LG LB-B2156QC, LB-B2206QC, LB-B2258QC, LMA36B2ALI, LMA48B2ALI Installation Manual

...

IMPORTANT

Please read through this manual. It contains valuable

information about your air conditioner. This manual may

help save time and money by explaining proper product

maintenance and preventing improper use.

PRECAUTIONS

Pay close attention to precautions in order to prevent

potential hazards and damage from misuse or improper

installation. LG is not responsible for any damages caused

by misuse of the product.

LG

Low Static Hide Away Type Air Conditioner

OWNER'S & INSTALLATION

MANUAL

LG

P/No.: MFL62760202

1.The following should be always observed for safety..............................

2. Installation of Indoor, Outdoor unit .........................................................

3. Connecting Pipes to the Indoor Unit .....................................................

4. Connecting Pipes to the Outdoor Unit ..................................................

5. IR Remote Sensor installation & operation detail.................................

6. Connecting Cables between Indoor Unit and Outdoor Unit ................

7. Air Purging of the Connecting Pipes and the Indoor Unit.................... 27

OUT-LINE OF INSTALLATION

Installation works Installation Parts Required tools

A)

B)

C)

D)

E)

F)

•

Four Type “A”

screws

•

Connecting cable

•

Level

•

Screw driver

•

Electric drill

•

Hole core drill (ø70mm)

1) Preparation of Piping...12

•

Pipes: Gas side

Liquid side

•

Insulated drain hose

•

Insulation materials

•

FlaringTools set

1) Connecting the pipes to

the Outdoor Unit ..........14

A) Circuit Breaker Detail......................16

•

Screw driver

•

Hexagonal Wrench (4mm/5mm)

•

Gas-leak Detector

2

4

3

12

14

14

16

Index Page No.

Selection of best location of indoor .....04

Ceiling dimension & Hanging blot detail........05

Filter convertible option.......06

Drain piping .........................07

Insulation of the piping & drain...08

Out door unit best location & piping ....10

B) Wiring diagram, wiring specification & interconnection

detail.................................. ................17

C) Outdoor Wire Routine & Pipe Routine.......25

8. Operating Instructions.................... ........................................................ 28

A) Indoor Unit, Outdoor Unit ...................... 28

B) Remote Control Preparation .. .............. 29

C) Remote Control Operations .. ............... 30

3

1. The following should be always observed for safety

• Please report to or take consent by the supply authority before connecting to the system.

• Be sure to read "THE FOLLOWING SHOULD BE ALWAYS OBSERVED FOR SAFETY" before

installing the air conditioner.

• Be sure to observe the cautions specified here as they include important items related to safety.

• The indications and meanings are as follows.

• After reading this manual, be sure to keep it together with the owner's manual in an accessible

place.

Could lead to death, serious injury, etc.

Do not install it yourself (customer).

Perform the installation securely referring to the

installation manual.

Install the unit securely in a place which can bear the

weight of the unit.

Perform electrical work according to the installation

manual and be sure to use an exclusive circuit.

Attach the electrical part cover to the indoor unit and

the service panel to the outdoor unit securely.

Be sure to use the part provided or specified parts for

the installation work.

Check that the refrigerant gas do not leak after

installation is completed.

Perform the drainage/piping work securely

according to the installation manual.

Use the specified wires to connect the indoor and the

outdoor units securely and attach the wires firmly to

the terminal board connecting sections so the stress

of the wires is not applied to the sections.

• Incomplete installation could cause injury due to fire, electric shock,

the unit falling or a leakage of water. Consult the dealer from whom

you purchased the unit or special installer.

• Incomplete installation could cause a personal injury due to

fire, electric shock, the unit falling or a leakage of water.

• When installed in an insufficient strong place, the unit could fall

causing injured.

• Incomplete connecting and fixing could cause fire.

• If the capacity of the power circuit is insufficient or there is

incomplete electrical work, it could result in a fire or an electric

shock.

• The use of defective parts could cause an injury or leakage of

water due to a fire, electric shock, the unit falling, etc.

• If there is a defect in the drainage/piping work, water

could drop from the unit and household goods could be

wet and damaged.

Do not install the unit in a place where an

inflammable gas leaks.

• If gas leaks and accumulates in the area surrounding the unit, it

could cause an explosion.

• If the electrical part cover if the indoor unit and/or the service

panel if the outdoor unit are not attached securely, it could result

in a fire or electric shock due to dust, water, etc.

Could lead to serious injury in particular environments when operated incorrectly.

WARNING

WARNING

CAUTION

CAUTION

4

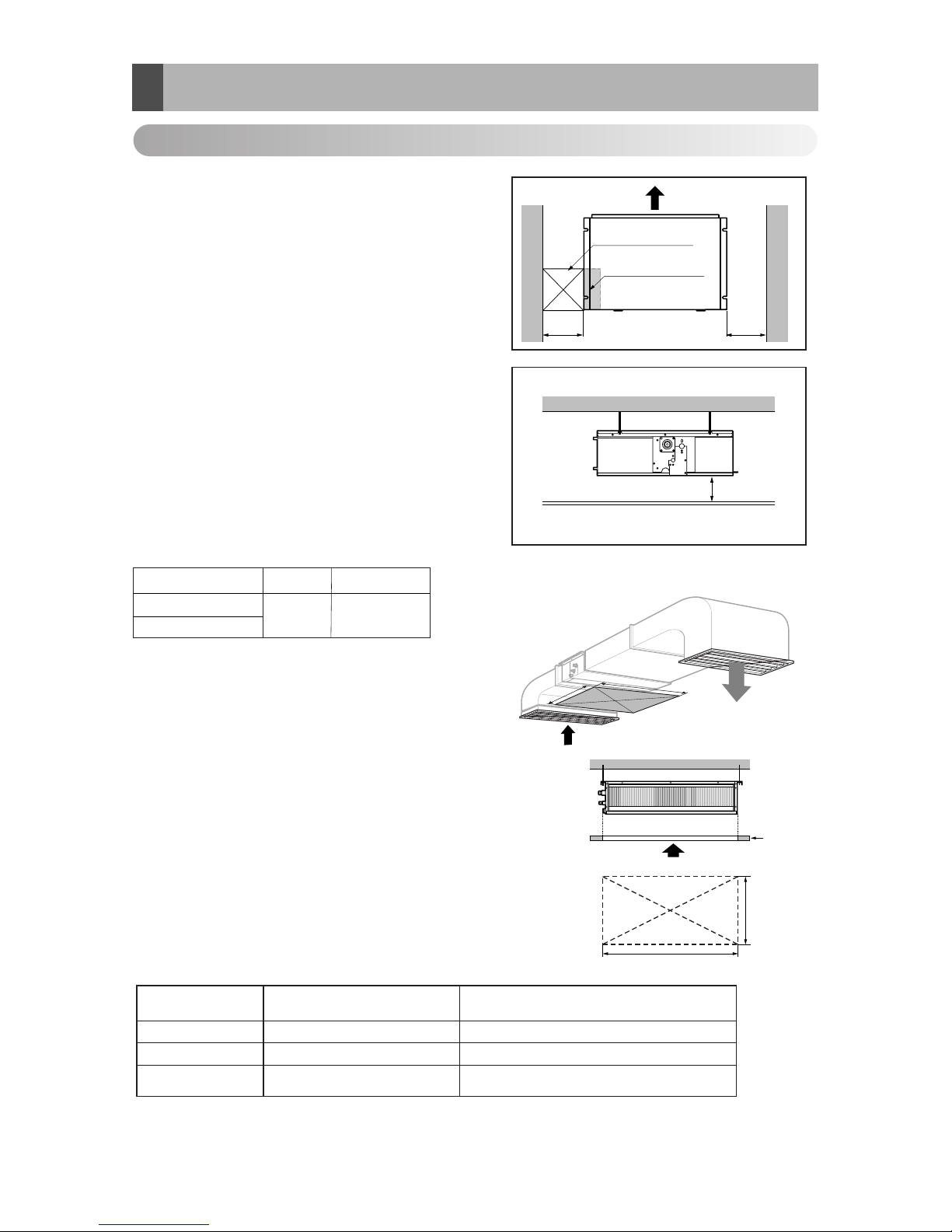

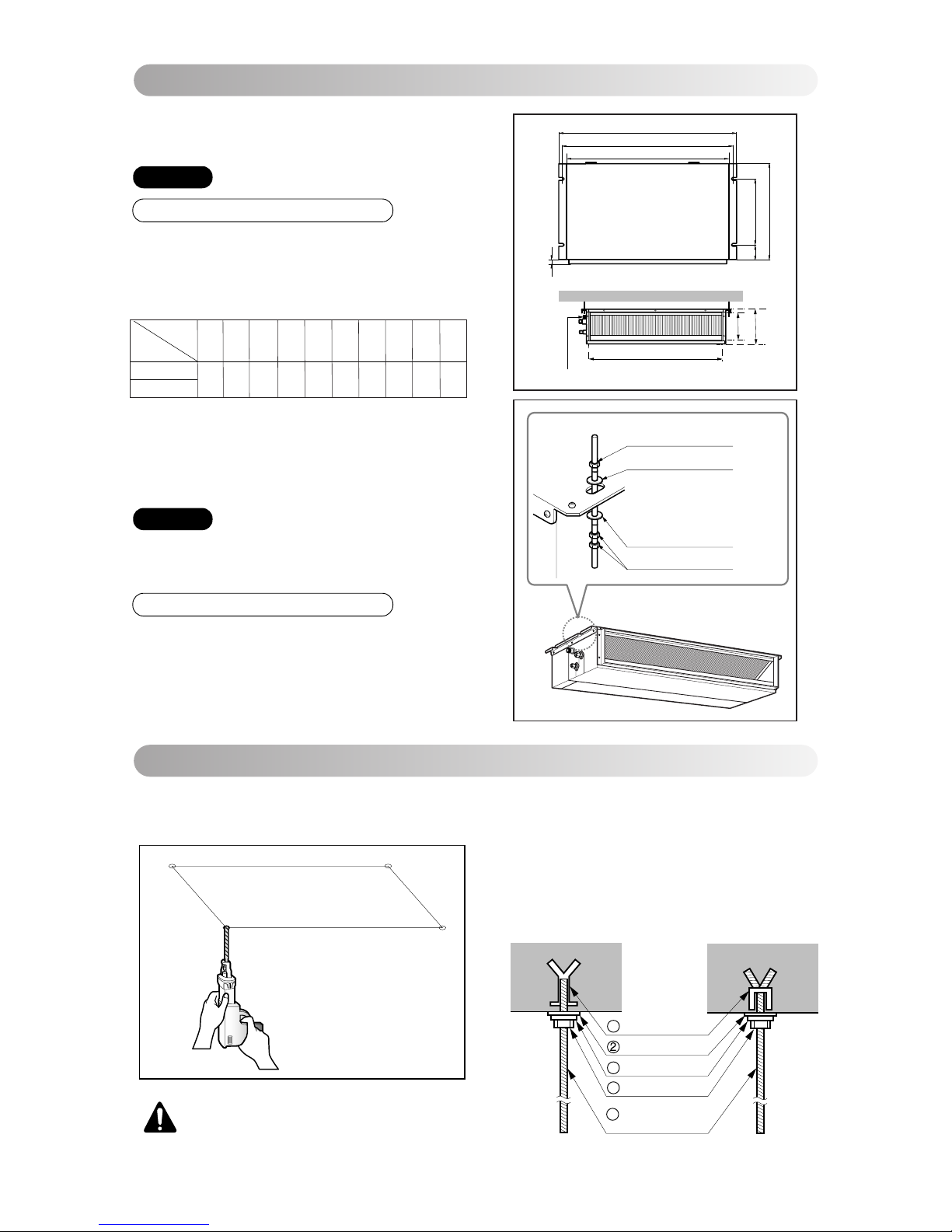

2). Installation of indoor & Outdoor.

Indoor unit

Install the air conditioner in the location that satisfies the following conditions.

• The place shall easily bear a load exceeding four times the

indoor unit’s weight.

• The place shall be able to inspect the unit as the figure.

• The place where the unit shall be leveled.

• The place shall easily connect with the outdoor unit.

• The place where the unit is not affected by an electrical

noise.

• The place where air circulation in the room will be good .

• There should not be any heat source or steam near the

unit

Confirm the positional relationship between the unit and

suspension bolts.

• Installation the ceiling opening to clean the filter or service

under the product.

A).Selection of the best location of Indoor

Inspection hole

(600 x 600)

Control box

H=20 or more

• Suitable dimension "H" is necessary to get a slooe

to drain as aiven in the fiaure

Side view

(unit: mm)

600600

A(Min)

B(Min)

Ceiling

Service Space

A

B

Capacity(Btu/h)

A

B

18/24/30k

600 1100

(Length: mm)

Low static Duct type

Minimum height for motor replacement.

Less than 20cm

Hole size should be

more than the size of IDU.

Insufficient space. Difficult for servicing

20cm to 100cm2

Sufficient space in the ceiling for servicing.

More than 100cm1

Remarks

Distance between

False ceiling & Actual ceiling

Number of

Inspection hole

[Inspection Hole Standard]

36/48/60k

B).Ceiling dimension and hanging bolt location

Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to absorb

unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a figure

for easy water drainage.

• A place where the unit will be leveled and that can support

the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

CASE 1

POSITION OF SUSPENSION BOLT

(Unit:mm)

18/24/30k BTU/h

1130 1180 383 575 93 190 21 1065 163 1100

Dimension

Capacity(Btu/h)

A B C D E F G H I J

CE

G

D

A

J

B

I

F

H

Drainage hole

Drain Pump use

M10 Nut

M10 washer

X 4

X 4

M10 Nut

M10 washer

X 4

X 8

CASE 2

POSITION OF CONSOLE BOLT

5

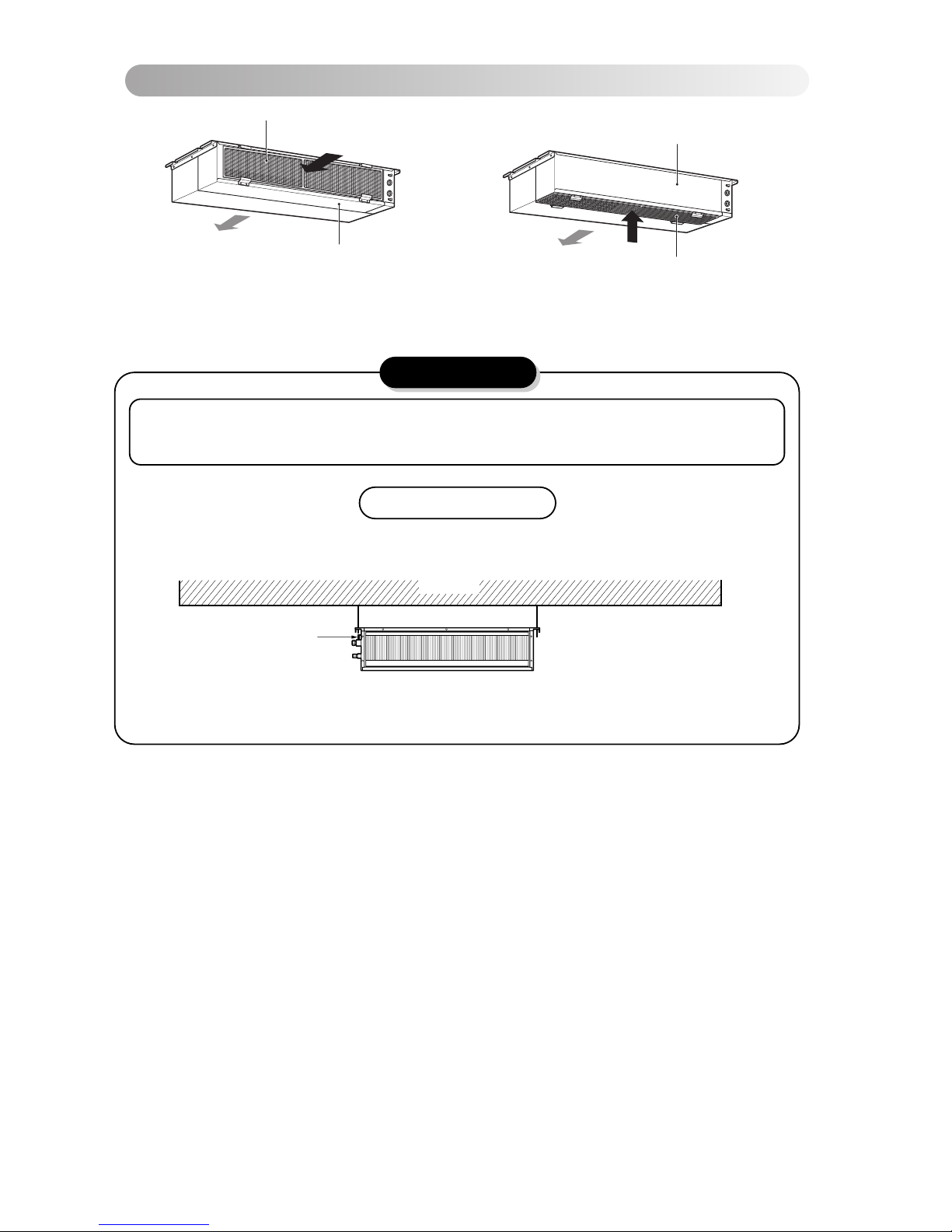

• Select and mark the position for fixing bolts.

• Drill the hole for set anchor on the face of ceiling.

• Insert the set anchor and washer onto the suspension bolts for locking the suspension bolts on the

ceiling.

•

Mount the suspension bolts to the set anchor firmly.

• Secure the installation plates onto the suspension

bolts (adjust level roughly) using nuts, washers

and spring washers.

1 Set anchor

Old building New building

Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

Indoor Unit Installation

CAUTION : Tighten the nut and bolt

to prevent unit falling.

36/48/60k BTU/h

• Low static duct type in case of suction from back

side.

• Low static duct type in case of suction from bottom

side.

Air Filter

Air outlet

Panel Rear

Air outlet

Air Filter

Panel Rear

C).Filter convertible option.

6

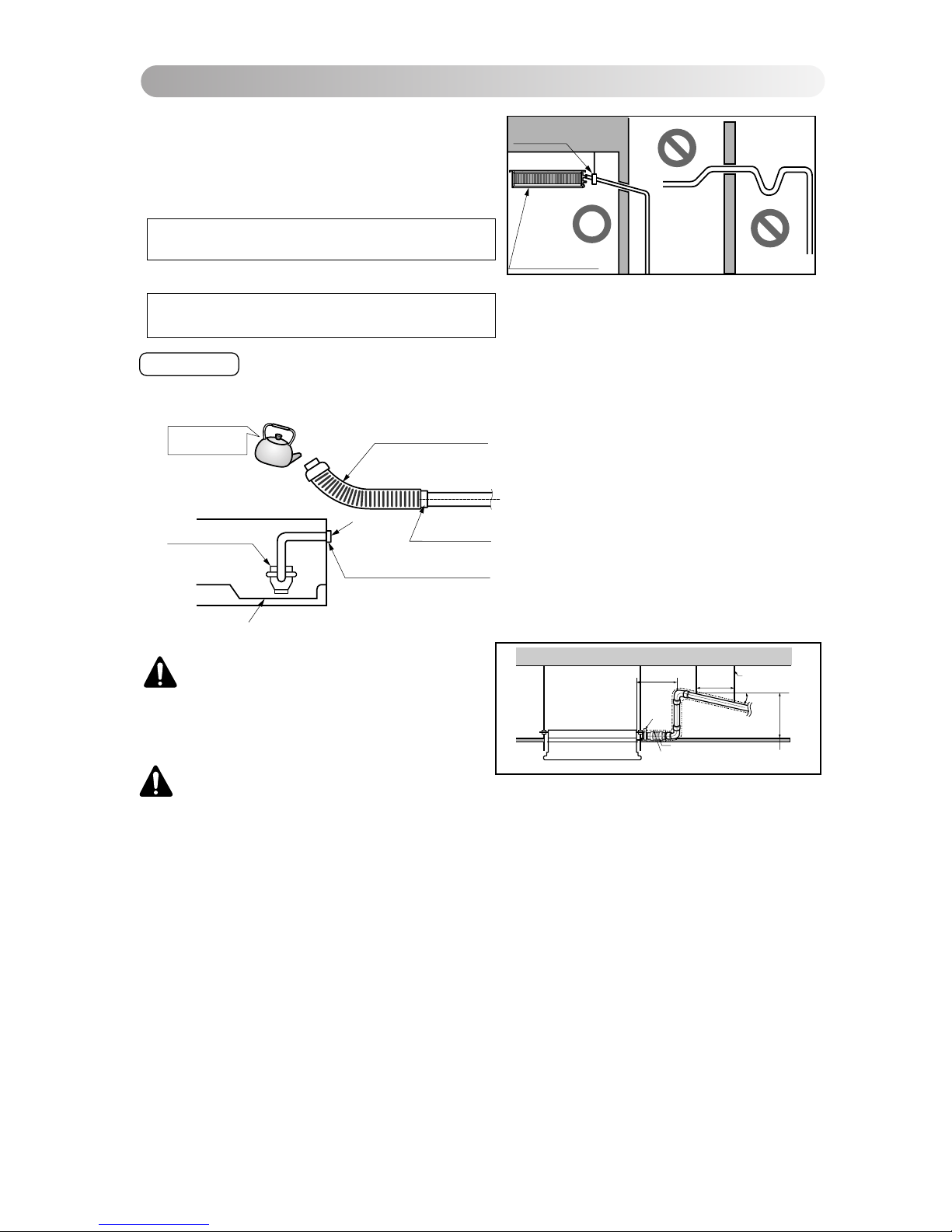

CAUTION

Ceiling

Drain Pump use

Drainage hole

Front of view

1. Install declination of the indoor unit is very important for the drain of the duct type air conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 19mm.

• The unit must be horizontal or declined to the drain hose connected when finished

installation.

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior

an d leav e it pr ovisi o nally until the te st

comes to an end.

• Feed water to the flexible drain hose and

check the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring

is complete.

• When the test is comple te, connect the

flexible drain hose to the drain port on the

indoor unit.

Drain test

Feed water

Drain Pump

Drain pan

Flexible drain hose

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip

• Drain piping must have down-slope (1/50 to 1/100): be sure not to

provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert extra force

on the drain port on the indoor unit.

• The outside diameter of the drain connection on the indoor unit is

32mm.

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe VP-25 and

pipe fittings

Heat insulation material: Polyethylene foam with thickness more than 8 mm.

Upward

routing

not allowed

Pipe clamp

Maintenance

drain port

Indoor unit

D). Drain Piping

7

CAUTION:

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method of

wiring, be guided by the circuit diagram posted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screws which fasten the wiring in the casing of electrical fittings are liable to come loose

from vibrations to which the unit is subjected during the course of transportation. Check them

and make sure that they are all tightly fastened. (If they are loose, it could give rise to burn-out

of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

1/50~1/100 slope

Hanger

distance

Hanger Bracket

Max 700mm

Flexible drain hose

Insulation

Metal

clamp

Max 300mm

1~15m

CAUTION : The supplied flexible drain

hose should not be curved, neither

screwed. The curved or screwed hose

may cause a leakage of water.

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point, fuse breaking, disturbance by the normal function of an overload protection device.

• Proper starting power is not given to the compressor.

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

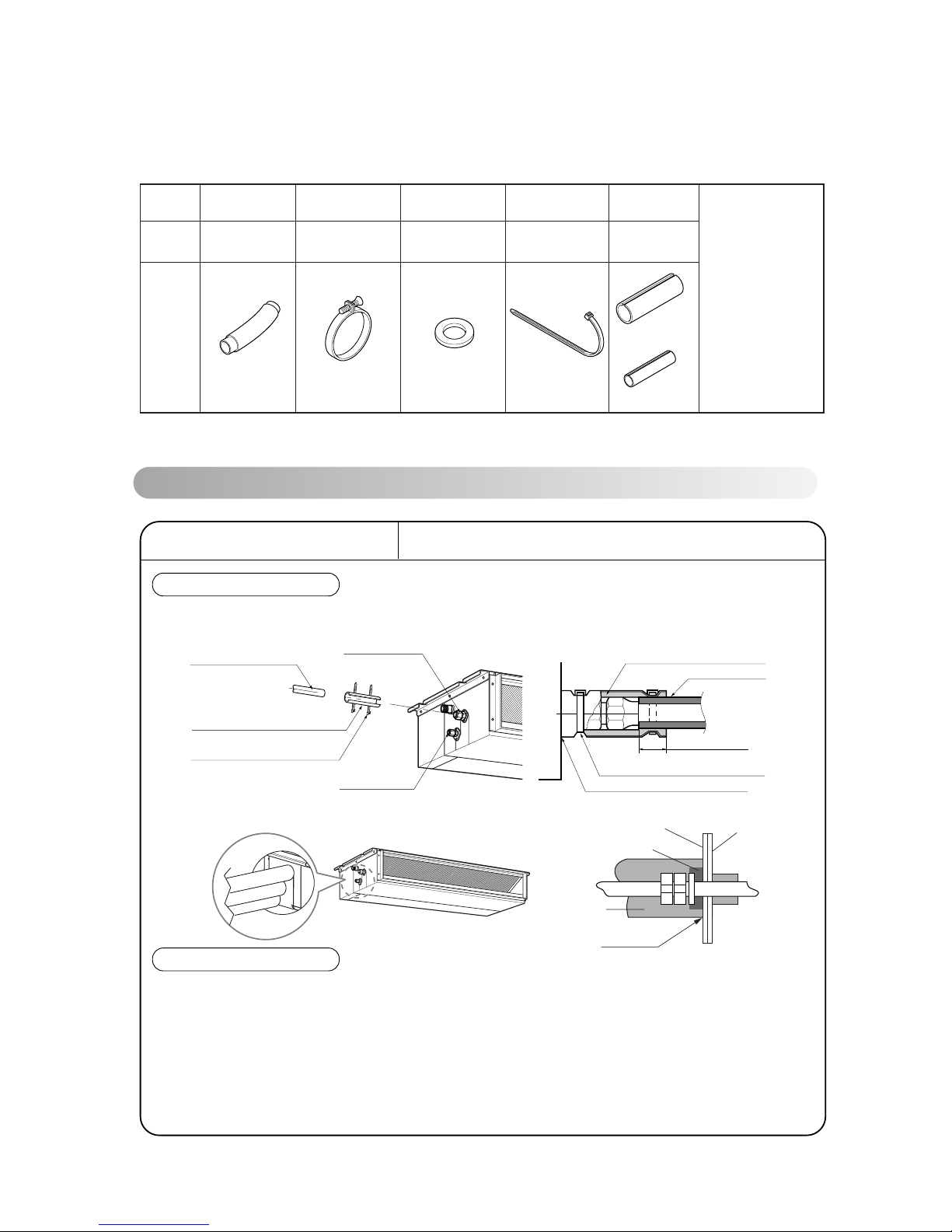

4 EA

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

2 EA

Insulation for

fitting

1 SET

Drain hose

1 EA

Clamp

(Tie Wrap)

8 EA

Washer for

hanging backet

(Other)

Standard Accessories

• Owner's manual

• Installation manual

8

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

After all workings are finished, check the working and operation.

• Air distribution ............... Is the air circulation good?

• Drain ............................. Is the drainage smoothly and no sweating?

• Gas leakage ................. Is the piping connection correctly?

• Wiring ........................... Is the wiring connection correctly?

• Lock-bolt ....................... Is the lock-bolt of compressor loosened?

• Insulation Is the unit fully insulated?

• Ground Is the unit safely grounded?

THERMAL INSULATION

TEST AND CHECK

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Local supply)

Thermal insulator for

piping(Local supply)

Hose clip for thermal insulator(Local supply)

Union for gas pipe

Refrigerant pipe and thermal

insulator(Local supply)

Union for liquid pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator

(Local supply)

Felt

Rubber

Insulation

No clearance

Cabinet

E). Insulation of the Piping & Drain

9

B

e

n

z

e

n

e

S

C

O

U

R

I

N

G

C

L

B

A

R

G

E

R

S

I

N

N

E

R

Care and maintenance

Indoor Unit

Caution: Before performing any maintenance, turn off the main power to the system.

Grille, Case, and Remote Control

Turn the system off before cleaning. To clean,

wipe with a soft, dry cloth. Do not use bleach or

abrasives.

Note:

Supply power must be disconnected before

cleaning the indoor unit.

Never use any of the followings:

• Water hotter than 40°C

Could cause deformation and/or

discoloration.

• Volatile substances

Could damage the surfaces

of the air conditioner.

Clean the filter with a vacuum or warm, soapy

water.

• If very dirty, wash with a solution of

detergent in lukewarm water.

• If hot water (50°C or more) is used, filter

may be deformed.

After washing with water, dry well in the shade.

Re-install the air filter.

Air Filter

The air filters behind Indoor unit

(the suction side) should be checked and cleaned

once every 2 weeks or more often if necessary.

1

2

3

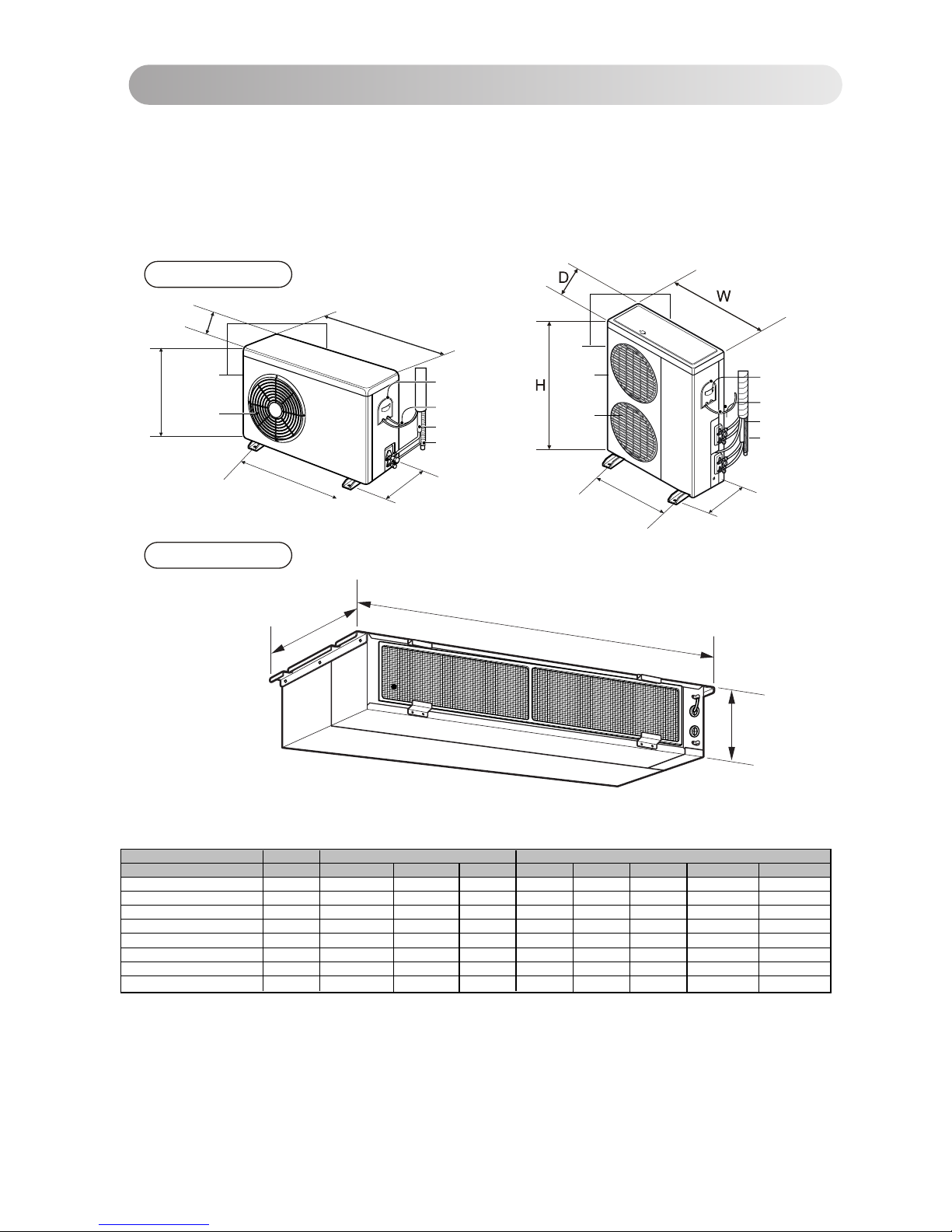

Indoor Unit Dimensions (mm)

CE

G

D

A

J

B

I

F

H

Drainage hole

Drain Pump use

(Unit:mm)

18/24/30k BTU/h

1130 1180 383 575 93 190 21 1065 163 1100

Dimension

Capacity(Btu/h)

A B C D E F G H I J

36/48/60k BTU/h

10

F). Outdoor Unit best location & piping.

The heat exchanger coils and panel vents of the

outdoor unit should be checked regularly. If clogged

with dirt or soot, the heat exchanger and panel vents

may be professionally steam cleaned.

Note:

Dirty or clogged coils will reduce the operating

efficiency of the system and cause higher

operating costs.

Outdoor Unit

Indoor Unit

Outdoor Unit

(Side)

(Rear)

Air outlet

vents

Air intake

vents

Connecting Wire

Connection Pipe

Drain Hose

Control Cover

H

D

W

W

H

D

L2

L1

(Rear)

(Side)

Air outlet

vents

Air intake

vents

L1

L2

Connecting Wire

Connection Pipe

Drain Hose

Control Cover

Model Capacity Indoor dimension Outdoor Dimnesion

W D H W D H L1 L2

LB-B2156QC

1.5 TR

1180 575 190 800 260 555 590 305

LB-B2206QC

2 TR

1180 575 190 800 260 555 590 305

LB-B2256QC / LB-B2258QC

2.5 TR

1180 575 190 870 320 655 545 350

JB-B2156QC

1.5 TR

1180 575 190 870 320 655 545 350

JB-B2258QC

2.5 TR

1180 575 190 870 320 800 545 350

LMA36B2ALI

1.5x2 TR

1180 575 190 870 320 655 545 350

LMA48B2ALI

2.0x2 TR

1180 575 190 906 406 1135 606 465

LMA60B2ALI

2.5x2 TR

1180 575 190 906 406 1135 606 465

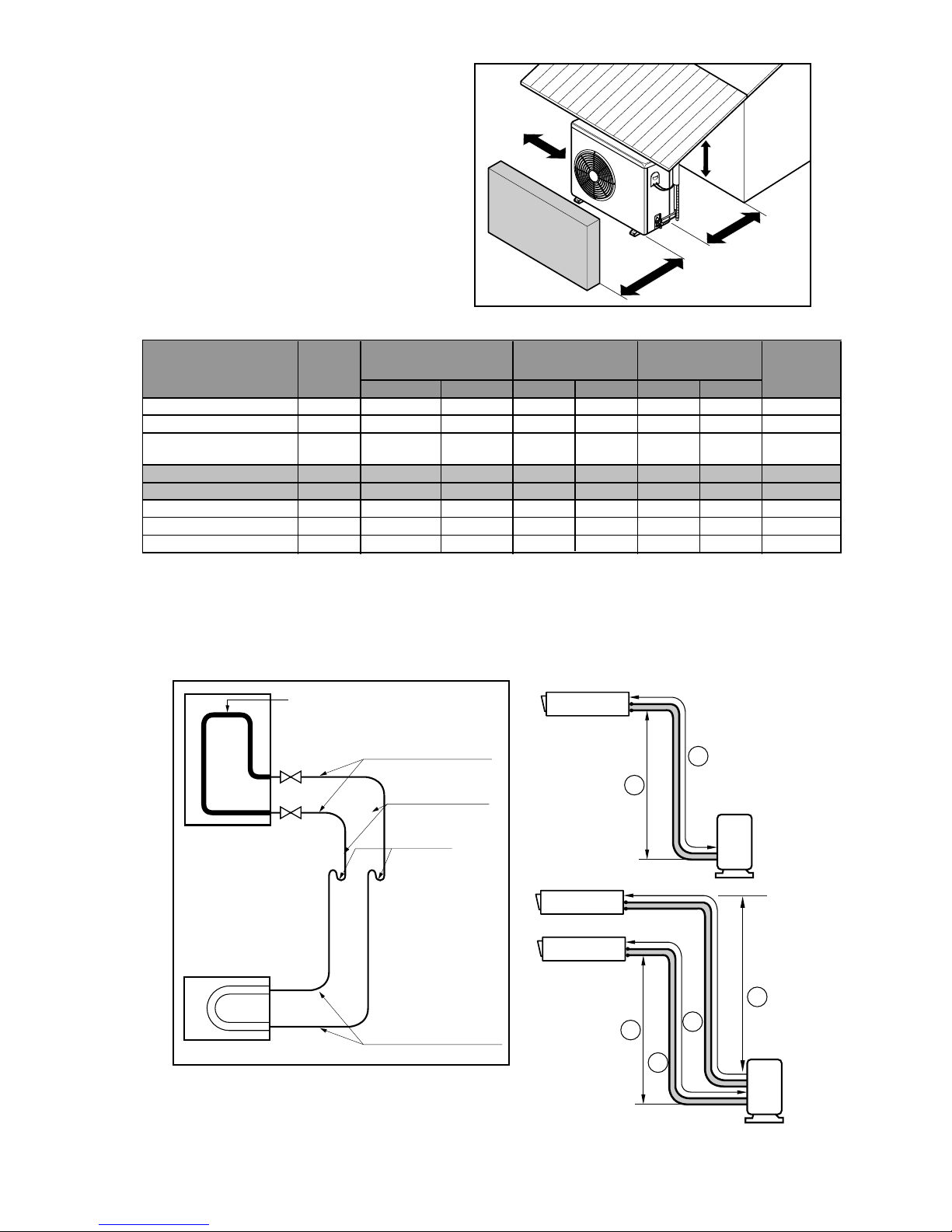

>>Outdoor unit space requirement.

•If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful

that heat radiation f rom t he condenser is not

restricted.

• There should not be any animals or plants

which could be aff ected by hot air

discharged.

• Ensure the spaces indicated by arrows f rom

the w all, ceiling, f ence or other obstacles.

>>Piping length and the elevation

More than

50cm

More than

50cm

More than

100cm

Sunroof

Fence or

obstacles

• Capacity is based on standard length and maximu m allowance

length is on the basis of reliability .

• Oil trap should be installed every 5 meters.

• If 18K model is installed at a distance of 15m, 150g of refrigerant

should be added [(15-5) x 15g = 150g].

10cm

Gas Liquid standard Max standard Max

1.5 TR 1/2" 1/4" 7.5 30 5 15 R-22 15gm

2 TR 5/8" 1/4" 7.5 30 5 15 R-22 20gm

2.5 TR 5/8" 3/8" 7.5 30 5 15 R-22 25gm

LB-B2156QC

LB-B2206QC

Length(A meter)

Model

Additional

Gas Charge

Pipi Sizes

( Dia In Inch)

Capacity

Elevation(B meter)

1.5 TR 5/8" 3/8" 7.5 80 5 35 R-410 30gmJB-B2156QC

JB-B2258QC 2.5 TR 5/8" 3/8" 7.5 80 5 35 R-410 30gm

11

LB-B2256QC/

LB-B2258QC

LMA36B2ALI 1.5x2 TR 1/2" x 2 1/4"x2 5 30 15 R-22 15gm

LMA48B2ALI 2.0x2 TR 5/8" x 2 1/4"x2 5 30 15 R-22 20gm

LMA60B2ALI 2.5x2 TR 5/8" x 2 3/8"x2 5 30 15 R-22 25gm

5

5

5

Indoor unit

Outdoor unit

B

A

U-Trap

Use seamless pipe

Flared connection (union)

Flared connections

Outdoor

Factory charged gas

Indoor

(Service valves)

Indoor unit

Outdoor unit

B

A

B

A

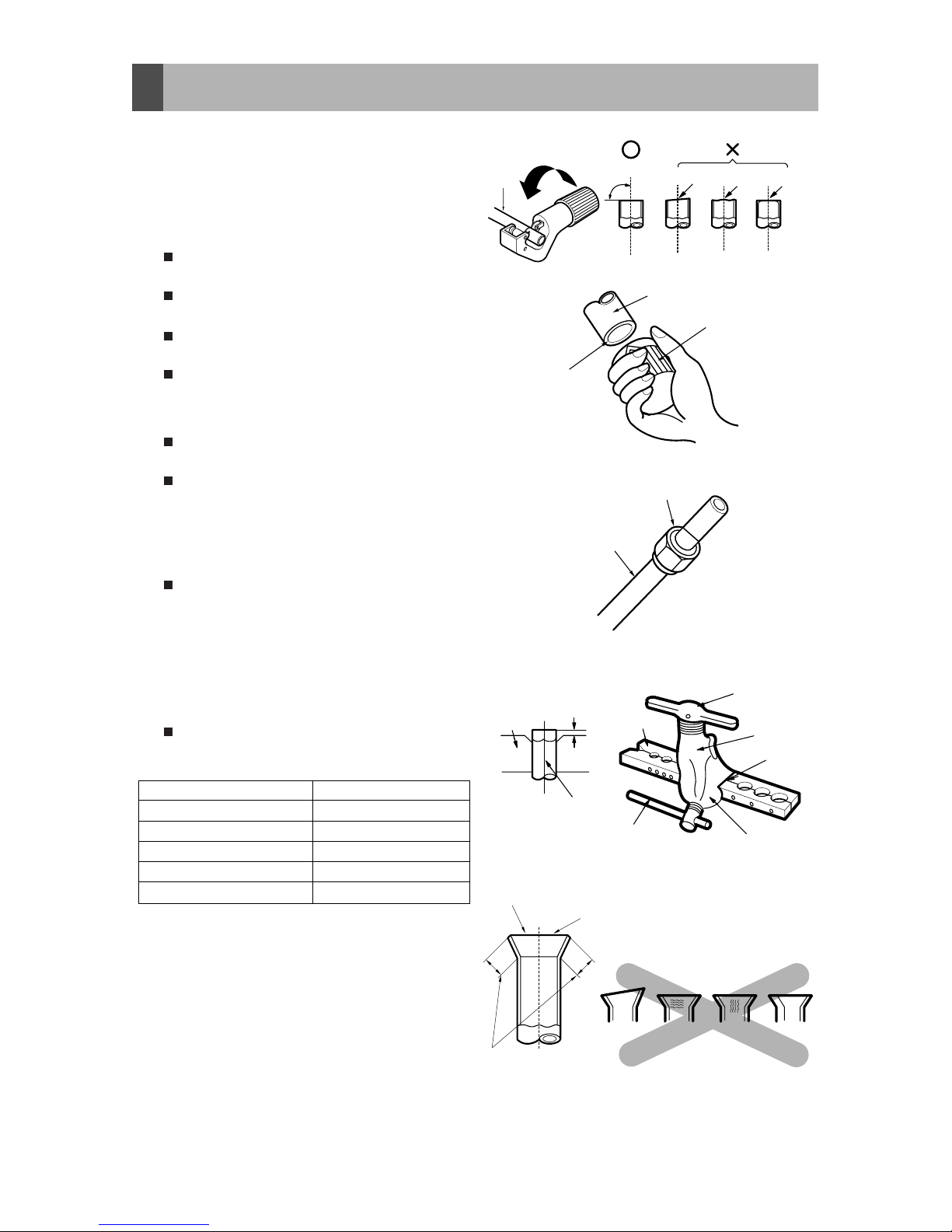

3-1. Preparation of Piping

3. Connecting Pipes to the Indoor Unit

Main cause of gas leakage is defect in

flaring work. Carry out correct flaring work

in the following procedure.

1) Cut the pipes and the cable.

Use the accessory piping kit or the pipes

purchased locally.

Measure the distance between the

indoor and the outdoor unit.

Cut the pipes a little longer than

measured distance.

Cut the cable 1.5m longer than the pipe

length.

2) Burrs removal

Completely remove all burrs from the cut

cross section of pipe/tube.

Put the end of the copper tube/pipe to

downward direction as you remove burrs

in order to avoid to let burrs drop in the

tubing.

3) Putting nut on

Remove flare nuts attached to indoor

and outdoor units, than put them on

pipe/tube having completed burr

removal.

(Not possible to put them on after flaring

work)

4) Flaring work

Carry out flaring work using flaring tool

as shown below.

Firmly hold copper tube in a bar(or die) as

indicated dimension in the table above.

5) Check

Compare the flared work with figure.

If flare is noted to be defective, cut off

the flared section and do flaring work

again.

Copper

tube

90

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Outside Diameter "A"

1/4" 0~0.5

3/8" 0.5~0.8

1/2" 0.5~0.8

5/8" 0.8~1.0

3/4" 1.0~1.3

12

Loading...

Loading...