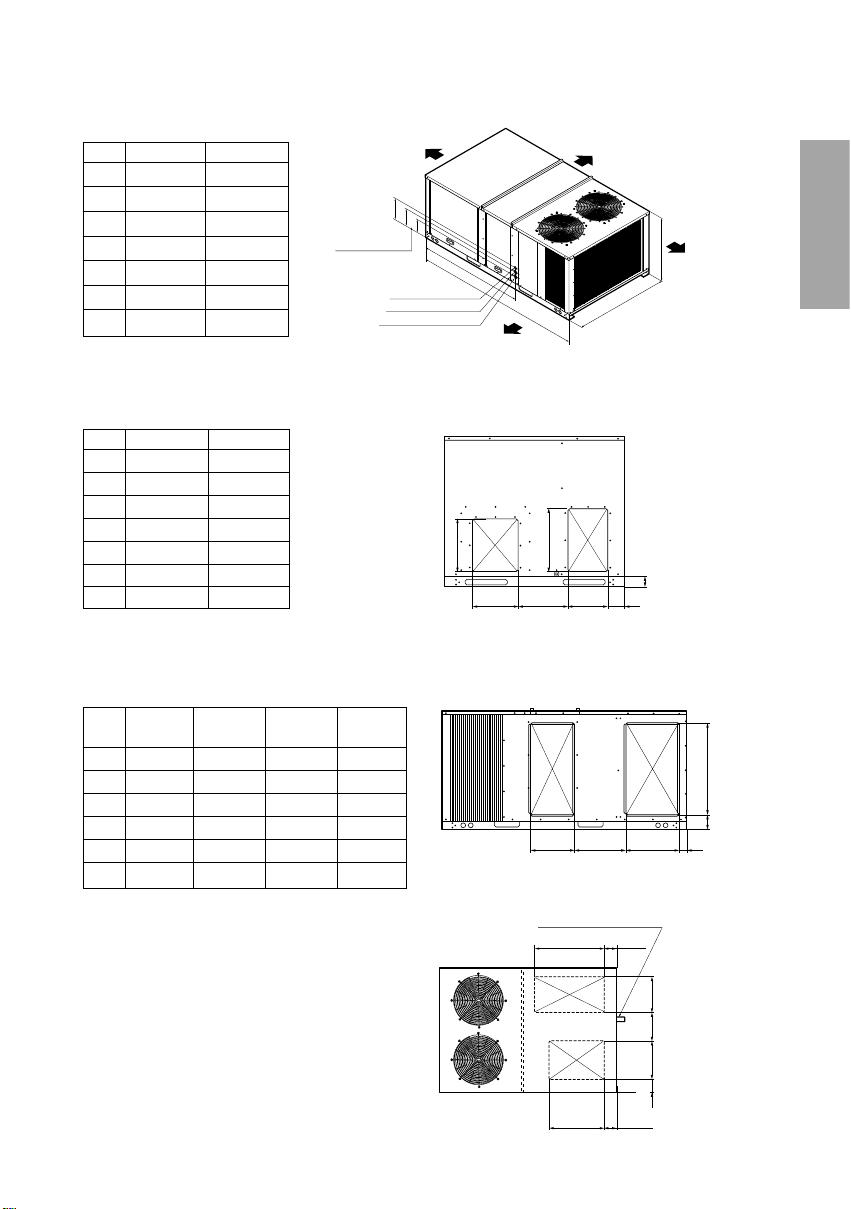

Horizontal Application Unit (Figure 1E)

Rear View Showing Duct Openings For Horizontal Air Flow

Horizontal Unit (Figure 1F)

Rear View Showing Duct Openings For Horizontal Air Flow

Down Flow Application Unit (Figure 1G)

(LK-0580CC, LK-0580HC)

LK-0580CC and LK-0580HC are

Convertible Unit

5

A

G

BCD

E

SUPPLY

RETURN

F

ab cd

e

f

S

U

P

P

L

Y

R

E

T

U

R

N

10,47(266)

9,25(235)

13,86(352)

6,26(159)

3,82(97)

16,38(416)

3,82(97)

22,28(566)

SUPPLY

RETURN

3/4" Condensate Location

Figure 1E

Rear View

Rear View

Figure 1F

Top View

Unit: inch(mm)

Figure 1G

Unit: inch(mm)

UNITS

LK-0580CC/0580HC LK-0680CH

A

B

C

D

E

F

G

13.86(352)

9.21(234)

10.47(266)

3.86(98)

4.33(110)

22.28(566)

16.38(416)

15.51(394)

8.43(214)

10.94(278)

2.87(73)

4.33(110)

24.25(616)

13.15(334)

a

b

c

d

e

f

15.47(393) 16.06(408) 24.53(623) 25.57(649.5)

16.18(411) 14.02(356) 9.17(233) 15.28(388)

18.82(478) 20.16(512) 24.53(623) 27.34(694.5)

2.40(61) 2.44(62) 2.36(60) 2.40(61)

5.35(136) 2.01(51) 5.08(129) 6.10(155)

26.89(683) 34.33(872) 40.24(1,022) 57.09(1,450)

Unit: inch(mm)

LK-0880CH

0880HH

LK-1080CH

1080HH

LK-1580CH

1580HH

LK-2080CH

2580CH

UNITS

Horizontal Application Unit(Figure 1D)

Rear View Showing Duct Openings For Horizontal Air Flow

l

n

m

k

j

Center Line of Hole

h

i

CLEARANCE 34"

CLEARANCE 46"

CLEARANCE 16"(HORIZONTAL)

CLEARANCE

34"

1" Dia. Hole Control Wires

1.5" Dia. Hole Power Wires

1.5" Dia. Hole Other Purpose

Figura 1D

UNITS

LK-1580CH/1580HH

LK-2080CH/2580CH

h

i

j

k

l

m

n

47.44(1,205) 65.35(1,660)

69.53(1,766) 74.02(1,880)

95.98(2,438) 109.21(2,774)

63.11(1,603) 69.69(1,770)

6.29(160) 7.68(195)

8.66(220) 11.89(302)

11.02(280) -

Unit: inch(mm)

3-1. Inspection

1) Check for damage after unit is unloaded. Report promptly, to the carrier, any damage found to unit. Do

not drop unit.

2) Check the unit nameplate to determine if the unit voltage is correct for the application. Determine if

adequate electrical power is available. Refer to the application specifications.

3) Check to be sure the refrigerant charge has been retained during shipment. Access to 1/4" flare

pressure taps may be gained by removing compressor compartment access panel.

3-2. Location and Recommendations

1) Unit Support

If unit is to be roof mounted check building codes for weight distribution requirements.

2) Location and Clearances

Installation of unit should conform to local building codes and the National Electrical Code.

Select a location that will permit unobstructed airflow into the condenser coil and away from the fan

discharge and permit unobstructed service access into the compressor compartment. Suggested

airflow clearances and service clearances are given in Figure 1.

3) Placing and Rigging

Rig the unit using either belt or cable slings. The sling eyelet must be placed through the lifting holes in

the base rail of the unit. The point where the slings meet the lifting eyelet should be at least 6 feet

above the unit. Use spreader bars to prevent excessive pressure on the top of the unit during lifting.

Important: The use of "spreader bars" is required when hoisting the unit (prevents damage to

sides and top). Top crating can be used as spreader bars.

4) Roof Mounted Units

Downflow units(only 5RT) should be mounted on a roof curb when possible. On new roofs, the curb

should be welded directly to the roof deck. For existing construction, nailers must be installed under

the curb if welding is not possible. Be sure attach the downflow ductwork to the curb before setting unit

in place.

When installing the unit, it must be level to insure proper condensate flow from the unit drain pan.

5) Slab Mount

"For ground level installation, the unit base should be adequately supported and hold the unit near

level. The installation must meet the guidelines set forth in local codes."

6

3. Installation of Unit

ENGLISH

Lifting Beam

Cable

or Chain

ClevisHoles in Base

Rail

Spreader Bar

Lifting Beam

Cable

or Chain

ClevisHoles in Base

Rail

Recommended

Rigging Method

Figure 2

ENGLISH

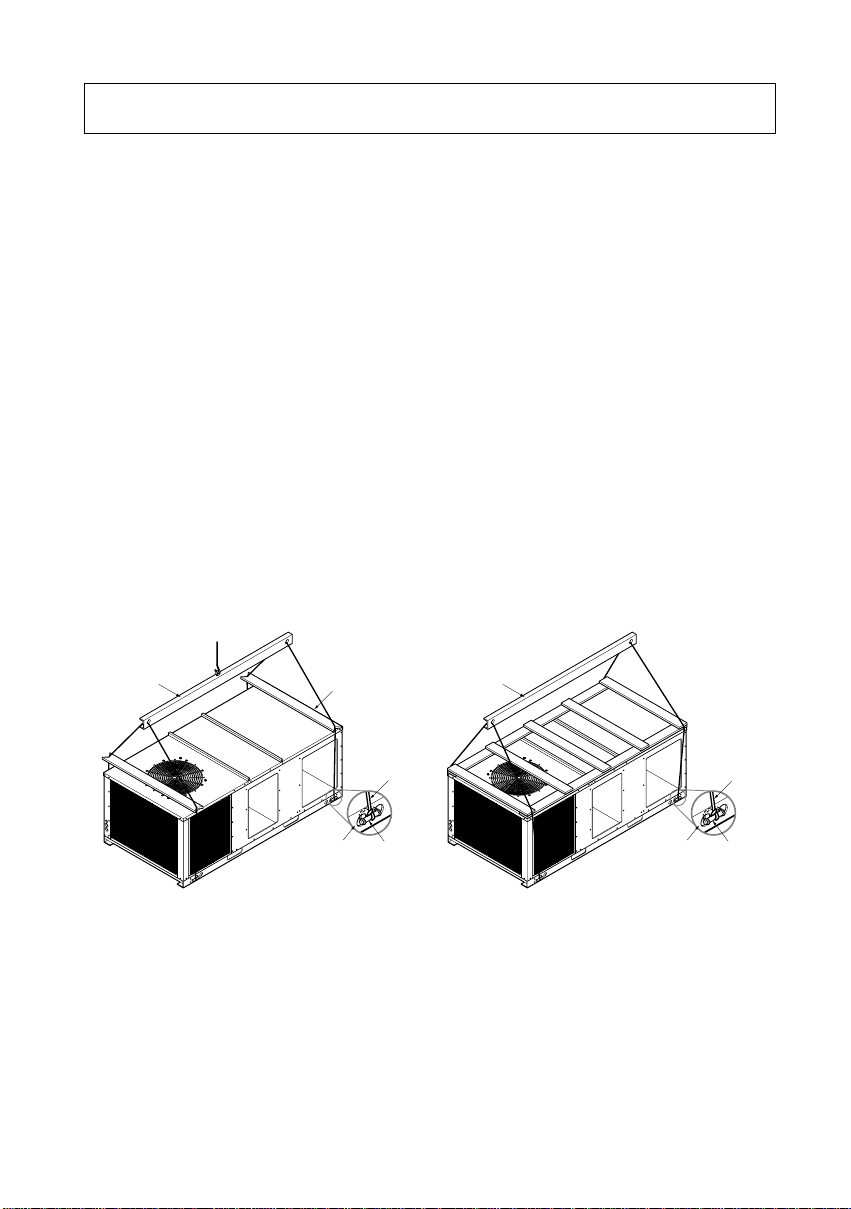

1. Attaching Downflow Ductwork to The Roof Curb (below 5.0RT)

Supply and return air flanges are provided on the roof curb for easy duct installation. All duct work

must be run and attached to the curb before the unit is set into place.

2. Ductwork construction guidelines

Connections to the unit should be made with three-inch canvas connectors to minimize noise and

vibration transmission.

Elbows with turning vanes or splitters are recommended to minimize air noise and resistance.

The first elbow in the ductwork leaving the unit should be no closer than three times blower diameter to

avoid turbulence and back pressure.

3. Attaching Horizontal Ductwork to the Unit

All conditioned air ductwork should be insulated to minimize heating and cooling duct losses. Use

minimum of 2" of insulation with a vapor barrier. The outside ductwork must be weather proofed

between the unit and the building.

When attaching ductwork to a horizontal unit, provide a flexible water tight connection to prevent noise

transmission from the unit to the ducts. The flexible connection must be indoors and molded out of

heavy canvas.

Note: Do not draw the canvas taut between the solid ducts.

IMPORTANT(below 5.0RT)

To convert to downflow, remove covers from the downflow supply and return air opening(painted side

out) and secure with sheet metal screw (see Figure 3)

7

4. Ductwork

Figure 3

Note:

SUTTLY OPENING

1. Remove the screw nearest to the

opening and pull the panel firmly toward

the outside of the unit to disengage the

back attachment.

RETURN OPENING

2. Remove right hand screw and move

panel to the right or remove both

screws.

HORIZONTAL RETURN

AIR COVER

HORIZONTAL SUPPLY

AIR COVER

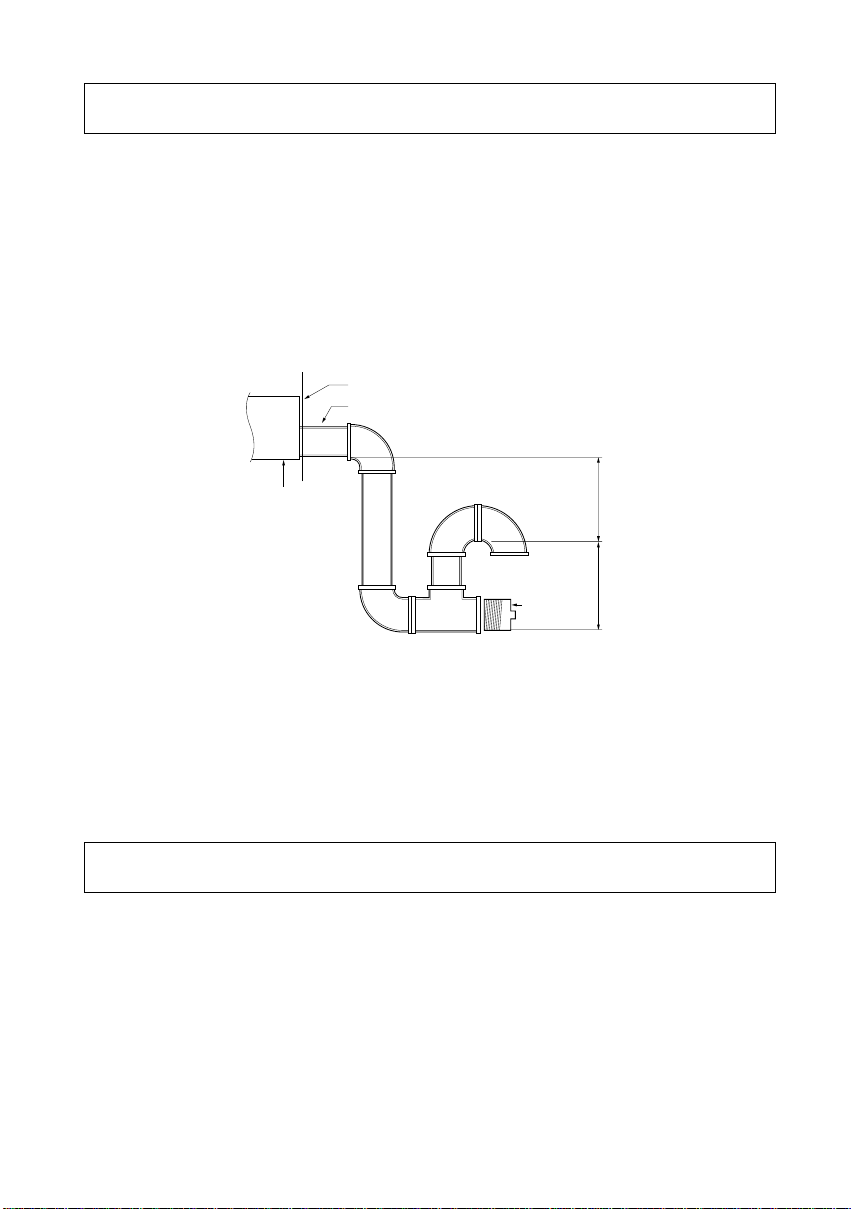

A. CONDENSATE DRAIN

A 3/4 inch male condensate drain connection is located on the corner of the unit next to the evaporator

section access panel. A trap should be installed and filled with water before starting the unit to avoid

air from being drawn through. Follow local codes and standard piping practices when running the drain

line. Pitch the line downward, away from the unit, and avoid long horizontal runs. See Figure 4.

Do not use reducing fittings in the drain lines.

The condensate drain must be:

1. Made of 3/4" pipe size.

2. Pitched 1/4" per foot to provide free drainage to convenient drain system.

3. Trapped

4. Must not be connected to closed drain system.

B. OUTDOOR COIL CONDENSATE DRAINAGE PRECAUTION

Condensate drains from the outdoor coil during the heating and defrost cycles. Normally this

condensate may be allowed to drain directly onto the ground/roof. A gravel bed is recommended to

prevent mud splashing.

WARNING : The unit should not be installed in an area where mud or ice could cause personal injury.

Remember that condensate drips from the outdoor coil during heat and defrost cycles

and that this condensate freezes when the temperature of the outdoor air is below

0°C(32°F)

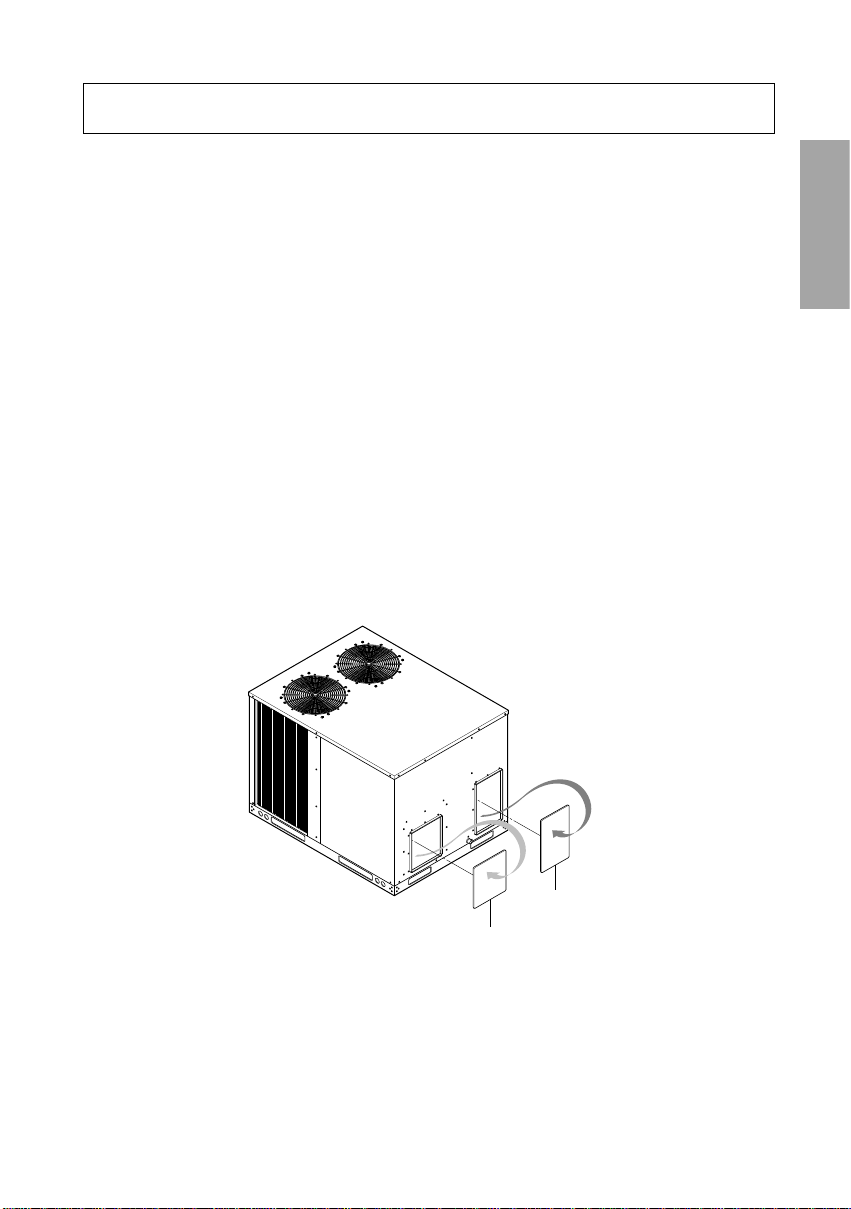

■ Above 7.5RT

This Unit Filters are anti-bacteria and washable type.

Access to the filters is made by removing the evaporator fan access panel. Each unit ships with free

filters, as determined by unit size.

On the filter access panel at the left side of the unit, "FILTER ACCESS PANEL" label is attached.

■ Below 6.25RT

This unit is shipped without a filter and is the responsibility of the installer to secure a filter in

the return air ductwork.

Important: Do not operate unit without filters in place.

8

5. Condensate Drain Piping

6. Filter Installation

Figure 4

Panel Enclosure

3/4 Inch Male

Static pressure

Drain Pan

Cleanout

1.5 Inches1.5 Inches

Plug

Loading...

Loading...