LG LFX28977ST/01, LFX28977WB/01, LFX28977SW/01, LMX28987 SERIES Service Manual

REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODEL :

LFX28977ST /01

LFX28977WB /01

LFX28977SW /01

ENC(Engineering Change Number)

LFX28977 /01

Loc No. SPECIFICATIONS

503F

120A

409E

405J

319C

319A

Cover Assembly, Lamp

Duct Assembly, Multi

LED Assembly

LED Assembly

Guide, Fan

Tray, Drip

- 2 -

CONTENTS

SAFETY PRECAUTIONS ....................................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................................. 3

2. PARTS IDENTIFICATION ................................................................................................................................................. 4

3. DISASSEMBLY ............................................................................................................................................................ 5-17

REMOVING AND REPLACING REFRIGERATOR DOORS ............................................................................................. 5

DOOR ............................................................................................................................................................................. 6-7

DOOR ALIGNMENT .......................................................................................................................................................... 7

FAN AND FAN MOTOR(Evaporator) ................................................................................................................................. 7

DEFROST CONTROL ASSEMBLY ................................................................................................................................... 8

LAMP ................................................................................................................................................................................. 8

MULTI DUCT ..................................................................................................................................................................... 9

MAIN PWB ..........................................................................................................................................................................9

DISPLAY PCB ....................................................................................................................................................................9

ICE BUTTON ASSEMBLY ..................................................................................................................................................9

FUNNEL REPLACEMENT ..................................................................................................................................................9

WATER BUTTON ASSMEBLY .........................................................................................................................................10

DUCT DOOR REPLACEMENT ........................................................................................................................................10

ICE CORNER DOOR REPLACEMENT ............................................................................................................................10

ICEMAKER ASSEMBLY ...................................................................................................................................................10

SUB PWB FOR WORKING DISPENSER ........................................................................................................................11

CAP DUCT MOTOR REPLACEMENT .............................................................................................................................11

AUGER MOTOR COVER .................................................................................................................................................12

HOW TO REMOVE A ICE BIN HOW TO REMOVE A ICE BIN.........................................................................................13

HOW TO INSERT A ICE BIN ............................................................................................................................................13

HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER ..............................................................................14-15

WATER VALVE DISASSEMBLY METHOD .....................................................................................................................16

FAN AND FAN MOTOR DISASSEMBLY METHOD .........................................................................................................16

PULL OUT DRAWER .......................................................................................................................................................17

4. ADJUSTMENT ........................................................................................................................................................... 18-19

COMPRESSOR ............................................................................................................................................................... 18

Introduction of E-Linear Compressor ...........................................................................................................................18-20

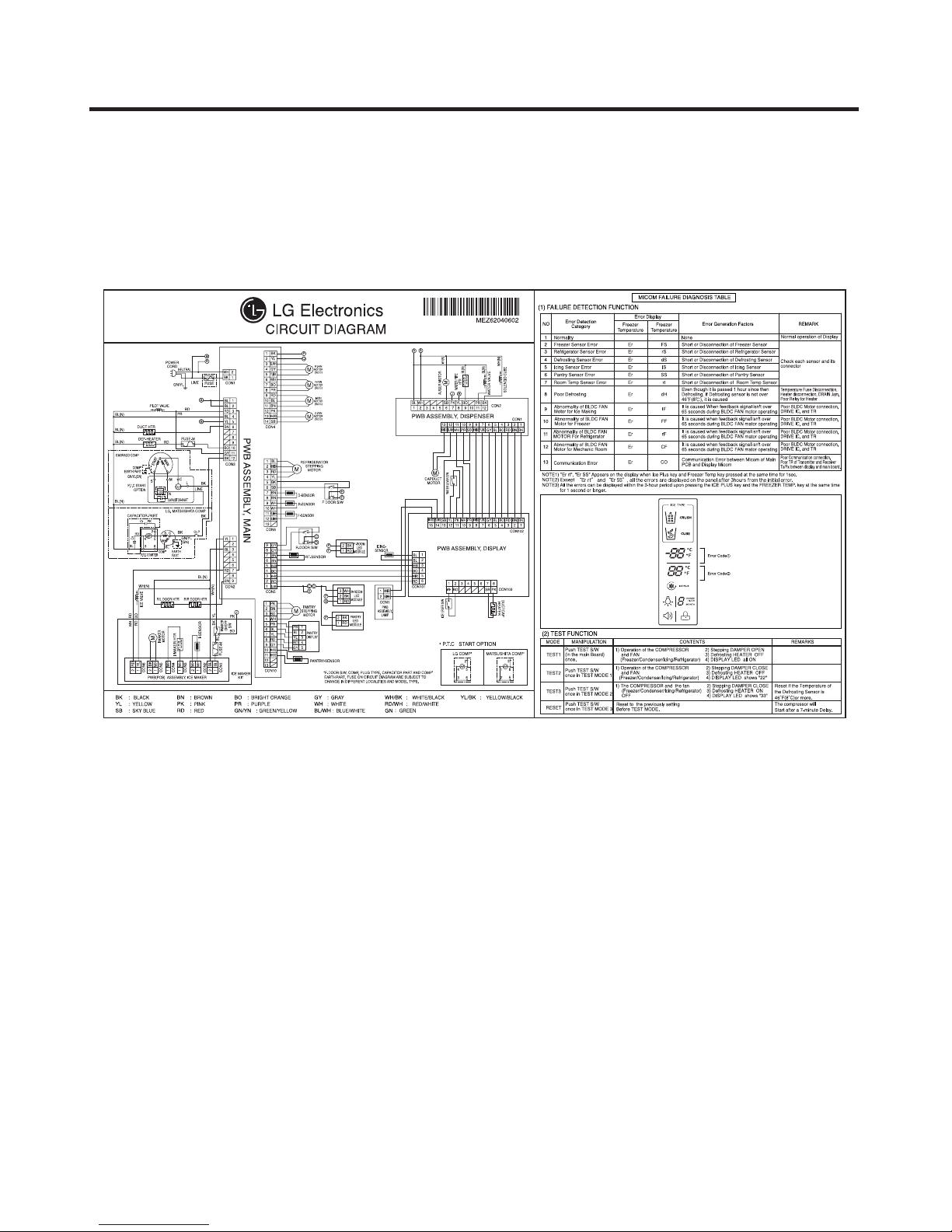

5. CIRCUIT DIAGRAM ........................................................................................................................................................ 21

6. TROUBLESHOOTING ................................................................................................................................................ 22-52

Error Code Summary ....................................................................................................................................................... 22

Troubleshooting With Error.......................................................................................................................................... 23-35

Troubleshooting Else .................................................................................................................................................. 36-54

7. COMPONENT TESTING INFORMATION .................................................................................................................. 55-63

8. TRBOUBLESHOOTING ............................................................................................................................................. 64-68

9. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER ........................................................................ 69-71

10. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM ........................................................................................... 72-76

11. EXPLODED VIEW & REPLACEMENT PARTS LIST

SAFETY PRECAUTIONS

Please read the following instructions before servicing your

refrigerator.

1. Unplug the power before handling any elctrical

componets.

2. Check the rated current, voltage, and capacity.

3. Take caution not to get water near any electrical

components.

4. Use exact replacement parts.

5. Remove any objects from the top prior to tilting the

product.

- 3 -

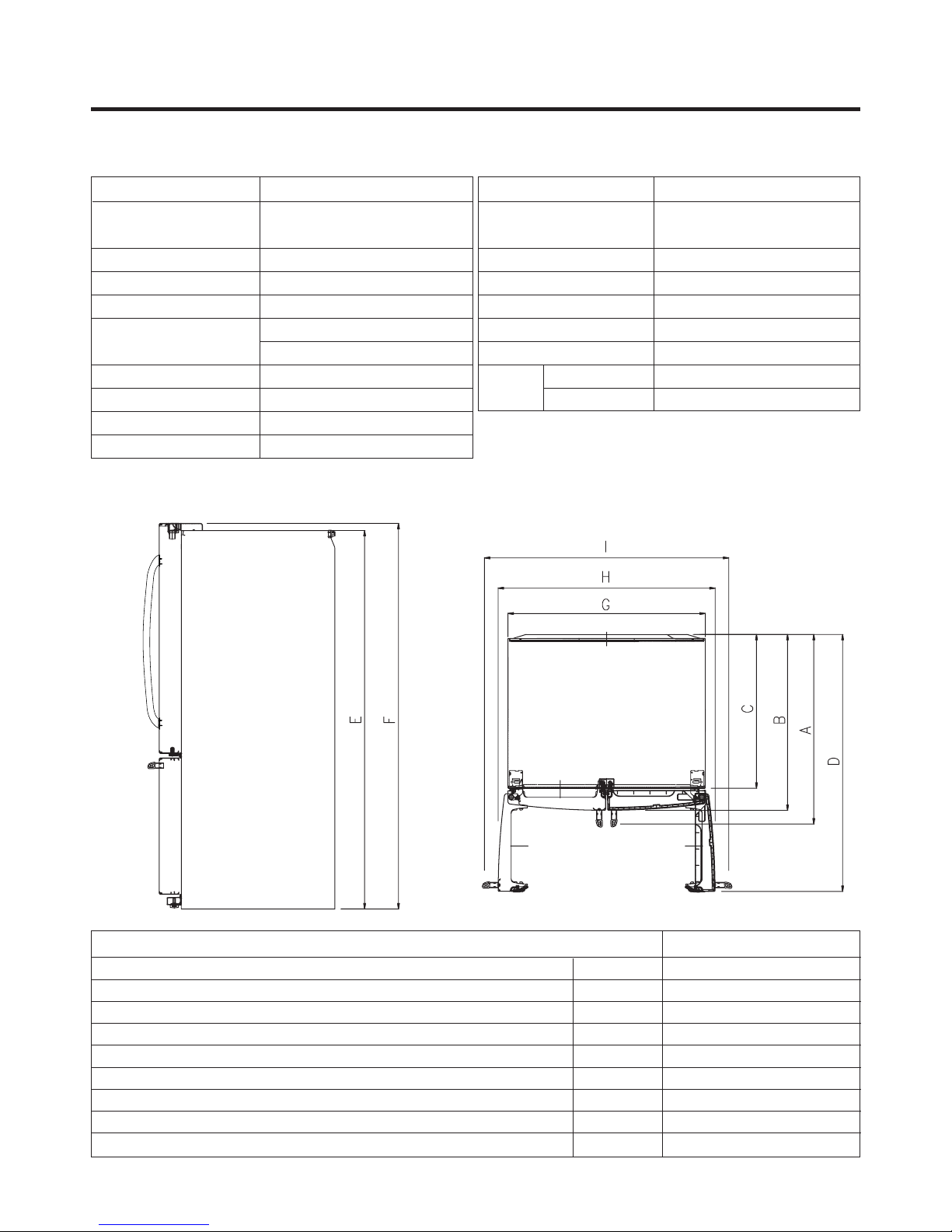

1. SPECIFICATIONS

28 cu.ft.

ITEMS

DOOR DESIGN

DIMENSIONS (inches)

NET WEIGHT (pounds)

COOLING SYSTEM

TEMPERATURE CONTROL

DEFROSTING SYSTEM

DOOR FINISH

HANDLE TYPE

INNER CASE

INSULATION

DIMENSIONS

SPECIFICATIONS

Side Rounded

3

35

/4 X 35 3/8 X 69 3/4 (WXDXH) 28cu.ft.

324(28cu.ft.)

Fan Cooling

Micom Control

Full Automatic

Heater Defrost

Embossed Metal, VCM, Stainless

Bar

ABS Resin

Polyurethane Foam

ITEMS

VEGETABLE TRAY

COMPRESSOR

EVAPORATOR

CONDENSER

REFRIGERANT

LUBRICATING OIL

DEFROSTING DEVICE

LAMP

REFRIGERATOR

FREEZER

SPECIFICATIONS

Clear Drawer Type

Linear

Fin Tube Type

Wire Condenser

R-134a (140 g)

ISO10 (280 ml)

SHEATH HEATER

LED Module(24)

LED Module(12)

Depth w/ Handles

Depth w/ Handles

Depth w/ o Door

Depth (Total with Door Open)

Height to Top of Case

Height to Top of Door Hinge

Width

Width (door open 90 deg. w/o handle)

Width (door open 90 deg. w/ handle)

Description LFX28977** /01

A

B

C

D

E

F

G

H

I

35 3/8 in

32 7/8 in

29 in

47 5/8 in

68 3/8 in

69 3/4 in

35 3/4 in

39 1/4 in

44 1/4 in

- 4 -

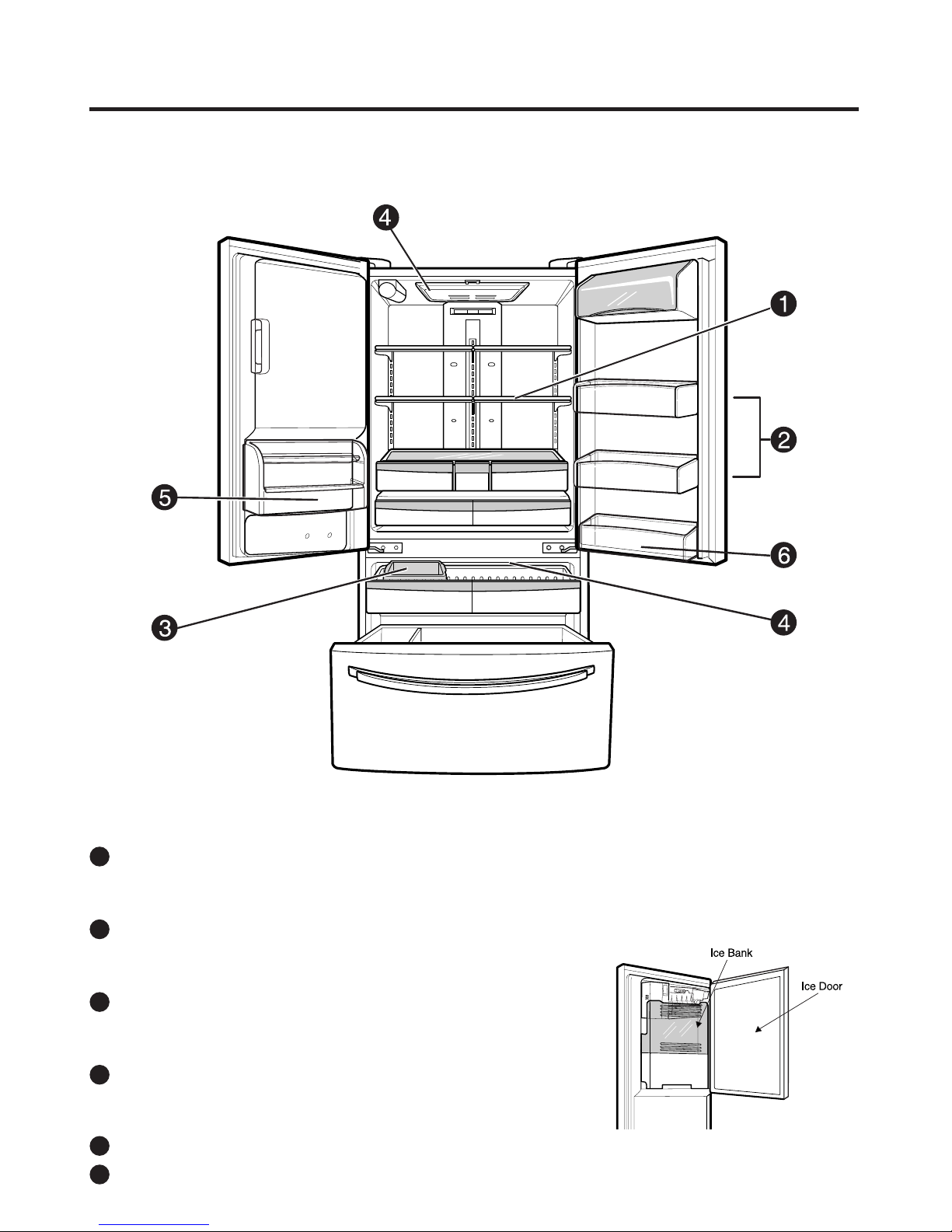

2. PARTS IDENTIFICATION

ADJUSTABLE REFRIGERATOR SHELVING

1

The refrigerator compartment shelves are adjustable to

allow flexibility for storage needs.

GALLON STORAGE BINS

2

Three interchangeable bins can be arranged to suit your

storage needs.

REMOVABLE ICE STORAGE BIN

3

The ice storage bin can be removed to fill ice buckets,

coolers, or pitchers.

LED INTERIOR LAMPS

4

Two separate LED arrays light the freezer and

refrigerator interiors.

5

SHORT N’TALL BIN

6

FIXED DOOR BIN

- 5 -

3. DISASSEMBLY

Correct

Incorrect

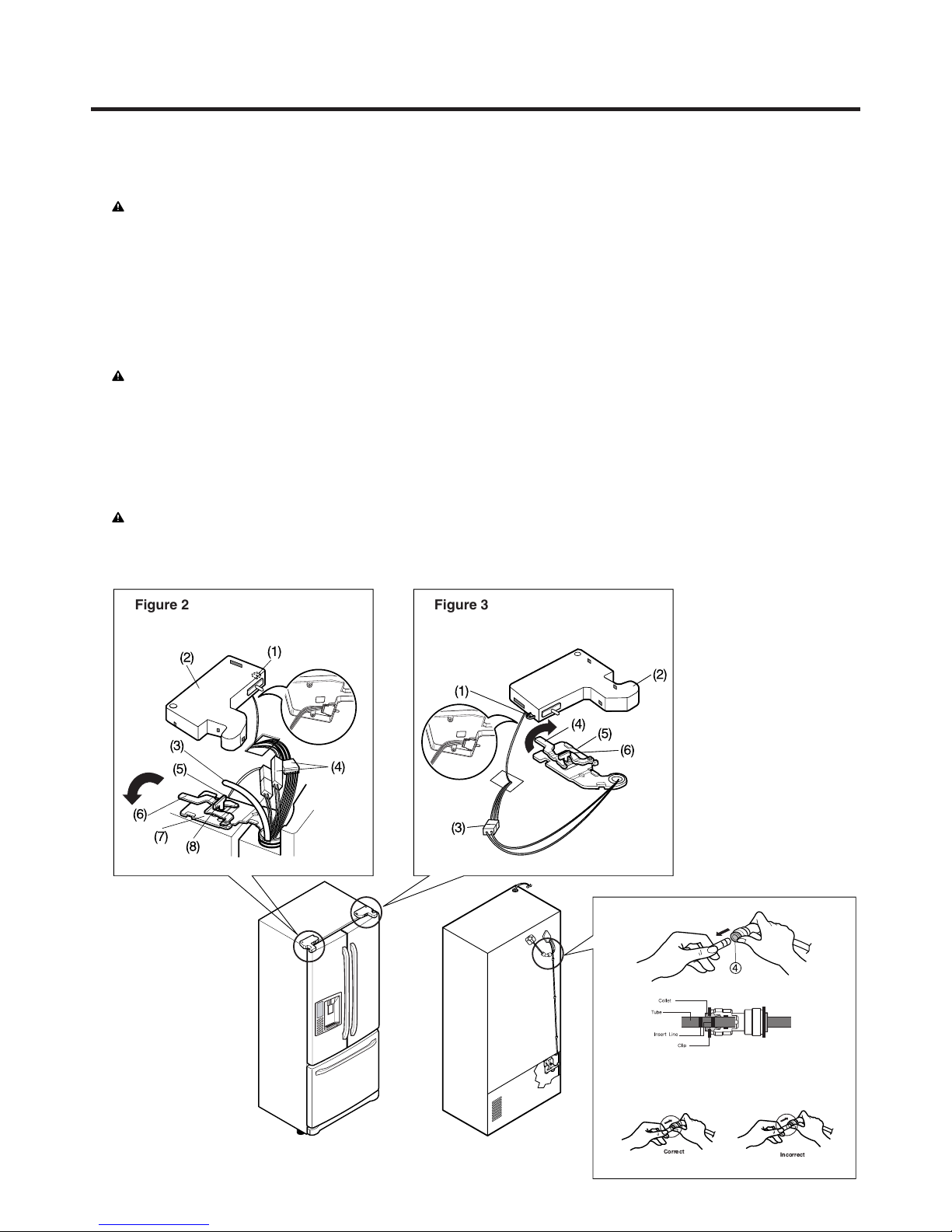

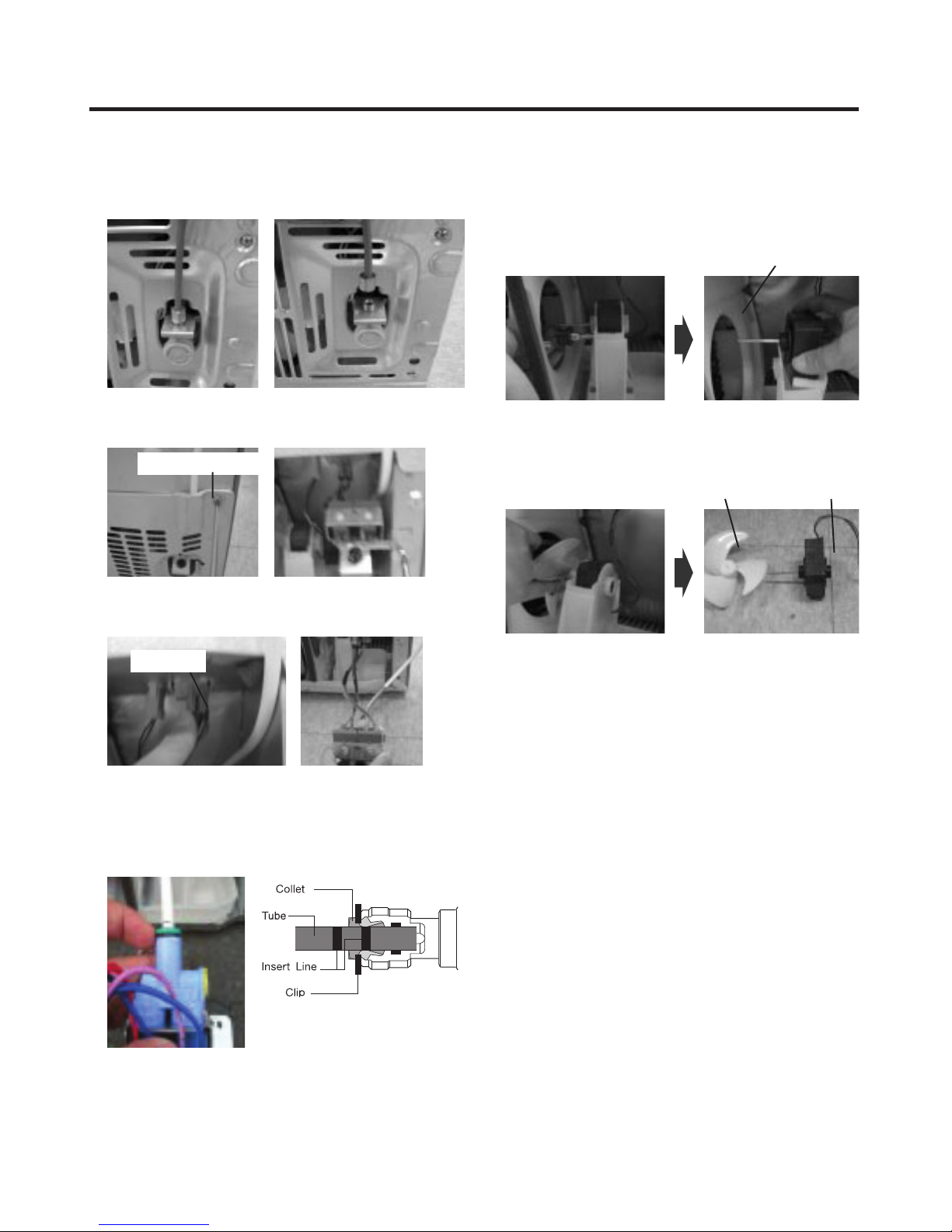

3-1 REMOVING AND REPLACING REFRIGERATOR DOORS

●

Removing Refrigerator Door

CAUTION: Before you begin, unplug the refrigerator. Remove food and bins from doors.

▶

Left Door -FIG. 2

1. Disconnect water supply tube by pushing back on the disconnect ring (4).-FIG. 1

2. Open door. Loosen top hinge cover screw (1).

Use flat tip screwdriver to pry back hooks on front underside of cover (3). Lift up cover.

3. Disconnect door switch wire harness (2). Remove cover.

4. Pull out the tube.

5. Disconnect the three wire harnesses (5). Remove the grounding screw (6).

6. Rotate hinge lever (7) counterclockwise. Lift top hinge (8) free of hinge lever latch (9).

CAUTION: When lifting hinge free of latch, be careful that door does not fall forward.

7. Place door, inside facing up, down onto a non-scratching surface.

▶

Right Door -FIG. 3

1. Open door. Loosen top hinge cover screw (1). Lift up cover (3).

2. Disconnect door switch wire harness (2). Remove cover.

3. Disconnect wire harness (5).

4. Rotate hinge lever (6) clockwise. Lift top hinge (7) free of hinge lever latch (8).

CAUTION: When lifting hinge free of latch, be careful that door does not fall forward.

5. Lift door up from middle hinge pin (9) door.

6. Place door, inside facing up, down onto a non-scratching surface.

Figure 2 Figure 3

Figure 1

1) Insert the tube until you can see only one of

the lines printed on the tube.

2) After inserting, pull the tube to ascertain that

it is secure.

3) Assemble clip.

- 6 -

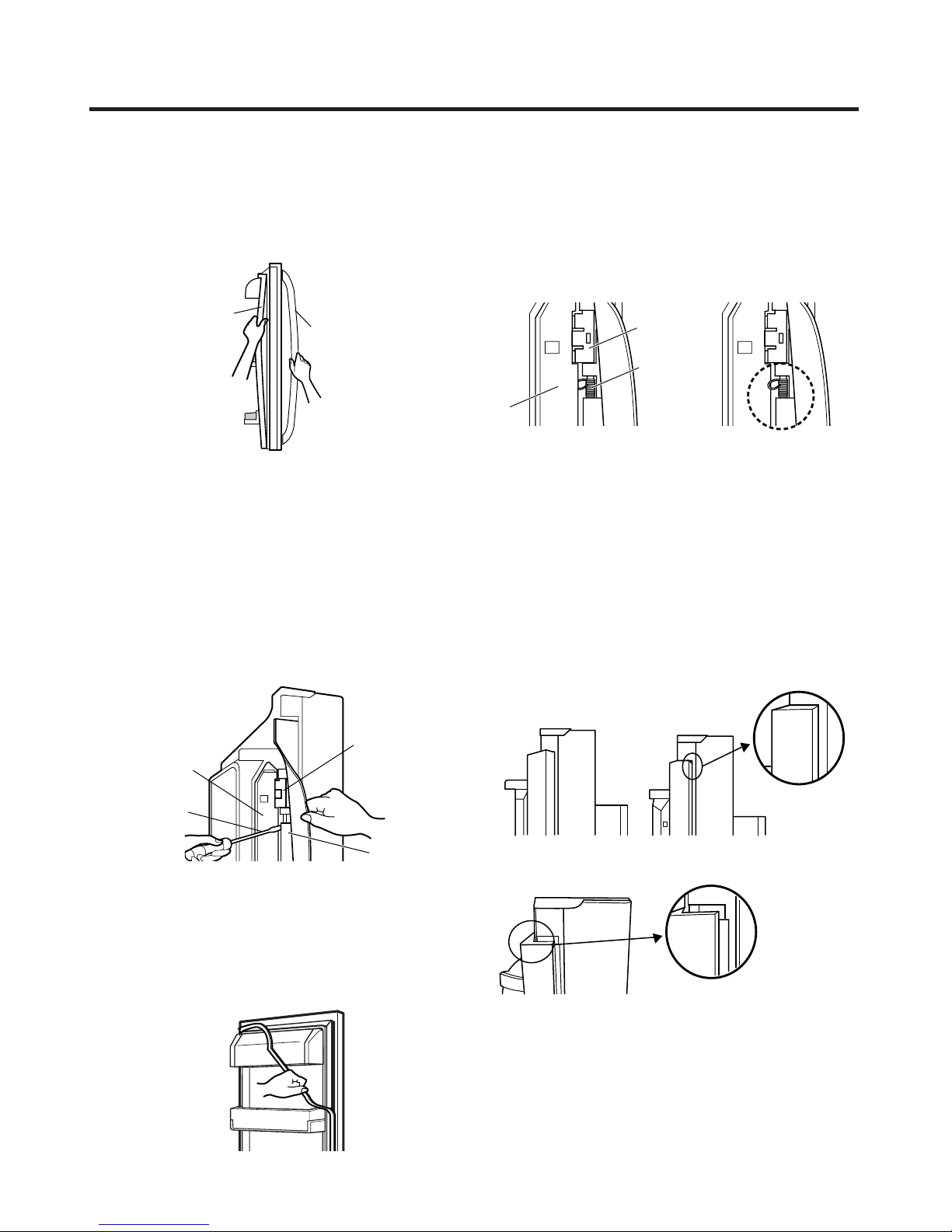

3-2 DOOR

●

Door Gasket Removal

1. Remove door frame cover

Starting at top of cover and working down, snap cover

out and away from door.

●

Door Gasket Replacement

1. Insert gasket bracket clips

1) Insert gasket bracket edge beneath door frame edge.

2) Turn upper gasket bracket spring so that the spring

ends are in the door channel.

3) Push in clip until you hear it snap securely into place.

Frame Cover

Handle

Figure 1

2. Remove gasket bracket clips

There are two clips on each door. Start bracket removal

near one of the middle clips.

1) Pull gasket back to expose gasket bracket clip and

door frame.

2) Insert a flat tip screwdriver into seam between gasket

bracket and door frame and pry back until clips snap

out.

3) Continue prying back along seam until all clips snap

out.

Gasket

Door

Bracket Clip

Frame

Gasket

Bracket Clip

Spring

Door

Frame

Correct Incorrect

Figure 4

4) Push in remaining clip until you hear it snap securely

into place.

Note: Make sure that no part of gasket bracket edge

protrudes from beneath door frame edge.

2. Insert gasket into channel

1) Snap gasket assembly into the door bracket.

<Inserting the Gasket Assembly into the Bracket Door>

Flat Tip

Screwdriver

3. Remove gasket

Pull gasket free from gasket channel on the three

remaining sides of door.

Gasket

Bracket

Figure 2

Figure 3

- 7 -

Incorrect

Correct

Figure 5

2) Press gasket into channels on the three remaining

sides of door.

3. Replace door frame cover

Starting at top of cover and working down, snap cover

back into door.

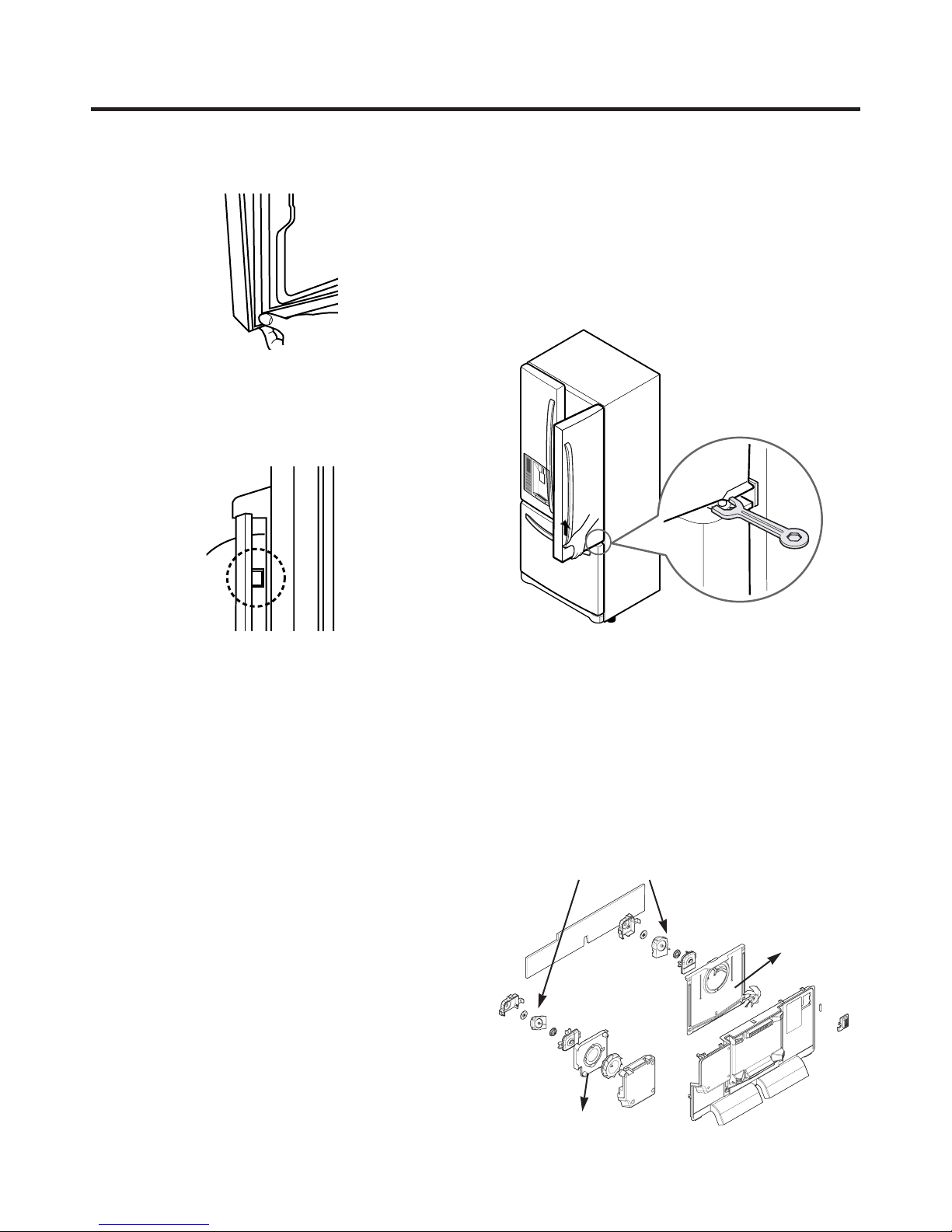

3-3 Door Alignment

If the space between your doors is uneven, follow the

instructions below to align the doors:

Remove the Base Grillie. Turn the leveling legs (CCW) to

raise or (CW) to lower the height of the front of the

refrigerator by using flat blade screw driver or 11/32"

wrench. Use the wrench (Included with the User Manual) to

adjust the bolt in the door hinge to adjust the height. (CCW

to raise or CW to lower the height.)

Figure 6

Figure 7

Figure 8

3-4 FAN AND FAN MOTOR(EVAPORATOR)

1. Remove the freezer drawer. (If your refrigerator has an

icemaker, remove the icemaker first)

2. Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

3. Remove the grille by removing four screws and pulling

the grille forward.

4. Remove the Fan Motor assembly by loosening 3 screws

and disassembling the shroud.

5. Pull out the fan and separate the Fan Motor and Bracket.

FAN MOTOR

Shroud

- 8 -

BRACKET

MOTOR

Figure 9

* Ice Fan Scroll Assembly Replacement

1) Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

2) Pull out the cover sensor to disassemble using tools

shown in the figure.

3) Pull out the cover grille to disassemble using tools

shown in the figure.

4) Put your hand into the inside of grille to disassemble

shown in the figure.

5) Disconnect wire harness of the grille

6) Remove the scroll assembly by loosening all screws

3-6 LAMP

Unplug Refrigerator, or disconnect power at the circuit

breaker.

If necessary, remove top shelf or shelves.

3-6-1 Refrigerator Compartment Lamp

1) Release 2 screws.

2) Hold both ends with your both hands and pull it

downward to remove it.

Figure 12

(1) (2)

(3) (4)

(5) (6)

3-5 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and

FUSE-M.

The Defrost Sensor works to defrost automatically. It is

attached to the metal side of the Evaporator and senses its

temperature. At 46F(8°C), it turns the Defrost Heater off.

Fuse-M is a safety device for preventing over-heating of

the Heater when defrosting.

1. Pull out the grille assembly. (Figure 10)

2. Separate the connector with the Defrost Control

assembly and replace the Defrost Control assembly after

cutting the Tie Wrap. (Figure 11)

GRILLE ASSEMBLY

DEFROST-CONTROL

ASSEMBLY

3) To remove the case lamp and cover lamp, release

another 2 screws as following picture.

3) Use a flat tool as shown below to remove the cover

lamp.

Figure 13

4) To remove the LED Assembly, open the Hook part to pull

it out as shown in the following picture.

Case, lamp

Cover, lamp

3-6-2 Freezer Compartment Lamp

1. Unplug refrigerator power cord form outlet.

2. Remove screw with driver.

3. Grasp the cover Lamp, pull the cover downward.

LED, Assembly

Figure 14

Figure 10

Figure 11

Figure 15

- 9 -

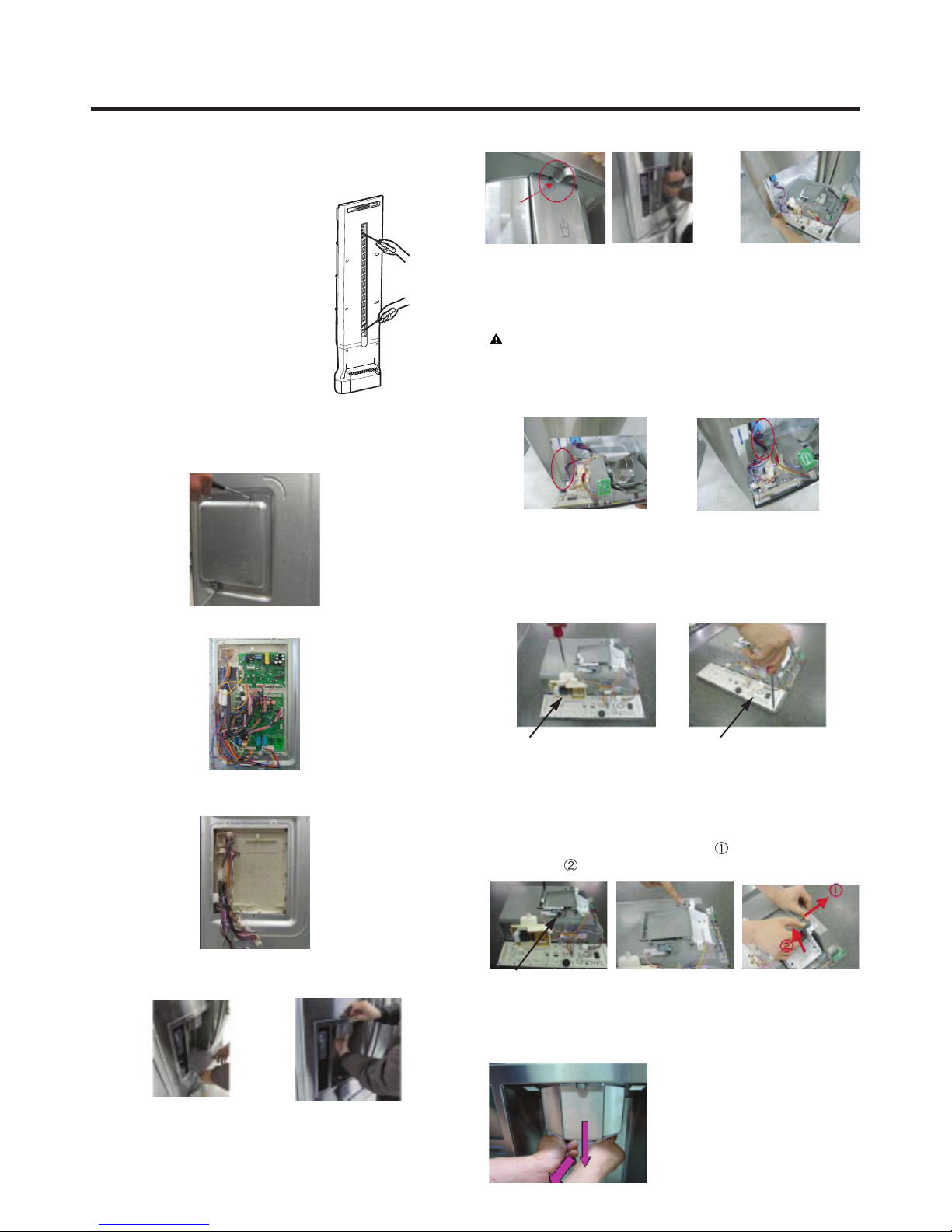

3-7 MULTI DUCT

1. Remove the upper and

lower Caps by using a

flat screwdriver, and

remove 2 screws.

(Figure 16)

2. Disconnect the lead wire

on the bottom position.

3-8 MAIN PWB

1) Loosen the 3 screws on the PWB cover.

2) Remove the PWB cover

Figure 16

3) If nozzle is interfered with button,

push and pull out the bottom of

button.

CAUTION: When replacing the dispensor cover in the

reverse order of removal, be careful that the lead wire

does not come out and the water tube is not pinched by

the dispensor.

4) Rmove the

connected part

of Lead wire.

3-10 DISPLAY PCB

As shown below, remove 1 case PCB fixing screw.

Remove the display PCB fixing screw.

3) Disconnect wire harness and replace the main PWB in

the reverse order of removal.

3-9 DISPENSER

1) Pull out the darin 2) Hold the inner side of

cover dispenser with

both hands at the handle

side to pull it out forward.

Case, PCB

Display PCB

3-11 ICE BUTTON ASSEMBLY

1) Remove the screw fixing the button lever.

2) Push the spring from the hanging hook to remove it.

3) Apply some pressure to the rib in

button in

Button Lever

direction.

direction and lift the

3-12 FUNNEL REPLACEMENT

Pull down and forward.

- 10 -

3-13 WATER BUTTON ASSMEBLY

1) Romove screws.

2) Grasp the Button assembly and lift up.

Button Lever

3-14 DUCT DOOR REPLACEMENT

1) Pull up and out on the dispenser cover to remove.

2) Disconnect the wire harness.

3) Remove the funnel

4) Replace in reverse order.

3-16 ICEMAKER ASSEMBLY

1) Loosen two screws as shown in the first picture.

2) Disconnect the wire harness & ground screw replace

theIcemaker assembly in the reverse order of removal.

3) It separates a ground connection screw.

3-15 ICE CORNER DOOR REPLACEMENT

1) Loosen the front screw as shown in the picture.

2) Lift up the hinge with one hand.

3) Pull out the Ice Corner Door with the other hand.

hinge

- 11 -- 11 -

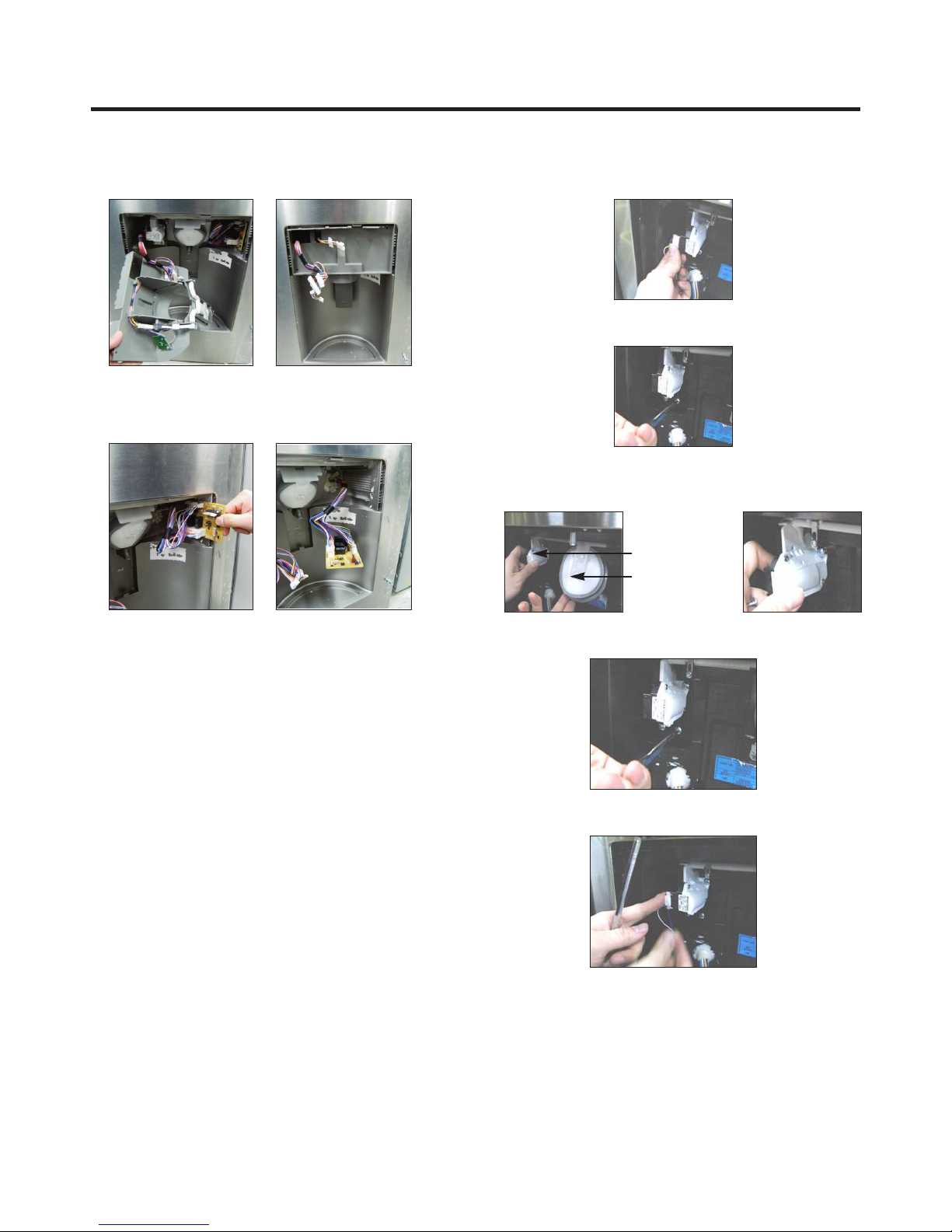

3-17 SUB PWB FOR WORKING DISPENSER

1) Loosen the screw on the sub PWB.

2) Pull the sub PWB down.

3) Disconnect the wire harness and replace the sub PWB in

the reverse order of removal.

3-18 CAP DUCT MOTOR REPLACEMENT

1) Separate the Housing of the Cap Duct Motor.

2) Unscrew 3 screws to disassemble the motor.

3) When replacing to a new Motor, always hold the Duct

Door with your hand to install the Motor.

Cap Duct Motor

Duct Door

4) Assemble on the screws.

5) Contract the Housing.

- 11 -

- 12 -

3-19 AUGER MOTOR COVER

1) After removing the icemaker remove the (5) stainless

screws holding the auger motor cover, shown in the

picutres below.

2) Grip the bottom of motor cover assembly and pull out it.

3) Disconnect wire harness of motor cover assembly.

There is a auger motor on the back, as shown in the

picture.

Auger Motor

- 13 -

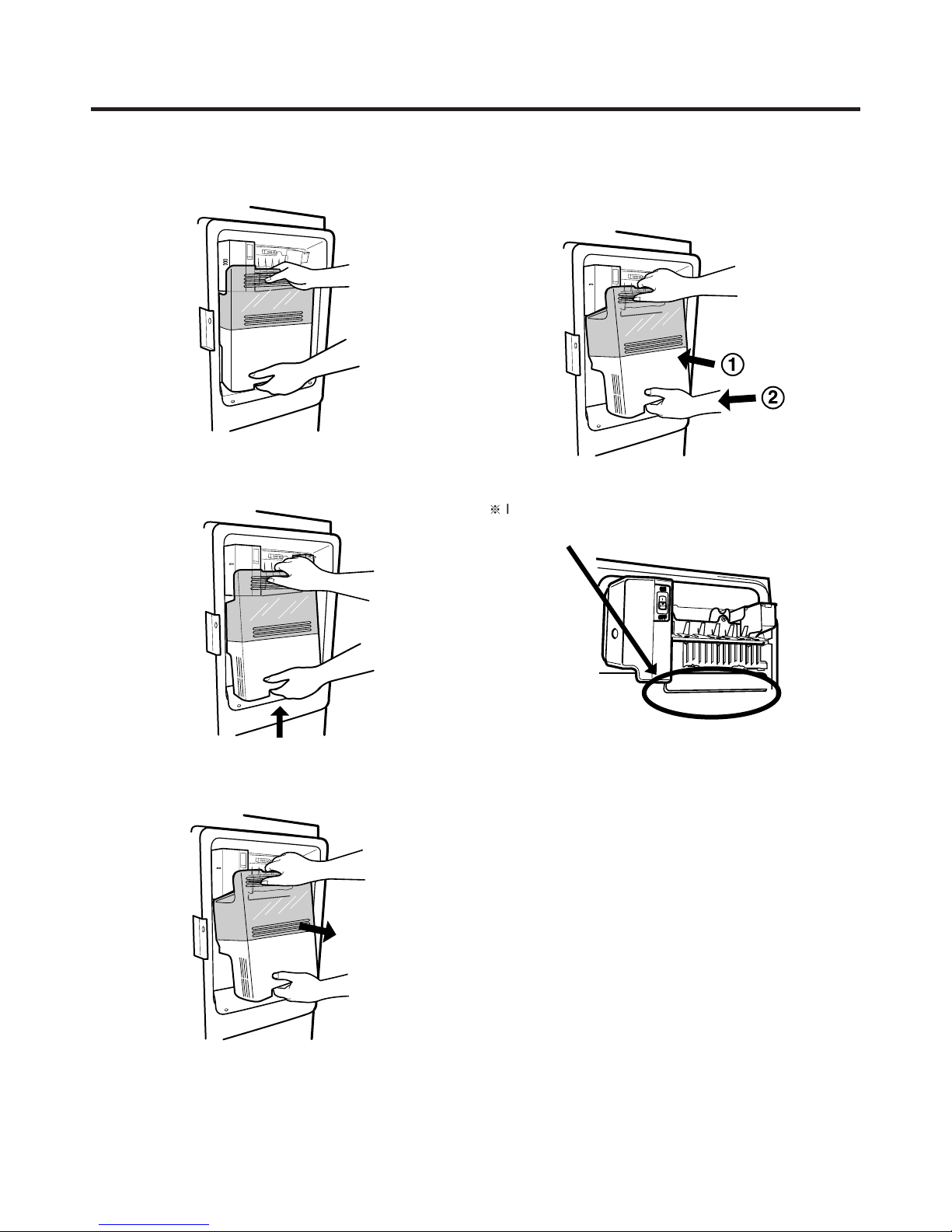

3-20 HOW TO REMOVE A ICE BIN

1) Grip the handles, as shown in the picture.

2) Lift the lower part slightly.

3-21 HOW TO INSERT A ICE BIN

1) Insert the Ice Bin, slightly tilting it to avoid touching the

Icemaker. (especially, icemaker lever)

※ Insert the ice bin carefully avoid contacting the automatic

shut off arm.

3) Take the Ice Bin out slowly.

- 14 -

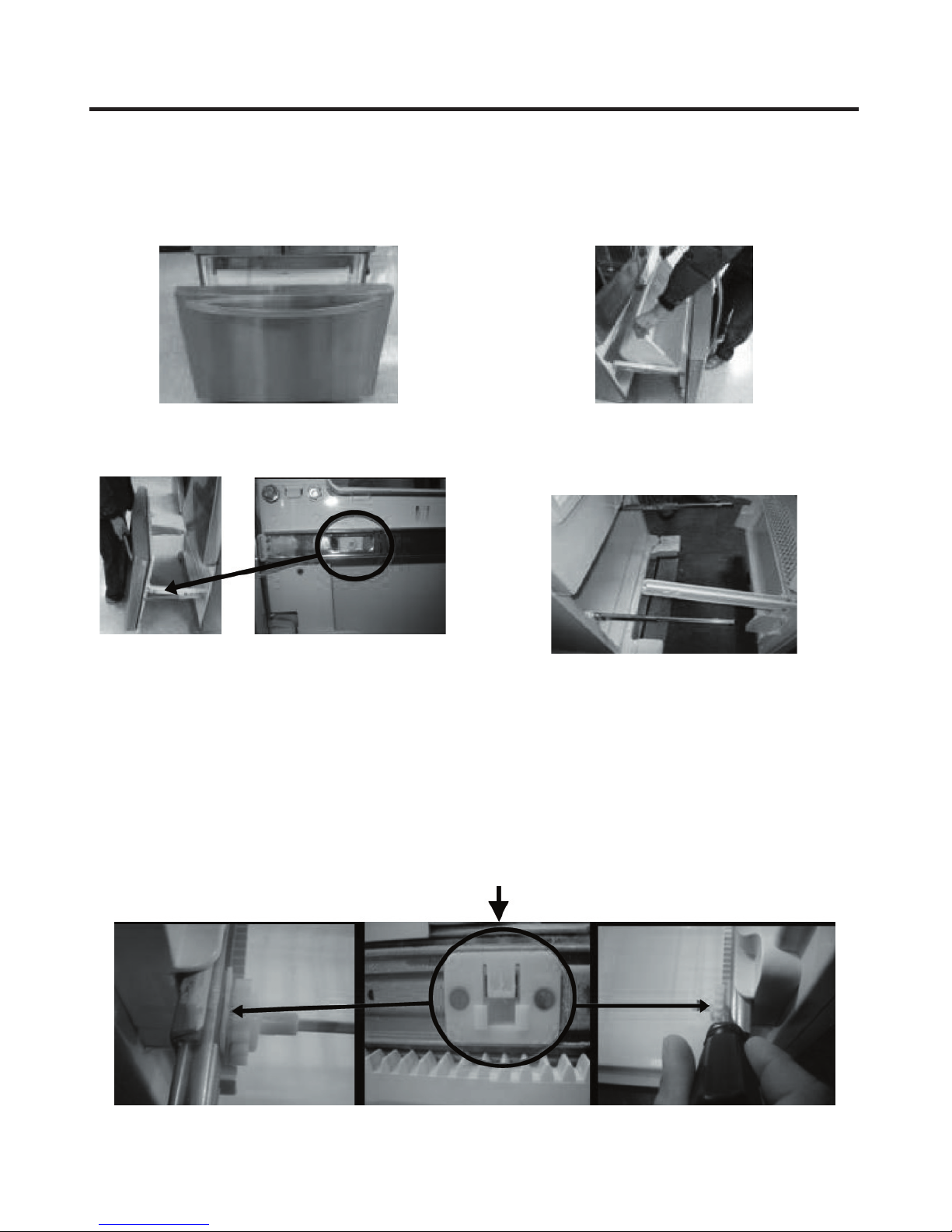

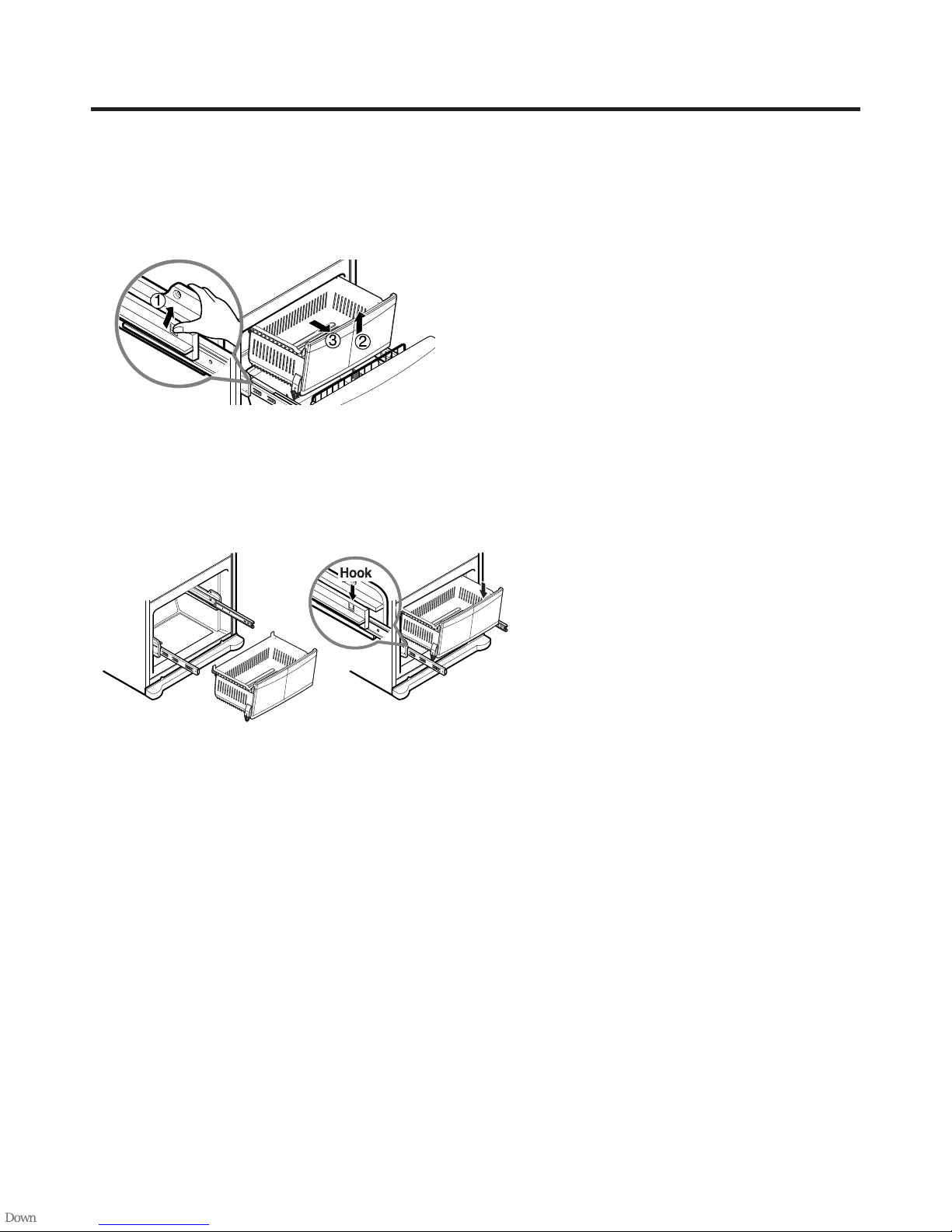

3-22 HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER

3-22-1 Follow Steps to Remove

Step 1) Open the freezer door. Step 2) Remove the lower basket.

Step 3) Remove the two screws from the guide rails

(one from each side).

Step 5) First: Remove the gear from the left side first by releasing the tab behind the gear, place a screwdriver between the

gear and the tab and pull up on the gear.

Second: Remove the center rail.

Third: Remove the gear from the right side by following the same steps for the left side.

Step 4) Lift the freezer door up to unhook it from the rail

support and remove.

Pull both rails to full extension.

NOTE: THIS TAB MUST BE PUSHED IN TO RELEASE THE GEAR.

- 15 -

3-22-2 Follow Steps to Reinstall

Step 1) Reinstall the right side gear into the clip.

Step 2) Insert the rail into the right side gear. Gears do not

need to be perpendicular to each other.

Step 4) The rail system will align itself by pushing the rails

all the way into the freezer section.

Pull the rails back out to full extension.

Step 3) Insert the rail into the left side gear, and insert the

gear into the clip.

Step 5) Reinstall the freezer door by inserting the rail tabs

into the guide rail.

Step 6) Reinstall the two screws into the guide rails

(one from each side).

Step 7) Reinstall the lower basket, and close the freezer

door.

- 16 -

3-23. WATER VALVE DISASSEMBLY METHOD

1) Turn off the water. Then separate the water line from the

valve.

3-24. FAN AND FAN MOTOR DISASSEMBLY

METHOD

1) Using a short screwdriver, loosen one SCREW in DRAIN

PIPE ASSEMBLY and one connected to the MOTOR

COVER.

MOTOR COVER

2) Separate the Mechanical Cover and Valve Screw.

Mechanical Cover

3) Separate the housing and pull out the valve.

Housing

4) Lay a dry towel on the floor and get ready to spill water

from the water filter. Pull out the Cilp. Then press te

collet to separate the tube from the connector and pour

out the water until emptied.

2) Pull and separate the FAN ASSEMBLY and MOTOR

turning counterclockwise based on the MOTOR SHAFT.

FAN ASSEMBLY MOTOR

The assembly is in the reverse order of the disassembly

and take special care for the following details.

1. Be careful not to bend the tube during assembly.

2. Press the WATER DISPENSER button until water pours

out and check for leakage in the CONNECTOR TUBE (It

differs by the water pressure but usually takes about 2

minutes until water pours out.)

- 17 -

3-25 PULL OUT DRAWER

Hook

To separate the drawer, push the front left and right hooks

in ① direction to pull up and remove.

Then gently lift the gear part of rear left and right side of the

drawer and pull it out in ③ direction.

To install, reposition the gear part of rear left and right side

of the drawer after pulling out both rails as much as

possible, and gently push down both left and right side

while checking the hook on the front part.

- 18 -

4. ADJUSTMENT

PTC STARTER

SEALED

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

3

6

5

S

N

L1

OVERLOAD PROTECTOR

Resistance Starter Capacitor Running

PTC

22

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use

extreme caution when performing repairs.

4-1-3 Note for usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

Particular Compressor in your product.

(4) Keep Compressor dry.

If the Compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result.

(5) When replacing the Compressor, be careful that dust,

humidity, and soldering flux don’t contaminate the inside

of the compressor. Dust, humidity, and solder flux

contaminate the cylinder and may cause noise,

improper operation or even cause it to lock up.

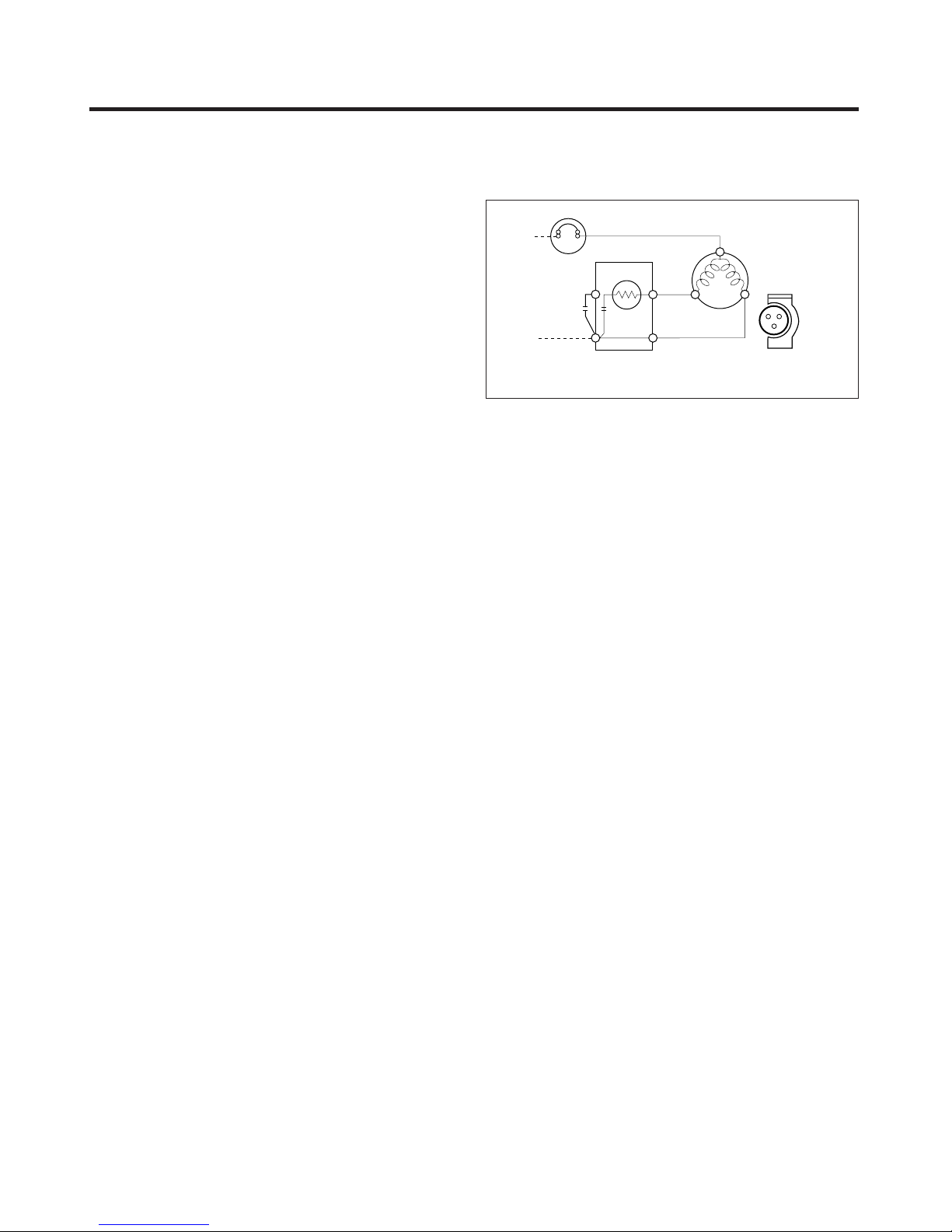

4-2-3 PTC-Applied Circuit Diagram

●

Starting Method for the Motor

4-2-4 Motor Restarting and PTC Cooling

(1) It requires approximately 5 minutes for the pressure to

equalize before the compressor can restart.

(2) The PTC device generates heat during operation.

Therefore, it must be allowed to cool before the

compressor can restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the compressor attempts to restart before the PTC

device is cooled, the PTC device will allow current to

flow only to the main winding.

(2) The OLP will open because of the over current

condition. This same process will continue (3 to 5 times)

when the compressor attempts to restart until the PTC

device has cooled. The correct OLP must be properly

attached to prevent damage to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part number

and model number. Use only approved substitute parts.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic

material consisting of BaTiO3.

(2) The higher the temperature is, the higher the resistance

value. These features are used as a starting device for

the Motor.

4-2-2 Role of PTC-Starter

(1) The PTC is attached to the Sealed Compressor and is

used for starting the Compressor Motor.

(2) The compressor is a single-phase induction motor.

The starting operation, the PTC allows current flow to

both the start winding and main winding.

4-2-6 Note for Using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the PTC, PTC

materials may fail due to breakdown of their insulating

capabilities.

(4) If the exterior of the PTC is damaged, the resistance

value may be altered. This can cause damage to the

compressor and result in a no-start or hard-to-start

condition.

(5) Always use the PTC designed for the compressor and

make sure it is properly attached to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part number

and model number. Use only approved substitute parts.

- 19 -

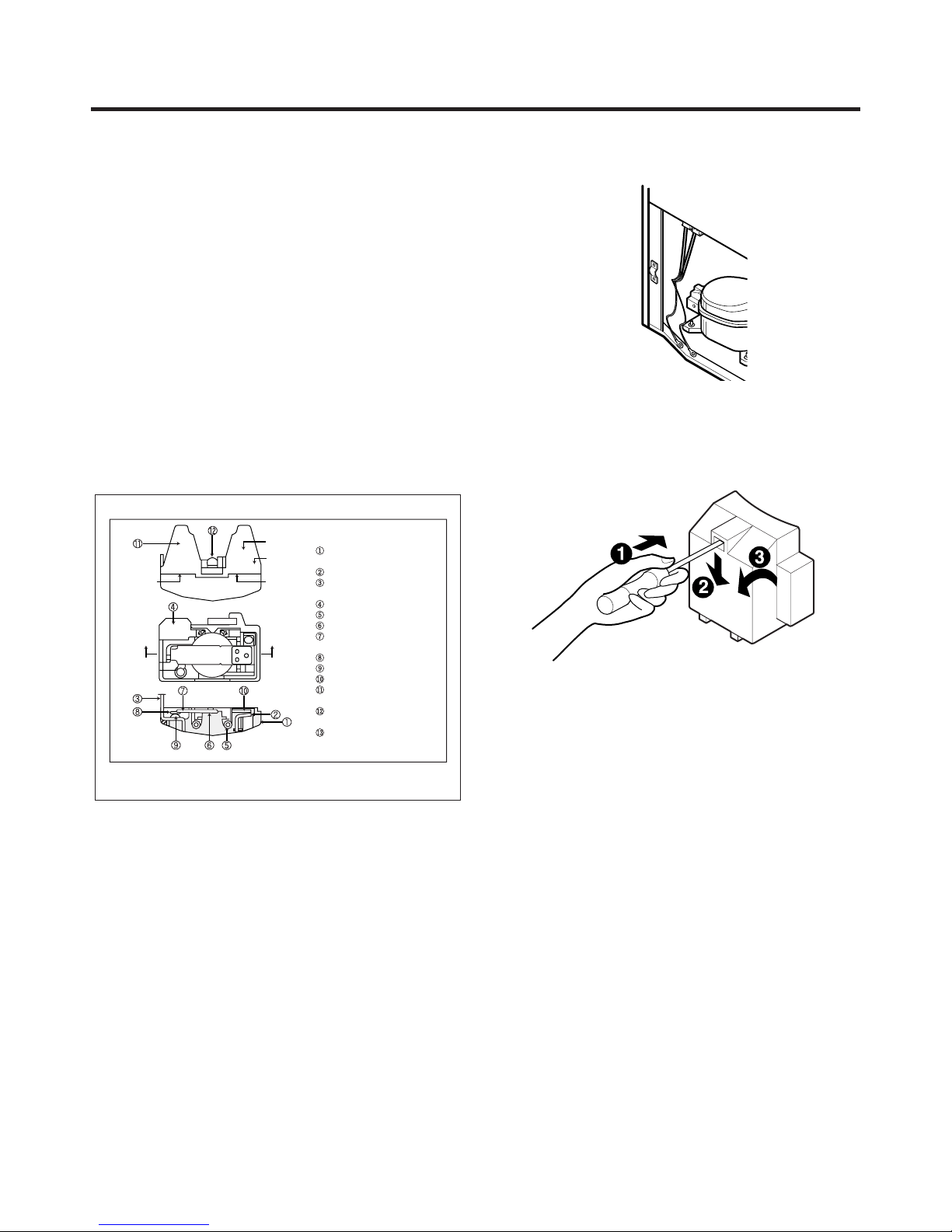

4-3 OLP (OVERLOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by opening the

circuit to the Motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the Compressor motor, the

Bimetal works by heating the heater inside the OLP, and

the OLP protects the Motor by cutting off the current

flowing to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Sealed Compressor used for

the Refrigerator. It prevents the Motor Coil from being

started in the Compressor.

(2) For normal operation of the OLP, do not turn the Adjust

Screw of the OLP in any way.

4-4 TO REMOVE THE COVER PTC

(1) Remove the Cover Back M/C.

(2) Disconnect two housing upper side of comp connected

in.

(3) Loosen two screws on comp base.

(OVERLOAD PROTECTOR cross section)

Customer part

number

12345678

Lot code/

date code

Physical

termination

part number

Electrical

characteristics

part number

330 FBYY -S1 BOX98

Part

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V -0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

Quick-connect terminal, brass,

conforms to UL 310, MEMA

DC-2, DIN 46344

Figure 19

(1) Remove the Cover Back M/C.

(2) Disconnect two housing upper side of comp connected

in.

(3) Loosen two screws on comp base.

- 20 -

5. CIRCUIT DIAGRAM

- 21 -

6. TROUBLESHOOTING

6-1. Error Code Summary

WARNING: When you check the Resistance values, be sure to turn off the power.

And wait for the voltage-discharge sufficiently.

NOTE) 3 hours before the error : Press the Ice Plus button and Freezer button simultaneously

3 hours after the error : All errors, except for "Er rt" "Er SS" error, are displayed.

Error Detection

NO

1

Freezer Sensor

2

3

4

5

6

7

8

Poor Defrosting Er dH

Abnormality of

BLDC FAN Motor

9

for Ice Making

Error Display

Category

Normality None

Error

Refrigerator

Sensor Error

Defrosting

Sensor Error

Icing Sensor

Error

Pantry sensor

error

Room Temp

Sensor Error

Freezer

Temperature

Er FS

Er rS

Er dS

Er IS

Er SS

Er rt

Er IF

Refrigerator

Temperature

Error Generation Factors Remark

Short or Disconnection

of Freezer Sensor

Short or Disconnection

of Refrigerator Sensor

Short or Disconnection

of Defrosting Sensor

Short or Disconnection

of Icing Sensor

Short or Disconnection

of Pantry Sensor

Short or Disconnectoin of

Room temp.sensor

Even though it is passed

1 hour since then Defrosting,

if Defrosting sensor is not

over 46°F(8°C), it is caused

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

Normal operation of Display

Check each sensor and its

connector.

Temperature Fuse

Disconnection, Heater

disconnection, DRAIN Jam,

Poor Relay for Heater

Poor BLDC Motor connection,

DRIVE IC, and TR

Abnormality of

BLDC FAN Motor

10

11

12

13

for Freezer

Abnormality of

BLDC FAN

MOTOR For

Refrigerator

Abnormality of

BLDC FAN Motor

for Mechanic

Room

Communication

Error

Er FF

Er rF

Er CF

Er CO

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

It is caused when feedback

signal isn’t over 65 seconds

during BLDC FAN motor

operating

Communication Error

between Micom of Main PCB

and Display Micom

- 22 -

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor BLDC Motor connection,

DRIVE IC, and TR

Poor Communication

connection,Poor TR of

Transmitter and Receiver

Tx/Rx between display and

main board.

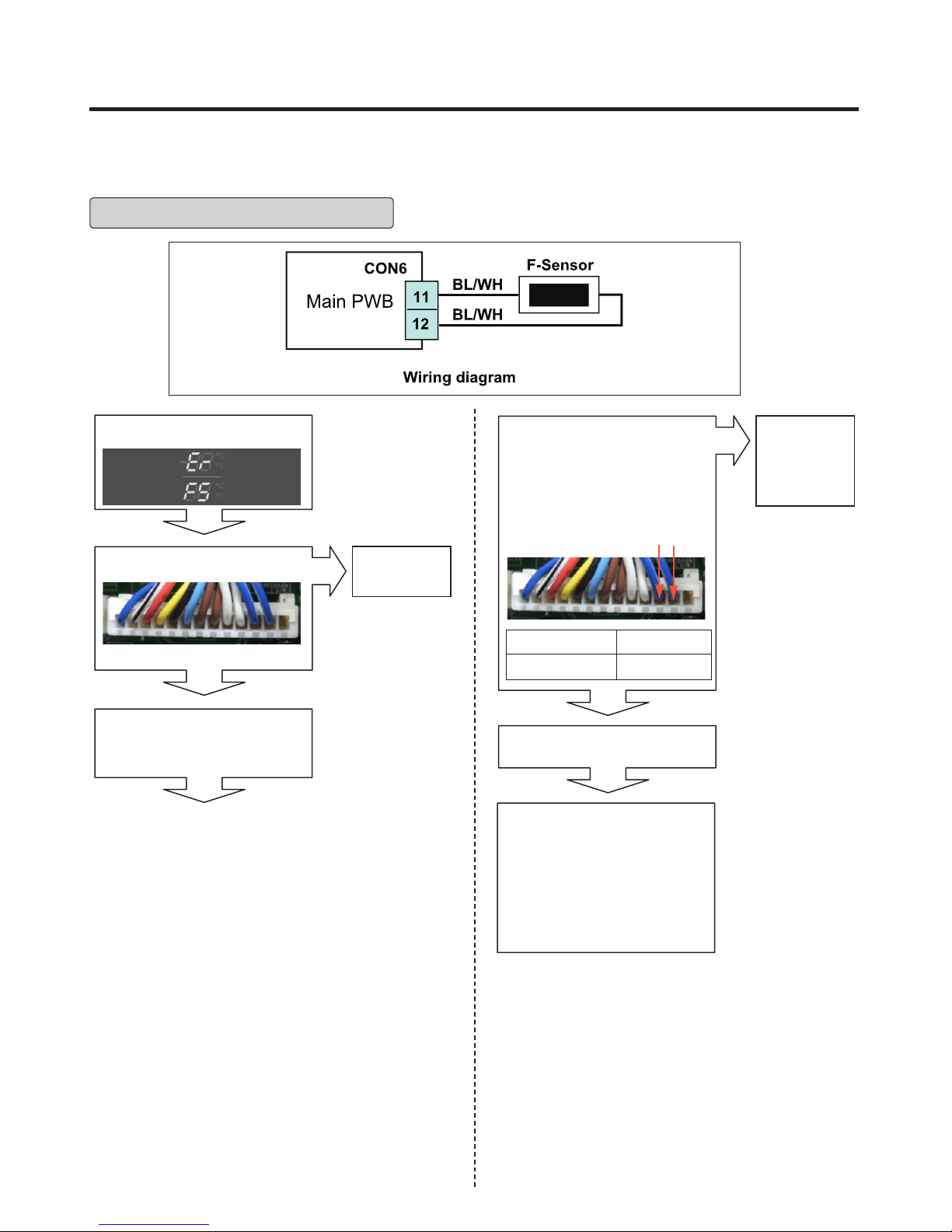

6-2. Troubleshooting With Error

Freezer Sensor Error

Is Er-FS displayed?

Yes

Is the connection loose?

No

Power Off

Tip : To protection of MICOM

Yes

Reconnect

Disconnect CON6 and

measure the value. Is

resistance value between

pins 11 & 12 of CON6 as

below? (BL/WH to BL/WH)

pin11 pin12

Test Point

Pin11 to pin12

Reconnect CON6 and Power

ON

If the ER-FS appears when

you press FREEZER key and

ICE PLUS Key at the same

time, Replace the main PWB.

(Position No:500A)

Otherwise, explain to the

customer!

Result

1.4 ~ 120 ㏀

Yes

No

Replace

F-sensor

(Position

No : 610C)

- 23 -

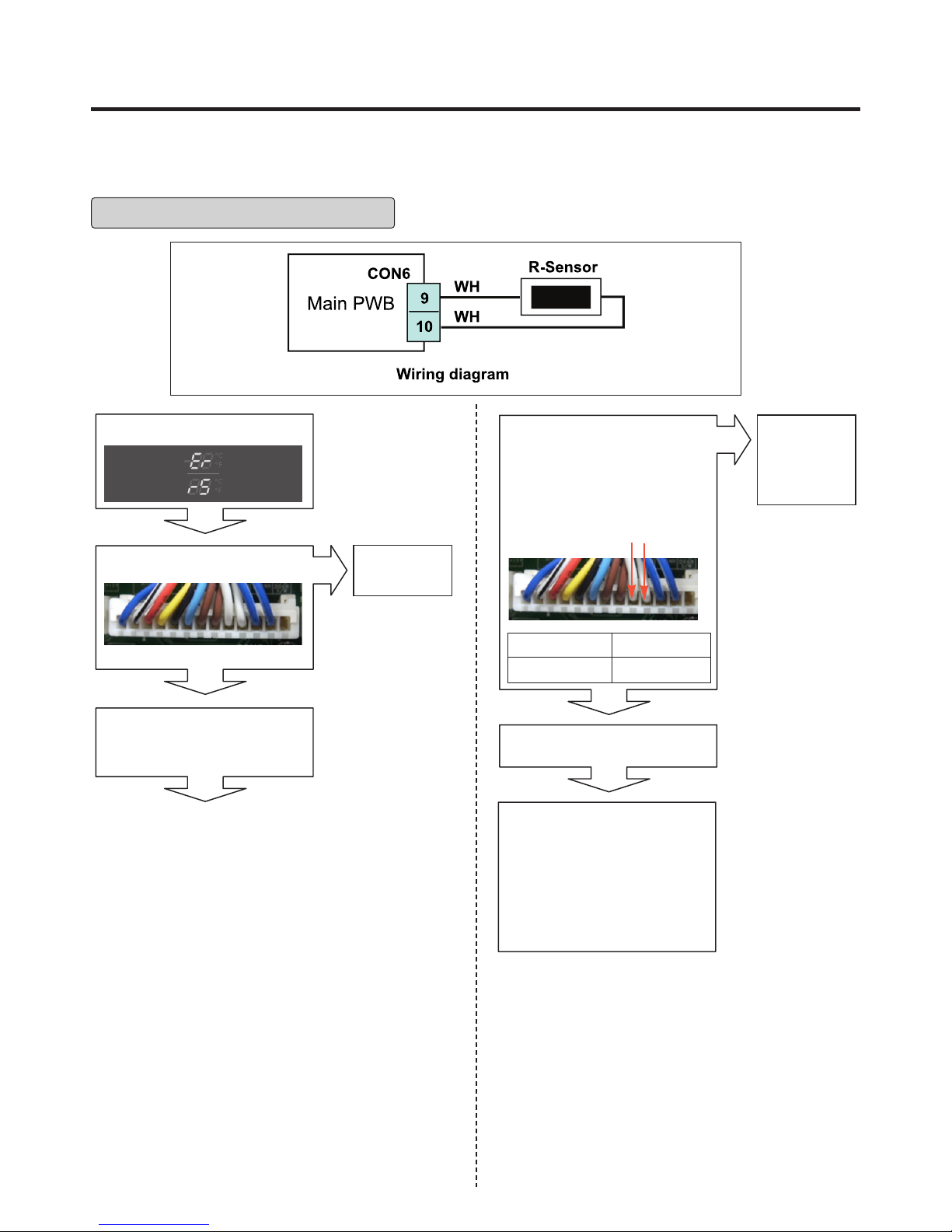

Refrigerator Sensor Error

Is Er-rS displayed?

Yes

Is the connection loose?

No

Power Off

Tip : To protection of MICOM

Yes

Reconnect

Disconnect CON6 and

measure the value. Is

resistance value between

pins 9 & 10 of CON6 as

below? (WH to WH)

pin9 pin10

Test Point

Pin9 to pin10

Reconnect CON6 and Power

ON

If the ER-rS appears when

you press FREEZER key and

ICE PLUS Key at the same

time, Replace the main PWB.

(Position No : 500A)

Otherwise, explain to the

customer!

Result

6 ~ 300 ㏀

Yes

No

Replace

R-sensor

(Position

No : 610B)

- 24 -

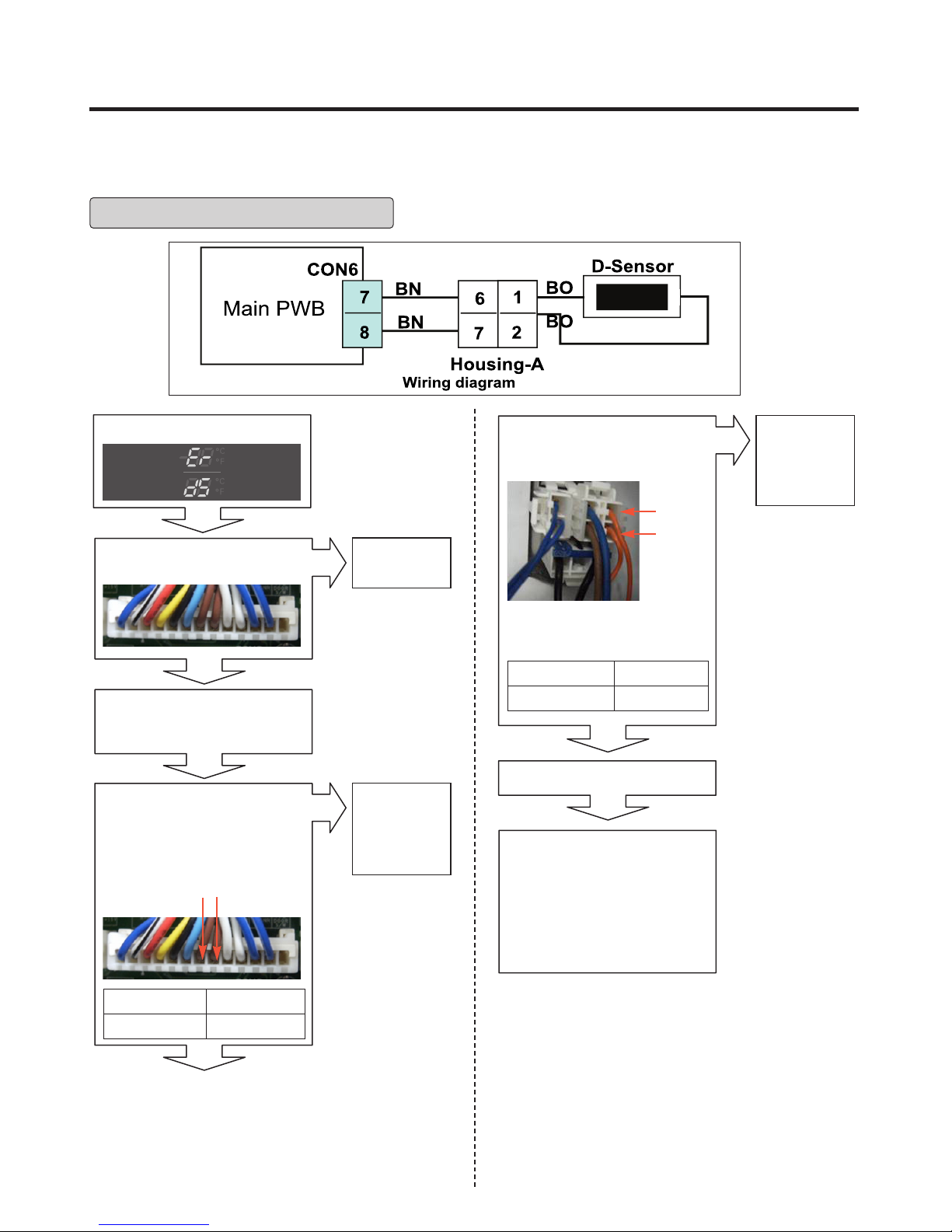

Defrost Sensor Error

Is Er-dS displayed?

Yes

Is the connection loose?

No

Power Off

Tip : To protection of MICOM

Disconnect CON6 and

measure the value. Is

resistance value between

pins 7 & 8 of CON6 as

below? (BN to BN)

pin7

pin8

Yes

No

Reconnect

Replace

D-sensor

(Position

No : 400A)

Is resistance value between

pins 1 & 2 of Housing- A as

below? (BO to BO)

pin1

pin2

Checking Open or Short

of wire

Test Point

Pin1 To pin2

Result

6 ~ 300 ㏀

Yes

Reconnect and Power ON

If the ER-dS appears when

you press FREEZER key and

ICE PLUS Key at the same

time, Replace the main

PWB.(Position No : 500A)

Otherwise, explain to the

customer!

No

Replace

D-sensor

(Position

No :400A)

Test Point

Pin7 to pin8

Result

6 ~ 300 ㏀

Yes

- 25 -

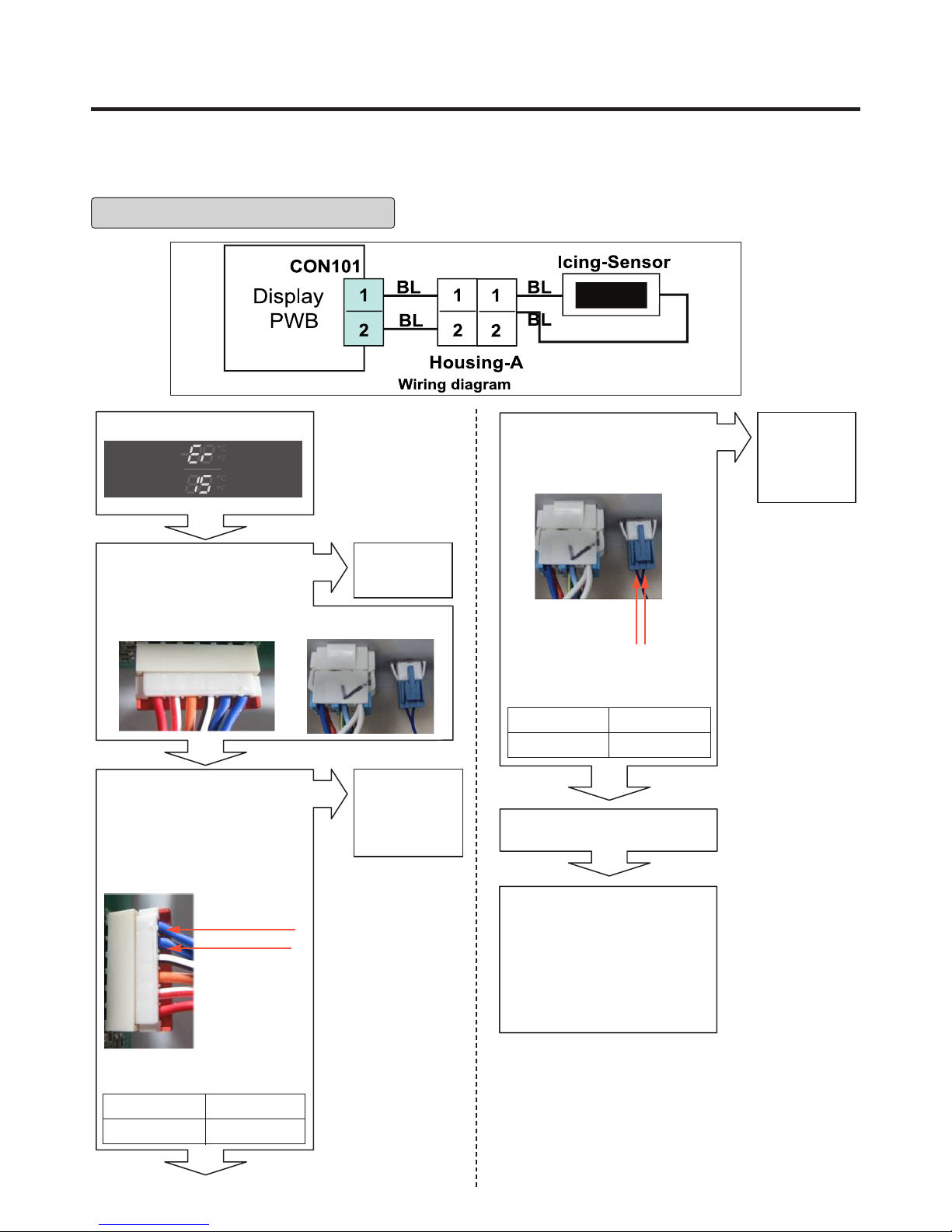

Icing Room Sensor Error

Is Er-IS displayed?

Yes

Is the connection loose?

Display PWB

No

Disconnect CON101 and

measure the value. Is

resistance value between

pins 1 & 2 of CON101 as

below? (BL to BL)

Yes

Inner of Icing door

No

Reconnect

Replace the

Icing-Sensor

(Position

No : 600B)

Is resistance value between

pins 1 & 2 of Housing- A as

below? (BL to BL)

pin1 BL

Checking Open or Short

of wire

Test Point

(1) To (2)

Yes

Reconnect and Power ON

pin2 BL

Result

1.4 ~ 120 ㏀

No

Replace the

Icing-Sensor

(Position

No : 600B)

pin1 BL

pin2 BL

Icing room Sensor Resistance

Test Point

pin1 To pin2

Result

1.4 ~ 120 ㏀

Yes

If the ER-IS appears when

you press FREEZER key and

ICE PLUS Key at the same

time, Replace Display PWB.

(Position No : 501A)

Otherwise, explain to the

customer!

- 26 -

Loading...

Loading...