LG LFX25973 Series, LFX28979 SERIES Service Manual

REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODEL : LFX25973**

COLOR : STAINLESS(ST)

WESTERN BLACK

SUPER WHITE

CONTENTS

1. SPECIFICATIONS ............................................................................................................................................ 3

2. PARTS IDENTIFICATION ................................................................................................................................ 4

3. DISASSEMBLY ........................................................................................................................................... 5-16

REMOVING AND REPLACING REFRIGERATOR DOORS ............................................................................ 5

DOOR ............................................................................................................................................................... 6

DOOR ALIGNMENT ........................................................................................................................................ 7

FAN AND FAN MOTOR(EVAPORATOR) ....................................................................................................... 7

DEFROST CONTROL ASSEMBLY ................................................................................................................. 7

LAMP ............................................................................................................................................................... 8

MULTI DUCT ................................................................................................................................................... 8

MAIN PWB........................................................................................................................................................ 8

DISPENSER .................................................................................................................................................... 9

DISPLAY PCB ................................................................................................................................................. 9

ICE BUTTON ASSEMBLY ............................................................................................................................... 9

WATER BUTTON ASSMEBLY ........................................................................................................................ 9

ICE COMPARTMENT DOOR REPLACEMENT .............................................................................................. 9

ICEMAKER REPLACEMENT ........................................................................................................................ 10

SUB PWB FOR WORKING DISPENSER ..................................................................................................... 10

CAP DUCT MOTOR REPLACEMENT ........................................................................................................... 11

HOW TO REMOVE THE ICE BIN ................................................................................................................. 12

HOW TO INSERT THE ICE BIN .................................................................................................................... 12

HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER .......................................................... 13-14

WATER VALVE DISASSEMBLY METHOD .................................................................................................. 15

FAN AND FAN MOTOR DISASSEMBLY METHOD ...................................................................................... 15

FREEZER DRAWER ..................................................................................................................................... 16

4. ADJUSTMENT ............................................................................................................................................... 17

COMPRESSOR ............................................................................................................................................. 17

5. CIRCUIT DIAGRAM ....................................................................................................................................... 18

6. TROUBLESHOOTING ...............................................................................................................................19-20

ERROR CODE SUMMARY .......................................................................................................................19-20

7. PCB PICTURE .......................................................................................................................................... 21-22

MAIN PCB ...................................................................................................................................................... 21

DISPLAY PCB & SUB PCB .......................................................................................................................... 22

8. TROUBLESHOOTING WITH ERROR DISPLAY ..................................................................................... 23-31

9. TROUBLESHOOTING WITHOUT ERROR DISPLAY .............................................................................. 32-40

10. REFERENCE .......................................................................................................................................... 41-44

11. COMPONENT TESTING INFORMATION .............................................................................................. 45-53

12. COMPRESSOR TROUBLESHOOTING.................................................................................................. 54-65

13. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER (ICE ROOM) ................................ 66-69

14. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER (FREEZER ROOM) ..................... 70-73

15. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ....................................................................... 74-77

FUNCTION ............................................................................................................................................. 74-77

16. EXPLODED VIEW ...................................................................................................................................... 1-7

SAFETY PRECAUTIONS

Please read the following instructions before servicing your

refrigerator.

1. Unplug the power before handling any elctrical

componets.

2. Check the rated current, voltage, and capacity.

3. Take caution not to get water near any electrical

components.

4. Use exact replacement parts.

5. Remove any objects from the top prior to tilting the

product.

- 2 -

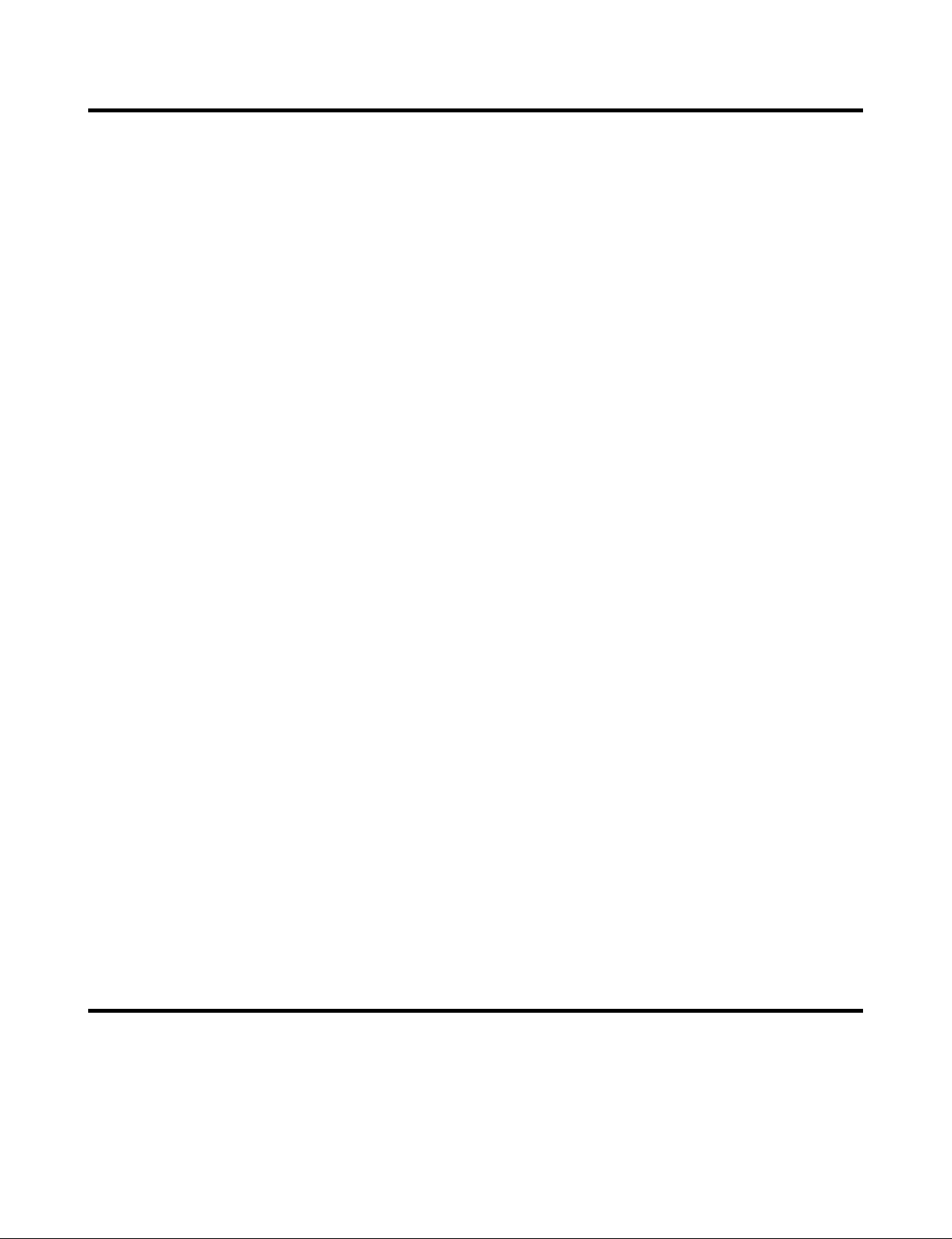

1. SPECIFICATIONS

25 cu. ft

ITEMS SPECIFICATIONS

DOOR DESIGN

DIMENSIONS (inches)

NET WEIGHT (pounds)

COOLING SYSTEM

TEMPERATURE CONTROL

DEFROSTING SYSTEM

DOOR FINISH

HANDLE TYPE

INNER CASE

INSULATION

DIMENSIONS

Side Rounded

35 3/4X 34 1/4X 69 3/4(WXDXH) 25cu.ft

308.65 (25cu.ft)

Fan Cooling

Micom Control

Full Automatic

Heater Defrost

PCM, Stainless

Bar

ABS Resin

Polyurethane Foam

ITEMS SPECIFICATIONS

VEGETABLE TRAY

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

LUBRICATING OIL

DEFROSTING DEVICE

REFRIGERATOR

LAMP

FREEZER

Opaque Drawer Type

Linear

Fin Tube Type

Spiral Condenser

R-134a (145g)

FREOLα8G (180 ml)

SHEATH HEATER

LED Module(21)

Bulb Lamp

Description LMX25973**

Depth w/ Handles

Depth w/o Handles

Depth w/o Door

Depth (Total with Door Open)

Height to Top of Case

Height to Top of Door Hinge

Width

Width (door open 90 deg. w/o handle)

Width (door open 90 deg. w/ handle)

- 3 -

A

B

C

D

E

F

G

H

I

34 1/4 in.

31 3/4 in.

27 7/8 in.

46 1/2 in.

68 3/8 in.

69 3/4 in.

35 3/4 in.

39 1/4 in.

44 1/4 in.

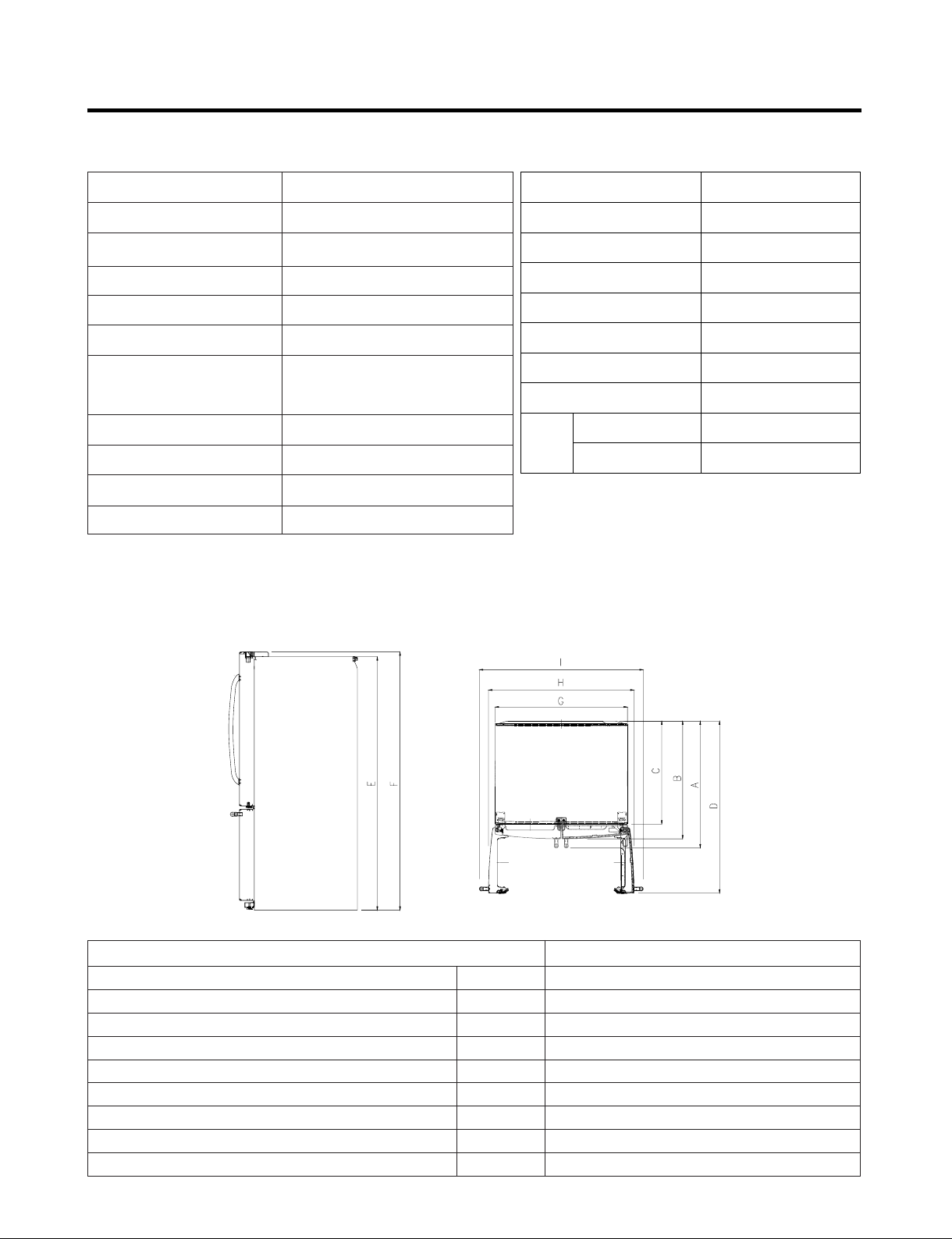

2. PARTS IDENTIFICATION

ADJUSTABLE REFRIGERATOR SHELVING

1

The refrigerator compartment shelves are adjustable to allow

flexibility for storage needs.

GALLON STORAGE BINS

2

Two interchangeable bins can be arranged to suit your

storage needs.

LED INTERIOR LAMPS

3

Refrigerator interior is lit by the LED array.

CAN STORAGE BIN

4

FIXED DOOR BINS

5

REMOVABLE ICE STORAGE BIN

6

The ice storage bin can be removed to fill ice buckets,

coolers, or pitchers

Auto Icemaker

7

- 4 -

3. DISASSEMBLY

(1)

(2)

(4)

(3)

(6)

(7)

(8)

(5)

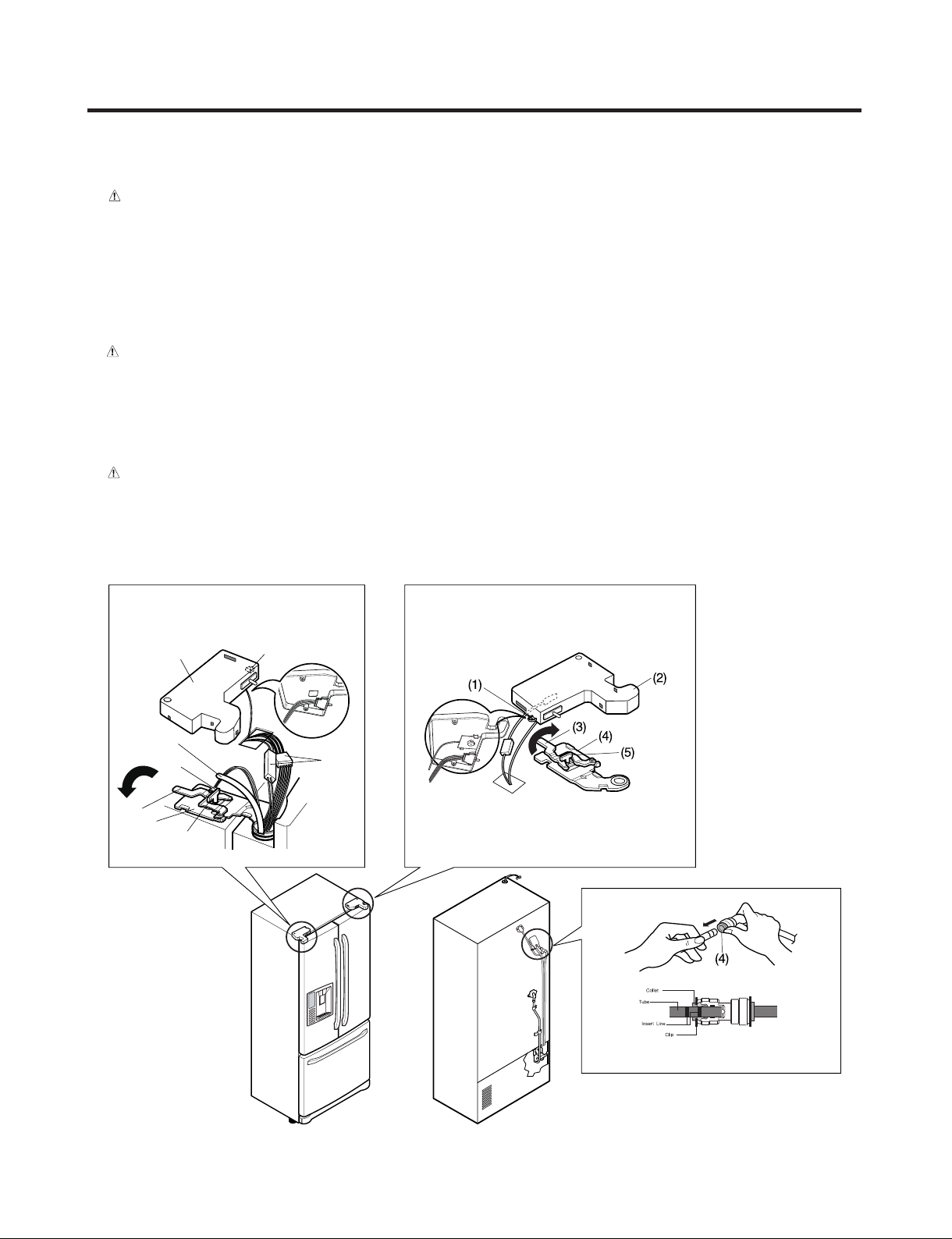

3-1 REMOVING AND REPLACING REFRIGERATOR DOORS

●

Removing Refrigerator Door

CAUTION : Before you begin, unplug the refrigerator. Remove food and bins from doors.

▶

Left Door -FIG. 2

1. Disconnect water supply tube by pushing back on the disconnect ring (4).-FIG. 1

2. Open door. Loosen top hinge cover screw (1).

Use flat tip screwdriver to pry back hooks on front underside of cover (2). Lift up cover.

3. Disconnect door switch wire harness. Remove cover.

4. Pull out the tube(3).

5. Disconnect the two wire harnesses (4). Remove the grounding screw (5).

6. Rotate hinge lever (6) counterclockwise. Lift top hinge (7) free of hinge lever latch (8).

CAUTION : When lifting hinge free of latch, be careful that door does not fall forward.

7. Place door, inside facing up, down onto a non-scratching surface.

▶

Right Door -FIG. 3

1. Open door. Loosen top hinge cover screw (1). Lift up cover (2).

2. Disconnect door switch wire harness. Remove cover.

3. Rotate hinge lever (3) clockwise. Lift top hinge (4) free of hinge lever latch (5).

4. Lift door from middle hinge pin and remove door.

CAUTION : When lifting hinge free of latch, be careful that door does not fall forward.

5. Place door, inside facing up, down onto a non-scratching surface.

Figure 2 Figure 3

Figure 1

- 5 -

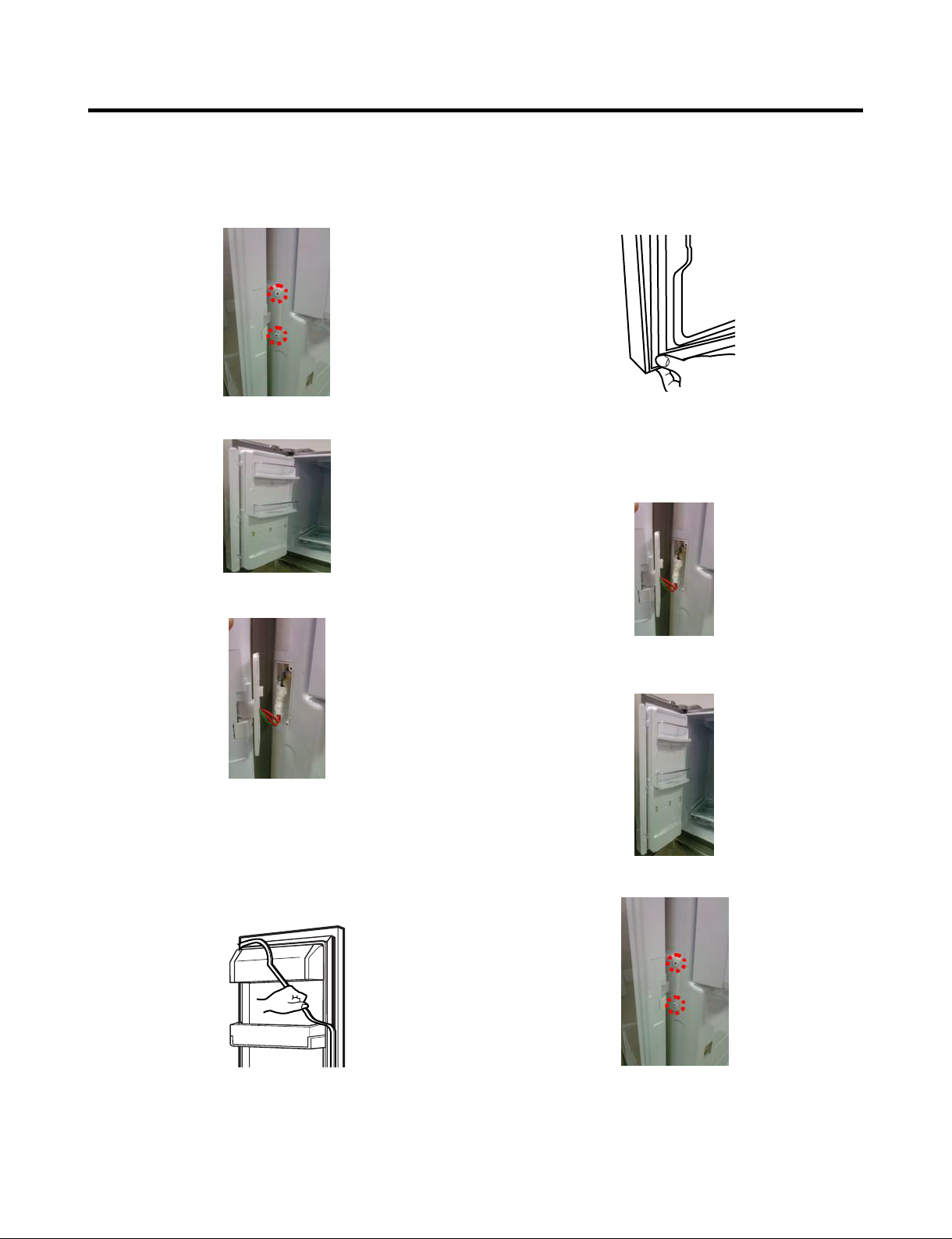

3-2 DOOR

●

Pillar Removal

1. Remove 2 screws.

2. Lift pillar up carefully.

3. Disconnect wire harness.

●

Door Gasket Replacement

1. Insert gasket into channel

Press gasket into channels on the four remaining

sides of door.

●

Pillar Replacement

1. Connect wire harness.

●

Door Gasket Removal

1. Remove gasket

Pull gasket free from gasket channel on the four

remaining sides of door.

2. Insert pillar into channel.

Inserting pillar assy’ into bracket, door

3. Assemble 2 screws.

- 6 -

3-3 DOOR ALIGNMENT

If the space between your doors is uneven, follow the

instructions below to align the doors:

Remove the Base Grillie. Turn the leveling legs (CCW) to

raise or (CW) to lower the height of the front of the

refrigerator by using flat blade screw driver or 11/32"

wrench. Use the wrench (Included with the User Manual) to

adjust the bolt in the door hinge to adjust the height. (CCW

to raise or CW to lower the height.)

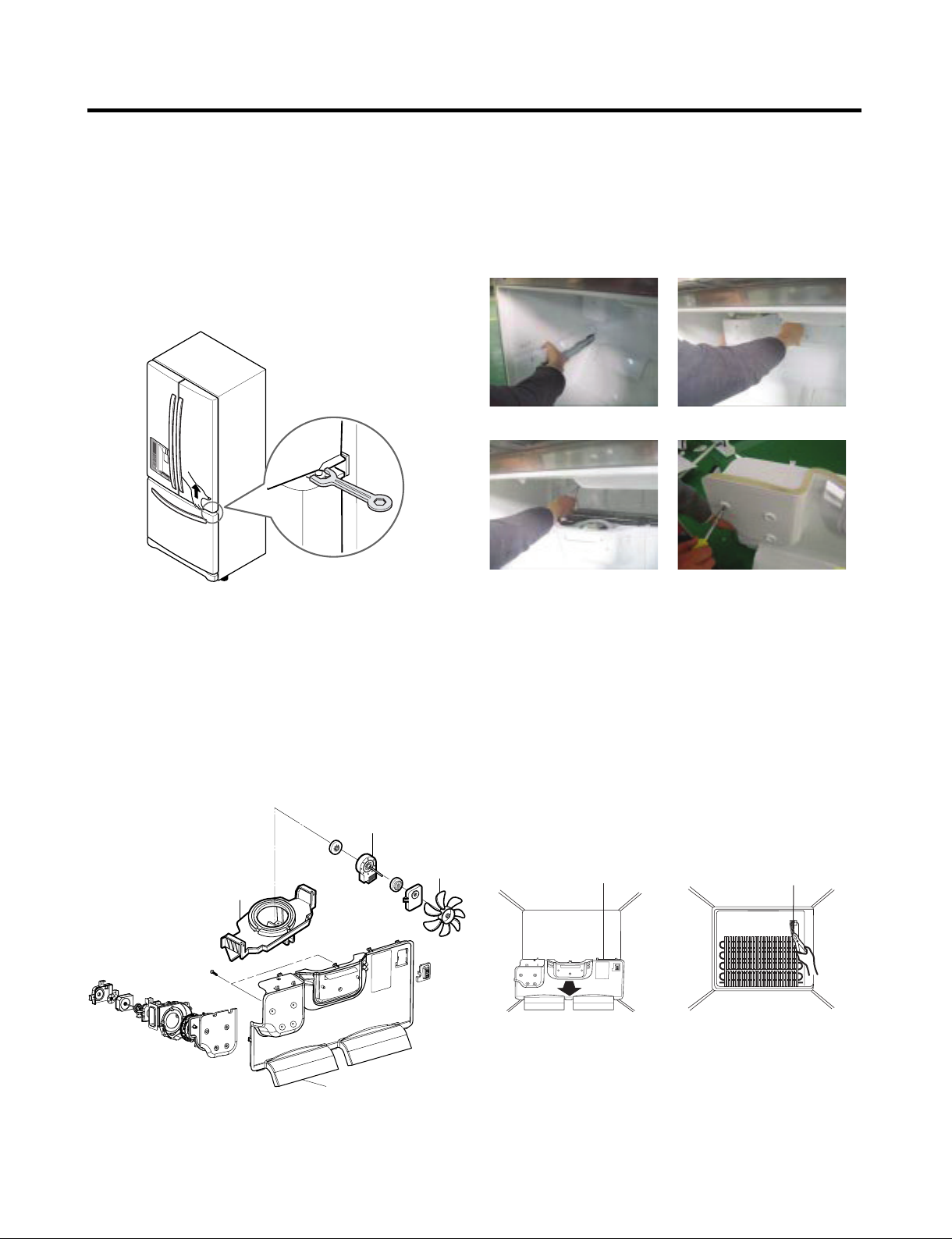

* Ice Fan Scroll Assembly Replacement

1) Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

2) Pull the grille forward as shown in the second picture.

3) Disconnect wire harness of the grille.

4) Remove the scroll assembly by loosening all screws.

(1) (2)

(3) (4)

3-4 FAN AND FAN MOTOR(EVAPORATOR)

1. Remove the freezer shelf.

2. Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

3. Remove the grille by removing one screw and pulling the

grille forward.

4. Remove the Fan Motor assembly by loosening 2 screws

and disassembling the shroud.

5. Pull out the fan and separate the Fan Motor and Bracket.

FAN MOTOR

BRACKET

MOTOR

Ice fan assembly

FAN

3-5 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and

FUSE-M.

The Defrost Sensor works to defrost automatically. It is

attached to the metal side of the Evaporator and senses its

temperature. At 46°F (8°C), it turns the Defrost Heater off.

Fuse-M is a safety device for preventing over-heating of the

Heater when defrosting.

1. Pull out the grille assembly. (Figure 4)

2. Separate the connector with the Defrost Control

assembly and replace the Defrost Control assembly after

cutting the Tie Wrap. (Figure 5)

GRILLE ASSEMBLY

Figure 4 Figure 5

DEFROST-CONTROL

ASSEMBLY

GRILLE

- 7 -

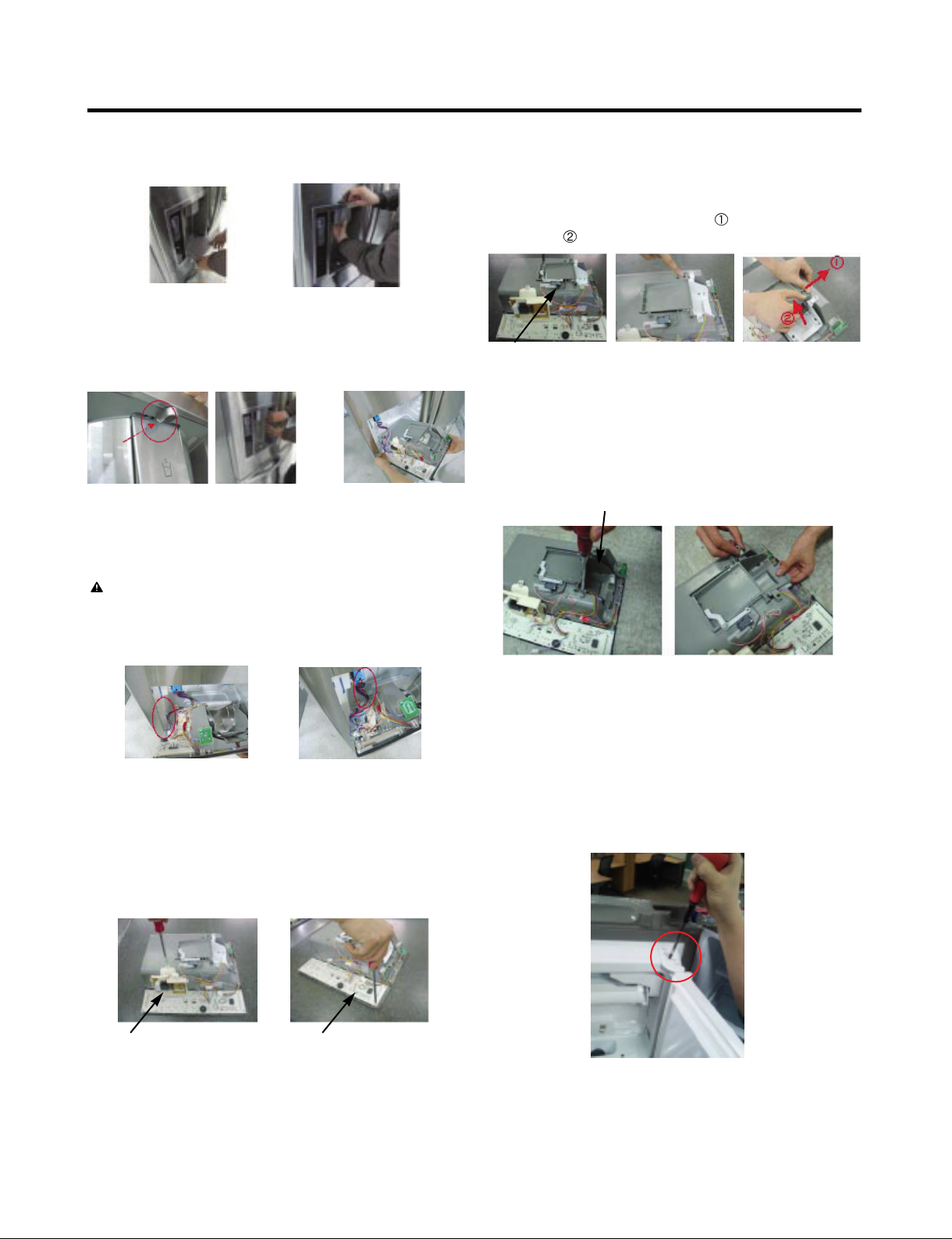

3-6 LAMP

Unplug Refrigerator, or disconnect power at the circuit

breaker.

If necessary, remove top shelf or shelves.

3-6-1 Refrigerator Compartment Lamp

1) Release 2 screws.

2) Hold both ends with your both hands and pull it

downward to remove it.

3) Use a flat tool as shown below to remove the cover

lamp.

3-7 MULTI DUCT

1. Remove the upper and

lower Caps by using a

flat screwdriver, and

remove 2 screws.

(Figure 6)

2. Disconnect the lead wire

on the bottom position.

Figure 6

3-8 MAIN PWB

1) Loosen 3 screws on the PWB cover.

4) As shown below, use a flat tool to remove the cover

lamp.

Cover, Lamp

3-6-2 Freezer Compartment Lamp

1. Unplug refrigerator power cord from outlet.

2. Remove screw with driver.

3. Grasp the cover Lamp, pull the cover downward.

LED, Assembly Case Lamp

2) Remove the PWB cover

3) Disconnect wire harness and replace the main PWB in

the reverse order of removal.

- 8 -

3-9 DISPENSER

1) Pull out the drain 2) Hold the inner side of

cover dispenser with

both hands at the handle

side to pull it out forward.

3) If nozzle is interfered with button,

push and pull out the bottom of

button.

CAUTION: When replacing the dispensor cover in the

reverse order of removal, be careful that the lead wire

does not come out and the water tube is not pinched by

the dispensor.

4) Remove the

connected part

of Lead wire.

3-11 ICE BUTTON ASSEMBLY

1) Remove the screw fixing the button lever.

2) Push the spring from the hanging hook to remove it.

3) Apply some pressure to the rib in

button in

Button Lever

direction.

direction and lift the

3-12 WATER BUTTON ASSMEBLY

1) Remove screws.

2) Grasp the Button assembly and lift up.

Button Lever

3-10 DISPLAY PCB

As shown below, remove 1 case PCB fixing screw.

Remove the display PCB fixing screw.

Case, PCB Display PCB

3-13 ICE COMPARTMENT DOOR REPLACEMENT

1) Loosen the front screw as shown in the picture.

2) Lift up the hinge with one hand.

3) Pull out the Ice Compartment Door with the other hand.

hinge

- 9 -

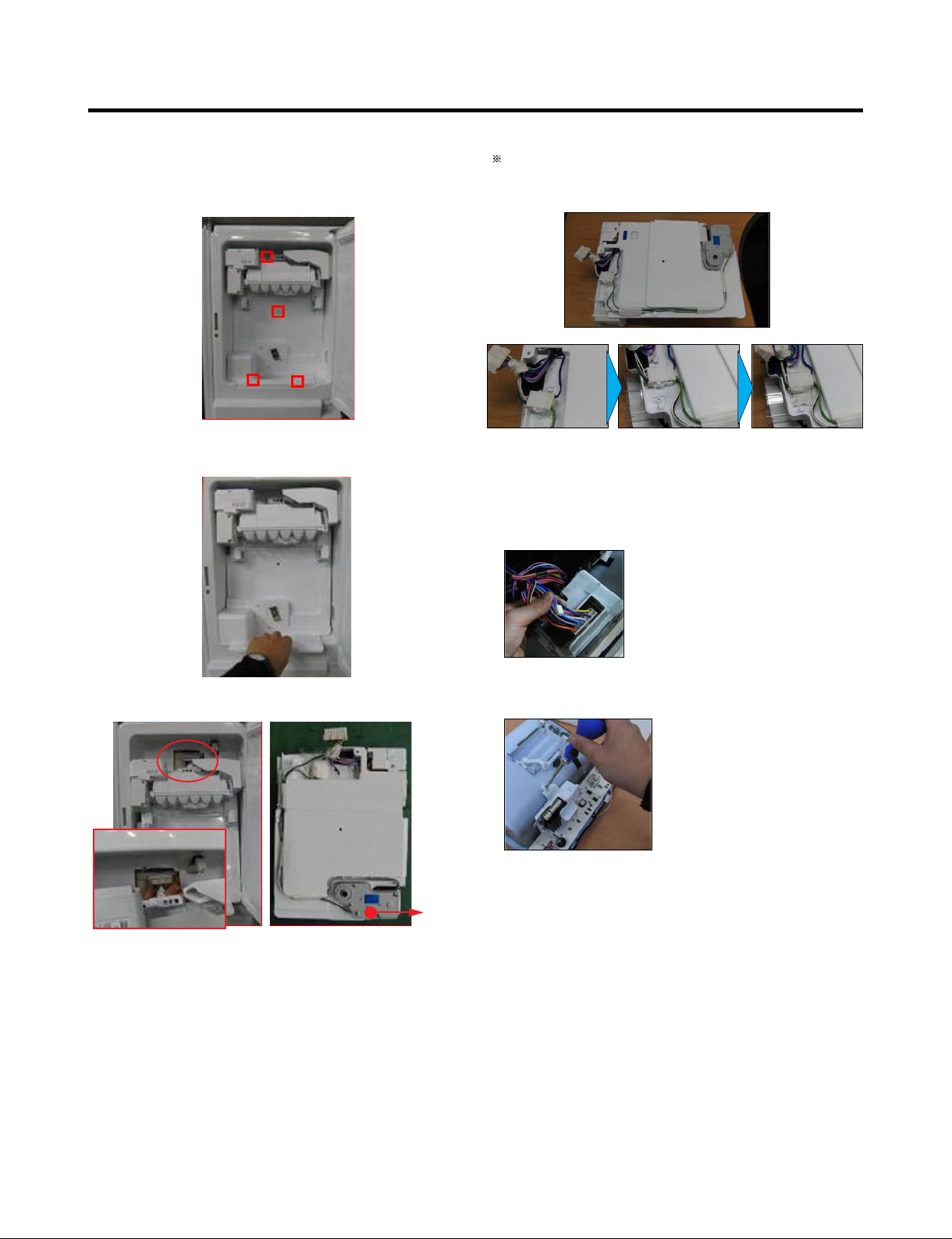

3-14 ICEMAKER REPLACEMENT

1) Remove the stainless screws marked in the picture

below.

2) Grasp the bottom of motor cover assembly and pull it out

slowly.

Caution: Check to see if the housing is stuck to mold and

taped. If the housing is not on its original position, it will

disturb Cover, motor to be positioned to the unit.

3-15 SUB PWB FOR WORKING DISPENSER

1) Disconnect the wire harness.

3) Disconnect wire harness from wall of compartment.

2) Loosen the screw on the sub PWB and replace the sub

PWB in the reverse order of removal.

In-door

motor

- 10 -

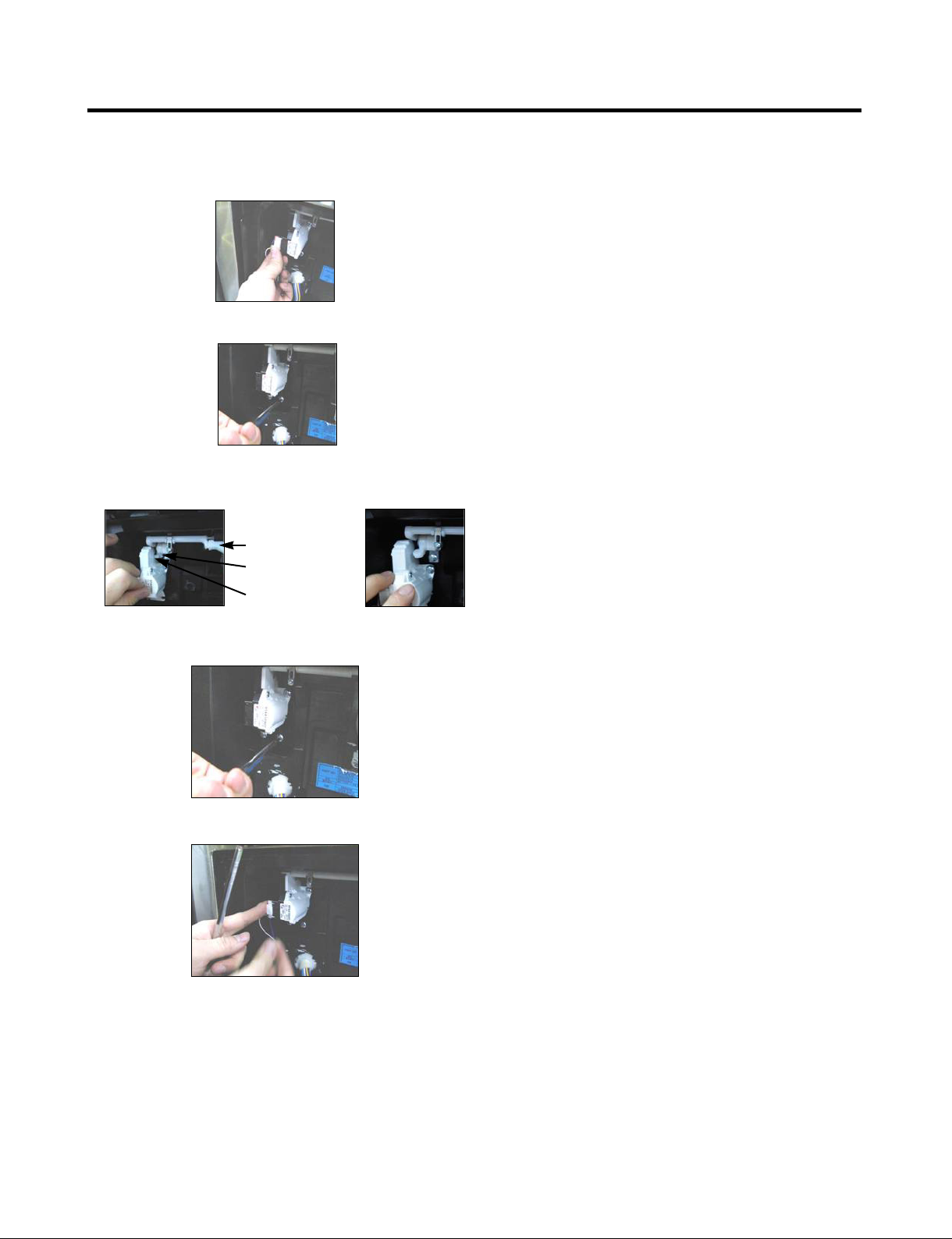

3-16 CAP DUCT MOTOR REPLACEMENT

1) Separate the Housing of the Cap Duct Motor.

2) Unscrew 3 screws to disassemble the motor.

3) When replacing to a new Motor, always check position of

the Duct Door and Link to install the Motor.

Duct Door

Link

Cap Duct Motor

NG Position

4) Assemble on the screws.

5) Connect the Housing.

- 11 -

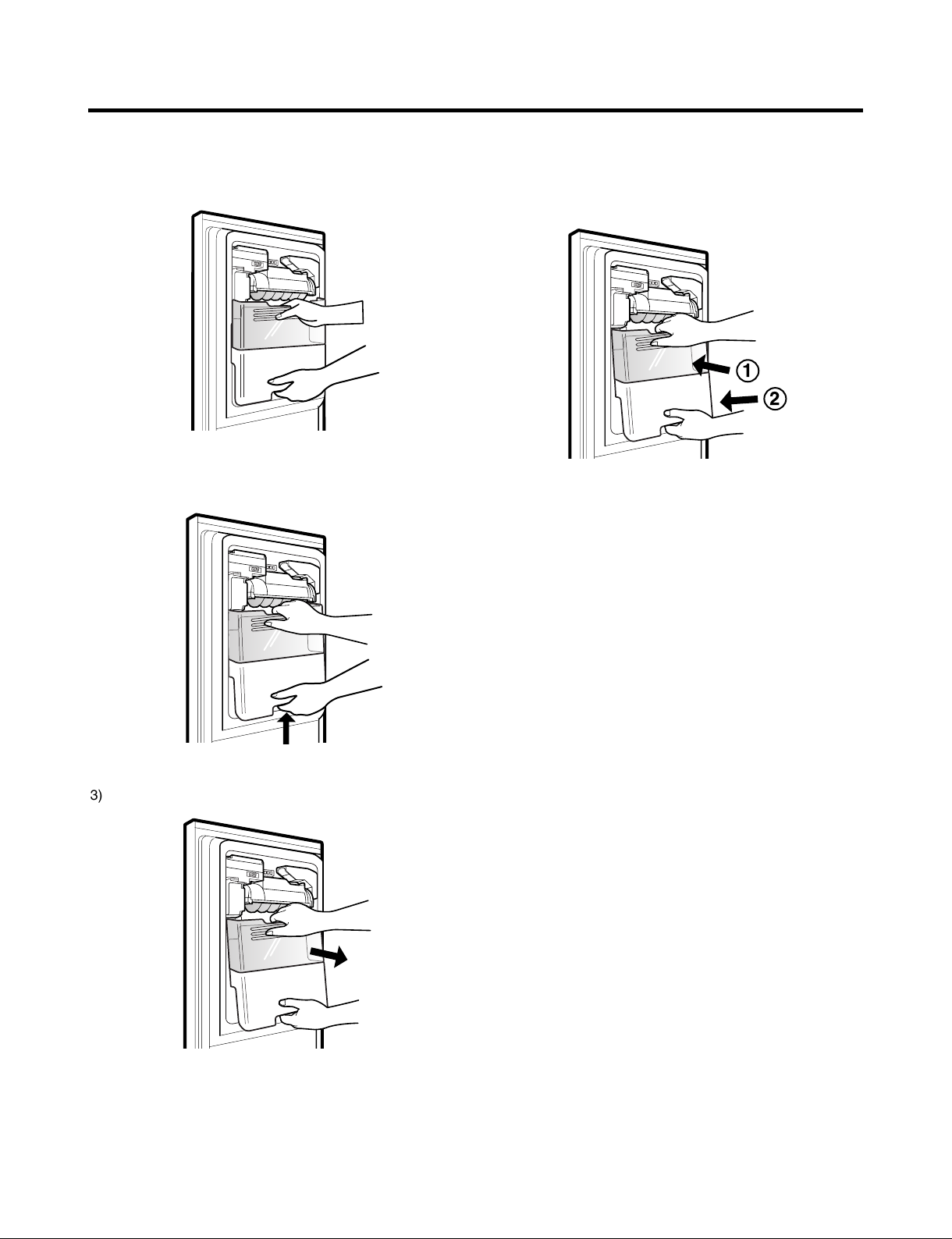

3-17 HOW TO REMOVE THE ICE BIN

1) Grip the handles, as shown in the picture.

2) Lift the lower part slightly.

3-18 HOW TO INSERT THE ICE BIN

1) Insert the Ice Bin, slightly tilting it to avoid touching the

Icemaker. (Especially, Ice-Detecting Sensor)

3) Take the Ice Bin out slowly.

- 12 -

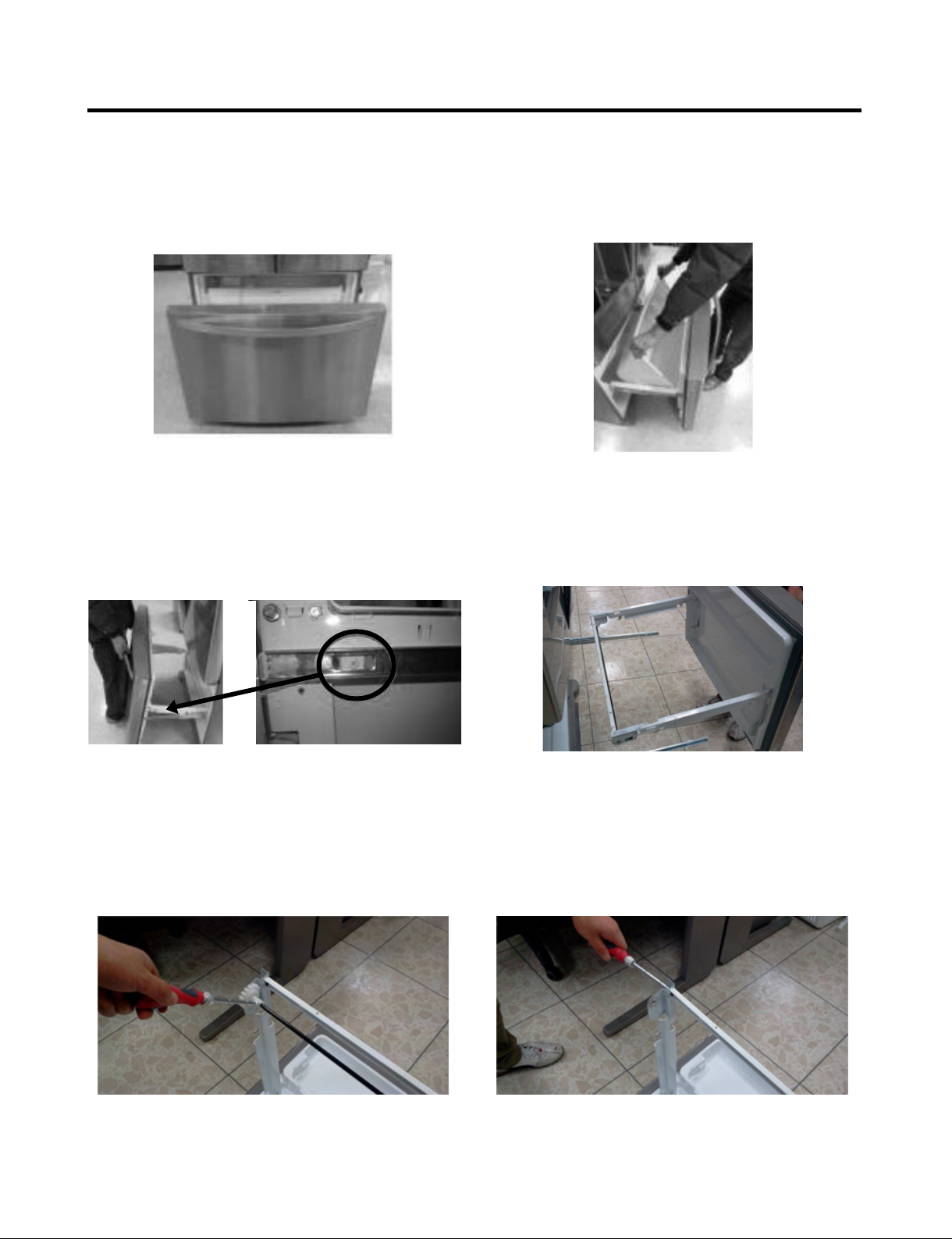

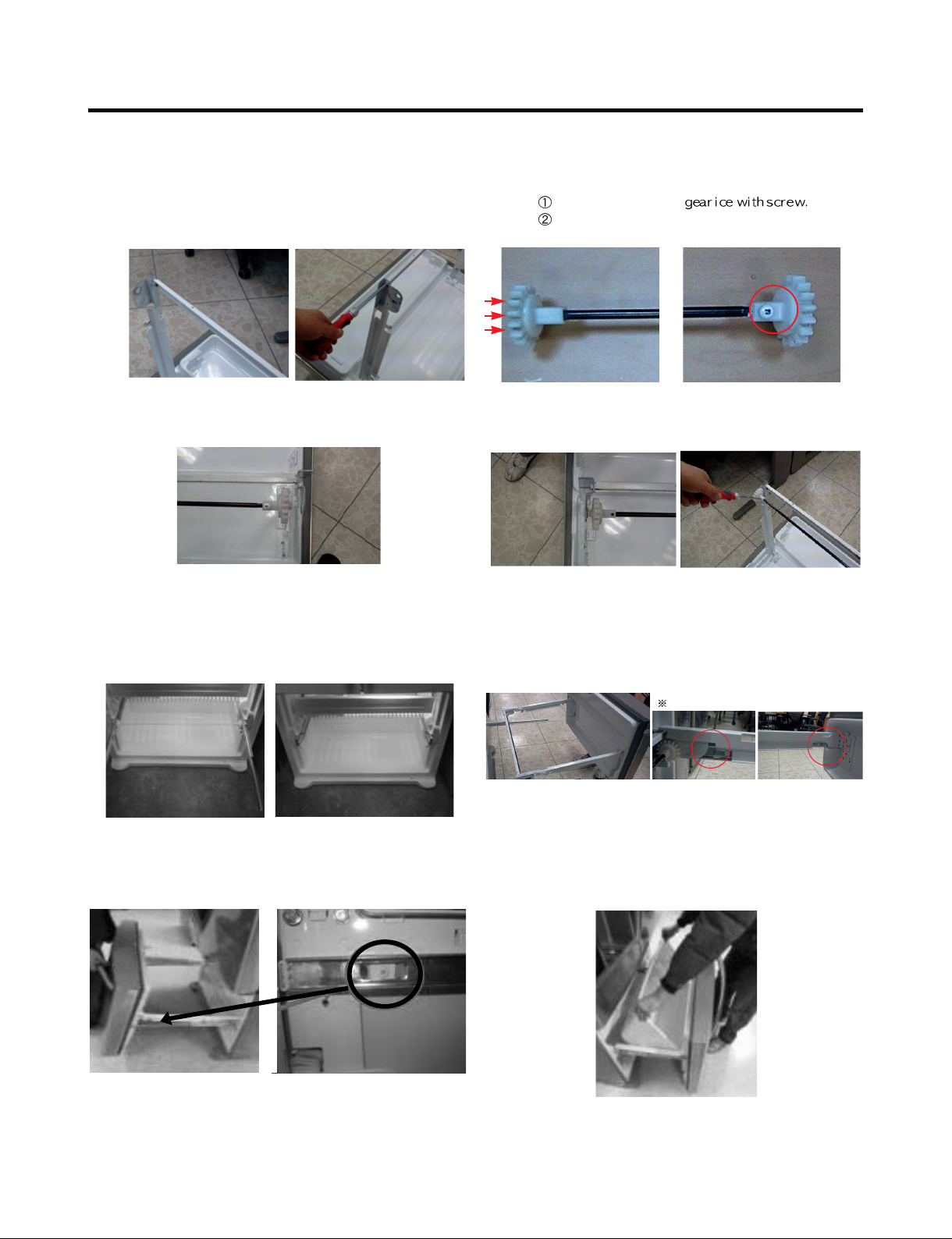

3-19 HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER

3-19-1 Follow Steps to Remove

Step 1) Open the freezer door.

Step 3) Remove the two screws from the guide rails (one

from each side).

Step 2) Remove the lower basket.

Step 4) Removal of the freezer door is done by lifting

clear of the rail support.Fully extend both rails.

Step 5) Remove only 1 screw of gear ice, and disassemble

the bar and gear ice

Step 6) Remove 2 screws of both side of supporter covers

tv and disassemble the supporter cover tv.

- 13 -

3-19-2 Follow Steps to Reinstall

Step 1) Insert both side of supporter cover tv into connector

rails, and then screw them.

Step 3) Put gear ice assembled with the bar by screw into

connector rail’s hole.

Step 5) The rail system will align itself by pushing the rails

all the way into the freezer section.

Pull the rails back out to full extension.

Step 2) Assemble a bar and

Push the otherside of the gear to inside of the bar.

Step 4) Insert opposite gear ice into connector rail and

screwthem

Step 6) Reinstall the freezer door by inserting the rail tabs

into the guide rail.

Step 7) Reinstall the two screws into the guide rails

(one from each side).

Assemble them like as pictures

Step 8) Reinstall the lower basket, and close the freezer

door.

- 14 -

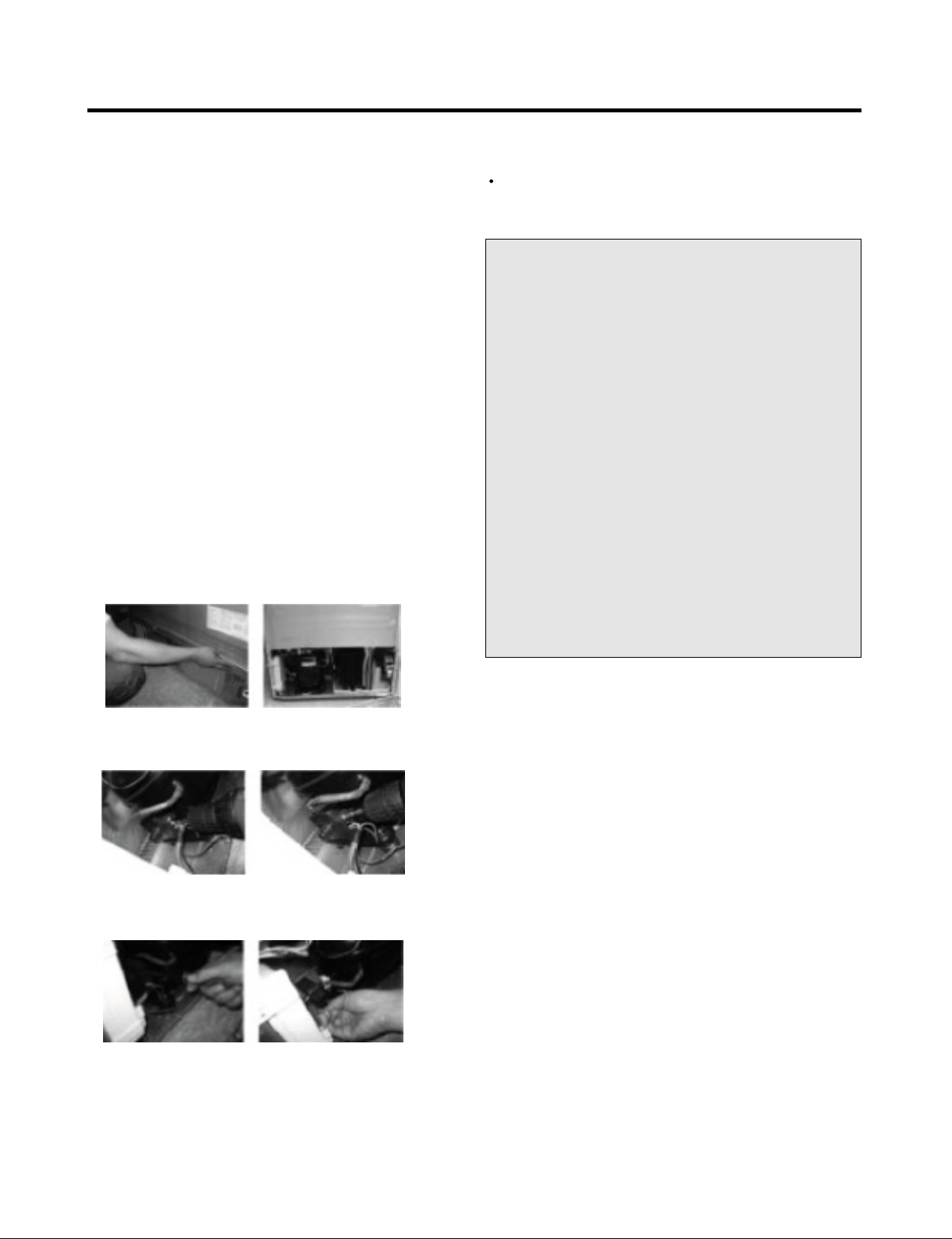

3-20 WATER VALVE DISASSEMBLY METHOD

1) Turn off the water. Then separate the water line from the

valve.

3-21 FAN AND FAN MOTOR DISASSEMBLY

METHOD

1) Using a short screwdriver, loosen one SCREW in DRAIN

PIPE ASSEMBLY and one connected to the MOTOR

COVER.

MOTOR COVER

2) Separate the Cover Back M/C and Valve Screw.

Cover Back M/C

3) Separate the housing and pull out the valve.

Housing

4) Lay a dry towel on the floor and get ready to spill water

from the water filter. Pull out the Cilp. Then press the

collet to separate the tube from the connector and pour

out the water until emptied.

2) Pull and separate the FAN ASSEMBLY and MOTOR

turning counterclockwise based on the MOTOR SHAFT.

FAN ASSEMBLY

The assembly is in the reverse order of the disassembly

and take special care for the following details.

1. Be careful not to bend the tube during assembly.

2. Press the WATER DISPENSER button until water pours

out and check for leakage in the CONNECTOR TUBE (It

differs by the water pressure but usually takes about 2

minutes until water pours out.)

MOTOR

Collet

Tube

Insert Line

Clip

- 15 -

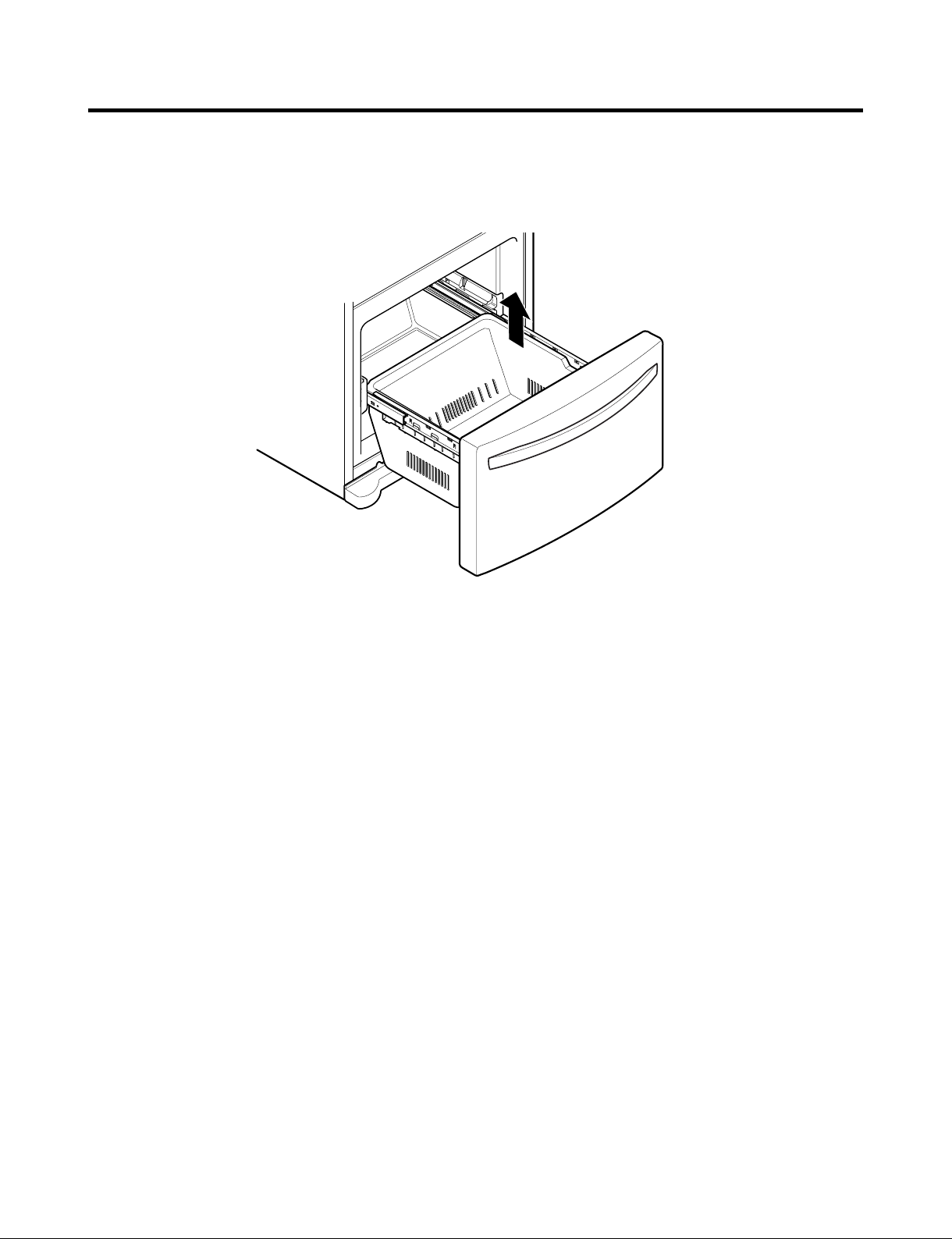

3-22 FREEZER DRAWER

To remove the freezer drawer, pull the drawer open to full extension. Remove the lower DuraBase ®basket by lifting the

basket from the rail system.

- 16 -

4. ADJUSTMENT

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the Cover PTC

Compressor may fail due to breakdown of their

insulating capabilities.

(4) Always use the Parts designed for the compressor and

make sure it is properly attached to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part number

and model number. Use only approved substitute parts.

4-1-3 Remove the cover PTC

4-1-4 Compressor protection logic

Since linear Comp conducts linear reciprocating motion,

we have protection logic for compressor, motor and PCB

as the below.

- Stroke Trip

During the operation, if stroke is above the target value,

decrease the target volt by 3V.

- Current Trip

Current trip is set in order to protect compressor

mechanical part and drive from the overcurrent that might

arise during the operation.

Check the current for every 416.7㎲ and if the Trip

exceeds 1.86Arms more than three times at Comp ON,

forcibly stop and restart six minutes later.

- Lock Piston Trip

If stroke is under 5mm even if the current is more than

14Arms, Take it as ‘piston lock’ and restart after 2’30” of

Comp OFF. Check the current and stroke for every

416.7㎲ and if the condition fits more than three times at

Comp ON, The Lock Point Trip occurs.

- IPM fault Trip

It occurs if FO signal received from IPM is LOW. For

every 416.7㎲, check whether FO signal is LOW. The trip

occurs if it is found three times during the five

periods(83ms).

(1) Remove the Cover Back M/C

(2) Loosen two screws on comp base

(3) Use a L-shaped flap tool to pry off the cover

(4) Assembly in reverse order of disassembly

- 17 -

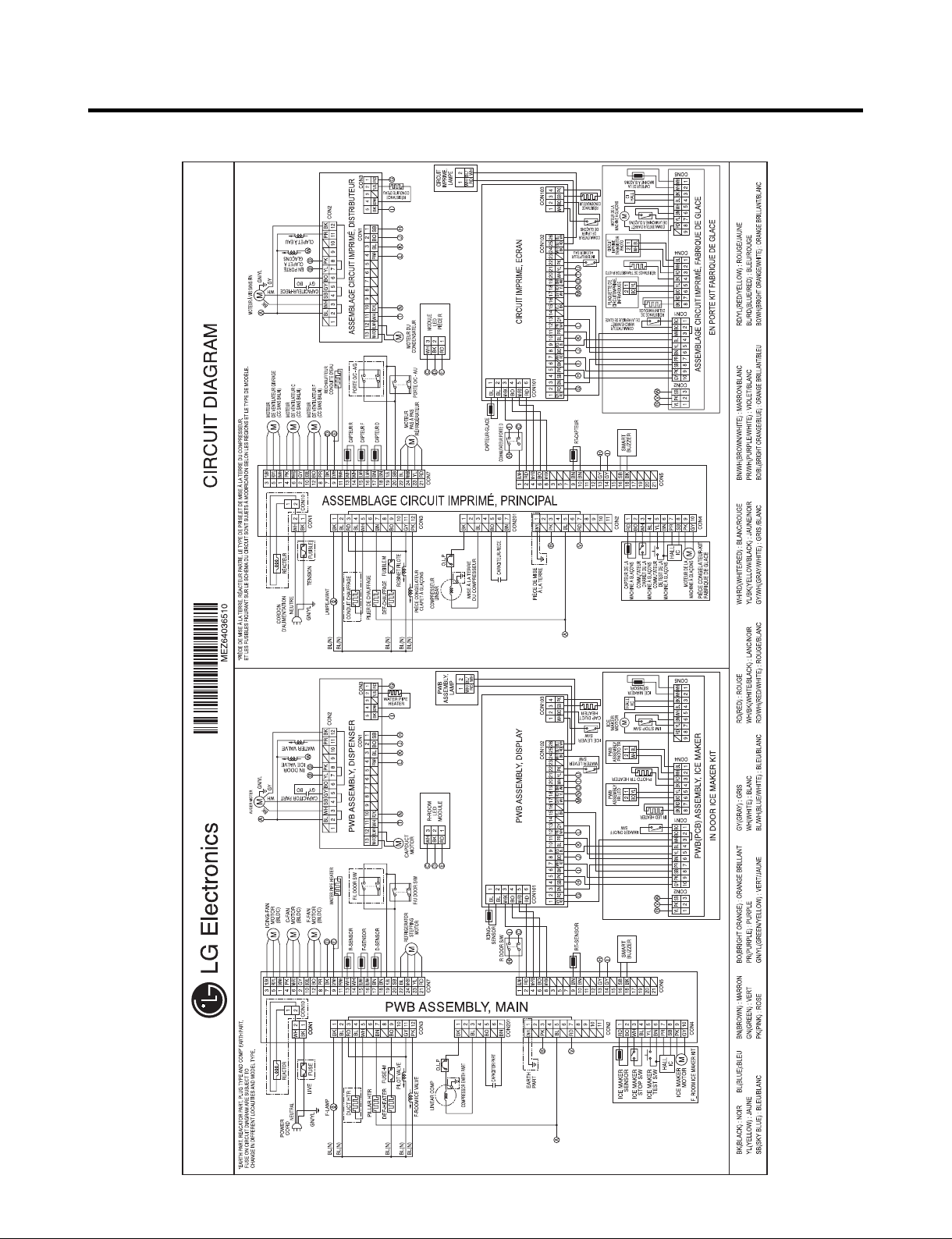

5. CIRCUIT DIAGRAM

- 18 -

6. TROUBLESHOOTING

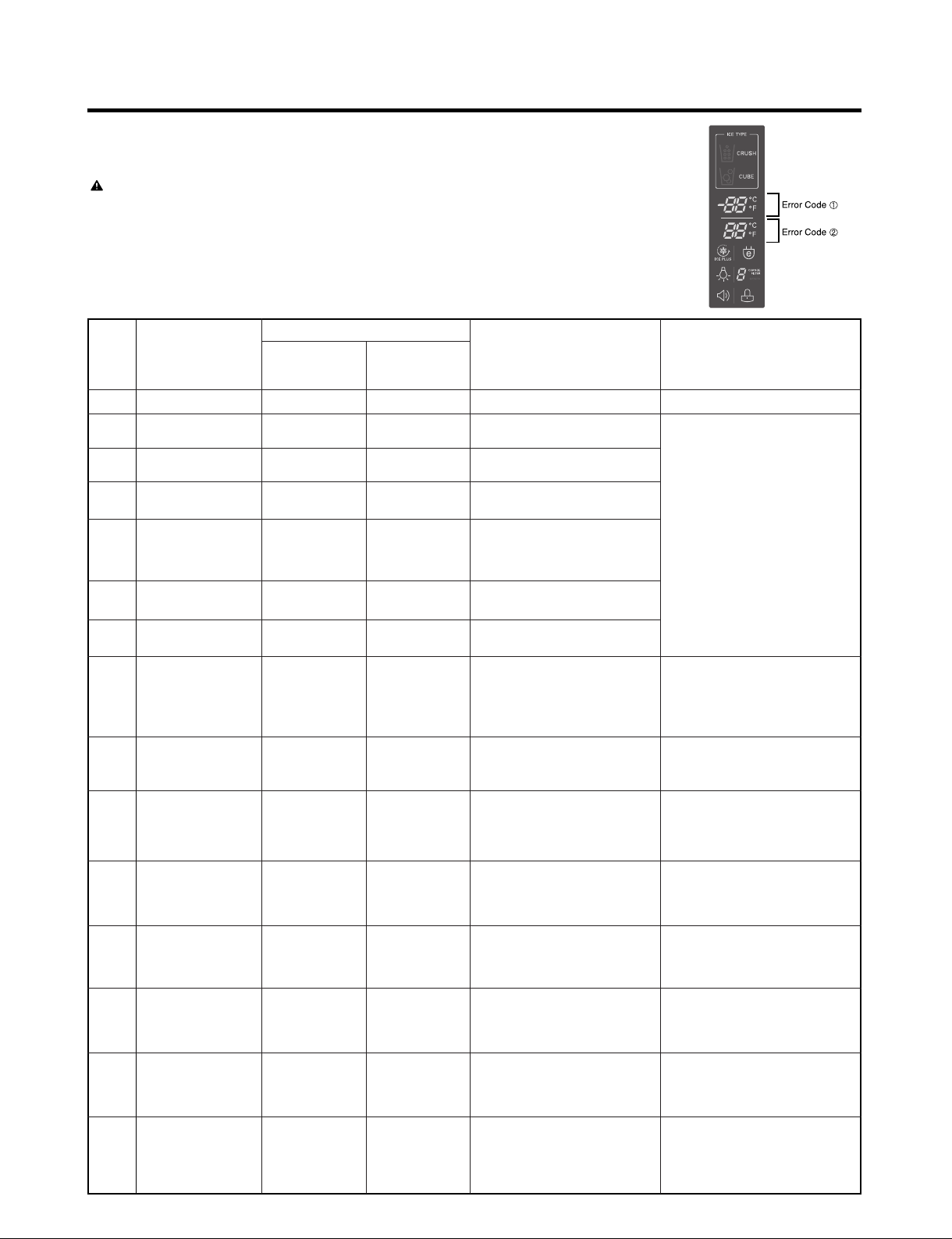

6-1 ERROR CODE SUMMARY

WARNING: When you check the Resistance values,

be sure to turn off the power.

And wait for the voltage-discharge sufficiently.

NOTE) 3 hours before the error : Press the Ice Plus button and Freezer button simultaneously

3 hours after the error : All errors, except for "Er rt", "Er SS",

"Er IS(except for Icing sensor)", "Er gF", "Er It" error, are displayed.

"Er IS" which is displayed without input of user is the error of Icing Sensor.

Error Display

Error Detection

NO

1 Normality None Normal operation of Display

2

3

4

5

6

7

8

9

Category

Freezer Sensor

Error

Refrigerator

Sensor Error

Defrosting

Sensor Error

Icing Sensor

Error

Pantry sensor

error

Room Temp

Sensor Error

Ice maker kit

defect

Flow

Meter(Sensor)

Defect

Freezer

Temperature

(Error code

Er FS

Er rS

Er dS

Er IS

Er SS

Er rt

Er It

Er gF

Refrigerator

Temperature

①)

(Error code ②)

Error Generation Factors Remark

Short or Disconnection

of Freezer Sensor

Short or Disconnection

of Refrigerator Sensor

Short or Disconnection

of Defrosting Sensor

Short or disconnection of

the sensor about Ice maker

(Icing sensor, Ice maker

sensor)

Short or Disconnection

of Pantry Sensor

Short or Disconnectoin of

Room temp.sensor

Other Electric system error

such as moter, gear, Hall IC,

operation circuit within I/M kit

Error of flow meter or water

input or low water pressure

Check each sensor and its

connector.

When the ice does not drop

even when the I/M Test S/W

is pressed

(same as model applied

Twisting Ice Maker before)

Error of flow meter or water

input or low water pressure or

flow meter connection

10 Poor Defrosting Er dH

11

12

13

14

15

Abnormality of

BLDC FAN Motor

for Ice Making

Abnormality of

BLDC FAN Motor

for Freezer

Abnormality of

BLDC FAN

MOTOR For

Refrigerator

Abnormality of

BLDC FAN Motor

for Mechanic

Room

Communication

Error

Er IF

Er FF

Er rF

Er CF

Er CO

Even though it is passed

1 hour since then Defrosting,

if Defrosting sensor is not

over 46°F(8°C), it is caused

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

Communication Error

between Micom of Main PCB

and Display Micom

- 19 -

Temperature Fuse

Disconnection, Heater

disconnection, DRAIN Jam,

Poor Relay for Heater

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor Communication

connection,Poor TR of

Transmitter and Receiver

Tx/Rx between display and

main board.

NO

Error Detection

Category

Error Display

Freezer

Temperature

(Error code

Refrigerator

Temperature

①)

(Error code ②)

Error Generation Factors

Remark

16

17

18

19

Freezer Shelf

Sensor Error

Freezer Shelf Ice

maker kit defect

Refrigerator Shelf

Icing Sensor Error

Refrigerator Shelf

Ice maker kit

Icing

defect

Er Id

Er IU

Er IS

Er It

Short or disconnection of the

sensor about freezer shelf

Ice maker (Icing sensor, Ice

maker sensor)

Other Electric system error

such as motor, gear, Hall IC,

operation circuit with in

freezer shelf I/M Kit

Short or disconnection of the

sensor about refrigerator

shelf Ice maker (Icing

sensor, Ice maker senseor)

Other Electric system error

such as motor, gear, Hall IC,

operation circuit with in

Check each sensor at it’s

connector.

When the ice does not drop

even when the freezer shelf

I/M Test S/W is pressed

Check each sensor at it’s

connector

When the ice dose not drop

even when the refrigerator

shelf I/M Test S/W is

- 20 -

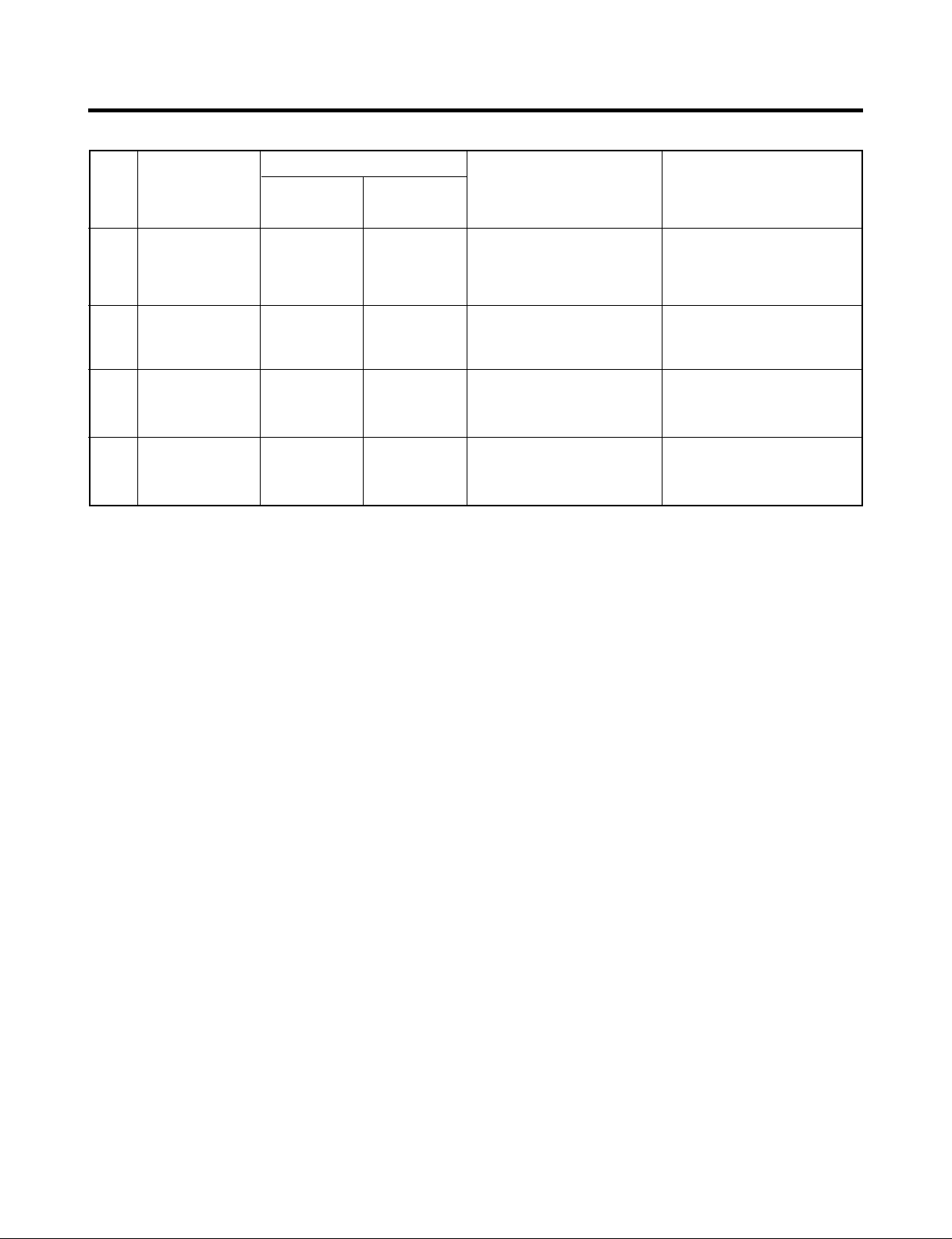

7. PCB PICTURE

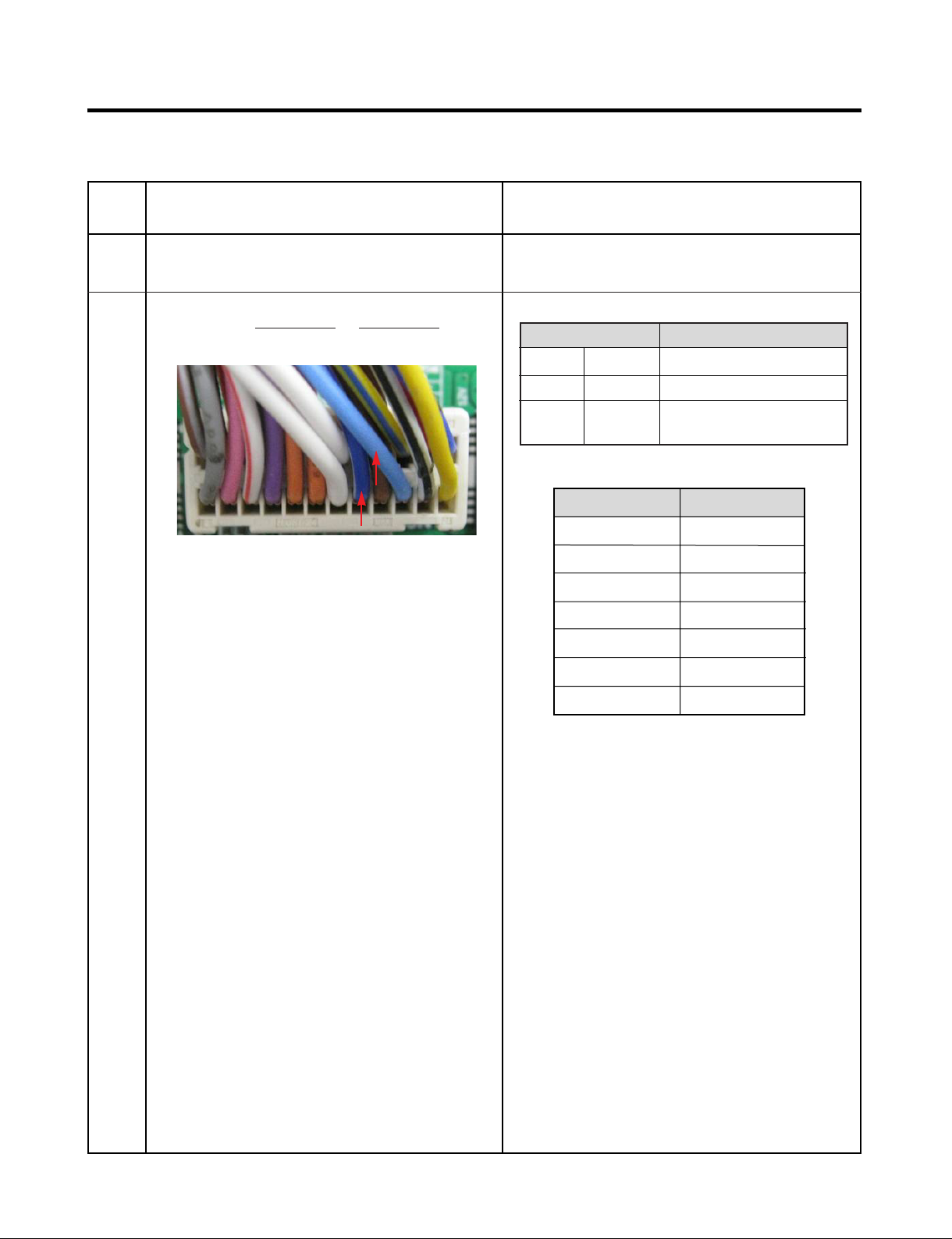

7-1 MAIN PCB

P/No & MFG

EBR73304220

(2011.07~)

CON1

CON201

Picture

CON2

CON3

CON5

CON7

CON4

- 21 -

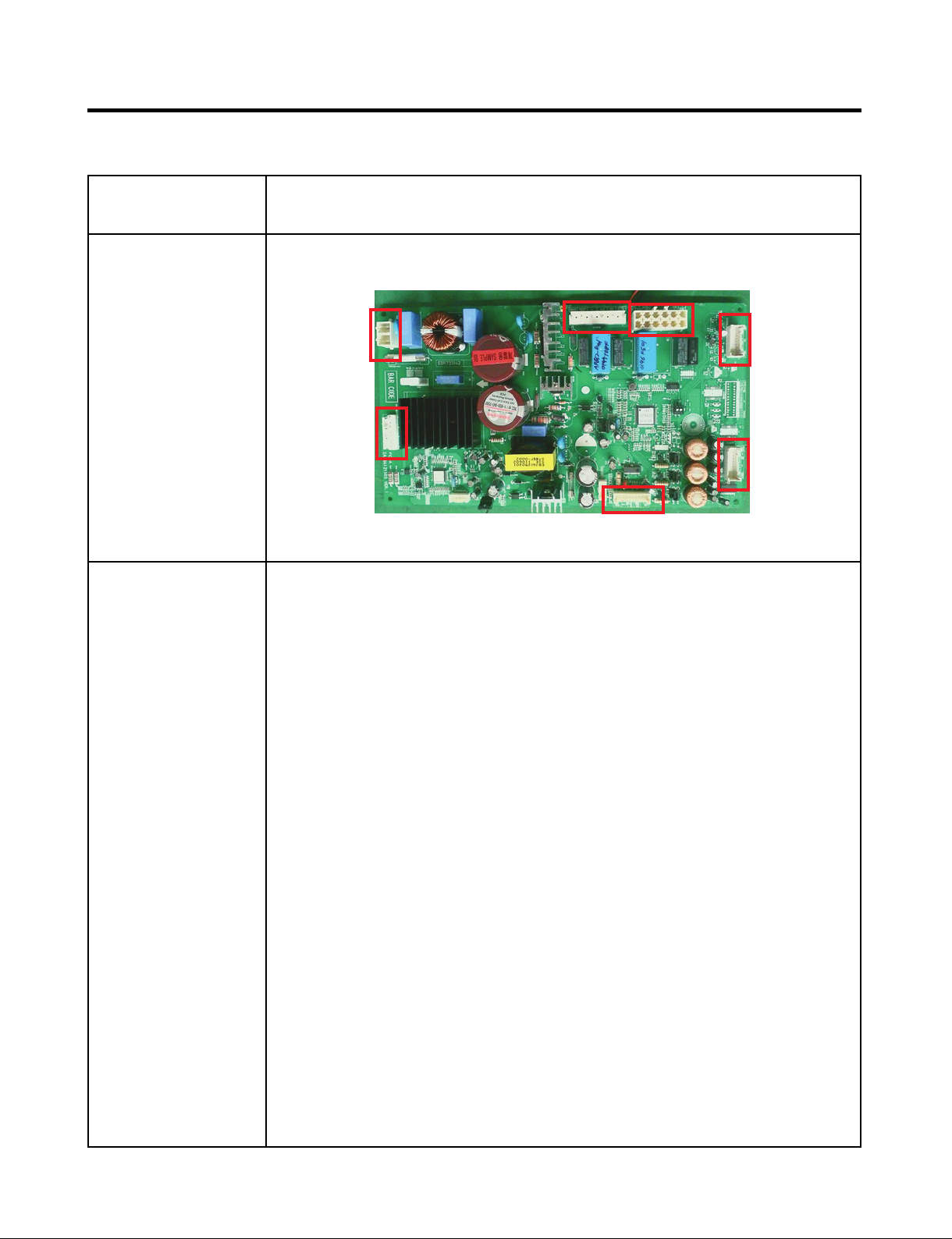

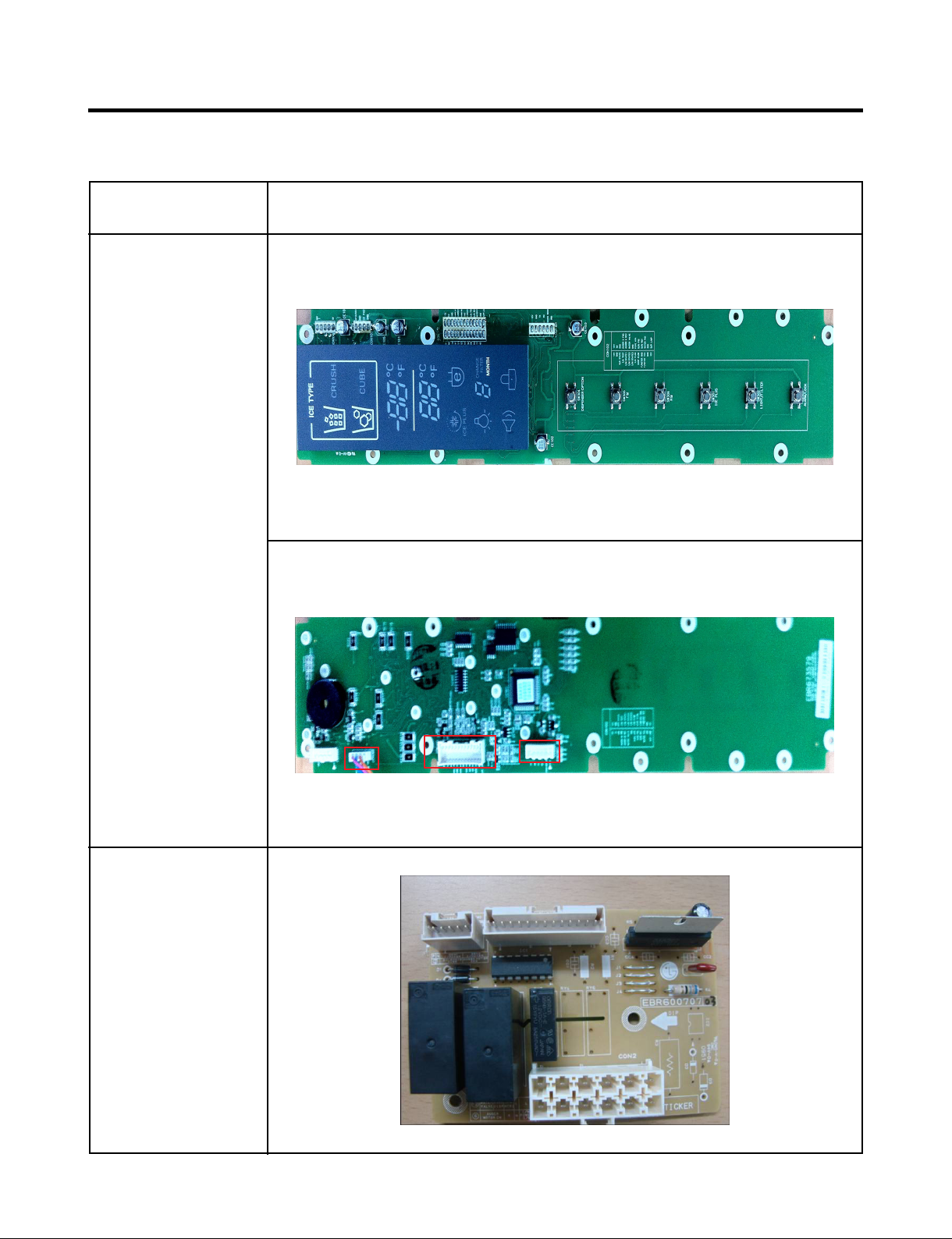

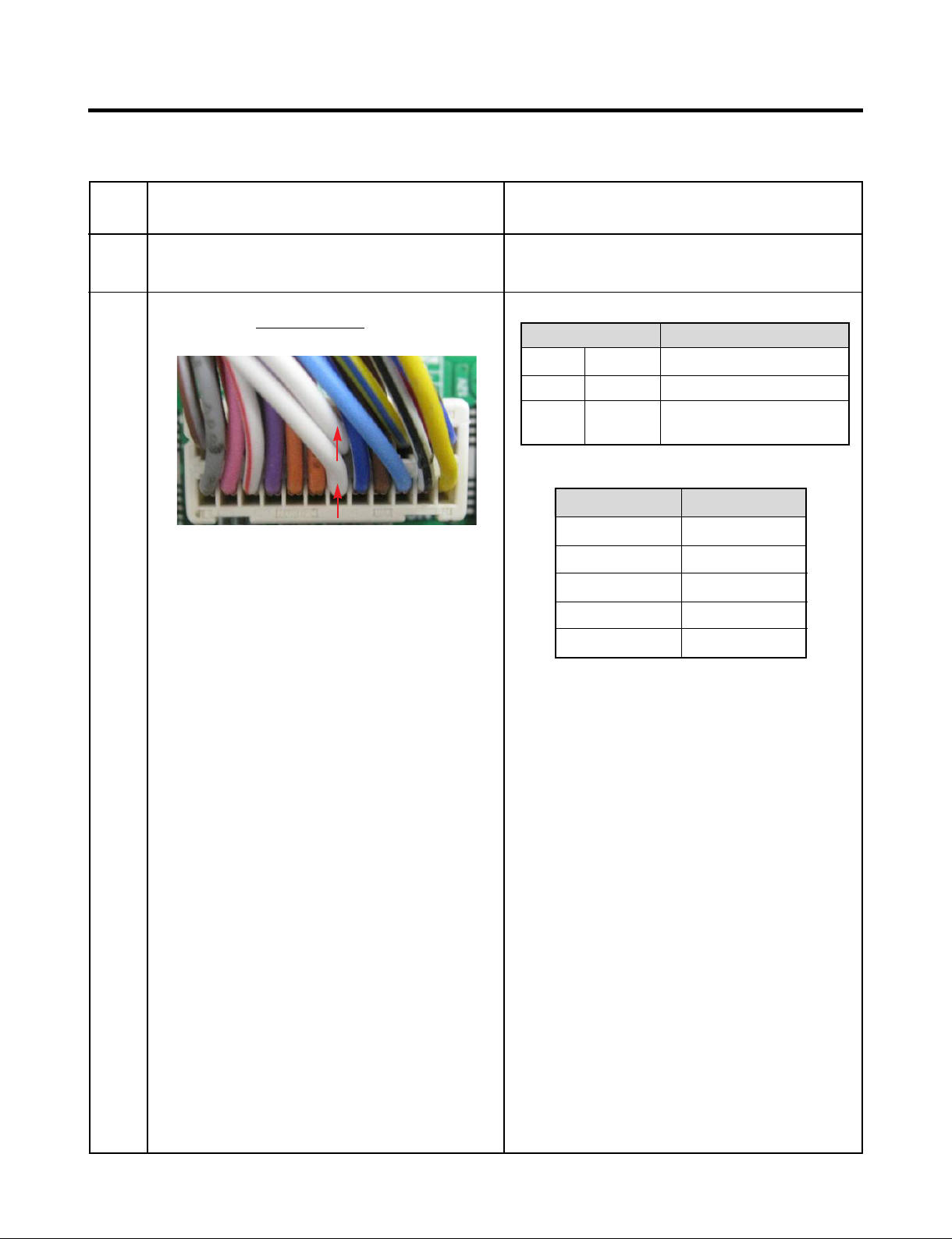

7-2 DISPLAY PCB & SUB PCB

P/No

Display PCB

EBR67357902

(2011.03~)

Picture

Sub PCB

EBR60070707

(2011.03~)

CON103 CON102

- 22 -

CON101

CON2

8.

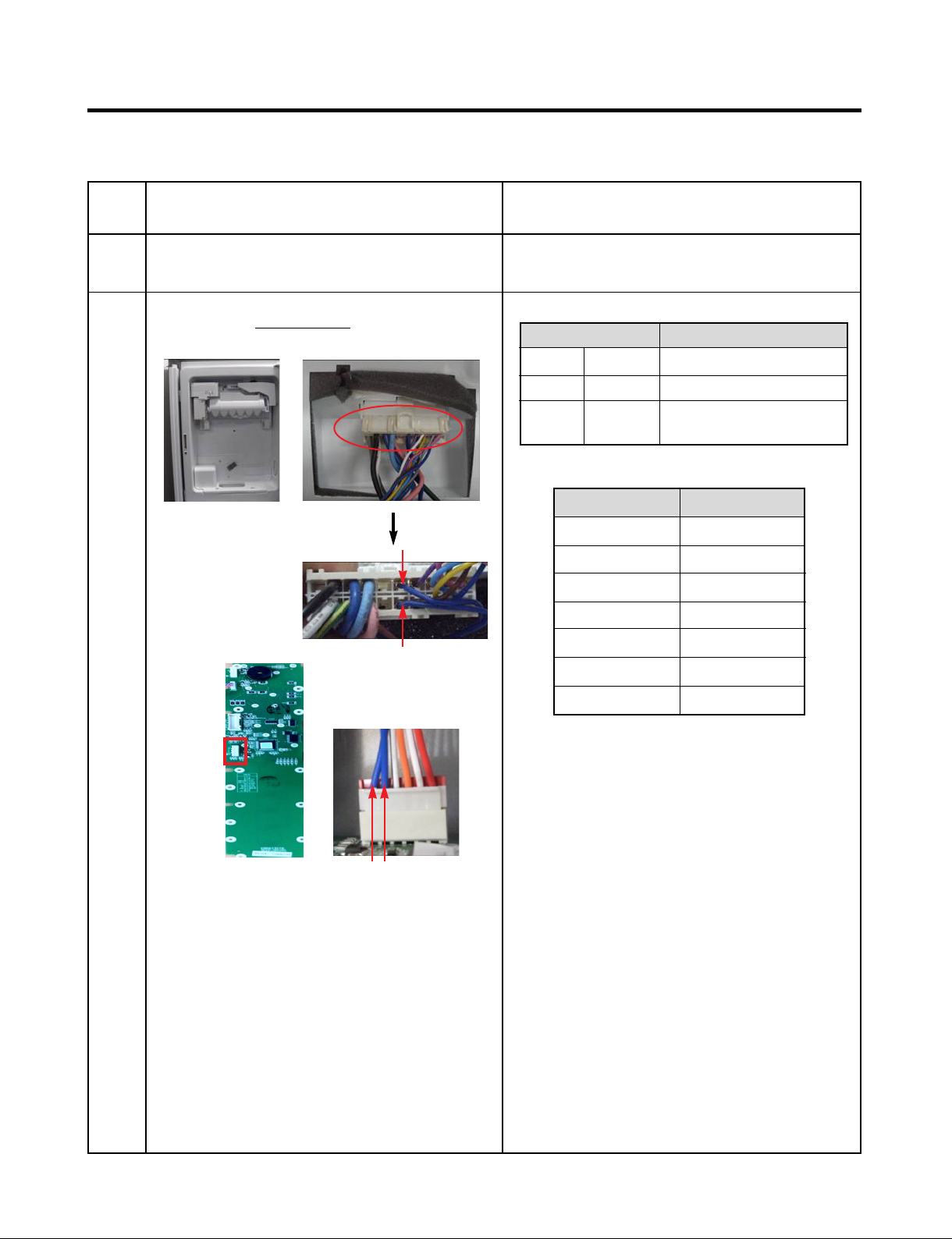

8-1 Freezer Sensor Error (Er FS)

TROUBLESHOOTING WITH ERROR DISPLAY

No

1

2

Checking flow

Check for a loose connection.

Check the Blue/White

CON7 on the main PCB

to Blue/White at

<CON7>

Result & SVC Action

Result SVC Action

Ω

0

OFF

Other

(1) To (2)

-22°F / -30°C

-13°F / -25°C

-4°F / -20°C

5°F / -15°C

14°F / -10°C

Short

Open

Normal

<Temperature table-1>

Change the sensor

Replace the refrigerator

Check the Temp and

resistance (Table-1)

Result

40 ㏀

30 ㏀

23 ㏀

17 ㏀

13 ㏀

23°F / -5°C

32°F / 0°C

※

The sensor is determined by

the temperature.

For example, 23㏀ indicates -4°F.

10 ㏀

8 ㏀

- 23 -

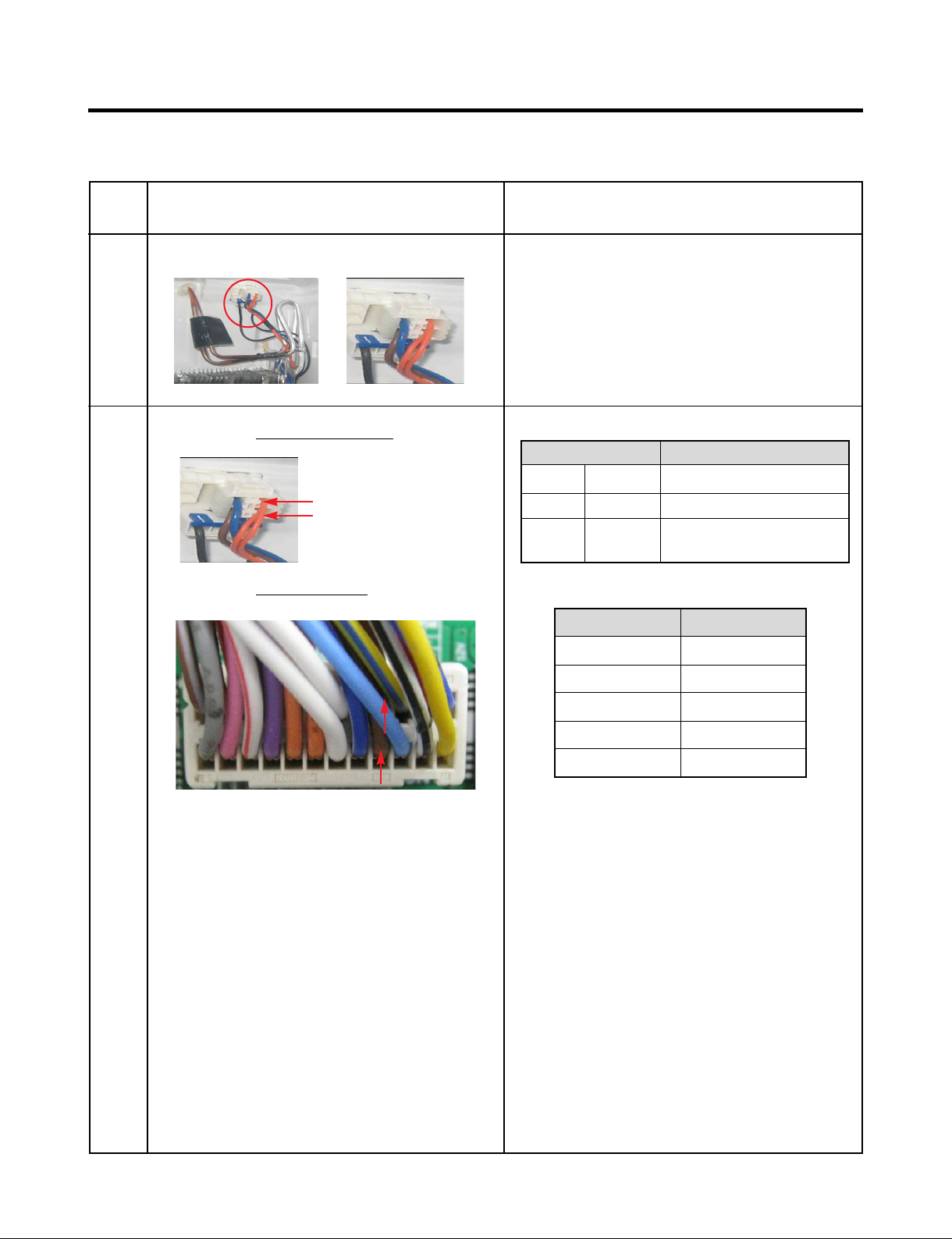

8-2 Refrigerator Sensor Error (Er rS)

No

1

2

Checking flow

Check for a loose connection.

Check the White to White

CON7 on the main PCB

<CON7>

at

Result & SVC Action

Result SVC Action

Ω

0

OFF

Other

Short

Open

Normal

<Temperature table-2>

(1) To (2)

23°F / -5°C

32°F / 0°C

41°F / 5°C

50°F / 10°C

59°F / 15°C

Change the sensor

Replace the refrigerator

Check the Temp and

resistance (Table-2)

Result

38 ㏀

30 ㏀

24 ㏀

19.5 ㏀

16 ㏀

※

The sensor is determined by

the temperature.

For example, 30㏀ indicates 32°F.

- 24 -

8-3 Icing Sensor Error (Er IS)

No

1

2

Checking flow

Check for a loose connection.

Check the Blue to Blue.

Result & SVC Action

Result SVC Action

Ω

0

OFF

Other

(1) To (2)

-22°F / -30°C

-13°F / -25°C

-4°F / -20°C

5°F / -15°C

14°F / -10°C

Short

Open

Normal

<Temperature table-1>

Change the sensor

Replace the refrigerator

Check the Temp and

resistance (Table-1)

Result

40 ㏀

30 ㏀

23 ㏀

17 ㏀

13 ㏀

CON101

23°F / -5°C

32°F / 0°C

※

The sensor is determined by

the temperature.

For example, 23㏀ indicates -4°F.

<CON101><Display>

10 ㏀

8 ㏀

- 25 -

8-4 Defrost Sensor Error (F dS)

No

1

2

Checking flow

Check for a loose connection.

Check the Orange to Orange.

Check the Brown to Brown at

CON7 on the main PCB

Result & SVC Action

Result SVC Action

Ω

0

OFF

Other

Short

Open

Normal

<Temperature table-3>

(1) To (2)

23°F / -5°C

Change the sensor

Replace the refrigerator

Check the Temp and

resistance (Table-3)

Result

38 ㏀

<CON7>

32°F / 0°C

41°F / 5°C

50°F / 10°C

59°F / 15°C

※

The sensor is determined by

the temperature.

For example, 30㏀ indicates 32°F.

30 ㏀

24 ㏀

19.5 ㏀

16 ㏀

- 26 -

Loading...

Loading...