Page 1

SINGLE-ZONE

HIGH EFFICIENCY

WALL MOUNT

ENGINEERING MANUAL

Single-Zone High Efficiency Systems

3/4 to 1-1/2 Tons

Models:

LS090HSV5

LS120HSV5

LS180HSV5

Page 2

PROPRIETARY DATA NOTICE

This document, as well as all reports, illustrations, data, information,

and other materials are the property of LG Electronics U.S.A., Inc., and are

disclosed by LG Electronics U.S.A., Inc. only in confidence.

This document is for design purposes only.

A summary list of safety precautions is on page 4.

For more technical materials such as submittals, catalogs, installation, best

practices, building ventilation, owner’s, and service manuals, visit

www.lghvac.com.

For continual product development, LG Electronics U.S.A., Inc., reserves the right to change specifications without notice.

© LG Electronics U.S.A., Inc.

Page 3

TABLE OF CONTENTS

CAUTION

Unit Nomenclature...........................................................................................................................................................................................................4

LG Air Conditioner Technical Solution (LATS)..........................................................................................................................................................5-6

High Efciency Standard Product Data...................................................................................................................................................................7-36

Mechanical Specications ......................................................................................................................................................................................... 8

General Data ......................................................................................................................................................................................................... 9

Electrical Data ............................................................................................................................................................................................................ 11

Functions, Controls, and Options .......................................................................................................................................................................... 12

Dimensions ............................................................................................................................................................................................................ 13-17

Acoustic Data ........................................................................................................................................................................................................ 18-21

Refrigerant Flow Diagrams .................................................................................................................................................................................... 22-23

Wiring Diagrams .................................................................................................................................................................................................... 24-26

Electrical Connections ........................................................................................................................................................................................... 27-30

Air Flow, External Pressure, Temp. Distribution ...................................................................................................................................................... 31-34

Accessories ........................................................................................................................................................................................................... 35-36

High Efciency Standard Performance Data--------------------------------------------------------------------------------------------------------------------------------37-45

Cooling Capacity Data ........................................................................................................................................................................................... 38-396

Heating Capacity Data ........................................................................................................................................................................................... 40-41

Maximum Heating Capacity Data .......................................................................................................................................................................... 42-43

Equipment Selection Procedure ............................................................................................................................................................................ 44-45

Introduction

High Efciency Standard Application Guidelines................................................................................................................................................. 46-55

Placement Considerations ..................................................................................................................................................................................... 47-51

Installing Outdoor Unit Indoors .............................................................................................................................................................................. 52-54

Refrigerant Piping Design ...................................................................................................................................................................................... 55

TABLE OF SYMBOLS

DANGER

This symbol indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

This symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This symbol indicates situations that may result in equipment or property damage accidents only.

This symbol indicates an action must not be completed.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

INTRODUCTION | 3

Page 4

UNIT NOMENCLATURE

Indoor Units and Outdoor Units

L SV 5N

L = LG

Frame Type:

A: Art Cool™

S: Standard

C: Four-Way Ceiling-Cassette

D: Ceiling-Concealed Duct (Low Static)

H: Ceiling-Concealed Duct (High Static)

V: Vertical-Horizontal Air Handling

N: Indoor Unit

U: Outdoor Unit

No N or U: System

Nominal Capacity

(Nominal cooling capacity in Btu/h):

9 = 9,000

12 = 12,000

18 = 18,000

24 = 24,000

36 = 36,000

42 = 42,000

48 = 48,000

S 180 H

System Type:

H = Heat Pump

Style:

SV = High Efficiency Inverter

VP = Gallery

YV = Premier

Single Zone High Efciency Standard Wall Mount Engineering Manual

EV = Mega

V = Standard Inverter

T = Thermostat Compatible

LV = Extended Piping

Generation:

4 | INTRODUCTION

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 5

LG AIR CONDITIONER

TECHNICAL SOLUTION (LATS)

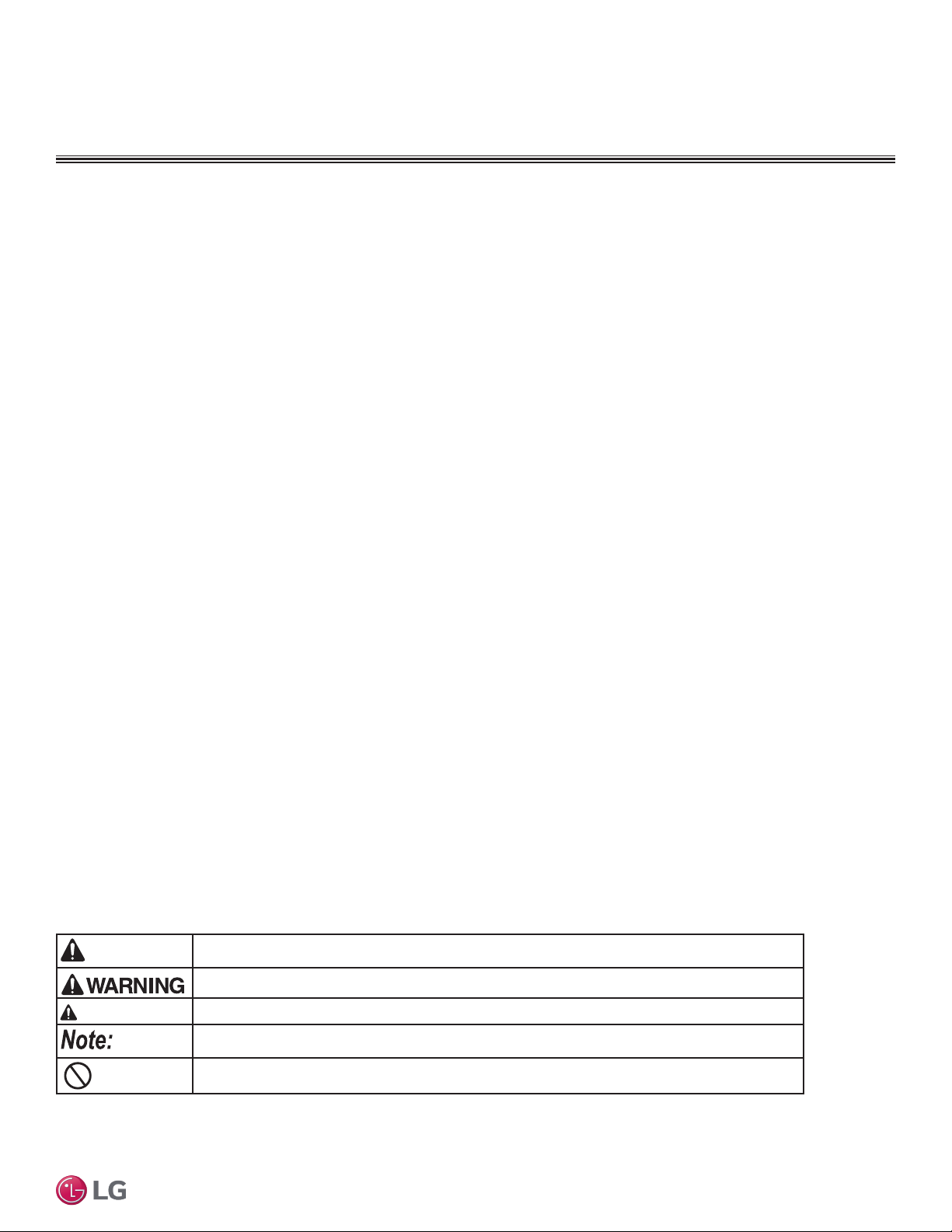

LG Air Conditioner Technical Solution (LATS) Software

A properly designed and installed refrigerant piping system is critical to the optimal performance of LG air-conditioning systems. To assist

engineers, LG offers, free of charge, LG Air Conditioner Technical Solution (LATS) software—a total design solution for LG air conditioning

systems. Contact your LG Rep for the best software program for your application.

To reduce the risk of designing an improper applied system or one that will not operate correctly, LG requires that LATS software be used on all projects.

Formats

LATS is available to LG customers in three user interfaces: LATS HVAC, LATS CAD2, and LATS Revit. All three LATS formats are available

through www.myLGHVAC.com, or contact an LG Sales Representative.

LATS HVAC is a Windows®-based application that aids engineers in designing LG Variable Refrigerant Flow (VRF), Multi F / Multi F MAX,

Single-Zone, and Energy Recovery Ventilator (ERV) systems.

*Windows® is a registered mark of Microsoft® Corporation.

LATS CAD2 combines the LG LATS program with AutoCAD®

software**. It permits engineers to layout and validate LG Multi V

Variable Refrigerant Flow (VRF), Multi F / Multi F MAX, Single-Zone,

and Energy Recovery Ventilator (ERV) systems directly into CAD

drawings.

LATS Revit integrates the LG LATS program with Revit® software**.

It permits engineers to layout and validate Multi V VRF systems

directly into Revit drawings.

**AutoCAD® and Revit® are both registered marks of Autodesk, Inc.

Figure 1: Example of LATS CAD2.

Features

All LG product design criteria have been loaded into the program,

making LATS simple to use: double click or drag and drop the

component choices. Build systems in Tree Mode where the

refrigerant system can be viewed. Switch to a Schematic diagram to

see the electrical and communications wiring.

LATS software permits the user to input region data, indoor and outdoor design temperatures, modify humidity default values, zoning, specify

type and size of outdoor units and indoor units, and input air flow and external static pressure (ESP) for ducted indoor units.

The program can also:

• Import building loads from a separate Excel file.

• Present options for outdoor unit auto selection.

• Automatically calculate component capacity based on design

conditions for the chosen region.

• Verify if the height differences between the various system

components are within system limits.

• Provide the correct size of each refrigerant piping segment and LG

Y-Branches and Headers.

• Adjust overall piping system length when elbows are added.

• Check for component piping limitations and flag if any parameters

are broken.

• Factor operation and capacity for defrost operation.

• Calculate refrigerant charge, noting any additional trim charge.

• Suggest accessories for indoor units and outdoor units.

• Run system simulation.

Introduction

Features depend on which LATS program is being used, and the type of system being designed.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

INTRODUCTION | 5

Page 6

LG AIR CONDITIONER

TECHNICAL SOLUTION (LATS)

LATS Generates a Complete Project Report

LATS software also generates a report containing project design parameters, cooling and heating design data, system component

performance, and capacity data. The report includes system combination ratio and refrigerant charge calculations; and provides detailed bill

of material, including outdoor units, indoor units, control devices, accessories, refrigerant pipe sizes segregated by building, by system, by

pipe size, and by pipe segments. LATS can generate an Excel GERP report that can imported into the LG SOPS pricing and ordering system.

Proper Design to Install Procedure

LG encourages a two report design-to-install-procedure. After the

design engineer determines building / zone loads and other details,

the engineer opens the LATS program and inputs the project’s

information. When the design is complete, the “Auto Piping” and

“System Check” functions must be used to verify piping sizes,

limitations, and if any design errors are present. If errors are found,

engineers must adjust the design, and run Auto Piping and System

Check again. When the design passes the checks, then the engineer

prints out a project “Shop Drawing” (LATS Tree Diagram) and

provides it to the installing contractor. The contractor must follow the

LATS Tree Diagram when building the piping system, but oftentimes

the design changes on the building site:

• Architect has changed location and/or purpose of room(s).

• Outdoor unit cannot be placed where originally intended.

• Structural elements prevent routing the piping as planned.

• Air conditioning system conflicts with other building systems (plumbing, gas lines, etc.).

The contractor must mark any deviation from the design on the Shop Drawing, including as-built straight lines and elbows. This “Mark Up”

drawing must be returned to the design engineer or Rep, who must input contractor changes into the LATS file. (Copy the original LATS

software file, save and rename as a separate file, and modify all piping lengths by double-clicking on each length and editing information.)

Like the shop drawing, the Auto Piping and System Check must also be run on this new “As Built” drawing. The design engineer or Rep must

then provide the final As Built file to the contractor. The Mark Up version must be compared to the As Built version for:

Figure 2: Example of a LATS Tree Diagram.

• Differences in pipe diameter(s). If incorrect diameters have been installed, the piping must be changed out. If pipe diameters have changed,

check to see if Y-Branches will also need to be changed.

• Changes to outdoor unit and indoor unit capacities. Capacities changes may impact line length changes.

• Additional refrigerant charge quantity (“Trim Charge”). Trim charge will change if piping lengths and diameters change. The As Built version

must reflect installed piping lengths to ensure correct trim charge.

All documents submitted by the contractor, as well as the Shop Drawing and the As Built Drawing files must be provided for commissioning

purposes. Model and serial numbers for all system components must also be submitted. If the steps previously detailed are not followed,

and all documents are not provided to the commissioning agent, the project runs the risk of not being commissioned and voiding any limited

warranty LG offers on the equipment.

Single Zone High Efciency Standard Wall Mount Engineering Manual

Contact your LG representative for the best software program for your application.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

6 | INTRODUCTION

©

Page 7

PRODUCT DATA

“Mechanical Specifications” on page 8

“General Data” on page 9

“Electrical Data” on page 11

“Functions, Controls, and Options”on page 12

“Dimensions” on page 13

“Acoustic Data” on page 18

“Refrigerant Flow Diagrams” on page 22

“Wiring Diagrams” on page 24

“Electrical Connections” on page 27

“Air Flow, External Pressure, and Temperature

Distribution” on page 31

“Accessories” on page 35

Page 8

MECHANICAL SPECIFICATIONS

General

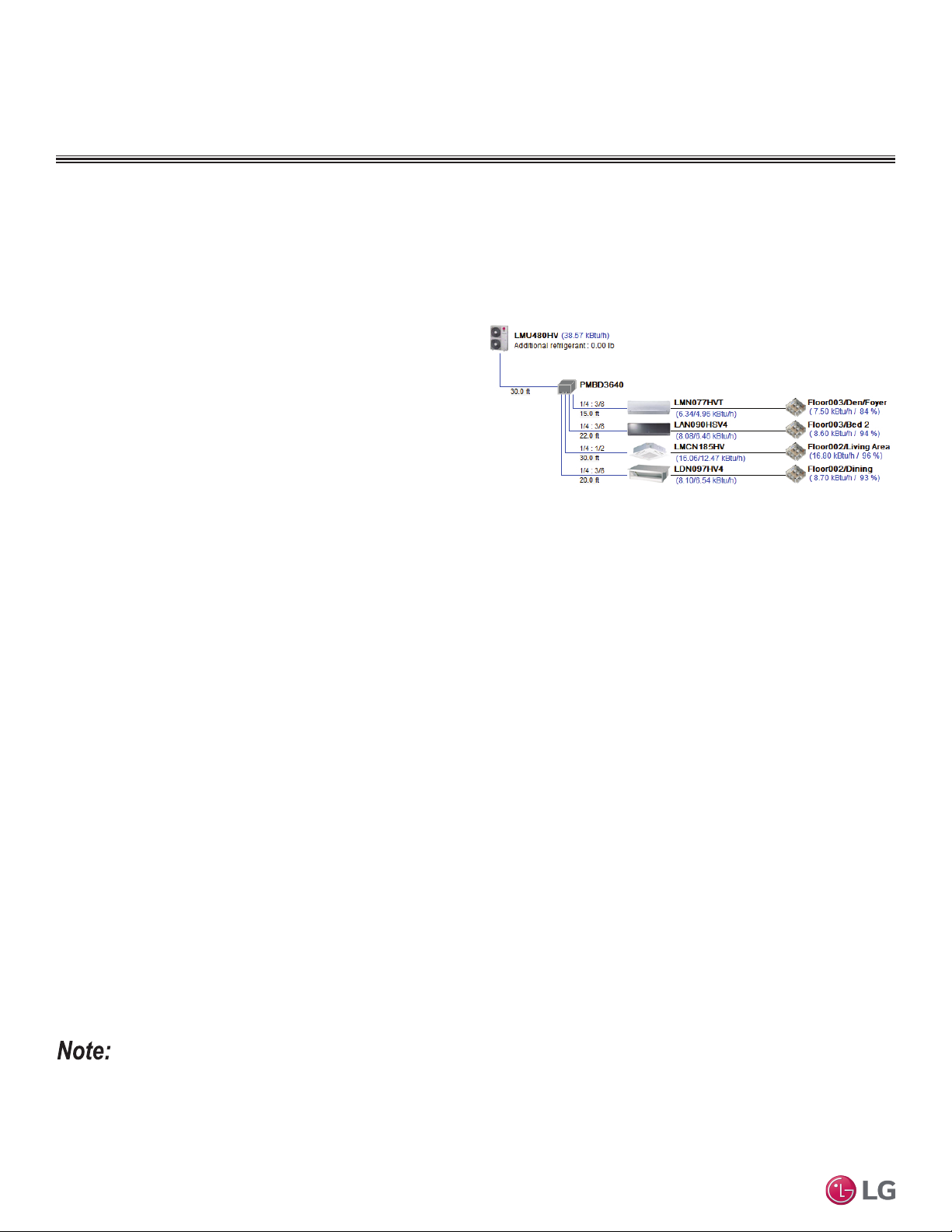

LG Single Zone High Efficiency Wall Mount systems are comprised

of a single outdoor unit connected to a single indoor unit with a

single refrigerant circuit.

These single zone systems can operate in either cooling or heating

mode. These systems are capable of changing mode within a

maximum time of three (3) minutes to ensure temperature can be

properly maintained.

LG Single Zone High Efficiency systems are manufactured in

a facility registered to ISO 9001 and ISO 14001, which is a set

of standards applying to environmental protection set by the

International Organization for Standardization (ISO). The units are

listed by Intertek Electrical Testing Laboratories (ETL) and bear the

ETL label. Wiring in these units are in accordance with the National

Electrical Code (NEC).

Temperature Ranges

Outdoor Unit

Operating ranges for outdoor units of 14°F to 118°F DB for cooling

and -4°F to +65°F WB for heating.

Indoor Unit

Operating ranges for indoor units of 53°F to 75°F WB for cooling and

60°F to 86°F DB for heating.

Figure 3: Single Zone High Efciency Wall Mount Indoor Unit.

Frequency ranges for the outdoor units are as follows:

LSU090HSV5 = 10-84 Hz

LSU120HSV5 = 10-92 Hz

LSU180HSV5 = 10-93 Hz

Overcurrent protection and vibration isolation are integrated with the

compressor.

Outdoor Unit Coil

Heat pump outdoor unit coils are made of a nonferrous construction

with louvered fins on copper tubing, and are protected with an

integral coil guard. Coil fans have a factory applied corrosion

resistant GoldFinTM material with hydrophilic coating. Drain pan

heaters are also available for the outdoor units—9,000 and 12,000

Btu/h outdoor units include factory-installed drain pan heaters; the

drain pan heater for the 18,000 Btu/h outdoor unit is offered as an

optional accessory

Installing an optional Low Ambient Wind Bafe Kit will allow operation

down to 0°F in cooling mode for these single zone systems.

Casing / Frame

Outdoor unit is constructed with pre-coated metal (PCM). Indoor unit

is constructed of heavy duty Acrylonitrile Butadiene Styrene (ABS)

and High Impact Polystyrene (HIPS) plastic.

Refrigerant System

The refrigeration system consists of a single refrigeration circuit and

uses R410A refrigerant. The outdoor unit is provided with factory

installed components, including a refrigerant strainer, four-way

reversing valve, electronic controlled expansion valve (EEV), high and

low side charging ports, service valves, and interconnecting piping.

Single Zone High Efciency Standard Wall Mount Engineering Manual

Refrigeration Oil Control

Heat pump outdoor units have a centrifugal oil separator and

controls to ensure sufficient oil supply is maintained, and that oil

does not travel with the refrigerant.

Compressors

The outdoor unit is equipped with one hermetic digitally controlled

inverter driven twin rotary compressor to modulate capacity

(modulation in 1 Hz increments).

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

8 | PRODUCT DATA

©

Fans and Motors

The outdoor unit includes one direct fan drive, variable speed

propeller type fan. The Brushless Digitally Controlled (BLDC)

fan motor shall have inherent protection, permanently lubricated

bearings, and variable speed with a maximum speed up to 950 rpm.

Raised guards are provided to limit contact with moving parts. The

outdoor unit has horizontal discharge airflow.

Electrical

These units are available in 208-230V, 60 Hz, 1-phase power supply.

These units are capable of operating within voltage limits of ±10%

rated voltage, and include overcurrent protection.

Controls

The indoor unit casing has a factory-standard, integral, infrared

sensor designed to communicate with the supplied LG wireless

handheld remote controller. An optional LG supplied wired controller

is available as an additional accessory. Communication between the

indoor unit and the outdoor unit is accomplished through 18 AWG

four-core, stranded, shielded power / communication cable. HSV5

indoor units have built-in Wi-Fi and can be controlled by LG’s Smart

ThinQ™ app on a smart device. A field-supplied Wi-Fi network and

smart device are required. The Smart ThinQ app is free, and is

available for Android™ and iOS. (Android is a trademark of Google

LLC.)

Page 9

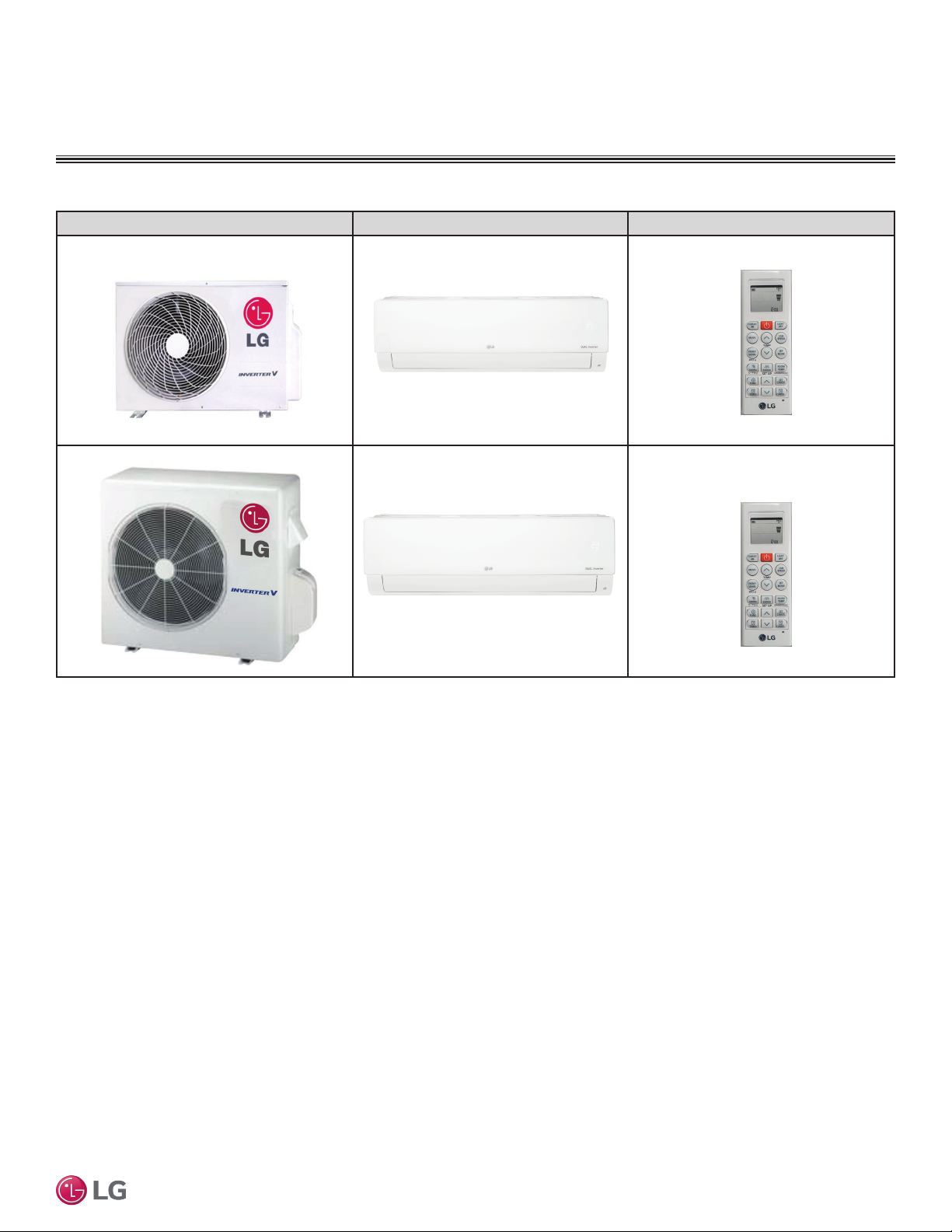

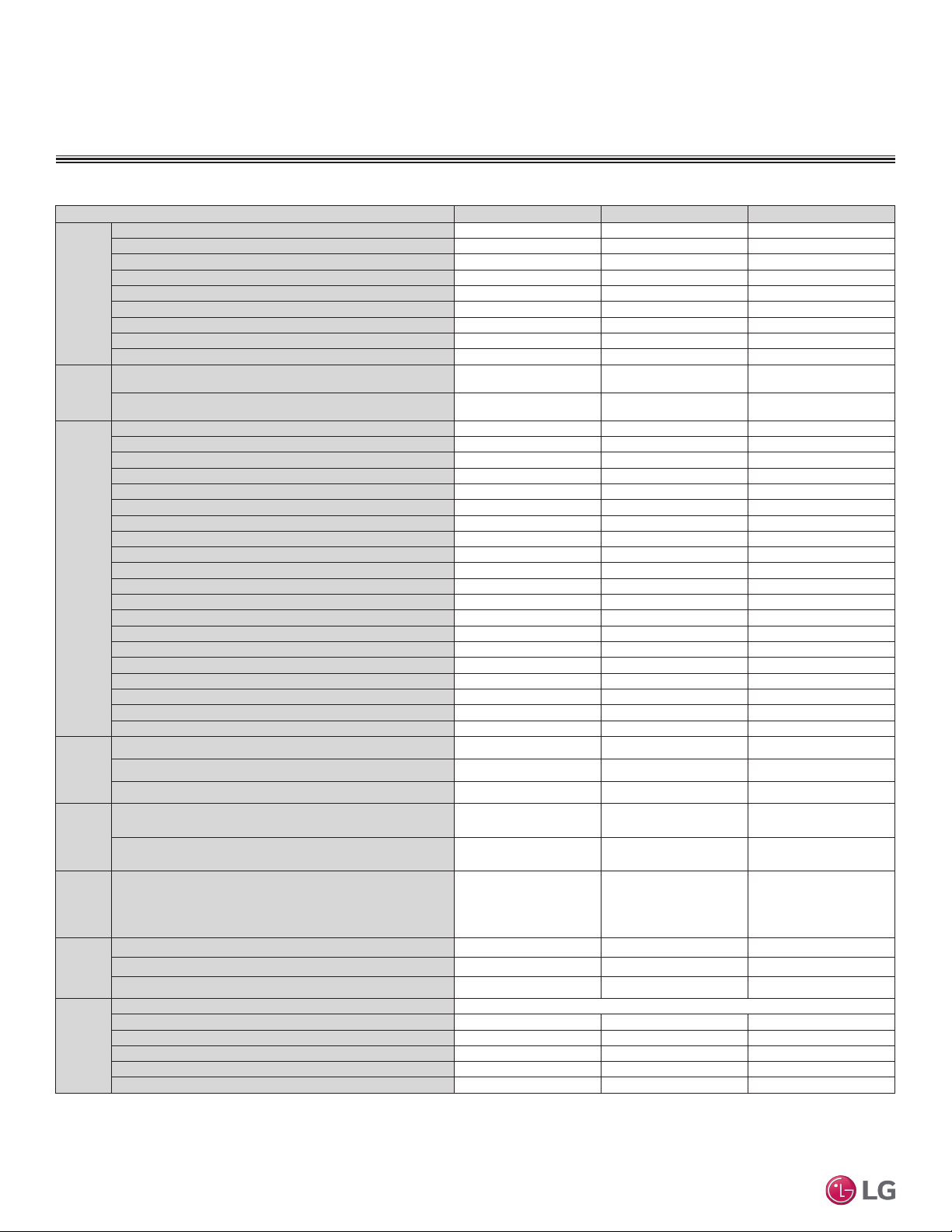

Table 1: Single Zone High Efciency Standard Wall Mount Unit Pairing Table.

Outdoor Unit Model Indoor Unit Model Wireless Remote Controller

LSU090HSV5, LSU120HSV5 LSN090HSV5, LSN120HSV5 AKB74955602

LSU180HSV5 LSN180HSV5 AKB74955602

GENERAL DATA

Pairing Table

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 9

Page 10

GENERAL DATA

Table 2: Single Zone High Efciency Standard Wall Mount Unit General Data.

System Model Number (IDU/ODU)

(LSN090HSV5/LSU090HSV5)

Cooling Capacity (Min/Rated/Max) (Btu/h)

Cooling Power Input1 (kW)

Heating Capacity (Min/Rated/Max) (Btu/h)

Heating Power Input1 (kW)

COP

Maximum Heating Capacity (Btu/h)

Outdoor 17 °F (WB)/Indoor 70 °F (DB)

Outdoor 5°F (WB)/Indoor 70 °F (DB)

Outdoor -4 °F (WB)/Indoor 70 °F (DB)

EER

SEER

HSPF

Power Supply (V/Hz/Ø)

Outdoor Unit Operating Range

2

Cooling (°F DB)

Heating (°F WB)

Indoor Unit Operating Range

Cooling (°F WB)

Heating (°F DB)

Indoor Temperature Setting Range

Cooling (°F)

Heating (°F)

Unit Data

Refrigerant Type

Refrigerant Control

Indoor Unit Sound Pressure Level dB(A) (H/M/L/Sleep)

3

4

Outdoor Unit Sound Pressure Level dB(A)4 (Cool/Heat)

Unit Weight (lbs)

IDU (Net/Shipping)

ODU (Net/Shipping)

Power Wiring / Communication Cable

5

(No. x AWG)

Compressor

Compressor Type (Qty)

Fan

Indoor Unit Type (Qty)

Outdoor Unit Type (Qty)

Motor/Drive

Airflow Rate

Indoor Unit

(Max. / H / M / L [CFM])

Cooling

Heating

Outdoor Unit (Max. [CFM])

Piping

Liquid Line (in.)

Vapor Line (in.)

Single Zone High Efciency Standard Wall Mount Engineering Manual

Condensate Drain O.D. / I.D. (in.)

Additional Refrigerant Charge (oz./ft.)

Pipe Length6 (Minimum/Standard/Maximum) (ft.)

Piping Length6 (no add’l refrigerant, ft.)

Max Elevation Difference (ft.)

EEV: Electronic Expansion Valve IDU: Indoor Unit ODU: Outdoor Unit

This unit comes with a dry helium charge.

This data is rated 0 ft above sea level with 24.6 of refrigerant line per indoor unit and a 0 ft level

difference outdoor and indoor units.

Cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and 67ºF wet

bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and 59ºF wet

bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

1

Power Input is rated at high speed.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

10 | PRODUCT DATA

©

LS090HSV5

1,023 ~ 9,000 ~ 12,625 1,023 ~ 12,000 ~ 13,785 3,070 ~ 18,000 ~ 29,515

0.20 ~ 0.62 ~ 0.87 0.20 ~ 0.96 ~ 1.35 0.30 ~ 1.43 ~ 2.00

1,023 ~ 10,900 ~ 17,061 1,023 ~ 13,600 ~ 22,178 3,070 ~ 21,600 ~ 38,898

0.20 ~ 0.71 ~ 1.89 0.20 ~ 1.04 ~ 1.97 0.66 ~ 1.73 ~ 3.98

11,080 (102%) 13,810 (102%) 22,340 (103%)

9,570 (88%) 11,930 (88%) 19,300 (89%)

8,310 (76%) 10,360 (76%) 16,760 (77%)

39 / 33 / 23 / 19 39 / 33 / 23 / 19 45 / 40 / 35 / 29

Twin Rotary (1) Twin Rotary (1) Twin Rotary (1)

459 / 338 / 317 / 194 459 / 338 / 317 / 194 706 / 530 / 477 / 371

459 / 338 / 317 / 229 459 / 338 / 317 / 229 706 / 547 / 494 / 371

9.8 / 24.6 / 82 9.8 / 24.6 / 82 9.8 / 24.6 / 114.8

(LSN120HSV5/LSU120HSV5)

LS120HSV5

(LSN180HSV5/LSU180HSV5)

LS180HSV5

4.50 3.83 3.66

14.52 12.50 12.58

23.50 22.70 21.50

11.30 11.40 10.20

208-230 / 60 / 1

14 ~ 118

-4 ~ +65

53 to 75

60 to 86

64 to 86

60 to 86

R410A

EEV

45 / 48 45 / 48 53 / 53

18.3 / 23.4 18.3 / 23.4 25.6 / 32.2

74.1 / 78.9 74.1 / 78.9 116.8 / 126.5

4 x 18

Cross Flow (1)

Propeller (1)

Brushless Digitally Controlled / Direct

1,165 1,165 2,119

ø1/4 ø1/4 ø3/8

ø3/8 ø3/8 ø5/8

27/32, 5/8 27/32, 5/8 27/32, 5/8

0.22 0.22 0.38

41 41 24.6

49.2 49.2 49.2

2

Optional low Ambient Wind Baffle Kit allows operation down to 0°F in cooling mode.

3

Take appropriate actions at the end of HVAC equipment life to recover, recycle, reclaim or destroy R410A

refrigerant according to applicable regulations (40 CFR Part 82, Subpart F) under section 608 of CAA.

4

Sound Pressure levels are tested in an anechoic chamber under ISO Standard 1996.

5

All communication / connection (power) cable from the outdoor unit to the indoor unit is field supplied

and must be a minimum of four-conductor, 18 AWG, stranded, shielded or unshielded (if shielded, it

must be grounded to the chassis of the outdoor unit only), and must comply with applicable local and

national codes. For detailed electrical information, please refer to electric characteristics on page 11.

6

Piping lengths are equivalent.

Page 11

ELECTRICAL DATA

Electrical Data

Table 3: Single Zone High Efciency Standard Wall Mount System Electrical Data.

Nominal

Tons

Unit Model No. Hertz Voltage

3/4 LS090HSV5

1 LS120HSV5 10.0 15.0 1 7.0 7.0 0.043 0.4 0.4

60 208 - 230 187 - 253

Voltage

Range

(Min. to Max.)

MCA MOP

Compressor

Quantity

10.0 15.0 1 7.0 7.0 0.043 0.4 0.4

1-1/2 LS180HSV5 13.0 20.0 1 9.6 9.6 0.124 0.25 0.4

Voltage tolerance is ±10%.

Maximum allowable voltage unbalance is 2%.

MCA = Minimum Circuit Ampacity.

Maximum Overcurrent Protection (MOP) is calculated as follows:

(Largest motor FLA x 2.25) + (Sum of other motor FLA) rounded

down to the nearest standard fuse size.

Compressor Motor

RLA

Cooling Heating

RLA = Rated Load Amps.

FLA = Full Load Amps.

Outdoor Fan Motor

kW FLA FLA

Indoor

Fan Motor

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 11

Page 12

FUNCTIONS, CONTROLS, OPTIONS

Table 4: Indoor Units—Functions, Controls and Options.

Indoor Unit Type LS090HSV5 LS120HSV5 LS180HSV5

Air Supply Outlet

Airflow Direction Control (Left / Right)

Airflow Direction Control (Up / Down)

Auto Swing (Left / Right)

Auto Swing (Up / Down)

Airow

Fan Speed Airflow Steps (Fan / Cool / Heat)

Natural Wind (Auto Wind)

Jet Cool / Jet Heat (Power Wind)

Comfort Air

Prefilter (Washable / Anti-fungal1)

Air

3M Micro Dust Filter

Purifying

Hot Start

Self Diagnostics

Defrost

Dry (Dehumidification) Operation

Auto Changeover

Auto Cleaning (Coil Dry)

Auto Restart Operation

Child Lock

1

Forced Operation

Sleep Mode

Timer (24 Hour On / Off)

Functions

Weekly Timer

Two Thermistor Control

1

1

Low Ambient Operation

Overheat Protection

Smart Diagnosis

Indoor Unit Display Type

Indoor Unit Display Light

Energy Saving

Mode Lock

AC Smart IV

ACP IV

Central

PI-485

Controllers

MultiSITE™ CRC1

1 1 1

5 Steps 5 Steps 5 Steps

6 Steps 6 Steps 6 Steps

√ √ √

√ √ √

6 / 6 / 6 6 / 6 / 6 6 / 6 / 6

√ √ √

√ / √ √ / √ √ / √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

7 Hour 7 Hour 7 Hour

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

Number Display Number Display Number Display

On / Off On / Off On / Off

√ √ √

Cooling Only Cooling Only Cooling Only

PACS4B000 PACS4B000 PACS4B000

PACP4B000 PACP4B000 PACP4B000

PMNFP14A1 PMNFP14A1 PMNFP14A1

PREMTBVC0 PREMTBVC0 PREMTBVC0

Remote

MultiSITE CRC1+

Controllers

MultiSITE Communications Manager

Solution

Integration

Single Zone High Efciency Standard Wall Mount Engineering Manual

Building

LonWorks® Gateway

AC Smart IV BACnet® Gateway

Unit

Network

ACP IV BACnet Gateway

Dry Contact

Wind Baffle Kit

2

Wi-Fi

Water Level Sensor Connection (for optional AG-9300-LG)

Other

Drain Pan Heater

Smart Inverter Monitoring System (SIMS)

√ = Standard feature

X = Not available

12 | PRODUCT DATA

¹Function can operate only when a wired remote controller is connected.

2

Wi-Fi is only compatible with 2.4 GHz band, and cannot be used when dry contact mode is active. When changing from Wi-Fi mode to dry contact mode,

normal operation resumes in approximately 3 minutes.

LonWorks® is a trademark of Echelon Corporation ; BACnet® is a registered trademark of ASHRAE.

Due to our policy of continuous product innovation, some specications may change without notication.

PREMTBVC1 PREMTBVC1 PREMTBVC1

PBACNBTR0A PBACNBTR0A PBACNBTR0A

PLNWKB100 PLNWKB100 PLNWKB100

PBACNA000 PBACNA000 PBACNA000

PQNFB17C2 PQNFB17C2 PQNFB17C2

PDRYCB100, PDRYCB300, PDRYCB400

ZLABGP01A ZLABGP01A ZLABGP02A

√ √ √

√ √ √

√ √ PQSH1201

√ √ √

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 13

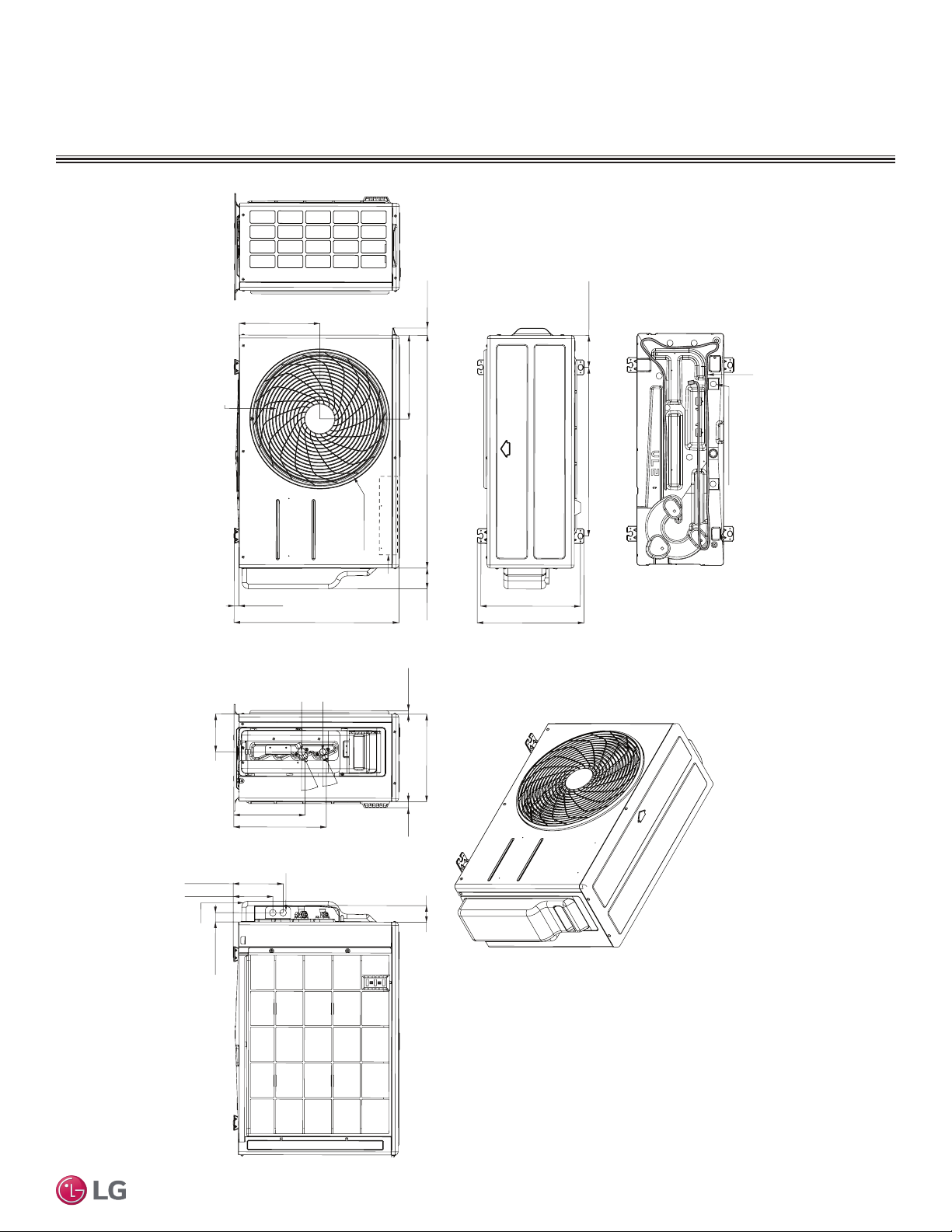

OUTDOOR UNIT DIMENSIONS

LSU090HSV5, LSU120HSV5

Unit : Inch (mm)

10-1/2(267)

Air Outlet

19/32 (15)

4-15/16 (125)

21-1/2 (545)

Connection

(Flared)

Vapor Pipe

(Flared)

Connection

Liquid Pipe

10-29/32 (277)

Ø17-11/32 (440)

Control Box

15/32 (11.5)

31/32 (24)

30-5/16 (770)

2-23/32 (69)

11-5/16 (288)

4-3/16 (106)

Sump Heater

Drain Hole 8-Ø13/16 (20)

22 (558)

Product Data

12-31/32 (330)

13-29/32 (353)

6-7/16 (163)

5-3/32 (129)

Service Valve Cover

1-7/32 (30.5)

25°

25°

9-5/16 (236)

12-1/16 (306)

Cable Hole

(Power)

Connection

Communication /

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

13/16 (20)

2-3/32 (54)

PRODUCT DATA | 13

Page 14

OUTDOOR UNIT DIMENSIONS

Unit : Inch (mm)

13-13/32 (340)

14-3/16 (360)

6-15/32 (164) 21-1/2 (546)

2-3/4 (69.5)

12-19/32 (320)

34-1/4 (870)

13-3/32 (333)

29/32 (22.5)

5-7/8 (149)

17/32 (13)

3-5/32 (79.5)

21-1/2 (571)

20-27/32 (529)

31-1/2 (800)

7-11/16 (195)

4-7/32 (107)

6-25/32 (172)

7/8 (22)

15-3/32 (383)

1-25/32 (45)

25°

14°

6-29/32 (175)

Liquid Pipe

Connection

(Flared)

Vapor Pipe

Connection

(Flared)

Service Valve Cover

Communication /

Connection (Power)

Cable Hole

Control Box

Air Outlet

Drain Hole 4-Ø13/16 (20)

LSU180HSV5

Single Zone High Efciency Standard Wall Mount Engineering Manual

14 | PRODUCT DATA

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 15

OUTDOOR UNIT CORNER WEIGHT AND

d

e

a

b

c

A

D

B

C

CENTER OF GRAVITY DIMENSIONS

Figure 4: LSU090-120-180HSV5 Outdoor Unit Corner Weight and Center of Gravity Dimensions.

Table 5: LSU090-120-180HSV5 Outdoor Unit Corner Weight and Center of Gravity Dimensions.

Weight (lb.) Center of Gravity (in.) Leg (in.) Corner Weight (lb.)

Shipping Net a b c d e A B C D

78.9 74.1 19-31/32 9-11/32 5-21/32 22 12-31/32 9.5 11.0 26.8 26.8

Model No.

LSU090HSV5,

LSU120HSV5

LSU180HSV5 126.5 116.8 21-3/32 13-25/32 6-23/32 21-1/2 13-13/32 21.1 16.4 38.6 40.7

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 15

Page 16

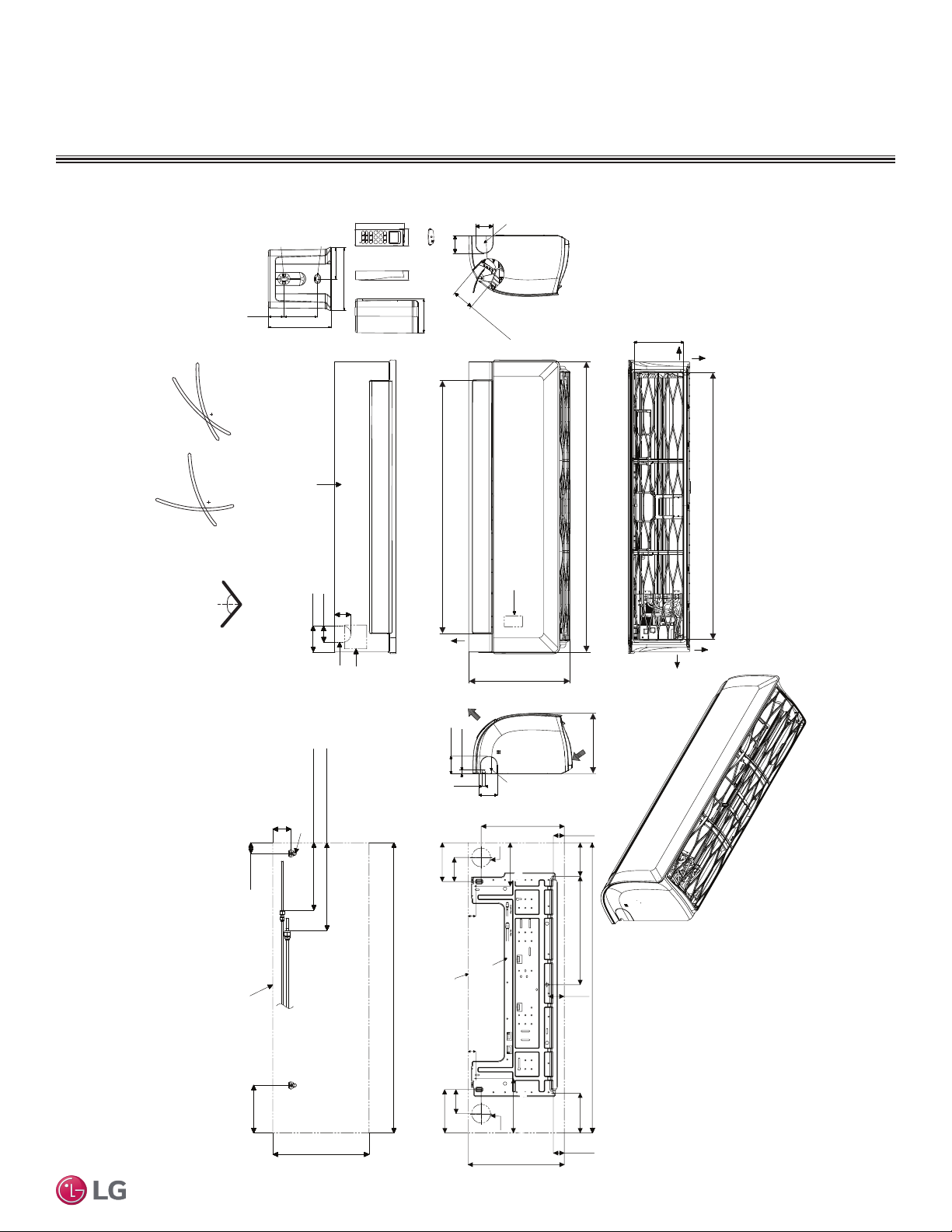

INDOOR UNIT DIMENSIONS

LSN090HSV5, LSN120HSV5

1/8 (3) x 1/4 (6)

1/4 (6) x 1/8 (3)

1-1/4 (31)

2-7/16 (61.5)

5-31/32 (152)

1-3/32 (50.2)

1-1/16 (26.2)

2-7/32 (56)

2 (51)

Routing

Knock Out

Hole

Refrigerant,

Drain Pipe

and Cable

Unit : Inch (mm)

85°

45°

15°

15°

55°

55°

5/8 (15.3)

Cooling Heating

1-9/32 (32.7)

(61)

2-13/32

* If airflow direction control is available,

Decoration Cover

Up & Down Left & Right

3-5/8 (92)

2-3/8 (60)

2-5/16

(59)

Terminal Block for

Power Supply and

Communication

Refrigerant, Drain

Pipe and Cable

Routing Knock Out Hole

Approx. 8-19/32 (218) to liquid pipe

Approx. 11-11/32 (288) to gas pipe

Connection

Drain Hose

1-27/32(47)

1-1/2 (38)

1-7/16 (33.5)

Air Outlet Hole

2 (51)

5-31/32 (152)

2-7/32 (56)

Air Outlet Hole

[28-5/32 (715)]

Bottom

Air Outlet

5/16 (8)

11/32 (9)

2-7/32(56)

3-27/32 (98)

Display & Remote

Controller Signal

Receiver

12-1/8 (308)

Refrigerant,

Drain Pipe

and Cable

Routing

Knock Out

Hole

10-11/32 (263)

5-19/32 (142)

Ø2-9/16 (65)

Air Intake

2-17/32 (64)

32-15/16 (837)

7-7/16 (189)

3-21/32 (93)

[5-29/32 (150)]

Air Intake Hole

Left

Right

Rear

Air Intake Hole

30-3/16 (767)

Rear

Single Zone High Efciency Standard Wall Mount Engineering Manual

Connecting Gas/Liquid Pipe

Unit Outline

5-3/16 (132)

12-1/8 (308)

Due to our policy of continuous product innovation, some specications may change without notication.

16 | PRODUCT DATA

29/32 (23)

Fixing the Installation Plate, Drilling Hole

Unit Outline

32-15/16 (837)

In Case of Left Side Piping

29/32 (23)

Installation Plate

12-1/16 (306)

32-15/16 (837)

2-15/32

(63)

5-9/32 (134)

7-5/8 (194)

7-27/32 (199)

7-27/32 (199)

Ø2-9/16 (65)

12-1/8 (308)

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

3-11/16 (94)

2-15/32 (63)

Page 17

INDOOR UNIT DIMENSIONS

Unit : Inch (mm)

[36-5/32 (918)]

Air Intake Hole

[6-11/16 (170)]

Air Intake Hole

[2-29/32 (74)]

Air Outlet Hole

Rear

39-9/32 (998)

2-1/4 (57)

2-7/32 (56)

3-17/32 (90)

Bottom

Air

Outlet

[34-11/32 (872)]

Air Outlet Hole

13-19/32 (345)

2-3/8 (60)

7/16(11)

Air Intake

8-9/32 (210)

13-19/32 (345)

39-9/32 (998)

6-15/32 (164)

1-15/32 (37)

2-15/32 (63)

In case of Left Side Piping

Unit Outline

Approx. 9-7/16 (240) to gas pipe

Approx. 6-5/16 (160) to liquid pipe

Connecting Gas/Liquid Pipe

2-3/8 (60)

2-3/8 (60)

Rear

Left

Right

If airflow direction control is available,*

Cooling Heating

Up & Down Left & Right

50°

15°

20°

85°

45°

50°

39-9/32 (998)

2-23/32 (69)

14-11/16 (373)

5-13/32 (137)

2-3/32 (53)

13-19/32 (345)

Ø2-9/16 (65)

3-9/32 (83)

Unit Outline

Fixing the Installation Plate, Drilling Hole

1-1/16 (27)

5-29/32 (150)

4-17/32 (115)

Ø2-9/16 (65)

3-9/32 (83)

5-9/32 (134)

1-1/16 (27)

2-3/32 (53)

11-13/16 (300)

7/16 (11)

2-3/8 (60)

5-29/32 (150)5-29/32 (150)

7-13/32 (188)7-13/32 (188)

2-7/16 (61.5)

1-7/16 (33.5)

1-9/32 (32.7)

2-13/32

(61)

5-31/32 (152)

1/4 (6) x 1/8 (3)

1/8 (3) x 1/4 (6)

5/8 (15.3)

1-1/4 (31)

1-3/32 (50.2)

1-1/16 (26.2)

Refrigerant,

Drain Pipe

and Cable

Routing

Knock Out

Hole

Refrigerant,

Drain Pipe

and Cable

Routing

Knock Out

Hole

Display & Remote

Controller Signal

Receiver

Terminal Block for

Power Supply and

Communication

Refrigerant, Drain

Pipe and Cable

Routing Knock Out

Hole

Installation Plate

Drain Hose

Connection

Decoration Cover

LSN180HSV5

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 17

Page 18

ACOUSTIC DATA

2.6 (0.8)

3.3 (1)

Microphone

Unit : ft. (m)

Indoor Units

Indoor Unit Sound Pressure Measurement

Figure 5: High Efciency Standard Wall Mount Indoor Unit Sound Level

Measurement.

• Measurements are taken 3.3 ft away from the front of the unit.

• Sound pressure levels are measured in dB(A) with a tolerance of

±3.

• Data is valid at nominal operation conditions. Operating conditions

are assumed to be standard.

• Reference acoustic pressure 0dB=20μPa

• Sound pressure levels are tested in an anechoic chamber under

ISO Standard 3745, and may be different according to the test

condition or equipment.

• Sound level will vary depending on a range of factors including the

construction (acoustic absorption coefficient) of a particular room in

which the unit was installed.

Indoor Unit Sound Pressure Levels

Table 6: High Efciency Standard Wall Mount Indoor Unit Acoustic Data.

Sound Pressure Levels (dB[A])

Model

H M L H M L

LSN090HSV5 39 33 23 39 33 23

LSN120HSV5 39 33 23 39 33 23

LSN180HSV5 45 40 35 45 40 35

Cooling Heating

LSN090HSV5 Sound Pressure Levels

Figure 6: Sound Pressure Level Diagrams for LSN090HSV5 Indoor Units.

LSN090HSV5

Cooling

80

■ High

▲ Medium

70

Single Zone High Efciency Standard Wall Mount Engineering Manual

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

18 | PRODUCT DATA

● Low

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Heating

80

70

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

■ High

▲

Medium

● Low

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Page 19

Cooling

LSN090HSV5

Heating

10

20

30

40

50

60

70

80

63 125 250 500 1000 2000 4000 8000

Octave Band Sound Pressure Level (dB re 20μPa )

■ High

Octave Band Center Frequency (Hz)

● Low

▲ Medium

NC-15

NC-20

NC-25

NC-30

NC-35

NC-40

NC-45

NC-50

NC-55

NC-60

NC-65

Approximate

Hearing

Threshold

10

20

30

40

50

60

70

80

63 125 250 500 1000 2000 4000 8000

Octave Band Sound Pressure Level (dB re 20μPa )

■ High

Octave Band Center Frequency (Hz)

● Low

▲

NC-15

NC-20

NC-25

NC-30

NC-35

NC-40

NC-45

NC-50

NC-55

NC-60

NC-65

Approximate

Hearing

Threshold

LSN120HSV5

Octave Band Center Frequency (Hz)

Medium

LSN120HSV5 and LSN180HSV5 Sound Pressure Levels

Figure 7: Sound Pressure Level Diagrams for LSN120-180HSV5 Indoor Units.

Cooling

80

70

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

■ High

▲

● Low

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

LSN180HSV5

Cooling Heating

80

■ High

▲

Medium

70

● Low

Heating

80

70

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

80

70

ACOUSTIC DATA

Indoor Units

■ High

MediumMedium

▲

● Low

■ High

▲

Medium

● Low

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Product Data

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 19

Page 20

ACOUSTIC DATA

3.3 ft. (1)

Center of

Outdoor Unit

Unit : ft. (m)

Outdoor Units

Outdoor Unit Sound Pressure Measurement

Figure 8: High Efciency Standard Wall Mount Outdoor Unit Sound

Level Measurement.

Outdoor Unit Sound Pressure Levels

Table 7: High Efciency Standard Wall Mount Outdoor Unit Acoustic Data.

Model

LSU090HSV5 45 48

LSU120HSV5 45 48

LSU180HSV5 53 53

Sound Pressure Levels (dB[A])

Cooling (Max.) Heating (Max.)

• Measurements are taken 3.3 ft away from the front of the unit.

• Sound pressure levels are measured in dB(A) with a tolerance of

±3.

• Data is valid at nominal operation conditions. Operating conditions

are assumed to be standard.

• Reference acoustic pressure 0dB=20μPa

• Sound pressure levels are tested in an anechoic chamber under

ISO Standard 3745, and may be different according to the test

condition or equipment.

• Sound level will vary depending on a range of factors including the

construction (acoustic absorption coefficient) of a particular room in

which the unit was installed.

LSU090HSV5 Sound Pressure Levels

Figure 9: Sound Pressure Level Diagrams for LSU090HSV5 Outdoor Units.

LSU090HSV5

Cooling Heating

80

▲ Front

●

70

60

50

40

Single Zone High Efciency Standard Wall Mount Engineering Manual

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

Back

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

80

70

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

▲ Front

●

Back

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

20 | PRODUCT DATA

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 21

ACOUSTIC DATA

LSU090HSV5

Cooling Heating

10

20

30

40

50

60

70

80

63 125 250 500 1000 2000 4000 8000

Octave Band Sound Pressure Level (dB re 20μPa )

●

▲ Front

Back

Octave Band Center Frequency (Hz)

NC-15

NC-20

NC-25

NC-30

NC-35

NC-40

NC-45

NC-50

NC-55

NC-60

NC-65

Approximate

Hearing

Threshold

10

20

30

40

50

60

70

80

63 125 250 500 1000 2000 4000 8000

Octave Band Sound Pressure Level (dB re 20μPa )

●

▲ Front

Back

Octave Band Center Frequency (Hz)

NC-15

NC-20

NC-25

NC-30

NC-35

NC-40

NC-45

NC-50

NC-55

NC-60

NC-65

Approximate

Hearing

Threshold

LSU120HSV5

Outdoor Units

LSU120HSV5 and LSU180HSV5 Sound Pressure Levels

Figure 10: Sound Pressure Level Diagrams for LSU120-180HSV5 Outdoor Units.

Cooling

80

70

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

▲ Front

●

Back

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

LSU180HSV5

Cooling

80

▲ Front

●

70

Back

Heating

80

70

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

Heating

80

70

▲ Front

●

Back

▲ Front

●

Back

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Product Data

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

60

50

40

30

Octave Band Sound Pressure Level (dB re 20μPa )

20

Approximate

Hearing

Threshold

10

63 125 250 500 1000 2000 4000 8000

Octave Band Center Frequency (Hz)

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 21

Page 22

REFRIGERANT FLOW DIAGRAMS

Field Pipin g

(Copper Tubing)

Field Pipin g

(Copper Tubing)

M

M

Heat

Exchanger

(Evaporato r)

Heat

Exchanger

(Condenser)

Compressor

2-Way Valve

Valve

Reversing

Indoor U nit Outdoor Unit

: Cooling

: Heating

EEV

Th1

Th4

Th3

Th6

Th7

Th8

Liquid Side

Vapor Side

3-

Way V alve

Th5

Th2

Ø3/8 Inches

Ø1/4 Inches

Refrigerant Flow Diagram for LSN / LSU090, 120HSV5

Table 8: Single Zone High Efciency Wall Mount LSN/LSU090-120HSV5 Thermistor Details.

Thermistor Description PCB Connector

TH1

TH2

TH3

TH4

TH5

Single Zone High Efciency Standard Wall Mount Engineering Manual

TH6

TH7

TH8

22 | PRODUCT DATA

Indoor air temperature thermistor

Evaporator inlet temperature thermistor

Evaporator middle temperature thermistor CN-TH3 (Indoor)

Evaporator outlet temperature thermistor

Outdoor air temperature thermistor

Condensing temperature thermistor

Discharge pipe temperature thermistor D_PIPE (Outdoor)

Water level sensor (optional)

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

CN-TH1 (Indoor)

CN-TH2 (Indoor)

C_PIPE/AIR (Outdoor)

Page 23

REFRIGERANT FLOW DIAGRAMS

Refrigerant Flow Diagrams for LSN / LSU180HSV5

Indoor U nit Outdoor Unit

Th1

Heat

Exchanger

(Evaporato r)

Th4

Th2

Th5

Th3

Field Pipin g

(Copper Tubing)

Liquid Side

Ø3/8 Inches

M

Field Pipin g

(Copper Tubing)

3-Way Valve

3-

Way V alve

EEV

M

Reversing

Valve

Th6

Heat

Exchanger

(Condenser)

Th7

Product Data

Vapor Side

Ø5/8 Inches

Accumulator

Compresso r

Th8

: Cooling

: Heating

Table 9: Single Zone High Efciency Wall Mount LSN/LSU180HSV5 Thermistor Details.

Thermistor Description PCB Connector

TH1

TH2

TH3

TH4

TH5

TH6

TH7

TH8

Indoor air temperature thermistor

Evaporator inlet temperature thermistor

Evaporator middle temperature thermistor CN-TH3 (Indoor)

Evaporator outlet temperature thermistor

Water level sensor (optional)

Outdoor air temperature thermistor

Condensing temperature thermistor

Discharge pipe temperature thermistor CN-TH2 (Outdoor)

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

CN-TH1 (Indoor)

CN-TH2 (Indoor)

CN-TH1 (Outdoor)

PRODUCT DATA | 23

Page 24

INDOOR UNIT WIRING DIAGRAM

LSN090HSV5, LSN120HSV5, LSN180HSV5

Wiring Diagram for LSN090, 120, 180HSV5

Single Zone High Efciency Standard Wall Mount Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

24 | PRODUCT DATA

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 25

OUTDOOR UNIT WIRING DIAGRAM

Wiring Diagram for LSU090, 120HSV5

LSU090HSV5, LSU120HSV5

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 25

Page 26

OUTDOOR UNIT WIRING DIAGRAM

LSU180HSV5

Wiring Diagram for LSU180HSV5

Single Zone High Efciency Standard Wall Mount Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

26 | PRODUCT DATA

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 27

ELECTRICAL CONNECTIONS

General Power Wiring / Communications Cable Guidelines

• Follow manufacturer’s circuit diagrams displayed on the inside of the control box cover.

• Have a separate power supply for the indoor units.

• Provide a circuit breaker switch between the power source and the indoor unit.

• Confirm power source specifications.

• Properly ground the outdoor unit and the indoor unit per National Electrical Code (NEC) and local codes.

• Connect the wiring firmly so that the wires cannot be easily pulled out.

• Confirm that the electrical capacity is sufficient.

• Power supply to the outdoor unit must be selected based on NEC and local codes. Maximum allowable voltage fluctuation ±10% or nameplate rated value.

• It is recommended that a circuit breaker is installed, especially if conditions could become wet or moist.

• Include a disconnect in the power wiring system. Add an air gap contact separation of at least 1/8 inch in each active (phase) conductor.

• Any openings where the field wiring enters the cabinet must be completely sealed.

Do not install power wiring to the outdoor unit and the communication / connection (power) cable to the indoor unit in the same conduit.

Use separate conduits.

Power Wiring / Communications Cable Specifications

• Power wiring to the outdoor unit must be solid or stranded, and must comply with the applicable local and national electric codes.

• Communication / connection (power) cable from the outdoor unit to the indoor unit must be a minimum of 18 AWG, four (4) conductor,

stranded, shielded or unshielded (if shielded, must be grounded to chassis at the outdoor unit only) and must comply with applicable local

and national codes.

• Communication cable from the indoor unit to optional remote controller is to be 22 AWG, three (3) conductor, twisted, stranded, unshielded.

Wiring must comply with all applicable local and national codes.

• Terminal screws may become loose during transport. Properly tighten the terminal connections during installation or risk electric shock,

physical injury, or death.

• Loose wiring may cause unit to malfunction, overheat, and catch fire, resulting in severe injury or death.

• Terminal screws may loosen during transport. Properly tighten the terminal connections during installation or risk equipment malfunction or

property damage.

• Loose wiring may cause unit malfunction, the wires to burnout or the terminal to overheat and catch fire. There is a risk of equipment malfunction or property damage.

A voltage drop may cause the following problems:

• Magnetic switch vibration, fuse breaks, or disturbance to the normal function of an overload protection device.

• Compressor will not receive the proper starting current.

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 27

Page 28

ELECTRICAL CONNECTIONS

208/230 VAC

Power Supply

Circuit Breaker

Ground Wiring

Outdoor Unit

Indoor Unit

Power Supply

Circuit Breaker

Ground Wiring

Outdoor Unit

Indoor Unit

Figure 11: LS090HSV5 and LS120HSV5 General Power / Communications System Schematic.

Figure 12: LS180HSV5 General Power / Communications System

Schematic.

• Use a conduit for the communications cable / power wiring from the outdoor unit to the indoor units.

• Make sure the communications cable / power wiring from the outdoor units to the indoor units, and the power wiring to the outdoor unit are

separate, otherwise, the outdoor unit operation may be affected by electrical noise and will malfunction or fail.

Figure 13: LS090-120HSV5 System Electrical Connections. Figure 14: LS180HSV5 System Electrical Connections.

Single Zone High Efciency Standard Wall Mount Engineering Manual

28 | PRODUCT DATA

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 29

ELECTRICAL CONNECTIONS

Verify the connectors are properly inserted.

C/BOX Cable (Plug type)

Extension cable

To Indoor Unit

CN-REMO

Terminal

TEMP

FAN

SPEED

OPER

MODE

Display

Screen

Button

*

*

*

RESET

Outdoor Unit Terminal Block

GND

GRN /

YLW

3

Controller Options

Single Zone High Efficiency Standard Wall Mount systems include a wireless handheld remote controller

(Model No. AKB74955602), but optional LG-suppled wired controllers are available. See “Functions,

Controls, Options”, or contact an LG representative for more information.

Wireless Handheld Remote Controller features:

• Display Panel: Displays operation conditions.

• On / Off Button: Turns system operation on and off.

• Mode Button: Selects the operation mode: Cooling, Heating, Auto, Dry

(Dehumidification), or Fan.

• Temp Up / Down Buttons: Adjusts the desired room temperature in the different modes.

• Fan Speed Button: Sets desired fan speed.

• Reset: Initializes the handheld remote control settings.

Wired Controller Connections

Optional controllers (see “Functions, Controls, Options”, or contact an LG representative for more

information) can connect to the Single Zone High Efficiency Standard Wall Mount indoor unit in one of

two different ways.

1. LG Wired Remote Extension Cable with Molex plug (PZCWRC1; sold separately) that connects to the

CN-REMO terminal on the indoor unit PCB.

2. Field-supplied controller cable that connects to the indoor unit terminal block (must be at least

UL2547 or UL1007, and at least FT-6 rated if local electric and building codes require plenum cable

usage). Communication cable from indoor unit to remote controller(s) is to be 22 AWG, 3-conductor,

twisted, stranded, unshielded. Wiring must comply with all applicable local and national codes.

Figure 17: AKB74955602 Wireless Handheld Remote Controller.

Buttons may differ depending on

model type.

Product Data

Figure 15: PZCWRC1 LG Wired Remote Extension Cable.

Figure 16: Wired Controller Connection on the Indoor Unit Terminal Block.

Indoor Unit Terminal Block

GND

1(L1 )2(L2)

3

CN-REMO

BR

BL

RD

When using eld-supplied controller cable, make sure to connect the yellow to yellow (communications wire), red to red (12V power wire), and

black to black (ground wire) terminals from the remote controller to the

indoor unit terminal blocks.

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 29

Page 30

ELECTRICAL CONNECTIONS

4 to 5 feet

above the floor

NO

NO

NO

YES

Remote Controller

TEMP

Remote Controller

TEMP

Re

m

o

t

e

Co

n

t

r

ol

ler

TEMP

Wired Controller Placement

Figure 18: Proper Location for the Wired Controller.

Wired controllers include a sensor to detect room temperature.

To maintain comfort levels in the conditioned space, the wired

controller must be installed in a location away from direct sunlight,

high humidity, and where it could be directly exposed to cold air.

Controller must be installed four (4) to five (5) feet above the floor

where its LED display can be read easily, in an area with good air

circulation, and where it can detect an average room temperature.

Do not install the wired controller near or in:

• Drafts or dead spots behind doors and in corners.

• Hot or cold air from ducts.

• Radiant heat from the sun or appliances.

• Concealed pipes and chimneys.

• An area where temperatures are uncontrolled, such as an outside

wall.

Assigning the Thermistor for Temperature Detection

Each indoor unit includes a return air thermistor assigned to sense the temperature. If a wired controller is installed, there is a choice

of sensing temperature with either the indoor unit return air thermistor or the thermistor in the wired controller. It is also an option to set

both thermistors to sense temperature so that indoor unit bases its operation on the first thermistor to reach the designated temperature

differential.

Single Zone High Efciency Standard Wall Mount Engineering Manual

30 | PRODUCT DATA

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

Page 31

Cooling

28(82)

26(79)

24(75)

2(6.6)

1(3.3)

0.5(1.6)

0.3(1)

Air Velocity m/s (ft./s)

1

0

0

10

2

2468

m

m

Temperature °C (°F)

ft.

032.8 6.613.119.726.2

1

0

0

10

2

2468

m

m ft.

3.3

0

6.6

ft.

3.3

0

6.6

ft.

032.8 6.613.119.726.2

22(72)

0.3(1)

0.5(1.6)

1(3.3)

1(3.3)

1(3.3)

2(6.6)

0.3(1)

0.3(1)

0.5(1.6)

0.5(1.6)

2(6.6)

2(6.6)

Air Velocity m/s (ft./s)

010 2468

m

m

1

0

1

2

3

4

3

2

4

5

5

Air Velocity m/s (ft./s)

010 2468

m

1

0

1

2

3

4

3

2

4

5

5

032.8

6.613.119.726.2 032.8 6.613.119.726.2

ft.

m

ft.

ft.

3.3

0

3.3

6.6

9.8

13.1

9.8

6.6

13.1

16.4

16.4

3.3

3.3

6.6

9.8

13.1

9.8

6.6

13.1

16.4

16.4

ft.

0

Side View

Discharge Angle : 35˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Top View

Discharge Angle : 35˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Air Speed 0.3 m/s (1 ft./s) Range : 13.0 m (42.7 ft.)

Top View

Discharge Angle : 35˚ (From the floor )

Vertical Louver : Left & Right

Fan Speed : Power

Table 10: High Efciency Standard Wall Mount Outdoor Unit Air Flow Rate and Static Pressure.

LSN090HSV5 and LSN120HSV5

AIR FLOW, EXTERNAL PRESSURE, AND

TEMPERATURE DISTRIBUTION

Model No. Air Flow Rate (CFM) Static Pressure (in. WG)

LSU090HSV5, LSU120HSV5 1,165 0.0329

LSU180HSV5 2,119 0.0384

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 31

Page 32

AIR FLOW AND TEMPERATURE DISTRIBUTION

Heating

LSN090HSV5 and LSN120HSV5, continued.

Air Velocity m/s (ft./s)

0.3(1)

m

10

ft.

0.5(1.6)

1(3.3)

1.5(4.9)

Side View

Discharge Angle : 55˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Air Velocity m/s (ft./s)

0.3(1)

0.5(1.6)

1(3.3)

2(6.6)

2(6.6)

2468

Temperature °C (°F)

m

ft.

2

6.6

m ft.

2

6.6

32(90)

1

3.3

0

0

0

032.8 6.613.119.726.2

m

ft.

5

16.4

4

13.1

3

9.8

2

6.6

1

3.3

0

0

1

3.3

m

ft.

24(75)

10

Air Velocity m/s (ft./s)

0.3(1)

26(79)

0.5(1.6)

28(82)

1(3.3)

30(86)

2468

2(6.6)

2(6.6)

1

3.3

0

0

0

032.8 6.613.119.726.2

ft.

m

16.4

5

13.1

4

9.8

3

6.6

2

3.3

1

0

0

3.3

1

Single Zone High Efciency Standard Wall Mount Engineering Manual

m

ft.

6.613.119.726.2 032.8 6.613.119.726.2

Top V iew

Discharge Angle : 55˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Air Speed 0.3 m/s (1 ft./s) Range : 13.5 m (44.3 ft.)

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

32 | PRODUCT DATA

©

2

6.6

3

9.8

4

13.1

5

16.4

010 2468

032.8

m

ft.

0.3(1)

0.5(1.6)

1(3.3)

6.6

2

9.8

3

13.1

4

16.4

5

010 2468

Top V iew

Discharge Angle : 55˚ (From the floor )

Vertical Louver : Left & Right

Fan Speed : Power

Page 33

LSN180HSV5

Cooling

2(6.6)

1(3.3)

0.3(1)

1.5(4.9)

0.5(1.6)

22(72)

24(75)

26(79)

28(82)

Air Velocity m/s (ft./s)

1

0

0

10

2

2468

m

m

Temperature °C (°F)

ft.

06.68.23 13.119.726.2

1

0

0

10

2

2468

m

m ft.

3.3

0

6.6

ft.

3.3

0

6.6

ft.

032.8 6.613.119.726.2

18(64)

0.3(1)

0.5(1.6)

1(3.3)

2(6.6)

2(6.6)

2(6.6)

1(3.3)

1(3.3)

0.5(1.6)

0.5(1.6)

0.3(1)

0.3(1)

Air Velocity m/s (ft./s)

0201 468

m

m

1

0

1

2

3

4

3

2

4

5

5

Air Velocity m/s (ft./s)

0201 468

m

1

0

1

2

3

4

3

2

4

5

5

06.68.23 13.119.726.2 06.68.23 13.119.726.2

ft.

m

ft.

ft.

3.3

0

3.3

6.6

9.8

13.1

9.8

6.6

13.1

16.4

16.4

3.3

3.3

6.6

9.8

13.1

9.8

6.6

13.1

16.4

16.4

ft.

0

Side View

Discharge Angle : 25˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Top View

Discharge Angle : 25˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Air Speed 0.3 m/s (1 ft./s) Range : 15.7 m (51.5 ft.)

Top View

Discharge Angle : 25˚ (From the floor )

Vertical Louver : Left & Right

Fan Speed : Power

AIR FLOW AND TEMPERATURE DISTRIBUTION

Product Data

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 33

Page 34

AIR FLOW AND TEMPERATURE DISTRIBUTION

LSN180HSV5, continued.

Heating

Air Velocity m/s (ft./s)

0.3(1)

0.5(1.6)

1(3.3)

m

10

ft.

1.5(4.9)

2(6.6)

Side View

Discharge Angle : 45˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Air Velocity m/s (ft./s)

0.3(1)

0.5(1.6)

1(3.3)

Temperature °C (°F)

m

ft.

2

6.6

24(75)

32(90)

m ft.

2

6.6

30(86)

1

3.3

26(79)

0

0

2468

0

06.68.23 13.119.726.2

ft.

m

16.4

5

13.1

4

9.8

3

m

10

ft.

Air Velocity m/s (ft./s)

0.5(1.6)

6.6

2

3.3

1

0.3(1)

28(82)

2468

1(3.3)

2(6.6)

1

3.3

0

0

0

032.8 6.613.119.726.2

ft.

m

16.4

5

13.1

4

9.8

3

6.6

2

3.3

1

2(6.6)

Single Zone High Efciency Standard Wall Mount Engineering Manual

m

ft.

Top View

Discharge Angle : 45˚ (From the floor )

Vertical Louver : Center

Fan Speed : Power

Air Speed 0.3 m/s (1 ft./s) Range : 18.3 m (60.0 ft.)

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

34 | PRODUCT DATA

©

0

0

3.3

1

6.6

2

9.8

3

13.1

4

16.4

5

0201 468

06.68.23 13.119.726.2 06.68.23 13.119.726.2

m

ft.

0.3(1)

Top View

Discharge Angle : 45˚ (From the floor )

Vertical Louver : Left & Right

Fan Speed : Power

0.5(1.6)

1(3.3)

2(6.6)

0

0

3.3

1

6.6

2

9.8

3

13.1

4

16.4

5

0201 468

Page 35

ACCESSORIES

LG Monitoring View (LGMV) Diagnostic Software and Cable

LGMV software allows the service technician or commissioning agent to connect a computer USB port

to the outdoor unit main printed circuit board (PCB) using an accessory cable without the need for a

separate interface device. The main screen for LGMV allows user to view the following real time data on

one screen:

• Actual inverter compressor speed

• Target inverter compressor speed

• Actual outdoor fan speed

• Target outdoor unit fan speed

• Actual superheat

• Target superheat

• Actual subcooler circuit superheat

• Target subcooler circuit superheat

• Main EEV position

• Subcooling EEV position

• Inverter compressor current transducer

value

• Outdoor air temperature

• Actual high pressure/saturation temperature

• Actual low pressure/saturation temperature

• Suction temperature

• Inverter compressor discharge temperature

• Constant speed compressor discharge

Additional screens can be accessed by tabs on the main screen:

1. Cycleview: Graphic of internal components including:

• Compressors showing actual speeds

• EEVs

• Indoor Units

• Liquid injection valves

2. Graph: Full screen graph of actual high and low pressures and high and low pressure limits. A

sliding bar enables user to go back in time and view data.

3. Control IDU: Enables user to turn on all IDU’s default setpoints of 86°F in heat mode or 64°F in

cool mode.

4. Setting: Converts metric values to imperial values.

5. Making Data: Recording of real time data to a separate file created to be stored on the user’s computer.

6. Loading Data: Recorded data from a saved “.CSV” file can be loaded to create an LGMV session.

7. Electrical Data: The lower half of main screen is changed to show the following:

• Inverter compressor

- Amps

- Volts

- Power Hz

- Inverter control board fan Hz

temperature

• Front outdoor coil pipe temperature

• Back outdoor coil pipe temperature

• Liquid line pipe temperature

• Subcooler inlet temperature

• Subcooler outlet temperature

• Average indoor unit (IDU) pipe temperature

• Inverter compressor operation indicator

light

• Four-way reversing valve operation

indicator light

• Pressure graph showing actual low pressure and actual high pressure levels

• Error code display

• Operating mode indicator

• Target high pressure

• Target low pressure

• PCB (printed circuit board) version

• Temperature and pressure sensors

• Four-way reversing valve

• Outdoor fans showing status and speeds

• Constant compressor

- Current transducer value

- Phase

• Software

version

• Installer

name

• Model no.

of outdoor units

• Site name

• Total number of connected indoor units

• Communication indicator lights

• Indoor unit capacity

• Indoor unit operating mode

• Indoor unit fan speed

• Indoor unit EEV position

• Indoor unit room temperature

• Indoor unit inlet pipe temperature

• Indoor unit outlet pipe temperature

• Indoor unit error code

Product Data

Figure 19: Sample Cycleview.

In lieu of connecting to the outdoor unit, user has the option to connect to the indoor unit with the use of a USB to RS-485 connector kit.

When connected through the indoor unit, user will not be able to record data.

This software can be used to both commission new systems and troubleshoot existing systems. LGMV data can be recorded to a “.CSV” file

and emailed to an LG representative to assist with diagnostic evaluations.

Recommended Minimum PC Configuration:

• CPU: Pentium

• Operating System: Windows® NT/2000/XP/Vista

• Main Memory: 256 MB

LGMV is available in different formats, including Mobile LGMV, which is a app for use on wireless devices. Contact your LG

Sales Representative for more information.

®

IV 1.6 GHz

• Hard Disk: 600 MB when operating

• Web Browser: Internet Explorer® 5.0

Due to our policy of continuous product innovation, some specications may change without notication.

LG Electr onics U.S.A., Inc., Engl ewood Cliffs , NJ. All rights re served. “LG” is a registe red trademark of LG Corp.

©

PRODUCT DATA | 35

Page 36

ACCESSORIES

LG Smart Inverter Monitoring System (SIMS)

SIMS can be used to display and graph operational data for single zone systems and respective

components (indoor unit and outdoor unit). SIMS also displays error codes and a troubleshooting guide.