Page 1

1-2

A AC :Alternating Current

ACC :Automatic Color Control

ACSS :Automatic Channel Setting System

ADJ :Adjust

A/E :Audio Erase

AFC :Automatic Frequency Control

AFT :Automatic Fine Tuning

AGC :Automatic Gain Control

A.H.SW :Audio Head Switch

ALC :Automatic Level Control

AM :Amplitude Modulation

AMP :Amplifier

ANT :Antenna

APC :Automatic Phase Control

ASS’Y :Assembly

AUX :Auxiliary

B B :Base

BGP :Burst Gate Pulse

BPF :Bandpass Filter

BS :Brodcasting Satellite

BW or B/W :Black and White

C C :Capacitor, Chroma, Collector

CAN :Cancel

CAP :Capstan

CAP.BRK :Capstan Brake

CAP.RVS :Capstan Reverse

CATV :Cable Television

CBA :Circuit Board Assembly

CCD :Charge Coupled Device

C.CTL :Chro Control, Capstan Control

CFG :Capstan Frequency Generator

CHROMA :Chrominance

CNR :Chroma Noise Redution

COMB :Combination

Comb Filter

COMP :Comparator

Composite

Compensation

CONV :Converter

C.ROT SW :Color Rotary Switch

CS :Chip Selcet

C.SYNC :Composite Synchronization

CTL DIV :Control Divide

CUR :Current

CYL :Cylinder

D D :Drum, Digital, Diode, Drain

D.ADJ :Drum Adjust

DC :Direct Current

D.CTL :Drum Control

DEMOD :Demodulator

DET :Detector

DEV :Deviation

DHP :Double High Pass

DIGITRON :Digital Display Tube

DL :Delay line

DOC :Drop Out Compensator

DUB :Dubbing

D.V SYNC :Dummy Vertical Synchronization

E E :Emitter

EE :Electric to Eletric

EMPH :Emphasis

ENA :Enable

ENV :Envelope

EP :Extended Play

EQ :Equalizer

EXP :Expander

F F :Fuse

FB :Feed Back

FBC :Feed Back Clamp

FE :Full Erase

FG :Frequency Generator

FL :Filter

FM :Frequency Modulation

F/R :Front/Rear

FS :Frequency Synthesizer

FSC :Subcarrier Frequency

F/V :Frequency Voltage

G GEN :Generator

H H :High, Horizontal

I IC :Integrated Circuit

IF :Intermediate Frequency

INS :Insert

L L :Low, Left, Coil

LD :LED

LD VTG CTL

:Loading Voltage Control

LECHA :Letter Character

L.M :Level Meter

LP :Long Play

LPF :Low Pass Filter

M MAX :Maximum

MD :Modulator

MECHA.CTL

:Mechanism Control

MIC :Microphone

MIN :Minimum

MIX :Mixer, Mixing

M.M. :Monostable, Multivibrator

MMV :Mono Multi Vibrator

MOD :Modulation, Modulator

MODEM :Modulator-Demodulator

MPX :Multiplex

N NR :Noise Reduction

O OSC :Oscillator

OSD :On Screen Display

P PB :Playback

PCB :Printed Circuit Board

P.CTL :Power Control

PRE-AMP :Preamplifier

P.F :Power Failure

PG :Pulse Generator

PLL :Phase Locked Loop

PREM.DET :Premire Detect

P.P :Peak-to-Peak

PS :Phase Shift

PWM :Pulse Width Modulation

PWR CTL :Power Control

Q Q :Transistor

QH :Quasi Horizontal

QSR :Quick Setting Record

QTR :Quick Timer Record

QV :Quasi Vertical

R R :Resistor, Right

RE(or RC) :Remocon, Receiver

REC :Recording

REC S ‘H’ :Record Start ‘Hight’

REF :Reference

REG :Regulated, Regulator

REMOCON :Remote Control(unit)

RF :Radio Frequency

R/P :Record/Playback

RTC :Reel Time Counter

S S :Serial

S.ACCEL :Slow Accel

SAOP :Second Audio Program

SC :Scart, Simulcast

S.DET :Secam Detect

SH :Shift

SHARP :Sharpness

SIF :Sound Intermediate Frequency

SLD :Side Locking

S/N :Signal to Noise Ratio

SP :Standard Play

ST :Stereo

SUB :Subtract, Subcarrier

SW or S/W :Switch

SYNC :Synchronization

SYSCON :System Control

T T :Coil

TP :Test Point

TR :Transistor

TRK :Tracking

TRANS :Transformer

TU :Tuner, Take-up

U UHF :Ultra High Frequency

UNREG :Unregulated

V V :Volt, Vertical

VA :Always Voltage

VCO :Voltage Controlled Oscillator

VGC :Voltage Gain Control

VHF :Very High Frequency

V.H.SW :Video Head Switch

VISS :VHS Index Search

VPS :Video Program System

VR :Variable Resistor or Volume

V-SYNC :Vertical Synchronization

VTG :Voltage

VV :Voltage to Voltage

VXO :Voltage X-tal Oscillator

W W :Watt

WHT :White

W/O :With out

X X-TAL :Crystal

Y Y/C :Luminance/Chrominance

YNR :Luminance Noise Reduction

Z ZD :Zener Diode

SECTION1 SUMMARY

KEY TO ABBREVIATIONS

LG L316

Page 2

1-3

Prior to shipment from the factory, the products are strictly inspected to confrom with the recognized product

safety and electrical codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced.

• Precautions during Servicing

1. Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and

certain parts of the product. When performing service, be sure to read and comply with these and other

cautionary notices appearing in the operation and service manuals.

2. Parts identified by the symbol and shaded (

Y

) parts are critical for safety.

Replace only with specified part numbers.

Note : Parts in this category also include those specified to comply with X-ray emission standards for

products using cathode ray tubes and those specified for compliance with various regulations

regarding spurious radiation emission.

3. Use Specified internal wiring. Note especially:

1) Double insulated wires

2) High voltage leads

4. Use specified insulating materials for hazardous live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulation sheets for transistor

5. Observe that wires do not contact heat producing

parts (heatsinks, oxide metal film resistors, fusible

resistors, etc.)

6. Check that replaced wires do not contact sharp edged

or pointed parts.

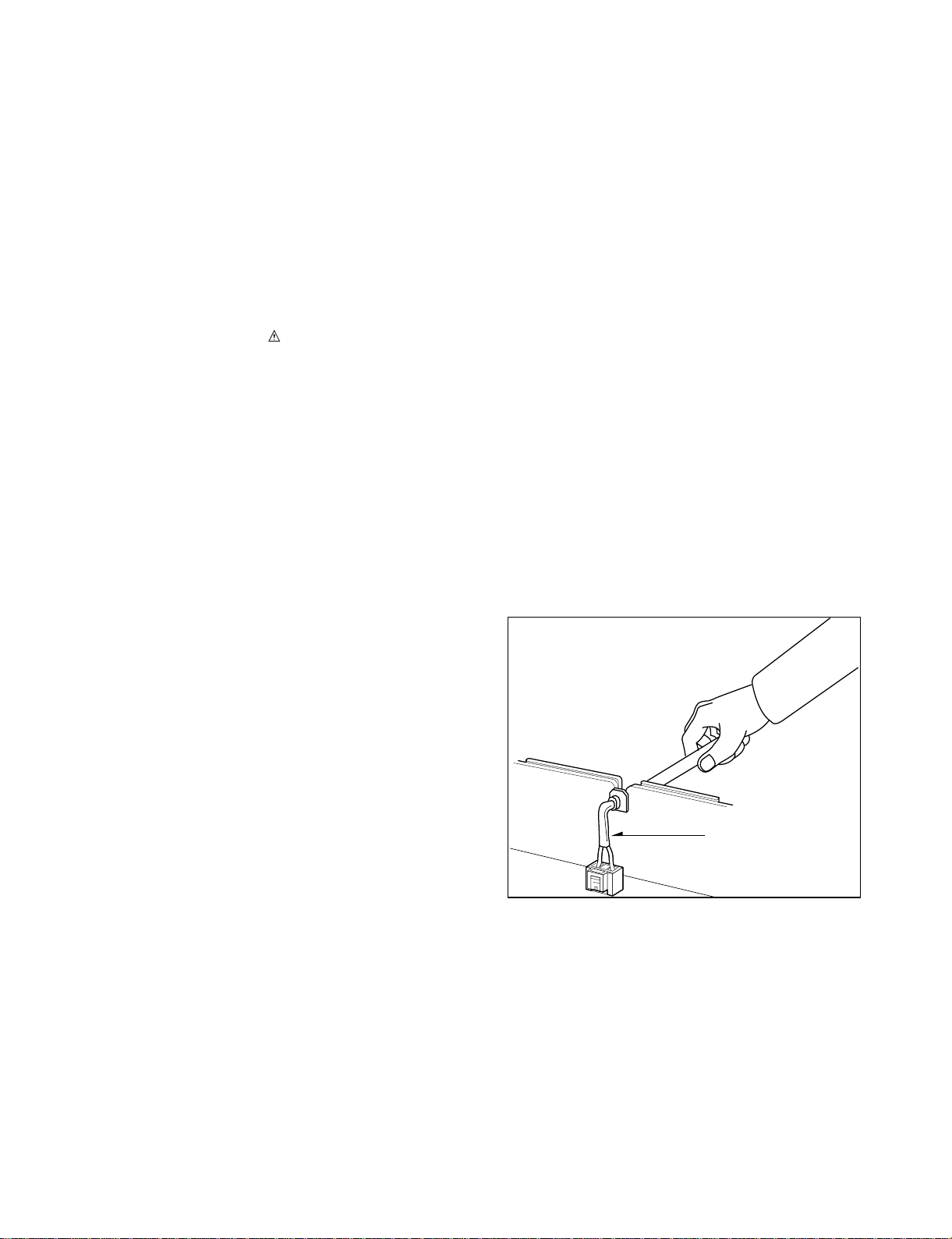

7. 1) When a power cord has been replaced, check

that A mark is made on the cord, under strain,

near the aperture, and the flexible cord is

subjected 100 times to a pull of 40N for a duration

of 1 second each.

2) During the test, the cord shall not be displaced by

more than 2mm

8. Also check areas surrounding repaired locations.

9. The internal wiring is secured so as not to approach the heating parts and high voltage parts by its shape.

So, these wires must be restored to its former state.

IMPORTANT SAFETY PRECAUTIONS

Fig. 1

Power code

Page 3

1-4

Fig. 3

SAFETY CHECK AFTER SERVICING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and

wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified

values in order to verify compliance with safety standards.

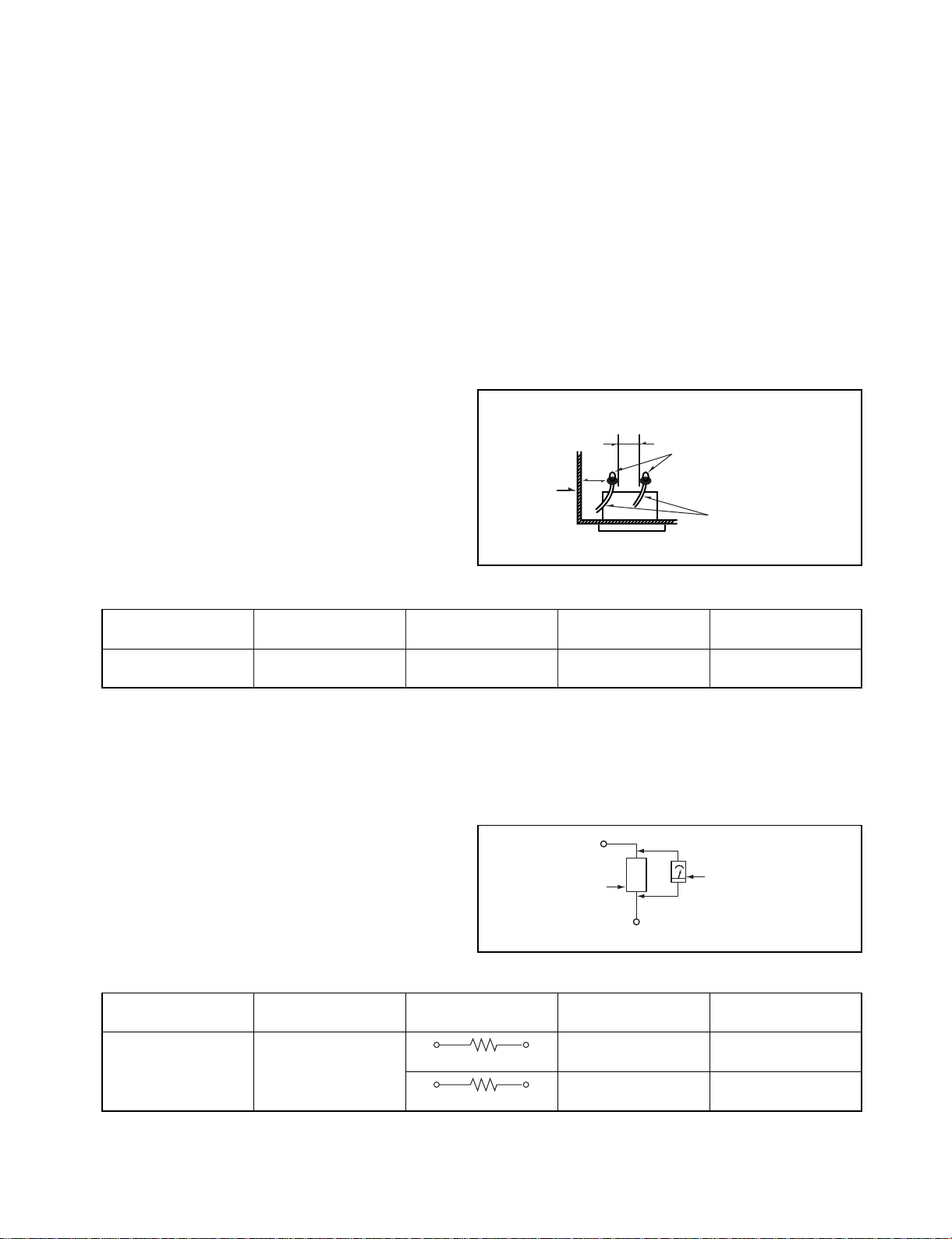

• Insulation resistance test

confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and audio input and output terminals, incrophone jacks,

earphone jacks, etc.) See table below.

• Dielectric strength test

Confirm specified dielectric strength or greater between power cord prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and

audio input and output terminals, incrophone jacks,

earphone jacks, etc.) See table below.

• Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic parts. See table below.

Table 1 : Ratings for selected areas

* Class II model only.

Note. This table is unofficial and for reference only. Be sure to confirm the precise values for your particular

country and locality.

• Leakage Current test

Confirm specified or lower leakage current between B(earth ground, power cord plug prongs) and externally

exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.)

Measuring Method: (Power ON)

Insert load Z between B(earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of

load Z. See figure and following table.

Table 2:Leakage current ratings for selected areas.

Note. This table is for IEC member only. Be sure to confirm the precise values for your particular country and

Note. locality.

Chassis

d

a

Primary circuit terminals

Fig. 2

AC Line Voltage

AC Line Voltage

100 to 130 V

200 to 240 V

*100 to 130 V

*200 to 240 V

Europe

Australia

Europe

Australia

Other terminals

Antenna earth

terminals

i

E 0.7m A peak

i E 2m A DC

i E 0.7m A peak

i E 2m A DC

F 10 MΩ/500 V DC

4kV 1 minute

F 6mm(d)

F 8mm(d)

(a Power cord)

Region

Load Z Leakage Current(i)

Earth Ground

(B) to :

Region

Insulation

Resistance

Dielectric

Strength

Clearance

Distance(d),(d)

2k

Ω

50k

Ω

Exposed

accessible

part

Load

Z

Earth Ground,

Power cord plug prongs

B

AC Voltmeter

Page 4

1-5

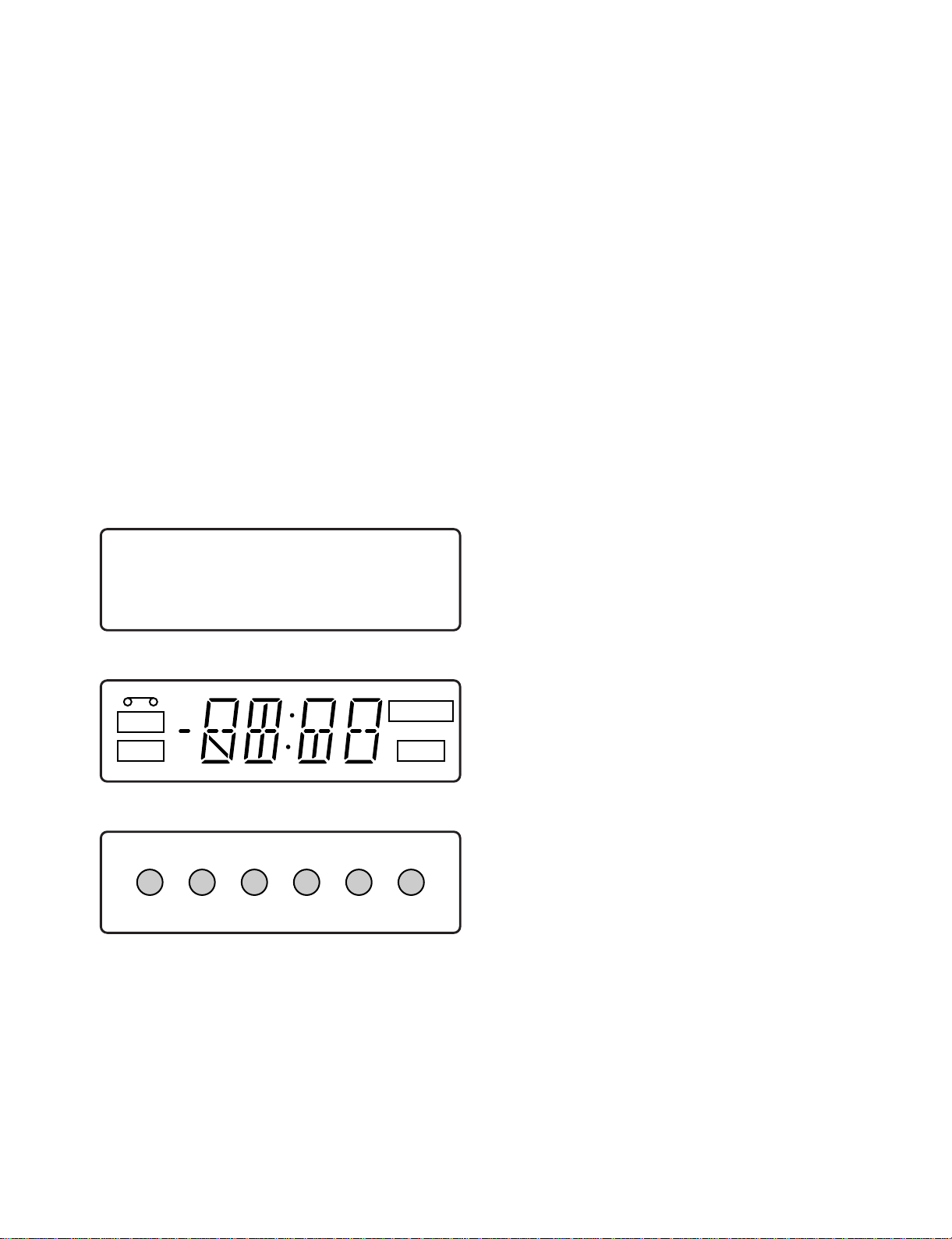

In case that defective EEPROM of PAL models is replaced, to operate these sets from the initial state MP KEY

must be repaired as well before delivering to the customer.

If MP KEY isn’t repaired the setting of RF OUT channel or LANGUAGE might be different from that for custormer’s country.

•MP KEY : In case of PAL VCR if holding the REC button on the front panel and the CLEAR button on the

remote control handset for 5 ~ 7 seconds with power being switch all and no tapes,

OK is displayed at FLD for FLD models and LED becomes on for LED CLOCK models.

This is the state that initializing EEPROM is finished.

(In case of PAL VCP if holding the REC button on the front panel and the MENU button on the

remote control handset for 5 ~ 7 seconds with power being off and no tapes, All the LED DOTs

become on. This is the state that initializing EEPROM is finished.)

•MP KEY's function : MP KEY sets EEPROM's data up to the initial state.

SERVICE NOTICE ON REPLACING EEPROM

TIMER

AM

REC

VCR

OK

• FLD MODEL:

MP KEY “OK”

• LED CLOCK MODEL:

MP KEY Switch all on a Light

• LED DOT MODEL:

MP KEY Switch all on a Light

Page 5

1-6

PREDICTED ERRORS OF MODULATOR & HOW TO COPE WITH THEM

CONTENT

Handle RF OUT CH by each region

For G : 30 ~ 40 ch

For I : 30 ~ 40 ch

30 ~ 40 ch

For G/K : 30 ~ 40 ch (G-initial for Australia)

30 ~ 40 ch (K-initial for CIS)

30 ~ 40 ch (G-initial for Southeast asia)

PREDICTED ERRORS

1. In RF Inteference, it is impossible to control from the outside.

2. After forwarding models with G/K system for G/K, it is difficult to change system.

HOW TO HANDLE

1. To subdivide CH according to model and region.

2. To adjust CH or System after open the top case.

Page 6

1-8

SPECIFICATIONS

General

Power.................................... AC110~240V, 50/60Hz

Power consumption .............. Approx. 10 Watts

Dimensions (W x H x D) ....... 360 x 94 x 230 mm

Weight................................... Approx. 3.0 Kg.

Operating temperature.......... 5 ~ 35°C

Operating humidity................ Less than 80%

Video

Television system.................. CCIR standard (625 lines, 50 fields), PAL/SECAM colour signal

Recording format .................. PAL/MESECAM/NTSC3.58/NTSC4.43

RF OUT................................. PAL/SECAM(G or K)

Input level.............................. 1.0Vp-p, 75 Ohm, unbalanced

Output level .......................... 1.0Vp-p, 75 Ohm, unbalanced

RF modulator ........................ UHF channels 32~40 (adjustable)

Audio

Input level.............................. -6 dBm, more than 47 kOhms

Output level........................... -6 dBm, less than 1.5 kOhms

Audio track ........................... Mono track

Audio frequency response .... 100 Hz ~ 10kHz(-6/+3 dBm)

• Design and specifications are subject to change without notice.

Page 7

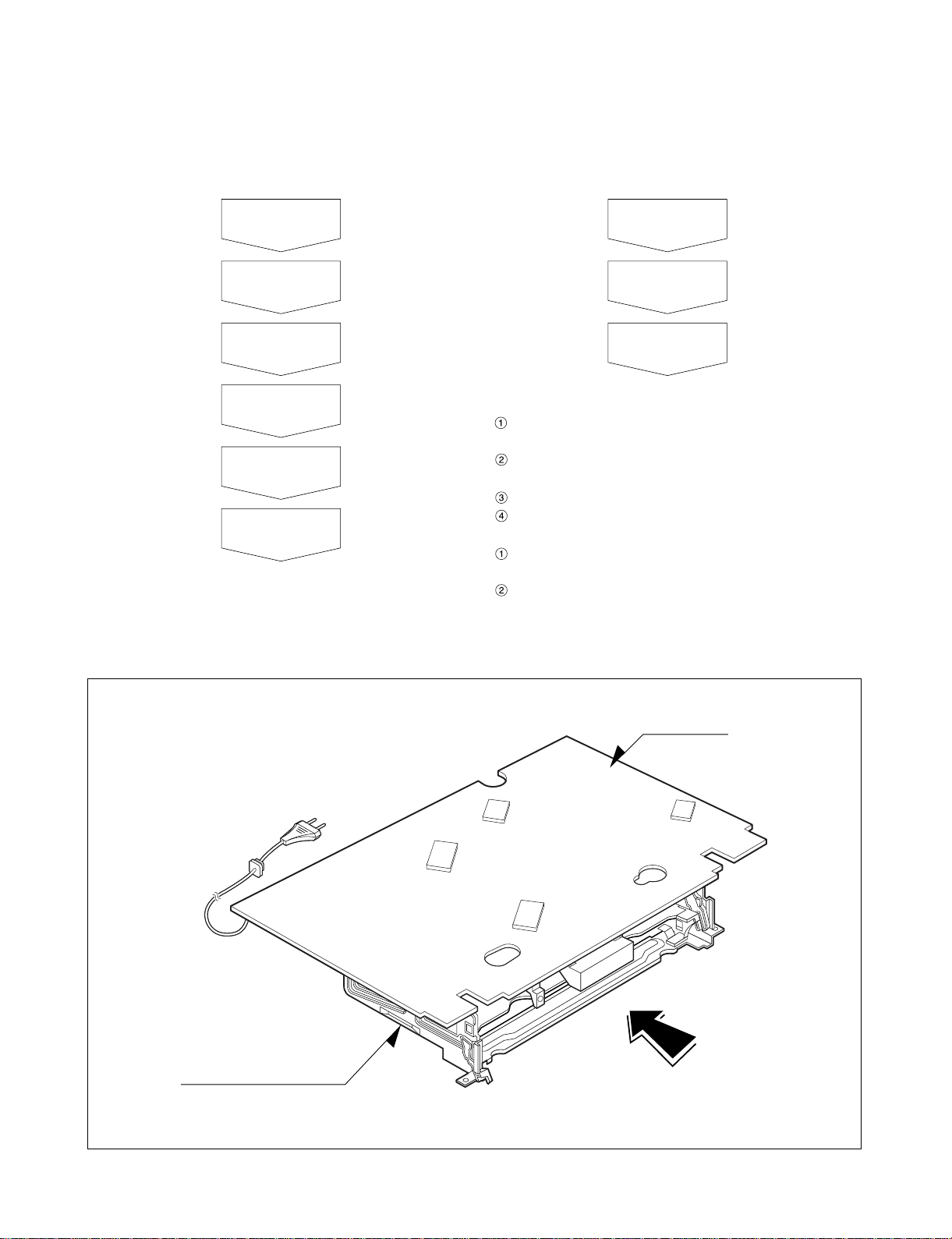

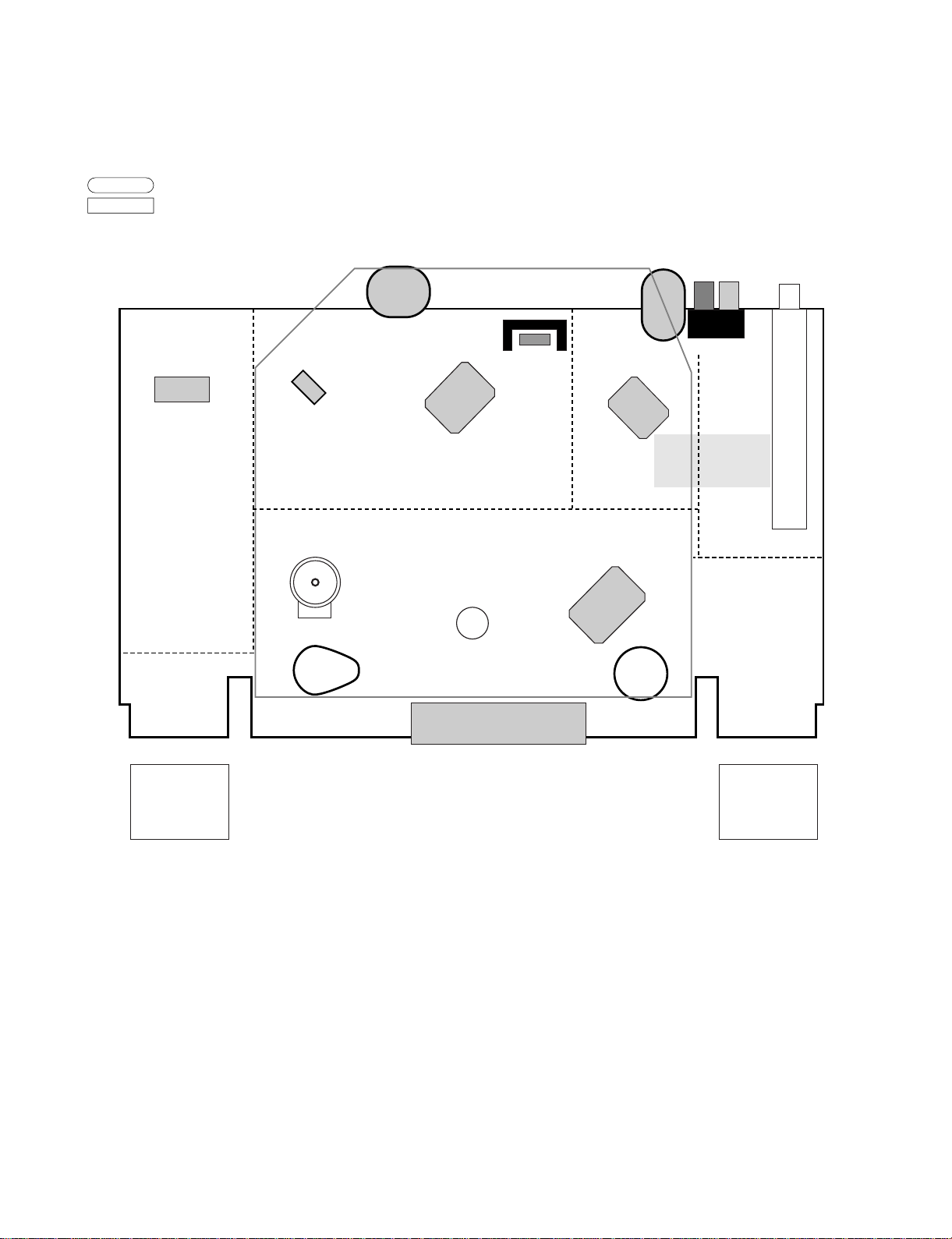

2-1

SECTION2 CABINET & MAIN FRAME

Fig.2-1

SERVICE METHOD

(1) Disassembly Flow

(Positioned Upside Down)

(2) Re-assembly Flow for service like Fig. 2-1

(3) To check and replace Electrical parts

1 Disassemble the unit according to

No.1) Disassembly Flow.

2 Re-assemble the unit according to

No.2) Re-assembly Flow.

3 Place the unit like Fig. 2-1

4 Check and replace Electrical parts.

NOTE :

1 Insert Video Cassette Tape inversely like Fig. 2-1

to check and replace defective parts.

2 In disassembling and reassembling, be careful not

to damaged CST switch.

Top Case

Bottom Cover

Front Panel

Housing & Deck

Assembly

Main C.B.A

LED C.B.A

LED C.B.A

Main C.B.A

Housing & Deck

Assembly

Housing y Mecanismo

Cassette Tape

(Upside Down)

C.B.A Princioal

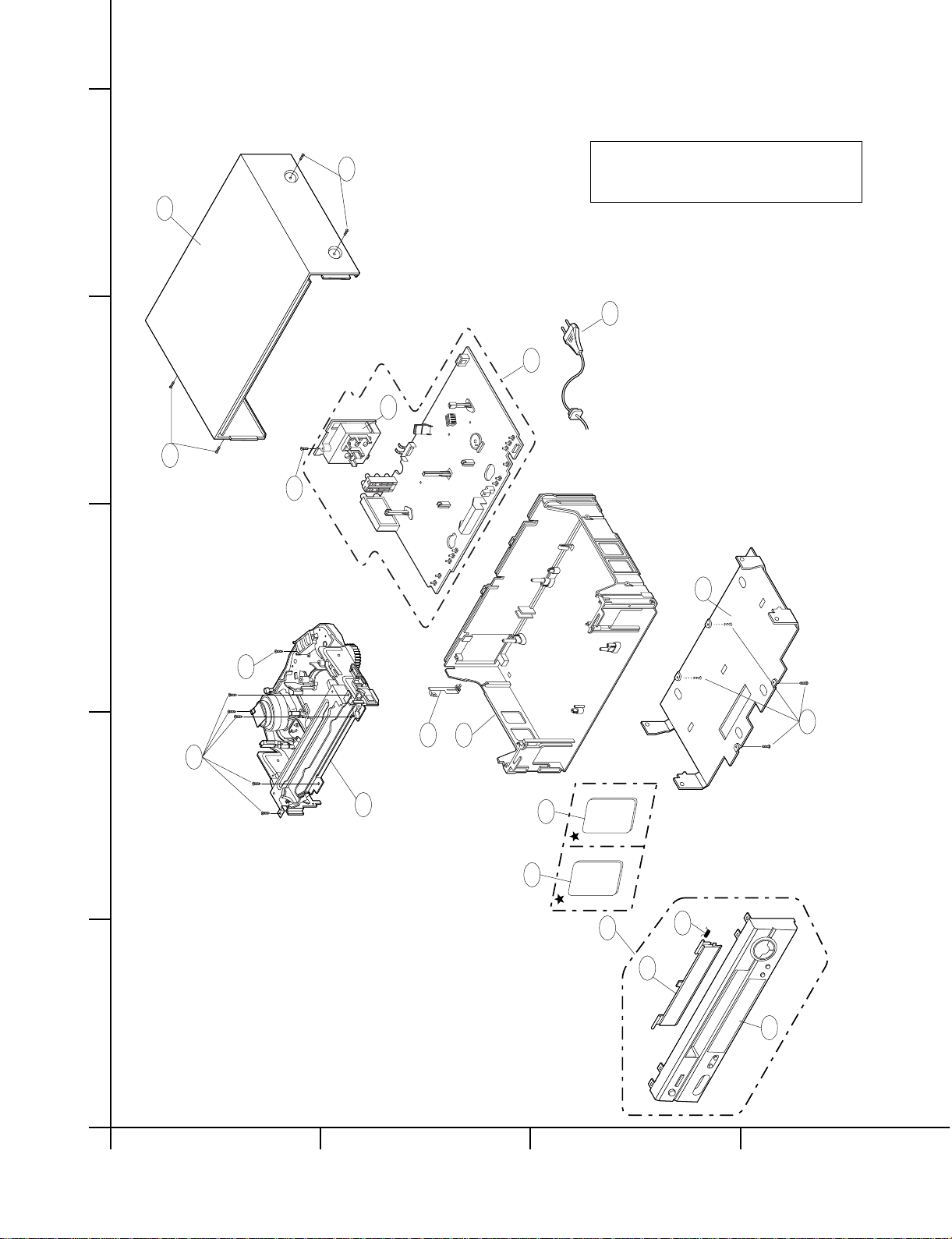

Page 8

2-2

EXPLODED VIEWS

1. Cabinet and Main Frame Section

283

280

284

261

260

457

A00

464

462

462

250

300

A43

330

452

457

320

A46

A42

A49

A

5

4

3

2

1

BCD

NOTE) Refer to “SECTION 5 REPLACEMENT

PARTS LIST” in order to look for the

part number of each part.

_ OPTIONAL PARTS

Page 9

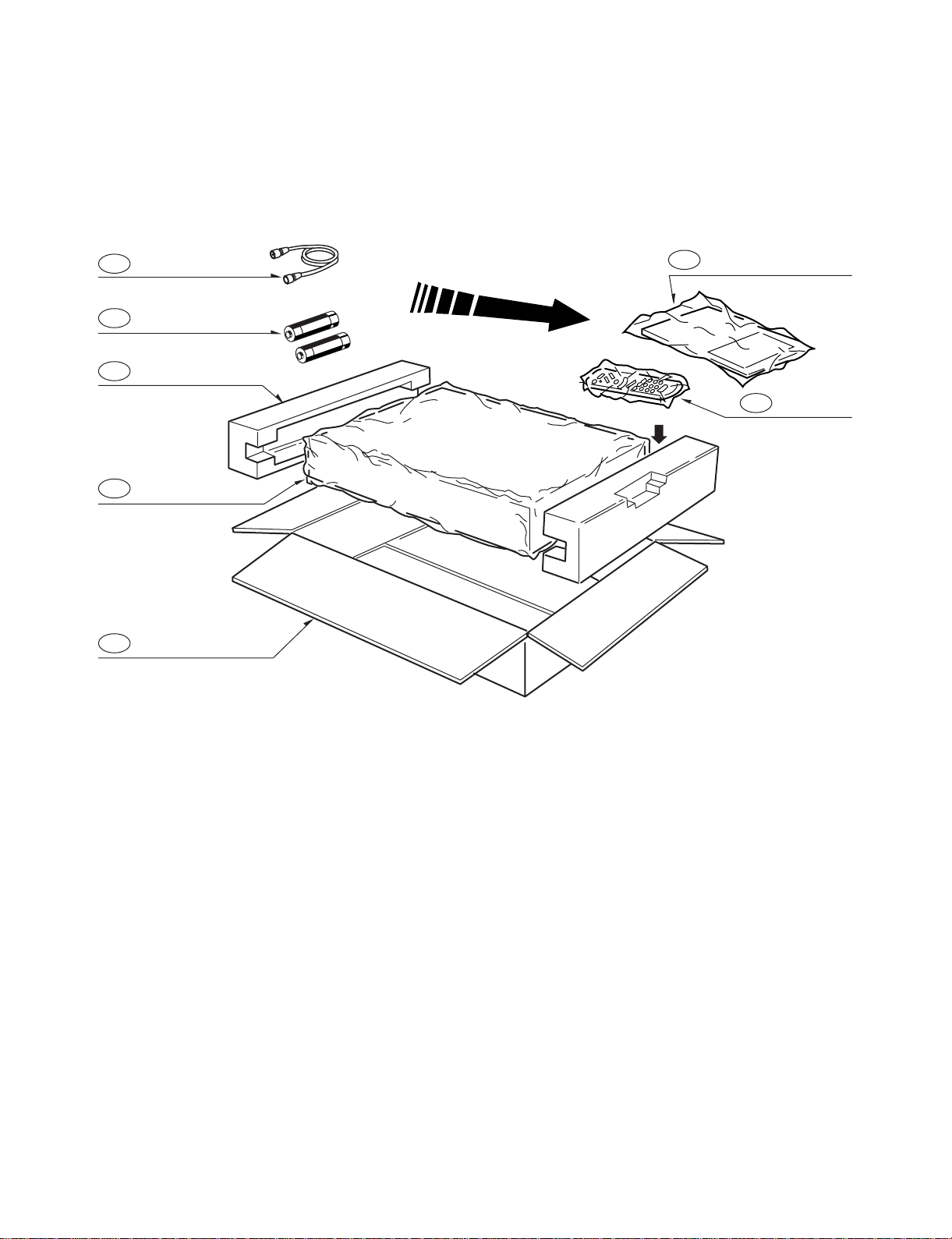

2-4

2. Packing Accessory Section

• Packing Accessory Section Part List

801

808

INSTRUCTION ASS'Y

BATTERY

810

CABLE SET ASS'Y

803

PACKING ASS'Y

804

SHEET CUSHION

802

BOX CARTON

(Optional Parts)

900

REMOCON

Page 10

3-13-1

Hi-Fi

AVCP

U-COM

S

M

P

S

SYSTEM

A/V

DECK CNT.

A/V JACK

M

O

D

U

L

A

T

O

R

MODULATOR

SMPS

DISP

KEY

BOARD(L)

KEY

BOARD(R)

: Measurement point

: Adjustment point

SECTION 3 ELECTRICAL

ELECTRICAL ADJUSTMENT POINTS ARRANGEMENT

Page 11

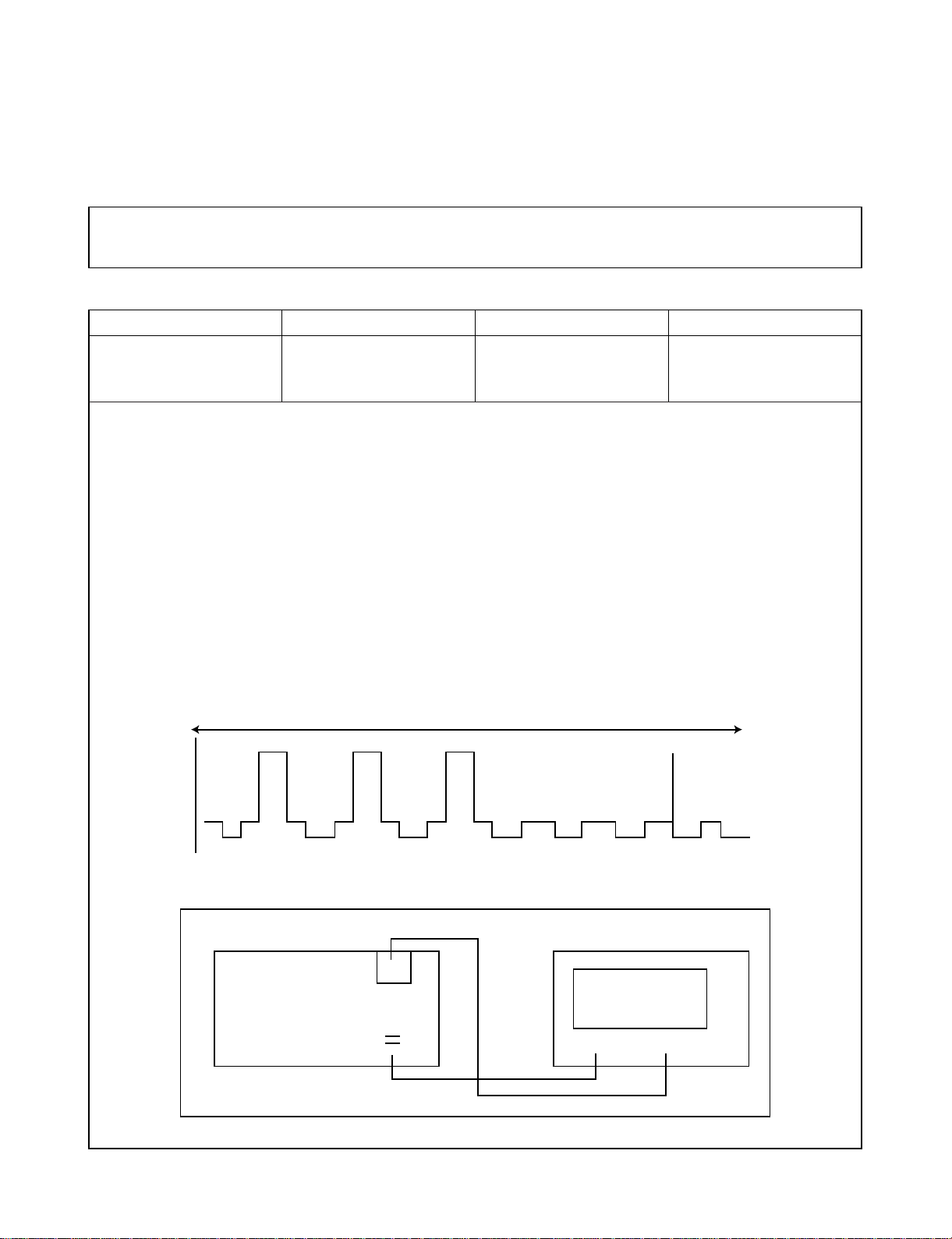

3-23-2

Fig. 3-2

ELECTRICAL ADJUSTMENT PROCEDURES

1. Servo Adjustment

1) PG Adjustment

• Test Equipment

• Adjustment And Specification

a) OSCILLOSCOPE

b) PAL TEST TAPE (VHS SP)

MODE

SP TAPE PLAY

• Adjustment Procedure and Caution

a) Insert the PAL SP Test Tape and play.

Note - Adjust the distance of X, pressing SET REC KEY and “OK” on RCU simultaneously. (3SEC

HOLD). In ININTIAL MODE, LED of POWER/CST IN/LP/EP/STANDBY is on .(TRK PRESET

MODE)

b) In TRK PRESET MODE,Pressing SET REC KEY and “OK” on RCU same, and then PG is adjusted

automatically. (LED of PLAY/REC is off.)

c) Connect the CH1 of the oscilloscope to the H/SW(W373, W374) and CH2 to the Video Out for the VCR.

d) Trigger the mixed Video Signal of CH2 to the CH1 H/SW(W373, W374), and then check the distance

(time difference), which is from the selected A(B) Head point of the H/SW(W373, W374) signal to the

starting point of the vertical synchronized signal, to 416 µsec ± 32 µsec.

• WAVEFORM

• CONNECTION

V.Out Jack

H/SW(W373, W374)

AUTO

PAL PG : 416 ± 32usec

NTSC : 412 ± 32usec

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

t=416 µ sec ± 32 µ sec

VIDEO

OUT

CH-1 CH-2

W373/W374

Page 12

3-33-3

• Caution and Refrence

1. PG Adjustment is operated when SERVO SYSTEM is in LOCKING, maximum of RF LEVEL.

2. Distance difference of A/B HEAD is within ± 32usec.

3. Difference of Adjustment Requirement and Test is within ± 32usec.

H/SW

Composite

VIDEO

6.5H(416usec±32usec)

Page 13

3-4

ELECTRICAL TROUBLESHOOTING GUIDE

1. Power Circuit(SMPS)

(1) No 5.3VA.

No 5.3VA.

Is the F101 normal?

Is the BD101 normal?

Is the R101 normal?

Does the oscillation waveform appear at

the IC101 Pin 7?

Is there DC voltage at the IC101 Pin 3?

Is there about 2.5V at the IC103 Vref ?

Is the D106 normal?

Check the Main PCB 5.3VA/5.0V

Line short?

Replace the F101

(Use the same Fuse).

Replace the BD101.

Replace the R101.

Is Vcc(about 15~19V) permittable at the

IC101 Pin 3?

Check or Replace the D103.

Replace the IC102.

Replace the IC103.

Replace the D106.

NO

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Page 14

3-5

Is the D109 normal?

Replace the D109.

Check 13VA/12VA Line of the

Main PCB short.

YES

YES

No 13VA.

Does 5.3VA work normally? Check whether 5.3VA is out of order.

YES

NO

NO

Is the D152 normal? Replace the D152.

Check or Replace the Motor Vcc.

YES

YES

No 12VA.

Does 13VA work normally? Check whether 13VA is out of order.

YES

NO

NO

7. Power Circuit(SMPS)

(2) No 13VA.

(3) No 12VA.

Page 15

3-6

1 Check the 13VA Line.

2 Check the Peripheral

Is about 5.5V put into the

Q155/Q157 Base?

Does the 13VA Line work normally?

Check or Replace the Q155/Q157.

YES

YES

NO

No 5V.

Is the Q156 Base “H”?

Is 5.3VA put into the Q155/Q157

collector?

Check the Power Control.

YES

YES

NO

NO

7. Power Circuit(SMPS)

(4) No 5V.

Page 16

3-7

2. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

Does the Noise level of the

screen change

periodically?

Do the CTL pulses appear

at the IC501 Pin 58?

Is adjusting the height of

the CTL Head accurate?

Readjust the height of the

CTL Head.

Replace the IC501.

Refer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Does the CFG waveform

appear at the IC501

Pin 49?

On tracking do the CTL

pulses move?

Does the Video Envelope

waveform appear at the

IC501 Pin 62?

Replace the IC501.

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

(2) When the Drum Motor

(2) doesn’t run.

Do the DPG/DFG Pulses

appear at the PMC01

Pin 11?

Check the Drum Motor

Ass’y.

Aren’t the foil patterns and

the Components between

IC501 Pin 47 and PMC01

Pin 12 short?

Replace the IC501.

Check Power.

Do the Drum PWM Pulses

appear at the IC501

Pin 29?

Aren’t the foil patterns and

the Components between

IC501 Pin 29 and PMC01

Pin 12 short?

Do the DPG/FG Pulses

appear at the IC501

Pin 47?

Do the Drum PWM Pulses

appear at the IC501

Pin 29?

Aren’t the connecting patterns and the Components

between IC501 Pin 29 and PMC01 Pin 12 short?

When the Drum Motor

doesn’t run,

Does 12VA appear at the

PMC01 Pin8?

Does DPG/DFG appear at

the PMC01 Pin 11?

Check the connector and

the Drum Motor Ass’y.

NO

YES

NO

NO

NO

NO

NO

YES

Page 17

3-8

Does the CFG signal appear at the

PMC01 Pin 1?

Does the PWM signal appear at the

IC501 Pin 28?

Does 2.8V appear at the PMC01 Pin 9?

Check the PMC01 and the Capstan

Motor Ass’y.

Does the Capstan PWM signal appear at

the IC501 Pin 28?

Aren’t the foil patterns and Components

between IC501 Pin 28 and PMC01

Pin 9 short?

Does the CFG signal come into the

IC501 Pin 49?

Aren’t the foil patterns and Components

between IC501 Pin 28 and PMC01

Pin 9 short?

2. SERVO CIRCUIT

(3) When the Capstan Motor doesn’t run,

NO

NO

NO

YES

YES

YES

YES

When the Capstan Motor doesn’t run,

Does 12VA appear at the PMC01?

Replace the IC501.

YES

NO

NO

YES

Refer to “SMPS(CAPSTAN/12Volt)

Trouble Shooting”.

Aren’t the foil patterns and component

between IC501 Pin 49 and PMC01 Pin 1

short?

Check the Capstan Motor Ass’y.

NO

Page 18

3-9

3. Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Check the Video Input

Jack.

(Line In Jack)

Does the Video signal

appear at the IC301 Pin 15?

Is 5V applied to the IC301

Pins 22, 47, 60, 84, 92?

Does the Video signal

appear at the IC301 Pin 29?

Does the Video signal

appear at the Emitter

terminal of the Q501?

Check the 5V Line.

(Power Circuit)

Is I2C BUS signal applied to

the IC301 Pins 73, 74?

Check C327. (AGC)

Replace the IC301.

Is there 5V on the Emitter

of Q501?

Replace the Q501.

Check the 5V Line.

(Power Circuit)

Check the System Circuit.

(Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’)

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Page 19

3-10

3. Y/C CIRCUIT

(2) When the Y(Luminance) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to the IC301

Pins 22, 47, 60, 84, 92?

Is the I2C Bus siganl applied

to the IC301 Pins 73, 74?

Does the normal RF signal

appear at the IC301 Pin 76?

Check the line of the 5.3V

Line. (Power Circuit)

Check the System Circuit.

(IC501 Pin 18)

Check the V.H.S/W level.

Replace the IC301.

Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’.

Is the V.H.S/W signal

applied to the IC301 Pin80?

Is V.H.S/W “H” about 4.5V

at the IC301 Pin 80?

Clean the Drum.

Check the path of the

Y(Luminance) RF signal.

Check the path of the

Y(Luminance) RF signal.

Does the Y(Luminance) RF

signal appear at the IC301

Pin 33?

Is the Y(Luminance) Video

waveform showed up at the

IC301 Pin 49?

Replace the IC301.

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Page 20

3-11

3. Y/C CIRCUIT

(3) When the C(Color) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to the IC301

Pins 22, 47, 60, 84, 92?

Does the oscillation signal

appear at the IC301

Pin 67, 71 ?

Check the line of the 5.3V

Line. (Power Circuit)

Replace the X301 or

the X302.

Check the Color Pass.

(Check the C347)

Replace the IC301.

Does the X301(3.58MHZ)

or X302(4.43MHZ) oscillate?

Check the circuit of the

IC301 Pins 55, 46, 45.

Does the Color signal

appear at the IC301 Pin42?

Replace the IC301.

NO

YES

YES

NO

NO

NO

YES

Page 21

3-12

3. Y/C CIRCUIT

(4) When the Video signal doesn’t appear on the screen in REC Mode,

Is the EE signal normal?

Is 5V applied to the IC301

Pins 22, 47, 60, 84, 92?

Does the RF signal appear

at the IC301 Pin 86?

Check EE Mode.

Check the System of REC

‘H’. (Q303 Base/IC501

Pin 22)

Replace the IC301.

Check the line of the 5.3V

Line.(Power Circuit)

Check PB Mode.

Is the REC ‘H’ signal

(about 4V) applied to the

Q303 Base?

Check the circuit of the

IC301 Pins 85, 86, 87.

Check REC Luminance

Pass & Color Pass.

Does PB Mdoe operate

normally?

Does the REC RF signal

appear at the IC301

Pins 86 ?

Check the Drum &

Drum Connector

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

Page 22

3-13

4. AUDIO CIRCUIT

(1) No sound in EE Mode

No sound in EE Mode.

No sound.

Is 5V applied to the IC301 Pin 92?

Is the Audio signal applied to the

IC301 Pin 4?

Does the Audio signal appear at the

IC301 Pin 6?

Check the connection of the Audio

out Jack.

Does the CLK/Data signal(I2C)

appear at the IC301 Pins 73, 74?

Replace the IC301.

Check the line of the 5V Line.

(Power Circuit)

Check the path of LINE/AUDIO.

Is the Audio Mute “High” signal applied

to the IC301 Pin 79?

Check the IC501 Pin 10.

(Audio Mute “H”.)

Check the circuit line of the 5V Line.

(Power Circuit)

Check the IC501 Pin 13 (CLK),

12 (Data) Line.

Check the connecting state between the

P3D02 Pin 6 and A/C Head.

Is the Audio Mute “H” applied to the

IC301 Pin 79?

Check the IC501 Pin 10.

YES

YES

YES

YES

YES YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

(2) No sound in PB MODE

No sound in PB Mode.

No sound.

Is 5V applied to the IC301 Pin 92?

Does the CLK/Data signal(I2C) appear at

the IC301 Pins 73, 74?

Does the Audio signal appear at the

IC301 Pin 95?

Does the Audio signal appear at the

IC301 Pin 6?

Replace the IC301.

NO

Check the IC501 Pin 13(CLK),

12(Data) Line.

NO

NO

NO

NO

NO

NO

NO

Page 23

3-14

3. Y/C CIRCUIT

(3) No sound in REC Mode,

No sound in REC Mode,

Sound is not recorded.

Is the Audio signal applied

to the IC301 Pin 4?

Refer to “No sound in PB

Mode,”.

Check the CLK/Date line

and replace the IC301

Check the path of Line

Audio.

Is the “High” signal applied

to the IC301 Pin 79?

Check the IC501 Pin 10

(Audio Mute “H”).

Replace the FL301 or the

Q301.

Check the line of the 5V

Power Circuit.

Check the Audio R/P/E

connector and Head.

Is Playback O.K.?

Does the Audio waveform

appear at the IC301 Pin 98?

Is 5V applied to the FL301

Pin 2 ?

Is 3.0~4.5V applied to the

Collector of the Q301 ?

Does the Erase signal

appear at the FL301 Pin 5?

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Page 24

3-15

5. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

(2) The unstable loading of a Cassette tape

Auto Stop

Does the SW30 waveform

appear at the IC501

Pin 18?

Do the T-UP Reel Pulses

appear at the IC501 Pin 3?

Is 12V applied to the

PMC01 Pin 8?

Check the Drum Motor

signal.

Does 5.0V appear at the

RS501?

Check the Q157 Power

Circuit.

Refer to “SMPS CAPSTAN

12 Volt Trouble Shooting”.

Is 5.3V applied to the

R544 ?

Refer to SMPS 5.3VA

troubleshooting.

Check the IC501

Pins 66, 67, 60, 69.

Do T/UP Reel Pulses

appear at the Q514

Base terminal ?

Replace the T/UP Reel

Sensor (RS501).

Check the CST SW and

the peripheral circuitry.

Replace the IC501.

The unstable loading of a

Cassette tape

Does the “H” signal appear

at the IC501 Pin 27 during

inserting the CST ?

Does the “H” signal appear

at the IC501 Pin 14 during

inserting the CST?

Check the Deck

Mechanism.

Caution :

Auto stop can occur because Grease or Oil is dried up

YES

YES

YES

NO

YES

YES

YES

NO

YES

NO

NO

NO

NO

NO NO

YES

YES

YES

Page 25

3-16

KEY doesn’t working.

Is 5VA applied to the IC501

Pin 55?

Does OSD display change

when a function button is

pressed?

Refer to “SMPS 5.3VA

Trouble Shooting”.

Replace the defective

switches.

YES

NO

NO

(3) KEY doesn’t working

Page 26

3-17 3-18

BLOCK & CIRCUIT DIAGRAMS

1. POWER(SMPS) BLOCK DIAGRAM

R101

C103

D151

J152

(MONO OPTION)

+

TO SYS

12VA(Cap)

D152

NOTES : Symbol denotes AC ground.

Symbol denotes DC chassis ground.

F101

R107

!

!

C112C113

HOT GND

!

!

!

4

3

2

6

4

7

9

8

10

11

3

1

2

IC102

IC103

!

BK

(BR)

WH

(BL)

PW101

!

TO SYS

13VA(DRUM)

TO Hi-Fi BUFFER

13VA

TO AVCP, OSD

5.1V

TO SENSOR MOD

5.1V

TO SYS, MOD

5.3VA

FROM SYS

P.CTL "H"

BD101

LINE FILTER

BLOCK

(C101, L102, C102)

DRIVE & S/W

BLOCK

(IC101, C109, D103, R103, C129,

R109, R125, R126, C135, BC101)

RECTIFIER &

SMOOTHING

(C116, D106,

L103, C117)

5V S/W

BLOCK

(Q155, R156, R157)

5V S/W

BLOCK

(Q157, R170, R171)

PWR CTL

BLOCK

(Q156, R161)

FEED-BACK

BLOCK

(R116, R117, R118,

R119, R120, R121,

C114)

RECTIFIER &

SMOOTHING

(D109, C120,

L104, C121)

12 REG BLOCK

(Q152, ZD152, C155,

Q162, C152, R152)

SNUBBER

BLOCK

(D102, R104,

C105, C106)

T101

TRANSFORMER

HOT CIRCUIT

Hi-Fi

OPTION

Page 27

3-19 3-20

2. Power(SMPS) Circuit Diagram

NOTE :

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during TUNER mode.

F101 is defective.

Power dead.

IC101 is defective.

Switching dead.

IC102, IC103 are

defective.

Switching error

D105 is defective.

36VA Power dead.

D109 is defective.

12VA Power dead.

D106 is defective.

5.4VA Power dead.

BD101,R101 are

defective.

Power dead.

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

Page 28

3-21 3-22

3. MODULATOR CIRCUIT DIAGRAM

Page 29

3-23 3-24

4. AUDIO BLOCK DIAGRAM(MONO MODEL ONLY) 5. Y/C BLOCK DIAGRAM

1) PB Mode

2) REC Mode

1) PB Mode

2) REC Mode

IC301

HA118717

VCA

DET

AMP

PB EQ

AMP

6

96

R/P HEAD

AUDIO OUT

V.H/SW30

System

(FROM u-COM)

V.ENV

(TO u-COM)

SP CH1

SP CH2

EP CH1

EP CH2

80

83

85

REC-AMP

86

REC-AMP

87

89

REC-AMP

90

REC-AMP

91

SP CH2

SP CH1

EP CH2

EP CH1

IC301

HA118725

76 77

System

System

X301 X302

67 69

X-tal

VCO/OSC

ACC

2M LPF

TRAP

629K

C LPF DEALY

FM AGC P.EQ G.EQ D LIM Y LPF

10

CTL Trap

fh Trap

HIFI Trap

DATA

(FROM u-COM)

Serial Cont

interface

CLOCK

(FROM u-COM)

73 6574

DEMO

S LPF

57 45 43 4271 46

C-CCD

6dB

AMP

CLOCK Drive

C-

SQUELCH

CLAMP

APC/ACC

DET

BDBPF

YNR NC

LPF

LPF

C.K

SYNC SEP

Sharpness

CONTROL

3640383733 35

+

+

VCA

Main

De-Empf

CCD LPF

98

L- DET

Main

Conv2

Main

Conv1

NL

De-eMPH

CLAMP

Y-CCD

MIX

AMP

SQUEL CH

CLEAR

SYNC

FBC

Video ALC

55

53

49

51

V. OUT

29

(TO u-COM)

28

(FROM u-COM)

31

30

32

D-V SYNC

System

System

(From REAR Jack)

A.IN

System

System

DATA

CLOCK

(FROM u-COM)

REC

AMP

VCA

AMP

4

DET

IC301

HA118717

98

6

R/P HEAD

AUDIO OUT

System

System

V. OUT

(TO u-COM)

D-V SYNC

(TO u-COM)

46

SQUEL CH

CLEAR

SYNC

FBC

Video ALC

VIDEO

AGC

ATT

-10dB

IC301

HA118725

HPF

AGC DET

LPF

APC/ACC

DET

SPFACC

CLAMP

D.E.

CLAMP

C-CCD

55

CLOCK Drive

53

49

Y-CCD

51

6dB

29

AMP

28

30

32

ATT

ATT

-10dB

-10dB

19

15 17 18 36 40 38 37 23 26 14 9 8 11

+

+

++

LINE 1

VIDEO IN

YNR

Main

Conv2

Main

Conv2

C-LPF 1

NL Emph

SYNC

SEP

57

45 7365 74 6967

JCA

(-4dB)

C-LPF 2

L-DET

CCD

LPF

FBC

Main

ALC

Emph

(FROM u-COM)

Serial Cont

interface

f0=1.68M

REC

MIX

B.E

C.K

FM

MOD

f/0DEV

Adjst

ATT

REC FILTER

Trap

X-tal

VCO/OSC

LPF

629K

TRAP

71

V.H/SW30

System

80

85

REC-AMP

SP CH2

86

REC-AMP

SP CH1

87

VCA

89

REC-AMP

EP CH2

90

REC-AMP

91

EP CH1

(FROM u-COM)

SP CH1

SP CH2

EP CH1

EP CH2

Page 30

3-25 3-26

6. A/V CIRCUIT DIAGRAM

1

2

4

7

3

6

3

3

9

12

13

8

59

10

11

WAVEFORM

Y. (REC)

C. (REC)

Y(PB)

Y/PB

C/PB

Y+C (PB)

C(PB)

Y+C (REC)

H/SW Level is defective..

Video Noise.

R333, C357, C358 are defective.

No Color.

L307, C349 are defective.

No Color.

R329 is defective.

No Color.

C332 is defective.

Video output level unstable

R322, R323, R324,

C320 are defective.

VIDEO Distortion

Page 31

3-27 3-28

22

25

PB FM

28

AMP

AMP

AMP

TO µ-COM

A.ENV

LINE OUT (R)

LINE OUT (L)

MOD. OUT

IC801

LA72634M

AGC

DET

R CH

BPF

L CH

BPF

SW.N.C

OUT

PUT

SELEC

TOR

AMP

ENV.

DET.

19

17

56

57

58

PNR

SW.N.C PNR

LIMIT

VCO

LPF

LINEI A.R

LINEI A.L

IC801

LA72634M

52

61

PNR/

AGC

LIMIT

VCO

LPF

PNR/

AGC

NORMAL A. OUT

TO IC301

Hi-Fi

HEAD

INPUT SELECTOR

26

53

7. Hi-Fi BLOCK DIAGRAM (Hi-Fi MODEL ONLY)

(PB MODE) (REC MODE)

Page 32

3-29 3-30

8. Hi-Fi CIRCUIT DIAGRAM (Hi-Fi MODEL ONLY)

Page 33

3-31 3-32

9. SYSTEM BLOCK DIAGRAM

Page 34

3-33 3-34

10. SYSTEM CIRCUIT DIAGRAM

WAVEFORM

VR501 is defective.

PB, PG will not operate.

RS501, RS502, Q514,

Q515 are defective.

Auto stop occurs.

R517 is defective.

OSD will not operate.

C576 is defective.

OSD will not operate.

C517 is defective.

OSD will not operate.

C512 is defective.

OSD is unstable.

R567 is defective.

OSD is unstable.

X501 is defective.

µ-COM will not operate.

Q501, Q503, L505 are

defective.

µ-COM is unstable.

ES501, ES502, LD501 are defective.

Tape mode not working.

(Taperemaing on reels)

Auto REW not working.

DOT MODEL

ONLY

Page 35

3-35 3-36

• WAVEFORMS

* IC301 Waveform Photographs

IC301 Pin 9

100mV/10msec DIV

VV/EE

(Main De-Emphasis out)

IC301 Pin 12

100mV/10msec DIV

PB

(Main De-Emphais

Peacking)

IC301 Pins 33, 36, 37

100mV/10msec DIV

VV/EE

Clamp Drive IN Pin 33

Y-out(to 1H CCD) Pin 36

Y-out(from 1H CCD) Pin 37

IC301 Pin 15

200mV/10msec DIV

EE

(VIDEO IN)

IC301 53 Pin

100mV/0.2msec DIV

REC/PB

(2fsc)

IC301 31 Pin

1.0V/20msec DIV

VV/EE

(C-SYNC OUT)

IC301 29 Pin

500mV/10msecDIV

VV/EE

(VIDEO OUT)

IC301 Pin 43

200mV/20msec DIV

PB

(C.OUT)

* IC501 Waveform Photographs

IC501 PIN 18

REC/PB MODE

1V/1msec

(V.H/SW)

IC501 PIN 19

QUE/REV MODE

1V/5msec

(DV.SYNC)

IC501 PIN 56

REC MODE

1V/5msec

(CTL+)

IC501 PIN 57

REC MODE

1V/5msec

(CTL-)

IC501 PIN 47

REC/PB MODE

1V/5msec

(DPFG)

IC501 PIN 49

REC/PB MODE

1V/2msec

(CFG)

IC501 PIN 40

EE/PB MODE

500mV/10usec

(CVin)

IC501 PIN 38

EE/PB MODE

500mV/10usec

(CVout)

IC301 Pins 46, 57

200mV/20msec DIV

VV/EE

from 1H CCD Pin 46

to 1H CCD Pin 57

IC301 Pin 67

100mV/0.2msec DIV

PB/REC

(3.58MHz X-TAL IN)

IC301 Pin 77

100mV/5msec DIV

PB

(PB RF out)

IC301 Pin 86

500mV/2msec DIV

SP REC

(REC RF)

IC301 Pin 90

500mV/2msec DIV

EP REC

(REC RF)

Page 36

• VOLTAGE SHEET

3-37 3-38

REC PB

MODE

PIN NO.

0.06

0.06

0.06

0.35

2.35

2.58

2.83

1.84

1.84

2.41

2.61

1.60

0.00

2.80

2.80

0.18

2.79

1.76

2.80

0.02

2.80

5.08

2.32

0.18

2.12

3.00

0.18

0.15

2.48

2.80

0.37

2.31

2.09

1.76

3.03

2.32

3.03

2.15

1.42

2.08

3.01

1.98

2.05

0.00

3.13

3.13

5.03

0.14

3.17

5.03

2.05

5.03

2.62

0.00

0.06

0.06

0.06

0.37

2.09

2.55

2.83

1.24

1.23

1.89

3.00

0.56

0.00

2.26

2.38

1.91

2.80

1.91

2.80

0.00

2.80

5.12

2.34

0.57

2.12

2.80

0.45

0.15

2.46

2.91

0.37

2.79

2.13

1.85

3.07

2.35

3.06

2.20

1.45

2.12

2.55

1.97

2.05

0.00

3.15

3.15

5.07

0.14

3.19

5.07

2.07

5.07

2.64

0.00

REC PB

MODE

PIN NO.

2.07

0.00

2.18

2.34

4.94

4.94

0.02

2.28

2.23

2.94

2.26

2.95

2.19

1.28

1.96

2.71

2.19

0.14

5.20

5.20

2.76

2.25

2.84

0.02

0.00

2.54

4.85

4.15

0.00

5.07

2.46

2.54

2.45

0.00

2.48

2.52

2.48

5.08

0.52

2.53

2.53

2.53

0.01

2.27

0.00

2.58

0.5

PULSE

PULSE

0

4.8

0.5

0.5

0.5

2.09

0.00

2.18

2.34

4.97

4.97

0.02

2.21

2.23

2.95

2.26

2.96

2.18

1.24

1.96

1.42

2.19

0.14

5.21

5.21

2.79

2.17

2.84

0.03

0.00

2.53

4.84

4.15

2.53

5.10

2.30

2.30

2.30

0.00

2.30

2.30

2.30

5.11

0.51

2.54

2.52

2.50

0.01

2.55

0.00

2.55

0.5

PULSE

PULSE

0

4.8

0.5

0.5

0.5

IC501

REC PB

MODE

PIN NO.

0

0

0

PULSE

PULSE

2.5

5.1

0

4.9

PULSE

0.1

5.1

PULSE

4.5

0

0

0

0

0

2.7

2.6

0

5.1

2.5(OSC)

2.3(OSC)

0

0.4(OSC)

0.4(OSC)

0

2.0(VIDEO)

0

2.0(VIDEO)

2.5(VIDEO)

5.0

2.9

2.5

0.9

0

PULSE

0.4

PULSE

0.6

2.5

2.5

0

2.5

5.1

PULSE

PULSE

2.5

5.1

5.1

0

0

0

0

0

0

PULSE

PULSE

2.5

5.0

0

4.9

PULSE

0.1

5.1

PULSE

0

0

0

0

0

5.0

2.7

2.6

0

5.1

2.5(OSC)

2.3(OSC)

0

0.5(OSC)

0.5(OSC)

0

2.0(VIDEO)

0

2.0(VIDEO)

2.5(VIDEO)

5.0

2.9

2.5

2.5

2.1

PULSE

0.4

PULSE

0.4

2.6

2.6

0

2.6

5.1

2.6

2.6

2.6

5.1

5.1

0

TAPE

REC PB

MODE

PIN NO.

0

0

5.2

5.2

5.2

0

0

0

0

5.1

0

5.1

5.1

0.6

0.5

0.5

0.37

0

2.48

1.96

2.48

0

0

0

0.22

2.48

2.5

2.49

2.52

5.03

2.51

2.49

0

4

4

4.87

0.23

4.09

0

2.45

4.09

4.02

2.35

0

2.52

5.03

5.18

5.18

0

0

2.54

5.03

2.51

0

0.1

5.2

5.2

5.2

0

0

0

0

0

5.1

5.1

5.1

0.6

0.5

0.5

0.37

0

2.5

2.5

2.5

0

0

0

0.17

2.47

2.48

2.48

2.52

5.06

2.48

2.47

5.11

2.77

2.77

4.98

1.3

2.03

0

0

2.03

2.03

0

0.24

2.57

5.07

5.18

5.18

0

0

2.54

5.06

2.43

IC801

REC PB

MODE

PIN NO.

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

2.51

2.51

2.52

2.51

0.21

0

0

2.49

1.97

2.48

0

0

2.48

5.04

0

1.52

2.48

0

4.31

4.46

4.31

0

9.15

0

9.15

0

2.48

2.42

2.44

2.45

2.44

0.73

0

0

2.51

2.43

2.5

0

0

2.5

5.07

0

1.66

2.5

0

4.34

4.48

4.32

0

9.14

0

9.14

0

2.5

IC301

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

REC REC REC

EMITTER COLLECTOR BASE

PB PB PB

Location

No.

Q5P1

Q5P2

Q5P3

Q5P4

Q5P5

Q5P6

Q505

Q501

Q502

Q5V1

Q514

Q515

Q503

0

0

0

0

0

0

0

3.0(VIDEO)

2.9(VIDEO)

0.3(VIDEO)

0

0

0

0.1

0.1

0.1

3.9

3.9

3.7

2.9

0

0

2.3(VIDEO)

PULSE

PULSE

3.0(VIDEO)

5.1

5.1

5.1

0

0

0

0.7

2.4(VIDEO)

2.4(VIDEO)

0

PULSE

PULSE

0

0

0

0

0

0

0

0

3.0(VIDEO)

2.9(VIDEO)

0.3(VIDEO)

0

0

0

0.1

0.1

3.9

0.1

3.9

3.7

2.9

0

0

2.3(VIDEO)

PULSE

PULSE

3.0(VIDEO)

5.1

5.1

0

5.1

0

0

0.7

2.4(VIDEO)

2.4(VIDEO)

0

PULSE

PULSE

0

MONO:0,

HIFI:TAPE

SP:0 ,LP/EP: 5.1

Loading...

Loading...